Page 1

Bulletin 1102C 400A / 600A Vacuum Contactor

AC Coil Replacement Instructions

(Cat 1102C-PK4D, -PK4A, -PK4N, -PK4B,

1102C-PK6D, -PK6A, -PK6N, -PK6B)

ATTENTION: To prevent electrical shock, disconnect from power source before installing or servicing. If coil failure is

suspected, check that secondary damage has not occurred that will render the contactor non-repairable.

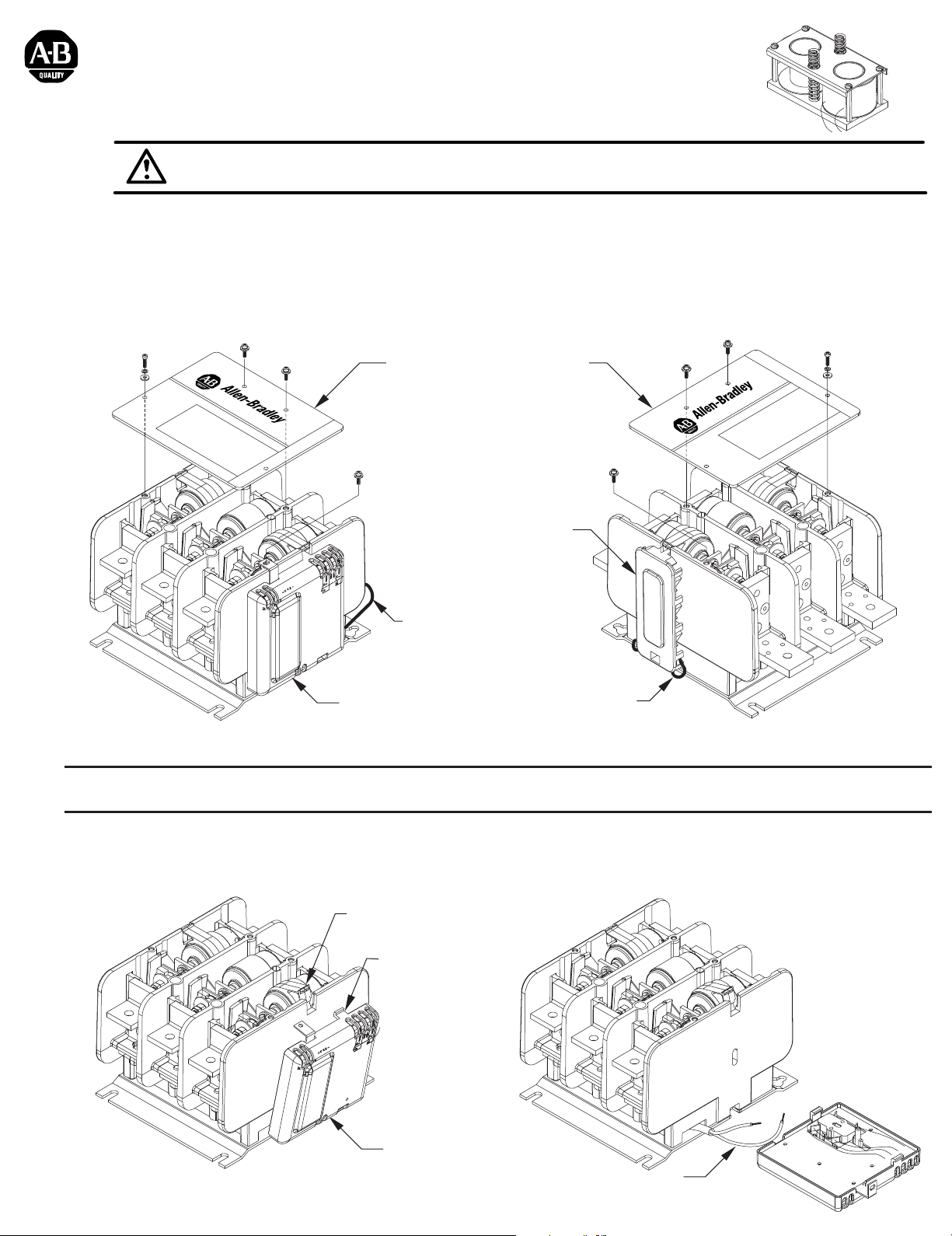

Coil Replacement

1. Disconnect all power cables (or bus work) and all control wiring to the contactor.

2. Remove the contactor from its mounted location. The contactor is best serviced in the tabletop position.

3. Disconnect the coil wire leads from the Control-Pak or Auxiliary (Figure 2B).

4. Remove the cover attachment hardware from the contactor and remove the cover (Figure 1).

CoverCover

VA

CUUM CONT

A

C

TO

R

VA

C

UUM

CONTAC

R

O

T

Auxiliary

Remove

Coil Wire

Leads from

Control-Pak

Control-Pak

Remove

Coil Wire

Leads from

400A

Figure 1

Auxiliary

600A

Note: The following instructions pertaining to the removal and reinstallation of the Control-Pak are applicable

to the Auxiliary

5. Remove the Control-Pak from the contactor by first rotating the retainer to release the top of the Control-Pak. Then

pull out the top of the Control-Pak (the tab must clear the notch) and then push Control-Pak slightly downward to

release lower tab that holds the Control-Pak to the housing (Figures 2A & 2B).

Rotate retainer to

release Control-Pak

This tab must

clear notch prior

to pushing

Control-Pak

downward.

Control-Pak

Coil Leads

Figure 2A Figure 2B

Page 2

Coil Replacement (Cont'd)

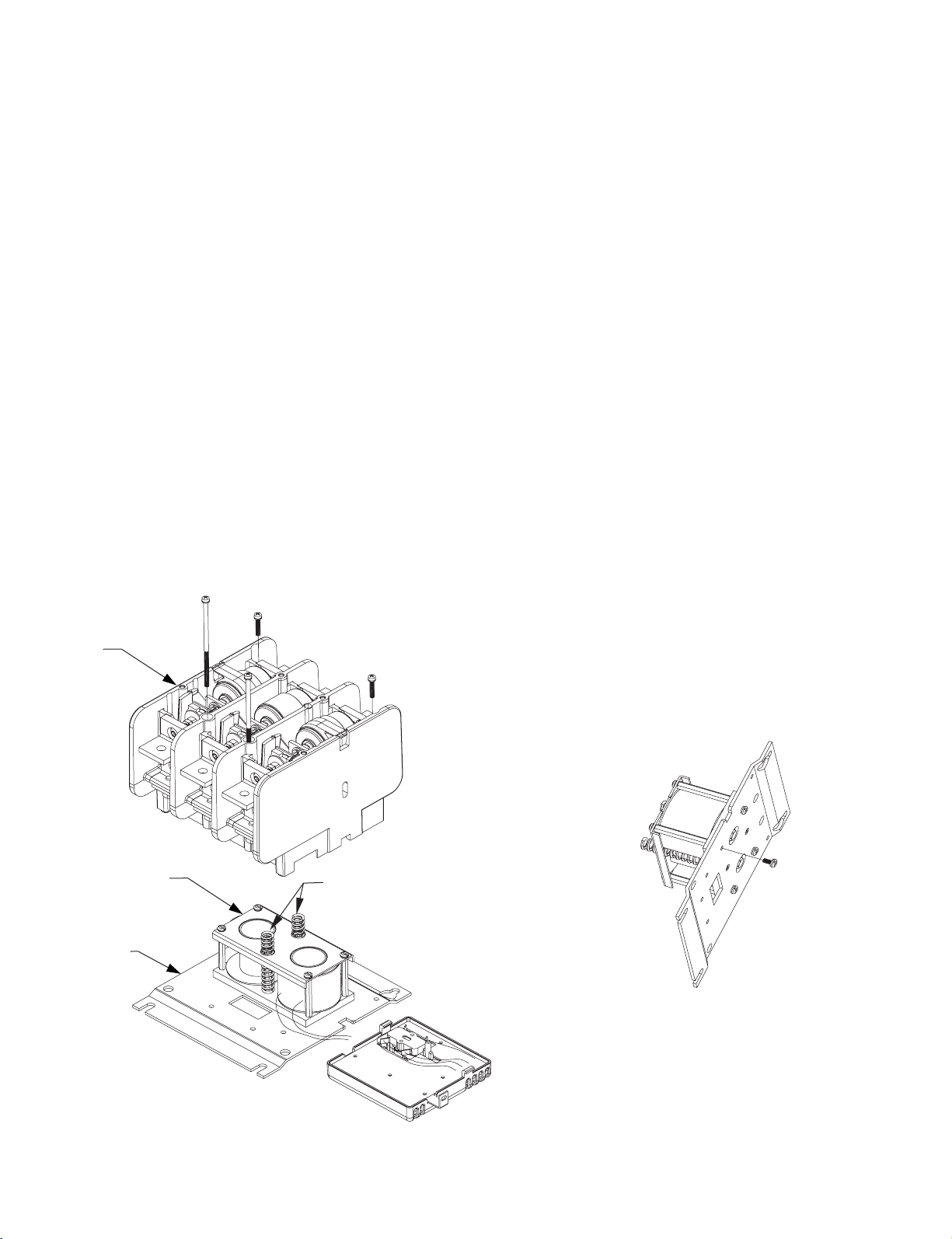

6. While supporting the Main Housing, remove the Main Housing from the Baseplate by removing the (4) screws which

hold the housing to the Baseplate. A long philips-head screwdriver (6 inch or longer) is needed as the four screws are

in deep wells (holes) in the Main Housing. Remove the shorter screws first. Separate the main housing assembly

from the Baseplate and set it aside (Figure 3).

7. Remove the Return Springs and set them aside (Figure 3). Turn the Base Assembly over and remove the (4)

screws that secure the Coil Assembly to the Baseplate (Figure 4).

8. Install new Coil Assembly in position using (4) screws (torque to 30 - 45 lb-inches). Replace the Return Springs by

placing them over the spring support pins located within the coil magnet core assembly making sure the return springs

are properly seated and not interfering with any of the control wiring (Figure 3).

9. Carefully replace the Main Housing assembly loosely, making sure it is orientated correctly. Ensure that no wires

are pinched between housing and baseplate. Carefully locate the magnetic armature poles (the poles sticking down

from the upper housing assembly) into the coil magnet core assembly. Note: This is a blind operation with careful

side to side motion. Pay close attention to alignment of the locating bosses located at the bottom of the main housing

assembly. To reattach the Main Housing assembly insert the main housing locating bosses into the two mounting

plate holes while compressing the return springs with the Main Housing. Start the four Main Housing screws into the

mounting plate. Tighten the mounting screws equally in a diagonal pattern approximately two turns at a time until

torqued to 28 lb-inches in the same diagonal pattern.

Main

Housing

Baseplate

Coil

Assembly

Return

Springs

Figure 3 Figure 4

(2)

Page 3

Coil Replacement (Cont'd)

10. Re-install the Control-Pak or Auxiliary (Figures 5A & 5B). First, rotate the Retainer upwards. Next, insert the

lower tab on the edge of the Control-Pak into the recess on the side of the contactor base. With proper installation,

the Actuator will fit into the hole in the slot in the side of the contactor housing. Using a thin rod or flat blade, lift the

Actuator up as necessary to insert it into the slot mentioned. Rotate the Retainer to its original position, which will

slide over the upper tab on the Control-Pak.

Thin rod or

flat blade

Control-Pak

Actuator

Thin rod or

flat blade

Actuator

must fit

into slot

shown

Figure 5A Figure 5B

Auxiliary

Control-Pak

11. Confirm position of (2) retainers (adjust if necessary) (See Figure 1).

12. Reinstall the cover and secure it with the original mounting hardware. NOTE: Cover must fit under metal

bracket on Control-Pak. Tighten the four screws in a diagonal pattern to 12 lb-in. (Figure 1).

13. Reattach the coil wire leads and any auxiliary control wires to the Control-Pak (tighten to 7 lb-inches).

14. Reinstall the contactor. Torque mounting screws to 50 - 75 lb-inches.

15. Reconnect the line and load conductors and tighten the main terminal hardware and bolts to 180 - 210 lb-inches

(3)

Page 4

42052-091-01 (1)

Printed in U.S.A.

Loading...

Loading...