Page 1

Installation Instructions

High Current 8 Input/8 Output

ArmorBlock I/O Module Series B

(Cat. No. 1792D-88HC)

41945

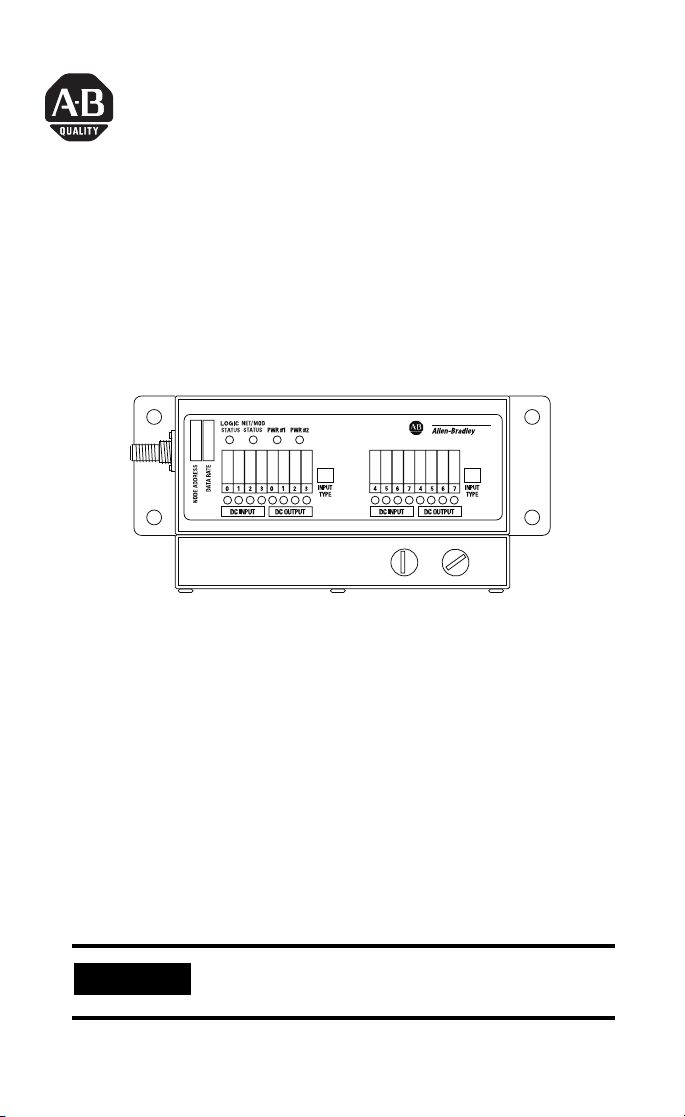

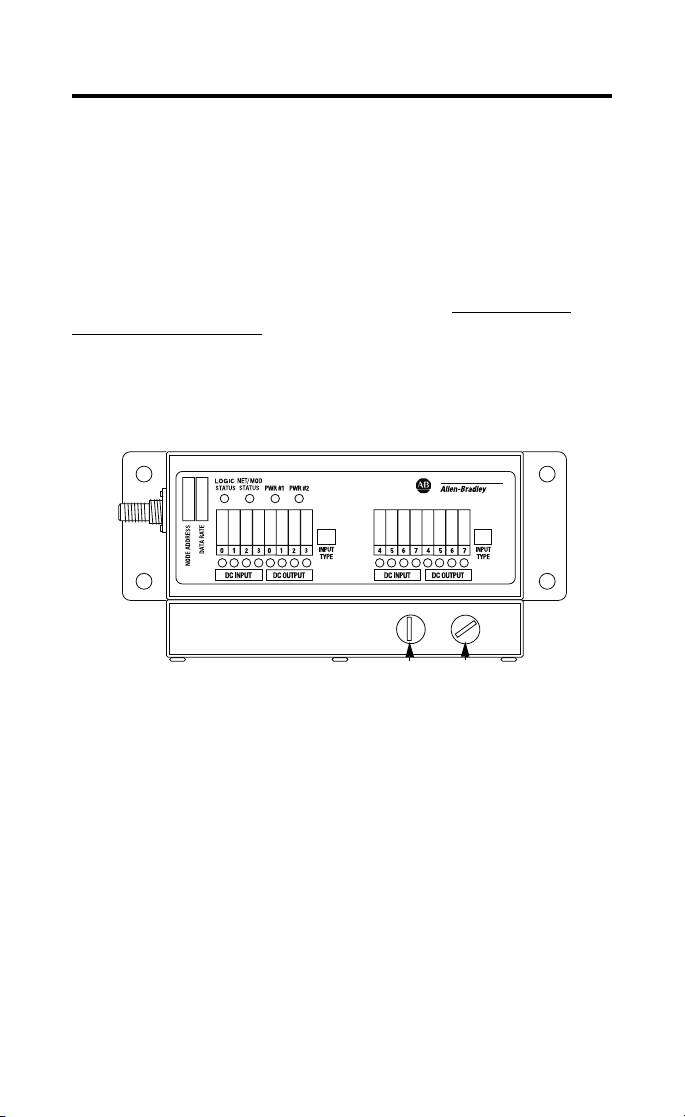

The High Current ArmorBlock™ I/O module (Cat. No. 1792D-88HC)

is a stand-alone 24V dc I/O product which communicates via a

DeviceNet™ network. The semi-sealed housing requires no

enclosure.

This module has 8 inputs and 8 outputs. Inputs are 24V dc PNP

(sourcing) or NPN (sinking) devices. Outputs are self-protected 24V

dc and are for sourcing only. Diagnostic features included are output

short circuit and open wire detection reported to the point level.

Check Your Package Contents

Your package contains:

• 1 High Current Module

• Installation Instructions

IMPORTANT

Mating connectors and/or cable assembly must be

ordered separately.

Publication 1792D-IN005D-EN-P - February 2002

Page 2

2 High Current 8 Input/8 Output ArmorBlock I/O Module Series B

ATTENTION

!

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of these

products must satisfy themselves that all necessary steps have been

taken to assure that each application and use meets all performance

and safety requirements, including any applicable laws, regulations,

codes and standards. In no event will Allen-Bradley be responsible or

liable for indirect or consequential damage resulting from the use or

application of these products.

Any illustrations, charts, sample programs, and layout examples

shown in this publication are intended solely for purposes of

example. Since there are many variables and requirements associated

with any particular installation, Allen-Bradley does not assume

responsibility or liability (to include intellectual property liability) for

actual use based upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in

whole or part, without written permission of Rockwell Automation, is

prohibited.

Throughout this publication, notes may be used to make you aware

of safety considerations. The following annotations and their

accompanying statements help you to identify a potential hazard,

avoid a potential hazard, and recognize the consequences of a

potential hazard:

Publication 1792D-IN005D-EN-P - February 2002

Identifies information about practices or

circumstances that can lead to personal injury or

death, property damage, or economic loss.

Page 3

High Current 8 Input/8 Output ArmorBlock I/O Module Series B 3

ATTENTION

!

IMPORTANT

Identifies information that is critical for

successful application and understanding of the

product.

Environment and Enclosure

This equipment is intended for use in a Pollution

Degree 2 industrial environment, in overvoltage

Category II applications (as defined in IEC

publication 60664-1), at altitudes up to 2000

meters without derating.

This equipment is considered Group 1, Class A

industrial equipment according to IEC/CISPR

Publication 11. Without appropriate precautions,

there may be potential difficulties ensuring

electromagnetic compatibility in other

environments due to conducted as well as

radiated disturbance.

This equipment is supplied as "enclosed"

equipment. It should not require additional

system enclosure when used in locations

consistent with the enclosure type ratings stated

in the Specifications section of this publication.

Subsequent sections of this publication may

contain additional information regarding specific

enclosure type ratings, beyond what this product

provides, that are required to comply with

certain product safety certifications.

See NEMA Standards publication 250 and IEC

publication 60529, as applicable, for

explanations of the degrees of protection

provided by different types of enclosure. Also,

see the appropriate sections in this publication,

as well as the Allen-Bradley publication 1770-4.1

("Industrial Automation Wiring and Grounding

Guidelines"), for additional installation

requirements pertaining to this equipment.

Publication 1792D-IN005D-EN-P - February 2002

Page 4

4 High Current 8 Input/8 Output ArmorBlock I/O Module Series B

ATTENTION

!

Install Your High Current I/O Module

To install the module you must:

• Set the node address

• Mount the module

• Connect the cable assembly to the module

• Connect the DeviceNet cable to the module

• Communicate with your ArmorBlock I/O module

More detailed information about each of these steps is in the

following procedures.

Preventing Electrostatic Discharge

This equipment is sensitive to electrostatic

discharge, which can cause internal damage and

affect normal operation. Follow these guidelines

when you handle this equipment:

• Touch a grounded object to discharge

potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on

component boards.

• Do not touch circuit components inside the

equipment.

• If available, use a static-safe workstation.

• When not in use, store the equipment in

appropriate static-safe packaging.

Set the Node Address

Valid node addresses are 00 to 63.

Set the node address using the rotary switches, RSNetWorx for

DeviceNet™, DeviceNetManager™, or another software configuration

tool. Setting the switches between 64 and 99 lets the software have

address control.

Each module is shipped with the node address set to 63 in the

module’s memory. The rotary switches are set for position 99 at

shipment. The switches are located on the bottom of the module.

Publication 1792D-IN005D-EN-P - February 2002

Page 5

High Current 8 Input/8 Output ArmorBlock I/O Module Series B 5

The two switches are:

• MSD (most significant digit)

• LSD (least significant digit)

To reset the node address, use a small blade screwdriver to rotate the

switches. Line up the small arrow on the switch with the number

setting you wish to use.

The rotary switches are read at module power up only. Settings

between 64 and 99 cause the module to use the last valid node

address stored internally. Example: The last setting was 40. If a

change is made to 68, and then you power up, the address will

default to 40. Use the mini caps to cover and seal node address

switch ports.

Refer to the illustration of the rotary switches below.

41945

MSD

LSD

The module is equipped with AutoBaud detect. AutoBaud lets the

module read the settings already in use on your DeviceNet network

and automatically adjusts to follow those settings. The module is

shipped with AutoBaud enabled.

Mount the Module

1. Place the module against the panel where you want it

mounted.

2. Drill holes in the panel that are aligned with the moving holes

on the module.

Publication 1792D-IN005D-EN-P - February 2002

Page 6

6 High Current 8 Input/8 Output ArmorBlock I/O Module Series B

3. Place screws through each of the 4 mounting holes and

tighten the screws until the module is firmly in place.

7.74in.

196.6mm

3.06in.

77.6mm

Side View

Front View

41945

2.63in.

66.7mm

42288

Connect the Cable Assembly to the Module

Inputs, outputs, and power can either be wired directly to a mating

connector, or through a cable assembly.

Connection Using a Connector Assembly

Use the Allen-Bradley user-fabricated connector assembly, catalog

number 1792D-88HCCON, with a hand crimp tool and follow the

instructions to crimp connector contacts onto field wires. (Purchase

the hand crimp tool from Positronic Industries, Inc., part number

9501 and 9502-1). See the connector pinouts on the next page.

ATTENTION

For maximum noise immunity, input cable return

wires must be properly terminated. When inputs

are connected in loopback, return wires should

be connected together.

!

Publication 1792D-IN005D-EN-P - February 2002

Page 7

High Current 8 Input/8 Output ArmorBlock I/O Module Series B 7

Connection Using a Prefabricated Harness Assembly

1. Connect the harness assembly, 1792D-88HCCBL, to field

wiring.

2. Connect the harness connector to the module.

The 1792D-88HC module connector pinout is shown below

(looking into the module connector).

1 2 3 4 5 6 7 8 9 10

11 12 13 14 15 16 17 18 19 20

21 22 23 24 25 26 27 28 29 30

Module Connector

The mating connector pinout is shown below (looking into the

mating connector).

10 9 8 7 6 5 4 3 2 1

20 19 18 17 16 15 14 13 12 11

30 29 28 27 26 25 24 23 22 21

42285

Mating/Harness Connector

Publication 1792D-IN005D-EN-P - February 2002

42323

Page 8

8 High Current 8 Input/8 Output ArmorBlock I/O Module Series B

The following table lists the signal for each pin number.

Pin Number Signal

1PWR1+

2 IN_0 (GRP 1)

3 IN_1 (GRP 1)

4 IN_2 (GRP 1)

5 IN_3 (GRP 1)

6 IN_0 (GRP 2)

7 IN_1 (GRP 2)

8 IN_2 (GRP 2)

9 IN_3 (GRP 2)

10 PWR2+

11 PWR1+

12 PWR1-

13 PWR1-

14 PWR1-

15 PWR1-

16 PWR2-

17 PWR2-

18 PWR2-

19 PWR2-

20 PWR2+

21 PWR1+

22 OUT_0 (GRP 1)

23 OUT_1 (GRP 1)

24 OUT_2 (GRP 1)

25 OUT_3 (GRP 1)

26 OUT_0 (GRP 2)

27 OUT_1 (GRP 2)

28 OUT_2 (GRP 2)

29 OUT_3 (GRP 2)

30 PWR2+

Publication 1792D-IN005D-EN-P - February 2002

Page 9

High Current 8 Input/8 Output ArmorBlock I/O Module Series B 9

Connect the DeviceNet Cable to the Module

Connect the DeviceNet wiring to the 5-pin micro-connector on the

module. The micro-connector pinout is shown below.

2

5

3

4

Looking into connector pins

IMPORTANT

Pin 1 Drain

(not connected internally)

Pin 2 V+

1

Pin 3 VPin 4 CAN_H

Pin 5 CAN_L

42286

If the devices (sensors) connected to the input

connections require Class 2 power to operate, the

DeviceNet connections of this equipment must be

powered by a Class 2 source.

Communicate with Your ArmorBlock I/O Module

This High Current module’s I/O is exchanged with the master

through a polled, cyclic, or change-of-state connection.

The module produces and consumes I/O data as follows:

Type of I/O Connections Consumes Produces

Polled 1 Byte 3 Bytes

Cyclic 1 Byte 3 Bytes

Change-of-State 1 Byte 3 Bytes

Polled - master initiates communication by sending its polled I/O

message to the module. The module consumes the message, updates

any outputs, and produces a response. If inputs are present, the

response contains the input data.

Cyclic - allows configuration of the block as an I/O client. The block

will produce and consume its I/O cyclically at the rate configured.

Publication 1792D-IN005D-EN-P - February 2002

Page 10

10 High Current 8 Input/8 Output ArmorBlock I/O Module Series B

Change-of-State - productions occur when an input changes or a

fault condition occurs. If no input or fault condition change occurs

within the expected packet rate, a heartbeat production occurs. This

heartbeat production tells the scanner module that the I/O module is

alive and ready to communicate. Consumption occurs when data

changes and the master produces new input data to the I/O block.

Refer to the table below for the word/bit definitions.

Bit 0706050403020100

Produces 0 OL7 OL6 0L5 0L4 0L3 0L2 0L1 0L0

Produces 1 NL7 NL6 NL5 NL4 NL3 NL2 NL1 NL0

Produces 2 I7 I6 I5 I4 I3 I2 I1 I0

Consumes 0 O7 O6 O5 O4 O3 O2 O1 O0

Where: OL=Output Overload NL=Output No Load I=Input O = Output

Refer to the table below for byte/bit descriptions.

Byte Bit Description

Produces 0 00-07 Output overload status

Produces 1 00-07 Output no load status

Produces 2 00-07 Input point status

Consumes 0 00-07 Output bits: When the bit is set (1), the output will

be turned on. Bit 00=output 00, bit 01=output 01,

bit 02=output 02, bit 03=output 03, bit 04=output

04, bit 05=output 05, bit 06=output 06, bit

07=output 07.

The DeviceNet Network uses advanced network technology,

producer/consumer communication, to increase network

functionality and throughput. Visit our web site at

http://www.ab.com/networks

for producer/consumer technology

information and updates.

Publication 1792D-IN005D-EN-P - February 2002

Page 11

High Current 8 Input/8 Output ArmorBlock I/O Module Series B 11

Troubleshoot with the Indicators

This module has the following indicators:

• Network/Module status indicator

• Logic status indicators

• Individual point status indicators

The following illustration shows status indicators.

Status Indicators

42287

The following table describes the network and module status

indicator.

Net/Mod Status Indicator

Indication Status

Off No power or auto bauding

Flashing Green/Off On line but not connected

Solid Green On line, link OK, connected

Flashing Red Recoverable fault-expansion module fault or module

Solid Red Unrecoverable fault

Green to Red to Off At powerup only - LED test

configuration error

I/O connection fault-one or more I/O connections in

the timed-out state

Communication failure-duplicate node address present

or incorrect baud rate

Publication 1792D-IN005D-EN-P - February 2002

Page 12

12 High Current 8 Input/8 Output ArmorBlock I/O Module Series B

The following table describes the logic status indicator.

Logic Status Indicators

State Status

Off Logic is disabled

Solid Green Logic is enabled

Flashing Green Local forces are applied and local logic is enabled

The following table describes the I/O status indicator.

I/O Status Indicators

Function LED

Auxiliary

Power

Group #1

Auxiliary

Power

Group #2

Outputs Green/

Inputs Yellow No valid input

Condition Module Illumination

Color

Yellow No auxiliary power

Auxiliary power present

Yellow No auxiliary power

Auxiliary power present

Output not energized

red

Output energized

Output shorted and latched off

Output No-load in OFF state

Val i d input

None

Yellow

None

Yellow

None

Green

Red, MS blink red

Blinking Red, MS blink Red

None

Yellow

For more information on indications, see the Technical Data,

publication 1792-TD001.

Publication 1792D-IN005D-EN-P - February 2002

Page 13

High Current 8 Input/8 Output ArmorBlock I/O Module Series B 13

Specifications

8 Input / 8 Output Module - Cat. No. 1792D-88HC

Input Specifications Max. Min.

Inputs per block 8, Configurable as sinking or sourcing in two groups of 4

Off-State Voltage 4 0

On-State Voltage 30 8

Off-State Current - 1.2mA

On-State Current 11mA (@30V dc) 2mA (@10V dc)

Output Specifications Max. Min.

Outputs per block 8 sourcing type in two groups of 4

Off Peak Blocking Voltage - 30V

On-State Voltage Drop 5Amp

On-State Current 5 Amp

Off-State Leakage 5 Amp

Module Current (all outputs) 40A -

Surge Current - for 10mS 5 Amp

repeatable every 2 sec. 10 Amp

General Specifications Max. Min.

DeviceNet Power: Voltage

Auxiliary Power Voltage

Group 1 and Group 2 Current

Indicators Net/Mod Status-red/green Auxiliary Power-yellow

Communication Rate

Dimensions (assembled to base)

inches - (millimeters)

10 Amp

10 Amp

10 Amp

Current

sourcing type is default

1V

1V

5A

10A

250uA

250uA

10A

20A

25V dc

75mA

30V dc

40A

Logic Status-green Input Point LED-yellow

Output Point LED-red/green

125Kbps @ 500 meters (1600 feet) for thick cable,

•

flat media length 375 meters

250Kbps @ 200 meters (600 feet) for thick cable, flat

•

media length 150 meters

500Kbps @ 100 meters (300 feet) for thick cable, flat

•

media length 75 meters

2.63H x 7.74W x 3.06D

(66.7H x 196.6W x 77.60D)

-

-

-

-

-

-

-

-

11V dc

125mA

8V dc (inputs)

10V dc (outputs)

40A

Publication 1792D-IN005D-EN-P - February 2002

Page 14

14 High Current 8 Input/8 Output ArmorBlock I/O Module Series B

General Specifications

Operational Temperature IEC 60068-2-1 (Test Ad, Operating Cold),

Storage Temperature IEC 60068-2-1 (Test Ab, Un-packaged Non-operating Cold),

Wiring Category

DeviceNet Conductors

Category

Relative Humidity IEC 60068-2-30 (Test Db, Un-packaged Non-operating

Shock Operating IEC60068-2-27: Test Ea (Unpackaged shock, ES#002)

Vibration IEC60068-2-6 (Test Fc, Operating):

Emissions CISPR 11:

ESD Immunity IEC 61000-4-2:

Enclosure Type Rating Meets IP52

Radiated RF Immunity IEC 61000-4-3:

EFT/B Immunity IEC 61000-4-4:

Surge Transient Immunity ±1kV line-line(DM) and ±2kV line-earth(CM) on signal ports

Conducted RF Immunity IEC 61000-4-6:

IEC 60068-2-2 (Test Bd, Operating Dry Heat),

IEC 60068-2-14 (Test Nb, Operating Thermal Shock):

–20 to 60°C (–4 to 140°F)

IEC 60068-2-2 (Test Bb, Un-packaged Non-operating Dry

Heat),

IEC 60068-2-14 (Test Na, Un-packaged Non-operating

Thermal Shock):

–40 to 85°C (–40 to 185°F)

Use 14-22 AWG wire with insulation

Temperature rating of 75°C min.

See Publication DN-6.7.2

1, 2

2

Damp Heat):

5 to 95% non-condensing

Operating 30g

Non-operating 50g

10g @ 10-500Hz

Group 1, Class A

4kV contact discharges

8kV air discharges

10V/m with 1kHz sine-wave 80%AM from 30MHz to

1000MHz

10V/m with 200Hz 50% Pulse 100%AM at 900Mhz

±2kV at 5kHz on signal ports

2kV line-earth (CM) on shielded ports

+

10Vrms with 1kHz sine-wave 80%AM from 150kHz to

80MHz

Publication 1792D-IN005D-EN-P - February 2002

Page 15

High Current 8 Input/8 Output ArmorBlock I/O Module Series B 15

General Specifications

Agency Certification

(when product is marked)

Technical Data (user information) Publication 1792-TD001

1. You use this conductor category information for planning conductor routing as described in the

system level installation manual.

2. See publication 1770-4.1, “Programmable Controller Wiring and Grounding Guidelines.”

3. See the Product Certification link at www.ab.com for Declarations of Conformity, Certificates, and

other certification details.

c-UR-us UL Recognized Component Industrial Control

Equipment, certified for US and Canada

3

European Union 89/336/EEC EMC Directive,

CE

compliant with:

EN 50081-2; Industrial Emissions

EN 50082-2; Industrial Immunity

EN 61326; Meas./Control/Lab., Industrial

Requirements

EN 61000-6-2; Industrial Immunity

3

Australian Radiocommunications Act, compliant

C-Tick

with:

AS/NZS 2064; Industrial Emissions

ODVA ODVA conformance tested to ODVA DeviceNet

specifications

This product has been tested at an Open DeviceNet Vendor

Association, Inc. (ODVA) authorized independent test laboratory and

found to comply with ODVA Conformance Test. Please contact the

ODVA website (http://www.odva.org) for listing of products tested by

ODVA independent test labs for further details.

Publication 1792D-IN005D-EN-P - February 2002

Page 16

ArmorBlock and DeviceNetManager are trademarks of Rockwell Automation.

RSNetWorx for DeviceNet is a trademark of Rockwell Software Inc.

DeviceNetManager is a trademark of Rockwell Automation Allen-Bradley Inc.

DeviceNet is a trademark of Open DeviceNet Vendor Association (ODVA).

Publication 1792D-IN005D-EN-P - February 2002 PN 957678-04

Supersedes Publication 1792D-IN005C-EN-P - February 2001 Copyright © 2002 Rockwell Automation. All rights reserved. Printed in the U.S.A.

Loading...

Loading...