Page 1

E3 and E3 Plus Solid-State

A

Overload Relay

Quick Start Guide

(Bulletins 193 and 592)

Page 2

2

ATTENTION

!

This guide does not replace the User Manual, publication

193-UM002_-EN-P, and is intended for qualified service personnel

responsible for setting up and servicing these devices. You must have

previous experience with and a basic understanding of electrical

terminology, configuration procedures, required equipment, and safety

precautions. The user manual can be downloaded from http://

literature.rockwellautomation.com.

Important User Information

Because of the variety of uses for the products described in this publication, those responsible

for the application and use of this control equipment must satisfy themselves that all

necessary steps have been taken to assure that each application and use meets all performance

and safety requirements, including any applicable laws, regulations, codes, and standards.

The illustrations, charts, sample programs and layout examples shown in this guide are

intended solely for purposes of example. Since there are many variables and requirements

associated with any particular installation, Rockwell Automation does not assume

responsibility or liability (to include intellectual property liability) for actual use based upon

the examples shown in this publication.

Rockwell Automation publication SGI-1.1, Safety Guidelines for the Application, Installation

and Maintenance of Solid-State Control (available from your local Allen-Bradley distributor),

describes some important differences between solid-state equipment and electromechanical

devices that should be taken into consideration when applying products such as those

described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or part, without

written permission of Rockwell Automation, is prohibited.

Publication 193-QR003B-EN-P - October 2009

Page 3

3

IMPORTANT

IMPORTANT

IMPORTANT

IMPORTANT

General Precautions

In addition to the specific precautions listed throughout this manual, the following general

statements must be observed.

The purpose of this publication is to serve as a guide for proper

installation. The National Electrical Code and any other governing

regional or local code overrules the information in this publication.A

hazard of personal injury/equipment damage exists if codes are

ignored during installation. Rockwell Automation cannot assume

responsibility for the compliance or proper installation of the E3

Overload Relay or associated equipment.

Only personnel familiar with the E3 Overload Relay and associated

machinery should plan to install, start up, and maintain the system.

Failure to comply may result in personal injury/equipment damage.

An incorrectly applied or installed E3 Overload Relay can result in

damage to the components or reduction in product life. Wiring or

application errors, such as incorrectly configuring the FLA Setting,

supplying incorrect or inadequate DeviceNet supply voltage,

connecting an external supply voltage to the input or thermistor

terminals, or operating/storing in excessive ambient temperatures may

result in malfunction of the E3 Overload Relay.

The E3 Overload Relay contains ESD (electrostatic discharge)

sensitive parts and assemblies. Static control precautions are required

when installing, testing, servicing, or repairing this assembly.

Component damage may result if ESD control procedures are not

followed. If you are not familiar with static control procedures, refer

to Allen-Bradley publication 8200-4.5.2, Guarding Against Electrostatic

Damage, or any other applicable ESD protection handbook.

Publication 193-QR003B-EN-P - October 2009

Page 4

4

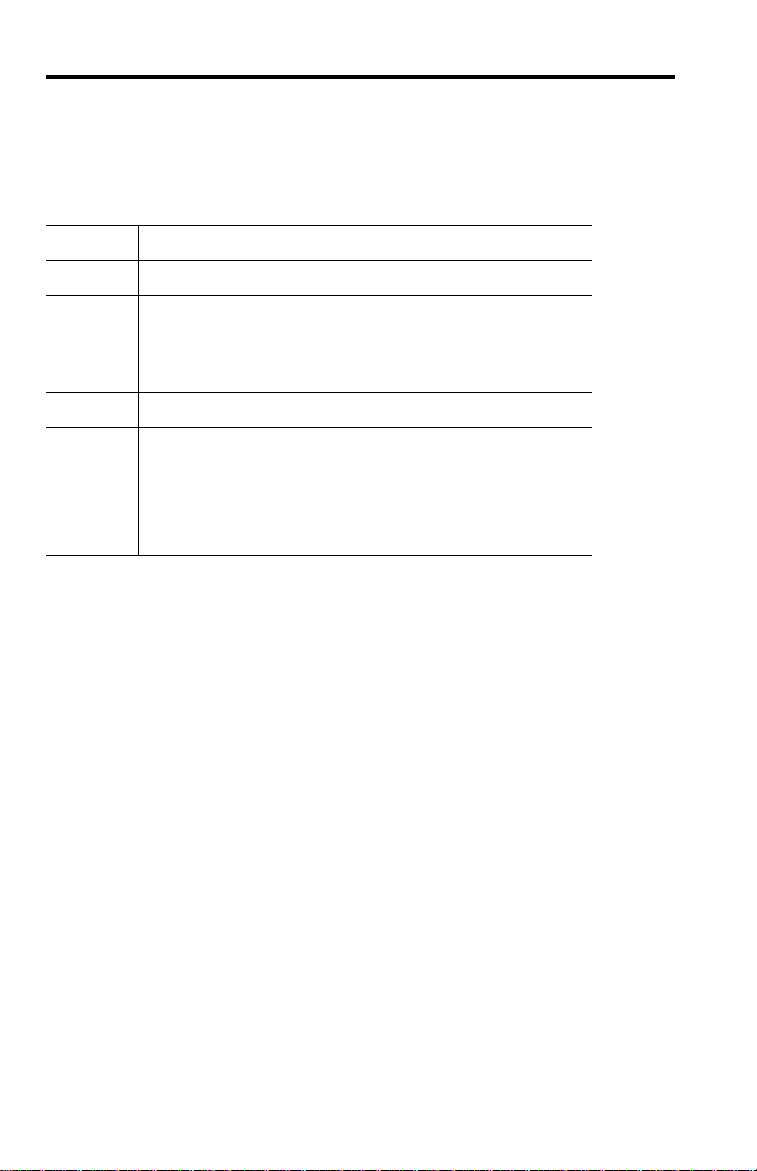

Introduction

Follow these steps to successfully commission the E3 Overload Relay:

Table 1: Commissioning Procedure

Step Description

1 Hardware Installation

2 Wiring Installation

3 DeviceNet Commissioning

4 Setup Requirements

– Typical Motor Connections

– External Current Transformer Applications (193-EC_ZZ or 592-EC_ZZ)

– External Ground Fault Sensor Applications (193-EC3_ _ , 592-EC3_ _ and

193-EC5_ _ , 592-EC5_ _)

Setup for Bulletin 193 or 592-EC1/EC2/EC3/EC5 Overload Relay

– Protective Trip and Warning Summaries

– Parameter Group Listing

Setup for Cat. No. 193-EC4 Current Monitor Relay

– Trip and Warning Summaries

– Parameter Group Listing

Publication 193-QR003B-EN-P - October 2009

Page 5

Hardware Installation

1

2

CLICK

3

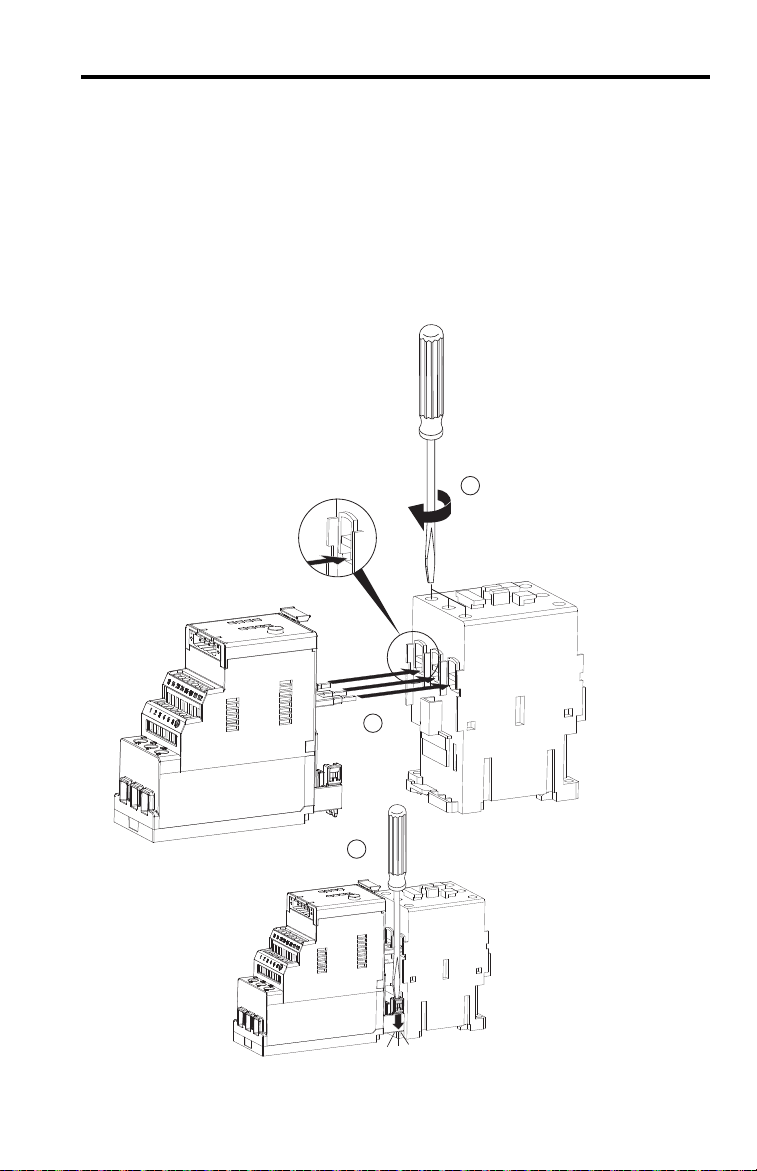

The following figures illustrate the starter assembly instructions.

Starter Assembly Instructions

Figure 1: 100-C09…C43 Starter Assembly Instructions (for use with Cat. Nos.

193-EC_ _B and -EC_ _D)

/tN

22 lb-in.

5

Publication 193-QR003B-EN-P - October 2009

Page 6

6

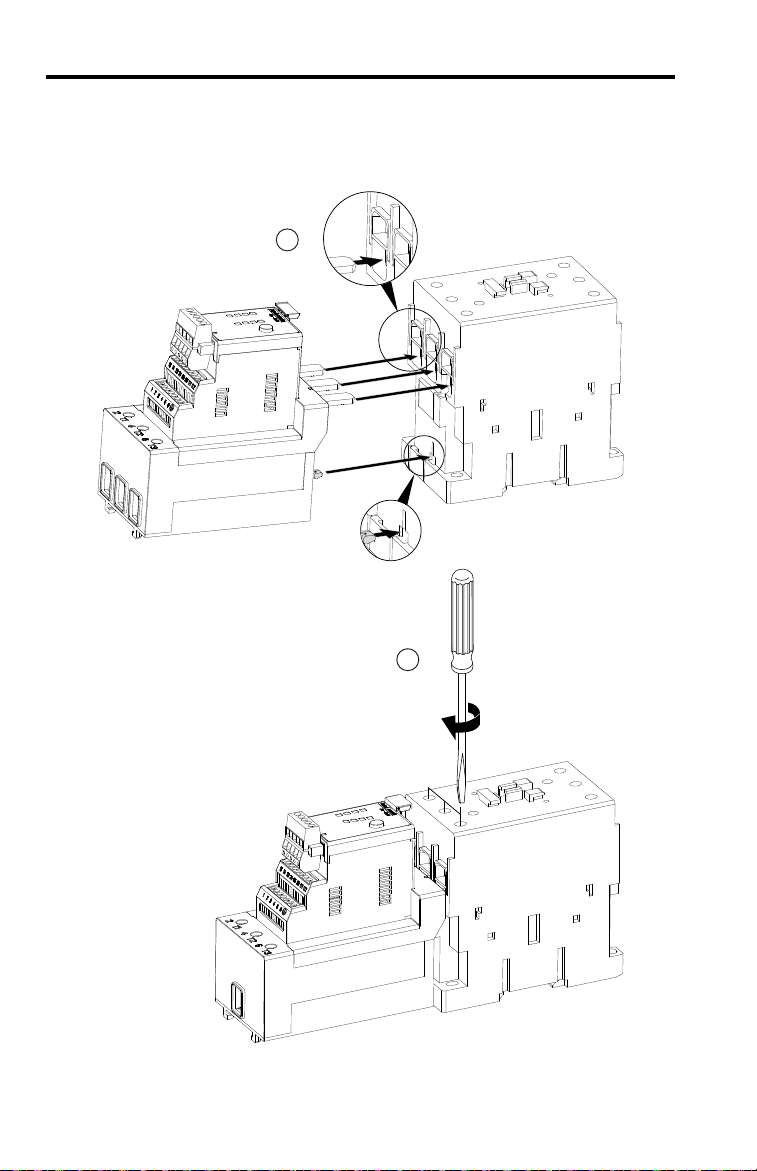

1

2

/tN

35 lb-in.

Figure 2: 100-C60…C85 Starter Assembly Instructions (for use with Cat. No.

193-EC_ _E).

Publication 193-QR003B-EN-P - October 2009

Page 7

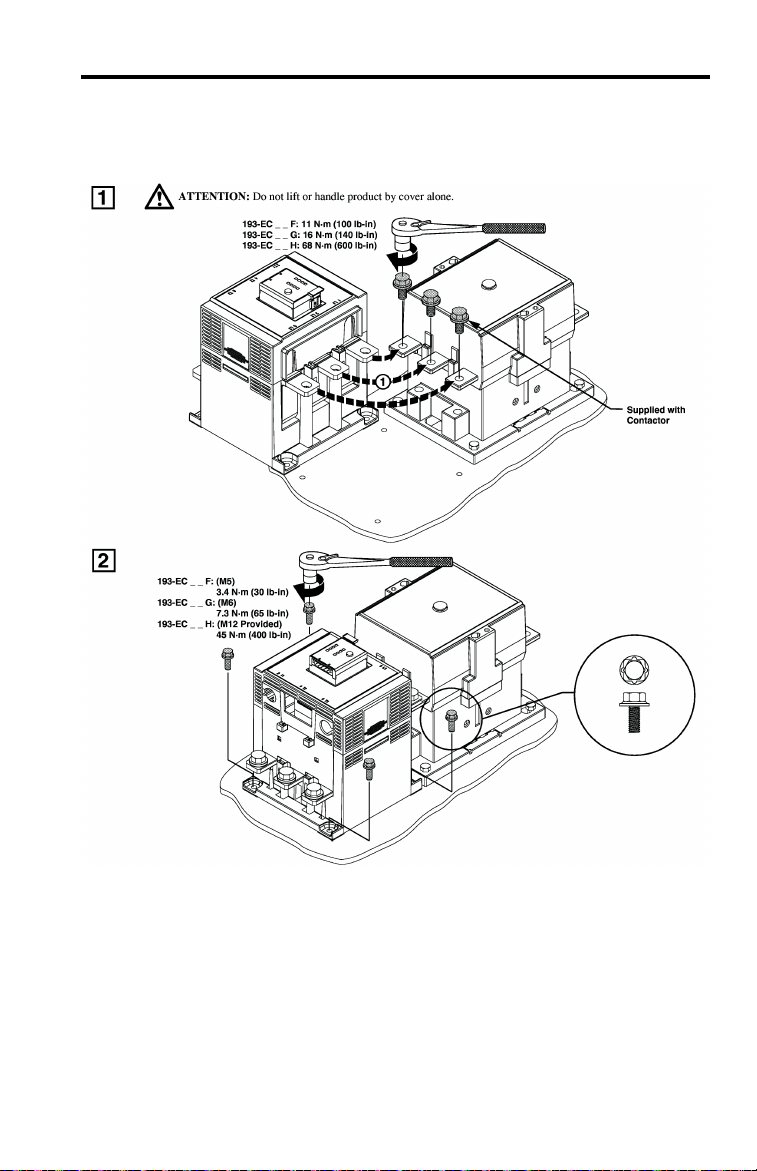

Figure 3: 100-D95...D860 Starter Assembly Instructions (for use with Cat. Nos.

193-EC_ _F, 193-EC_ _G, and 193-EC_ _H).

7

Publication 193-QR003B-EN-P - October 2009

Page 8

8

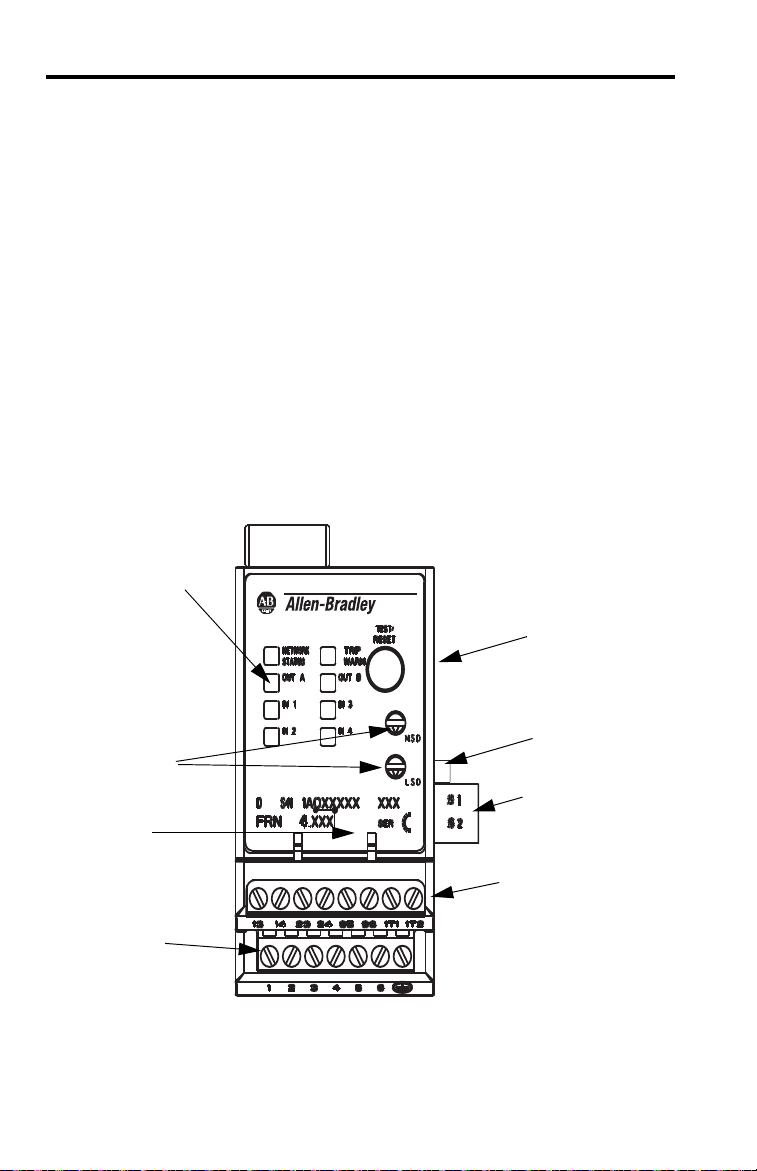

E3 PLUS

LED Status Indicators

DeviceNet Port

Input Terminals

Test/Reset Button

Node Address Switches

(Series B and later)

Output and PTC Terminals

Ground Fault Sensor Input

Voltage Input Module

Connection

(193/592 EC5 only)

Wiring Installation

Typical Motor Connections

Refer to the product nameplate or user manual for power lug termination information

including:

• Terminal wire size and torque specifications

• Maximum wire lengths

• Lug kit catalog numbers (108…1250 A)

For reliable input signal processing, input wiring should be routed in raceways separate from

power cabling.

Terminal Designations

Figure 4: E3 and E3 Plus Feature Overview

Publication 193-QR003B-EN-P - October 2009

Page 9

Control Terminals

The following table defines the E3 Overload Relay control terminal designations.

Table 2: Control Terminal Designation

9

Ter mi na l

Designation

1 IN 1 General-purpose sinking input number 1

2 IN 2 General-purpose sinking input number 2

3 IN 3 General-purpose sinking input number 3 ➊➋

4 IN 4 General-purpose sinking input number 4 ➊➋

5V+

6V+

7 IN 5 General-purpose sinking input number 5 ➋

8 IN 6 General-purpose sinking input number 6 ➋

13/14 OUT A Output A

23/24 OUT B Output B ➊➋

95/96 Trip Relay Trip Relay

IT1/IT2 PTC Thermistor (PTC) input ➊➍

S1/S2 — External ground fault sensor input ➋➎

➊ Features are available only with the E3 Plus Overload Relay (cat. nos. 193/592-EC2and 193/592-EC3).

➋ Available only on cat. nos. 193/592-EC5_ _.

➌ An earth ground connection to this terminal will assist in obtaining compliance with electromagnetic

compatibility requirements.

➍ The use of shielded cable is recommended for the positive PTC thermistor circuit to assist in obtaining

compliance with electromagnetic compatibility requirements.

➎ Available only on cat. nos. 193/592-EC3_ _ and 193/592-EC4_ _.

Reference Description

+24V DC supply for inputs

End Earth Ground ➌

DeviceNet Terminals

The following table defines the DeviceNet connector terminal designations.

Table 3: DeviceNet Terminal Designation

Terminal Signal Function Color

1 V- Common Black

2 CAN_L Signal Low Blue

3 Drain Shield Non-insulated

4 CAN_H Signal High White

5 V+ Power Supply Red

Publication 193-QR003B-EN-P - October 2009

Page 10

10

ATTENTION

!

Grounding

The following grounding recommendations are provided to ensure electromagnetic

compatibility compliance during installation:

• The earth ground terminal of the E3 Overload Relay shall be connected to a solid

earth ground via a low-impedance connection

• Installations employing an external ground fault sensor shall ground the cable shield

at the sensor with no connection made at the E3 Plus Overload Relay

• The PTC thermistor cable shield shall be grounded at the E3 Plus Overload Relay

with no connection made at the opposite end

Wiring Diagrams

When working on energized circuits, do not rely on the voltage and

current information provided by the E3 and E3 Plus for personal

safety. Always use a portable voltage or current measurement device

and measure the signal locally.

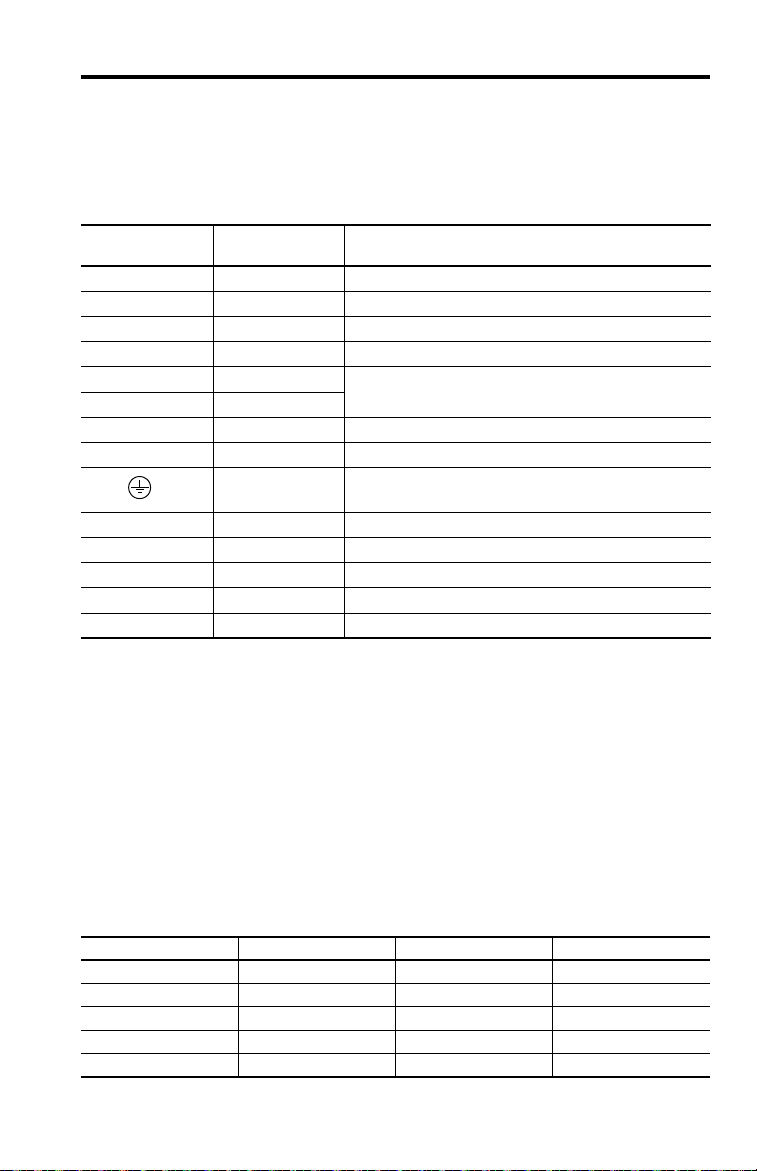

Figure 5: Three-Phase D.O.L & Single-Phase Wiring Diagrams

L1 L2 L3

Voltage Input Module

(For 193/592-EC5 only)

Publication 193-QR003B-EN-P - October 2009

Three-Phase Direct-On-Line

Wiring Diagram

L2 L3

L1

E3/E3Plus

2/T1 4/T2 6/T3

T1T2T3

M

S.C.P.D.

Single-Phase Full-Voltage

Wiring Diagram

L1

L1 L2 L3

L1 L2 L3

E3/E3Plus

E3/E3Plus

E3/E3Plus

2/T1 4/T2 6/T3

2/T1 4/T2 6/T32/T1 4/T2 6/T3

2/T1 4/T2 6/T3

2/T1 4/T2 6/T3

T1

T2

M

L2

L1 L2

Voltage Input Module

(For 193/592-EC5 only)

Page 11

11

IMPORTANT

IMPORTANT

IMPORTANT

Parameter 27, Single/Three Ph, should be set to single-phase for

single-phase devices and three-phase for three-phase devices.

In single-phase devices, traditional single-phase wiring (connecting

T2 to L3) will result in a vector imbalance of current flowing through

the E3 Plus Overload Relay. This will result in inaccurate ground fault

reporting and protection.

External Current Transformer Application (Cat. No. 193-EC_ZZ)

E3 and E3 Plus Overload Relays (Cat. No. 193-EC_ZZ) are designed for use with separately

mounted, customer-supplied current transformers (CTs) as required in higher-current

applications. The FLA setting range is 9…5000 A for these units, with a legal setting range

per the user’s manual. Parameter 78, CT Ratio, is provided for setting the current transformer

ratio to be installed.

Current Transformer Specifications

The 193-EC_ZZ Overload Relays are intended for use with a CT having a secondary current

rating of 5 A. The installer shall provide one CT for each motor phase and shall connect the

CT secondary leads to the appropriate E3 Overload Relay power terminals as shown in Figure

7: on page 13. The CT shall have an appropriate ratio rating as detailed in the user’s manual.

Additionally, the CT shall be selected to be capable of providing the required VA to the

secondary load, which includes the E3 Overload Relay burden of 0.1 VA at the rated

secondary current and the wiring burden.

Finally, the CT shall be rated for protective relaying to accommodate the high inrush currents

associated with motor startup and shall have an accuracy of

range.

≤±2% over its normal operating

ANSI (USA) Class C5 B0.1

CSA (Canada) Class 10L5

IEC (Europe) 5 VA Class 5P10

The improper selection of a current transformer can result in the E3

Overload Relay reporting inaccurate motor operational data and

possible motor damage. The selected current transformer must be

rated for protective relaying applications.

Publication 193-QR003B-EN-P - October 2009

Page 12

12

IMPORTANT

6x

6x

OR

y

C

t

s

d

y

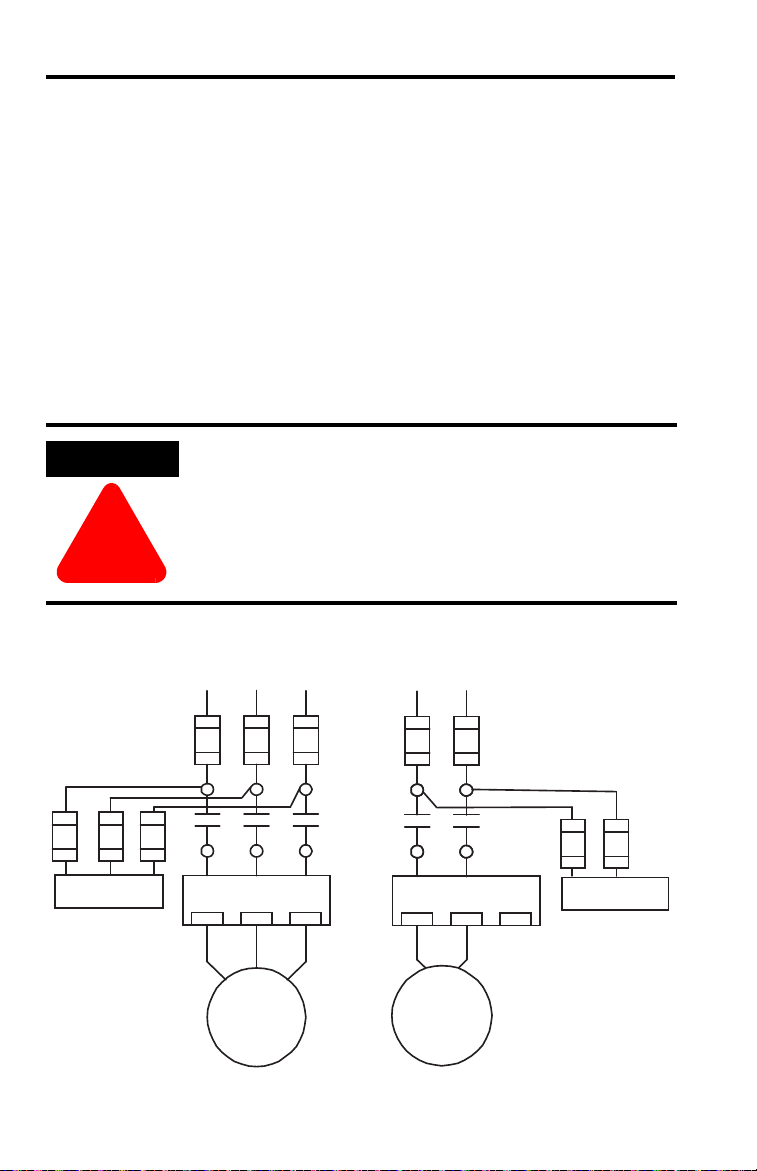

Installation Instructions

Cat. No. 193-EC_ZZ Overload Relays are designed to be installed in cat. no. 193-ECPM2

panel mount adapters and connected to separately mounted current transformers. For a panel

mount adapter assembly, refer to the instructions included with the panel mount adapter. The

E3 Overload Relay must be mounted a distance equal to, or greater than, six times the cable

diameter (including insulation) from the nearest current-carrying conductor or current

transformer. For applications employing multiple conductors per phase, the diameter of each

cable should be added and multiplied by six to determine the proper placement distance for

the E3 Overload Relay.

Figure 6: Cat. No. 193-EC_ZZ Overload Relay Mounting Placement

Primar

urren

Transformer

E3 Overloa

Rela

Placement of the E3 Overload Relay closer than the recommended

distance of six times the cable diameter may compromise its current

reporting and protection capabilities.

Publication 193-QR003B-EN-P - October 2009

Page 13

13

C

3

3

3E3

/2

3

/4

T

/1

/3

L

3/6

/1

3/5

y

C

t

s

y

C

t

s

Figure 7: External CT Connection Diagrams

IE

Primar

urren

Transformer

L

L2

L1

E

T1

T2

Primar

urren

Transformer

L

L2/3L

L1

T1/2T2/4T

T

External Potential (Voltage) Transformer Application

(Cat. No. 193/592-EC5_ _)

The E3 Plus Overload Relay Catalog Number 193/592-EC5_ _ can be used with external

step-down potential transformers (PTs). The PT ratio is programmed into the E3 Plus by

entering the primary winding rating into Parameter 289, PT Pri, and the secondary winding

rating into Parameter 290, PT Sec. The voltage mode is also programmed into the E3 Plus by

selecting the appropriate mode in Parameter 156, Vol t Mode. The E3 Plus will support Wye,

Delta, and Open Delta voltage modes with potential transformers.

Publication 193-QR003B-EN-P - October 2009

Page 14

14

Load

L1 L2 L3

Line

N/GND

L1 L2 L3

Wye Connection with PTs

Load

L1 L2 L3

Line

L1 L2 L3

Open Delta Connection with PTs

Figure 8: External PT Connection Diagrams

Line

L1 L2 L3

L1 L2 L3

Delta Connection with PTs

Load

Publication 193-QR003B-EN-P - October 2009

Page 15

15

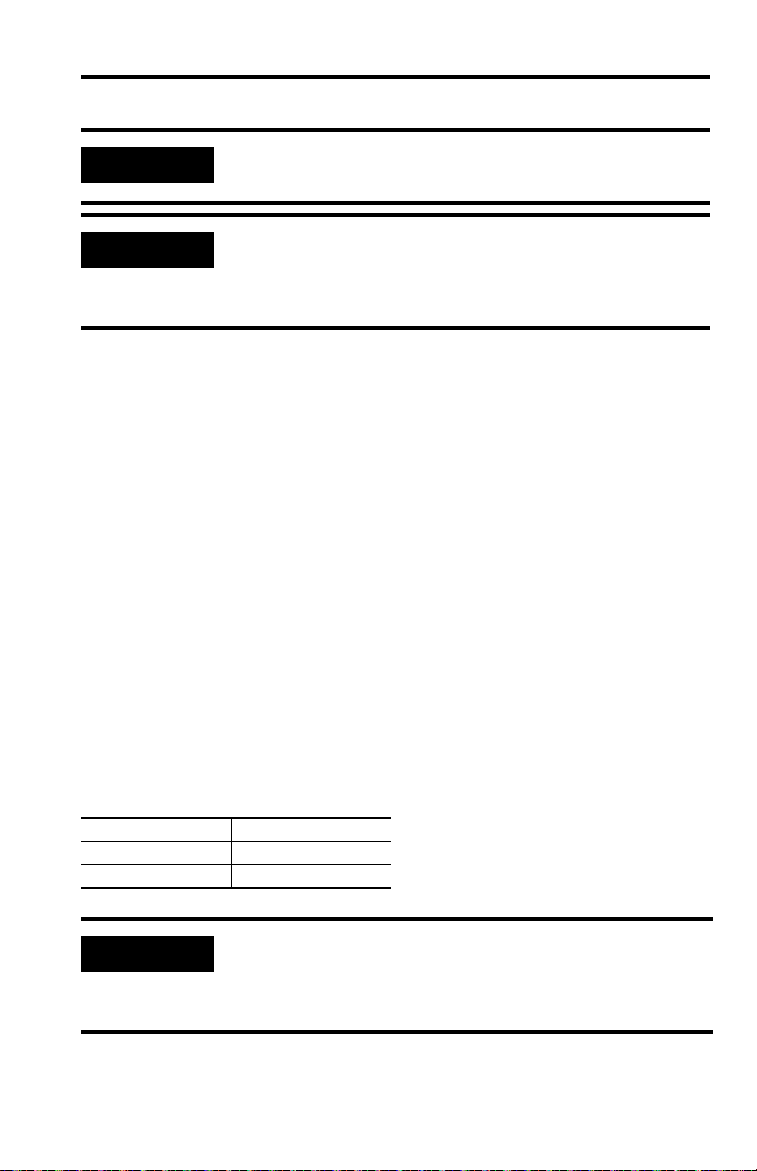

External Ground Fault Sensor Application

(Cat. Nos. 193/592-EC3_ _, 193/592-EC4_ _, and 193/592-EC5_ _)

Cat. Nos. 193/592-EC3_ _, 193/592-EC4_ _, and 193/592-EC5_ _ E3 Plus Overload Relays

are intended to provide ground fault protection when used with the cat. no. 193-CBCT

external ground fault (core balance) sensor. The ground fault sensor mounts separately from

the E3 Plus Overload Relay and must be placed within three meters of the relay. The

customer-supplied cable for wiring the ground fault sensor to the E3 Plus Overload Relay

should meet the specifications outlined in Table 1.9 on page 15.

_

Table 1.9 Ground Fault Sensor Terminals (S1 and S2)

Wire type Shielded, twisted pair

Cross section

Tor q ue

0.2…4.0 mm

0.55 N

2

(#24…12 AWG)

•m (5 lb-in.)

Power Cable Installation Instructions

1. All power cables (including the neutral when used) must pass through the sensor

window. The equipment ground conductor (the conductor used to carry the

non-current-carrying metal parts of equipment, as defined by Article 100 of the

NEC), must not pass through the sensor window.

2. The power cables through the sensor window should be straight, tightly bundled,

centered in the window, and perpendicular to the sensor for a length equal to, or

greater than, six times the cable diameter (including insulation) from the sensor.

3. All other conductors with available currents in excess of 1,000 A should be placed a

distance equal to, or greater than, six times the cable diameter (including insulation)

from the sensor.

4. The power cables of the branch circuit to be protected by the E3 Plus Overload Relay

must not be grounded on the load side of the ground fault sensor.

5. If the power cables are enclosed in a conducting jacket, the jacket must be grounded

on the line side of the sensor. The jacket must not pass through the sensor window,

but must be cut at the window and joined with a conductor that passes outside the

sensor window.

6. The power system may be solidly grounded or grounded through an impedance at its

source as long as the impedance allows a magnitude of fault current to flow that is

within the 1…5 A operational range of the E3 Plus Overload Relay (193/592-EC2_

_) or the 20 mA…5 A operational range of the E3 Plus Overload Relay (193/

592-EC3

_ _, 193/592-EC4_ _, and 193/592-EC5_ _).

Publication 193-QR003B-EN-P - October 2009

Page 16

16

IMPORTANT

MOTOR

L1 L2

L3

S1

S2

S1

S2

193-CBCT_

Ground

Fault

Sensor

E3 Plus

Overload Relay

Figure 10: Ground Fault Sensor Mounting Placement

GF Sensor

90˚

Power

Cables

6x

6x

Figure 11: Power Cable Configuration — Two Cables per Phase

1

L3 L1

1

L2 L2

L1

L3

The spacer is a short (approximately 10 times

the cable diameter in length) piece of cable

with no connections to any terminal.

Figure 12: Ground Fault Sensor Wiring to the E3 Plus Overload Relay

Publication 193-QR003B-EN-P - October 2009

The shield of the twisted pair cable must be connected to earth

ground at the sensor, with no connection made at the E3 Plus

Overload Relay.

Page 17

17

IMPORTANT

DeviceNet Node Commissioning

Overview

E3 Overload Relays are shipped with a default software node address (MAC ID) setting of 63

and the data rate set to Autobaud. Each device on a DeviceNet network must have a unique

node address which can be set to a value from 0…63.

Keep in mind, most DeviceNet systems use address 0 for the master device (scanner) and

node address 63 should be left vacant for introduction of new slave devices. The node

address and data rate for series B or later, E3 Overload Relays can be changed using software

or by setting the hardware switches that reside on the front of each unit. While both methods

yield the same result, it is good practice to choose one method and deploy it throughout the

system.

The following recommendations are intended to ensure a trouble-free

startup and operation:

1. Use the node commissioning tool in RSNetWorx or the

DeviceNet configuration terminal (cat. no. 193-DNCT) when

modifying the E3 node address. Do not use the General tab found

in the product window in RSNetWorx. The node commissioning

tool ensures the device goes through a hard reset and requires

the user to upload the most current parameter information from

the device prior to making configuration changes.

2. Ensure you have the most current configuration information

prior to saving an RSNetWorx configuration file.

3. If you intend to employ the ADR function of the DeviceNet

scanner, ensure the device configuration is as you intend it

BEFORE saving it to memory.

4. Be aware the Restore Device Defaults button in RSNetWorx will

reset the E3 Overload Relay node address setting to 63. For

Series B or later devices, the hardware node address switches take

precedence over the software node address setting.

Publication 193-QR003B-EN-P - October 2009

Page 18

18

Figure 13: Node Address Switches

Table 2: Node Address Setting

Switch Settings Description

0…63 The node address setting is determined by the switch values when set in this range.

64…99 For switch settings in this range, the node address setting is determined by the software

99 Factory default setting.

Note: For node address switch values in the range of 0…63, cycle power to the E3 Overload Relay to

initialize the new setting.

setting using the RSNetWorx for DeviceNet configuration tool.

Setup Requirements

Setup for Cat. Nos. 193/592-EC1/EC2/EC3/EC5 Overload Relays

After the E3 Overload Relay is installed according to the guidelines specified in this manual,

apply power to the overload relay’s DeviceNet connector. After applying power, the following

sequence should occur:

1. The Trip relay should close 2.35 seconds later and the TRIP/WARN LED will not

flash (unless a Non-Volatile Fault previously existed or a fault condition is present).

2. At the same time, the NETWORK STATUS LED should flash green for

approximately two seconds, then red for a 1/4 second. If autobaud is enabled and the

E3 Overload Relay is connected to an active network, the green LED will continue to

flash once the baud rate has been determined. If the E3 Overload Relay is not

connected to an active network, the LED will not continue to flash.

3. Once the E3 Overload Relay has been allocated by a master, the NETWORK

STATUS LED will turn solid green.

After being powered up, use the DeviceNet Configuration Terminal (Cat. No. 193-DNCT) in

order to set up the parameters. There are five basic parameters that need to be established

before using the protective functions. These parameters are listed under the OVERLOAD

SETUP menu and include: Single/Three Phase, Full Load Current (FLA) Setting, Trip Class,

Overload/PTC Reset mode, and Overload Reset Level. (Note: You will need to program

additional parameters when customer-supplied CTs are used.)

Once these parameters are set, the E3 Overload Relay is functional. Use the ADVANCED

SETUP menu to set other parameters per the specific application requirements.

Publication 193-QR003B-EN-P - October 2009

Page 19

Protective Trip/Warning Summaries & Parameter Group Listing

(Cat. Nos. 193/592-EC1/EC2/EC3/EC5)

Table 3: Trip Summary

19

Tri p

Function

Overload Enabled ➋➋Trip Class

Phase Loss Enabled ➌➌0.1…25.0 s 1.0 s 0…250 s 0 s

Ground Fault

(193/592-EC2)

Ground Fault

(193/592-EC3)

Stall Disabled 100…600% ➎ 600% ➎ 0…250 s➎10 s➎ ——

Jam Disabled 50…600% 250% 0.1…25.0 s 5.0 s 0…250 s 10 s

Underload Disabled 10…100% FLA ➏50% 0.1…25.0 s 5.0 s 0…250 s 10 s

PTC Disabled — — — — — —

Current

Imbalance

Comm Fault Enabled — — — — — —

Comm Idle Disabled — — — — — —

Remote Trip Disabled — — — — — —

Voltage Input

Module

Hardware Fault

➐

Undervoltage

L-L ➐

Overvoltage L-L ➐ Disabled 0...65535 500 0.1…25.0 s 1.0 s 0…250 s 10 s

Tri p

Enable

Factory

Default

Disabled Internal 1…5 A 2.5 A 0.0…25.0 s 0.5 s 0…250 s 10 s

Disabled External

Disabled 10…100% 35% 0.1…25.0 s 5.0 s 0…250 s 10 s

Disabled — — — — — —

Disabled 0...65535 1 00 0.1…25.0 s 1.0 s 0…250 s 10 s

Trip Level Settings Trip Delay Settings Inhibit Time

Range Default Range Default Range Default

Tri p Cl ass10——

0.02…5 A ➍

5…30

2.5 A 0.0…25.0 s 0.5 s 0…250 s 10 s

Settings ➊

Voltage

Unbalance ➐

Phase Rotation ➐ Disabled 1…2 1 — — 0…250 s 10 s

Under

Frequency ➐

Over Frequency ➐ Disabled 0…250 63 0.1…25.0 s 1.0 s 0…250 s 10 s

Under Real

Power ➐

Over Real

Power ➐

Disabled 0…100 75 0.1…25.0 s 1.0 s 0…250 s 10 s

Disabled 0…250 57 0.1…25.0 s 1.0 s 0…250 s 10 s

Disabled 0…32767 0.1…25.0 s 1.0 s 0…250 s 10 s

Disabled 0…32767 0.1…25.0 s 1.0 s 0…250 s 10 s

Publication 193-QR003B-EN-P - October 2009

Page 20

20

Table 3: Trip Summary

Tri p

Function

Under

Consumed

kVAR ➐

Over Consumed

kVAR ➐

Under

Generated

kVAR ➐

Over Generated

kVAR ➐

Under Power

kVA ➐

Over Power kVA ➐ Disabled 0…32767 0.1…25.0 s 1.0 s 0…250 s 10 s

Under Power

Factor Lagging

➐

Over Power

Factor Lagging

➐

Under Power

Factor Leading

➐

Over Power

Factor Leading

➐

➊ The inhibit time setting parameters are applicable to both the trip and warning functions.

➋ FLA Setting range and default values are dependent upon the current rating of the product. See the user

manual for more information.

➌ Phase loss trip level is factory-set at a current imbalance greater than or equal to 100% and is not

user-adjustable.

➍ Must use Ground Fault Sensors (Cat. No. 193-CBCT_).

➎ Stall protection is only applicable during the motor starting sequence. If any phase of current falls below the

programmed Stall Trip Level, stall protection is disabled.

➏ 50…100% for devices with FRN 1.003 and earlier.

➐ Available on 193/592-EC5 only.

Tri p

Enable

Factory

Default

Disabled 0…32767 0.1…25.0 s 1.0 s 0…250 s 10 s

Disabled 0…32767 0.1…25.0 s 1.0 s 0…250 s 10 s

Disabled -32767…0 0.1…25.0 s 1.0 s 0…250 s 10 s

Disabled -32767…0 0.1…25.0 s 1.0 s 0…250 s 10 s

Disabled 0…32767 0.1…25.0 s 1.0 s 0…250 s 10 s

Disabled -100…0 -90 0.1…25.0 s 1.0 s 0…250 s 10 s

Disabled -100…0 -95 0.1…25.0 s 1.0 s 0…250 s 10 s

Disabled 0...100 90 0.1…25.0 s 1.0 s 0…250 s 10 s

Disabled 0...100 95 0.1…25.0 s 1.0 s 0…250 s 10 s

Trip Level Settings Trip Delay Settings Inhibit Time

Range Default Range Default Range Default

Settings ➊

Publication 193-QR003B-EN-P - October 2009

Page 21

Table 4: Warning Summary

21

Warning

Function

Overload Disabled 0…100%➋ 85% — —

Phase Loss — — — — —

Ground Fault (193/592-EC2) Disabled Internal 1…5 A2.0 A 0…250 s 10 s

Ground Fault (193/592-EC3) Disabled External

Stall — — — — —

Jam Disabled 50…600% 150% 0…250 s 10 s

Underload Disabled 10…100%➍ 70% 0…250 s 10 s

Thermistor (PTC) Disabled — — — —

Current Imbalance Disabled 10…100% 20% 0…250 s 10 s

Comm Fault Disabled — — — —

Comm Idle Disabled — — — —

Voltage Input Module

Hardware Fault r

Under Voltage L-L r Disabled 0...65535 400 0…250 s 10 s

Over Voltage L-L ➎ Disabled 0...65535 490 0…250 s 10 s

Voltage Unbalance ➎ Disabled 0…100 85 0…250 s 10 s

Phase Rotation ➎ Disabled 1…2 1 0…250 s 10 s

Under Frequency ➎ Disabled 0…250 58 0…250 s 10 s

Over Frequency ➎ Disabled 0…250 62 0…250 s 10 s

Under Real Power ➎ Disabled 0…32767 0…250 s 10 s

Over Real Power ➎ Disabled 0…32767 0…250 s 10 s

Under Consumed kVAR ➎ Disabled 0…32767 0…250 s 10 s

Over Consumed kVAR ➎ Disabled 0…32767 0…250 s 10 s

Under Generated kVAR ➎ Disabled -32767…0 0…250 s 10 s

Over Generated kVAR ➎ Disabled -32767…0 0…250 s 10 s

Under Power kVA ➎ Disabled 0…32767 0…250 s 10 s

Over Power kVA ➎ Disabled 0…32767 0…250 s 10 s

Under Power Factor Lagging ➎ Disabled -100…0 -95 0…250 s 10 s

Over Power Factor Lagging ➎ Disabled -100…0 -90 0…250 s 10 s

Under Power Factor Leading ➎ Disabled 0...100 95 0…250 s 10 s

Over Power Factor Leading ➎ Disabled 0...100 90 0…250 s 10 s

Warning

Enable

Factory

Default

Enabled — — — —

Warning Level Settings Inhibit Time Settings ➊

Range Default Range Default

0.02…5 A ➌

2.0 A 0…250 s 10 s

➊ The inhibit time setting parameters are applicable to both the trip and warning functions.

➋ Overload warning setting is entered as a percentage of the thermal capacity utilized.

➌ Must use Ground Fault Sensors (Cat. No. 193-CBCT_).

➍ 50…100% for devices with FRN 1.003 and earlier.

➎ Available on 193/592-EC5 only.

Publication 193-QR003B-EN-P - October 2009

Page 22

22

Table 5: Parameter Group Listing

Monitor

Params

1 L1 Current

2 L2 Current 28 FLA Setting 53 Program Lock 25 Warning Enable 56 NonVol Baud Rate

3 L3 Current 29 Trip Class 54 Set to Defaults 27 Single/Three Ph 58 COS Mask

4 Average Current

5 L1 % FLA

6 L2 % FLA 78 CT Ratio 30 OL/PTC ResetMode 61 Assy Word0 Param

7 L3 % FLA 31 OL Reset Level 62 Assy Word1 Param 71 OutB Pr FltState

8 Average % FLA 32 OL Warning Level 63 Assy Word2 Param 72 OutB Pr FltValue

9 % Therm Utilized 33 PL Inhibit Time 64 Assy Word3 Param

10 GF Current 34 PL Trip Delay

11 Current Imbal 35 GF Inhibit Time

12 OL Time To Trip 36 GF Trip Delay

13 OL Time To

Reset 37 GF Trip Level

14 Trip Status 38 GF Warn Level

15 Warning Status 39 Stall Enbld Time

16 Trip Log 0 40 Stall Trip Level

17 Trip Log 1 41 Jam Inhibit Time

18 Trip Log 2 42 Jam Trip Delay

19 Trip Log 3 43 Jam Trip Level

20 Trip Log 4 44 Jam Warn Level

21 Device Status 45 UL Inhibit Time

22 Firmware 46 UL Trip Delay

23 Dev Config 47 UL Trip Level

90 Warn Log 0➊ 48 UL Warn Level

91 Warn Log 1➊ 49 CI Inhibit Time

92 Warn Log 2➊ 50 CI Trip Delay

93 Warn Log 3➊ 51 CI Trip Level

94 Warn Log 4➊

95 Elapsed Time➊ 78 CT Ratio

96 Starts

Counter➊ 83 IN 1 Assignment

97 Starts

Available➊ 84 IN 2 Assignment

98 Time To Start➊ 85 IN 3 Assignment

➊

Series C (FRN 4.00 and higher)

Overload

Setup Reset/Lock Advanced Setup

27 Single/

Three Ph 26 Trip Reset 24 Trip Enable 55 AutoBaudEnable 65 OutA Pr FltState 79 Comm Override

30 OL/PTC

ResetMode 103 Test Enable* 28 FLA Setting 59 Output Assembly

31 OL Reset

Level 104 Clear Queue* 29 Trip Class 60 Input Assembly

52 CI Warn Level

86 IN 4 Assignment

87 2-Spd Net Enable

88 2-Speed FLA Set

89 GF Trip Inhibit

99 Starts/Hour➊

100 Starts Interval➊

101 PM - # Starts➊

102 PM - Oper. Hours➊

105 GF Warn Delay➊

106 GF Sensing Range➊

DeviceNet

Setup

Output

Setup DeviceLogix

66 OutA Pr

FltValue

67 OutA DN

FltState 81 Net outputs

68 OutA DN

FltValue

69 OutA DN

IdlState

70 OutA DN

IdlValue

73 OutB DN

FltState

74 OutB DN

FltValue

75 OutB DN

IdlState

76 OutB DN

IdlValue

80 Network

Override

82 Net Out COS

Mask

Publication 193-QR003B-EN-P - October 2009

Page 23

23

Table 6: Parameter Group Listing, Continued

➋

Trip Snapshot

➋

Device

Logix

79 Comm

Override 132 Trip History 0 144 SS L1 Current 160 V Trip Status 156 Volt Mode 173 L1 Real Power 157 Power Scale

80 Network

Override 133 Trip History 1 145 SS L2 Current 161 V Warn Status 158 V Trip Enable 174 L2 Real Power 225 PW Trip Enable

81 Net outputs 134 Trip History 2 146 SS L3 Cu rrent 162 L1-L2 Voltage 159 V Warn Enable 175 L3 Real Power 226 PW Warn Enable

82 Net Out COS

Mask 135 Trip History 3 147 SS %TCU 163 L2-L3 Voltage 215 UV Inhibit Time 176 Total Real Power 241 UW Inhibit Time

o Series C (FRN 5.00 and Higher)

➌ 193/592-EC5 Only

Tri pWa rn

History

136 Trip History 4 148 SS GF Current 164 L3-L1 Voltage 216 UV Trip Delay 177 L1 Reactive Power 242 UW Trip Delay

137 Warn History 0 149 SS L1-L2 Voltage 165 Ave Voltage L-L 217 UV Trip Level 178 L2 Reactive Power 243 UW Trip Level

138 Warn History 1 150 SS L2-L3 Voltage 166 L1-N Voltage 218 UV Warn Level 179 L3 Reactive Power 244 UW Warn Level

139 Warn History 2 151 SS L3-L1 Voltage 167 L2-N Voltage 219 OV Inhibit Time 180 Tot Reactive Power 245 OW Inhibit Time

140 Warn History 3 152 SS Tot Real Pwr 168 L3-N Voltage 220 OV Trip Delay 181 L1 Apparent Power 246 OW Trip Delay

141 Warn History 4 153 SS Tot kVAR 169 Ave Voltage L-N 221 OV Triip Level 182 L2 Apparent Power 247 OW Trip Level

142 TripHistory Mask 15 4 SS Tot kVA 170 Volt Unbalance 222 OV Warn Level 183 L3 Apparent Power 248 OW Warn Level

143 WarnHistory Mask 155 SS Total PF 171 Volt Frequency 223 Ph Rot Inhib Time 184 Tot Apparent Power 249 UVARC Inhibit Time

299 V TripHist Mask 172 V Phase Rot 224 Ph Rot Trip 185 L1 PF 250 UVARC Trip Delay

300 V WarnHist Mask 229 V UnhalInhib Time 186 L2 PF 251 UVARC Trip Level

301 PW TripHist Mask 230 V UnbalTripDelay 187 L3 PF 252 UVARC Warn Level

302 PW WarnHist Mask 231 V UnbalTrip Level 188 Total PF 253 OVARC Inhibit Time

Voltage

➌ Voltage Setup ➌

Monitor

Power Monitor

➌ Power Setup ➌

232 V UnbalWarnLevel 189 kWh 10E6 254 OVARC Trip Delay

233 UF Inhibit Time 190 kWh 10E3 255 OVARC Trip Level

234 UF Trip Delay 191 kWh 10E0 256 OVARC Warn Level

235 UF Trip Level 192 kWh 10E-3 257 UVARG Inhibit Time

236 UF Warn Level 193 kVARh Con 10E6 258 UVARG Trip Delay

237 OF Inhibit Time 194 kVARh Con 10E3 259 UVARG Trip Level

238 OF Trip Delay 195 kVARh Con 10E0 260 UVARG Warn Level

239 OF Trip Level 196 kVARh Con 10E-3 261 OVARG Inhibit Time

240 OF Warn Level 197 kVARh Gen 10E6 262 OVARG Trip Delay

289 PT Pri 198 kVARh Gen 10E3 263 OVARG Trip Level

290 PT Sec 199 kVARh Gen 10E0 264 OVARG Warn Level

200 kVARh Gen 10E-3 265 UVA Inhibit Time

201 kVARh Net 10E6 266 UVA Trip Delay

202 kVARh Net 10E3 267 UVA Trip Level

203 kVARh Net 10E0 268 UVA Warn Level

204 kVARh Net 10E-3 269 OVA Inhibit Time

205 kVAh 10E6 270 OVA Trip Delay

206 kVAh 10E3 271 OVA Trip Level

207 kVAh 10E0 272 OVA Warn Level

208 kVAh 10E-3 273 UPFLG Inhibit Time

209 kW Demand 274 UPFLG Trip Delay

210 Max kW Demand 275 UPFLG Trip Level

211 VAR De mand 276 UPFLG Warn Level

212 Max VAR Demand 277 OPFLG Inhibit Time

213 VA Demand 278 OPFLG Trip Delay

214 Max VA Demand 279 OPFLG Trip Level

227 PW Trip Status 280 OPFLG Warn Level

228 PW Warnn Status 281 UPFLD Inhibit Time

282 UPFLD Trip Delay

283 UPFLD Trip Level

284 UPFLD Warn Level

285 OPFLD Inhibit Time

286 OPFLD Trip Delay

287 OPFLD Trip Level

288 OPFLD Warn Level

291 Demand Period

292 Num of Periods

Publication 193-QR003B-EN-P - October 2009

Page 24

24

Setup for Cat. No. 193-EC4 Current Monitor Relay

After the E3 Plus Current Monitor Relay is installed according to the guidelines specified in

this manual, apply power to the relay’s DeviceNet connector. After applying power, the

following sequence should occur:

1. The Trip relay should close 2.35 seconds later and the TRIP/WARN LED will not

flash (unless a Non-Volatile Fault previously existed or a fault condition is present).

2. At the same time, the NETWORK STATUS LED should flash green for

approximately two seconds, then red for a 1/4 second. If autobaud is enabled and the

E3 Plus Current Monitor Relay is connected to an active network, the green LED will

continue to flash once the baud rate has been determined. If the E3 Plus Current

Monitor Relay is not connected to an active network, the LED will not continue to

flash.

3. Once the E3 Plus Current Monitor Relay has been allocated by a master, the

NETWORK STATUS LED will turn solid green.

After being powered up, use the DeviceNet Configuration Terminal (Cat. No. 193-DNCT) in

order to set up the parameters. There are six basic parameters that need to be established

before using the trip functions. These parameters are listed under the ADVANCED SETUP

menu and include: L1 UC Trip Level, L2 UC Trip Level, L3 UC Trip Level, L1 OC Trip Level,

L2 OC Trip Level, and L3 OC Trip Level. After the parameters have been configured, enable

the specific trip bit as described in Table 7: for Parameter 24 (Trip Enable) to energize the relay

when conditions are met.

Once these parameters are set, the E3 Plus Current Monitor Relay is functional. Use the

ADVANCED SETUP menu to set other parameters per the specific application

requirements.

Publication 193-QR003B-EN-P - October 2009

Page 25

Protective Trip/Warning Summaries & Parameter Group Listing

(Cat. No. 193-EC4)

Table 7: Trip Summary

25

Tri p

Function

Ground Fault Disabled 0.02…5 A 2.5 A 0.0…25 s 0.5 s 0…250 s 10 s

L1

Undercurrent

L2

Undercurrent

L3

Undercurrent

L1

Overcurrent

L2

Overcurrent

L3

Overcurrent

L1 Loss Disabled — — 0.5…25 s 0.5 s 0…250 s 1.0 s

L2 Loss Disabled — — 0.5…25 s 0.5 s 0…250 s 1.0 s

L3 Loss Disabled — — 0.5…25 s 0.5 s 0…250 s 1.0 s

Comm Fault Disabled — — — — — —

Comm Idle Disabled — — — — — —

Remote Trip Disabled — — — — — —

Trip Enable

Factory

Default

Disabled 0.2…45 A — 0.1…25 s 1.0 s 0…250 s 1.0 s

Disabled 0.2…45 A — 0.1…25 s 1.0 s 0…250 s 1.0 s

Disabled 0.2…45 A — 0.1…25 s 1.0 s 0…250 s 1.0 s

Disabled 0.4…270 A — 0.1…25 s 1.0 s 0…250 s 1.0 s

Disabled 0.4…270 A — 0.1…25 s 1.0 s 0…250 s 1.0 s

Disabled 0.4…270 A — 0.1…25 s 1.0 s 0…250 s 1.0 s

Trip Level Settings Trip Delay Settings Inhibit Time

Range Default Range Default Range Default

Settings

Publication 193-QR003B-EN-P - October 2009

Page 26

26

Table 8: Warning Summary

Warning

Function

Ground Fault Disabled 0.02…5 A 2.0 A 0.0…25 s 0.0 s 0…250 s 10 s

L1

Undercurrent

L2

Undercurrent

L3

Undercurrent

L1

Overcurrent

L2

Overcurrent

L3

Overcurrent

L1 Loss Disabled — — — — 0…250 s 1.0 s

L2 Loss Disabled — — — — 0…250 s 1.0 s

L3 Loss Disabled — — — — 0…250 s 1.0 s

Comm Fault Disabled — — — — — —

Comm Idle Disabled — — — — — —

Remote Trip Disabled — — — — — —

Warning

Enable

Factory

Default

Disabled 0.2…45 A — — — 0…250 s 1.0 s

Disabled 0.2…45 A — — — 0…250 s 1.0 s

Disabled 0.2…45 A — — — 0…250 s 1.0 s

Disabled 0.4…270 A — — — 0…250 s 1.0 s

Disabled 0.4…270 A — — — 0…250 s 1.0 s

Disabled 0.4…270 A — — — 0…250 s 1.0 s

Warning Level

Settings

Range Default Range Default Range Default

Warning Delay Settings Inhibit Time

Settings

Publication 193-QR003B-EN-P - October 2009

Page 27

Table 9: Parameter Group Listing (Cat. No. 193-EC4)

27

Monitor

Params

1 L1 Current 26 Trip Reset 24 Trip Enable 55 AutoBaudEnable 65 OutA Pr FltState 79 Comm Override

2 L2 Current 53 Program Lock 25 Warning Enable 56 NonVol Baud Rate 66 OutA Pr FltValue 80 Network Override

3 L3 Current 54 Set to Defaults 35 GF Inhibit Time 58 COS Mask 67 OutA DN FltState 81 Net Outputs

10 GF Current 103 Test Enable 36 GF Trip Delay 59 Output Assembly 68 OutA DN FltValue

14 Trip Status 104 Clear Queue 37 GF Trip Level 60 Input Assembly 69 OutA DN IdlState

15 Warning Status 38 GF Warn Level 61 Assy Word0 Param 70 OutA DN IdlValue

16 Trip Log 0 83 IN 1 Assignment 62 Assy Word1 Param 71 OutB Pr FltState

17 Trip Log 1 84 IN 2 Assignment 63 Assy Word2 Param 72 OutB Pr FltValue

18 Trip Log 2 85 IN 3 Assignment 64 Assy Word3 Param 73 OutB DN FltState

19 Trip Log 3 86 IN 4 Assignment 74 OutB DN FltValue

20 Trip Log 4 89 GF Trip Inhibit 75 OutB DN IdlState

21 Device Status 101 # of Starts 76 OutB DN IdlValue

22 Firmware 102 Operating Hours

23 Dev Config 105 GF Warn Delay

90 Warn Log 0 106 GF Sensing Range

91 Warn Log 1 107 UC Inhibit Time

92 Warn Log 2 108 L1 UC Trip Level

93 Warn Log 3 109 L1 UC Trip Delay

94 Warn Log 4 110 L1 UC Warn Level

95 Elapsed Time 111 L2 UC Trip Level

96 Starts Counter 112 L2 UC Trip Delay

Reset / Lock Advanced Setupt DeviceNet Setup Output Setup

113 L2 UC Warn Level

114 L3 UC Trip Level

115 L3 UC Trip Delay

116 L3 UC Warn Level

117 OC Inhibit Time

118 L1 OC Trip Level

119 L1 OC Trip Delay

120 L1 OC Warn Level

121 L2 OC Trip Level

122 L2 OC Trip Delay

123 L2 OC Warn Level

124 L3 OC Trip Level

125 L3 OC Trip Delay

126 L3 OC Warn Level

127 LL Inhibit Time

128 L1 Loss Trip Delay

129 L2 Loss Trip Delay

130 L3 Loss Trip Delay

DeviceLogix

82 Net Out COS

Mask

Publication 193-QR003B-EN-P - October 2009

Page 28

28

ATTENTION

!

ATTENTION

!

Table 10: Parameter Group Listing (Cat. No. 193-EC4), Continued

132 Trip History 0 144 SS L1 Current

133 Trip History 1 145 SS L2 Current

134 Trip History 2 146 SS L3 Current

135 Trip History 3 148 SS GF Current

136 Trip History 4

137 Warn History 0

138 Warn History 1

139 Warn History 2

140 Warn History 3

141 Warn History 4

142 TripHistory Mask

143 WarnHistory Mask

➊ Series C (FRN 5.00 and Higher)

TripWarn History ➊ Tri p Snap shot ➊

Short-Circuit Ratings

To prevent electrical shock, disconnect from power source before

installing or servicing

Select the motor branch circuit protection that complies with the

National Electrical Code and any othergoverning regional and local

codes

The Bulletin 193/592 E3 Overload relay is suitable for use on circuits capable of delivering

not more than the RMS symmetrical amperes listed in the followign tables:

Publication 193-QR003B-EN-P - October 2009

Page 29

29

Table 11: Standard Fault Short-Circuit Ratings per UL 508 and CSA 22.2, No. 14

Cat. No. Max. Available Fault

Current [A]

193-EC_B, 592EC_T 5000

193-EC_D, 592EC_C 5000

193-EC_E, 592EC_D 10000

193-EC_F 10000

193-EC_G 18000

193-EC_H 42000

193-EC_Z 5000

Max. Voltage [V]

600

Publication 193-QR003B-EN-P - October 2009

Page 30

30

Table 12: High Fault Short-Circuit Ratings per UL 508 and CSA 22.2, No. 14 with

Bulletin 100-C and 100-D contactors

Cat. No. Contactor Max.

100-C09 9

100-C12 12 20

100-C16 16 30

100-C23 23 30

100-C30 30 50

100-C37 37 50

100-C43 43 70

100-C60 60 80

100-C72 72 100

100-C85 85 150

100-D210 210 400

100-D250 250 400

100-D300 300 500

100-D210 210 400

100-D250 250 400

100-D300 300 500

100-D300 300 500

100-D420 420 600

193-EC1

193-EC2

193-EC3

193-EC4

193-EC5

_B

_D

_E

FF, ZZ 100-D95 95 200

FF, ZZ 100-D110 110 200

FF, ZZ 100-D140 140 250

GF, ZZ 100-D180 180 300

GG, ZZ

HG, ZZ

JG, ZZ

Starter

FLC [A]

Max. Available

Fault Current

[A]

100000 600

Max.

Voltage

[V]

Max. Class J or CC

Fuse [A]

20

Publication 193-QR003B-EN-P - October 2009

Page 31

31

Table 13: High Fault Short-Circuit Ratings per UL 508 and CSA 22.2, No. 14 with

NEMA contactors

Cat. No. Contactor

592-EC1

592-EC2

592-EC3

592-EC5

Size

_T 00 100000 600 — 20 —

_C

_C 1 100000

_C 2 100000

_D 3 100000

Max. Available

Fault Current

[A]

0 100000

Max.

Voltage

[V]

Max. UL Fuse [A] Circuit Breaker/

240

480

600 30 30 —

240

480

600 30 50 —

240

480 60 100 —

600 60 100 —

240 200 350

480 100 200

600 100 200

Table 14: IFC Short-Circuit Ratings per EN60947-4-1

RJ

30

30

60

30

100

30

30

100

50

200

Limiter

FDB 3025/

LFB3070R

FDB 3025/

LFB3070R

FDB 3050/

LFB3035R

FDB 3050/

LFB3035R

FDB 3100/

LFB3150R

FDB 3150/

LFB3150R

FDB 3125/

LFB3150R

FDB 3100/

LFB3150R

Cat. No. Prospective

Short-Circuit

Current I

[A]

r

193-EC_B, 592EC_T 1000

193-EC_D, 592EC_C 3000

193-EC_E, 592EC_D 5000

193-EC_F 10000

193-EC_G 18000

193-EC_H 30000

193-EC_Z 1000

Conditional

Max. Voltage [V]

Short-Circuit

Current Iq [A]

100000 690

Publication 193-QR003B-EN-P - October 2009

Page 32

32

Fuse Coordination

Table 15: IEC Type 1 and Type II Fuse Coordination with Bulletin 100-C and 100-D

Contactors per EN60947-4-1

Cat. No. Contactor Max.

100-C09 9

100-C12 12 20 20

_B

100-C16 16 30 30

100-C23 23 40 40

100-C30 30

_D

100-C37 37 50 50

100-C43 43 70 70

100-C60 60 80 80

_E

100-C72 72 100 100

193-EC1

193-EC2

193-EC3

193-EC4

193-EC5

100-C85 85 5000 150 150

FF, ZZ 100-D95 95

FF, ZZ 100-D110 110 200 200

FF, ZZ 100-D140 140 250 250

GF, ZZ 100-D180 180 300 300

100-D210 210 400 400

GG, ZZ

100-D250 250 400 400

100-D300 300 500 500

100-D210 210 400 400

HG, ZZ

100-D250 250 400 400

100-D300 300 500 500

100-D300 300 500 500

JG, ZZ

100-D420 420 600 600

Starter

FLC [A]

Prospective

Short-Circuit

Current I

1000

3000

10000

r

[A]

Conditional

Short-Circuit

Current I

[A]

q

100000 600

Max.

Voltage

[V]

Type I

with Class

J Fuse [A]

20 15

50 50

200 200

Type II

with

Class J

Fuse [A]

Publication 193-QR003B-EN-P - October 2009

Page 33

Table 16: Type 1 and Type II Fuse Coordination with NEMA Contactors

33

Cat. No. Contactor

592-EC_T 00 9 1000

592-EC_C 0, 1 18, 27 3000 30 30

592-EC_C 2 45 3000 60 60

592-EC_D 3 90 5000 200 200

Size

Max.

Starter

FLC [A]

Prospective

Short-Circuit

Current Ir [A]

Conditional

Short-Circuit

Current Iq [A]

100000 600

Max.

Voltage

[V]

Type I with

Class J

Fuse [A]

20 20

Type II

with Class

J Fuse [A]

Publication 193-QR003B-EN-P - October 2009

Page 34

Publication 193-QR003B-EN-P - October 2009 PN-37176

Supercedes publication 193-QR003A-EN-P - January 2008 Copyright ©2009 Rockwell Automation, Inc. All Rights Reserved. Printed in USA

Loading...

Loading...