Page 1

cobas b 221 system

Service Manual

Page 2

COBAS, COBAS B and LIFE NEEDS ANSWERS

are trademarks of Roche.

©2009 Roche Diagnostics

Roche Diagnostics GmbH

D-68298 Mannheim

Germany

www.roche.com

Page 3

cobas b 221 system

Version History

Manual Version Software Version Version date Changes

1.0 1.0 May 2003 First edition

2.0 2.0 March 2004 Chapter 2, 3, 4, 5, 6, 7, 8, 9

3.0 3.01 June 2004 Chapter 2, 3, 4, 6, 8, 9

4.0 4.00 December 2004 Chapter 1, 2, 3, 6, 7, 8, 9

4.1 4.02 July 2005 All chapters

5.0 5.00 November 2005 Parts A, B, D, E, G

6.0 5.00 March 2006 All chapters

7.0 6.00 December 2006 All chapters

8.0 7.00 December 2007 All chapters

9.0 n./a. May 2009 Chapter 2, 3, 6, 7

Language Order Number

English 03309614001

Edition notice

cobas b 221 system

Service Manual

cobas b 221 system In the course of 2006 the Roche OMNI S system was rebranded under the Roche

e

For more information, see:

Software on page G-5

Service Manual on page G-6

This manual is for the maintenance and repair of the cobas b 221 system.

Diagnostics professional IVD user brand cobas®.

Systems with a serial number of 5001 or above are cobas b 221 systems.

Systems with a serial number up to 5000 are Roche OMNI S systems.

Every effort has been made to ensure that all the information contained in this

manual is correct at the time of printing. However, Roche Diagnostics GmbH reserves

the right to make any changes necessary without notice as part of ongoing product

development.

Any customer modification to the instrument will render the warranty or service

agreement null and void.

Software updates are done by Roche Service representatives.

Roche Diagnostics May 2009

Service Manual · Version 9.0 3

Page 4

Intended use

cobas b 221 system

This manual contains all of the information required for the maintenance and repair

of the cobas b 221 system.

The user must be familiar with the function and operation of the instrument to fully

understand the processes described here.

e

For more information about cobas b 221 system instructions, refer to:

cobas b 221 system Instructions for Use

cobas b 221 system Reference Manual

Observe the service and repair procedures described in this manual and use only

genuine Roche replacement parts and Roche-approved materials to guarantee the full

functionality of the cobas b 221 system.

e

For the order numbers of replacement parts, refer to the cobas b 221 system Spare Part

List.

e

For an overview of possible revisions and available software versions, see:

Software on page G-5

Service Manual on page G-6

Copyrights

Trademarks

Contact address

Manufacturer

© 2009 Roche Diagnostics GmbH, All rights reserved.

The contents of this document may not be reproduced in any form or communicated

to any third party without the prior written consent of Roche Diagnostics. Every

effort is made to ensure its correctness. Subject to change without notice.

COBAS, COBAS B, LIFE NEEDS ANSWERS, ROCHE OMNI, AUTOQC,

ROCHE MICROSAMPLER, COMBITROL, AUTO-TROL and COBAS BGE LINK

are trademarks of Roche.

Roche Diagnostics GmbH

D-68298 Mannheim / Germany

www.roche.com

Roche Diagnostics May 2009

4 Service Manual · Version 9.0

Page 5

cobas b 221 system

Table of contents

Ver si on Hi st or y 3

Edition notice 3

Intended use 4

Copyrights 4

Trademarks 4

Contact address 4

Preface 7

How to Use This Manual 7

Where to Find Information 7

Conventions used in this manual 8

System Description Part A

1 Safety information

Important information A-5

Operating safety information A-6

Important notes and warnings A-6

Disinfectants A-7

ESD protection measures A-8

2 Fluid actions

Fluid actions overview A-13

Pin assignment of S2 and S3 Fluid Packs A-19

T&D positions A-20

Measurement A-21

Calibration A-31

Servicing Part B

3 Protected software functions

Protected setup B-5

Protected system functions B-11

Protected infos B-12

Protected DB functions B-13

4 Components

Important notes B-19

Shutdown B-19

Removing the rear panel B-20

Folding up the central measuring unit B-20

T&D system (Turn & Dock) B-21

Fluid mixing system (FMS) B-33

Sample distributor (SD) B-35

BG measuring chamber B-40

ISE measuring chamber (cobas b 221<3>–<6>

systems only) B-42

MSS measuring chamber (cobas b 221<5/6> systems

only) B-44

Measuring chamber cartridge B-48

COOX module (cobas b 221<2/4/6> systems only)

B-51

tHb/SO

module (cobas b 221<1/3/5> systems only)

2

B-62

Peristaltic pumps (PP) B-64

Bottle compartment B-67

Vacuum system B-73

Valve s B -8 1

Mainboard unit B-89

Interface unit B-91

Touch screen/PC unit B-95

Printer B-108

Fan unit B-110

Replacing the valve bus cable B-110

Replacing the actuator bus main controller cable

B-112

Barcode scanner B-113

5 AutoQC module

AutoQC preparation for maintenance B-119

Initial installation of the AutoQC module B-119

Replacing the AutoQC module B-120

Replacing the AQC snap lock B-122

Replacing the AQC magnetic valve B-123

Replacing the AQC board B-124

Replacing the YZ distributor board B-125

Replacing the Z distributor board B-126

Replacing the flex cable (short) B-127

Replacing the flex cable (long) B-128

AQC sample tube B-129

Replacing the X motor B-131

Replacing the Y motor B-132

Replacing the Z motor B-132

Replacing the AutoQC steel tube B-133

Replacing the AQC temperature sensor B-134

Replacing the wash port B-135

Replacing the toothed belt (short) B-136

Replacing the toothed belt (long) B-137

Maintenance Part C

6 Maintenance

Decontamination C-5

cobas b 221<1/3/5> systems (tHb/SO2) C-10

cobas b 221<2/4/6> systems (COOX) C-12

AutoQC module C-14

Troubleshooting Part D

7 Troubleshooting

Important Notes D-11

Roche Diagnostics May 2009

Service Manual · Version 9.0 5

Page 6

General information D-11

System stops D-13

Module stops D-37

System warnings D-51

Valu e f l ag s D- 5 8

USB troubleshooting D-91

Touch screen/PC unit troubleshooting D-91

Important test routines D-95

Sensor limits (Sensor report) D-135

Glossary Part E

Glossary E-3

Index Part F

Index F-3

cobas b 221 system

Versions Part G

8 Versions

Software G-5

Service Manual G-6

Roche Diagnostics May 2009

6 Service Manual · Version 9.0

Page 7

cobas b 221 system

Preface

This manual contains all of the information required for the maintenance and repair

of the cobas b 221 system.

The user must be familiar with the function and operation of the instrument to fully

understand the processes described here.

e

For more information about cobas b 221 system instructions, refer to:

cobas b 221 system Instructions for Use

cobas b 221 system Reference Manual

Observe the service and repair procedures described in this manual and use only

genuine Roche replacement parts and Roche-approved materials to guarantee the full

functionality of the cobas b 221 system.

e

For the order numbers of replacement parts, refer to the cobas b 221 system Spare Part

List.

e

For an overview of possible revisions and available software versions, see:

Software on page G-5

Service Manual on page G-6

How to Use This Manual

o

Keep this manual in a safe place to ensure that it is not damaged and remains available for use.

o

This Service Manual should be easily accessible at all times.

To help finding information quickly, there is a table of contents at the beginning of

the book and each chapter. In addition, a complete index can be found at the end.

Where to Find Information

In addition to the Service Manual, the following documents are also provided to assist

in finding desired information quickly:

o cobas b 221 system Instructions for Use

o cobas b 221 system Operator’s CD

o cobas b 221 system Reference Manual

o cobas b 221 system Short Instruction

o cobas b 221 system Service Manual (PDF or iSDoc version in GRIPS)

o cobas b 221 system Spare Part List (PDF or iSDoc version in GRIPS)

Roche Diagnostics May 2009

Service Manual · Version 9.0 7

Page 8

Conventions used in this manual

Visual cues are used to help locate and interpret information in this manual quickly.

This section explains formatting conventions used in this manual.

Symbols The following symbols are used:

Symbol Used for

a Procedural step

o List item

e

h Call up of screen

Cross-reference

Note All sections or text locations marked with

Caution / Warning All sections / passages that are marked with this

Biohazard Risk of infection!

cobas b 221 system

"NOTE" describe safe procedures that are

intended to provide the user with additional help.

symbol describe procedures and/or indicate

conditions or dangers that could damage or lead

to a malfunction in the cobas b 221 system, and

which therefore should never be attempted to

avoid potential injuries (to patients, users and

third parties).

High Voltage Passages that are marked with this symbol warn

of an immediate danger in connection with

electrical wiring or components.

ESD protection measures All sections or passages that are marked with this

symbol warn of specific dangers in connection

with static discharge. Packages that are marked

with this symbol must only be opened by trained

technical staff.

Invisible Laser Radiation Avoid direct radiation to eyes

Laser Class 3R according to EN 60825-1

P0 < 5 mW

λ = 635 - 850 nm

e

For more information about warning symbols, refer to the cobas b 221 system Intructions

for Use.

e

For more information about ESD protection measures, see ESD protection measures on

page A-8.

Roche Diagnostics May 2009

8 Service Manual · Version 9.0

Page 9

cobas b 221 system

Abbreviations The following abbreviations are used:

Abbreviation Definition

A

ADC Analogue to digital converter

ANSI American National Standards Institute

AQC AutoQC

B

BG Blood Gases

C

CCD Charge coupled device

CMOS Complementary Metal-Oxide Semiconductor

E

EEPROM Electrically erasable programmable read-only memory

e.g. exempli gratia – for example

EC European community

EN European standard

ESD Electro Static Discharge

F

FMS Fluid Mixing System

FTP File Transfer Protocol

H

HIV Human Immunodeficiency Virus

HW Hardware

I

IEC International Electrical Commission

IfS Interference sensor (part of the MSS cartridge)

ISE Ion selective electrode

IVD In vitro Diagnostics

L

LCD Liquid Cristal Display

M

MC Measuring chamber

MOS Metal-Oxide Semiconductor

MSDS Material safety data sheet

MSS Metabolite Sensitive Sensor

Q

QC Quality control

R

REF Reference solution for ISE module

S

S1 S1 Rinse Solution

S2 S2 Fluid Pack

S3 S3 Fluid Pack A

Roche Diagnostics May 2009

Service Manual · Version 9.0 9

Page 10

Abbreviation Definition

SCD Sample container detection

SD Sample distributor

SIP Sample inlet path

SW Software

T

T&D Turn and Dock

TTL Transisitor-Transistor Logic

U

USB Universal Serial Bus

V

V19 Valve 19

VM FMS Mixing Valve

VPP (=VPS) Vacuum pump protector

cobas b 221 system

Roche Diagnostics May 2009

10 Service Manual · Version 9.0

Page 11

System Description

1 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

2 Fluid actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11

A

May 2009

Page 12

Page 13

cobas b 221 system 1 Safety information

Tab le of co nt ent s

Safety information

Before the maintenance and repair of the cobas b 221 system, it is essential that the

warnings, cautions, and safety requirements contained in this manual are read and

understood by the user.

In this chapter

Important information ................................................................................................... 5

Operating safety information ......................................................................................... 6

Important notes and warnings ....................................................................................... 6

Disinfectants .................................................................................................................... 7

Deproteinizer .............................................................................................................7

Other disinfectants .................................................................................................... 7

ESD protection measures ................................................................................................ 8

Explanation of the phenomenon .............................................................................. 8

Influence of electrostatic charges on components ................................................... 8

Why is ESD protection so important today? ............................................................9

How can ESD protection be guaranteed? .................................................................9

Conclusion .................................................................................................................9

Chapter

1

Roche Diagnostics May 2009

Service Manual · Version 9.0 A-3

Page 14

1 Safety information cobas b 221 system

Tab le of co nt ent s

Roche Diagnostics May 2009

A-4 Service Manual · Version 9.0

Page 15

cobas b 221 system 1 Safety information

Important information

Important information

This Service Manual contains vital warning and safety information.

This instrument is only intended for one area of application which is described in the

instructions. The most important prerequisites for use, operation, and safety are

explained to ensure smooth operation. No warranty or liability claims will be covered

if the instrument is used in ways other than those described or if the necessary

prerequisites and safety measures are not observed.

The instrument may be operated only by persons whose qualifications enable them to

comply with the safety measures that are necessary during operation of the

instrument.

To avoid direct contact with biological materials, always wear appropriate protective

equipment such as lab clothing, protective gloves, safety glasses and, if necessary, a

face mask. Additionally a face shield must be worn if there is a potential of a

splashback. Appropriate disinfection and sterilization procedures must be followed.

To avoid direct contact with biological materials, wear lab clothing, protective gloves,

protective glasses and, if necessary, mouth cover and apply disinfection and

sterilization procedures.

Explanation

Adjustments and maintenance performed with removed covers and connected power

may be attempted only by a qualified technician who is aware of the associated

dangers.

Instrument repairs are only to be performed by the manufacturer or qualified service

personnel.

Only accessories and supplies either delivered by or approved by Roche are to be used

with the instrument. This ensures the performance and measuring accuracy of the

unit. These items are manufactured especially for use with this instrument and meet

the highest quality requirements.

Operation of the instrument with solutions whose composition is not consistent with

that of the original solutions' can negatively affect, above all, the long-term

measurement accuracy. Deviations in the composition of the solutions can also

decrease the service life of the electrodes.

The quality control requirements must be completed at least once daily for safety

reasons. Because the measurement results delivered by the instrument depend not

only on the instrument's proper operation but also on a variety of external influences

(for example: preanalytics), the results produced by this instrument should be

appraised by an expert before additional measures are taken based on the results.

Meaning: Important, see the cobas b 221 system Instructions for Use.

Roche Diagnostics May 2009

Service Manual · Version 9.0 A-5

Page 16

1 Safety information cobas b 221 system

Operating safety information

Operating safety information

The instrument has been constructed and tested according to the following

European Standards:

o IEC/EN 61010-1

o IEC/EN 61010-2-101

o IEC/EN 61010-2-081 + A1

It was delivered from the factory in flawless condition with regards to safety features.

In order to preserve this condition and ensure safe operation, the user must respect

the notices and warnings that are contained in this Service manual.

o This equipment is a Class I laser product, and it complies with FDA Radiation

Performance Standards, 21 CFR Subchapter J (only valid for cobas b 221<1/3/5>

systems with tHb/SO

o This instrument is classified under the protection class I according to

IEC/EN 61010-1.

o The instrument meets the conditions for overvoltage category II.

o The instrument meets the conditions for contamination level 2.

o Do not operate the instrument in an explosive environment or in the vicinity of

explosive anesthetic mixtures containing oxygen or nitrous oxide.

o If objects or liquids enter the internal areas of the instrument, remove the

instrument from its power supply and allow an expert to check it thoroughly

before using it again.

o The instrument is suitable for long-term operation indoors.

module).

2

o

The power cord may be plugged only into a grounded socket. When using an extension cord,

make sure it is properly grounded.

o

Any rupture of the ground lead inside or outside the instrument or a loose ground connection

can render hazardous operation of the instrument. Intentional disconnection of the grounding

is not permitted.

o

The instrument is not suitable for operation with a direct current power supply. Use only the

original mains plug delivered with the cobas b 221 system.

o

The use of controls or adjustments or performance of procedures other than those specified

herein may result in hazardous radiation exposure.

Important notes and warnings

o

Never operate the analyzer in the vicinity of volatile or explosive gases

(e.g. anesthetic gases, etc.)!

o

The instrument must be connected to a 2-pin, grounded socket.

o

The power cable and the plug must be undamaged. Damaged power cables and plugs must be

replaced immediately.

o

Before opening the back panel switch off the instrument and disconnect the power cable.

o

Replace damaged fuses with the specified type of fuse.

Roche Diagnostics May 2009

A-6 Service Manual · Version 9.0

Page 17

cobas b 221 system 1 Safety information

Disinfectants

o

Service and repair work must be done only as specified in this manual. Unqualified service or

repair work may result in warranty claims not being granted.

o

Use only suitable tools and test instruments for service and repair work.

o

Do not allow fluids to enter the interior of the instrument, because this may damage the

electronics.

o

Use only slightly moistened cloths or cotton sticks to clean the instrument.

Disinfectants

Use only liquid disinfectant such as protein remover (Roche deproteinizer) or an alcohol-based

(about 70%) surface disinfectant.

Do not spray disinfectant directly onto the instrument because this could cause malfunctions in the

electronics.

Do not use any type of bleaching agent. Exception: Roche Deproteinizer.

Deproteinizer

Composition Aqueous NaOCl solution with active chlorine (≤ 2%)

Hazards identification Due to the basic and oxidizing character of the reagent ("Deproteinizer") local

First aid measures

Other disinfectants

Do not attempt to clean/decontaminate any part of the instrument before shutting it down and

unplugging it from the power source.

Before plugging in the instrument again and switching it on always wait for 15 minutes to allow the

disinfectant to evaporate.

irritations after contact with eyes, skin or mucous membranes cannot be excluded.

After inhalation:

After skin contact:

After eye contact:

After drinking:

breath fresh air, drink large amounts of water

wash with generous amounts of water, remove contaminated clothing

rinse eyes with generous amounts of water, contact an eye specialist

drink large amounts of water, avoid vomiting, contact a doctor

Use standard alcohol-based (70%) disinfectants to clean the surface of the

instrument. Read the product information first.

Never use standard disinfectant to clean the tubes and tubing paths under any circumstances!

Do not use any type of bleaching agent. Exception: Roche Deproteinizer.

Roche Diagnostics May 2009

Service Manual · Version 9.0 A-7

Page 18

1 Safety information cobas b 221 system

ESD protection measures

ESD protection measures

ESD = Electrostatic Sensitive Device

Explanation of the phenomenon

The most frequent cause of electrostatic discharge is friction of various materials such

as plastic, synthetic fiber, hard rubber or paper.

It can also be caused by bending or applying pressure to a material.

Discharges that are dangerous to components occur when "charged" bodies or

components do not have a discharge connection (ground) to discharge the

electrostatic charge.

The discharges normally do not have a high capacity, but there are often voltage

differences in the range of several thousand volts. The discharges are perceived as

small shocks or visible sparks.

Examples: o Shoes with rubber soles:

Friction is caused by walking. A person develops an electrical charge different

from the ground. A discharge occurs when an object (e.g. door handle) is

contacted.

o Synthetic fiber clothing:

Discharge is audible and is visible in darkness.

The dryer the air the greater the risk of electrical discharge caused by friction.

Eectrostatic charges are less likely to build up in humid air, particularly when saturated with water

vapor.

The probability of ESD phenomena is therefore particularly great in a northern hemisphere winter

in centrally heated rooms where the humidity is low.

Influence of electrostatic charges on components

If a person with an electrostatic charge touches a component, a discharge over a

connection of an IC or semiconductor element may occur. The resulting voltages may

damage the component.

Critical situations can occur while repairing or testing components if they are lying

on a more or less conductive surface (e.g. table top) and a person with an electrostatic

charge touches them. A discharge through a critical component connection can also

occur in this case.

Roche Diagnostics May 2009

A-8 Service Manual · Version 9.0

Page 19

cobas b 221 system 1 Safety information

ESD protection measures

Why is ESD protection so important today?

Formerly, current controlling semiconductors were mostly used (TTL, normal

transistors, etc.).

Today the principle of current logic is virtually the only technology in use in MOS

and CMOS components.

Currents generated by an electrostatic discharge (as much as several kV!) destroy the

sensitive component inputs or cause hidden damage. This damage is generally not

immediately detectable.

Another effect is that the clearances inside the ICs continuously become smaller. The

internal wires become thinner and thinner, the allowable maximum input voltages

become smaller and the effects of any discharges become more and more critical.

How can ESD protection be guaranteed?

A continuous discharge is required when working on an electronic assembly. Do this

as follows:

o Use ESD wrist bands (special wrist bands connected to a protective ground).

o Repairs and tests on assemblies must only be conducted on tables with ESD mats

connected to grounds or ESD wrist bands.

o Always pick up components at the edge (e.g. like a photo).

o Components must always be transported in ESD packages or appropriate storage

or shipping containers (use original packaging!).

o Shoes with rubber soles or clothing of synthetic fibers must not be worn in

workshops where electronic components are repaired.

o Use a humidifier if necessary to maintain optimum humidity in the work area.

o Do not touch assemblies or components with the hand after testing.

o Always transport and ship assemblies or components for repair in ESD protective

packaging only. This will prevent further damage that may result in

misinterpretation of the original cause of the fault.

The ESD mat consists of materials that have a very low, defined conductivity (1012 ohms).

The following materials prevent charges caused by friction from building up and protect the

component from damage.

o

ESD mats

o

ESD packages

o

Shipping containers

Conclusion

Of course, not all circuit boards and electronic assemblies require such careful

handling. An electrical board that only carries simple plug connectors does not

require ESD packaging.

In cases of doubt always use ESD packaging.

Roche Diagnostics May 2009

Service Manual · Version 9.0 A-9

Page 20

1 Safety information cobas b 221 system

ESD protection measures

Roche Diagnostics May 2009

A-10 Service Manual · Version 9.0

Page 21

cobas b 221 system 2 Fluid actions

Tab le of co nt ent s

Fluid actions

This chapter provides information about the fluidic actions of the cobas b 221 system.

In this chapter

Fluid actions overview ..................................................................................................13

cobas b 221<1> system ...........................................................................................13

cobas b 221<2> system ...........................................................................................14

cobas b 221<3> system ...........................................................................................15

cobas b 221<4> system ...........................................................................................16

cobas b 221<5> system ...........................................................................................17

cobas b 221<6> system ...........................................................................................18

Pin assignment of S2 and S3 Fluid Packs ..................................................................... 19

S2 Fluid Pack ............................................................................................................19

S3 Fluid Pack A (cobas b 221<5/6> systems only) ................................................ 19

T&D positions ...............................................................................................................20

Measurement .................................................................................................................21

Sample input ............................................................................................................ 21

Sample distribution ................................................................................................. 23

Aspirating MSS standby solution and starting FMS .............................................25

Washing the measuring chamber vicinity ..............................................................27

Wash i ng t Hb/ SO

Recalibrating BG/ISE and drying tHb/SO

Calibration .....................................................................................................................31

BG/ISE cleaning ....................................................................................................... 31

Calibrating the conductivity for CAL A or CAL B ................................................32

O

zero point calibration ........................................................................................34

2

Na conditioning .......................................................................................................35

Mix1/Mix2 calibration, aspirating BG/ISE reference solution .............................36

O2-air calibration .................................................................................................... 38

Aspirating MSS reference solution, calibration with standby solution ................ 39

CAL 1 Calibration ...................................................................................................41

or COOX and preparing Mix1 .................................................28

2

or COOX ...........................................29

2

Chapter

2

Roche Diagnostics May 2009

Service Manual · Version 9.0 A-11

Page 22

2 Fluid actions cobas b 221 system

Tab le of co nt ent s

CAL 2/CAL 3/CAL 4 Calibration ........................................................................... 42

COOX calibration ...................................................................................................43

Roche Diagnostics May 2009

A-12 Service Manual · Version 9.0

Page 23

cobas b 221 system 2 Fluid actions

Fluid actions overview

Fluid actions overview

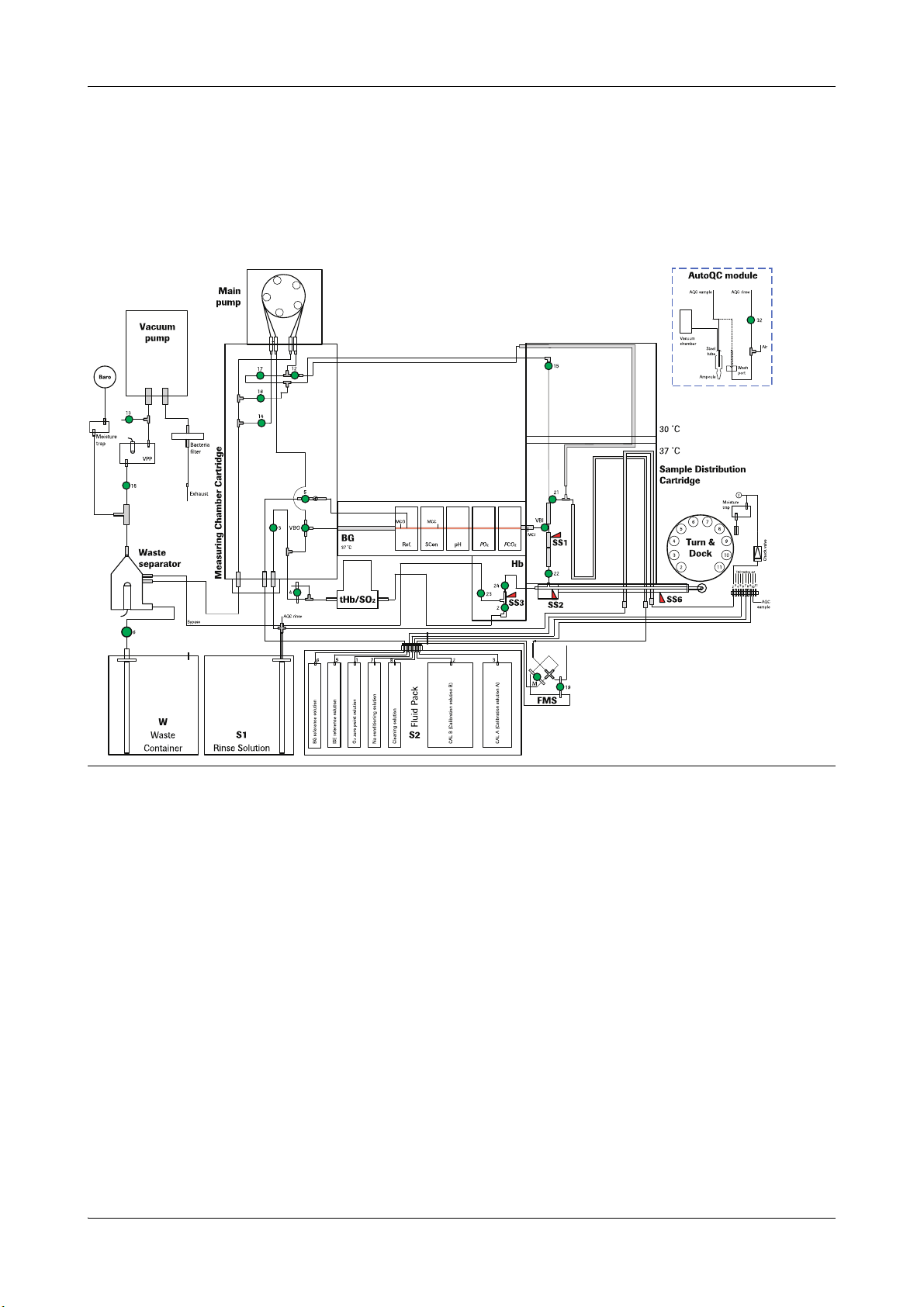

cobas b 221<1> system

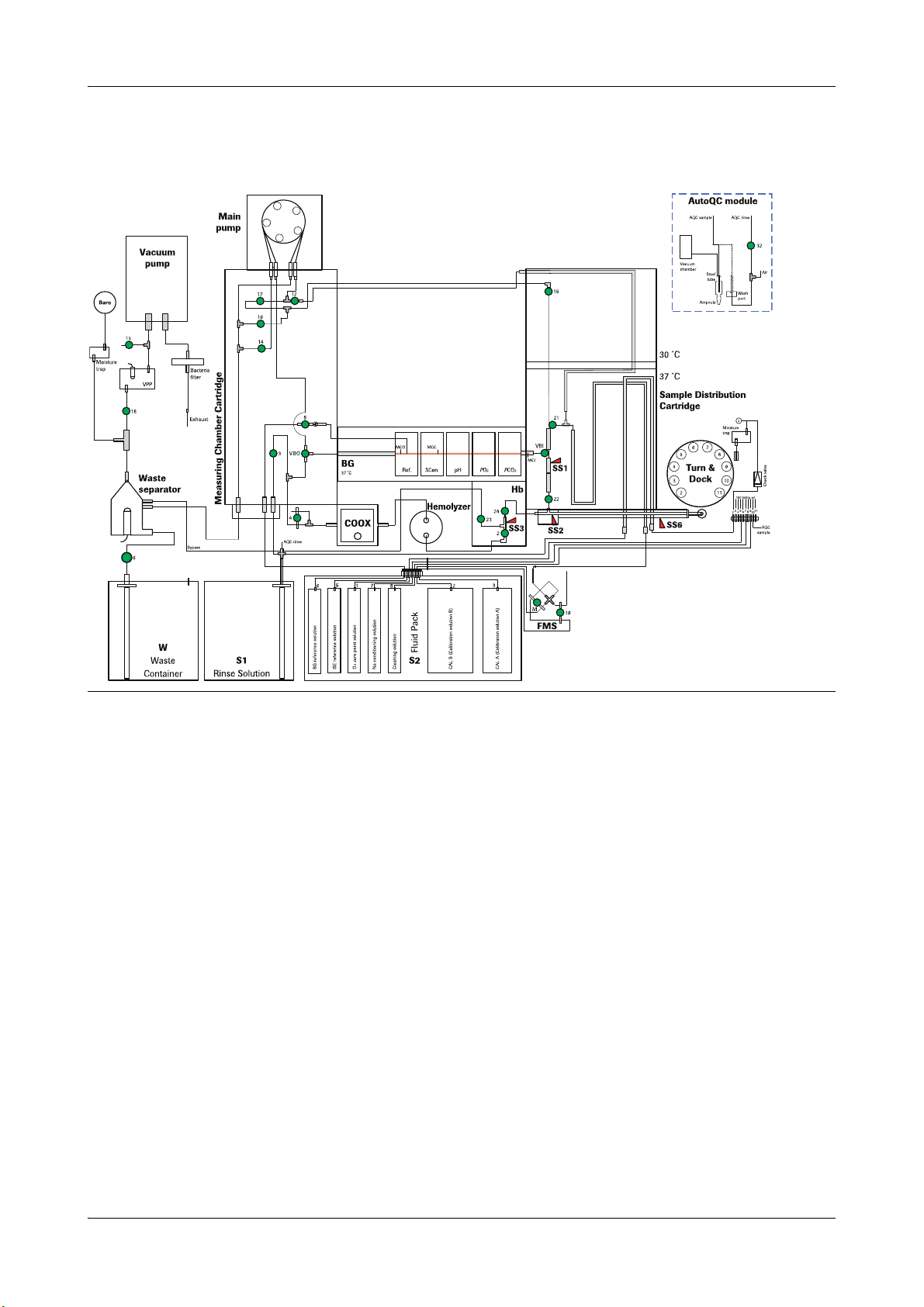

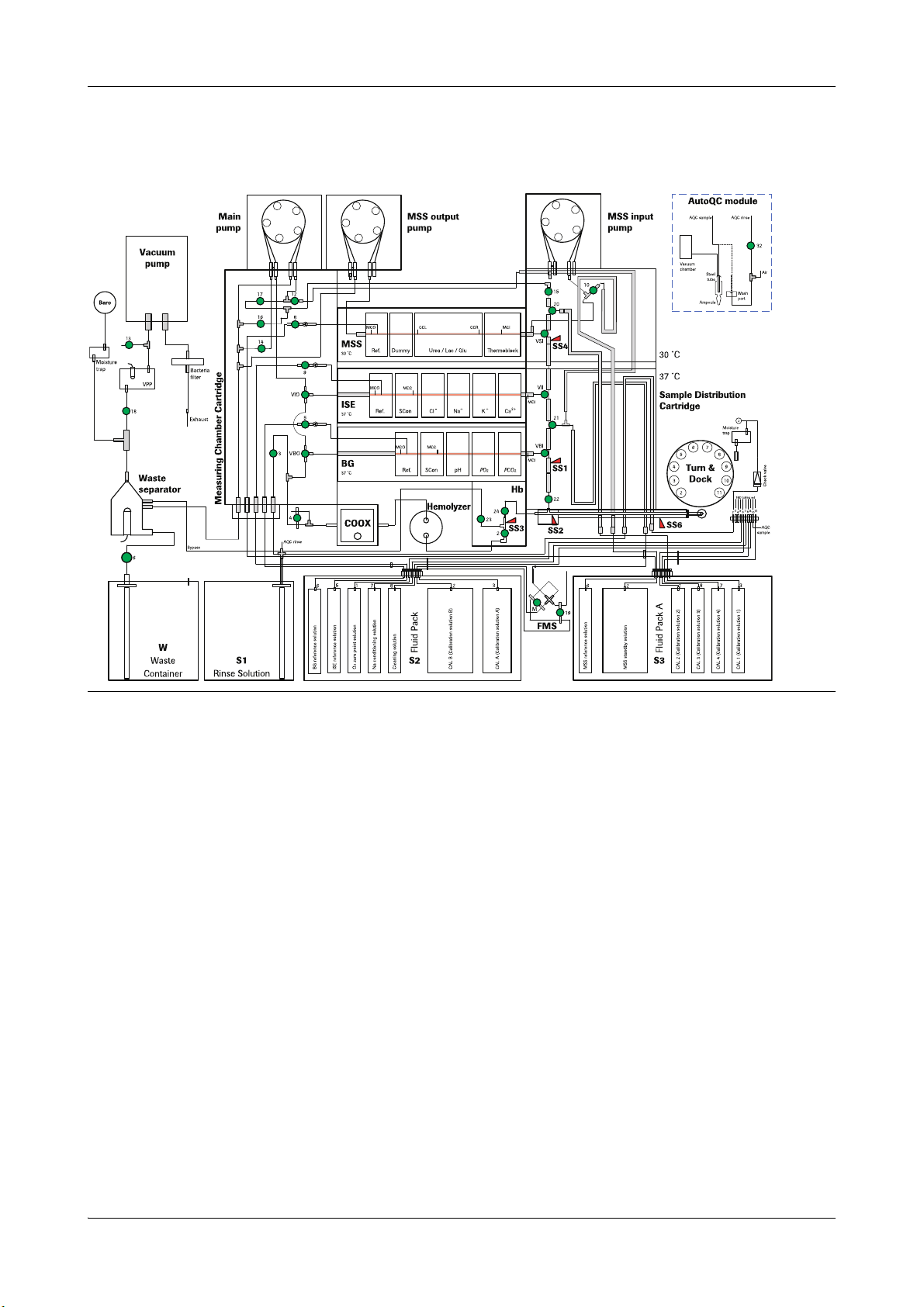

Figure A-1 cobas b 221<1> system

Roche Diagnostics May 2009

Service Manual · Version 9.0 A-13

Page 24

2 Fluid actions cobas b 221 system

Fluid actions overview

cobas b 221<2> system

Figure A-2 cobas b 221<2> system

Roche Diagnostics May 2009

A-14 Service Manual · Version 9.0

Page 25

cobas b 221 system 2 Fluid actions

Fluid actions overview

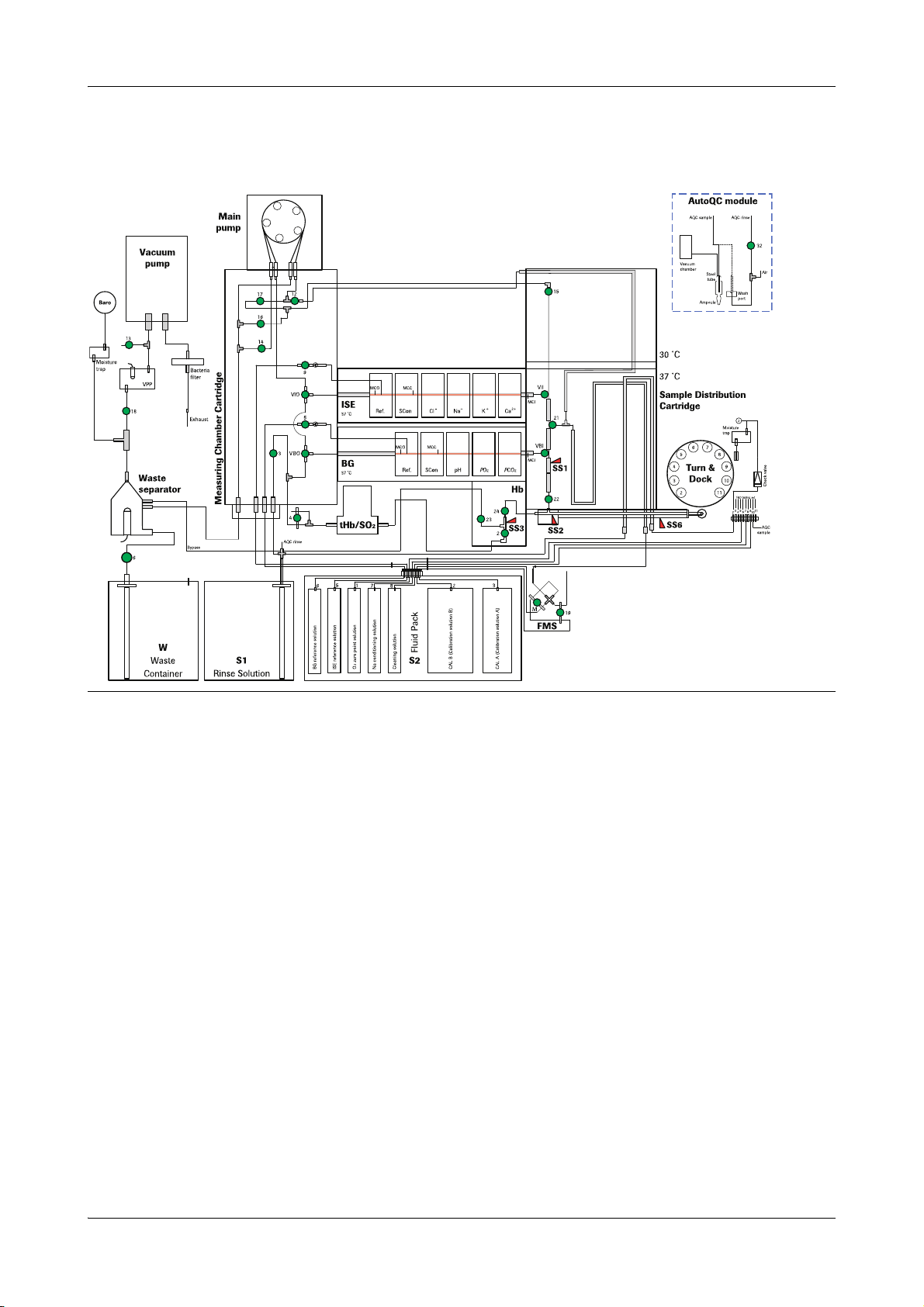

cobas b 221<3> system

Figure A-3 cobas b 221<3> system

Roche Diagnostics May 2009

Service Manual · Version 9.0 A-15

Page 26

2 Fluid actions cobas b 221 system

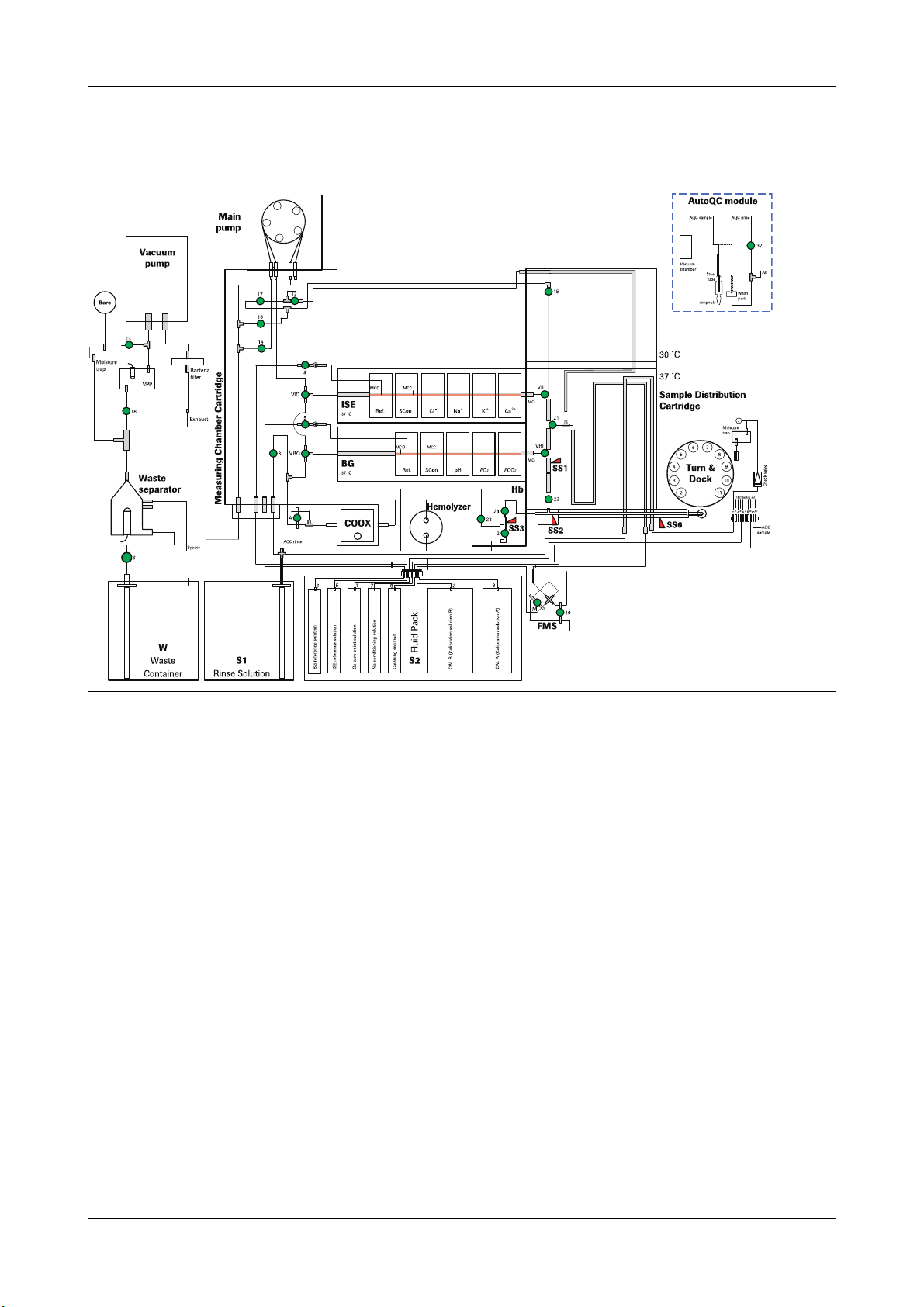

Fluid actions overview

cobas b 221<4> system

Figure A-4 cobas b 221<4> system

Roche Diagnostics May 2009

A-16 Service Manual · Version 9.0

Page 27

cobas b 221 system 2 Fluid actions

Fluid actions overview

cobas b 221<5> system

Figure A-5 cobas b 221<5> system

Roche Diagnostics May 2009

Service Manual · Version 9.0 A-17

Page 28

2 Fluid actions cobas b 221 system

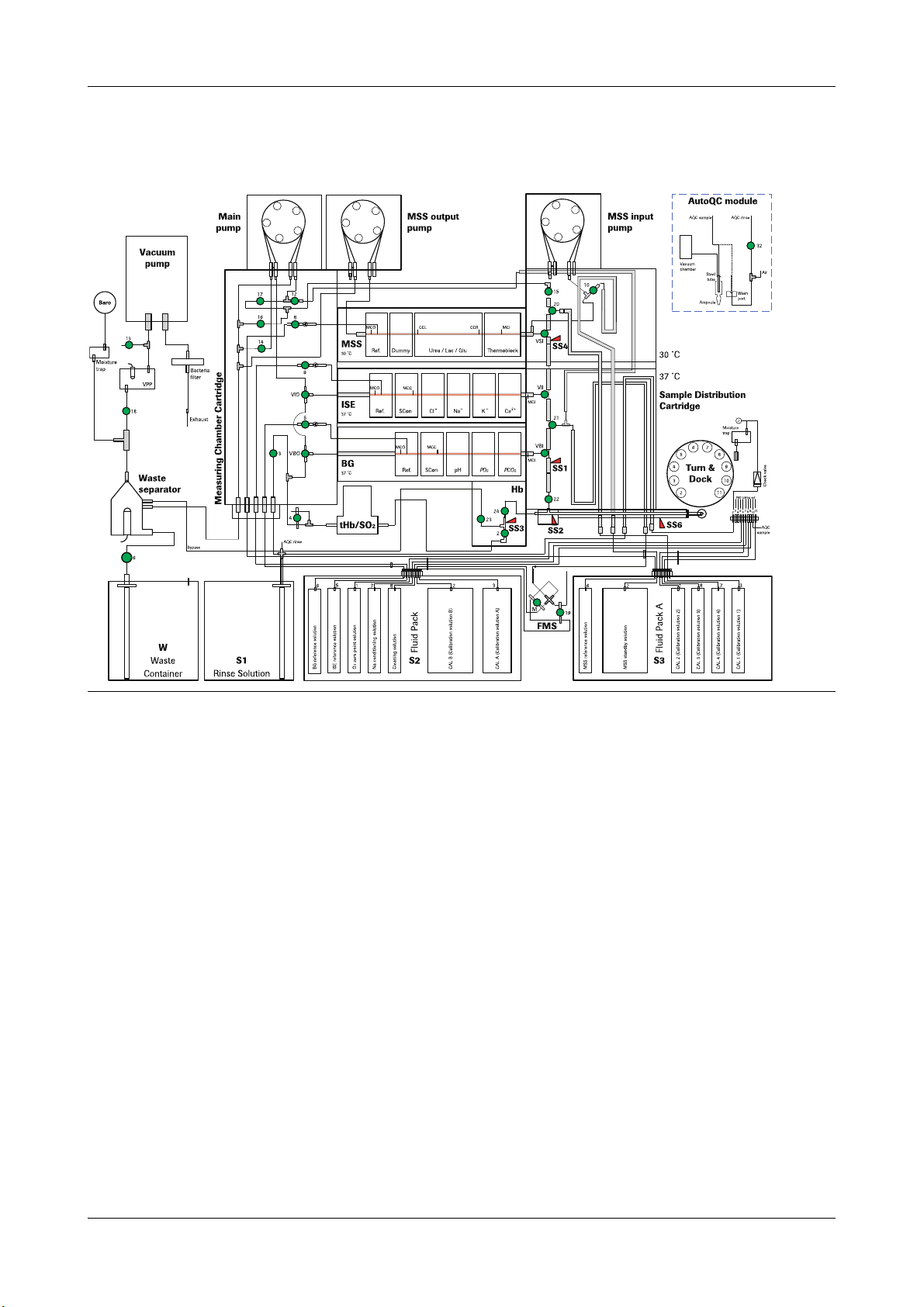

Fluid actions overview

cobas b 221<6> system

Figure A-6 cobas b 221<6> system

Roche Diagnostics May 2009

A-18 Service Manual · Version 9.0

Page 29

cobas b 221 system 2 Fluid actions

C

D

F

E

B

A

G

H

C

D

F

E

B

A

G

H

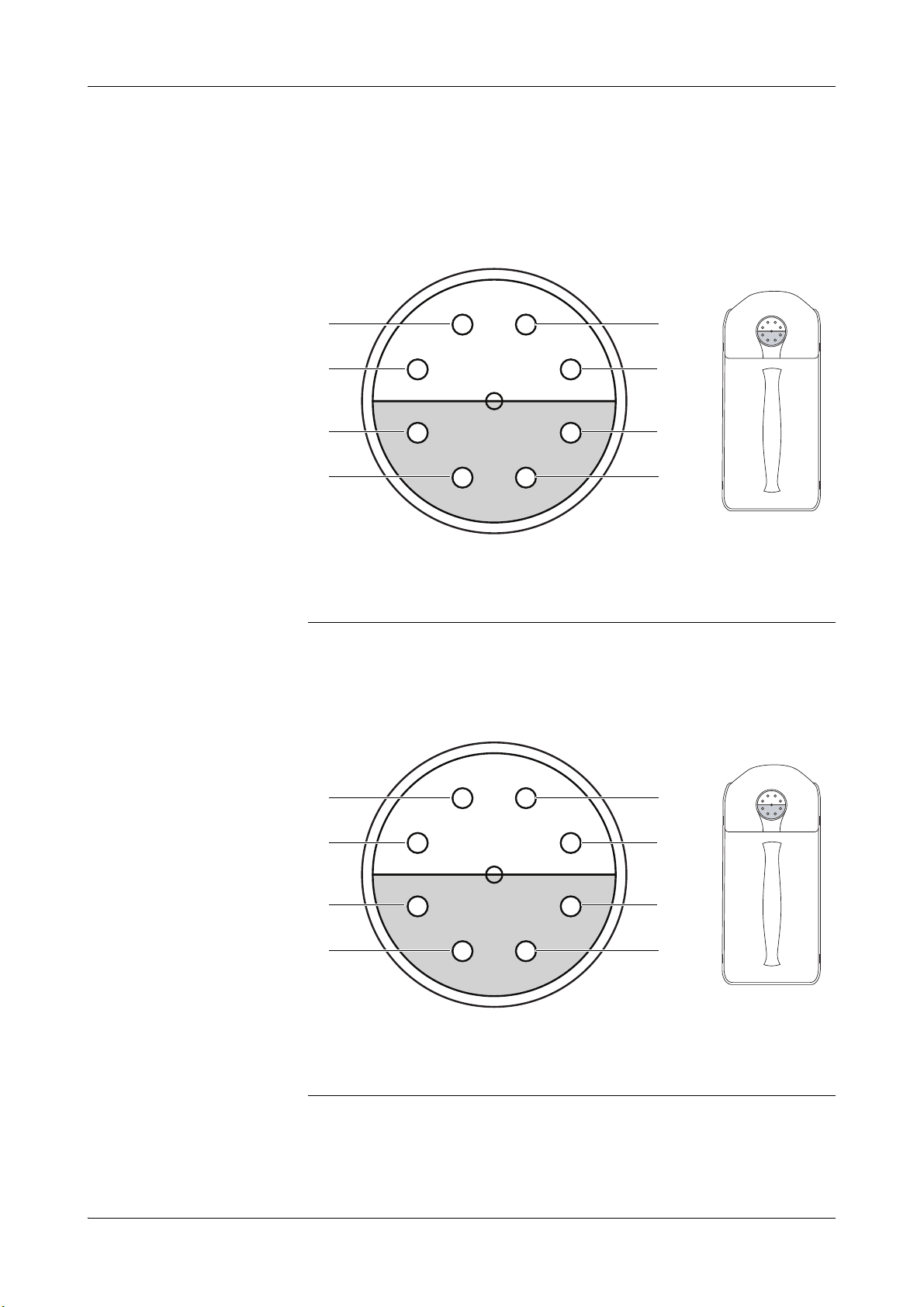

Pin assignment of S2 and S3 Fluid Packs

Pin assignment of S2 and S3 Fluid Packs

S2 Fluid Pack

A O2 zero point solution

B CAL B (calibration solution)

C CAL A (calibration solution)

D empty

Figure A-7 Pin assignment of S2 Fluid Pack

S3 Fluid Pack A (cobas b 221<5/6> systems only)

E ISE reference solution

F BG reference solution

G Na conditioning solution

H Cleaning solution

A CAL 2 (calibration solution 2)

B MSS standby solution

C CAL 1 (calibration solution 1)

Roche Diagnostics May 2009

Service Manual · Version 9.0 A-19

D empty

Figure A-8 Pin assignment of S3 Fluid Pack A

E empty

F MSS reference solution

G CAL 4 (calibration solution 4)

H CAL 3 (calibration solution 3)

Page 30

2 Fluid actions cobas b 221 system

D

C

A

B

E

F

I

J

K

H

G

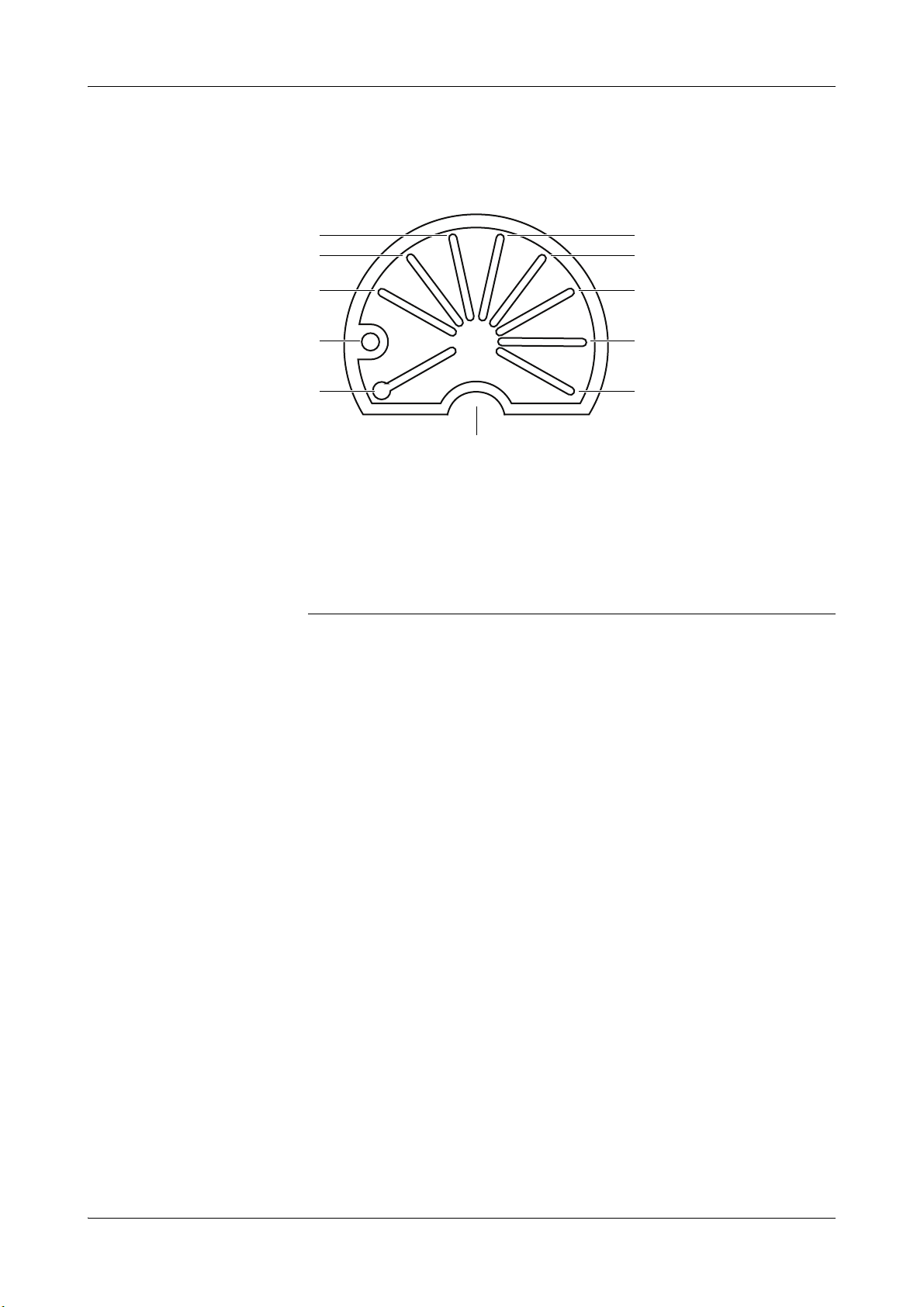

T&D positions

T&D positions

A 1: Releases the fill port for placing a sample

B 2: S1 Rinse Solution

C 3: Position for "aspiration from the syringe“

D 4: Dock position

E 5: O

F 6: CAL 2 from S3 Fluid Pack A

Figure A-9 T&D positions

zero point solution from S2 Fluid Pack

2

(cobas b 221<5/6> systems only)

G 7: Na conditioning solution from S2 Fluid

Pack

H 8: CAL 3 from S3 Fluid Pack A

(cobas b 221<5/6> systems only)

I 9: Cleaning solution from S2 Fluid Pack

J 10: AutoQC connection

K 11: CAL 4 from S3 Fluid Pack A

(cobas b 221<5/6> systems only)

Roche Diagnostics May 2009

A-20 Service Manual · Version 9.0

Page 31

cobas b 221 system 2 Fluid actions

A

B C D E F G

Measurement

Measurement

Sample input

Injecting sample

A V24

B Waste separator

Figure A-10 Injecting sample

C V23

D SS3

Sample path: o fill port >

E SS2

F SS6

G Fill port

The sample container is detected by a light barrier on the T&D module.

o sample inlet path >

o SS2

o When the sample has reached SS2 the user is prompted (by beeping and prompt

window) to remove the sample container.

Roche Diagnostics May 2009

Service Manual · Version 9.0 A-21

Page 32

2 Fluid actions cobas b 221 system

A

B

C

Measurement

Excess sample material: o V24 (open) >

o V23 (open) >

o Bypass >

o Waste separator

Aspirate sample

A Main pump

B SS2

Figure A-11 Aspirate sample

Sample path: o fill port >

C Fill port

The sample container is detected by a light barrier on the T&D module. The sample is

aspirated through the cross channel with the main pump.

o sample inlet path >

o SS2

o When the sample has reached SS2 the user is prompted (by beeping and prompt

window) to remove the sample container.

Roche Diagnostics May 2009

A-22 Service Manual · Version 9.0

Page 33

cobas b 221 system 2 Fluid actions

C

A

B

DEF

G

F

LKJ

H/I

I

Measurement

Sample distribution

A Waste separator

B Wash rail

C Main pump

D MSS output pump

E Position MSS

F Position ISE

G Separate MSS

Figure A-12 Sample distribution

H Separate BG

I Position BG, separate ISE

J Separate tHb/SO

K Position tHb/SO2 or COOX

L S1 Rinse solution

When the sample is detected by SS2 the sample distribution is started. The sequence

of the individual aspiration phases depends on the existing or requested modules.

or COOX

2

Separating BG: The start of the sample is aspirated from SS2 to SS1. The volume SS2-SS1 is specified

for filling the BG measuring chamber.

Separating tHb/SO

or COOX: One sample segment is aspirated from SS2 to SS3. The volume SS2-SS3 is specified for

2

filling the tHb/SO2 or COOX module.The user can specify in the setup whether

tHb/SO2 / COOX or ISE is separated first.

Roche Diagnostics May 2009

Service Manual · Version 9.0 A-23

Page 34

2 Fluid actions cobas b 221 system

Measurement

Positioning BG and

separating ISE:

This aspiration process assumes that the sample column tip is at SS1. It is aspirated

via VBI and VBO with the main pump. The start of the sample movement is detected

by the conductivity (breaking of the calibration solution column in the measuring

chamber). If this does not occur at the right time, an aspiration error is displayed. The

positioning of the sample is controlled by the MCI-MCO contact path. If a timeout

occurs because an excessively low signal or a non-reproducible conductivity signal, an

aspiration error is displayed. During the aspiration the sample is "observed" with SS1;

if the volume of the sample is too small, this interferes with the aspiration process.

After closing the VBI the ratio of the conductivities of MCI-MCO to MCI-MCC is

checked. If there are air bubbles in the MCI-MCO area, this can result is the

aspiration process restarting and the VBI opening again. When the corresponding

conductivity level is reached, the positioning of the sample is complete.

During the BG positioning ISE is separated between SS2 and SS1.

Positioning ISE: This aspiration process is similar to positioning BG. If an ISE measurement is not

required, the remainder of the sample is aspirated to VII through the sample

distributor to establish the required initial state for a subsequent MSS positioning.

Separating MSS and

A sample segment is aspirated to the SS4.

washing rail:

Positioning MSS: The sample is aspirated by turning the MSS output pump and opening the VSI. The

tearing of the standby solution and the start of the sample is detected by the

conductivity at the MSS input. Then it must also be possible to detect the tearing of

the standby solution and the sample start, at which the MSS output pump is stopped.

The completed sample positioning is checked again for freedom from bubbles via the

conductivity distances.

Positioning tHb/SO

or COOX: The sample segment for measurement of tHb/SO2 or COOX is positioned last. The

2

valves V2, V4, V17 and V16 are opened and aspirated with the main pump. The

sample is still hemolyzed in the event of a COOX measurement.

Roche Diagnostics May 2009

A-24 Service Manual · Version 9.0

Page 35

cobas b 221 system 2 Fluid actions

ABC

G

F

E

D

Measurement

Aspirating MSS standby solution and starting FMS

A MSS output pump

B MSS input pump

C Aspirating MSS standby solution

D CAL B

Figure A-13 Aspirating MSS standby solution and starting FMS

The MSS is positioned in four subsections:

Preconditioning by aspiration of

standby solution (1)

This process is done before aspiration of the sample. A little reference solution is

aspirated via V8 and the MSS reference electrode and is checked with the conductivity

section at the MSS output.

e

For more information, see Aspirating MSS reference solution, calibration with standby

solution on page A-39.

Then the measuring chamber is filled with standby solution.

E CAL A

F Starting FMS

G MSS standby solution

Roche Diagnostics May 2009

Service Manual · Version 9.0 A-25

Page 36

2 Fluid actions cobas b 221 system

Measurement

Aspirate sample The sample is aspirated by turning the MSS output pump and opening the VSI.

e

For more information, see Sample distribution on page A-23.

The tearing of the standby solution and the start of the sample is detected by the

conductivity at the MSS input. Then it must also be possible to detect the tearing of

the standby solution and the sample start, at which the MSS output pump is stopped.

The completed sample positioning is checked again for freedom from bubbles via the

conductivity distances.

Aspiration of standby solution

(2) to determine glu and lac

Aspiration of standby solution

(3) to determine urea

The determination of the MSS measurement values is always based on the reference

potential of the standby solution; for this reason the MSS cassette is filled with

standby solution (by stopping the MSS input pump) after washing out the sample

(with a mixture of standby solution and air by rotating the two MSS pumps). The

quality of the aspiration is assessed by the conductivity distance at the MSS output.

The MSS input pump is used to fill the tube in the lateral channel (with standby

solution), for defined aspiration (aspirating the standby solution) of the MSS

measuring chamber cassette and for washing valve V10.

The MSS cassette is filled with standby solution again. The quality of the aspiration

and the stroke (after repeated aspiration of standby solution) is assessed by the

conductivity distance at the MSS output.

The sample segment for measurement of tHb/SO

or COOX is positioned last. The

2

valves V2, V4, V17 and V16 are opened and aspirated with the main pump.

e

For more information, see Sample distribution on page A-23.

The sample is still hemolyzed in the event of a COOX measurement.

At the same time the FMS is started for these procedures (for the pending

recalibration of the BG and ISE modules) and mixed from the A and B Mix1

solutions.

Roche Diagnostics May 2009

A-26 Service Manual · Version 9.0

Page 37

cobas b 221 system 2 Fluid actions

A B

DC

Measurement

Washing the measuring chamber vicinity

A Vacuum pump

B T&D module (position 2)

Figure A-14 Washing the measuring chamber vicinity

C Waste separator

D S1 Rinse solution

This section is used to clean sample residues from the aspiration path, the bypass and

the sample distributor.

The T&D disk docks at position 2 (S1 Rinse solution); then a rinse solution-air mix is

aspirated into the waste separator over the aspiration path and the bypass or the

sample distributor (with V15 and V16 open) by creating a low pressure with the

vacuum pump. The correct rinse solution to air ratio is assessed with the SS2 sensor.

Roche Diagnostics May 2009

Service Manual · Version 9.0 A-27

Page 38

2 Fluid actions cobas b 221 system

AB

G

D

C

F

E

Measurement

Washing tHb/SO2 or COOX and preparing Mix1

A Vacuum pump

B Main pump

C Preparing Mix1

D Waste separator

Figure A-15 Washing tHb/SO2 or COOX and preparing Mix1

When the measuring chamber area is clean, the tHb/SO2 or COOX module is washed.

The vacuum pump runs rinse solution "in the reverse direction" from V3 through the

measuring module to the Hb cartridge; air packets are mixed in through V4 to

increase the cleaning effect.

Mix1 is aspirated from the FMS to the FMS tube simultaneously.

Then the measuring chamber area is dried. During this procedure the T&D disk is

undocked with the vacuum pump running until the measuring chamber area is dry.

The valve positions are the same as when washing the measuring chamber area.

e

For more information, see Washing the measuring chamber vicinity on page A-27.

E S1 Rinse solution

F Washing tHb/SO

G FMS

or COOX

2

Roche Diagnostics May 2009

A-28 Service Manual · Version 9.0

Page 39

cobas b 221 system 2 Fluid actions

A B C

GFED

Measurement

Recalibrating BG/ISE and drying tHb/SO2 or COOX

A Vacuum pump

B Main pump

C Recalibrating BG/ISE

D Waste separator

Figure A-16 Recalibrating BG/ISE and drying tHb/SO2 or COOX

E V4

F Drying tHb/SO

G FMS

2

To recalibrate BG and ISE the main pump first aspirates a mixture of air (from a

reservoir between sample distributor and measuring chamber cartridge) and Mix1

through the measuring chambers. When this has sufficiently washed them, the

measuring chambers are filled with Mix1 by shutting off the air feed.

This filling is assessed by conductivity measurement: with liquid solution a stable and

plausible value must be measured between MCI and MCO.

Then the inlet valve is closed and reference solution is aspirated through valves V5 or

V9 until a clear increase in conductivity between MCI and MCO can be detected.

e

For more information, see Mix1/Mix2 calibration, aspirating BG/ISE reference solution on

page A-36.

or COOX

Roche Diagnostics May 2009

Service Manual · Version 9.0 A-29

Page 40

2 Fluid actions cobas b 221 system

Measurement

Finally the outlet and reference valves are closed and the conductivity is checked

again.

After each washing of the BG or ISE, the rail is washed and emptied to counteract

electrical couplings to the pump elastomer.

Along with the recalibration the tHb/SO

or COOX module is dried. Air is aspirated

2

into the waste separator with the vacuum pump through V4, measuring module, V2

and V23.

Before the instrument is released for the next measurement, Mix1 residue is aspirated

into the waste separator with the main pump with valves V22, V15 open.

Roche Diagnostics May 2009

A-30 Service Manual · Version 9.0

Page 41

cobas b 221 system 2 Fluid actions

C

A B

D

Calibration

Calibration

BG/ISE cleaning

A Main pump

B T&D module (position 9)

Figure A-17 BG/ISE cleaning

C Waste separator

D Cleaning solution

This procedure removes deposits in the BG or ISE measuring chamber. The required

cleaning solution is in the S2 Fluid Pack and is aspirated into the measuring chambers

through the T&D disk (position 9), the aspiration channel and the sample distributor.

The calibration of the conductivity is performed next.

Roche Diagnostics May 2009

Service Manual · Version 9.0 A-31

Page 42

2 Fluid actions cobas b 221 system

A

C DB

Calibration

Calibrating the conductivity for CAL A or CAL B

A Main pump

B CAL B

Figure A-18 Calibrating the conductivity for CAL A or CAL B

FMS adjustment: This procedure starts by aspirating the FMS through V19 (air) until it is empty. After

a short pressure equalization V19 is closed and CAL B is aspirated into the BG

measuring chamber (

CAL B must be detected in the BG measuring chamber by the conductivity measuring

distance within a set period (after 9.64 sec at the earliest and after 12.34 sec at the

latest).

C CAL A

D FMS

e

Figure A-18).

Roche Diagnostics May 2009

A-32 Service Manual · Version 9.0

Page 43

cobas b 221 system 2 Fluid actions

Calibration

Calibrating the conductivity for

CAL B

Calibrating the conductivity for

CAL A

In this section the conductivity of calibration solution CAL B is precisely measured in

the BG and ISE measuring chamber. The precision of this measurement is very

significant for Mix1 and Mix2, because they are based on this measurement.

CAL B is already in the sample distributor at V21. The BG measuring chamber is

cleaned with a mixture of air and CAL B after the FMS adjustment. Then the BG

measuring chamber is filled with CAL B with no air bubbles and the conductivity is

determined.

Then CAL B is aspirated into the ISE measuring chamber and also measured there.

This procedure is similar to the calibration of the conductivity for CAL B, with the

only difference being that a FMS adjustment is not made first.

Roche Diagnostics May 2009

Service Manual · Version 9.0 A-33

Page 44

2 Fluid actions cobas b 221 system

ED

A

B C

Calibration

O2 zero point calibration

A Main pump

B O2 electrode

C T&D module (position 5)

Figure A-19 O2 zero point calibration

This procedure determines the second calibration point of the O2 electrode. The O2

zero point solution is in the S2 Fluid Pack and is aspirated into the BG measuring

chamber with the vacuum pump and the main pump through the T&D disk (position

5) and the aspiration channel through SS2 and SS1.

After completing this procedure the measuring chamber area is briefly washed.

e

D Waste separator

E O2 zero point solution

For more information, see Washing the measuring chamber vicinity on page A-27.

Roche Diagnostics May 2009

A-34 Service Manual · Version 9.0

Page 45

cobas b 221 system 2 Fluid actions

A

F

B C D

E

Calibration

Na conditioning

A Vacuum pump

B Main pump

C Na electrode

Figure A-20 Na conditioning

D T&D module (position 7)

E Waste separator

F Na conditioner

This procedure is necessary to retain the sensitivity of the Na electrode. The Na

conditioner is in the S2 Fluid Pack and is aspirated into the ISE measuring chamber

with the vacuum pump and the main pump through the T&D disk (position 7) and

the sample inlet path through SS2 and SS1.

After this procedure the measuring chamber area is washed, and the tHb/SO

2

or

COOX module is also washed and Mix1 is prepared.

e

For more information, see:

Washing the measuring chamber vicinity on page A-27

Washing tHb/SO

or COOX and preparing Mix1 on page A-28

2

In the case of the tHb/SO2 module a calibration is conducted during the washing

procedure by measuring the rinse solution values.

Roche Diagnostics May 2009

Service Manual · Version 9.0 A-35

Page 46

2 Fluid actions cobas b 221 system

A DB C

IE F G H

Calibration

Mix1/Mix2 calibration, aspirating BG/ISE reference solution

A Main pump

B Aspirating BG reference solution

C Aspirating ISE reference solution

D Mix1/Mix2 Calibration

E BG Reference solution

Figure A-21 Mix1/Mix2 calibration, aspirating BG/ISE reference solution

F ISE Reference solution

G CAL B

H CAL A

I FMS

Roche Diagnostics May 2009

A-36 Service Manual · Version 9.0

Page 47

cobas b 221 system 2 Fluid actions

Calibration

Mix1 Calibration This section refers to the BG and ISE measuring chamber only. The Mix1 mixture is

prepared similarly to a recalibration in the sample distributor after a measurement

and is ready for entry to the measuring chamber at V21.

e

For more information, see Recalibrating BG/ISE and drying tHb/SO2 or COOX on

page A-29.

The main pump first aspirates a mixture of air (from a reservoir between sample

distributor and measuring chamber cartridge) and Mix1 through the measuring

chambers. When this has sufficiently washed them, the measuring chambers are filled

with Mix1 by shutting off the air feed.

This filling is assessed by conductivity measurement: with liquid solution a stable and

plausible value must be measured between MCI and MCO.

Then the inlet valves are closed and reference solution is aspirated through valves V5

or V9 until a clear increase in conductivity between MCI and MCO can be detected.

Finally the outlet and reference valves are closed and the conductivity is checked

again.

Mix2 Calibration The fluid procedure corresponds exactly to the Mix1 calibration.

The only difference is the mixture ratio of CAL A and CAL B:

Mix1: 33.3% CAL A

66.6% CAL B

Mix2: 60.0% CAL A

40.0% CAL B

The Mix2 calibration determines the slopes of the BG electrodes CO

with all ISE electrodes.

and pH along

2

Roche Diagnostics May 2009

Service Manual · Version 9.0 A-37

Page 48

2 Fluid actions cobas b 221 system

A B C

Calibration

O2-air calibration

A Main pump

B O2 electrode

Figure A-22 O

C T&D module (position 4)

-air calibration

2

This procedure determines the first calibration point of the O2 electrode. Ambient air

is slowly aspirated from the T&D disk (position 4) into the BG measuring chamber

over the aspiration channel and sample distributor.

Then the electrodes are conditioned with Mix1.

e

For more information, see Mix1/Mix2 calibration, aspirating BG/ISE reference solution on

page A-36.

Roche Diagnostics May 2009

A-38 Service Manual · Version 9.0

Page 49

cobas b 221 system 2 Fluid actions

A B

C D E F

Calibration

Aspirating MSS reference solution, calibration with standby solution

A MSS output pump

B Calibration with standby solution

C Waste separator

Figure A-23 Aspirating MSS reference solution, calibration with standby solution

D Aspirating MSS reference solution

E MSS Reference solution

F MSS Standby solution

Roche Diagnostics May 2009

Service Manual · Version 9.0 A-39

Page 50

2 Fluid actions cobas b 221 system

Calibration

The MSS cassette is calibrated in the following sequence:

First a MSS standby solution packet is positioned through a metal pipe in the sample

distributor and valves V10 and VSI into the MSS measuring chamber which is called

"Ref. point D1". Following this one of the calibration solutions (CAL 1, CAL 2, CAL 3

or CAL 4) is aspirated and positioned into the MSS measuring chamber. After this

another MSS standby solution packet is positioned into the MSS measuring chamber

which is called "D2" and last followed by a third MSS standby solution packet called

"D3".

For instruments with Urea installed only: The reference measurement for urea is done

by aspirating reference solution after positioning the "D1" and the "D2" packets.

e

For more information, see:

CAL 1 Calibration on page A-41

CAL 2/CAL 3/CAL 4 Calibration on page A-42

Roche Diagnostics May 2009

A-40 Service Manual · Version 9.0

Page 51

cobas b 221 system 2 Fluid actions

A

C

B

D

Calibration

CAL 1 Calibration

A MSS output pump

B V20

Figure A-24

C Waste separator

D Calibration solution CAL 1

This procedure determines the sensitivity of the sensors. CAL 1 is aspirated into the

MSS measuring chamber from the S3 Fluid Pack A through a metal pipe in the

sample distributor and valves V20 and VSI and measured. The positioning is checked

by conductivity measurements.

Roche Diagnostics May 2009

Service Manual · Version 9.0 A-41

Page 52

2 Fluid actions cobas b 221 system

A

C

B

D E F

Calibration

CAL 2/CAL 3/CAL 4 Calibration

A MSS output pump

B T&D module (CAL 2=Pos.6, CAL 3=Pos.8, CAL 4= Pos.11)

C Waste separator

Figure A-25 CAL 2/CAL 3/CAL 4 Calibration

CAL 2 Calibration This procedure determines the linearity of the sensors. CAL 2 is aspirated from the

S3 Fluid Pack A via the T&D disk (position 6), sample inlet path and sample

distributor into the MSS measuring chamber and measured.

CAL 3 Calibration This procedure determines the interference sensitivity of the sensors. CAL 3 is

aspirated from the S3 Fluid Pack A via the T&D disk (position 8), sample inlet path

and sample distributor into the MSS measuring chamber and measured.

CAL 4 Calibration This procedure determines the interference sensitivity of the sensors. CAL 4 is

aspirated from the S3 Fluid Pack A via the T&D disk (position 11), sample inlet path

and sample distributor into the MSS measuring chamber and measured.

D CAL 2

E CAL 3

F CAL 4

Roche Diagnostics May 2009

A-42 Service Manual · Version 9.0

Page 53

cobas b 221 system 2 Fluid actions

A

G

B

C D E F H

Calibration

COOX calibration

A Main pump

B Aspirate excess out

C Waste separator

D Position calibrator

Figure A-26 COOX calibration

E Separator COOX

F SS2

G Calibrator input

H Fill port

Roche Diagnostics May 2009

Service Manual · Version 9.0 A-43

Page 54

2 Fluid actions cobas b 221 system

Calibration

The calibration does not begin automatically but must be initiated by the user. The fill

port of the T&D module is released for input from an external tHb calibrator.

Once the SS2 sensor has detected the solution and the sample container has been

removed, the positioning begins: a separation at the SS3 sensor is made, then the

excess solution is aspirated out through the sample distributor. The calibration

solution is now aspirated through V2 and the hemolyzer through the cuvette with the

main pump. The optical measurement and storage of the cuvette layer thickness is

made here.

Finally the COOX module is washed and dried.

e

For more information, see:

Washing tHb/SO

Recalibrating BG/ISE and drying tHb/SO

or COOX and preparing Mix1 on page A-28

2

or COOX on page A-29

2

Roche Diagnostics May 2009

A-44 Service Manual · Version 9.0

Page 55

Servicing

3 Protected software functions . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

4 Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-15

5 AutoQC module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-117

B

May 2009

Page 56

Page 57

cobas b 221 system 3 Protected software functions

Tab le of co nt ent s

Protected software functions

This chapter provides information about the protected software functions of the

cobas b 221 system.

In this chapter

Protected setup ................................................................................................................5

Sample counter .......................................................................................................... 5

Baro settings ..............................................................................................................5

Miscellaneous settings ...............................................................................................6

Serial number ............................................................................................................6

Instrument type ......................................................................................................... 6

Polarization voltages ...............................................................................................10

COOX module (cobas b 221<2/4/6> systems only) ............................................. 10

AutoQC module ...................................................................................................... 10

Log monitor ............................................................................................................. 11

Protected system functions ........................................................................................... 11

System backup / restore ...........................................................................................11

AQC adjustment ...................................................................................................... 12

Protected infos ............................................................................................................... 12

Service log file export .............................................................................................. 12

Protected DB functions ................................................................................................. 13

Delete all databases .................................................................................................. 13

Delete databases & archives ....................................................................................13

Chapter

3

Roche Diagnostics May 2009

Service Manual · Version 9.0 B-3

Page 58

3 Protected software functions cobas b 221 system

Tab le of co nt ent s

Roche Diagnostics May 2009

B-4 Service Manual · Version 9.0

Page 59

cobas b 221 system 3 Protected software functions

A

Protected setup

Protected setup

Sample counter

This function allows manual editing of the internal sample counter. See Samples for

the sum of all samples input (can be edited by the keyboard symbol), QC samples for

the number of QC samples input (can be edited by the keyboard symbol) and

Measurements for the number of measurements made (can be edited by the keyboard

symbol).

Baro settings

This function allows various barometer settings to be manually edited.

The following options are available:

P_atm, SENS, ZERO In case of errors read the factory settings from the label on the vacuum control board

and type them in here. See Figure B-1 on page B-5.

Baro [mmHg] input the baro value with the keyboard symbol.

[Update EEPROM] this key allows the data of the vacuum EEPROM to be updated by the cobas b 221

system software. The data on the hard disk are written to the EEPROM.

A Label

Figure B-1 Baro settings, factory settings (label)

P_atm, SENS and ZERO are default settings which may only be changed in case of errors according

to the values on the label!

IMPORTANT:

o

From approx. 3000 m above sea level or air pressure < 526 mmHg (70.13 kPa), the

specifications for parameter PO

used for evaluation of the clinical decisions.

o

After successful installation, the parameter must be permanently deactivated!

are no longer fulfilled and the parameter must no longer be

2

Roche Diagnostics May 2009

Service Manual · Version 9.0 B-5

Page 60

3 Protected software functions cobas b 221 system

Protected setup

Miscellaneous settings

This function is used to activate various auxiliary programs and service actions.

The following options are available:

[Demo mode] This function simulates the cobas b 221 system with all measurement values for

demonstration purposes. The measurement values are not calibrated; instead they are

spread around a mean value.

[Logon with Operator ID] This function allows a user to logon to the instrument by entering the operator ID

only (without password).

[Measurement report

[Cal. intervals U.S.] This key reduces the 2P calibration interval of PO

[Service mode] This key activates an external keyboard connected to the cobas b 221 system.

[Hotline info] This key edits the information hotline (that appears under Customer Information).

[cobas b 221 auto.] This key will switch instruments with serial number > 5000 to cobas b 221 system.

Roche OMNI S]

Serial number

With deactivated function no operator ID will be printed on the measurement report.

operator ID]

from 72 hours to the 2P

2

calibration interval of the other parameters to correspond to specific legal

requirements in the USA.

[Bili] This key activates (green) or deactivates (red) the parameter bilirubin

(cobas b 221<2/4/6> systems only). If activated, bilirubin will be ready for

measurement after a calibration.

[cobas b 221

This key switches the instrument to Roche OMNI S or to the cobas b 221 system.

This function assigns a serial number after pressing the keyboard symbol. Be sure the

serial number is the same as the serial number on the name plate on the rear panel of

the instrument.

Instrument type

Changing instrument type

This function is used to define the instrument type that is valid for the respective

instrument. Marking the desired instrument types and pressing the key [Save and

exit] assigns the new type to the cobas b 221 system software.

The key [Load default setup] resets any changes made to the instrument type and

loads the default settings of the instrument stored on the hard disk.

Load the allowed default setup

It is only allowed to load the default setup according to the available module configuration.

Roche Diagnostics May 2009

B-6 Service Manual · Version 9.0

Page 61

cobas b 221 system 3 Protected software functions

Protected setup

Instrument Setup Configuration

cobas b 221<1> system 10 BG + tHb

cobas b 221<2> system 20 BG + COOX

cobas b 221<3> system 30 BG + ISE + tHb

cobas b 221<4> system 40 BG + ISE + COOX

cobas b 221<5> system 50 BG + ISE + tHb + Glu/Lac

cobas b 221<6> system 60 BG + ISE + COOX + Glu/Lac

61 BG + ISE + COOX + Glu/Lac/Urea

Ta b le B - 1 Instrument configurations

e

For details, see Fluid actions overview on page A-13.

After replacing the touch screen/PC unit or the hard disk, assign the valid instrument type and load

the default settings. When system stop 10005 occurs after replacing the touch screen/PC unit or the

hard disk and booting the PC, assign the valid instrument type and load the default settings.

Load default setup

Following default settings will be loaded depending on the instrument type:

Setting Default Comment

1P cal. interval 60 min

2P cal. interval 12 hours

System calibration interval 24 hours

System calibration start time 05:00

Full backup: Start day Sunday

Full backup: Start time 00:00

Incemental backup: Start time 00:00

DB export: compression OFF

DB export: separator 1;2

DB export: file name export

DB export: decimal point 12.34

Print sensor report OFF

Print parameter report ON

Print measurement report ON

Auto. cut OFF

Density 4

ASTM host ------

ASTM port ------

Enable ASTM OFF

Tra n sm i t l og d at a OFF

Economy mode: OFF

Economy mode: daily: start time 18:00

Economy mode: daily: stop time 05:00

Economy mode: weekly OFF

Ta b le B - 2 Default settings

Roche Diagnostics May 2009

Service Manual · Version 9.0 B-7

Page 62

3 Protected software functions cobas b 221 system

Protected setup

Setting Default Comment

Economy mode: weekly: start day Friday

Economy mode: weekly: start time 18:00

Economy mode: weekly: stop day Moday

Economy mode: weekly: stop time 05:00

Aspirate from syringe ON

Auto patient ID OFF

Auto save results ON

Apply corrections ON

Supress negative values ON

Display – message box 30 sec

Switch to measurement report 10 sec

Display – measurement report 10 sec

Automatic menu back 3600 sec

Remove sample cont. warning 1 10 sec

Remove sample cont. warning 2 20 sec

Log off user 900 sec

Sound ON

Vo l um e 3

Cal. intervals U.S. OFF

SW upgrade: Server 0.0.0.0

SW upgrade: Path -----

SW upgrade: User anonymous

SW upgrade: Password 0

Language German

Date format TT.M.JJJJ

Time format HH:MM

Log monitor prinout OFF

Log file generations 5

Log file entries 30000

Module priority BG-COOX-ISE-MSS

Activated for calibrations ON for all measurement

parameters

Activated for measurements ON for all measurement

parameters

QC lock ON for all measurement

parameters

QC warning OFF for all measurement

parameters

activated Multirules rule 1 and rule 2 for all measurement

parameters

AutoQC timing all times deleted

Ta b le B - 2 Default settings

Roche Diagnostics May 2009

B-8 Service Manual · Version 9.0

Page 63

cobas b 221 system 3 Protected software functions

Protected setup

Setting Default Comment

AutoQC mat assignment all settings deleted

Service mode OFF

PC Demo mode OFF

Ta b le B - 2 Default settings

Default maintenance schedule:

Maintenance Remind. Interval Samples

BG cleaning No Never 500

ISE cleaning No Never 200

MSS cleaning No Never ---

COOX cleaning No Never 20

tHb cleaning No Never 20

Change SD cartridge No 1095 days ---

Change MC cartridge No 1095 days ---

Change Hb cartridge No 1095 days ---

Change main pump tubing No 365 days ---

Change MSS output pump

tubing

Change MSS input pump

tubing

Change FMS tubing No 365 days ---

Change V6, V13, V18 tubing No 365 days ---

Change fill port No 365 days ---

Change T&D tubing No 365 days ---

Change AQC steel tube No 365 days ---

Change AQC barex tube No 365 days ---

Change AQC wash port No 365 days ---

Ta b le B - 3 Default maintenance schedule

No 365 days ---

No 365 days ---

Unmodified settings:

o User management

o Profile management

o Measurement reports

o Instrument type

o Network settings

o QC material setup and QC timing

o Sample counter

o COOX adjustments

o Serial number

o AQC module

o AQC temperature correction

o Bili

o Units

Roche Diagnostics May 2009

Service Manual · Version 9.0 B-9

Page 64

3 Protected software functions cobas b 221 system

Protected setup

Polarization voltages

Upol O

Upol MSS (cobas b 221<5/6> systems only)

2

The keyboard symbol under Upol O2 can be used to change the polarization voltage of

the oxygen electrode (default value 750 mV). The [Adjust] key is used to confirm and

import the newly defined value.

The keyboard symbol under Upol MSS can be used to change the polarization voltage

of the MSS sensors (default value -350 mV). The [Adjust] key is used to confirm and

import the newly defined value. The polarization voltage can only be changed with

the MSS cassette inserted.

COOX module (cobas b 221<2/4/6> systems only)

Setup

The number of samples during a measurement is shown under Scans

(1, 2, 4, 8 and 16 samples are possible).

The duration of sampling during a measurement is shown under Integration time

(12 ms to 12000 ms are possible).

COOX switches

COOX adjustments

AutoQC module

This setting is intended for internal purposes only and must be changed only when specifically

directed!

The [Suppress negative values] key activates (green) or deactivates (red) the

suppression of the output of negative values during a measurement. The

measurement values are set to 0 in the event of activation and a matching tHb

compensation is made.

The offset values for the polychromator bilirubin are stored here. After replacing the

polychromator bilirubin, the touch screen/PC unit or the hard disk, they must be reentered by means of entering the code. The code is located on the polychromator and

must be entered using the keyboard symbol under Set.

The [Set default value] key loads the default settings of the polychromator bilirubin

stored on the harddisk.

The [Temperature correction] key activates (green) or deactivates (red) the

temperature correction of the pH, PO2 and PCO2 measurement values during a QC

measurement to receive standardized measurement results.

Roche Diagnostics May 2009

B-10 Service Manual · Version 9.0

Page 65

cobas b 221 system 3 Protected software functions

Protected system functions

Log monitor

The [Log monitor printout] key activates (green) or deactivates (red) the output of all

log monitor data at the internal thermal printer.

The keyboard symbol can also be used to specify the number of generations and the

number of log file entries in the printout.

Deactivate this function to prevent permanent stress on the thermal printer!

Protected system functions

System backup / restore

This function allows to backup all instrument related data to USB mass storage. It is

intended to be used when replacing the hard disk, replacing the touch screen/PC unit

or for a full backup.

Important system backup information

The data from the system backup may only be imported on the same instrument on which the

backup was created. If this is not considered this may lead to incorrect patient measurements, which

may result in incorrect clinical decisions, possibly endangering the patient's health.

USB mass storage required

This function uses USB mass storage.

e

For detailed requirements, see USB troubleshooting on page D-91.

a Starting the system backup

1

At the ready screen, press h [System] > [Protected functions] > [System backup

/ restore].

2

Press h [Save system data].

The system data are being prepared and the instrument software will be restarted.

3

After restart of the software, press h [Save system data on USB device].

The system data will be saved into the folder "Roche\data\". This process may take

several minutes.

After replacing the hard disk, replacing the thouch screen/PC unit or to restore the

backup do the following.

a Restoring the system backup

1

At the ready screen, press h [System] > [Protected functions] > [System backup

/ restore].

2

Press h [Load system data from USB device].

Roche Diagnostics May 2009

Service Manual · Version 9.0 B-11

Page 66

3 Protected software functions cobas b 221 system

Protected infos

3

Press h [Activate system data].

The instrument software will be restarted and the restored system data is available.

AQC adjustment

The start [Start] key initializes a position compensation of the AutoQC motors to

ensure that ampoules are pierced at the correct position after replacement of the

AutoQC board. This should be performed in the course of AQC maintenance.

To avoid damage, the AQC ampoule mats must be removed from the AQC ampoule block before

starting the adjustment!

Be aware of possible injuries due to moving parts!

Protected infos

Service log file export

USB functionality

When USB mass storage devices (USB flash drives) are connected to the instrument export and

import will use USB instead of floppy disk. Export to and import from USB mass storage requires

software version 5.00 or higher to be installed on instruments using touch screen/PC units version

4.X or higher and interface unit cobas b 221 system > SN 3000.

This function exports log files to USB mass storage or to a floppy disk.

The naming of the logfile archive is as follows:

logfile_xxxx_yyyyyy_zzzz.pck

x...serial number

y...date

z...time

In case of USB, the destination folder is Roche\log\.

When there is too little free space on the floppy disk, data can be deleted. If this is confirmed with

„Yes“, all existing data on the floppy disk will be deleted.

The log file may not be exported during any active procedures (calibration, measurement, fill

routines, diagnostics, ...).

Roche Diagnostics May 2009

B-12 Service Manual · Version 9.0

Page 67

cobas b 221 system 3 Protected software functions

Protected DB functions

Protected DB functions

Delete all databases

This function is used to delete all patient, measurement, QC measurement,

calibration and instrument databases.

The instrument will be restarted!

Delete databases & archives

This function deletes all databases and archives (corresponds to backups).

Roche Diagnostics May 2009

Service Manual · Version 9.0 B-13

Page 68

3 Protected software functions cobas b 221 system

Protected DB functions

Roche Diagnostics May 2009

B-14 Service Manual · Version 9.0

Page 69

cobas b 221 system 4 Components

Tab le of co nt ent s

Components

This chapter provides general information about components of the cobas b 221

system.

In this chapter