Reznor Euro-T 2025D, Euro-T 2045D, Euro-T 2030D, Euro-T 2035D, Euro-T 2055D Installation Commisioning Servicing & User Instructions

...

®

0505T2DOGBEN

GAS FIRED AIR HEATERS TYPE EURO-T 2000 D

Forced Convection Duct Appliances with

Automatic Ignition and Fanned Flues for use as:

Type B22 - C12 - C32

INSTALLATION COMMISSIONING SERVICING

& USER INSTRUCTIONS

These appliances meet the following EC Directives:

Dir. CE 90/396/EEC: GAD

Dir. CE 89/336/EEC: EMC

Dir. CE 73/23/EEC: LVD

PLEASE READ THIS DOCUMENT CAREFULLY BEFORE COMMENCING INSTALLATION AND LEAVE IT WITH THE

USER OR ATTACHED TO THE APPLIANCE OR GAS SERVICE METER AFTER INSTALLATION.

INDEX

Page

1. General ............................................................................................................................................................................... 2

2. Technical data .................................................................................................................................................................... 3

3. Installing.............................................................................................................................................................................. 6

4. Combustion, Air supply and flue system ............................................................................................................................. 9

5. Gas connection................................................................................................................................................................. 11

6. Electrical connection ......................................................................................................................................................... 11

7. Commissioning, lighting and operation ............................................................................................................................. 12

8. Maintenance ..................................................................................................................................................................... 13

9. Fault finding ...................................................................................................................................................................... 16

10. Spare parts list.................................................................................................................................................................. 17

11. Gas conversion................................................................................................................................................................. 18

12. Health and Safety Statement ............................................................................................................................................ 19

13. User instructions ............................................................................................................................................................... 20

If optional equipment was ordered and supplied with this air heater, please refer to additional instructions for option(s).

SECTION 1. GENERAL

1.1 Before installation, check that the appliance as

described on the packaging label is in accordance

with the correct type and model as specified on the

data plate and complies with your customer order.

1.2 After unpacking the appliance, leave it fastened to the

wooden pallet until it has been suspended or until just

before base mounting. This affords protection to the

painted underside which is normally exposed to view

after installation.

1.3 Please read this document before commencing

installation.

1.4 These instructions are only valid for the country of use

indicated on the appliance i.e.: GB - IE. If these

symbols are not shown, it is necessary to obtain

appropriate technical instructions which will provide

information concerning the necessary modification of

the appliance for the conditions of use in the country

concerned. Such instructions may be obtained upon

request from your supplier.

1.5 Check that the local distribution conditions of

electricity supply, type of gas and pressure, and

adjustment of the appliance are compatible.

1.6 When installed in Great Britain the total installation

must comply with the requirements and

recommendations of British Standard BS 6230

1991. "Installation of Gas Fired Forced Convection

Air Heaters for Commercial and Industrial Space

Heating".

The Installation must also be in accordance with the

relevant requirements of "The Gas Safety (Installation

and Use regulations) and (Amendment Regulations

1990)" and The "Building" and "Electrical Regulations"

(in GB the IEE Regulations).

The requirements of the "Local Building Standards

Office", the premises "Insurance" undertaking and

the"Fire Office" must also be observed.

1.7 Unauthorized modification of this appliance or

departure from use in the manner for which it was

intended by the manufacturer or installation in a

manner contrary to these instructions, may constitute

a hazard and jeopardize all warranties. Deviations

should only be carried out after formal consent has

been obtained from the manufacturer.

1.8 Ensure the environment in which the air heater will be

installed will not create a hazard i.e. where excessive

(volatile) dust, flammable or corrosive substances

and/or vapors and combustible materials may be

present.

1.9 This appliance has been tested, and set according to

the data plate before leaving the factory.

1.10 These air heaters may be used as a gas fired heating

module in an air handling appliance or in conjunction

with a cooling packaged appliance.

When applied in such manner the installation

instructions contained in this document must be

complied with as appropriate. The fitting within

another housing must take into account the gas fired

appliance requirements of the appropriate CE

standard, EN 1020 " Non-domestic gas-fired forced

convection air heaters for space heating incorporating

a fan to assist transportation of combustion air and/or

flue gases" PrEN 1020 is in course of preparation and

may be applied until the final document is published,

0505T2D0GBEN 2/21

(anticipated 1996)

1.11 The criteria recommended in this document regarding

airflow pressures, temperature rise, firing rates and

fitting methods must be strictly complied with, wether

or not the appliance is used as a duct heater or as

part of an multi-functional appliance, to ensure

satisfactory operation.

SECTION 2. TECHNICAL DATA

Table 1. Appliance Data Standard Efficiency Models

EURO-T Standard Model #

EURO-T Low NOx #

Gas category 'Cat.'

Air supply and flue type

Heat input (Hs) 'Qn'

Heat input (Hi) 'Qn'

High heat output

Number of jets

Jet size

Gas supply

pressure 'P'1

Burner pressure 2

Gas consumption

Gas service connection (not supply line size)

Electrical supply

Electrical rating

Protection grade

Appliance weight net

Appliance weight gross (shipping)

4

natural gas

propane/butane

natural gas

propane

butane

natural gas

natural gas 3

propane

butane

1 Maximum gas pressure at inlet to appliance = 50,0 mbar

2 All casing panels fitted, service door open

3 Natural gas G20, caloric heating value 10,5 kWh/m

Propane G31, caloric heating value 12,88 kWh/kg

Butane G30, caloric heating value 12,66 kWh/kg

4 Total electrical rating during the start-up period " 30 seconds is increased by 130 W and is not included on the appliance

data plate or in the above table

kW

kW

kW

i mm

i mm

mbar

mbar

mbar

mbar

m3/h

kg/h

kg/h

kg

" kg

2025D 2030D 2035D 2045D 2055D 2075D 2095D

2525D 2530D 2535D 2545D 2555D 2575D 2595D

II

28,8

26,0

22,8

2.70

2.06

2.10

80

88

3

on Hs @ 15EC & 1013 mbar

35,2

31,7

27,8

4

2.4

1.35

3.36

2.52

2.60

85

96

42,7

38,5

33,7

5

2.2

1.25

(GB) = 17.5 (IE) = 20.0

4.10

3.05

3.12

230/240V 1 N - 50Hz

2H3

B22 - C12 - C32

49,9

45,0

39,4

7

37.0

28.0

8.50

4.76

3.56

3.64

Rc :

180 W

IP20

99

109

63,2

57,0

49,9

9

6.10

4.51

4.61

115

126

2.4

1.35

86,5

78,0

68,3

12

8.30

6.18

6.31

139

152

115,4

104,0

91,0

16

11.00

8.25

8.42

171

187

0505T2D0GBEN

3/21

Table 2 Appliance Data Higher Efficiency Models

EURO-T Standard Model #

EURO-T Low NO

High fire heat output

Note: All other data as standard model

Model #

x

kW 23.7 28.9 35.1 41.0 51.9 71.0 94.7

2026D 2031D 2036D 2046D 2056D 2076D 2096D

2526D 2531D 2536D 2546D 2556D 2576D 2596D

Table 3 Minimum air volumes for maximum temperature rise. Standard Appliance

Standard model Euro-T...

High efficiency model Euro-T...

Minimum air volume

Maximum temperature rise _T

3

m

K

/h

2025D 2030D 2035D 2045D 2055D 2075D 2095D

2026D 2031D 2036D 2046D 2056D 2076D 2096D

1800

2200

2660

3110

37

Table 4 Minimum air flows for maximum temperature rise. Low NO

Maximum air volume

Maximum temperature rise _T

N.B. The maximum static pressure that may be applied to the Euto-T...D series is 800 Pa

Standard model Euro-T...

High efficiency model Euro-T...

m

K

Figure 1 Pressure loss for air flow passing

2525D 2530D 23535D 2545D 2555D 2575D 2595D

2526D 2531D 2536D 2546D 2556D 2576D 2596D

3

/h

2080

2540

Figure 2. Combustion circuit Dew-point occurrence

3080

Models

x

3600

32

4555

Euro-T... D series air heaters

3940

5400

6240

7190

8300

0505T2D0GBEN

4/21

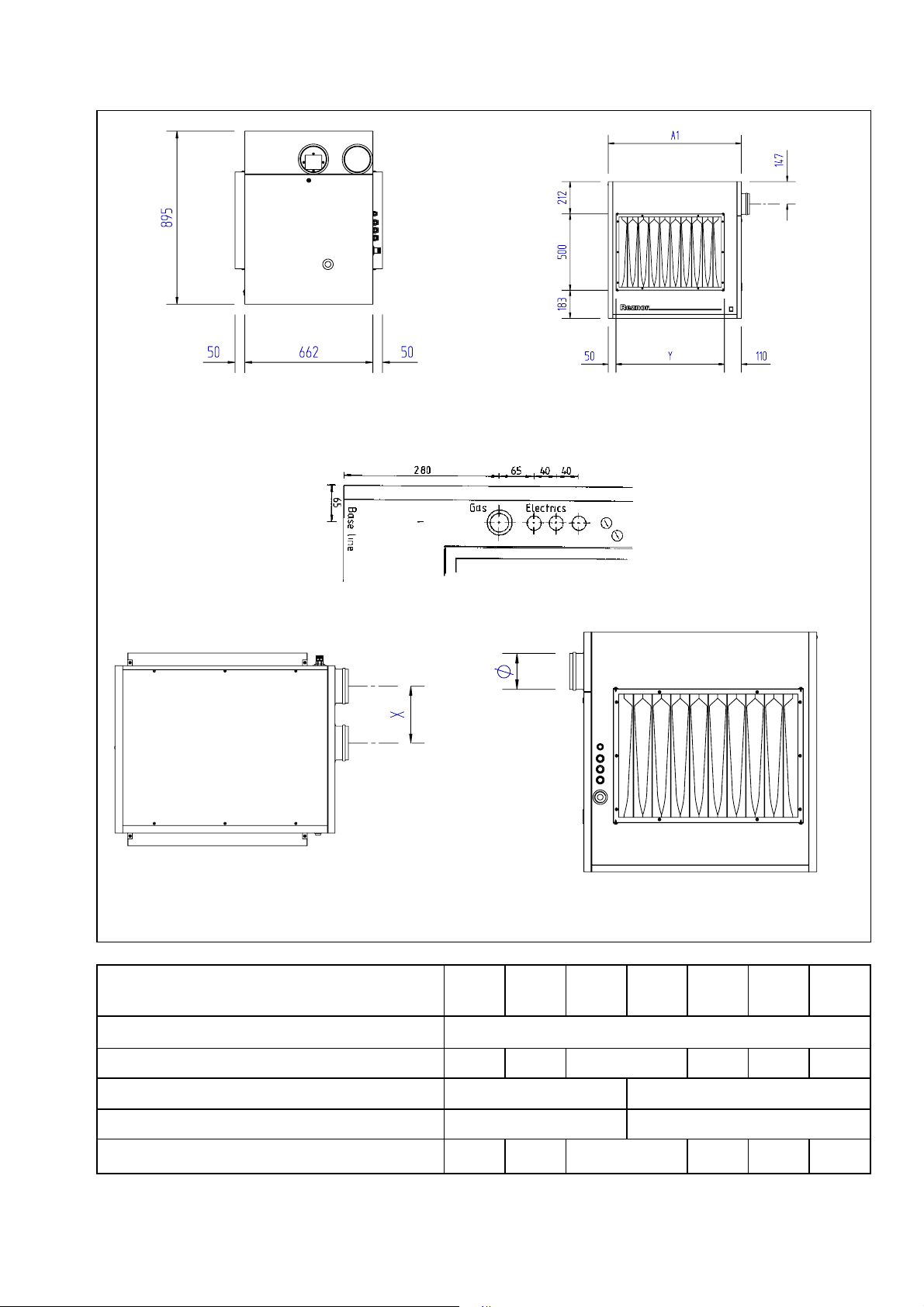

Figure 3. DIMENSIONS

As standard Left hand side (controls side) Front

Gas, electrical & controls connections location

Top plan Rear

Table 5 Dimensions reference figure 3

Model

Dimensions

A1 Width overall

i Flue & combustion air intake socket internal i

X Flue & combustion air intake socket centres

Y Duct flange width front and back

2..25

2..26

520

360

2..30

2..31

590

102

140

620

2..35

2..36

730

570

2..45

2..46

2..55

2..56

870 1080 1360

710

2..75

2..76

132

225

920 1200

2..95

2..96

0505T2D0GBEN

5/21

SECTION 3 INSTALLING

3.1 When installed as an in-line duct heater i.e. not fitted

within an air handling appliance cabinet it is

necessary to ensure that clearance is maintained

around the appliance from combustible materials and

for service access. The clearances necessary to

ensure safety for combustibles is 150 mm on all

sides. Service access should be allowed on the

controls side of the appliance equal to the width of

the air heater plus 200 mm, this distance allows for

the removal of the burner tray assembly, necessary

en servicing the appliance.

3.2 Ensure that the structural elements which will be

used to suspend or support the appliance, are

adequate to carry the weight of the appliance and its

ancillary components i.e. flue system and any

connected duct-work.

3.3 Ensure that the air heater is installed in a level plain.

3.4 If the air heater is to be base mounted in an open

position then it must be secured to supporting

devices.

3.5 4 suspension brackets with holes φ 10.5 mm are

available as optional accessories.

Use 10 mm i rods for suspending the heater when

using the Reznor options.

3.6 If the appliance is to be suspended or base mounted

from cantilever brackets, specially designed wall

brackets should be manufactured to suit the

application respecting the clearances indicated in 3.1

above and the live load factors the appliance will

impose.

3.7 After suspension, the air heater should be rigid so as

to avoid placing a strain on the flue system, gas

services electrical wiring and duct-work.

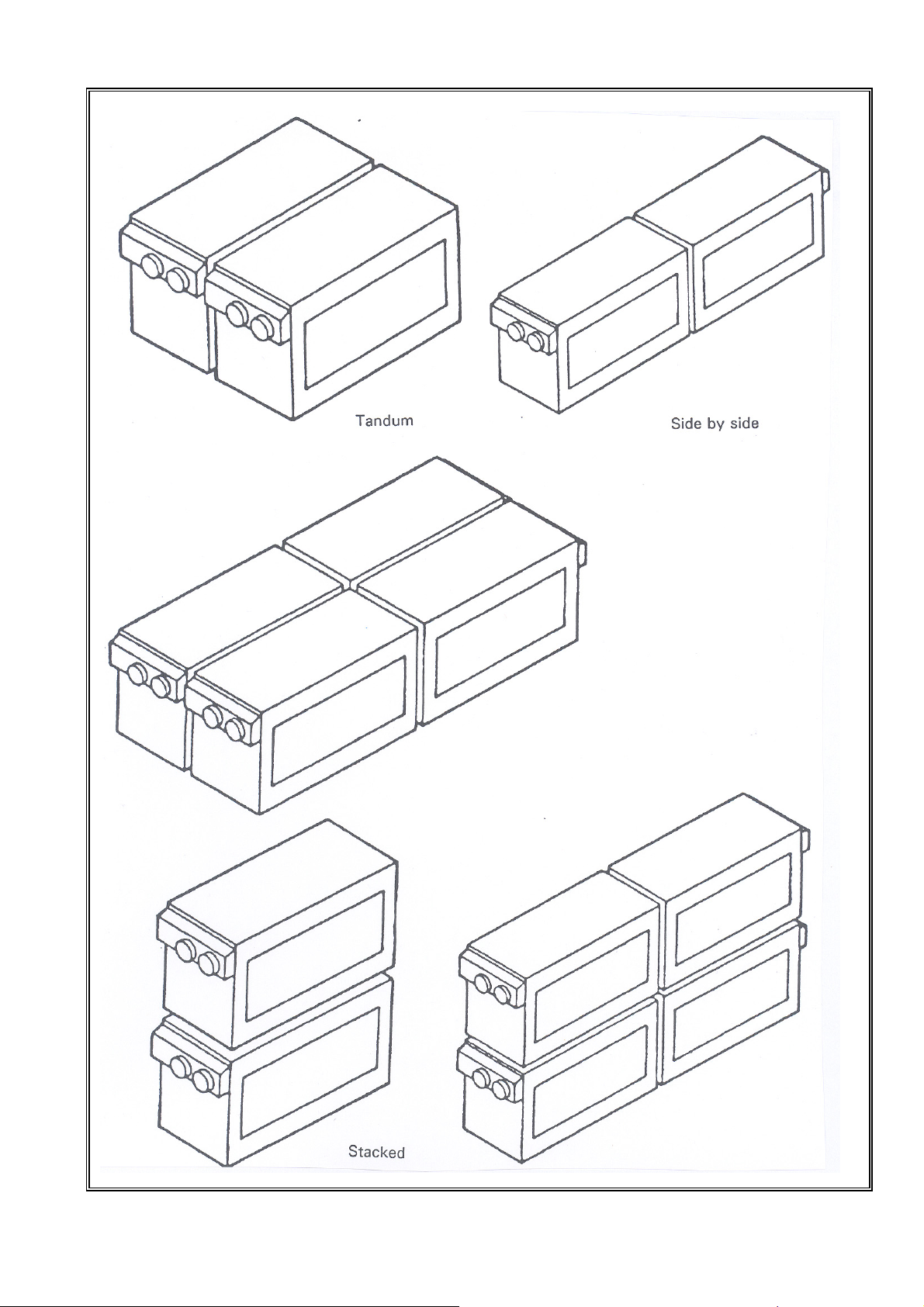

3.8 Euro-T.. Series D air heaters, wether or not they are

installed within an air handling appliance may be

installed in multiple form as illustrated in figure 4. In

all instances the air flow passed through the

appliance/s should not exceed the volumes required

to ensure that dew point conditions within the

combustion circuits/s as indicated in figure 3 do not

occur.

By-passes should be constructed as necessary to

ensure that the optimum temperature rises are met

taking into account the pressure resistance of the air

heater as indicated in figure 2.

When designing by-pass ducts ensure that the

requirements for service access, flue and controls

connections are maintained. An adjustable damper

should be included within by-pass ducts to enable air

flow pressure and volume to be adjusted after

installation.

When fitting Euro-T.. air heaters in a side by side

configuration it is necessary to specify this requirement

when ordering type D models. Whilst the air may be

passed through the appliance from either end, provision

for locating the thermal over-heat (limit) control device

has to be made so that the air off side (the hottest side)

is monitored for this purpose.

3.8 Figure 5. illustrates the recommended principle that

should be used for the connection of ducts or air

handling appliance element transitions.

A positive seal must be maintained between the air

circuit and the air heater, this is particularly important

when the air heater is installed within an air handling

cabinet. A neutral pressure zone around the appliance

must be maintained to ensure that the atmospheric

burner operates at all times at normal ambient pressure.

3.9 Figure 6 illustrates some of the situations to be avoided

when connecting an air handler to the appliance. A rule

of connecting a straight length of duct equal to 3 times

an equivalent duct diameter onto the appliance should

be maintained whenever possible. It is essential that an

even air flow is distributed across the heat exchanger to

ensure that the heat is scrubbed from all the exchanger

elements thus preventing hot spots which will greatly

reduce the working life of the air heater.

Always avoid installing a centrifugal fan so that the swirl

effect created by the direction of rotation is counter

directive. As well as the effect of uneven air flows,

excessive loss of static pressure is created resulting in

inefficiency of the fan.

Where it is necessary to connect a transition section as

part of the connection then the degree of taper in any

plain should not be greater than 15E. Abrupt transitions

create excessive pressure drops and lead to uneven air

distribution across the air heater.

0505T2D0GBEN

6/21

Figure 4. Arrangements for applying multi-heater combinations

0505T2D0GBEN

7/21

Loading...

Loading...