Page 1

Workshop Repair Manual

Manual gearbox

Type Range

JC7 Scénic RX4

Reduction gearing section

For the gearbox section

refer to the JB - JC manual

77 11 298 942

"The repair methods given by the manufacturer in this document are based on the

technical specifications current when it was prepared.

The methods may be modified as a result of changes introduced by the manufacturer

in the production of the various component units and accessories from which his

vehicles are constructed."

FEBRUARY 2001

© RENAULT 2001

EDITION ANGLAISE

All copyrights reserved by Renault.

Copying or translating, in part or in full, of this document or use of the service part

reference numbering system is forbidden without the prior written authority of Renault.

Page 2

Contents

MANUAL GEARBOX

21

Identification 21-1

Gears 21-1

Section and tightening torques (in daNm) 21-3

Tightening torques (in daNm) 21-4

Special tooling 21-5

Repairing the reduction gearing 21-6

Page

Page 3

MANUAL GEARBOX

MANUAL GEARBOX

121

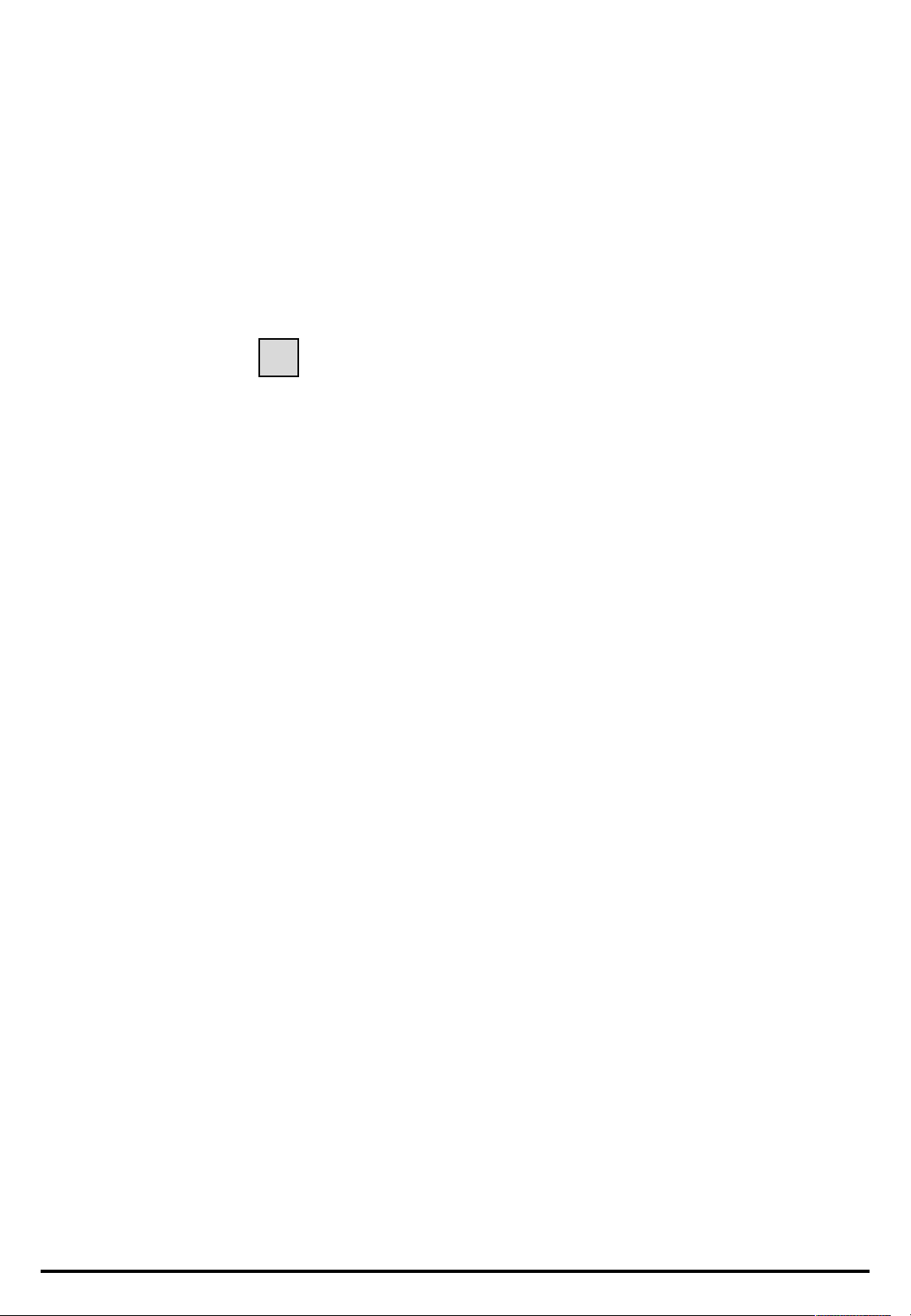

Marking (1), on the gearbox casing, indicates:

A Gearbox type

B Gearbox index

C Fabrication number

D Factory of manufacture

Identification

Identification

21

Ratios

Index Type 1

JC7-000 J64 (F4R) 11/41 21/43 28/39 31/34 37/33 11/39 15/61 22/18 15/41

JC7-001 J64 (F9Q) 11/41 21/43 28/37 35/34 39/31 11/39 15/61 22/18 15/41

st

nd

2

rd

3

th

4

th

5

Re-

verse

gear

Final

drive

Tachome-

ter

21-1

Reduc-

tion

gearing

Page 4

MANUAL GEARBOX

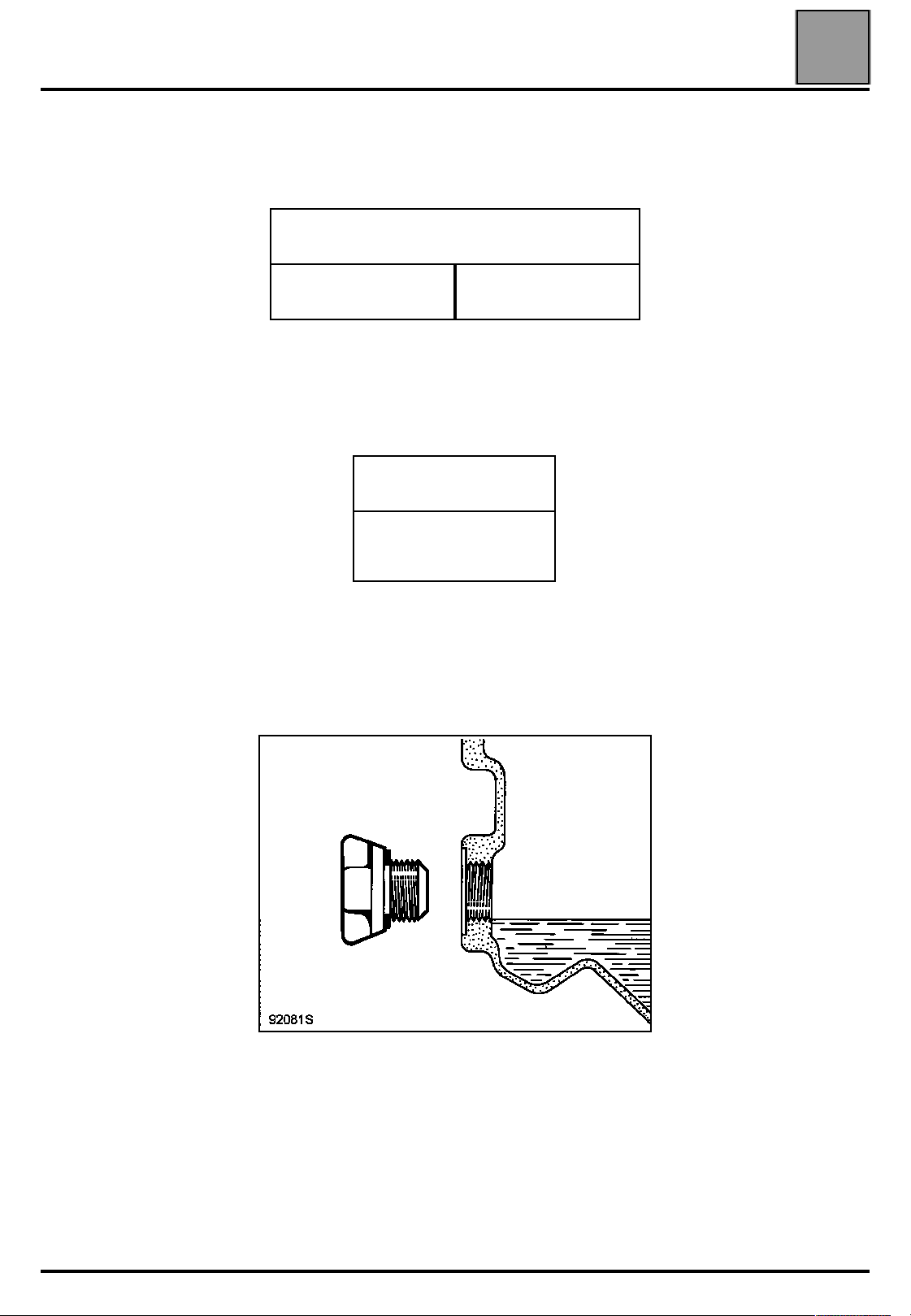

CAPACITY (in litres)

Capacities - Lubricants

Capacities - Lubricants

5-speed gearbox

JC7 3.3

Viscosity grade

21

TRX 75W 80W

CHECKING THE LEVEL

Fill up to the level of the hole

21-2

Page 5

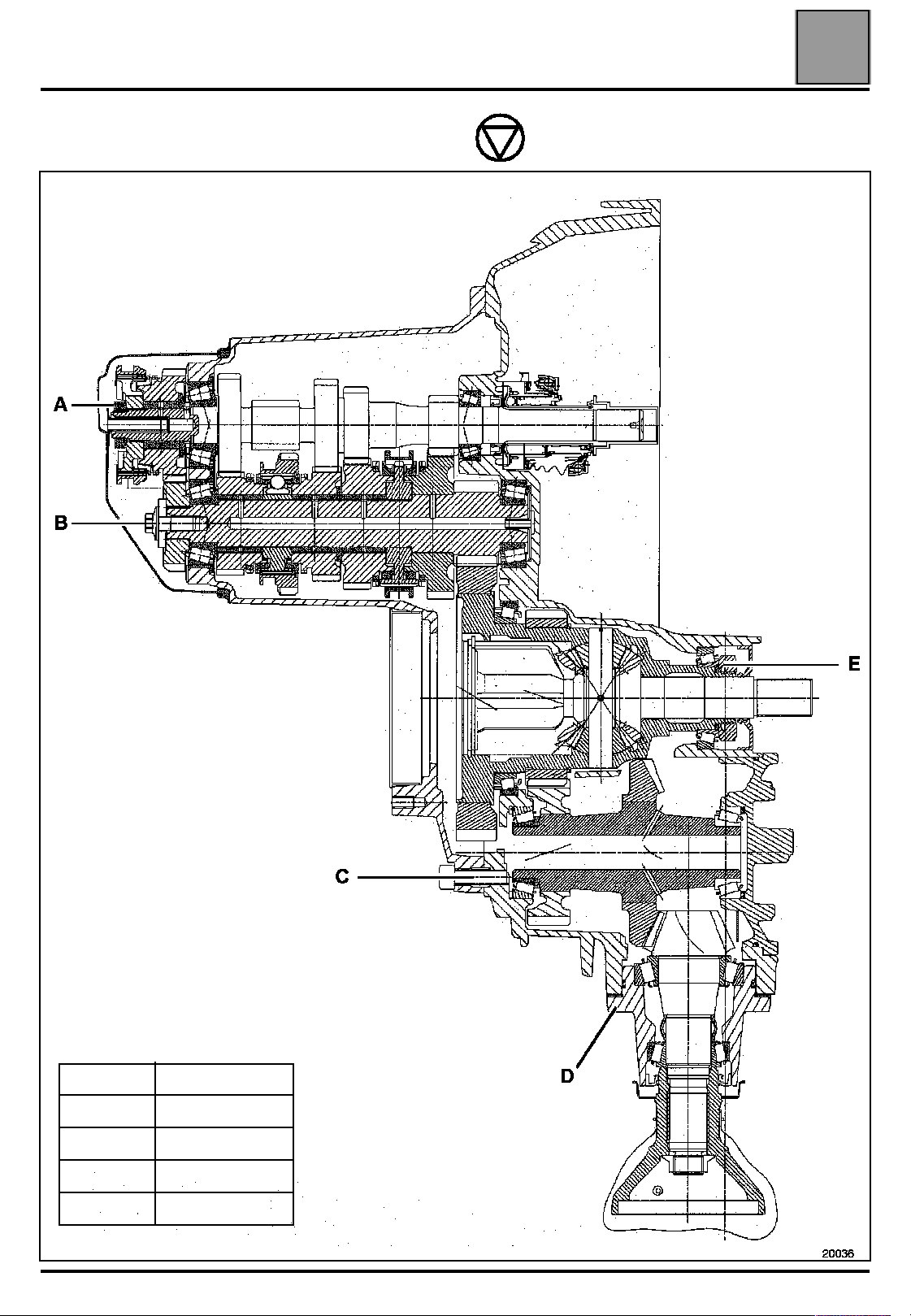

MANUAL GEARBOX

Section and tightening torques (in daNm)

Section and tightening torques (in daNm)

MANUAL GEARBOX JC7 (tightening torques in daNm)

21

A16

B 7

C 3.5

D 3.5

E15

20036

21-3

Page 6

MANUAL GEARBOX

Tightening torques (in danm)

Tightening torques (in danm)

Description Torque in daNm

Bolt joining the gearbox casing to the clutch casing 2.5

th

Body (point of resistance of 5

Rear cover bolt 2.5

Drain plug 2.5

Reversing light switch 2.5

Left driveshaft gaiter mounting bolt 2.5

) 2

21

Joining the gearbox to the cylinder casing 5

21-4

Page 7

MANUAL GEARBOX

Special tooling

Special tooling

B. Vi. 1161 Steel plate to attach DTI gauge + pre-load adjust shims

B. Vi. 1389 Rules for measurements on automatic gearbox

B. Vi. 1419 Bearing positioning tool

B. Vi. 1554 Reduction gearing repair kit

B. Vi. 1556 Tool for supporting the intake flange

B. Vi. 1581 Gearbox support plate

B. Vi. 1582 Input shaft support plate

RECOMMENDED TOOLING

General purpose puller pliers ∅ 42 (example: U 49M + U49D8 Facom)

Swivel head DESVIL stand

Torque testing wrench

21

21-5

Page 8

MANUAL GEARBOX

Repairing the reduction gearing

Repairing the reduction gearing

DISMANTLING THE REDUCTION GEARING

Fit the B. Vi. 1581 support plate on a DESVIL stand.

Fit the gearbox on the B. Vi. 1581 support.

21

REMOVING BEARINGS

Remove the bearings using an antisticking pin.

NOTE: the gearbox differential must be removed

(refer to the JB-JC manual for removing/refitting)

before any operation can be carried out on the

reduction gearing.

Remove:

– the reduction gearing shaft (A),

– the cover (B).

Remove the reduction gearing.

On the inside, it is necessary to break the bearing

cage in order to position the jaws of the antisticking pin

on the bearing flange base.

21-6

Page 9

MANUAL GEARBOX

Repairing the reduction gearing

RE-FITTING THE BEARINGS

Fit the bearings as far as the thrust bearing on the

casing using index tool D from the B. Vi. 1554 kit.

21

Cover side

Fit onto B. Vi. 1582.

REMOVING BEARING RETAINERS

Remove the retainers using a ∅ 42 extractor and an

inertia extractor.

WARNING: take care not to mix the pre-stressed

setting shims.

Gearbox housing side

REFITTING THE RETAINERS

After refitting the original prestressed shim, refit the

housing side retainer to the press using tools C-F from

the B. Vi. 1554 kit and the B. Vi. 1419 rod.

WARNING: the shim and the cover side retainer must

be refitted after their pre-stress value has been

determined.

21-7

Page 10

MANUAL GEARBOX

Repairing the reduction gearing

SETTING THE REDUCTION GEARING

PRE-STRESS

Housing side: dimension X

Position the reduction gearing in the housing and fit

the retainer, cover side, on its bearing.

Fit tool G from the B. Vi. 1554 kit on the bearing

retainer.

Pass the cable inside the reduction gearing and attach

a 20 kg weight

21

Cover side: dimension X'

Measure between the cover plane (A) and the mating

face of the pre-stressing shim (B) using B. Vi. 1389

and calculate the difference to determine dimension

X'.

Remember to subtract the thickness of the rule.

Measuring on the cover plane:

19258

Measure between the housing plane and the top of the

retainer using B. Vi. 1389 (dimension X).

Remember to subtract the thickness of the rule.

19260

Measuring on the shim mating face:

19261

19259

21-8

Page 11

MANUAL GEARBOX

Repairing the reduction gearing

Measure the difference between the two dimensions

(X and X') and add 0.09 mm to this amount to

determine the thickness of the pre-stressing shim.

Example:

X X' Value for pre-stressing shim

14.65 12.97

Select the shim closest to 1.77 from the kit.

Fit the shim and the retainer using tool C-F from the

B. Vi. 1554 kit.

14.65 - 12.97 = 1.68 (+0.09) =

1.77

21

Fit the cover with a new O-ring and tighten the bolts to

a torque of 3.5 daNm.

19262

19263

21-9

Page 12

MANUAL GEARBOX

Repairing the reduction gearing

REPLACING THE INPUT SHAFT BEARINGS

Measure the distance between the end of the shaft

and the conical spacer shim (A), before removing the

shaft on the casing.

Then read the thickness of this shim (A).

21

Remove:

– the clamp and the input shaft using the press,

19264

Fit the assembly on B. Vi. 1582 and remove the prestressing nut using B. Vi. 1556.

– the bearing using an antistick pin.

21-10

Page 13

MANUAL GEARBOX

Repairing the reduction gearing

Refit the bearing using the B tool from the B. Vi. 1554

kit.

21

Refit the retainers using tools A and C-F from the

B. Vi. 1554 kit.

Remove the interior retainers using a roll pin punch.

21-11

Page 14

MANUAL GEARBOX

Repairing the reduction gearing

NOTE: the bearings are pre-stressed by deformation

of the spacer (A).

A new spacer must be fitted and use tool D from the

B. Vi. 1554 kit to fit a small bearing to leave a slight

play (B) so that the spacer is not deformed

prematurely.

21

Fit the lip seal using tool E from the B. Vi. 1554 kit.

18560

Fit the shaft in the casing, with a new pre-stressing

spacer, and fit the small bearing using the press and

tool D from the B. Vi. 1554 kit.

19266

19265

21-12

Page 15

MANUAL GEARBOX

Repairing the reduction gearing

Partly fit the inlet clamp (so that there is always a slight

play between the bearing and the pre-stressing

spacer).

21

Check the bearings' pre-stress using a torque tester

(A).

The inlet shaft must turn under a torque of 1.15 Nm.

If the torque value is incorrect, gradually tighten the

nut to obtain the correct pre-stress setting.

WARNING: never loosen the nut: if pre-stressing

is too high, repeat the removal operation to

replace the pre-stress spacer.

Fit the assembly on B. Vi. 1582.

Tighten the nut to approximately 26 daNm using

B. Vi. 1556.

19267

21-13

Page 16

MANUAL GEARBOX

Repairing the reduction gearing

CHECKING THE CONIC DISTANCE

Measure between the end of the shaft and the conical

spacer shim (as during removal).

21

Fit the assembly on the gearbox with a new O-ring and

tighten the bolts to a torque of 3.5 daNm.

19264

Calculate the difference between these two values

(before removal and after refitting).

Increase the shim if the value is higher.

Decrease the shim if the value is higher.

Example (in mm):

Before

removal

56.80 56.90 + 0.10 2.10

Value of new conic distance shim:

2.10 + 0.10 = 2.20

Select from the kit the shim closest to 2.20.

After

refitting

Difference

Value of

original

shim

21-14

Page 17

MANUAL GEARBOX

Repairing the reduction gearing

Check play of teeth:

Fit a bolt (V) in one of the inlet shaft flange holes.

Fit a dial gauge using the plate from B. Vi. 1161 so

that the probe is in contact with one of the bolt flats.

Measure the play by gently swivelling the inlet shaft.

Measure this play four times, turning the inlet shaft

about ten times, and moving the bolt (V) into another

hole in the flange.

Average it.

The play must be between 0.15 and 0.25 mm.

21

If the play is not correct, reduce or increase the shims

which are behind the reduction gearing bearing

retainers.

To reduce the play, decrease the shim thickness on the

side opposite the ring and transfer this to the ring side

(to retain the same bearing pre-stress).

To increase the play, do the reverse.

21-15

Loading...

Loading...