Page 1

SMC Controllers

Bulletin 150

Application

and Product

Guide

Page 2

Please Read!

This manual is intended to guid qualified personnel in th

installation and operation of this product.

Because of the variety of uses for this equipment and because of the

differences between this solid-state equipment and electromechanical

equipment, the user of and those responsible for applying this

equipment must satisfy themselves as to the acceptability of each

application and use of the equipment. In no event will Allen-Bradley

Company, Inc. be responsible or liable for indirect or consequential

damages resulting from the use or application of this equipment.

The illustrations shown in this manual are intended solely to illustrate

the text of this manual. Because of the many variables and

requirements associated with any particular installation, the AllenBradley Company, Inc. cannot assume responsibility or liability for

actual use based on t he illu str ative uses and applications.

No patent liability is assumed by Allen-Bradley Company, Inc., with

respect to use of information, circuits, or equipment described in this

text.

Reproduction of the content of this manual, in whole or in part,

without written permission of the Allen-Bradley Company, Inc. is

prohibited.

For Smart M otor Controller technical support, contact your AllenBradley representative.

In the United States and Canada you may also call 1-800-765-SMCS (765-7627) for assistance during the hours of

8:00 AM to 12:00 noon and 1:00 PM to 4:30 PM (Central Time Zone) from Monday through Friday.

Important User Information

The information in this manual is organized in numbered chapters.

Read each chapter in sequence and perform procedures when you are

instructed t o do so. Do not proceed to t he next c ha pter u n til you have

complete d al l pr ocedures.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION: Identifies information about practices

or circumstances t hat c an le ad to personal injury or

!

Attentions help you:

• identify a hazard

• avoid the hazard

• recogniz e t he conse quences

Important: Identifies information that is especially important for

STC, SMC-2, SMC PLUS, SMC Dialog Plus, SMB, and Accu-Stop are trademarks of the Allen-Bradley

Company, Inc. DeviceNet is a trademark of the

death, property damage, or economic loss.

successful application and understanding of this product.

Open DeviceNet

Vendor Association, Inc.

Page 3

Table of Contents

Chapter 1 STC Starting Torque Controller

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Modes of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Across-the-Line Response . . . . . . . . . . . . . . . . . . . . . 1-2

STC Controller Response . . . . . . . . . . . . . . . . . . . . . . 1-2

Across-the-Line Response Versus STC

Controller Response . . . . . . . . . . . . . . . . . . . . . . . 1-2

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Suitable Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Chapter 2 SMC-2 Smart Motor Controller

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Modes of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Soft Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Current Limit Start . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Full Voltage Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Fault Trips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Series Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Description of Interface Options . . . . . . . . . . . . . . . . . 2-8

Soft Stop Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Wiring Diagram with Interface Option . . . . . . . . . . . . . 2-9

Overload Relay Option . . . . . . . . . . . . . . . . . . . . . . . .2-10

Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-10

Chapter 3 SMC Dialog Plus Smart Motor Controller

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Starting Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Soft Start with Selectable Kickstart . . . . . . . . . . . . . . . 3-2

Current Limit Start . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Dual Ramp Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Full Voltage Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Page 4

toc–ii

Table of Contents

Chapter 3 (cont.)

Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

LCD Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Keypad Programming . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Electronic Overload . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Built-in Communication Port . . . . . . . . . . . . . . . . . . . . 3-5

Stall Protection and Jam Detection . . . . . . . . . . . . . . . 3-6

Phase Rebalance . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Metering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Fault Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Auxiliary Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Energy Saver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Modular Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Control Terminal Description . . . . . . . . . . . . . . . . . . . . 3-9

Power Supply Board . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Logic Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-10

Soft Start without Options . . . . . . . . . . . . . . . . . . . . . .3-10

Current Limit Start without Options . . . . . . . . . . . . . . .3-11

Dual Ramp Start without Options . . . . . . . . . . . . . . . .3-12

Full Voltage Start without Options . . . . . . . . . . . . . . . .3-14

Typical Wiring Diagrams (without options) . . . . . . . . . . .3-15

Control Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

Soft Stop Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-19

Programming - Soft Start with Soft Stop Option . . . . .3-21

Pump Control Option . . . . . . . . . . . . . . . . . . . . . . . . .3-23

Programming - Pump Control Starting and Stopping . .3-25

Preset Slow Speed Option . . . . . . . . . . . . . . . . . . . . .3-27

Programming - Soft Start with Preset Slow

Speed Option . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-29

SMB Smart Motor Braking Option . . . . . . . . . . . . . . . .3-32

Programming - Soft Start with SMB Smart Motor

Braking Option . . . . . . . . . . . . . . . . . . . . . . . . . . .3-34

Accu-Stop/Slow Speed with Braking Option . . . . . . . .3-36

Accu-Stop Option . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-37

Programming - Soft Start with Accu-Stop Option. . . . .3-38

Accu-Stop/Slow Speed with Braking Option . . . . . . . .3-41

Slow Speed with Braking Capability . . . . . . . . . . . . . .3-42

Programming - Soft Start with Slow Speed

with Braking Capability . . . . . . . . . . . . . . . . . . . . .3-43

Chapter 4 Application Profiles for the SMC Dialog

Plus Controller

Page 5

Table of Contents

Chapter 5 SMC Dialog Plus Controller

Special Application Considerations

SMC Dialog Plus Controllers in Drive Applications . . . . . . 5-1

Use of Protective Modules . . . . . . . . . . . . . . . . . . . . . . . 5-1

Current Limit Fuses (Overcurrent Protection of SCRs) . . . 5-3

Motor Overload Protection. . . . . . . . . . . . . . . . . . . . . . . . 5-4

Phase Rebalance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Stall Protection and Jam Detection . . . . . . . . . . . . . . . . . 5-5

Built-in SCANport Communications . . . . . . . . . . . . . . . . 5-5

Power Factor Capacitors. . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Multi-motor Applications . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Special Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Wye-Delta . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-8

Part Winding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Wound Rotor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Synchronous . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9

Altitude De-rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

Isolation Contactor . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-10

SMC Dialog Plus Controller with Bypass Contactor (BC) .5-11

SMC Dialog Plus Controller with Reversing Contactor . . .5-11

SMC Dialog Plus Controller as a Bypass to an AC Drive .5-12

SMC Dialog Plus Controller with a Bulletin 1410

Motor Winding Heater . . . . . . . . . . . . . . . . . . . . . . . . . .5-13

Motor Torque Capabilities with SMC Dialog Plus

Controller Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

SMB Smart Motor Braking . . . . . . . . . . . . . . . . . . . . .5-14

Preset Slow Speed . . . . . . . . . . . . . . . . . . . . . . . . . . .5-14

Accu-Stop . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

Energy Saver . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15

Energy Saver Operation . . . . . . . . . . . . . . . . . . . . . . .5-15

Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-16

Application Requirements . . . . . . . . . . . . . . . . . . . . . .5-17

Preliminary Estimates . . . . . . . . . . . . . . . . . . . . . . . . .5-17

toc–iii

Chapter 6 SMC Product Line Applications Matrix

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Mining and Metals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Food Processing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Pulp and Paper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Petrochemical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Transportation and Machine Tool . . . . . . . . . . . . . . . . . . 6-6

OEM Specialty Machine . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Lumber and Wood Products . . . . . . . . . . . . . . . . . . . . . . 6-8

Water/Wastewater Treatment and Municipalities . . . . . . 6-9

Page 6

toc–iv

Table of Contents

Chapter 7 Design Philosophy

Philosophy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Line Voltage Conditions . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Current and Thermal Ratings . . . . . . . . . . . . . . . . . . . . . 7-1

Mechanical Shock and Vibration . . . . . . . . . . . . . . . . . . . 7-1

Set-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Chapter 8 Reduced Voltage Starting

Introduction to Reduced Voltage Starting . . . . . . . . . . . . 8-1

Reduced Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Solid-state . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-6

Chapter 9 Solid-state Starters Using SCRs

Solid-state Starters Using SCRs . . . . . . . . . . . . . . . . . . . 9-1

Chapter 10 Reference

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-1

Motor Output Speed/Torque/Horsepower . . . . . . . . . . . .10-1

Torque and Horsepower . . . . . . . . . . . . . . . . . . . . . . . . .10-1

Locked-Rotor Torque (LRT) . . . . . . . . . . . . . . . . . . . . .10-3

Pull-Up Torque (PUT) . . . . . . . . . . . . . . . . . . . . . . . . . .10-3

Breakdown Torque (BT) . . . . . . . . . . . . . . . . . . . . . . .10-3

Full-load Torque (FLT) . . . . . . . . . . . . . . . . . . . . . . . . .10-4

Full-load Current . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-4

Locked-rotor Current . . . . . . . . . . . . . . . . . . . . . . . . .10-4

kVA per Horsepower is Calculated as Follows: . . . . . .10-5

Motor Output for NEMA Design Designations

Polyphase 1–500 HP . . . . . . . . . . . . . . . . . . . . . . . . . . .10-7

Calculating Torque (Acceleration Torque Required for

Rotating Motion) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-11

Calculating Horsepower . . . . . . . . . . . . . . . . . . . . . . . . .10-12

Inertia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-12

Torque Formulas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-13

AC Motor Formulas . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-14

Torque Characteristics on Common Applications . . . . . .10-15

Electrical Formulas . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-17

Ohm’s Law: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-17

Power in DC Circuits: . . . . . . . . . . . . . . . . . . . . . . . . .10-17

Calculating Motor Amperes . . . . . . . . . . . . . . . . . . . . . .10-18

Other Formulas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-19

Calculating Accelerating Force for Linear Motion: . . . .10-19

Page 7

Table of Contents

Chapter 10 (cont.)

Engineering Constants . . . . . . . . . . . . . . . . . . . . . . . . . .10-19

Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-19

Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-19

Weight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10- 20

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-20

Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-20

Mathematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-20

Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-20

Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-21

Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-21

Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-21

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-21

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-21

Power/Energy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-21

Work/Inertia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-22

Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-22

Rotation/Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-22

Mathematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-22

Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-22

Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-22

Conversion Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10-23

toc–v

Page 8

SMC Controllers

The Allen-Bradley SMC Controller lines offer a broad range of

products for starting or stopping AC induction motors from 1/3 HP to

6,000 HP. Th e innovative features, compact d esign, and available

enclosed controllers meet world-wide industry requirements for

controlling motors. Whether you need to control a single motor or an

integrated automation system, our range of controllers meet your

required needs with the Starting Torque Controller (STC) and Smart

Motor Controller family (SMC-2, SMC PLUS, and SMC Dialog

Plus).

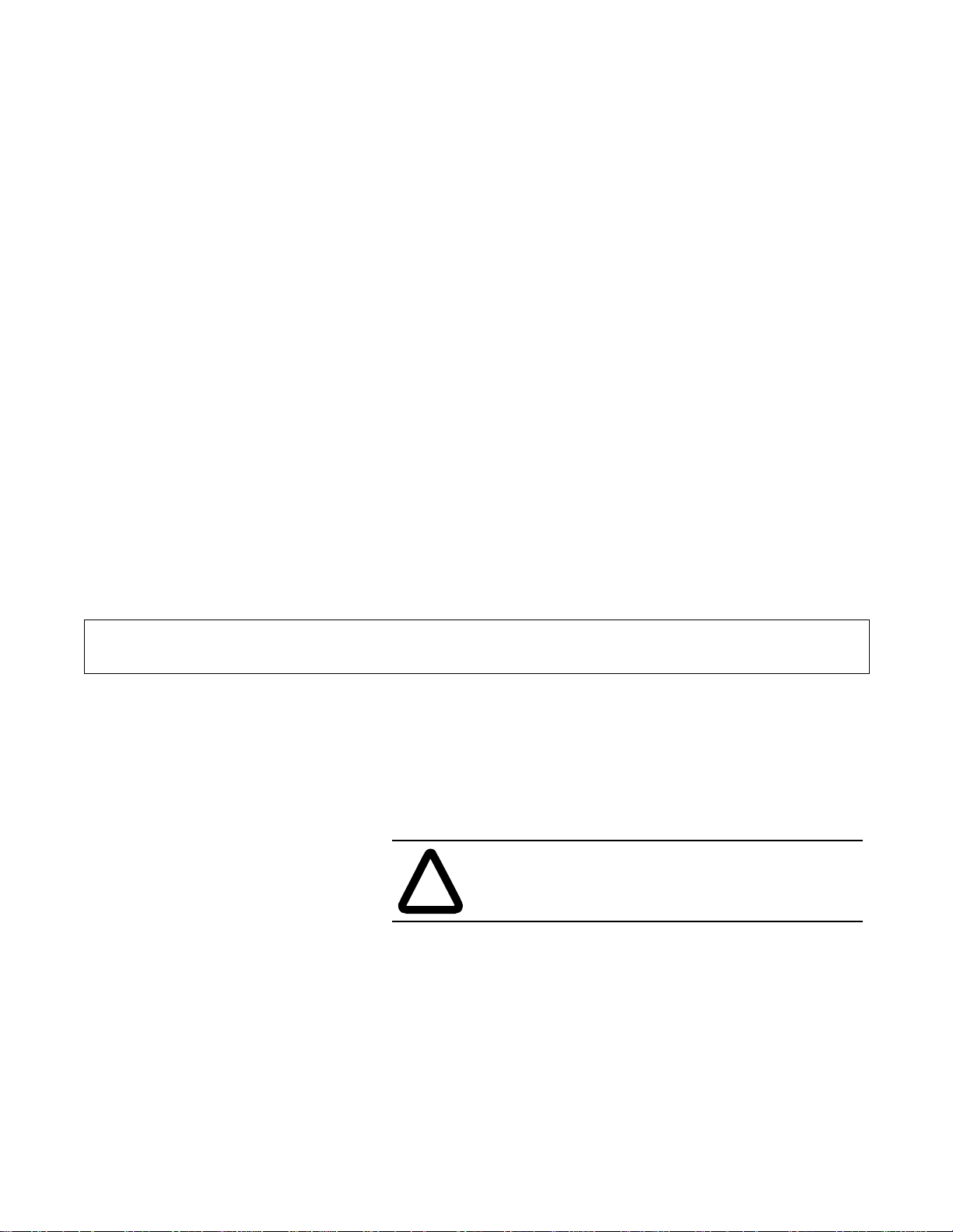

Features

Soft Start

Kickstart

Current Limit Start

Dual Ramp Start

Full Voltage Start

Energy Saver

Soft Stop

Pump Control

Preset Slow Speed

SMB Smart Motor Braking

Accu-Stop

Slow Speed with Braking

Single-phase Operation

Normal/Up-to-speed Aux

Fault Contact

Modular Design

Overload Protection

Metering

Communication

Backlit LCD Display

Programming Keypad

Phase Reversal

Phase Rebalance

Jam Detection

Underload Detection

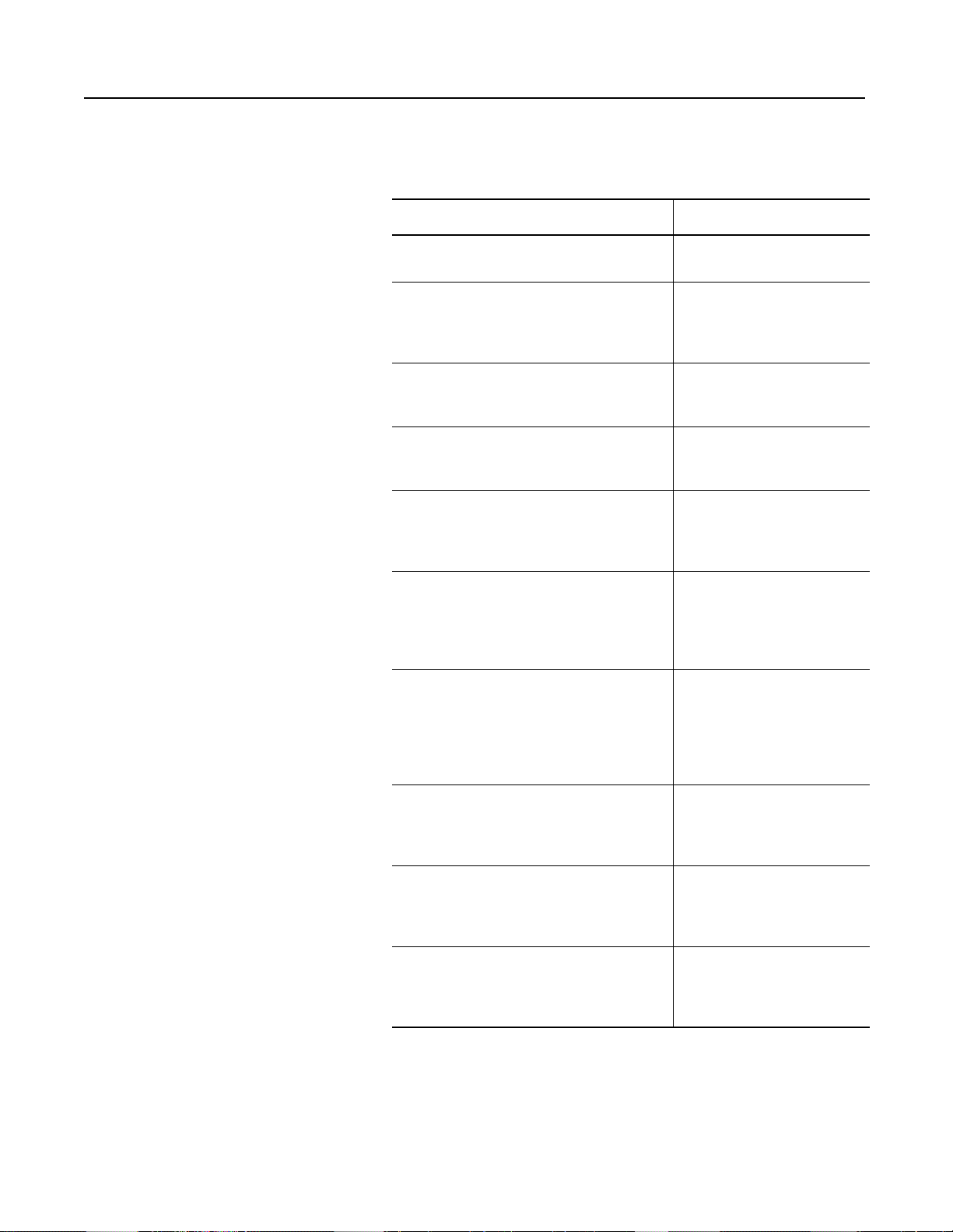

STC Controller SMC–2 Controller

100–240V

1-phase

1–22A

200–600V

3-phase

1–22A

200–600V

1–97A

SMC Dialog Plus

Controller

200–600V

1–1000A

①

= Available

① Included with the Accu-Stop option

Page 9

STC Starting Torque Controller

Chapter 1

Description

The STC Starting Torque Controller is designed for low horsepower

single-phase and three-phase squirrel cage induction motors. It is

intended to relieve the starting torque surge encountered in typical

across-the-line starting. This will provide smoother starts and

decrease downtime due to shock and vibration related problems.

The STC is a global product available in three current rated sizes: 11,

16, an d 22 Amp, with voltage rang e s f rom 100–60 0V , 50/60 Hz., UL

Listed, CSA Approved, and CE labeled. Its compact design makes

new installations as well as retrofitting easy. Setting the initial torque

and ramp time of the controller is accomplished with digital rotary

switches.

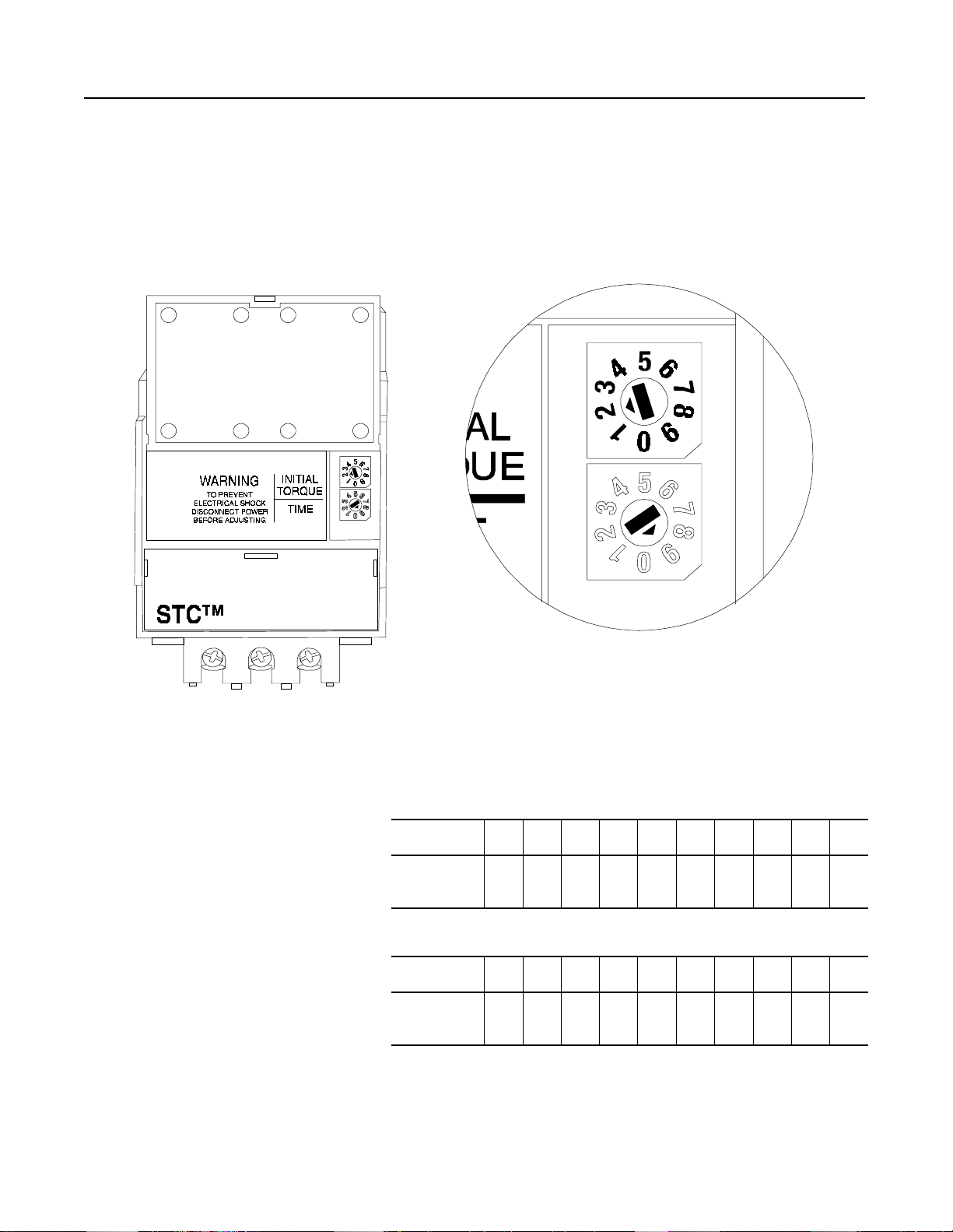

Figure 1.1 STC Controller (11, 16, and 22 Amps)

Page 10

1-2

STC Starting Torque Controller

Modes of Operation

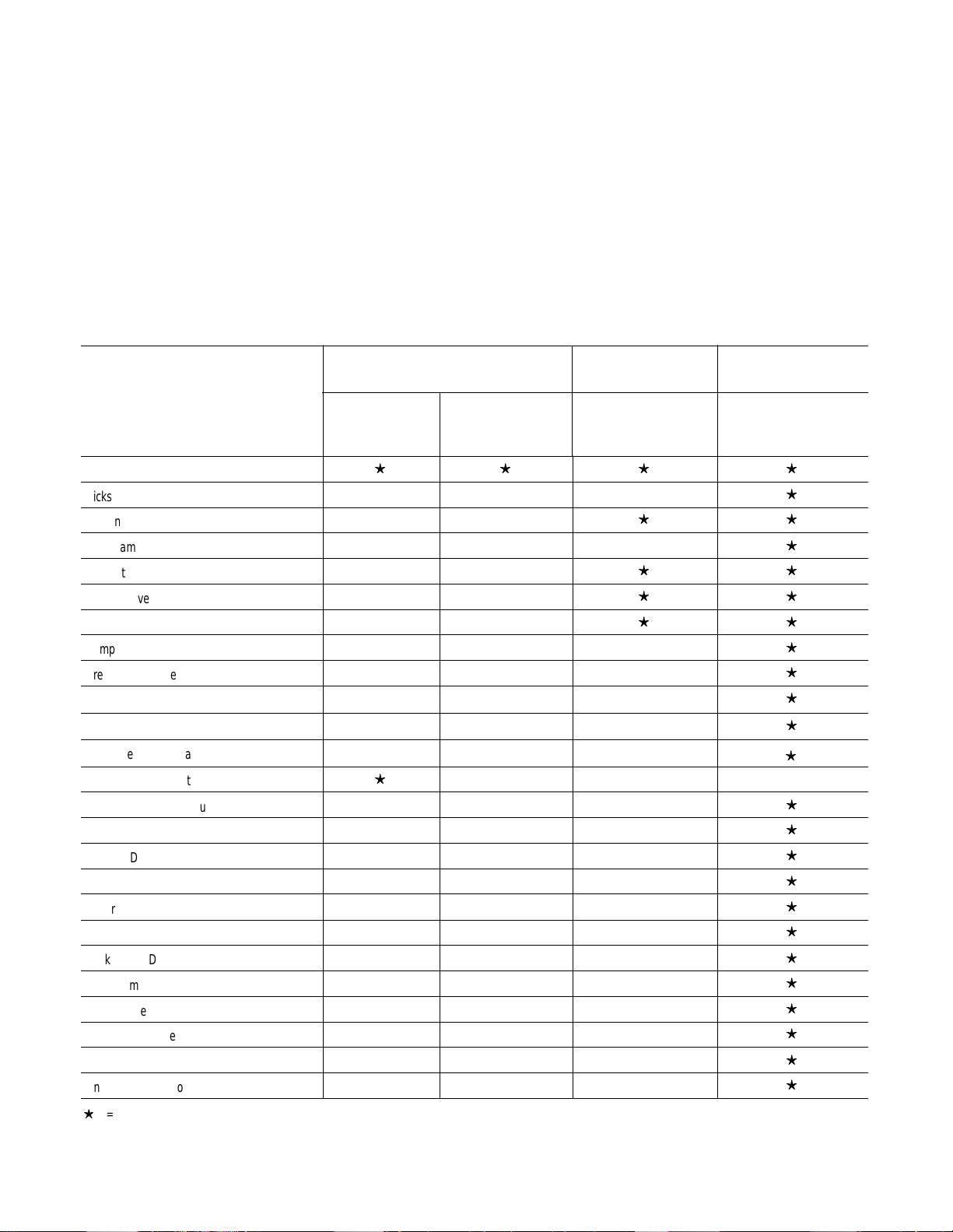

Across-the-Line Response

Excessive motor starting torque can damage the motor and driv

equipment. Figure 1.2 illustrates the torque developed in a typical

across-the-line start.

Figure 1.2 Torque Developed in a Typical Across-the-Line Start

10

75

50

Tor qu e

NM

25

0

-25

-50

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

Time (sec.)

STC Controller Response

The STC controller r educes the ma gnitu de of st ar ting torque surges as

illustrated in Figure 1.3. This limits the starting shock to the motor

and drive train.

Figure 1.3 STC Controller Respons

10

75

Tor qu

NM

50

25

0

-25

-50

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

Time (sec.)

Across-the-Line Response Versus STC Controller Response

Figure 1.4 compares a typical across-the-line start response and the

STC control ler respo nse.

Figure 1.4 Across-the-Line Response Versus STC Controller Response

100

75

50

Torque

NM

25

0

-25

-50

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7

Time (sec.)

Page 11

STC Starting Torque Controller

1-3

Features

Adjustments

The STC controller is a compact device with feed through wiring for

ease of installation. To set up the controller, ad just the digital rotary

switches. The initial torque value is set between 10 and 80% of

locked rotor torque. The voltage ramp time is adjustable from 0.1 to

4.5 seconds. This flexible combination enables the STC controller to

be installed in a wide variety of applications.

Figure 1.5 STC Controller Adjustments

T1

T2

2

T3

4

6

Digital Rotary switches for easy adjustments

Table 1.A Initial Torque Level (Nominal)

Position

% of Locked

Rotor Torque

Table 1.B

Position

Time

(Seconds)

0123456789

10 15 20 25 30 40 50 60 70 80

Voltage Ramp Time (Nominal)

0123456789

0.1 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5

(With Initial Torque Set At 0)

Page 12

1-4

STC Starting Torque Controller

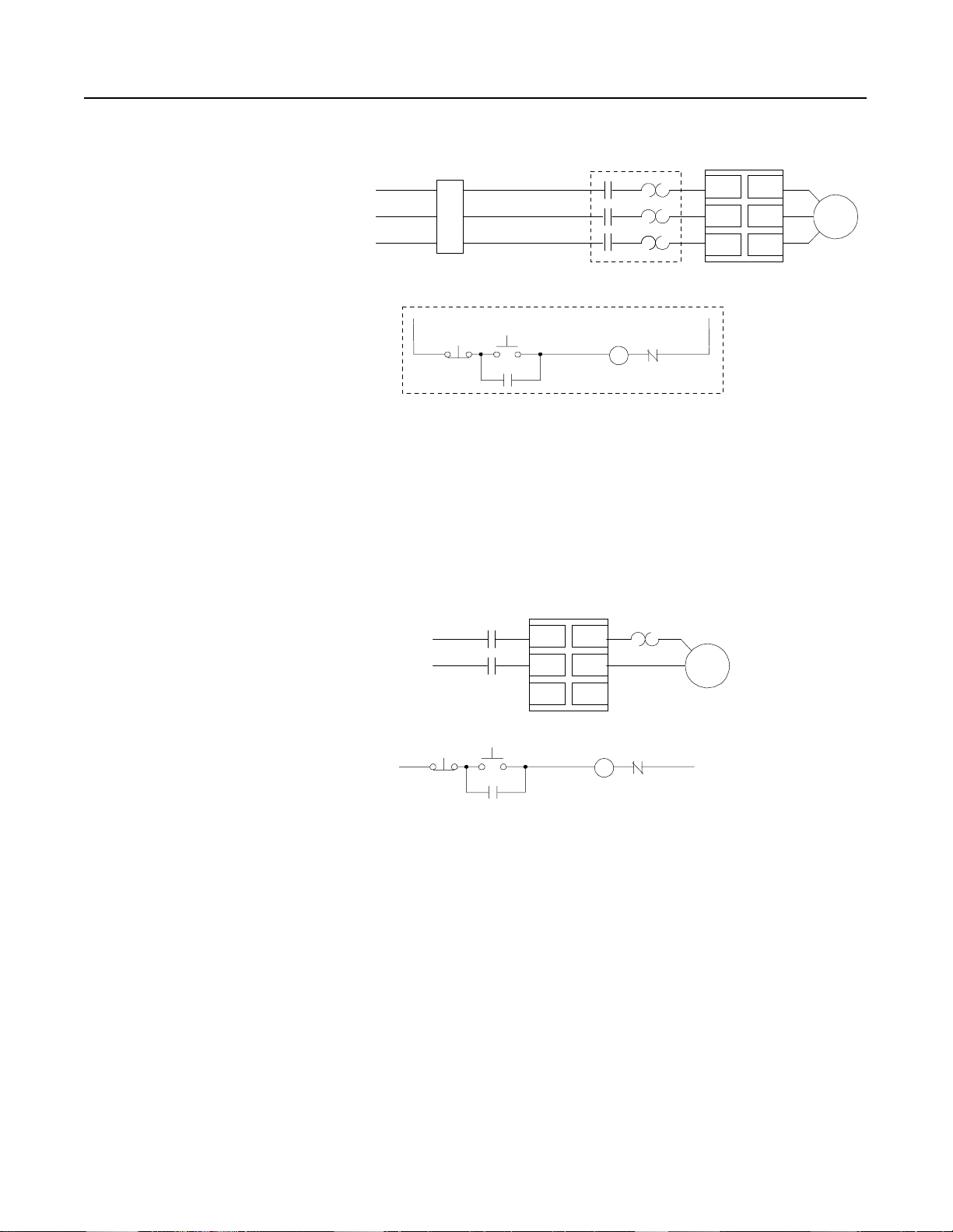

Wiring Diagrams

Figure 1.6 Typical Wiring Diagrams for STC Controller in Three-phase

Applications

M

L1/1

Power Input

3-Phase

Protection

Branch

➀

Start

Stop

➀

➀

M

➀

Existing Motor

Starter

➀

O.L.

M

Starting Torque

➀

➀

T1/2

L2/3

T2/4

L3/5

T3/6

Controller

Existing Control Circuit

Customer supplied

➀

Figure 1.7 Typical Wiring Diagrams for STC Controller in Single-phase

Applications

Starting Torqu

M

L1

L2

M

Control ler

L1/1

T1/2

L2/3

T2/4

➀

L3/5

T3/6

O.L.

➀

1Ø

Motor

➀

Motor

➀

Start

M

➀

➀

➀

O.L.

M

➀

➀

Stop

Customer supplied

➀

Page 13

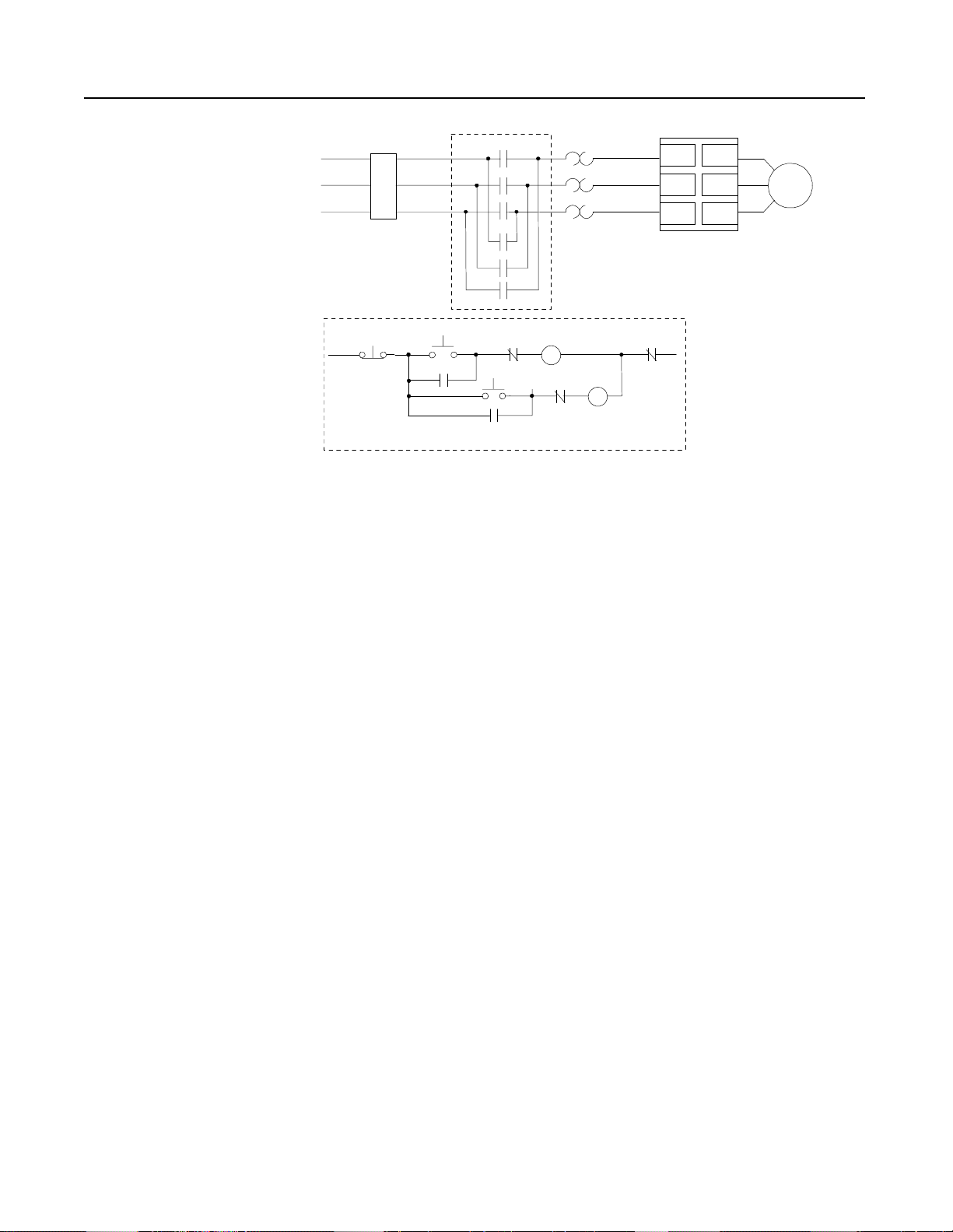

STC Starting Torque Controller

Stop

➀

F

➀

F

➀

R

➀

R

➀

➀

➀

➀

➀

Forward

➀

Reverse

➀

3-Phase

F

R

Power Input

Branch

Protection

➀

Overload Rela

(O.L.)

➀

Starting Torque

Contro ller

➀

F

R

Figure 1.8 Typical Wiring Diagrams for STC Controller – Reversing

L1/1

T1/2

Motor

Customer supplied

O.L.

L2/3

T2/4

L3/5

T3/6

Existing Control Circuit

1-5

Page 14

1-6

STC Starting Torque Controller

Suitable Replacement

Applications

The STC controller is a suitable replacement for:

• W ye-delta Starters

• Resistor Ballast Starters

• Line Reactors

• Clutches

• Flywheels

• Fluid Coup lings

• Other Mechanical and Electrical Soft Start Devices

In this section a few of the many STC controller applications are

described.

Illustrations are included to he l p identify the particular application.

Motor ratings are specified but this may vary in other typical

applications.

Typical applications include:

• Bridge Cranes

• Trolleys

• Monorails

• Shrink Wrap Machines

• Overhead Doors

• Conveyor

• Material Handling Equipment

• Compressors

• Fans and Pumps

• Lifts

• Elevators

• Grinders

•Mixers

Page 15

STC Starting Torque Controller

1-7

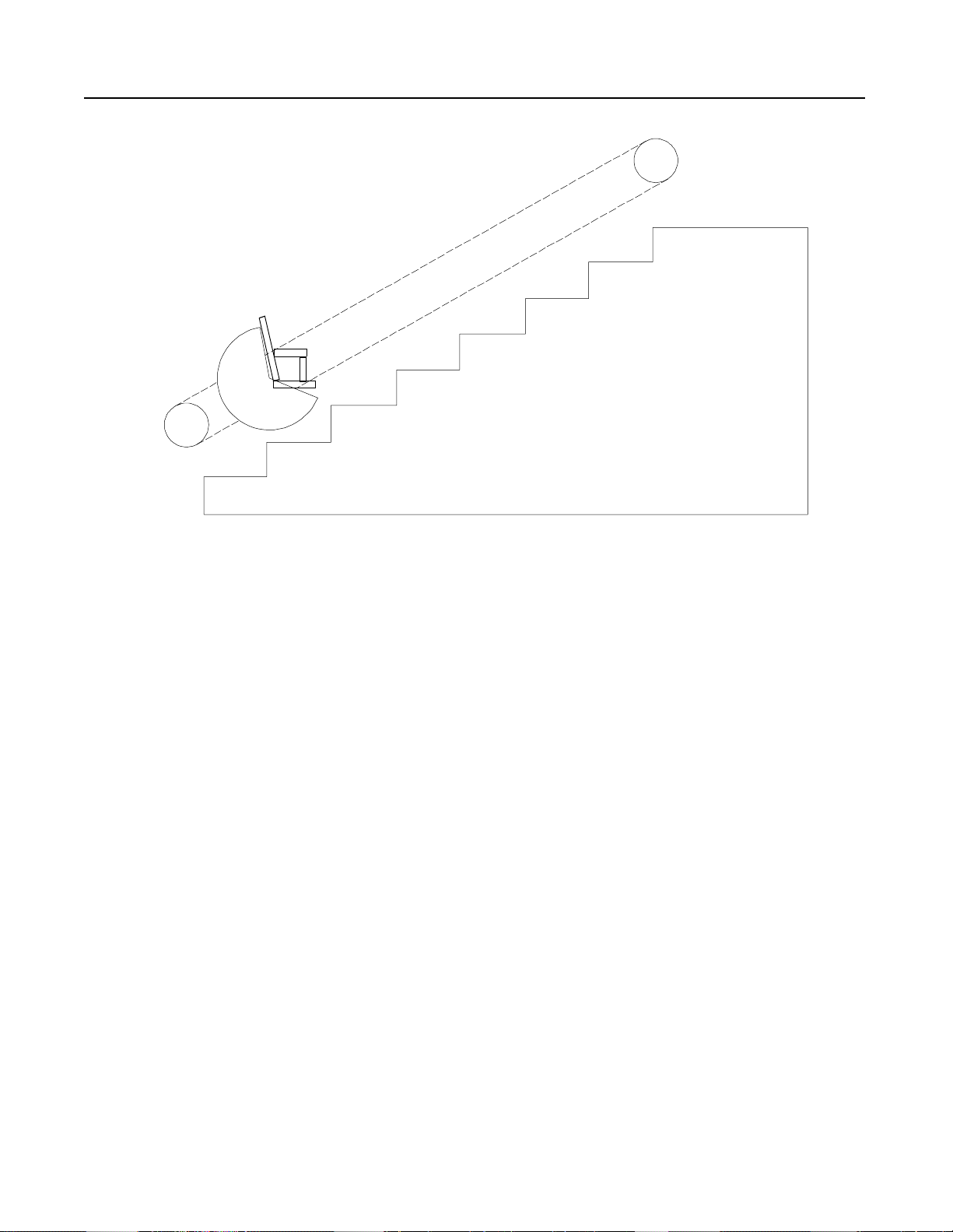

Applications (cont.)

Figure 1.9 Chair Elevator

Problem: A single-pha se chain driven chair elev ator was started

across-the-line. The starting torque caused the chair to

lurch during the start and occasionally caused chain

alignment problems.

Solution: An STC controller was installed to provide controlled

acceleration.This minimized the mechanical shock

encountered during across-the-line starting and reduced

alignment problems. It also allowed for regularly

scheduled preventive maintenance inspections, rather

than emergency maintenance repair.

Page 16

1-8

STC Starting Torque Controller

Applications (cont.)

Figure 1.10 Paint Shaker

Problem: The commercial paint shaker was operated with a single

phase motor and used across-the-line starting. This

method of starting caused the facility’s line voltage to

dip. The building’s fluorescent lighting, with electronic

ballasts, was extremely sensitive to line voltage dips and

would momentarily shut off when the paint shaker was

started.

Solution: A single-phase STC controller was used to provide a soft

start to t he paint shaker. The ramp time was set to three

seconds, thereby eliminating the line voltage dip.

Page 17

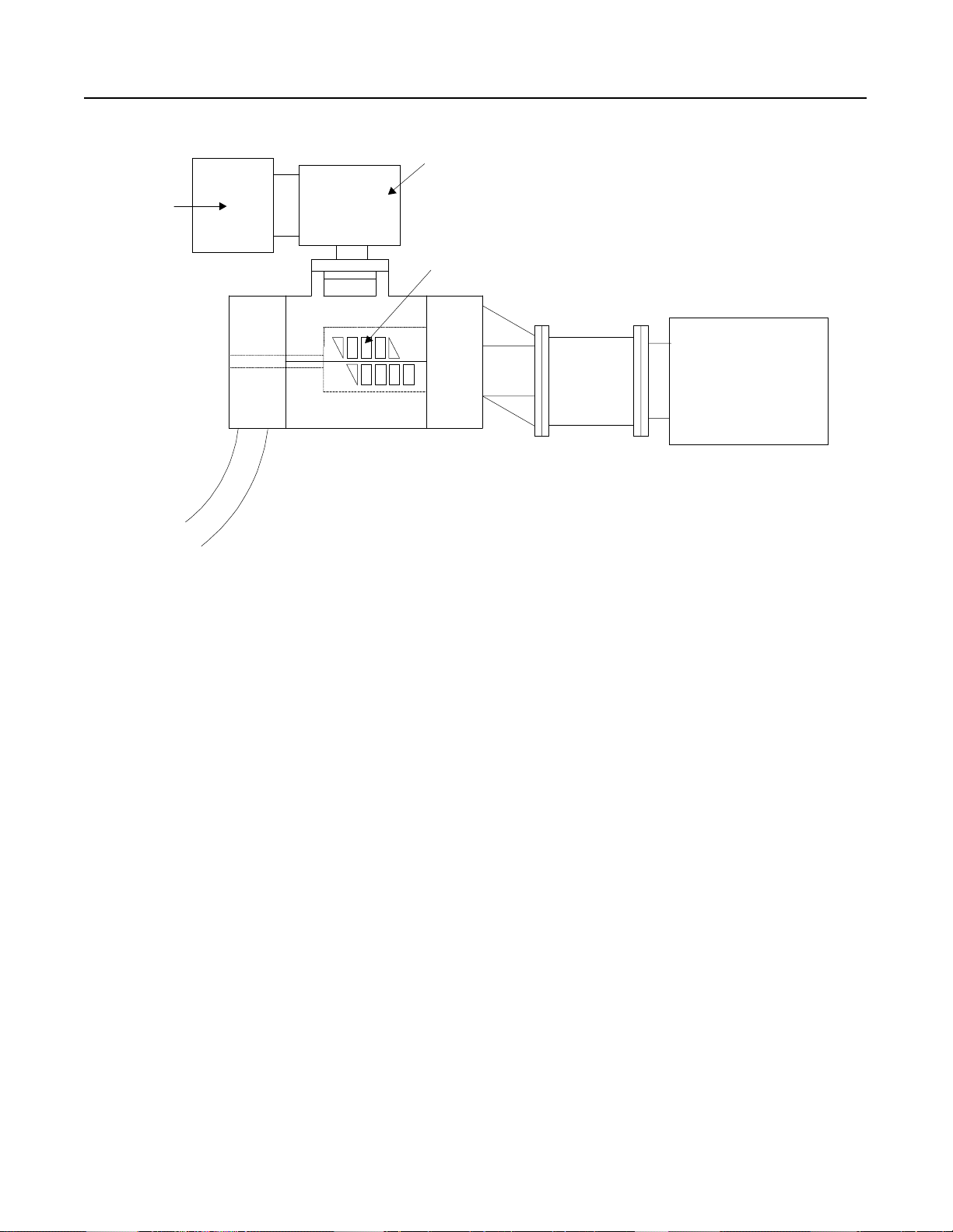

Figure 1.11 Chain Conveyor with Torque Control

Bundle Bundle

Motor

STC Starting Torque Controller

Chain

1-9

480 Volts

7.5 HP

Problem: A chain conveyor is used for transporting bundles of

paper . Due to the high sta rting torque the co nveyor motor

applies to the chain during startup, the chain was

breaking on an average of once per day. Maintenance of

the con veyor caused interruptions in the production

schedule.

Solution: The STC controller was installed to reduce the starting

torque on the motor and mechanical system. This

resulted in less downtime and higher productivity. The

STC controller was easy to retrofit due to its compact

size and feed through wiring.

Page 18

1-10

STC Starting Torque Controller

Applications (cont.)

Figure 1.12 Crane with Torque Control

480 Volts

2 HP

Traverse Motor (STC Controlled)

Tra ck

Load

Problem: An overhead crane required frequent jogging due to

adjustments in the traverse (horizontal) position. An

across-the-line starter was used and this caused overshoot

or undershoot when trying to position over a load.

Solution: The STC controller was installed in the application. By

reducing the starting torque of the motor, this allowed th

crane to be positioned effectively. This meant fewer

starts were required to position the crane over the load.

This solution reduced the maintenance required as well

as improved the productivity of the crane. The STC

controller was a cost effective solution.

Page 19

STC Starting Torque Controller

Figure 1.13 Aircraft Hangar Door

1-11

480 Vol

2 Hp

Chain

Motor

Problem: A chain driven aircraft hangar door was started across-

the-line. The starting torque caused chain alignment

problems. This required frequent inspection and

maintenance.

Solution: An STC controller was installed to provide controlled

acceleration. This minimized the mechanical shock

encountered during across-the-line starting and reduced

maintenance inspection. The digital adjustments of the

STC controller were easily set and did not drift with ag

or vibration.

Page 20

Chapter 2

SMC-2 Smart Motor Controller

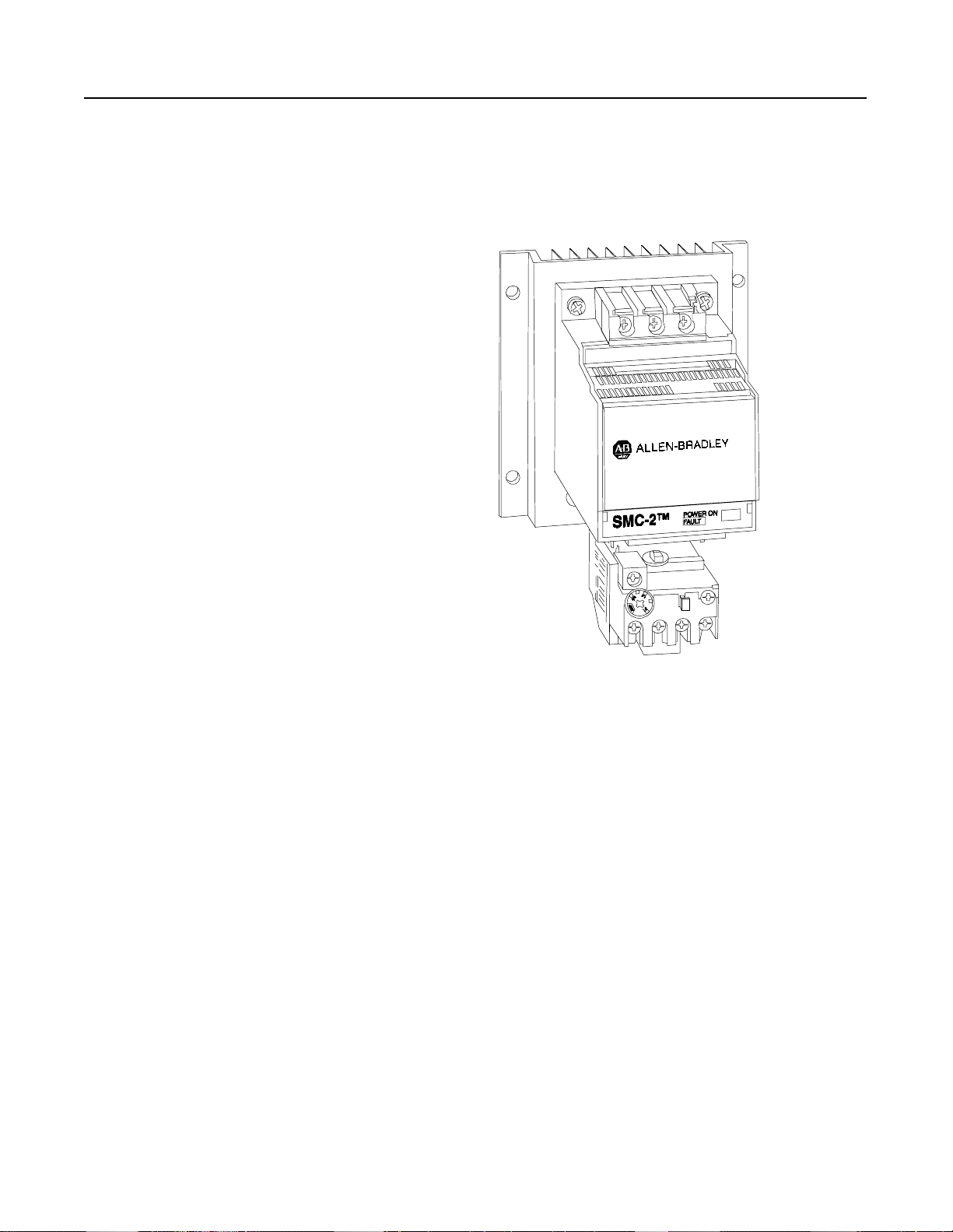

Description

The SMC-2 Smart Motor controller is a compact, multi-functional

solid state controller used in starting standard three-phase squirrel

cage induction motors and controlling resistive loads.

The SMC-2 p ro duc t line includes c urr e nt range s from 5–9 7 Amps,

200 to 600V, 50/60 Hz., UL Listed, CSA Approved, and CE labeled.

This covers applications up to 75 horsepower.

Figure 2.1 SMC-2 Controller (5–97 Amps)

Modes of Operation The following modes of operation are standard within a single

controller:

• Soft Start

• Current Limit Start

• Full Voltage Start

The built-in energy saver feature allows the controller to conserv

energy on applications where the motor is lightly loaded or unloaded

for long periods of time.

Page 21

2-2

Start Run

Percent

Voltage

Initial

Torque

100%

Time (seconds)

SMC-2 Smart Motor Controller

Modes of Operation (cont.)

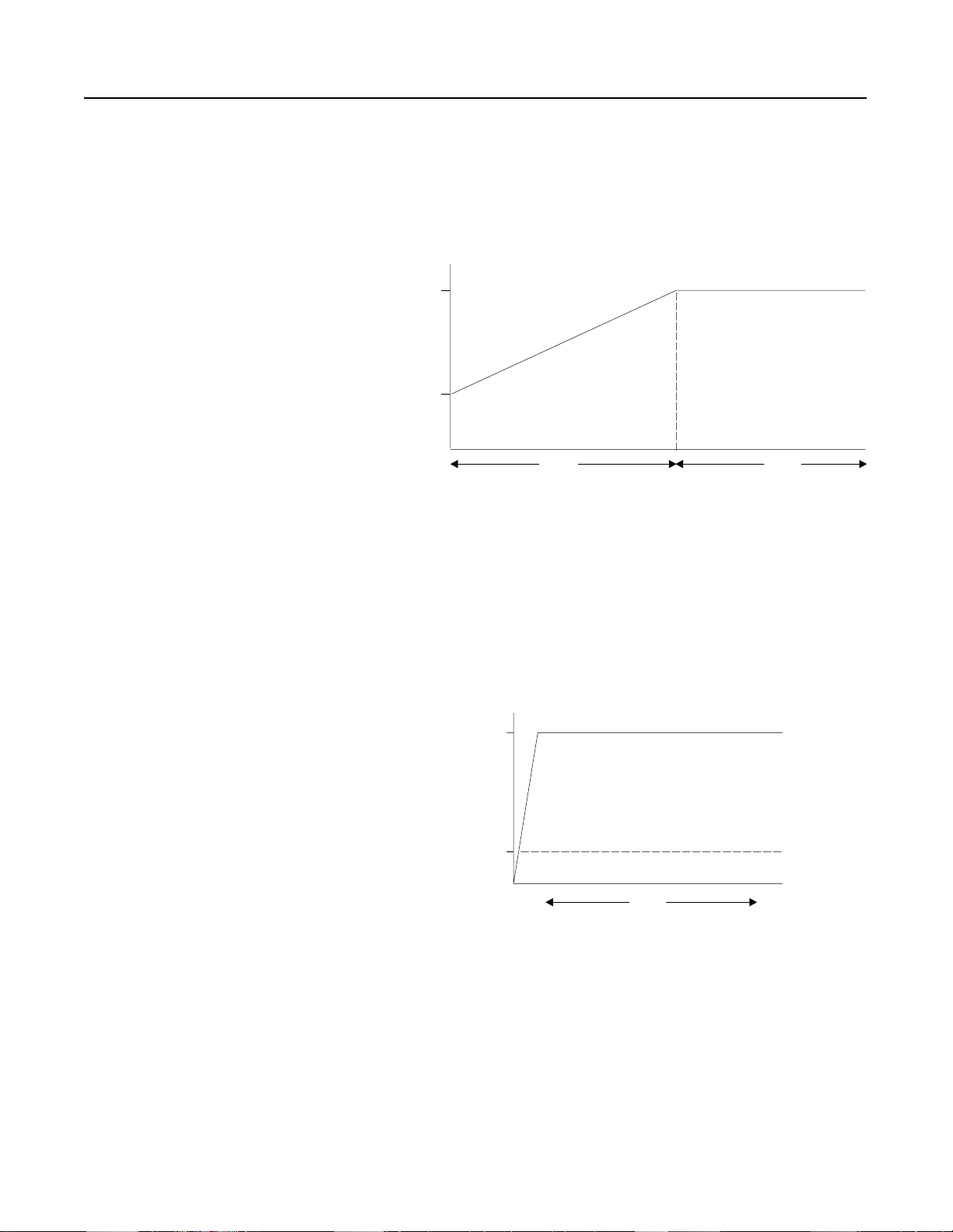

Soft Start

This is th e m o st co mmon me t hod of s tar t ing . The initi al torque value

is set between 0 – 70% of locked rotor torq ue. The motor voltage is

steplessly increased dur ing the acceleration ramp period, which is

adjustable from 2–30 seconds.

Figure 2.2 Soft Start

Current Limit Start

This starting mode is used when it is necessary to limit the maximum

starting c urrent. This can be adjuste d from 25 t o 550% of full load

amperes. The current limit starting time is customer set. If the motor

is not up to speed after the selected time, the motor will transition to

full voltage

Figure 2.3 Current Limit Start

550

Percent

Full Loa

Amp

25

Start

Time (seconds)

Page 22

SMC-2 Smart Motor Controller

100%

Percent

Voltage

Time (seconds)

2-3

Full Voltage Start

This mode is used in applications requiring across-the-line starting.

The ramp time is l ess than 1/10 second.

Figure 2.4 Full Voltage Start

Features

Fault Trips

There is a single red LED on the front of the SMC-2 controller for

diagnostic in di c ati o n. Wh en three -phase power is a ppl ied to the

controller, the LED will be on.

The SMC-2 controller monitors the following fault conditions:

• Shorted SCR (pre-start only)

• Phase Loss (line side and pre-start only

• Stalled Motor (when stall switch is on)

If a shorted SCR or phase loss exists, the SMC-2 controller will not

start and the LED will flash. If a stalled motor condition exists, th

controller s h uts down and flashe s the LED. In the event three-phase

input power is lost, the LED turns off.

Page 23

2-4

SMC-2 Smart Motor Controller

Adjustments

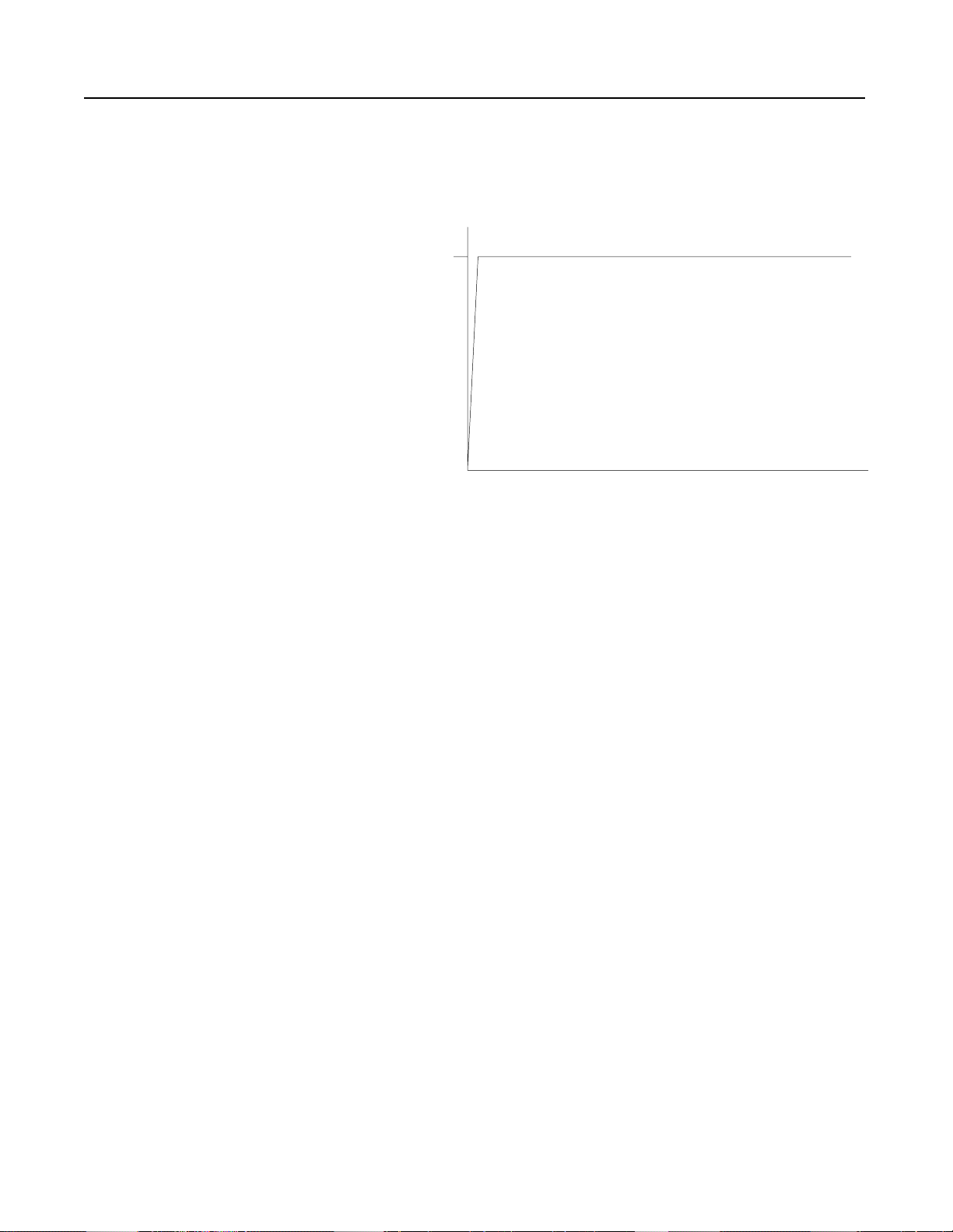

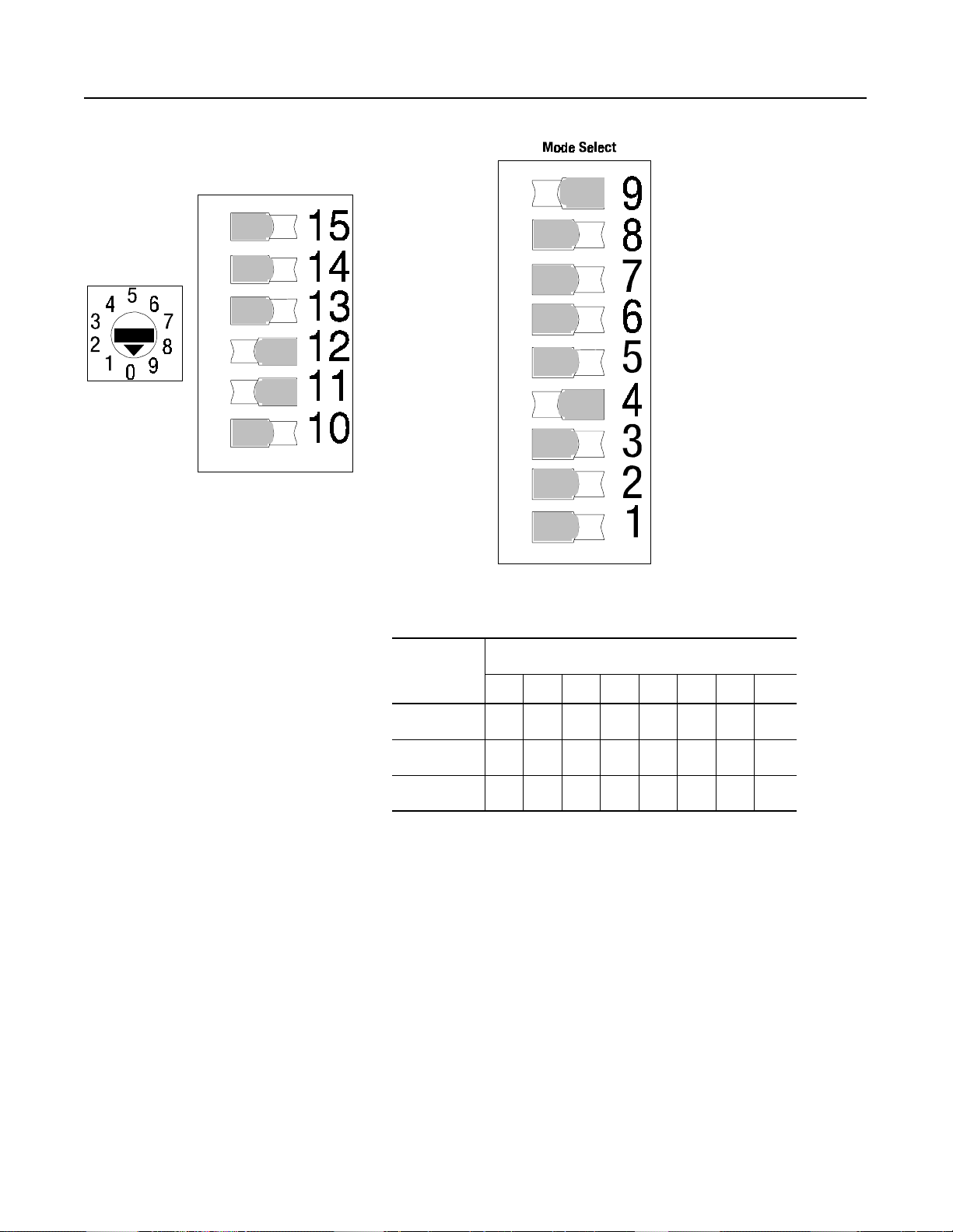

Figure 2.5 SMC-2 Soft Start

Mode Selec

Time Select

Starting Time

Initial Torque Leve

NOTE:

The switches shown above are for a 10 second Soft Start with a 3 0

Starting Time

Starting Time

Soft Stopping Time (Active

only with interface option)

Soft Stopping Time (Active

only with interface option)

Soft Stopping Time (Active

only with interface option)

initial torque and 25 seconds soft stop.

Full Voltage Start

Current Limit

Energy Saver Select

(ON OFF)/

50/60 H

(ON/OFF)

Auxiliary Contact (Up-to-Speed./Instant.)

(Active only with interface option)

ON Positio

Stall Select

(ON/OFF)

Soft Stop Selec

(Active only with interface option)

Must be OFF when Soft Stop not use

Soft Stop Select

(Active only with interface option)

Must be OFF when Soft Stop not use

Table 2.A Rotary Position Initial Torque Level

Position

% of Locked

Rotor Torque

0123456789

0125102030405070

Table 2.B Soft Start Time

Switch

Number

15 Off On Off On Off On Off

14 Off Off On On Off Off On

13 Off Off Off Off On On On

2 5 10 15 20 25 30

Time (seconds)

Table 2.C Soft Stop (Available only with interface option)

Switch

Number

5 101525354555110

Time (seconds)

12 Off On Off On Off On Off On

11 Off Off On On Off Off On On

10 Off Off Off Off On On On On

Page 24

SMC-2 Smart Motor Controller

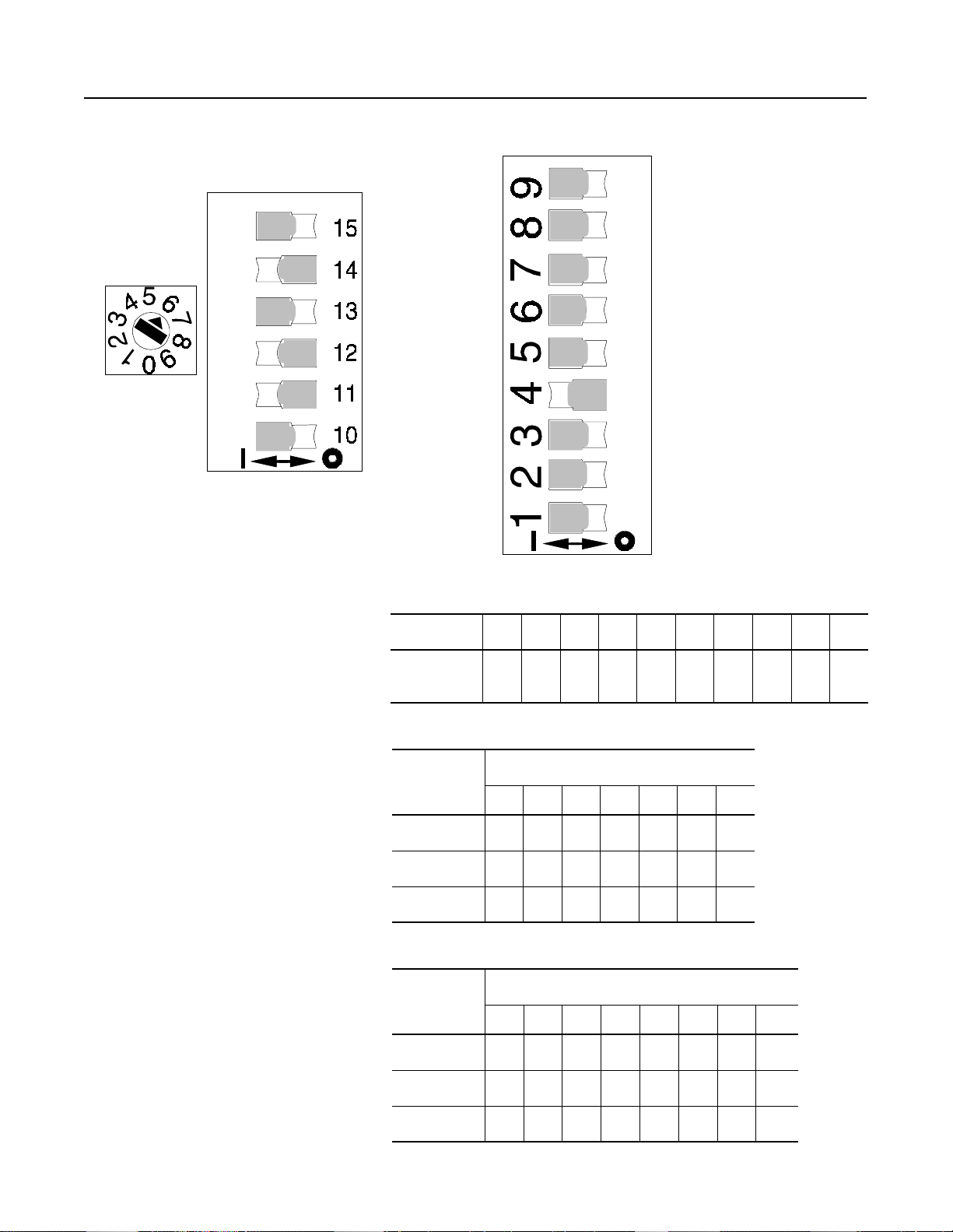

Figure 2.6 SMC-2 Current Limit Selection

2-5

Time Select

Starting Time

Starting Time

Current Limit Level

NOTE:

The switches shown above are for a 15 second, 300 percent

Starting Time

Soft Stopping Time (Active

only with interface option)

Soft Stopping Time (Active

only with interface option)

Soft Stopping Time (Active

only with interface option)

current limit start with a 25 second soft stop

Table 2.D Rotary Position % Current Limit

Position

OFF Position

Current Limit

Energy Saver Select

(ON OFF)/

50/60 H

(ON/OFF)

Auxiliary Contact (Up-to-Speed./Instant.)

(Active only with interface option)

ON Positio

Stall Select

(ON/OFF)

Soft Stop Selec

(Active only with interface option)

Must be OFF when Soft Stop not used

Soft Stop Select

(Active only with interface option)

Must be OFF when Soft Stop not used

0123456789

% of Full

Load Amps

25 50 100 200 250 300 350 450 500 550

Table 2.E Current Limit Start Time

Switch

Number

15 Off On

14 Off Off

13 Off Off

Time (seconds)

15 30

Table 2.F Soft Stop (Available only with interface option)

Switch

Number

5 101525354555110

12 Off On Off On Off On Off On

11 Off Off On On Off Off On On

Time (seconds)

10 Off Off Off Off On On On On

Page 25

2-6

SMC-2 Smart Motor Controller

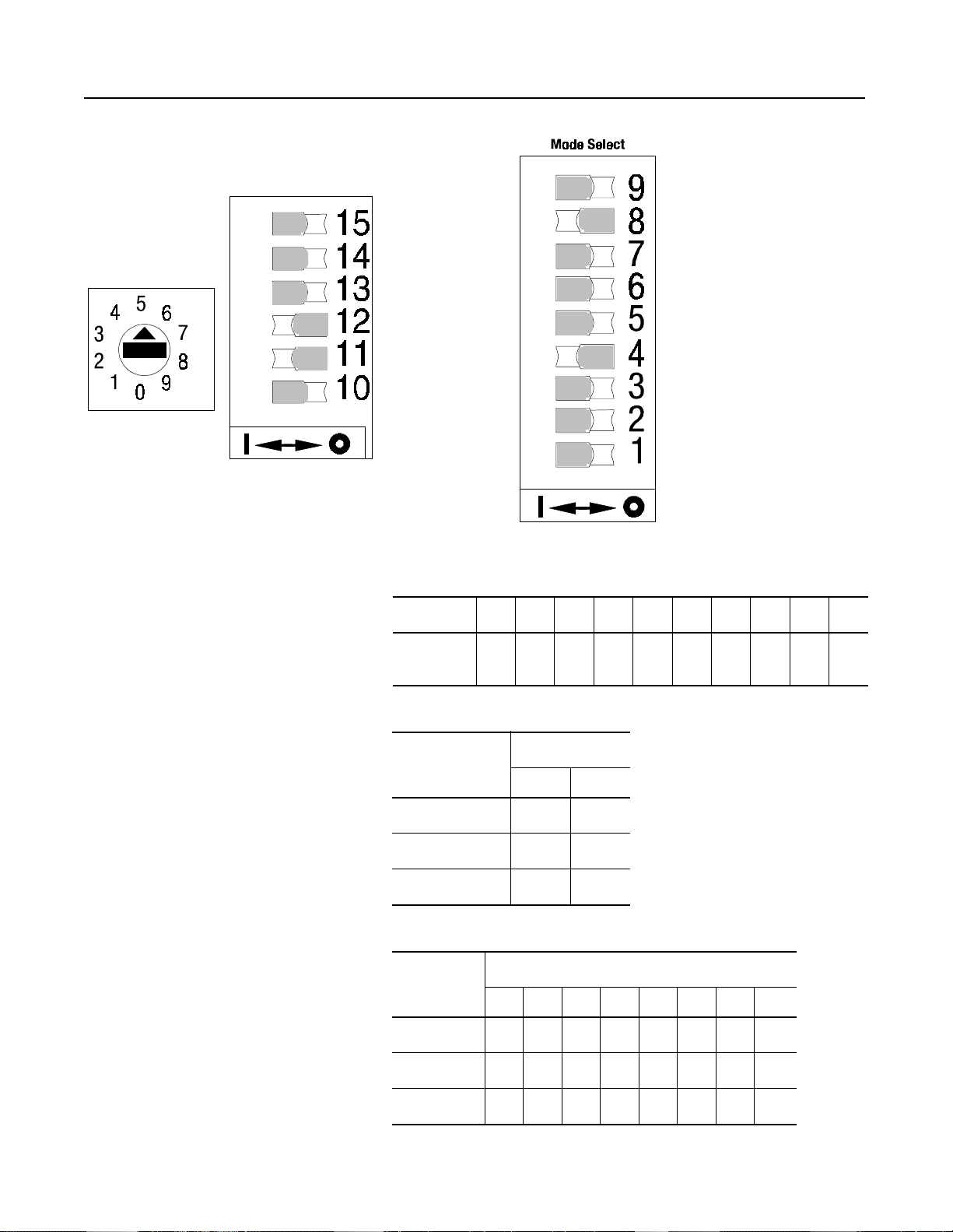

Adjustments (cont.)

Initial Torque Leve

Time Select

Figure 2.7 SMC-2 Full Voltage Selection

Full Voltage

Starting Time

Starting Time

Starting Time

Soft Stopping Time (Acti v

only with interface option

Soft Stopping Time (Active

only with interface option

Soft Stopping Time (Active

only with interface option

Current Limit

Energy Saver Select

(ON OFF)/

50/60 H

(ON/OFF)

Auxiliary Contact (Up-to-Speed./Instant.)

(Active only with interface option)

ON Positio

Stall Select

(ON/OFF)

Soft Stop Selec

(Active only with interface option)

Must be OFF when Soft Stop not use

Soft Stop Select

(Active only with interface option)

Must be OFF when Soft Stop not use

Table 3.G Soft Stop (Available only with interface option)

Switch

Number

12 Off On Off On Off On Off On

11 Off Off On On Off Off On On

10 Off Off Off Off Off On On On

5 101525354555110

Time (seconds)

Page 26

SMC-2 Smart Motor Controller

2-7

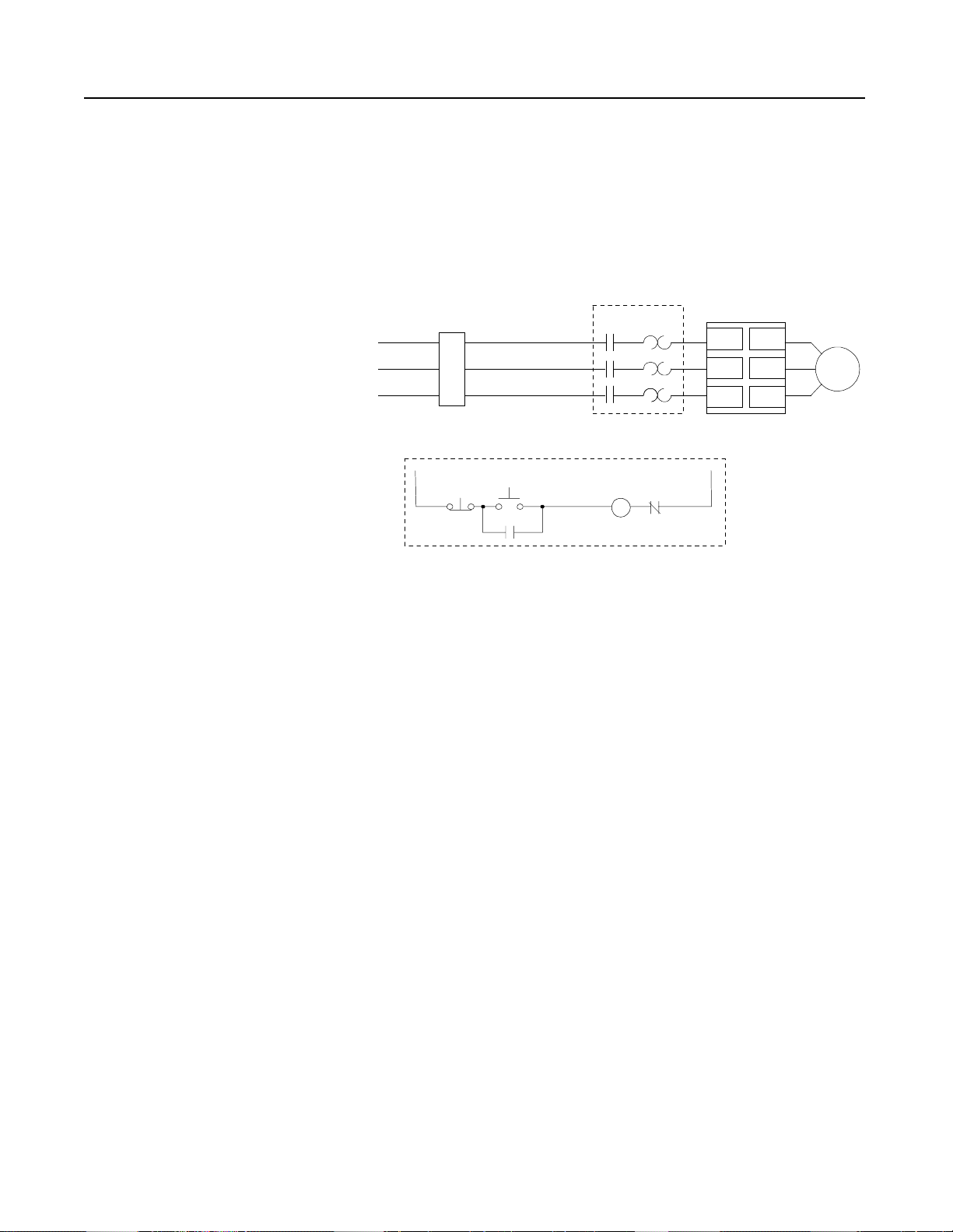

Wiring Diagram

Series Controller

The SMC-2 controller is designed to operate with an

electromechanical starter. The series mode has the following

features:

• Simplified initial installation – no need for additional wiring

• Easy retrofits – works with existing electromechanical starter

Figure 2.8 Wiring Diagram for Series Controller

M

T1/2

➀

L1/1

T2/4

L2/3

T3/6

L3/5

SMC-2

Controller

Existing Control Circuit

Power Input

3-Phase

Branch

Protection

Stop

Customer supplied.

➀

➀

➀

Start

➀

➀

M

Overload Relay

(O.L.)

➀

O.L.

M

➀

Motor

➀

Page 27

2-8

SMC-2 Smart Motor Controller

Options

Description of Interface Options

The SMC-2 controller is designed to be operated by an external

device. An optional interface is available for the SMC-2 controller.

This offers the following features:

• ON/OFF control directly to the controller through an external

device. In many applications the interface ma y e l i mi nate the

need for an additional contactor. This reduces the panel space

required.

• A configurable auxiliary contact which operates as either an

instantaneous or up-to-speed contact.

• Soft Stop. This extends stopping time to minimize load shifting

or spillage d uring stopping.

Figure 2.9 Interface Option (5–16 Amps)

This option is available as a plug-in module for the 5–16 Amp

devices. For 24–97 Amp devices, the interface is included as an

integral part of the logic design. It is not a plug-in device like th

5–16 Amp interface option.

Soft Stop Option

This function can be used in applications that require an extended

coast to rest. The voltage ramp downtime can be set from 5–110

seconds. The starting and stop ping times are independently adjusted.

The load will stop when the voltage drops to a point where the load

torque is greater than the motor torque.

Figure 2.10 Soft Start with Soft Stop

100

Percent

Voltage

Inititial

Tor que

Start Run

Soft Sto

Coast

Soft Sto

Time (Seconds)

Page 28

SMC-2 Smart Motor Controller

Wiring Diagram with Interface Option

Control power requirement for the interface option is 5VA at 120V

and 15VA at 240V. Auxiliary contact rating is NEMA C300, 2.5

Amps, 20–250V AC: 1 Amp, 12–30V DC.

Figure 2.11 Wiring Diagram with Interface Option

L1/1

Power Input

3-Phase

Protection

Branch

➀

➀

C.C.T.

Stop

➀ ➂

SMC-2 Controlle

➀

Start

➀

L2/3

L3/5

T1/2

T2/4

T3/6

Overload Relay

( O . L . )

O.L.

➀

➀

Motor

➀

2-9

10 20 30 40 50 60

Interface Option

Customer supplied

➀

Maximum fuse size 10A, 250V.

➁

For two wire control, remove stop/start push buttons and

➂

connect two wire device between terminals 10 and 30

Auxiliar

Contact

Page 29

2-10

SMC-2 Smart Motor Controller

Options (cont.)

Overload Relay Option

To save additional panel space, IEC overload relays may be mounted

directly to the 5, 9, and 16 Amp SMC-2 controllers.

Figure 2.12 SMC-2 Controller with Bulletin 193 Overload Relay (5–16 Amps)

Applications In this section a few of many applications are described, as well as

why the particular control method was selected. For example,

tumbler drum is described using a soft start feature. We will then

“build” upon this application to describe how the SMC-2 controller

options can be used to improve the tumbler drum performance and

productivity.

Illustrations are included to he l p identify the particular application.

Motor ratings are specified but this may vary in other typical

applications.

Page 30

SMC-2 Smart Motor Controller

Figure 2.13 Conveyor with Soft Start

2-11

480 Vol

7.5 HP

LOG

Motor

Chain

LOG

Problem: A conveyor is used to transport logs. The drive chain was

breaking due to uncontrolled start-up. This caused

interruptions in the production schedule and lost

productivity. Panel space was very limited.

Solution: Due to its compact design, the SMC-2 controller was

easily installed in the space vacated by the previous

starter. A 10-second soft start was selected. This

reduced the starting torque and the shock to the

mechanical sy ste m.

Page 31

2-12

SMC-2 Smart Motor Controller

Applications (cont.)

Figure 2.14 Tumbler with Soft Start

480 Volts

50 HP

Loading Door

Tumbler D rum

Motor

Drive Chain

Problem: A tumbler used in a na il finishing process was breaking

the drive chain due to the uncontrolled acceleration from

the across-the-line start. In addition, a reversing starte

was needed to position the drum to the top position for

loading the product. Due to lack of co ntrolled

acceleration, numerous jogs were used to position the

drum. The stopping time was not a con cer n in this

application. In addition, single phasing of the motor was

a frequent problem, causing premature motor failure.

Solution: The SMC-2 controller was installed after the reversing

contactor to control the starting torque of the motor. This

prevented the snapping of the drive chain on the start up

which increased the life of the chain and reduced th

downtime on the tumbler. In addition, the SMC-2

controller made it easier to jog the drum into position for

loading and unloading. (The SMC-2 controller slowed

the acceleration rate to prevent overshoot.) This helped

improve the prod uctivity of the l oad ing and unloading

process. In addition, the SMC-2 controller could quickly

detect the phase failure during starting. The controller

would prevent starting until the line had been corrected.

This added additional s tandard protection to the motor

and system.

Page 32

SMC-2 Smart Motor Controller

Figure 2.15 Power Walk with Soft Start and Soft Stop Option

240 Volts

15 HP

Motor

2-13

Problem: A power walk at an a ir po rt req u ire d a soft star t to prevent

damage to the drive chain gearbox on start-up. A soft

stop was also required in case the power walk would b

shut off while people were still on the belt. There would

be multiple units at the site, and a controller that could be

quickly installed and adjusted was required.

Solution: The SMC-2 controller with the Interface option was

designed into the system. A 10-second soft start with the

Energy Saver enabled was selected. A 10-second soft

stop was also selected. This allowed the power walk to

have a controlled start and stop. D ur ing p eriods where

the walk was unloaded, the SMC-2 controller Energy

Saver reduced the voltage to the motor, minimizing the

magnetic losses of the motor.

Page 33

2-14

SMC-2 Smart Motor Controller

Applications (cont.)

Pallet

Figure 2.16 Towline Conveyor with Soft Start and Soft Stop Option

480 Volts

15 HP

Load Load

Gearbox

Motor

Problem: A towline conveyor at the en d of a production line had

frequent damage to the gearbox due to the starting torque

from acr oss -the -li ne starting of the motor. There were

frequent spills on both starting and stopping of the

conveyor system.

Solution: The SMC-2 controller with the Interface option was

installed. Starting and stopping times of 15 seconds were

selected. The reduced torque starting prevented shock to

the gearbox and kept the load from shifting on st art-up.

The soft stop prevented the load shifts while stopping.

The SMC-2 c on t ro ller met the application requirements

and was a cost effective solution.

Page 34

SMC-2 Smart Motor Controller

Figure 2.17 Bottle Filler with Soft Start and Soft Stop Option

480 Volts

1 HP

Filler

2-15

Problem: A bottle filler line had product spillage upon starting and

stopping. An across-the-line starter w as used to start th

motor. In addition, the application required an auxiliary

contact that would energize when the motor was up to

speed.

Solution: The SMC-2 controller was installed and set for a 10-

second soft start with a 20-second soft stop. This

controlled the starting torque a n d prevented the sudden

start that w ould cause t h e bottles to spi ll. The soft stop

extended the stopping time eliminating load shift while

stopping. T h e auxiliar y conta c t was configured to

change state when the motor was up to speed.

Page 35

2-16

SMC-2 Smart Motor Controller

Applications (cont.)

Motor

Figure 2.18 Grinder with Soft Start

575 Volts

20 HP

Grinding

Wheel

Gearbox

Problem: Due to the high starti ng torque developed from starting

the motor across-the-line, the gears driving a grinding

wheel were frequently damaged. T his resulted in

unscheduled downtime for repair. T his application

required a rugged device because vibration at the control

panel was a problem.

Solution: The SMC-2 controller was installed and set for a

20-second acceler ation time. This reduced the starting

torque and the downtime for repairs on the grinder. In

addition, the benefit of the Energy Saver was realized

when the motor was running lightly loaded. The SMC-2

controller meets the same shock and vibration

requirements as electromechanical devices, therefore it

met the durability requirements.

Page 36

SMC-2 Smart Motor Controller

Figure 2.19 Passenger Elevator

2-17

Problem: A passenger e l evator i n a parking structure r equ ired a soft

start to el imin ate the jolt w hi ch occurred during an

across-the-line start. Due to the size of the en closure, the

soft starter must fit in the space vacated by the

electromechanical motor starter.

Solution: An SMC-2 c o nt rolle r with the Int erfa ce o p t ion was

installed. The starting time was set for 10 seconds. This

reduced the starting torque and eliminated the jolt during

the start. The Interface option allowed all control wiring

to be connected directly to the SMC-2 controller, thereby

eliminating the need for the electromechanical motor

starter. The small size of the SMC-2 controller allowed it

to fit easily into the space vacated by th

electromechanical motor starter.

Page 37

2-18

SMC-2 Smart Motor Controller

Page 38

Chapter 3

SMC Dialog Plus Smart Motor Controller

Description

When the Smart Motor Controller (SMC) was first introd uced in

1986, its modular design, digital set-up, and microprocessor control

set the standard for soft starters. Since its launch in 1989, the SMC

PLUS controller has been in a class by itself, providing unmatched

performance with innovative starting and stopping options. Now, the

SMC Dialog Plus controller achieves a higher level of

sophistication with greatly enhanced protection, expanded

diagnostics, a nd t he a b ility to log the motor’s operation (amps, kW,

and power factor), as well as the option to “dialog” with various

network protocols.

While the SMC Dialog Plus controller incorporates many new

features into its design, it remai ns easy to set-up and operate. You can

make use of as few or as many of the features as your application

requires.

The SMC Dialog Plus controller is a compact, modular, multifunctional solid-state controller used in starting three-phase squirrel

cage induction motors and controlling resistive loads. The SMC

Dialog Plus product line includes current ratings from 24 to 1000

Amps, 200 to 600V, 50/60Hz. This covers applications up to 1000

horsepower. The SMC Dialog Plus c on troller meets applicab l

standards and requirements.

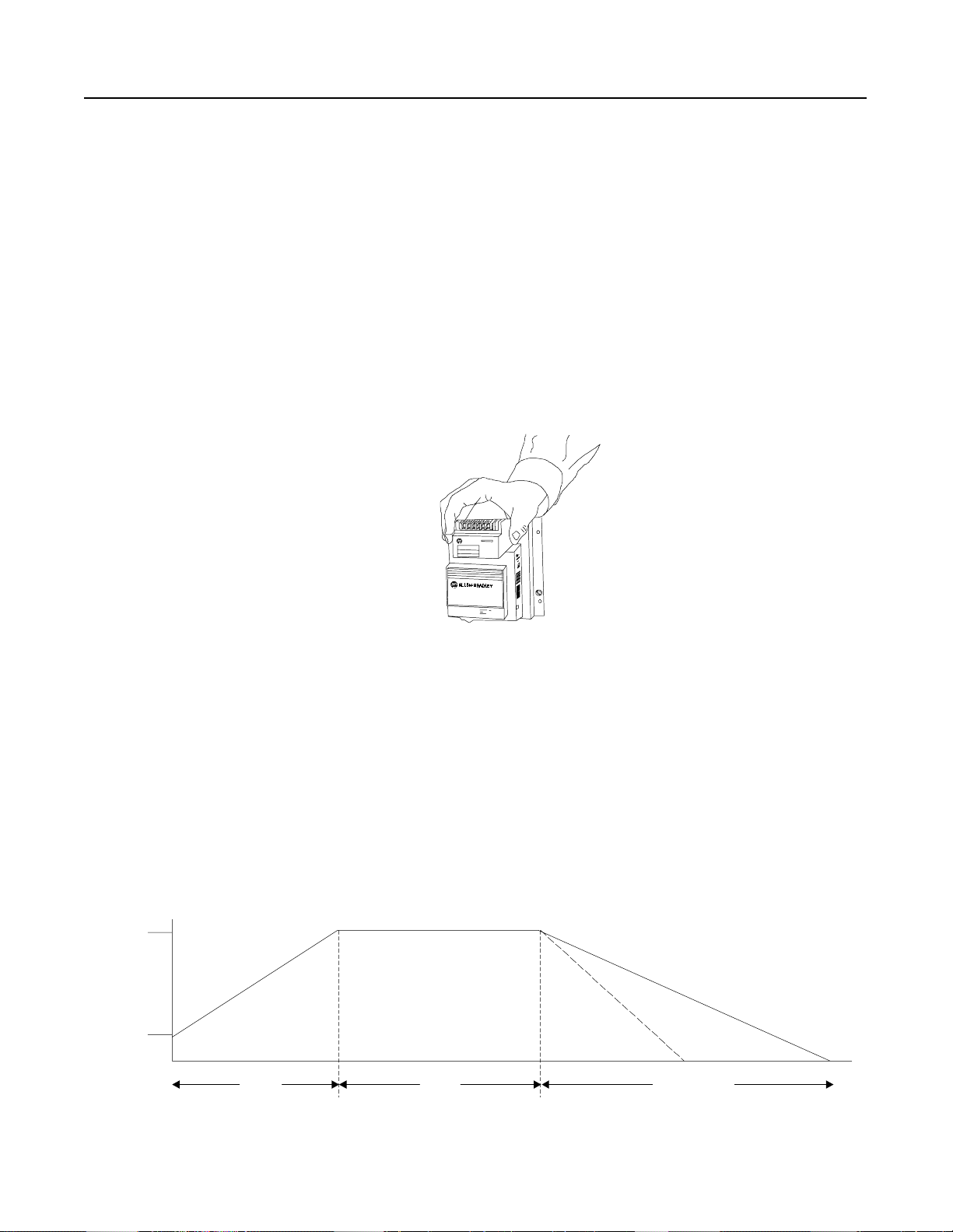

Figure 3.1 SMC Dialog Plus Controller (24–1000 Amps)

Page 39

3-2

SMC Dialog Plus Smart Motor Controller

Starting Methods

The following starting methods are standard within the controller:

• Soft Start with Selectable Kickstart

• Current Limit Start

• Dual Ramp Start

• Full Voltage Start

Optional fea tu res include:

• Soft Stop

• Pump Control

• Preset Slow Speed

•SMB Smart Motor Brake

• Accu-Stop/Slow Speed with Braking

Soft Start with Selectable Kickstart

This meth od h a s the m o st general app li c a tion. The motor is given an

initial torque setting, which is user adjustable from 0 to 90% of

locked rotor torque. From the initial torque level, the output voltag

to the motor is steplessly increased during the acceleration ramp time,

which is user adjustable from 0 to 30 seconds. If, during the voltag

ramp operation, the SMC Dialog Plus controller senses that the moto

has reached an up-to-speed condition, the output voltage will

automatically switch to full voltage.

The kickstart feature provides a boost at start-up to break away loads

that may require a pulse of high torque to get started. It is intended to

provide a current pulse of 550% of full load current and is user

adjustable from 0.0 to 2.0 seconds.

Figure 3.2 Soft Start with Selectable Kickstart

Percent

Voltage

Kickstart

100%

Initial

Torque

Start Run

Time (seconds)

Page 40

SMC Dialog Plus Smart Motor Controller

Percent

Voltage

Initial

Torque #1

100

Start #1 Run #1

Ramp #2

Ramp #1

Start #2

Time (seconds)

Run #2

Initial

Torque #2

3-3

Current Limit Start

This starting method provides a fixed reduced voltage start and is

used when it is necessary to limit the maximum starting current. Th

starting current is user adjustable from 50 to 600% of full load

amperes. The current limit starting time is user adjusta ble from 0 to

30 seconds.

Figure 3.3 Current Limit Start

600%

Percent

Full Load

Current

50%

Start

Time (seconds)

Dual Ramp Start

This starting method is useful on applications with varying loads and

varying starting torque requirements. Dual Ramp Start offers the user

the ability to select between two separate Soft Start profiles with

separately adjustable ramp times and initial torque settings.

Figure 3.4 Dual Ramp Start

Page 41

3-4

10 0

Percent

Voltage

Time (seconds)

SMC Dialog Plus Smart Motor Controller

Starting Methods (cont.)

Full Voltage Start

This meth od is used in appli c ations requ iring across-the- l ine starting.

The SMC Dialog Plus controller perf orms like a solid-state contactor.

Full inrush current and locked rotor torque are realized.

Figure 3.5 Full Voltage Start

Features

LCD Display

A two line, sixteen character b acklit LCD display provides parameter

definition with straightforward text so that controller set-up may be

accomplished without a reference manual. Parameters are arranged

in an organized four level menu structure for ease of programming

and fast access to parameters.

Keypad Programming

Programming of param et ers is accomplished through a five button

keypad on the fro nt of the SMC Di alog P lu s controller. The five

buttons include up and down arro ws, an Enter button, a Select button,

and an Escape button. The user needs only to enter the correct

sequence of keystrokes for programming the SMC Dialog Plus

controller.

Figure 3.6 LCD Display with Keypa

Page 42

SMC Dialog Plus Smart Motor Controller

3-5

Electronic Overload

The SMC Dialog Plus controller meets applicable requirements as

motor overload protective device. Overload protection is

2t

accomplished electronically through an I

algorithm.

The overload is programmable, providing the user with flexibility.

The overload trip class is selectable for class 10, 15, 20, or 30

protection. The tr i p current is set by entering th e motor’s full load

current rating and the service factor.

Thermal memory i s i n cl u de d t o a ccurately model motor operating

temperature. Ambient insensitivity is inherent in the electronic

design of the o v er lo ad .

Note: The current sensing capability of the SMC Dialog Plus

controller i s d i sa b le d du ring b y pass operat ion. The Bulletin

825 Converter Module is required to provide current

feedback in these applications.

Built-in Communication Port

A serial interface port is furnished as standard with the SMC Dialog

Plus controller. This communication port allows for connection to a

Bulletin 1201 Hu m an Interface Module. It a l so allows fo r a variety of

other communications, including Allen-Bradley’s Remote I/O, DH485, RS 232/422/485-DF1, and DeviceNet network through the

connection to the Bulletin 1203 communication modules.

Page 43

3-6

Stall

60 0

Percent

Full

Load

Current

Time (seconds)

Programmed Start Time

100%

Running Jam

Percent

Full

Load

Current

Time (seconds)

User Programmed Trip Level

SMC Dialog Plus Smart Motor Controller

Features (cont.)

Stall Protection and Jam Detection

Motors can experience locked rotor currents and develop maximum

torque in the event of a stall (during start) or a jam (after full speed is

reached). These conditions can result in winding insulation

breakdown or mechanical damage to the connected load.

The SMC Dialog Plus controller prov ides both sta ll and jam detection

for enhanced motor and system protection. Stall protection allows the

user to program a maximum stall time of up to 10 seconds. Jam

detection allows the user to determine the jam level as a percentage o

the motor’s full load current rating, and a trip delay time of up to 10

seconds.

Note: The stall trip delay time is in addition to the programmed

start time.

Figure 3.7 Stall Protection

Figure 3.8 Jam Detection

Page 44

SMC Dialog Plus Smart Motor Controller

SMC Dialog Plus

Supply

Voltage

501V

480V

462V

Motor

3-7

Phase Rebalance

As little a s 4% supply vo l ta ge un balanc e ca n resul t in a 20% current

unbalance a n d a 25% in cr e ase in motor tem p era t u re, possibly

triggering a premature failure of the motor. The SMC Dialog Plus

controller continuously monitors the incoming three-phase line

voltage balance and adjusts the output voltage automatically to

balance the three-phase currents drawn by the motor.

Figure 3.9 Phase Rebalance

Notes: (1) Phase Rebalance is not active during bypass operation.

(2) Phase rebalance requires the use of the converter modul

(Bulletin 825) and fanning strip (Cat. No. 150-NFS).

Metering

The SMC Dialog Plus controller contains several power monitoring

parameters as standard. These parameters include:

• Three-phase Current • Three-phase Voltage

• Power in kW • Power Usage in kWH

• Power Factor • Elapsed Time

• Motor Thermal Capacity Usage

Fault Indication

The SMC Dialog Plus controller monitors both the pre-start and

running modes. If the controller senses a fault, the SMC Dialog Plus

controller shuts down t h e motor and displays the appropriate fault

condition in the LCD display. The controller monitors the following

conditions:

• Open Gate • L i ne Fault

• Undervoltage • Underload

• Overvoltage • Excessive Starts/Hour

• Voltage Unbalance • Overtemperature

• Phase Reversal • Stall

• Power Loss • Jam

• Overload • System

Any fault condition will ca u se t he auxiliary co ntacts to change state

and the hold- in circuit to release.

Page 45

3-8

SMC Dialog Plus Smart Motor Controller

Features (cont.)

Auxiliary Contacts

Three hard contacts are provided as standard with the SMC Dialog

Plus controller. The first two contacts are programmable for Normal/

Up-to-sp ee d . The third con tact is program mable for Normal/Fault.

Energy Saver

The built-in Energy Saver feature is integral to the SMC Dialog Plus

controller and may be applied to applications whe re the motor is

lightly loade d or unloaded for long periods of time. With the Energy

Saver feature enabled, the SMC Dialog Plus controller continuously

monitors the l oading of the motor wi th its internal feedback circuitry.

Because the output voltage is SCR control led, moto r power losses can

be reduced by decreasing the motor terminal voltage.

Note: The Energy Saver feature is not available when a bypass

contactor is used.

Modular Design

The SMC Dialog Plus controller packaging is designed for industrial

environments. The mod u lar i ty of co n tr ol and power modules featur

plug-in functionality. There are no gate wires to remove and no

soldering is required. Common control modules reduce inventory

requirements.

Figure 3.10 Exploded View of the 24 Amp SMC Dialog Plus Controller

Page 46

SMC Dialog Plus Smart Motor Controller

3-9

Control Terminal Description

The SMC Dialog Plus controller contains 20 control terminals on the

front of the controller. These control terminals are described below.

See Figure 3.11.

Power Supply Board

Terminal Number Description

11 Control Power Input

12 Control Power Common

13 Controller Enable Input

14 Logic Ground

15 Dual Ramp/Option Input

16 Start Input

17 Stop Input

18 Auxiliary Relay Common

19 N.O. Auxiliary Contact 1 (Normal/Up-to-speed)

20 N.C. Auxiliary Contact 2 (Normal/Up-to-speed)

Logic Board

Terminal Number Description

21 Not Used

22 Not Used

23 Not Used

24 Not Used

25 Common (Converter Module)

26 Phase A Input (Converter Module)

27 Phase B Input (Converter Module)

28 Phase C Input (Converter Module)

29 N.O./N.C. Auxiliary Contact 3 (Normal/Fault)

30 N.O./N.C. Auxiliary Contact 3 (Normal/Fault)

Figure 3.11 SMC Dialog Plus Controller Control Terminals

Page 47

3-10

SMC Dialog Plus Smart Motor Controller

Adjustments

Soft Start without Options

The following parameters are specifically used to provide and adjust

the voltage ramp supplied to the motor

Para mete r Range

Starting Mode

This must be programmed for “Soft Start.”

Ramp Time #1

This sets the time period during which the

controller will ramp the output voltage.

Initial Torque #1

The initial output voltage level for the voltage

ramp is established and adjusted with this

parameter.

Kickstart Time

A boost of 550% of full load current is provided

to the motor for the programmed time period.

Stall Delay

Allows the user to program the stall protection

delay time. The delay time begins after the

start time has timed out.

Soft Start, Current Limit

0 to 30 seconds

0 to 90% of locked rotor torque

0.0 to 2.0 seconds

0 to 10 seconds

Energy Saver

The Energy Saver feature monitors the motor

load, phasing back the voltage output to the

motor when the motor is lightly loaded or

unloaded for an extended period of time.

Aux Contacts 1&2

Two form C contacts are provided as standard

with the SMC Dialog Plus controller. These

contacts are located at terminals 18, 19, and

20. Aux Contacts 1&2 allows the user to

configure the operation of the contacts.

Aux Contact 3

A third auxiliary contact is provided between

terminals 29 and 30. Aux Contact 3 allows the

user to program the operation of the contact.

Contact 3 Config

This parameter provides the user with the

ability to program the “powered-up” state of

the third auxiliary contact.

Parameter Mgmt

The newly programmed parameters values can

be saved to memory, or the factory default

parameter values can be recalled.

Off, On

Normal, Up-to-speed

Normal, Fault

N.O., N.C.

Ready, Default Init., Recll Frm EE,

Store In EE

Page 48

SMC Dialog Plus Smart Motor Controller

3-11

Current Limit Start without Options

To apply a fixed reduced voltage o utput to the motor, the following

parameters are provided for user adjustment.

Para mete r Range

Starting Mode

This must be programmed for “Current Limit.”

Ramp Time #1

This sets the time period during which the

controller will hold the fixed reduced voltage

output before switching to full voltage.

Current Limit Level

This provides adjustability for the reduce

voltage output level to the motor.

Kickstart Time

A boost of 550% of full load current is provided

to the motor for the programmed time period.

Stall Delay

Allows the user to program the stall protection

delay time. The delay time begins after the

start time has timed out.

Energy Saver

The Energy Saver feature monitors the motor

load, phasing back the voltage output to the

motor when the motor is lightly loaded or

unloaded for an extended period of time.

Aux Contacts 1&2

Two form C contacts are provided as standard

with the SMC Dialog Plus controller. These

contacts are located at terminals 18, 19, and

20. Aux Contacts 1&2 allows the user to

configure the operation of the contacts.

Soft Start, Current Limit

0 to 30 seconds

50 to 600% of full load current

0.0 to 2.0 seconds

0 to 10 seconds

Off, On

Normal, Up-to-speed

Aux Contact 3

A third auxiliary contact is provided between

terminals 29 and 30. Aux Contact 3 allows the

user to program the operation of the contact.

Contact 3 Config

This parameter provides the user with the

ability to program the “powered-up” state of

the third auxiliary contact.

Parameter Mgmt

The newly programmed parameters values can

be saved to memory, or the factory default

parameter values can be recalled.

Normal, Fault

N.O., N.C.

Ready, Default Init., Recll Frm EE,

Store In EE

Page 49

3-12

SMC Dialog Plus Smart Motor Controller

Adjustments (cont.)

Dual Ramp Start without Options

The SMC Dialog Plus controller provides the user with the ability to

select between two soft start profiles. To obtain Dual Ramp Start

control, the following parameters are available in the “Advanced

Setup” progr ammi ng mode.

Note: The Dual Ramp Start feature is only a va ila ble with the

standard control module.

Parameter Range

Advanced Setup

The user must select the “Advanced Setup”

programming mode in order to obtain access to

the Dual Ramp Start parameters

Starting Mode

This must be programmed for “Soft Start.”

Dual Ramp

This allows the user to choose between two

soft start profiles defined by:

Ramp Time #1 and Initial Torque #1

Ramp Time #2 and Initial Torque #2

When the Dual Ramp feature is selected, the

ramp time/initial torque combination is

determined by a hard contact to input terminal

15. A low input signal to terminal 15 signifies

that ramp time/initial torque #1 are selected. A

high input signal to terminal 15 signifies that

ramp time/initial torque #2 are selected.

—

Soft Start, Current Limit

No, Yes

Ramp Time #1

This determines the time period in which the

controller will ramp the output voltage to the

motor for the first soft start setup.

Initial Torque #1

The initial reduced voltage output level for the

first soft start setup is established and adjusted

with this parameter.

Ramp Time #2

This determines the time period in which the

controller will ramp the output voltage to the

motor for the second soft start setup.

Initial Torque #2

The initial reduced voltage output level for the

second soft start setup is established and

adjusted with this parameter.

Kickstart Time

A boost of 550% of full load current is provided

to the motor for the programmed time period.

0 to 30 seconds

0 to 90 % of locked rotor torque

0 to 30 seconds

0 to 90 % of locked rotor torque

0.0 to 2.0 seconds

Page 50

SMC Dialog Plus Smart Motor Controller

Dual Ramp Start without Options (cont.)

Parameter Range

Stall Delay

Allows the user to program the stall protection

delay time. The delay time begins after the

start time has timed out.

Energy Saver

The Energy Saver feature monitors the motor

load, phasing back the voltage output to the

motor when the motor is lightly loaded or

unloaded for an extended period of time.

Aux Contacts 1&2

Two form C contacts are provided as standard

with the SMC Dialog Plus controller. These

contacts are located at terminals 18, 19, and

20. Aux Contacts 1&2 allows the user to

configure the operation of the contacts.

Aux Contact 3

A third auxiliary contact is provided between

terminals 29 and 30. Aux Contact 3 allows the

user to program the operation of the contact.

3-13

0 to 10 seconds

Off, On

Normal, Up-to-speed

Normal, Fault

Contact 3 Config

This parameter provides the user with the

ability to program the “powered-up” state of

the third auxiliary contact.

Parameter Mgmt

The newly programmed parameters values can

be saved to memory, or the factory default

parameter values can be recalled.

N.O., N.C.

Ready, Default Init., Recll Frm EE,

Store In EE

Page 51

3-14

SMC Dialog Plus Smart Motor Controller

Adjustments (cont.)

Full Voltage Start without Options

The SMC Dialog Plus controller may be programmed to provid

full voltage start in whi ch t he o u tput vol ta g e to th e mot or re aches full

voltage in 1/4 second.

Parameter Range

Start Mode

This must be programmed for “Soft Start.”

Ramp Time #1

This must be programmed for “0” seconds.

Initial Torque #1

This must be programmed for 90% of locked

rotor torque.

Kickstart Time

This must be programmed for “0” seconds.

Stall Delay

Allows the user to program the stall protection

delay time. The delay time begins after the

start time has timed out.

Energy Saver

The Energy Saver feature monitors the motor

load, phasing back the voltage output to the

motor when the motor is lightly loaded or

unloaded for an extended period of time.

Soft Start, Current Limit

0 to 30 seconds

0 to 90% of locked rotor torque

0.0 to 2.0 seconds

0 to 10 seconds

Off, On

Aux Contacts 1&2

Two form C contacts are provided as standard

with the SMC Dialog Plus controller. These

contacts are located at terminals 18, 19, and

20. Aux Contacts 1&2 allows the user to

configure the operation of the contacts.

Aux Contact 3

A third auxiliary contact is provided between

terminals 29 and 30. Aux Contact 3 allows the

user to program the operation of the contact.

Contact 3 Config

This parameter provides the user with the

ability to program the “powered-up” state of

the third auxiliary contact.

Parameter Mgmt

The newly programmed parameters values can

be saved to memory, or the factory default

parameter values can be recalled.

Normal, Up-to-speed

Normal, Fault

N.O., N.C.

Ready, Default Init., Recll Frm EE,

Store In EE

Page 52

SMC Dialog Plus Smart Motor Controller

3-15

Typical Wiring Diagrams (without options)

Figure 3.12 Typical Wiring Diagram for Standard Controller

L1/1

T1/2

3-Phase

Input Power

Protection

Fast-acting

➀

Branch

➀

➀

➁

11 12 13 14 15 16 17 18 19 20

SCR Fuses

(optional)

➀

➀

Stop

➀

Start

➀

L2/3

L3/5

T2/4

T3/6

M

➀

21 22 23 24 25 26 27 28 29 30

Customer supplied.

①

Refer to the controller nameplate to verify the rating of the control power input voltage.

②

Internal

Auxiliary

Contacts

Page 53

3-16

SMC Dialog Plus Smart Motor Controller

Typical Wiring Diagrams

(without options)

Figure 3.13 Typical Wiring Diagram for Dual Ramp Applications

Control Power

Ramp 1 ➀Ramp 2

11 12 13 14 15 16 17 18 19 20

➁

Start

SMC Dialog Plus

Control Terminals

Stop

➀

➀

Internal

Auxiliary

Contacts

21 22 23 24 25 26 27 28 29 30

Customer supplied.

①

Refer to the controller nameplate to verify the rating of the control power input voltage.

②

Note: The Dual Ramp feature is only available with the standard control module.

Page 54

SMC Dialog Plus Smart Motor Controller

3-17

Figure 3.14 Typical Wiring Diagram for Start-Stop Control via the SCANport

Control Power

➁

➂

11 12 13 14 15 16 17 18 19 20

21 22 23 24 25 26 27 28 29 30

Customer supplied.

①

Refer to the controller nameplate to verify the rating of the control power input voltage.

②

If Soft Stop, Pump Control, or SMB Smart Motor option is installed, place additional jumper to

③

terminal 15.

Page 55

3-18

SMC Dialog Plus Smart Motor Controller

Typical Wiring Diagrams

(without options) (cont.)

Figure 3.15 Typical Wiring Diagram for Retrofit Applications

L1/1

3-Phase

Input Power

Branch

Protection

➀

Fast-acting

SCR Fuses

(Optional)

➀

➀

➀

Starter

OL

Existing Motor

L2/3

L3/5

T1/2

T2/4

T3/6

M

Start

Stop

➀

➀

M

➀

➀

M

➁

11 12 13 14 15 16 17 18 19 20

21 22 23 24 25 26 27 28 29 30

Customer supplied.

①

Refer to the controller nameplate to verify the rating of the control power input voltage.

②

Page 56

SMC Dialog Plus Smart Motor Controller

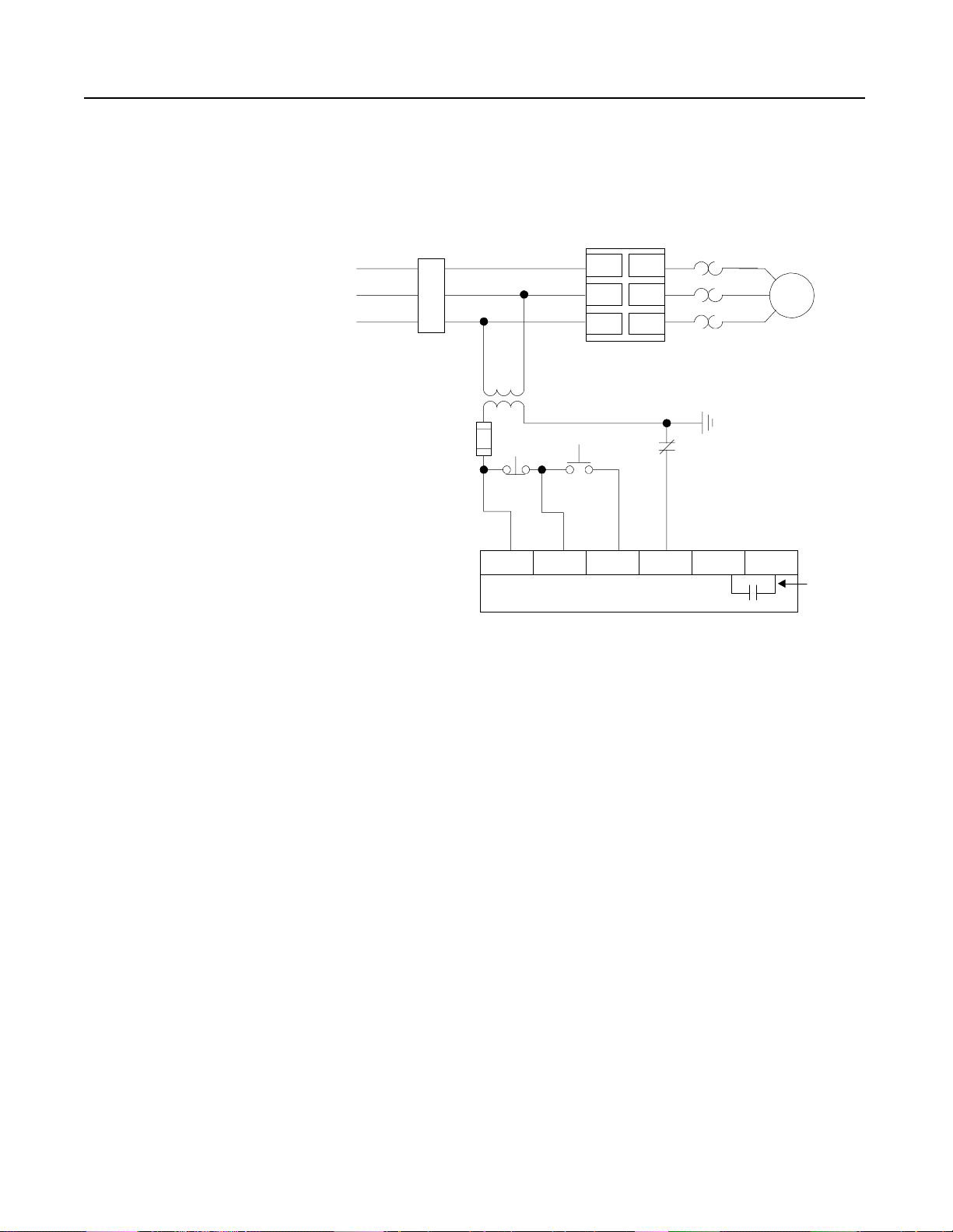

Start Run Soft Stop

Coast-to-rest

Soft

Stop

Kickstart

Initial

Torque

100%

Percent

Voltage

Time (seconds)

3-19

Control Options

The SMC Dialog Plus controller offers a variety of unique control

options that provide enhanced motor starting and stopping

capabilities. Please note that the options are mutually exclusive and

must be specified at the time of order entry.

• Soft Stop

• Pump Control

• Preset Slow Speed

•SMB Smart Motor Braking

• Accu-Stop/Slow Speed with Braking

Soft Stop Option

The Soft Stop option can be used in applications requiring an

extended coast-to-rest. The voltage ramp down time is use

adjustable from 0 to 60 seconds. The Soft Stop time is adjusted

independently from the start time. The load will stop when the

voltage drops to a point where the load torque is greate r th an th

motor torque.

Figure 3.16 Soft Stop Option

ATTENTION: Soft Stop is not intended to be used as

an emergency stop. Refer to the applicable standards for

!

emergency stop requirements

Page 57

3-20

SMC Dialog Plus Smart Motor Controller

Control Options (cont.)

Soft Stop Option (cont.)

Figure 3.17 Typical Wiring Diagram for Soft Stop Option

Control Power

11 12 13 14 15 16 17 18 19 20

➁

Soft Stop

Stop

➀

➀

Start

➀

21 22 23 24 25 26 27 28 29 30

Customer supplied.

①

Refer to the controller nameplate to verify the rating of the control power input voltage.

②

Page 58

SMC Dialog Plus Smart Motor Controller

Programming - Soft Start with Soft Stop Option

The basic parameter set-up for Soft Start selection with Soft Stop

option follows:

Para mete r Range

3-21

SMC Option

“Soft Start” will be displayed.

Starting Mode

Allows the user to program the SMC Dialog Plus

controller for the type of starting that best fits

the application.

Ramp Time

This sets the time period during which the

controller will ramp the output voltage.

Initial Torque

The initial reduced voltage output level for the

voltage ramp is established and adjusted with

this parameter.

Kickstart Time

A boost of 550% of full load current is provided

to the motor for the programmed time period.

Stall Delay

Allows the user to program the stall protection

delay time. The delay time begins after the

start time has timed out.

Energy Saver

The Energy Saver feature monitors the motor

load, phasing back the voltage output to the

motor when the motor is lightly loaded or

unloaded for an extended period of time.

Aux Contacts 1&2

Two form C contacts are provided as standard

with the SMC Dialog Plus controller. These

contacts are located at terminals 18, 19 and

20. Aux Contacts 1&2 allows the user to

configure the operation of the contacts.

Aux Contact 3

A third auxiliary contact is provided between

terminals 29 and 30. Aux Contact 3 allows the

user to program the operation of the contact.

Contact 3 Config

This parameter provides the user with the

ability to program the “powered up” state of the

third auxiliary contact.

Soft Stop Time

This parameter allows the user to program the

soft stop (voltage ramp down) time that best fits

the application.

Parameter Mgmt

The newly programmed parameters values can

be saved to memory, or the factory default

parameter values can be recalled.

—

Soft Start, Current Limit

0 to 30 seconds

0 to 90% of locked rotor torque

0.0 to 2.0 seconds

0 to 10 seconds

Off, On

Normal, Up-to-speed

Normal, Fault

N.O., N.C.

0 to 60 seconds

Ready, Default Init., Recll Frm EE,

Store In EE

Page 59

3-22

Motor

Speed

Push Button

Start

Stop

Soft Stop

Auxiliary

Contacts

Norma

Up-to-speed

Start Run

Open

Open

Open

Closed

Closed

Closed

100

Coast-to-rest

If Soft Stop Selected

If Coast-to-rest Selected

Soft Stop

Time (seconds)

Soft Stop

SMC Dialog Plus Smart Motor Controller

Control Options (cont.)

Soft Stop Option (cont.)

Figure 3.18 Soft Stop Option Sequence of Operation

!

ATTENTION: The user has the ultimat

responsibil ity to determine whic h stopping mode is best

suited to the application and will meet applicable

standards for operator safety on a particular machine.

Page 60

SMC Dialog Plus Smart Motor Controller

Pump Start Run Pump Stop

Motor

Speed

100

3-23

Pump Control Option

The SMC Dialog Plus controller’s unique interactive Pump Control is

designed to reduce fluid surges in pumping systems. It provides

closed loop acceleration and deceleration control of centrifugal pump

motors without the need for feedback devices.

Figure 3.19 Pump Control Option

Time (seconds)

ATTENTION: Pump Stop is not intended to be used

as an emergency stop. Refer to the applicable st andards

!

for emergency stop requirements.

Page 61

3-24

SMC Dialog Plus Smart Motor Controller

Control Options (cont.)

Figure 3.20 Typical Wiring Diagram for Pump Control Option

Control Power

11 12 13 14 15 16 17 18 19 20

➁

Pump Stop

➀

Stop

Start

➀

➀

21 22 23 24 25 26 27 28 29 30

Customer supplied.

①

Refer to the controller nameplate to verify the rating of the control power input voltage.

②

Page 62

SMC Dialog Plus Smart Motor Controller

Programming - Pump Control Starting and Stopping

The basic parameter set-up for the Pump Control Starting and

Stopping follows:

Para mete r Range

3-25

SMC Option

“Pump Control” will be displayed.

Starting Mode

Allows the user to program the SMC Dialog Plus

controller for the type of starting that best fits

the application.

Ramp Time

This sets the time period during which the

controller will ramp the output voltage.

Initial Torque

The initial reduced voltage output level for the

voltage ramp is established and adjusted with

this parameter.

Kickstart Time

A boost of 550% of full load current is provided

to the motor for the programmed time period.

Stall Delay

Allows the user to program the stall protection

delay time. The delay time begins after the

start time has timed out.

Energy Saver

The Energy Saver feature monitors the motor

load, phasing back the voltage output to the

motor when the motor is lightly loaded or

unloaded for an extended period of time.