Page 1

Installation Instructions

Cat. No. 1792-IB8 Series B

To: See page:

Install

the ArmorBlock Module

Connect the Wiring to the ArmorBlock Module

Communicate with Y

Configure Y

Manager Configuration T

Configure Y

Manager Configuration T

Reset Faults 25

Configure Y

For this reference information

Default Configuration

Status indicators

Troubleshooting 34

Specifications 35

our ArmorBlock Module

our ArmorBlock Module Of

ool

our ArmorBlock Module Online Using the DeviceNet

ool

our ArmorBlock Module with EDS Files

fline Using the DeviceNet

3

8

10

11

17

28

See page:

14

34

This 1792 ArmorBlock I/O block module (Cat. No. 1792-IB8)

contains I/O circuits, a built-in power supply, and a built-in DeviceNet

I/O adapter. Because of its sealed housing, this 1792 I/O block requires

no enclosure. It is compatible with PLC or SLC programmable

controllers using DeviceNet scanners. The I/O values are accessible

from the PLC or SLC programmable controller data table.

This ArmorBlock module has no switches to set. You set module

parameters using the DeviceNet Manager Software (cat. no.

1787-MGR) or similar configuration tool.

ArmorBlock is a trademark of Allen-Bradley Co. Inc.

Publication 1792-5.2 – October 1996

Page 2

ArmorBlock 8 Input Module2

European Union Directive Compliance

If this product is installed within the European Union or EEA regions

and has the CE mark, the following regulations apply.

EMC Directive

This apparatus is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) using a technical construction

file and the following standards, in whole or in part:

• EN 50081-2 EMC – Generic Emission Standard, Part 2 –

Industrial Environment

• EN 50082-2 EMC – Generic Immunity Standard, Part 2 –

Industrial Environment

The product described in this manual is intended for use in an industrial

environment.

Low Voltage Directive

This apparatus is also designed to meet Council Directive 73/23/EEC

Low Voltage, by applying the safety requirements of EN 61131–2

Programmable Controllers, Part 2 – Equipment Requirements and

Tests.

For specific information that the above norm requires, see the

appropriate sections in this manual, as well as the following

Allen-Bradley publications:

• Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

• Automation Systems Catalog, publication B111

Publication 1792-5.2 – October 1996

Page 3

ArmorBlock 8 Input Module

Install Your ArmorBlock Module

Installation of the ArmorBlock module consists of:

• setting the node address in the ArmorBlock module

• mounting the ArmorBlock module

• connecting the wiring

• communicating with your module

• configuring the parameters

Set the Node Address

Each ArmorBlock comes with its internal program set for node address

63. To set the node address, you need the following:

• host computer with DeviceNet Manager Software (or similar

configuration software tool)

• 1770-KFD RS-232 module (or similar interface)

• suitable cables to connect the 1770-KFD to your module and to

connect the 1770-KFD to your host computer

3

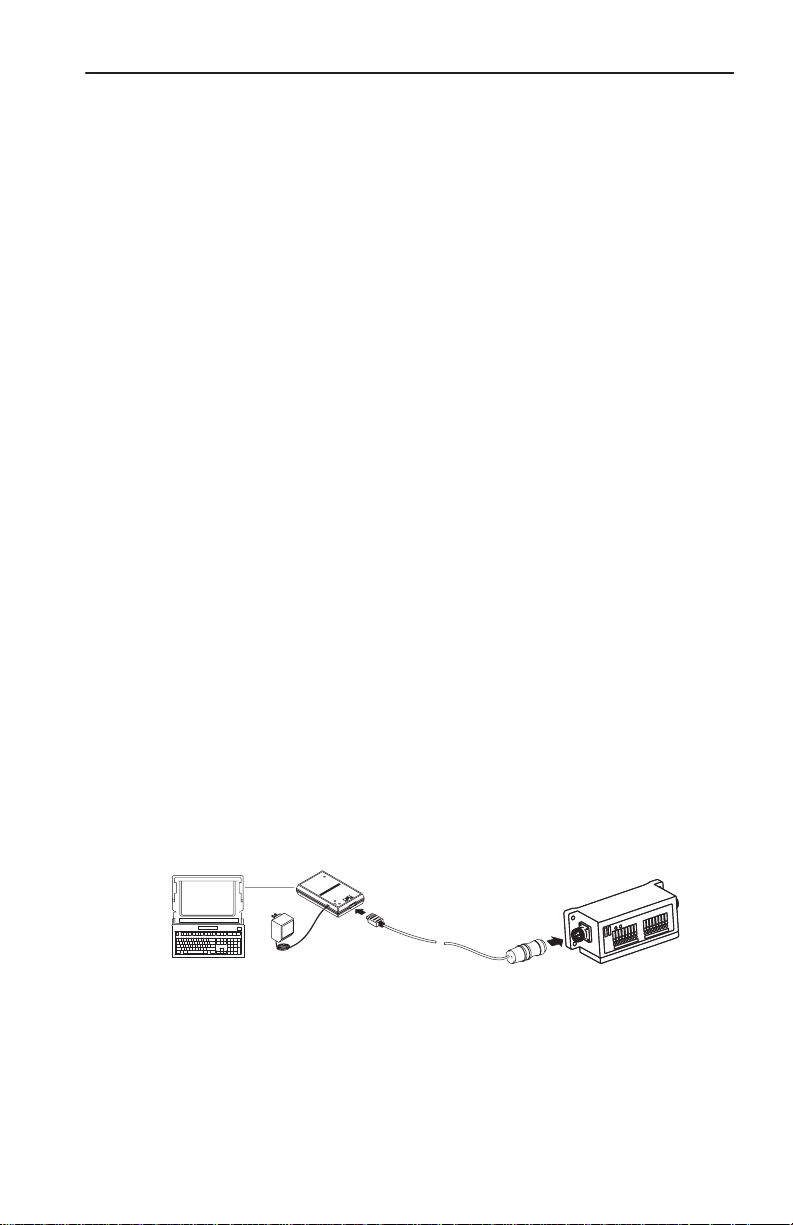

Set the node address to meet your system requirements as follows:

1. Set up a system (as shown below) to communicate with your

ArmorBlock module.

Power

from 9V DC Power-Supply Adapter

1770-KFD

RS-232 module

open style connector to

sealed mini-female cable

host computer with the

DeviceNet Manager software

power supply

Publication 1792-5.2 – October 1996

Page 4

ArmorBlock 8 Input Module4

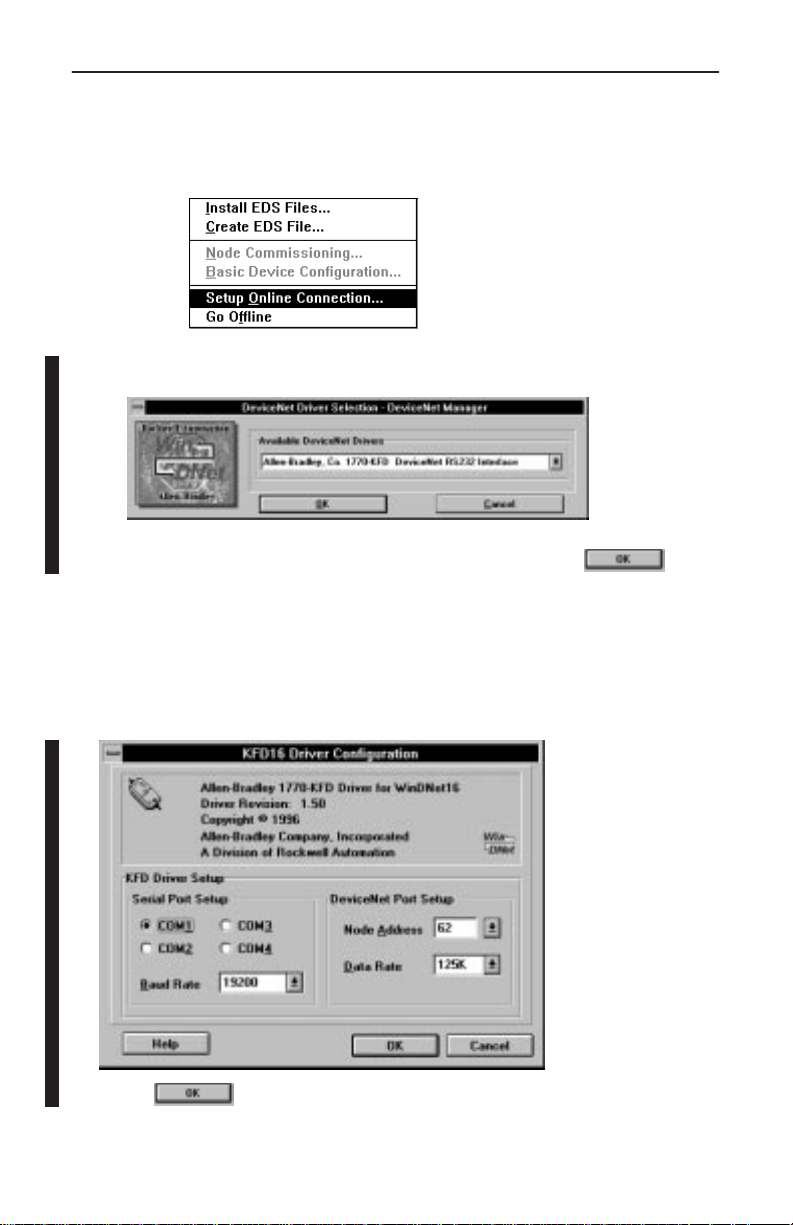

2. Using DeviceNet Manager Software, go online using the “Setup

Online Connection” selection on the utility pulldown menu.

3. The DeviceNet Driver selection screen appears.

Select the driver for your application and click on .

4. The Driver configuration screen lets you:

• set the data rate

• set the interface adapter node address

• select the interface adapter serial port

• set interface adapter baud rate

Click on to go online.

Publication 1792-5.2 – October 1996

Page 5

ArmorBlock 8 Input Module

5

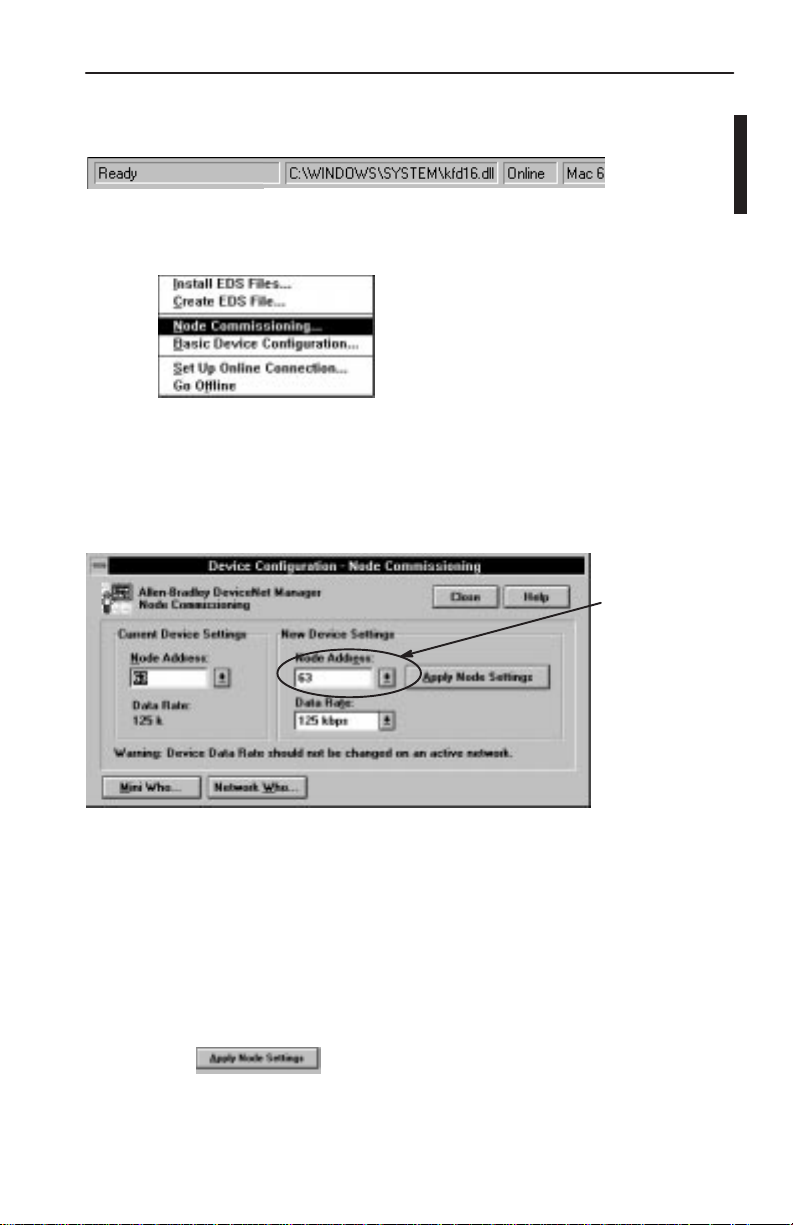

5. The bar at the bottom of the screen will tell you when you go online.

6. At the utility pulldown, select “Node Commissioning.”

7. You can set the node address on the “Device Configuration – Node

Commissioning” screen. Note that the node address “out of the box”

setting is 63. Set the desired node address per your system

requirements.

Set new node

address here.

You can also set the data rate on this screen, if required. However,

your module is shipped with the “autobaud” parameter enabled.

This assures that the module will be at the correct data rate for any

network to which it is connected. To change the data rate, you must

first disable autobaud on the parameter screen, then return to the

“Device Configuration – Node Commissioning” screen and enter

the new data rate.

8. Click on

to apply the new node settings.

9. Repeat the above procedure to set the node addresses of any

additional ArmorBlock modules you want to install.

Publication 1792-5.2 – October 1996

Page 6

ArmorBlock 8 Input Module6

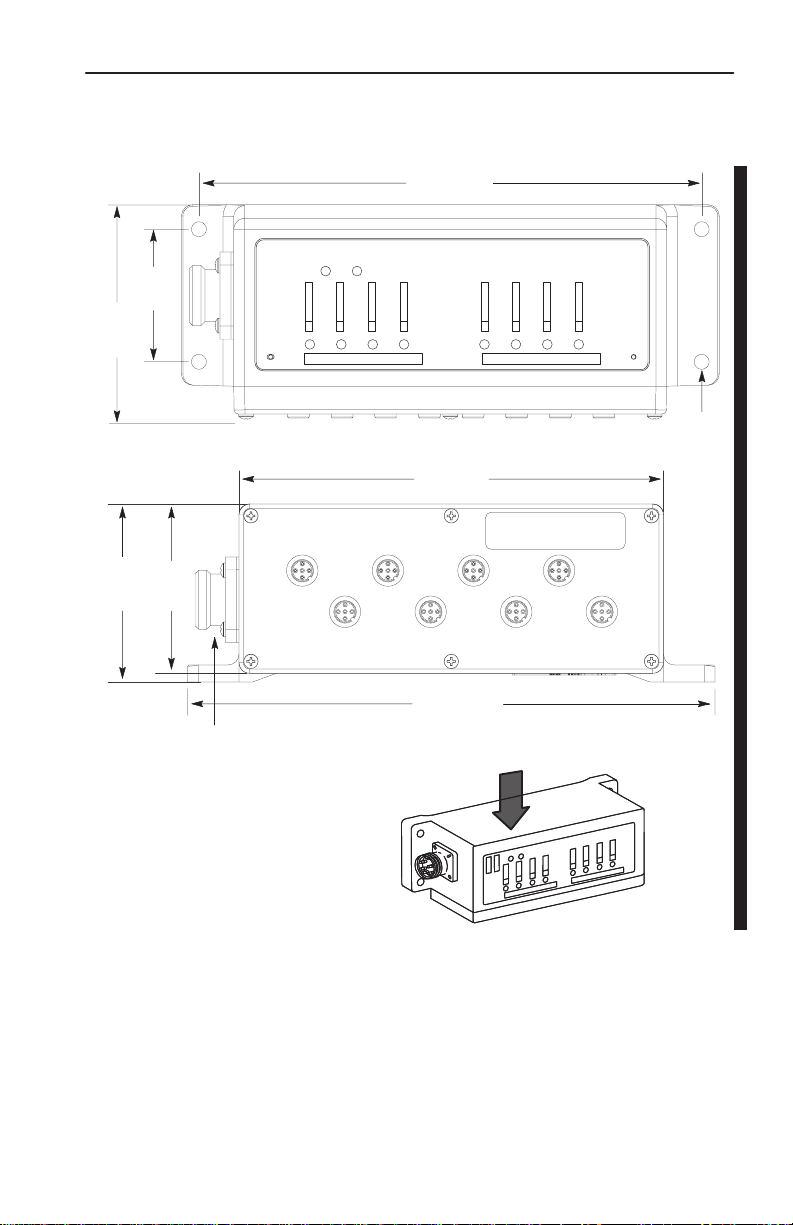

Mount the ArmorBlock Module

Mount the block module directly to the machine or device. Complete

mounting dimensions are shown below. Note that the block dimensions

allow direct connection of a T-port tap (cat. no. 1485P-P1N5-j) to the

DeviceNet connector. (Refer to publication 1485-6.7.1 for cabling

details.)

The ArmorBlock module has a sloping top and a gap at the rear to

allow water or other liquids to run off during washdowns. The flow

through the gap prevents buildup of debris under the block.

Preferred mounting position is with the microconnectors pointing

down. However, the block can be mounted in any orientation.

Publication 1792-5.2 – October 1996

Page 7

Mounting Dimensions

.

1.90

(48.3)

3.055

(77.6)

Inches

(Millimeters)

2.63

(66.7)

2.5

(63.5)

ADDRESS

NODE

ArmorBlock 8 Input Module

25

7

7

(184.2)

ARMORBLOCK

MOD/NET

INPUT

STATUS

FAULT

TE

RA

DATA

1792-IB8

I/O

4

mounting holes

for #10 screws

6.24

(158.5)

Block dimensions allow T

-port tap

connection directly onto connector

For washdown installations,

or excessively moist areas,

mount block with micro

connectors down.

7.74

(196.6)

Direction

of liquid flow

Publication 1792-5.2 – October 1996

Page 8

ArmorBlock 8 Input Module8

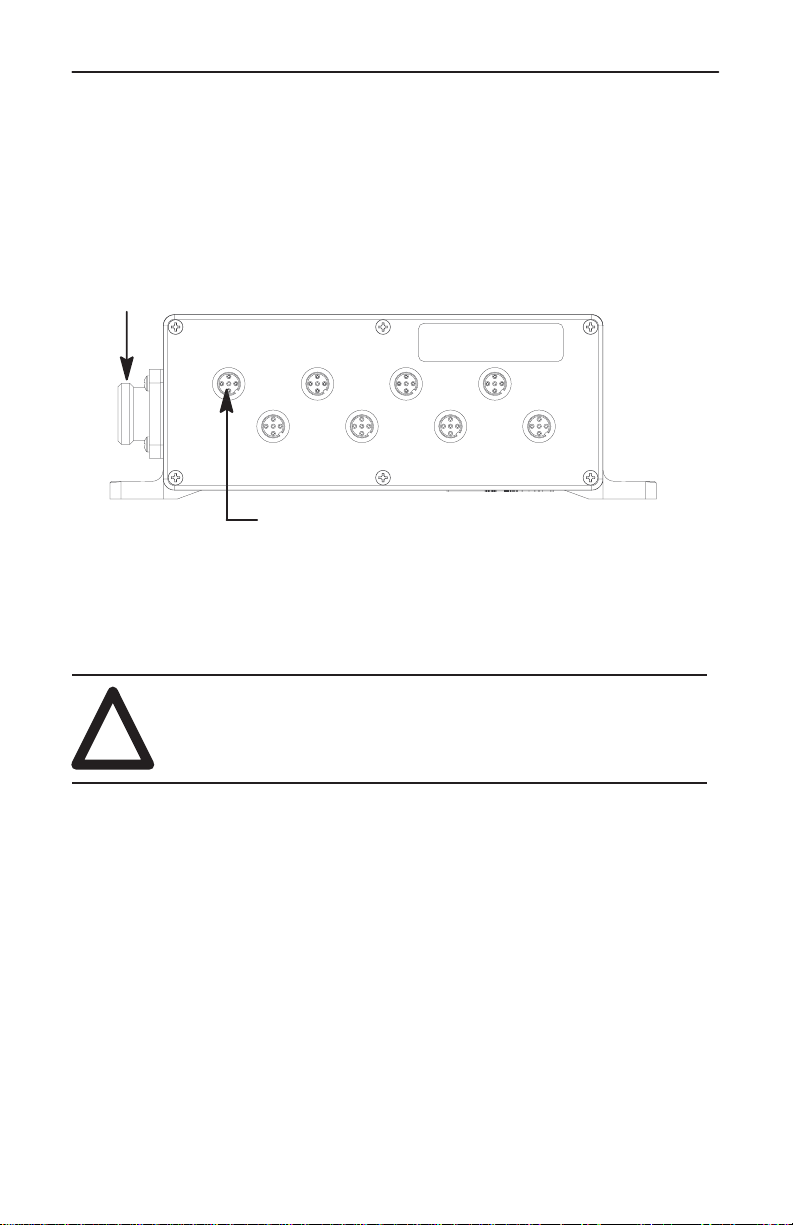

DeviceNet mini connector

Connect the Wiring to the ArmorBlock Module

The block module uses quick disconnect, screw-on style connectors

for:

• I/O input wiring

• the DeviceNet connector

0

2

1

8 micro connectors for signal wiring

4

3

5

6

7

Micro plugs are included with your module. Use these plugs to cover

and seal unused ports.

Pinout diagrams for these connectors are shown below.

ATTENTION: All connectors must be securely

tightened to properly seal the connections against leaks

!

and maintain NEMA 4X and 6P requirements.

Publication 1792-5.2 – October 1996

Page 9

ArmorBlock 8 Input Module

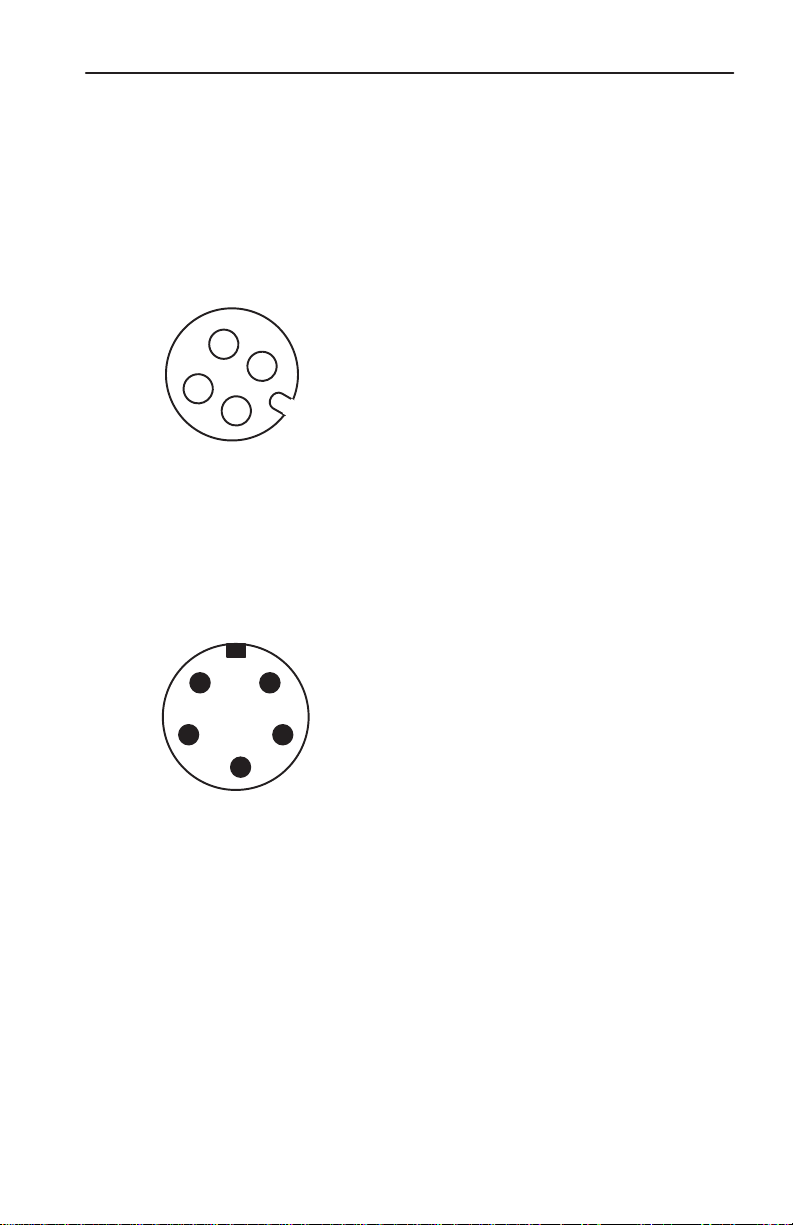

Connecting the Input Wiring

Connect input wiring to the micro connectors which screw into mating

connectors on the side of the block.

Make connections as shown below.

I/O Input Micro Connector

9

4

1

3

2

(View into socket)

Pin 1 = Sensor Source Voltage Positive

Pin 2 = Not used

Pin 3 = Negative/Return

Pin 4 = Signal

Connecting the DeviceNet Wiring

Connect DeviceNet wiring to the 5-pin mini connector on the end of

the block. Connections are shown below.

DeviceNet Mini Connector

1

2

(View into pins)

5

4

3

Pin 1 = Drain (Bare)

Pin 2 = V+ (Red)

Pin 3 = V– (Black)

Pin 4 = CAN–HI (White)

Pin 5 CAN–LO (Blue)

Note: Colors are

DeviceNet standard

Publication 1792-5.2 – October 1996

Page 10

ArmorBlock 8 Input Module10

Communicate with Your ArmorBlock Module

This ArmorBlock module acts as a slave in a master/slave environment.

It is both a “polled device” and a “change of state device.”

When configured as a polled device, a master initiates communication

by sending its polled I/O message to the ArmorBlock module. The 8

input module scans the inputs and fault bit producing a response that

reflects their status.

When configured as a “change of state” device, productions occur

when an input changes or an input source voltage fault occurs. If

neither has occurred within the “expected packet rate,” a heartbeat

production occurs. This heartbeat production tells the scanner module

that the ArmorBlock module is alive and ready to communicate.

Bit 07 06 05 04 03 02 01 00

Produces I7 I6 I5 I4 I3 I2 I1 I0

Produces S Reserved

Where: I = Input

S = Sensor source voltage fault

Word Bit Description

Produces100–07 Input bits – bit 00 corresponds to input 0, bit 01 to input 1, and

Produces

Publication 1792-5.2 – October 1996

00–06 Reserved

2

07 Sensor source voltage fault bit – this bit is set (1) when the sensor

so on.

0 = input off; 1 = the input is on.

source voltage is faulted.

Page 11

ArmorBlock 8 Input Module

Configure Your Armor Module Offline Using the

DeviceNet Manager Configuration Tool

To configure your ArmorBlock module offline:

• add the device to the network

• set the parameters for the device

• save the parameters to a file

Note: You cannot actually configure your device offline. You can set

and save the parameters to a file for downloading to the device when

you go online.

11

Publication 1792-5.2 – October 1996

Page 12

ArmorBlock 8 Input Module12

Adding a Device to the Network

Action Response

At

the network screen, click on the

“add device” button.

At the “add device to network”

screen, click on “discrete I/O” in

the device type box.

Then click on the desired ArmorBlock device.

Select the device node

address for this device.

Click on the OK button when you have selected your device.

Add more devices as necessary.

Publication 1792-5.2 – October 1996

Page 13

ArmorBlock 8 Input Module

13

Configure your Device Parameters

After adding the devices to the network, you must configure them. You

have 2 choices:

• highlight the device, and click on the button, or

• double-click on the device to bring up the device configuration

screen.

The software displays

the parameter status.

For detailed device information on this device, click on .

Publication 1792-5.2 – October 1996

Page 14

ArmorBlock 8 Input Module14

Configuring the Parameters

Default settings for the 8 input module are:

autobaud when

of

f to on delay

on to of

f delay

reset faulted I/O

enabled, matches device baud rate to network baud

rate at powerup

time from a valid input signal to recognition by the block

module

time from input signal dropping below the valid level to

recognition by the block module

reset sensor source voltage

1. Double click on the parameter you want to change.

The software displays

the parameter number,

name and value.

Read only parameters

(designated by an R)

are also shown.

Parameters can be

viewed all at once,

configuration only, or

I/O only.

The parameter screen appears.

enable

0ms delay

0ms delay

nothing selected

2. Click on the radio button to select a different setting. To save the

setting, click on

. To cancel any changes, click on

.

Publication 1792-5.2 – October 1996

Page 15

ArmorBlock 8 Input Module

15

3. For help about a specific parameter, click on . A screen

similar to this will appear. To continue, click on

4. Continue with any additional parameters you want set for your

block module. For the 8 input module, additional parameters

include: off-to-on delay, on-to-off delay and reset faulted I/O

.

When you have completed each parameter selection, click on the

button. This returns you to the device configuration

screen.

You can save these parameters to a file for downloading to the device

when online, or print them to a text file for hard copy use.

Publication 1792-5.2 – October 1996

Page 16

ArmorBlock 8 Input Module16

Saving to a File

1. To save those parameters to a file, click on the

button.

You see this screen.

2. Choose the file name, file type (.dcf), directory, and drive to which

you want to save the file.

3. Click on the

button to save.

Printing to a Text File

1. If you choose to save your changes to a text file, click on the

button.

A screen similar to the following will appear.

Publication 1792-5.2 – October 1996

Page 17

ArmorBlock 8 Input Module

2. Choose the file name, file type (.TXT), directory and drive to which

you want to save the file.

17

3. Click on the

hard copy for future reference.

button to save. Use this file to print out as

Online Help

Online help is available on all screens. Click on to

bring up pertinent information concerning the device configuration you

are selecting.

Additionally, help is available on each parameter screen by clicking on

.

Configure Your Armor Module Online Using the

DeviceNet Manager Configuration Tool

The procedure for online configuration is similar to the offline

configuration procedure previously described. You must:

• establish the interface to the network

• add the device to the network from the Add Device to Network

screen

• access and configure the device parameters

Establish the Interface

1. Select the “set up online connection” at the Utilities pulldown menu.

Publication 1792-5.2 – October 1996

Page 18

ArmorBlock 8 Input Module18

2. The configuration screen for your selected driver appears. You can:

• set the node address

• set the data rate

• select the interface adapter serial port

• set the interface adapter baud rate

3. After setting the parameters, click on the button. The

system will automatically go online, as shown at the bottom of the

screen.

Online

will also appear in the Network area.

Publication 1792-5.2 – October 1996

Page 19

Add the Device to the Network

Action Response

At

the network screen, click on the

“add device” button.

At the “add device to network”

screen, click on “discrete I/O” in

the device type box.

ArmorBlock 8 Input Module

19

Important: The

screen (from the Utilities pulldown menu). See page 3.

Then click on the desired ArmorBlock device.

Select the device node

address for this device.

Click on the OK button when you have selected your device.

Add more devices as necessary.

node address can only be set at the “Node Commissioning”

Publication 1792-5.2 – October 1996

Page 20

ArmorBlock 8 Input Module20

4. Click once on the device you wish to configure on the project screen

and choose

.

The device configuration screen appears.

If you have Parameter Status is

Not previously modified default settings Default Values

Modified parameters but have not saved them Modified

Modified and saved parameter settings Current

Clicked on “Load from File” File Values

Clicked on “Load from Device” Device Values

Publication 1792-5.2 – October 1996

Page 21

5. Load parameters.

If you want to load parameters Choose

From a file

You see this screen.

Choose the drive, file type, and directory to

load the file from.

Select the file name so that it is highlighted

and choose

Note: The product code, type and

revision must be identical in order to load

a file from one device to another.

From the selected device

ArmorBlock 8 Input Module

21

From default settings

Publication 1792-5.2 – October 1996

Page 22

ArmorBlock 8 Input Module22

6. Modify the parameter.

If you want to Choose

Modify a parameter

You

Click on the settings you wish to activate.

T

o save these settings,

choose

T

o save these settings to the device,

choose

see a screen similar to this one.

o use default settings,

T

choose

T

o cancel any changes,

choose

For help about a specific parameter

parameter and then

choose

You can view parameters online by clicking on

Any changes that occur for a parameter will be reflected

on the screen.

Publication 1792-5.2 – October 1996

, click on the

Page 23

ArmorBlock 8 Input Module

7. Save parameters to a file, to the device, or print to a file.

If you want to Choose

Save parameters

to a file

You

see this screen.

23

Select the drive, file type, directory

would like to save and choose

, and file name to which you

Save parameters to

the selected device

Print to a file

You

see this screen.

Select the drive, file type, directory

would like to save and choose

, and file name to which you

8. To exit from the Enhanced Configuration screen,

click on

.

Publication 1792-5.2 – October 1996

Page 24

ArmorBlock 8 Input Module24

Monitoring

Parameters Online

You can monitor parameters at the Device Configuration screen or at

the selected parameter screen.

The start monitor button on the Device Configuration screen allows

you to monitor all of the parameters online. To monitor parameters:

Click on the

button to start the

monitor.

The monitor function starts after a few seconds.

1.The status line

flashes “monitoring.”

2.The monitoring function

is indicated by an

asterisk moving down

next to the parameters.

3.The monitor button changes to and

only “modify parameter” and “stop monitoring” are active.

4.Click on the button to stop monitoring.

To monitor an individual parameter:

1. Select the parameter on the Device Configuration screen.

2. Highlight the parameter and click on “Modify Parameter.”

3. Click on “Start Monitor” on the individual parameter screen.

Publication 1792-5.2 – October 1996

Page 25

ArmorBlock 8 Input Module

Reset Faults

There are various ways to reset faults on an ArmorBlock module.

• cycle power to the module by disconnecting, then reconnecting the

DeviceNet connector

• use the Reset Faulted I/O feature on the parameter screen

• use the explicit message program control feature

Note: This

Reset Faults Online Using the Parameter Screen

To reset faults online, return to the network screen and proceed as

follows:

module contains a circuit to protect the DeviceNet power supply from short

circuits in an attached sensor or sensor cable. If you connect a sensor while the

module is powered, the surge current produced by the sensor can cause the

module to fault. This operation is normal. If this occurs, reset the module.

1.Click on the faulted device.

2.Then click on the Configure

Device button.

25

Publication 1792-5.2 – October 1996

Page 26

ArmorBlock 8 Input Module26

The device configuration screen appears. Select the Reset Faulted I/O

parameter.

After selecting

the parameter, click on the

modify parameter button.

The configuration screen for the selected parameter appears.

1.Click on the desired

selection to reset.

2.Then click on the

OK button to apply.

3.You will be returned to

the configuration screen.

Click on ”Save to Device”

to apply the change.

Publication 1792-5.2 – October 1996

Page 27

ArmorBlock 8 Input Module

Reset Faults using Explicit Message Program Control

You can also reset inputs using the Explicit Message Program Control

feature on the Scanner module master. Refer to the specific scanner

publications for information on using this feature.

The format for the reset explicit message transaction block must

contain 6 words as shown below:

Word Input Fault

27

Transaction

Transaction Body W

HeaderWord 0

W

W

W

W

ord 1

ord 2

ord 3

ord 4

ord 5

TXID – CMD/STATUS

PORT – SIZE

Service = 32 hex – MAC ID

Class = 1D hex

Instance = 1

Attribute = 0

Attribute Data = 0

Publication 1792-5.2 – October 1996

Page 28

ArmorBlock 8 Input Module28

Configure Your Armor Module Using EDS Files

Current versions of DeviceNet Manager software include ArmorBlock

module support. If you are using a version of DeviceNet Manager

software that does not include ArmorBlock module Electronic Data

Sheets (EDS) files in its library, you can use the following information

to create the file.

If you are using a configuration tool other than DeviceNet Manager,

you can also use the following information to create the EDS file.

(Note: This EDS file was current at the time of printing. Contact your

nearest district office for information on later files.)

$ Electronic Data Sheet for Armor Block I/O (1792–IB8)

[File]

DescText = ”1792–IB8 Armor Block I/O EDS File”;

CreateDate = 04–18–96;

CreateTime = 12:00:00;

ModDate = 0–17–96;

ModTime = 16:00:00;

Revision = 2.1; $ EDS revision.

[Device]

VendCode = 1;

VendName = ”Allen–Bradley Company, Inc.”;

ProdType = 7;

ProdTypeStr = ”General Purpose Discrete I/O”;

ProdCode = 1025;

MajRev = 2;

MinRev = 1;

ProdName = ”Armor Block I/O 8 input”;

Catalog=”1792–IB8”;

UCMM = 0; $ UCMM is not supported.

[IO_Info]

Default = 0x0001; $ The default I/O type is polled I/O.

PollInfo =

0x0001, $ Polled I/O device.

1, $ Input1 entry is the default input connection.

1; $ Output1 entry is the default output connection.

Input1 =

2, $ The size in bytes that this connection produces.

0, $ All bits of this connection are significant.

0x0001, $ Only Polled I/O is compatible.

”IB8 Production Data”, $ Name of Connection.

6, $ Path length.

”20 04 24 0E 30 03”, $ Path to I/O Production Assembly.

”This connection contains data from inputs in byte 0 and sensor source voltage status

at bit 7 of byte 1.”;

[ParamClass]

MaxInst = 13; $ 4 configurable and 9 read–only parameters.

Descriptor = 0x09;$ Stub param instances in eeprom.

CfgAssembly = 0x66; $ The config assembly is instance #102 of assy obj.

[Params]

Publication 1792-5.2 – October 1996

$$$$$$$$$$ Help string $$$$$$$$$$$

Page 29

ArmorBlock 8 Input Module

$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$

$$$$$$$$$$

Param1 = $ Disable Autobaud

0, $ reserved

6, $ Link Path Size

”20 03 24 01 30 64”, $ Link Path to disable autobaud attribute.

0x0002, $ No support for settable path, scaling, scaling links, or

$ real time update of value. Value is gettable and

$ Settable. Enumerated strings are supported.

4, $ Data Type – boolean

1, $ Data Size

”Autobaud”, $ Parameter Name

””, $ Units String

$$$$$$$$$$ Help string $$$$$$$$$$$

”Enable takes effect after next powerup. Disable is required to set fixed baud rate, no

power cycle is required.”,

0,1,0, $ Min, Max, and Default values

1,1,1,0,0,0,0,0,0; $ Not Used

$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$

$$$$$$$$$$

Param2 = $ Input filter Off_to_On Delay selection

0, $ reserved

6, $ Link Path Size

”20 0F 24 02 30 01”, $ Link Path to param instance. The param instance

$ decodes the enumerated parameter into engineering

$ units (micro seconds).

0x0002, $ No support for settable path, scaling, scaling links,

$ or real time update of value. Value is gettable and

$ Settable. Enumerated strings are supported.

2, $ Data Type – unsigned int

2, $ Data Size – (in bytes)

”Off–to–On Delay”, $ Parameter Name

”ms”, $ Units String

$$$$$$$$$$ Help string $$$$$$$$$$$

”Signal must be present for this delay period before module detects the change.”,

0,4,0, $ Min, Max (max enumeration #), and Default values

1,1,1,0,0,0,0,0,0; $ Not Used

$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$

$$$$$$$$$$

Param3 = $ Input filter On_to_Off Delay selection

0, $ reserved

6, $ Link Path Size

”20 0F 24 03 30 01”, $ Link Path to param instance. The param instance

$ decodes the enumerated parameter into engineering

$ units (micro seconds).

0x0002, $ No support for settable path, scaling, scaling links,

$ or real time update of value. Value is gettable and

$ Settable. Enumerated strings are supported.

2, $ Data Type – unsigned int

2, $ Data Size – (in bytes)

”On–to–Off Delay”, $ Parameter Name

”ms”, $ Units String

$$$$$$$$$$ Help string $$$$$$$$$$$

”Signal must be present for this delay period before module detects the change.”,

0,4,0, $ Min, Max (max enumeration #), and Default values

1,1,1,0,0,0,0,0,0; $ Not Used

29

Publication 1792-5.2 – October 1996

Page 30

ArmorBlock 8 Input Module30

$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$

$$$$$$$$$$

Param4 = $ Reset Faulted I/O

0, $ reserved

6, $ Link Path Size

”20 0F 24 04 30 01”, $ Link Path to param instance.

0x0002, $ No support for settable path, scaling, scaling links,

8, $ Data Type – unsigned short int

1, $ Data Size – (in bytes)

”Reset Faulted I/O”, $ Parameter Name

””, $ Units String

$$$$$$$$$$ Help string $$$$$$$$$$$

”This resets the voltage supplied to sensors. A reset will only be accepted if a fault

exists.”,

0,1,0, $ Min, Max (max enumeration #), and Default values

1,1,1,0,0,0,0,0,0; $ Not Used

$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$

$$$$$$$$$$

Param5 = $ Input 1 value

0, $ reserved

6, $ Link Path Size

”20 08 24 01 30 03”, $ Link Path to Input 1 value attribute.

0x0030, $ No support for settable path, scaling, or scaling

8, $ Data Type – unsigned short int

1, $ Data Size – (in bytes)

”Input 1 Value”, $ Parameter Name

””, $ Units String

$$$$$$$$$$ Help string $$$$$$$$$$$

”This parameter is the current value of Input 1.”,

0,1,0, $ Min, Max, and Default values

1,1,1,0,0,0,0,0,0; $ Not Used

$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$

$$$$$$$$$$

Param6 = $ Input 2 value

0, $ reserved

6, $ Link Path Size

”20 08 24 02 30 03”, $ Link Path to Input 2 value attribute.

0x0030, $ No support for settable path, scaling, or scaling

8, $ Data Type – unsigned short int

1, $ Data Size – (in bytes)

”Input 2 Value”, $ Parameter Name

””, $ Units String

$$$$$$$$$$ Help string $$$$$$$$$$$

”This parameter is the current value of Input 2.”,

0,1,0, $ Min, Max, and Default values

1,1,1,0,0,0,0,0,0; $ Not Used

$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$

$$$$$$$$$$

Param7 = $ Input 3 value

Publication 1792-5.2 – October 1996

$ or real time update of value. Value is gettable and

$ Settable. Enumerated strings are supported.

$ links.

$ Value is gettable only.

$ Enumerated strings are not supported.

$ links.

$ Value is gettable only.

$ Enumerated strings are not supported.

Page 31

ArmorBlock 8 Input Module

0, $ reserved

6, $ Link Path Size

”20 08 24 03 30 03”, $ Link Path to Input 3 value attribute.

0x0030, $ No support for settable path, scaling, or scaling

$ links.

$ Value is gettable only.

$ Enumerated strings are not supported.

8, $ Data Type – unsigned short int

1, $ Data Size – (in bytes)

”Input 3 Value”, $ Parameter Name

””, $ Units String

$$$$$$$$$$ Help string $$$$$$$$$$$

”This parameter is the current value of Input 3.”,

0,1,0, $ Min, Max, and Default values

1,1,1,0,0,0,0,0,0; $ Not Used

$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$

$$$$$$$$$$

Param8 = $ Input 4 value

0, $ reserved

6, $ Link Path Size

”20 08 24 04 30 03”, $ Link Path to Input 4 value attribute.

0x0030, $ No support for settable path, scaling, or scaling

$ links.

$ Value is gettable only.

$ Enumerated strings are not supported.

8, $ Data Type – unsigned short int

1, $ Data Size – (in bytes)

”Input 4 Value”, $ Parameter Name

””, $ Units String

$$$$$$$$$$ Help string $$$$$$$$$$$

”This parameter is the current value of Input 4.”,

0,1,0, $ Min, Max, and Default values

1,1,1,0,0,0,0,0,0; $ Not Used

$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$

$$$$$$$$$$

Param9 = $ Input 5 value

0, $ reserved

6, $ Link Path Size

”20 08 24 05 30 03”, $ Link Path to Input 5 value attribute.

0x0030, $ No support for settable path, scaling, or scaling

$ links.

$ Value is gettable only. Enumerated strings are not

$ supported.

8, $ Data Type – unsigned short int

1, $ Data Size – (in bytes)

”Input 5 Value”, $ Parameter Name

””, $ Units String

$$$$$$$$$$ Help string $$$$$$$$$$$

”This parameter is the current value of Input 5.”,

0,1,0, $ Min, Max, and Default values

1,1,1,0,0,0,0,0,0; $ Not Used

$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$

$$$$$$$$$$

Param10 = $ Input 6 value

0, $ reserved

6, $ Link Path Size

”20 08 24 06 30 03”, $ Link Path to Input 6 value attribute.

Publication 1792-5.2 – October 1996

31

Page 32

ArmorBlock 8 Input Module32

0x0030, $ No support for settable path, scaling, or scaling

8, $ Data Type – unsigned short int

1, $ Data Size – (in bytes)

”Input 6 Value”, $ Parameter Name

””, $ Units String

$$$$$$$$$$ Help string $$$$$$$$$$$

”This parameter is the current value of Input 6.”,

0,1,0, $ Min, Max, and Default values

1,1,1,0,0,0,0,0,0; $ Not Used

$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$

$$$$$$$$$$

Param11 = $ Input 7 value

0, $ reserved

6, $ Link Path Size

”20 08 24 07 30 03”, $ Link Path to Input 7 value attribute.

0x0030, $ No support for settable path, scaling, or scaling

8, $ Data Type – unsigned short int

1, $ Data Size – (in bytes)

”Input 7 Value”, $ Parameter Name

””, $ Units String

”This parameter is the current value of Input 7.”,

0,1,0, $ Min, Max, and Default values

1,1,1,0,0,0,0,0,0; $ Not Used

$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$

$$$$$$$$$$

Param12 = $ Input 8 value

0, $ reserved

6, $ Link Path Size

”20 08 24 08 30 03”, $ Link Path to Input 8 value attribute.

0x0030, $ No support for settable path, scaling, or scaling

8, $ Data Type – unsigned short int

1, $ Data Size – (in bytes)

”Input 8 Value”, $ Parameter Name

””, $ Units String

”This parameter is the current value of Input 8.”,

0,1,0, $ Min, Max, and Default values

1,1,1,0,0,0,0,0,0; $ Not Used

$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$$

$$$$$$$$$$

Param13 = $ Input status

0, $ reserved

6, $ Link Path Size

”20 1D 24 01 30 05”, $ Link Path to Dicrete Input Group status attribute.

0x0032, $ No support for settable path, scaling, or scaling

$ links.

$ Value is gettable only. Enumerated strings are not

$ supported.

$ links.

$ Value is gettable only. Enumerated strings are not

$ supported.

$$$$$$$$$$ Help string $$$$$$$$$$$

$ links.

$ Value is gettable only. Enumerated strings are not

$ supported.

$$$$$$$$$$ Help string $$$$$$$$$$$

$ links.

Publication 1792-5.2 – October 1996

Page 33

ArmorBlock 8 Input Module

$ Value is gettable only.

$ Enumerated strings are supported.

8, $ Data Type – unsigned short int

1, $ Data Size – (in bytes)

”Input Status”, $ Parameter Name

””, $ Units String

$$$$$$$$$$ Help string $$$$$$$$$$$

”This parameter is the current status of the sensor source voltage”,

0,1,0, $ Min, Max, and Default values

1,1,1,0,0,0,0,0,0; $ Not Used

[Groups]

Group1=”Configuration”,3,1,2,3;

Group2=”I/O”,10,4,5,6,7,8,9,10,11,12,13;

[EnumPar]

Param1=”Enable”,”Disable”;

Param2=”0 ms”,”2 ms”,”4 ms”,”8 ms”,”16 ms”;

Param3=”0 ms”,”2 ms”,”4 ms”,”8 ms”,”16 ms”;

Param4=”Nothing Selected”,”Reset Sensor Source Voltage”;

Param13=”Healthy”,”Faulted”;

33

Publication 1792-5.2 – October 1996

Page 34

ArmorBlock 8 Input Module34

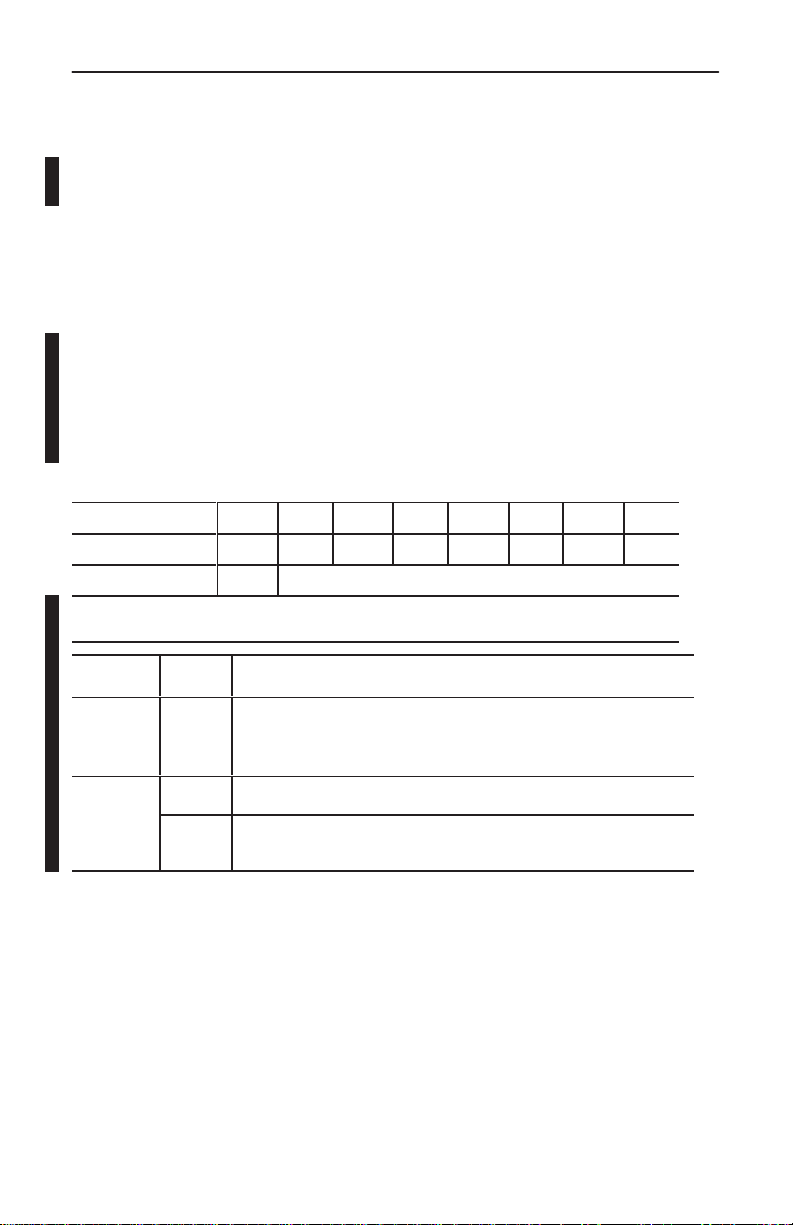

Troubleshoot with the Indicators

The ArmorBlock I/O module has 3 types of indicators:

• Mod/Net status indicator

• Input fault indicator

• individual I/O status indicators

Mod/Net Status Indicator

MOD/NET

STATUS

TE

RA

ADDRESS

DATA

NODE

Input I/O Status Indicators

Note: This module contains a circuit to protect the DeviceNet power supply from short circuits

in an attached sensor or sensor cable. If you connect a sensor while the module is

powered, the surge current produced by the sensor can cause the module to fault. This

operation is normal. If this occurs, reset the module (page 25).

Input Fault Indicator

INPUT

FAULT

ARMORBLOCK

1792-IB8

I/O

Mod/Net

Status Indicator

Indication Status

No

power

OFF

Flashing Green/OFF

Solid Green

Flashing Red

Solid Red

Green to Red to Of

1

This only occurs when Autobaud is disabled, and the module is set to an incorrect baud rate.

Input

Fault Indicator

f

, or no network access, or incorrect baud rate

On-line but not connected

On-line, link okay

, connected

Recoverable fault

Critical failure, or duplicate node address present

At powerup only – The module is autobauding

Indication Status

Sensor

OFF

Solid Red

Input

I/O Status Indicator

source voltage operating correctly

1 or more Sensor source voltage shorts

Indication Status

OFF No

Yellow V

Publication 1792-5.2 – October 1996

valid input signal present

alid input signal present

1

Page 35

ArmorBlock 8 Input Module

Specifications

8

Input Module – Cat. No. 1792-IB8

Input Specifications

Inputs per Block 8 sinking

On-state Voltage Range 10–30V dc

On-state Current Maximum

Minimum

Off-state Voltage Maximum 5V dc

Off-state Current Minimum 1.5mA

Transition Voltage 5–10V dc

Transition Current 1.5–3.0mA

Input Impedance Maximum 5K ohms

Input Signal Delay Off to On

On to Off

Sensor Source Voltage

Current

Indicators Mod/Net Status – red/green

General Specifications

DeviceNet Power Voltage

Current

Surge Current at Power Up Less than 10A for 5ms

Dimensions Inches

Millimeters

Connectors 1792-IB8A/B – Aluminum connectors

Power Dissipation Maximum 1.9 Watts

Thermal Dissipation Maximum 6.5 BTU/hr

Specifications continued on next page.

6.0mA @ 30V dc

2.0mA @ 10V dc

0ms, 2ms, 4ms, 8ms, 16ms

0ms, 2ms, 4ms, 8ms, 16ms

10–25V dc

50mA per point, 0.4A total per module

Input Fault – red

I/O Status – yellow (customer field side driven)

11.0 – 25.0V dc

100mA (no powered sensors)

500mA (full sensor load)

2.6H X 7.7W X 3.06D

66H X 195W X 77.7D

1792-IB8S/B – Stainless Steel Connectors

35

Publication 1792-5.2 – October 1996

Page 36

ArmorBlock 8 Input Module36

•

General Specifications

Environmental Conditions

Operational Temperature

Storage Temperature

Relative Humidity

Shock Operating

Non-operating

Vibration

–25 to 70oC (–13 to 158oF)

–40 to 85oC (–40 to 185oF)

up to 100%

30 g peak acceleration, 11(+

50 g peak acceleration, 11(+

1)ms pulse width

1)ms pulse width

Tested 10 g @ 10–500Hz per IEC 68-2-6

Conductors Refer to publication 1485-6.7.1 for information

on cabling for your DeviceNet module.

Enclosure Meets or exceeds NEMA 4X and 6P, IP67

1200psi, 140oF hosedown

Agency Certification

(when product or packaging is marked)

• CSA certified

• CSA Class I, Division 2, Groups A, B, C, D

certified

• UL listed

• CE marked for all applicable directives

This

product has been tested at an Open DeviceNet V

Inc. (ODV

with ODVA Conformance Test Software V

A) authorized independent test laboratory and found to comply

ersion FT 1.2/1.0.

endor Association,

Worldwide representation.

Argentina •

Colombia • Costa Rica • Croatia • Cyprus • Czech Republic • Denmark • Ecuador • Egypt • El Salvador

Finland •

Indonesia •

Mexico •

Puerto Rico • Qatar • Romania • Russia–CIS • Saudi Arabia • Singapore

Africa, Republic • Spain • Sweden

United Kingdom • United States • Uruguay • V

Allen-Bradley Headquarters, 1201 South Second Street, Milwaukee, WI 53204 USA,

Tel: (1) 414 382-2000 Fax: (1) 414 382-4444

Publication

Publication 1792-5.2 – October 1996

Supersedes

Australia • Austria • Bahrain • Belgium

France • Germany • Greece • Guatemala • Honduras • Hong Kong • Hungary • Iceland • India

Ireland • Israel • Italy • Jamaica •

Netherlands

1792-5.2 – October 1996

1792-5.2 – December 1995

• New

Zealand • Norway

• Switzerland • T

• Brazil •

Bulgaria • Canada • Chile • China, PRC

Japan • Jordan • Korea • Kuwait • Lebanon

• Pakistan •

enezuela • Y

Peru

• Philippines •

aiwan

• Thailand • T

ugoslavia

Copyright 1996 Allen-Bradley Company

Poland • Portugal

• Slovakia • Slovenia •

urkey • United Arab Emirates

• Malaysia •

•

South

PN955126–03

, Inc. Printed in USA

•

•

•

Loading...

Loading...