Page 1

INSTRUCTION MANUAL DĆ3979

ACCESSORY

REMOTE ADAPTER KIT

MODEL NUMBER 14C220

The

equipment described below should be installed only by qualified electrical maintenance personnel

familiar with the construction and operation of the equipment and the hazards involved.

DANGER

CONTROLLER EQUIPMENT IS AT LINE VOLTĆ

AGE WHEN AĆC POWER IS CONNECTED TO

POWER UNIT IN THE MINP

THE

TROLLER. THUS, AĆC POWER MUST BE REĆ

MOVED FROM THE UNIT BEFORE IT IS SAFE

TO TOUCH INTERNAL PARTS OF THE CONĆ

TROLLER. PERSONAL INJURY MAY RESULT

UNLESS POWER IS REMOVED.

AK PL

US CON

Ć

DESCRIPTION

The

optional

cating

troller.

In

addition to a Remote Operator Adapter Module, this

Kit

contains all the mounting hardware necessary to se

cure the Module. (Refer to Figure

also

need to order 2 additional options from Reliance.

Briefly,

done:

D Select the blank Remote Operator ,Station Cover

Faceplate if not supplied as standard. Otherwise.

order Model Number 14C200.

D Order a Remote Operator Adapter Kit, Model

14C220. (This unit provides a connection point for

the

D Specify a Reliance Remote Operator Control StaĆ

tion.

Reliance offers a variety of Remote Operator Stations

are compatible with the MinP

that

to T

fer

Remote Operator Adapter Kit allows the lo

of operator controls some distance from the

1.)

However

the following three steps describe what must

Remote Station .)

Connect it to the controller

able 1.A).

.

ak Plus controller

Con

, one may

. (Re

be

Ć

Ć

Ć

Ć

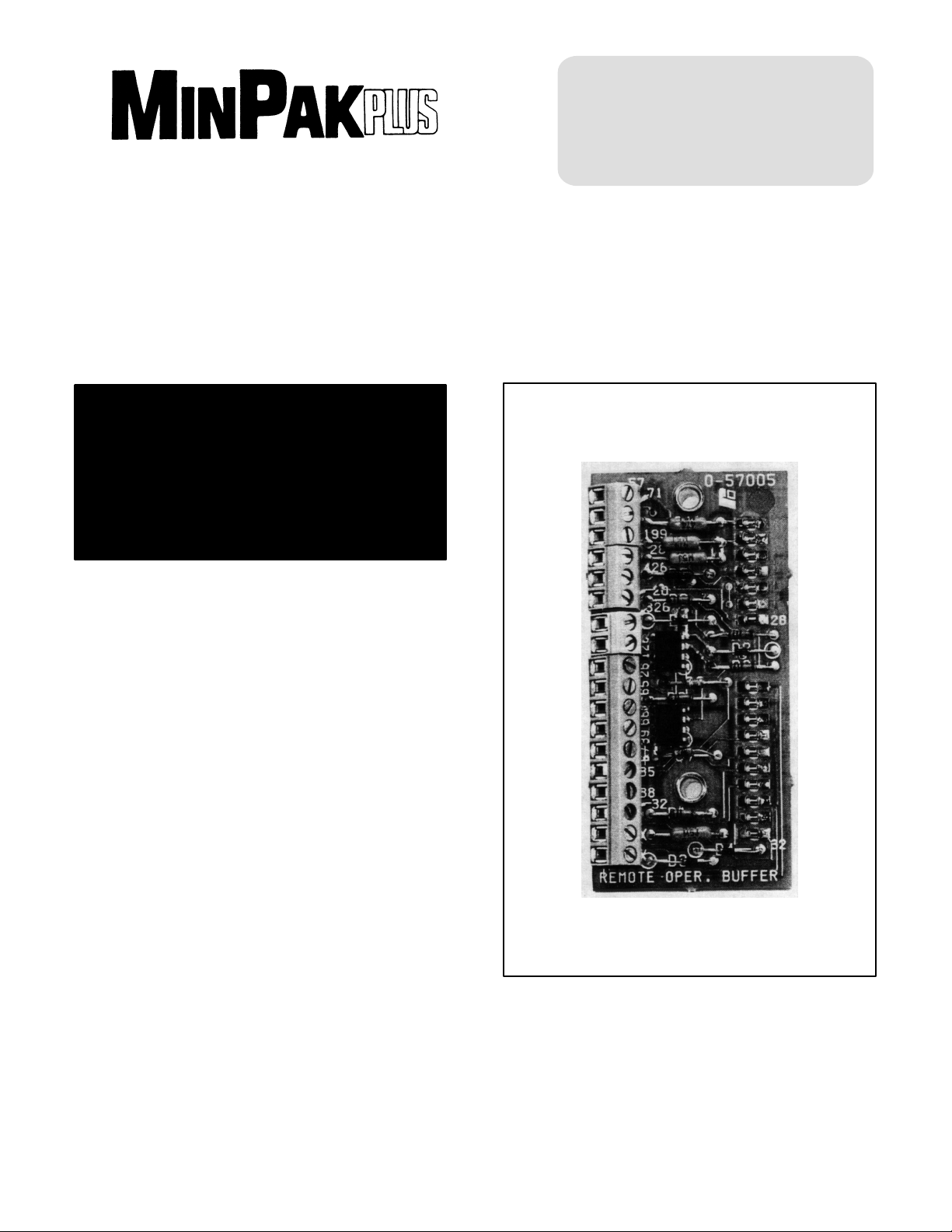

Figure 1 - Remote Operators Adapter Module

W/Terminal Markings

Page 2

TABLE 1.A

MinPak Plus

Operator s

REMOTE OPERATOR CONTROL STATIONS

When Using a

Controller

With:

Basic features

(standard unidirecĆ

tional Station)

NEMA Type 4

Station with basic

features

ExplosionĆproof

Station with basic

features

Basic features plus

armature reversing

(standard reversing

Station)

NEMA Type 4 StaĆ

tion for reversing

ExplosionĆproof

Station for reversing

Specify

Functions Provided

'

Station

Model

Start/Stop

Rocker Switch

Speed Setting

Potentiometer

Run/Jog

Selector

Forward/Reverse

Selector

9C45 yes yes yes no

9C18 yes yes yes no

9C17 yes yes yes no

9C46 yes yes yes yes

9C19 yes yes yes yes

9C16 yes yes yes yes

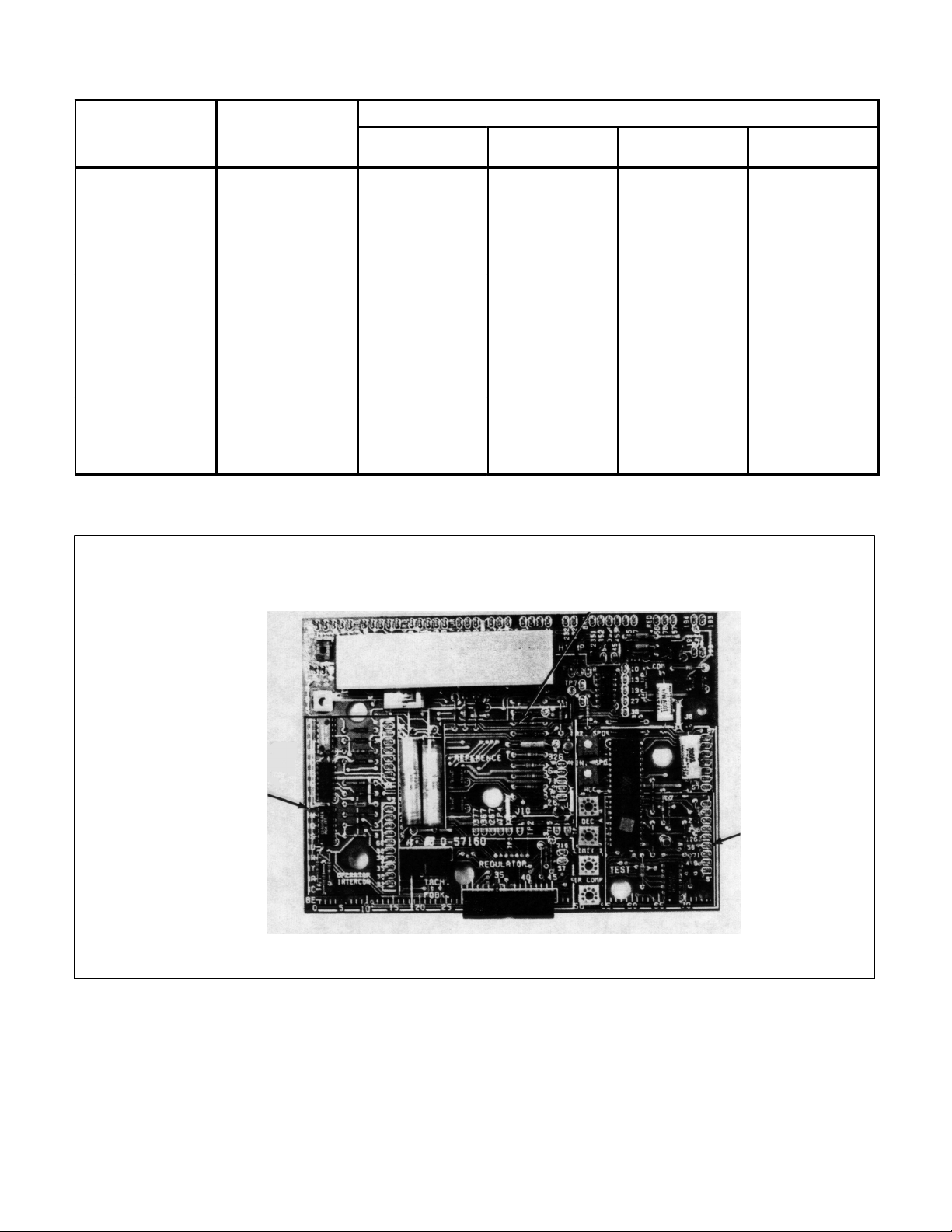

REMOTE OPERATOR

ADAPTER MODULE

&

SWITCH

RECEIVER

MODULE

AREA

REFERENCE

AREA

Figure 2 Ċ Regulator Module Kit Locations

TEST

AREA

Page 3

INSTALLATION

WARNING

BEFORE ATTEMPTING TO INSTALL THE MINĆ

PAK PLUS MODIFICATION KIT, DISCONNECT

AND LOCK OUT ALL SOURCES OF INCOMING

POWER TO THE CONTROLLER.

Locate the area on the Regulator Module where the

1.

Remote Operator Adapter Module is to be

mounted. Place the Module in the proper orientaĆ

the edge with 10 holes should be aligned over

tion:

the 10 pins. (Refer to Figure 2). Carefully, slowly

and gently press the Module down on the pins

until it bottoms out. Use the 2 screws to secure

it.

2. Based on the specific control capability of the ReĆ

Operator Station chosen, select the required

mote

wires specified in T

3. Draw

the wires into

conduit. Then cut individual wires to lengths

cated

required for connection to the kit's terminal strip.

according to Figure 3.4, D

Wire

able 7.B, DĆ3937.

the Controller through the dedi

Ć3937.

WARNING

EXCESSIVE LENGTHS OF BARE WIRE COULD

CAUSE SHORTS AND/OR GROUNDS. STRIP

MINIMAL

INSULA

TION FROM EACH WIRE.

4. Visually inspect all wiring. Check wire placement

against diagrams. Look for grounds and shorts

caused

is

by broken

grounded.

insulation. Make sure the conduit

5. Attach the blank faceplate onto the cover if not alĆ

supplied. F

ready

vided

in Instruction Manual D

ollow installation instructions pro

Ć3977 MinP

ak Plus lo

Ć

Ć

cal operator station faceplate. Be sure to attach

ground

wire to cabinet door

.

DANGER

IT IS NECESSARY TO ATTACH THE FACTORY

CONTROLLER GROUND WIRE TO THE CONĆ

Ć

TROLLER CABINET DOOR VIA THE LOCAL

OPERATORS STATION FACEPLATE. PERĆ

SONAL INJURY MAY RESULT IF THIS PRACĆ

TICE IS NOT FOLLOWED.

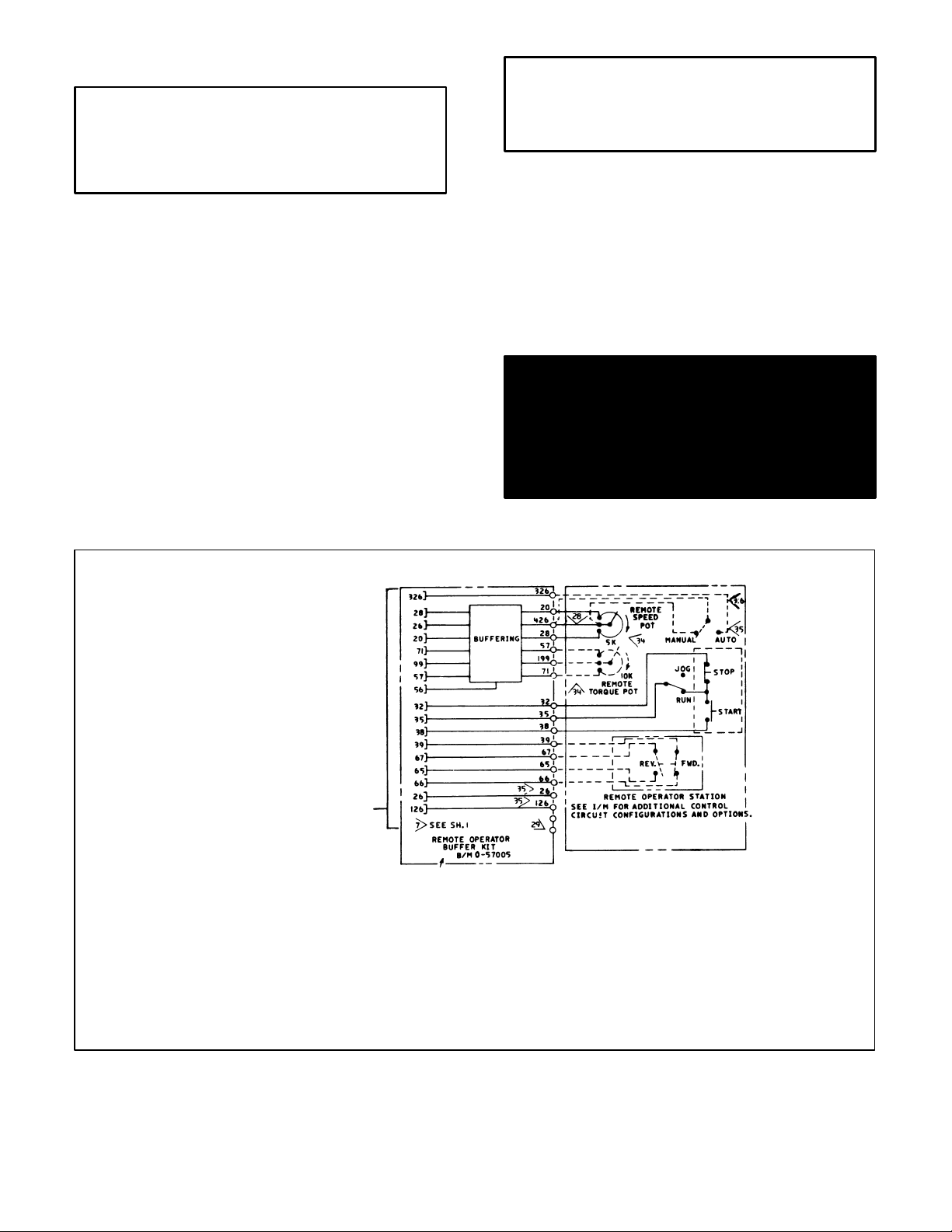

PRINTED CIRCUIT BOARD

NOT ARRANGED IN

ORDER SHOWN.

Figure 3 - Remote Operator Adapter Kit Schematic Diagram

35> When remote operator buffer kit is used with

switch receiver kit auto/manual switch is conĆ

nected to 326126 and 26 (instead of 326 426 and

POT wiper) on the remote operator butter kit terĆ

minal board. The respective pins mate with NC

232 and 32 on the switch receiver kit.

36 > If NOT using an auto/manual switch for automatic

operation only jumper terminals 426 and 326.

Page 4

U.S. Drives Technical Support

Tel: (1) 262.512.8176, Fax: (1) 262.512.2222, Email: support@drives.ra.rockwell.com, Online: www.ab.com/support/abdrives

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication D-3979- 1999 Copyright © 1999 Rockwell Automation, Inc. All Rights Reserved. Printed in USA.

Loading...

Loading...