Page 1

Installation Instructions

SynchLink Base Block

Catalog Number 1751-SLBA

This document describes how to install and use the 1751-SLBA SynchLink™ base

block.

Topic Page

Important User Information 2

SynchLink Overview 3

Installing the Base Block 4

Wiring the Base Block 6

Indicators 8

Mounting Dimensions 9

European Communities (EC) Directive Compliance 10

Hazardous Location information 11

Rockwell Automation Support 13

Specifications 14

Related Publications

Publication Title Publication Number

SynchLink Base Block Installation Instructions 1751-IN001A-EN-P

SynchLink 4-port Splitter Block Installation Instructions 1751-IN002A-EN-P

SynchLink Bypass Switch Block Installation Instructions 1751-IN003A-EN-P

ControlLogix SynchLink Module Installation Instructions 1756-IN575A-EN-P

SynchLink System Overview 1756-SO008A-EN-P

ControlLogix SynchLink Module User Manual 1756-UM521A-EN-P

Publication 1751-IN001A-EN-P - March 2001

Page 2

2 SynchLink Base Block

ATTENTION

!

Important User Information

Because of the variety of uses for the products described in this publication, those

responsible for the application and use of this control equipment must satisfy

themselves that all necessary steps have been taken to assure that each application

and use meets all performance and safety requirements, including any applicable

laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in this guide

are intended solely for purposes of example. Since there are many variables and

requirements associated with any particular installation, Allen-Bradley does not

assume responsibility or liability (to include intellectual property liability) for actual

use based upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application, Installation

and Maintenance of Solid-State Control (available from your local Allen-Bradley

office), describes some important differences between solid-state equipment and

electromechanical devices that should be taken into consideration when applying

products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or part,

without written permission of Rockwell Automation, is prohibited.

Throughout this manual we use notes to make you aware of safety considerations:

Identifies information about practices or circumstances that can

lead to personal injury or death, property damage or economic

loss.

Attention statements help you to:

• identify a hazard

• avoid a hazard

• recognize the consequences

IMPORTANT

Publication 1751-IN001A-EN-P - March 2001

Identifies information that is critical for successful application

and understanding of the product.

Page 3

SynchLink Base Block 3

SynchLink Overview

We designed the SynchLink system to provide the synchronization and coordination

of drive and motion control applications that are based on ControlLogix™ and

PowerFlex 700s™ stations.

About the SynchLink Base Block

The base block converts optical signals coming from a SynchLink station to

electrical signals, and then re-times and retransmits them simultaneously to a

maximum of four 4-port splitter blocks. It also supplies power to splitter blocks.

The base block requires a 24V dc power supply. The power supply connection is

made via field wiring to a screw connector plug. The base block is DIN

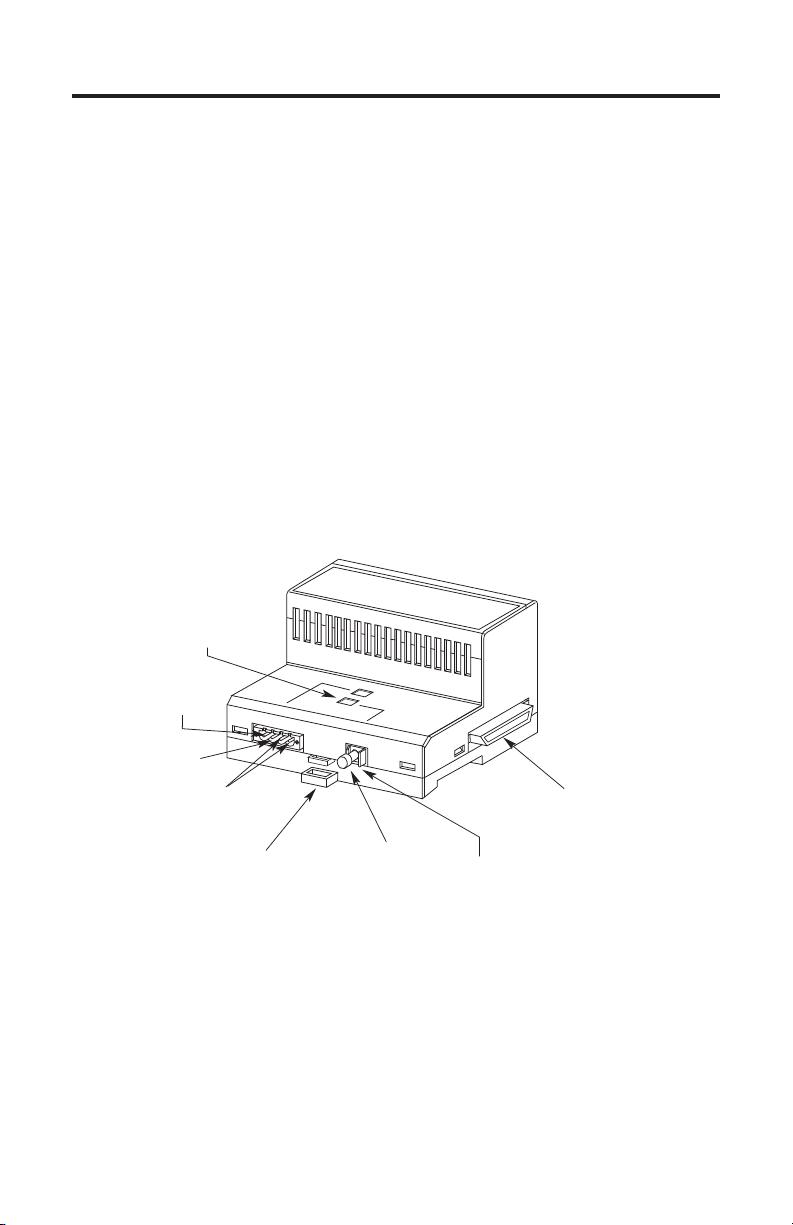

rail-mounted and is housed in a two-piece plastic enclosure. Figure 1 identifies the

components of the base block.

Figure 1 - Components of the base block

Indicators

+24V dc

(pin 4)

24V dc

Common

(pin 3)

Not Connected

(pins 1 and 2)

Module locking tab

Protective cap

Backplane Connector

Fiber Optic Receiver

31202-M

Publication 1751-IN001A-EN-P - March 2001

Page 4

4 SynchLink Base Block

ATTENTION

!

Prevent Electrostatic Discharge

Electrostatic discharge can damage integrated circuits or

semiconductors if you touch backplane connector pins.

Follow these guidelines when you handle the base block:

• Touch a grounded object to discharge static potential.

• Wear an approved wrist-strap grounding device.

• Do not touch the backplane connector or connector pins.

• Do not touch circuit components inside the base block.

• If available, use a static-safe work station.

• When not in use, keep the base block in its static-shield

box.

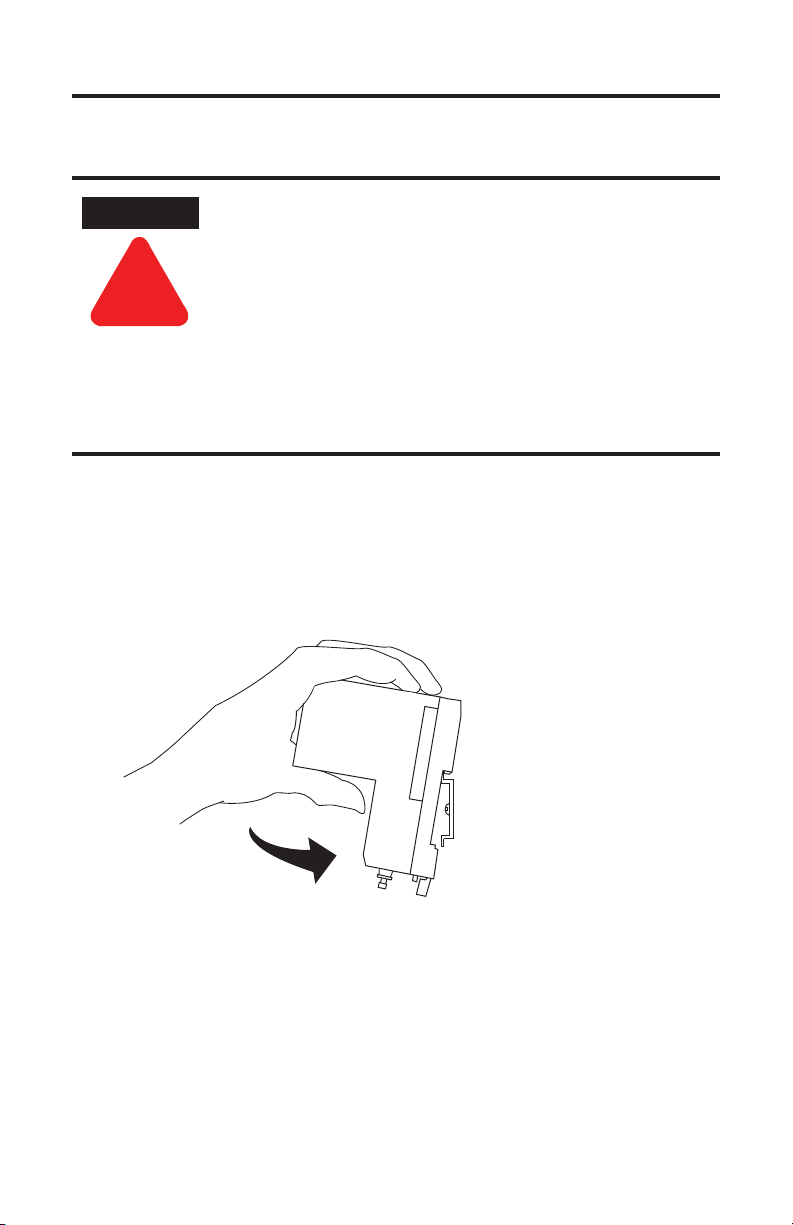

Installing the Base Block

To install the base block on the DIN rail:

1. Position the base block on the 35×7.5mm DIN rail (Allen-Bradley catalog

number 199-DR1) at a 30° angle.

Publication 1751-IN001A-EN-P - March 2001

31203a-M

Page 5

SynchLink Base Block 5

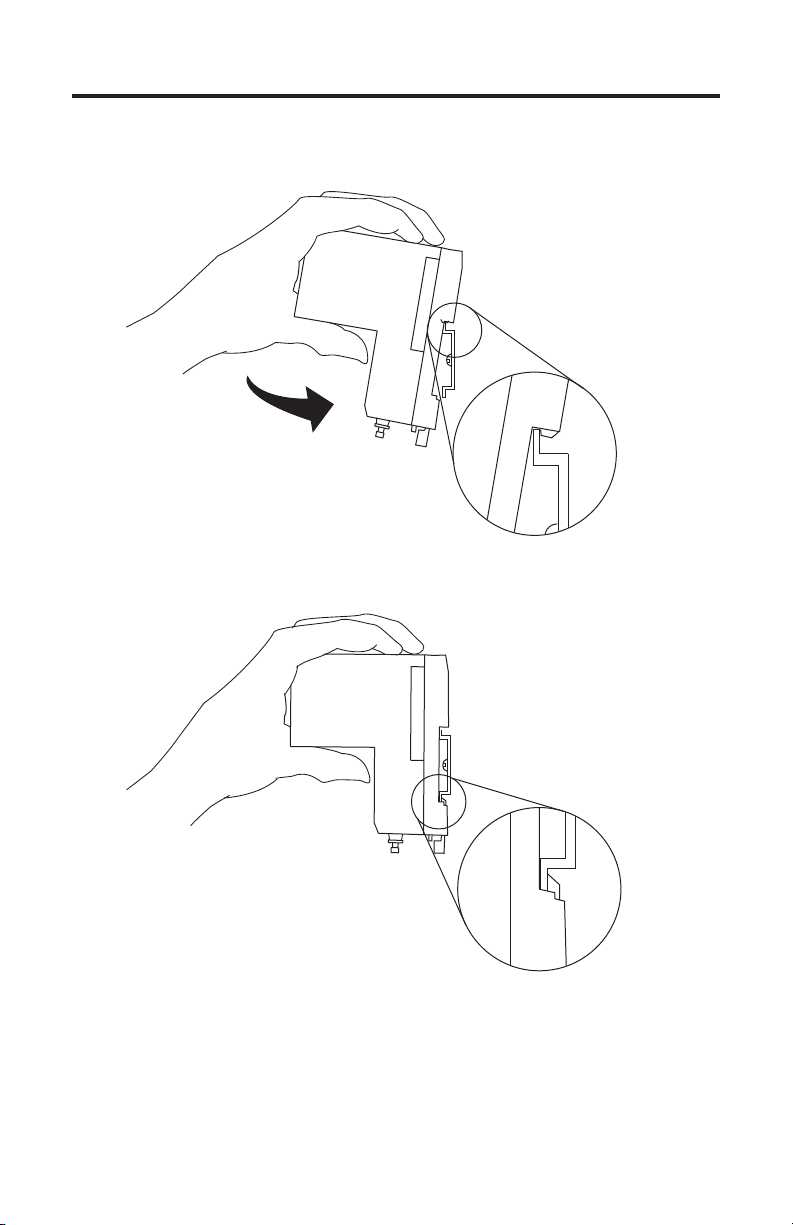

2. Hook the lip of on the rear of the base block onto the top of the DIN rail

and rotate the base block onto the rail.

31203b-M

3. Press the base block down to the DIN rail until flush.

31203c-M

The locking tab should snap into position and lock the base block to the

DIN rail. If the tab does not snap into position, follow step 4. If the tab does

snap into position, proceed to step 5.

Publication 1751-IN001A-EN-P - March 2001

Page 6

6 SynchLink Base Block

ATTENTION

!

ATTENTION

!

4. Use a screwdriver to move the locking tab down while you press the base

block flush onto the DIN rail. Release the locking tab to lock the base block

into place. If necessary, push up on the locking tab to lock the base block

into place.

5. Once you attach the base block to the DIN rail, slide the base block to the

left.

Be certain that you secure the base block and 4-port

Splitter blocks together with DIN rail anchors. Failure to

do so may result in loss of communication and/or

damage to blocks.

Failure to use the DIN rail interlocks in hazardous

location installations could cause an explosion.

The total number of 4-port splitters that can be attached to the base block

cannot exceed four.

IMPORTANT

6. Connect the block wiring as shown in Wiring the Base Block.

If you exceed the base block’s power limit, you may

cause damage to the base block.

Wiring the Base Block

To wire the base block and connect power:

Do not look directly into the fiber ports or fiber cables. Light

levels may cause damage to eyesight.

1. Connect pre-terminated fiber optic cable to the fiber optic connector shown

in Figure 1. That is, connect RxIN to SynchLink station transmitter, TxIN.

Publication 1751-IN001A-EN-P - March 2001

Page 7

SynchLink Base Block 7

2. Pre-wire the removable connector plug as shown on the base block label.

The wire length between the 24V dc power supply and the base block must

be less than 3m.

Connect To pin

+24V dc 4

24V dc Common 3

Pins 1 and 2 are not connected.

Pin 1 Pin 2 Pin 3 Pin 4

Power Supply and digital Input Connector

(front view)

31248-M

IMPORTANT

Do not connect 24V dc Common to Chassis Ground.

3. Insert the removable connector plug into the mating connector receptacle on

the base block.

Pin 4 Pin 3 Pin 2 Pin 1

Connector receptacle on base (front view)

31249a-M

4. Screw the removable connector to the base block with the left and right

mounting screws.

IMPORTANT

Make sure the base block and splitter blocks are

attached and secured prior to applying power to the

base block. Failure to do so may cause damage to the

base block and companion blocks.

Publication 1751-IN001A-EN-P - March 2001

Page 8

8 SynchLink Base Block

Indicators

Figure 2 identifies the status indicators on the base block.

Figure 2 - Status indicators

POWER ON

Status Indicators

RxIN

31222-M

Indicator When LED is ON

Power ON 24V dc power is applied to the block

RxIN optical signals are received from the SynchLink station

Publication 1751-IN001A-EN-P - March 2001

Page 9

Mounting Dimensions

Figure 3 provides mounting dimensions for the base block.

Figure 3 - Mounting dimensions

4.084 in.

(104 mm)

3.94 in.

(100 mm)

3.6 in.

(91.4 mm)

3.81 in.

(98 mm)

SynchLink Base Block 9

2.76 in.

(70.1 mm)

31232-M

Publication 1751-IN001A-EN-P - March 2001

Page 10

10 SynchLink Base Block

European Communities (EC) Directive Compliance

If this product has the CE mark it is approved for installation within the European

Union and EEA regions. It has been designed and tested to meet the following

directives.

EMC Directive

This product is tested to meet the Council Directive 89/336/EC Electromagnetic

Compatibility (EMC) by applying the following standards, in whole or in part,

documented in a technical construction file:

• EN 50081-2 EMC - Generic Emission Standard, Part 2 - Industrial Environment

• EN 50082-2 EMC - Generic Immunity Standard, Part 2 - Industrial Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low Voltage, by

applying the safety requirements of EN 61131-2 Programmable Controllers, Part 2 Equipment Requirements and Tests. For specific information required by EN

61131-2, see the appropriate sections in this publication, as well as the

Allen-Bradley publication Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1.

Open style devices must be provided with environmental and safety protection by

proper mounting in enclosures designed for specific application conditions. See

NEMA Standards publication 250 and IEC publication 529, as applicable, for

explanations of the degrees of protection provided by different types of enclosure.

Publication 1751-IN001A-EN-P - March 2001

Page 11

SynchLink Base Block 11

WARNING

!

Hazardous Location information

The following information applies when operating this equipment in

hazardous locations:

Products marked “CL I, DIV 2, GP A, B, C, D” are suitable for use in Class I Division

2 Groups A, B, C, D, Hazardous Locations and nonhazardous locations only. Each

product is supplied with markings on the rating nameplate indicating the hazardous

location temperature code. When combining products within a system, the most

adverse temperature code (lowest “T” number) may be used to help determine the

overall temperature code of the system. Combinations of equipment in your system

are subject to investigation by the local Authority Having Jurisdiction at the time

of installation.

EXPLOSION HAZARD

• Do not disconnect equipment unless power has been

removed or the area is known to be nonhazardous.

• Do not disconnect connections to this equipment unless

power has been removed or the area is known to be

nonhazardous. Secure any external connections that mate

to this equipment by using screws, sliding latches, threaded

connectors, or other means provided with this product.

• Substitution of components may impair suitability for Class

I, Division 2.

• If this product contains batteries, they must only be

changed in an area known to be nonhazardous.

Publication 1751-IN001A-EN-P - March 2001

Page 12

12 SynchLink Base Block

AVERTISSEMENT

!

Informations sur l’utilisation de cet équipement en environnements

dangereux :

Les produits marqués « CL I, DIV 2, GP A, B, C, D » ne conviennent qu’à une

utilisation en environnements de Classe I Division 2 Groupes A, B, C, D dangereux

et non dangereux. Chaque produit est livré avec des marquages sur sa plaque

d’identification qui indiquent le code de température pour les environnements

dangereux. Lorsque plusieurs produits sont combinés dans un système, le code de

température le plus défavorable (code de température le plus faible) peut être

utilisé pour déterminer le code de température global du système. Les

combinaisons d’équipements dans le système sont sujettes à inspection par les

autorités locales qualifiées au moment de l’installation.

RISQUE D’EXPLOSION

• Couper le courant ou s’assurer que l’environnement est

classé non dangereux avant de débrancher l’équipement.

• Couper le courant ou s’assurer que l’environnement est

classé non dangereux avant de débrancher les connecteurs.

Fixer tous les connecteurs externes reliés à cet équipement

à l’aide de vis, loquets coulissants, connecteurs filetés ou

autres moyens fournis avec ce produit.

• La substitution de composants peut rendre cet équipement

inadapté à une utilisation en environnement de Classe 1,

Division 2.

• S’assurer que l’environnement est classé non dangereux

avant de changer les piles.

Publication 1751-IN001A-EN-P - March 2001

Page 13

SynchLink Base Block 13

Rockwell Automation Support

Rockwell Automation offers support services worldwide, with over 75 sales/support

offices, over 500 authorized distributors, and 260 authorized systems integrators

located throughout the United States alone, plus Rockwell Automation

representatives in every major country around the world. Contact your local

Rockwell Automation representative for:

• sales and order support

• product technical training

• warranty support

• support service agreements

Obtain Pre-Sales Product Support

If you need to contact Rockwell Automation for pre-sales product support, try one

of the following methods:

• Call your local Rockwell Automation representative

• Network Pre-sales support line, 1.440.646.3638 (3NET)

• Pre-Sales e-mail, RACle3net@ra.rockwell.com

Obtain Technical Product Support

If you need to contact Rockwell Automation for technical assistance, try one of the

following methods:

• Call your local Rockwell Automation representative

• Post-Sales Technical Support, 1.440.646.5800

• Fax Back system, 1.440.646.5436 (requires a touch-tone telephone)

• Web Links http://www.ab.com — as a registered member, open to

http://www.ab.com/mem/technotes/techmain.html

Publication 1751-IN001A-EN-P - March 2001

Page 14

14 SynchLink Base Block

Specifications

Power Supply To comply with CE Low Voltage directives, you must use a

Input Voltage Rating 0.6A @ 24V dc nominal

Output Voltage Rating 1.2A @ 5.1V dc nominal

Input Voltage Range 20V dc to 30V dc

Communication Rate 5M bit/s

Power Consumption 600mA maximum for external 24V supply based on worst case

Terminal Block Torque Requirements 5-7 in-lb. maximum

Environmental Conditions

Shock Operating

Fiber Optic Cable

Power Conductors

(1)

Operating Temperature 0ºC - 60ºC

Storage Temperature -40ºC - 85ºC

Relative Humidity 5 to 95%, 0ºC - 60ºC non-condensing

Non-operating

Vibration Tested 5 g @ 10 - 500Hz per IEC 68-2-6

Fiber Type 200/230 micron HCS (Hard Clad Silica)

Fiber Termination Type Versalink V-System

Assemblies Cable assemblies can be ordered from Allen-Bradley, catalog

Maximum Length 300 meters

Minimum Length 1 meter

Wire Size 12 gauge maximum, 24 gauge minimum (#12 AWG to 24

Category

Maximum Length 3 meters

Safety Extra Low Voltage (SELV) or a Protected Extra Low

Voltage (PELV) power supply to power this base block.

Use a NEC/CEC Class 2 power supply in order to comply with

UL and CSA requirements.

A regulated power supply is recommended.

block loading (four splitters)

30g peak acceleration, 11 (

50g peak acceleration, 11 (

number 1403-CFxxx (xxx = length in meters); or from Lucent

Technologies, Specialty Fiber Technologies division.

AWG), stranded

(2)

2

± 1)ms pulse width

± 1)ms pulse width

Publication 1751-IN001A-EN-P - March 2001

Page 15

SynchLink Base Block 15

Agency Certifications

When product is marked:

Listed Industrial Control Equipment

Certified Process Control Equipment

Certified Class I, Division 2, Group A, B, C, D

Marked for all applicable directives

marked for all applicable acts

(1)

This product must be mounted within a suitable system enclosure to prevent personal injury resulting from accessibility to

live parts. The interior of this enclosure must be accessible only by the use of a tool. This industrial control equipment is

intended to operate in a Pollution Degree 2 environment, in overvoltage category II applications, (as defined in IEC

publication 664A) at altitudes up to 2000 meters without derating.

(2)

You use this category information for planning conductor routing as described in publication 1770-4.1, “Industrial

Automation Wiring and Grounding Guidelines.”

N223

Publication 1751-IN001A-EN-P - March 2001

Page 16

Notes:

Allen-Bradley, ControlLogix, PowerFlex 700s, and SynchLink are trademarks of Rockwell Automation.

Publication 1751-IN001A-EN-P - March 2001 PN 957345-10

© 2001 Rockwell International Corporation. Printed in the U.S.A.

Loading...

Loading...