Page 1

FINISHER

(A666)

Page 2

10 January 1997 OVERALL MACHINE I NFO R M ATI O N

1. OVERALL MACHINE INFORMATION

1.1 SPECIFICATIONS

Paper Size: Standard copying/Stack mode

Maximum: 11" x 17"/A3

Minimum: 5

(lengthwise)

Staple Mode

11" x 8

1/2

" (sideways)/A4 (sideways)

1/2

" x 8

1/2

" (lengthwise)/A6

Paper Weight: Standard copying/Stack mode

2

14 lb. ~ 42 lb. /52 g/m

~ 157 g/m2

(face-up mode)

17 lb. ~ 28 lb./64 g/m

2

~ 105 g/m

(face-down mode)

Staple Mode

2

17 lb. ~ 21 lb. /64g/m

~ 80g/m

Paper Capacity: Standard copying/Stack mode

250 sheets (face-up mode)

1/2

1000 sheets : 8

" x 11"/A4 or smaller

(21 lb. / 80g/m

mode)

500 sheets : 8

1/2

" x 14"/B4 or smaller

(21 lb. /80g/m

Staple Mode

30 sets (80 g/m, 20 pages per set)

Stapler Capacity: 2 to 20 sheets (21 lb. /80g/m

2

Staple Position: 1 position (Oblique)

2

2

2

)(face-down

2

) (face-down mode)

)

Staple Replenishment: Cartridge exchange (2,000 staples/cartridge)

Power Source: DC 24V, DC 5V (from the copier)

Power Consumption: 60W

Weight: 28 kg

Size: 520 x 550 x 750 mm

A666-1

Options

Page 3

OVERALL MACHINE INFORMATION 10 January 1997

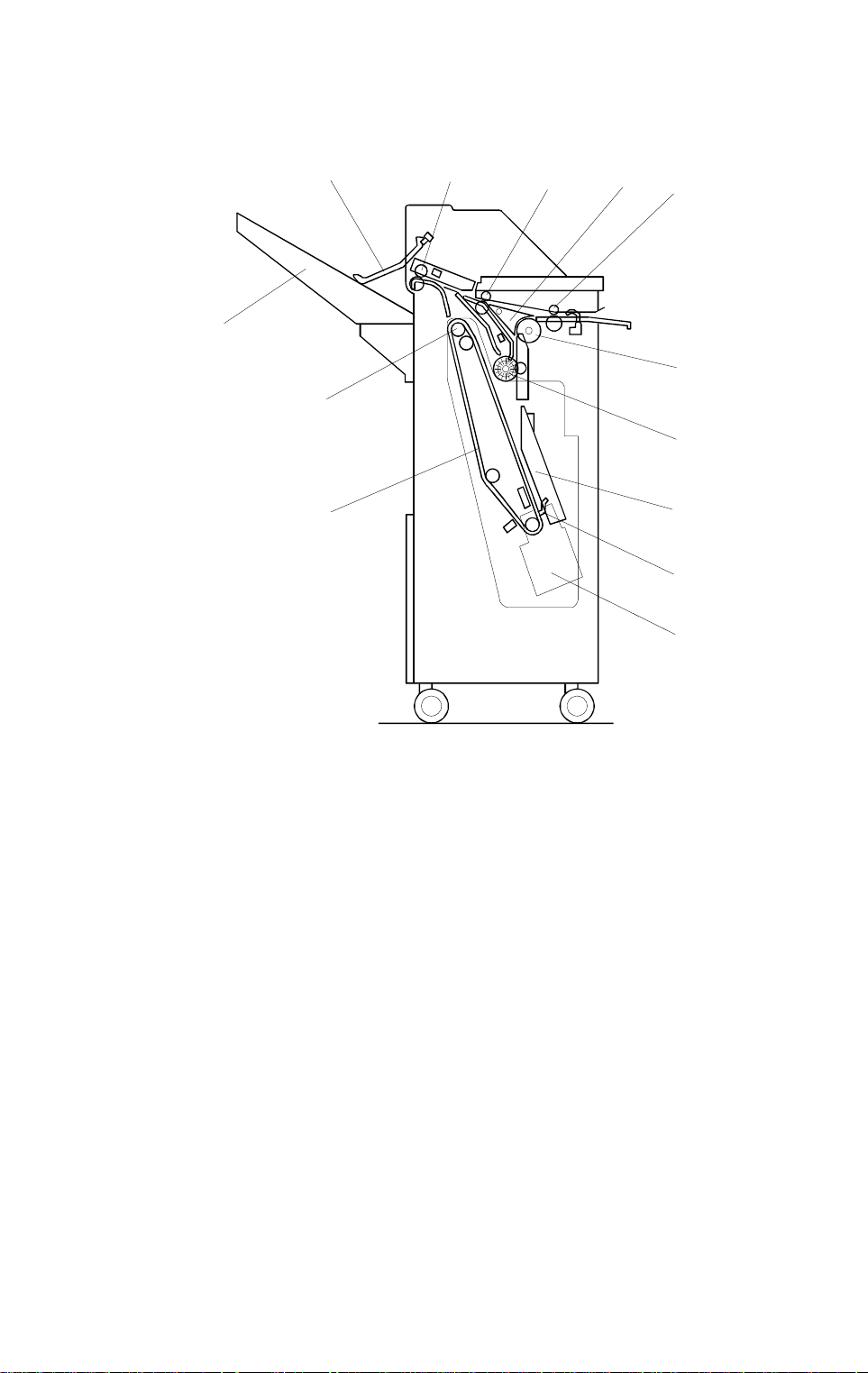

1.2 MECHANICAL COMPONENT LAYOUT

1

432

5

13

6

12

7

11

8

9

10

1. Stack Height Sensor Feeler

2. Exit Roller

3. Transport Roller

4. Junction Gate

5. Entrance Roller

6. Turn Roller

7. Alignment Roller

A666V500.wmf

8. Jogger Unit Guide

9. Stack Stopper

10. Stapler Unit

11. Feed-out Belt

12. Feed-out Roller Belt Drive

13. Shift Tray

A666-2

Page 4

10 January 1997 OVERALL MACHINE I NFO R M ATI O N

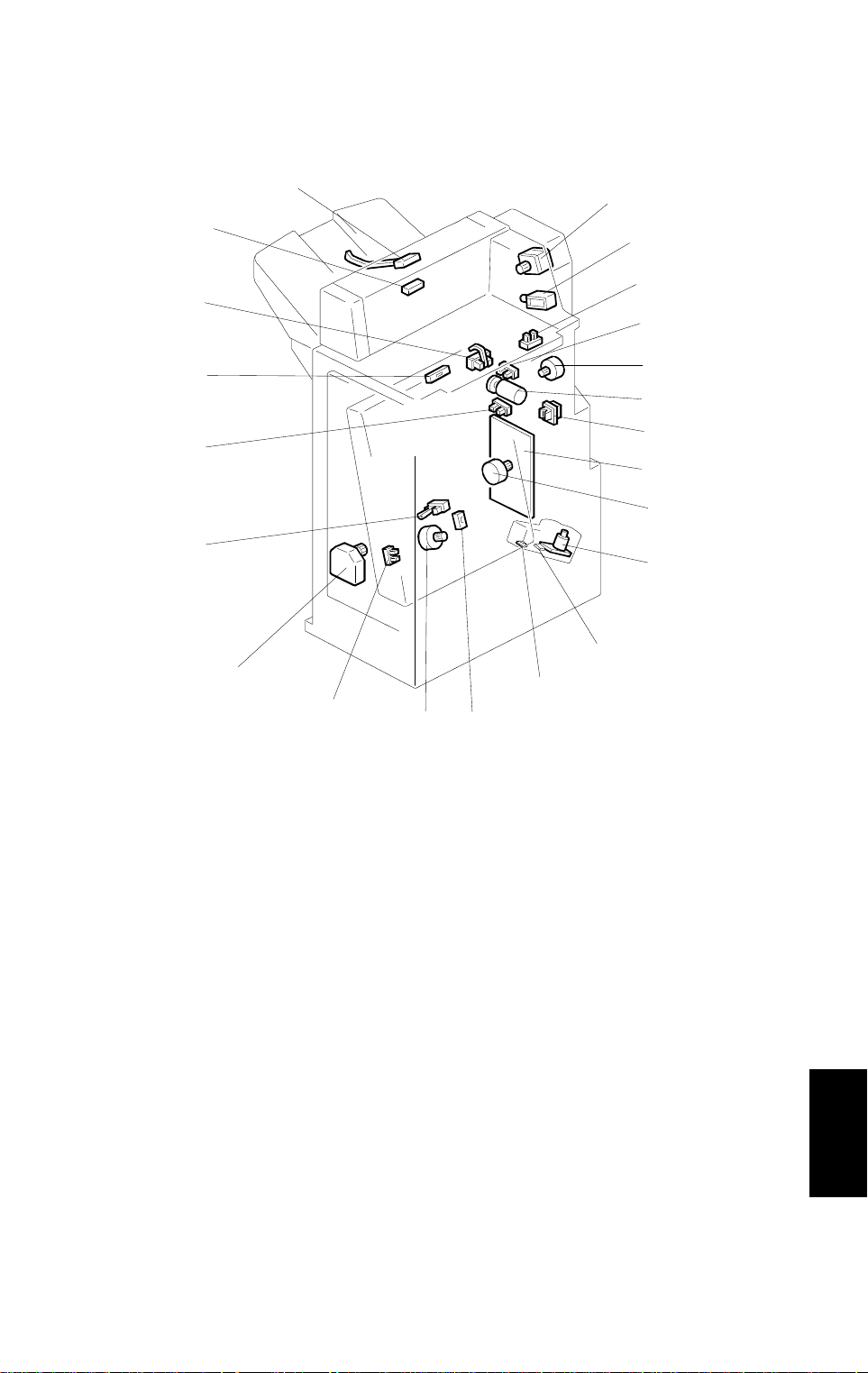

1.3 ELECTRICAL COMPONENT LAYOUT

22

21

20

19

18

1

2

3

4

5

6

7

8

9

17

16

15

1. Transport Motor

2. Junction Gate Solenoid

3. Upper Cover Open Sensor

4. Shift Tray Position Sensor

5. Entrance Motor

6. Shift Motor

7. Jogger Unit Set Switch

10

11

14

12

13

A666V501.wmf

12. Staple End Switch

13. Jogger Unit Paper Sensor

14. Jogger Motor

15. Jogger HP Sensor

16. Shift Tray Lift Motor

17. Feed Belt HP Sensor

18. Shift Tray Lower Limit Sensor

8. Finisher Drive Board

9. Feed-out Motor

10. Staple Motor

11. Hammer HP Sensor

19. Inverter Sensor

20. Entrance Sensor

21. Exit Sensor

22. Stack Height Sensor

A666-3

Options

Page 5

OVERALL MACHINE INFORMATION 10 January 1997

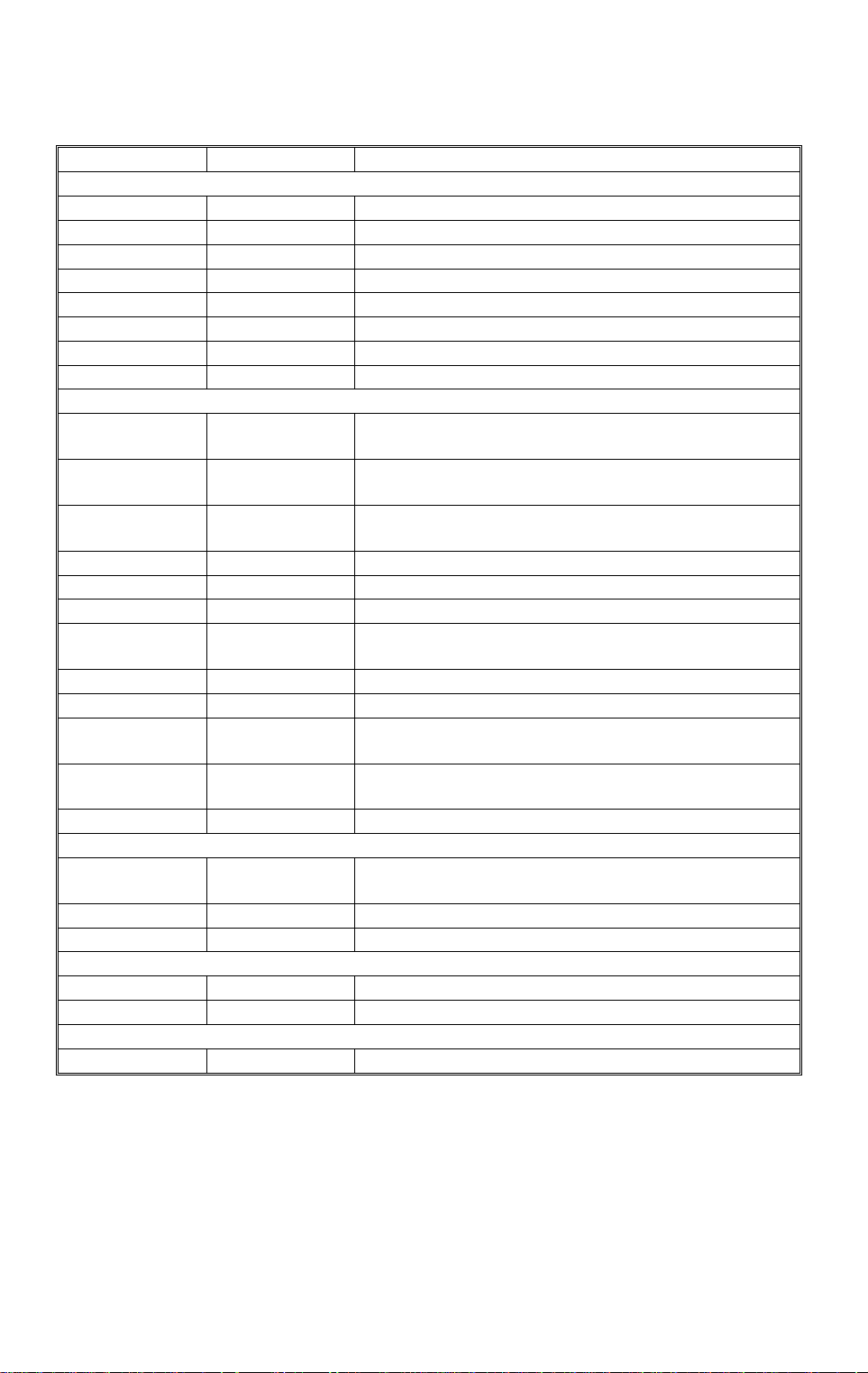

1.4 ELECTRICAL COMPONENT DESCRIPTION

Symbol Name Function Index No.

Motors

M1 Transport Drives the transport rollers and the exit roller.

M2 Shift Tray Lift Moves the shift tray up or down.

M3 Feed-out Drives the fee d- feed out belt.

M4 Jogger Moves the jogger fence.

M5 Entrance Drives t he entrance roller.

M6 Shift Moves the shift motor to front or rear.

M7 Staple Drives the staple hammer.

Sensors

S1 Entrance Detects the copy paper enterin g the finisher and

detects misfeeds.

S2 Inverter Detects the trailing edge of the paper to change the

rotation direc tion of the transpor t mo tor

S3 Jogger Unit

Paper

S4 Exi t Detects misfeed s in the exit area.

S5 Feed-out Belt HP Detects the ho m e position of the feed-out belt.

S6 Jogger HP Detects the jo gger home positio n.

S7 Shift Tray Lower

Limit

S8 Shift Position Detects the stop position of the shift motor.

S9 Stack Height Detects when the copy stack is prope r height.

S10 Upper Cover

Open

S11 Staple HammerHPDetects the hom e position of the stapl e hammer.

Detects the paper in the jogger unit and detects

misfeeds.

Detects the lower limit position of the shift tray.

Detects whether the upper cover is opened or not.

Switches

SW1 Jogger Unit Set Cuts the +24V power withi n the finisher when the

jogger unit is pul l ed out.

SW2 Staple End Detects when the staples have run out.

Solenoid

SOL1 Junction Gate Drives the junction gate.

PCBs

PCB1 Finisher Drive Controls overall f i nisher operation .

A666-4

Page 6

10 January 1997 OVERALL MACHINE I NFO R M ATI O N

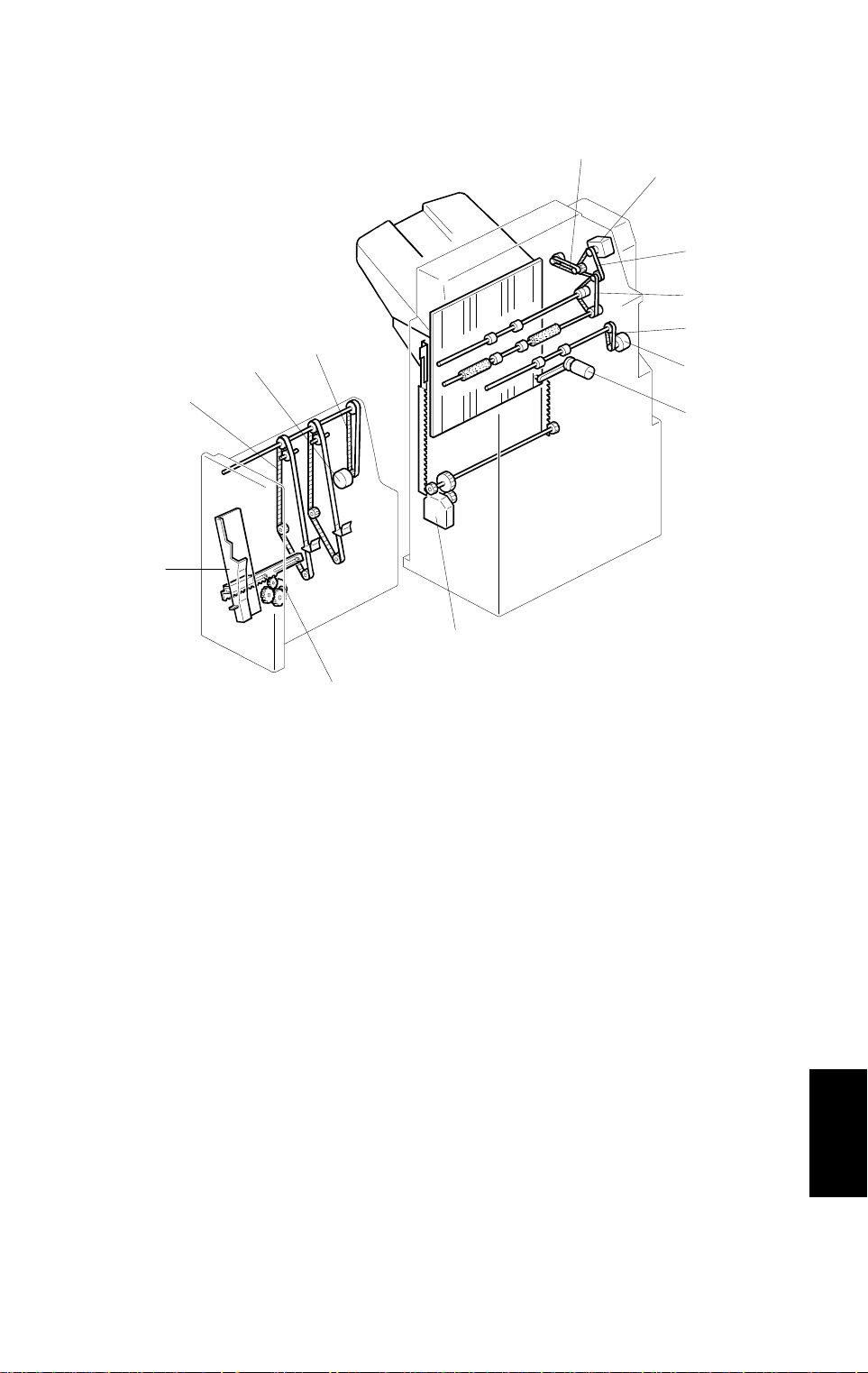

1.5 DRIVE LAYOUT

1

2

3

4

12

13

11

10

1. Exit Roller Driv e Belt

2. Transport Motor

5

6

7

8

A666V502.wmf

9

8. Shift Tray Lift Motor

9. Jogger Motor

3. Transport Drive Belt

4. Inverter Drive Belt

5. Entrance Drive Belt

6. Entrance Motor

7. Shift Motor

10. Jogger Fence

11. Stack Feed Belt

12. Feed-out Motor

13. Feed-out Drive Belt

Options

A666-5

Page 7

DETAILED DESCRIPTION S 10 January 1997

2. DETAILED DESCRIPTIONS

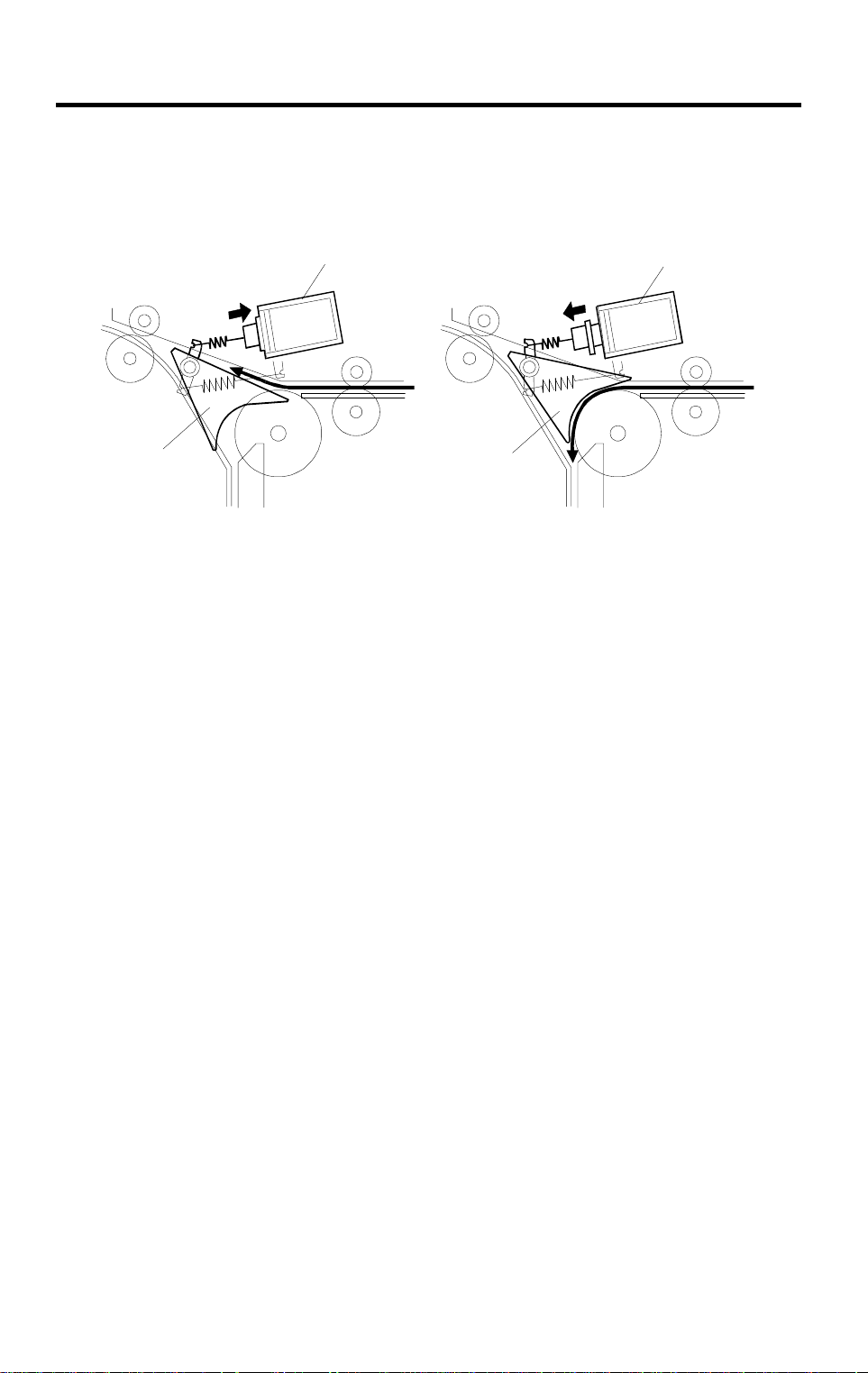

2.1 JUNCTION GATE MECHANISM

[B]

[A]

[B]

[A]

A666D500.wmf

When the entrance sensor is activated in face-up mode, the junction gate

solenoid [A] turns on and the junction gate [B] is closed. Then, the paper is

transported directly to the shift tray and its maximum speed is 180 mm/s.

When the entrance sensor is activated in face-down or staple mode, the

junction gate solenoid [A] stays off and the junction gate [B] is open. Then the

paper is transported to the jogger unit.

A666-6

Page 8

10 January 1997 DETAILED DESCRIPTIO NS

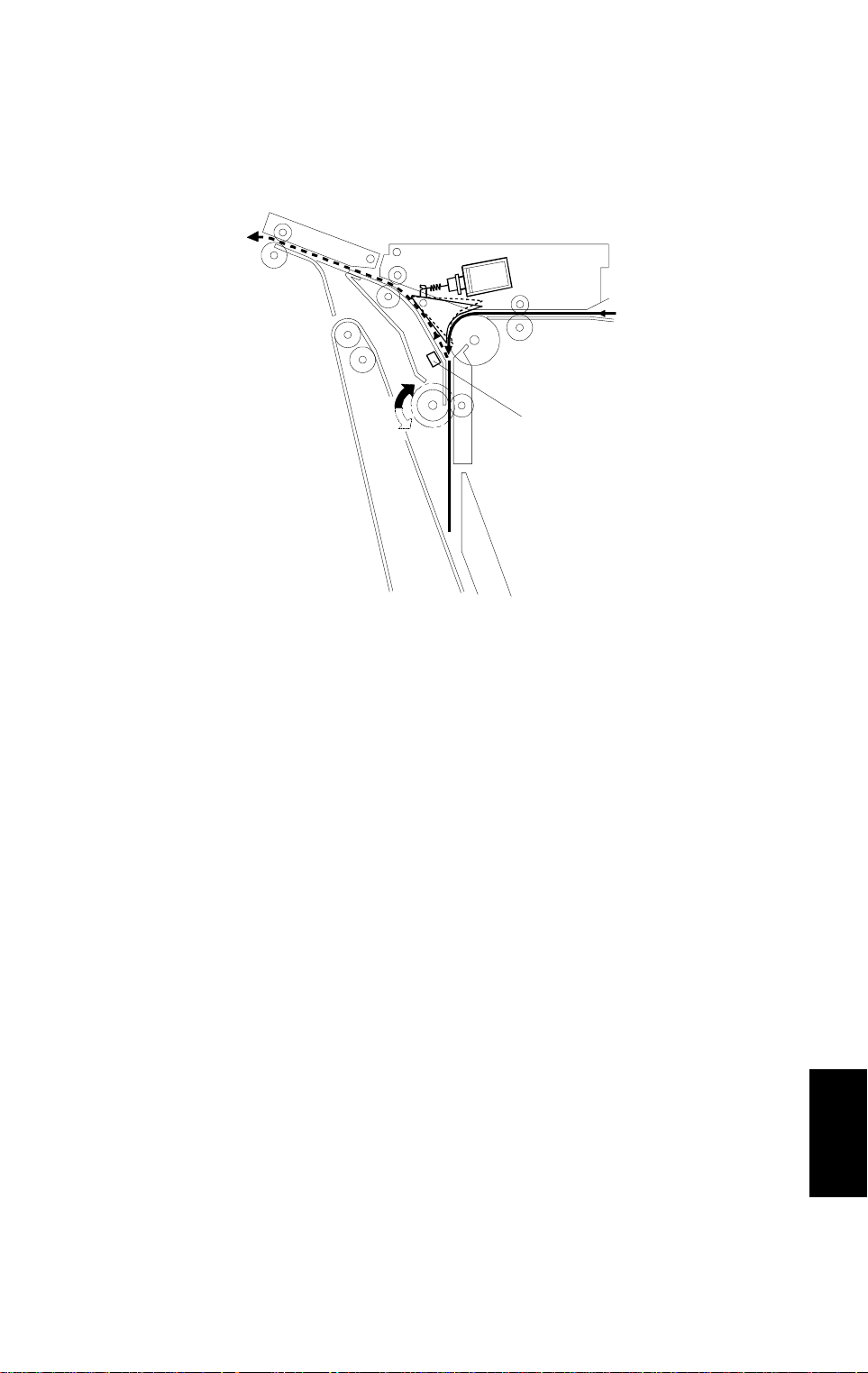

2.2 PAPER REVERSING MECHANISM

[A]

A666D501.wmf

The paper is sent to the staple unit when face-down mode is selected. The

paper is transported to the staple unit at 180 mm/s until the trailing edge of

the paper turns off the copier exit sensor. After the exit sensor is turned off,

the paper transport speed is changed to 500 mm/s.

When the trailing edge of the paper passes through the inverter sensor [A],

the transport motor turns off. Then, the transport motor turns on in reverse

and the paper is transported to the shift tray.

A666-7

Options

Page 9

DETAILED DESCRIPTION S 10 January 1997

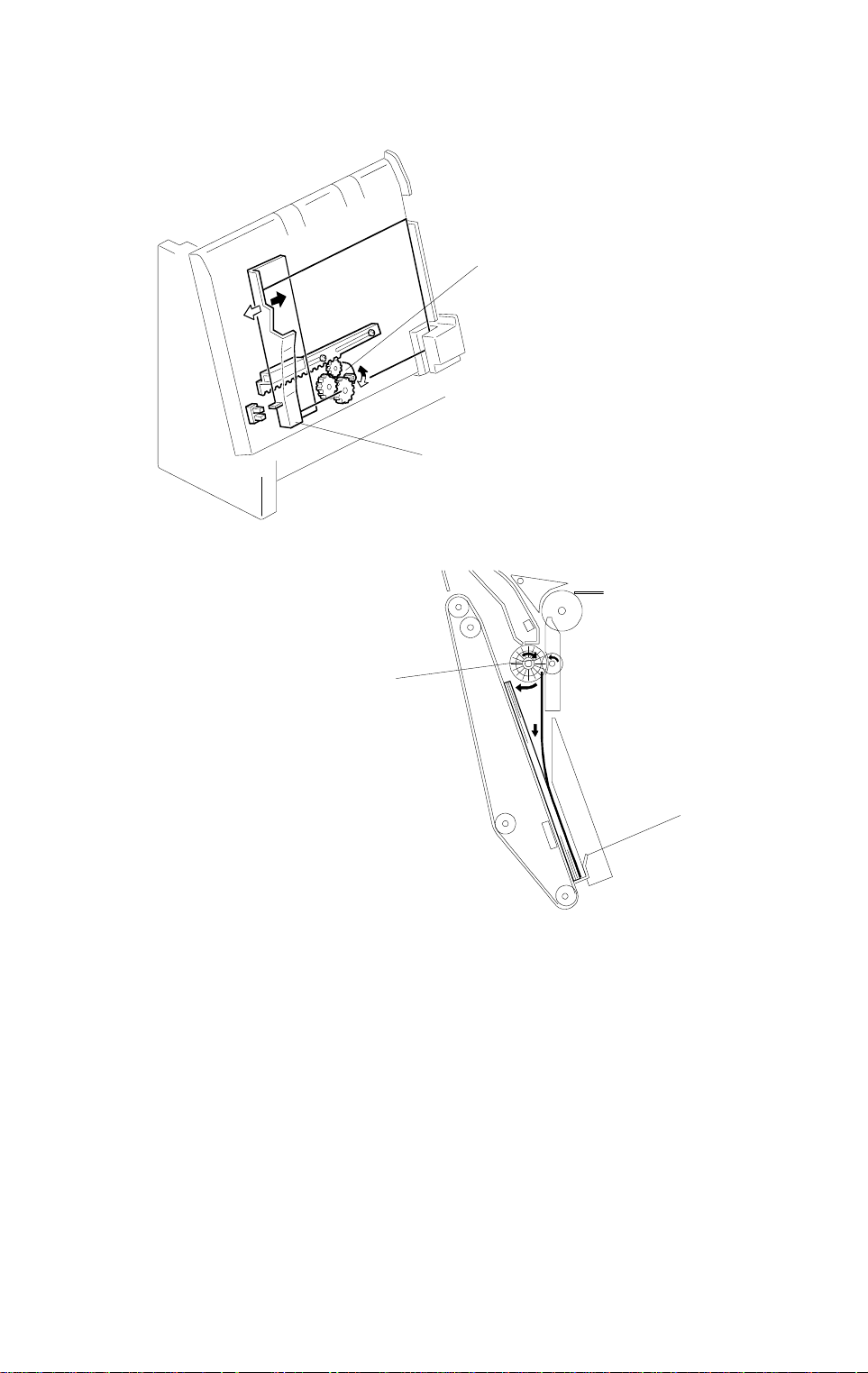

2.3 JOGGER UNIT PAPER POSITIONING MECHANISM

[A]

[B]

A666D503.wmf

[C]

[D]

A666D502.wmf

In staple mode, each sheet of copy paper is vertically and horizontally

aligned when it arrives in the jogger unit.

For the horizontal alignment, the jogger motor [A] moves the front jogger

fence [B] to align the copies.

For the vertical alignment, the brush roller [C] pushes the trailing edge of the

paper against the stack stopper [D]. The position of the stack stopper

depends on the paper size (LT or A4), and is changed by the feed-out motor.

A666-8

Page 10

10 January 1997 DETAILED DESCRIPTIO NS

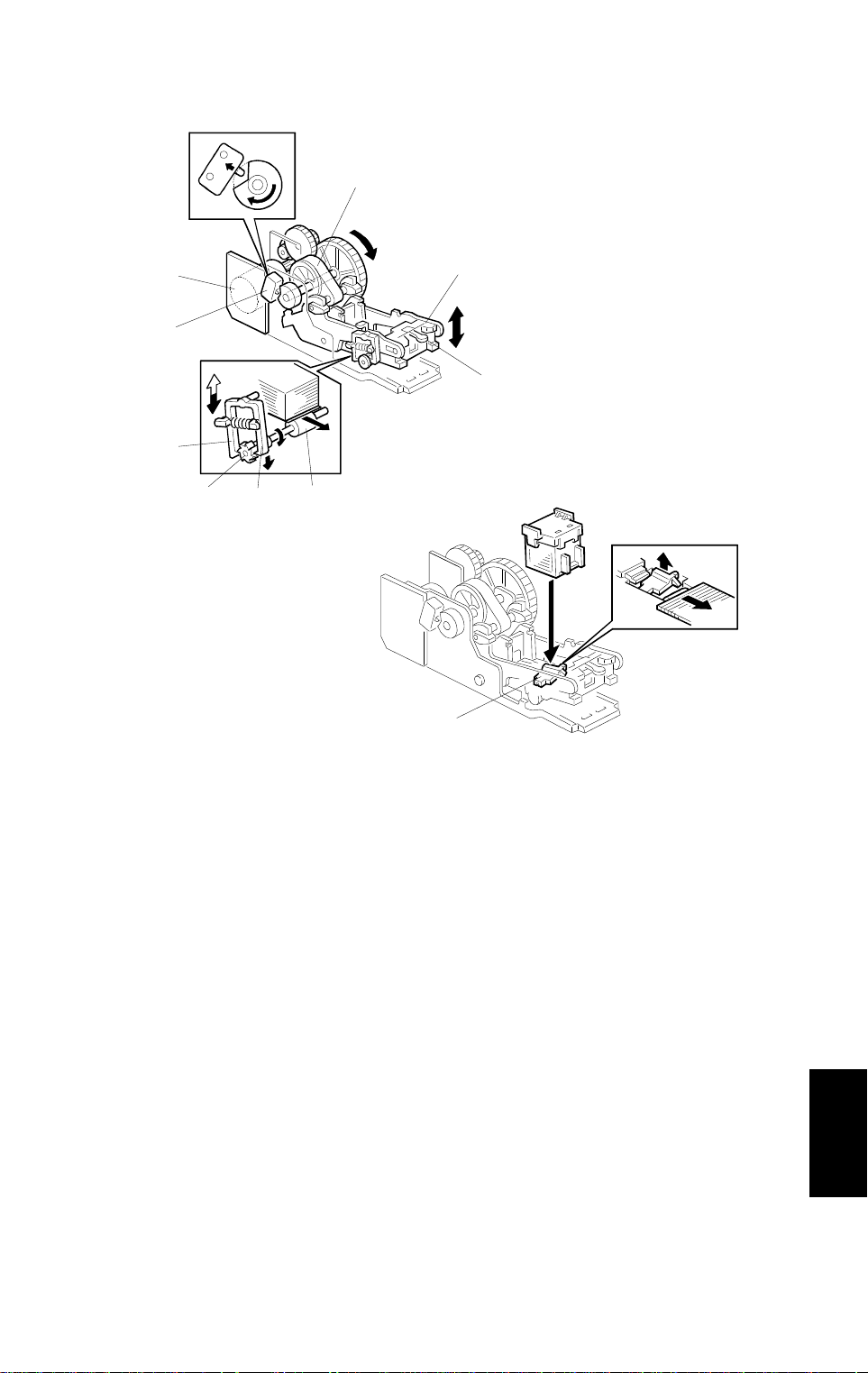

2.4 STAPLER

[C]

[B]

[A]

[D]

[J]

[G]

A666D508.wmf

[E] [H]

[F]

[I]

A666D504.wmf

The staple hammer [A] is driven by the stapler motor [B] via gears, a

eccentric cam [C].

When the aligned copies are brought to the stapling position by the brush

roller and jogger fence, the stapler motor [B] turns on. When the cam [C]

completes one rotation, the staple hammer home position sensor [D] turns

off, detecting the end of the stapling operation. The staple motor then turns

off.

The feed gear [E] drives staple feed roller [F] to feed a sheet of staples. The

feed gear is driven by the long hook [G] when the hammer moves up and by

the short hook [H] when the hammer moves down.

When there is only one sheet of staples left in the cartridge, the actuator [I]

moves up and the staple end sensor is activated.

When jammed staples are left in the staple unit, release and move up the

staple guide [J] to remove the jammed staples.

Options

A666-9

Page 11

DETAILED DESCRIPTION S 10 January 1997

2.5 FEED OUT MECHANISM

[C]

[B]

[A]

[D]

A666D505.wmf

After the copies have been stapled, the feed-out motor [A] turns on to drive

the feed out belt. The stack stopper [B] on the feed-out belt transports the set

of stapled copies up,(its speed is 450 mm/s) and feeds it towards the shift

tray. Approximately 500 ms after the feed-out motor turns on, it stops for 500

ms. At this moment, the exit roller [C] catches the stapled copies to feed them

out to the shift tray. Then, the feed-out motor turns on again until the stack

stopper actuates the feed-out belt home position sensor [D].

The transport motor drives the brush roller and the exit roller [C] (speed 500

mm/s). The transport motor turns on when the feed-out motor turns on at the

start of feed-out to drive brush roller. This prevents the brush roller from

disturbing the smooth upward passage of the leading edge of the copy set at

the start of paper feed. After 200 ms, the transport motor turns off and on

again in reverse to feed out the set of staple copies.

A666-10

Page 12

10 January 1997 DETAILED DESCRIPTIO NS

2.6 SHIFT TRAY UP/DOWN MECHANISM

[F]

[E]

[G]

[B]

[A]

[H]

[C]

[D]

A666D506.wmf

The shift tray lift motor [A] controls the vertical position of the shift tray [B]

through the gears [C,D]. When the main switch is turned on, the tray is

initialized at the upper position. The trays upper position is detected when the

shift tray pushes up actuator feeler[E] until the actuator turns on the stack

height sensor [F]. Then the shift tray lift motor turns in reverse until the stack

height sensor turns off.

During copying, the actuator feeler [E] gradually rises as the copy stack

grows. When the stack height sensor [F] turns on, the shift tray lift motor

lowers the shift tray [B] until the sensor is off.

When the actuator [G] turns off the lower limit sensor [H], copying stops. After

copying ends and machine is stopped and the copies are removed, the shift

tray rises until the stack height sensor [F] is on. Then the shift tray lift motor

turns in reverse until the stack height sensor turns off.

Options

A666-11

Page 13

DETAILED DESCRIPTION S 10 January 1997

2.7 SHIFT TRAY SIDE-TO-SIDE MECHANISM

[E]

[C]

[A]

[F]

[B]

[D]

[B][F]

A666D507.wmf

The horizontal position of the shift tray is controlled by the shift motor [A] and

the shift motor disk [B]. After one set of originals is copied and delivered to

the shift tray [C], the shift motor turns on, driving the shift motor disk and the

lever [D]. The shift tray base plate [E] is positioned by the lever, creating the

side-to-side movement required to stagger the copies.

When the shift motor disk [B]has rotated 180 degrees (when the shift tray is

fully shifted across), the cut-out in the shift motor disk turns on the shift

position sensor [F] and the shift motor [A] stops. The next set of copies is

then delivered. The motor turns on, repeating the same process and moving

the tray back to the previous position.

A666-12

Page 14

10 January 1997 DETAILED DESCRIPTIO NS

2.8 TIMING CHART

2.8.1 Face-up Mode (A4: 2 sheets)

0123456

COPIER FINISHER

START

Shift ON

Exit Sensor

FINISHER COPIER

Complete Paper Exit

FINISHER

Entrance Sensor

0.25s

Exit Sensor

Shift Home Sensor

Stack Height Sensor

Entrance Motor

Transport Motor

Junction Gate Solenoid

Shift Motor

Shift Tray Lift

20 cpm

25 cpm

A666D510.wmf

A666-13

Options

Page 15

DETAILED DESCRIPTION S 10 January 1997

2.8.2 Face-down Mode (A4: 2 sheets)

0123456

COPIER FINISHER

START

Exit Sensor

FINISHER COPIER

Complete Paper Exit

FINISHER

Entrance Sensor

0.25s

Inverter Sensor

Exit Sensor

Shift Position

Stack Height Sensor

Entrance Motor

Transport Motor

Shift Motor

Shift Tray Lift Motor

20 cpm

25 cpm

A666D509.wmf

A666-14

Page 16

10 January 1997 DETAILED DESCRIPTIO NS

2.8.3 Staple Mode (A4: 2 sheets)

COPIER FINISHER

START

Staple ON

Exit Sensor

FINISHER COPIER

Complete Paper Exit

FINISHER

Entrance Sensor

Inverter Sensor

Exit Sensor

Shift Home Sensor

Stack Height Sensor

Jogger Unit

Paper Sensor

Hammer HP Sensor

Entrance Motor

0

12345678

0.50s

0.50s

0.40s

Transport Motor

Jogger Motor

Feed-out Motor

Staple Motor

Shift Motor

Shift Tray Lift Motor

20 cpm

25 cpm

A666D511.wmf

Options

A666-15

Page 17

DETAILED DESCRIPTION S 10 January 1997

2.8.4 Jam Detection

1. Face-up Mode

Jam 1:

Jam 2:

Jam 3:

The entrance sensor stays on for 4.2 s.

The exit sensor stays off 3.5 s after the entrance sensor turns on.

The exit sensor stays on for 2.0 s.

2. Face-down Mode

Jam 1:

Jam 2:

Jam 3:

Jam 4:

Jam 5:

The entrance sensor stays on for 4.2 s.

The inverter sensor stays off 1.5 s after the entrance sensor turns on.

The inverter sensor stays on for 4.2 s.

The exit sensor stays off 0.6 s after the inverter sensor turns off.

The exit sensor stays on for 1.2 s.

3. Staple Mode

Jam 1:

Jam 2:

Jam 3:

Jam 4:

The entrance sensor stays on for 2.5 s.

The inverter sensor stays off 1.5 s after the entrance sensor turns on.

The inverter sensor stays on for 0.8 s.

The jogger unit paper sensor stays off 0.5 s after the inverter sensor

turns off.

Jam 5:

Jam 6:

Staple Jam:

The exit sensor stays off 1.05 s after the feed-out motor turns on.

The exit sensor stays on for 0.85 s.

The staple hammer HP sensor stays off 0.48 s after the staple

motor turns on.

A666-16

Page 18

10 January 1997 DETAILED DESCRIPTIO NS

2.8.5 Verall Electrical Circuit

Finisher Drive Baord

Motors

Main

Frame

/TXD

/RSD

Finisher

Connection

Solenoid

Sensors

Switches

A666D512.wmf

All components (motors, sensors, solenoid and switches) are controlled by

the finisher drive board and the communication between the main frame and

finisher uses a serial signal.

When the finisher is connected, the finisher connection signal to the main

frame is grounded. Then the main frame detects that the finisher is

connected.

A666-17

Options

Page 19

INSTALLATION PROCEDURE 10 January 1997

3. INSTALLATION PROCEDURE (AD1/AD1E)

A666I507.wmf

A666I505.wmf

CAUTION

+

A666I500.wmf

A666i501.wmf

Unplug the copier power cord and turn off the main switch before

starting the following procedure.

1. Unpack the finisher. Then remove all tapes and cushions.

A666-18

Page 20

10 January 1997 INSTALLATION PROCEDURE

[B]

[C]

[D]

[A]

[E]

A666I502.wmf

[F]

[G]

A666I506.wmf

2. Push the hook [A] of the face-up tray shaft cover [B] and remove it.

3. Remove the face-up tray [C].

4. Remove the caps [D] and the connector cover [E].

5. Peel off the backing of the double sided tapes [F] of the grounding plate

[G].

6. Insert the grounding plate between the copier and the paper bank as

shown.

Options

A666-19

Page 21

INSTALLATION PROCEDURE 10 January 1997

[B]

[A]

A666I503.wmf

[D]

[F]

[E]

[C]

A666I504.wmf

7. Install the front [A] and rear [B]connecting bracket. (2 screws each)

8. Pull out the stapler unit [C] and confirm that locking lever [D] has been

drawn out.

9. Align and install the finisher to connecting brackets and lock them in

place by pushing the locking lever [D].

10. Secure the locking lever [D] (1 screw) and push the staple unit into the

finisher.

11. Install the shift tray [E] (1 snap ring).

12. Connect the cable [F]to the copier.

13. Plug in the copier power cord.

14. Turn the ac and main switches on. and check if the document feeder

works properly.

A666-20

Page 22

10 January 1997 PREVENTIVE MAINTENANCE

4. PREVENTIVE MAINTENANCE

NOTE:

The amounts mentioned as the PM interval indicate the number of

prints.

Symbol key: C:Clean , R:Replace , L:Lubricate , I:Inspect

ITEM EM 100K 200K 300K NOTE

RollersCCCCAlcohol or water

Bushings

SensorsCCCCDry cloth

IIII

Use Launa oil or

equivalent

A666-21

Options

Page 23

SERVICE TABLES 10 January 1997

5. SERVICE TABLES

5.1 LED TABLE

LED No. 100 LED No. 101 FUNCTION

ON OFF When the entrance sensor is ON (Paper Detected)

OFF ON When the inver t er sensor is ON (Paper Detected)

ON ON When the exit sensor is ON (Paper Detected)

NOTE:

Check the sensors by setting DIP SW 100/101 to Sensor Check

Mode(see below).

5.2 DIP SWITCH TABLE

5.2.1 Factory Setting

[ 0 : OFF 1 : ON ]

DIP SW 100 DIP SW 101

43214321

00000000

5.2.2 Stapling Position Adjustment

[ 0 : OFF 1 : ON ]

DIP SW 100 DIP SW 101 STAPLING POSITION

43214321

0 0 0 0 0 0 0 1 + 1.0 mm (down)

0 0 0 0 0 0 1 0 + 2.0 mm (down)

00000100–1.0 mm (up)

00001000–2.0 mm (up)

5.2.3 Sensor Check

[ 0 : OFF 1 : ON ]

DIP SW 100 DIP SW 101

43214321

10000000

When checking the sensors , see the LED table (5.1).

A666-22

Page 24

10 January 1997 SERVICE TABLES

5.2.4 FREE RUN WITHOUT PAPER

How to do a free run

1. Turn off the main and AC switches, and unplug the machine.

2. Select the free run mode with DIP switches (see below).

3. Disconnect connector 102 on the finisher drive board.

4. Plug in the machine and turn on the power (AC and main switches).

5. To stop the free run, pull out the staple unit.

DIP SW 100 DIP SW 101 FUNCTION

43214321

0 1 1 1 0 0 0 0 Staple Mo de (2 Pages)

0 1 1 1 0 0 0 1 Staple Mode ( 5 Pages)

0 1 1 1 0 0 1 0 Staple Mo de (10 Pages)

0 1 1 1 0 1 0 0 Staple Mo de (15 Papers)

0 1 1 1 1 0 0 0 Staple Mo de (20 Pages)

11110000Face Down Mode (2 Pages)

11110001Face Down Mode (5 Pages)

11110010Face Down Mode (10 Pages)

11110100Face Down Mode (15 Pages)

11111000Face Down Mode (20 Pages)

A666-23

Options

Page 25

REPLACEMENT AND ADJUSTMENT 10 January 1997

6. REPLACEMENT AND ADJUSTMENT

6.1 EXTERIOR REMOVAL

[I]

[E]

[B]

[A]

[H]

[B]

[I]

[G]

[C]

[D]

A666R500.wmf

1. Remove the shift tray [A] (1 snap ring).

NOTE :

The shift tray cannot be removed if it is at its uppermost position.

2. Remove the rear cover [B] (3 screws).

3. Remove the front cover [C] (2 screws).

4. Remove the front inner cover [D] (3 screws).

5. Remove the upper cover [E] (2 screws).

6. Remove the rear upper cover [F] (1 screw).

7. Remove the upper entrance cover [G] (2 screws).

8. Remove the front and rear tray covers [H,I] (2 screws)

9. Remove the left cover [J](2 screws).

A666-24

Page 26

10 January 1997 REPLACEMENT AND ADJUSTMENT

6.2 ALIGNMENT BRUSH ROLLER REPLACEMENT

[A]

[B]

[C]

[A]

[D]

[C]

A666R501.wmf

1. Remove the front and rear covers.

2. Pull out the jogger unit

3. Remove the E-ring [A], slide off the pulley [B], then remove 2 bushings

[C].

NOTE:

When reinstalling, the metal bushing goes at the front side.

4. Remove the alignment brush roller assembly [D].

A666-25

Options

Page 27

REPLACEMENT AND ADJUSTMENT 10 January 1997

6.3 BELT TENSION ADJUSTMENT

[A]

[C]

[B]

A666R502.wmf

1. Remove the rear cover.

2. Loosen the 2 screws [A] of the transport motor bracket and tighten them

again to adjust the two tension belts [B,C].

A666-26

Page 28

10 January 1997 REPLACEMENT AND ADJUSTMENT

6.4 STACK HEIGHT SENSOR REPLACEMENT

[A]

[B]

1. Remove the front, rear, and upper covers.

2. Remove the stack height sensor actuator [A] (1 screw).

3. Replace stack height sensor [B] (1 connector).

A666R503.wmf

A666-27

Options

Page 29

REPLACEMENT AND ADJUSTMENT 10 January 1997

6.5 EXIT SENSOR REPLACEMENT

[B]

[C]

[A]

A666R504.wmf

1. Remove the front, rear, and upper covers.

2. Remove the exit guide unit [A] (1 screw).

3. Remove the discharge brush and the exit guide plate [B] (2 screws).

4. Remove the exit sensor [C] (1 screw and 1 connector).

A666-28

Page 30

10 January 1997 REPLACEMENT AND ADJUSTMENT

6.6 INVERTER SENSOR REPLACEMENT

[A]

A666D505.wmf

[B]

1. Remove the front, front inner, and rear covers.

2. Slide out the jogger unit.

3. Remove the entrance guide plate [A] (4 screws).

4. Remove the inverter sensor ass’y [B] (1 screw and 1 connector).

5. Replace the inverter sensor.

A666-29

Options

Page 31

FNISHER (A666) ELECTRICAL COMPONENT LAYOUT

22

1

21

20

19

18

17

2

3

4

5

6

7

8

9

10

11

16

15

12

13

14

A666S501.WMF

Page 32

Symbol Index No. Function P to P

Motors

M1 1 Transport D13

M2 16 Shift Tray Lift F13

M3 9 Feed-out H13

M4 14 Jogger G13

M5 5 Entrance B13

M6 6 Shift E13

M7 10 Staple J14

Sensors

S1 20 Entrance E4

S2 19 Inverter F4

S3 13 Jogger Unit Paper K5

S4 21 Exit I4

S5 17 Feed-out Belt HP J5

S6 15 Jogger HP J5

S7 18 Shift Tray Lower Limit G4

S8 4 Shift Position G4

S9 22 Stack Height H4

S10 3 Upper Cover Open E4

S11 11 Staple Hammer HP J13

Switches

SW1 7 Jogger Unit Set K12

SW2 12 Staple End I13

Solenoid

SOL1 2 Junction Gate A13

PCB

PCB1 8 Finisher Drive B8

2

Page 33

(

)

12345678910111213141516

A

FINISHER (A666) POINT TO POINT DIAGRAM

B

C

D

Upper Cover Open

E

F

Shift Tray Lower Limit

G

Shift Position Sensor

H

Stack Height Sensor

I

SYMBOL TABLE

J

▼

▲

[ ] Voltage

K

Main Machine

Senosr

Entrance Sensor

Inverter Sensor

Sensor

Exit Sensor

DC Line

Pulse Signal

Signal Direction

Active Low

Active High

[+24 V]

[+24 V]

[+24 V]

[+24 V]

NC

GND

GND

GND

GND

GND

NC

[+5 V]

Finisher Set [▼5]

/TXD [▼5]

/RXD [▼5]

Stop [▼5]

GND

GND

-1

CN221

S10

S1

S2

S7

S8

S9

S4

-2

-3

-1

-2

-3

-1

-2

-3

-1

CN205

-2

-3

-1

-2

-3

-1

-2

-3

-1

CN213CN223CN204CN212CN211

-2

-3

Feed-out Belt H.P

Sensor

Jogger H.P Sensor

Jogger Unit Paper

Sensor

CN2-12

-11

-10

CN1-11

-10

-9

-8

-7

-6

-5

-4

-3

-2

-1

-9

-8

-3

-1

-6

-5

-4

-3

-2

-1

-3

-2

-6

-5

-4

-3

-2

-1

CN202CN201

CN203

S5

S6

S3

-1

-2

-3

-4

-5

-6

-1

-2

-3-1

-1

-2

-3

-4

-5

-6

CN207CN208

CN206

-1

-2

-3

-1

-2

-3

-1

-2

-3

CN101-12

-11

-10

CN102-6

CN104-6

CN105-3

CN106-13

-12

-11

-10

CN107-10

[+24 V]

[+24 V]

[+24 V]

-9

[+24 V]

-8

NC

-7

GND

-6

GND

-5

GND

-4

GND

-3

NC

-2

GND

-1

[+5 V]

[▼5] Finisher Set

-5

[▼5] /TXD

-4

[▼5] /RXD

-3

[▼5] Stop

-2

GND

-1

GND

[+5 V]

-5

[▼5] Upper Cover Option

-4

GND

-3

[+5 V]

-2

[▼5] Entrance

-1

GND

[+5 V]

-2

[▲5] Inverter

-1

GND

[+5 V]

[▲5] Shift Tray Lower Limit

GND

[+5 V]

-9

[▼5] Shift Position

-8

GND

-7

NC

-6

[+5 V]

-5

[▲5] Stack Height

-4

GND

-3

GND

-2

[▲5] Exit

-1

[+5 V]

NC

-9

[+5 V]

-8

GND

-7

[▼5] Feed-out Belt H.P

-6

[+5 V]

-5

[▲5] Jogger H.P

-4

GND

-3

GND

-2

[▲5] Jogger Unit Paper

-1

[+5 V]

Finisher Drive

Junction Gate [▼24]

PCB 1

Shift Tray Lift (+) [▲24]

Shift Tray Lift (-) [▲24]

Stapler Unit Set [▼5]

Staple Hammer H.P [▼5]

Jogger Unit Set [▲24]

[+24 V]

[+24 V]

[+24 V]

NC

A [▼24]

/A [▼24]

B [▼24]

/B [▼24]

[+24 V]

[+24 V]

NC

A [▼24]

/A [▼24]

B [▼24]

/B [▼24]

Shift (+) [▲24]

Shift (-) [▲24]

[+24 V]

A [▼24]

/A [▼24]

B [▼24]

/B [▼24]

[+24 V]

[+24 V]

[+24 V]

NC

A [▼24]

/A [▼24]

B [▼24]

/B [▼24]

GND

Staple End [▼5]

GND

Staple (-) [▲24]

Staple (-) [▲24]

Staple (+) [▲24]

Staple (+) [▲24]

[+24 V]

CN110-1 -1

-2

CN111-1

-2

-3

-4

-5

-6

-7

CN112-1

-2

-3

-4

-5

-6

-7

CN113-1

-2

CN114-1

-2

CN115-1

-2

-3

-4

-5

-6

CN116-1

-2

-3

-4

-5

-6

-7

CN108-9

CN103-1

-1

-2

-8

-3

-7

-4

-6

-5

-5

-6

-4

-7

-3 -3

-2

-8

-1 -1

-9

-2

-2

-1 -2

-7

-6

-5

-4

-3

-2

-1

-7

-6

-5

-4

-3

-2

-1

-2

-1 -2

-2

-1 -2

-6

-5

-4

-3

-2

-1

-7

-6

-5

-4

-3

-2

-1

-9

-8

-7

-6

-5

-4

CN309

-2

CN300

CN301

CN302

CN303

CN304

CN305

CN306

-1

-2

-3

-4

-5

-6

-7

-1

-2

-3

-4

-5

-6

-7

-1

-1

-1

-2

-3

-4

-5

-6

-1

-2

-3

-4

-5

-6

-7

CN209-1

SW1

M5

M1

M6

M2

M4

Stapler Unit

-2

-3

-4

-5

-6

-7

Junction Gate Sol.SOL1

Entrance Motor

Transport Motor

Shift Motor

Shift Tray Lift Motor

Jogger Motor

Feed-out MotorM3

SW2

S11

M7

Staple End SW

Staple Hammer

H.P Sensor

Staple Motor

Jogger Unit Set Switch

A

B

C

D

E

F

G

H

I

J

K

12345678910111213141516

Loading...

Loading...