Page 1

Bulletin 1102C 400A Vacuum Contactor

Vacuum Interrupter Phase Assembly

Replacement Instructions

(Cat 1102-VB4)

ATTENTION: To prevent electrical shock, disconnect from power source before installing or servicing.

Vacuum Interrupter Phase Assembly Replacement (Used with Vacuum Contactors: 1102C-COA93,

-COB93, -COD93, -COG93, -COH93, -CON93)

1. Disconnect all power cables (or bus work) and all control wiring to the contactor.

2. Remove the contactor from its mounted location. The contactor is best serviced in the tabletop position.

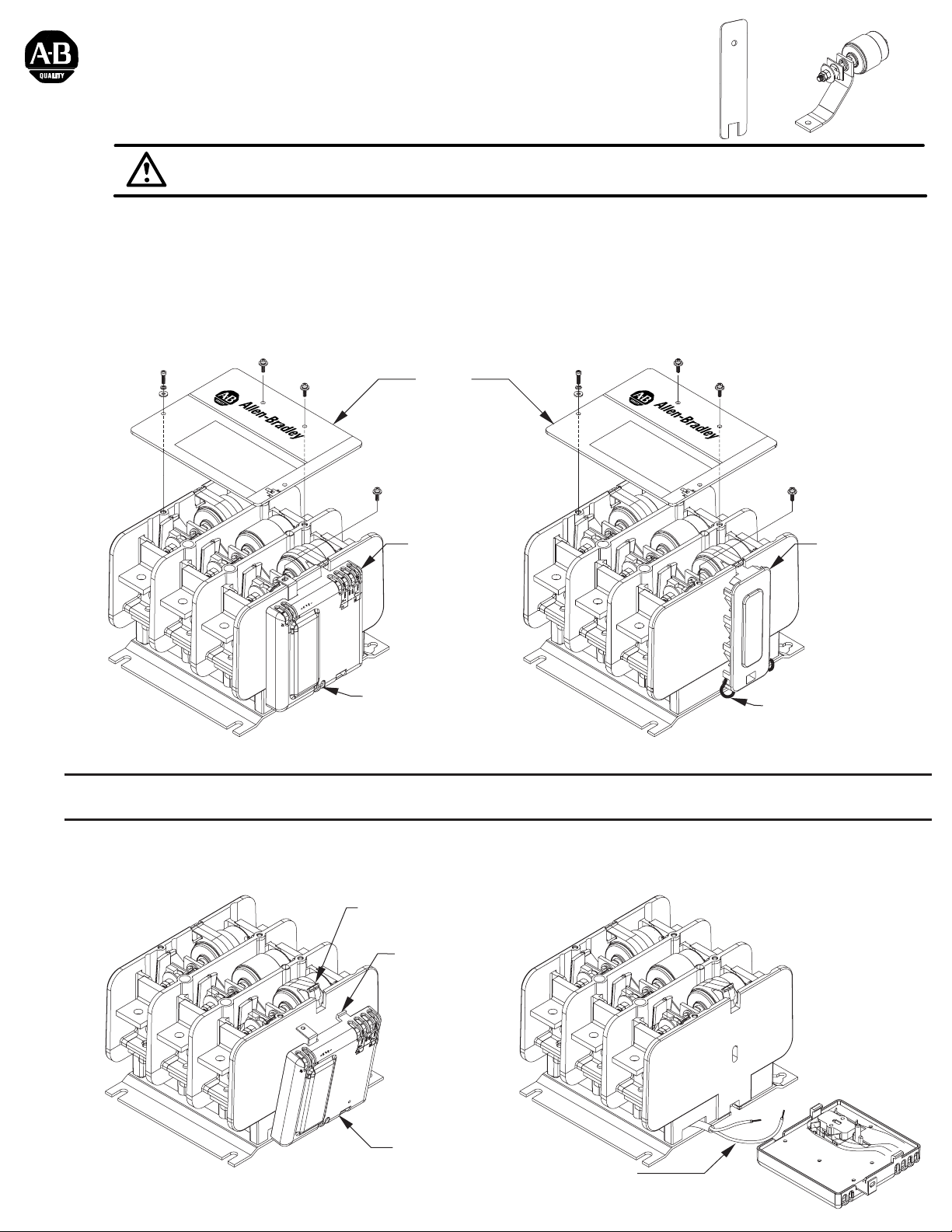

3. Remove the cover attachment hardware from the contactor and remove the cover (Figure 1).

4. Disconnect the coil wire leads from the Control-Pak or Auxiliary (Figure 2B).

Cover

V

A

CUUM CONT

A

C

T

O

R

V

A

CUUM

C

ON

T

A

CTO

R

AC Coil (With Control-Pak)

Control-Pak

Disconnect Coil Wires

from Control-Pak

Figure 1

Disconnect Coil Wires

from Auxiliary

DC Coil (With Auxiliary 1195C-N5)

Auxiliary

Note: The following instructions pertaining to the removal and reinstallation of the Control-Pak are

applicable to the Auxiliary.

5. Remove the Control-Pak from the contactor by first rotating the retainer to release the top tab of the Control-

Pak. Then pull out the top of the Control-Pak (the tab must clear the notch) and then push Control-Pak slightly

downward to release lower tab that holds the Control-Pak to the housing (Figures 2A & 2B).

Rotate retainer to

release Control-Pak

This tab must

clear notch prior

to pushing

Control-Pak

downward.

Control-Pak

Coil Leads

Figure 2A Figure 2B

Page 2

Vacuum Interrupter Phase Assembly Replacement (Cont'd)

6. Locate the replacement Interrupter Phase Assembly that needs to be replaced. It is recommended that all three

interrupters be replaced at the same time.

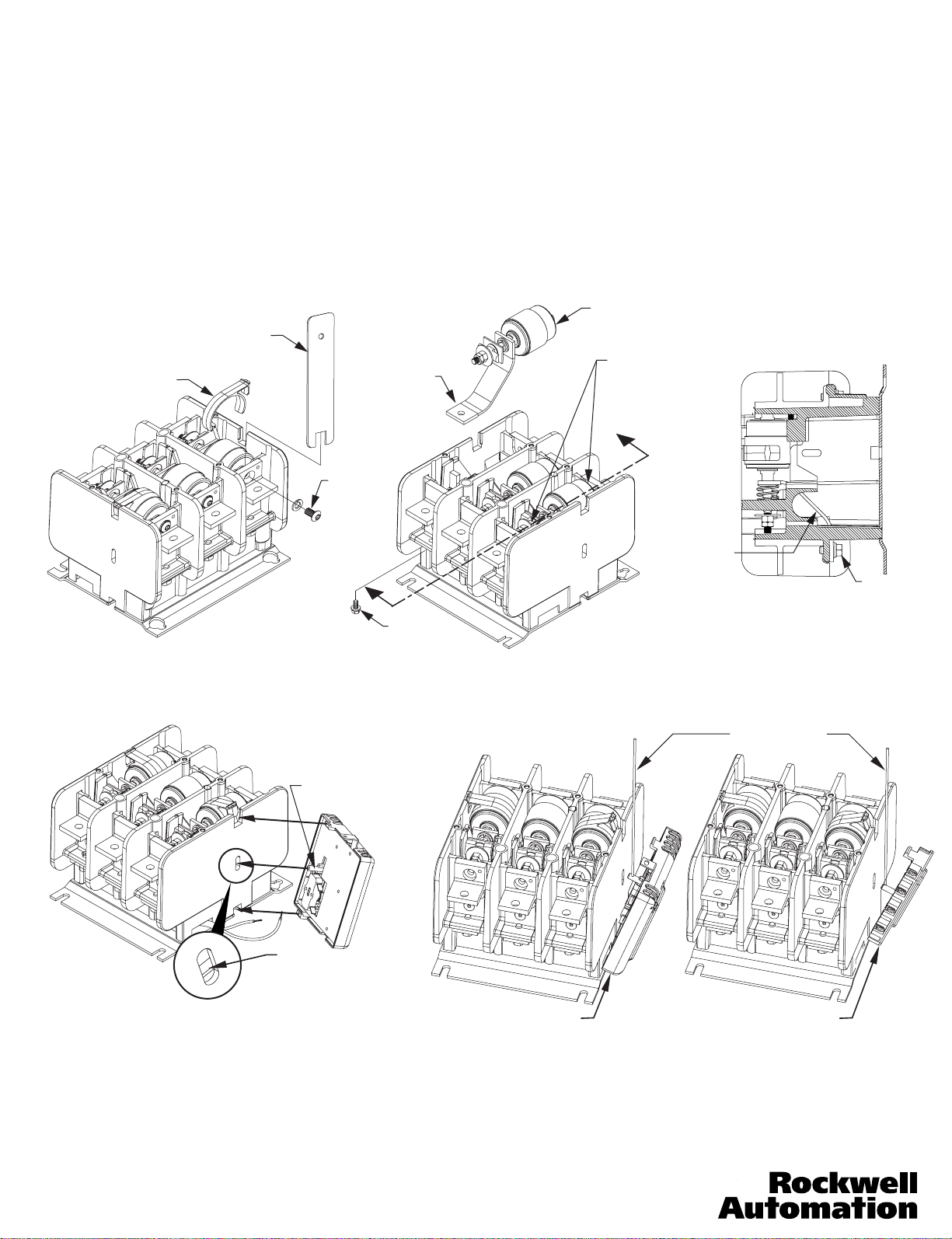

7. For the outer interrupters, remove the Retainer. While holding the Interrupter in position with the provided wrench,

remove the screw from the line side terminal (Figure 3).

8. Remove the shunt screw from the load side terminal (See Section A-A). This will free the shunt. Carefully remove

the interrupter assembly (Figure 4).

9. The replacement interrupter is factory set for contact gap and does not require adjustment. The flexible shunt will

feed through the flexible shunt path in the molding of the contactor and the assembly can be pushed firmly back into

place (See Figure 4 showing locations for applying hand pressure to snap interrupter into plastic molding), observe the

adjacent phases to see precisely how this is positioned. While holding the Interrupter in position with the provided

wrench, replace the line terminal screw (Figure 3). Replace the shunt connection hardware (Figure 4). Torque screw to

60 - 80 lb-inches.

supplied with kit

Retainer

Special wrench

Shunt

Terminal

Screw

Interrupter

Phase Assembly

Pressure points

for interrupter

installation

A

Shunt

A

Shunt

Figure 3 Figure 4

Screw

SECTION A-A

Shunt

Screw

10. Reinstall the Control-Pak (Figures 5A & 5B). First, insert the lower tab into the recess on the side of the contactor

base. With proper installation, the Actuator will fit into the hole in the slot in the side of the contactor housing. Using a

thin rod or flat blade, lift the Actuator up as necessary to insert it into the slot mentioned.

Thin rod or

flat blade

Control-Pak

Actuator

Actuator

must fit into

slot shown

Figure 5A

Control-Pak

Figure 5B

Auxiliary

11. Reinstall the cover and secure it with the original mounting hardware. NOTE: Cover must fit under metal bracket

on Control-Pak. Tighten the four screws in a diagonal pattern to 12 lb-inches. (Figure 1).

12. Reattach the coil wire leads and any auxiliary control wires to the Control-Pak (tighten to 7 lb-inches).

13. Reinstall the contactor. Torque mounting screws to 50 - 75 lb-inches.

14. Reconnect the line and load conductors and tighten the main terminal hardware and bolts to 180 - 210 lb-inches.

42052-094-01 (1)

Printed in U.S.A.

Loading...

Loading...