Page 1

Installation Instructions

Size 36 Connector Kit for MPL-B9xx Motor Power

Catalog Number 2090-MPPC-X163

About This Publication

This publication provides wiring instructions for the Allen-Bradley Size 36 Connector Kit.

This connector kit provides an a 1½ NPT connection for conduit enclosing the power wire

run between the power connector on a MPL-B9xx motor and its input power source.

The MP-Series Installation Instructions, publication MP-IN002, details the motor interface.

Wire the Connector Kit

Refer to the illustration and the power connector pinout for your MPL-B9xx motor when

wiring this connector.

Tools you need to assemble the connector include a wire cutter, wire stripper, flatblade

screwdriver Ø 2.5 mm (0.10 in.) maximum, and solder iron.

ATTENTION

IMPORTANT

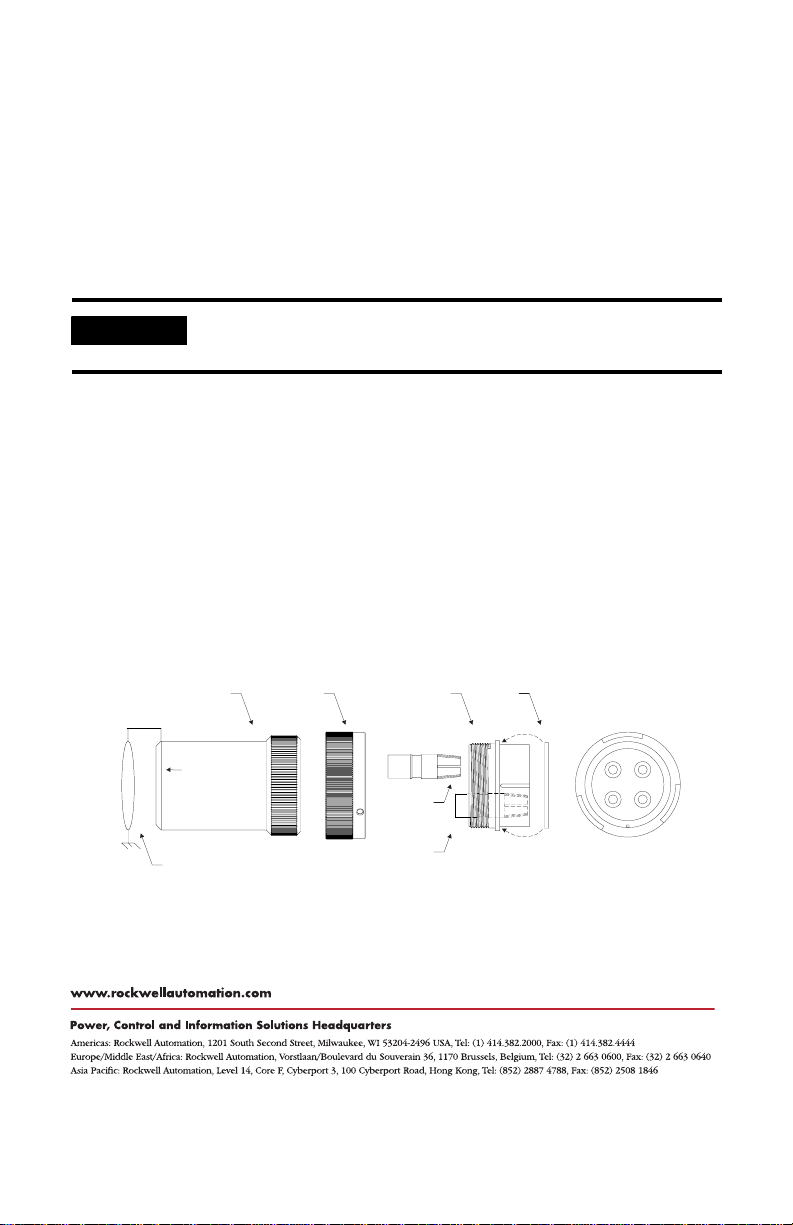

Connector components are assembled in the order shown in the figure.

1. Thread each power wire through the connector backshell and lock ring.

Do not use a petroleum based, or similar lubricant when inserting the pins into

the housing. This may effect the dielectric characteristics of the connector, and

the retention of the pins.

Alcohol or a lubricant that cleanly evaporates is recommended.

Always make effective electrical contact between the wire and pin connection.

360° shielding must be provided from the connector backshell to the driv e.

Publication MP-IN011B-EN-P - April 2007

Page 2

2. Secure a contact pin on each wire lead.

a. Strip th e w i r e lead to 16.5 mm (0.65 in.).

b. Fully insert the lead into the contact pin to the full depth of the pin.

Less than 2.5 mm (0.1 in.) of wire should be visible betwe en t he contact pin and

the wire insulation.

c. Solder or crimp the lead to the contact pin.

IMPORTANT

If soldering the wire-to-pin con nect ion, provide an adequate cooling period

before inserting the pin.

3. Insert each connector pin in the appropriate location of the connector housing.

a. Verify the pin location before beginning to insert the pin.

b. Insert each contact pin fully.

The groove in the contact should fully engage the rib in the connector hole. The

contact should extend 8.9 mm (0.350 in.) from the rear of the connector housing.

4. Repeat steps 2 and 3 for each of the four power leads.

5. Fully seat the O-ring over the smooth end of the connector housing.

6. Thread the connector housi ng into the backshell, and hand-tight en.

Backshell Lock Ring

Backshell

threaded

1 1/2 NPT.

360° power wire

shielding required.

Allen-Bradley and Rockwell Aut omation are trademar ks of Rockwell Automation, Inc.

Four (4) pins extend

8.9 mm (0.35 in.) from

back of housing.

Connector

Housing

Contact

Pin

O-ring Rear View of Connector

Fully seat o-ring

on connector

housing.

with Pin Locations

D

A = U Power B = V Power

C = W Power D = Grou nd

A

B

C

Publication MP-IN011B-EN-P - April 2007

Supersedes publication MP-IN011A-EN-P December 2006 Copyright © 2007 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

Loading...

Loading...