Page 1

Workshop Repair Manual

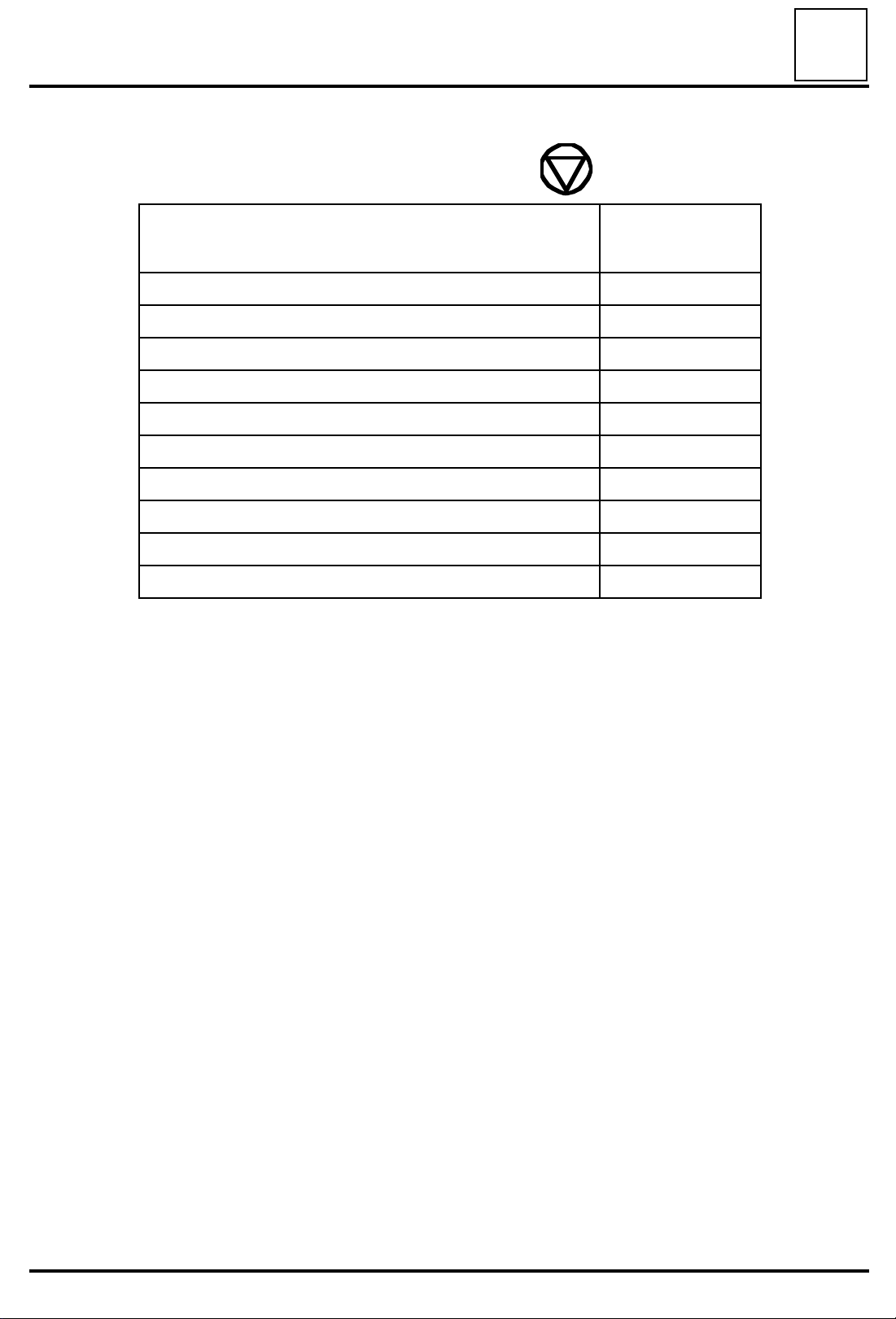

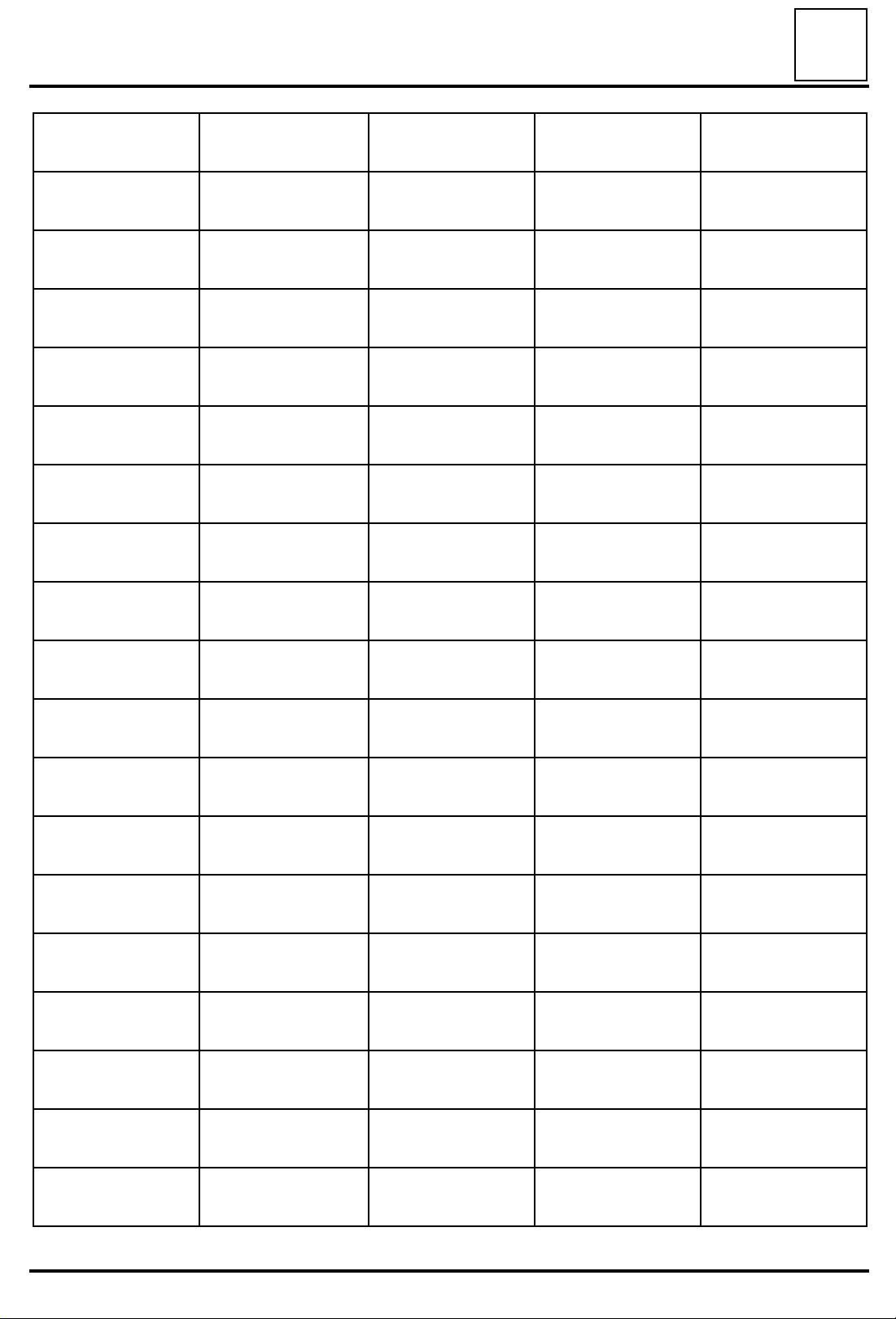

Manual gearboxes

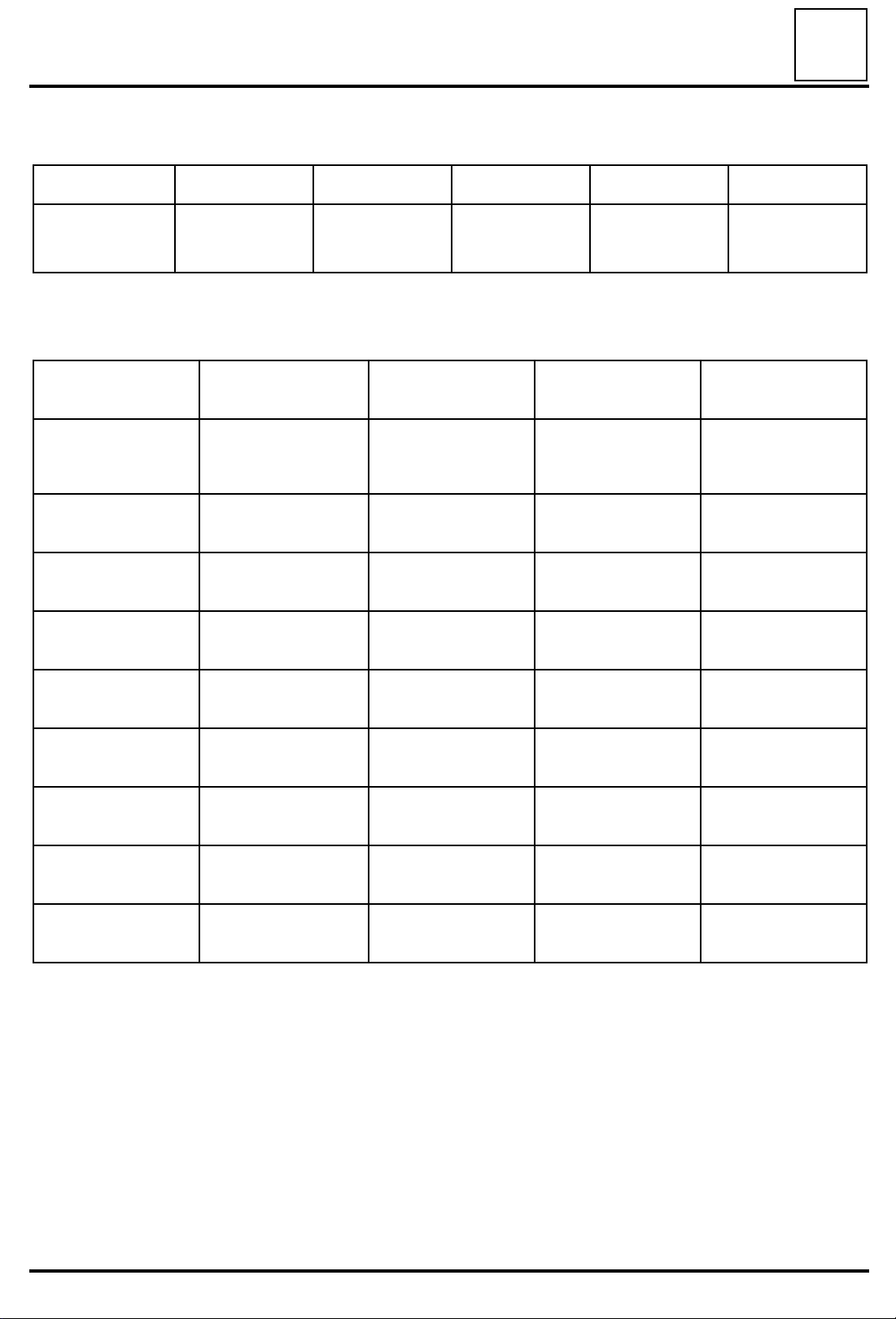

Vehicle

Type

JB0 JB1 JB2 JB3 JB4 JB5 JC5

Renault 5 X X X X X

Extra X X X

Renault 9 X X X X X

Renault 11 X X X X X

Renault 19 X X X X X

Renault 21 X X

Clio X X XXXX

Twingo X

Laguna X X

Mégane X X X

This document cancels and replaces JB Gearbox manual part number

77 11 093 922 and JC5 Gearbox manual part number

77 11 092 186

and technical notes

n° 1978, 2127, 2229A, 2284A, 2383A, 2457A.

77 11 192 787 FEBRUARY 1997 Edition Anglaise

"The repair methods given by the manufacturer in this document are

based on the technical specifications current when it was prepared.

The methods may be modified as a result of changes by the manufacturer

in the production of the various component units and accessories from

which his vehicles are constructed".

C

Renault 1997

All copyrights reserved by Renault.

Copying or translating, in part or in full, of this document or use of the

service part reference numbering system is forbidden without the prior

written authority of Renault.

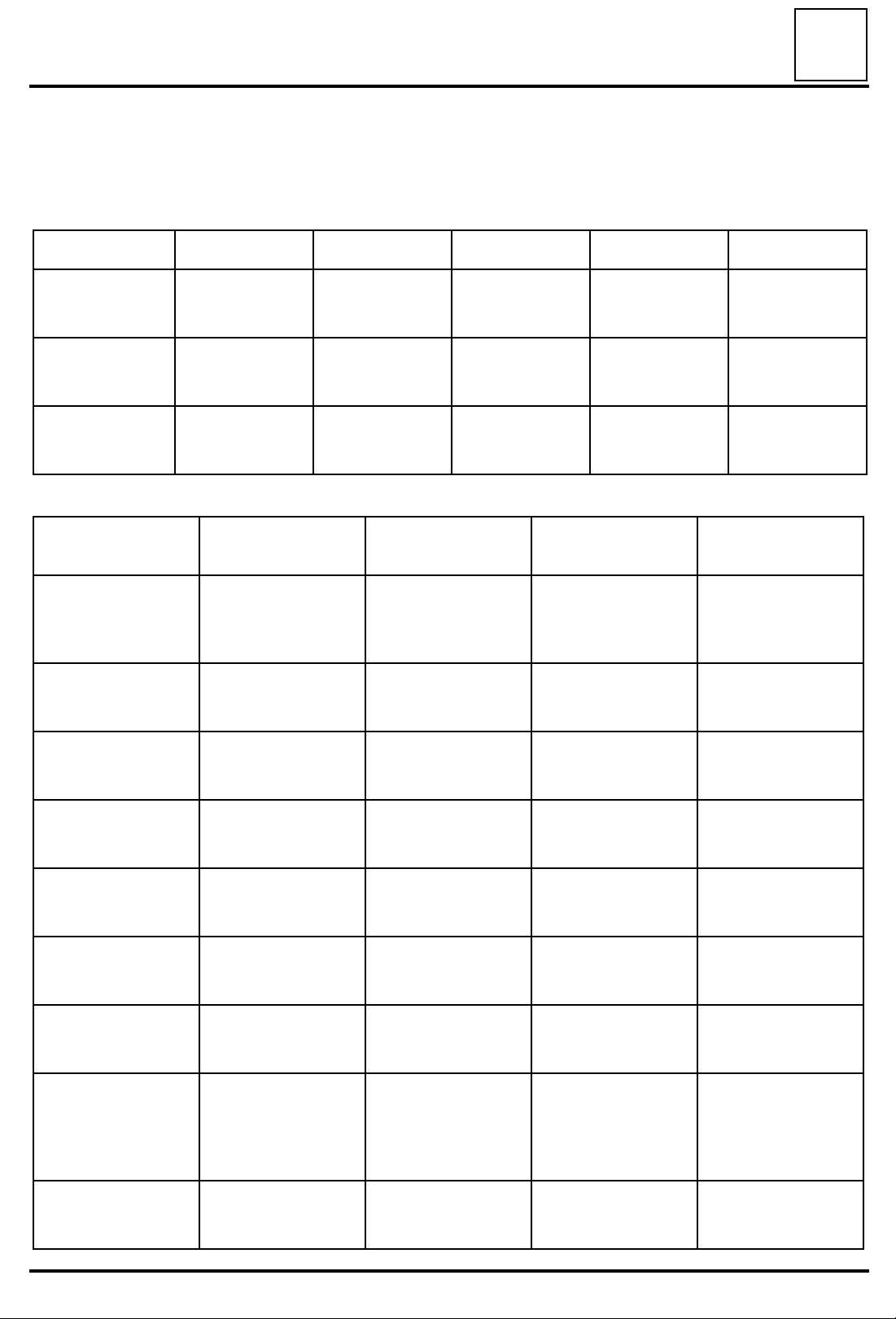

Page 2

Contents

ENSEMBLE MOTEUR ET BAS

MANUAL GEARBOX

21

Pages

Section view

Identification

Cross section - tightening torques

Gears

Capacity - Lubricants

Special points

Modifications

Consumables

Parts which must always be changed

Special tools

Gearbox repair

Shafts

Differential

21-1

21-2

21-3

21-8

21-28

21-29

21-30

21-32

21-32

21-33

21-37

21-44

21-62

Internal controls

Lubrication channel

Reverse gear shaft

Reverse gear brake

Speedometer

Thrust pad guide tube

Assembling the housings

Exploded view parts directory

Exploded views

21-76

21-79

21-80

21-81

21-84

21-89

21-97

21-107

21-108

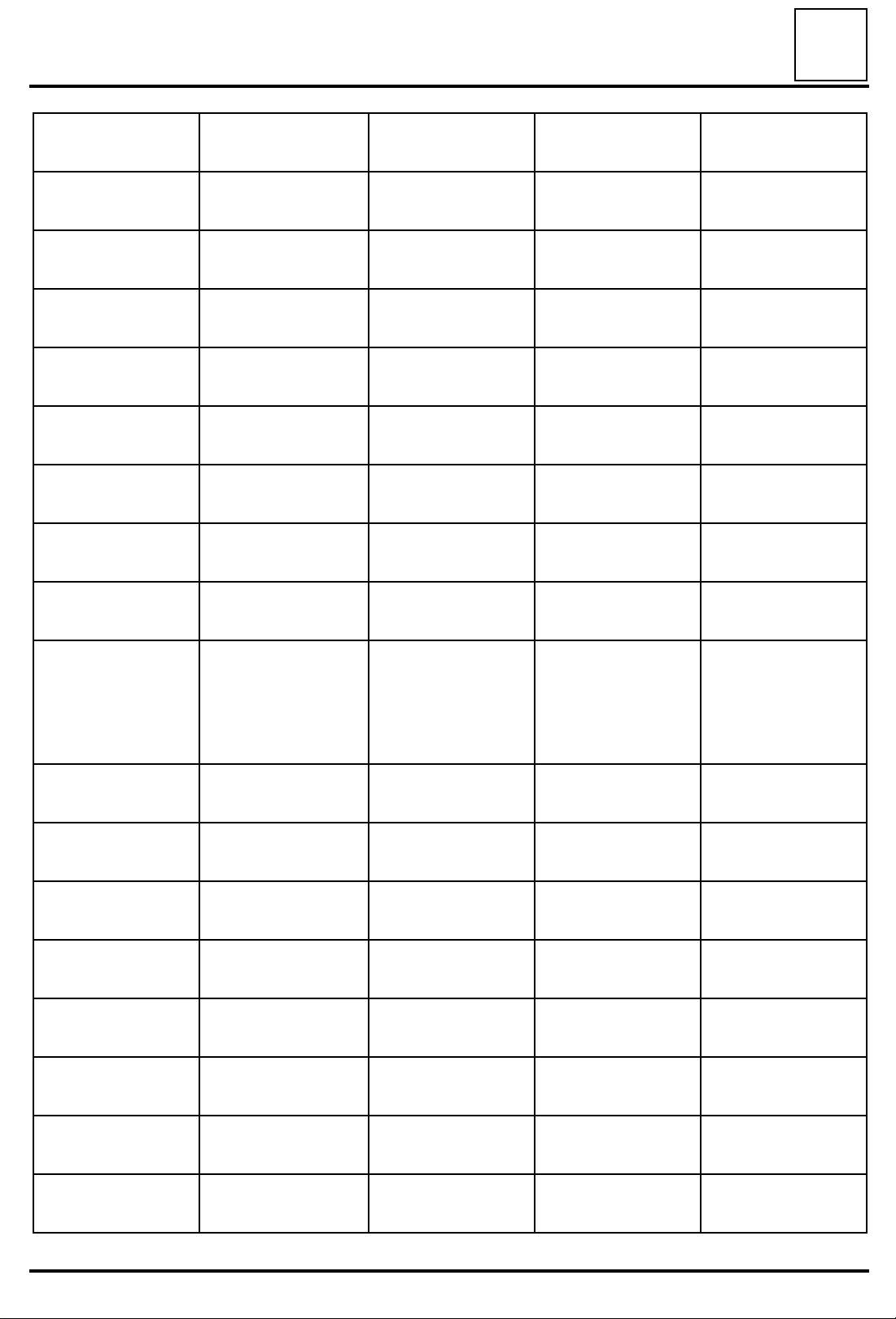

Page 3

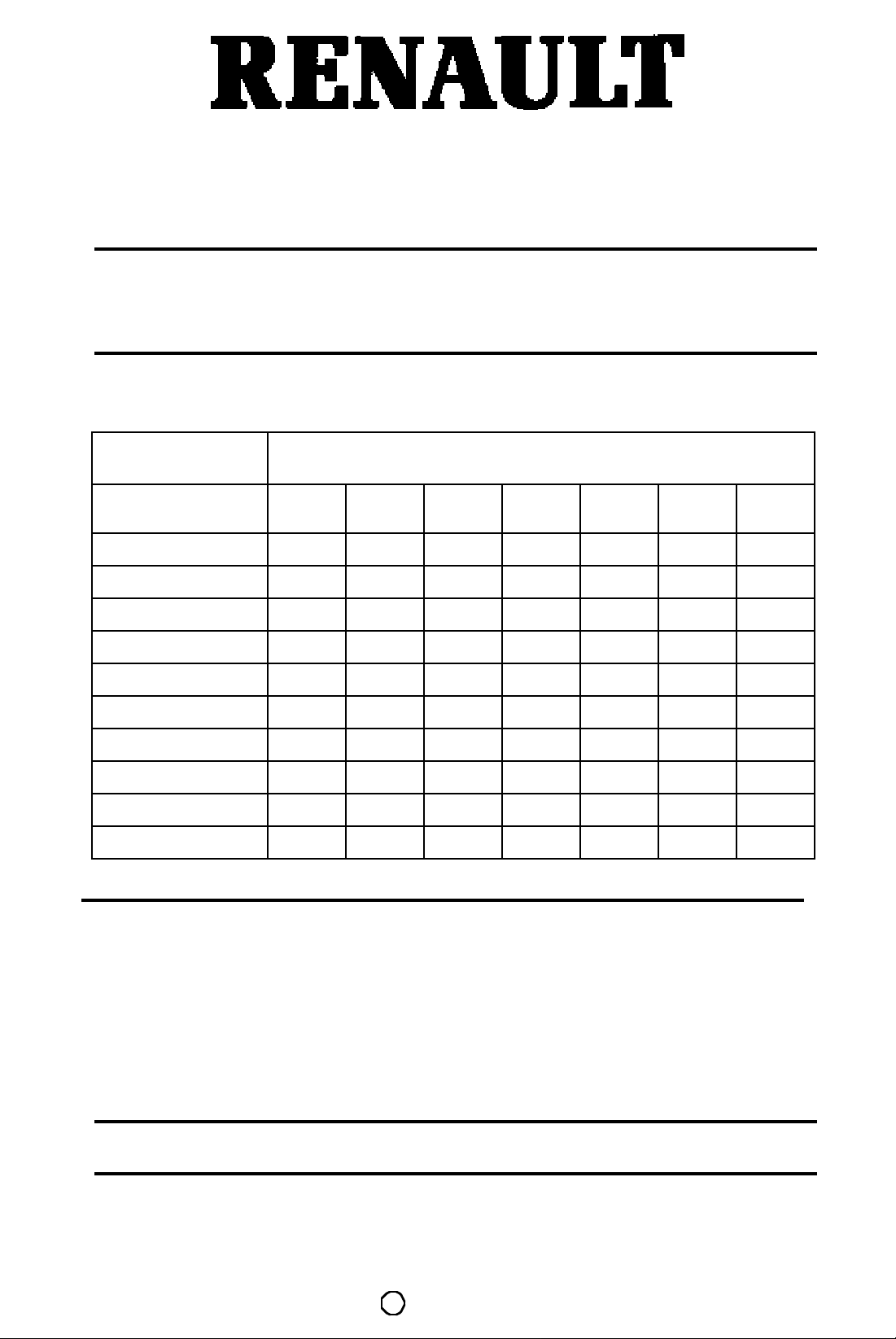

JB0

JB2

JB4

MANUAL GEARBOX

Section view

21

JB1

JB3

JB5

JC5

DI2101

21-1

DI2102

Page 4

MANUAL GEARBOX

Identification

21

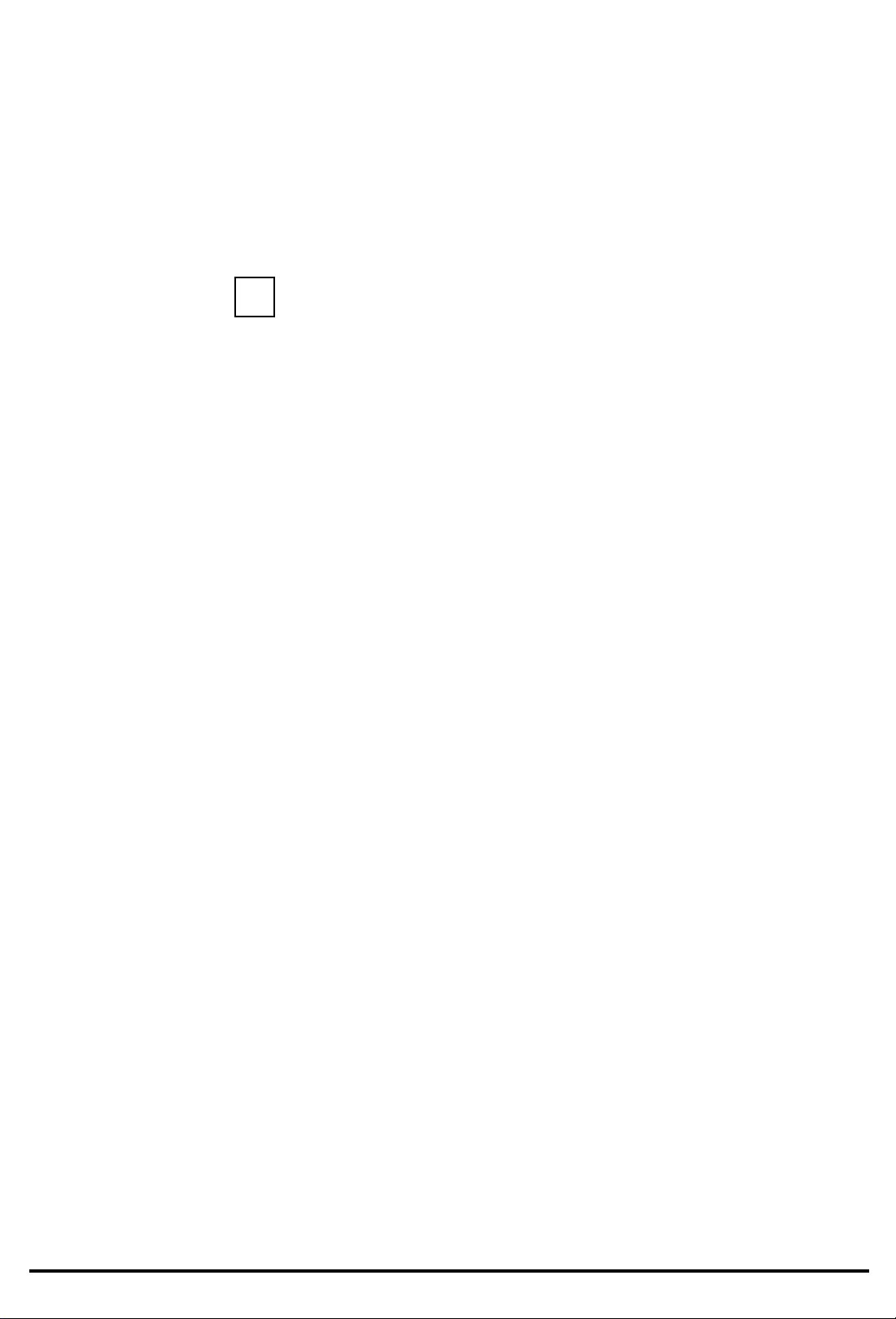

DI2117-2

st

1

assembly

TYPE

A

XXX - XX

000000

90775

At A : Gearbox type.

At B : Gearbox suffix.

At C : Production number.

B

C

DI2117-1

nd

2

assembly

000JB0

D C

E

A

D

At A : Gearbox type.

At B : Gearbox suffix.

At C : Production number.

At D : Manufacturing factory.

At E : A notch if the gearbox is assembled

At F : Homologation letter.

At G : Letter preceding production numbers

X

X00000

G

F

000JB0 AA

X 0 0 0 0 0 0 0

with a C or E engine.

greater than 999 999.

BA

B

C

90 775

Following saturation of the production numbering system on the identification plate of JB and JC gearboxes,

a new numbering system will be in force for numbers greater than 999 999 (at C).

These will have a letter in place of the first number, (at G).

21-2

Page 5

MANUAL GEARBOX

Cross-section and Tightening torques (in daN.m)

21

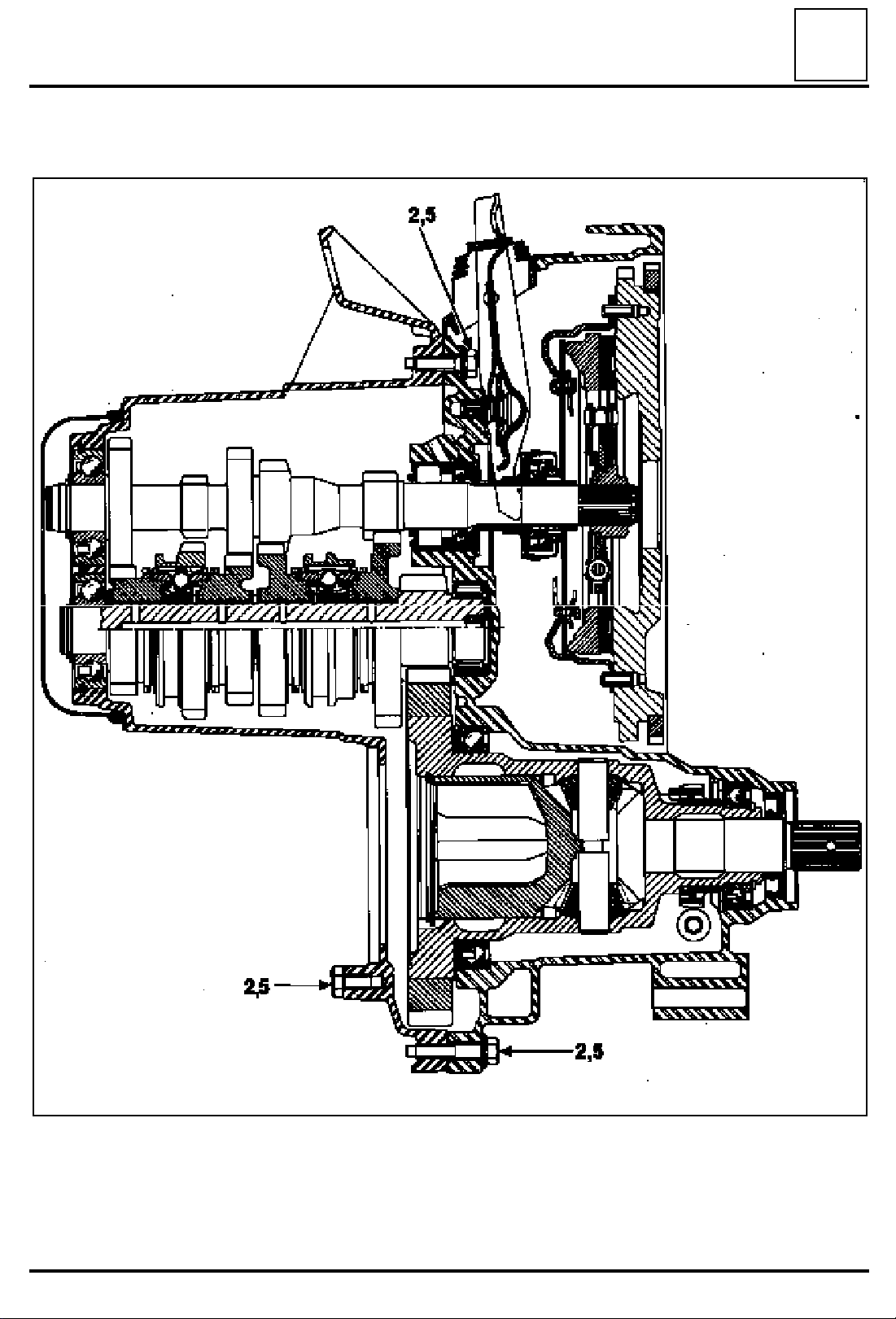

JB 4-speed manual gearbox - 1

st

assembly

21-3

85680R

Page 6

MANUAL GEARBOX

Cross-section and Tightening torques (in daN.m)

21

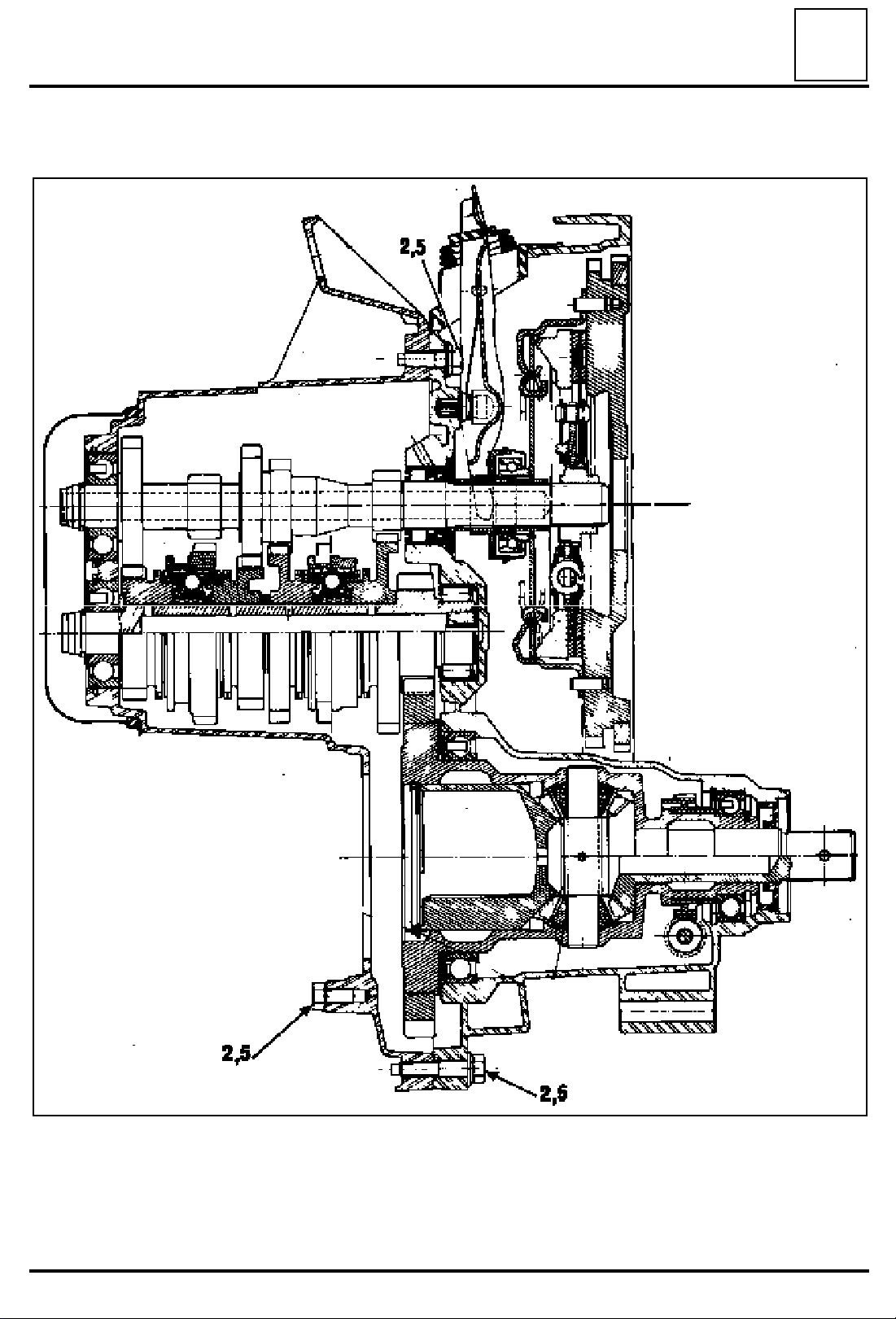

JB 4-speed manual gearbox - 2

nd

assembly

21-4

88519R

Page 7

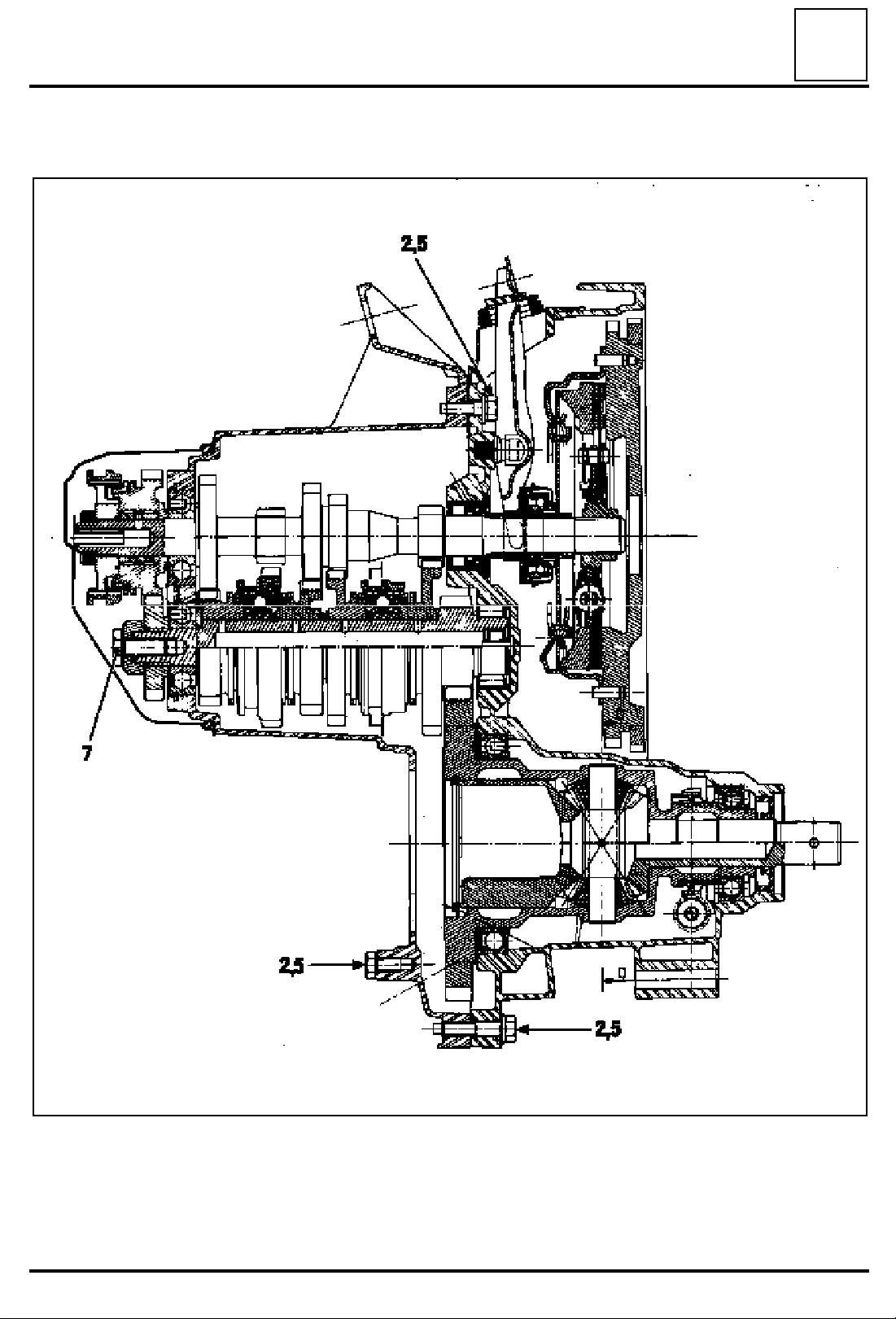

MANUAL GEARBOX

Cross-section and Tightening torques (in daN.m)

5-speed manual gearbox

21

21-5

90674R1

Page 8

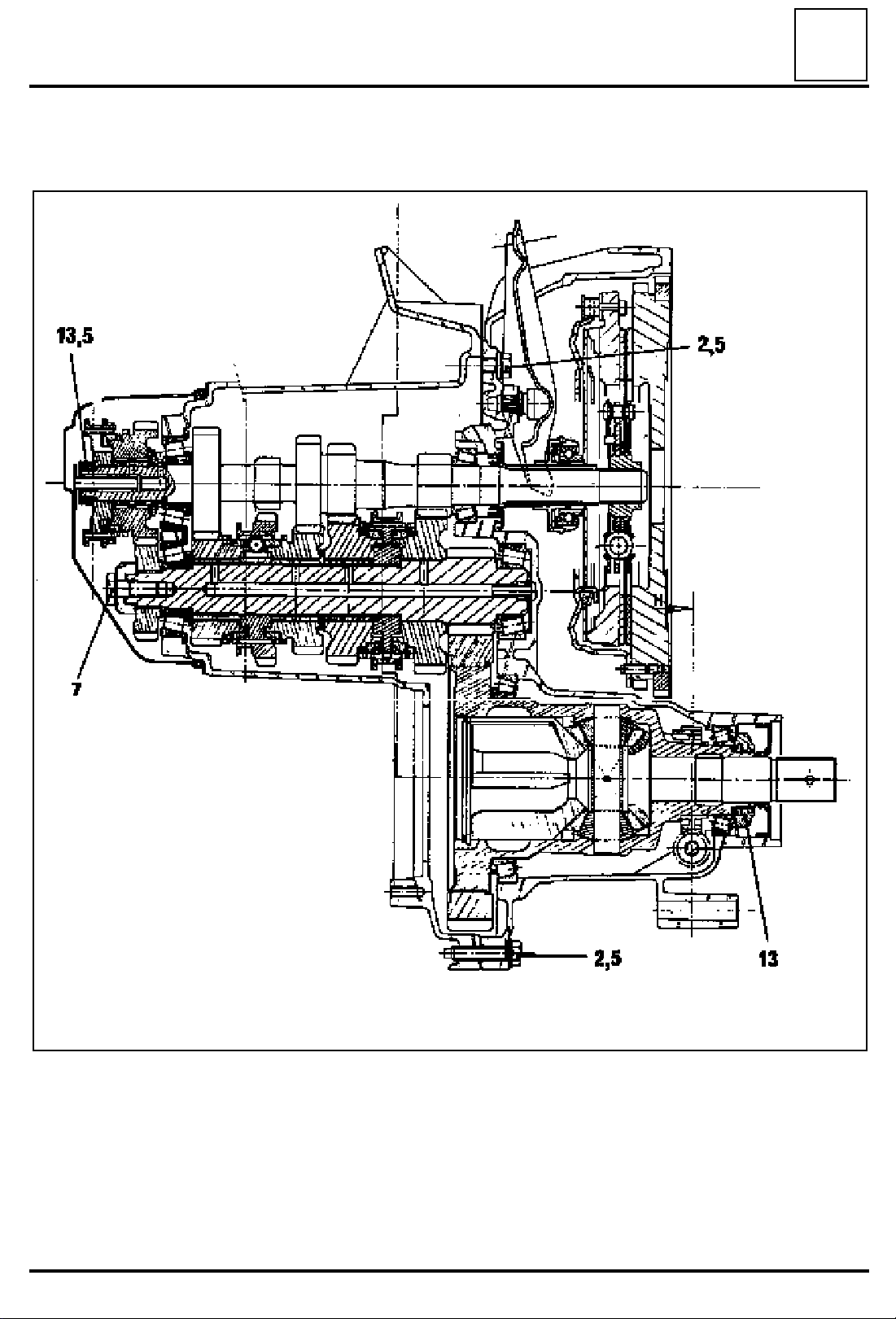

MANUAL GEARBOX

Cross-section and Tightening torques (in daN.m)

JC 5-speed manual gearbox

21

DI2126

21-6

Page 9

MANUAL GEARBOX

Tightening torques

Tightening torques

21

Description

Bolt securing the mechanism housing to the clutch housing 2.5

Output shaft bolt 7

Input shaft nut 13.5

Body (5th gear detent) 2

Rear cover bolt 2.5

Thrust pad guide tube bolt 2.5

Drain plug 2.5

Reversing lights switch 2.5

Bolt securing the left-hand drive shaft bellows 2.5

Bolt securing the gearbox to the cylinder block 5

Torque in

daN.m

21-7

Page 10

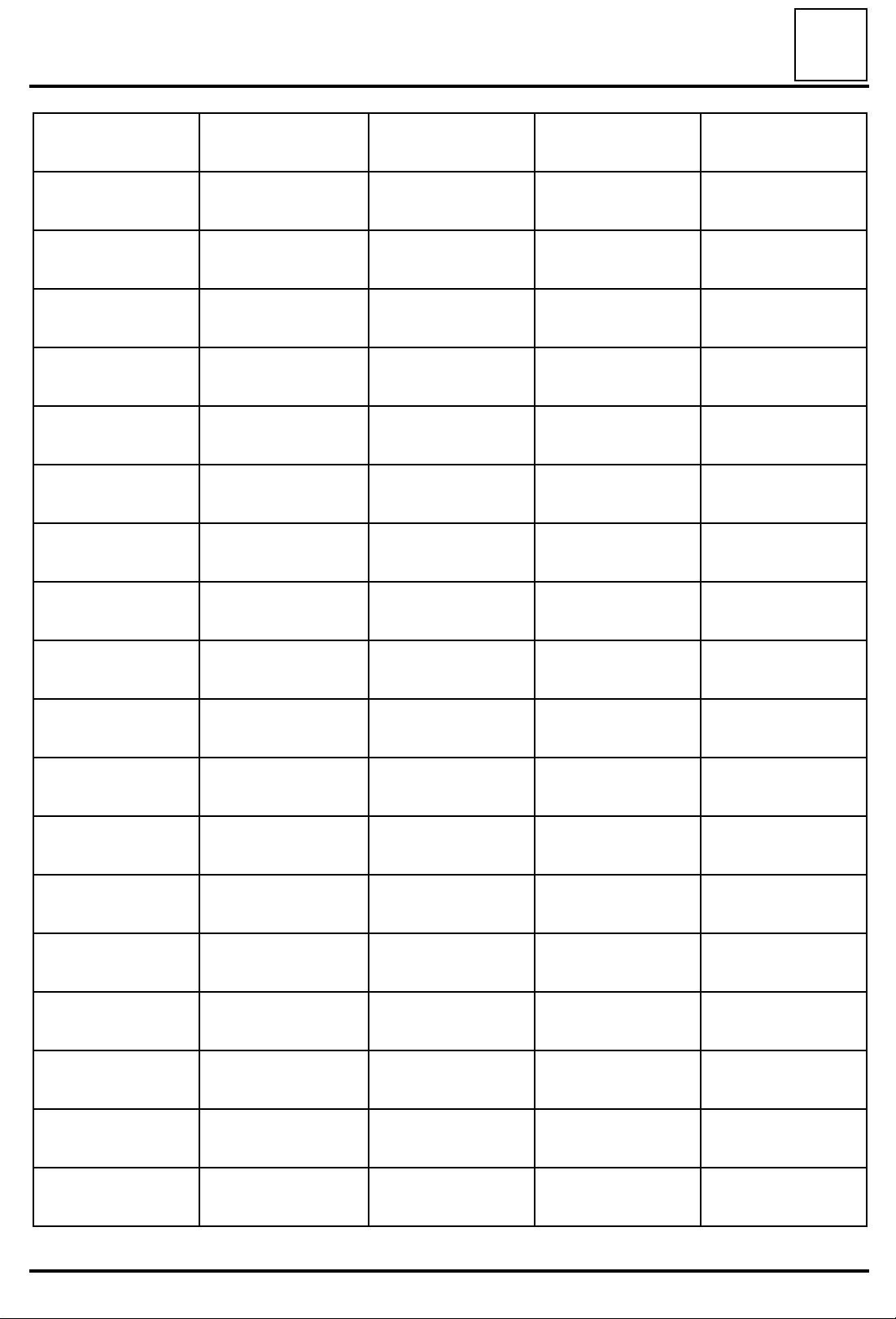

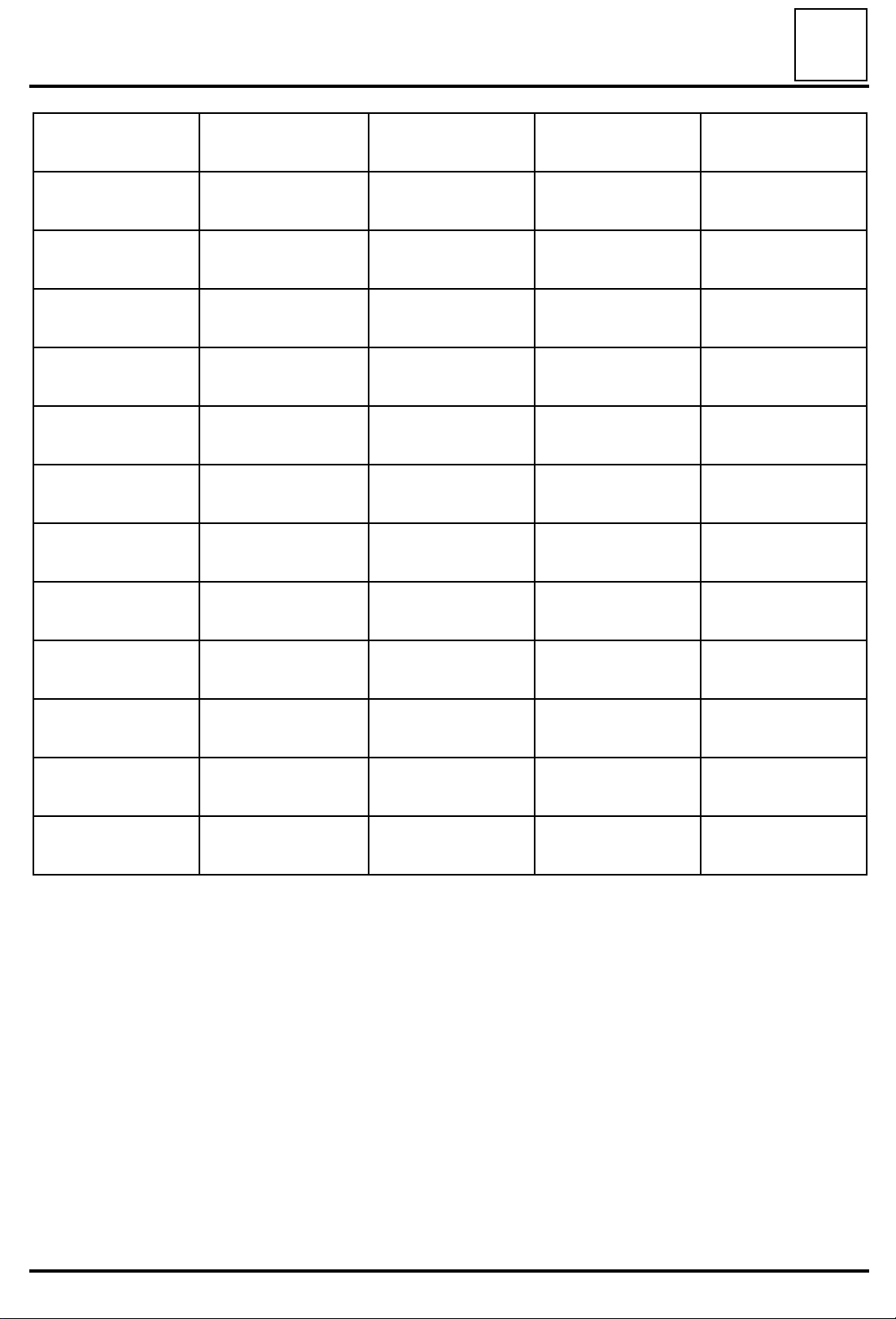

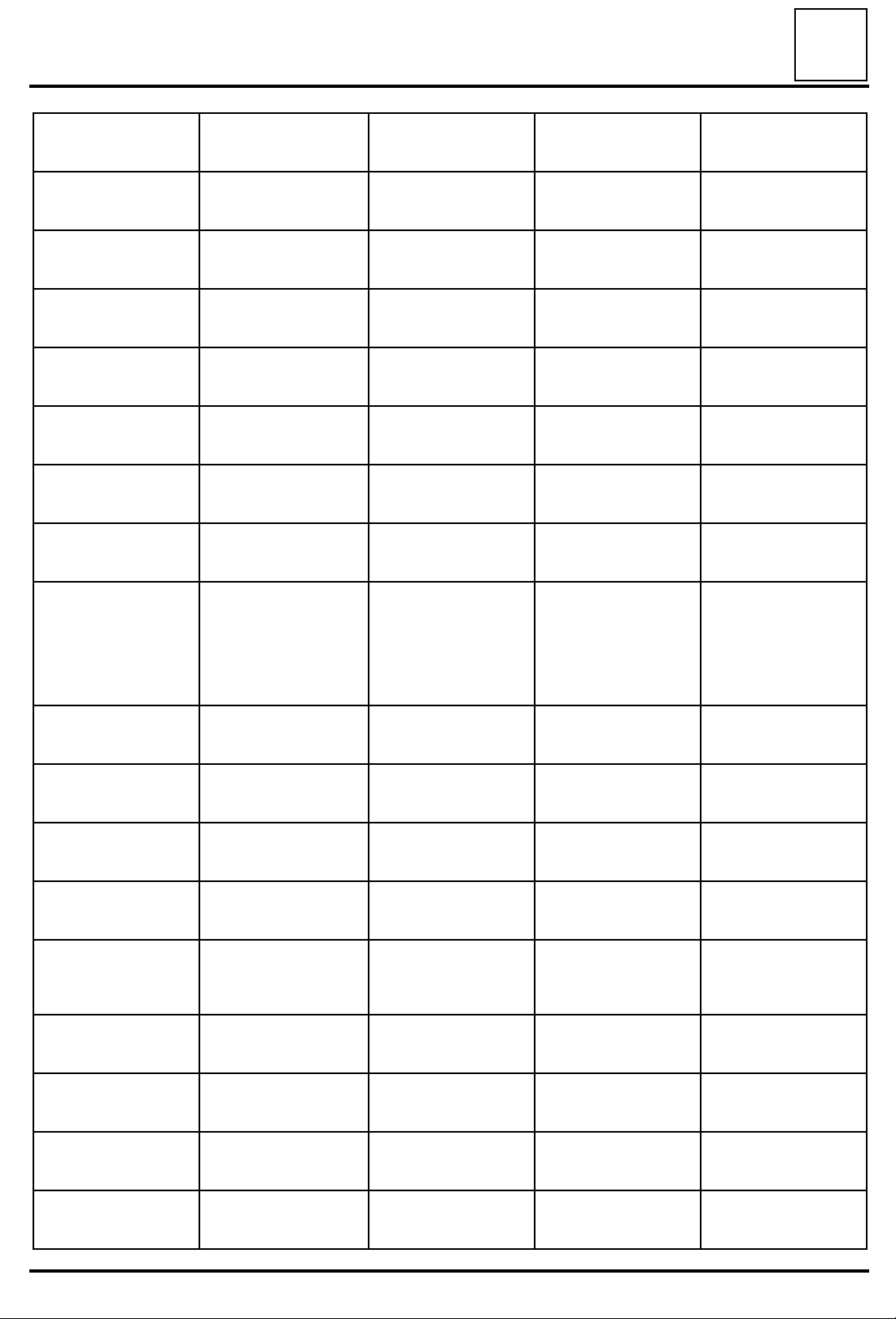

MANUAL GEARBOX

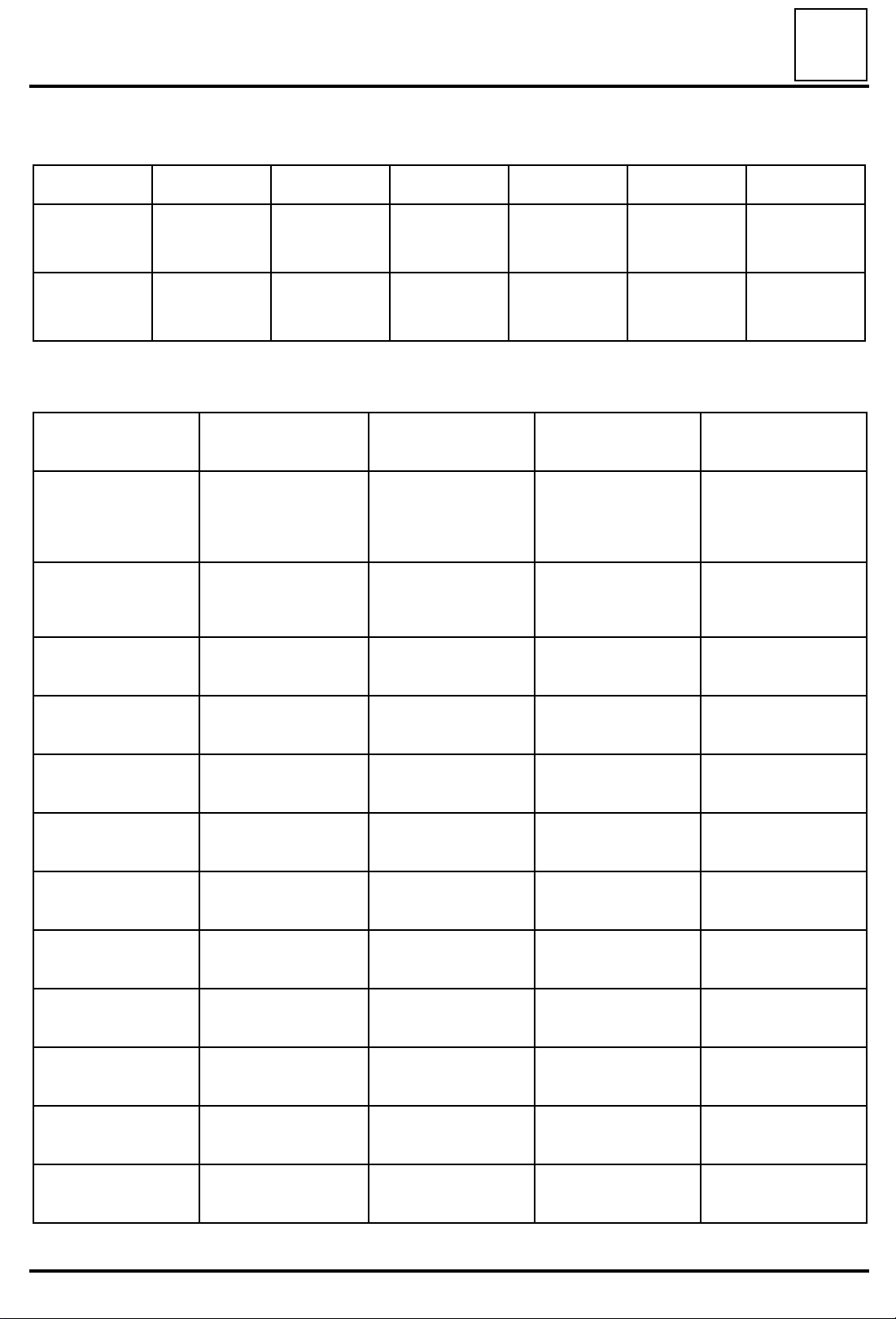

Gears

These tables group together all of the gears

available for JB gearboxes.

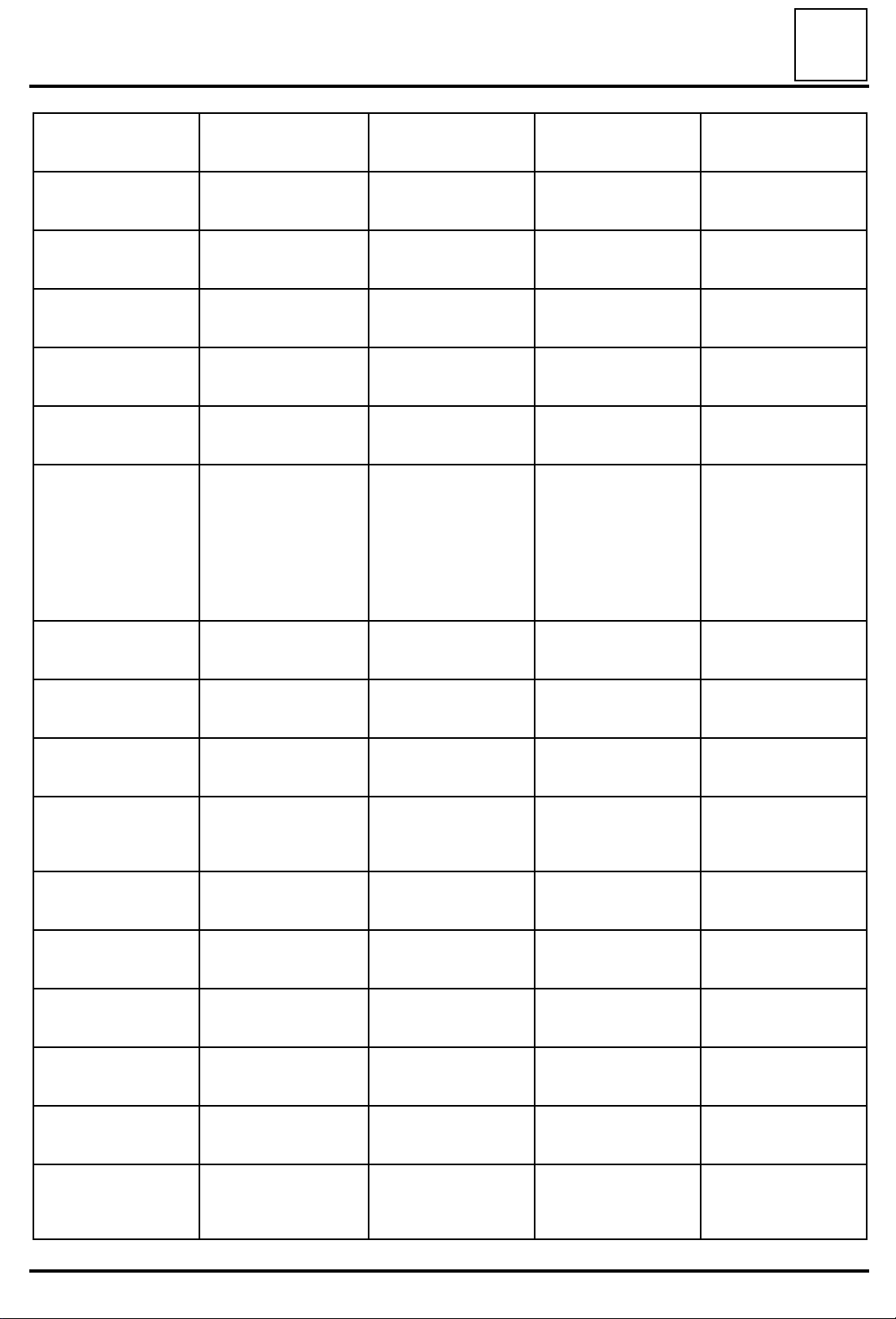

JB0 gear table

Gear 1st 2nd 3rd 4th Reverse

21

11

A

B

C

Gearbox suffixes Vehicles Differential ratio

000

003 L 422

004

-39

11

-41

11

-41

L 421 - L 422 - L 425

B/C/S 371

B/C 372

C 37S

L 422

B/C 372

16

-33

19

-39

21

-43

15

--

58

14

--

59

15

--

58

25

-33

25

-33

28

-37

Speedometer drive

gear

21

--

19

21

--

19

21

--

19

31

-28

31

-28

31

-28

11

-- 26

39

11

-- 26

39

11

-- 26

39

Gear

A

A

A

006 L 422 - L423

008

009 B/C/S 404

010 F 404

011

014 F 400

L422

B/C 372

L 421 - L 422 - L 423

L425 - L 426

B/C/S 371

B/C 372 - B/C 375

F 401 - F 40H

14

--

59

15

--

58

19

--

59

16

--

57

15

--

58

14

--

63

21

--

19

21

--

19

21

--

20

21

--

19

21

--

19

21

--

19

B

B

B

B

B

B

21-8

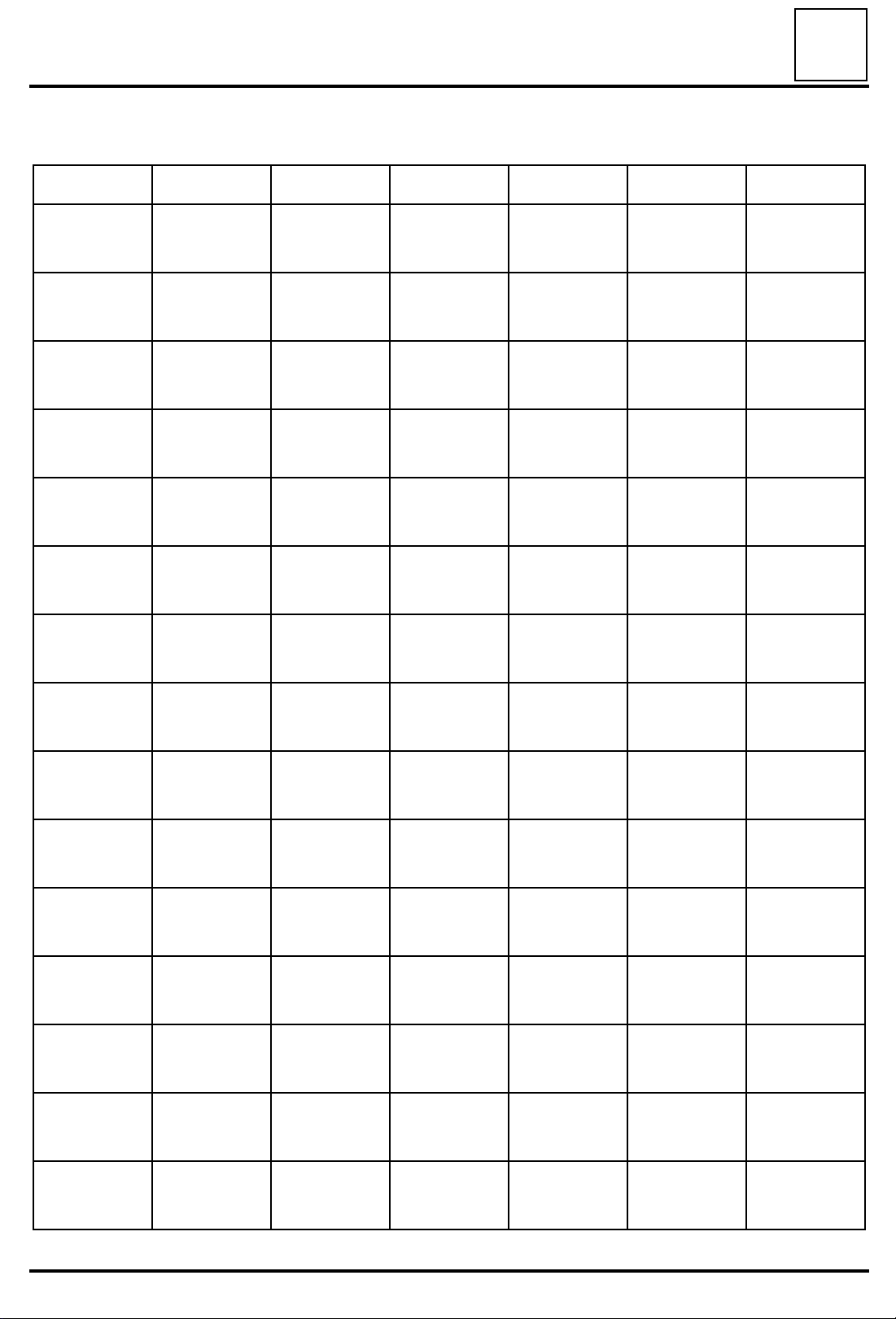

Page 11

MANUAL GEARBOX

Rapports

21

Gearbox suffixes Vehicles Differential ratio

L 422 - L 423

016

017

018 F 401

019

021 B 372 - B 401

022 F 400

023

024 F 404

025 F 401

028

029 B/C/S 401

031 B/C/S 571

032

033 F 401 - F 404 - F 40H

034 B/C 57N

035 F 40F

036 F 40F

038 F 404

B 372 - B 373

B/C 401

B/C/L 531 - B/C/L 532

B/C/L 537 - B/C/L 53P

B/C/L 53R

B/C/L 53H

K/S 480

B/C 37S

F 401 - F 40H

B/C/L/S 530

B/C 400

F 401 - F 40T

B/C 572

C 57A

14

--

59

16

--

57

15

--

58

15

--

56

14

--

59

14

--

63

15

--

58

16

--

57

15

--

58

15

--

58

17

--

56

16

--

55

16

--

57

15

--

58

16

--

57

15

--

61

15

--

61

15

--

61

Speedometer drive

gear

21

--

19

21

--

19

21

--

19

21

--

19

21

--

19

21

--

19

21

--

19

21

--

19

21

--

19

21

--

20

21

--

20

21

--

20

21

--

20

21

--

19

21

--

19

21

--

19

21

--

20

21

--

19

Gear

B

C

B

C

C

C

C

C

C

C

C

C

C

C

C

C

C

C

21-9

Page 12

MANUAL GEARBOX

Gears

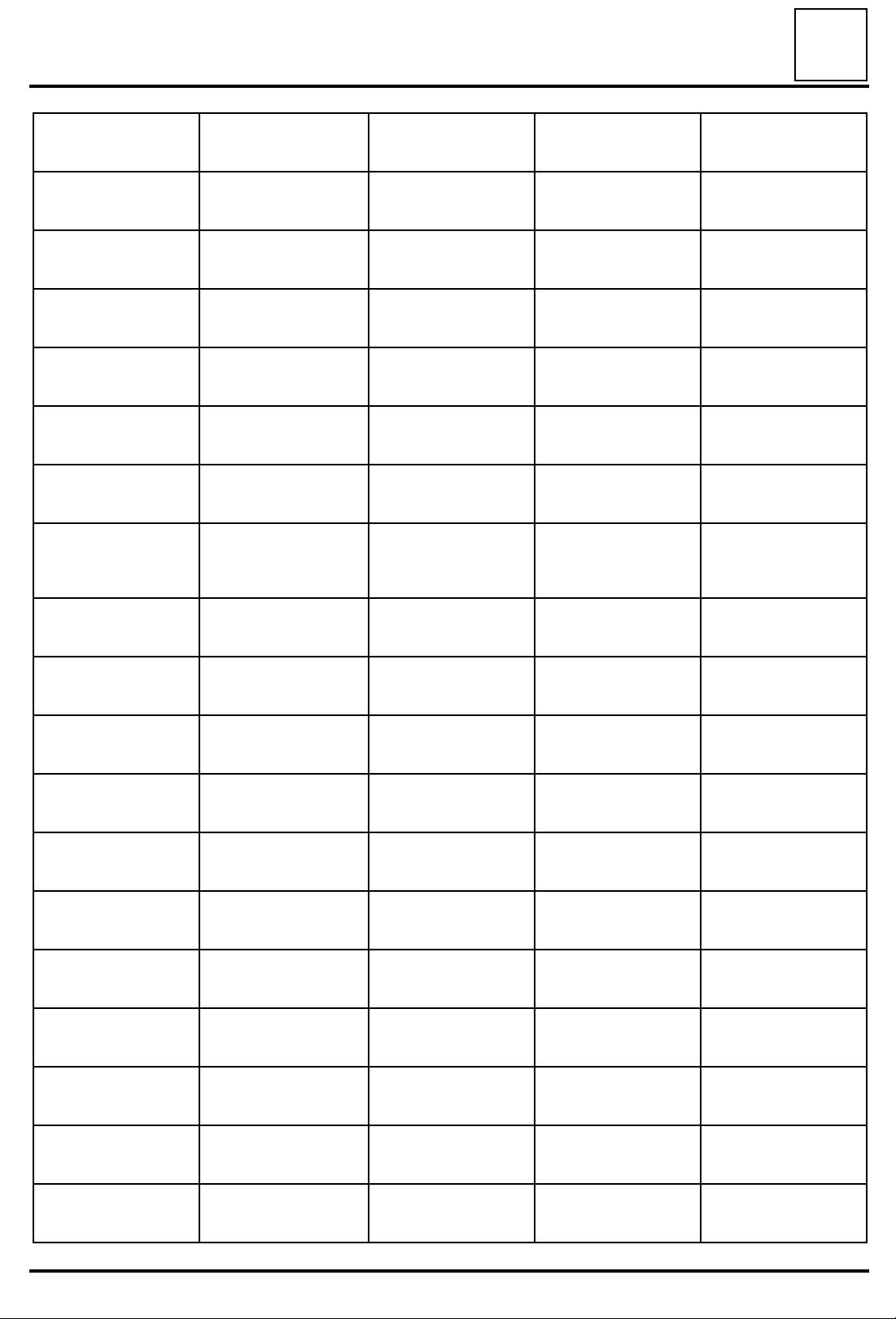

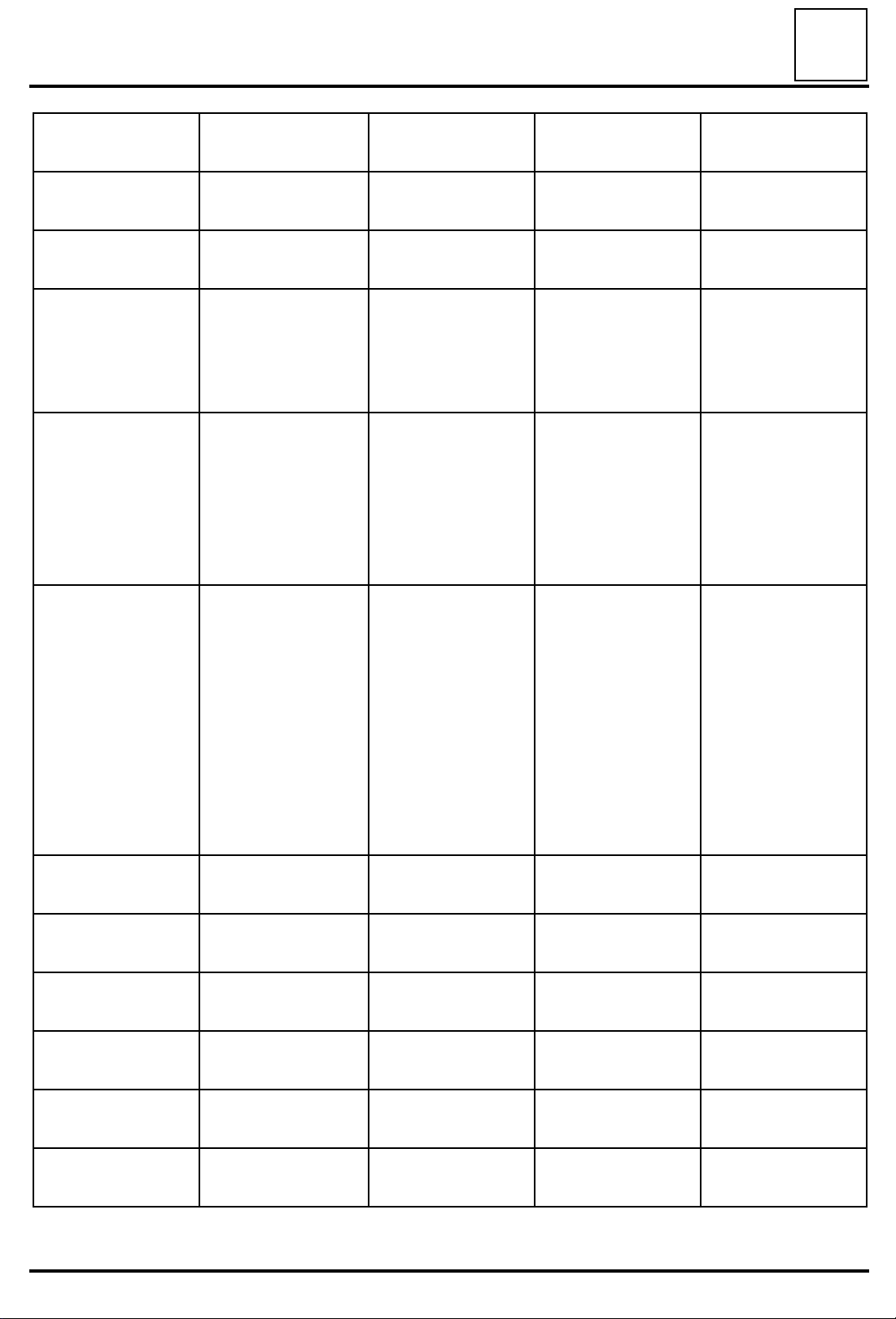

JB1 gear table

Gear 1st 2nd 3rd 4th 5th Reverse

21

11

A

B

C

D

E

F

G

-39

11

-41

11

-39

11

-41

11

-41

11

-41

11

-34

16

-33

16

-33

16

-33

19

-39

21

-43

22

-41

22

-41

25

-33

26

-33

25

-33

25

-33

28

-37

28

-37

28

-37

31

-28

31

-28

31

-28

30

-29

30

-29

30

-29

30

-29

33

-25

37

-27

37

-27

34

-27

39

-31

41

-31

39

-31

11

-- 26

39

11

-- 26

39

11

-- 26

39

11

-- 26

39

11

-- 26

39

11

-- 26

39

11

-- 26

39

M

11

H

I

J

K

L

N

-41

11

-41

11

-37

11

-41

11

-37

11

-37

11

-41

21

-43

21

-43

22

-41

21

-43

22

-41

22

-41

21

-43

28

-37

28

-39

28

-37

28

-39

28

-37

28

-37

28

-37

30

-39

34

-35

30

-39

34

-35

30

-29

30

-39

30

-29

41

-31

34

-28

39

-31

39

-32

41

-31

39

-32

39

-32

11

-- 26

39

11

-- 26

39

11

-- 26

39

11

-- 26

39

11

-- 26

39

11

-- 26

39

11

-- 26

39

11

O

-41

21

-43

28

-37

30

-29

41

-31

11

-- 26

39

21-10

Page 13

MANUAL GEARBOX

Gears

21

Gearbox suffixes Vehicles Differential ratio

L 421 - L 422 - L 423

001

002 L 421

003 L 422 - L 423

004

005

006

007

008 B/C 373

009

011

012 B 373

013 B/C/S 404

014

015

016

018

019

B/C 371 - B/C 372

B/C 373

L 421 - L 424

B/C/S 374

L 422 - L 423

B/C 372 - B 373

L 424

B/C 374

L 424

B/C 374

L 421 - L 422 - L 423

L 424 - L 42A - L 42C

L 42R - L 42S

B/C 371 - B/C 372

B/C/S 373

B/C 37A - B/C 37C

B 37R - B/S 37S

L 424 - B/C/S 374

F 401 - F 402 - F 407

F 40H

L 424

B/C 374

L 424

B 374

L 422 - L 423

B/C 372 - B 373

B 374

L 423

B/C 373

B/C 402

L 424

B/C/S 374

F 404

14

--

59

15

--

58

15

--

58

15

--

58

14

--

59

15

--

58

14

--

59

14

--

59

15

--

61

15

--

58

15

--

61

17

--

56

15

--

58

16

--

57

17

--

56

14

--

63

15

--

58

Speedometer drive

gear

21

--

19

21

--

19

21

--

19

21

--

19

21

--

19

21

--

19

21

--

19

ELECTRONIC

SPEEDOMETER

21

--

19

21

--

19

ELECTRONIC

SPEEDOMETER

21

--

20

21

--

19

21

--

19

21

--

19

21

--

19

21

--

19

Gear

A

A

B

C

A

C

C

A

D

E

E

E

E

E

D

D

D

21-11

Page 14

MANUAL GEARBOX

Gears

21

Gearbox suffixes Vehicles Differential ratio

16

020 B/C 404

021 F 404

022 B 402

F 401 - F 402 - F 407

023

024 B/C 53

025

026 F 402

027

028 B/C/S 404

029

030

031 B/C/S 404

032 F 404

033

034

035

F 40H - F 40M

B/C/L 532

L 423 - L 424 - L 42A

L 42C - L 42S

B/C 373 - B/C 37A

B 37C

F 401

B/C/L/S 537

B/C/L/S 530

B/C/L/ 53A

B/C/L 53R

F 402

B/L 53H

B 402

B/C 480

K/S 480

B/C/L 53G

F 404

L 424

B/C/S 374

L 423

B 373

B/C/L 531

B/C/L 53P

B/C/S 401

B/C 403

B/C/S 407

B 40H

--

57

15

--

61

15

--

61

15

--

58

15

--

57

15

--

61

15

--

58

15

--

58

17

--

56

15

--

61

15

--

58

16

--

57

15

--

61

14

--

63

16

--

57

16

--

55

Speedometer drive

gear

21

--

20

21

--

19

21

--

19

21

--

19

21

--

19

21

--

19

21

--

19

21

--

19

21

--

20

21

--

19

21

--

19

21

--

20

21

--

19

21

--

19

21

--

19

21

--

20

Gear

D

D

D

E

E

E

D

E

E

E

E

E

E

E

E

E

21-12

Page 15

MANUAL GEARBOX

Gears

21

Gearbox suffixes Vehicles Differential ratio

B/C 400

036

037

038

039 B/C 570

041 X 57

042 X 40

043

044 F 401 - F 40H

045

046

047 F 40F

048

049 F 40A

050 F 40F

051 F 407

052 C06 3

053 X 57

054 BA0 E

F 401

F 40T

C 402

B/C/S 40F

B/C 402

B/C 40F

B/C/S 571

B/C/S 572 - B/C 573

B/C 57A - B/C 57B

B/C 57J - B/C 57L

B/C 57T

B/C 57N

B/C 57P

B/C/S 572

B/C/S 57A

B/C/S 57R

F 40A - F 40U

F 40V - F 40Y

15

--

61

17

--

56

16

--

57

14

--

59

14

--

59

15

--

61

16

--

57

15

--

58

14

--

59

14

--

59

14

--

63

14

--

63

14

--

63

14

--

63

14

--

59

15

--

56

14

--

59

15

--

61

Speedometer drive

gear

21

--

20

21

--

20

21

--

20

21

--

20

21

--

20

21

--

20

21

--

20

21

--

19

21

--

19

21

--

20

21

--

19

21

--

19

21

--

20

21

--

20

21

--

19

21

--

20

21

--

20

21

--

19

Gear

E

E

E

E

F

F

E

E

F

G

E

E

E

E

E

H

F

E

21-13

Page 16

MANUAL GEARBOX

Gears

21

Gearbox suffixes Vehicles Differential ratio

15

057 X 06

061

066 X 57

068

069

070 X 53 - F 40

071 X 57

072 X 57

074 X 57

080 X 57

082 X 57

085 B/C 57

087 B/C 57

095

097 JA0 E

099

100 F 40

104 X 57

X 06

with AC

BA0 A - BA0 U

DA0

X 06

with AC

BA0 E

SA0 E

BA0

DA0

--

56

15

--

58

15

--

56

15

--

56

15

--

58

15

--

61

16

--

57

15

--

59

15

--

58

15

--

56

16

--

57

15

--

56

15

--

56

15

--

61

14

--

63

15

--

58

15

--

61

17

--

56

Speedometer drive

gear

21

--

20

21

--

20

21

--

20

21

--

19

21

--

20

21

--

19

21

--

20

21

--

19

21

--

19

21

--

20

21

--

20

21

--

20

21

--

19

21

--

19

21

--

18

21

--

19

21

--

19

21

--

20

Gear

H

I

I

E

E

E

E

F

E

I

E

I

E

E

K

E

E

E

21-14

Page 17

MANUAL GEARBOX

Gears

21

Gearbox suffixes Vehicles Differential ratio

17

105 X 57

106

107 F 40

109 F 40

110 F 40

111

119

120

123

124

126 F 40

129

130

131 X 57

132 C 06

137 C 06

138 B/C 57

140 X 57

BA0

DA0

X 53

X 48

BA0 L

BA0 F

BA0 L

BA0 F

BA0 L

BA0 P

BA0 L

BA0 F

BA0

SA0

BA0 E

JA0 E

--

56

15

--

58

15

--

58

15

--

58

16

--

57

16

--

57

15

--

58

15

--

58

15

--

58

15

--

58

16

--

61

15

--

56

14

--

63

17

--

56

15

--

56

15

--

56

15

--

56

15

--

56

Speedometer drive

gear

21

--

20

21

--

19

21

--

19

21

--

19

21

--

19

21

--

19

21

--

19

21

--

19

21

--

19

21

--

19

21

--

19

21

--

19

21

--

18

21

--

20

21

--

20

21

--

20

21

--

20

21

--

20

Gear

E

E

E

E

D

D

J

J

J

J

E

E

K

H

L

L

K

I

21-15

Page 18

MANUAL GEARBOX

Gears

21

Gearbox suffixes Vehicles Differential ratio

14

141 X 57

142 XA0

143 XA0

144 X06

145 X06

164 XA0

165 XA0

166 B/DA0

167 B/DA0

168 XA0

169 XA0

170 BA0

--

59

15

--

56

15

--

56

15

--

58

15

--

58

15

--

58

15

--

58

15

--

58

15

--

58

15

--

56

15

--

56

15

--

58

Speedometer drive

gear

21

--

20

21

--

19

21

--

19

21

--

20

21

--

20

21

--

19

21

--

19

21

--

19

21

--

19

21

--

19

21

--

19

21

--

19

Gear

F

E

E

M

M

M

M

M

M

O

O

N

21-16

Page 19

MANUAL GEARBOX

Gears

JB2 gear table

Gear 1st 2nd 3rd 4th Reverse

21

11

A

B

Gearbox suffixes Vehicles Differential ratio

000

001 X53

002

004 X48

005 F40

-41

11

-41

K/L/S 481

K/L 482

K/L 48M

B/K/L/S 481

B/K/L 482

K/L 48M

19

-39

21

-43

17

--

56

16

--

55

17

--

56

17

--

56

17

--

56

25

-33

28

-37

Speedometer drive

gear

21

--

19

21

--

19

21

--

19

21

--

19

21

--

19

31

-28

31

-28

11

-- 26

39

11

-- 26

39

Gear

A

B

B

A

B

21-17

Page 20

MANUAL GEARBOX

Gears

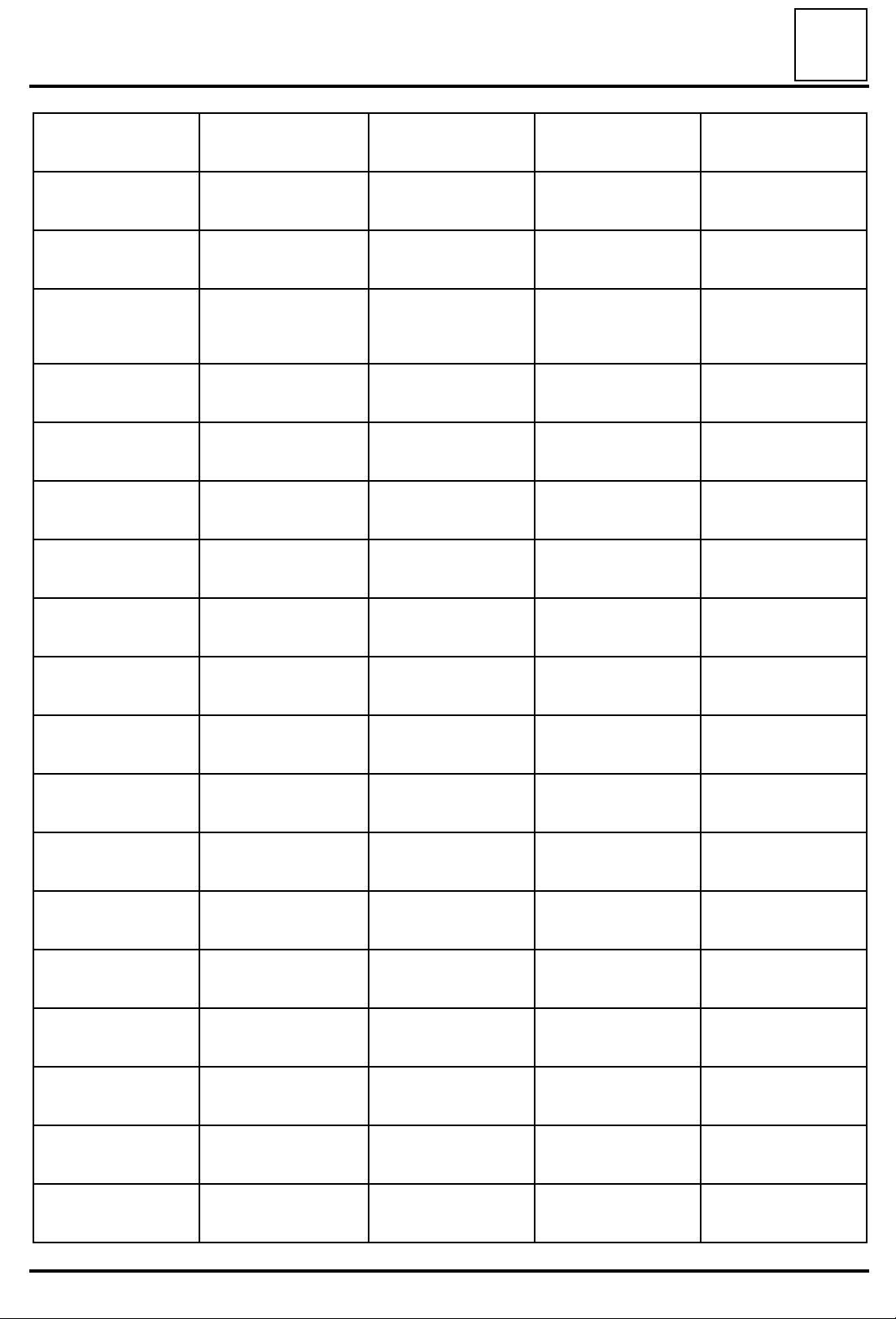

JB3 gear table

Gear 1st 2nd 3rd 4th 5th Reverse

21

11

A

B

C

D

E

F

G

-41

11

-34

11

-41

11

-41

11

-34

11

-34

11

-41

19

-39

19

-35

21

-43

22

-41

22

-41

19

-35

21

-43

25

-33

25

-33

28

-37

38

-37

28

-37

25

-33

28

-39

30

-29

30

-29

30

-29

30

-29

30

-29

30

-29

34

-35

34

-27

33

-25

39

-31

41

-31

41

-31

39

-31

34

-28

11

-- 26

39

11

-- 26

39

11

-- 26

39

11

-- 26

39

11

-- 26

39

11

-- 26

39

11

-- 26

39

M

11

H

I

K

L

N

O

-34

11

-34

11

-34

11

-34

11

-41

13

-45

11

-41

22

-41

19

-35

19

-35

22

-41

21

-43

21

-43

21

-43

28

-37

25

-33

25

-33

28

-37

28

-37

28

-37

28

-39

34

-35

30

-29

30

-29

30

-29

30

-29

30

-29

34

-35

34

-28

34

-27

41

-31

39

-41

41

-31

41

-31

39

-32

11

-- 26

39

11

-- 26

39

11

-- 26

39

11

-- 26

39

11

-- 26

39

11

-- 26

39

11

-- 26

39

11

P

-34

22

-41

28

-37

30

-29

42

-31

11

-- 26

39

21-18

Page 21

MANUAL GEARBOX

Gear

21

Gearbox suffixes Vehicles Differential ratio

001

002

003 B/C 376

005 X 42

006 X 42

008 X 42

009 C 405

010

011

012 B 376

013

014 C 405

017

019 C 409

020 X 42

021

022 K/L 482

B/C 37F - B/C 376

L 426 - L 42F

B/C 375

L 425

L 426 - L 42F

L 42L - L 42N

B/C 376 - B/C 37F

B/C 37G - B/C 37L

B 37M - C 37N

K/L/S 481 - K/L/S 482

K/L 48F

B/C 375

L 425

B 376

L 426

B 376

L 481 - L 482

K/L 48E - K/L 48J

K/L 48N

L 42E

B/C 37E

16

--

57

15

--

61

16

--

57

17

--

56

16

--

57

15

--

61

15

--

56

16

--

57

15

--

61

16

--

57

15

--

61

15

--

56

15

--

61

15

--

58

15

--

61

14

--

59

15

--

58

Speedometer drive

gear

21

--

19

ELECTRONIC

SPEEDOMETER

ELECTRONIC

SPEEDOMETER

21

--

19

21

--

19

21

--

19

ELECTRONIC

SPEEDOMETER

21

--

19

ELECTRONIC

SPEEDOMETER

ELECTRONIC

SPEEDOMETER

21

--

19

ELECTRONIC

SPEEDOMETER

21

--

19

21

--

20

21

--

19

21

--

19

21

--

19

Gear

A

B

A

A

A

A

B

A

C

B

A

C

A

B

B

B

B

D

B

A

21-19

Page 22

MANUAL GEARBOX

Gears

21

Gearbox suffixes Vehicles Differential ratio

16

023 B/C 408

024

026

027

028

029 X 53

030 X 53

031

032 C 405

033 C 409

034 B/C 408

B/C 40G

B/C 40K

C 376 - B/C 37D

B/C 37F - B 37H

B/C 37L - C 37N

L 42D - L 42L

L 42F - L 42N

K/L/S 481 - K/L/S 482

K/L 48F - K/L 48M

B/K/L/S 481

B/K/L/S 482

B/K/L/ 484

B/K/L/ 48E - K 48F

B/K/L 48J

L/B 48L - K/L 48M

K/C 48N

B/C/L 533 - L 53B

B/C/D 53C

B/C/L 53M

L 42D - L 42F

L 42N - C 37D

B/C 37F - B 37H

C 37N

B/K/L/S 481

B/K/L/S 482

K/L 48E

B/K/L 48F

B/K/L/S 48H

K/L 48M

B/C/L 533

B/C/L/S 534

B/C/L 53B

B/C 53E

B/C/L 53C

B/C/L/S 53J

B/K 482

B 533

B/L 536

--

57

16

--

57

16

--

57

15

--

61

16

--

57

15

--

61

14

--

59

15

--

58

15

--

56

15

--

58

16

--

57

Speedometer drive

gear

21

--

20

21

--

20

21

--

19

21

--

19

21

--

19

21

--

19

21

--

19

21

--

19

ELECTRONIC

SPEEDOMETER

21

--

20

21

--

20

Gear

A

B

A

D

C

C

B

C

B

E

C

21-20

Page 23

MANUAL GEARBOX

Gears

21

Gearbox suffixes Vehicles Differential ratio

035

036

037

038

041

044

045 B/C 574

046

047 B/L 57B

048 C 575 - C 57D

050 F 40N - F 40P

051

059 X 53 - X 48

060 X 53 - X 48

062 X 42 - X 48

064 X 57

066 X 57

067 X 53

B/C 40G

B/C 40K

L 425

B/C 375

L 42E

B/C 37E

B/C/D/L 53C

B/C/L 53F

B 376

L 426

K/L 48U

B/C/S 576

B/C/S 57L

B/C/L 539

B/C/D/L 53D

B/C 574 - B/C 57C

B/C 57U

B/C/L 539

B/C/D/L 53D

16

--

57

15

--

61

14

--

59

15

--

61

17

--

56

15

--

61

16

--

55

15

--

58

16

--

55

14

--

59

15

--

58

15

--

61

15

--

61

16

--

57

14

--

59

17

--

56

15

--

58

16

--

55

Speedometer drive

gear

21

--

20

ELECTRONIC

SPEEDOMETER

21

--

19

21

--

19

21

--

20

21

--

19

21

--

20

21

--

20

21

--

19

21

--

19

21

--

19

21

--

19

21

--

19

21

--

19

21

--

19

21

--

20

21

--

20

21

--

19

Gear

E

B

E

C

C

F

C

D

C

F

C

F

D

C

E

C

E

C

21-21

Page 24

MANUAL GEARBOX

Gears

21

Gearbox suffixes Vehicles Differential ratio

15

078 X 57

080

083 X 53

097 F 40

100 B 56B

101 B 56B

102 B 56B

103 X 57

106 BA0 G

108 B/K 56

113 K 56

132 K 56

140 X 56

142

143

170

BA0

JA0

BA0

SA0

BA0

DA0

BA0

LA0

--

61

15

--

61

15

--

61

16

--

57

15

--

58

16

--

57

15

--

61

17

--

56

15

--

61

15

--

58

16

--

57

15

--

58

15

--

56

15

--

59

15

--

61

15

--

61

Speedometer drive

gear

21

--

19

21

--

18

21

--

19

21

--

19

21

--

18

21

--

18

22

--

18

21

--

20

21

--

19

21

--

18

21

--

18

21

--

18

21

--

18

21

--

18

21

--

19

21

--

18

Gear

E

M

H

C

G

M

G

C

P

O

M

G

M

S

P

C

21-22

Page 25

MANUAL GEARBOX

Gears

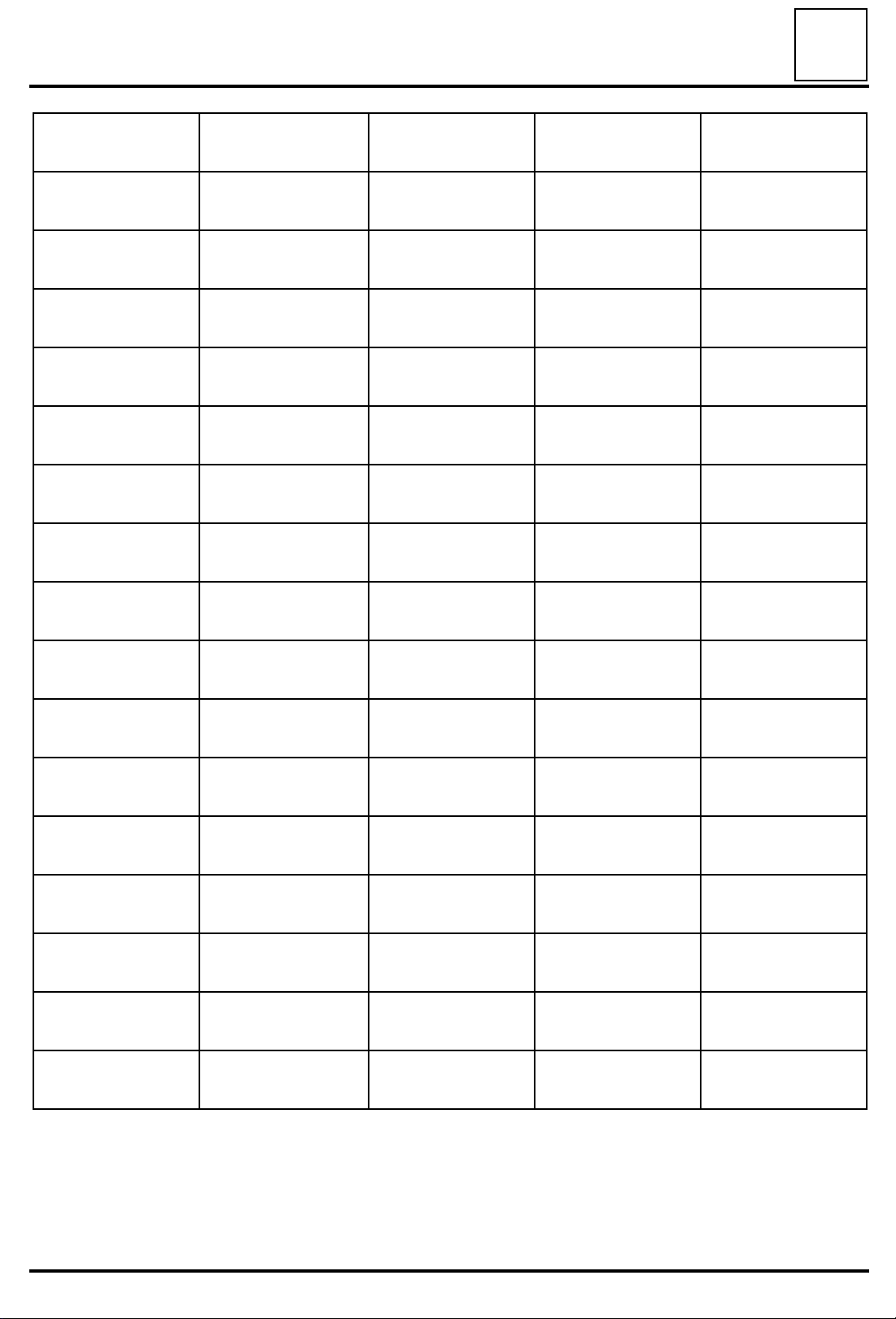

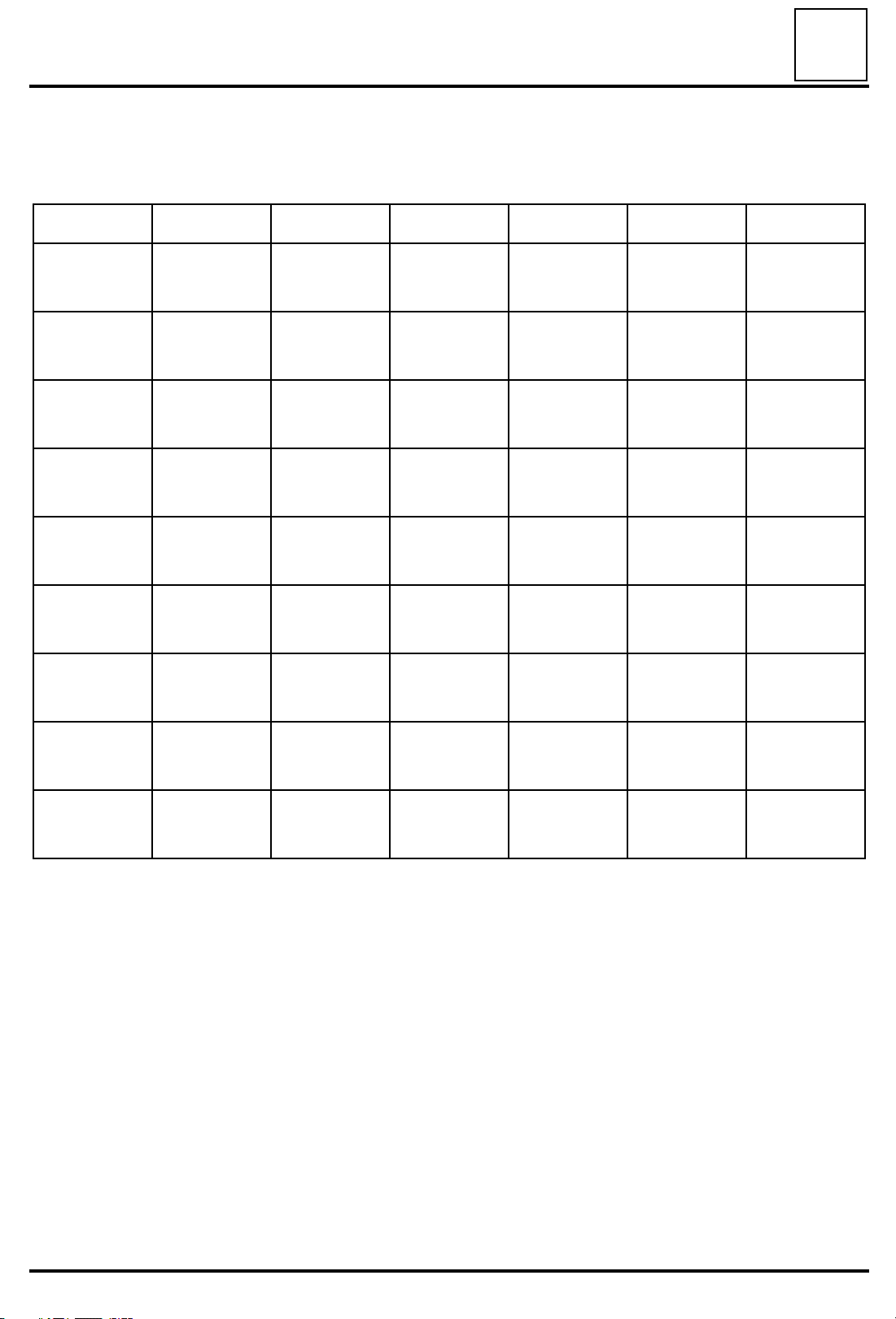

JB4 gear table

Gear 1st 2nd 3rd 4th Reverse

21

11

A

Gearbox suffixes Vehicles Differential ratio

000

001 X 400

002 X 401

003 X 40F

004

005 B/C 53

006 B/C 53

007 B/C 53

008 X 57

-41

L 421 - L 425

F 40F

B/C 537

C 375

X 40F

X 571

19

-39

15

--

58

15

--

58

17

--

56

16

--

57

16

--

55

16

--

57

16

--

57

15

--

58

16

--

57

25

-33

Speedometer drive

gear

21

--

19

21

--

20

21

--

20

21

--

20

21

--

20

21

--

19

21

--

19

21

--

19

21

--

20

31

-28

11

-- 26

39

Gear

A

A

A

A

A

A

A

A

A

21-23

Page 26

MANUAL GEARBOX

Gears

JB5 gear table

Gear 1st 2nd 3rd 4th 5th Reverse

21

11

A

B

Gearbox suffixes Vehicles Differential ratio

000

001

002 B/C 403

003

004 B/C 400

005

006

007

008 B/C 40F

009

010 B/C 572

015 B/C/S 572

-41

11

-34

L 421 - L 422

B/C/L 42S

B/C 371 - S 372

B/C/S 375

B/L/S 530

B/C/S 401

B/C 403 - B/C 407

B/C 40H - B/C 40J

B/C 40M

B/C 402 - B/C 407

B/C/S 40F

B/C 402 - B/C 40F

B/C/S 571

B/C/L 531

C 53P

F 401

F 40 H

L 422 - L 423

B/S 372

B 373

19

-39

19

-35

25

-33

25

-33

15

--

61

16

--

55

15

--

61

17

--

56

15

--

61

16

--

57

16

--

57

15

--

58

15

--

58

15

--

61

16

--

57

14

--

59

30

-29

30

-29

Speedometer drive

gear

21

--

19

21

--

20

21

--

20

21

--

20

21

--

20

21

--

20

16

--

57

21

--

19

21

--

20

21

--

19

21

--

20

21

--

20

34

-27

33

-25

11

-- 26

39

11

-- 26

39

Gear

A

A

B

A

A

A

A

A

A

A

A

A

21-24

Page 27

MANUAL GEARBOX

Gears

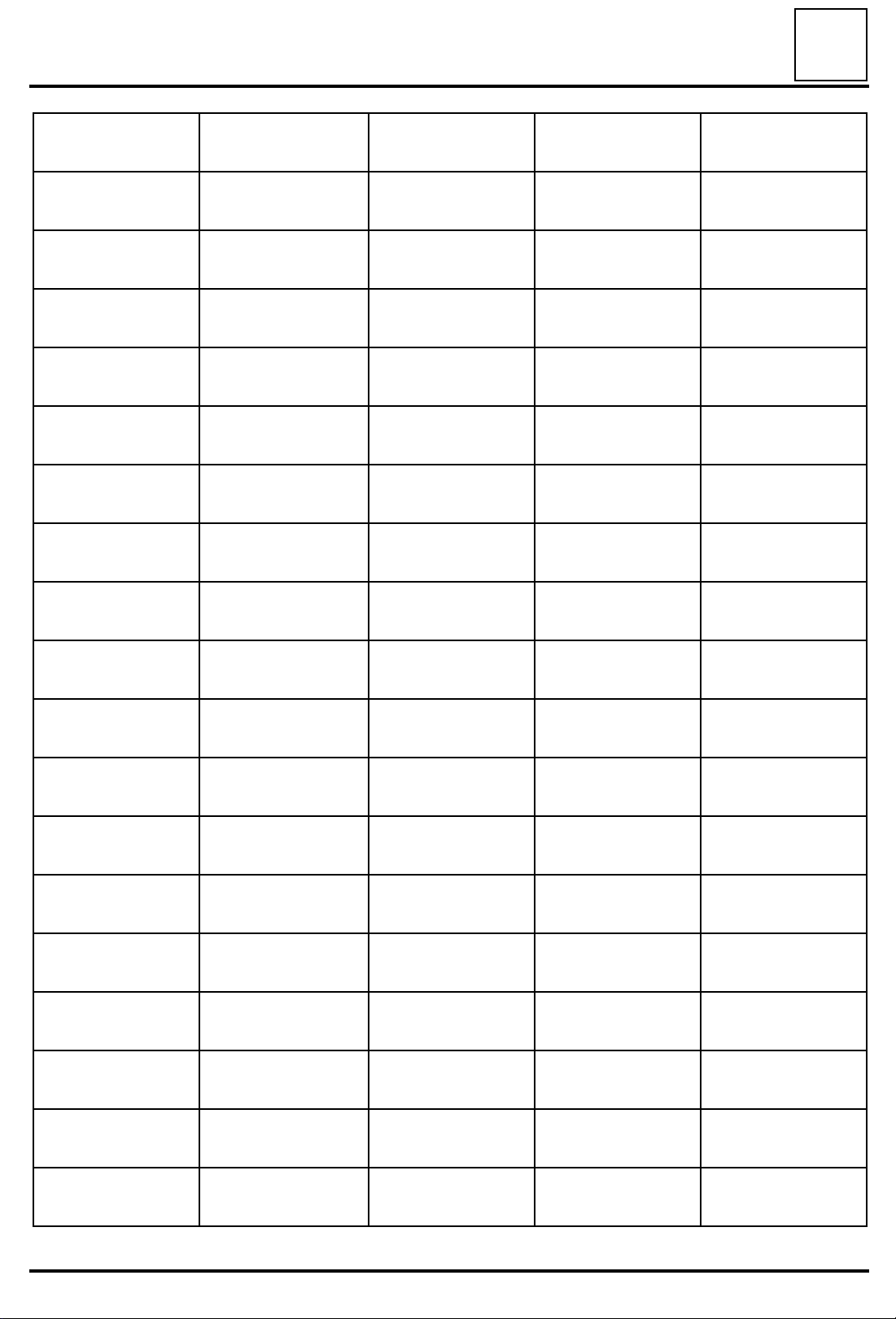

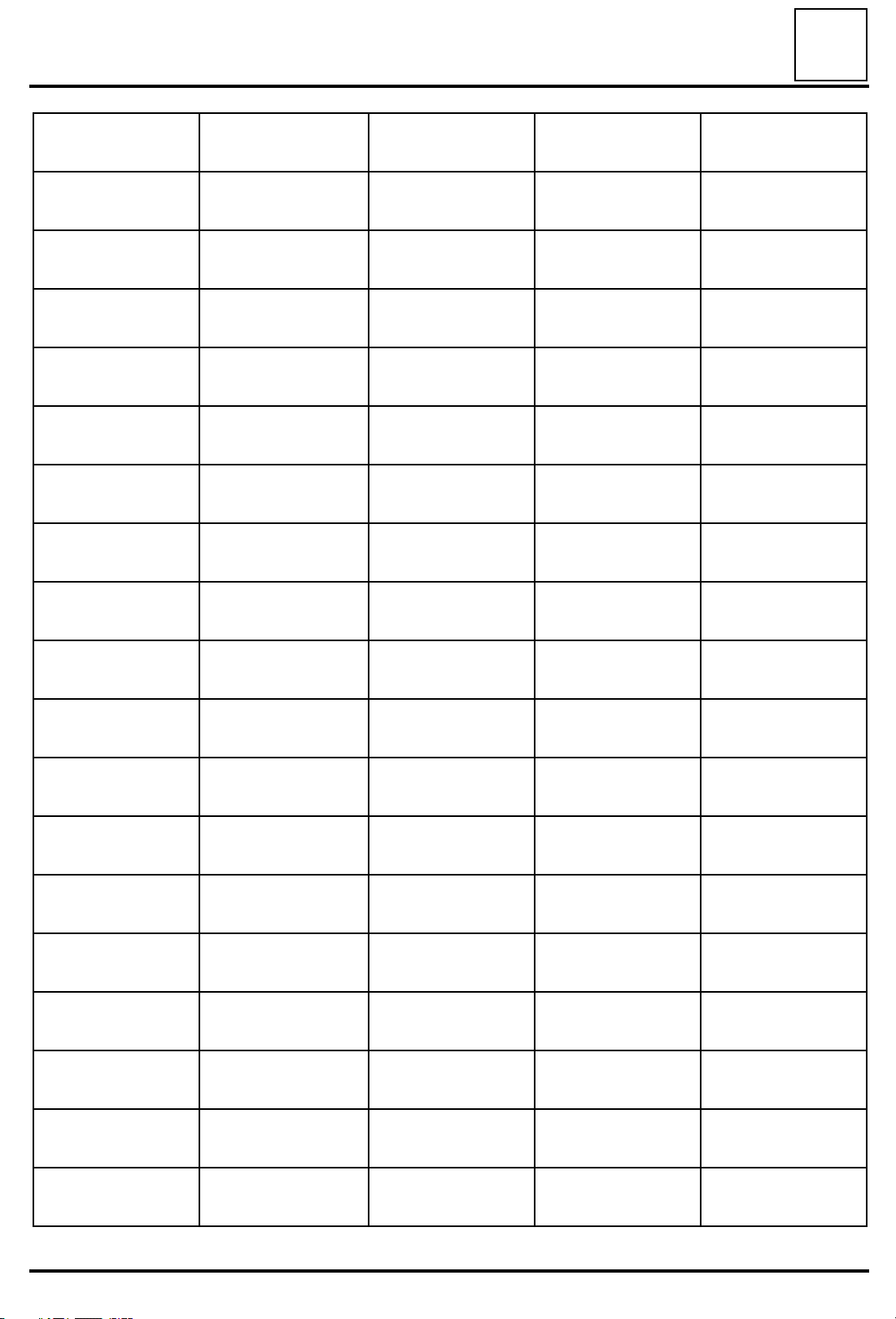

These tables group together all of the gears

available for

Gear 1st 2nd 3rd 4th 5th Reverse

JJJJCCCC5555

gearboxes.

21

11

A

B

C

D

E

F

G

-41

11

-41

11

-41

11

-34

11

-41

11

-41

11

-37

21

-43

21

-43

22

-41

22

-41

21

-43

21

-43

22

-41

28

-37

28

-37

28

-37

28

-37

28

-37

28

-37

28

-39

35

-34

31

-29

35

-34

34

-35

35

-34

35

-34

31

-34

41

-31

42

-31

41

-31

39

-31

42

-31

39

-31

37

-33

11

-- 26

39

11

-- 26

39

11

-- 26

39

11

-- 26

39

11

-- 26

39

11

-- 26

39

11

-- 26

39

11

H

I

-37

11

-41

22

-41

21

-43

28

-37

28

-39

34

-35

31

-34

39

-32

39

-32

11

-- 26

39

11

-- 26

39

21-25

Page 28

MANUAL GEARBOX

Gears

21

Gearbox suffixes Vehicles Differential ratio

17

002 X 53K

004 B 56C

005 X 56

014 X 57

016 B 56C

017 X 56

022 B 56C

024 B 56C

025 XA0

026 JA0

028 B 56

029 B 56

032 B/K 56

033 B/K 56

036 K/S 56

037 B/K 56

038 B/K 56

039 B/K 56

--

56

15

--

58

15

--

56

15

--

61

15

--

61

15

--

61

15

--

61

15

--

58

15

--

61

15

--

61

15

--

61

15

--

61

15

--

58

15

--

61

15

--

56

15

--

61

15

--

61

15

--

61

Speedometer drive

gear

21

--

19

21

--

18

21

--

18

21

--

29

22

--

18

22

--

18

22

--

18

21

--

18

21

--

18

21

--

18

21

--

18

21

--

18

21

--

18

22

--

18

21

--

18

21

--

18

21

--

18

21

--

18

Gear

A

B

C

D

E

E

B

F

H

F

G

G

F

E

F

G

G

G

21-26

Page 29

MANUAL GEARBOX

Gears

21

Gearbox suffixes Vehicles Differential ratio

15

040 B/K 56

044 X 56

045 X 56

047 B/K 56

048 B/K 56

052 XA0

053 XA0

066 JA0

067 JA0

075 B 56

076 B 56

--

61

15

--

58

15

--

61

15

--

61

15

--

61

17

--

56

15

--

61

15

--

61

15

--

61

15

--

61

15

--

61

Speedometer drive

gear

21

--

18

21

--

18

22

--

18

22

--

18

22

--

18

21

--

29

21

--

18

22

--

18

22

--

18

22

--

19

22

--

18

Gear

G

C

B

G

G

A

H

I

E

H

H

21-27

Page 30

MANUAL GEARBOX

Capacity - Lubricants

21

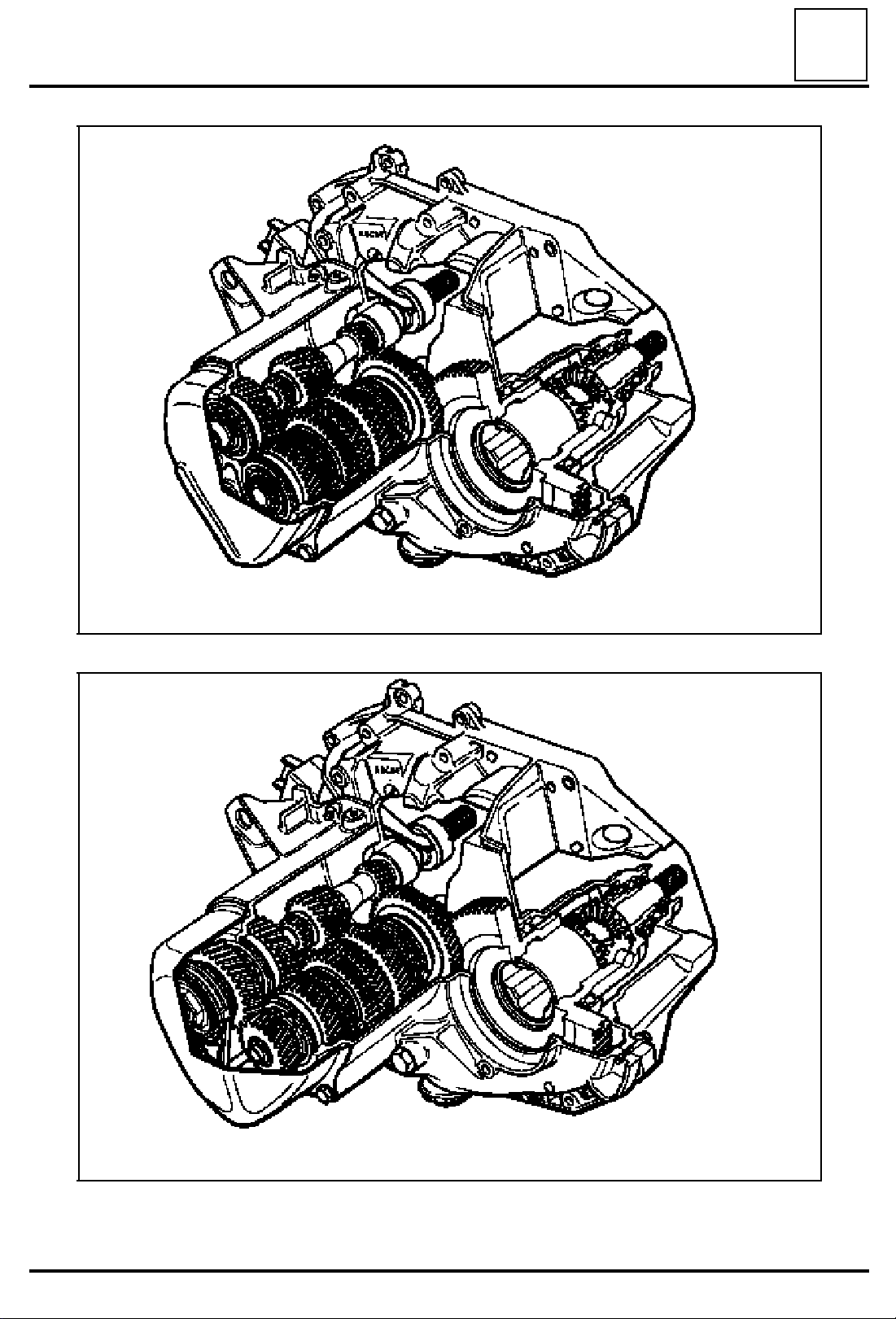

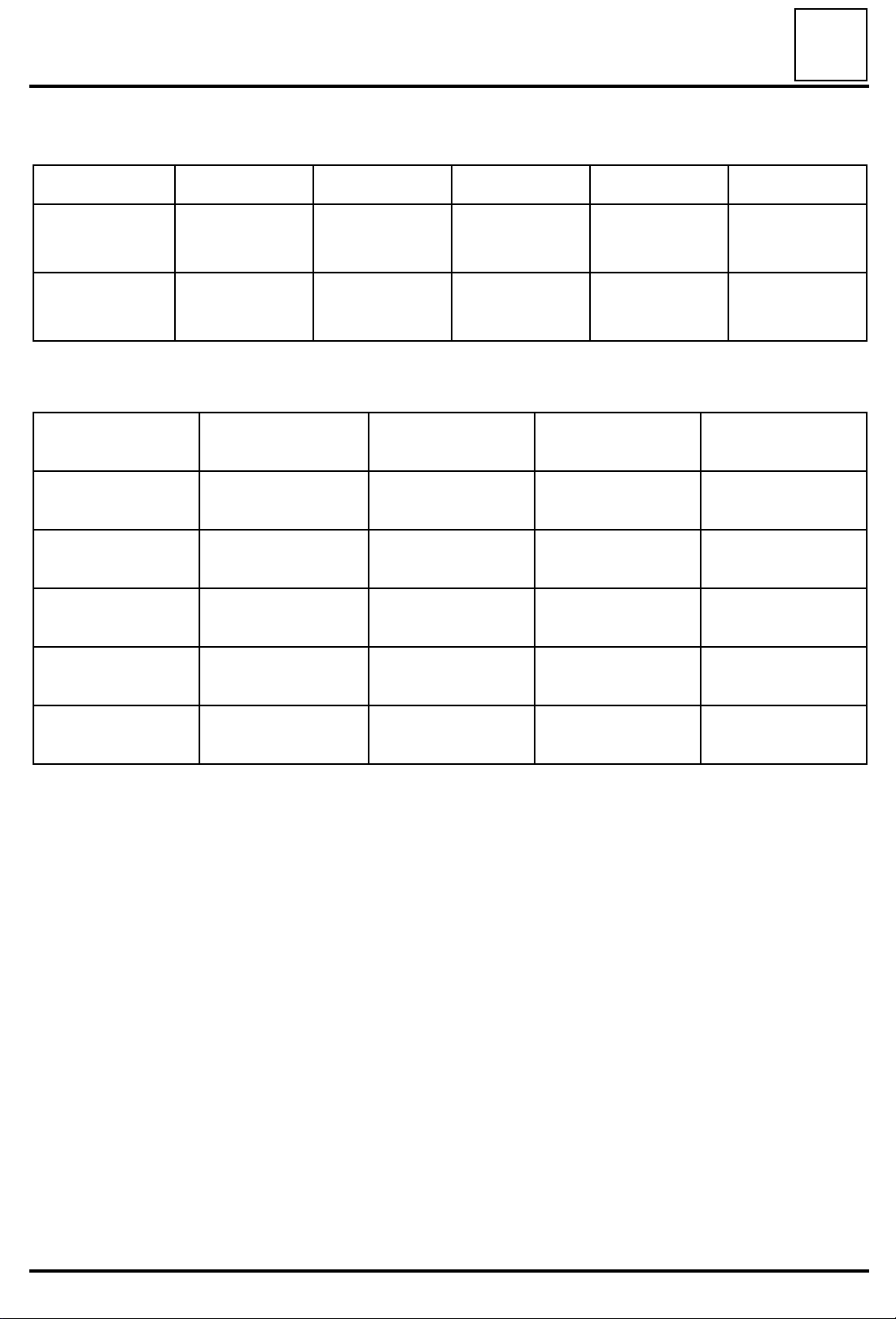

CAPACITY (in litres)

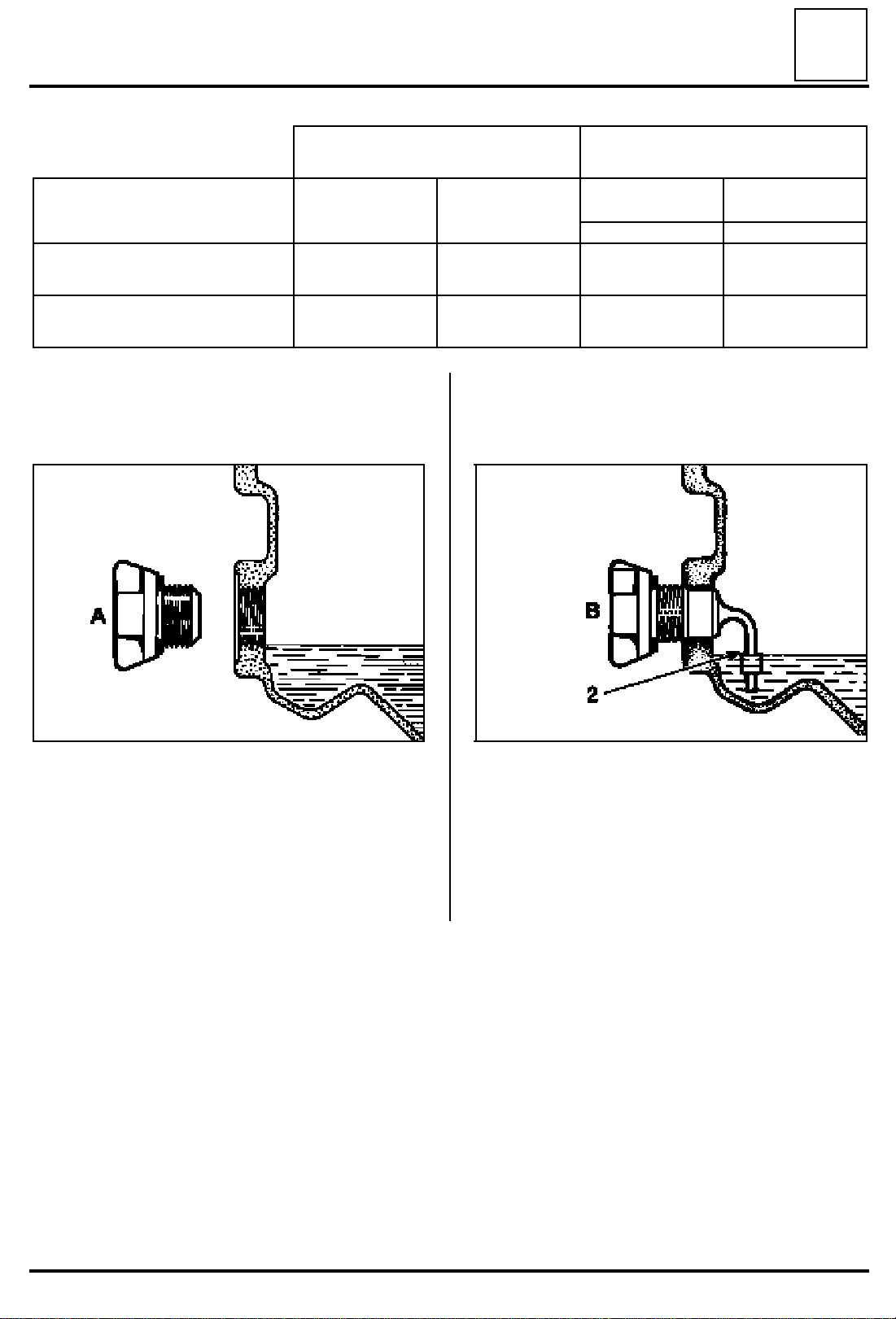

Plug with no dipstick:

normal level

Plug with dipstick:

low level

Plug with no dipstick:

From September 89

LLLLEEEEVVVVEEEELLLL CCCCHHHHEEEECCCCKK

KK

Plug (A) with no dipstick Plug (B) with dipstick

JB0

JB2

JB4

JB4

5-speed gearbox4-speed gearbox

3.25

2.8 JB5 2.90

2.8 JB5 2.90

JB1

JB3

JC5

3.40

3.1

92081R DI2127

Fill to the level of the opening. Wipe the dipstick section.

Replace the plug without tightening it, dipstick

directed downwards.

Remove the plug, the level should be on the boss

(2).

21-28

Page 31

MANUAL GEARBOX

Special points

21

Gearboxes

JB0 4 forward gears

JB2

JB4 1 reverse gear

JB1 5 forward gears

JB3

JB5 1 reverse gear

JC5

are fitted with BORG-WARNER synchronisers.

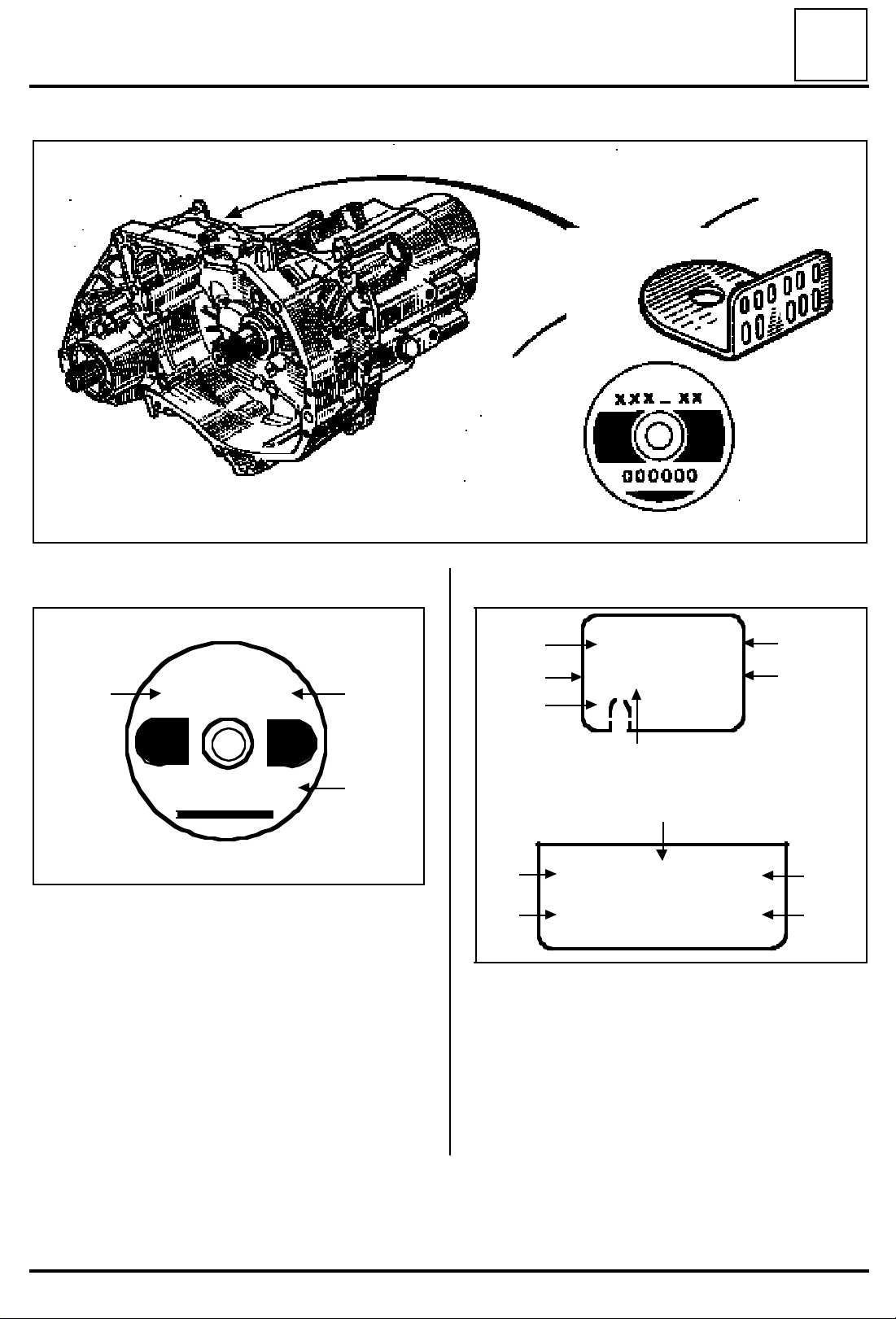

GGGGEEEEAAAARRRR GGGGRRRRIIIIDD

DD

R 1 3 5

2 4

B.V. JB

DDDDIIIIFFFFFFFFEEEERRRREEEENNNNTTTTIIIIAAAALL

The differential cannot be adjusted.

Two types of bearing assembly are used, either

with balls or with tapered rollers.

SSSSHHHHAAAAFFFFTTTTSS

The lip seal and the guide tube bearing rollers are

in direct contact with the input shaft.

If the mating surface is imperfect, the input shaft

must be changed.

The hubs are fitted free on the output shaft and

their sideways movement is checked by thrust

washers.

The reverse gear is sold fitted to the shaft.

The thrust pad guide tube can only be removed

following removal of the clutch housing.

The use of 037M00 equipment simplifies the

operation, refer to the procedure on page 21-92.

LL

SS

To engage reverse gear, raise the locking ring (A)

and move the lever.

DI2128

MMMMAAAATTTTCCCCHHHHEEEEDDDD PPPPAAAARRRRTTTTSS

Synchroniser hubs and sliding gears.

SS

IIIINNNNTTTTEEEERRRRNNNNAAAALLLL CCCCOOOONNNNTTTTRRRROOOOLLLLSS

The fifth gear fork has two plastic pads which are

greased via a mechanism housing channel.

The pins are fitted on the selection finger one

after the other.

SSSSPPPPEEEECCCCIIIIAAAALLLL FFFFEEEEAAAATTTTUUUURRRREEEESSSS OOOOFFFF TTTTHHHHEEEE JJJJCCCC5555 GGGGEEEEAAAARRRRBBBBOOOOXX

Adoption of tapered bearings on the input and

output shafts.

Setting of the input and output lines.

Guide tube with double sealing on the housing

and clutch shaft which can be removed without

opening the gearbox.

Strengthening of the mechanism and clutch

housings.

Widening of the teeth.

SS

XX

In all cases, it is advisable to mark the sliding gears

in relation to the hubs and to mark the hubs in

relation to the shafts.

21-29

Page 32

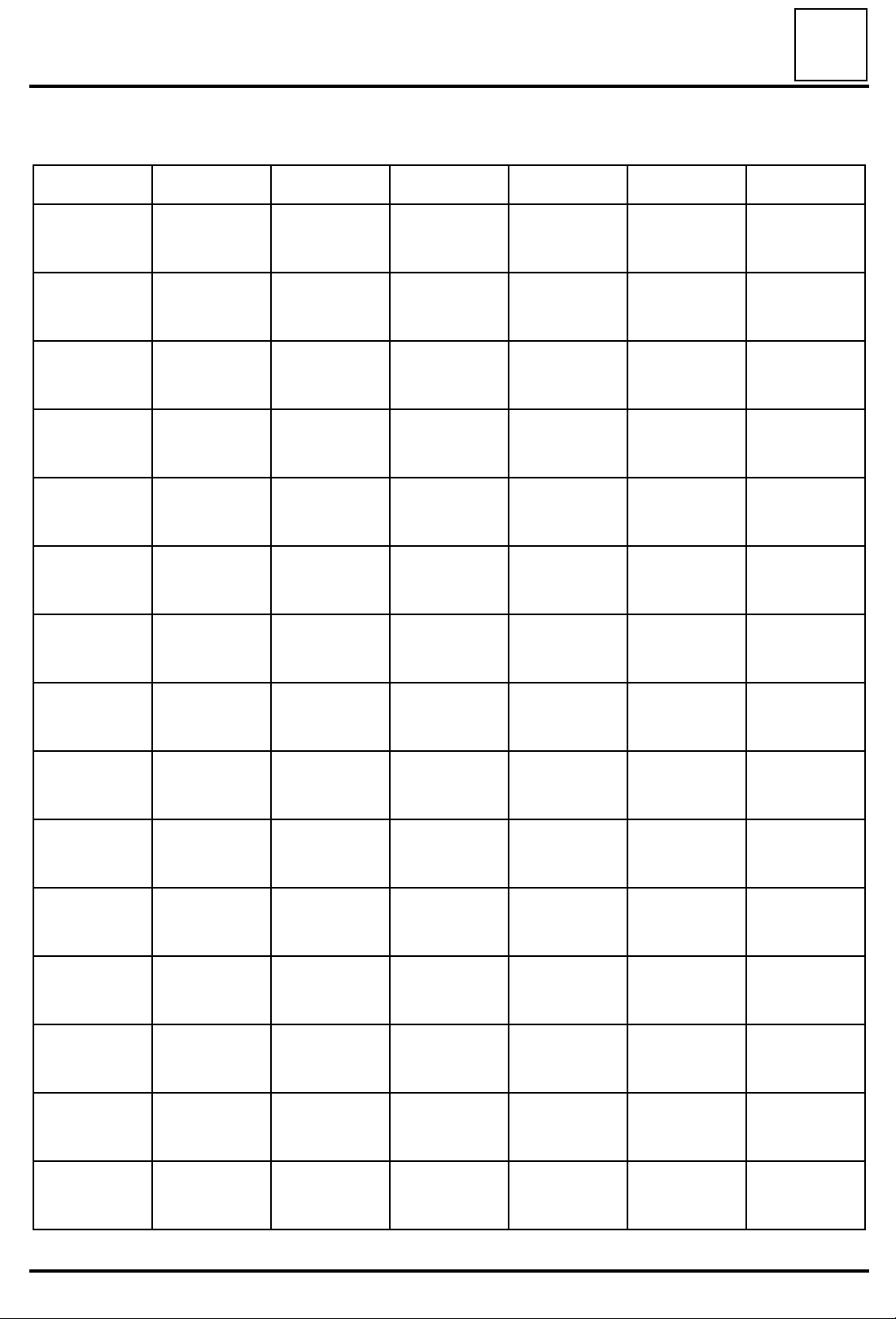

5th gear fixed gear mounting

MANUAL GEARBOX

Modifications

21

st

1

assembly

nd

2

assembly

rd

3

assembly

DI2133 87180R7

th

4

assembly

* Glue using "Loctite Frenbloc"

87180-1R86322R2

Special features:

Reduction of the tapping depth at the end of the

output shaft into which the 5th gear fixed gear

mounting bolt is inserted.

It is essential to fit a 27mm long bolt.

21-30

Page 33

MANUAL GEARBOX

Modifications

Widening of the teeth of the 5th gear on JB1/JB3 gearboxes.

21

Fixed gears

Idle gears

Thrust washer

dimension A

(mm)

1st assembly 5.5 14.1 13.7 13 237.3

nd

2

assembly 7.5 12.1 15.7 15 239.3

* Only the hub dimension changes, the sliding gear remains identical for both assemblies.

** Following the modification to the length of the fork shaft, the position of the fork pads changes by 2 mm.

* Hub

Dimension B

JB1 and JB3 27 teeth

JB3 25 teeth

JB1 and JB3

JB3 33 teeth

Idle gear

Dimension C

(mm)

(mm)

34 teeth

Fixed gear

Dimension D

(mm)

** Fork shaft

Dimension E

(mm)

21-31

87180R3

Page 34

MANUAL GEARBOX

Consumables

Type Packaging Part N° Component

Clutch fork pad.

Clutch fork pivot.

Molykote "BR2" 1 Kg box 77 01 421 145

Loctite 518 24 ml syringe 77 01 421 162 Housing assembly surfaces.

LLLLooooccccttttiiiitttteeee FFFFRRRREEEENNNNBBBBLLLLOOOOCC

CC

24 cc flask 77 01 394 071

Clutch thrust pad guide tube

Right-hand sun wheel grooves.

5th gear fixed gear and hub.

Input and output shaft nut.

Output shaft bolt.

21

RRRRHHHHOOOODDDDOOOORRRRSSSSEEEEAAAALLLL 55556666666611

EEEEXXXX:::: CCCCAAAAFFFF 4444////66660000 TTTTHHHHIIIIXXXXOO

11

Ends of the roll pins on the drive shaft.

OO

100 g tube 77 01 404 452

Switch threads.

Parts which must always be changed

When they have been removed:

- the lip seals,

- the O-rings,

- the stop rings,

- the thrust pad guide tube,

- the differential ball bearings,

- the speedometer crown wheel (JB2 - JB3,

differential fitted on tapered bearings),

- the speedometer shaft and gear,

- the roll pins,

- the output shaft and differential nuts,

- the rings under the gears,

- the input and output shaft bearing circlips.

21-32

Page 35

MANUAL GEARBOX

Special tools

21

Figure

90723S

90722S

77743S1

Procedures

reference

B. Vi. 22-01 00 01 216 401 Bearing extractor body.

B. Vi. 28-01 00 01 227 301 Bearing extractor with claws.

B. Vi. 31-01 00 01 259 401

Part

number

Description

Set of 3 pins for fitting the 5 mm diameter roll

pins.

84519-1S

86095S

86096-1S

86097S

B. Vi. 902-01 00 00 090 201

B. Vi. 945 00 00 094 500

B. Vi. 946 00 00 094 600

B. Vi. 947 00 00 094 700

Tool for fitting circlips to the input and output

shafts.

Mandrel for fitting the sun wheel seal.

Mandrel for fitting the snap ring on the sun

wheel.

Mandrel for fitting the bearings in the

mechanism housing.

21-33

Page 36

MANUAL GEARBOX

Special tools

21

Figure

86098S

90664S

87213S

Procedures

reference

B. Vi. 949 00 00 094 900

B. Vi. 950-02 00 00 095 002

B. Vi. 1 000 00 00 100 000

Part

number

Description

Fork roll pins fitting and removal tool.

Adaptable gearbox stand on the Desvil stand.

Extractor for the 5th fixed gear on the output

shaft, use with B.Vi. 22-01.

87571S

86097S

90594S

90592S

B. Vi. 1 007 00 00 100 700 Claws for B.Vi. 28-01.

B. Vi. 1 030 00 00 103 000

B. Vi. 1 057 00 00 105 700

B. Vi. 1 058 00 00 105 800

Mandrel for fitting bearings into mechanism

housing.

Tool for inhibiting rotation of the differential,

JB and JC gearboxes.

Mandrel for fitting the output seal on JB and

JC gearboxes, differential end.

21-34

Page 37

MANUAL GEARBOX

Special tools

21

Figure

90588S

91218-1S

93229S

Procedures

reference

B. Vi. 1 059 00 00 105 900

B. Vi. 1 078 00 00 107 800

B. Vi. 1 162 00 00 116 200

Part

number

Description

Rings for fitting differential bearings, JB / JC

gearbox.

Tool for fitting the crown wheel sensor

mounting spring on the JB 3 gearbox.

Mandrel for changing the control shaft

bearing rings.

93190S

93461S

84328S

B. Vi. 1 170 00 00 117 000

B. Vi. 1 175 00 00 117 500 5th fixed gear mounting bolt.

Emb. 880 00 00 088 000 Clutch fork roll pin extractor (JC gearbox).

Emb. 1163 00 00 116 300 Thrust pad guide tube extraction and fitting

Extractor for the 5th gear hub on the input

shaft.

tool (JC gearbox).

93068S1

21-35

Page 38

MANUAL GEARBOX

Special tools

21

Figure

93226S1

93407S1

69306-1S

Procedures

reference

B. Vi. 1 161 00 00 116 100

B. Vi. 1 165 00 00 116 500

Roul. 15-01 00 01 331 601 Shaft protective end piece, internal diameter

Part

number

Description

Dial gauge support plate and pre-load presetting washers.

Tool for extracting the output shaft bearing

on the clutch-differential housing.

16 mm.

21-36

Page 39

MANUAL GEARBOX

Gearbox repair

Parts must be removed and handled on a work bench with a covering which protects against impact

(rubber or thick plastic).

21

SSSSEEEEPPPPAAAARRRRAAAATTTTIIIINNNNGGGG TTTTHHHHEEEE HHHHOOOOUUUUSSSSIIIINNNNGGGGSS

Remove the thrust pad and the fork from inside

the housing.

Special features of the JC5 gearbox

Remove the two thrust pad guide tube mounting

bolts.

SS

Extract the guide tube lip seal carefully using 2

screwdrivers.

::

NNNNOOOOTTTTEEEE::

The guide tube-lip seal assembly must be changed

whenever it is removed.

All types:

Remove the bolts located inside the clutch

housing.

Fit tool Emb. 1163 on the guide tube and tighten

it.

To this, tighten tool Emb. 880 and extract the

guide tube.

92949R

92950R

88482R

If necessary, remove the centring pins placed at

(D) and (E).

21-37

Page 40

MANUAL GEARBOX

Secure the gearbox to the adaptable stand

B. Vi. 950-02 on the DESVIL base.

Gearbox repair

92958R1

21

90664R

::

NNNNOOOOTTTT EEEE::

In order to allow removal of the differential fitted

on tapered bearings (JB2 - JB3), stand B. Vi. 950-

02 must be used or stand B. Vi. 950-01 must be

modified.

Saw the support plate B Vi. 950 as shown below.

Remove the rear housing. This must be removed

in the horizontal centreline of the gearbox as it

has a lubrication nozzle located in the input shaft

bore.

90670R

21-38

Page 41

MANUAL GEARBOX

Gearbox repair

21

4-speed gearbox

The two input and output shaft circlips and their

respective washer.

5-speed gearbox

Engage 1st gear with the gear lever and 5th gear

by sliding the 5

th

gear fork on its shaft.

Remove the input shaft nut (27 mm) and the

output shaft bolt.

Using tool B. Vi. 31-01 remove the 5

pin placing a piece of wood behind the shaft to

support it.

th

gear fork

92957R

Remove the 5th gear detent (P).

85979R

Place the gearbox in neutral again.

21-39

Page 42

MANUAL GEARBOX

Gearbox repair

21

Extract the 5th gear synchroniser hub using tool

B Vi. 1170.

93236R

On the output shaft

Remove the shouldered washer (64).

Extract the 5

th

gear fixed gear.

DI2129

Remove the 5

Fit tool B. Vi. 1170 onto the 5th gear and turn it in

order to position the sliding gear grooves and the

hub grooves opposite each other.

Remove the 5

th

gear fork and sliding gear.

th

gear assembly.

86045S

21-40

Page 43

MANUAL GEARBOX

Gearbox repair

21

Two options:

1. Using tool B. Vi. 28-01 fitted with claws B. Vi.

1007 and inserting the protective end piece

Rou 15-01.

Remove the mechanism housing mounting bolts.

Remove the reverse gear ball indentation U-clip,

retrieve the spring and the ball.

88575R1

2. Using tools B. Vi. 22-01 and B. Vi. 1000.

92962S

It is advisable to fit two magnets or to close the

openings (C) in order to retrieve the 1/2 and 3/4

shaft locking balls and springs.

93065R

87201R

21-41

Page 44

MANUAL GEARBOX

Pull the control shaft outwards; the gear

engagement finger is then placed in the 5

detent.

Gearbox repair

th

gear

Place the 1/2 shaft (29) and the reverse gear (32)

in neutral).

Remove the 3/4 shaft (30) from the housing bore

sliding it in the fork and remove the shaft-fork

assembly.

Raise and separate the input and output shafts

and remove the reverse gear shaft (32).

21

Detach and raise the mechanism housing fitted

with the 5th gear shaft.

Unpin the 3/4 fork (31) using tool B. Vi. 949.

93230R

92954R1

Simultaneously pull the two shafts (input output) and the assembled 1/2 fork shaft, (29 and

34).

Remove the assembly and retrieve the locking

plunger (35) located in the 1/2 shaft (29).

Hold the output shaft in a vertical position, 1

gear at the bottom, so as not the drop the gears.

In the housing:

st

92953R1

- retrieve the locking plungers (33), (36) and (37)

for the 5-speed gearbox,

- remove the magnet (B) and clean it.

21-42

Page 45

MANUAL GEARBOX

Gearbox repair

21

86046R

Retrieve the interlock plunger (35) located in the

1st/2nd shaft as well.

Cleaning the housings:

The housing assembly surfaces must not in any

circumstances by scratched using a metal tool but

must be cleaned using a cloth soaked in a cleaning

product and dried using compressed air.

If necessary, hone any burrs.

21-43

Page 46

JB gearbox

MANUAL GEARBOX

Shafts

21

IIIINNNNPPPPUUUUTTTT SSSSHHHHAAAAFFFFTT

The input shaft cannot be repaired.

There is no adjustment to be carried out.

On shafts which have a jet (B), this cannot be

removed. Clean the 5th gear lubrication hole.

TT

DI2130

As the lip seal and the guide tube bearing rollers

are in direct contact with the shaft, check the

condition of the mating surface (A). If there are

any scratches or faults in appearance, change the

input shaft.

21-44

Page 47

JB gearbox

MANUAL GEARBOX

Shafts

21

IIIINNNNPPPPUUUUTTTT AAAANNNNDDDD OOOOUUUUTTTTPPPPUUUUTTTT SSSSHHHHAAAAFFFFTTTTSSSS OOOONNNN TTTTHHHHEEEE JJJJBBBB0000 AAAANNNNDDDD JJJJBBBB2222 GGGGEEEEAAAARRRRBBBBOOOOXXXXEEEESS

Modification to the circlip groove on the input and output shafts and to the spring washer fitted to them.

1st assembly 2nd assembly

91011-2R 91011-1R

SS

Assembly with spring washer "R" ∅ 35.6 mm

thickness 2.6 mm.

DI2131

It is essential to fit spring washers which correspond to the shafts.

To identify the new shafts, only the input shaft has a mark: Groove "G" on the 1st/2nd shaft.

Special features:

New shape and displacement of the circlip groove

by 0.2 mm.

Y = X - 0.2

New spring washer "R" ∅ 33 mm thickness 2.4

mm.

On JB2 gearboxes, this modification is accompanied by the fitting of sealed bearings (∅ 62 mm).

21-45

DI2132

Page 48

JC gearbox

MANUAL GEARBOX

Shafts

21

IIIINNNNPPPPUUUUTTTT SSSSHHHHAAAAFFFFTT

As the lip seal is in direct contact with the input shaft, check the condition of mating surface P.

If there are any scratches or faults in appearance, change the input shaft.

TT

86058S

Input shaft bearings

Bearing pre-load adjustment

Value specified to obtain the correct bearing pre-load

(new bearings).

Means of checking:

Dial gauge and support B. Vi. 1161

with standard washer

thickness 0.62 mm

with tapered rollers

Fitting in an"X" configuration

by washers

0 mm

93227S6

93227S4

Thickness of replacement washers supplied.

92951R1

Step of 0.04 mm

Range: 0.92 to 1.16 mm

93227S5

21-46

Page 49

JC gearbox

MANUAL GEARBOX

Shafts

21

IIIINNNNPPPPUUUUTTTT SSSSHHHHAAAAFFFFTTTT ((((ccccoooonnnntttt))

Changing bearings:

- Using a bearingextractor, placed between the

bearing cone and the first gear teeth, taking

care not to damage it.

Extract the cone using a press.

))

If the bearings are changed their pre-load must

always be set.

Refitting:

Fit the bearing using a press use tool B. Vi. 1171 or

using a tool made on site taking the load under

st

the 1

gear teeth.

- On the Clutch Differential housing.

Extract the bearing outer race using a 39.5 mm

external diameter tube engaged from outide

the housing.

- On the mechanism housing.

Proceed in the same manner as previosusly

using tool B. Vi. 1167 or using a tool made on

site.

Note: The gear teeth should not have be chipped or show signs of excessive wear. Ensure

that the lip seal surface is not scratched and

does not show any signs of abnormal wear.

::

NNNNOOOOTTTTEEEE::

The bearings must be changed if they are scratched or shows signs of overheating or excessive

wear.

92999S 93269R

::

NNNNOOOOTTTTEEEE::

As the lip seal is in direct contact with the input

shaft, it is essential that its mating surface is not

scratched when the bearing is fitted.

21-47

Page 50

JC gearbox

MANUAL GEARBOX

Shafts

21

IIIINNNNPPPPUUUUTTTT SSSSHHHHAAAAFFFFTTTT ((((ccccoooonnnntttt))

Changing bearings

Refitting:

Fit the outer race to the Clutch-Differential

housing using tool B. Vi. 1166 or equivalent.

))

Then adjust the bearing pre-loads.

The thickness "E" of the setting washer

determines the pre-load of the input shaft

bearings.

93002-1R

The mechanism housing twin bearing outer races

are fitted using tool B. Vi. 1164 or equivalent.

93259R2

93001R

21-48

Page 51

JC gearbox

MANUAL GEARBOX

Shafts

21

IIIINNNNPPPPUUUUTTTT SSSSHHHHAAAAFFFFTTTT ((((ccccoooonnnntttt))

Adjusting the pre-load of the input shaft

bearings:

- Clutch housing without differential and

without output shaft.

- Fit the input shaft with the bearings and the

0.62 mm pre-setting washer B. Vi. 1161 (small

external diameter).

- Fit the mechanism housing, position the

gearbox bolts and tighten them to the

specified torque.

- Fit the dial gauge support plate B. Vi. 1161 to

the driveshaft gaiter retaining position.

))

- Position the dial gauge with its magnetic base.

A) Turn the input shaft by several revolutions to

settle the bearings.

B) Set the dial gauge to zero.

C) Pull the input shaft upwards.

D) Read the value on the dial gauge.

Repeat the operations several times (A to D).

Calculate the average of the values read.

Calculating the value of the setting washer

Specified value + pre-setting washer value +

average of the values read on the dial gauge =

value of the pre-load setting washer.

Example : (Values in mm)

92951R

0 + 0.48 + 0.62 = 1.10

Specified Average Pre-setting Pre-load

value of values washer setting washer

read value value

Note:

A set of setting washers of thickness 0.92 mm to

1.16 mm rising in stages of 0.04 mm are supplied

as a replacement part.

21-49

Page 52

JB gearbox

MANUAL GEARBOX

Shafts

21

OOOOUUUUTTTTPPPPUUUUTTTT SSSSHHHHAAAAFFFFTT

TT

DI2134

RRRREEEEMMMMOOOOVVVVIIIINNNNGGGG TTTTHHHHEEEE GGGGEEEEAAAARRRRSS

Place the output shaft in a vice fitted with soft

jaws and remove the assembly from right to left.

RRRREEEEFFFFIIIITTTTTTTTIIIINNNNGG

Refit in the reverse order to removal coating each

gear with oil.

Follow the direction of fitting:

- of the hubs and sliding gears of the 1st, 2nd, 3rd,

- the synchroniser roller springs: stop tabs fitted

GG

th

4

and 5th gear synchronisers.

at the circlip end.

SS

WWWWAAAARRRRNNNNIIIINNNNGG

Two types of synchroniser roller springs are used:

the "Z"-shaped springs are replaced by "heart"shaped springs.

GG

91222S

90669S

21-50

Page 53

JB gearbox

MANUAL GEARBOX

Shafts

21

Consequently, the "heart"-shaped springs can

only be used with modified idle gears.

Idle gear detail (E)

91221R

The 45° input chamfer (E) for the groove and

tongue joint under the synchronisation cone will

only allow the fitting of "Z"-shaped springs.

91222R1

Idle gear detail (E)

21-51

91221-1R

SSSSPPPPEEEECCCCIIIIAAAALLLL FFFFEEEEAAAATTTTUUUURRRREE

Idle gears which have a 20° input chamfer (E)

allow the fitting of both "heart"-shaped and "Z"shaped springs. However, it is essential that

springs on the same synchronisation assembly

are not mixed.

EE

Page 54

JB gearbox

MANUAL GEARBOX

Shafts

The circlips must always be changed.

When refitting the circlips, use circlip pliers on one

side in order to separate the jaws and flat pliers

on the opposite side to prevent the circlips from

twisting.

21

84508S

21-52

Page 55

JB gearbox

MANUAL GEARBOX

Shafts

21

CCCCHHHHAAAANNNNGGGGIIIINNNNGGGG TTTTHHHHEEEE BBBBEEEEAAAARRRRIIIINNNNGGGGSSSS OOOONNNN TTTTHHHHEEEE MMMMEEEECCCCHHHHAAAANNNNIIIISSSSMM

HHHHOOOOUUUUSSSSIIIINNNNGG

1st assembly: thickness 17 mm

2nd assembly: thickness 17.5 mm

3rd assembly: thickness 17.5 mm with offset

When changing the bearing, it is essential to fit a

bearing which is identical to the original.

RRRREEEEMMMMOOOOVVVVAAAALL

Separate the circlips using circlip pliers and expel

the bearing towards the inside of the housing

using a hammer.

RRRREEEEFFFFIIIITTTTTTTTIIIINNNNGG

Place the new circlips in their seats positioning the

jaws correctly.

GG

groove.

LL

GG

MM

The cone-shape of the tool allows the clrclips to

be separated in the seat of the housing and allows

the bearing to be inserted.

Ensure that the circlips are correctly positioned in

the bearing groove in order to prevent movement

of the bearing in the bore.

CCCCHHHHAAAANNNNGGGGIIIINNNNGGGG TTTTHHHHEEEE BBBBEEEEAAAARRRRIIIINNNNGGGG OOOONNNN TTTTHHHHEEEE CCCCLLLLUUUUTTTTCCCCHH

DDDDIIIIFFFFFFFFEEEERRRREEEENNNNTTTTIIIIAAAALLLL HHHHOOOOUUUUSSSSIIIINNNNGG

Cut the plastic nozzle located in the centre of the

bearing at its base.

Fit tool B. Vi. 1165 and extract the bearing.

GG

HH

85985S

Fit the bearings to tools B. Vi. 947 (JB0 - JB1 - JB2 JB3) or B. Vi. 1 030 (JB4 and JB5), groove at the

opposite end to the input cone.

Push in the tool with the bearing using a hammer

or a press.

21-53

93408R

::

NNNNOOOOTTTTEEEE::

Ensure that the extractor is positioned correctly

under the bearing cones.

Page 56

JB gearbox

MANUAL GEARBOX

Shafts

21

RRRREEEEFFFFIIIITTTTTTTTIIIINNNNGG

Position the deflector then the bearing using a

press, flush with the internal surface of the

housing.

Crimp the bearing using a chisel observing the

crimping depth (X).

X = 0.9 to 1.3 mm

GG

85704R

21-54

Page 57

JC gearbox

MANUAL GEARBOX

Shafts

21

OOOOUUUUTTTTPPPPUUUUTTTT SSSSHHHHAAAAFFFFTT

TT

DI2135

Output shaft bearings

Adjusting the bearing pre-load

Specified value for obtaining the correct bearing preload (new bearings).

Means of measurement:

Dial gauge and support B. Vi. 1161

with 1.60 mm thick pre-setting washer.

with cone-shaped rollers

Fitting in an "X" configuration

by washers

0.26 mm

93227S6

93227S4

Thickness of washers supplied as replacement parts.

92952S

Step of 0.04 mm

Range: 2.15 to 2.43 mm

93227S5

21-55

Page 58

JC gearbox

MANUAL GEARBOX

Removing the gears

The inner hubs under the 2nd, 3rd, 4th gears are

interference-fit. They must be changed when they

are replaced.

Remove:

- the bearing,

- the pre-load setting washer,

- the 4th gear,

- the 3/4 sliding gear.

Using a press, remove the inner hub, hub, 3rd gear

assembly pressing under the teeth of the 3rd gear

claw.

Shafts

21

94440S

Using a press, remove theinner hubs, 1st and 2

gears, hub, sliding gear assembly, taking the load

under the 1st gear.

nd

94441S

In all cases, it is advisable to mark the position of

the sliding gears in relation to the hubs.

Parts check:

The gear teeth and the claws should not have any

chips or be excessively worn.

Also ensure that the surfaces of the shaft and the

internal walls of the gears do not show any signs

of seizing or abnormal wear.

Hubs-sliding gears:

Ensure that the hubs and their sliding gears have

no chips and are not excessively worn.

Bearings:

21-56

The bearings must be changed if they are

scratched, show signs of overheating, or are

excessively worn.

Page 59

JC gearbox

MANUAL GEARBOX

Shafts

21

Changing bearings:

- Detach the bearing cone from its support on

the drive pinion teeth taking care not to

damage the teeth.

- Extract the cone using a press.

Fit tool B. Vi. 1165 and extract the bearing.

93408R

- On the clutch-differential housing:

Cut the plastic nozzle located in the centre of

the bearing at its base.

92998S

::

NNNNOOOOTTTTEEEE::

Ensure that the extractor is positioned correctly

under the bearing cones.

- On the mechanism housing:

Extract the bearing outer race using tool B. Vi.

1167.

21-57

Page 60

JC gearbox

MANUAL GEARBOX

Shafts

21

RRRREEEEFFFFIIIITTTTTTTTIIIINNNNGG

Position the outer race using tool B. Vi. 1164 or

equivalent.

GG

On the output shaft:

Fit the cone using a press with the load on the

used bearing cone.

Note:

The bearing pre-load must always be set when the

bearings are changed.

A heated plate with a 150°C setting must be used

for refitting.

Refitting:

Place the new inner hubson a cold heated plate.

Heat them for 15 minutes, with the thermostat at

150°C.

93001R

On the clutch-differential housing:

Fit the lubrication nozzle.

Fit the complete bearing using tool B. Vi. 1167 or

equivalent.

94587S

All of the cleaned and checked parts will be

gradually coated with oil as they are refitted.

93002R

21-58

Page 61

JC gearbox

MANUAL GEARBOX

Shafts

21

Refit the 1st gear.

Place the 1/2 sliding gear on the hub and refit the

synchroniser springs.

Align and make flush the notches of the hub with

the notches of the synchronisation rings.

Refit the 2nd gear and the thrust washer.

For the inner hubs under the 3

carry out the same operations as previously.

Refit:

- the inner hub under the 3rd gear.

- the 3rd gear

- the 3/4 sliding gear hub,

- the 3/4 synchroniser.

Observe the direction of fitting of the "heart"shaped springs: flat part fitted at the synchroniser

hub end.

Take care to align the notches on the hub with the

bosses on the synchroniser ring.

rd

and 4th gears,

Refitting the inner hubs :

Using pliers, remove an inner hub from the

heated plate and fit it to the shaft.

When the inner hub is on the shaft, using a press

and a 33 mm interior diameter tube, place the

inner hub in correct contact with hub.

92997S

91222-1S

21-59

Page 62

JC gearbox

MANUAL GEARBOX

Shafts

Refit:

- the inner hub under the 4th gear,

- the 4th gear,

- the pre-load setting washer,

- the bearing.

Check that the idle gears rotate freely and check

the changing of the various gears.

Then adjust the bearing pre-loads if necessary.

Note:

The adjustments must be carried out shaft by

shaft without the differential.

21

The thickness of the setting washer "F"

determines the pre-load of the output shaft

bearings.

93259R1

21-60

Page 63

JC gearbox

MANUAL GEARBOX

Shafts

21

Adjusting the pre-load of the output shaft bearings

- Clutch housing without the differential and wi-

thout the input shaft.

- Position the output shaft in the clutch housing

with the bearings and the 1.60 mm pre-setting

washer B. Vi. 1161 or equivalent, (large external diameter).

- Fit the mechanism housing.

- Fit the gearbox bolts and tighten them to the

specified torque.

- Fit dial gauge support plate B. Vi. 1161 or equi-

valent on the the driveshaft mountings.

Fit the dial gauge with its magnetic base.

A) Turn the output shaft by several revolutions to

position the bearings.

B) Set the dial gauge to zero.

C) Pull the output shaft upwards.

D) Read the value on the dial gauge.

Repeat the operations several times (A to D).

Calculate the average of the values read.

Calculating the value of the pre-load setting

washer

Specified value + pre-setting washer value +

average of values read on the dial gauge = value

of the pre-load setting washer.

92952R

Example : (Values in mm)

0.26 + 0.49 + 1.60 = 2.35

Specified Average Pre-setting Pre-load

value of values washer setting washer

read value value

Note:

A set of setting washers of thickness 2.15 mm to

2.43 mm rising in steps of 0,04 mm is supplied as a

replacement part.

21-61

Page 64

MANUAL GEARBOX

Differential

21

DDDDIIIIFFFFFFFFEEEERRRREEEENNNNTTTTIIIIAAAALLLL ((((FFFFIIIITTTTTTTTIIIINNNNGGGG TTTTOOOO BBBBAAAALLLLLLLL BBBBEEEEAAAARRRRIIIINNNNGGGGSSSS))))

DI2137

21-62

Page 65

MANUAL GEARBOX

Differential

21

DDDDIIIIFFFFFFFFEEEERRRREEEENNNNTTTTIIIIAAAALLLL ((((DDDDIIIIFFFFFFFFEEEERRRREEEENNNNTTTT AAAASSSSSSSSEEEEMMMMBBBBLLLLIIIIEEEESSSS))

DI2138 DI2139

IIIINNNN----PPPPRRRROOOODDDDUUUUCCCCTTTTIIIIOOOONNNN SSSSOOOOLLLLUUUUTTTTOOOONN

1st assembly

with circlip 40

thickness: 1.75

with circlip 40

thickness: 1.75

nd

2

assembly

with circlip 40

thickness: 2.5

NN

rd

3

assembly

))

GEARBOX WITH BEADGEARBOX WITHOUT BEAD

th

4

assembly

with circlip 40

thickness: 2.5

DI2140 DI2141 DI2142 DI2143

RRRREEEEPPPPAAAAIIIIRRRR SSSSOOOOLLLLUUUUTTTTIIIIOOOONN

(if the bearing is changed)

DI2144

NN

DI2145

21-63

Page 66

MANUAL GEARBOX

Differential

21

DDDDIIIIFFFFFFFFEEEERRRREEEENNNNTTTTIIIIAAAALL

((((FFFFIIIITTTTTTTTIIIINNNNGGGG TTTTOOOO BBBBAAAALLLLLLLL BBBBEEEEAAAARRRRIIIINNNNGGGGSSSS))

RRRREEEEMMMMOOOOVVVVAAAALL

This operation is carried out after separating the

housings.

Remove the O-ring (38).

Strike the lip seal using a pin extractor and a small

hammer in order to tilt it.

Remove the seal taking care not to damage the

splines on the sun wheel.

LL

))

LL

The differential is extracted by pushing on the sun

wheel (52) using a press. Extract (43) if the

housing is fitted with it, then (44).

Turn the assembly over.

Tighten the housing (45) in a vice with soft jaws.

Remove the snap ring (46) and remove the shim

(47).

Extract the tripod sun gear (48) and remove the

planet gear shaft (49).

55

JJJJBBBB4444----JJJJBBBB55

Remove the pin (74) and remove the planet gear

shaft (49).

Retrieve the sleeve (73) and remove (50 and 51)

attaching the washers to their respective planet

gears.

Remove the shouldered sun gear.

86031S

Using a press:

- place a board under the crown wheel to

support it,

- push the clutch housing and the differential to

free the circlips (40) and extract it.

If necessary, remove the speedometer crown

wheel, the speedometer shaft and the gear.

::

NNNNOOOOTTTTEEEE::

these parts must always be changed once

they have been removed.

CCCCHHHHEEEECCCCKKKKIIIINNNNGGGG PPPPAAAARRRRTTTTSSSS::

Check the condition of:

- the teeth,

- the bearing surfaces,

- the washers (of the planet gears),

- the grooves,

- the housing.

::

21-64

Page 67

MANUAL GEARBOX

Differential

21

DDDDIIIIFFFFFFFFEEEERRRREEEENNNNTTTTIIIIAAAALL

CCCCHHHHAAAANNNNGGGGIIIINNNNGGGG BBBBEEEEAAAARRRRIIIINNNNGGGGSS

Crown wheel end bearing

RRRREEEEMMMMOOOOVVVVAAAALL

Pass a flat bar inside the gearbox and place it flat

on the bearing.

Press on the press using a lengthened tube and

extract the bearing.

LL

SS

LL

Shouldered sun gear end bearing

RRRREEEEMMMMOOOOVVVVAAAALL

Remove the circlips (66) retaining the bearing (65)

in its seat, then, using a press, remove the bearing

towards the inside of the housing using a 50

diameter sleeve.

LL

85705R2

85705S1

RRRREEEEFFFFIIIITTTTTTTTIIIINNNNGG

The bearing housing (C) must be directed to the

end opposite the crown wheel.

Push on the bearing using a press, using tool B. Vi.

1 059, with the load on the bearing outer ring.

GG

RRRREEEEFFFFIIIITTTTTTTTIIIINNNNGG

The bearing housing (C) must be directed to the

end opposite the crown wheel.

Use a 65 diameter sleeve pressing on the bearing

outer housing (65).

GG

86317-1R

85705R3

Change the bearing retaining circlips.

21-65

Page 68

MANUAL GEARBOX

Differential

21

DDDDIIIIFFFFFFFFEEEERRRREEEENNNNTTTTIIIIAAAALL

RRRREEEEFFFFIIIITTTTTTTTIIIINNNNGGGG ---- SSSSppppeeeecccciiiiaaaallll ppppooooiiiinnnntt

LL

JB - 1

JB - 2

tt

st

Assembly

nd

Assembly

DI2146

RRRREEEEFFFFIIIITTTTTTTTIIIINNNNGG

Refit:

-1

-2nd and 3rd assembly (44) then (41).

-4th assembly and repair solutions: (44) then (43)

NNNNOOOOTTTTEEEE::

GG

st

assembly: (44) then (43) and (41).

and (41).

::

in all cases direct (44) as below.

DI2147

It is essential to fit a new pin (74) (tool B. Vi. 31-

01).

Place the speedometer crown wheel (41), notch in

the housing seat.

Refit the new speedometer gear and shaft using

flat pliers.

Ensure that it is clipped correctly.

85798R

Replace the differential in the clutch and differential housing.

Using a press:

- place a wooden shim under the crown wheel,

- ensure that the thickness of the circlips corresponds to the width of the groove,

- fit the circlips (40) onto the tapered guide (1) of

tool B. Vi. 946, then fit the tapered guide to the

sun wheel,

- fit tool (2) B. Vi. 946 on the tapered guide (1)

and push using the press until the circlips are

positioned in its groove. Remove tool B. Vi. 946,

- turn the assembly and check the rotation of the

speedometer gear.

21-66

Page 69

MANUAL GEARBOX

Differential

21

DDDDIIIIFFFFFFFFEEEERRRREEEENNNNTTTTIIIIAAAALL

LL

The seal is refitted using tool B. Vi. 945 made up

of:

- a seal protector (A),

- a tool for fitting the seal (B).

86123R

86095R

Fit the protector (A) coated with oil to the sun

wheel and position the seal (C) coated with oil

using tool (B).

86122R

21-67

::

NNNNOOOOTTTTEEEE::

the lip seal can be changed on the vehicle

with the gearbox in place.

Page 70

MANUAL GEARBOX

Differential

21

DDDDIIIIFFFFFFFFEEEERRRREEEENNNNTTTTIIIIAAAALLLL ((((FFFFIIIITTTTTTTTIIIINNNNGGGG OOOONNNN CCCCOOOONNNNEEEE----SSSSHHHHAAAAPPPPEEEEDDDD BBBBEEEEAAAARRRRIIIINNNNGGGGSSSS))

))

Differential bearings

DI2148

with tapered rollers

fitting in an O configuration

93227S3

21-68

Page 71

MANUAL GEARBOX

Differential

21

DDDDIIIIFFFFFFFFEEEERRRREEEENNNNTTTTIIIIAAAALL

RRRREEEEMMMMOOOOVVVVAAAALL

This operation is carried out after separating the

housings.

Remove the O-ring (38).

Strike the lip seal using a pin extractor and a small

hammer in order to tilt it.

Remove the seal taking care not to damage the

splines on the sun wheel.

LL

LL

Remove the gearbox mounting nut.

90667-1S

Retrieve the bearing pre-load setting shim (79).

86031S

Immobilise the differential housing - crown wheel

assembly using tool B. Vi. 1 057 secured to the

housing.

Remove the assembly pushing on the sun wheel.

Turn the assembly over.

Tighten the housing (45) in a vice with soft jaws.

Remove the snap ring (46) and remove the shim

(47).

Extract the tripod sun wheel (48).

Remove the pin (74) and remove the planet gear

shaft (49).

90595R

21-69

Page 72

MANUAL GEARBOX

DI2146

Retrieve the sleeve (73) and remove (50 and 51)

attaching the washers to their respective planet

gears.

Differential

21

Remove the shouldered sun wheel.

If necessary, remove the speedometer crown

wheel, the speedometer shaft and the gear.

NNNNOOOOTTTTEEEE::::

they have been removed .

Checking parts:

Check the condition of:

- the teeth,

- the bearing surfaces,

- the washers (of the planet gears),

- the grooves,

- the housing.

Changing the crown wheel end bearings