Renault 32 661 Service Manual

RENAULT TRUCKS

32 661 - GB -

10/2004

GEARBOX OPTIDRIVER 2

RANGE FAMILY VARIANT

RENAULT MAGNUM

DXi 12

440 - 480

The above information may change in the course of time. Only the "Consult" section of the workshop manuals

repertory in standard N° 10320 serves as reference.

17RD

150FX17SD

17TD

32 661

32.6

32.6 . . . .

32.6 . . . .

50 21 014 334

32 661

CONTENTS

Generalities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1 →→→→ 15

Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1 →→→→ 3

— General features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B1-5 → 6

— Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B2-1 → 5

— Dimensions and tolerances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B3-1 → 1

Tools / Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1 →→→→ 14

Stripping and mounting on stand. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-1 →→→→ 3

— Clutch slave cylinder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D1-3 → 4

— Mounting on stand N° 1000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D2-1 → 2

— Stripping the gearbox on stand N° 1000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D3-1 → 8

1

Primary shaft and output shaft seals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E-1 →→→→ 7

Dismantling of the gearbox. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .F-1 →→→→ 15

Transmission control unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G-1 →→→→ 13

Oil pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H-1 →→→→ 5

Range change. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1 →→→→ 16

Primary shaft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . J-1 →→→→ 6

Secondary shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .K-1 →→→→ 11

Reverse shaft . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . L-1 →→→→ 4

Countershaft. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . M-1 →→→→ 7

Assembly of the gearbox. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .N-1 →→→→ 19

© RENAULT TRUCKS SA 10/2004 - Imprimé en France - le 11/2004

50 21 014 334

32 661

A-1

GENERALITIES

RENAULT TRUCKS 10/2004

A-2

32 661

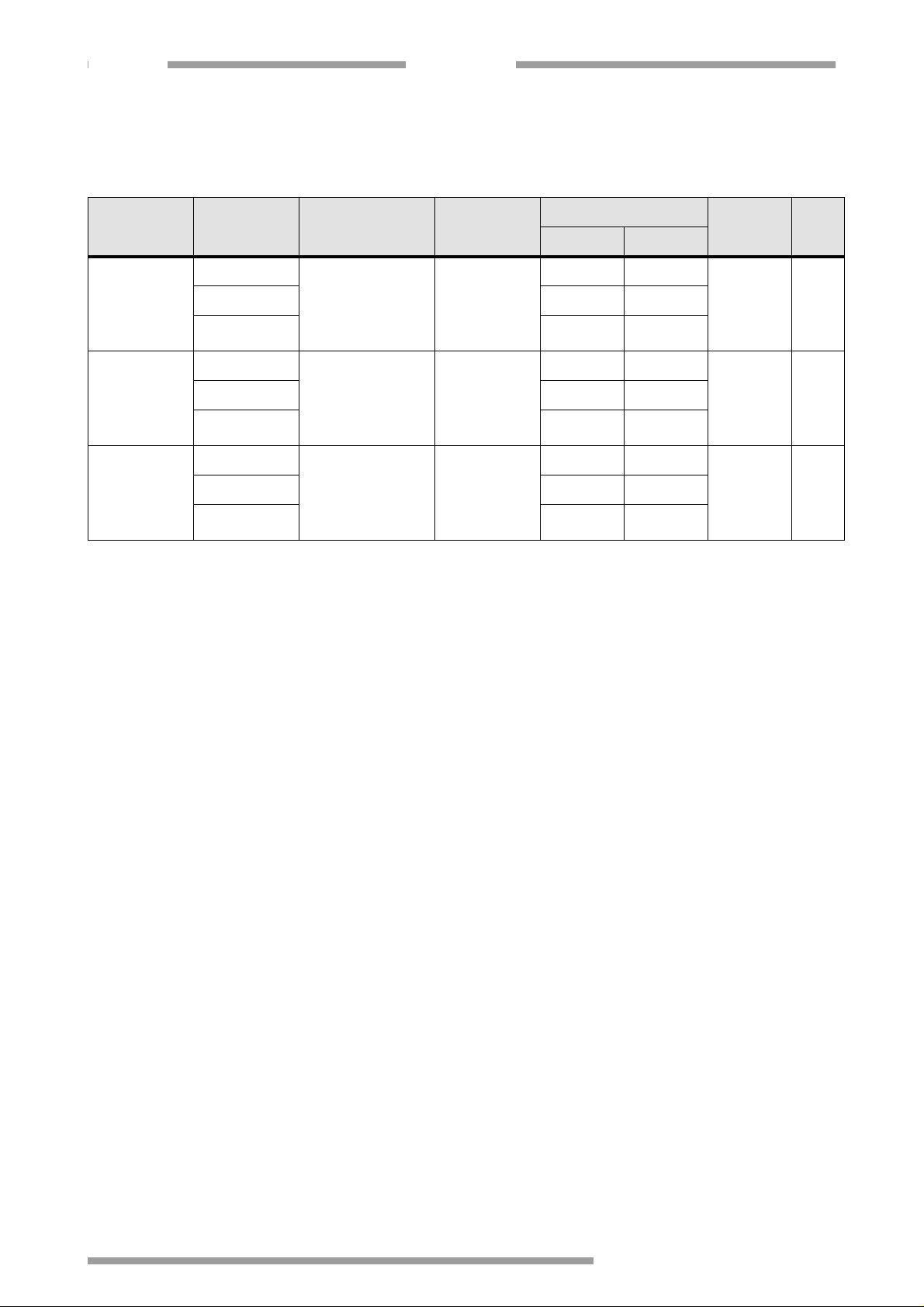

APPLICABILITY

Range Family Title Variant

RENAULT

MAGNUM

DXi 12

440 - 480

RENAULT

MAGNUM

DXi 12

440 - 480

RENAULT

MAGNUM

DXi 12

440 - 480

RENAULT

MAGNUM

DXi 12

440 - 480

RENAULT

MAGNUM

DXi 12

440 - 480

17RD

17SD

17TD

17RD

17SD

17TD

17RD

17SD

17TD

17RD

17SD

17TD

17RD

17SD

17TD

Warnings 150FX 31/03/2003 A-3

Conventional

symbols

General

instructions

Presentation

of the gearbox

Transmission

control unit

150FX 23/05/2002 A-4

150FX 07/10/2002 A-6

150FX 28/08/2003 A-7

150FX 28/08/2003 A-8

Applicability date

Start End

Updating

Page

N°

RENAULT

MAGNUM

DXi 12

440 - 480

RENAULT

MAGNUM

DXi 12

440 - 480

RENAULT

MAGNUM

DXi 12

440 - 480

RENAULT

MAGNUM

DXi 12

440 - 480

RENAULT

MAGNUM

DXi 12

440 - 480

17RD

17SD

17TD

17RD

17SD

17TD

17RD

17SD

17TD

17RD

17SD

17TD

17RD

17SD

17TD

Countershaft

disc brake

Power flow diagram 150FX 27/08/2003 A-11

Lubrication system 150FX 24/06/2003 A-13

Sensors and

electrical

connections

Sensors and

ompressed air

system unions

150FX 29/08/2003 A-10

150FX 24/06/2003 A-14

150FX 24/06/2003 A-15

RENAULT TRUCKS 10/2004

32 661

Warnings

In this document, safety instructions are symbolized as follows:

DANGER! NON-OBSERVANCE OF THE PROCEDURE DESCRIBED OR LACK OF CARE OR ATTENTION, RISK CAUSING

SERIOUS INJURY OR EVEN DEATH.

WARNING! Any different or inappropriate working method risks causing damage to the product.

NOTE! Draws attention to particular or important points of the method.

A-3

Comply without fail with the regulations in force relative to the recovery and treatment of used parts and

waste.

RENAULT TRUCKS 10/2004

A-4

Conventional symbols

Fitting

Tighten to torque (Nm) (left-hand thread) Tighten by indicated value

Tighten to torque (Nm) (right-hand thread) Loosen by indicated value

Tightening torque with lubricated threaded

hardware

Dimensioning

Tightening ... Greater than or equal to ...

Equal to Wear limit

32 661

Repair

... Less than ... Machining limit or dimension

... Greater than ... Maximum out-of-true

... Less than or equal to ... Maximum parallelism error

Force to be exerted in the direction shown

(hammer - press)

Heat or cool: Temperature in degrees

Celsius (e.g. + 80 °C)

Weld bead Grease or oil (see "Consumables" table)

Repair time - Heating time Mark - Assemble according to marking

Smear or coa t (see "Consumables" t able)

Fill to level (see "Technical Data" and

"Consumables" table)

RENAULT TRUCKS 10/2004

Adjustment

32 661

Rotating friction torque Turn anti-clockwise

A-5

Turn in alternate direction s

Turn clockwis e

Place in contact Move in the direction shown

Dimension to be assured (mm)

Various information

Exhaust - Outlet Operation with a sequence

Intake - Inlet Involves

Weight in kg (example: 275 kg)

Turn anti-clockwise (the figure shows the

number of turns)

Turn clockwise (the figure shows the

number of turns)

Return to numbered operation Connected with numbered operation

Depending on versions or options Withdraw - Delete

Wrong

Correct

Injection ... to ...

Repair dimension Inspect - Check condition of part

Part to be replaced Danger for persons, vehicle or equipment

Direction of disassembly

(the arrow shows the direction)

Direction of assembly

(the arrow shows the direction)

RENAULT TRUCKS 10/2004

A-6

32 661

General instructions

Practical advice

Prior to any work:

– Clean the major unit and its surrounds (See Driving Servicing Handbook, "Vehicle washing").

– Ensure the batteries are disconnected.

– Mark the pipes and wiring harnesses, if necessary.

– Protect all ports to prevent the ingress of foreign matter.

– Before disconnecting an air pipe, drop the circuit pressure.

– If liquid is splashed onto the bodywork, clean quick l y with a cl ea nin g pr odu ct rec om men ded by RENAULT

TRUCKS.

Preparation prior to assembly:

Carefully clean and check all the parts.

Do not unpack a new bearing until you are ready to install it. Do not clean off the protective grease on new

bearings.

Old seals and lock-plates must be discarded and new ones fitted.

Never force fit parts with copp er or brass punches or drifts. Alway s use a specially adapted driver to prevent

ingress of metal particles into the casings and bearings. Always oil parts prior to force fitting.

Always apply grease on the inside of seal ring lips.

Shrink fitted parts are to be heated with a hot air blower or in an oven. etc. Flame heating is strictly forbidden.

When using a torque multiplier, calibrate the torque wrench/multiplier unit at the required torque loading.

Fastening, locking, sealing and adhesive products:

Prior to assembly, carefully clean the product application surfaces of the parts. Old product residue is to be

removed. Threaded portions are to be brushed, tapped and, if necessary, cleaned with a suitable product.

Using the product:

Always adapt the recommended product while observing the utilization conditions appearing on the pack:

– Surface finish,

– Working temperature,

– Reaction, drying, etc. time,

– Shelf life.

Observe the assembly method so as to guarantee the quality of the repair.

RENAULT TRUCKS 10/2004

Presentation of the gearbox

32 661

A-7

The gearbox consists of 3 main parts.

– The clutch casing (7), which also serves as front wall for the gearbox.

– The basic gearbox casing (13), which contains the primary shaft, the secondary shaft, the countershaft, the

reverse shaft, the selector mechanism integrated in the transmission control unit, together with the range

change and the splitter.

– The range change casing (3), which contains the epicyclic gear train for the range change and the output

shaft (10).

The principal gearbox parts are:

– Primary shaft (8),

– Secondary shaft (9),

– Range change (10), with selector mechanism (4),

– Intermediate shaft (11), with disc brake (6),

– Reverse shaft (12), with oil pump drive shaft (5),

– Transmission control unit (1), with gear change mechanism.

The countershaft and reverse shaft gears and all the basic gears are on the secondary shaft, with the range

change sun gear on the secondary shaft. The countershaft gears are fixed.

The range change, which consists of an epicyclic gear train forms integral part of the output shaft.

The oil pump drive shaft forms integral part of the reverse shaft.

RENAULT TRUCKS 10/2004

A-8

32 661

Transmission control unit

The transmission control unit is located above the gearbox.

The gears are selected by means of the gear selector. When a gear

is selected, the system first of all reduces the engine torque to an acceptable level and the gearbox is put into neutral.

When the gearbox is in neu tral, t he e ngi ne s pe ed i s adjus ted s o a s

to choose the correc t engine speed for the gear se lected and the

gear is then engaged.

The control unit casing cover serves to house the following components:

– 3 electrical connections,

– 1 transmission control unit (TECU),

– 9 solenoid valves,

– 1 pressure sensor.

The control unit casing cover includes 3 electrical connections:

– I: vehicle communication ,

– II: retarder,

– III: clutch.

The control unit casing cover serves to house 9 solenoid valves:

– 1: solenoid valve 1

– 2: solenoid valve 2

– 3: solenoid valve 3

– R: reverse solenoid valve

– B: disc brake solenoid valve,

– LR: low range solenoid valve,

– HR: high range solenoid valve,

– HS: high split solenoid valve,

– LS: low split solenoid valve.

st

gear,

nd

gear,

rd

gear,

RENAULT TRUCKS 10/2004

32 661

The following are located in the control unit casing:

– 4 parallel cylinders: splitter, 2/3, 1/R and range change,

– 4 induction sensors for the piston positions,

– 2 speed sensors, one for the secondary shaft and another for

the countershaft,

– 1 oil temperature sensor and selector forks for the splitter and

basic gearbox casing.

A: splitter cylinder

B: 1/R cylinder

C: 2/3 cylinder

D: range change cylinder

E: splitter cylinder posit ion sens or

A: range change cylinder position sensor

B: countershaft speed sensor

C: secondary shaft speed sensor

nd

D: 2

and 3rd gears cylinders position sensor

st

E: 1

and reverse gears cylinders position sensor

A-9

RENAULT TRUCKS 10/2004

A-10

32 661

Countershaft disc brake

The countershaft disc brake is placed at the front of the gearbox, on

the end of the countershaft. It is designed to brake gearbox rotating

components when a moving off gear is activated. This device serves

to eliminate wear, noise and fr iction in the gear box. The dis c brak e

is activated by an built-in air-operated ram.

RENAULT TRUCKS 10/2004

Power flow diagram

st

1

gear 2nd gear

32 661

A-11

rd

3

gear 4th gear

th

gear 6th gear

5

th

7

gear 8th gear

RENAULT TRUCKS 10/2004

A-12

32 661

th

9

gear 10th gear

th

11

gear 12th gear

Reverse R1 Reverse R2

Reverse R3 Reverse R4

RENAULT TRUCKS 10/2004

Lubrication system

32 661

A-13

The gearbox is lub ri cated by a co mbi na tio n of splash (for th e coun ter s haft and th e r ever s e s haf t) and by an oi l

pump (A) (for the primary shaft, the secondary shaft and the range change).

An oil filter (B), of the cartridge type, is fitted on the delivery side of the oil pump. It is located on the filter housing

and is accessible from the outside. The filter is protected by a cover located on the range change casing.

The oil is delivered to the secondary shaft to lubricate and cool the range change gears as well as the primary

shaft and secondary shaft bearings.

RENAULT TRUCKS 10/2004

A-14

32 661

Sensors and electrical connections

I: vehicle communication

II: retarder

III: clutch servo control

A: speed sensor

Wiring connecting the control unit connector (II) to the retarder.

Wiring connecting the control unit connector (I) to the speed sensor

and to the chassis wiring.

Wiring connecting the control unit connector (III) to the clutch servo

control.

RENAULT TRUCKS 10/2004

32 661

Sensors and compressed air system unions

Compressed air connections between the control unit and the clutch

servo control.

Compressed air connections between the control unit and the

countershaft disc brake .

A-15

Compressed air connections between the control unit and the

compressed air tank.

RENAULT TRUCKS 10/2004

A-16

32 661

RENAULT TRUCKS 10/2004

32 661

B1-1

TECHNICAL DATA

RENAULT TRUCKS 10/2004

B1-2

General features

32 661

APPLICABILITY

Range Family Title Variant

RENAULT

MAGNUM

DXi 12

440 - 480

RENAULT

MAGNUM

DXi 12

440 - 480

RENAULT

MAGNUM

DXi 12

440 - 480

17RD

17SD

17TD

17RD

17SD

17TD

17RD

17SD

17TD

Identification plate 150F X 09/10/200 3 B1-5

Generalities 150FX 19/06/2003 B1-6

Gearing 150FX 19/06/2003 B1-6

Applicability date

Start End

Updating

Page

N°

RENAULT TRUCKS 10/2004

Tightening torques

32 661

B1-3

Range Family Title Variant

RENAULT

MAGNUM

DXi 12

440 - 480

RENAULT

MAGNUM

DXi 12

440 - 480

RENAULT

MAGNUM

DXi 12

440 - 480

RENAULT

MAGNUM

DXi 12

440 - 480

RENAULT

MAGNUM

DXi 12

440 - 480

17RD

17SD

17TD

17RD

17SD

17TD

17RD

17SD

17TD

17RD

17SD

17TD

17RD

17SD

17TD

Definitions 150FX 08/04/2004 B2-1

Standard nut and

bolt tightening

torques table

Basic gearbox 150FX 19/06/2003 B2-3

Transmission

control unit

Range change 150FX 19/08/2003 B2-4

150FX 08/04/2004 B2-2

150FX 19/08/2003 B2-3

Applicability date

Start End

Updating

Page

N°

RENAULT

MAGNUM

DXi 12

440 - 480

RENAULT

MAGNUM

DXi 12

440 - 480

RENAULT

MAGNUM

DXi 12

440 - 480

RENAULT

MAGNUM

DXi 12

440 - 480

RENAULT

MAGNUM

DXi 12

440 - 480

17RD

17SD

17TD

17RD

17SD

17TD

17RD

17SD

17TD

17RD

17SD

17TD

17RD

17SD

17TD

Clutch slave

cylinder

Retarder 150FX 22/08/2003 B2-4

Heat exchanger 150FX 22/08/2003 B2-4

Oil pump 150FX 04/03/2004 B2-5

Oil filter 150FX 11/03/2004 B2-5

150FX 22/08/2003 B2-4

RENAULT

MAGNUM

DXi 12

440 - 480

17RD

17SD

17TD

RENAULT TRUCKS 10/2004

Countershaft 150FX 20/06/2003 B2-5

B1-4

Dimensions and tolerances

32 661

Range Family Title Variant

RENAULT

MAGNUM

DXi 12

440 - 480

RENAULT

MAGNUM

DXi 12

440 - 480

RENAULT

MAGNUM

DXi 12

440 - 480

RENAULT

MAGNUM

DXi 12

440 - 480

17RD

17SD

17TD

17RD

17SD

17TD

17RD

17SD

17TD

17RD

17SD

17TD

Shafts 150FX 19/06/2003 B3-1

Oil pump 150FX 08/03/2004 B3-1

Range change 150FX 08/03/2004 B3-1

Primary shaft 150FX 08/03/2004 B3-1

Applicability date

Start End

Updating

Page

N°

RENAULT TRUCKS 10/2004

General features

Identification plate

– 1: Component designation

– 2: Spare part number

– 3: Service category

– 4: Factory part number

– 5: Gearbox serial number

Component symbolization

32 661

B1-5

V VOLVO

T Transmission

24 Maximum torque = 2400 Nm

12 Number of forward speeds

B Model

Serial number details

2001 Year of manufacture

40 Week of manufacture

1 Day of week

0001 Manufacturing sequence number

RENAULT TRUCKS 10/2004

B1-6

32 661

Generalities

Make VOLVO

Type VT2412BGSS-AGS non synchromesh

Range change Synchromesh

Splitter Synchromesh

Number of speeds

Forward 12

Reverse 4

Weight without oil 265 kg

Length 916 mm

Gearing

Gear position Step-down ratio

1

2

3

4

5

6

7

8

9

10

11

12

st

nd

rd

th

th

th

th

th

th

th

th

th

14.94:1

11.73:1

9.04:1

7.09:1

5.54:1

4.35:1

3.44:1

2.70:1

2.08:1

1.63:1

1.27:1

1.00:1

Reverse R1/R2 17.48/13.73:1

Reverse R3/R4 4.02/3.16:1

RENAULT TRUCKS 10/2004

32 661

B2-1

Tightening torques

Definitions

Tightening torques

There are several types of tightening:

– Tightening to torque (in Nm)

– Tightening to angle (in °)

– Tightening to torque-angle (in Nm + °)

Torq ues gi ven in Nm are nominal torques (average value calculated on the basis of the minimum torque and the

maximum torque).

The tightening precision class defines the tolerance of this torque in percent as a function of the nominal torque

applied.

For standard threaded hardware, use the following table.

For other torques, see the following page(s).

"FIH" type (Nylstop) locknuts must be replaced whenever removed. "DRH" type (oval) locknuts can be reused. If locknuts (DRH, FIH or other) are re-used, make absolutely certain that the screw-thread of the bolt

protrudes least two threads above the top edge of the nut.

RENAULT TRUCKS 10/2004

B2-2

32 661

Standard nut and bolt tightening torques table

The tightening torque values given in the table are based on standard 01.50.4002 and apply to new nuts and bolts

fitted dry and re-used nuts and bolts with oil applied to the screw-threads. If any nuts and bolts are replaced, it is

absolutely essential to use nuts and bolts recommended by th e RENAULT TRUCKS Spare Parts Departmen t

(coefficient of friction in compliance with standard 01.50.4002).

Tightening torques for conventional nut and bolt hardware to "metric system"

standard 01.504.002 (H: normal and HE: flanged)

Diameter and pitch

of nuts and bolts

6 x 1.00

8 x 1.25

10 x 1.50

12 x 1.75

14 x 2.00

16 x 2.00

18 x 2.50

20 x 2.50

22 x 2.50

24 x 3.00

Quality class 8.8 Quality class 10.9

10 ± 1.5

24 ± 4

48 ± 8

85 ±15

140 ± 25

220 ± 35

290 ± 45

430 ± 70

580 ± 90

740 ± 120

12 ± 2

30 ± 5

60 ± 10

105 ± 20

175 ± 30

275 ± 45

360 ± 55

540 ± 90

730 ± 120

900 ± 140

RENAULT TRUCKS 10/2004

Basic gearbox

32 661

B2-3

Oil drain plug 35

±±±±5

Nm

Fan shroud union, oil filler 2 turns min. through 45° upwards

Clutch casing to basic gearbox casing securing bolt

(tighten in diametrically opposed sequence).

M16,

M12.

Oil cooler securing nut 50

Primary shaft cover securing bolt 50

Secondary shaft cover securing bolt

200

75

40

±±±±25

±±±±10

±±±±5

±±±±5

±±±±5

Nm

Nm

Nm

Nm

Nm

(tighten in diametrically opposed sequence).

±±±±5

Countershaft cover se cu ring bol t

40

Nm

(tighten in diametrically opposed sequence).

±±±±5

Countershaft disc brake cover securing bolt 50

Nm

Countershaft disc brake air pipe union Tighten by hand then through3/4

of a turn.

±±±±3

±±±±4

±±±±1.5

±±±±3

+20/-10

±±±±5

±±±±5

±±±±3

±±±±5

±±±±2

±±±±2

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Countershaft disc brake pipe fastener securing bolt 20

Brake pipe union 25

Slave cylinder securing stud 8

Reverse gear cover securing bolt 20

Clutch fork securing bolt 120

Oil level sight: should not normally be loosened. 35

Aspiration pipe anchorage securing bolt 40

Aspiration pipe flange securing bolt 20

Oil pressure sensor notched plug 25

Temperature sensor 18

Isolating plates securing bolt 8

Transmission control unit

Control unit to basic gearbox casing securing bolt

(tighten in diametrically opposed sequence).

Control unit cover securing bolt 24

Countershaft and secondary shaft speed sensors securing bolts 6

Wiring harness guide securing bolt 6

Gear selection and step-down cylinders securing bolt 18

Gear selection cylinders position sensors securing bolt 7

RENAULT TRUCKS 10/2004

75

±±±±10

±±±±4

±±±±0.6

±±±±0.6

±±±±1.5

±±±±0.7

Nm

Nm

Nm

Nm

Nm

Nm

B2-4

Range change

32 661

Range change to basic gearbox casing securing bolt 75

Speed selector fork locking bolt, burred with a centre-punch to lock,

then lubricated at the time of tightening.

Output shaft speed sensor 25

Flange nut, burred with a centre-punch to lock 400

PTO cover securing bol t

(tighten in diametrically opposed sequence).

Selector fork shaft cover securing bolt 40

Range change safety interlock securing bolt 20

Range change safety interlock locking plug 30

Clutch slave cylinder

Clutch slave cylinder to basic gearbox casing securing nut 24

Slave cylinder air plug 22

Slave cylinder securing stud 8

±±±±10

±±±±7

75

±±±±5

+150/-50

±±±±5

40

±±±±5

±±±±3

±±±±5

±±±±4

±±±±3

±±±±1.5

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Nm

Retarder

Retarder securing bolt. 15

Retarder to range change casing securing nut: Tighten using a

±±±± 5°

torque wrench, then tighten to 45

angle in 2 passes.

Oil filler plug 70

±±±±5

30 Nm

±±±±10

Heat exchanger

Heat exchanger to range change casing securing bolt 80 Nm

Oil drain plug 20 Nm

Oil filler plug 70

Coolant drain plug 25

Adapter plate to heat exchanger securing bolt 30 Nm

±±±±10

±±±±3

Nm

Nm

Nm

Nm

RENAULT TRUCKS 10/2004

32 661

Oil pump

Oil pump to basic gearbox casing securing bolt: the countersunk

head bolts is to be tightened first.

Oil pump cover securing bolt 20

By-pass valve plug 45

Oil aspiration pipe flange secu ri ng bol t 20

Oil distributor threaded plug 250

Oil filter

40

±±±±5

±±±±3

±±±±5

±±±±3

±±±±35

B2-5

Nm

Nm

Nm

Nm

Nm

Oil filter cover securing bolt 40

Relief valve plug 45

Countershaft

Reverse gear nut 450

Third gear nut 400

±±±±5

±±±±5

±±±±100

±±±±50

Nm

Nm

Nm

Nm

RENAULT TRUCKS 10/2004

B2-6

32 661

RENAULT TRUCKS 10/2004

Loading...

Loading...