Page 1

HIF-6880USMPT

Page 2

CAUTION: Before servicing the chassis, read the " important service safety information"

section on page 2 of this manual.

PORTABLE RADIO CASSETTE WITH CD&MP3 PLAYER

SPECIFICATIONS CONTENTS

AM/FM TUNER SECTION

ANTENNA SYSTEM

TUNING RANGE

AUDIO SECTION

SPEAKER IMPEDANCE : 4 OHM

GENERAL : 5W x 2

POWER INPUT : ~AC 230V-50Hz

AC POWER CONSUMPTION

MAIN DIM : 160(L)x230(W)x 260(H)mm

SPEAKER DIM : 133(L) x195(W) x257.5(H)mm

WEIGHT : 7.4Kg

AM: FERRITE BAR

FM: LEAD WIREAND

AM: 522 - 1620 kHz

FM: 87.5 - 108 MHz

IMPORTANT SERVICE SAFETY INFORMATION---2

DISASSEMBLY INSTRUCTIONS--------------------- 3

ADJUSTMENT LOCATIONS----------------------------4

ALIGNMENT PROCEDURES----------------------5 -12

VOLTAGE CHARTS--------------------------------13 - 15

IC BLOCK DIAGRAMS----------------------------16 -20

BLOCK DIAGRAM---------------------------------------21

WIRING DIAGRAM-------------------------------------22

SCHEMATIC DIAGRAMS-------------------------23 -30

PRINTED CIRCUIT BOARDS---------------------31 -34

EXPLODED VIEW/PARTS LIST (CABINET)---35 - 37

SERVICE PUBLICATION

NOTE: All the specifications and features are subject to change without notice.

Page 3

IMPORTANT SERVICE SAFETY INFORMATION

1. SAFETY PRECAUTIONS

Before returning a unit to the customer, always make a safety

check of the entire unit, including, but not limited to the

following items:

a. Be sure that no built-in protective devices are defective

and/or have been defeated during servicing.

(1)protective shields are provided to protect both the

technician and the customer. Correctly replace all

missing protective shields including any removed for

servicing convenience.

(2)when reinstalling the chassis and/or other assemblies in

the cabinet, be sure to put back in place all protective

devices, including , but not limited to , nonmetallic

control knobs, insulating fishpapers. adjustment and

compartment covers/shields and isolating resistor/

capacitor networks. Do not operate this or permit it to be

operated Without all protective devices correctly

installed and functioning .

b. Be sure that there are no cabinet openings through which

an adult or child might be able to inser t their fingers and

contact a hazardous voltage. Such openings include, but

are not limited to, excessively wide cabinet ventilation

slots, and an improperly fitted and/or incorrectly secured

cabinet back cover.

c. Leakage current hot check - with the unit completely

reassembled ,plug the AC line cord directly into a 120V

AC outlet. (Do not use an isolation transformer during this

test.) Use a leakage current tester or a metering system

that complies with American National standards Institute

(ANSI) C101.1 Leakage Current for Appliances and

Underwriters Laboratories(UL) 1410 (50.7). WITH THE

UNIT AC switch first in the ON position And then in the

OFF position, measure from a known earth ground (metal

water pipe, conduit, etc.) To all exposed metal parts of

the Unit (antennas, handle bracket, metal cabinet, screw

heads , metallic overlays, control shaft, etc.) Especially

any exposed metal parts that offer an electrical return

path to the chassis. Any current measured must not

exceed 0.5 milliamp, reverse the unit power cord plug in

the outlet and repeat test .

ANY MEASUREMENTS NOT WITHIN THE LIMITS

SPECIFIED HERENING INDICATE A POTENTIAL SHOCK

HAZARD THAT MUST BE ELIMINATED

RETURNING THE

UNIT TO THE CUSTOMER.

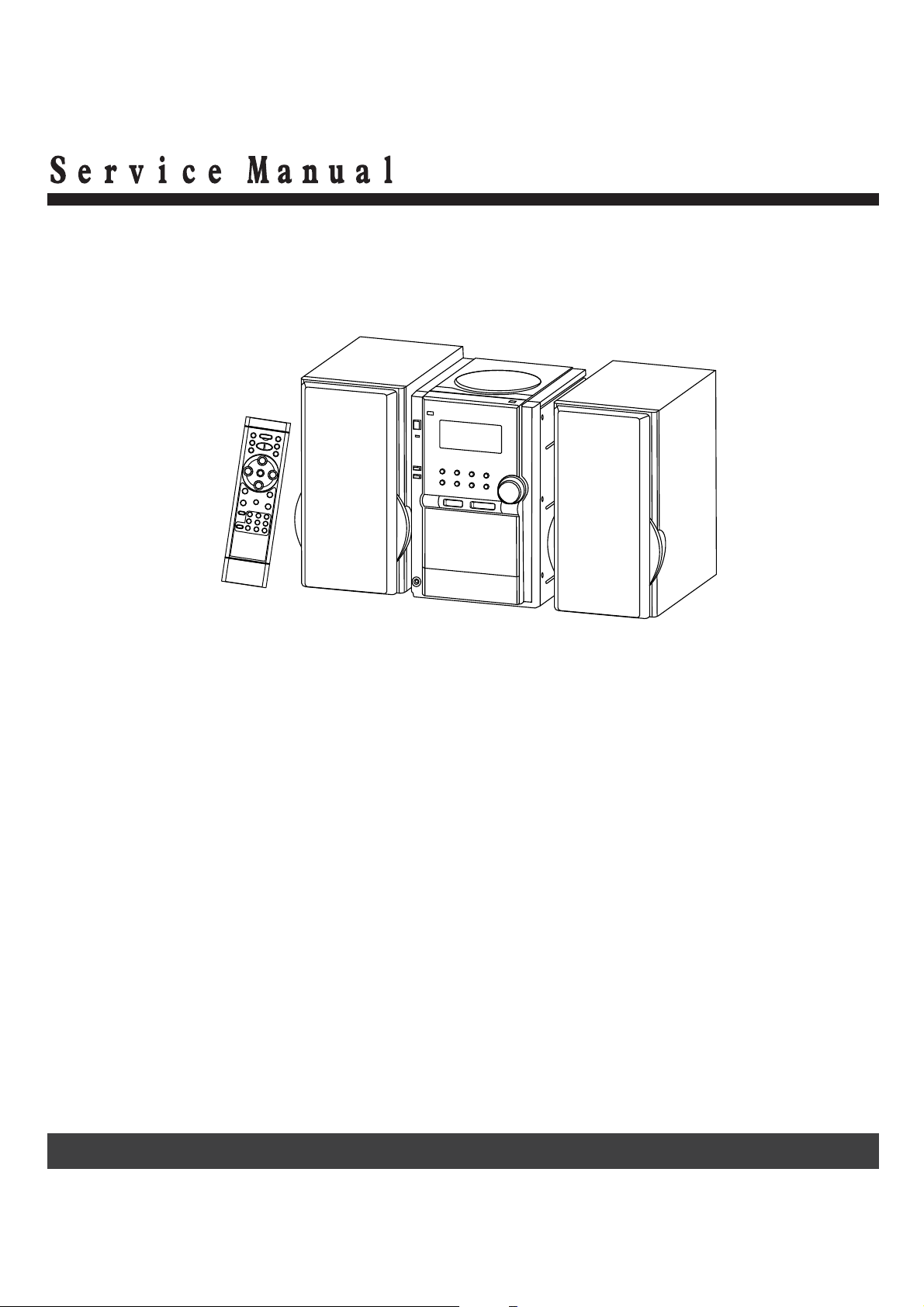

AC LEAKAGE TEST

DEVICE

UNDER

TEST

2-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

TEST ALL

EXPOSED METAL

SURFACES

(READING SHOULD

NOTBEABOVE

0.5mA)

LEAKAGE

CURRENT

TESTER

EARTH

GROUND

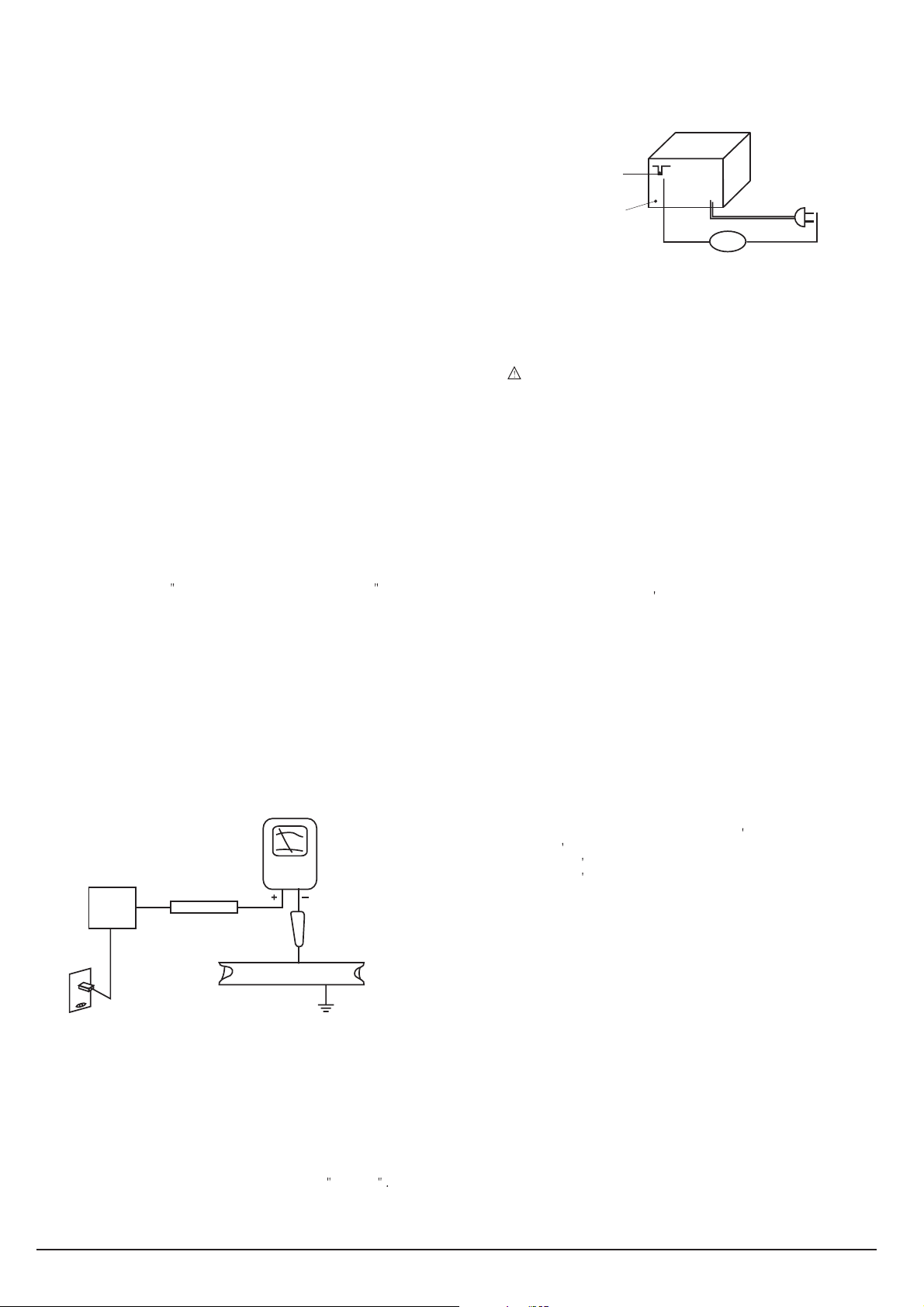

d. Insulation resistance test cold check:

unplug the power supply cord and connect a jumper wire

between the two prongs of the plug .

Turn on the power switch of the unit.

Measure the resistance with an ohmmeter between

jumpered AC PLUG AND EACH Exposed metallic cabinet

part on the unit, such as screw heads, antenna, control

shafts, handle brackets, etc. When the exposed metallic

part has a return path to the chassis , the reading should

be between 1 and 5.2 megohms. When there is no return

path to the chassis, the reading must be infinite If it is

not within the limits specified, there is the possibility of a

shock hazard, and the unit must be repaired and

rechecked before it is returned to the customer.

ANTENNA

TERMINAL

EXPOSED

METAL

PART

OM

OHMMETER

2. PRODUCT SAFETY NOTICE

some electrical and mechanical par ts have special safety

related characteristics which are often not evident from

visual inspection. Nor can the protection they give

necessarily be obtained by replacing them with

components rated for higher voltage , wattage, etc. Par ts

that have special safety characteristics are identified by

a on schematic and parts list. Use of a substitute

replacement that dose not have the same safety

characteristics as the recommended replacement par t

might create shock, fire, and/or other hazards. Product

safety is under review continuously and new instructions are

issued whenever Appropriate.

3. Servicing precautions

CAUTION: before servicing the unit covered by this service

by this service manual and its supplements. Read and follow

the SAFETY PRECAUTIONS on this page.

NOTE: if unforeseen circumstances create a conflict

between the following servicing precautions and any of the

Safety precautions, always follow the safety precautions.

Remember: safety first.

General servicing precautions.

a. Always unplug the unit s AC power cord from the AC

power source Before:

(1)removing or reinstalling any component, circuit board,

module or any other unit assembly.

(2)disconnecting or reconnecting any unit electrical plug or

other Electrical connection.

(3)connecting a test substitute in parallel with an electrical

capacitor caution: a wrong part substitution or incorrect

polarity installation Of electrolytic capacitors may result in

an explosion hazard

b. Do not defeat any plug/socket b+ voltage interlocks with

which the unit covered by this service manual might be

equipped.

c. Do not apply AC power to this unit and/or any its electrical

assemblies unless all solid-state device heat sinks are

correctly installed.

d. Always connect a test unit instrument s ground lead to

the unit s chassis ground before connecting the test

instrument s positive lead always remove the test

instrument s ground lead last.

4. Laser precautions

Warning!

(1)When servicing.(In case it isnecessary to confir m laser

Beam emission ) be sure not toplace your eyes any

closer than1or 30cm from the surface of the objective

lens on the optical pickup block.

HANDLING THE LASER PICKUP

( 2)Laser Diodesare Extremely Susceptibleto damage from

static electricity even if a static discharge dies not ruin

the diode, it can shorten its life or cause it to work

improperly.When replacing the pickup, usea conductive

maton the floorand desk and wear a wrist band

connected to groundthrough a 1Mohm resistor

to protect the laser diode from static damage. If thelens

should get dusty, blow off thedust carefully fromthe

object.

(3)There areno adjustable partsin the pickup assembly. If it

is defective, replace the wholepickup assembly.

CAUTION: USE OF CONTROLS, ADJUSTMENTS OR

PERFORMANCE OF PROCEDURES HEREIN MAY

DANGER: IF INTERLOCK FAILS OR IS DEFEATED, THE LASER

RESULT IN HAZARDOUS RADIATION

LIGHT IS ABLE TO FUNCTION. THE LASER IS

INVISIBLE, AVOID DIRECT EXPOSURE TO BEAM.

EXPOSURE.

2

Page 4

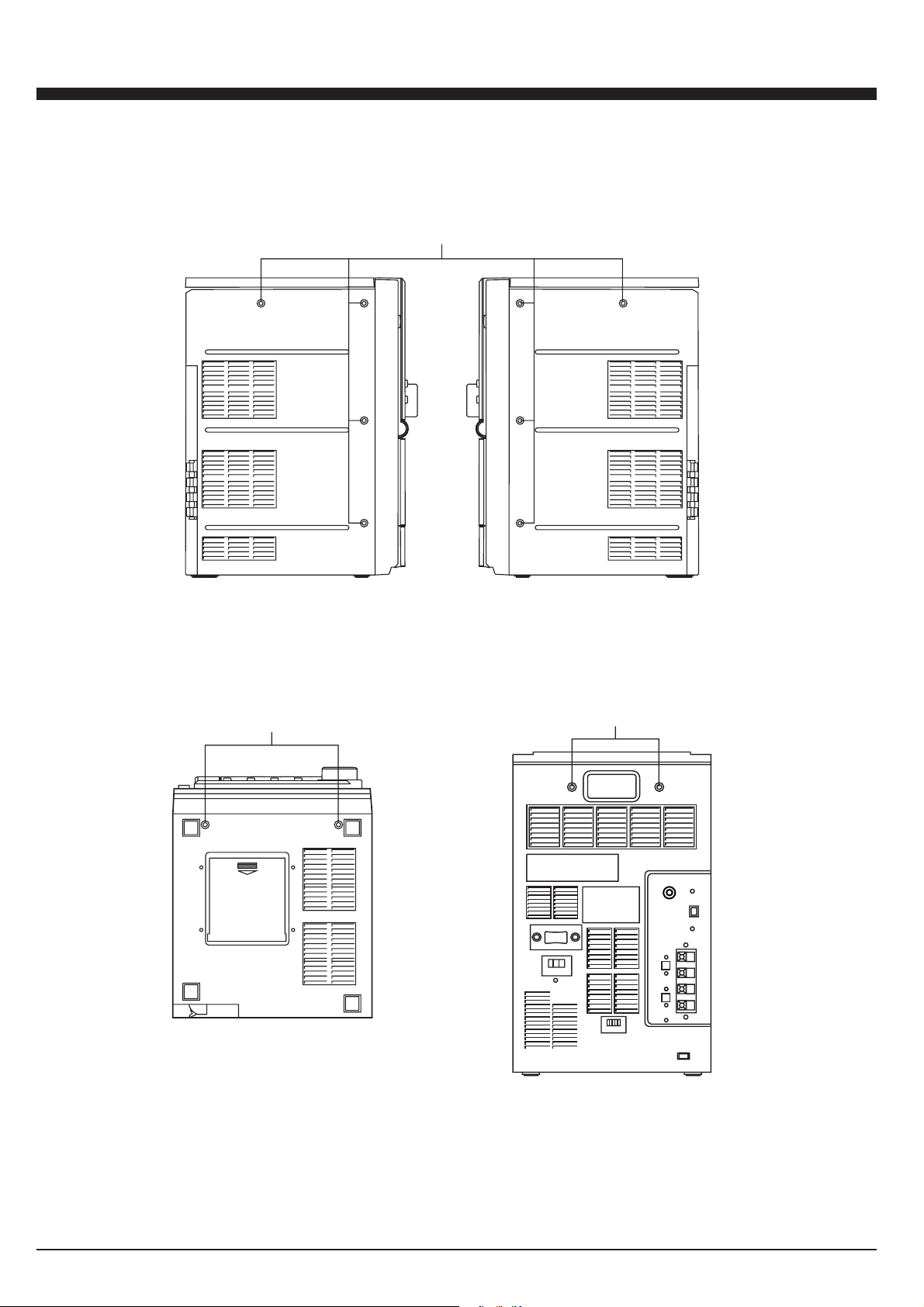

MODEL NE -562

DISASSEMBLY INSTRUCTIONS

SCREW3X10PA

SCREW3X10PA

SCREW3X10PA

3

Page 5

ADJUSTMENT LOCATIONS

4

Page 6

ALIGNMENT PROCEDURES

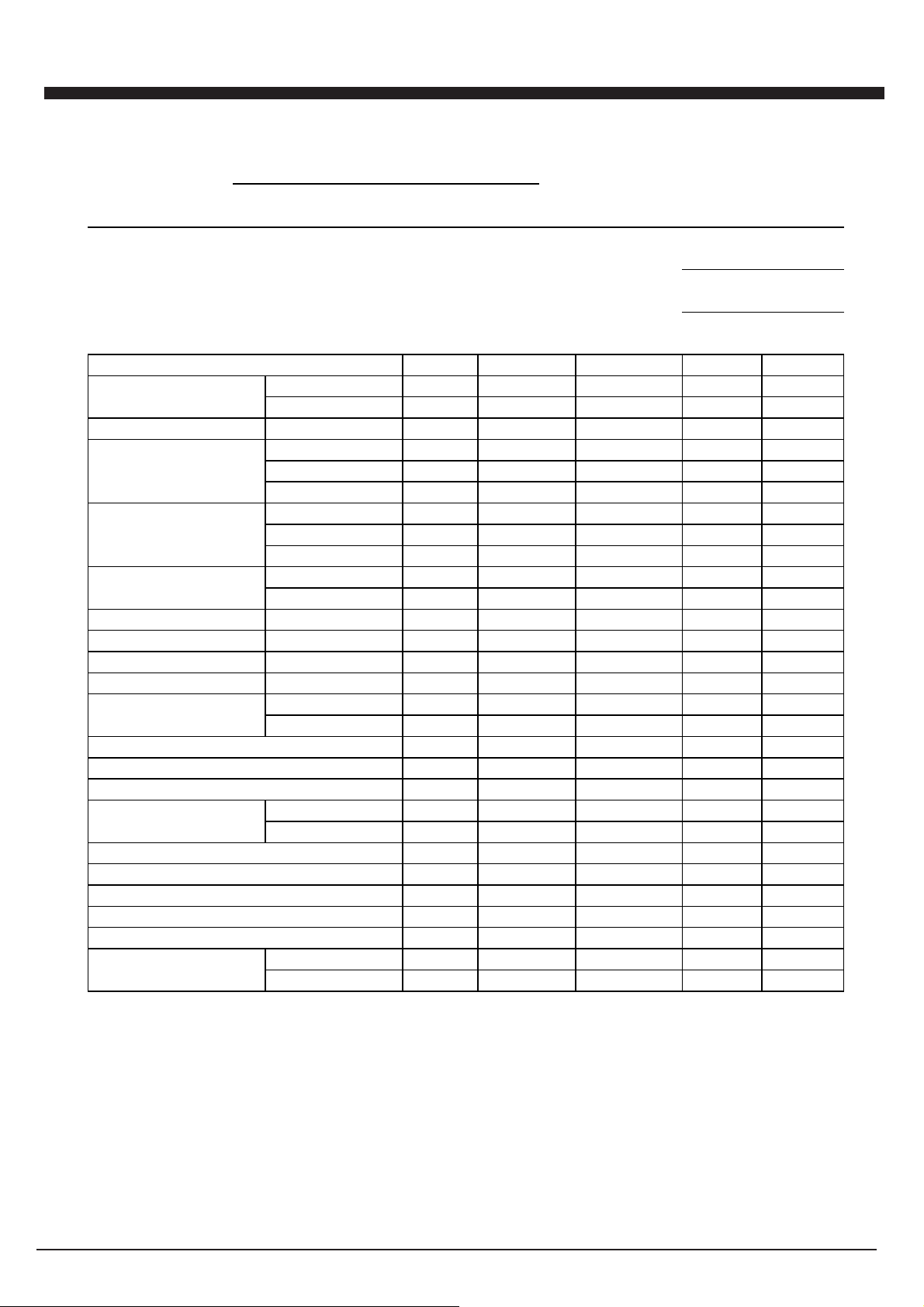

CASSETTE SECTION NE-562MP3 DATE:12-ARP-2004

STEP ITEM TEST EQUIPMENT TEST TAPE ADJUST REMARK

1 MOTOR SPEED WOW/FLUTTER METER MTT-111N (1)CHECK MOTOR

ADJ. & WITH FREQ. COUNTER (3KHz) SPEED TO 3KHz +3%-2% TAPE

WOW/FLUTTER CONNECT TO SPEAKER POSITION

CHECK OR DUMMY LOAD

2 HEAD AZIMUTH AC VOLT METER MTT-113N ADJUST THE R/P HEAD TAPE

OSCILLOSCOPE (6.3KHz) SCREW FOR MAX POSITION

CONNECT TO SPEAKER OUTPUT

OR DUMMY LOAD

3 PLAYBACK SAME AS ABOVE MTT-257 CHECK FREQ TAPE

FREQ RESPONSE TO MEET POSITION

RESPONSE SPECIFICATION

4 RECORDING AC VOLT METER BLANK RECORED & TAPE

OCILLOSCOPE TAPE PLAYBACK FORM FM POSITION

CONNECT TO SPEAKER SIGNA TO MEET

OR DUMMY LOAD SPECIFICATIONS: REC

FM SIGNAL GEN LEVEL, DISTORTION &

CONNECT TO ANT. FREQ. RESPONSE

INPUT 1mV,40KHz DEV.

5

Page 7

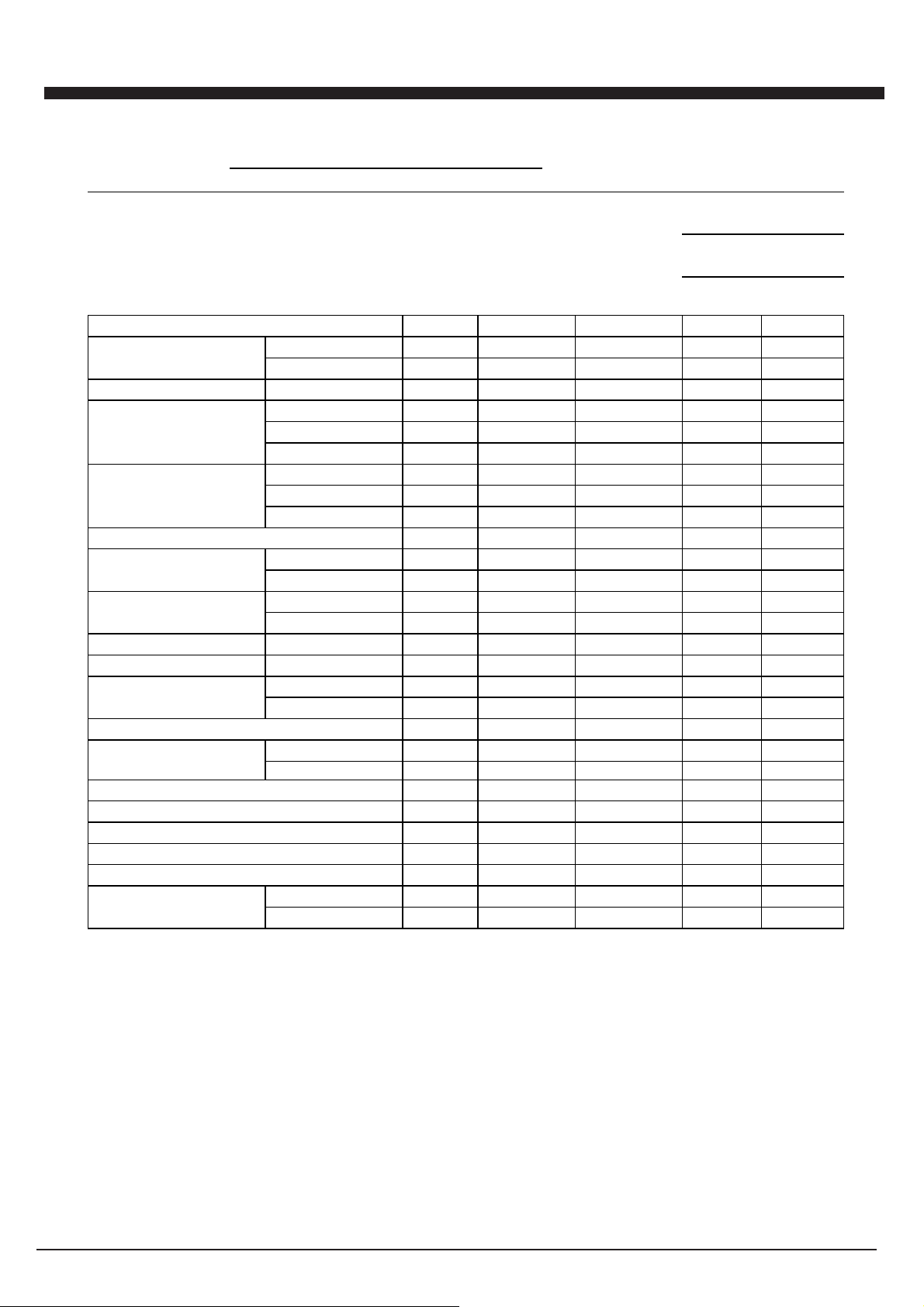

ALIGNMENT PROCEDURES

CASSETTE SECTION NE-562MP3 DATE:28-JUL-2004

STEP ITEM TEST EQUIPMENT TEST TAPE ADJUST REMARK

1 MOTOR SPEED WOW/FLUTTER METER MTT-111N (1)CHECK MOTOR

ADJ. & WITH FREQ. COUNTER (3KHz) SPEED TO 3KHz +3%-2% TAPE

WOW/FLUTTER CONNECT TO SPEAKER POSITION

CHECK OR DUMMY LOAD

2 HEAD AZIMUTH AC VOLT METER MTT-113N ADJUST THE R/P HEAD TAPE

OSCILLOSCOPE (6.3KHz) SCREW FOR MAX POSITION

CONNECT TO SPEAKER OUTPUT

OR DUMMY LOAD

3 PLAYBACK SAME AS ABOVE MTT-257 CHECK FREQ TAPE

FREQ RESPONSE TO MEET POSITION

RESPONSE SPECIFICATION

4 RECORDING AC VOLT METER BLANK RECORED & TAPE

OCILLOSCOPE TAPE PLAYBACK FORM FM POSITION

CONNECT TO SPEAKER SIGNA TO MEET

OR DUMMY LOAD SPECIFICATIONS: REC

FM SIGNAL GEN LEVEL, DISTORTION &

CONNECT TO ANT. FREQ. RESPONSE

INPUT 1mV,40KHz DEV.

6

5

Page 8

ALIGNMENT PROCEDURES

MODEL:HIF-6880USMPT

FM AND AM RF ALIGNMENT CHART ( IF ) Date:

Step item Input Circuit Output Circuit Tuner Adj - Adjustment

Setup Setup setting Point

Unless otherwise specified set switches as follows:

FM Function: FM

Adjust generator frequency to a center of the FM band where no FM broadcast exists

IF Connect FM IF Connect Co19 and GND FM in band Adjust for straight and

1 Adjustment sweep output IF-OUT terminal to end T304 symmetrical S-curve

terminal to IC302 IF sweep input terminal with max.amplitude.

2 FM Headphone jack or 87.5 MHz L303 Adjust L301 for max output

Band setup speaker terminal 108MHz Done

FM SG ANT. Headphone jack or 90.1 MHZ L302 Adjust for max.output and

3 Tracking (1) Terminal 90.1 MHz, speaker terminal MONO best waveform

1kHz, +-22.5kHz dev

4 Tracking (2) 106.1 MHz, 1 kHz Headphone jack or 106.1 MHz CT303 Same as above.

+-22.5 MHz dev speaker terminal

5 Repeat steps 3 and 4.

MW

IF Connect standard loop Connect input terminal MW in band Adjust tor max. amplitude

1 Adjustment antenna to output ter- genescope to detector end T302 with symmetrical 450 kHz.

minal of genescope output

2 MW Headphone jack or 522 kHz T301 Adjust L135 for max output

Band speaker terminal 1620 kHz CT302 Adjust CT133 for max output

3 Tracking (1) 612 kHz 400 kHz, Headphone jack or 612 kHz T303 Adjust for max.output and

3% mod speaker terminal best waveform

4 Tracking (2) 1404 kHz 400 kHz, Headphone jack or 1404 kHz CT301 Same as above.

3% mod speaker terminal

5 Repeat steps 3 and 4.

TAPE SECTION

HEAD ADJUSTMENT (AZIMUTH)

10 kHz test tape (example:MTT-114N) must be used for this adjustment. Connect to VTVM or oscilloscope to the headphone JCK or speaker terminal Press the play button.

Adjust the azimuth by using a screw driver to maintain the maximum L & R output voltage. Adjust tape. Please secure the

azimuth position by using locking paint.

RECODING BIAS OSCILLATOR FREQUENCY ADJUSTMENT

Connect the frequency counter to of R601 two ends.

Press REC button of tape .

Adjust T201 obtain 60 kHz +-100 HZ

6

7

Page 9

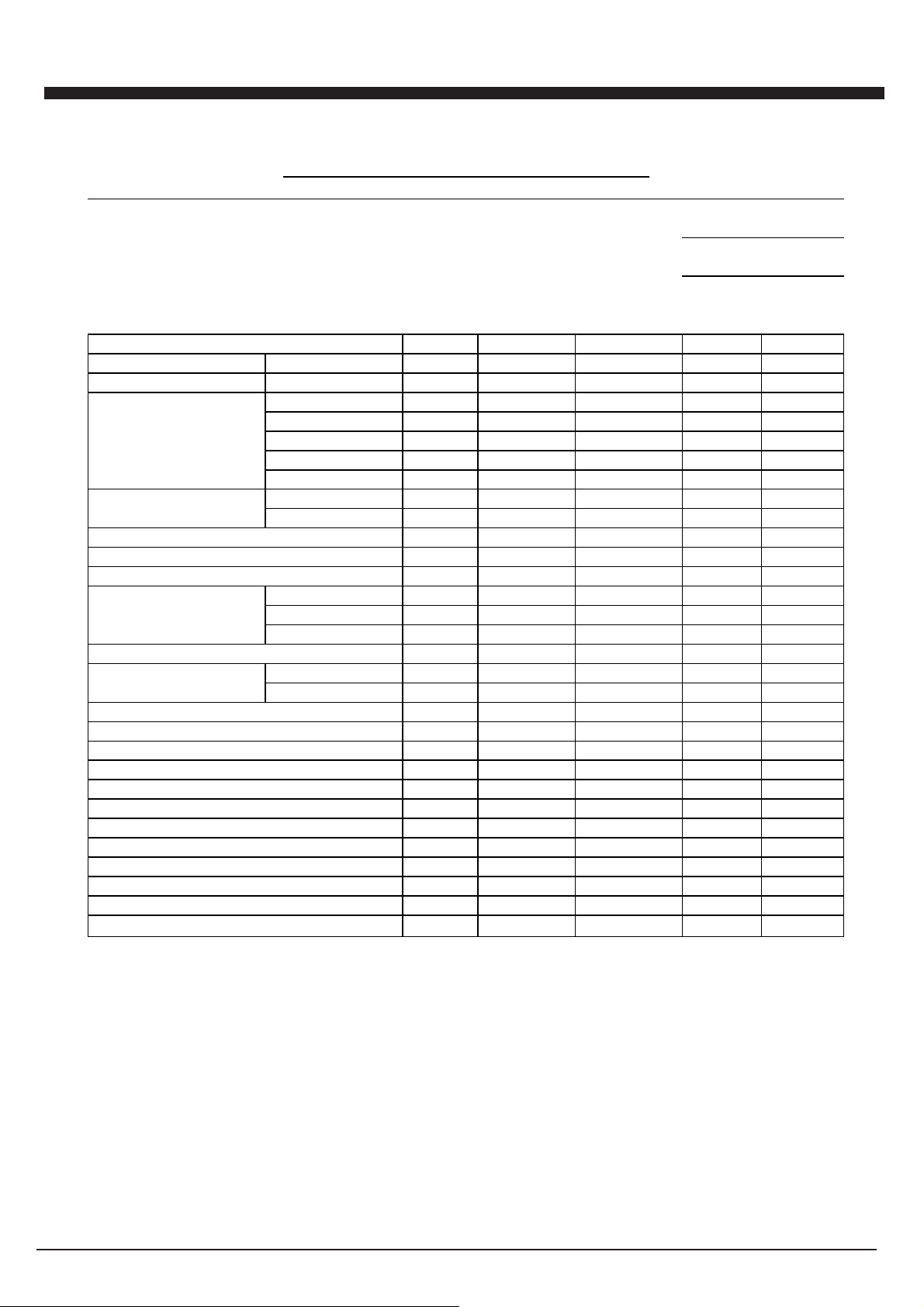

ALIGNMENT PROCEDURES

FM RECEIVER PERFORMANCE DATA

MODEL: NE-563PLL+MP3 (5W) Date:

Band: FM

Supply Voltage: AC 230 V Measured By:

Standard Output: 50 mw

Dummy Load: 4 ohm Approved By:

Modulation: 1 KHz 22.5 KHZ DEV

EQ or Tone at Flat Place Bass OFF Place

Measuring Items Unite Norm Limit Sample1 Sample2

Frequency Range Low MHz 87.5 +/-0.3

High MHz 108 +/-0.3

IF Frequency MHz 10.7 +/-0.2

30db Quieting 90.1 MHz db 18 26

Sensitivity 98.1 MHz db 18 26

106.1 MHz db 18 26

Auto Locked 90.1 MHz db 26 32

Sensitivity 98.1 MHz db 26 32

106.1 MHz db 26 32

ACA +300 KHz db 20 15

( 2-Signal ) -300 KHz db 20 15

Image Rejection AT 106.1 MHz db 22 16

IF Rejection AT 90.1 MHz db 50 40

-3db Limiting Sens . 1mv I/P db 18 26

AM Suppression 1mv I/P db 35 30

S/N (1mv input Mono db 50 45

W/A-Fliter) Stereo db 35 30

Stereo Sens db 20 26

Stereo Lamp On Sens. db 20 26

Separation R/L db 25 20

Freq.Response-3db Low Hz 80 ≦100

(W/50uS Pre-emphasis) High KHz 10 ≧8

Modulation Hum 1 mv I/P db 40 35

Hum & Noise(min.vol.) mv 1 3

Output (10% Dist) (MOD=40KHz) mW 4500 4000

Total Harmonic Distortion 1 mv I/P % 1 3

OSC Drop Out 1 mv I/P V

Current No signal mA

Consumption Max mA

8

7

Page 10

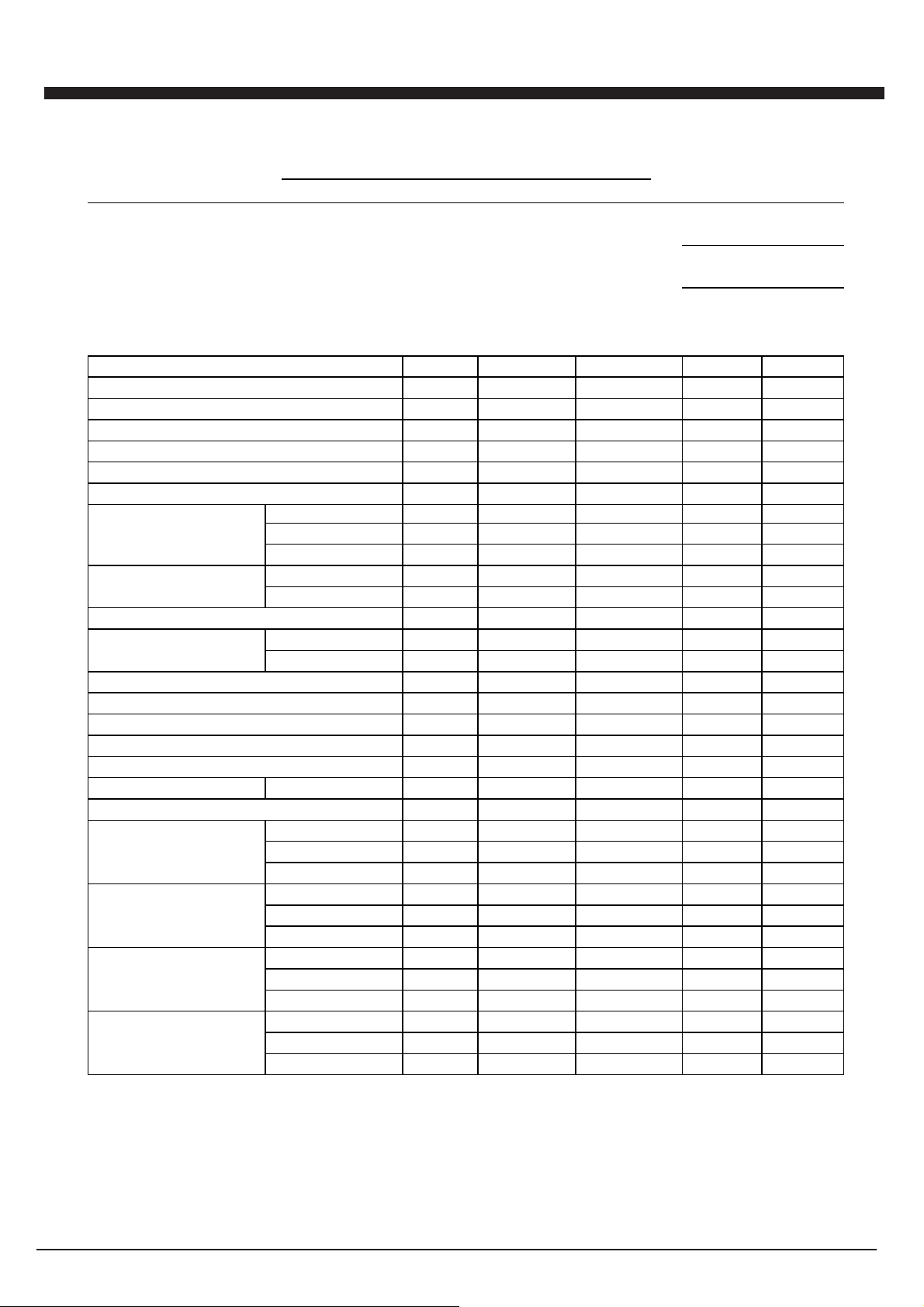

ALIGNMENT PROCEDURES

MW RECEIVER PERFORMANCE DATA

MODEL: NE-563PLL+MP3 (5W) Date:

Band: MW

Supply Voltage: AC 230 V Measured By:

Standard Output: 50 mw

Dummy Load: 4 Ohm Approved By:

Modulation: 1 KHz 30%

EQ or Tone at Flat Place Bass OFF Place

Measuring Items Unite Norm Limit Sample1 Sample2

Frequency Range Low KHz 522 +/-10

High KHz 1620 +/-10

IF Frequency KHz 450 +/-2

20db Quieting 612 KHz dB/M 60 66

Sensitivity 999 KHz dB/M 60 66

1404 KHz dB/M 60 66

Auto Locked 612 KHz dB/M 66 70

Sensitivity 999 KHz dB/M 66 70

1404 KHz dB/M 66 70

S/N 5mv/M dB 35 30

ACA +9 KHz dB 18 12

-9 KHz dB 18 12

Band Width-6dB +Side KHz 3 10

-Side KHz 3 10

Image Rejection AT 1404 KHz dB 35 30

IF Rejection AT 612 KHz dB 50 40

Spuerious Response 4-10MHz dB 40 35

10-30MHz dB 50 45

AGC FOM-10db 100mv/M dB 45 35

Audio Freq. Low Hz 80 ≦100

Response-6db High KHz 2.4 ≧2.0

Modulation Hum 100 mv/M dB 38 32

Hum (Volume At Min) mv 1 3

Output (10% Dist) (MOD=80%) mW 4500 4000

Total Harmonic Distortion 5mv/M % 2 4

OSC Drop Out 5mv/M V

Current No signal mA

Consumption Max mA

8

9

Page 11

ALIGNMENT PROCEDURES

CASSETTE PLAYBACK PERFORMANCE DATA

MODEL: NE-563 PLL&MP3 (5W) Date:

Supply Voltage: AC 230 V

Standard Output: 50 mw Measured By:

Dummy Load: 4 Ohm

0DB=1V Approved By:

EQ or Tone at Flat Place Bass OFF Place

Tape Speed 4.76cm/sec.1

Measuring Items Unite Norm Limit Sample1 Sample2

Tape Speed Enor at 3 KHz % +3/-2

WOW & Flutter at 3 KHz % 0.25 0.35

Play Freq Response at Hz dB

P/B S/N (1K odB) DC Opetation dB

Min Vol Hum & Noise AC Optetaion mv 1 3

Max Vol Hum & Noise AC Optetaion mv 20 30

10% THD Output (1KHz odB) RMS mw 4500 4000

THD at Hz %

-10dB 1KHz at 1 KHz % 1 3

Track Crosstalk dB 40 30

Channel Separation R-L dB 40 30

Channel Balance -10dB 1KHz dB 1 3

No Signal Current Min. Vol. Blank Tape mA

Max Output Max. Vol A

Play Torque g/cm

F.F Torque g/cm

Rew Torque g/cm

Time for Play Min

Time for F.F Sec

Time for Rew Sec

Play Level Tape = 0dB Ref dB 0 0

CD Play 1KHz-10dB dB -2 - 4

Radio FM 1KHz 40KHz dB +/-1 +/-3

7

/

I n

8

at 125 Hz dB +/-3 +/-6

at 1 KHz dB 0 0

at 10 KHz dB +/-3 +/-6

at KHz dB

AC Optetaion dB 45 40

at KHz %

L-R dB 40 30

10

9

Page 12

ALIGNMENT PROCEDURES

CASSETTER REC/PLAY PERFORMANCE DATA

MODEL: NE-563 PLL&MP3 (5W) Date:

Supply Voltage: AC 230 V

Standard Output: 50 mw Measured By:

Dummy Load: 4 Ohm

0DB=1V Approved By:

EQ or Tone at Flat Place Bass OFF Place

7

/

Tape Speed 4.76cm/sec.1

Measuring Items Unite Norm Limit Sample1 Sample2

Rec Blas System AC KH z 55 60

Erasing System Magnet 6PA

Erasing Ratio dB 38 33

ALC Compresion Time for 20db dB

Stansatding up for -20db at 90% Sec

Recovery time for -20db at 90% Sec

R/P Frep Response at 100 Hz dB +/-3 +/-6

REC CD(-20dB) at 1 KHz dB 0 +/-3

R/P S/N Built Mic dB

R/P THD at -10dB 1KHz % 5 10

R/P Channal Separation L-R dB 40 30

(1KHB 0dB) R-L dB 40 30

Record Level Tape = -10dB dB 0 0

CD 1KHz -20dB dB +/-2 +/-4

Radio FM 1KHz 12.5KHz dB +/-2 +/-4

Remote Control Sensitivity m 7 5

Headphone Out Level (32 ohm) mW 20 15

Bass Tone Action at Hz dB

Prest EQ REF O/P 0dB PASS

100 Hz dB +4 +/-2

CLASSIC 1K Hz dB +3 +/-2

ROCK 1K Hz dB +3 +/-2

10K Hz dB +6 +/-2

100 Hz dB - 4 +/-2

POP 1K Hz dB - 2 +/-2

100 Hz dB +6 +/-2

JAZZ 1K Hz dB +2 +/-2

I n

8

at 10 KHz dB +/-3 +/-6

FM 1mv/in dB 38 33

10K Hz dB +8 +/-2

100 Hz dB +8 +/-2

10K Hz dB - 4 +/-2

10K Hz dB +4 +/-2

10

11

Page 13

ALIGNMENT PROCEDURES

NELSON ELECTRONICS LTD

CD PLAYBACK PERFORMANCE DATA

MODEL: NE-563 PLL+MP3 (5W) Date:

Supply Voltage: AC 230 V

Standard Output: 50 mw Measured By:

Dummy Load: 4 Ohm

0dB=1V Approved By:

EQ or Tone at Flat Place Bass OFF Place

Measuring Items Unite Norm Limit Sample1 Sample2

WOW & Flutter %

Play Freq Response at 40 Hz dB - 2 +/-3

(0dB) at 61 Hz dB - 1 +/- 2

at 127 Hz dB 0 +/-2

at 1 KHz dB 0 0

at 10 KHz dB 0 +/-2

at 20 KHz dB -3 - 5

P/B S/N (YEDS) DC Opetation dB

AC Optetaion dB 55 50

Hum & Noise Min Vol mv 2 3

( AC Optetaion) Max Vol mv 5 8

10% THD Output RMS mw 4500 4000

THD (-20dB) at 1 KHz % 1 3

Channel Separation R-L dB 40 30

YEDS (0dB) L-R dB 40 30

Channel Balance (1KHz -10dB) dB 1 3

Black Spot PHILIPS-444A UM 800 600

Finger Prints PHILIPS-444A TRACK 19 18

Interruption PHILIPS-444A UM 800 600

Deflection 731RA MM 1 0.9

Eccentricity 712R UM 210 140

Access Operation First Sec

Time Last Sec

MP3 PLAYBACK PERFORMANCE DATA

MP3 Playback Transfer Rate kbps 8~384

MP3 Max Readable Folder Folde 200

MP3 Max Readable Files File 500

MP3 Sampling Frequency KHz 32/44.1/48; 16/22.05/24; 8/11.025/12.

11

12

Page 14

VOLTAGE CHARTS

IC VOLTAGE TABLE

{DC12V,NO SIGNAL INPUT (EXCEPT FM STEREO BAND),VOLUME MINMUN}

AC 230V 50HZ LA1823 &LC72131 & AN7312 & PT2313L

MODEL : NE-562MP3 5W TA8229K & PT2221 & S3C825AX27

TUNER LA1823+LC72131 S1l9226X01 & KA9259D & S5L9279X01 & JF1M16SDT-7

PINS 12345678910111213141516

AM

FM 1.29 1.29 4.43 4.43 2.16 0 0.02 3.38 4.42 1.29 1.28 0.3 3.67 3.74 3.7 0.73

FM.ST 1.29 1.29 4.43 4.43 2.16 0 0.02 3.38 4.42 1.29 1.28 0.3 3.67 3.74 3.7 0.73

IC302

LA1823 PINS 17 18 19 20 21 22 23 24

AM

FM 0.74 1.25 1.39 4.47 4.46 4.39 0 0.91

FM.ST 0.74 1.25 1.39 4.47 4.36 4.39 0 0.91

1.27 1.27 4.61 4.61 2.62 0 0.02 3.38 4.5 1.29 1.28 0.35 4 0.03 0.15 0.74

0.74 1.25 0.32 4.61 4.61 4.61 0 0

PINS 12345678910111213141516

AM

2.25 00333.64 3.78 3.78 0 0.02 4.45 0.3 0 0 0 0.22

FM 2.19 0 0 0.2 3 3.64 3.9 0.02 0 0.02 4.45 0 0 0 0.3 2.18

IC301 FM.ST 2.2 0 0 0.2 3 3.64 3.79 3.79 0 0.02 4.45 0 0 0 0.2 2.18

LC72131

PINS 17 18 19 20 21 22

AM

4.5 0.82 0.82 3.1 0 2.3

FM 4.5 0.82 0.82 3.1 0 2.3

FM.ST 4.5 0.82 0.82 3.1 0 2.3

IC201 PINS 1234567891011121314

AN7312 TAPE

01031.41.3001.31.43066

PINS 12345678910111213141516

RADIO

6.34 0 3.18 3.18 3.19 3.2 3.19 3.18 3.18 3.18 3.18 3.19 3.18 3.18 3.18 3.18

CD 6.34 0 3.18 3.18 3.19 3.2 3.19 3.18 3.18 3.18 3.18 3.19 3.18 3.18 3.18 3.18

TAPE 6.34 0 3.18 3.18 3.19 3.2 3.19 3.18 3.18 3.18 3.18 3.19 3.18 3.18 3.18 3.18

IC602

PT2313L

VOLUM PINS 17 18 19 20 21 22 23 24 25 26 27 28

EQ RADIO

3.19 3.2 3.18 3.19 3.18 3.2 3.2 3.2 0 0.22 3.05 3.19

FUN CD 3.19 3.2 3.18 3.19 3.18 3.2 3.2 3.2 0 0.22 3.05 3.19

TAPE 3.19 3.2 3.18 3.19 3.18 3.2 3.2 3.2 0 0.22 3.05 3.19

IC601 PINS 123456789101112131415

TA8229K POWER

0 16.8 9 17.5 9.1 17 0 17.2 9.1 0.5 0 0 0.6 0 0

13

12

Page 15

VOLTAGE CHARTS

PINS 12345678910111213141516

DRAM 3.41 2.52 2.42 0 2.2 2.21 3.41 2.2 2.2 0 2.19 2.2 3.41 0 3.41 3.41

U7

SDRAM PINS 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

16M

PINS 12345678910111213141516

DRAM 3.41 0 0 3.41 00003.41 00000.21 3.41 0

PINS 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

DRAM 0.11 1.69 3.41 0 3.41 2.44 2.45 0 2.41 2.45 3.41 2.43 2.44 0 2.43 2.45

PINS 49 50

DRAM 2.45 0

RADIO

1.41 00000000002.88 0 1.39 1.32 0

CD 1.41 00000000002.88 0 1.39 1.32 0

TAPE 1.41 00000000002.88 0 1.39 1.32 0

AUX 1.41 00000000002.88 0 1.39 1.32 0

PINS 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

RADIO

1.08 1.36 2.87 0 0 0.86 0.3 0.08 0 2.92 1.39 2.92 2.92 2.92 0 1.05

CD 1 1.36 2.87 0 0 2.87 2.87 2.87 0 2.92 1.39 2.92 2.92 2.92 0 1.05

TAPE 1 1.36 2.87 0 0 2.87 0.3 0.25 0 2.92 1.39 2.92 2.92 2.92 0 1.05

U2 AUX 1 1.36 2.87 0 0 2.87 0.3 0.25 0 2.92 1.39 2.92 2.92 2.92 0 1.05

S3C825A

PINS 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

RADIO

0 0 002.86 1.81 2.86 00002.73 2.73 3.4 3.54 2.91

CD 0 2.88 0 0 2.86 1.81 2.86 0 0 2.79 0 0 0 0.06 0.3 2.91

TAPE 00002.86 1.81 2.86 00002.73 2.73 0.03 0.7 2.91

AUX 00002.86 1.81 2.86 00002.73 2.79 0.03 0.7 2.91

PINS 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64

RADIO

0 0 2.88 0 2.88 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42

CD 2.91 0 2.88 0 2.88 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42

TAPE 2.91 0 2.88 0 2.88 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42

AUX 2.91 0 2.88 0 2.88 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42

PINS 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

RADIO

1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42

CD 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42

TAPE 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42

AUX 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42 1.42

PINS 12345678910111213141516

MOTOR 3.7 3.7 1.69 1.69 7.38 4.99 4.99 0 1.69 1.69 3.7 3.72 0 0 3.72 3.72

U5

KA9259D PINS 17 18 19 20 21 22 23 24 25 26 27 28

MOTOR 3.72 3.72 1.69 4.32 8 0 1.69 1.69 1.69 3.72 3.72 0

14

13

Page 16

VOLTAGE CHARTS

Y

MODEL NE -562

PINS 12345678910111213141516

DSP

1 2.07 0 0 0 2.07 0 0 1.7 1.69 3.38 3.38 1.69 0 0 0

PINS 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

DSP

3.38 1.66 000003.38 000003.38 0 0

U3

S5L9279 PINS 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

DSP

0 0 3.38 0 0 3.31 3.37 3.38 0 2.07 0 2.45 2.46 2.51 2.46 2.48

PINS 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64

DSP

2.46 2.48 2.09 0 0 2.4 2.82 2.62 2.7 0.77 0.73 0.36 2.76 2.07 0 1.13

PINS 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80

DSP

0 2.76 1.72 3.38 3.38 0 3.38 0 0 3.38 3.38 1.69 0000

PINS 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96

DSP

0 0 1.61 1.7 2.07 0 2.88 0 2.75 1.63 0 0.06 0000

PINS 97 98 99 100

DSP

0 0.07 1.69 0

PINS 12345678910111213141516

SSP

1.71 1.75 1.69 1.52 1.7 3.38 1.7 0.82 1.69 1.68 1.72 1.63 3.38 2.79 2.82 2.87

U1

S1L9226 PINS 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

SSP

2.87 0.07 1.69 0 0 0 1.71 1.71 1.71 1.71 1.71 1.71 1.71 1.71 1.71 1.71

PINS 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48

SSP

0 1.71 1.66 1.66 3.37 0 1.71 1.71 1.71 1.71 1.69 1.22 0.89 2.5 1.71 2.45

IC602 PINS 1 2 3 RE901 PINS 1 2 3

KA7808

14 0 8 RECEIVEER 4.4 0 4.4

Q607 PINS E B C Q304 PINS E B C

8050

5.8 4.3 12.9 9014C 10.3 11 16.8

Q620 PINS E B C Q303 PINS E B C

8050

6.2 6.8 10 8050C 4.5 5.2 7.6

REMARK : ALL THE DATA IN THE TABLE IS FOR.REFERENCE ONL

FOR FM.ST BAND , FM STEREO INDICATOR MUST BE ON.

15

Page 17

MODEL NE -562

IC BLOCK DIAGRAM

16

Page 18

MODEL NE -562

IC BLOCK DIAGRAM

17

Page 19

MODEL NE -562

IC BLOCK DIAGRAM

18

Page 20

MODEL NE -562

IC BLOCK DIAGRAM

19

Page 21

MODEL NE -562

IC BLOCK DIAGRAM

20

Page 22

BLOCK DIAGRAM

21

Page 23

WIRING DIAGRAM

22

Page 24

SCHEMATIC DIAGRAMS

23

22

Page 25

SCHEMATIC DIAGRAMS

23

24

Page 26

SCHEMATIC DIAGRAMS

25

24

Page 27

SCHEMATIC DIAGRAMS

25

26

Page 28

SCHEMATIC DIAGRAMS

26

27

Page 29

SCHEMATIC DIAGRAMS

27

28

Page 30

SCHEMATIC DIAGRAMS

29

28

Page 31

SCHEMATIC DIAGRAMS

30

28

Page 32

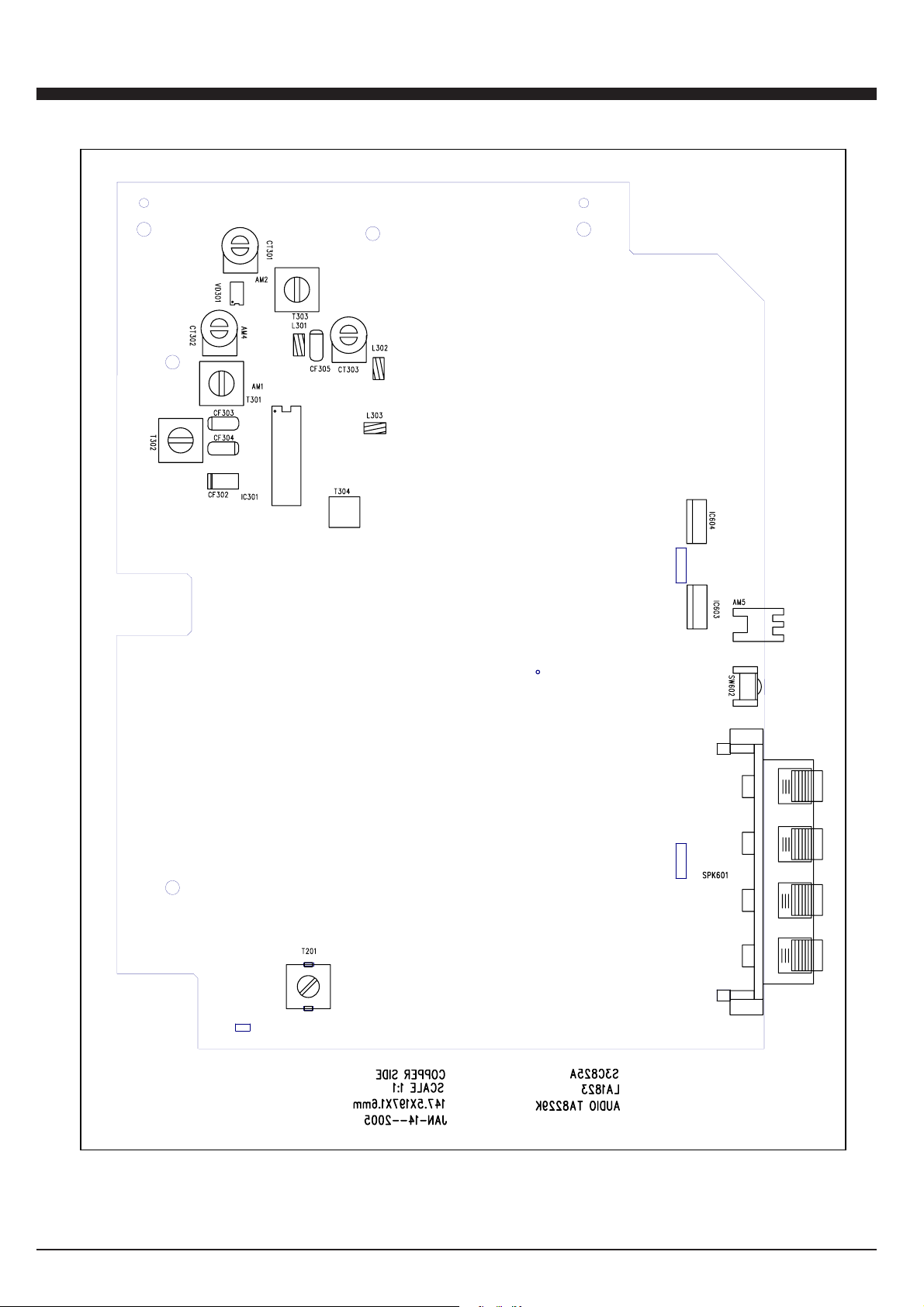

173-056320-01

PRINTED CIRCUIT BOARDS

173-056301-09

31

Page 33

PRINTED CIRCUIT BOARDS

173-056320-01

32

Page 34

PRINTED CIRCUIT BOARDS

33

Page 35

173-0563�1-09

PRINTED CIRCUIT BOARDS

173-056351-01

173-056356-01

34

Page 36

MODEL NE -562

EXPLODED VIEW/PARTS LIST (CABINET)

35

Page 37

EXPLODED VIEW/PARTS LIST (CABINET)

56

57

36

Page 38

MODEL NE -562

EXPLODED VIEW/PARTS LIST (CABINET)

O.

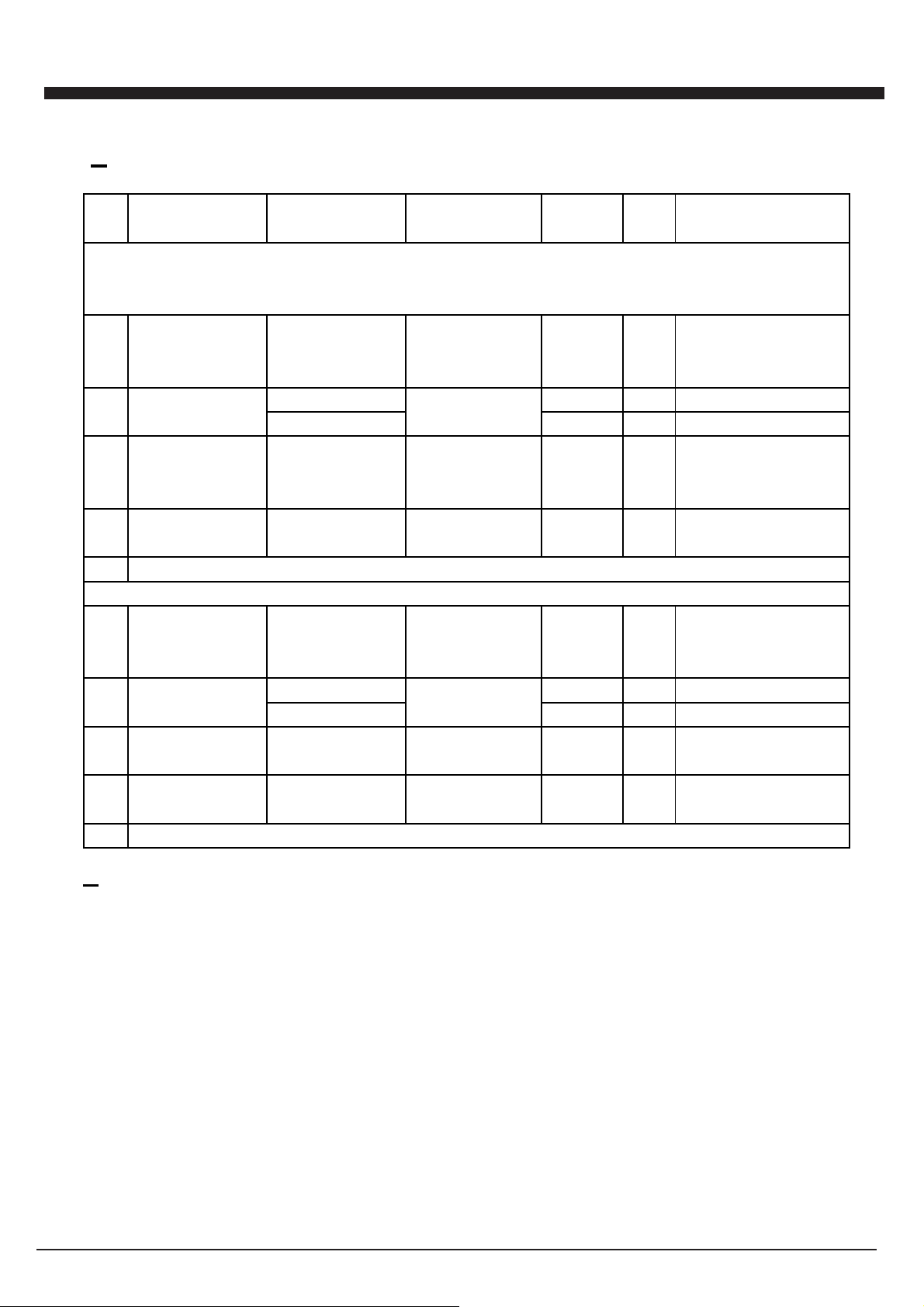

ITEM PART NO. DESCRIPTION QTY ITEM PART NO. DESCRIPTION QTY

1 357-056220-6500 CASSETTE KNOB COVER 1 54 238-056200-11 CASS DOOR DECORATION 1

2 358-056210-6500 CASSETTE DOOR 1 55 188-000402-00 LEAF SWITCH 1

3 333-056200-8890 FRONT LENS 1 56 461-000050-01 Cd pcb mounting bracket 1

4 425-059501-1C20 CASSETTE KNOB – PLAY 1 57 461-000051-01 Cd pcb mounting bracket 1

5 425-059500-1C20 CASSETTE KNOB 5 58 188-012721-01 AC POWER SWITCH 1

6 177-023502-03 STEREO JACK 1

7 311-056281-6500 FRONT CABINET 1 P1 173-059205-01 HEARPHONE JACK BOARD 1

8 303-000090-0201 MOUNTING POST REV. 6 P2 173-056303-01 FUNCTION KEY BOARD 1

9 420-056210-3890 VOLUME BUTTON RING 1 P3 173-056302-0102 USB SOCKET BOARD 1

10 188-011522-01 TACT SWITCH 11 P4 173-056301-09 MEMORY CARD BOARD 1

11 408-0562-141860 FUNCTION BUTTON 8 P5 173-056220-0102 A/F+R/P+5W BOARD 1

12 472-056211-1000 FUNCTION KNOB BASE 1 P6 173-056656-0101 R/P BOARD 1

13 412-056212-2500 MUTE BUTTON 1 P7 173-056651-0102 MCU+CD SERVO BOARD 1

14 148-250001-101 LED 1 P8 173-056209-01 BACK LIGHT BOARD 1

15 403-056214-2500 POWER/STANDBY BUTTON 1 P9 173-056304-01 VOLUME BOARD 1

16 133-6038LM-5A10 IR RECEIVER 1 P10 173-056205-0101 VOLUME LIGHT BOARD 1

17 199-000002-01 OIL DAMPER 1

18 408-056217-2490 CD OPEN BUTTON 1 S1 203-300200-10 SCREW 3X10 PA 44

19 148-030000-40 LED 3 S2 203-300200-12 SCREW 3X12 PA 7

20 134-056220-051 LCD 1 S3 203-350800-14 SCREW 3.5X14 PWA 4

21 461-056222-1100 LCD REFLECTOR 1 S4 207-261600-10 SCREW 2.6X10PWB-10W 4

22 461-056222-1100 LCD BRACKET 1

23 461-05920-1010 CASSETTE DOOR BRACKET 1

24 303-000082-0001 CASSETTE KNOB FIXER 1

25 218-057512-32 DECK THL-21SB-1592P 1

26 400-056211-2490 VOLUME KNOB 1

27 464-056206-1000 VOLUME KNOB SHAFT 1

28 420-056210-3890 VOLUME KNOB RING 1

29 463-05620V-1000 VOLUME KNOB ADAPTOR 1

30 188-011532-02 TACT SWITCH 2

31 057520-53J0 BATTERY DOOR 1

32 381-057510-53J0 BATTERY BOX 1

33 262-001510-10 RUBBER FOOT 8

34 156-582313-03 X’FORMER 1

35 211-003115-15 BELT MOTOR DIA 1

36 199-000060-02 MOTOR PULLY 1

37 322-059561-53J0 REAR CABINET 1

38 177-070000-011 SPEAKER TERMINAL 1

39 461-05923G-1010 GEAR BRACKET 1

40 460-056202-1000 CD DOOR GEAR 1

41 460-056201-1000 ADAPTOR GEAR 1

42 460-056200-1000 MOTOR GEAR 1

43 461-05622M-1000 MOTOR BRACKET 1

44 143-450220-03 MOTOR 1

45 213-000005-16 CUSHION RUBBER 4

46 219-DA11BV-ZS CD MECHANISM 1

47 303-000072-1301 DUST COVER 1

48 202-082201-01 HEAT-SINK 1

49 238-056200-01 CASS KNOB COVER 1

50 183-100060-02 FERRITE BAR 1

51 374-059240-53J0 CD BRACKET 1

52 371-059221-6501 CD DOOR 1

53 375-059200-8KT0 CD DOOR LENS 1

37

Loading...

Loading...