Page 1

Test Equipment Depot - 800.517.8431 - 99 Washington Street Melrose, MA 02176 - TestEquipmentDepot.com

LR-60B/LS-60 Latching Crimp Heads Instructions

WARNING

Read and understand

these instructions, the

electrical tool instructions, the instructions

for the dies to be used,

connector to be crimped and the warnings and instructions for all

equipment and material being used before operating this tool to

reduce the risk of serious personal injury.

the instructions for the

SAVE THESE INSTRUCTIONS!

• Keep your fingers and hands away from the crimp head during

the crimping cycle. Your fingers or hands can be crushed, fractured

or amputated if they are caught between the dies or the components

and any other object.

• Do not use on energized electrical lines to reduce the risk of elec-

trical shock, severe injury and death. Tool is not insulated Use

appropriate work procedures and personal protective equipment when

working near energized electrical lines.

• Large forces are generated during product use that can break or

throw parts and cause injury. Stand clear during use and wear appropriate protective equipment, including eye protection.

• Never repair a damaged head.A head that has been welded, ground,

drilled or modified in any manner can break during use. Never replace

individual components. Discard damaged heads to reduce the risk of

injury.

• Use proper tool, die, connector and cable combination. Improper

combinations can result in an incomplete or improper crimp which increases the risk of fire, severe injury or death.

NOTICE

Sel

ection of appropriate materials and joining methods is the

responsibility of the system designer and/or installer. Before any installation is attempted, careful evaluation of the specific re quire ments should be

completed. Consult connector manufacturer for selection information.

Description

RIDGID®LR-60B/LS-60B Latching Crimp Head Tools are designed to

crimp electrical compression connectors to their respective wire when

used with appropriate dies.

The tool is available either as an interchangeable head (For RIDGID

RE 6/RE 60 or Ilsco Electrical Tool) or as part of a dedicated tool (RIDGID

RE-600 series tools).

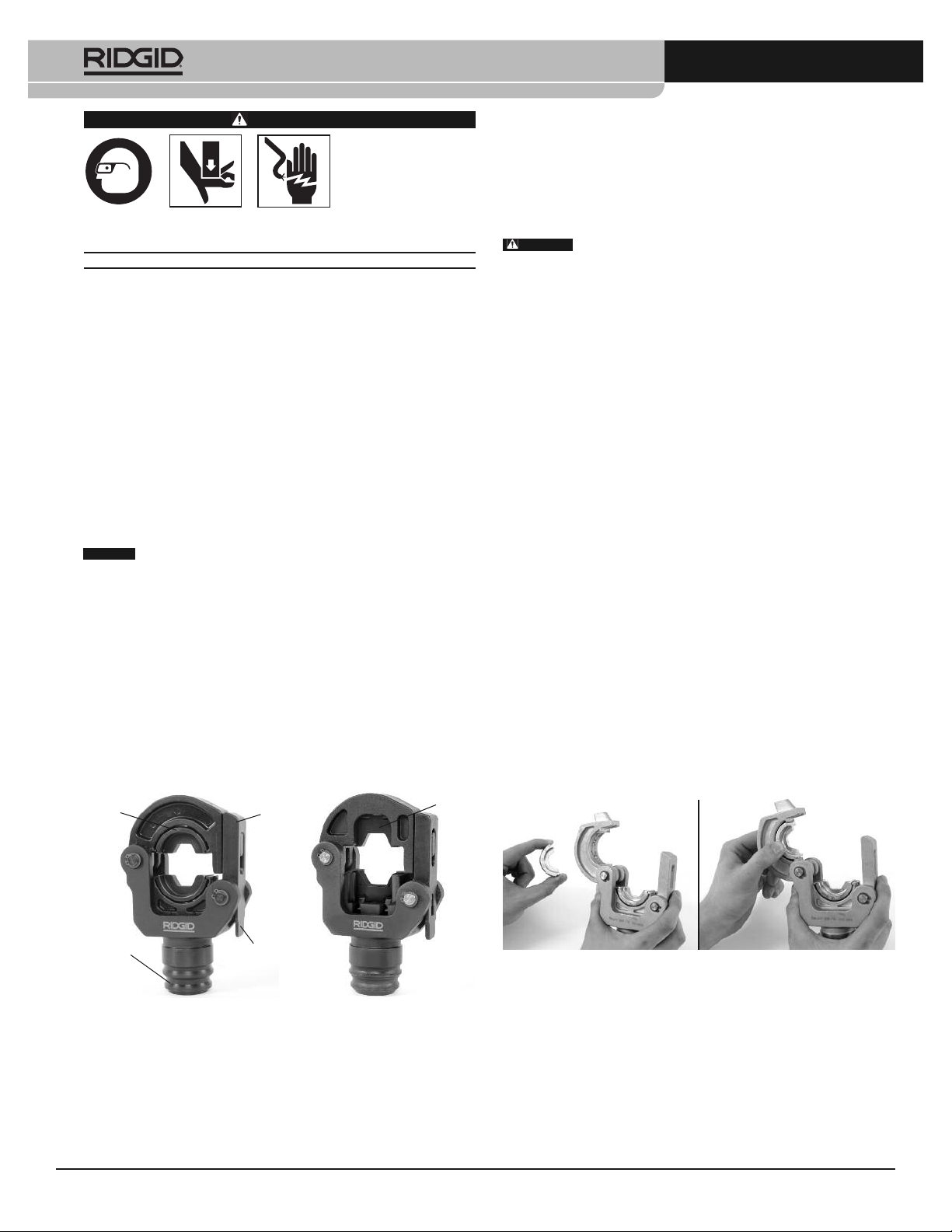

Round

Dies

Latch

Square

Dies

Max. Cable Size...................300 mm

2

185 mm

600 MCM 350 MCM

Go to RIDGID.com/CrimpDies for the RIDGID Crimp Die/Electrical

Connector Compatibility Charts.

Tool Input Force ...................60 kN (6-ton) (13,500 lbs.)

QCS Coupling Type .............6T QCS and 60kN QCS

Interchangeable Head

Weight..................................3.4 lbs. (1.6 kg) 3.4 lbs. (1.6 kg)

WARNING

Do not use LR-60B/LS-60B Crimp Heads with RIDGID

RE 53 Electrical Crimp Tools. This may cause incomplete crimps.

Inspection/Maintenance

Inspect the Latching Crimp Head before each use for issues that could

affect safe use.

1. Remove battery from electrical tool.

2. Clean any oil, grease or dirt from the tool and head, including handles and controls. This aids inspection and helps prevent the machine from slipping from your grip.

3. Inspect the head for:

• Proper assembly and completeness.

• Wear, corrosion or other damage. Make sure that the latch works

properly and securely closes.

• Presence and readability of head markings.

• See electrical tool manual for inspection and maintenance of the

QCS coupling

If any issues are found, do not use the tool until corrected.

4. Inspect the electrical tool and any other equipment being used as

directed in their instructions. Confirm that the crimp dies are a clean,

undamaged matched set.

5. Lubricate the head pivot points with a light weight general purpose

lubricating oil. Wipe off any excess oil.

Set Up/Operation

1. Prepare the connection to be crimped per the connector manufacturer’s instructions.

2. Choose the appropriate crimp dies and equipment for the application per their specifications. Make sure all equipment is inspected

and set up per its instructions.

3. Remove battery from electrical tool. Open the Latching Crimp Head

by pressing the latch release. Insert matching dies into the head.

Dies should fit snugly and securely, and the crimping profiles should

®

®

align. Do not force dies into head. If there are any issues with die fit,

do not use the tool. Do not operate tool without dies installed.

Do not use with 12 ton or 130 kN dies. This could cause improper

crimp connections.

2

QCS

Coupling

Latch

Release

Figure 2 – Installing Dies in Crimp Head

4. Changing Heads with QCS Coupling – See electrical tool manual.

Figure 1 – Round Crimp Head Square Crimp Head

(Interchangeable versions)

Specification

Dies Used ............................Commercially Commercially

RIDGID Die Series...............RDD-60, RDK-60 SDD-60

Printed 2/17

EC42593 REV. D

LR-60B LS-60B

Available Round Available Square

60 kN & 6 Ton 60 kN

Conforming to DIN

48083 Type 6M

©2015, 2017 RIDGID, Inc.

The Emerson logo and RIDGID logo are registered trademarks of Emerson Electric Co. or RIDGID, Inc. in the U.S. and other countries.

All other trademarks belong to their respective holders.

5. With dry hands install the tool battery.

6. If needed, open the head by pressing the latch release and close

the head around the connector to be crimped. Make sure that the

latch is fully closed – do not operate the tool with the latch open or

partially open.

7. Follow all compression connector manufacturers’ instructions for

crimp location. Some wire sizes may require more than one crimp

per connection.

Center the connector squarely against the crimp profile in the stationary die. Improper placement can make an incorrect crimp or

damage the equipment.

999-999-472.09

Page 2

LR-60B/LS-60B Latching Crimp Heads Instructions

If making a single crimp, line up the dies within the lines on the connector. If making multiple crimps on the connector, ensure there is

enough room to evenly space crimps between lug lines.

Stationary Die

Figure 3 – Aligning the Connector in the Dies

8. With hands clear of the head and other moving parts, operate the

Electrical Tool as per its instructions. After a complete cycle the ram

will retract and the tool will stop. If the ram does not retract, the crimp

is not complete and must be repeated.

9. If the ram does not fully retract, press the electrical tool pressure release button. If needed, move the head and repeat the procedure for

multiple crimps.

10. Remove the crimped connection from the head.

11. Inspect and test the connection in accordance with fitting supplier instructions, normal practice and applicable codes.

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

Loading...

Loading...