Page 1

Installation Instructions

Bulletin 1405 (M610) Operating Instructions

Overview

The MiniPowermonitor (1405-M610) measures and displays voltage

and current parameters of low voltage AC power systems:

• Line-to-neutral and line-to-line voltages

• Instantaneous currents

• 15-minute averaged currents

• Peak currents

L-L

V

L1

L1-L2

L2

L2-L3

L3

L1-L3

V

L-N

A

15min

max

F

The MiniPowermonitor is a compact unit, with a 96 x 96 mm (3.78 x

3.78 in) front panel and a depth of only 65 mm (2.56 in).

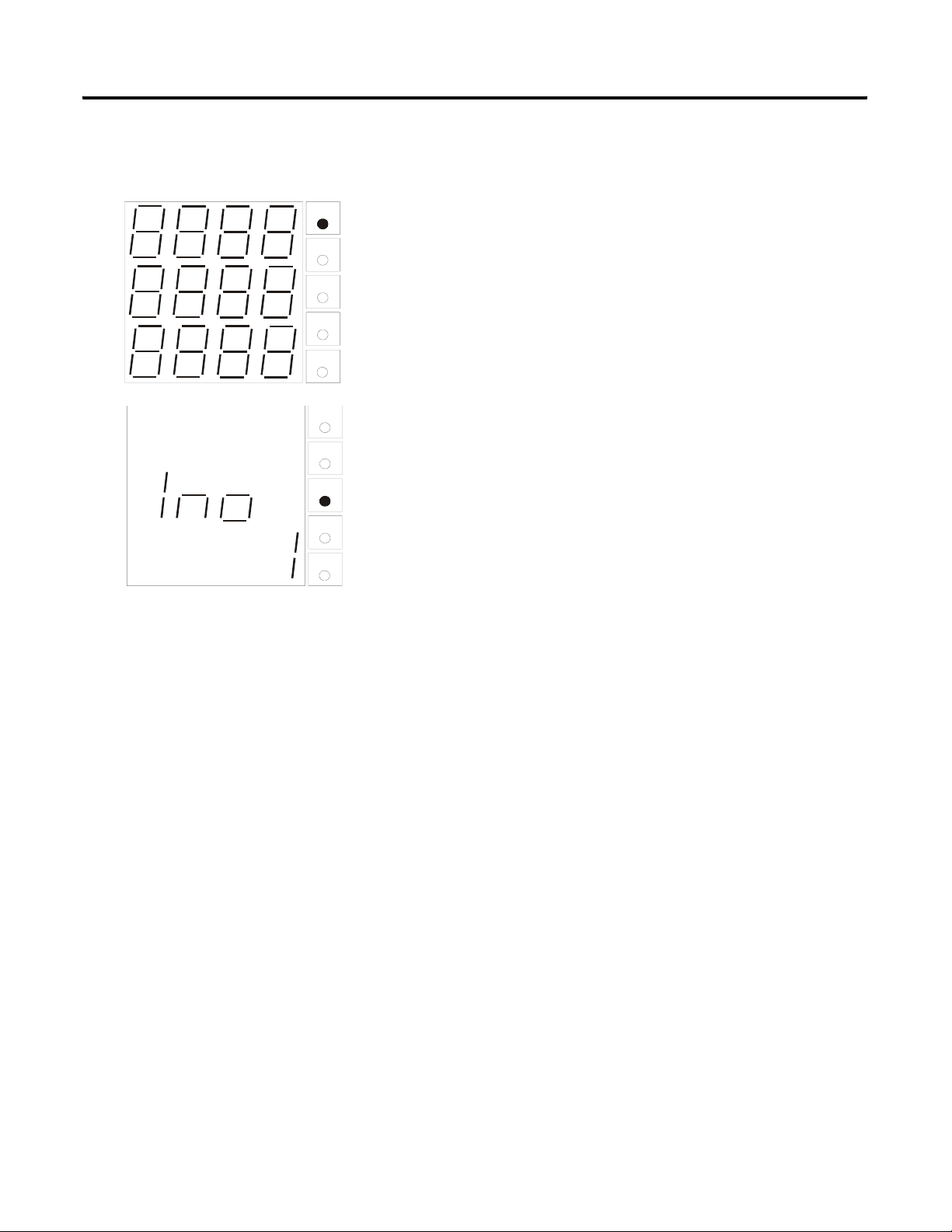

The module’s display is arranged in 3 lines, each with 4 digits. The red

14 mm (0.55 in) high LED characters are easily readable from a

distance, in high ambient light conditions, and from acute viewing

angles. The measurement mode is indicated by 5 LED lamps that

show which parameter is displayed at that time.

Phase voltage and current measurements are made by sequential

scanning at 2 samples per second, so that 3 phase measurements are

made in 1.5 seconds. The updated average current value is displayed

approximately every 60 seconds, interjected into the cyclical sequence

of displayed parameters. Parameter values can be read out of

sequence, using the function (F) key on the front panel.

1 Publication 1405-IN001B-EN-P - October 2003

Page 2

2 Bulletin 1405 (M610) Operating Instructions

Installation

Only qualified personnel should install and wire this equipment. Refer

to the following safety guidelines prior to installation.

ATTENTION

ATTENTION

Only qualified personnel, following accepted safety

procedures, should install and wire the

MiniPowermonitor. Before beginning any work,

disconnect all sources of power and verify that they

are de-energized and locked out. Failure to follow

these instructions may result in personal injury or

death, property damage or economic loss.

Never open a current transformer (CT) secondary

circuit with primary current applied. Wiring between

the CTs and the MiniPowermonitor should include a

shorting terminal block in the CT secondary circuit.

Shorting the secondary with primary current present

allows other connections to be removed if needed.

An open CT secondary with primary current applied

produces a hazardous voltage, which can lead to

personal injury, death, property damage or economic

loss.

1. Install your MiniPowermonitor within a suitable enclosure. Make

sure the enclosure provides adequate clearance for ventilation

and wiring of the module.

dimensions and spacing guidelines for the MiniPowermonitor.

2. Determine your wiring mode and install wiring between the

MiniPowermonitor and your power system.

Connections on page 3 for more information.

3. Configure the current transformer (CT) ratios to match those

used in your power system connections.

Transformer Ratio Setting and Display Test on page 4 for more

information.

Refer to Dimensions on page 6 for

Refer to Input

Refer to Current

Grounding

MiniPowermonitors do not need to be grounded because of the

isolated enclosures. Follow all local requirements for grounding of PT

and CT secondaries.

Publication 1405-IN001B-EN-P - October 2003

Page 3

Bulletin 1405 (M610) Operating Instructions 3

Input Connections

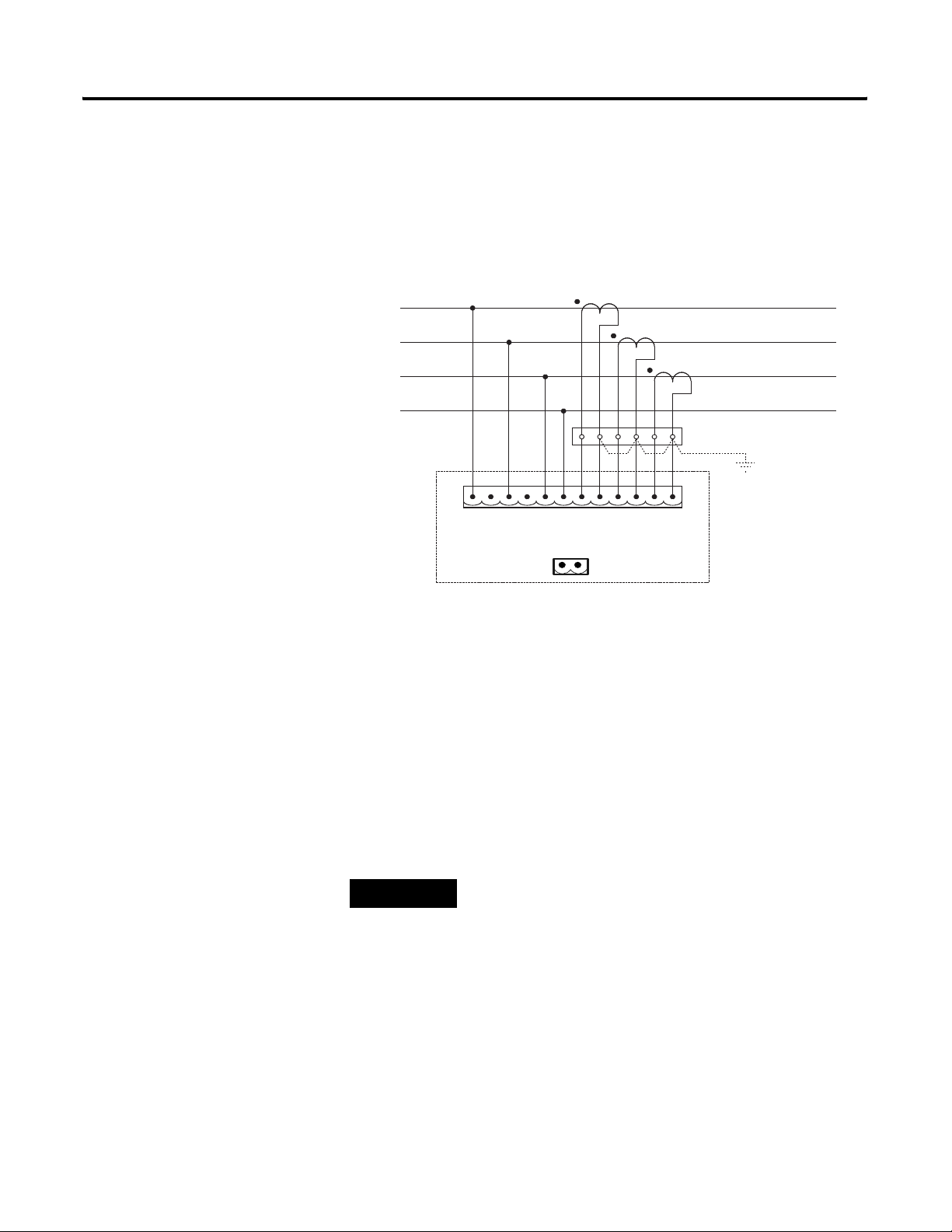

Input connections are at the rear, through a single 12-way plug-in

terminal block with spring clamps. The terminal block can accept wire

2

I2+

I2-

).

Shorting terminal block

(Wye connection optional)

Gnd

(if req'd)

I3-

I3+

sizes from 28 to 14 AWG (0.08 to 2.5 mm

L1

L2

L3

N

L1

L2

L3

N

I1-

I1+

M610

N

L1

The module uses industry-standard current transformers with a 5A

secondary for line current measurement.

• Internal shunt resistance for 5A current transformers: 0.01 ohm.

Aux Supply: With this option, instrument power is supplied by a

separate 120V or 240V line, independent of the measured power lines.

A second connector block (2-pin, spring-clamp terminals type) is

added at the rear with this option.

TIP

Terminals 2 and 4 (counting from left to right) are

not used. No connections should be made to these

terminals.

A unit with the 120V supply option is not designed to operate on

240V or any other voltage. Likewise, a unit with the 240V supply

option is not designed to operate on 120V or any other voltage. Units

designed for 400V and 480V operation do not have an auxiliary

supply connection and receive power from the measurement line.

Ensure that each unit is properly supplied with a power source that

matches the voltage designation of your unit.

Publication 1405-IN001B-EN-P - October 2003

Page 4

4 Bulletin 1405 (M610) Operating Instructions

L 1

L1 - L2

L 2

L1 - L3

L 3

L2 - L3

L 1

L1 - L2

L 2

L1 - L3

L 3

L2 - L3

Current Transformer Ratio Setting and Display Test

To select one of the pre-programmed standard current transformer

V

L- L

ratios, start with the module switched-off. Press and hold the function

“F” key while switching on the power, and for about 3 additional

V

L- N

seconds.

A

All segments of the LED displays and all the LED lamps light up one

after the other in rapid sequence to confirm the integrity of the

15

min

displays.

Max

Press the function “F” key again to initiate the current transformer

ratio setting routine. When it is pressed once, the value “1” is

V

L- L

displayed on the third line of the display. This is the first in the series

of industry-standard current ratio values that are pre-programmed in

V

L- N

the 1405-M610. It is indicated as the nominal value of the line current

(I

nominal

A

15

min

Pressing the function “F” key repeatedly steps the displayed value

through each successive standard current transformer ratios. The

Max

transformer ratio is I

transformer secondary rating.

values of I

).

nominal

:

nominal

:1 or I

nominal

:5, depending on the current

You may select from the following

(1)

1 / 2

/ 5 / 10 / 15 / 20 / 25 / 30 / 40 / 50 / 60 / 75 / 80 / 100 / 125

/ 150 / 200 / 250 / 300 / 400 / 500 / 600 / 750 / 800 / 1000 / 1200 /

1250 / 1500 / 1600 / 1800 / 2000 / 2500 / 3000 / 4000.

Publication 1405-IN001B-EN-P - October 2003

(1)

The actual value is 2.5A

Page 5

L 1

L1 - L2

L 2

L2 - L3

L 3

L1 - L3

Bulletin 1405 (M610) Operating Instructions 5

When the desired value is reached, the module is switched off without

pressing the function key any further. The ratio is now set and

protected against power interruptions. Now whenever the module is

switched on, this pre-set value is used for measuring line currents.

The ratio setting in existence when the power is switched off is the

same value that is valid when the power is switched on again, without

pressing the function key.

Measuring Operation

After the module has been switched on, the software version is

V

L- L

displayed for three seconds, after which the module starts scanning,

L- N

V

measuring, and displaying the power line parameter values. It starts

with the parameter that was selected whenever the “n” function was

A

last invoked. If a parameter was being held on display using the “r”

15

min

function when the module was last switched off, the module displays

the present values of that same parameter.

Max

L 1

L1 - L2

L 2

L2 - L3

L 3

L1 - L3

L 1

L 1

L1 - L2

L1 - L2

L 2

L 2

L2 - L3

L2 - L3

L 3

L 3

L1 - L3

L1 - L3

L 1

L1 - L2

L 2

L2 - L3

L 3

L1 - L3

In its normal sequential display mode, the measured parameter values

are displayed in the following sequence:

V

L- L

L- N

V

A

15

min

• Line-to-line voltages

• Line-to-neutral voltages

• Instantaneous phase currents

• Average phase currents

Max

V

L- L

V

L- L

• Peak phase currents

Press and hold the function key (“F”) to select one of three functions.

The selected function is indicated by the left-most character of lowest

L- N

V

L- N

V

line, and interpreted as follows:

A

A

• ‘n’: Key pressed for 0 to 2 seconds: skips the present parameter,

15

min

15

min

Max

Max

and displays the next parameter

• ‘r’: Key pressed for 2 to 4 seconds: sequential display of

parameters, on/off

• ‘c’: Key pressed for 4 to 8 seconds: re-sets average and peak

V

L- L

L- N

V

A

current values

The present parameter can be skipped and any other parameter

displayed by manual stepping, even if the automatic sequencing

mode (‘r’) is active. Similarly the ‘c’ mode can be invoked at any time

15

min

to delete the existing average and peak current measurements.

Max

Publication 1405-IN001B-EN-P - October 2003

Page 6

6 Bulletin 1405 (M610) Operating Instructions

Dimensions

Specifications

Panel cut-outs should be 92 x 92 mm (3.6 x 3.6 in).

Table 1 Measured Parameters

Voltage V

Instantaneous Current

Average Current (15 min.)

Peak Current

Measuring Rate Approximately 2 measurements per second

Update Time 1.5 Seconds

/ V

L1 - L2

V

/ V

L1 - N

IL1 / IL2 / I

L2 - L3

L2 - N

L3

/ V

/ V

L3-L1

L3-N

Publication 1405-IN001B-EN-P - October 2003

Table 2 Digital Displays

Typ e 7 Segment LED, Red

Lines x Characters 3 x 4

Character Height 14 mm (0.55 in)

Table 3 General Parameters

Parameter Value

Nominal Voltage Per Catalog Version

Units with separate 120V or 240V supply: 600V

Units powered from 400V measurement line: 400V

Units powered from 480V measurement line: 480V

Voltage Range 0.8 V to 1.1V * (nominal voltage)

Current Range 0.0 A to 6.0 A

Page 7

Bulletin 1405 (M610) Operating Instructions 7

Table 3 General Parameters

Parameter Value

Temperature Coefficient < 0.01% / K

Input Impedance (Voltage Inputs) 2 Mohm (Lx to N)

Input Impedance (Current Inputs) 0.01 ohm at 5A

Overload Rating Voltage 110% (continuous)

Current 200% (continuous)

Frequency Range 47 to 63 Hz

Power Consumption 3W typical

Operating Temperature +5°C to +50°C (+41°F to +122°F)

Storage Temperature -20°C to +70°C (-4°F to +158°F)

Protection Class Enclosure IP 20 (IP 65 with optional protective

(1)

)

hood

Terminals IP 00

Weight Approximately 0.3 kg

Front Dimensions 96 mm x 96 mm (3.78 in x 3.78 in)

Breakdown Rating Per DIN 41700

Depth 65 mm (2.56 in)

Panel Mounting Spring Clamps

Agency Certifications UL, CE

(1)

The optional hood, catalog number 1405-PRO, can be ordered separately. Contact your Rockwell Automation

distributor for additional information.

Table 4 Measurement Accuracy and Range

Parameter Percent of Reading Nominal Value Operating Range Maximum Limit

Volts ±1% 240V rms 10V rms to 347V rms L-N

or 17V rms to 600V rms

400V rms L-N or 690V

rms L-L

L-L

Current ±1% 5 Amps 0.1 Amps to 6 Amps 10 Amps

Publication 1405-IN001B-EN-P - October 2003

Page 8

8 Bulletin 1405 (M610) Operating Instructions

Product Approvals

UL/CUL

cULus Listed, File E96956, per UL508, the Standard for Industrial

Control Equipment.

CE Certification

If this product bears the CE marking, it is approved for installation

within the European Union and EEA regions. It has been designed to

meet the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards, in

whole, documented in a technical construction file:

• EN 50081-2 - Generic Emission Standard, Part 2 - Industrial

Environment

• EN 61000-6-2 - Generic Immunity Standard, Part 2 - Industrial

Environment.

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low

Voltage, by applying the safety requirements of EN/IEC 61010-1.

This equipment is classified as open equipment and must be installed

(mounted) in an enclosure during operation as a means of providing

safety protection.

International Standard IEC 529 / NEMA / UL 508 Degree of

Protection

The MiniPowermonitor is rated as IP10 degree of protection per

International Standard IEC 529. It is considered an open device per

NEMA and UL 508.

Publication 1405-IN001B-EN-P - October 2003

Page 9

Catalog Number Explanation

Bulletin 1405 (M610) Operating Instructions 9

1405-M610-400-1A

Bulletin Number

1405 = MiniPowermonitor

1

- 120V and 240V connections are via a separate connection

2

- 400V and 480V connections are via the measurement line

Device Category

M610 = Volt and

Amp Meter

Power Supply

Voltage

No Designator =

120V 60 Hz

120 = 120V 60 Hz

240 = 240V 60 Hz

400 = 400V 50 Hz

480 = 480V 60 Hz

Current Input

1A = 1A current

inputs

1

No Designator =

5A current inputs

1

2

2

Publication 1405-IN001B-EN-P - October 2003

Page 10

10 Bulletin 1405 (M610) Operating Instructions

Publication 1405-IN001B-EN-P - October 2003

Page 11

Bulletin 1405 (M610) Operating Instructions 11

Publication 1405-IN001B-EN-P - October 2003

Page 12

Rockwell Automation Support

Rockwell Automation provides technical information on the web to assist you in using our products. At

http://support.rockwellautomation.com, you can find technical manuals, a knowledge base of FAQs, technical and

application notes, sample code and links to software service packs, and a MySupport feature that you can customize

to make the best use of these tools.

For an additional level of technical phone support for installation, configuration and troubleshooting, we offer

TechConnect Support programs. For more information, contact your local distributor or Rockwell Automation

representative, or visit http://support.rockwellautomation.com.

Installation Assistance

If you experience a problem with a hardware module within the first 24 hours of installation, please review the

information that's contained in this manual. You can also contact a special Customer Support number for initial help

in getting your module up and running:

United States 1.440.646.3223

Monday – Friday, 8am – 5pm EST

Outside United States Please contact your local Rockwell Automation representative for any technical support issues.

New Product Satisfaction Return

Rockwell tests all of our products to ensure that they are fully operational when shipped from the manufacturing

facility. However, if your product is not functioning and needs to be returned:

United States Contact your distributor. You must provide a Customer Support case number (see phone number

above to obtain one) to your distributor in order to complete the return process.

Outside United States Please contact your local Rockwell Automation representative for return procedure.

Publication 1405-IN001B-EN-P - October 2003 12 PN 40055-219-01(2)

Supersedes Publication 1405-IN001A-EN-P - July 2003 Copyright © 2003 Rockwell Automation, In c. All rights reserved. Printed in the U.S.A.

Loading...

Loading...