Page 1

2013

Page 2

Release 1.0 - 24/04/2013

2

USER MANUAL

CONTENTS

1. OVERVIEW OF THE CAR.......................................................................4

2. CONTACTS ...........................................................................................5

2.1. Organizers ....................................................................................... 5

2.2. Technical contacts ............................................................................ 5

2.3. Manufacturer.................................................................................... 5

2.4. Renault Sport extranet ...................................................................... 6

3. OVERALL DESCRIPTION ......................................................................7

3.1. Dimensions ...................................................................................... 7

3.2. Capacities........................................................................................ 8

3.3. Technical Specifications ..................................................................... 8

4. USE......................................................................................................9

4.1. Switch panel .................................................................................... 9

4.2. Starting procedure.......................................................................... 10

4.3. Safety procedure ............................................................................ 10

4.5. Ballast location............................................................................... 11

5. CHASSIS............................................................................................ 12

5.1. Basic Setup.................................................................................... 12

5.2. Setup adjustment ........................................................................... 13

5.3. Aero setup ..................................................................................... 13

5.4. Suspension geometry...................................................................... 15

5.4.1. Toe/Camber shims position ........................................................ 15

5.4.2. Rear bracket position................................................................. 16

5.5. Damper setting .............................................................................. 17

5.6. Front antiroll stiffness setting ........................................................... 18

5.7. Brakes........................................................................................... 19

5.7.1. Discs / Pads bedding in procedure............................................... 19

5.7.2. Wear ....................................................................................... 19

5.8. Nosebox cap change ....................................................................... 19

5.9. Tightening torques.......................................................................... 20

6. ENGINE ............................................................................................. 21

7. TRANSMISSION / GEARBOX..............................................................22

7.1. Clutch bleeding procedure................................................................ 22

7.2. Ratio charts ................................................................................... 23

7.3. Lubrification................................................................................... 23

7.4. Glue components............................................................................ 24

7.5. Gears ............................................................................................ 24

7.6. Selector......................................................................................... 26

7.7. Differential..................................................................................... 28

7.8. Final drive...................................................................................... 29

7.9. Bearings ........................................................................................ 31

7.10. Clutch shaft.................................................................................. 34

7.11. Rebuilding of the gearbox .............................................................. 35

7.12. Gear shift setup............................................................................ 36

8. ELECTRONICS....................................................................................37

8.1. Dashboard ..................................................................................... 37

8.1.1. Driver pages ............................................................................ 37

Page 3

Release 1.0 - 24/04/2013

3

8.1.2. Diag pages............................................................................... 38

8.1.3. Diag CAN ................................................................................. 39

8.1.4. Display settings ........................................................................ 40

8.1.5. Dash configuration .................................................................... 40

8.1.6. Synthesis operation................................................................... 43

8.2. Details of the transponder connector................................................. 44

8.3. Composition of the PI Data system kit ............................................... 44

The repair procedures prescribed by the manufacturer in this manual have been written in compliance with the

technical specifications in force at publication issuing date. They are subject to modifications in case of changes

made by the manufacturer to the production of the various components and accessories of his brand name

vehicles".

All copyrights are reserved to RENAULT SPORT TECHNOLOGIES.

Reproducing or translating this document, even partially, and using the spare parts reference numbering system

are prohibited without the previous written consent of SIGNATECH AUTOMOBILES

© RENAULT SPORT TECHNOLOGIES 2013

Page 4

Release 1.0 - 24/04/2013

4

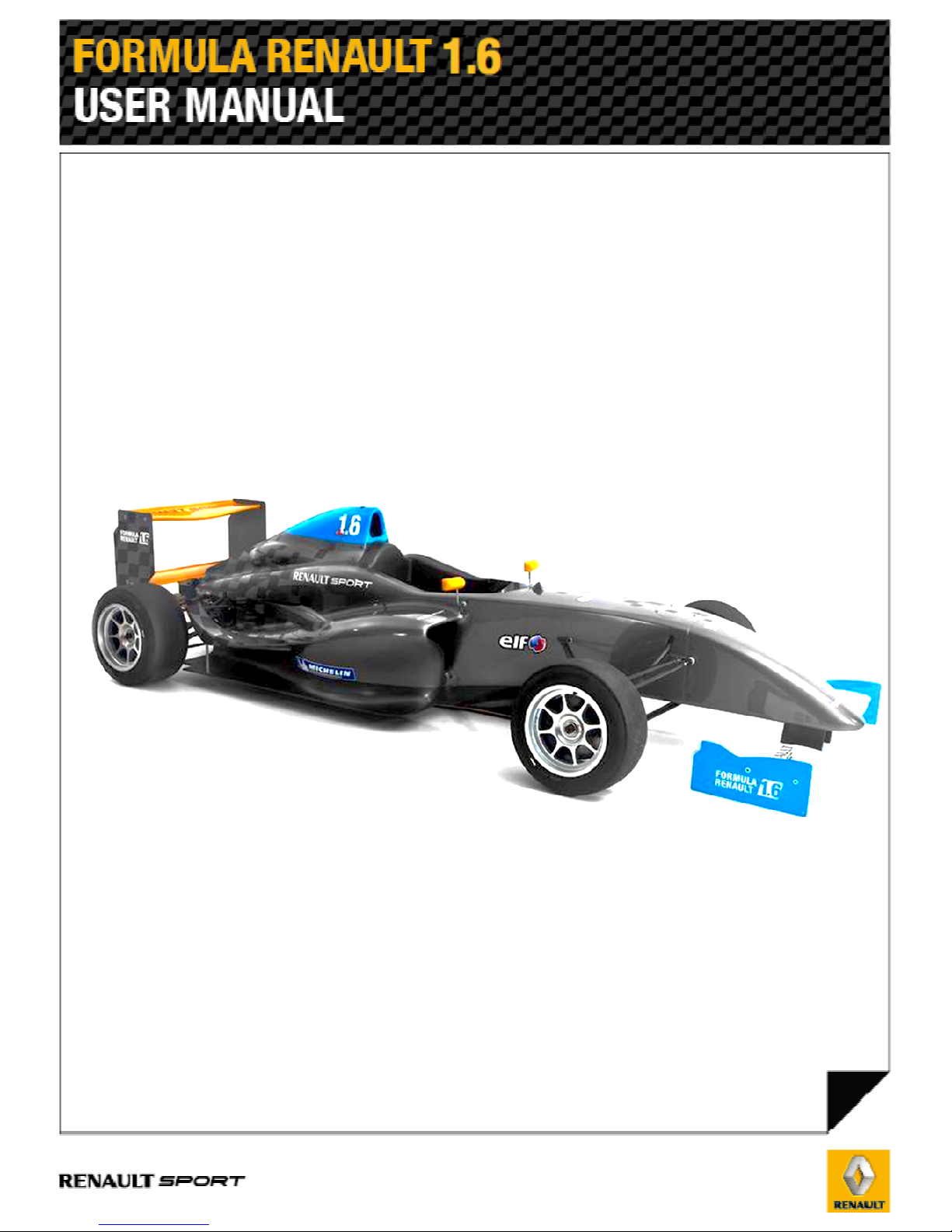

1. OVERVIEW OF THE CAR

Page 5

Release 1.0 - 24/04/2013

5

2. CONTACTS

2.1. Organizer

Renault Sport Technologies

ZA Courtaboeuf 2

14, Avenue des Tropiques

91978 Les Ulis Courtaboeuf Cedex

FRANCE

Tel : +33-1 76 82 40 00

Sporting coordinator: Rudy Thomann

rudy.thomann@renault.com

2.2. Technical contacts

For any questions or advice, please contact:

Racing Technical Support:

Guillaume Argy

Tel : +33-1 76 84 18 93

Mob: +33-6 84 93 86 46

guillaume.argy-renexter@renault.com

Renault Sport Technologies

ZA Courtaboeuf 2

14, Avenue des Tropiques

91978 Les Ulis Courtaboeuf Cedex

FRANCE

Tel : +33-1 76 82 40 00

Fax : +33-1 76 82 12 40

http://extranet.renault-sport.com

Racing Technical Dpt Referent:

Julien Jehanne

Tel : +33-1 76 82 41 25

julien.jehanne-renexter@renault.com

2.3. Manufacturer

Racing Technical Support:

Lionel Chevalier

Tel : +33-2 48 02 01 77

lionel@signature-team.com

Signatech Automobiles

Parc Esprit 1

Rue Michael Faraday

18000 Bourges

France

Tel/Fax :+33-2 48 02 01 77

Spare Parts:

Florent Pacholak

Tel : +33-2 48 02 01 77

signatech@signature-team.com

-

Page 6

Release 1.0 - 24/04/2013

6

2.4. Renault Sport extranet

The Renault Sport Extranet website is accessible for every FR1.6 owners, after asking for

an access directly from the welcome page of the website:

http://extranet-competition.renault-sport.com/

or

All the technical documents issued are available through this website:

- Technical Regulations

- User Manual

- Technical Bulletins & Information Notes

-

Spare parts catalogue

-

Softwares

-

HQ Loom drawings and so on.

Page 7

Release 1.0 - 24/04/2013

7

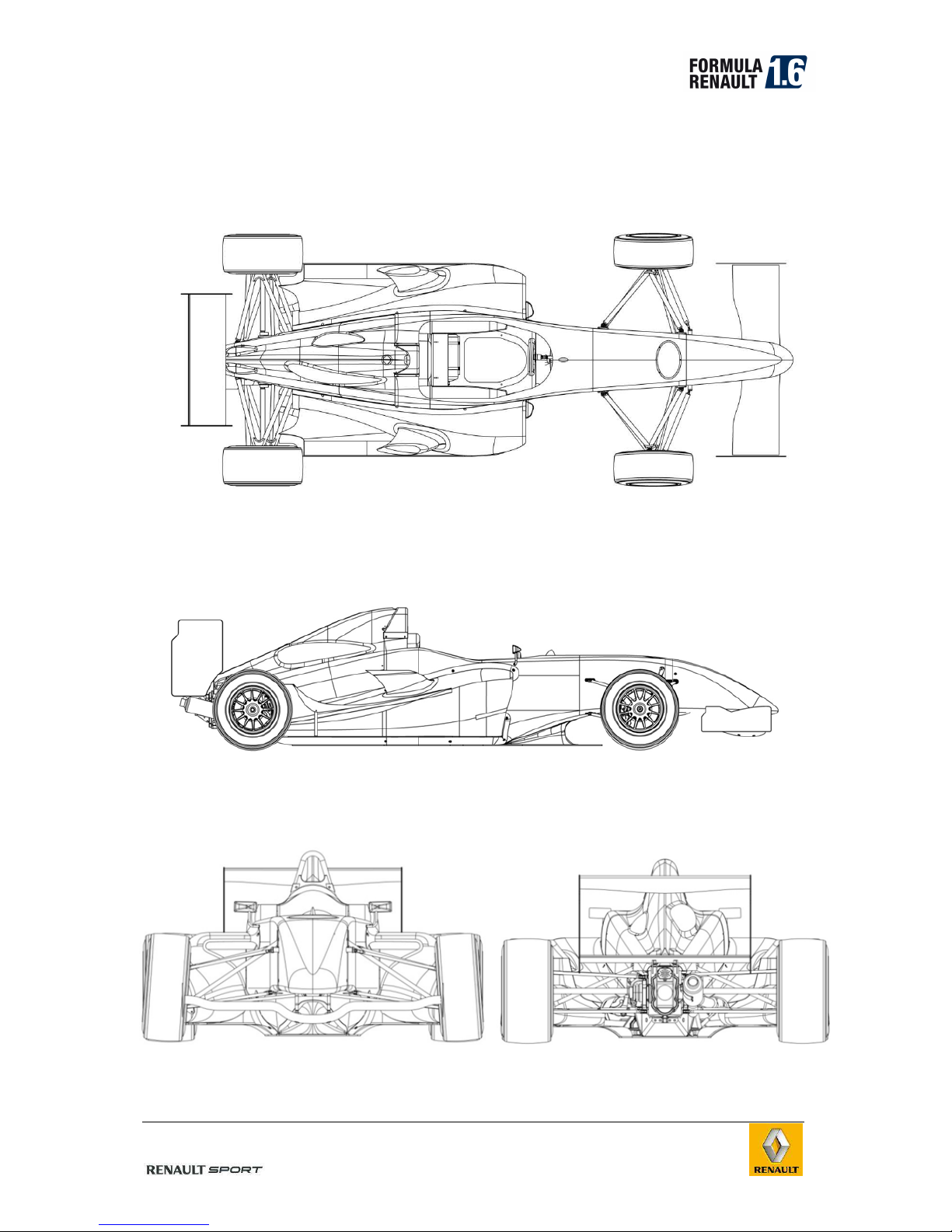

3. OVERALL DESCRIPTION

3.1. Dimensions

Overall length 4118 mm

Overall width 1670 mm

Overall height 999 mm

Wheelbase 2651 mm

Front track 1486 mm

Rear track 1436 mm

Front overhang 935 mm

Rear overhang 531 mm

Page 8

Release 1.0 - 24/04/2013

8

3.2. Capacities

Products Quantity Characteristics

Petrol 43 L Unleaded 98

Engine oil Around 6.5 L Elf HTX 825 (10W60)

Gearbox oil 2.1 L Elf HTX 735 (75W90)

Coolant 6 L -

Brake fluid 0.4 L Elf HTX 115

Clutch fluid 0.15 L Elf HTX 115

3.3. Technical Specifications

Weight 470 kg without driver and fuel (with catalyser exhaust)

Front

suspension

Push road, mono damper unit (non adjustable)

Rear

suspension

Push road, twin damper unit (non adjustable)

Rims : one piece Speedline aluminium alloy rim with

central nut

Rims size : Fr 8"x13" Rr 10"x13

Kumho tyres : Fr 180/53x13 Rr 220/54x13

Wheels

Dunlop tyres : Fr 175/535x13 Rr 230/535x13

4 piston Alcon calipers, 274x18.5mm ventilated discs

Brakes

Right/Left foot adjustable pedal

Renault Sport

Type : K4M 854 – 1.6L

Max power : 140 bhp @ 6800 rpm

Max torque : 160 Nm @ 4500 rpm

Engine

Max revs : 7200 rpm

SADEV SL66

5 front gears + one reverse gear

Shift cut system

Transmission

Free differential

Page 9

Release 1.0 - 24/04/2013

9

4. USE

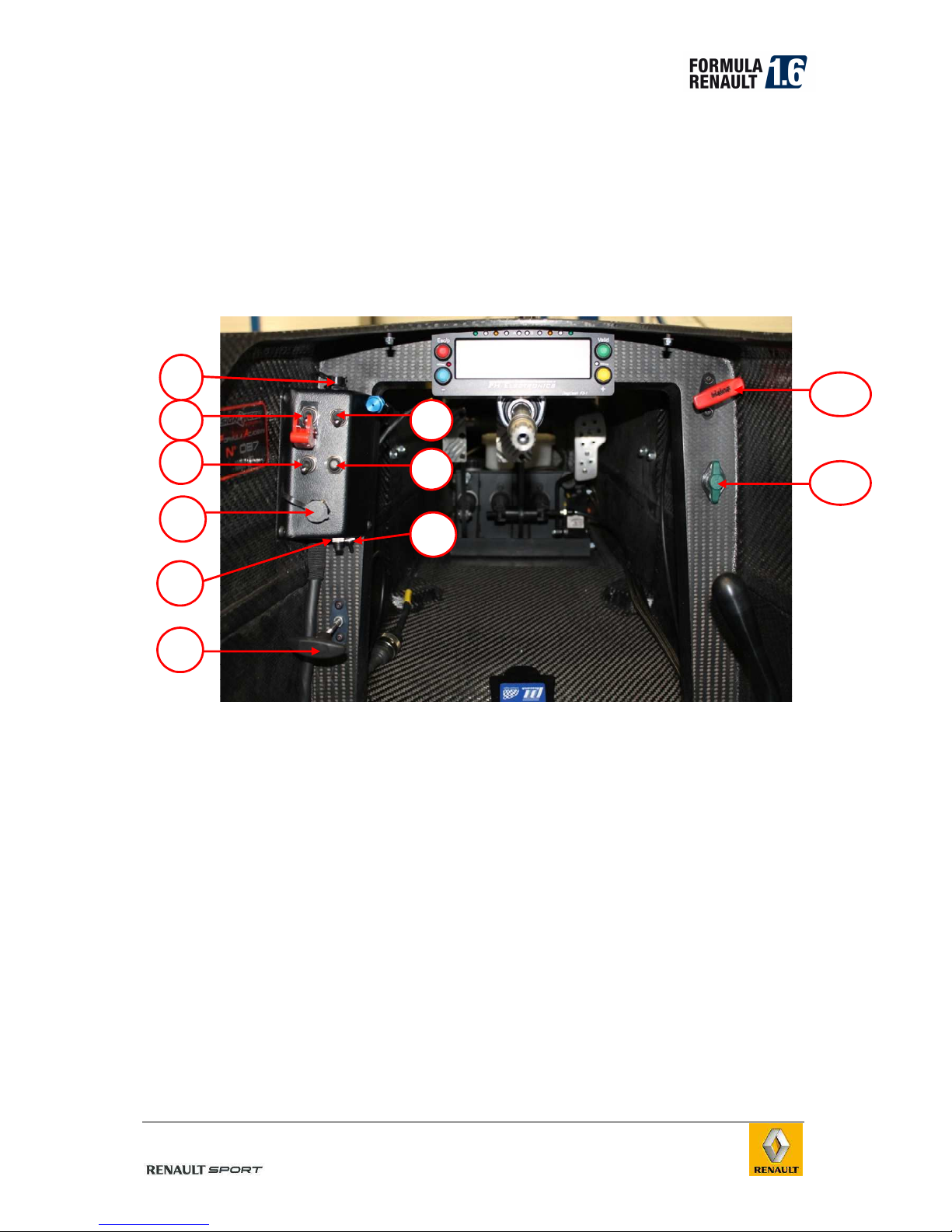

4.1. Switch panel

8

7

9

11

10

2

3

1

4

5

6

1- Unused Connector

2- Main switch

3- Rain light switch

4- Connector for the mechanic electronic throttle (joystick)

5- Dashboard reset

6- Neutral and reverse handgrip

7- Ignition switch

8- Starter button

9- Fuel pump switch for drain tank

10- Fire extinguisher handgrip

11- Brake balance handgrip (clock wise increases front brake pressure)

“ON” is the up position of the switches

Page 10

Release 1.0 - 24/04/2013

10

4.2. Starting procedure

• Switch the master switch and the ignition on.

• No throttle.

• Push the starter button few seconds. The engine must start.

• If the engine doesn’t start, switch ignition off and on and push the starter

button again.

• After starting you can accelerate gently.

• Warm the engine up to 80°C before running.

4.3. Safety procedure

Switch ignition and master switch off.

For transportation it’s easy to disconnect the electrical system by unscrewing the

main fuse (100A).

In case of fire, the driver pulls the handgrip on the right side of the steering

wheel or an external person pulls the red ring on the right side of the roll hoop.

This action triggers the extinguisher and switches the electrical system off. After

this action, the electrical system can be on again only by pushing the fire switch

on the extinguisher ones (Spare parts catalog page 14 Ref 12).

Fire extinguisher cables are located in two points:

Behind the roll hoop Inside the cockpit

Page 11

Release 1.0 - 24/04/2013

11

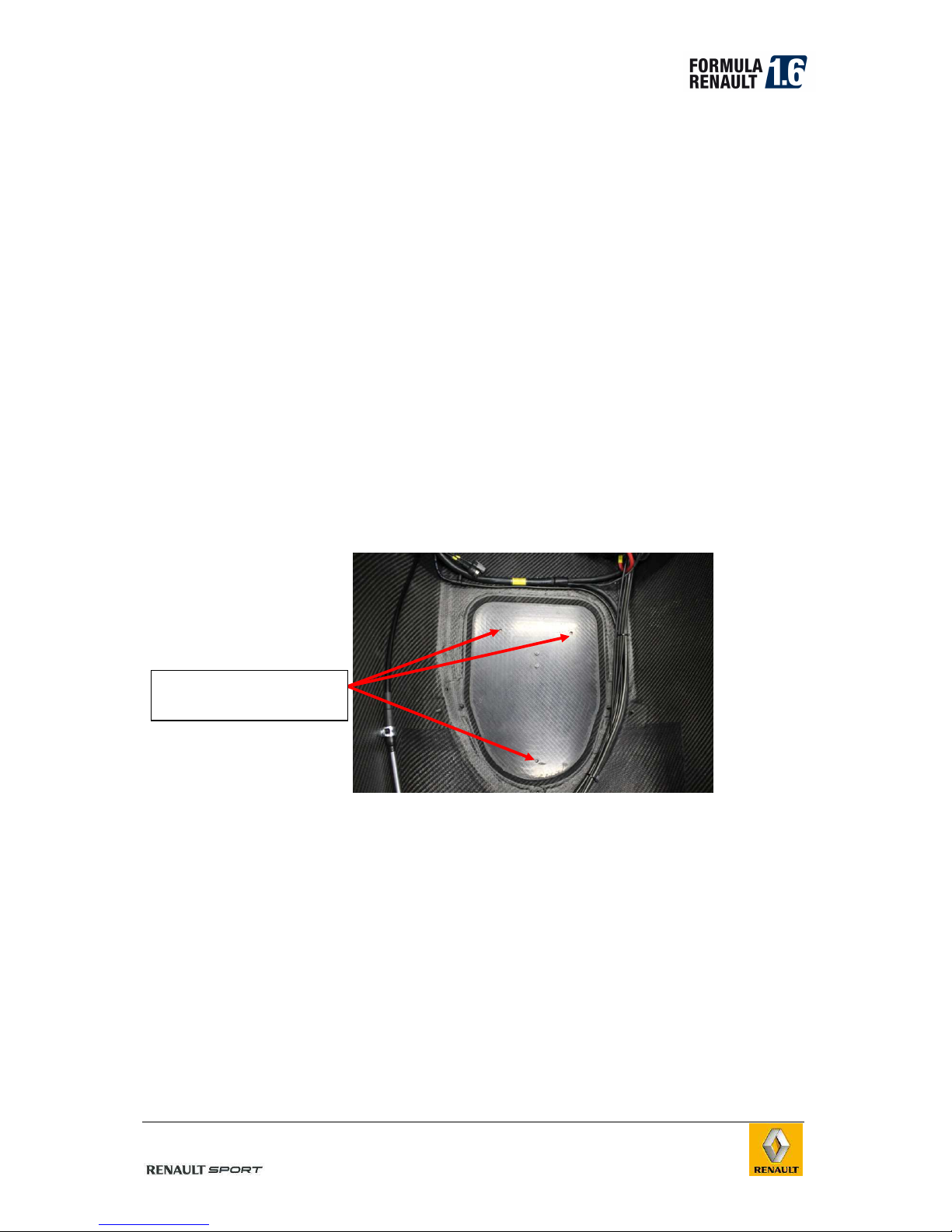

4.5. Ballast location

The ballast must be placed inside the cockpit, under the driver seat.

The lead ballast has to be fitted between the bottom of the chassis and the

stainless steel cover.

Ballast system are described as follows:

• 3mm stainless steel cover : 2.0kg

• 1.5 mm lead ballast: 1.5kg

Maximum ballast weight possible: +/- 15kg.

You can only fit the steel cover plate.

Mounting screws: 3 FHC M5 with diam5x12 washers and nylstop nuts. Length

depending of the thickness of the ballast

Ballast mounting

holes

Page 12

Release 1.0 - 24/04/2013

12

5. CHASSIS

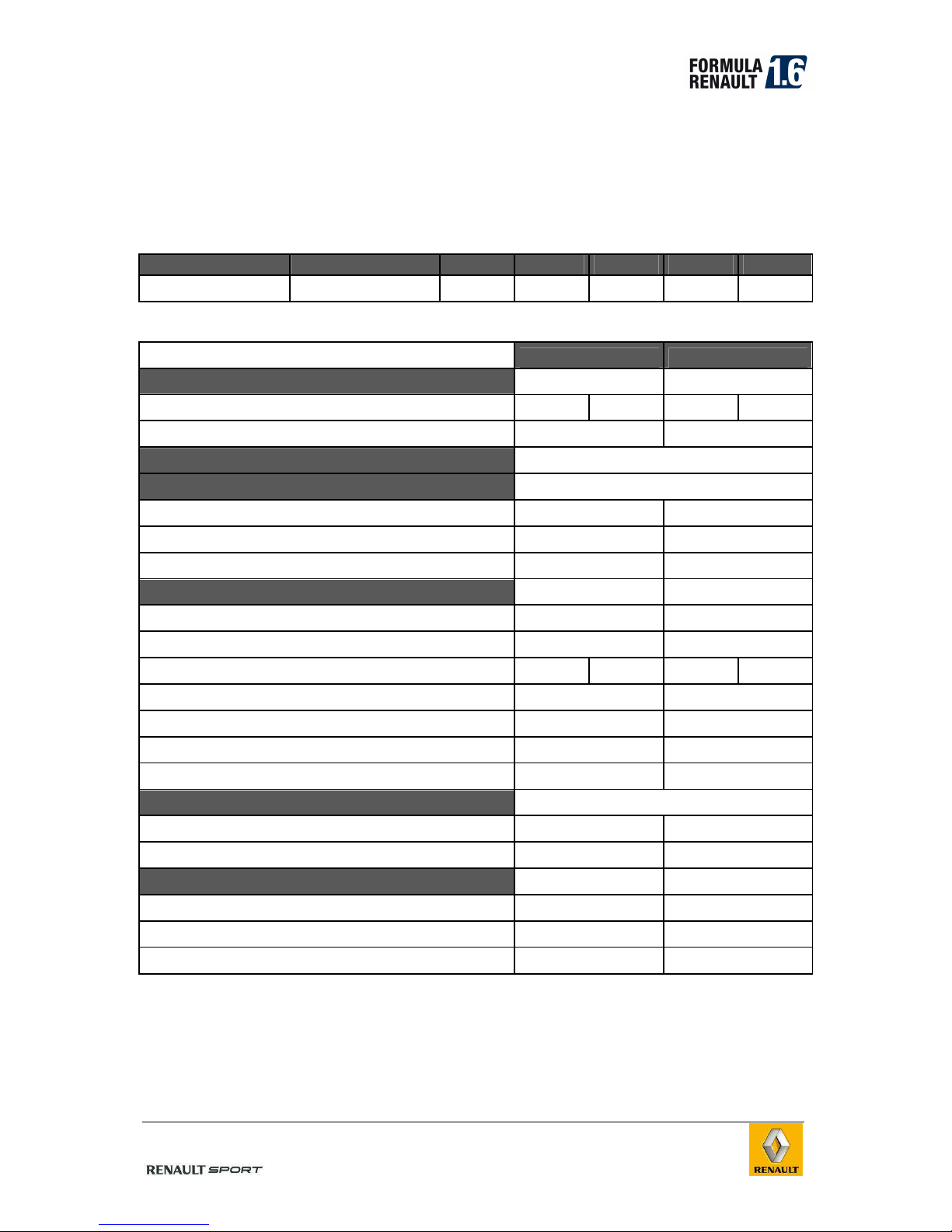

5.1. Basic Setup

Gearbox Final drive 1st 2nd 3rd 4th 5th

SADEV SL66 10/31 11/35 14/31 18/30 19/25 25/27

Front Rear

SPRINGS

Spring Stiffness [lb/in - daN/mm] 800 14 700 12.3

Motion Ratio Wheel / Damper 0.86 1.18

DAMPERS Nadal Tech non adjustable

ANTIROLL

Bellevilles Stack 11x1

Motion Ratio Wheel / Bellevilles 1.77

Element Stiffness [daN/mm] 81

GEOMETRY

Ride Height [mm] 18 33

Castor [°] 10°

Camber [°] -3.5° -3.5° -2.5° -2.5°

Toe per Wheel 1,5 mm OUT 1 mm IN

Roll centre position vs ground [mm] 23 52

Anti-Dive 38% 15%

Anti-Squat 40%

WINGS

Main [°] 4° 9°

Flap [°]

P2 = 3°

TYRES

Pressure [bar] @ 20° C 1.2 1.2

Hot Pressure [bar] 1.5-1.6 1.5-1.6

Kumho Circumference [mm] 1665 1696

Page 13

Release 1.0 - 24/04/2013

13

Shim thickness available: 1 mm, 1.5 mm and 2 mm.

5.2. Setup adjustment

Adjustment Front Rear

RIDE HEIGHT change

1 turn of damper platform

(2mm)

1.7 mm 2.4 mm

CAMBER change

1 mm shim 0.285° 0.278°

3.5mm shim 1° 0.97°

+10mm ride height -0.3° +0.15°

TOE change

1 turn (1mm)

0.653° around 4 mm at the

Wheel

1.5 flat 1 mm at the wheel

1mm shim

0.157° around 1 mm at the

wheel

CASTER change

1mm shim 0.218°

WING change

1mm shim -0.6°

Special damper spanners are available (one for each size of platform)

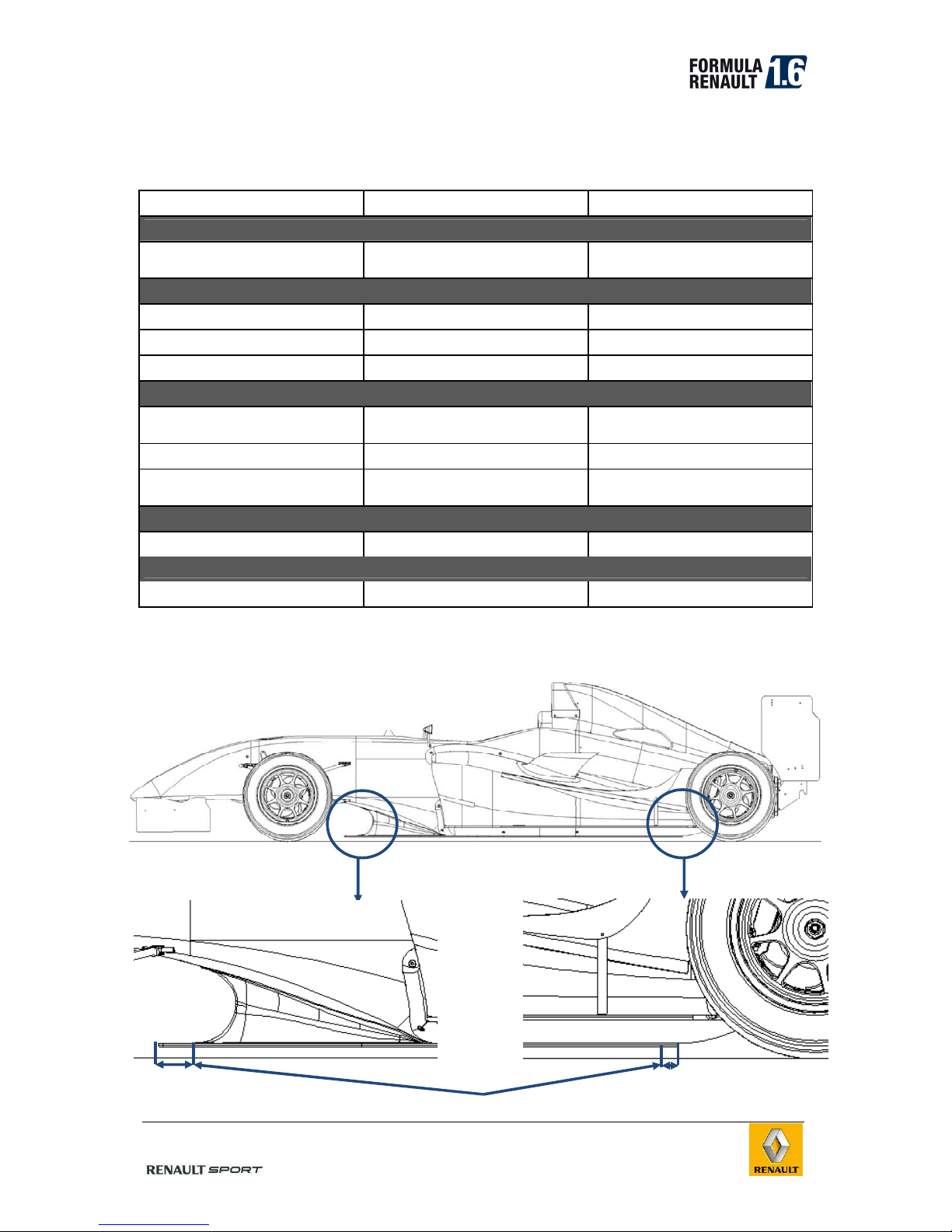

5.3. Aero setup

15 mm

Ride Height Measurement Place

166 mm

Page 14

Release 1.0 - 24/04/2013

14

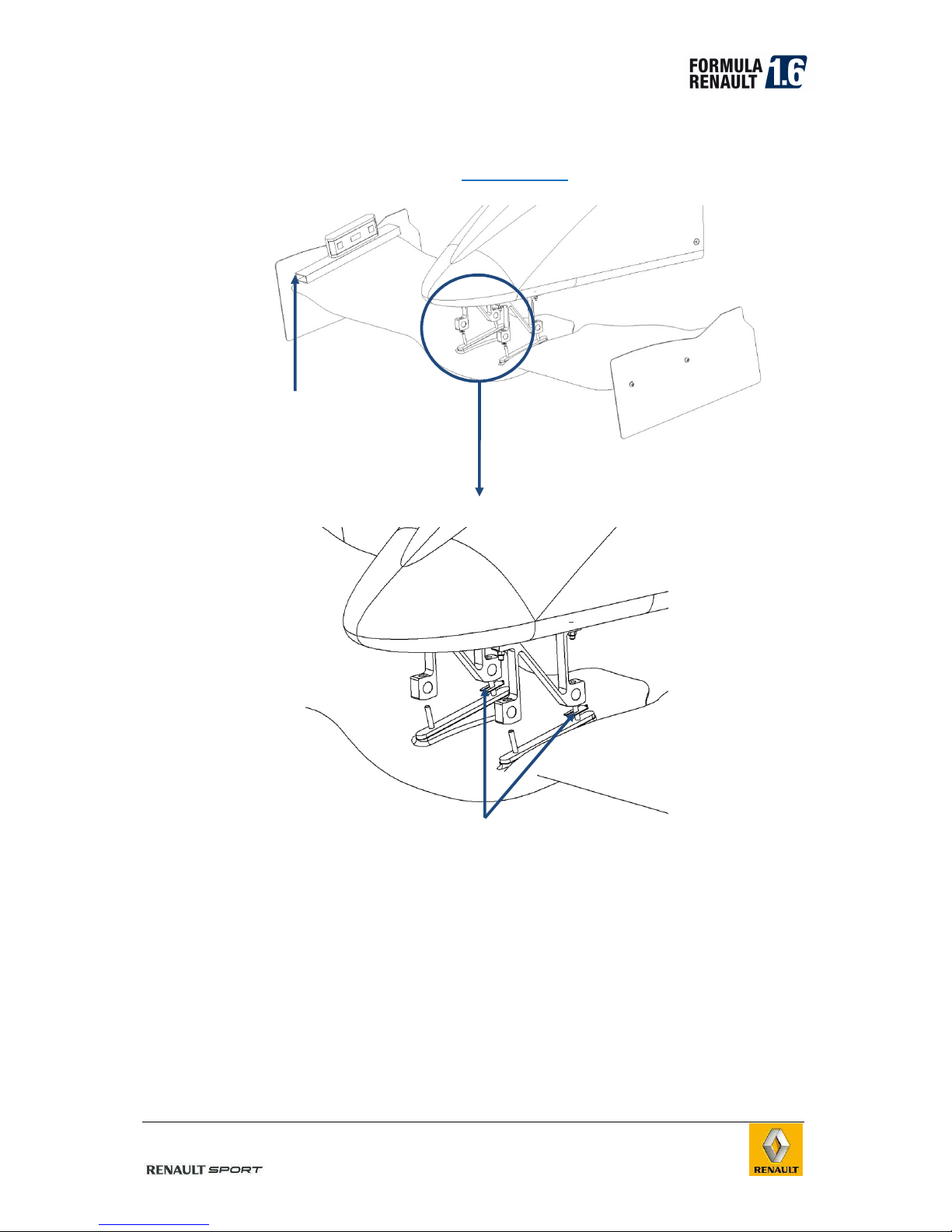

Flap Angle adjustment – shims position

The front wing shims must only be fitted on the rear of the front wing brackets.

Available shims thickness: 0.5mm, 1mm and 2mm.

Without shims, the wing angle is 5° (Maximum value)

Front wing

Wing angle measurement place

0° parallel to the car floor or to

the reference plan on the top of

the bellhousing

Page 15

Release 1.0 - 24/04/2013

15

Rear wing

P1 = 0°

P2 = 3°

P

3 = 6°

P2 = 9°

P1 = 0°

0° parallel to the car floor or to the reference plan on the top of the bellhousing

5.4. Suspension geometry

5.4.1. Toe/Camber shims position

Front Camber Shim

s:

0.5-1-1.5-2mm

Page 16

Release 1.0 - 24/04/2013

16

Rear toe and camber shims are the same.

5.4.2. Rear bracket position

Only one rear bracket position is allowed (red fixing points)

Rear Camber Shim

s:

0.5-1-1,5-2mm

Rear Toe Shim

s:

0,5-1-1,5-2mm

Page 17

Release 1.0 - 24/04/2013

17

5.5. Damper setting

force [kg]

Speed

[mm/sec] bump min bump bump max rebound min rebound rebound max

20

14,35 15,60 16,85 -13,16 -14,30 -15,44

100

44,34 48,20 52,06 -50,05 -54,40 -58,75

160

58,88 64,00 69,12 -71,02 -77,20 -83,38

gas force measured at middle stroke = 15kg +-1,5kg

all measures are done at 30ºC shock temperature

Force (kgf)

-80

-60

-40

-20

0

20

40

60

-86,3

73,9

20 40 60 80 100 120 140

0,0 163,3

Velocity (mm/sec)

Page 18

Release 1.0 - 24/04/2013

18

5.6. Front antiroll stiffness setting

The front antiroll stiffness is set by a Belleville washer stack.

Belleville dimensions: diam 31.4 x 16.4mm thickness 1.75mm

Only following Belleville stacks with the corresponding spacers are allowed:

Stack Spacer

Stiffness

(daN/mm)

Max Deflection

(mm)

4x2 <<>><<>> 6x1 >>>>>>

444 2.4

5x2 <<>><<>><< 4x1 >>>>

355 3.0

6x2 <<>><<>><<>> 4x1 >>>>

296 3.6

7x2 <<>><<>><<>><<

254 4.2

8x2 <<>><<>><<>><<>>

222 4.8

9x2 <<>><<>><<>><<>><<

197 5.4

5x1 <><><

9x1

>>>>>>>>>

178 3.0

6x1 <><><>

7x1

>>>>>>>

148 3.6

7x1 <><><><

6x1

>>>>>>

127 4.2

8x1 <><><><> 5x1 >>>>>

111 4.8

9x1 <><><><>< 4x1 >>>> 99 5.4

10x1 <><><><><> 4x1 >>>>

89 6.0

11x1 <><><><><>< 81 6.6

12x1 <><><><><><> 74 7.2

13x1 <><><><><><>< 68 7.8

14x1 <><><><><><><> 63 8.4

15x1 <><><><><><><>< 59 9.0

16x1 <><><><><><><><>

56 9.6

Take care to respect the mounting direction of the Belleville stack with the

smaller diameter of the Belleville in contact with the preload nut.

If the Belleville stack needs a spacer, the spacer has to be mounted after the

Belleville stack with the bigger diameter in contact with the preload nut.

Page 19

Release 1.0 - 24/04/2013

19

5.7. Brakes

5.7.1. Discs / Pads bedding in procedure

•

During the first 2 laps do not over heat the new brake discs and pads.

Brake earlier than usually and with less brake pressure (50%)

Don’t be aggressive, warm progressively the brakes by small and frequent

braking: every 10 seconds.

•

After 2 laps, do half slow lap to cool down the brakes

•

Do again 2 laps like the first ones but with more brake pressure (75%)

•

Do half lap to cool down the brakes and so after 5 laps you can brake like

usualy.

5.7.2. Wear

Disc nominal thickness: 18.5mm

Disc minimal thickness: 16.5mm

5.8. Nosebox cap change

In case of nosebox cap damage, it’s possible to change it.

•

Cut the nosebox cap at the mentioned dimensions.

Around 20mm of the nose cap is still on the nosebox.

•

Unstick carefully this part of the nose cap.

Take care not to damage the main part of the nosebox.

•

Use “AR

ALDITE 2031” to bond the new nose cap.

For safety reason it’s forbidden to repair the nosebox if the honeycomb is

damaged.

Page 20

Release 1.0 - 24/04/2013

20

5.9. Tightening torques

Bolt and nut Nm

M5 10

M6 14

M8 25

M10 Roll Hoop 35

M10 40

M18 Wheel Nut 140

M20 Wheel Stud 180

Brake Bleeder 12

Page 21

Release 1.0 - 24/04/2013

21

6. ENGINE

•

Optimum water temperature: 90°C

•

Maximum water temperature: 105°C

•

Maximum oil temperature: 140°C

•

Revs limiter: 7200 rpm

•

Engine oil and filter oil change : every 2500km

•

Engine air filter cleaning: every 1000km

•

Engine must be checked in case of an 8000RPM over rev

Page 22

Release 1.0 - 24/04/2013

22

7. TRANSMISSION / GEARBOX

The SADEV SL66-14 gearbox, is a

sequential 5 front gears & one reverse

gear with cut off system. Its weight is

approximately 36 kg.

It is equipped with a bevel gear

differential.

7.1. Clutch bleeding procedure

Page 23

Release 1.0 - 24/04/2013

23

Oil level plug

7.2. Ratio charts

7.3. Lubrification

Oil capacity: 2.1 L (at drain plug level)

1rst drain Drain frequency Viscosity

After a 50Km running-in Each meeting 75W90

PARTICULAR PRECAUTIONS

No additives should be added to the oil. The

resulting consequences are not in any

circumstances covered by the SADEV supplier.

When topping up the gearbox oil, do not mix any

other oil with that already in the box.

Gear Ratio Ref.

11x35

1st

(0,314)

14x31

2nd

(0,451)

D669002036J6J1

18x30

3rd

(0,6)

C66141830606J

19x25

4th

(0,76)

C66141925606J

25x27

5th

(0,925)

C66142527606J

Final drive

Secondary

shaft

10

Crown

wheel

31

Reverse gear

Primary shaft

11

Reverse gear 16

Secondary

shaft

36

Page 24

Release 1.0 - 24/04/2013

24

1

FOUT90020081

Diff locking tool

4

3

STORAGE AND USE

Be particularly careful with any bottles which are open when used:

- Close the bottle again properly after use to prevent the introduction of

water or dirt.

- Store bottles horizontally, protected from severe weather.

- Do not store bottles close to a washing station.

- Do not decant the oil into larger containers.

WASHING UNDER PRESSURE

When the gearbox is removed, seal all openings correctly to prevent the ingress

of water into the gearbox.

7.4. Glue components

Glue components and tightening torque are shown in the rebuild section.

WARNING:

Glue components have been chosen during tests sessions. Only ‘Loctite’ brand

components must be used.

Consequences of false glue component choice can’t be ensured by Sadev.

7.5. Gears

Removing

-

Engage neutral

-

Drain the gearbox through the lower

plug (clean the oil level plug magnet)

-

Disconnect the potentiometer

-

Lock the differential using the dedicated

tool.

-

Remove the end cap (1) (4 M6 bolts)

Remove the secondary shaft nut (2) , its circlip

and stopping washer

Caution : It is left hand threaded.

-

Remove the back housing (3) (8 M7

nuts)

Page 25

Release 1.0 - 24/04/2013

25

2

5

9

8

6

7

Caution : The secondary shaft, only guided with taper roller bearing and rested

against the teeth, can drop a little.

-

Remove the fork axle (4).

-

Remove the gears 5th, 4th, 3rd, 2nd

& 1st and reverse wheels, and all

other parts of the primary and

secondary stacks.

-

Remove the reverse gear idler bolt

(5).

Caution : It is glued, so use a hot air

gun.

-

Remove the reverse gear idler

-

Remove the clutch shaft (7) (see

7.10)

-

Remove the primary shaft (6).

Reinstallation

-

Clean and check the conditions of the parts. Clean the mating surfaces of

the housings.

-

Reinstall the primary shaft

(support the clutch shaft to

slide the primary shaft)

-

Install the reverse gear idler

(tighten the reverse gear idler

bolt bonded with Loctite 648 to

5.5daN.m)

-

Reinstall all the parts in the

reverse order as for removing.

Lightly lubricate them with

gearbox oil before fitting.

-

Install the fork pin and make sure the fork actuating pins are in the

relevant barrel slots. (Tool FOUT0085003 and check the barrel is in neutral

position)

Set up the primary & secondary stacks clearance (you can do this

simultaneously).

-

Primary stack adjusting shim (8):

o If you did refit all the original parts, refit the original shim.

o If not : install the finest shim of the set (F90020181), and close the

gearbox (without glu or seal component & tighten the nuts moderatly).

o Remove the differential (see 7.7), and check the primary stack axial

clearance.

Page 26

Release 1.0 - 24/04/2013

26

o Choose the ideal adjusting shim (after setting, the primary line must be

tight form 0 to 0.1mm) re-install the differential, re-open the gearbox

and install it.

-

Secondary stack preload adjusting shim (9):

o In exclusion of wheels, wheels bearings, dogring & forks, if you did refit

all the original parts, refit the original shim.

o If not : install the thickest (2.5mm) shim of the set (F90020121), and

close the gearbox (without glu or seal component & tighten the nuts

moderatly).

o Tighten the secondary shaft nut to 18daN.m (left hand thread)

o Remove the differential (see 7.7), and check the secondary stack axial

clearance “X”.

o Calculate the shim thickness : 2.5mm – X. Choose the nearest thicker

shim, re-install the differential remove the secondary shaft nut, reopen the gearbox and install it.

-

Coat the rear housing mating surface with Loctite 518, and install it.

Thighten the M7 nuts to 2.2daN.m

-

Tighten the secondary shaft nut to 18daN.m (left hand thread), and install

its stopping washer & the circlip.

-

Coat the end cap mating surface with Loctite 518, and install it. Thighten

the M6 bolts bonded with Loctite 222 to 1.5daN.m

-

Reinstall and adjust the potentiometer

.

7.6. Selector

Removing the selector axle

-

Engage reverse gear

-

Drain the gearbox through the lower drain plug (Clean the drain plug

magnet)

-

Remove the external axle (1) (2 M7 bolts).

-

Remove the reverse gear unlocking cable.

-

Remove the control closing block with the cut off switch (2) (2 M7 bolts).

-

Remove the dual pin rock pusher (3) (2 M5 bolts)

-

Introduce a round magnet FACOM (4) in the pusher guide hole and raise

the dual pin rock making sure it is not in contact with the barrel.

-

Keeping the dual pin rock raised, make the selector axle turn ¼ of a turn

and extract it from the control closing block side.

Page 27

Release 1.0 - 24/04/2013

27

Reinstallation of the selector axle

-

Clean and check the conditions of the parts

-

Check the barrel is in reverse position. This position is visible when looking

at the barrel through the selector axle hole : in reverse position, there is a

notch on the barrel to let the selector axle go through.

-

Put the dual pin rock into the selector axle.

-

Insert the selector axle in the housing with the same position as when

removing it.

-

Drive in the selector axle until the spring is completely compressed, turn it

¼ of a turn (in the opposite way to removing) and check the double

ratchet is correctly installed in the barrel.

-

Install the dual pin rock pusher (3) (2 M5 bolts, Loctite 222, 0.5daN.m),

control closing block with the cut off switch (2) (2 M7 bolts, Loctite 222,

2.2daN.m), Remove the external axle (1) (2 M7 bolts, Loctite 222,

2.2daN.m) and the reverse cable, being careful to clean and degrease all

the screws

.

Removal of barrel

-

Engage neutral

-

Drain the gearbox through the lower drain

plug (Clean the drain plug magnet)

-

Remove the reverse gear unlocking cable &

the potentiometer

-

Remove the indexor (1)

-

Lock the differential using the dedicated tool

-

Remove the end cap (4 M6 bolts)

-

Remove the secondary shaft nut, its circlip

and stopping washer

Caution : It is left hand threaded.

2 3

1

4

2

1

4

3

Page 28

Release 1.0 - 24/04/2013

28

1

2

-

Remove the back housing (2)

-

Remove the fork pin (3) and disengage the forks to get out the fork

actuating pins from the barrel slots

-

Remove the barrel (4)

Reinstallation of the barrel

-

Clean and check the condition of the parts

-

Install the barrel taking care it’s resting well in its main housing bearing.

-

Adjust the barrel clearance:

o If you refit all the original parts, refit the original shim.

o If not : install the finest shim of the set (F90020041), and close the

gearbox (without glu or seal component & tighten the nuts

moderatly).

o Remove the differential (see 7.7), and check the barrel axial

clearance.

o Choose the ideal adjusting shim (after setting, the clearance must

be as near of 0mm as possible) re-install the differential & re-open

the.

-

Install the chosen barrel clearance adjusting shim

-

Check the barrel is in neutral position.

-

Install the fork pin and make sure the fork actuating pins correctly fit the

barrel slots. (Tool FOUT0085003)

-

Coat the rear housing mating surface with Loctite 518, and install it.

Thighten the M7 nuts to 2.2daN.m

-

Tighten the secondary shaft nut to 18daN.m (left hand thread), and install

its stopping washer & the circlip.

-

Coat the end cap mating surface with Loctite 518, and install it. Thighten

the M6 bolts bonded with Loctite 222 to 1.5daN.m

- Reinstall and adjust the potentiometer.

7.7. Differential

Removing

-

Engage the neutral

-

Drain the gearbox through the

lower drain plug (Clean the drain

plug magnet)

-

Remove the differential housing

(1) (11xM8 bolts)

-

Remove the differential (2)

Page 29

Release 1.0 - 24/04/2013

29

3

4

5

Rebuild operation

-

Remove the bevel gears stops (3)

(12xM6 bolts each)

-

Remove the bevel gears (4) noting

their mounting side.

-

Remove the dowel pins (5)

-

Remove the planet gears, their axles

and the nut.

-

Clean an check the good conditions

of the parts (change them if

necessary).

-

Reinstall the planet gears, their axles and the nut.

-

Reinstall new dowel pins.

-

Reinstall the bevel gear (taking care of their mounting side).

-

Reinstall the bevel gears stops. (for each one, tighten the 12xM6 bolts

bonded with Loctite 243 to 1.5DaN.m)

-

Before re-installing, check the condition of the final drive (crownwheel and

secondary shaft) and if necessary, change it (see 7.8)

Reinstallation

-

Clean the threads , bolts & mating surfaces of the differential & main

housings.

-

Install the differential.

-

Coat the differential/main housing mating surface with Loctite 518.

-

Install the differential housing (tighten the 11xM8bolts bonded with Loctite

222 to 2.2DaN.m)

-

Fill up the gearbox with oil to the Oil level.

7.8. Final drive

Removal

-

Engage neutral

-

Drain the gearbox through the lower plug (clean the oil level plug magnet)

-

Disconnect the potentiometer

-

Lock the differential using the dedicated tool. (FOUT90020081)

-

Remove the end cap (4 M6 bolts)

-

Remove the secondary shaft nut, its circlip and stopping washer

Caution : It is left hand threaded.

Page 30

Release 1.0 - 24/04/2013

30

2

1

4

3

1

-

Remove the differential (see 7.7)

-

Remove the gears (without primary shaft) (see 7.5)

-

Remove the secondary shaft

Secondary shaft

-

Set the secondary shaft advance :

-

Note the dimensions engraved

inside the main housing (about

109.5mm) and on the secondary

shaft (about 90mm)

-

Make the following operation :

housing dimension – shaft

dimension – 18 = shim thickness

-

Install the corresponding thickness shim (1), and the conical bearing on

the shaft (2).

-

Reinstall the secondary shaft and its gears (see 7.5).

Crownwheel

-

Remove the differential bearings (see

7.9)

-

Remove the crownwheel. (8xM10

bolts)

-

Clean and check the parts condition.

-

Install the new crownwheel (tighten

the M10 bolts bonded with Loctite 648

to 9DaN.m)

-

Install the differential bearings (see

7.9)

-

Check the two differential bearings

shim thicknesses, addition them and

note the result (B).

-

Set the final drive clearance :

-

Install the FOUT90020401 (1) tool, and

for each tooth of the tool, check the

final drive clearance

.

The average clearance must be of 0.1 to

0.2mm.

If the clearance is too high : make the crown

wheel and pinion closer by increasing the

spacer thickness at the ring gear side

(2) and

Page 31

Release 1.0 - 24/04/2013

31

decreasing the opposite spacer thickness (3) : you must keep the same total

thickness

If the clearance is too low : separate the crown wheel and pinion by decreasing

the spacer thickness at the ring gear side and increasing the opposite spacer

thickness : you must keep the same total thickness

-

Process again until getting good values.

-

Reinstall the gears (see 7.5)

7.9. Bearings

Primary shaft bearings

-

Remove the primary shaft (see 7.5)

-

Remove the bearing (2) and spacer

(3) on primary shaft using a press,

taking care not to damage it

-

Clean and check the condition of

bearing journal

-

Fit the new bearing using a press

making sure it is correctly seated on

its journal.

-

Fit the spacer making sure it is well

positioned against the bearing inner

race.

-

Refit a new dowel pin

-

Remove the back housing lip seal

-

Heat the back casing using a hot air gun to approximately 120°C

-

Position an extractor FACOM (ref. U.49AD5) on the primary shaft bearing

loosened in the back casing and extract it with a slide hammer

3

2

3

2

Page 32

Release 1.0 - 24/04/2013

32

4

-

Clean and check the conditions of the bearing journal

-

Put the new bearing using a press (or heating the shaft to approx. 120°C)

making sure it is correctly seated in its housing

-

Install a new lip seal in the back housing.

-

Install the primary shaft and set up the primary line shims (see 7.5)

Barrel bearings

-

Remove the barrel (see 7.6)

-

Remove the barrel bearing (4)

using a press and taking care

not to damage it

-

Clean and check the condition

of the bearing journal

-

Install the new bearing using a

press and making sure it is well

positioned against the shoulder

-

Remove the back casing lip seal

-

Heat the back casing using a hot air gun to approximately 120°C

-

Position an extractor FACOM (ref. U.49AD5) on the primary shaft bearing

loosened in the back casing and extract it with a slide hammer

-

Clean and check the conditions of the bearing journal

-

Put the new bearing using a press making sure it is correctly seated in its

housing

-

Install the lip seal in the back housing after checking its condition

-

Reinstall the barrel (see 7.6)

Secondary shaft bearings

-

Remove the differential and the

secondary shaft (see 7.8)

-

Remove the front plate (1) (11xM6

bolts)

-

Remove the back casing lip seal

-

Heat the back casing using a hot air

gun to approximately 120°C

-

Extract the external ring from the

back casing by hitting the ring

through the oil way hole

-

Clean and check the condition of the

bearing journal

-

Fit the new ring using a press and

1

Page 33

Release 1.0 - 24/04/2013

33

2

making sure is correctly seated in its housing

-

Install the lip seal in the back housing after checking its condition

-

Extract the external ring from the main casing hitting the ring by the 3

dedicated holes (2)

-

Clean and check the condition of the bearing journal

-

Put the new ring using a press and making sure is correctly seated in its

housing

-

Remove the secondary shaft bearing using possibly the tool FACOM (ref.

U.53T1) taking care not to damage the bearing journal

-

Clean and check the condition of the bearing journal

-

Install the new bearing using a press and making sure it is well positioned

against the spacer adjuster

-

Reinstall the differential and the gears (see 7.5)

-

Reinstall the front plate. (tighten the 11xM6 bolts bonded with LOCTITE

222 to 0.5DaN.m)

Differential bearings

-

Remove the differential (see 7.7)

-

Remove the differential case

bearings (1) using a press and

taking care not to damage it

-

Clean and check the parts

condition.

-

Fit the new bearings using a

press making sure it is correctly

seated on its journal.

2

1

2

1

Page 34

Release 1.0 - 24/04/2013

34

-

Set the bearings preload (only if you changed the main housing, the

differential housing, the differential case or the bearings):

Caution : You will have to set the final drive clearance too (see §6-4-3).

-

Install the differential and the thinnest shims (2) (1.5mm) between each

bearing and its housing.

-

Install the differential housing, tightening the bolts moderately.

-

Measure the axial clearance of the differential “A”.

Note : It is tight mounted, so you will have to push hard from one side and then

from the other of de differential case to check the clearance.

-

Make the following operation : A+3mm+0.1mm=B

Caution : Note it, this is an important measure for the final drive clearance set

up.

-

Remove the differential.

-

Reinstall the differential (see 7.7). On each side, use shim thicknesses

equal to B/2.

7.10. Clutch shaft

Removal

-

Drain the gearbox through

the lower drain plug (Clean

the drain plug magnet)

-

Remove the lip seal from

the front side of the

gearbox

-

Remove the circlip which

retains the clutch shaft

bearing

-

Remove the clutch shaft

Reinstalling

-

Clean and check the conditions of the parts

-

Reinstall the clutch shaft inserting it in the primary shaft (mesh a speed

and lock the differential if necessary)

-

Reinstall a circlip to lock the clutch shaft bearing

-

Reinstall a new lip seal

1

2

Page 35

Release 1.0 - 24/04/2013

35

7.11. Rebuilding of the gearbox

In Sadev workshop rebuilding

Notes :

-

The gearboxes are delivered leaded and numbered.

-

The absence of lead 'Sadev' imposes a careful attitude in the event of

minor or major problem to us, and applies to complete reserve of our

share if necessary.

Return gear boxes to revision :

At the time of the return of the gearboxes in our buildings, a certain procedure of

delivery has to be respected, so that our intervention can be total, and practical

(casing ' closed' for passage to the bench).

We must receive the complete product as described below:

-

Release bearing in place

-

entry and exit of lubrication closed by plugs envisaged for this purpose

(Goodridge, SpeedFlow…)

-

Gear box drained and cleaned

-

Drain plug and drain plug seal in place

-

Differential in place

-

A card specifying the kilometers of the special stage and connection since

the last service, available near our sales department

The absence of elements can be specified on the card, but in case of doubt, the

material will be send back re-equipped.

Administrative procedure:

1. Send a request for service to SADEV sales department

2. Forward The material and its card (description above) in our workshops

3. Approve the estimate presented by SADEV sales department

4. APPROXIMATELY 2 TO 3 WEEKS OF DELIVERY TIME MUST BE

CONSIDERED

Personal revision:

After sale parts for customers who want to proceed a revision by themselves, are

delivered only by SADEV sales service.

SADEV IS NOT RESPONSIBLE FOR ANY DAMAGE FOLLOWING A REVISION NOT

EXECUTED IN A SADEV AGREED TECHNICAL SERVICE (LIST ON DEMAND).

As every mechanical part which is dedicated for racing, there

is not warranty at all from our side.

Page 36

Release 1.0 - 24/04/2013

36

7.12. Gear shift setup

-

Pull the gear shift level to upshift. No need to use clutch and to throttle off.

The ignition cut is automatic and has to be set-up.

There is a switch cut on the left side of the gear box at the end of the

barrel drive axle. It’s screwed with shims to adjust its position. Each car is

delivered with a set of shims. When reducing the thickness of the shims,

the ignition cut is earlier in the level movement.

-

As soon as the barrel drive axle starts moving (first mm), the ignition has

to be cut off. It’s possible to check the cut off position without running

engine.

-

Switch ignition on. The EDiag LED on the right of the dashboard is

flashing. When pushing the barrel drive axle, the LED turns on

permanently.

Page 37

Release 1.0 - 24/04/2013

37

8. ELECTRONICS

8.1. Dashboard

8.1.1. Driver pages

Three driver pages are available.

You can change the driver pages by pushing the red button.

Mechanic

Diag/EC

Revs - Direction

Revs - Direction

Validatio

Increment

Decrement

Page change and

Shift

Alarm

pulse on the red button

pulse on the red button

pulse on the red button

Page 38

Release 1.0 - 24/04/2013

38

Diag menu

One of the

three

driver pages

Laptime

Min/max

Alarm

Custom

Laptime

displaying screen

Min/Max

displaying screen

Time alarm

displaying screen

Mechanic

page 1

Mechani

c page 2

-

The color of the arrows corresponds to

the color of the BP

-Simple arrow = short pulse

-Double arrow = long pulse

8.1.2. Diag pages

To access to the different Diag pages :

-

Hold the green button down until this page appears :

-

-

Move the cursor with the blue or yellow button to access the 4 different

Diag (Lap time ; Mini/Maxi ; Alarm ; Custom).

-

When the cursor is located on the Diag you want, press the green button

to display the page, and scroll it.

-

Push the red button to exit.

Details on the 4 Diag pages:

•

Lap time: displays the lap times made.

Sec: indicates the session by a letter.

Lap: indicates which lap of the session.

Time: indicates the lap time.

Start time of the lap

Date of the lap

Page 39

Release 1.0 - 24/04/2013

39

With the blue or yellow button, you can select a lap time. The date

and beginning hour of this lap are displayed in the two little windows

located on the right.

•

Mini-Maxi: mini and maxi values of each parameter are displayed.

To display all the parameters, scroll with the blue or yellow button.

You can reset the values by pressing the blue and yellow buttons

simultaneously until crosses (x) appear.

•

Alarm: displays how long, in seconds, the parameter has remained

in "alarm" .

To display another parameter, scroll by pushing the blue or yellow

buttons.

To reset the alarms completely, just press the blue and yellow

buttons simultaneously, until the length figures are back to zero (all

the duration of the different parameters will be reset at the same

time).

•

Custom: these pages allow to display other parameters in "real

time".

Push the green button to scroll down.

8.1.3. Diag CAN

You can access to the diag can page by pushing simultaneously the blue and

yellow button when the dash is displaying the first mechanic page.

Mechanic

page

1 Mechanic

page 2

Page 40

Release 1.0 - 24/04/2013

40

8.1.4. Display settings

To reach the display settings, press together the red and green buttons and hold

them down until the page appears. To move within the different parameters, you

have to use the green button. To change the value, you need to press the blue

button in order to set the value down, and the yellow one to rise it up. Values go

from 1 to 10.

•

Contrast: to setup the shade between the screen background and the

written indications.

•

Backlight: to modify the brightness of the screen background.

•

Led: to set up the brightness of the LEDs.

•

Day and night: Set up for night or daylight.

8.1.5. Dash configuration

To reach the configuration menu, push the green button before to raise the

ignition switch. Once the page is displayed, move the cursor with the blue or

yellow buttons. When the cursor is on the parameter to tune, use the green

button to validate and the red one to exit.

Configuration

menu

Driver

Led

Gear

Rpm+Speed

Led

config.

screen

Gear

config.

Rpm + Speed

config. screen

About…

About… screen

Alarm

Alarm

config.

Beacon

Beacon

config.

-The color of the arrows

corresponds to the color of the BP

-Simple arrow = short pulse

-Double arrow = long pulse

Push the green button

before to raise the ignition

switch

Page 41

Release 1.0 - 24/04/2013

41

Details on the configuration pages:

•

Beacon: to set up the timing parameters.

Press the green button to select one of the three parameters and

the blue or yellow one to adjust the time in seconds.

Min lap time: to set the minimum gap time between two laps (to avoid

in between beacons on the track).

Display delay: to set the delay in seconds, between the time the

beacon is set off and the lap time displayed on the screen.

Display time: to set the length of time, during which the lap time

remains displayed.

•

Alarms: to set the min and the max values of warning of the

different parameters.

You go from one value to the other by pushing the green button and

you adjust the value thanks to the blue and yellow buttons (the unit

value is displayed next to the given parameter).

•

Gear: to set the minimum and maximum of each gear (in volt)

In the little window on the right, you have the voltage value given

by the barrel potentiometer for the current gear engaged (R; N; 1).

Setting example : for the first gear

-

Put the first gear

-

Check the value displays in the box current input

-

Move the cursor with the green button on the first row

-

Adjust the min and max values to “frame” the current input

value with the blue or yellow button

.

NB: keep a little margin between the max value of a gear and the

min value the following gear.

Page 42

Release 1.0 - 24/04/2013

42

•

Led: to set the revs leds and the shift led switch on (on top of the

dash).

You switch from a value to the other by pushing the green button

and you tune the value with the blue and yellow buttons.

Bargraph first led: to set the first bargraph led (green) switch

on.

Bargraph last led: to set the last bargraph led (orange) switch

on.

Led shift:

to set the revs (rpm) for which the shift led lights.

•

RPM+Speed:

Allow to adjust the number of top per rotation on engine target for

the calculation of the engine revs, and the number of top per

rotation on the wheel target and the circumference of the wheel (in

mm) for the calculation of the vehicle speed.

You switch from one value to the other by pushing the green button,

and you adjust the value with the blue and yellow buttons.

•

About:

This window contains information about the Firmware used in this

Dash, the date of the firmware and the appliance specific

configuration.

Page 43

Release 1.0 - 24/04/2013

43

8.1.6. Synthesis operation

Configuration

menu

Diag menu

Home

Screen

Delay 3s

Driver

Page 1

Driver

Page 2

Driver

Page 3

Laptime

Min/max

Alarm

Custom

Laptime displaying screen

Mini maxi displaying screen

Time alarm displaying screen

Mechanic

page 1

Mechanic

page 2

Led

Gear

Rpm +Speed

Led config screen

Gear config screen

Rpm + Speed

config screen

About…

About… screen

Can

Diag

Alarm

Alarm config screen

Beacon

Beacon config screen

To access the config.

menu : Push the green

button before to raise the

ignition switch

Page 44

Release 1.0 - 24/04/2013

44

8.2. Details of the transponder connector

DTM04-2P connector

Pin1: +12V

Pin2: Ground

8.3. Composition of the PI Data system kit

•

One PI compact logger Signatech spec with an integrated lateral

accelerometer

•

One compact flash card

o Note: This card must not exceed 2GB memory

•

One steering angle sensor with its fastening

•

Two wheel speed sensors

•

Two brake pressure sensors with its hoses, bleeders and support

•

One beacon receiver

•

The PI Toolbox and Pectel Card Management sofwares

Loading...

Loading...