RIDGID KJ-5000 User Manual

KJ-5000Manual

Water Jetting Machine

KJ-5000 Water Jetting Machine

Table of Contents

Recording Form For Machine Serial Number ............................................................................................................1

Safety Symbols..............................................................................................................................................................2

General Power Tool Safety Warnings

Work Area Safety ........................................................................................................................................................2

Electrical Safety ..........................................................................................................................................................2

Personal Safety ..........................................................................................................................................................2

Tool Use And Care ......................................................................................................................................................2

Service ........................................................................................................................................................................3

Water Jetter Safety ........................................................................................................................................................3

Description, Specifications And Standard Equipment

Description ..................................................................................................................................................................4

Specifications..............................................................................................................................................................4

Standard Equipment ..................................................................................................................................................4

Machine Assembly

Engine Oil ..................................................................................................................................................................5

Pump/Gearbox Oil ......................................................................................................................................................5

Pre-Operation Inspection..............................................................................................................................................5

Machine and Work Area Set-Up....................................................................................................................................6

Water Supply ..............................................................................................................................................................7

Drain Preparation ........................................................................................................................................................7

Hose Set-Up ..............................................................................................................................................................7

Jetter Hose Selection Chart ........................................................................................................................................9

Jetter Nozzle Selection Chart ....................................................................................................................................9

Operating Instructions..................................................................................................................................................9

Jetting the Drain ........................................................................................................................................................11

Draining Water from System......................................................................................................................................12

Using Water Jetter Machine as a Pressure Washer ..................................................................................................12

Pressure Washer Operation ......................................................................................................................................13

Hose Reel Brake Adjustment ....................................................................................................................................13

Transportation and Storage ......................................................................................................................................13

Maintenance Instructions

Cleaning....................................................................................................................................................................13

Engine ......................................................................................................................................................................13

Battery ......................................................................................................................................................................13

Pump Lubrication/Maintenance ................................................................................................................................14

Gearbox Lubrication..................................................................................................................................................14

Preparing Pump for Cold Weather Storage ..............................................................................................................14

Optional Equipment ....................................................................................................................................................14

Machine Storage..........................................................................................................................................................14

Service And Repair......................................................................................................................................................15

Disposal ......................................................................................................................................................................15

Troubleshooting ..........................................................................................................................................................15

Maintenance Log ........................................................................................................................................................16

Lifetime Warranty ..........................................................................................................................................Back Cover

*Original Instructions - English

ii

KJ-5000

Water Jetting Machine

WARNING!

Read this Operator’s Manual

carefully before using this

tool. Failure to understand

and follow the contents of

this manual may result in

electrical shock, re and/or

serious personal injury.

KJ-5000 Water Jetting Machine

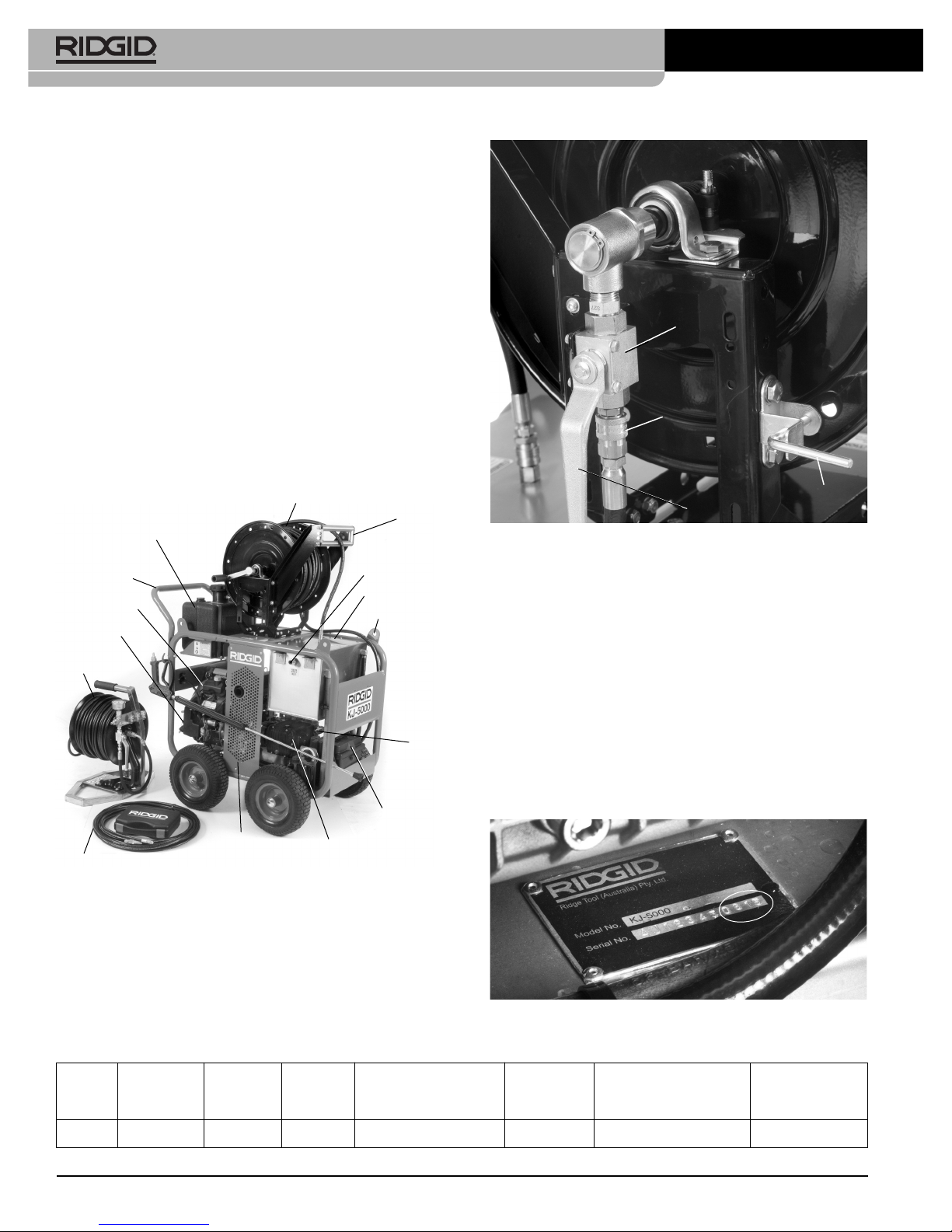

Record Serial Number below and retain product serial number which is located on nameplate.

Serial

No.

KJ-5000 Water Jetting Machine

Safety Symbols

In this operator’s manual and on the product, safety symbols and signal words are used to communicate important safety information. This section is provided to improve understanding of these signal words and symbols.

his is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages that follow this

T

symbol to avoid possible injury or death.

DANGER

WARNING

CAUTION

NOTICE

NOTICE indicates information that relates to the protection of property.

This symbol means read the operator’s manual carefully before using the equipment to reduce the risk of injury. The operator’s manual contains important information on the safe and proper operation of the equipment.

This symbol means always wear safety glasses with side shields or goggles when handling or using this equipment to reduce

the risk of eye injury.

This symbol indicates the risk of high pressure water directed at body parts, causing skin puncture and injection injuries.

This symbol indicates the risk of the jetter hose whipping, and causing striking or injection injuries.

This symbol indicates the risk of breathing carbon monoxide and causing nausea, fainting or death.

This symbol indicates the risk of fire and explosion from gasoline or other sources causing burns and other injury.

DANGER indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING indicates a hazardous situation which, if not avoided, could result in death or serious injury.

AUTION indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

C

General Safety Rules

WARNING

Read and understand all instructions. Failure to follow all instructions listed below may result in

electric shock, fire, and/or serious injury.

SAVE THESE INSTRUCTIONS!

Work Area Safety

• Keep work area clean and well lit. Cluttered bench-

es and dark areas invite accidents.

Personal Safety

• Stay alert, watch what you are doing and use common sense when operating a power tool. Do not

use a tool while you are tired or under the influence

of drugs, alcohol, or medication. A mo ment of inat-

tention while operating power tools may result in serious

personal injury.

• Dress properly. Do not wear loose clothing or jew-

elry. Contain long hair. Keep your hair, clothing

and gloves away from moving parts. Loose clothes,

jewelry, or long hair can be caught in moving parts.

• Do not operate power tools in explosive atmo-

spheres, such as in the presence of flam mable liquids, gases, or dust. Power tools create sparks which

may ignite the dust or fumes.

• Keep bystanders, children, and visitors away while

operating a power tool. Distractions can cause you to

lose control.

Electrical Safety

• Avoid body contact with grounded surfaces such

as pipes, radiators, ranges and refrigerators. There

is an increased risk of electrical shock if your body is

grounded.

2

• Do not overreach. Keep proper footing and balance

at all times. This enables better control of the tool in

unexpected situations.

• Use safety equipment. Always wear eye protection.

Dust mask, non-skid safety shoes, hard hat, or hearing

protection must be used for appropriate conditions

will reduce personal injuries.

Tool Use And Care

• Do not force the tool. Use the correct tool for your

application. The correct tool will do the job better and

safer at the rate for which it is designed.

• Do not use the power tool if the switch does not

J-5000 Water Jetting Machine

K

turn it ON and OFF. Any power tool that cannot be

ontrolled with the switch is dangerous and must be

c

repaired.

Store idle tools out of the reach of children and

•

other untrained persons. Tools are dangerous in

the hands of untrained users.

• Maintain tools with care. Keep cutting tools sharp

and clean. Properly maintained tools with sharp cutting

edges are less likely to bind and are easier to control.

• Check for misalignment or binding of moving

parts, breakage of parts and any other condition

that may affect the tool’s operation. If damaged,

have the tool serviced before using. Many acci-

dents are caused by poorly maintained tools.

• Use only accessories that are recommended by the

manufacturer for your model. Accessories that may

be suitable for one tool, may become hazardous when

used on another tool.

Service

• Tool service must be performed only by qualified

repair personnel. Service or maintenance performed

by unqualified personnel could result in a risk of injury.

• When servicing a tool, use only identical replace-

ment parts. Follow instructions in the Maintenance

section of this manual. Use of unauthorized parts or

failure to follow Maintenance Instructions may create a

risk of electrical shock or injury.

creases the risk of injury, including burns, and damage

o the jetter.

t

• One person must control the jetting process and

ater flow. If the jetter hose comes out of the drain, the

w

operator must be able to shut off the water flow to

reduce the risk of the jetter hose whipping, causing

striking and high pressure injection injuries.

• Always use appropriate personal protective equip-

ment while handling and using drain cleaning

equip ment. Drain may contain chemicals, bacteria

and other substances that may be toxic, infectious,

cause burns or other issues. Appropriate personal

protective equipment (PPE) includes safety glasses

and gloves, and may also include equipment such as

latex or rubber gloves, face shields, goggles, protective

clothing, respirators, head protection, hearing protection

and steel toed footwear.

• Practice good hygiene. Use hot soapy water to

wash hands and other body parts exposed to drain

contents after handling or using drain cleaning

equipment. Do not eat or smoke while operating or han-

dling drain cleaning equipment. This will help prevent

contamination with toxic or infectious material.

• Do not spray toxic or flammable liquids. This will

reduce the risk of burns, fire, explosion or other injury.

• Gasoline and its vapors are highly flammable and

explosive. See engine manual for precautions to

reduce the risk of burns, explosions and serious injury

while handling and using gasoline.

Water Jetter Safety

WARNING

This section contains important safety information

that is specic to this tool.

Read these precautions carefully before using this

Drain Cleaning Machine to re duce the risk of electrical shock or other serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE!

Keep this manual with machine for use by the operator.

• Never operate the jetter with the hose end outside of

the drain. Hose can whip, causing striking injuries and

spray can penetrate skin and cause serious injury.

• High pressure water can inject under skin resulting

in serious injury including amputation. Do not

direct spray at people or animals.

• Do not operate jetter above the 5075 psi pressure

rating or 60°C (inlet water temperature). This in -

• Engines produce carbon monoxide, a colorless,

odorless poison gas. Breathing carbon monoxide can cause nausea, fainting or death. Do not start

and run engine in an enclosed area, even if doors

and windows are open. Only operate outside.

• Hot surfaces can cause burns and fire. Keep body

parts and flammable material away from hot surfaces.

• Read and understand this manual, the engine

manual and the warnings and instructions for all

equipment and material being used with this tool

before operating. Failure to follow all warnings and

instructions may result in property damage and/or

serious injury.

• Follow all applicable workplace health and safety

regulations and guidelines concerning the use of

this equipment.

®

If you have any question concerning this RIDGID

product:

– Contact your local RIDGID®distributor.

– Visit RIDGID.com/au/en to find your local Ridge Tool

contact point.

3

KJ-5000 Water Jetting Machine

– Contact Ridge Tool Technical Service Department at

ridgid.australia@emerson.com, or call 1800 743 443.

Description, Specications

And Standard Equipment

Description

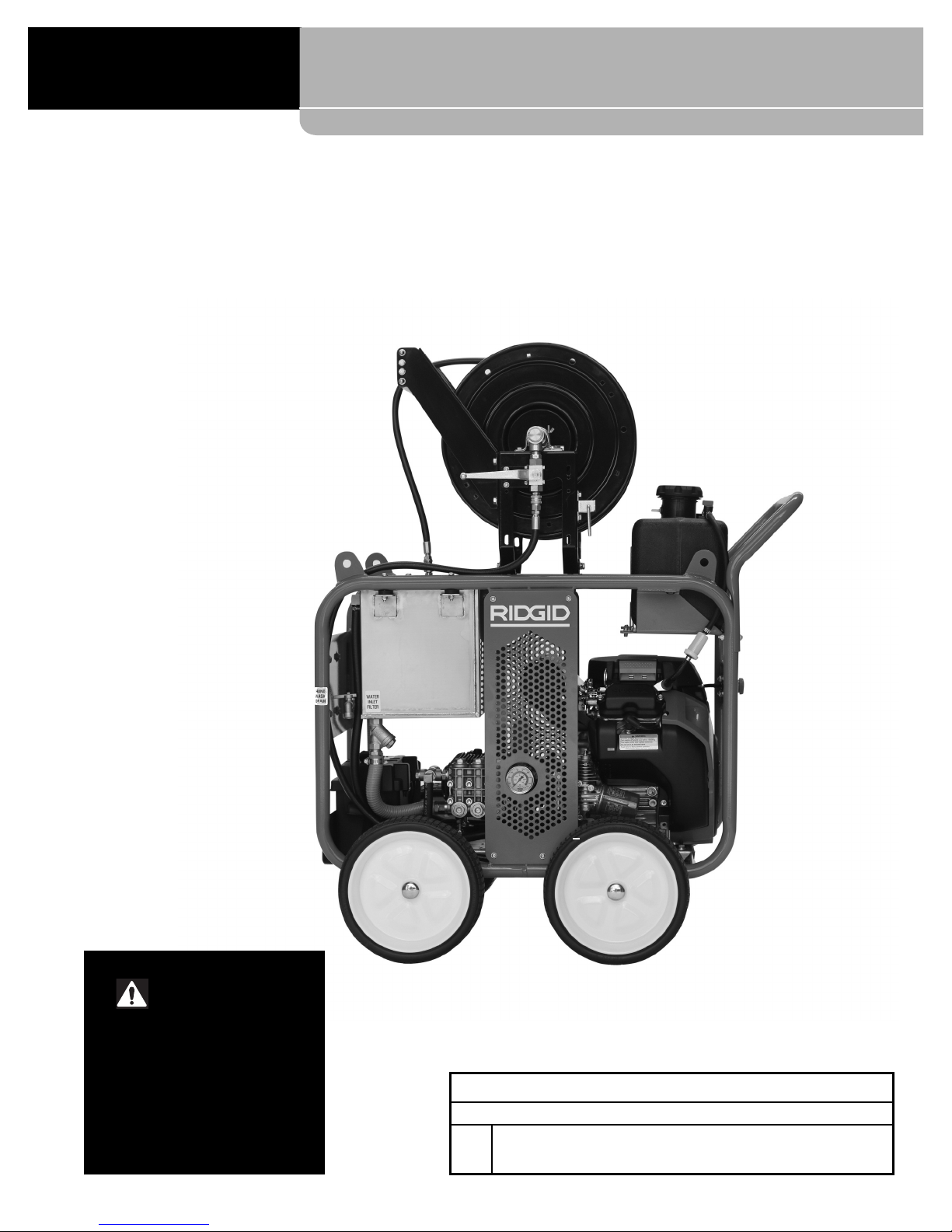

The RIDGID®KJ-5000 Engine Powered Water Jetting

Machine is a portable high pressure water jetter designed

to use a combination of water pressure and flow to clear

grease, sludge, sediment and roots out of drains. A highly flexible and lightweight hose is propelled through the

drain pipe by the reverse jets on the jetter nozzle, and

when retrieved scrubs the line flushing debris away. The

KJ-5000 Water Jetter equipped with a gasoline engine to

drive the triplex plunger pump. A 36 liter water tank with

low water level shut-off allows operation with low water

supply flow rates.

rimary Hose Reel

P

Fuel Tank

Handle

Engine

Engine Controls

Remote Reel

with Hose

Wash Wand

Whip Hose and Nozzle Box

Figure 1 – KJ-5000 Water Jetting Machine

Battery Isolator

uide Hose

G

Water

Inlet/Supply

Water Tank

Lift Points

Pump

y

ter

at

B

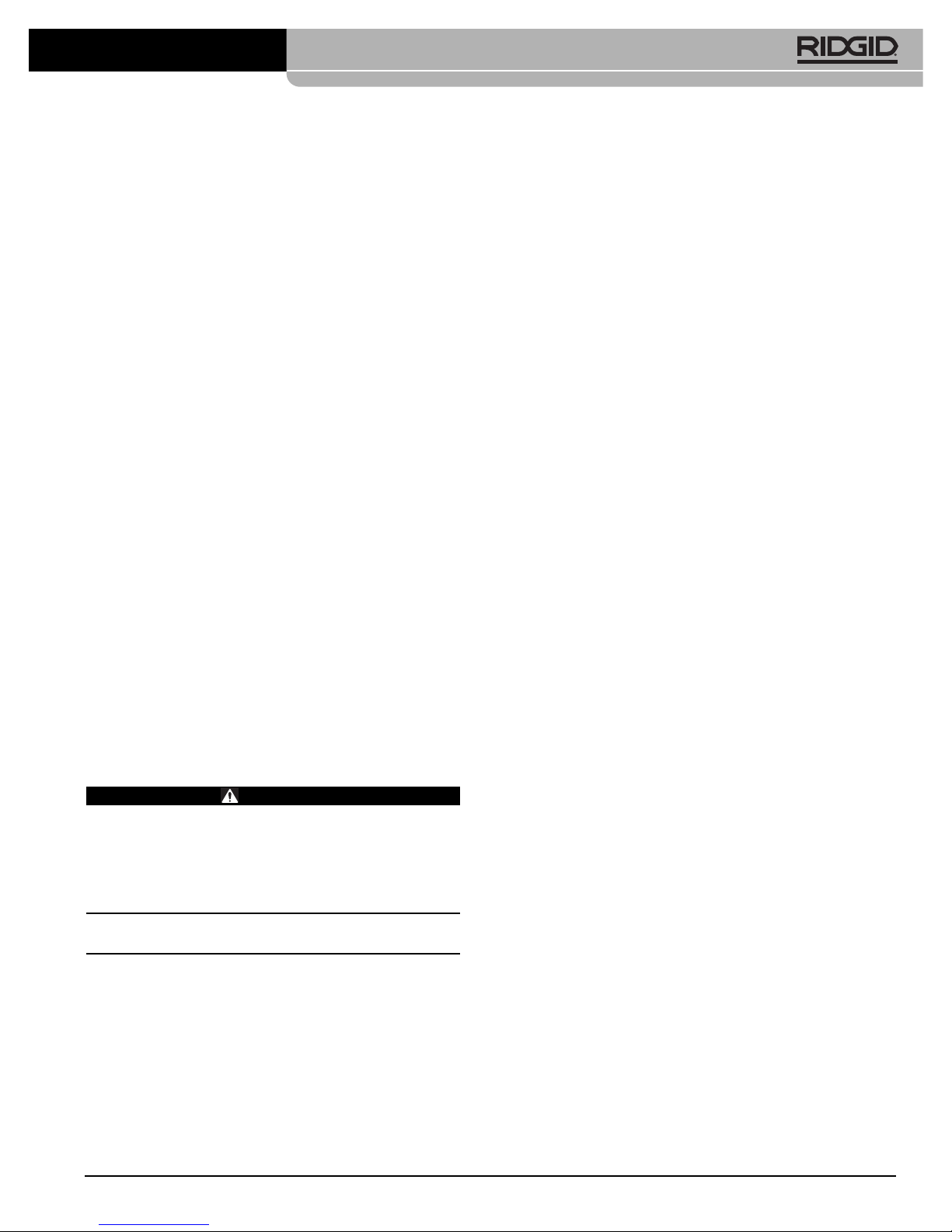

Ball Valve

Lead Hose

with Quick

Connect

ocking Pin

L

Handle

Figure 2 – Hose Reel

Standard Equipment

All KJ-5000 Water Jetters come with:

• Primary hose reel with 60m of 3/8" jetter hose

• Remote hose reel with 60m of 1/4" jetter hose

• 15m flexible leader hose with nozzle

• Appropriate Jetter Nozzles

• Nozzle Cleaning Tool

• Wash wand

• Engine Operator’s Manual

• Operator’s Manual

See the RIDGID catalog for specific equipment supplied

with each catalog number.

Specications

Jetter Engine Pressure Flow Rate Drain Line Capacity Water Tank Maximum Hose Length Weight (kg)

Model Displacement (PSI/BAR) (LPM) (inch/mm) (liters) (meters/feet) (with Primary

(cc) Hose Reel, dry)

KJ-5000 690 5075/350 23 2"/50mm - 10"/250mm 36L Up to 100m (328 ft) 195 kg

4

Figure 3 – Machine Serial Number

Loading...

Loading...