Operating and

installation instructions

REMKO SLN series

Swimming pool dehumidifiers

SLN 45, SLN 65, SLN 85

Edition GB – N12

Read the instructions prior to performing any task!

Contents

Safety notes

Air dehumidification

Testing the water quality

Unit description

Set-up

Commissioning

Unit function

Wireless remote control

Care and maintenance

Troubleshooting

Fault and information messages

Diagram, cooling cycle

4

5-7

8

9

10-12

13-14

15

16-18

19

20

21

22

Electrical wiring diagram

Intended use

Customer service and guarantee

Environmental protection and recycling

Exploded view of the unit

Spare parts list

RS-485 interface

USB interface

Maintenance protocol

Technical data

Carefully read this operating manual prior to commissioning/using

the units!

This operating manual is a translation of the German original.

27-29

32-33

23

24

24

24

25

26

30

31

These original instructions are an integral part of the unit

and must always be kept in the vicinity of the installation location

or on the unit itself.

Subject to modifications; no liability accepted for errors or misprints!

3

REMKO SLN Series

Safety notes

The units have been subjected to

extensive material, functional and

quality inspections prior to delivery.

However, dangers can result

from the units if they are used

improperly or not as intended by

untrained personnel.

The following notes must be

observed in full:

■

The units may not be installed

or operated in explosive

environments

■

The units must not be installed

or operated in atmospheres

containing oil, sulphur or salt

■

The units must not be exposed

to direct jets of water

■

An unobstructed air inlet and

air outlet must be guaranteed

at all times

■

The air-inlet grill must always

be kept free of dirt and loose

objects

■

The units must not be covered

during operation

■

Never stick foreign objects into

the units

■

All electrical cables on

the outside of the units must

be protected against damage

(e.g. by animals etc.)

■

The units are only permitted

to be set up or installed in

the intended position (upright)

■

Unobstructed and frost-proof

condensate drainage must

be ensured at all times

■

The unit connections must

always be established

according to the applicable

installation regulations

CAUTION

The units must be set up and

installed in such a way that

they are easily accessible

for monitoring, repair and

maintenance work.

4

Air dehumidification

The correlations occurring

when air is dehumidified are based

on physical laws.

These are depicted here

in graphical form in order

to provide you with a brief

overview of the principles

of air dehumidification.

The use of

REMKO air dehumidifiers

– Even if windows and doors

are well insulated, water and

moisture are still capable of

penetrating thick concrete walls.

– The water required for setting

in the production of concrete,

mortar and plaster etc. may only

be diffused after 1-2 months.

– Even moisture trapped

in the masonry after highwater or a flood is released very

slowly.

– The same is also true

of moisture contained in stored

materials for example.

The moisture (water vapour)

released from parts of a building

or materials is absorbed by

thesurrounding air. As a result,

the moisture content increases,

which ultimately gives rise

to corrosion, mould, rot, peeling

of paint and other unwanted

damage.

By way of example, the diagram

shows the corrosion rate of metal

in different levels of humidity.

Corrosion rate

Rel. humidity %

It is evident that the corrosion rate

below 50 % relative humidity (RH)

is low, and below 40 % is negligible.

The corrosion rate increases

significantly above 60 % RH.

This threshold for damage

as the result of humidity also

applies to other materials, such

as powdery substances, packaging,

wood and electronic units.

Buildings may be dried in a variety

of ways:

1. By heating and air exchange:

The air in the room is heated

in order for moisture to be

removed and then this air is fed

outside. All of the energy that

is involved is lost together with

the moist air that is released.

2. By air dehumidification:

The moist air that is present

within an enclosed space is

continuously dehumidified

according to the condensation

principle.

With regard to energy

consumption, air dehumidification

has one distinct advantage:

Energy expenditure is limited

exclusively to the air volumes

present. The mechanical heat that

is released by the dehumidification

process is fed back into the room.

Under normal use,

the

air dehumidifier

uses

approximately 25 % of

the energy that is required

for the

“heating and ventilating”

principle.

Relative air humidity

Our ambient air is a gaseous

mixture which always contains

a certain volume of water

in the form of water vapour.

This volume of water is specified

in g per kg of dry air (absolute

moisture content).

1 m3 of air weighs approx. 1.2 kg

at 20 °C

Depending on the temperature,

each kg of air is only capable of

absorbing a certain volume of

water vapour. Once this capacity

has been reached, the air is

referred to as “saturated” and has

a relative humidity (RH) of 100 %.

Relative humidity is understood

to mean the ratio between

the current quantity of water

vapour in the air and the maximum

possible quantity of water vapour

at the same temperature.

The ability of the air to absorb

water vapour increases as

the temperature rises. I.e.

the maximum possible (absolute)

water content becomes greater

as the temperature rises.

5

Verdampfer Kondensator

°C

30

25

20

15

% r.F.

100

90

80

70

60

50

40

30

20

10

+

+

-

Lufttemperatur

Luftfeuchte

Verlauf

Luftrichtung

Evaporator Condenser

Air temperature

Air humidity

Air direction

% RH

Progression

REMKO SLN Series

Temp. Water vapour content in g/m3 at humidity of

°C

-5 1.3 1.9 2.6 3.3

+10 3.8 5.6 7.5 9.4

+15 5.1 7.7 10.2 12.8

+20 6.9 10.4 13.8 17.3

+25 9.2 13.8 18.4 23.0

+30 12.9 18.2 24.3 30.3

40 % 60 % 80 % 100 %

Drying materials

Building materials and structures

are capable of absorbing

considerable volumes of water,

such as brick 90-190 l/m³, heavy

concrete 140-190 l/m³ and

limestone 180-270 l/m³.

The drying of moist materials such

■

The air containing water vapour

is constantly circulated through

the REMKO air dehumidifier.

The air is dehumidified and,

slightly heated, leaves the unit

in order to re-absorb water

vapour

as masonry is effected as follows:

■

In this way, the moisture

■

The moisture

moves from

the inside

contained in the material

is reduced gradually

The material is dried!

of the material

to its surface

The accumulated condensate is

collected in the unit and drained

■

Evaporation occurs on

off from there.

the surface = transfer of water

vapour to the ambient air

The condensation

of water vapour

Because the capacity for

the maximum possible volume

of water vapour increases as the air

is heated, the volume of water

vapour contained remains constant

and so relative humidity falls.

In contrast, because the capacity

for the maximum possible volume

of water vapour decreases as

the air is cooled, the volume

of water vapour contained remains

constant and so relative humidity

increases.

If the temperature continues to

fall, the capacity for the maximum

possible volume of water vapour

is reduced so much so that it is

ultimately equal to the volume of

water vapour contained in the air.

This temperature is referred to as

the dew point. If the air is cooled

to below dew point, the volume

of water vapour in the air will

become greater than the maximum

possible volume of water vapour.

At this point, the water vapour

begins to precipitate.

It then condenses to water.

Humidity is then removed from

the air.

As it flows through or over the evaporator, the air stream is cooled

to dew point. The water vapour condenses, and is collected

in a condensate trap from where it is drained off.

6

Examples of condensation include

steamed-up window panes

in winter, or the moisture on

the outside of a cold drinks bottle.

As the relative humidity of the air

increases, so too does the dew

point, making it easier for

the temperature to fall below it.

Condensation heat

The Energy transferred to the air

from the condenser consists of:

1. The amount of heat derived

beforehand in the evaporator.

2. The electrical drive energy.

3. The condensation heat released

by liquefying the water vapour.

Energy must be supplied when

liquid is converted into a gas.

This energy is designated

as evaporation heat.

It does not cause any increase

in temperature, but is required

to convert a liquid into a gas.

Conversely,

energy is released

when gas is liquefied, this is

designated as condensation heat.

The amount of energy from

evaporation heat and condensation

heat is the same.

For water, this is:

2250 kJ/kg (4.18 kJ = 1kcal)

From this it is evident that

the condensation of water vapour

causes a large quantity of energy

to be released.

If the moisture that it is to be

condensed is not introduced

by evaporation in the room itself,

but from outside, e.g. through

ventilation, the condensation heat

released contributes to the heating

of the room.

When dehumidifying, a heat

cycle is created, whereby heat is

consumed for evaporation and

released for condensation.

When dehumidifying fed air,

a larger contribution of heat is

created, which manifests itself as

a temperature increase.

Generally speaking, the time

required for the drying process

is not only dependent on

the output of the unit, but is

determined to a greater extent by

the speed at which the material

or building section loses its

moisture.

7

REMKO SLN Series

Testing the water quality

Water quality

The correct combination of chemicals in swimming pools in indoor areas is of major importance to the health of

the users and for systems in the vicinity of the swimming pool and its plant room.

Inadequately treated water leads to poor hygiene, whilst water that has been excessively treated gives off

chlorine into the air, which can irritate the eyes and lead to respiratory problems. At the same time, an incorrect

combination of chemicals in the water can lead within a very short time to the destruction of all systems including the dehumidifier and other systems that have been installed for air treatment.

The following tables contain the limit values for swimming pools in indoor areas in accordance with

EN/ISO 12944-2, corrosivity category C4.

These limit values must be observed, otherwise the guarantee is voided

When adding chemicals

The following guideline values apply to swimming pools when adding chemicals:

Chemical values ppm

Free chlorine content 1,0 - 2,0

Combined chlorine content max. 1/3 of the free chlorine content

pH value 7,2 - 7,6

Total alkalinity 80 - 150

Calcium hardness 250 - 450

Total dissolved solids < 2000

Sulphates < 360

With own production of chlorine

The following guideline values apply to swimming pools with own production of chlorine:

Chemical values ppm

Salt (NaCl) < 30000

Total dissolved solids < 5 500

pH value 7,2 - 7,6

Total alkalinity 80 - 150

Calcium hardness 250 - 450

Sulphates < 360

Langelier saturation index

To make sure the various water quality parameters remain within an acceptable range, the Langelier saturation

index should be applied.

8

Unit description

The units have been designed for

universal and straightforward air

dehumidification.

Their compact dimensions allow

the units to be transported

and set up/installed with ease

in the adjacent room.

The units operate in accordance

with the condensation principle

and are equipped with

a hermetically sealed refrigerant

system and low-noise and lowmaintenance fan(s).

The fully-automated electronic

controller, an integrated hygrostat

and connection ports for

condensate drainage provided by

the customer ensure continuous

fault-free operation.

The units are reliable and conform

to the fundamental health and

safety requirements of the

appropriate EU stipulations.

The units are used in all locations

where dry air is a must and where

economic consequential damage

(such as that caused by mould)

must be prevented.

The units have been designed

exclusively for installation in

a suitable adjacent room by way

of a duct interface.

The units may be used to

dehumidify

areas such as:

■

Private swimming pools

■

Spa areas

■

Fitness centres

■

Storage rooms

■

Archives

■

Museums

Operating sequence

The units are switched on and

off using the integrated hygrostat.

The hygrostat is set to 60 % RH

in the factory.

The respective unit function is

indicated by a multi-colour LED

display on the front of the unit.

The fan extracts the moist room air

through the lower duct connector

and filter.

Heat is removed from the room

air on the cold evaporator.

The air is then cooled to below

dew point. The water vapour

contained in the room air is then

deposited as condensate or rime

on the evaporator fins.

On the condenser, the cold and

dehumidified air is warmed up

again and discharged back into

the room via the upper duct

connectors with a temperature

increase of around 5 °K above

the room temperature.

The processed, dry air therefore

continuously mixes with the room

air.

Continuous circulation of the room

air through the unit gradually

reduces the relative humidity (% RH)

in the room to the desired humidity

level.

Schematic depiction of the workings of the SLN 45-85 air dehumidifier

Warmed and

dehumidified air

Moist room air

Adjacent room

REMKO

SLN

Swimming pool

9

REMKO SLN Series

Set-up

For optimum and safe use

of the units, the following notes

must be followed in full:

■

Two duct openings must

be created in the wall between

the room to be dehumidified

and the installation room

before the units are installed

in the adjacent room.

The inside dimensions

of these openings can be taken

from the sketch.

■

The openings must be created

in such a way that the air

in the room to be dehumidified

can be extracted through

the lower duct (with filter) in

an unrestricted manner and

blown out through the upper

duct.

■

The unit must be mounted

upright to ensure that

the condensate can drain freely.

■

Observe the illustrated

minimum gaps between

theunit and the ceiling and

floor in the installation room

to ensure safe operation.

■

The wall fittings must be adjusted

to the required length before

assembling the duct interfaces.

The max. wall strength is

limited to 290 mm. Ensure

that the embossed side is not

damaged when adjustments are

made.

Wall-mounted bracket for the units

SLN 45

437 437

SLN 65

341 341 341

SLN 85

450 450 450

■

Fit the air circulation inlet filter,

the grille installation fittings and

the ventilation grille together

with the wall supports.

■

Install both duct interfaces into

the duct openings.

■

Fit the duct piece together

with the filter into the lower

duct opening where the air in

the room being dehumidified

is to be extracted.

■

From the adjacent room side,

connect the unit connection

fittings together with the selfsealing profile to the

All measurements in mm

Series Dimension A Dimension B Clear wall opening

SLN 45 464 998 110 x 610

SLN 65 614 1148 110 x 760

SLN 85 949 1483 110 x 1095

Mounting the units on the wall

20

110

395

110

90

65

10

304

min.

403

68

700

Detailed information

on the wall-mounted

bracket

min.

730

A

B

444

294

All measurements in mm

Duct interface found in the wall

opening.

■

The unit must never be

mounted in the immediate

vicinity of heaters or other

■

Secure the wall spacers provided

sources of heat.

with the unit to the bottom

corners of the unit using

adhesive.

■

The room being dehumidified

must be closed to

the neighbouring atmosphere.

■

Affix the wall-mounted bracket

to the wall in the adjacent room

and hang the unit on it.

■

Avoid having opened windows

and doors etc., and avoid

frequent entry to or exit from

■

The unit is connected to

the room as much as possible.

the duct interfaces that are

already mounted on the wall

by way of the self-sealing profile

lips on the unit connection

fittings.

■

In order to achieve optimum

room air circulation using

the dehumidifier, the supply

and exhaust air openings must

remain clear.

Location of the wall-mounted bracket using the example of the unit SLN 65

Condensate water drain

The condensate water drain is

located on the unit's base.

The condensate drainage is

connected to the discharge nozzle

supplied.

A solid or flexible ½” discharge

connector can be installed on this.

■

The discharge hose must always

be laid at an incline of at least

2 % so that the water can flow

unhindered from the drip tray.

■

Alternatively, a condensate

pump can be fitted to the unit

in order to pump the condensate

water to a drainage point

located at a higher level.

■

If drainage is to be carried out

through the wall, the relevant

measures such as holes for

correct condensate drainage

must be taken before installing

the unit.

min. 403

Location of the condensate drain

110290 110

395

min. 730 178

Detailed information

on the wall-mounted

bracket

min. 225 700 min. 225

All measurements in mm

430

All measurements in mm

56

■

See the diagram at the side for

information on the location

of the drainage connection.

Access to the controller

Remove the front plate after

opening the lock on the underside.

Lift the cover vertically upwards

and then pull away from the unit

horizontally.

The controller is located behind

the top cover of the internal

housing parts above the

compressor.

The controller is accessed

by removing the 2 screws on

the front of the internal housing

parts.

11

REMKO SLN Series

Mounting the unit exchange

adapter

If the SLN unit is replacing

aprevious model, then the unit

exchange adapter is required.

This is affixed using the sealing

tape provided as shown in

the image. Attach the adapter

in such a way that it covers

the existing apertures in the wall

and creates a seal at the wall

where the sheet-metal edges were

affixed previously.

Once the adapter has been fitted

to the wall correctly, the unit can be

hung on the bracket that is fitted

to the adapter. The rubber lips

together with the unit housing and

the adapter create a complete seal.

NOTE

Unit exchange adapter

Make sure that there are no

air leaks as these will severely

impair the functionality of

the unit.

Mounting the units with an adapter

12

Commissioning

Before commissioning the unit

or if local requirements dictate,

the air-inlet grill and air-outlet

grill must be checked for

contamination.

The units are operated using

an integrated hygrostat that is set

to 60 % RH (default value for spas

and indoor swimming pools).

If the room humidity is below

60 % RH, the unit does not start.

If the relative humidity is

above 60 %, the unit starts

the dehumidification process

automatically.

If you would like to make changes

to the hygrostat settings, remove

the front housing cover and

the control board cover located

in the upper section in order

to access the control board.

NOTE

Interrupting the operation

of the unit before

the compressor has run for

6 minutes will activate a restart

lock lasting approx. 4 minutes.

Control board

The units are equipped with

an electronic controller.

This features various interfaces and

a display. The following section

describes these features in detail.

Control board, front

Display and operator panel

The display is a four-digit seven

segment display. The first two

digits are used to display the

respective “code”, e.g. rHXX, for

setting the room humidity and

the last two digits correspond

to the value set.

USB interface

The information on the USB interface

can be found further on in this manual.

RS-485 interface

The information on the RS-485

interface can be found further

on in this manual.

EXT RH/T

These terminals allow you to

connect up an external electronic

humidity and temperature probe.

The temperature probe must

be an NTC probe with 10 kΩ

at 25 °C and a B25/85 of 3969

K. The humidity probe must be

designed for a voltage supply of

12 V DC and feature an analogue

voltage output of 0-10_V with

max. 10 mA.

NOTE

If the air humidity is lower

that the set value, the unit will

not start up, even if the mains

voltage is connected.

NOTE

When the unit is switched on

or off using the main switch,

a signal is issued upon startup

and the LED display lights

up blue as soon as the unit

is ready for operation. Once

all conditions have been met,

the dehumidifying process

begins.

Code Value

In the standard view, no code is

shown on the display. It is only

the value of the humidity currently

measured that is displayed.

The operator panel with

the buttons “Up”, “Down” and

“OK” can be found on the righthand side of the front of the

control board. These can be used

to navigate around the menu

structure of the control board and

to couple the control board with

a wireless remote control.

ALARM

The alarm contacts are two

potential-free contacts that are

open in an unswitched state.

The RUN contact is closed when

the compressor is in operation.

The FAIL contact is closed when

there is a malfunction in the unit.

12VDC

Relays can be controlled via

the HEAT contacts in order to

switch the external heating on

and off. They are active when

the °C option in the menu is set to

a value.

13

REMKO SLN Series

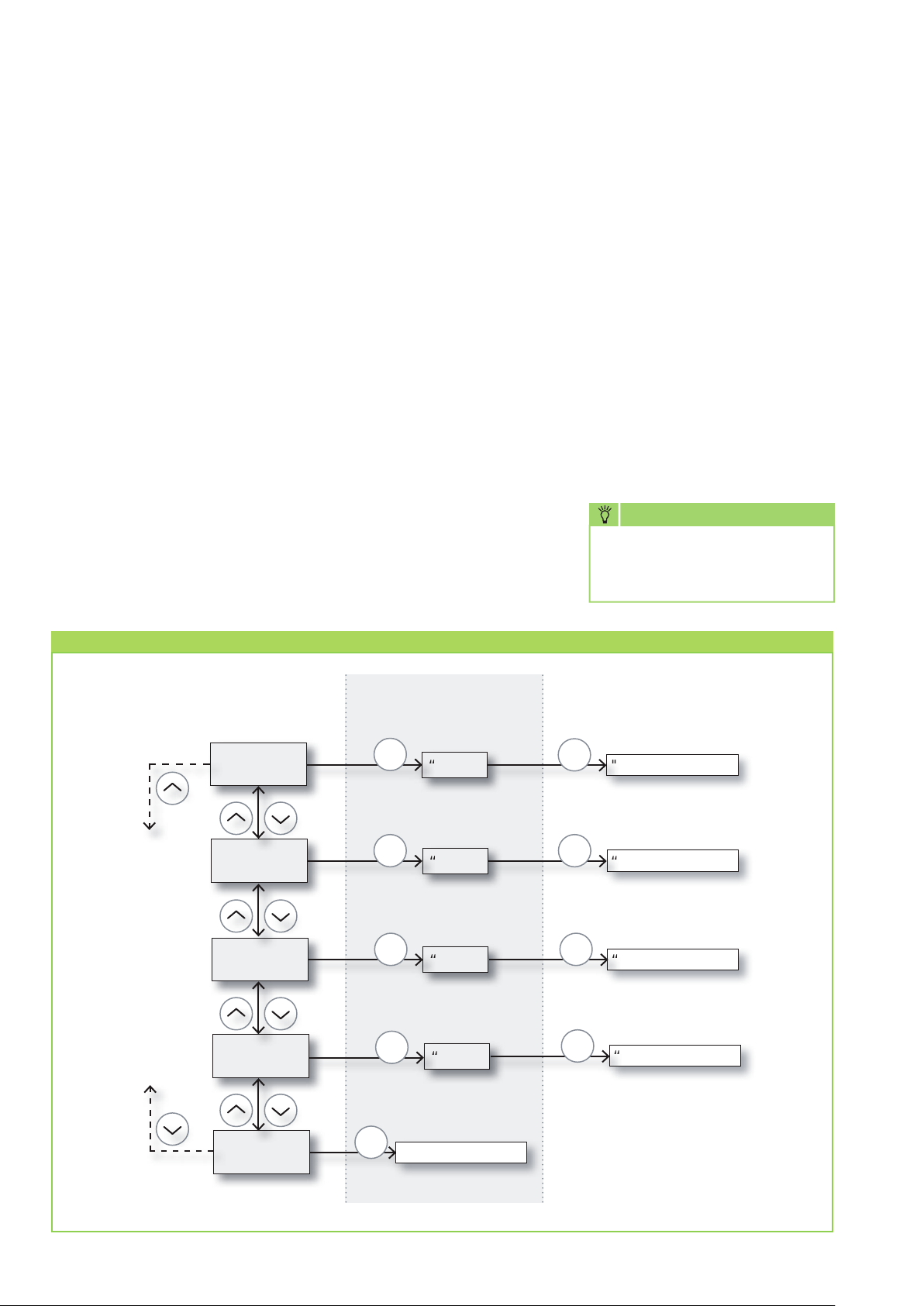

Menu structure

To define the setpoints using

theintegrated operator panel, hold

down the “OK” key for 5 seconds

so that the display switches from

the humidity currently measured

to the menu item rHXX.

If you would like to exit

the menu, do not press any

keys on the operator panel for

10 seconds.

Menu items

Code: RH

The code “RH” stands for

the relative air humidity that

the unit should reach. The value

can be set between 40 and

99 % RH. The default value is 60.

Code: °C

The code “°C” stands for external

heating control with the aim

of reaching a defined setpoint.

The value can be set to between

05 and 34. This value is set to

“OF” by default.

Code: EF

The code “EF” stands for external

heating control with the aim of

reaching the specified air humidity

more quickly. The set value may

differ from the setpoint humidity

so that the external heating can

either operate permanently or

merely provide a support function.

The value can be set between 40

and 99 % RH. The default value is

set to “OF” in this case.

Code: SI

The code “SI” stands for

themaintenance interval that

the operator or fitter requires.

Thisvalue is indicated in weeks

and can be set from 01 to 99.

Thedefault value is “OF.”

Code: tE

The code “tE” stands for testing

and the value “St” for self-test.

To start the self-test, press “OK”

and to cancel it, hold the down

key down for 5 seconds.

NOTE

The corresponding terminals

for these options are located on

the control board of the unit.

Menu structure of the SLN air dehumidifier

1. Level

rHXX

°CXX

External heating

EFXX

External fan

SIXX

Service interval

2. Level

OK

OK OK

OK

OK

“Value”

“Value”

“Value”

“Value”

OK

OK

OK

3. Level

"Value confirmed"

“Value confirmed"

“Value confirmed”

“Value confirmed”

14

tESt

Self-test

OK

“Test confirmed”

Unit function

Fan control

When the control board puts

the dehumidifier into operation,

the fan(s) switch on together

with the compressor.

Defrosting

The units feature an intelligent

and active defrosting function.

If the room temperature is below

20 °C, the evaporator will start to

ice up after a short time.

If the evaporator probe registers

a temperature of less than 5 °C

on the evaporator surface,

the unit only continues to

run in dehumidification mode for

a further 30 minutes.

Once this time has expired,

the fans stop and the solenoid

valve for hot-gas defrosting opens.

When the evaporator probe

registers a temperature higher

than 5 ºC again, the solenoid

valve closes and the unit resumes

dehumidification.

Compressor control

The compressor has a 6 minute

restart delay as a safety function.

The delay period must elapse

before it is possible to restart

the compressor.

This safety function protects

the compressor against an

overload caused by overly high

pressure in the cooling cycle.

In order to prevent damage

to the condenser, the units are

equipped with a mechanism

that prevents the compressor

being immediately switched back

on after it is switched off via

the mains power supply.

The compressor does not switch

back on until after a waiting time

of approx. 30 seconds!

Safety circuit

If the temperature exceeds 55 °C

on the condenser (e.g. due to a

fan failure or an overly high room

temperature (higher than 36 °C)),

the compressor stops automatically

to prevent an overload.

As soon as the temperature

on the condensor permits

dehumidification again, the unit

starts up automatically.

15

REMKO SLN Series

Wireless remote control

Wireless remote control

Wireless remote control allows

an SLN unit to be operated

and adjusted in a simple and

convenient manner. The current

humidity and temperature can be

viewed on the wireless remote

control and the setpoint humidity

can be adjusted.

The wireless remote control is

intended for use with the dehumidifier

models SLN 45-65-85.

The wireless remote control has

a coverage distance of up to

50 metres from the installation

location of the unit.

Overview of the display

Design of the wireless remote

control

The wireless remote control is

equipped with a large, clear display

and has operating buttons for

the different options Up, Down,

Left, Right and Enter.

The display values and the air

humidity scale have a value range

of 0 to 99 % RH.

The display values and the air

temperature scale have a value

range of 0 °C to 40 °C.

Information display

The information display shows

the setpoint values for the unit.

Fault messages together with

the fault symbols are also

displayed here.

Humidity indicator

and scale

External fan

Operating button control options

Dehumidification External heating

Fault symbol Information display

Up

Left

(Decrease value)

Remote control lock Battery indicator

Wireless symbol

Service Temperature indicator

and scale

Right

(Increase value)

Power supply

The wireless remote control can

be powered using 2 AAA batteries

with 1.5 V each or can be powered

externally using the USB cable

provided.

16

Down

Enter

(Change menu item)

Coupling

Connecting the antenna

The antenna is located on

the control board inside the unit

or can be fitted there. This will

be pre-installed if the unit

is delivered together with

the remote control.

Before fitting the antenna,

disconnect the unit from the power

supply. Then slacken the two

fastening screws on the underside

of the unit, tilt the front cover of

the unit and lift it up. In the upper

right area, remove the two screws

on the board cover and remove

the cover. Pull the control board

forwards, screw the antenna

into place and bend it forwards.

Once the antenna is screwed in

place and the board has been

returned to the previous position,

the unit can now be provided

with power in order to couple it

with the wireless remote control.

Then screw the housing parts back

into place.

Location of the control board

Connecting the antenna

Switching on and coupling

the remote control

The wireless remote control must

be coupled with the unit before

it can be used. To do so, carry out

the following steps.

1. Insert the batteries provided

into the battery compartment

on the rear of the wireless remote

control.

2a. The remote control will search

for the unit for two minutes.

During this time, the remote

control display flashes every

2 seconds.

2b. During the search phase,

hold down the Up and Down

keys on the operator panel of

the control board at the same time

for 5 seconds.

3. If coupling was successful,

the unit sends a serial number

to the wireless remote control

and the wireless symbol is

displayed.

4. The swimming pool

dehumidifier confirms

the connection by displaying

the code “Conn” for a period

of 3 seconds.

This procedure can also be carried

out using several remote controls

so that an air dehumidifier can

be controller by several remote

controls.

Coupling failure

If the wireless remote control

fails to couple with the unit,

the fault symbol becomes visible,

“Conn” is shown permanently

on the display and the wireless

symbol flashes.

The wireless remote control

needs to be reset before a new

coupling attempt can be made.

To do so, hold the Left key on

the wireless remote control down

for 10 seconds.

17

REMKO SLN Series

General

The wireless remote control

displays the values for humidity

and temperature at all times.

The values only disappear when

a malfunction arises.

Depending on which function

is currently active, one or more

of the symbols appear in the

centre of the display.

User setup menu

Hold down the Enter key for

3 seconds to open the user setup

menu.

In this menu it is possible to switch

between the wireless remote

control symbols using the Up and

Down keys provided the

corresponding option of “OF” has

been set to a value on the control

board itself. Please read pages

11 and 12 to set these values.

User setup menu symbols

External heating

Fitter setup menu

Hold down the Right key for

5 seconds to open the fitter setup

menu. At this point it is possible

to access all four menu items. It is

also necessary to set the respective

“OF” option on the control board

to a specific value to enable access.

Fitter setup menu symbols

External heating

Dehumidification

External fan

Maintenance interval

Fault messages

The fault messages correspond

to the alarm messages which can

also be shown on the unit’s control

board display. To make the alarm

message recognizable, the fault

symbol is also displayed on

the wireless remote control.

Fault priority

In the event that several faults

occur at the same time, only

the fault with the highest priority

is displayed.

Fault priority

HP High priority

LP

SEnS

Abt

AbrH Low priority

NOTE

Do not simply reset the fault

messages without establishing

the cause first.

Maintenance message

Unlike the other fault messages,

the maintenance message can

be acknowledged or reset via

the wireless remote control.

This is due to the fact that it is

a purely informative message.

Maintenance message

Dehumidification

The Left and Right keys can be

used to set these parameter values.

The parameter is confirmed as

a new setpoint using the Enter

key. When this is confirmed,

the remote control switches back

to the symbol and exits the menu.

If you would like to exit the user

setup menu, do not press any

keys on the remote control for

10 seconds.

18

Examples of fault messages

Sensor fault

Overly high

pressure level

detected

Generally speaking, the fault

messages can only be reset

on the display panel of the

control board. The unit must be

thoroughly inspected and the fault

reset following rectification each

and every time.

No changes can be made to

the setpoints in the setup menus

while there is an active fault.

Proceed as follows to set up

the new maintenance interval.

1. Hold down the Right key for

5 seconds to open the fitter menu.

2. Use the Up and Down keys

to navigate to the maintenance

symbol.

3. Use the Right and Left keys to

change the 0 value to the required

maintenance interval.

4. Confirm the new maintenance

interval by pressing the Enter key.

Care and maintenance

NOTE

Regular care and maintenance

is fundamental to a long

service life and fault-free

operation of the unit.

All moving parts have a lowmaintenance permanent coat

of lubricant. The refrigerant system

is designed as a hermetically sealed

system and may only be repaired

by a specialist.

■

Observe the regular care and

maintenance intervals

■

In accordance with

the operating conditions,

the units must be checked as

and when required, but at least

once per year, by a specialist

to ensure that they are in

a condition that is safe to use

■

Keep the units free of dust and

other debris

■

If the unit is contaminated,

it can be cleaned using

a vacuum cleaner. The

condensor in particular must

be vacuumed thoroughly

Cleaning the suction filter

Check the suction filter at regular

intervals and clean if necessary.

The filter is secured in a bracket

behind the intake openings.

CAUTION

Check the intake

openings, as well as filters,

regularly for contamination.

■

Light filter contamination can be

remedied with careful blowing

or suction

■

Heavier contamination may

be remedied by rinsing the filter

in a lukewarm (max. 40 °C)

soap solution Finally, always

rinse the filter carefully with

clear water and allow to dry

■

Before refitting the filter, ensure

that its fully dry and that no

damage has been sustained

■

The units may only be operated

with the filter in place

and

outlet

Operating LED

The multi-colour LED display

is located at the upper edge

in the centre of the unit. They

indicate the current operating

state of the unit.

Legend of the LED colours

The LED lights up “blue” and

stays that way when the unit is

connected to the mains power

supply.

The LED lights up “green”

and stays that way when

the compressor is in operation

and the unit is in dehumidifying

ordefrosting mode.

The LED lights up “yellow”

and stays that way when the unitis

operating in wireless remotecontrol

mode.

The LED lights up “red” when

a fault has occurred. Please refer

to the Troubleshooting chapter

torectify the fault.

■

If the evaporator’s fins are

heavily soiled, they can be

cleaned carefully with soapy

water

■

Never subject to direct jets

of water e.g. pressure washers

etc.

■

Never use abrasive or solvent-

based cleaners

■

Use only suitable cleaners, even

for heavy contamination

NOTE

Heavily contaminated filters

must be replaced with new

parts.

Only original replacement

parts may be used.

Cleaning the condensate

water collection tray

To ensure that the condensate

water that accumulates can always

drain freely, the collection tray for

the condensate and the drain must

be cleaned regularly.

19

REMKO SLN Series

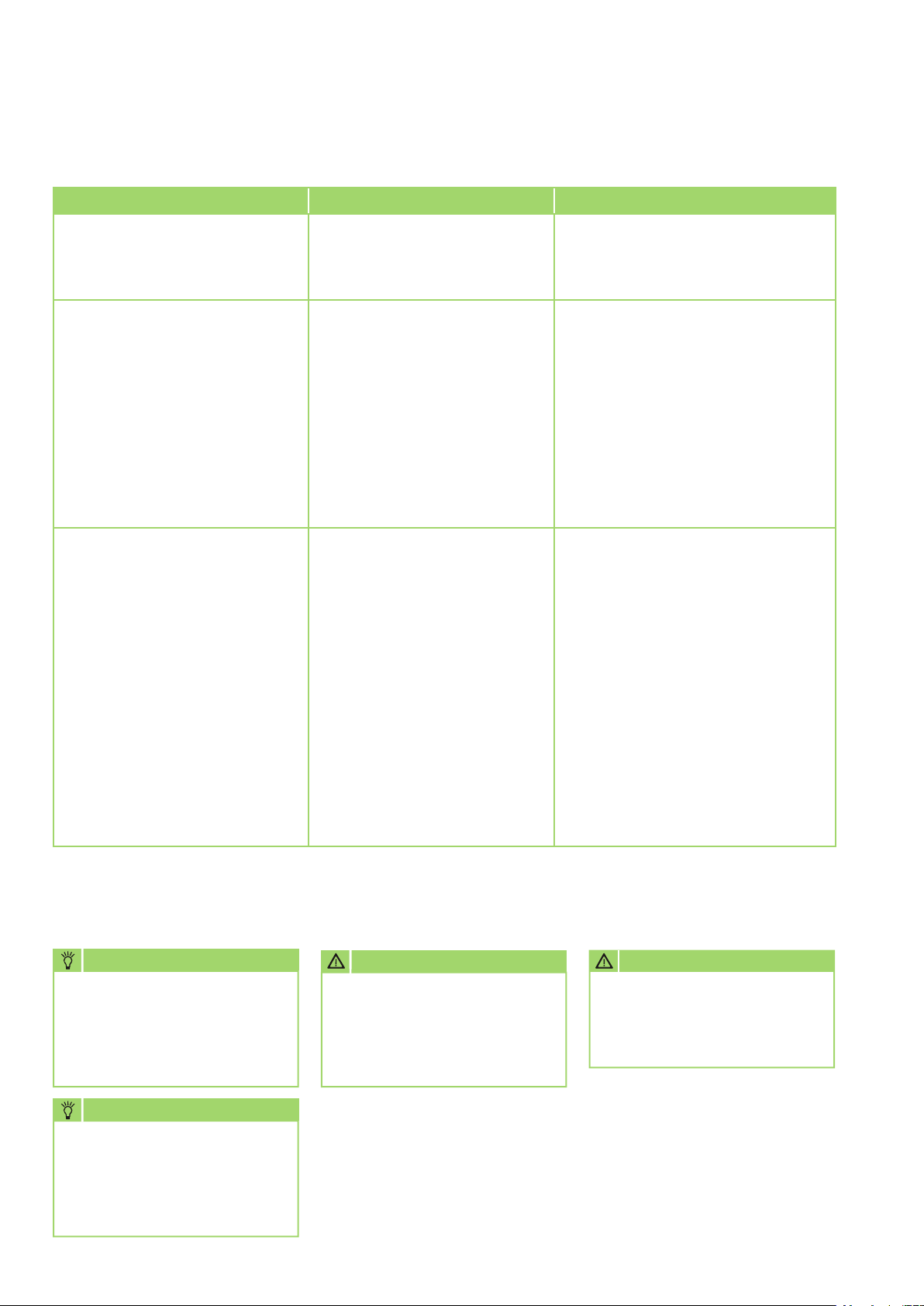

Troubleshooting

Malfunction Possible cause Remedial measures

•Theunitdoesnotstart.

•Thedisplaydoesnotlightup.

•Theunitdoesnotstart.

•Displayindicatesincorrecttype.

•Thecompressordoesnotstart. The compressor switched off

No mains voltage. • Checkthepowersupplyorfuses

Air humidity in room too low.

The unit is outwith its usable

limits of 10 - 36 °C.

automatically due to an overly

high condensor temperature.

Lack of air ventilation.

Overly high ambient

temperature.

Contaminated filter/intake

device.

or switches on site.

• Checktheintegratedhygrostatand

set it to a low relative humidity,

e.g. < 40 % RH.

• Checktheroomconditionsand

alter as required.

Check the following points if the unit

does not start after 45 minutes:

• Checkifthefan(s)is/areworking.

• Checkiftheintakelteris

contaminated.

• Checkthattheintakeandoutlet

openings are free of contamination.

• Checkifthecondensorns

are contaminated.

• Checkiftheroomtemperature

is above 36 °C.

If the room temperature is above

36°C, the unit must be switched

off.

NOTE

If it is not possible to determine

the cause of the fault, switch

off the unit immediately and

disconnect it from the mains power

supply to prevent further damage.

NOTE

If all of the functional checks

have been carried out without

any findings, please contact

an authorised service station.

20

CAUTION

Work on the refrigerant

system and on the electrical

equipment must only be

conducted by a speciallyauthorised specialist!

CAUTION

Prior to maintenance

or repair work, the unit

must be disconnected from

the mains power supply.

Fault messages

Code and

value

LOSS

Abt

AbrH

SEnS Sensor fault, causes the unit to stop

The connection to the remote

control has been lost

Ambient temperature is outwith

the permissible range

Air humidity is outwith the

permissible range

Cause Remedial measures

When the connection is restored, acknowledge

by clicking “OK”.

Acknowledgement not possible. Automatic reset as soon

as the temperature has returned to the permissible range.

Acknowledgement not possible. Automatic reset as soon

as the air humidity has returned to the permissible range.

Press the Up or Down key to see which probe is affected.

Exchange the probe if necessary.

COnd - condensor probe

EUAP - evaporator probe

RH°t - humidity and temperature probe

Acknowledgement possible only by way of unlocking

sequence. Initiate the sequence by pressing the “OK”

key.

Malfunction must be established and rectified

LP Low pressure level detected

HP High pressure level detected

Unlocking sequence

Once the unlocking sequence has been initiated, the unit displays the information “Loc”. If the Down key

is pressed at this point, the information display switches to “UnLo” which displays the unlocking option.

If “UnLo” is confirmed with the “OK” key, the unit is enabled again.

by specialist personnel. Acknowledgement possible

only by way of unlocking sequence. Initiate the sequence

by pressing the “OK” key.

Malfunction must be established and rectified

by specialist personnel. Acknowledgement possible

only by way of unlocking sequence. Initiate the sequence

by pressing the “OK” key.

Information messages

Code and

value

Log

After inserting a USB memory stick

into the USB interface

Occurrence Comment

Once the USB stick has been inserted, the process

of copying the log data from the internal memory

to the USB memory stick is initiated and declared

as finished by the information “Log”.

21

REMKO SLN Series

Cooling cycle

7

1

3

SLN 45 - 85

5

6

2

4

Legend:

1. Compressor

2. Evaporator

3. Condenser

4. Thermal expansion valve

5. Dry filter

6. Solenoid valve

7. Fan

22

We reserve the right to modify the dimensions and design as part of the ongoing technical development process.

Electrical wiring diagram

SLN 45 - 85

Electronic control board

Remote

Display

Legend:

FAN 1 = fan motor 1

FAN 2 = fan motor 2

FAN 3 = fan motor 3

CAP 1 = capacitor 1

CAP 2 = capacitor 2

CAP 3 = capacitor 3

L

N

PE

USB

RS485

_

Ext. RH/T

COMP. = compressor

VALVE = solenoid valve

RUN = potential-free contact

FAIL = potential-free contact

HEAT 1/2 = 12 V supply voltage

for controlling relays

NOTE

Alarm

12 V DC

Operator panel

Bedienfeld

Fan motors:

SLN 45 = FAN 1

SLN 65 = FAN 1 and FAN 2

SLN 85 = FAN 1, FAN 2 and

FAN 3

CAUTION

A main switch should be installed

NOTE

at a suitable and easily accessible

Prior to maintenance

or assembly work, the unit

must be disconnected from

the mains power supply.

We reserve the right to modify the dimensions and design as part of the ongoing technical development process.

point in the mains supply line.

We recommend using a mains

supply line of 2.5 mm² for

the units.

Assembly and maintenance

work on the units may only

be carried out by authorised

and qualified technicians.

23

REMKO SLN Series

Intended use

The units are designed exclusively

for dehumidification purposes

on the basis of their structural

design and equipment.

A failure to observe

the manufacturer's specifications,

the respective local legal

requirements or arbitrary

alterations to the units, exempts

the manufacturer from liability

for resulting damage.

NOTE

Operation other than the types

listed in this operating manual

is prohibited.

With non-observance,

any manufacturer liability

or guarantee claims are voided.

Customer service and

guarantee

As a prerequisite for any guarantee

claims to be considered, it is

essential that the ordering party

or their representative complete

and return the “Certificate of

guarantee” to REMKO GmbH &

Co. KG at the time when the units

are purchased and commissioned.

The units are tested several times

to verify their correct function.

However, if malfunctions should

arise that cannot be remedied by

the operator with the assistance of

the troubleshooting section, please

contact your specialist dealer or

contractual partner.

Environmental protection and recycling

Disposal of packaging

When disposing of packaging

material, please consider our

environment.

Our units are carefully packed

and delivered in stable transport

packaging and, if applicable, on

a wooden pallet.

The packaging materials are

environmentally-friendly and can

be recycled.

By recycling packaging materials,

you make a valuable contribution

to the reduction of waste and

conservation of raw materials.

Therefore, only dispose of

packaging material at appropriate

collection points.

CAUTION

Copyright

The redistribution, even

in part, or the use of

this documentation for

purposes other than intended

is strictly prohibited without

the written authorisation of

REMKO GmbH & Co. KG

.

NOTE

Setting and maintenance work

may only be carried out by

authorised and qualified

technicians.

Important information

concerning recycling

The units are operated with

environmentally-friendly and

ozone-neutral R407C refrigerant.

The mixture of refrigerant and oil

within the unit must be disposed

of properly in accordance with

the statutory or locally-applicable

regulations.

Disposal of the old unit

The manufacturing process for

the units is subject to continuous

quality control.

Only high-grade materials are

processed, the majority of which

are recyclable.

You also contribute to

environmental protection by

ensuring that your old equipment

is only disposed of in an

environment friendly manner.

Therefore, only bring the old

unit to an authorised recycling

business or to an appropriate

collection point

.

24

Exploded view of the unit

2

3

4

1

8

22

21

5

6

7

9

10

11

12

13

14

15

20

19

18

17

16

25

REMKO SLN Series

Spare parts list

No. Designation SLN 45 SLN 65 SLN 85

1 Wall-mounted bracket

2 Wall spacer

3 Cable gland

4 Series terminals on DIN rail

5 Control board

6 Holder for control board with operator panel

7 Condenser fan

8 Compressor capacitor

9 Spatter guard

10 Compressor

11 Compressor accessories

12 Solenoid valve

13 Dry filter

14 Copper piping set

15 Condensate tray

16 Housing cover

17 Fan module

18 Fan

19 Evaporator

20 Condenser

21 Temperature valve

22 Compressor insulation.

- Air circulation intake filter (duct)

EDP no. on request

26

When ordering replacement parts, please always state the EDP no. and unit number (see name plate)!

RS-485 interface

The RS-485 interface uses the Modbus RTU protocol as a slave unit. The unit does not have an address.

Settings: 115200, N, 8, 1. It accepts queries for any address.

Code functions

0x06 Present single register

0x10 Present multiple register

0x03 Read holding register

Register Byte

2 Comp_state 0 1 0

2

3 Fan_state 0 1 0

4 Sole_state 0 1 0

3

5 ExFan_state 0 1 0

6 Heat1_state 0 1 0

4

7 Heat2_state 0 1 0

8 Alarm1_state 0 1 0

5

9 Alarm2_state 0 1 0

10

6

11

Database

parameters

Evap_temp1

(decimal)

Evap_temp1

(fraction)

Min Max Hr. Description

Compressor status:

0 – Compressor stopped 1 – Compressor running

Fan status:

0 – Fan stopped 1 – Fan running

Solenoid valve:

0 – closed

1 – open

Extractor fan status:

0 – Fan stopped

1 – Fan running

Status HEAT 1:

0 – HEAT 1 off

1 – HEAT 1 on

Status HEAT 2:

0 – HEAT 2 off

1 – HEAT 2 on

Output alarm 1:

0 – Alarm output off

1 – Alarm output on

Output alarm 2:

0 – Alarm output off

1 – Alarm output on

-40 100 0

-40 100 0

Temperature of evaporator 1:

Decimal: Can be used as an integer value for

temperature.

Fraction: Can be converted to a decimal value.

To obtain the total value, use the equation for

floating-point numbers: “Value = decimal +

(fraction/256)”.

12

7

13

Evap_temp2

(decimal)

Evap_temp2

(fraction)

-40 100 0

-40 100 0

Temperature of evaporator 2:

Use as described above.

27

REMKO SLN Series

Register Byte

14

8

15

16

9

17

18

10

19

20

11

21

Database

parameters

Cond_temp1

(decimal)

Cond_temp1

(fraction)

Aux_temp

(fraction)

Aux_temp

(fraction)

Amb_temp

(decimal)

Amb_temp

(fraction)

Amb_hum

(high byte)

Amb_hum

(low byte)

Min Max Hr. Description

-40 100 0

-40 100 0

-40 100 0

-40 100 0

-40 100 0

-40 100 0

0 100 0

Condenser temperature:

Use as described above.

Auxiliary probe temperature:

Use as described above.

Ambient air temperature:

Use as described above.

Ambient air humidity:

High byte is insignificant and always contains

zero. Only low byte can be used.

12

13

16

17

18

19

22 RH_set 40 95 40 Humidity setpoint.

23 RH_Fan 40 95 40 Humidity setpoint for extractor fan start.

24

25

30 Fail_start 0 1 0 Status of Fail_start mode.

31 SB_mode 0 1 0 Standby mode status.

32 DEH_mode 0 1 0 Dehumidification status.

33 Ice_mode 0 1 0 Defrosting mode.

34 LP_mode 0 1 0 LP fault mode status.

35 Sens_mode 0 1 0 Sensor fault mode status.

36 HP_mode 0

37 Amb_mode 0 1 0 Ambient fault mode status.

Temp_set

(decimal)

Temp_set

(fraction)

0 36 0

1 0 HP fault mode status.

Temperature setpoint:

Used in the same way as Evap_temp1.

28

20

38

39

AmbT_

mode

AmbRH_

mode

0 1 0 Ambient temperature fault mode status.

0 1 0 Ambient humidity fault mode status.

Register Byte

Database

parameters

Min Max Hr. Description

21

22

23

41

42

40

41

42

43

44

45

number (high)

number (low)

Software version

(main version)

Software version

(minor version)

HP alarm temp.

HP alarm temp.

80

Fan_function 0 1 0 Activate fan function in standby mode.

81

82

Time_wait_fan 60 7200 3600

83

SW build

SW build

(decimal)

(fraction)

0

65535 x Software build number.

0

0 255 x Main version number of the software.

0 255 x Minor version number of the software.

HP faults occur when Cond_temp1 is greater than

0 99 60

this value.

Used in the same way as Evap_temp1.

Waiting time until fan starts up in standby mode,

if activated (seconds).

43

44

45

84

Time_run_fan 15 600 60

85

Fan operating time in standby mode, if activated

(seconds).

86 RH_Fen 0 1 0 Activate/deactivate extractor fan function.

87 Service_ena 0 1 0 Activate/deactivate maintenance interval function.

88

Service_int 0 99 0 Maintenance interval value in weeks.

89

29

REMKO SLN Series

USB interface

The USB interface is used for transferring data logs from the unit to a USB stick.

The unit data is saved every three hours and stored in the internal memory. Switching the status to fault mode

also triggers the storage of data.

If the memory is completely full, the oldest logs are overwritten by the newest logs.

When a USB stick is inserted into the USB interface, all of the logs that have been recorded are saved in the CSV

file “data_log.csv”. The data is the internal memory is not deleted as a result of this process and can therefore

be transferred to several USB sticks.

The data log is saved in the form of the following parameters:

Database parameters Size (bits) Output text CSV column

Work_time 32 <dd:mm:hh:ss> Time stamp

Amb_temp 8 <Value> T_amb

Amb_int_temp 8 <Value> T_amb_int

Amb_ext_temp 8 <Value> T_amb_ext

Aux_temp 8 <Value> T_aux

Cond_temp1 8 <Value> T_cond

Evap_temp1 8 <Value> T_evap1

Evap_temp2 8 <Value> T_evap2

Temp_set 8 <Value> T_set

Amb_hum 8 <Value> RH_amb

Amb_int_hum 8 <Value> RH_amb_int

Amb_ext_hum 8 <Value> RH_amb_ext

RH_set 8 <Value> RH_set

RH_Fan 8 <Value> ExtFanSet

Evap_temp_err 1 EVAP Error

Cond_temp_err 1 COND Error

Aux_temp_err 1 AUX Error

Amb_int_err 1 AMB_INT Error

Amb_ext_err 1 AMB_EXT Error

SB_mode 1 SB Mode

Startup_mode 1 STARTUP Mode

DEH_mode 1 DEH Mode

Ice_mode 1 ICE Mode

LP_mode 1 LP Mode

HP_mode 1 HP Mode

Sens_mode 1 SENS Mode

AmbT_mode 1 AMBT Mode

AmbRH_mode 1 AMBRH Mode

Service_ena 1 ENABLED Mode

30

Maintenance protocol

Unit type: .................................. Unit number: ...................................

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Unit cleaned - outside -

Unit cleaned - inside -

Condenser cleaned

Evaporator cleaned

Fan function checked

Unit checked for damage

Safety devices checked

All fastening screws checked

Electrical safety check

Test run

Comments: ..........................................................................................................................................................

✍

.............................................................................................................................................................................

.............................................................................................................................................................................

.............................................................................................................................................................................

1. Date: ..............

..............................

Signature

6. Date: ..............

..............................

Signature

11. Date: ............

..............................

Signature

16. Date: ............

..............................

Signature

2. Date: ..............

..............................

Signature

7. Date: ..............

..............................

Signature

12. Date: ............

..............................

Signature

17. Date: ............

..............................

Signature

3. Date: ..............

..............................

Signature

8. Date: ..............

..............................

Signature

13. Date: ............

..............................

Signature

18. Date: ............

..............................

Signature

4. Date: ..............

..............................

Signature

9. Date: ..............

..............................

Signature

14. Date: ............

..............................

Signature

19. Date: ............

..............................

Signature

5. Date: ..............

..............................

Signature

10. Date: ............

..............................

Signature

15. Date: ............

..............................

Signature

20. Date: ............

..............................

Signature

Unit to be maintained only by authorised specialists in accordance with the statutory regulations.

31

REMKO SLN Series

Technical data

Series SLN 45 SLN 65 SLN 85

Daily dehumidification capacity at 30 °C and 80 % RH Litres/day 47 78 104

Daily dehumidification capacity at 30 °C and 60% RH Litres/day 35.5 56.2 78.8

Operational temperature range °C 10 to 36

Usable humidity range

Air volume m

% RH 40 to 100

3

/h 400 680 900

Power supply V/Hz 230/1~/50

Max. power consumption kW 0.9 1.5 1.8

Max. rated current consumption A 3.8 6.6 8

Max. switching voltage from RUN and FAIL contact V 50 50 50

Max. switching current from RUN and FAIL contact A 0.5 0.5 0.5

HEAT contact voltage V 12 12 12

Maximum current limit of a HEAT contact mA 60 60 60

Refrigerant

1)

R407C

Refrigerant quantity kg 0.7 0.9 1.2

Sound pressure level L

pA

1m

Depth / Width / Height mm

dB (A) 43 44 47

294/998/700 294/1148/700 294/1483/700

2)

Weight kg 57 66 77

IP enclosure class X4 X4 X4

EDP no. 616455 616655 616855

1) Contains greenhouse gas according to Kyoto protocol 2) Noise level measurement DIN 45635 - 13 - KL 3 carried out at duct openings

Capacity diagram SLN 45

40

35

30

25

20

Room temperature [°C]

15

B

A

10

5

0

0 0,5 1 1,5 2 2,5

32

C

Dehumidification capacity [l/h]

40% r.F.

A

60% r.F.

B

80% r.F.

C

Capacity diagram SLN 65

40

35

40% r.F.

A

60% r.F.

B

30

25

20

Room temperature [°C]

15

B

A

10

5

0

0 0,5 1 1,5 2 2,5 3 3,5 4

C

Dehumidification capacity [l/h]

80% r.F.

C

Capacity diagram SLN 85

40

35

30

25

Room temperature [°C]

20

15

B

A

10

5

0

0 1 2 3 4 5

C

Dehumidification capacity [l/h]

40% r.F.

A

60% r.F.

B

80% r.F.

C

Notes

REMKO INTERNATIONAL

... and also right in your neighbourhood!

Take advantage of our experience and advice

REMKO GmbH & Co. KG

Air conditioning and heating technology

Im Seelenkamp 12 D-32791 Lage

Telephone +49 5232 606-0

Fax +49 5232 606-260

E-mail info@remko.de

Internet www.remko.de

Consulting

Thanks to intensive training,

our consultants are always

completely up-to-date when

it comes to technical expertise.

This has given us the reputation

of being more than just

an excellent, reliable supplier:

REMKO, a partner who helps

to solve problems.

Sales

REMKO offers not just a well

established sales network both

nationally and internationally, but

also has exceptionally highly-

qualified sales specialists.

REMKO employees in the field

are more than just sales

people: above all, they must

be advisers to our customers

in air conditioning and heating

technology.

Customer service

Our units operate precisely and

reliably. However, in the event

of a malfunction REMKO

customer service is quickly

on the scene. Our extensive

network of experienced dealers

guarantees quick and reliable

service.

We reserve the right to make technical changes and provide no warranty as to the accuracy of this data!

Loading...

Loading...