Page 1

Installation Instructions

SYNCPRO II™

Publication 1902-IN001B-EN-E

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from

) describes some

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Product Description

Table of Contents

Chapter 1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Synchronous Motor Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Protection Theory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Optional Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Display/Metering Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Typical Synchronous Starter Components . . . . . . . . . . . . . . . . . . . . . . . . . 11

Motor Contactor (M) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Motor Contactor Pilot Relay (CR1 or MR) . . . . . . . . . . . . . . . . . . . . 11

Field Voltage Relay (FVR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Equipment Shutdown Relay (ESR) (Included with SyncPro II) . . 11

Phase Angle Transducer (Included with SyncPro II). . . . . . . . . . . . . 11

Discharge Resistor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Field Contactor (FC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Resistors Rf1 and Rf2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Analog/Digital Pulse Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Input/Output Descriptive Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Listing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Field Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Fault Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Custom. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

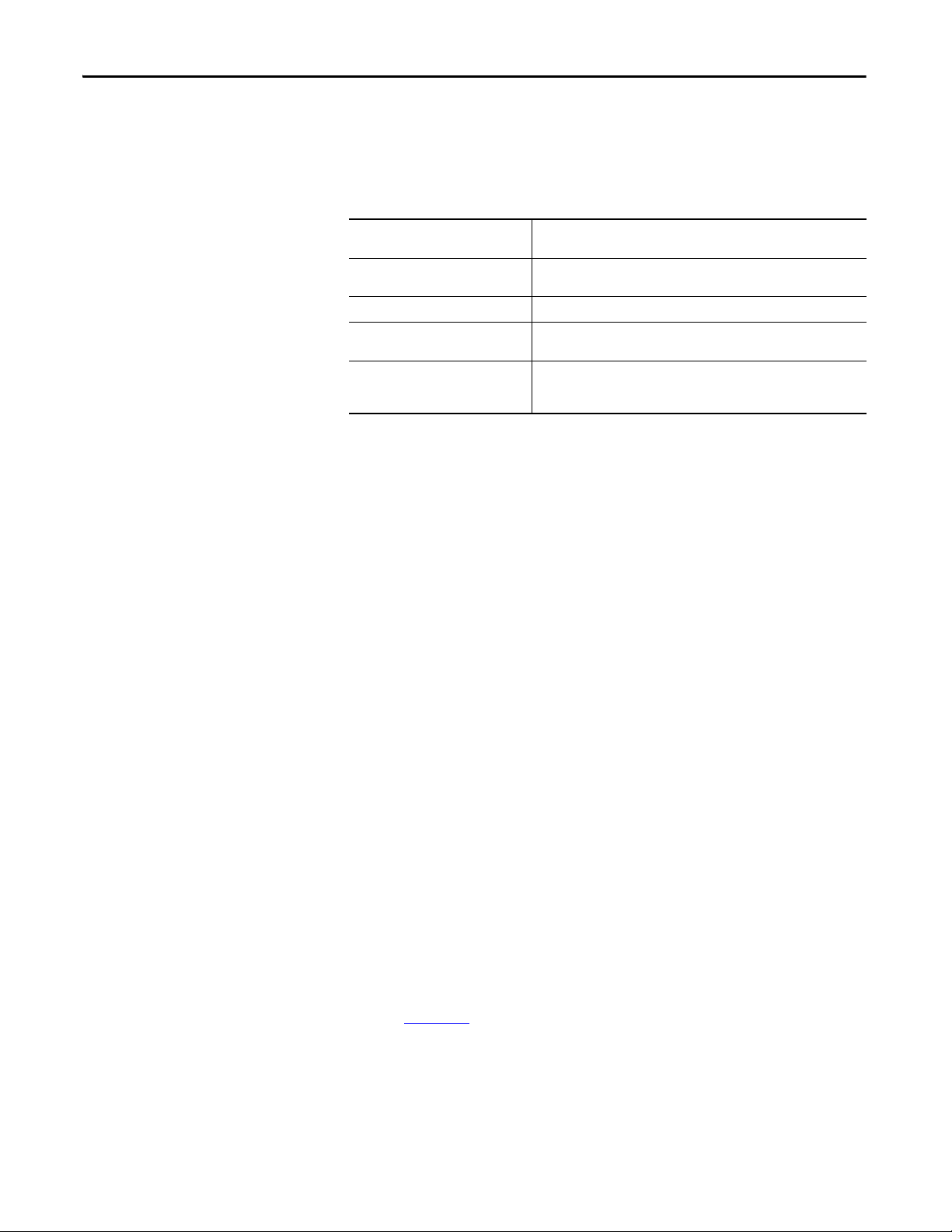

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

For Phase Angle Transducer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

PVc C400 Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

MicroLogix 1500 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Receiving and Storage

Installation

Chapter 2

Receiving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Chapter 3

Arrangements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Component Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Open Frame Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Wiring Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Rockwell Automation Publication 1902-IN001B-EN-E - April 2013 3

Page 4

Table of Contents

Chapter 4

Setup and Commissioning

Programming SyncPro II

Setup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

RF1 & RF2 Resistor Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Procedure for Selection of Resistors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

RF1 & RF2 Resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

“RF” Resistor tap settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Chapter 5

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Main Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

SyncPro II Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

View Set Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Set Point 1: Minimum Percent Synchronous Slip Frequency . . . . . 41

Set Point 2: Operating Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Set Point 3: Function Number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Set Point 4: Squirrel-Cage Protection Trip Time (at 95% speed). . 43

Set Point 5: Squirrel-Cage Protection Trip Time (at 50% speed). . 43

Set Point 6: Squirrel-Cage Protection Trip Time (at stall) . . . . . . . . 43

Set Point 7: Incomplete Sequence Trip Time Delay. . . . . . . . . . . . . . 44

Set Point 8: Power Factor Trip. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Set Point 9: Power Factor Trip Time Delay . . . . . . . . . . . . . . . . . . . . . 44

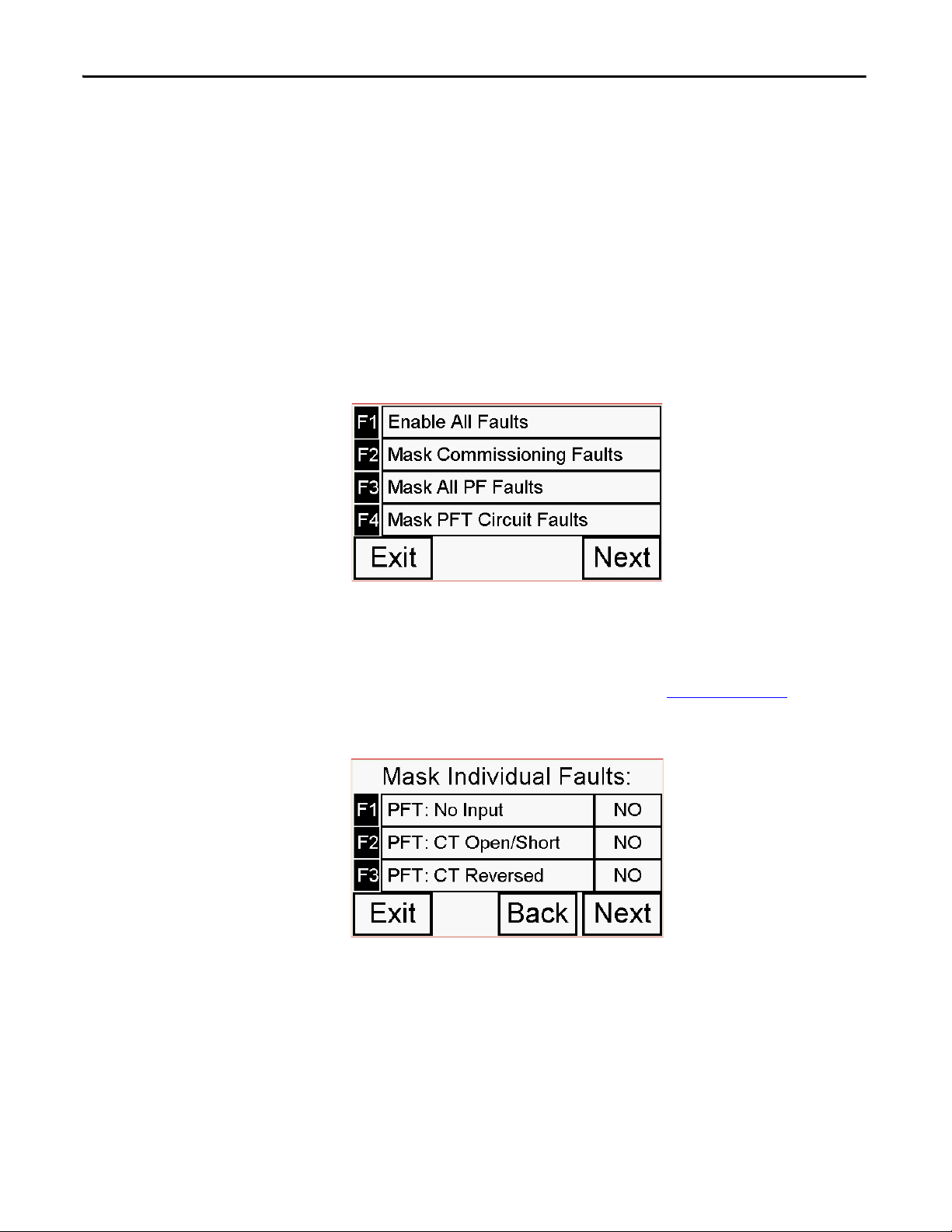

Set Point 10: Diagnostic Fault Mask. . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Edit Set Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Set Point 1: Minimum % Synchronous Slip Frequency. . . . . . . . . . . 45

Set Point 2: Operating Frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Set Point 3: Function Number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Set Point 4: Squirrel-Cage Protection Trip Time (at 95% speed). . 47

Set Point 5: Squirrel-Cage Protection Trip Time (at 50% speed). . 47

Set Point 6: Squirrel-Cage Protection Trip Time (at stall) . . . . . . . . 47

Set Point 7: Incomplete Sequence Trip Time Delay. . . . . . . . . . . . . . 47

Set Point 8: Power Factor Trip. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Set Point 9: Power Factor Trip Time Delay . . . . . . . . . . . . . . . . . . . . . 48

Set Point 10: Diagnostic Fault Mask. . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Alarm History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Access Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Chapter 6

Monitoring

4 Rockwell Automation Publication 1902-IN001B-EN-E - April 2013

Phase Angle/Power Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Fault Detection and Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Power Factor Circuit Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Page 5

Chapter 7

Table of Contents

Troubleshooting

Spare Parts

Last Trip Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Chapter 8

SyncPro II Spare Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Rockwell Automation Publication 1902-IN001B-EN-E - April 2013 5

Page 6

Table of Contents

Notes:

6 Rockwell Automation Publication 1902-IN001B-EN-E - April 2013

Page 7

Product Description

IMPORTANT

Chapter 1

Introduction

The SyncPro II consists of a programmable small logic controller

(MicroLogix™ 1500) with the following additional peripheral items:

• PanelV iew™ Component Terminal C400

• Power Factor Transducer

• Analog/Digital Pulse Board

• Conditioning Resistors

• Interposing Relays FSR and ESR

The SyncPro II system is designed to provide supervisory protection and field

control to a brush-type synchronous motor controller, proper field application

timing, squirrel-cage protection against long acceleration and stall conditions as

well as running pullout protection by monitoring motor power factor. When

combined with a suitable induction motor protection relay, the SyncPro II

provides the necessary overload protection to the brush-type synchronous

motor.

Although the SyncPro II makes use of some standard MicroLogix 1500

programmable controller components, it is imperative that the controller is a

dedicated unit expressly for the control and protection of the field of a single

synchronous motor. The firmware and hardware configuration must only be

used for its designed purpose. Do not attempt to modify the controller in any

way for another use. No additional PLC control cards can be added nor should

the firmware/program be modified.

Related Documentation

The following publications contain information for components associated with

the SyncPro II.

Publicati on 2711C-IN001_-EN-P PanelView Component Terminal - Installation Instructions

Publicati on 1900-2.10

Publicati on 900-1.0

Publicati on SGI-1.1 Safety Guidelines for Application, Installation and Maintenance

Publicati on 1764-UM001_-EN-P

Rockwell Automation Publication 1902-IN001B-EN-E - April 2013 7

Measuring for Synchronous Motor Data

Synchronous Motor Control

MicroLogix 1500 Programmable Controller

Page 8

Chapter 1 Product Description

Synchronous Motor Theory

The synchronous motor is a commonly used industrial motor favored for its

higher efficiency, superior power factor, and low inrush currents. Typical

applications that benefit from the constant operating speed include refiners, head

box fan pumps, chippers, etc. Synchronous motors are particularly well suited to

low RPM applications. The synchronous brush-type motor is composed of a

three-phase stator winding, a DC rotor winding, and a squirrel-cage winding.

The stator winding is identical to that of an induction motor and, as such, the

direction of motor rotation depends on the rotation of the stator flux. The

direction can be changed by reversing two of the stator leads, just as it does with

induction motors.

The rotor contains laminated poles which carry the DC field coils that are

terminated at the slip rings. It also has a squirrel-cage winding composed of bars

embedded in the pole faces and shorted by end rings. The squirrel-cage winding

is also known as “damper” or “amortisseur” winding. This winding enables the

motor to accelerate to near synchronous speed so that the DC supply can be

applied to the field windings for synchronizing the motor to the line (typically

95%).

These field windings are connected through slip rings to a discharge resistor

during start up. The resistor is required to dissipate the high voltages that are

induced into the field windings from the stator, and it is removed from the circuit

when the DC field voltage is applied. The synchronous motor can be compared

to a transformer, with the three-phase stator resembling the primary and the field

winding acting like a secondary. Through this transformer action, an induced

voltage is generated in the motor field during starting. The induced signal can be

used to protect the squirrel-cage winding by monitoring the motor speed during

acceleration and to determine when the DC field can be excited for

synchronization. At zero speed, the frequency induced into the field is 60 Hz, at

95% speed the frequency induced is 3 Hz (for a 60 Hz system).

Once at 95% speed, the DC field is supplied with either 125 V DC or 250 V DC

and the discharge resistor is removed from the circuit. The excitation in the field

windings creates north and south poles in the rotor which lock into the rotating

magnetic field of the stator. The slip rings are used to connect the field windings

to the discharge resistor and static exciter. It is at these slip rings that the field

resistance of the motor can be measured to confirm the required field voltage and

current at rated power factor. If, for example, the field voltage is 125 V DC and

the current is 20 amps DC, then the resistance measured should be about 6 Ω,

based on Ohms Law.

8 Rockwell Automation Publication 1902-IN001B-EN-E - April 2013

Page 9

Product Description Chapter 1

Protection Theory

Theory of Operation

When the NOT STOP and START signals go high, an internal timer is started

(see Figure 4

start can be initiated. The timer is preset based on the slip frequency of the

motor. If the timer expires prior to achieving the maximum asynchronous speed,

the starting sequence will halt, the TRIP output will be dropped and the

PanelView will display a message indicating the faulted condition. The TRIP

signal is restored when there are no faults and the Fault/Reset PB input is

received.

NOTE: The NOT STOP and START can be tied together to indicate a RUN

condition to control the device without separate signals. The RUN output

follows the start input if the motor is permitted to start, (i.e. no faults and the

EQUIPMENT SHUTDOWN is high).

If the programmed percentage of synchronous speed is obtained within set time

limits, the FIELD RELAY is energized. The power factor is now monitored and

displayed on the PanelView. If the power factor drops below the programmed

values, the TRIP and FIELD RELAY outputs will be dropped and the

PanelView 300 will display a message indicating the faulted condition. Under

normal conditions the FIELD RELAY is maintained until the NOT STOP

signal is removed.

and Figure 5). The START signal must be dropped before another

The slip frequency is calculated from a square wave input representing the slip

frequency. Based on this frequency, the allowable starting time is calculated. This

calculation is based on three set points which are entered by the user, as well as a

‘function order’ used to shape the curve. The three required set points for

squirrel-cage protection trip time are:

• Set Point 4: at synchronizing = 95%

• Set Point 5: at 50% speed

• Set Point 6: at stalled

The time curve between stalled frequency and 50% speed is assumed to be linear.

The time between 50% speed and the synchronizing speed is to the nth order

such that unity makes it linear, 2-5 makes it exponential in nature. The higher the

order, the shorter the times near to 50% speed and the higher the times near the

synchronous speed set point (i.e. bottom of curve (time vs. frequency) is flatter

and then rises more steeply).

NOTE: If the time set point at the maximum programmed percentage of

synchronous speed is set below that of the extended stall (i.e. 50% speed curve),

the function between 50% speed and synchronous speed will also be treated as

linear. (For example, the slope between 50% speed and synchronizing speed is

flatter than the slope between stalled and 50% speed).

Rockwell Automation Publication 1902-IN001B-EN-E - April 2013 9

Page 10

Chapter 1 Product Description

When the maximum programmed percentage of synchronous speed (set point) is

obtained, the field coil is energized on the falling pulse of the negative square

wave (i.e. a rising sinusoid) from the slip frequency generator. A fixed time period

after synchronization, the autoload signal is raised. The field coil is energized

only if the TRANSITION COMPLETE has been received.

Display/Metering Features

Squirrel-Cage Winding Protection Protects the squirrel-cage winding from long acceleration and stall

conditions during starting.

Field Winding Application Control The signal that triggers application of the field excitation when the

programmed asynchronous speed is obtained.

Incomplete Sequence Timing Relay Trips the system if the overall starting time is exceeded.

Pull Out Protection Monitors the lagging power factor during running to detect a loss of

synchronism

Fiel d Voltage Failure Rel ay Input Monitors the condition of the static exciter output. This relay must be

supplied by the customer if the SyncPro II is not supplied as a configured

unit within an Allen-Bradley motor controller.

Optional Equipment

• Field Current Failure Relay

• Load and Unload Auxiliary Contacts – The outputs are energized 2 sec.

after the field is applied and is maintained until the field is removed.

The product in conjunction with the PanelView 300e Micro Terminal (PV) will

perform the following metering/display functions:

• display all detected fault conditions

• display the slip frequency and starting time during startup

• display the power factor during run mode.

• accept set points for the following:

– maximum % asynchronous speed [% of synchronous speed]

– power factor set point and trip delay

– maximum allowable time at stalled state (maximum slip

– maximum allowable time at 50% speed

– maximum allowable time at synchronizing speed (typically at 95%

speed)

– function order (allows adjustment of the slope of the acceleration/stall

time trip curve).

– incomplete sequence timer trip delay

– fault mask for PF transducer diagnostics

Refer to Chapter 5

10 Rockwell Automation Publication 1902-IN001B-EN-E - April 2013

for complete details.

Page 11

Product Description Chapter 1

Typical Synchronous Starter Components

Motor Contactor (M)

The following details outline some of the common components that which the

SyncPro II can be connected to, or are part of the SyncPro II protection package.

The motor contactor is used to provide and switch the power supplied to the

motor stator. It is controlled by the SyncPro II package and is necessary to remove

stator power in the event of a stop command or a trip condition. Two normally

open contactor auxiliaries may be required; one mandatory N.O. contact to give

contactor status information to the SyncPro II, and one may be needed as a holdin contact for the main control circuit.

Motor Contactor Pilot Relay (CR1 or MR)

This interposing relay allows the SyncPro II output to pick up the main contactor

coil. The power requirements of the pick-up coils used in most medium voltage

motor starters would exceed the switching capability of the 1764-24BWA output

contact.

Field Voltage Relay (FVR)

When energized, this DC relay indicates that the DC exciter supply is healthy

and producing an adequate level of DC excitation. The field voltage relay is

required to prevent starting the motor unless DC excitation is available. A field

voltage relay is recommended as the SyncPro II does not have the ability to

determine the level of the exciter output voltage. It is needed to prevent

unnecessary starts when synchronization cannot occur.

Equipment Shutdown Relay (ESR) (Included with SyncPro II)

The ESR relay combines the status of customer supplied protective and interlock

devices to a single contact input on the SyncPro II.

When ESR is energized, it is an indication that all external trip and interlock

contacts to the SyncPro II are in a "not tripped" condition. All external trips and

interlocks must be wired in series with the ESR coil in order to be properly

addressed by the SyncPro II.

Phase Angle Transducer (Included with SyncPro II)

The phase angle transducer provides a conditioned 4...20 mA signal to the analog

module of the SyncPro II system. The transducer is factory calibrated to provide a

specific output at zero (0) lagging power factor, at 1.0 or unity power factor, and

at zero (0) leading power factor. These factory settings must not be altered.

Rockwell Automation Publication 1902-IN001B-EN-E - April 2013 11

Page 12

Chapter 1 Product Description

The SyncPro II processor scales and interprets this signal to compare it to the

power factor trip set point and to cause a trip to occur if the power factor drops

below the programmed value for more than the specified power factor trip time

delay. If the DC excitation is lost, a low voltage condition exists, or the motor is

being overloaded to a point where the motor can no longer maintain

synchronous speed, the motor power factor will react by dropping to a very

lagging value. This indicates that the motor is slipping poles and the controller

should be shut down to protect the motor.

The phase angle transducer monitors voltage across lines 1 and 2, along with the

current in line 3 to obtain a power factor reading. When the reading is below the

set points programmed, the SyncPro II will shut down the starter.

Discharge Resistor

The discharge resistor is specified by the motor manufacturer for a specific

application to obtain correct starting and pull in torques and to provide a means

of discharging the motor induced field voltage when starting and stopping the

motor. The field winding has more turns than the stator winding and when

power is applied to the stator, the field acts like the secondary windings of a

current transformer. A field winding without a discharge path will produce a

voltage greater than its insulation rating, and as such, requires a means to

discharge or limit the voltage. If the discharge resistor is not connected during a

start, the induced voltage can build to a point where the field winding insulation

can be damaged. The resistor is also used to provide reference points to the

SyncPro II synchronous motor protector (see Chapter 4

).

Field Contactor (FC)

The field contactor provides two normally open and one normally closed power

poles. The normally open contacts apply DC power to the motor field windings

when the contactor is energized. Prior to energization and after de-energization,

the normally closed pole makes the path to the discharge resistor to allow the

dissipation of energy induced in the field during starting. It also provides a path

to discharge the stored energy in the large inductive motor field winding on

stopping of the motor.

Resistors RF1 and RF2

These resistors are used to attenuate the voltage which reaches the analog/digital

pulse board. Set up of these resistors is important because if the signal voltage to

the board is too low (too much resistance) then pulses will not be produced. If

too little resistance is used, the voltage may be too high which could damage the

analog/digital pulse board (see Figure 10 on page 33

).

12 Rockwell Automation Publication 1902-IN001B-EN-E - April 2013

Page 13

Product Description Chapter 1

IMPORTANT

Analog/Digital Pulse Board

This board converts the voltage sinusoidal waveform across the discharge resistor

and, by examining the zero crossings, creates a digital pulse train of an equal

frequency to the induced slip frequency occurring in the discharge resistor. At

start (zero speed), the frequency will be 60 Hz, at 95% speed, the frequency will

be 3 Hz (for a 60 Hz system). This feedback is used by the SyncPro II to

determine the speed of the motor at any time during acceleration and when the

motor has reached the desired speed set point to synchronize.

Input/Output Descriptive Control

Listing

NOT STOP INPUT (I:2/0)

This signal must be maintained high for the SyncPro II to operate. When the

signal is taken low, the software identifies this as a normal stop for the motor.

The SyncPro II does NOT have control over stopping the motor. The main

portion of the motor controller performs this control function.

The NOT STOP signal must be given in parallel to that of the hardware, i.e.

from the same PLC output or push button.

START INPUT (I:2/1)

The rising edge of this signal starts the operation of the SyncPro II. This signal is

maintained high for two-wire control or may be dropped after initial starting if

three-wire control is used. In both cases, this signal controls the START output.

After a fault has occurred, this input must be taken low before another start

command will be recognized (see Figure 4

RUN OUTPUT (O:0/1)

and Figure 5).

This output is used to control motor starting. It is the START input conditioned

by all permissives. That is to say that this output will follow the state of the input

as long as all permissives are met. Thus in two-wire control, this output is actually

a RUN command and will stay high until either a fault occurs or a stop is issued.

In three-wire control the output is maintained only as long as the input is

maintained, a fault occurs, or a stop is issued.

Rockwell Automation Publication 1902-IN001B-EN-E - April 2013 13

Page 14

Chapter 1 Product Description

EQUIPMENT SHUTDOWN RELAY (ESR) INPUT (I:2/7)

This fault input is used to group all external faults. It notifies the SyncPro II that

the system has stopped for an external reason. The SyncPro II will send a message

indicating the reason for the stoppage. In the normal state this signal is held high,

going low on a fault condition. While this signal is low, a start signal will not be

accepted. Typically, all emergency stops or external faults (i.e. overloads, motor

protection relays) will be wired to an ESR relay. This relay is then fed into the

SyncPro II for logging and control and also tied into the hardware to stop the

motor.

TRIP OUTPUT (O:0/0)

This output is high during normal conditions. When the SyncPro II detects a

fault, the output goes low and the SyncPro II stops the motor

typically wired into the ESR circuit. It will be set high when there are no faults

and the FAULT RESET PB is momentarily raised high.

. The trip output is

Field Application

TRANSITION COMPLETE CONTACT INPUT (I:2/6) (OPTIONAL)

The field relay output will not be energized until this input permissive is given. Once

the field relay is picked up, this permissive is no longer required. If the permissive

is not given prior to the squirrel-cage protection timing out or the incomplete

sequence timing out, the SyncPro II will fault and stop the motor.

If unused, it must be tied high. This input is intended for an external input such as

the RUN contact of an autotransformer starter. It prevents synchronization until

the autotransformer starter has first transitioned to full voltage RUN mode.

FIELD RELAY OUTPUT (O:0/2)

This output controls the field contactor relay which applies the field to the

motor. This output is energized when the transition complete permissive is given

and the synchronous setpoint has been reached. The field is then applied either on

the rising waveform or after a fixed time period of one second if the motor

synchronizes on reluctance torque. The output is dropped whenever the NOT

STOP is removed, the EQUIPMENT SHUTDOWN RELAY is removed, or a

fault is detected.

14 Rockwell Automation Publication 1902-IN001B-EN-E - April 2013

Page 15

Product Description Chapter 1

Feedback

MOTOR CONTACTOR FEEDBACK CONTACT INPUT (I:2/8)

This input indicates to the SyncPro II that the motor contactor is closed,

confirming that the motor is running. It also allows the SyncPro II to detect a

fault in the contactor circuit.

FIELD CONTACTOR FEEDBACK CONTACT INPUT (I:2/5)

This input indicates to the SyncPro II that the field contactor has picked up,

confirming that the field has been applied. (The signal must come from the

auxiliary of the coil which ultimately applies the field, i.e. contactor.) If missing,

the SyncPro II detects a fault in the field circuit.

TRIP/RESET PB INPUT (I:2/2)

This input from the push button on the panel will reset any fault condition in the

SyncPro II. Once no fault exists, the fault condition will be removed from the

PanelView and the TRIP output will be set.

Fault Detection

FIELD VOLTAGE RELAY INPUT (I:2/3)

When the signal is low, it indicates a lack of field voltage. This input is monitored

for a fault condition only while starting, prior to applying the field. Tie this input

high if it is not used. When this contact is high, it verifies that the static exciter is

providing an appropriate DC voltage.

FIELD CURRENT RELAY INPUT (I:2/4) (OPTIONAL)

When the signal is low, it indicates a lack of field current. This input is monitored

for a fault condition after the field has been applied. Tie this input high if it is not

used. This optional input verifies there is DC current flowing from the static

exciter to the motor field. It is redundant since the power factor trip feature will

trip if the field current is lost.

POWER FACTOR INPUT (I:1/0)

The signal supplied to the SyncPro II is from the Phase Angle Transducer,

representing a power factor of zero (0) lagging to zero (0) leading respectively.

Note that the SyncPro II firmware has been tailored to this specific transducer.

No substitution is allowed.

Rockwell Automation Publication 1902-IN001B-EN-E - April 2013 15

Page 16

Chapter 1 Product Description

SLIP GENERATOR POWER INPUT (I:0/1)

This fault input is monitored during idle and starting periods. It is normally held

high by the power supply to the Slip Pulse Generator.

SLIP GENERATOR NEGATIVE INPUT (-) (I:0/0)

Connect to the negative terminal (N) of the Slip Pulse Generator.

SLIP GENERATOR POSITIVE INPUT (+) (I:0/2)

Connect to the positive terminal (P) of the Slip Pulse Generator.

Status

AUTO LOAD OUTPUT (O:0/3)

Output is energized two seconds after the field is applied and remains closed

until the field is removed from the motor by a stop or a fault.

SCP TRIP OUTPUT (O:0/8)

Output is set high when a Squirrel-Cage Protection Fault occurs. It is reset when

the TRIP output goes high after pushing the reset button. This signal can be used

for indication, via a pilot light, or it can be used as an optional trip output.

MOTOR PULLOUT TRIP OUTPUT (O:0/9)

Output is set high when the power factor lags for longer than the programmed

trip time delay indicating that the motor has pulled out. It is reset when the TRIP

output goes high after pushing the reset button. This signal can be used for

indication, via a pilot light, or it can be used as an optional trip output.

INCOMPLETE SEQUENCE TRIP OUTPUT (O:0/10)

Output is set high when an Incomplete Start Sequence Fault occurs. It is reset

when the TRIP output goes high. This signal can be used for indication, via a

pilot light, or it can be used as an optional trip output.

Custom

I:2/10 to I:2/15 are custom fault inputs. If any are true, they trip the unit off.

16 Rockwell Automation Publication 1902-IN001B-EN-E - April 2013

Page 17

Product Description Chapter 1

Specifications

General

Operating Power

Input Line Voltage 120V AC, 50/60 Hz

Input Current 0...5 A

Temperature and Humidity

Temperature

(Maximum Ambient)

Humidity 5...95% (non-condensing)

Operating: 0...40ºC (32...104ºF)

Storage: -20...65ºC (-4...149ºF)

Maximum temperature: 40 ºC (104 ºF)

For Phase Angle Transducer

General

Accuracy 3% span

Housing Flame retardant plastic case

Weight 2.4 kg maximum

Climate

Storage -20...70 ºC (-4...158 ºF)

Temperature range Operational at 0...60 ºC (32...140 ºF)

Calibrated at 23 ºC (73 ºF)

Humidity Up to 95% relative humidity, non-condensing

Input

Frequency 50/60 Hz

Current 0.2...10 A

Range (A) 20...120%

Burden 5 VA maximum

Voltage 115...230V, ±10%

Range (V) ±20% (20...120% with separate auxiliary)

Overload Capacity

Six times rated current for 30 s

1.25 rated voltage for 10 s

Electrical Tests

Dielectric Test 2 kV RMS per BS 5458

Impulse Test 5 kV transient as BEAMA 219 and BS 923

Surge Withstand ANSI C37-90A

Certification CSA Approved

Burden 1 VA maximum

PVc C400 Specifications

MicroLogix 1500 Specifications

See Publication 2711C-IN001_-EN-P, pages 30...31.

See Publication 1764-UM001_-EN-P, Appendix A.

Rockwell Automation Publication 1902-IN001B-EN-E - April 2013 17

Page 18

Chapter 1 Product Description

Notes:

18 Rockwell Automation Publication 1902-IN001B-EN-E - April 2013

Page 19

Receiving and Storage

IMPORTANT

Chapter 2

Receiving

Storage

Upon receiving the controller, remove the packing and check for damage that

may have occurred during shipping. Report any damage immediately to the

claims office of the carrier.

If the SyncPro II is an integral component of a brush-type synchronous starter,

special receiving and handling instructions will apply. For details, refer to the

service manual provided with the equipment.

It is important to consider the following storage requirements if you are not

installing your controller immediately after receiving it.

• Store the controller in a clean, dry, dust-free environment.

• Storage temperature must be maintained between -20...65 °C (-4...149 °F).

• Relative humidity must not exceed 95%, non-condensing.

Rockwell Automation Publication 1902-IN001B-EN-E - April 2013 21

Page 20

Chapter 2 Receiving and Storage

Notes:

22 Rockwell Automation Publication 1902-IN001B-EN-E - April 2013

Page 21

Installation

Chapter 3

Arrangements

The SyncPro II is offered in three arrangements.

Component Level

The SyncPro II may be ordered as individual components for maximum

flexibility when installing the controller. The user may then mount the

components in a configuration most suitable to his main motor controller

equipment layout. Care must be exercised to ensure the SyncPro II processor has

adequate ventilation provided around it. Refer to Figure 6

the components.

Figure 1 - SyncPro II Component Configuration

for typical wiring of

Rockwell Automation Publication 1902-IN001B-EN-E - April 2013 23

Page 22

Chapter 3 Installation

IMPORTANT

18.02 [458]

16.75 [425]

13.29

[338]

18.95

[481]

20.00

[508]

0.38[10]

13.75[349]0.63 [16]

0.36 [9] dia.

(4) Mounting Holes

5.1

[113]

Front View

Side View

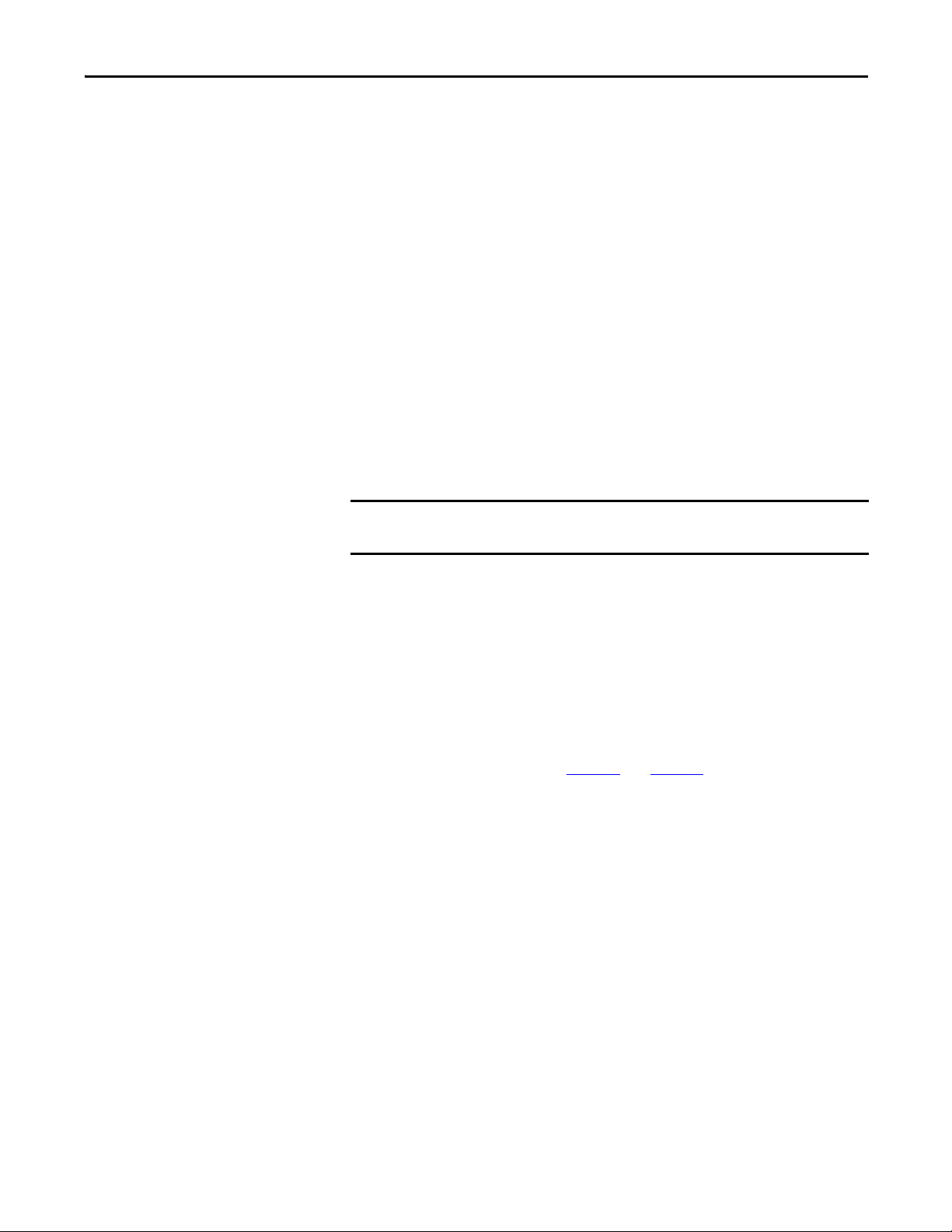

Open Frame Configuration

The SyncPro II components are mounted on a panel, except the PanelView

display module and the illuminated push button for trip indication and reset

function. See Figure 2

installation within the main controller is possible with this arrangement.

Figure 2 - Mounting Dimensions

for mounting dimensions of the main unit panel. Quick

The PanelView is supplied with a two-meter cord for connection with the

SyncPro II processor. Mount the PanelView in a suitable location to make this

connection.

24 Rockwell Automation Publication 1902-IN001B-EN-E - April 2013

Page 23

Figure 3 - Component Layout

Bul. 1606 DC Power Supply

FSR, ESR Relays

SyncPro II

Phase Angle Transducer

Terminal Blocks

Analog/Digital Pulse

Conver ter Board

Conditioning Resistors,

RF1 and RF2

Installation Chapter 3

Grounding

Integral to a completed low voltage or medium voltage controller

The SyncPro II is also available as a component of a Rockwell Automation/AllenBradley synchronous motor controller, incorporating the components shown in

Figure 3

remain the same.

The grounding required by the SyncPro II panel has been brought to a common

grounding bar mounted on the panel. It is important that once the unit is installed,

that this grounding bar is wired to the starter ground bus. It is important that a proper

ground is made as the SyncPro II has a number of low voltage signals which, if not

properly grounded, may be vulnerable to noise causing erratic operation.

. Although the layout in the starter is different, control and functionality

Rockwell Automation Publication 1902-IN001B-EN-E - April 2013 25

Page 24

Chapter 3 Installation

Wiring Guidelines

The SyncPro II can accept either two- or three-wire control. The control chosen

will determine the configuration of the control hardware. Consider the following

two inputs and single output when selecting the type of control:

I:2/0 NOT STOP input

I:2/1 START input

O:0/1 RUN output

If using two-wire control, the two inputs (I:2/0 and I:2/1) are tied together.

They are both low in order to stop the SyncPro II (see Summary

on page 32) and

both high in order to run the device. To start the device after a fault, the START

input (I:2/1) must be taken low and then closed again. In this configuration, the

RUN output acts as a run command (see Figure 4

).

If using three-wire control, the NOT STOP input must be maintained high in

order to run the device. Momentarily opening this input will cause the SyncPro II

to stop (see Summary

on page 32). Momentarily closing the START input will

start the SyncPro II (given that all permissives are satisfied). In this configuration,

the RUN output acts as a start command (see Figure 5

Figure 4 - Two-wire Control

).

In both cases, the RUN output will follow the state of the START input,

provided that all starting conditions are met. Note that in all cases, stopping the

motor is done via the hardwired control circuit logic, and notification only is

given to the SyncPro II.

Figure 4

shows a typical two-wire control circuit. The selector switch is used to

control the NOT STOP and the START as a pair. It is also used to ensure the

motor is stopped via the hardwired control circuit logic, (even though in this case

the RUN output will be removed when the selector switch is turned off ).

26 Rockwell Automation Publication 1902-IN001B-EN-E - April 2013

Page 25

Installation Chapter 3

The ESR circuit ensures the motor is stopped for any fault condition occurring

either externally or when detected by the SyncPro II. Once the ESR has dropped

out (detected by the loss of I:2/7), the selector switch must be switched off and

on to initiate a start. This prevents a premature start if the fault condition is

cleared and the selector switch is still in the run position.

Figure 5

shows a typical three-wire control circuit. The STOP PB must be

maintained high in order to initiate a start and to run the system. The button also

ensures that the motor is stopped via the hardware circuit. The momentary

START PB is used to create a RUN (START) output signal of the same duration

as the input signal as long as there are no faults detected by the SyncPro II.

Figure 5 - Three-wire Control

Rockwell Automation Publication 1902-IN001B-EN-E - April 2013 27

Page 26

Chapter 3 Installation

L1

____V AC, 3Ø, __Hz

ISOLATING SWITCH

DOOR INTERLOCK

CURRENT LIMITING

GRDL2 L3

POWER FUSES

R1

R2

(-)

(+)

F1

F2

G

NPC

V

(+)

PULSE CONVERTER

ANALOG/DIGITAL

R

W

BLK

(-)

DANGER

AUTOMATICALLY.

SEVERE INJURY OR DEATH.

OF LOAD CAN RESULT IN

UNEXPECTED ENERGIZATION

RESETTING ANY DEVICE.

CONTROL SIGNAL BEFORE

REMOVE MAIN CONTACTOR

CONTROLLER

MAY AUTOMATICALLY

RESET OR RESETS

START/RE-START AFTER

A PROTECTIVE DEVICE IS

!

REFER TO DIMENSION DRAWING FOR COMPONENT SIZING NOT SHOWN ON THIS DRAWING.

REMOTE EQUIPMENT

LOW VOLTAGE DOOR MOUNTED DEVICE

"IEEE" NUMBER FOR PROTECTIVE DEVICE

CUSTOMER

WIRING

NOTESNOTESNOTES

D

LEGENDLEGENDLEGEND

SYNCHRONOUS

MOTOR

MPS

COM

INPUT 1

INPUT 2

Y1-

Y12

Y14

RX

BUL. 825P MODULAR PROTECTIVE SYSTEM

AUX 2

CBCT

PTC

(THERMISTOR)

INPUT

ALARM

AUX 1

TO MCM

COMCOM

INPUT 3INPUT 3

INPUT 5INPUT 5

INPUT 4INPUT 4

OUTPUTOUTPUT

ANALOGANALOG

5454

4343

4444

5353

3333

3434

I-I-

I+I+

6363

6464

Y26Y26

Y22Y22

Y24Y24

Y2-Y2-

120 V PIO OPTION CARD

AUX

AUX

AUX

AUX

TRIP

24

S1

S2

13

23

14

A2-

98

95

96

A1+

T1

T2

3

4

5

6

FRONT PANEL

LOCAL PROGRAMMING

PORT

POWER

FAILSAFE

FAILSAFE

NON

RS232

POWER APPLIED. THE FOLLOWING FACTORY INSTALLED

OUTPUT RELAY CONTACTS SHOWN WITHOUT CONTROL

BUL.825P TO BE PROGRAMMED BY THE CUSTOMER

AUX.1/ALARM - NON FAIL SAFE

CONTACT POWER-UP STATES ARE IN EFFECT:

BEFORE START-UP.

AUX.2 - NON FAIL SAFE

TRIP - FAIL SAFE

BUL.825P NOTES:

D

2

1

46

35

CONVERTER MODULE

BLK

W

PRIMARY FUSES

CURRENT LIMITING

FROM RECTIFIER ASSEMBLY

SHT.2, LINE K-238

FROM SHT.4

LINE H-415

FROM RECTIFIER ASSEMBLY

SHT.2, H-238

LINE C-301

BLK

B

R

W

DEVICENET

OPTION CARD

TO DEVICENET NETWORK

RTD 1 - RTD 12

BUL.825P RTD MODULE

MPSRTD

+

23

+

24

N

240VAC

120VAC

N

25

26

NOT USED

19

20

21

22

FIBRE OPTIC

CONNECTOR

SHOWN ON SHT.3

500M MAX.

L3

L2

L1

N

PHASE

VOLTAGE

INPUT

MIO OPTION CARD

(OPTIONAL)

AND/OR PROTECTION RELAYS.

WILL OVERRIDE METERING DEVICES

USE OF SHORTING TERMINAL BLOCK

CAUTION:

SHORTING

TERMINAL

BLOCK

BLK

W

PHASE ANGLE TRANSDUCER

BLK

W

V

VA

V

DANGER

INDUCED FIELD VOLTAGES

HIGH VOLTAGE

CONTACT WITH

SYNCHRONOUS MOTOR

EXCEED 1000 VOLTS.

STARTING AND MAY

IN SEVERE INJURY.

FIELD CONNECTED

COMPONENTS CAN RESULT

OR DEATH

ARE PRESENT DURING

!

LIVE CIRCUIT

MORE THAN ONE

DANGER

!

LINE B-202

3 PHASE

H3

X3

H1

H2

X1

X2

VV

VV

TO SHT.3

TO SHT.2

TO SHT.3

LINE D-331

FROM SHT.3

LINE E-337

LINE N-302

TO SHT.3

LINE C-318

TO SHT.3

LINE D-330

90

91

VB

PT

____ ____

120 120

FFF__E __E __E

VCVBVA

____

120

500

CPT

VAA

VCA

F5

1.0AF51.0A

47A

46B

44A

42A

STB

PAT

1

12

52

1

12

51

__EF2

6

__EF2

5

ISa

7

46A

47

46

44

42

CM

GFCT

100:1

113

1L2A

1L1A

104

103

M

101

RF

102

RF

105

A/DPC

F1

F2

CT1

CT3

CT2

T3

T2

T1

RD

304

F1

F1

F1

IS

Figure 6 - Typical Wiring A

28 Rockwell Automation Publication 1902-IN001B-EN-E - April 2013

Page 27

Figure 7 - Typical Wiring B

DOOR MOUNTED POTENTIOMETER IS USED TO ADJUST THE MOTOR FIELD

CURRENT UP TO THE MAXIMUM VALUE.

FIELD CURRENT SETTINGS:

HIGH TEMPERATURE WIRE

NOTES

LEGEND

(-)

RECTIFIER TRANSFORMER

LIMITING FUSES

PRIMARY CURRENT

BOARD

SWITCH

FIELD

SNUBBER

SECONDARY FUSES

TB2

SW1

PSRB

115 230

FU

4

POT

AMMETER

DC

COMMAND

DOOR

2+1

-

687

3

FIELD CURRENT

MAX. LIMIT POT.

COMMAND

REMOTE

FIRING

9

5

10

TB3

4

5

TB1

132

ENABLE

REMOTE

R56

(0.5V)

(0-10V)

(0-10mA)

COM

SIG

+10V@10mA

COM

SIG

+10V@10mA

CONTROL

VOLTAGE

SELECTOR

SWITCH

(+)

BOARD

SCR FIRING

SINGLE PHASE

FCRO4100

DISCHARGE RESISTOR

SWITCH

HEATSINK

THERMOSTAT

RECTIFIER ASSEMBLY

RECTIFIER

STACK

+

DC AMMETER

FROM SHT.3

LINE D-319

FOR 125VDC EXCITER OUTPUT JUMPER X1-X3, X2-X4 FOR 160V AC.

FOR 250V DC EXCITER OUTPUT JUMPER X2-X3 FOR 320V AC

SCR+X2

SCR-X1

BLK

W

BR

BR

R

-

(7)

(4)

R

W

(5)

(2)

(6)

(3)

BLK

(NOT USED)

THERMOSTAT

24 VAC

THERMOSTAT

687

534

687

534

1

2

1

2

J9

MOV

THERMOSTAT

NEG-K

2

21

J7

1

- BUS

34

3

4

656

5

NEG-G

R2-K

R2-G

MOV

(3)

6

4

5

3

12

7

THERMOSTAT

+ BUS

(NOT USED)

(NOT USED)

(NOT USED)

MOV

L1

L2

2

P8

J8

1

3

4

657

8

RST

L3

8

(3)

R

R

R2

(1)

+

G

K

(7)

(6)

(1)

X2

(5)

(4)

G

K

SCR-X2

(2)

K

G

(7)

(6)

(1)

X1

(5)K(4)

G

SCR+X1

(2)

-X2

+X2

G44

125

125

GKK

J2 J2

-X1

+X1

215

6

J1

G

56K1

2

J1

G

K

L2

L1

J3

545

4

2

3

1

2

3

1

77

+5

COM 11

12

COM

SIG HI

9108

12

11910

8

+12

I

6541231

65423

1

J6

J4

3

4

P7

P9

WRW

R

R

W

R

W

SFSB

DRS

HST

SCRFB

TO SHT.1

LINE Q-111

TO SHT.1

LINE Q-103

FROM SHT.1

LINE G-111

LEM

POWER

SUPPLY/

REGULATOR

BOARD

D

D

LOW VOLTAGE DOOR MOUNTED DEVICED

FROM SHT.3

LINE D-333

12

1

12

1

3

3

A

118

117

RTR

X1

X3

X2

X4

H1

H2

____kVA

160V/320V

113

114

112

111

FSR

116

115

108

109

110

(3)

(2)

(1)

FIELD CURRENT ADJUST

115

5

DCCT

105

116

106

107

113

114

53

52

103104

5

Installation Chapter 3

Rockwell Automation Publication 1902-IN001B-EN-E - April 2013 29

Page 28

Chapter 3 Installation

SNUBBER FIELD SWITCH BOARD

P9 J9

I:2/08

I:2/02

SYNCPRO II

RECTIFIER

7

J9 P9

8

O:0/00

SS

VHz

TEST SUPPLY POINT

O:0/02

O:0/01

SS

AC COMMON

I:2/01

I:2/00

REMOVE JUMPER WHEN CONNECTING REMOTE EQUIPMENT

REFER TO DIMENSION DRAWING F OR COMPONENT SIZING NOT SHOWN ON THIS DRAWING.

REMOTE EQUIPMENT

CUSTOMER WIRING

METAL OXIDE VARISTOR

NOTES

MOV

LEGEND

CTB

CUSTOMER TERMINAL BLOCKS

SFSB

FIELD SWITCH

EQUIPMENT SHUTDOWN

RELAY (ESR)

RELAY (FSR)

BACK INTO NORMAL OPERATION.

ENSURE JUMPERS ARE REMOVED BEFORE PUTTING STARTER

IF THESE SYNCPRO CONTACTS HAVE BEEN JUMPERED OUT.

THE STARTER CONTRO L CAN BE OPERATED IN TEST MODE, ONLY

D D

D

D

RTD 4

32

44

434142

40393837363435

33

RTD 11RTD 12 RTD 10 RTD 9

3130292827

18141716151213

11

RTD 6RTD 7RTD 8 RTD 5

03

100908

070506

04

02

01

RTD 3 RTD 2 RTD 1

RTN

-

+

RTN

-

+

RTN

-

+

RTN

-

+

RTN

-

+

RTN

-

+

RTN

-

+

RTN

-

+

RTN

-

+

RTN

-

+

RTN

-

+

RTN

-

+

(825P)

L1

(825P)

(825P)

MAIN CONTACTOR (M)

MOV

32

1

EC

-

+

4

TCO

12

11

AUX CCO

5

6

L1

G

+-

V

V

V

AUXILIARY RELAY (MX)

SS

D

DRUN

OFF

L2J3

LOW VOLTAGE DOOR MOUNTED DEVICED

FROM SHT.1, LINE C-117

CUSTOMER BEFORE START-UP.

INTELLIVAC NOTES:

ARE IN EFFECT:

CONTACTOR STATUS - FAIL SAFE

MODULE STATUS - FAIL SAFE

OUTPUT RELAY CONTACTS SHOWN WITHOUT

CONTROL POWER APPLIED. THE FOLLOWING FACTORY

INSTALLED CONFIGURATION/POWER-UP STATES

INTELLIVAC TO BE PROGRAMMED/CONFIGURED BY THE

V

- INTELLIVAC MODULE VACUUM CONTACTOR AUXILIARY INPUTAUX

- INTELLIVAC MODULE EXTERNAL CAPACITOR INPUTEC

- I

NTELLIVAC MODULE CLOSING COIL OUTPUTCCO

- MAIN CONTACTOR INT ELLIVAC MODULEM-IV

- INTELLIVAC MODULE TRIP COIL OUTPUTTCO

TO SYNCPRO II

SHT.4, LINE C-422

DC POWER SUPPLY

TO SHT.1

LINE Q-108

TO SHT.4

LINE H-413

PANELVIEW

TO SYNCPRO II

D

D

SHT.4, LINE C-422

ETB

EXCITER

TERMINAL BLOCKS

RECTIFIER

ASSEMBLY FAN

52

52

7473727170

2

2

91

90

91

90

91

90

14A

VC

14

VA

VB

(1) (2)

(3) (4)

NORMAL

OFF

TEST

X

X

14

MX

67

MX

MX

MX

66

6061626364

65

1

14

F5

F5

VAA

VCA

F7

1A

251

51

111

12

3

4

4A

134

4A

123152

G

M

H

M

K

L

36

37

12313034333532

53

54

541253

14

14

1

58

14A

59

12

1

G

R

317316 319318MX

313 322307

321311

M-

IV

15 16

CONTACTOR

STATUS

M-IV

910

CLOSE

M-IV

F7

2.0A

C

M

M

17

20

13

M

15

AB N

MPSRTD

INPUT POWER

MPS

INPUT POWER

MPSRTD

SCRFB

INPUT POWER

MPS

95 96

98

TRIP

1

35

M

34

IJ

23

START

1A

STOP

2

SYNCPRO II

TRIP OUTPUT

SYNCPRO II

FSR OUTPUT

SYNCPRO II

RUN OUTPUT

SYNCPRO II

NOT STOP/START INPUT

SYNCPRO II

TRIP/RESET

SYNCPRO II

MAIN CONTACTOR INPUT

PAT

INPUT POWER

219 428

325

313 429

THERMOSTAT

6

11

12

4A

FSR

ESR

2

4

50

7

10

8

9

ISb

(7) (8)

X

(5)(6)

X

F3 4.0A

60120

TS

12

ESR

54

2

53

R

TRIP/RESET

31

MF

51

30

1

E

ESR

Figure 8 - Typical Wiring C

30 Rockwell Automation Publication 1902-IN001B-EN-E - April 2013

Page 29

Figure 9 - Typical Wiring D

1764-24BWA

DC

COM 1

+24V

POWER

OUT

DC

COM 0

DC

COM 2

VAC

NEUT

VAC/

VDC 0

VAC/

VDC 1

VAC/

VDC 2

VAC/

VDC 3

VAC/

VDC 4

120/240

VAC

EARTH

GND

VAC/

VDC 5

MicroLogix 1500

SLOT: BASE

1764-24BWA

MicroLogix 1500

SLOT: BASE

AC

COM 2

1769-IF4X0F2

MicroLogix 1500

SLOT: #1

1769-IA16

MicroLogix 1500

SLOT: #2

INPUT MODULE

R

W

BLK

(C)

(N)

(P)

#14 AWG

G

PANELVIEW

START

TRIP RESET

FLR INPUT

(NOT USED)

TRANSITION COMPLETE

(NOT USED)

MAIN CONTACTOR

FEEDBACK

FROM SHT.3

LINE G-325

FROM SHT.3

LINE G-321

NOT STOP

FROM SHT.3

LINE G-311

AUTOLOAD CONTROL

TO SHT.3, LINE F-318

TO SHT.1

LINE Q-106

TO SHT.3, LINE F-314

TO SHT.3, LINE F-316

TO CHASSIS GROUND

SQUIRREL CAGE MOTOR

PROTECTION TRIP

INCOMPLETE SEQUENCE TRIP

MOTOR PULLOUT

TRIP

AUTOLOAD CONTROL

TO SHT.3, LINE F-318

TO SHT.3, LINE F-314

TO SHT.3, LINE F-316

FROM SHT.3

LINE E-337

FROM SHT.3

LINE 339

D

(4-20mADC)

+-

FVR INPUT (NOT USED)

AC

COM 1

12

98

98

99

PA TRANSDUCER

91

71

14

2

53

73

74

72

50

4

54

70

FSR

ESR

31

1

69

68

1

58

3

3

12

1

12

1

12

1

MOV

NOTES

LEGEND

LOW VOLTAGE DOOR MOUNTED DEVICED

REFER TO DIMENSION DRAWING FOR COMPONENT

SIZING NOT SHOWN ON THIS DRAWING.

1764-LPR PROCESSOR

ANALOG INPUT MODULE

Installation Chapter 3

Rockwell Automation Publication 1902-IN001B-EN-E - April 2013 31

Page 30

Chapter 3 Installation

In this case (three-wire) since the START signal is only momentary, the hardware

must perform the sealing function using the control relay, CR. The START

output is really an extension of the START input, except that the output is

conditioned by any fault conditions.

The ESR circuit ensures the motor is stopped for any fault condition occurring

either externally or when detected by the SyncPro II. Once the ESR has dropped

out, a start will not be permitted until the fault condition is reset.

It should be noted that in all cases, the TRIP output is removed when a fault is

detected. This fault includes both external hardware faults (as recognized by the

EQUIPMENT SHUTDOWN signal) and faults which are generated by the

SyncPro II such as a power factor trip.

Summary

1. The RUN output will follow the state of the START input, given there are

no faults detected by the SyncPro II.

2. Once a fault is detected, the START input must be taken low before the

RUN output will be allowed to operate.

3. All motor stopping must be controlled by hardwired control circuit logic.

The SyncPro II is only notified of the stoppage to determine what is

happening. Any time the motor stops without first removing NOT STOP

input, an error condition will be detected.

4. When using three-wire control, a contact from the CR relay must be used

to seal in around the RUN output.

32 Rockwell Automation Publication 1902-IN001B-EN-E - April 2013

Page 31

Setup and Commissioning

Chapter 4

Setup

Check the following components of the SyncPro II once it has been installed.

RF1 & RF2 Resistor Setup

The synchronous motor field discharge resistor feedback resistors (RF1, RF2) are

necessary to attenuate the induced voltage waveform which appears across the

field discharge resistor during starting (Figure 11

reduce the voltage which is seen at the terminals of the analog/digital pulse

converter to a level which is acceptable to the optoisolators on the board.

Guidelines for resistor settings are contained in Tab le 1 on pa ge 3 6

The resistance value shown is the amount of resistance which is required on each

lead which is connected to the A/D pulse board (F1, F2). For example, if the

induced voltage on the discharge resistor is 1000V at zero speed and 600V at 95%

speed (across the entire discharge resistor), then it is necessary to select taps on

the RF1 and RF2 to provide 20 k

Figure 10 - Discharge Resistor Installation

Ω at RF1 and 20 kΩ at RF2.

). The resistors (RF1, RF2)

.

These settings must be made prior to any start attempt.

Rockwell Automation Publication 1902-IN001B-EN-E - April 2013 33

Page 32

Chapter 4 Setup and Commissioning

EXAMPLE

EXAMPLE

0 speed rms voltage across 1 Ω 56 / 2.828 = 20V rms

95% speed rms voltage across 1

Ω 34 / 2.828 = 12V rms

0 speed rms current across 1

Ω 20V / 1Ω = 20A rms

95% speed rms current across 1

Ω 12V / 1Ω = 12A rms

Determining the induced voltage which will appear across the discharge resistor

during starting can be done two ways.

1. If motor data is available the voltage can be determined by multiplying the

discharge resistance by the induced currents at zero and 95% speed as given

by the motor manufacturer.

Induced current @ 0% speed: 20 A

Induced current @ 95% speed:12 A

Discharge resistance: 50

Ω

Therefore:

Induced voltage @ 0% speed: 20A x 50

Induced voltage @ 95% speed: 12A x 50

Ω = 1000V

Ω = 600V

2. A measurement can be taken using a storage oscilloscope or a strip chart

recorder, see publication 1900-2.10

for correct set point values. The

waveform obtained will have a peak value which must be converted to an

rms value. This is done by dividing the peak-to-peak value by 2

√2 or 2.828.

When doing this, a portion of the discharge resistor only should be used, 1 Ω can

then be used to determine the value which will be on the entire resistor.

A strip char t recording is taken across a 1 Ω portion of a 50 Ω discharge

resistor. The following peak to peak values are obtained:

0 speed: 56V p-p

95% speed: 34V p-p

Therefore:

Once the induced voltage has been determined, make the appropriate selection

from Tab le 1 on pa ge 36

then be determined to the appropriate taps on the R

. Wires from each end of the discharge resistor should

F1 and RF2 resistors. Both

the 0 and 95% speed induced voltages must fall between the upper and lower

limits defined on the chart.

34 Rockwell Automation Publication 1902-IN001B-EN-E - April 2013

Page 33

Setup and Commissioning Chapter 4

Procedure for Selection of Resistors

RF1 & RF2 Resistor

RD = Discharge resistance __________ Ω

RSD = Sample resistance __________ Ω

Vpp0 = 0% speed peak to peak voltage __________ V (Vpeak@0)

Vpp95 = 95% speed peak to peak voltage __________ V (Vpeak@95)

Vrms 0 = Induced voltage (0% speed) __________ V (Vrms@0) Vp0/2.828

Vrms 95 = Induced voltage (95% speed) __________ V (Vrms@95) Vp95/2.828

Io = Induced current (0% speed) __________ A (Arms@0)Vrms0/Rs

I95 = Induced current (95% speed) __________ A (Arms@95)Vrms95/Rs

V0 = Induced voltage (0% speed) __________ V I0 x Rd

V95 = Induced voltage (95% speed) __________ V I95 x Rd

0 speed induced voltage across the entire discharge resistor 50 Ω * 20 A= 1000V

95% speed induced voltage across the entire di scharge resistor 50 Ω * 12 A = 600V

R

F1/RF2 Resistance Required __________ Ω

“RF” Resistor tap settings

Figure 11 - Discharge Resistor Setup

Rockwell Automation Publication 1902-IN001B-EN-E - April 2013 35

Page 34

Chapter 4 Setup and Commissioning

IMPORTANT

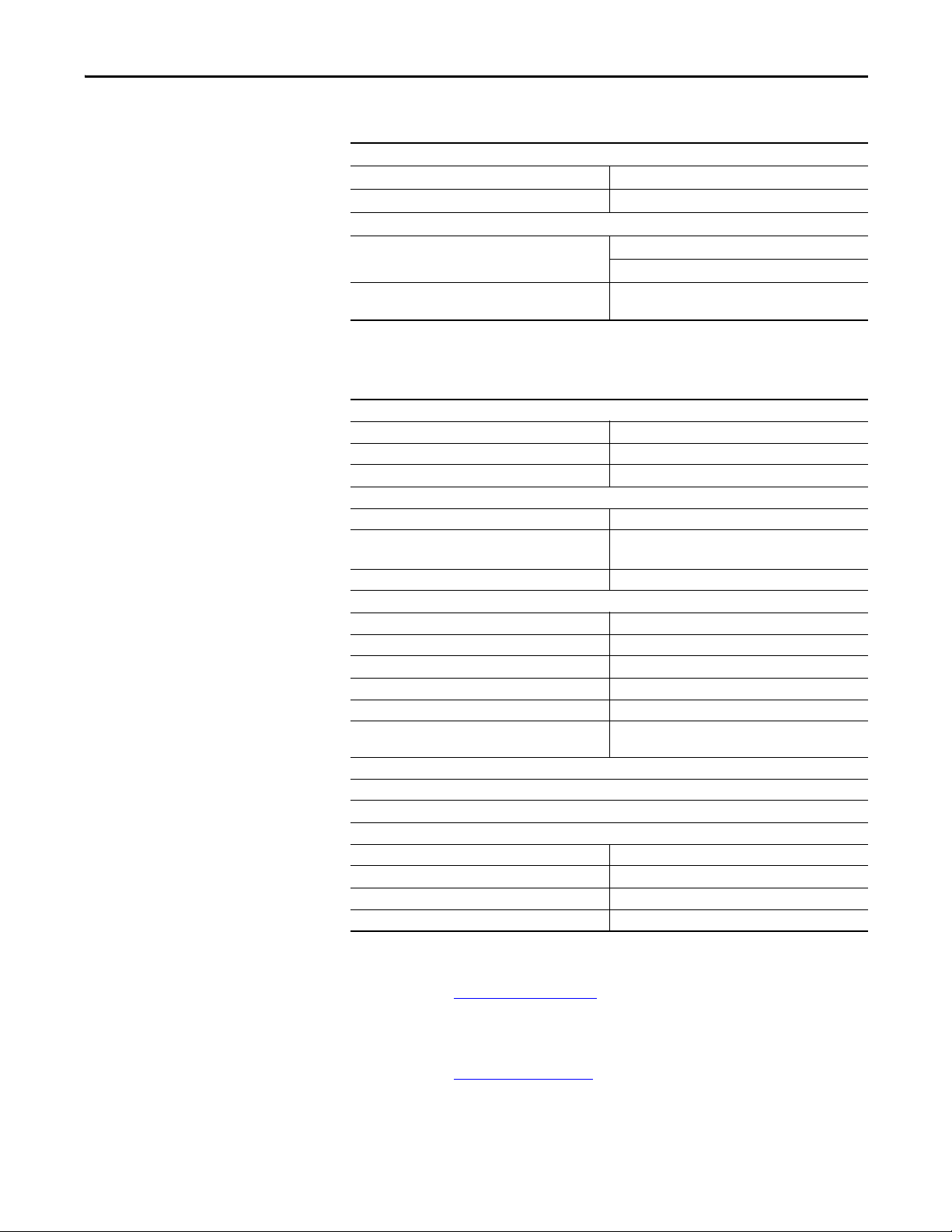

Table 1 - Feedback Resistor Values • Synchronous Field Feedback Board

RF1/RF2 Resistance (KΩ)

2.5 80 160

5160320

7.5 230 480

10 320 640

12.5 400 800

15 490 950

17.5 560 1100

20 640 1300

(1) Resistance value is per resistor (two required).

(1)

Lower Limit Upper Limit

Usable Voltage Range

Motor induced currents will cause a voltage to be produced across the

synchronous motor starter field discharge resistor. This voltage is connected to

the feedback resistors and the tap to be selected on these resistors is dependent on

this voltage level. For example, if the discharge resistor value is 20 Ω and the

induced currents are 30 A at 0 speed and 18 A at 95% speed, then the induced

voltage seen by the feedback resistors will range from 600V (0 speed) to 360V

(95% speed). The selection would then be 10 k

Ω on each of the two resistors.

Commissioning

In the event that the induced voltage proves to be higher than allowed by the

chart, it will be necessary to tap the field discharge resistor at a point which will

allow the value to fall within the chart. Contact Rockwell Automation for

assistance at 1-519-740-4790.

1. Complete and verify that the setup procedures (see page 33) have been

completed. This should include verifying that the parameters programmed

into the SyncPro II are appropriate for the motor. See Chapter 5

for

further details on programming.

2. Verify that the SyncPro II has been wired into the motor starter circuit as

indicated by the wiring diagram.

3. Remove the wire from the Field Contactor Relay (FCR) coil either at the

I/O point (0:0/2) or at the FCR coil itself. Tie back and insulate the wire

so that it cannot accidentally short out to ground or another electrical

point. This will disable the field contactor so that the starter will not

attempt to synchronize.

The contactor must be disabled in this manner rather than removing

the field cables from the contactor. The discharge path through the

discharge resistor must be maintained; otherwise, a voltage high

enough to damage the field insulation will occur at the open field

windings. This is similar to the effect which occurs if a current

transformer secondary winding is left open circuited.

36 Rockwell Automation Publication 1902-IN001B-EN-E - April 2013

Page 35

Setup and Commissioning Chapter 4

4. If during the previous setup procedure for the discharge resistors RF1 and

F2, the induced currents were not known, then the next step would be to

R

bump the motor with the R

method detailed in publication 1900-2.10

F1 and RF2 resistors disconnected. The

for determining the motor data

by measurement using a strip chart recorder should be done at this time.

The R

F1 and RF2 resistors should then be set up as shown in Figure 11

with the data obtained. It is necessary to use jumpers at the SyncPro II trip

output, and the run output, for the motor bump.

ATTENTION: During the jogging procedure, the SyncPro II does not

protect the motor. Monitor the procedure closely to avoid damage to

the motor.

ATTENTION: Do not use jumpers at the ESR contact as this will also

eliminate any external protective trips such as line overcurrent, fault

protection, etc. which are still necessary for the bump. See Figure 8

for

the jumper placement, and the points at which to disconnect the wires.

ATTENTION: During synchronization, voltages that may exceed 1000

volts are present at the Rf1 and Rf2 resistors. To avoid shock hazard, do

not touch the resistors.

The phase angle transducer, as wired from the factory, is set up for the customer

to run his wiring with an ABC line orientation. If this was not observed, the user

has two options. First, the line cables can be moved (switching any two incoming

lines will do) so that ABC now exists (BCA or CAB are also acceptable), OR the

current transformer leads to the transducer can be swapped at the transducer.

5. If the RF1/RF2 connections were removed for step 4, they should now be

reconnected at this point and set to the appropriate tap. The motor may

now be bumped for rotation. Allow the motor to accelerate to rated

subsynchronous speed and monitor the following items at this time.

• The time to accelerate to rated subsynchronous speed

• The point at which the I/O point 0:0/2 picks up (which normally

would energize the field contactor) occurs to see if it appears to be

occurring at 95% speed

• Monitor Power Factor during acceleration. It should be lagging.

• This will also prove that the power factor transducer connection is in

the correct orientation with the incoming current and voltages. If the

polarity is incorrect, switching the C3A and C3B connections should

correct the situation.

The phase angle transducer connections are correct provided that the transducer

power and voltage reference inputs are connected to Line 1 and 2 and the current

reference is Line 3. If the incoming connections into the starter have been made

B-A-C, rather than A-B-C, the polarity will also be incorrect even though the

correct starter lines have been brought to the transducer. In either event, the

correction is the same, reverse the C3A and the C3B current transformer

connections.

Rockwell Automation Publication 1902-IN001B-EN-E - April 2013 37

Page 36

Chapter 4 Setup and Commissioning

ATT EN TI ON : To avoid damage to the motor, do not allow the motor to run

without synchronizing (at 95% speed) for longer than required to perform this

test. Most motors are only capable of running for about 60 seconds at 95%

speed without synchronizing.

6. After completing the actions in Step 5, if the equipment appears to be

operating in the correct manner, then the leads can be reconnected to the

FCR coil which was removed in Step 3.

7. The motor can now be normally started. Once the motor has

synchronized, a good check is to vary the DC excitation. Verify that when

the DC current to the field is reduced, the motor power factor becomes

more lagging and if increased, the motor power factor becomes more

leading. Verify that the MicroLogix is getting all the inputs according to

the circuit diagram.

38 Rockwell Automation Publication 1902-IN001B-EN-E - April 2013

Page 37

Programming SyncPro II

Chapter 5

Overview

The SyncPro II programming is performed via the PV300 display unit provided.

The SyncPro II menu structure has been designed to optimize workflow. Please

refer to Menu Map below.

Figure 12 - Programming Menu Map

Rockwell Automation Publication 1902-IN001B-EN-E - April 2013 39

Page 38

Chapter 5 Programming SyncPro II

Main Menu

SyncPro II Status

The main menu provides access to the following screens.

SyncPro II Status Provides idle, starting, running status information

View Set Points Allows viewing of SyncPro II operation and protection set points.

Edit Set Points Allows viewing of SyncPro II operation and protection set points

Alarm History Lists alarm/fault history recorded with relative time stamping

Access Code Allows users to log in or log out to provide access control to operation and protection set points.

Settings Allow editing of general HMI configuration such as language, relative time/date stamp

These screens are displayed when the motor is idle, starting, or running. The

PVc C400 automatically switches to one of the following screens after a period of

inactivity.

Figure 13 - Ready Mode

Ready mode (Figure 13) indicates the SyncPro II has not detected any software or

hardware faults and is ready to start.

Figure 14 - Starting Mode

During the Starting mode (Figure 14), the motor slip frequency in Hz power factor in %,

and time to a squirrel cage protection in seconds are displayed. The power factor value is

accompanied by either a < or >

symbol to indicate lagging or leading power factor. Typical

power factor readings during staring are lagging. If leading power factor is displayed, please

confirm voltage and current input connections for proper sequencing (e.g. V

, Ic).

ab

40 Rockwell Automation Publication 1902-IN001B-EN-E - April 2013

Page 39

Programming SyncPro II Chapter 5

operating

slipMinimum

f

f

SP

_

1

=

Figure 15 - Running Mode

In the Running mode, the slip frequency and power factory is displayed. During

normal operation, the slip frequency is 0 Hz, and power factor is approximately

100% for unity.

View Set Points

Figure 16 - Minimum Slip Frequency

Set Point 1: Minimum Percent Synchronous Slip Frequency

This set point determines the percentage of synchronous speed at which the DC

voltage is to be applied by the field switch/contactor. The SyncPro II monitors

the frequency of the induced voltage across the discharge resistor during starting.

When this frequency indicates that the motor has achieved the desired sub

synchronous speed at which it is allowable to synchronize, the SyncPro II

energizes the coil of the field switch/contactor. The SyncPro II ensures that the

application of the field contactor coincides with the rising edge of the induced

voltage waveform which makes for a smooth transition. If the motor pulls into

synchronism due to reluctance torque, the SyncPro II will detect no pulses and

then will apply DC voltage to the field after a one second delay.

Rockwell Automation Publication 1902-IN001B-EN-E - April 2013 41

Page 40

Chapter 5 Programming SyncPro II

operating

fSP =

2

bab

a

x

b

spsp

x

sp

a

spsp

sp

spsp

spa

b

ba

kttBMfta

k

ff

k

BMft

ff

k

MftB

ff

tt

M

fffiftSP

ffiftSP

ttfFSP

+=+=

−

=

−−

−

=

−=

−

−

=

<≤=

<=

=

,

)(

,

)(

,

,

,

),,(

%50

14

1%50

26

6%50

65

2%503

%503

3

Set Point 2: Operating Frequency

This set point determines the operating system frequency. This allows the

SyncPro II to properly determine the appropriate minimum percent slip

frequency.

Figure 17 - Function Number

Set Point 3: Function Number

The function number entry determines the slope of the curve between the 50%

speed trip time and the 95% speed trip time – set point 4 and 5. Although the trip

time is set as 50% and 95% speed, the intermediate points between these values

can be shaped to cause the trips for 51% and 94% to occur more or less quickly

depending on which function number is selected. According to Figure 17

time is allowed when function 1 is selected, and less time is allowed when

function 5 is selected.

, more

42 Rockwell Automation Publication 1902-IN001B-EN-E - April 2013

Page 41

Programming SyncPro II Chapter 5

44 sp

tSP =

55 sp

tSP =

66 sp

tSP =

Table 2 - Function Numbers

Variable Function Number

t

sp4

t

sp5

t

sp6

f Detected slip frequency

f

sp1

f