RKI Instruments OX-03, CO-03, HS-03 Operating Manual

www.rkiinstruments.com

03 Series:

OX-03, CO-03, HS-03

Versions

Operator’s Manual

Part Number: 71-0304

Revision: C

Released: 9/26/18

03 Series Operator’s Manual

WARNING

Read and understand this instruction manual before operating

instrument. Improper use of the gas monitor could result in

bodily harm or death.

Periodic calibration and maintenance of the gas monitor is essen-

tial for proper operation and correct readings. Please calibrate

and maintain this instrument regularly! Frequency of calibration

depends upon the type of use you have and the sensor types.

Typical calibration frequencies for most applications are between

1 and 3 months, but can be required more often or less often

based on your usage.

03 Series Operator’s Manual Warranty

Warranty

RKI Instruments, Inc. warrants the OX-03 Single Gas Monitor sold by us to

be free from defects in materials, workmanship, and performance for a

period of two (2) years from the date of shipment from RKI Instruments,

Inc. and warrants the CO-03 and HS-03 Single Gas Monitors sold by us for

three (3) years from the date of shipment from RKI Instruments, Inc. This

includes the instrument and the original sensor. Replacement parts are

warranted for one (1) year from the date of their shipment from RKI

Instruments, Inc. Replacement sensors are warranted for two (2) years

from the date of their shipment from RKI Instruments, Inc. Any parts found

defective within their warranty period will be repaired or replaced, at our

option, free of charge. This warranty does not apply to those items, which

by their nature, are subject to deterioration or consumption in normal

service, and which must be cleaned, repaired, or replaced on a routine

basis. Examples of such items are as follows:

Warranty is voided by abuse including mechanical damage, alteration,

rough handling, or repair procedures not in accordance with the instruction

manual. This warranty indicates the full extent of our liability, and we are

not responsible for removal or replacement costs, local repair costs,

transportation costs, or contingent expenses incurred without our prior

approval.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER WARRANTIES

AND REPRESENTATIONS, EXPRESSED OR IMPLIED, AND ALL OTHER

OBLIGATIONS OR LIABILITIES ON THE PA RT OF RKI INSTRUMENTS, INC.

INCLUDING BUT NOT LIMITED TO THE WARRANTY OF MERCHANTABILITY OR

FITNESS FOR A PARTICULAR PURPOSE. IN NO EVENT SHALL RKI

I

NSTRUMENTS, INC. BE LIABLE FOR INDIRECT, INCIDENTAL, OR

CONSEQUENTIAL LOSS OR DAMAGE OF ANY KIND CONNECTED WITH THE USE

OF ITS PRODUCTS OR FAILURE OF ITS PRODUCTS TO FUNCTION OR OPERATE

PROPERLY.

This warranty covers instruments and parts sold to users only by

authorized distributors, dealers, and representatives as appointed by RKI

Instruments, Inc.

We do not assume indemnification for any accident or damage caused by

the operation of this gas monitor and our warranty is limited to replacement

of parts or our complete goods.

Absorbent cartridges

Filter elements, disks, or sheets

Pump diaphragms and valves

Table of Contents 03 Series Operator’s Manual

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Case . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Sensor Gasket, Sensor Membrane, and Charcoal Filter . . . . . . . . . . . . . . . . . . 10

Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

LCD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Control Buttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Alarm LED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Buzzer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Vibrator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

IrDA Port . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Printed Circuit Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Protective Rubber Boot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Alligator & Belt Clips . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Start Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Start-up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Performing a Fresh Air Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Turning Off the 03 Series . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Measuring Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Adjusting the Buzzer Volume . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Display Mode, CO-03 and HS-03 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Display Mode, OX-03 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Data Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

03 Series User Setup Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Calibration Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Calibration Frequency. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Using Calibration Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Setting the Date and Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Performing a Fresh Air Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

03 Series Operator’s Manual Table of Contents

Performing an Automatic Span Adjustment

(Zero Adjustment for OX-03) in A--CAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Performing an Easy Span Adjustment (Zero Adjustment for OX-03) in E--CAL.. 44

Performing a Manual Span Adjustment (Zero Adjustment for OX-03) in M--CAL 50

Performing a Bump Test in BUMP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Viewing the Instrument’s Firmware Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Setup Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Using Setup Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Setting the Date and Time in DATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Performing a Fresh Air Adjustment in AIR. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Performing an Automatic Span Adjustment

(Zero Adjustment for OX-03) in A--CAL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Performing an Easy Span Adjustment (Zero Adjustment for OX-03) in E--CAL.. 62

Performing a Manual Span Adjustment (Zero Adjustment for OX-03) in M--CAL 63

Setting the Alarm Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Adjusting the Bump Test Limit Check Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Setting the Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Replacing the Batteries. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Replacing the Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Replacing the Sensor Membrane and Charcoal Filter . . . . . . . . . . . . . . . . . . . . 74

Parts List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

WARNING: Understand this manual before operating the 03 Series.

Substitution of components may impair intrinsic safety.

To prevent ignition of a hazardous atmosphere, batteries

must only be changed in an area known to be

nonhazardous. This unit has not been tested in an

oxygen enrich ed atmosphere (above 21%).

6 • Introduction 03 Series Operator’s Manual

Introduction

Using an advanced microprocessor controlled detection system, the 03

Series Personal Single Channel Gas Monitor detects the presence of either

carbon monoxide (CO), hydrogen sulfide (H

2

S), or oxygen (O

2

). The 03

Series’ compact size and easy-to-use design make it ideally suited for a

wide range of applications, including sewage treatment plants, tunnels,

hazardous waste sites, petrochemical facilities, oil fields, mines, and

chemical plants. The 03 Series is even small enough to be placed

conveniently in a pocket. The 03 Series offers the following features:

• Compact design

• Fast, accurate response with backlit digital liquid crystal display (LCD)

• Visual, audible, and vibration alarms

• Microprocessor control for reliability, ease of use, and advanced

capabilities

• Resistance to RF (radio frequency) interference

• Datalogging including interval trend data and alarm trend data

• Peak, STEL, and TWA indication for CO-03 & HS-03

• Minimum and maximum indication for OX-03

• Over range alarm

• Gas, battery, sensor failure, and system failure alarms

• Over 3,000 hours operation on one set of alkaline batteries

• Rotatable alligator clip for “hands free” gas monitoring, belt clip optional

• CSA certification for intrinsic safety in Class I, Division I, Groups A, B,

C, and D hazardous atmospheres

WARNING: The 03 Series detects oxygen deficiency and elevated

levels of oxygen, carbon monoxide, and hydrogen

sulfide, all of which can be dangerous or life threatening.

When using the 03 Series, you must follow the

instructions and warnings in this manual to assure

proper and safe operation of the unit and to minimize the

risk of personal injury. Be sure to maintain and

periodically calibrate the 03 Series as described in this

manual.

03 Series Operator’s Manual Specifications • 7

Specifications

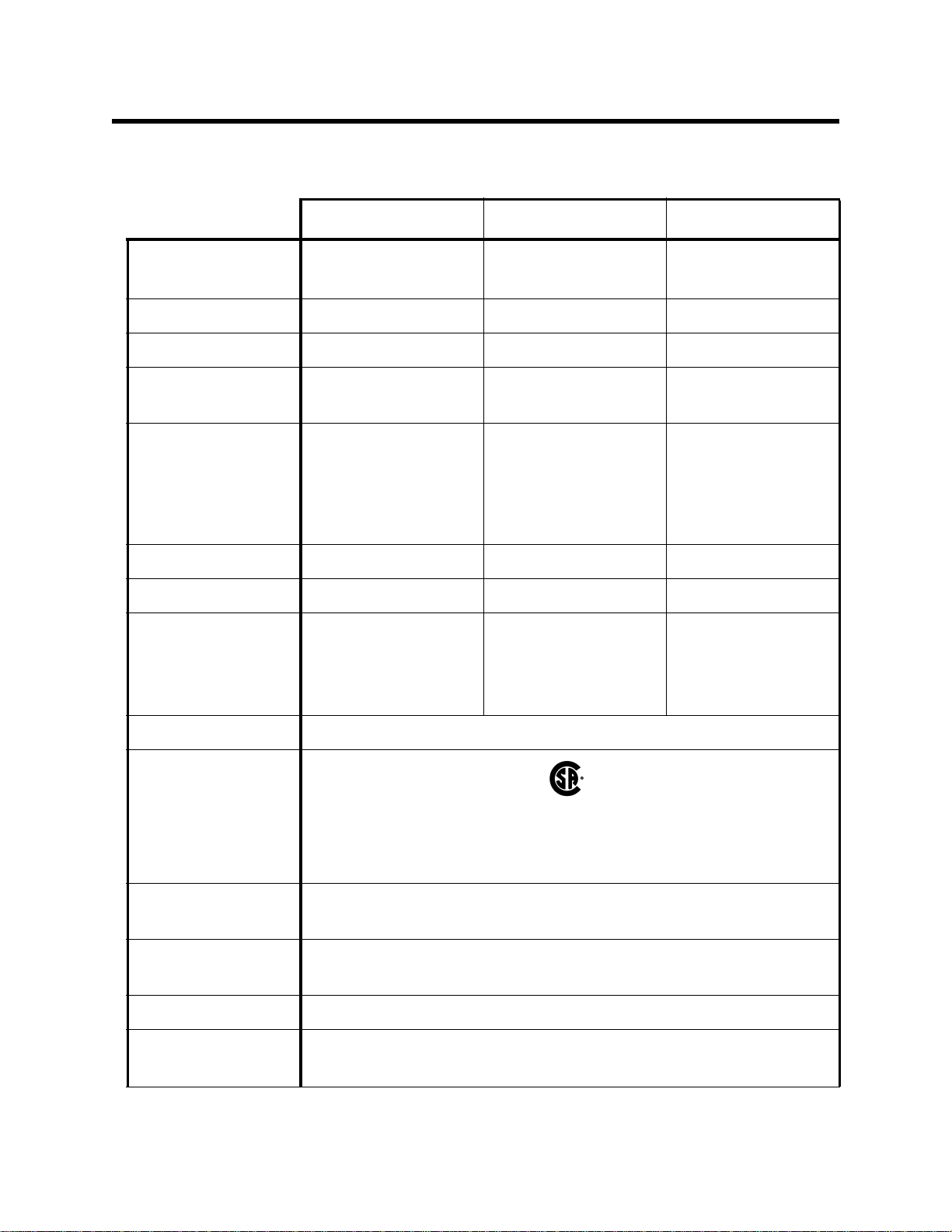

Table 1: 03 Series Specifications

CO-03 HS-03 OX-03

Target Gas Carbon Monoxide

(CO)

Hydrogen Sulfide

(H

2

S)

Oxygen

(O

2

)

Detection Range 0 to 500 ppm 0 to 100.0 ppm 0 to 40.0% vol.

Display Increment 1 ppm 0.5 ppm 0.1% vol.

Detection

Principle

Electro Chemical Electro Chemical Galvanic Cell

Alarm Points Low

High

TWA

STEL

25 ppm

50 ppm

25 ppm

200 ppm

Low

High

TWA

STEL

5.0 ppm

30.0 ppm

1.0 ppm

5.0 ppm

Low 19.5% vol.

(decreasing)

High 23.5% vol.

(increasing)

Sampling Method Diffusion Diffusion Diffusion

Response Time T90 in 30 seconds T90 in 30 seconds T90 in 20 seconds

Accuracy ± 5% of reading or

± 5 ppm CO

(whichever is

greater)

± 5% of reading or

± 2 ppm H

2

S

(whichever is

greater)

± 0.5% O

2

Indication Digital LCD

Safety/Regulatory

C US

186718

CSA classified, “C/US”, as Intrinsically Safe. Exia. Class I,

Groups A, B, C, & D. Temperature Code T3C.

Power Two AAA size alkaline batteries standard, Duracell MN2400 or

PC2400

Continuous

Operating Hours

At 25 °C: Over 3,000 hours, no alarms or backlighting

Case High-impact plastic, dust and weather proof

Standard

Accessories

• Rubber protective boot

• Alligator clip

8 • Specifications 03 Series Operator’s Manual

Optional

Accessories

• Calibration adapter

• Calibration kit

•Belt clip

• Wrist strap

• IrDA/USB cable for downloading data to computer

• Product CD, includes 03 Series Datalogging Program and

03 Series User Setup Program

Dimensions and

Weight

2.2” (54mm) W x 2.6” (67mm) H x 0.9” (24mm) D;

2.8 oz. (80 g)

Operating Temp. &

Humidity

-20°C to +50°C, 16 - 95% RH

(non condensing)

-20°C to +50°C,

0 - 95% RH (non

condensing)

Table 1: 03 Series Specifications

CO-03 HS-03 OX-03

03 Series Operator’s Manual Description • 9

Description

This section describes the components of the 03 Series.

Case

The 03 Series’ sturdy, high-impact plastic case is blue and consists of a

front and rear case. The case is suitable for use in many environmental

conditions, indoors and out. The unit is dust proof and weather resistant.

The front case has an LCD (liquid crystal display) that shows various

indications. Below the LCD are two black control buttons. The left button is

labeled “AIR” and the right button is labeled “POWER MODE”.

The buzzer opening is located in the top left corner of the front case. To the

right of the buzzer is the diffusion port for the sensor.

The alarm LED lens is located at the top of the front case.

The battery compartment is located in the rear case. Access to the

compartment is accomplished by turning the captive battery cover screw

counterclockwise and by removing the battery cover.

There are two spring bars on the rear case. One is on the left and one is on

the right. They are the same type of spring bar that is used to retain a

watch band and are used to mount the alligator clip or optional belt clip.

A feature in the lower left corner of the rear case is used to install the

optional wrist strap.

Bat tery Cover Screw

Battery Cover

CO

AIR

CO-03

LCD

Buzzer Opening

IrDA Port

Control Buttons

Wrist St r ap

Connection

POWER

MODE

Dif f usion Port

Alarm LED

Figure 1: Components of the 03 Series

10 • Description 03 Series Operator’s Manual

Sensor Gasket, Sensor Membrane, and Charcoal Filter

The sensor membrane is a paper-like filter disk that is held in place by the

sensor gasket and fits into a recessed area on the inside of the front case.

The sensor membrane covers the diffusion port and protects the sensor

from dirt and moisture. The sensor membrane should be inspected

periodically and replaced if contaminated by dirt or moisture. See

“Replacing the Sensor Membrane and Charcoal Filter” on page 74 for

sensor membrane replacement instructions.

The CO-03 includes a charcoal filter disk which is located in the sensor

gasket. The charcoal filter disk removes gases from the sampled air that

will cause a response on the CO sensor such as H

2

S and certain

hydrocarbons. If false or elevated CO readings are noticed, especially in

the presence of H

2

S, change the charcoal filter disk. See “Replacing the

Sensor Membrane and Charcoal Filter” on page 74 for replacement

instructions.

Sensor

The 03 Series uses either an oxygen, CO, or H

2

S sensor. The sensor is

protected by the white sensor membrane which is held in place by the

sensor gasket. The sensor membrane allows ambient air to diffuse past it

to the sensor. The three sensors used in the three 03 Series models use

different detection principles as described below.

Oxygen Sensor

The oxygen sensor is a galvanic type of sensor. A membrane covers the

cell and allows gas to diffuse into the cell at a rate proportional to the partial

pressure of oxygen. The oxygen reacts in the cell and produces a voltage

proportional to the concentration of oxygen. The voltage is measured by

the 03 Series’ circuitry, converted to a measurement of gas concentration,

and displayed on the LCD.

CO and H

2

S Sensors

The CO and H

2

S sensors are electrochemical sensors that consist of two

precious metal electrodes in an acid electrolyte. A gas permeable

membrane covers the sensor face and allows gas to diffuse into the

electrolyte. The gas reacts in the sensor and produces a current

proportional to the concentration of the target gas. The current is amplified

by the 03 Series’ circuitry, converted to a measurement of gas

concentration, and displayed on the LCD.

LCD

The LCD is visible through the front case. When the 03 Series is in

Measuring Mode, the target gas concentration, battery condition, and

alarm indications are displayed on the LCD. Various other items are

03 Series Operator’s Manual Description • 11

displayed when the LCD is in other modes, such as Calibration Mode.

When either of the two control buttons are pressed, the LCD backlight

comes on for 20 seconds.

Control Buttons

Below the LCD are two control buttons: POWER MODE and AIR. The

POWER MODE button turns the 03 Series on and off. The functions

performed by the control buttons are summarized in the following table:

Alarm LED

The 03 Series has one red alarm LED. It alerts you to gas, low battery, and

sensor failure alarms. The alarm LED is located at the top of the front case

beneath a clear plastic lens.

Buzzer

A solid-state electronic buzzer is mounted inside the 03 Series. An opening

in the top left corner of the front case allows the buzzer’s sound to emanate

from the case. The buzzer sounds for gas alarms, unit malfunctions, and

the dead battery alarm. It also serves as an indicator during normal use of

the various LCD display options.

Vibrator

A vibrating motor (vibrator) is mounted inside the 03 Series. The vibrator

vibrates momentarily during the power-up sequence and for gas alarms.

Table 2: 03 Series Control Buttons

Button Function

POWER MODE

• Turns the unit on and off.

• Turns the LCD back light on.

• Resets the alarm circuit (gas alarms).

• Enters Display Mode.

• Enters Calibration Mode with the AIR button.

• Enters Setup Mode with the AIR button.

AIR

• Turns the LCD back light on.

• Adjusts LCD reading when the fresh air

adjustment is performed.

• Enters Calibration Mode with the POWER MODE

button.

• Enters Setup Mode with the POWER MODE

button.

• Increases or decreases settings when the unit is in

Calibration Mode or Setup Mode.

12 • Description 03 Series Operator’s Manual

IrDA Port

An infrared (IR) communications port is located just to the left of the alarm

LED at the top of the front case beneath the clear lens. The data

transmitted through the port is in standard IrDA protocol. A computer’s

infrared port or an IrDA/USB cable connected to a computer’s USB port

can be used to download data saved by the 03 Series to a computer using

the 03 Series Data Logger Management Program. See the 03 Series Data

Logger Management Program operator’s manual for data logging and

downloading instructions.

Printed Circuit Board

The primary function of the 03 Series’ printed circuit board is to amplify the

signal sent to it from the sensor, convert the signal to a meaningful

measurement of gas concentration, display the gas concentration on the

LCD, store STEL, TWA, and peak gas readings, and activate the alarm

circuit if an alarm point has been reached. It monitors battery level, battery

failure, and sensor failure. It also controls various operating modes of the

unit.

NOTE: The printed circuit board contains no user serviceable parts.

Batteries

Two AAA-size alkaline batteries run the 03 Series. At 25°C the alkaline

batteries last at least 3,000 hours. The battery icon on the LCD shows

remaining battery life.

When the 03 Series detects low battery voltage, a low battery warning is

activated. When battery voltage is too low for normal operation, the 03

Series sounds a dead battery alarm.

The alkaline batteries can be replaced by removing the battery cover on

the rear case. Turn the captive battery cover screw counterclockwise to

release the door. See “Replacing the Batteries” on page 70 for detailed

battery changing instructions.

WARNING: To prevent ignition of a hazardous atmosphere, batteries

must only be changed in an area known to be

nonhazardous.

AVERTISSEMENT:Pour éviter l’inflammation d’une atmosphère

dangereuse, les batteries doivent uniquement être

modifiés ou facturés dans une zone connue comme non

dangereuse.

03 Series Operator’s Manual Description • 13

NOTE: Use of batteries not specified by RKI Instruments, Inc. will void the

CSA classification and may void the warranty. See “Replacing the

Batteries” on page 70.

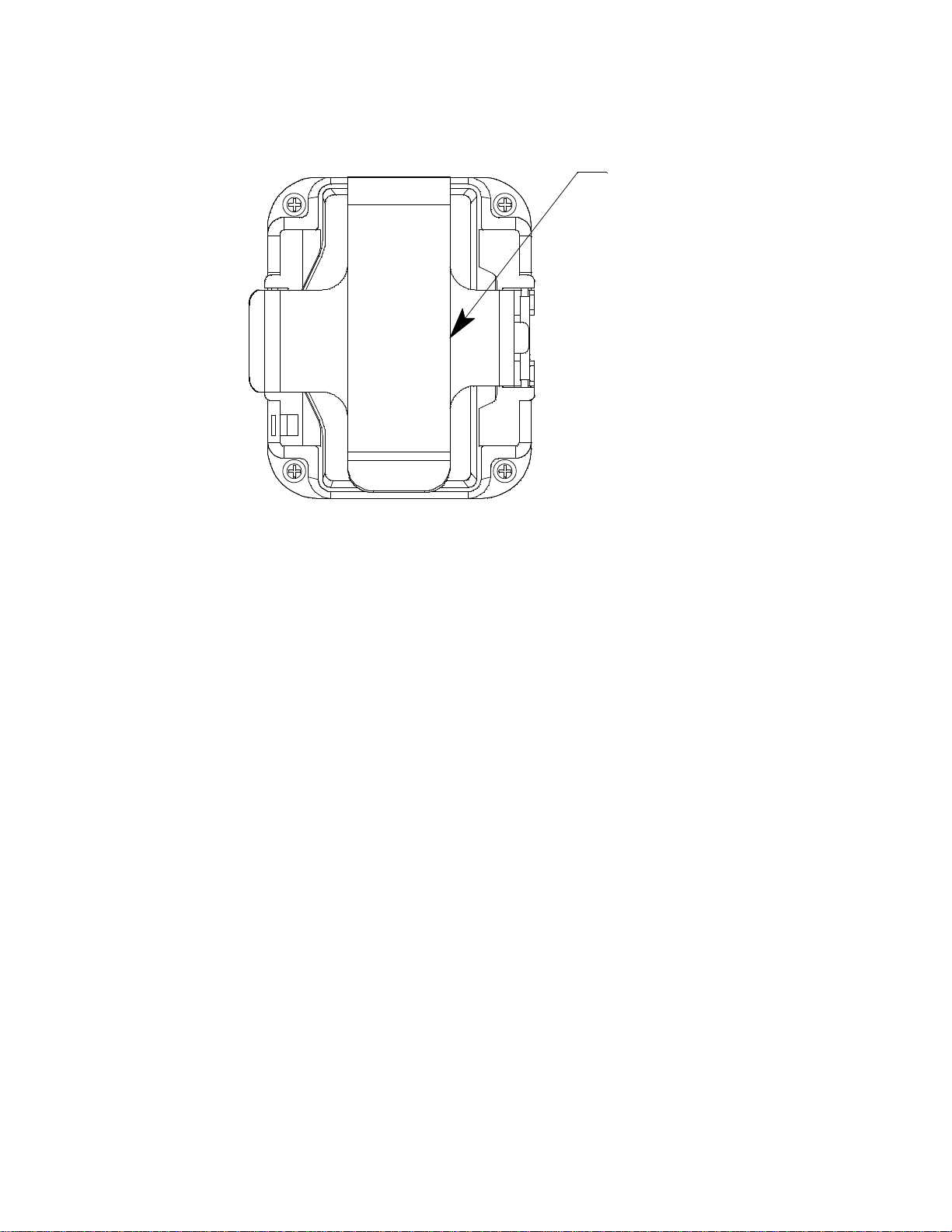

Protective Rubber Boot

A protective rubber boot is installed over the 03 Series.

Figure 2: Rubber Boot

Alligator and Belt Clips

The 03 Series is available with two types of clips: the alligator clip

(standard) and the belt clip (optional). The alligator clip is shown in Figure 3

below. The alligator clip can be used to attach the 03 Series to clothing or a

belt. Teeth in the clip’s jaws prevent the unit from slipping off. The clip can

be rotated in 45 degree turns if necessary.

Figure 3: Alligator Clip

Side Front

Open

Alligator Clip

Closed

14 • Description 03 Series Operator’s Manual

The belt clip is shown in Figure 4 below and is used to easily clip the 03

Series on a belt.

Figure 4: Belt Clip

Belt Clip

03 Series Operator’s Manual Start Up • 15

Start Up

This section explains how to start up the 03 Series and to get it ready for

operation.

NOTE: The screens shown in this section are for a CO-03. If you are

using a different version of the 03 Series, your instrument screen

will vary slightly from those shown below.

Start-up Procedure

1. Press and briefly hold down the POWER MODE button. The backlight

will turn on and all the display segments will turn on. Release the button

when you hear a beep.

2. The vibrator vibrates and the alarm light flashes momentarily.

3. The initial startup screen depends on how Bump Fail Behavior is set.

This parameter along with the Cal. Limit Display and Cal. Limit Check

parameters mentioned in Step 5 and the Auto Zero Adjustment

parameter mentioned in Step 12 below cannot be set using the 03

Series’ instrument menus, but are set using the 03 Series User Setup

Program. See the 03 Series User Setup Program Operator’s Manual for

information regarding changing various instrument parameters that are

not available for adjustment in the instrument’s operating modes.

•If Bump Fail Behavior is set to None (factory setting) or if it is set to

Can Not Use and the most recently performed bump test passed,

proceed to Step 5.

•If Bump Fail Behavior is set to Can Not Use and the most recently

performed bump test failed, the following screen will appear.

The instrument cannot be used until a successful bump test or

calibration is performed. See “Calibration Mode” on page 36 for

instructions.

4. If Cal. Limit Display is set to Off, proceed to Step 6.

C.AL

FAIL

16 • Start Up 03 Series Operator’s Manual

5. If Cal. Limit Display is set to On (factory setting), the screen that

appears next depends on how Cal. Limit Check is set.

• If the unit is due for calibration and Cal. Limit Check is set to

Confirm to use (factory setting), then the following screen sequence

will occur.

The alarm LED and buzzer will pulse several times.

To continue the startup sequence without performing a calibration,

press and release the AIR button. Continue to Step 6.

To perform a calibration, press and release the POWER MODE

button. Depending on the value entered into the One Touch Cal

Time parameter using the 03 Series User Setup Program, the

instrument will display either the A--CAL menu item or the E--CAL

menu item in Calibration Mode. See “Calibration Mode” on page 36

for instructions.

WARNING: You must press either the POWER MODE or AIR button to

continue. If you do not press a button, the buzzer will

continue to beep and the LED will continue to flash for 6

seconds every 5 seconds.

MODE

C.LIMIT

CAL

YES

C.LIMIT

CAL

AIR

C.LIMIT

CAL

NO

C.LIMIT

CAL

C.LIMIT

CAL

C.LIMIT

CAL

03 Series Operator’s Manual Start Up • 17

• If the unit is due for calibration and Cal. Limit Check is set to Can’t

use, then the following screen sequence will occur.

The alarm LED and buzzer will pulse several times. Press and

release the POWER MODE button. Depending on the value entered

into the One Touch Cal Time parameter using the 03 Series User

Setup Program, the instrument will display either the A--CAL menu

item or the E--CAL menu item in Calibration Mode. The above

screen will remain on the display until the unit is either turned off or

Calibration Mode is entered. The 03 Series cannot be used until a

complete calibration has been performed either by selecting A--

CAL, E--CAL, or M--CAL in the Calibration Mode menu. See

“Performing an Automatic Span Adjustment (Zero Adjustment for

OX-03) in A--CAL” on page 39, “Performing an Easy Span

Adjustment (Zero Adjustment for OX-03) in E--CAL” on page 44, or

“Performing a Manual Span Adjustment (Zero Adjustment for OX-

03) in M--CAL” on page 50 for calibration instructions.

WARNING: You must perform a successful calibration in order to

continue to normal operation. If you do not perform a

successful calibration, the screen sequence will

continue, the buzzer will continue to beep, and the LED

will continue to flash for 6 seconds every 5 seconds and

the unit will not enter normal operation.

• If a calibration is due and Cal. Limit Check is set to None, the

sequence below will occur twice.

MODE

C.LIMIT

FAIL

YES

C.LIMIT

FAIL

C.LIMIT

FAIL

MODE

C.LIMIT

YES

C.LIMIT

C.LIMIT

0d 0d

0d

18 • Start Up 03 Series Operator’s Manual

Press and release the POWER MODE button during this time to go

to the A--CAL or E--CAL menu item in Calibration Mode depending

on the value entered into the One Touch Cal Time parameter of the

03 Series User Setup Program. If no button is pressed, the

instrument will continue with the warmup sequence in Step 6 once

the sequence shown above has finished.

• If calibration is not due, then the following screen appears for a few

seconds indicating when the next calibration is due. “NEXT” and

“CAL” alternate on the bottom of the screen.

NOTE: The following screens in Step 6 only appear if Bump Test Limit

Display is set to On using the 03 Series User Setup Program. The

standard factory setting for this function is Off.

6. If Bump Test Limit Display is set to Off (factory setting), proceed to

Step 8.

7. If Bump Test Limit Display is set to On using the 03 Series User Setup

Program, the next screen will depend on how Bump Test Limit Check

is set in Setup Mode or using the 03 Series User Setup Program.

• If the unit is due for bump testing and Bump Test Limit Check is set

to Confirm to use (factory setting), then the following screen

sequence will occur.

CAL.

14. 2.17

180d

NEXT

14. 2.17

180d

BUMP

teSt

YES

NOW

teSt

MODE

BUMP

teSt

NOW

teSt

NO

BUMP

teSt

AIR

NOW

teSt

03 Series Operator’s Manual Start Up • 19

The alarm LED and buzzer will pulse several times.

To continue the startup sequence without performing a bump test,

press and release the AIR button. Continue to Step 8.

To perform a bump test, press and release the POWER MODE

button. The instrument will display the BUMP menu item in

Calibration Mode. See “Performing a Bump Test in BUMP” on

page 53 for instructions.

WARNING:You must press either the POWER MODE or AIR button to

continue. If you do not press a button, the screen

sequence will continue, the buzzer will continue to beep

and the LED will continue to flash for 6 seconds every 5

seconds.

• If the unit is due for bump testing and Bump Test Limit Check is set

to Can’t use, then the following screen sequence will occur.

The alarm LED and buzzer will pulse several times. Press and

release the POWER MODE button to go to the BUMP menu item in

Calibration Mode. The above screens will remain on the display until

the unit is either turned off or Calibration Mode is entered. The 03

Series cannot be used until a bump test has been performed. See

“Performing a Bump Test in BUMP” on page 53 for bump test

instructions.

WARNING:You must perform a successful bump test in order to

continue to normal operation. If you do not perform a

successful bump test, the buzzer will continue t o beep and

the LED will continue to flash for 6 seconds every 5

seconds and the unit will not enter normal operation.

BUMP

FAIL

YES

NOW

FAIL

MODE

BUMP

FAIL

NOW

FAIL

20 • Start Up 03 Series Operator’s Manual

• If a bump test is due and Bump Test Limit Check is set to None,

the sequence below will occur twice.

Press and release the POWER MODE button during this time to go

to the BUMP menu item in Calibration Mode. If no button is pressed,

the instrument will continue with the warmup sequence in Step 8

once the sequence shown above has finished.

NOTE: If a successful calibration is performed, the next bump test date is

reset and starts over even though a bump test was not performed.

• If bump testing is not due, then the following screen appears for a

few seconds indicating when the next bump test is due. “NEXT” and

“BUMP” alternate on the bottom of the screen.

8. The Date/Time Screen appears for a few seconds.

This screen displays the current date and time.

9. The Battery Voltage Screen appears for a few seconds.

MODE

BUMP

YES

BUMP

BUMP

0d 0d

0d

BUMP

14. 2.17

180d

NEXT

14. 2.17

180d

8:20

2014

1.31

bAtt

3.0

V

03 Series Operator’s Manual Start Up • 21

The screen displays the current battery voltage.

CAUTION: If the unit gives a low batt ery warning or dead battery alarm,

change the alkaline batteries before using the unit.

10.The display then indicates the following items for about a second each:

• Full scale value

• Warning setpoint (low gas alarm)

• Alarm setpoint (high gas alarm)

• STEL alarm setpoint (CO and H2S only)

• TWA alarm setpoint (CO and H2S only)

11. If the 03 Series experiences a sensor failure during start up, the

following screen will appear.

The instrument cannot be used if a sensor failure occurs. Replace the

failed sensor.

12. If Auto Zero Adjustment is set to On (factory setting is Off), then the

03 Series will perform an automatic fresh air adjustment.

If the fresh air adjustment is successful, the unit will proceed to Normal

Mode. If the sensor fails the air adjustment, the screen will indicate the

failure. If a failure occurs, press and release the POWER MODE button

to proceed to Normal Mode. Replace the failed sensor as soon as

possible.

SENSOR

FAIL

ZERO

AUTO

- - - -

22 • Start Up 03 Series Operator’s Manual

WARNING: If the Auto Zero Adjustment feature is turned on, mak e

sure that you start-up the 03 Series in a known fresh air

environment, an environment free of combustible or toxic

gasses and of normal oxygen content, 20.9%. If you do

not start-up the unit in a fresh air environment, the fresh

air adjustment will not be accurate.

13.The 03 Series is now operating in Measuring Mode and monitoring for

gas. The Normal Operation Screen appears and the instrument beeps

once.

The gas concentration of the target gas is displayed along with the

battery charge level in the lower left corner. The heart symbol displayed

in the upper right corner flashes while the instrument is functioning

properly. If it disappears or is steadily on, the unit is experiencing a

microprocessor error. The backlight turns off after 20 seconds.

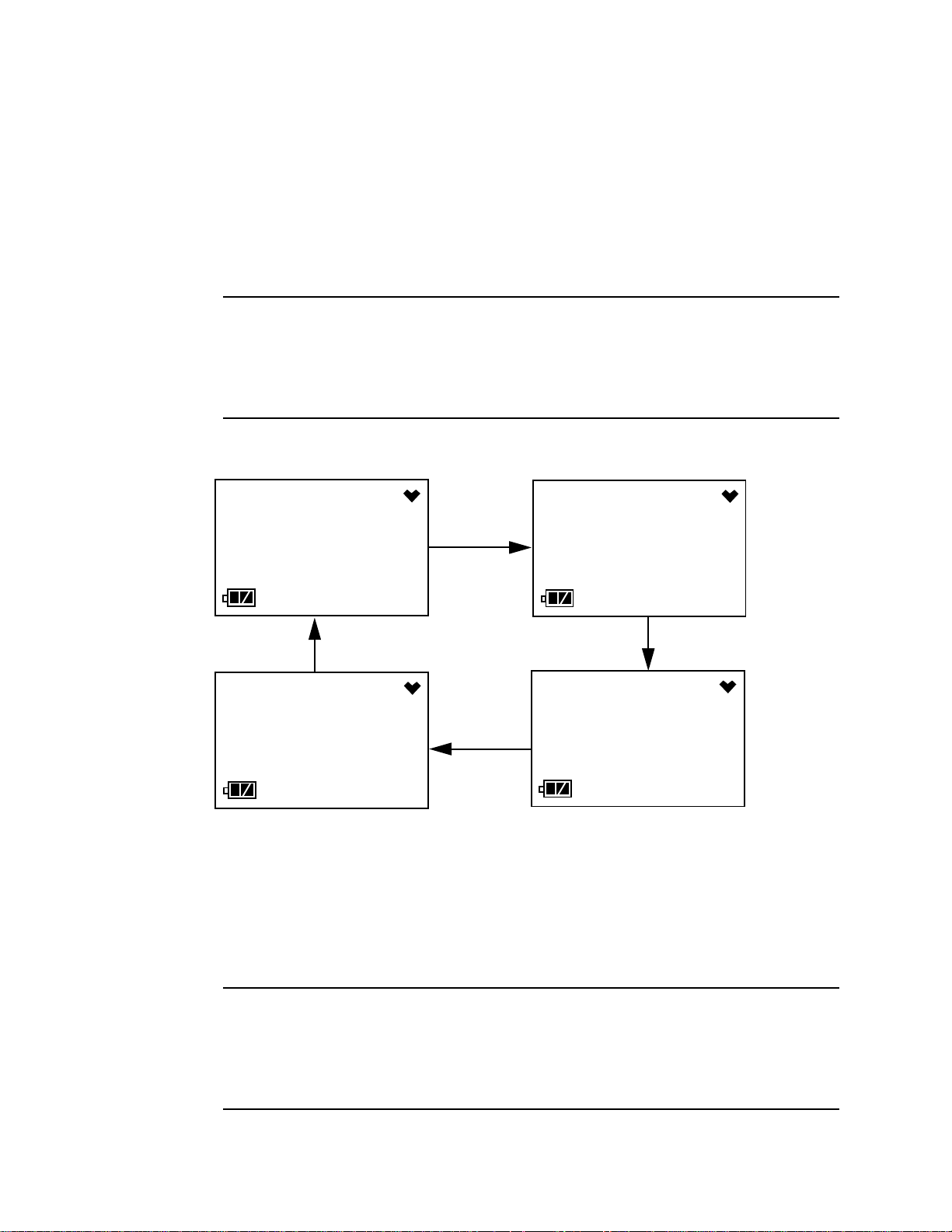

Performing a Fresh Air Adjustment

Before using the 03 Series, set the fresh air reading. Performing this

adjustment ensures accurate gas readings in the monitoring environment.

1. Find a fresh air environment of normal oxygen content (20.9%) that is

free of toxic or combustible gases.

2. With the unit on and in Measuring Mode, press and hold the AIR button.

The LCD displays “hold” prompting you to hold the AIR button.

CO

ppm

0

AIR

HOLD

- - - -

03 Series Operator’s Manual Start Up • 23

3. Release the AIR button when the following screen appears. The unit

will set the reading to 0 ppm (20.9% for the OX-03) and return to

Measuring Mode.

Turning Off the 03 Series

1. Press and hold the POWER MODE button for about five seconds to

turn off the unit. The buzzer will pulse while the POWER MODE button

is being pressed before the unit turns off.

2. Release the button when the LCD is blank. The unit is off.

NOTE: If Power Off Password Protection is turned On (factory setting is

Off) using the 03 Series User Setup Program, a password is

required to turn the 03 Series off. When the password screen

appears, adjust each digit with the AIR button and press and

release the POWER MODE button to move on to the next digit.

Once the password has been entered, the instrument will shut off

and the LCD will be blank.

ADJ

- - - -

24 • Operation 03 Series Operator’s Manual

Operation

This section describes Measuring Mode, setting the buzzer volume,

Display Mode, and alarm indications.

NOTE: The screens shown in this section are for a CO-03. If you are

using a different version of the 03 Series, your instrument screen

will vary slightly from those shown below.

Measuring Mode

In Measuring Mode, the battery level and target gas concentration are

displayed on the LCD. The battery icon has three bars visible when the

batteries have a full charge. As the battery charge decreases, the bars will

gradually disappear, one by one. The heart symbol displayed in the upper

right corner flashes while the instrument is functioning properly. If it

disappears or is steadily on, the unit is experiencing a microprocessor

error.

The target gas concentration is displayed in the middle of the LCD. On the

CO-03, CO is displayed in parts per million (ppm). On the HS-03, H

2

S is

displayed in ppm. On the OX-03, oxygen is displayed as volume percent.

Adjusting the Buzzer Volume

The buzzer volume on the 03 Series can be adjusted while in Measuring

Mode if Buzzer Volume Selection is set to On (factory setting is Off). The

Buzzer Volume Selection setting can be adjusted using the 03 Series

User Setup Program. The default buzzer volume setting is HI. If it is

changed to LO, the setting will revert back to HI the next time the

instrument is turned on.

1. Make sure the 03 Series is in the Measuring Mode Normal Operation

screen.

2. Press and hold the POWER MODE and AIR buttons simultaneously.

NOTE: To avoid entering Display Mode, press the AIR button slightly

sooner than pressing the POWER MODE button.

Release both buttons when the instrument starts simulating an alarm

CO

ppm

0

Loading...

Loading...