Page 1

Technical Bulletin No. RTB-054

2 [B]

SUBJECT: Finisher Tray Control DATE: Nov. 15, ’93

PAGE: 1 of 2

PREPARED BY: H.Terashita

CHECKED BY:

CLASSIFICATION:

Action Required

Troubleshooting

Retrofit Information

Since the finisher tray will not be raised during a continuous copy run even if the copies

have been removed from the tray, the following copies may not be stacked correctly on the

tray.

As the field’s request to enable the tray to raise up in the above situation, new tray control

software has been added to the current software. The new operation software runs only

when you turn on DIP SW 101-1 on the finisher main PCB. Note that the factory setting of

DIP SW 101-1 is off.

The part number of the EPROM has been changed from A3535120 to A3535130. The

part number of the main PCB remains the same.

The detailed tray control of the new

software is as follows:

Revision of service manual

Information only

Other

FROM: Copier Technical Support Section

MODEL: F200 X Finisher

1 [A]

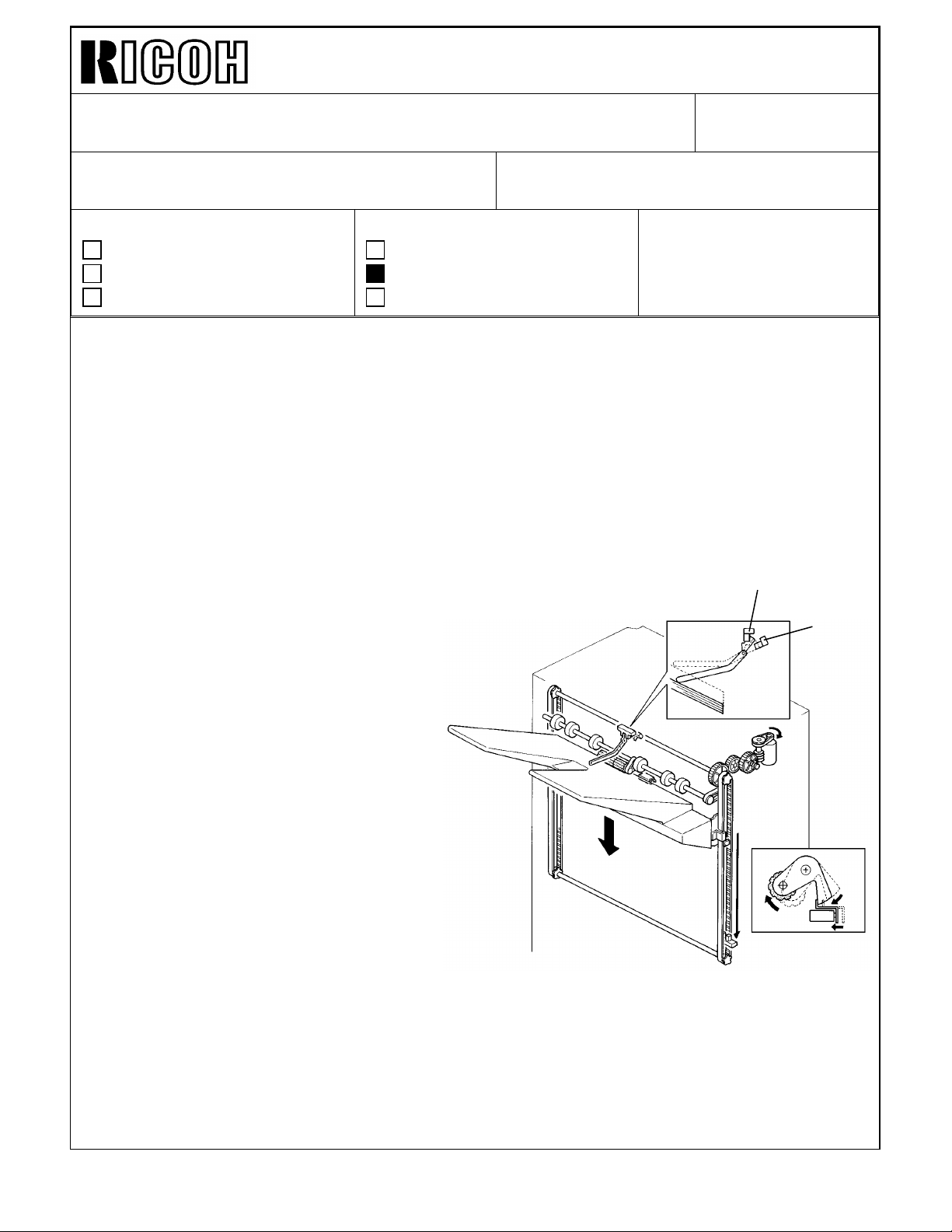

The tray position is controlled by

referring to two stack height sensors,

1[A] and 2[B].

1. In the Tray Shift Mode

When the copies are removed from the

tray during a continuous copy run, stack

height sensor 1 [A] is actuated. Then

the tray drive motor lifts the tray up until

height sensor 2 [B] is actuated.

However, height sensor 2 will be

actuated when the following copies are

fed out to the tray. Therefore, the tray lift

operation is stopped while sensor 2 is

actuated by the copy. The tray resumes

its lift operation until sensor 2 is actuated.

If sensor 2 is actuated for 3 seconds or more, the machine determines that the tray has

been lifted to the upper limit, and lowers the tray for 50msec (Approx. 1mm).

Page 2

Technical Bulletin No. RTB-054

2 [B]

SUBJECT: Finisher Tray Control DATE: Nov. 15, ’93

PAGE: 2 of 2

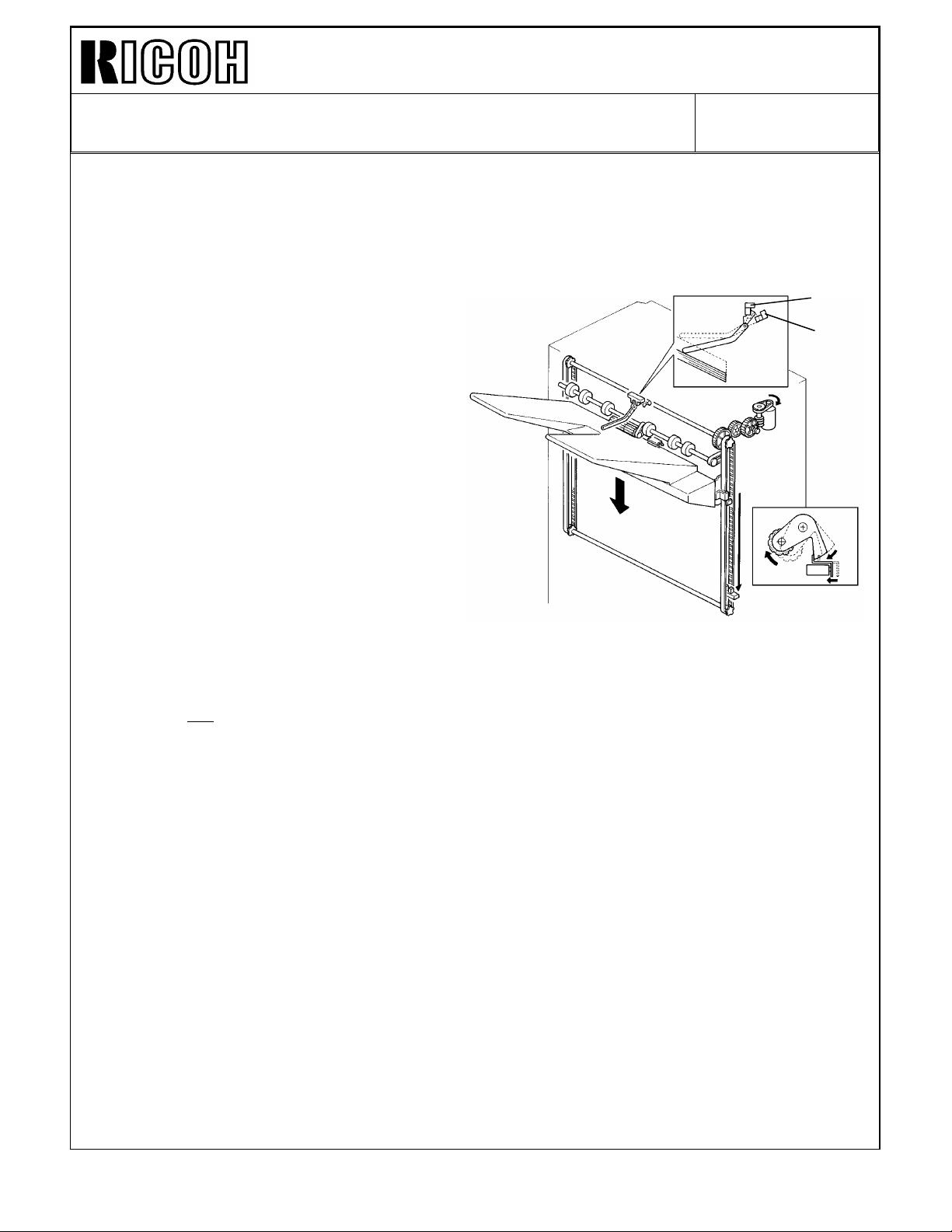

2. In the Staple Modes

Since the tray is stopped at the position where sensor 1 is actuated in the Staple modes, it

is not possible to detect if the copies on the tray have been removed during a copy cycle.

With the new software, the tray is lifted

when the papers have been removed from

the tray as follows:

1. When the stapled papers are fed out

onto the tray (1.25 seconds after the

finisher exit sensor is de-actuated), the

machine starts to lift the tray.

2. When the sensor 1 is de-actuated, the

machine lowers the tray.

3. When the sensor 1 is actuated, the

machine stops the tray.

The tray, therefore, moves up and down

during the copy run in the staple modes.

NOTE: Note that the tray operation frequency becomes very high with the new software.

Since the tray drive motor will get a high load especially when many copies remain on the

tray, we cannot guaranty the motor life with this new software and therefore the new

software is not selected as the factory setting.

1 [A]

Loading...

Loading...