Page 1

User Manual

Elevator Panel Solution

Bulletin 150-E

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

available from

) describes some

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the

consequence

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Introduction

Table of Contents

Chapter 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Component Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Base Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Fault Contactor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Function Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Motor Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Starter Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

For 6 or 12 Lead Wye-Delta Wound Motors . . . . . . . . . . . . . . . . . . . . . 8

For 3- or 9-Lead Closed Delta-Type Motors . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 2

Installation & Wiring

Programming

Troubleshooting

Unpacking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Terminal Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Delta Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Delta Connection (continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Line Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Line Connection (continued) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Delta-Connected Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Line-Connected Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Chapter 3

DIP Switch Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Motor FLA Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Motor Overload Trip Curves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Input & Output Timing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Chapter 4

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Diagnostics Indication. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Troubleshooting Steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Repair Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Specifications

Chapter 5

Electrical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Dimensions & Shipping Weights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Rockwell Automation Publication 150-UM009D-EN-P - February 2011 3

Page 4

Table of Contents

4 Rockwell Automation Publication 150-UM009D-EN-P - February 2011

Page 5

Chapter

Base

Controller

Fault

Contactor

1

Introduction

This manual provides and overview of the installation, set-up, and typical

operation of the Allen-Bradley hydraulic elevator and escalator starter. This solidstate starter solution is designed to operate 3-phase standard squirrel cage

induction motors and can be connected to a 6 or 12 lead Wye-Delta or standard 3

or 9 lead motors. Through the use of LINE or INSIDE-THE-DELTA control,

the solid-state solution can provide ultimate control of the motor. The advantages

of a solid-state solution include the following:

• Provides smooth motor starting.

• Reduces current surges on weak electrical systems.

• Reduces starting torque of the motor, wich helps to reduce mechanical

stress on system components.

• Helps meet both local and regional electrical codes when reduced voltage

starting is a requirement.

• Eliminates voltage and current spikes associated with traditional WyeDelta starters.

• Maximizes the life of the motor with reduced electrical strain.

• Reduces general system maintenance requirements for improved uptime.

Component Overview

The starter is made up of two components, the base controller and a fault

contactor.

Figure 1 - Bulletin 150-E Components

Rockwell Automation Publication 150-UM009D-EN-P - February 2011 5

Page 6

Chapter 1 Introduction

Base Controller

The base controller is a standard product that uses a number of intelligent

features to provide advanced motor control and simple diagnostics. The base

controller consists of the elements necessary to control the motor. These elements

include:

• a main micro-processor

• current sensing

• built-in adjustable overload

• solid-state power modules, and

• electro-mechanical bypass contacts.

Through the use of simple DIP switch configuration, the product can be

configured for a variety of modes. The default configuration uses the built-in

current sensing to limit current to the motor during starting. Once up to speed,

the base controller transitions to the run mode by transitioning to internal bypass

contactors and changing the state of the auxillary contact. The internal bypass

contactor provides decreased heating during run and removes the SCRs from the

circuit.

Fault Contactor

The fault contactor is controlled through the fault contact of the controller.

When control power is applied to the controller, the normally open fault contact

closes and applies control power to the coil of the contactor. The fault contact

will open, removing power from the fault contactor, and thus disabling the motor

during any one of the following events:

• The power is removed from the controller.

• The motor has developed a problem including overloading due to one of

the following:

– Mechanical or electrical reasons

– Ground faults or

– Motor short circuits.

• The starter has detected an internal problem such as a shorted SCR or

overtemperature condition.

6 Rockwell Automation Publication 150-UM009D-EN-P - February 2011

Page 7

Introduction Chapter 1

Function Overview

The Bulletin 150-E elevator panel provides solution to both advanced motor

control and simple diagnostics. The following information provides a brief

overview of the basic product features.

Motor Control

Current Limit Through the use of internal current sensors, the SMC™ will regulate the current

Soft Start The voltage is ramped from an initial set point to full voltage over the programmed

Soft Stop The voltage is ramped down from full voltage and applied to the motor over a

level applied to the motor over the programmed period of time. This type of motor

control produces a slow start and insures that the current does not exceed the

programmed level. This is the standard configuration of the device and aligns well

with traditional applications.

period of time. This type of motor control produces a smooth start in less time

than the current limit setting. However, the current is not restricted.

programmed period of time. The result is a smooth stop.

Diagnostics

Overload Provides protection of the motor for over current conditions. This feature offers a

OverTemperature

Phase

Reversal

Phase Loss/

Open Load

Phase

Imbalance

Shorted SCR Each time the SMC initiates a start, it checks to see if the SCRs are operating

user-selectable setting called the trip class, which can be used to accommodate

different applications and motor types. When the motor draws more than the

nominal value of current for a period of time, the device will fault on a motor

overload fault.

A built-in self-monitoring method for detecting a SCR over-temperature condition. If

the internal temperature exceeds a design threshold, the device will fault on a SCR

Overtemp fault.

The user can select the phase relationship of the incoming power. If this phase

relationship changes, the device will fault indicating a problem.

When any one of the incoming 3 phases are lost, the controller will fault indicating

a phase loss condition has occurred.

When enabled, will detect if a phase imbalance condition exists and fault the unit.

A phase imbalance is defined as a 65% differential between the highest and

lowest phase for more than 3 seconds.

correctly. If the controller is unable to properly turn on and off any one of the SCRs,

the device will fault on a Shorted SCR fault.

Rockwell Automation Publication 150-UM009D-EN-P - February 2011 7

Page 8

Chapter 1 Introduction

Starter Selection

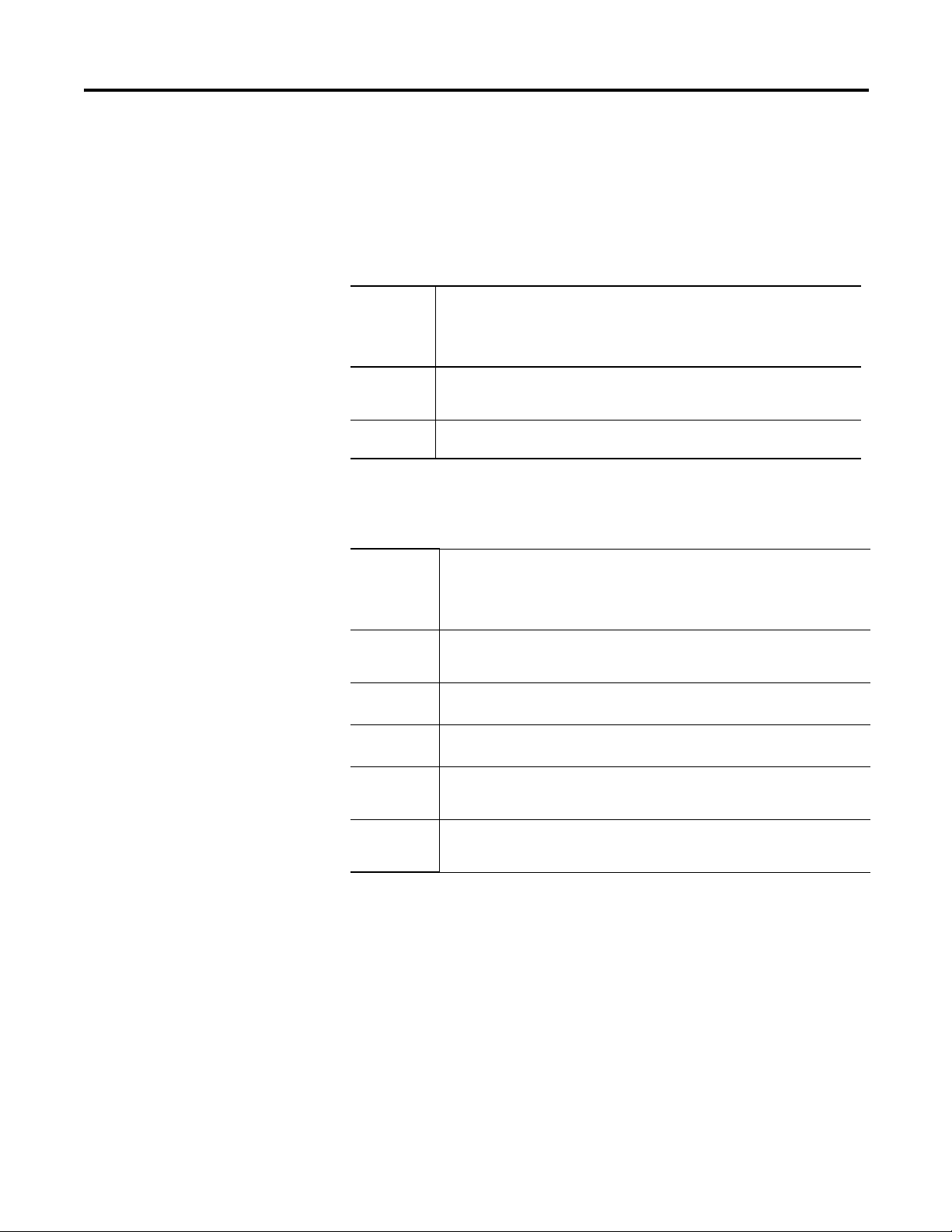

For 6 or 12 Lead Wye-Delta Wound Motors

The following table lists the catalog numbers that can be used with 6 or 12 lead

Wye-Delta motors. For proper operation, the connection should be verified

during installation. Sample connection diagrams for INSIDE-THE-DELTA

connected motors are included in the Installation and Wiring section found later

in this manual.

Table 1 - Cat. Nos. For Use with 6- or 12-Lead Wye-Delta Motors

Hp at Nominal Ratings

200V 240V 480V 575V 120V 230V

10 10 20 30 10.9…32.9

15 15 30 40 17…51 150-E51NCE-FC 150-E51NCA-FC

20 20 40 60 21.3…64 150-E64NCE-FC 150-E64NCA-FC

20 25 50 60 24.7…74

30 40 75 100 34.7…104 150-E104NCE-FC 150-E104NCA-FC

40 50 100 150 49…147 150-E147NCE-FC 150-E147NCA-FC

75 75 150 200 59…234

Motor FLA must fall within the specified range to operate correctly.

➊

Overload Range ➊

Control Voltage Cat. Nos.

150-E32NCE-FC 150-E32NCA-FC

150-E74NCE-FC 150-E74NCA-FC

150-E234NCE-FC 150-E234NCA-FC

For 3- or 9-Lead Closed Delta-Type Motors

The following table lists the catalog numbers that can be used with 3- or 9-lead

closed delta type motors. For proper operation, the connection should be verified

during installation. Sample connection diagrams for LINE connected motors are

included in the Installation and Wiring section found later in this manual.

Table 2 - Cat. Nos. For Use with 6 or 12 Lead Closed Delta-Type Motors

Hp at Nominal Ratings

200V 240V 480V 575V 120V 230V

5 5 10156.3…19 150-E32NCE-FC 150-E32NCA-FC

7.510202510…30

10 10 25 30 12.3…37

10 15 30 40 14.3…43 150-E74NCE-FC 150-E74NCA-FC

15 20 40 50 20…60

25 30 60 75 28.3…85

40 50 100 125 34…135

Motor FLA must fall within the specified range to operate correctly.

➊

Overload Range

➊

Control Voltage Cat. Nos.

150-E51NCE-FC 150-E51NCA-FC

150-E64NCE-FC 150-E64NCA-FC

150-E104NCE-FC 150-E104NCA-FC

150-E147NCE-FC 150-E147NCA-FC

150-E234NCE-FC 150-E234NCA-FC

8 Rockwell Automation Publication 150-UM009D-EN-P - February 2011

Page 9

Installation & Wiring

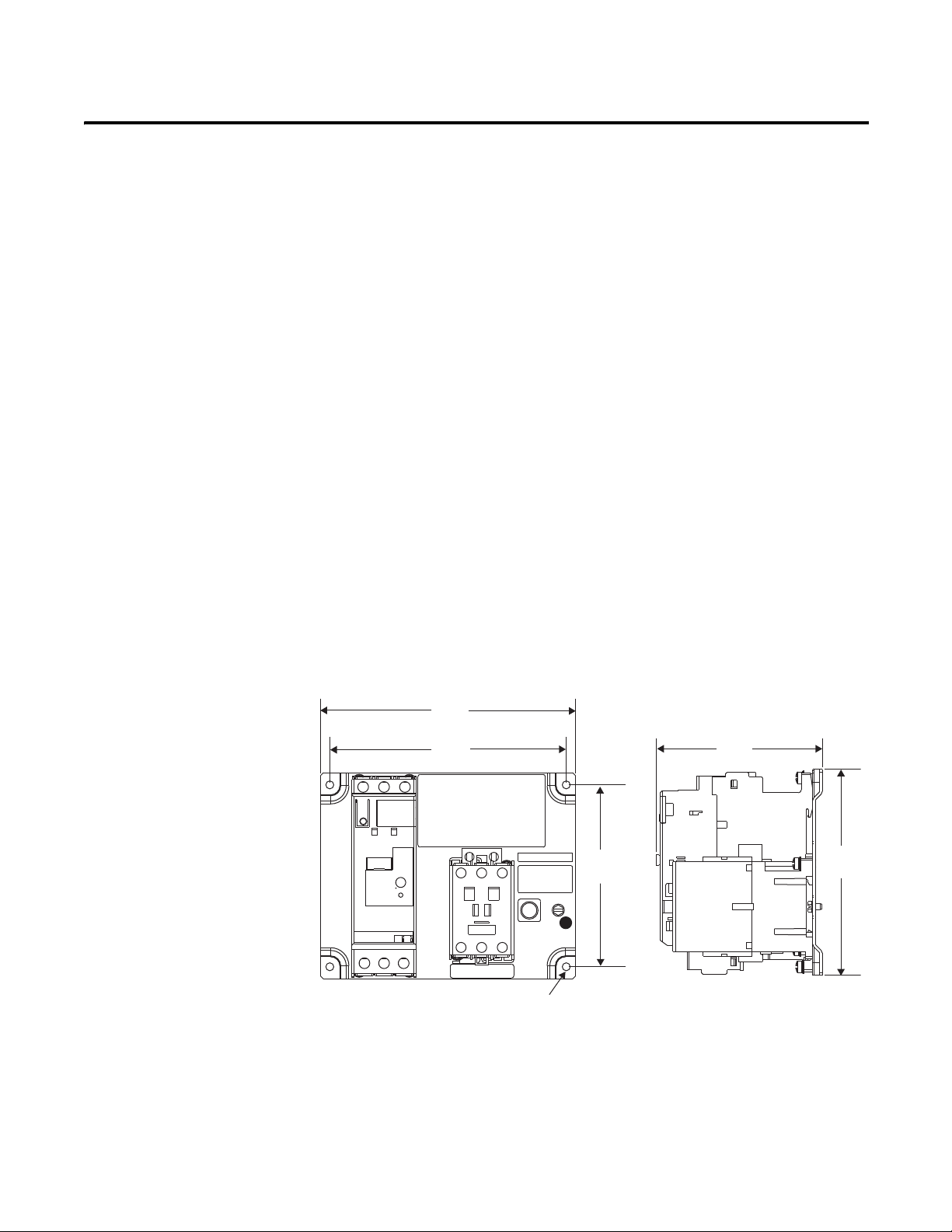

4.56

(115.7)

5.67

(144.0)

7.01

(178.0)

6.50

(165.1)

5.00

(127.0)

4X Ø 0.220 thru

(5.6)

CAT. XXXXXXXX SER. B

T6 T4 T5

1

Chapter

2

Unpacking

Mounting

Dimensions

Prior to installation, unpack the starter panel from its packaging and perform a

complete visual inspection of the panel. Inspect all components including the

controller, wiring, and fault contactor for damage related to shipping and

handling. Claims for damage must be made to the carrier as soon as possible after

receipt of the shipment.

The small footprint of the starter panel makes it ideal for mounting in the same

space previously occupied by legacy solid state starters and traditional Full

Voltage starters. The starter panel does not require mounting requirements

beyond the basic footprint of the panel.

The product may incorporate a small cooling fan. There are no additional cooling

requirements for the product. However, it is good practice to leave at least 6

inches (15.24 cm) of free space above and below the unit for ideal air flow.

Figure 2 - Panel Dimensions for 32, 51, & 64 A Elevator Panels

This screw is intended to secure a prepared bonding conductor (e.g., a bonding conductor with a crimped-

➊

Rockwell Automation Publication 150-UM009D-EN-P - February 2011 9

on lug) or a suitable terminal for connection of an unprepared bonding conductor (e.g., a bonding

conductor with a stripped wire end). This screw is not intended for a direct field wiring connection of an

unprepared bonding conductor or equipment grounding conductor.

Page 10

Chapter 2 Installation & Wiring

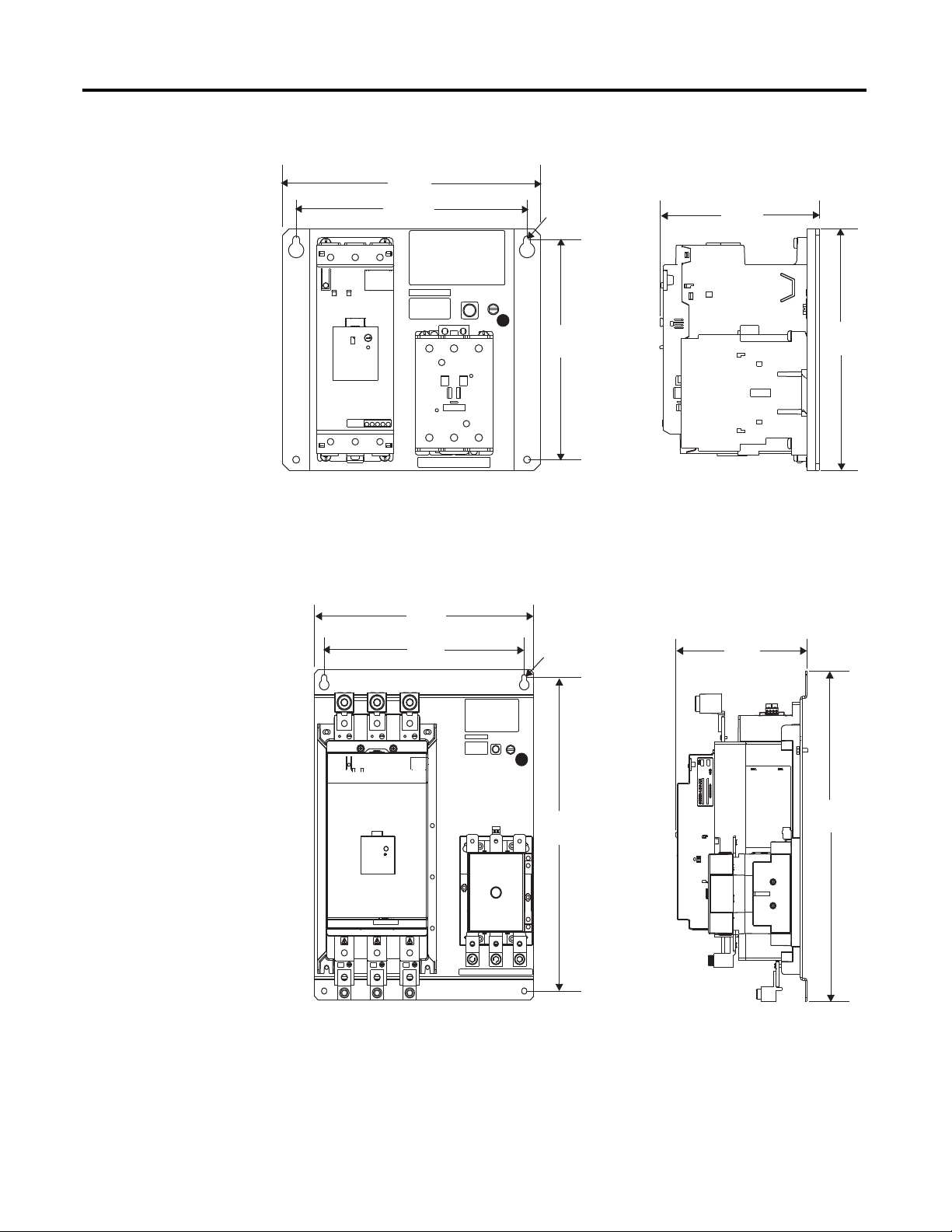

8.86

(225.0)

5.82

(147.9)

9.45

(240.0)

8.46

(215.0)

8.07

(205.0)

4X Ø 0.260 Thru

(6.6)

CAT. XXXXXXXX SER. B

1

T6 T4 T5

20.28

(515.0)

8.52

(216.4)

1

4X Ø 0.343 thru

(8.7)

CAT. XXXXXXXX SER. B

14.25

(362.0)

13.00

(330.2)

19.27

(489.5)

T6 T4 T5

Figure 3 - Panel Dimensions for 74, 104, & 147 A Elevator Panels

➊

This screw is intended to secure a prepared bonding conductor (e.g., a bonding conductor with a crimped-

on lug) or a suitable terminal for connection of an unprepared bonding conductor (e.g., a bonding

conductor with a stripped wire end). This screw is not intended for a direct field wiring connection of an

unprepared bonding conductor or equipment grounding conductor.

Figure 4 - Panel Dimensions for 234 A Elevator Panels

➊

This screw is intended to secure a prepared bonding conductor (e.g., a bonding conductor with a crimped-

on lug) or a suitable terminal for connection of an unprepared bonding conductor (e.g., a bonding conductor

with a stripped wire end). This screw is not intended for a direct field wiring connection of an unprepared

bonding conductor or equipment grounding conductor.

10 Rockwell Automation Publication 150-UM009D-EN-P- February 2011

Page 11

Installation & Wiring Chapter 2

Installation Precautions

The following precautions are provided as guidance for proper installation of this

controller. As this product was designed to be used in a variety of applications,

not all precautions mentioned are relevant to your particular application. In all

cases, the local codes and standards governing this type of product must be

observed.

Motor Branch Protection and Disconnecting Means

• The controller featues motor overload protection. However, it does not

have means to protect itself from a short circuit condition. Suitable branch

circuit protection and coordination must be provided per the NEC, or the

equivalent local electrical code.

Electrical Noise Suppression

• Electrical noise can be generated from various sources connected to the

same power as the controller. Sources of noise include: inductive loads (i.e.

relays and solenoids), large motors and machinery, Variable Frequency

Drives, and other high frequency devices (i.e. welders).

• Electrical noise can enter the product through power and control wiring

and cause damage to solid-state components.

• Mitigation of electrical noise can be accomplished through the following

methods:

– Proper wiring practices including grounding, use of shielded cable

where appropriate, and separation of power, control, and signaling

wires.

– Use of surge suppression devices on inductive loads.

– Use of isolation transformers for high frequency generators.

Power Factor Correction Capacitors (PFCC).

• PFCCs must always be used on the line side of the controller. Use of

PFCCs on the output side of the controller will damage the starter.

Rockwell Automation Publication150-UM009D-EN-P - February 2011 11

Page 12

Chapter 2 Installation & Wiring

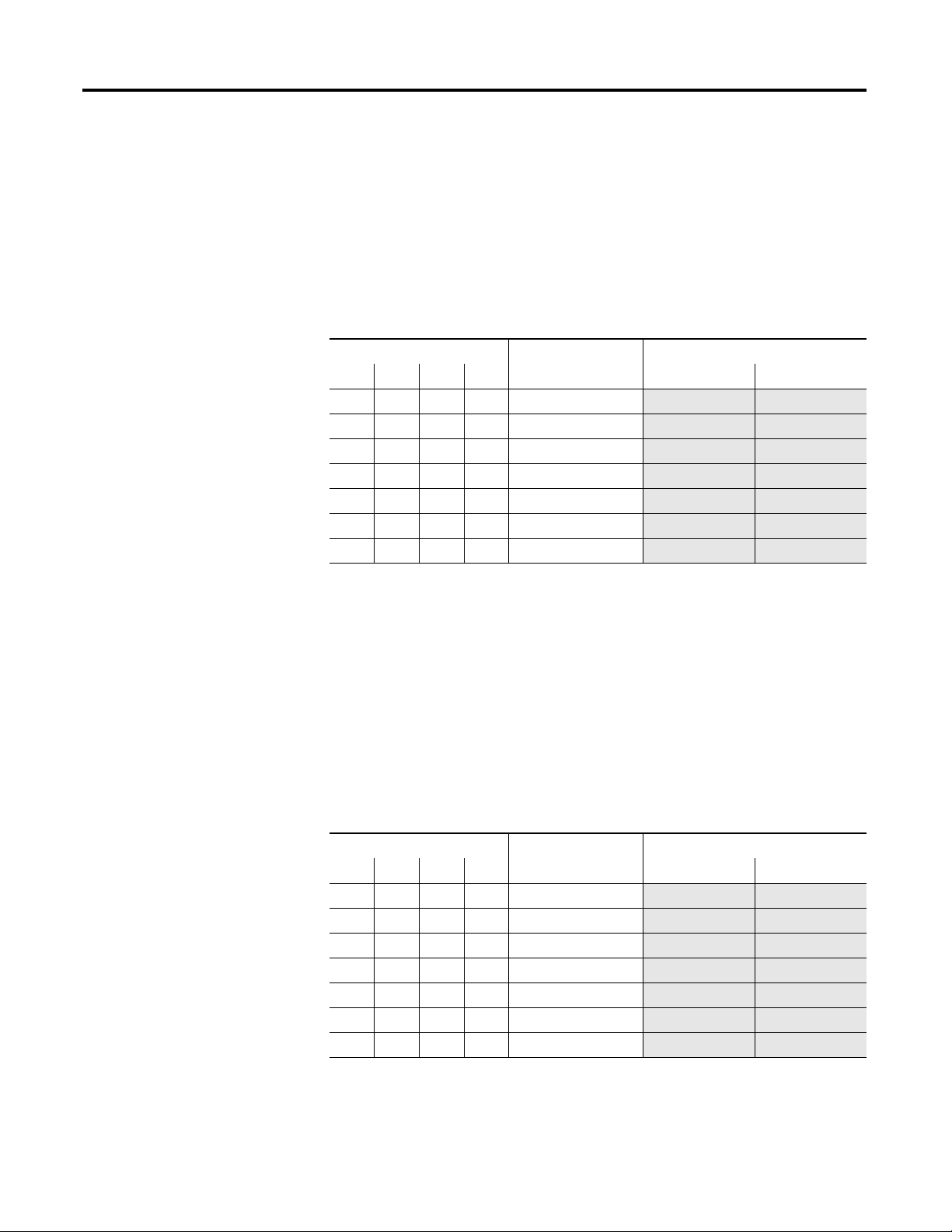

Terminal Torque Specifications

Table 3 - Controller Information

Controller

Size

32/51/64 Wire size 14…4 AWG

74/104/147 Wire size 14…3/0 AWG

234 Wire size 6…250 AWG

Units Line Load Control

(2.5…25 mm

Torque 20…25 lb-in.

(2.3…2.8 Nm)

(2.5…95 mm2)

Torque 100…110 lb-in.

(11.3…12.4 Nm)

(16…120 mm2)

Torque 275 lb-in.

(31 Nm)

Table 4 - Fault Contactor Information

Controller

Size

32/51/64 Wire size 14…6 AWG

74/104/147 Wire size 14…2 AWG

234 Wire size 6…300 AWG

Units Line Load Control

(2.5…16 mm

Torque 13…31 lb-in.

(2.3…3.5 Nm)

(2.5…35 mm2)

Torque 31…52 lb-in.

(3.5…6 Nm)

(16…150 mm

Torque 250 lb-in.

(28 Nm)

Power Terminals

2

)

2

)

2

)

14…6 AWG

(2.5…16 mm2)

20…22.5 lb-in.

(2.3…2.6 Nm)

14…1 AWG

(2.5…50 mm2)

100…110 lb-in.

(11.3…12.4 Nm)

6…250 AWG

(16…120 mm2)

275 lb-in.

(31 Nm)

Power Terminals

14…6 AWG

(2.5…16 mm2)

13…31 lb-in.

(2.3…3.5 Nm)

14…2 AWG

(2.5…35 mm2)

31…52 lb-in.

(3.5…6 Nm)

6…300 AWG

(16…150 mm2)

250 lb-in.

(28 Nm)

24…14 AWG

(0.2…2.5 mm2)

4.4…8 lb-in.

(0.5…0.9 Nm)

24…14 AWG

(0.2…2.5 mm2)

4.4…8 lb-in.

(0.5…0.9 Nm)

24…14 AWG

(0.2…2.5 mm2)

4.4…8 lb-in.

(0.5…0.9 Nm)

16…12 AWG

(1…4 mm2)

8.9…13 lb-in.

(1…1.5 Nm)

16…12 AWG

(1…4 mm2)

8.9…13 lb-in.

(1…1.5 Nm)

2x 16…12 AWG

(2x 1…4 mm2)

12…20 lb-in.

(1.4…2.3 Nm)

12 Rockwell Automation Publication 150-UM009D-EN-P- February 2011

Page 13

Installation & Wiring Chapter 2

1 — Contol Power (L1)

2 — Contol Common (L2)

4 — Start Enable

13 — Up-To-Speed Indication

Incoming Line Connections

T1 T2 T3 T6 T4 T5

L1 L2 L3

L1 L2 L3

[1] [4]

[2] [5]

[6] [3]

T3/6

L3/5

L2/3

T2/4

L1/1

T1/2

Incoming Lines

L1

L2 L3

[6] MOTOR [3]

SMC

FC

SMC

[1] MOTOR [4]

FC

[2] MOTOR [5] FC

SMC

(T6) (T3)

(1)

(L1)

(2)

(T1)

(T2) (T5)

(6)

(T3)

(5)

(L3)

(T1) (T4)

(4)

(T2)

(3)

(L2)

6 LEAD MOTOR CONNECTIONS

STARTER

TERMINALS

MOTOR

TERMINALS

T1 T2 T3 T6 T4 T5 JUMPER

1 2 3 6 4 5 N/A

MOTOR

T1 T2 T3

T6 T4 T5

3 6

2 4

1 5

234A ONLY

JUMPER

110/120V

220/240V

FAN

FAN

1 2 3 4

1 2 3 4

SMC CONTROL WIRES

FC

A1 A2 IN1 IN2 97 98 13 14

1 2

13

4

(A2) (A1)

1 2 1 2

SMC

1/L1 3/L2 5/L3

2/T1 4/T2 6/T3

A1 A2 IN1 IN2 97 98 13 14

FC

1/L1 3/L2 5/L3

T6 T4 T5

Delta Connection

Figure 5 - Diagram, Power, & Motor Wiring

Rockwell Automation Publication150-UM009D-EN-P - February 2011 13

Page 14

Chapter 2 Installation & Wiring

12 LEAD 230V LOW VOLTAGE MOTOR CONNECTIONS

STARTER

TERMINALS

MOTOR

TERMINALS

T1 T2 T3 T6 T4 T5 JUMPER

1&7 2&8 3&9 6&12 4&10 5&11 N/A

12 LEAD 460V HIGH VOLTAGE MOTOR CONNECTIONS

STARTER

TERMINALS

MOTOR

TERMINALS

T1 T2 T3 T6 T4 T5 JUMPER

1 2 3 12 10 11 4&7

5&8

6&9

[1] [4]

[2] [5]

[6] [3]

[12] [9]

[7] [10]

[8] [11]

[12] [9] [6] [3]

[2] [5] [8] [11]

[1] [4] [7] [10]

MOTOR

T1 T2 T3

T6 T4 T5

7 11

1 5

8 10

2 4

3 6

9 12

L2/3

T2/4

Incoming Lines

L1

L2 L3

SMC

MOTOR

FC

MOTOR

SMC

FC

FC

SMC

MOTOR

(1)

(L1)

(2)

(T1)

(T6) (T3)

(6)

(T3)

(5)

(L3)

(T2) (T5)

[12] [9] [6] [3]

(4)

(T2)

(3)

(L2)

(T1) (T4)

[1] [4] [7] [10]

[2] [5] [8] [11]

Incoming Lines

L1

L2 L3

SMC

[1] MOTOR [4]

FC

[6] MOTOR [3]

SMC

FC

(1)

(L1)

(2)

(T1)

(T6) (T3)

[12] [9]

[2] MOTOR [5] FC

SMC

(T2) (T5)

(6)

(T3)

(5)

(L3)

(T1) (T4)

(4)

(T2)

(3)

(L2)

[7] [10]

[8] [11]

L1/1

T1/2

T3/6 L3/5

L2/3

T2/4

T1 T2 T3

T6 T4 T5

MOTOR

3

2

1

12

10

11

4

7

8 5

9

6

T3/6

L3/5

L1/1

T1/2

Delta Connection (continued)

14 Rockwell Automation Publication 150-UM009D-EN-P- February 2011

Page 15

Installation & Wiring Chapter 2

Line Connection

1 2

FC

(A2) (A1)

4

A1 A2 IN1 IN2 97 98 13 14

1 — Contol Power (L1)

2 — Contol Common (L2)

4 — Start Enable

13 — Up-To-Speed Indication

FAN

1 2 3 4

1 2 1 2

110/120V

234A ONLY

JUMPER

Figure 6 - Diagram, Power, & Motor Wiring

13

SMC CONTROL WIRES

FAN

1 2 3 4

220/240V

L1

T1

L1

FC

T6

T1/2 L1/1

(1)

(L1)

(2)

(2)

(T1)

(T1)

[1]

L2

T2

L2

FC

T4

[2]

[2]

T2/4 L2/3

(3)

(L2)

(4)

(T2)

[3]

L3

T3

L3

FC

T5

T3/6 L3/5

(5)

(L3)

(6)

(T3)

Incoming Line Connections

L1 L2 L3

1/L1 3/L2 5/L3

SMC

A1 A2 IN1 IN2 97 98 13 14

2/T1 4/T2 6/T3

T1 T2 T3

L1 L2 L3

1/L1 3/L2 5/L3

FC

T6 T4 T5

T6 T4 T5

[1]

[3]

T6 T4 T5

2

1

3

MOTOR

3 LEAD MOTOR CONNECTIONS

STARTER

TERMINALS

MOTOR

TERMINALS

T6 T4 T5 JUMPER

1 2 3 N/A

Rockwell Automation Publication150-UM009D-EN-P - February 2011 15

Page 16

Chapter 2 Installation & Wiring

Line Connection (continued)

L1

T1/2 L1/1

T1

L1

FC

T6

[7]

(1)

(2)

[1]

(L1)

(T1)

[6]

L2

T2/4 L2/3

T2

L2

FC

T4

[2]

[4]

[8]

(3)

(4)

(L2)

(T2)

[9]

T3

L3

FC

T5

[5]

[3]

L3

T3/6 L3/5

(5)

(6)

(L3)

(T3)

L1

T1

L1

FC

T6

T1/2 L1/1

(1)

(L1)

(2)

(T1)

[4] [7]

[1]

L2

T2

L2

FC

T4

[2]

[9] [6]

T2/4 L2/3

(3)

(L2)

(4)

(T2)

[5] [8]

[3]

L3

T3

L3

FC

T5

T3/6 L3/5

(5)

(L3)

(6)

(T3)

[2]

[8]

[4]

[7]

[1]

[6]

T6 T4 T5

2

4 8

7 5

1 3

MOTOR

6 9

9 LEAD 230V LOW VOLTAGE MOTOR CONNECTIONS

STARTER

TERMINALS

MOTOR

TERMINALS

T6 T4 T5 JUMPER

1, 6, 7 2, 4, 8 3, 5, 9 N/A

[9]

[5]

[3]

[2]

[5] [8]

[4] [7]

[1]

T6 T4 T5

1

[3][9] [6]

2

3

MOTOR

9

6

9 LEAD 460V HIGH VOLTAGE MOTOR CONNECTIONS

STARTER

TERMINALS

MOTOR

TERMINALS

T6 T4 T5 JUMPER

1 2 3 4&7

5&8

6&9

8 5

4

7

16 Rockwell Automation Publication 150-UM009D-EN-P- February 2011

Page 17

Installation & Wiring Chapter 2

SCPD

MOTOR

1

SMC

(power connections)

FC

FC

FC

L3 T5

L2 T4

L1 T6

E-STOP

FC

START

UTS

INDICATION

GROUND

ENABLE

A1 A2

SMC CONTROL TERMINALS

A1 A2 IN1 IN2 97 98 13 14

OVERLOAD/

FAULT

AUX#1

(UTS)

H3 H2

H1 H4

X1 X2

TRANS.

L1/1

L2/3

L3/5

T1/2

T2/4

T3/6

1

1

1

Delta-Connected Controller

Figure 7 - Typical Control Wiring

➊ Customer supplied

Rockwell Automation Publication150-UM009D-EN-P - February 2011 17

Page 18

Chapter 2 Installation & Wiring

SCPD

MOTOR

1

SMC

(power connections)

FC

FC

FC

L3 T5

L2 T4

L1 T6

E-STOP

FC

START

UTS

INDICATION

GROUND

ENABLE

A1 A2

SMC CONTROL TERMINALS

A1 A2 IN1 IN2 97 98 13 14

OVERLOAD/

FAULT

H3 H2

H1 H4

X1 X2

TRANS.

L1/1

L2/3

L3/5

T1/2

T2/4

T3/6

1

1

1

AUX#1

(UTS)

Line-Connected Controller

Figure 8 - Typical Control Wiring

18 Rockwell Automation Publication 150-UM009D-EN-P- February 2011

➊

Customer supplied.

Page 19

Programming

Chapter

3

DIP Switch Settings

The 150-E elevator controller is programmed through DIP switches located on

the front of the controller. All functionality is defined by these settings. The

following tables define the settings available within the SMC™ controller. Default

settings are indicated by the shaded areas.

Table 5 - Start Time

Settings

(seconds)

2 OFF OFF

5ONOFF

10 OFF ON

15 ON ON

Table 6 - Start Mode

Mode Setting Switch #3

Current Limit OFF

Soft Start ON

Table 7 - Current Limit/Initial Torque Level

Switch #1 Switch #2

In Current Limit mode, a set level of current is applied to the

motor over the start time. In Soft Start mode, the device will

ramp the torque from the initial level to 100% over the start

time.

This defines the time the controller will ramp or

limit current to the motor. The controller can

determine when the motor is up-to-speed (UTS),

therefore it may transition to bypass before this

time expires. If the motor does not reach speed

before the time expires, the controller will

continue under SCR control and not close the

bypass contactor.

% FLA/ % Torque Switch #4 Switch #5

150%/15% OFF OFF

250%/25% ON OFF

350%/35% OFF ON

450%/65% ON ON

Table 8 - Soft Stop Time

Settings (seconds) Switch #6 Switch #7

OFF OFF OFF

1x start time ON OFF

2x start time OFF ON

3x start time ON ON

Rockwell Automation Publication 150-UM009D-EN-P- February 2011 19

The level indicated by this programming applies an

initial level of current or torque to the motor for the

start time. For example, if switch #3 is set to OFF,

the device will perform a current limit start at the

level indicated by these switches.

Soft Stop reduces the voltage applied to the

motor over the programmed period of time. The

soft stop is complete when the soft stop timer

has expired or the current measured drops below

50% of the FLA setting.

Page 20

Chapter 3 Programming

Table 9 - Phase Rotation

Setting Switch #9

The allowable phase rotation of the motor is defined by this switch.ABC rotation OFF

CBA rotation ON

Table 10 - Phase Imbalance

Setting Switch #10

Enabled OFF

Disabled ON

The controller has the ability to monitor for imbalance between phase

currents. This protection feature can be user-disabled.

Table 11 - Overload Trip Class

Setting Switch #11 Switch #12

OFF OFF OFF

10 ON OFF

15 OFF ON

20 ON ON

The controller incorporates, as standard, electronic

overload protection. This motor overload protection is

accomplished electronically with the use of internal current

transformers on each of the three phases. The controller’s

overload protection is programmable, providing the user

with flexibility.

Table 12 - Overload Reset

Setting Switch #13

Manual OFF

Auto ON

In manual reset mode, the fault can only be reset by pushing the ‘Push to

Reset’ button on the front of the controller. In auto reset mode, the unit will

automatically reset when the unit determines the motor has cooled to 75%

of its thermal capacity.

Table 13 - Aux #1 Setting

Setting Switch #14 The operation defines the operation of the Auxiliary contacts. Normal

Normal OFF

Up-to-Speed ON

mode means that the contact will change state immediately when a

start/run command is given. Up-to-Speed mode means that the contact

will change state only when the controller is in bypass. Aux#2, when

added, will operate opposite of this programming.

Table 14 - Motor Connection Type

Setting Switch #15

Delta OFF

Line ON

In DELTA connection mode, the device is designed to control a 6 or 12 lead

motor. In LINE connection mode, the device is designed to control a 3 or 9

lead motor.

Table 15 - Stop Delay

Setting(seconds) Switch #16

0.0 OFF

0.75 ON

20 Rockwell Automation Publication 150-UM009D-EN-P- February 2011

When the delay is programmed, the motor will continue to run

for the programmed period of time after the run command is

removed from the controller.

Page 21

Programming Chapter 3

∆ 32

19

Delta FLA

Line FLA

∆ 11

7

∆ 22

13

Service Factor _ _

FLA _ _

Service Factor < 1.15

Service Factor ≥ 1.15

= 0.9 X FLA

= 1.0 X FLA

= 1.0 X FLA

OR

Maximum Continuous Rated

(MCR) Motors

Motor FLA Requirements

The front of the SMC controller contains a dial which is used for setting the

actual FLA of the motor. The label is designed to accommodate motors

connected in the LINE or DELTA mode. To determine the proper setting, look

at the motor’s nameplate and set the dial accordingly. The dial setting can be

modified depending on the service factor of the motor.

Figure 9 - FLA Setting of Motor

Motor Overload Trip Curves

The trip class should be set according to the motor’s maximum permissible locked

rotor time or the general thermal capabilities. Consult the motor manufacturer

for recommendations on setting the trip class.

Figure 10 - Trip Class

Class 15

1000

800

600

400

200

80

60

40

20

8

6

4

2

0.8

0.6

0.4

0.2

4

2

1

6

100

10

1

0.8

0.6

0.4

0.2

0.1

8

10

1000

100

10

t (sec)

0.1

Class 10

800

600

400

200

80

60

40

20

8

6

4

2

1

0.8

0.6

0.4

0.2

4

2

1

1000

800

600

400

200

100

10

1

6

0.1

8

10

Multiple of FLA

Rockwell Automation Publication 150-UM009D-EN-P- February 2011 21

COLD START

HOT START

Class 20

80

60

40

20

8

6

4

2

4

2

1

6

8

10

Page 22

Chapter 3 Programming

Basic Timing Diagram, No Soft Stop

Possible Aux Contact Configuration

On

Off

Control Power

Start Enable

Fault Contact

(Fault Contactor)

Closed

Open

Up-to-Speed

Normal

Fault Occurs

Fault Reset

On

Off

Closed

Open

Closed

Open

Input & Output Timing

Figure 11 - Input & Output Timing

22 Rockwell Automation Publication 150-UM009D-EN-P- February 2011

Page 23

Troubleshooting

Chapter

4

Introduction

The following topics are designed to assist in the troubleshooting and

maintenance of the SMC™ controller. The items mentioned in this section are not

intended to be all-inclusive and it is expected that these items should be used as

reference only.

For safety of maintenance personnel as well as others who might be exposed to

electrical hazards associated with maintenance activities, follow the local safety

related work practices (i.e., the NFPA 70E, Part II in the United States).

Maintenance personnel must be trained in the safety practices, procedures, and

requirements that pertain to their respective job assignments.

SHOCK HAZARD:

Hazardous voltage is present in the motor circuit even when the 150-E

controller is off. To avoid shock hazard, disconnect the main power

before working on the controller, motor, and control devices (such as

Start-Stop push buttons). Procedures that require parts of the

equipment to be energized during troubleshooting, testing, etc., must

be performed by properly qualified personnel, using appropriate local

safety work practices and precautionary measures.

ATTENTION: Disconnect the controller from the motor before

measuring insulation resistance (IR) of the motor windings.

Voltages used for insulation resistance testing can cause SCR

failure. Do not make any measurements on the controller with an IR

tester (megger).

Diagnostics Indication

The LED on the front of the product provides limited status information

regarding the condition of the controller. The conditions are as follows:

• LED Off — No control power or start command given.

• LED On — The device is active with starting, running, or stopping.

• LED Flashes — A fault has been experienced. Refer to table below for

additional explanation.

Rockwell Automation Publication150-UM0009D-EN-P - February 2011 23

Page 24

Chapter 4 Troubleshooting

Table 16 - LED Fault Indication & Diagnostics

Flashes Fault Type Possible Fault Explanations Possible Solutions

1Overload • Motor overload condition present.

2 Over-Temperature • Controller ventilation blocked.

3 Phase Reversal • Incoming supply voltage is not the expected sequence. • Check power wiring.

4 Phase Loss/

Open Load

5 Phase Imbalance • Unbalanced Phase Currents (> 65% differential).

6 Shorted SCR • Shorted SCR.

7Test • Intended operation. • Reset fault.

12 Check Sum • Internal software corruption. • Replace device.

• FLA dial adjustment is not matched to motor type.

• Controller duty cycle exceeded.

• Cooling fan not working.

• Ambient temperature exceeded.

• Failed control module.

• Over-current condition with Overload disabled.

• Missing Supply Phase.

• Missing or unable to detect motor connection.

• Incoming line voltage problem.

• Welded or latched bypass contactor.

• Check for motor overload condition.

• Verify actual motor current does not exceed FLA.

• Verify/reset the FLA dial adjustment.

• Program/modify the Overload setting for load or duty

cycle required.

• Check for proper ventilation.

• Verify duty cycle.

• Connect or replace cooling fan.

• Wait for controller to cool or provide external coolin.

• Replace control module.

• Adjust dip switch #9 for desired sequence.

• Check for open line (i.e. open fuse).

• Check for incorrect wiring to load.

• Verify proper operation of the fault contactor.

• Verify connection type to motor (LINE or DELTA).

• Ensure product is sized correctly for motor.

• Check motor current in each phase to verify imbalance.

Motor current imbalance can indicate potential motor

problem.

• Verify connection type (LINE or DELTA) and verify setting.

• Perform continuity check across power poles (L1 – T1, L2

– T2, L3 – T3). Measurements should exceed 10 k ohms.

For best results, remove line and load motor connections.

• Cycle power to device and attempt to restart. If fault

persists, replace device.

24 Rockwell Automation Publication 150-UM0009D-EN-P - February 2011

Page 25

Troubleshooting Chapter 4

Troubleshooting Steps

Control Device Status Solution

Prestart - no start command given but device is faulted. LED Flashing • Reset fault.

Motor fails to start after start command given. LED Off • Check control power.

Motor attempts to start after start command is given,

but fails to reach an up-to-speed condition.

Motor stops abruptly and fails to restart. LED Off • Check for a blown fuse or tripped circuit breaker.

Fault contactor fails to close when power is applied. All Conditions • Verify wiring to the coil. The contactor should close when power is

Table 17 - Troubleshooting Steps

• Allow device to cool (overload or SCR over temp). Reset fault.

• Cycle power to device.

• Check control circuit connections.

LED ON • Verify proper operation of fault contactor or isolation devices.

• Check connections to the motor.

• Verify line power and frequency are within specifications.

LED Flashing • Reference the LED Fault Indication & Diagnostics Table for information

related to specific fault codes.

LED ON • Verify proper operation of the fault contactor or isolation devices.

• Verify line power and frequency are within specifications.

• Try increasing the initial torque or current limit setting.

LED Flashing • Reference the LED Fault Indication & Diagnostics Table for information

related to specific fault codes.

• Ensure the control power and start command are present.

• Verify proper operation of the fault contactor or isolation devices.

LED ON • Verify proper operation of the fault contactor or isolation devices.

LED Flashing • Reference the LED Fault Indication & Diagnostics Table for information

related to specific fault codes.

applied to the controller.

• Verify voltage across the coil (A1 to A2).

• Check the resistance of the coil. Replace, if measured open.

• Verify internal contact of the controller (terminals 97/98) are properly

changing state. Replace the controller if the contact does not operate

correctly.

Rockwell Automation Publication150-UM0009D-EN-P - February 2011 25

Page 26

Chapter 4 Troubleshooting

Repair Parts

Table 18 - Repair Parts

Panel Controller Contactor Fans Contactor Coil

150-E32NCE-FC 150-E32NCD 100-C37D00

(optional)

150-CF64

150-E64NCE-FC 150-E64NCD 100-C37D00

150-E74NCE-FC 150-E74NCD 100-C43D00

150-E104NCE-FC 150-E104NCD 100-C60D00 TE473

150-E147NCE-FC 150-E147NCD 100-C85D00 TE473

150-E234NCE-FC Complete Device 150-E234NCD

100-D180ED00 41391-801-03 TGE865Control Module 150-ES1BX

Power Pole 150-FPP135C

150-E32NCA-FC 150-E32NCD 100-C37KA00

150-E64NCA-FC 150-E64NCD 100-C37KA00

150-E74NCA-FC 150-E74NCD 100-C43KA00

150-E104NCA-FC 150-E104NCD 100-C60KA00 TE858

150-E147NCA-FC 150-E147NCD 100-C85KA00 TE858

150-E234NCA-FC Complete Device 150-E234NCD

100-D180EA00 41391-801-03 TGE866Control Module 150-ES1BX

Power Pole 150-FPP135C

150-CF147

(optional)

150-CF64

150-CF147

TC473150-E51NCE-FC 150-E51NCD 100-C37D00

TD473

TC858150-E51NCA-FC 150-E51NCD 100-C37KA00

TD858

26 Rockwell Automation Publication 150-UM0009D-EN-P - February 2011

Page 27

Specifications

Chapter

5

Electrical

Table 19 - Power Circuit

UL/cUL/CSA IEC

Rated Operational Voltage 200…600V AC 200…500V~

Rated Insulation Voltage 600V AC 500V~

Di-electric Withstand 2200V AC 2500V~

Repetitive Peak 200…600V AC: 1600 500V~: 1600

Rated Impulse Voltage 6 kV

Overvoltage Category III

Number of Poles Equipment designed for 3-phase only

Operating Frequency 50/60 Hz

Controller Utilization Category 32/52/64 AC-53b: 3.5-15:3585

74/104/147 AC-53b: 4.5-30:1770

234 AC-53b: 3.5-30:1770

Overlad Current Range (Amps) Line Delta

32 6.3...19 10.9...32.9

51 10...30 17...51

64 12.3...37 21.3...64

74 14.3...43 24.7...74

104 20...60 34.7...104

147 28.3...85 49...147

234 34...135 59...234

Rockwell Automation Publication 150-UM009D-EN-P - February 2011 27

Page 28

Chapter 5 Specifications

Table 20 - Control Circuit

UL/cUL/CSA IEC

Rated Operational Voltage 100...120V AC, 200...240V AC 120~, 240~

Rated Insulation Voltage — 300V~

Di-electric Withstand — 3000V

Rated Impulse Voltage 3 kV

Operating Frequency 50/60 Hz

Control Power Requirements 32/52/64 215 mA @ 120 V AC ,

180 mA @ 240 V AC

74/104/147 200 mA @ 120 V AC ,

100 mA @ 240 V AC

234 200 mA @ 120 V AC ,

120 mA @ 240 V AC

Fan Power Requrements 32/52/64 —

74/104/147 —

234 20VA

Table 21 - Short Circuit Capabilities

Short Circuit Performance Type 1

Device Current Rating Maximum Fuse Size & Type

70 A - RK5 5 kA

32

125 A - K5 5 kA

125 A - RK5 5 kA

51

200 A - K5 10 kA

125 A - RK5 5 kA

64

200 A - K5 10 kA

150 A - RK5 5 kA

74

250 A - J 10 kA

200 A - RK5 5 kA

104

400 A - J 10 kA

250 A - RK5 10 kA

147

400 A - J 10 kA

400 A - RK5 10 kA

234

450 A - K5 10 kA

Maximum Available Fault

Rating

28 Rockwell Automation Publication 150-UM009D-EN-P - February 2011

Page 29

Specifications Chapter 5

Table 22 - Auxillary Contacts (Fault & Aux #1)

UL/cUL/CSA IEC

Rated Operational Voltage 250V AC/30V DC 250V~ / 30V DC

Rated Insulation Voltage 250V 250V~

Di-electric Withstand —4 kV

Rated Impulse Voltage 1500 V AC 2000V-

Operating Frequency 50/60 Hz

Utilization Category D300 AC-15/DC

Control Circuit Type Electro-magnetic Relay

Number of Contacts 1

Contact Type Normally Open (N.O.)

Current Type AC/DC

Rated Operational Current (max) 0.6 A @ 120 V~ and 0.3 A @ 240V~

Conventional Thermal Current (lth) 1 A

Make/Break VA 432/72

Mechanical

Table 23 - Mechanical

Resistance to Vibration Operational 1.0 G Peak, 0.15 mm (0.006 in) displacment

Non-Operational 2.5 G Peak, 0.38 mm (0.015 in) displacment

Resistance to Shock Operational 15 G

Non-Operational 5.5 G

Environmental

Table 24 - Environmental

Operating Temperature 0…50 °C (32…122 °F) Open

0…40 °C (32…104 °F) Enclosed

Altitude 2000 m (6560 ft)

Humidity 5…95% (non-condensing)

Pollution Degree 2

Rockwell Automation Publication150-UM009D-EN-P - February 2011 29

Page 30

Chapter 5 Specifications

A

D

E

C

B

Ø Hole

4x

CAT. XXXXXXXX

SER. B

T6 T4 T5

Dimensions & Shipping Weights

Figure 12 - Dimensions

Table 25 - Dimensions & Shipping Weights

Controller Size

32/52/64 74/104/147 234

A (Width) 178

(7.01)

B (Height) 144

(5.67)

C (Depth) 115.7

(4.56)

D 165.1

(6.5)

E 127

(5)

4X Ø

(Hole Dimensions) 5.6

(0.22)

Approximate Weight 4 lbs (2 kg) 14 lbs (6 kg) 51 lbs (23 kg)

NOTE: Dimensions are in millimeters followed by inches unless otherwise specified.

240

(9.45)

225

(8.86)

147.9

(5.82)

215

(8.46)

205

(8.07)

6.6

(0.26)

362

(14.25)

515

(20.28)

216.4

(8.52)

330.2

(13.0)

489.5

(19.27)

8.7

(0.343)

30 Rockwell Automation Publication 150-UM009D-EN-P - February 2011

Page 31

Page 32

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support/

application notes, sample code and links to software service packs, and a MySupport feature that you can customize to make the

best use of these tools.

For an additional level of technical phone support for installation, configuration, and troubleshooting, we offer TechConnect

support programs. For more information, contact your local distributor or Rockwell Automation representative,

or visit http://www.rockwellautomation.com/support/

Installation Assistance

If you experience a problem within the first 24 hours of installation, review the information that is contained in this manual.

You can contact Customer Support for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or

Canada

Use the Worldwide Locator

your local Rockwell Automation representative.

, you can find technical manuals, a knowledge base of FAQs, technical and

.

at http://www.rockwellautomation.com/support/americas/phone_en.html, or contact

New Product Satisfaction Return

Rockwell Automation tests all of its products to ensure that they are fully operational when shipped from the manufacturing facility.

However, if your product is not functioning and needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number (call the phone number above to obtain

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

one) to your distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document,

complete this form, publication RA-DU002

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

, available at http://www.rockwellautomation.com/literature/.

Publication 150-UM009D-EN-P - February 201132 40055-251-01 DIR 40055-251 (Version 04)

Supersedes Publication 150-UM009C-EN-P - August 2009 Copyright © 2011 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

Loading...

Loading...