REMKO ATY

ATY 261 DC, ATY 351 DC

Inverter wall - room air conditioner in split - design

Operation · Technology · Spare parts

Edition GB – V08

Contents

Safety notes

Environmental protection and recycling

Warranty

Transport and packaging

Equipment description

Operation

Shutdown

Care and maintenance

Troubleshooting and customer service

Control and resistance

Installation instructions for qualified personnel

Installation

Monitoring for leaks

4

4

4

5

5

6-14

15

15-16

17-18

19

20-23

23-25

25

Condensate drain

Electrical connection

Electrical connection diagram

Electrical circuit diagram

Before commissioning

Add refrigerant

Commissioning

Unit dimensions

Technical data

Exploded view

Spare parts list

Declaration of conformity

Read these operating instructions carefully before

commissioning / using the device!

26

26-27

27

28

28

28

29

30

31

32-33

32-33

34

Made by REMKO

These instructions are an integral part of the system and must always

be kept near or on the device .

Subject to modifications; No liability accepted for errors or misprints!

3

REMKO ATY

Safety notes

Carefully read this manual before

putting commissioning the

equipment. It provides useful

tips and information as well

as hazard warnings to prevent

injury or material damage .

Failure to follow the directions

in this manual can result in

endangerment to persons, the

environment and the equipment

itself and will void any claims for

liability.

■

Keep this manual and the

refrigerant datasheet near the

unit.

■ The unit may only be set up and

installed by qualified personnel.

■ The setup, connection and

operation of the unit and

its components must be in

accordance with the operating

conditions stipulated in this

manual and comply with all

applicable local regulations.

■ Mobile units must be set up

securely on suitable surfaces

and in an upright position.

Stationary units must be

permanently installed for

operation.

■ Modification of equipment

and components supplied by

REMKO is not permitted and

can cause malfunctions.

■ Equipment and components

may not be operated in areas

where there is an increased

risk of damage. Observe the

minimum clearances.

■ The electrical voltage supply

is to be adapted to the

requirements of the equipment.

■ The operational safety

of equipment and components

is only assured if they are used

as intended and fully assembled.

Safety devices may not be

modified or bypassed.

■ Do not operate equipment

or components with obvious

defects or signs of damage.

■ All housing parts and openings,

e.g. air inlets and outlets, must

be free of foreign objects, fluids

or gases.

■ The equipment and components

must be kept an adequate

distance from flammable,

explosive, combustible,

aggressive and dirty areas

or atmospheres.

■ Touching equipment parts can

result in burns or injury.

■ Installation, repair and

maintenance work may only

be carried out by authorised

specialists. Visual inspections

and cleaning can be performed

by the operator as long as the

equipment is not under voltage.

■ Take appropriate hazard

prevention measures when

performing installation, repair

or maintenance work or

cleaning the equipment.

■ The equipment or components

are not to be exposed to any

mechanical stresses, extreme

levels of humidity or direct

sunlight.

Environmental

protection and

recycling

Disposal of packaging

All products are packed for

transport in environmentally

friendly materials. Make a valuable

contribution to reducing waste

and sustaining raw materials. Only

dispose of packaging at approved

collection points.

Disposal of equipment

and components

Only recyclable materials are used

in the manufacture of the devices

and components,

Help protect the environment

by ensuring that the devices

or components (for example

batteries) are not disposed

in household waste, but

only in accordance with

local regulations and in

an environmentally safe manner,

e.g. using certified firms and

recycling specialists or at collection

points.

Warranty

In order to make warranty claims,

it s essential that the ordering

party or their representative

complete and return the "certificate

of warranty" and "commissioning

report" to REMKO GmbH &

Co. KG at the time when the

equipment was purchased and

commissioned. The warranty

conditions are detailed in the

"General terms and conditions".

Only the contractual parties can

strike special agreements beyond

these conditions. In this case, first

contact the contractual partner.

4

Transport and

Packaging

The equipment is shipped in sturdy

transport packaging. Immediately

check the equipment on delivery

and make note of any damage

or missing parts on the delivery

note and inform the forwarding

agent and your contractual partner.

No warranty can be assumed

for later claims.

Equipment description

The ATY 261-351 DC room air

conditioning units have a REMKO

ATY...AT outdoor component as

well as an ATY...IT indoor unit.

When in cooling mode,

the outdoor component serves

to release the heat extracted

by the indoor unit from the

room being cooled. In heating

operation, the heat absorbed

by the outdoor component

can be discharged through

the indoor unit into the room

being heated. In both operating

modes, the performance of the

compressor precisely adjusts itself

to the demand, thereby regulating

the nominal temperature with

minimal temperature variations.

This "inverter-technology"

results in energy savings over

conventional split systems and

also reduces noise emissions

to a particularly low level. The

outdoor component can be

installed outdoors or indoors.

The latter requires the fulfilment

of certain conditions. The indoor

unit is designed to be mounted

high up on indoor walls. Operation

takes place using an infrared

remote control.

The outdoor component consists

of a refrigerant circuit with

compressor, fin condenser,

condenser fan, reverse flow valve

and throttle element. The outdoor

component is controlled via the

controller of the indoor unit.

The indoor unit consists of a fin

vaporiser, vaporiser fan, regulation

system and condensation pan.

Floor consoles, wall consoles,

refrigerant pipes and condensation

pumps are available as accessories.

Schematic of outdoor refrigerant circuit

Reverse flow valve

Condenser fan

Condenser Filter dryer Flow regulator

Refrigerant circuit diagram for the indoor unit

Vaporiser

System configuration

Indoor area

Indoor unit

Electr. power supply line Control line

Condensation line

Outdoor area

Outdoor component

M

M

Capillary tube

Vaporiser fan

Injection line

Condensation line

Compressor

Connection valve

Suction line

Connection valve

Injection line

Connection to suction pipe

Connection to injection line

Suction line

Stop valve

Condenser fan

The connection between the indoor unit and the outdoor component is

made by way of the refrigerant lines.

5

REMKO ATY

Operation

The indoor unit is easily operated using the standard infrared remote control. The indoor unit beeps to

acknowledge the correct transmission of data. If it is not possible to program the indoor unit using the remote

control, it can also be manually operated.

Manual operation

The indoor unit can also be started

manually. To do so, press the

button on the right side of the unit

to activate the automatic mode.

In manual operation, the following

settings apply:

Automatic operation:

Above 21°C = cooling operation,

set temperature 24°C

under 21°C = heater operation,

set temperature 24°C

Fan speed AUTO

Press the button on the infra-red

remote control to interrupt manual

operation.

Display on indoor unit

The display illuminates according to the settings. In operation, the display

lights up, the selected mode and the nominal temperature are shown.

Display on indoor unit

Power

Unit turned on

Ion generator

switched on

Air circulation

mode set

SET

TURBO

C

Timer operation

Display

Display of

coded error

messages, room

and nominal

temperature

Fan speed

Stage 1, 2 and 3 and

Auto (blinking)

Infrared remote control

The infrared remote control sends

the programmed settings over

a distance of up to 6 m to the

receiver of the indoor unit. Data

will only be received correctly

if the remote control is pointed

at the receiver and no objects

obstruct the transmission path.

First insert the batteries supplied

on delivery (2 x type AAA) into

the remote control. To do so,

pull off the flap of the battery

compartment and insert the

batteries according to their

polarization (see marks).

1 max. distance 6 m

max. 6 m

NOTE

Faults are indicated

by codes (see chapter

Troubleshooting and

customer service).

NOTE

Replace discharged batteries

immediately with a new set in

order to avoid risk of leakage.

It is recommended that the

batteries are removed if the

equipment is shut down for

longer periods.

6

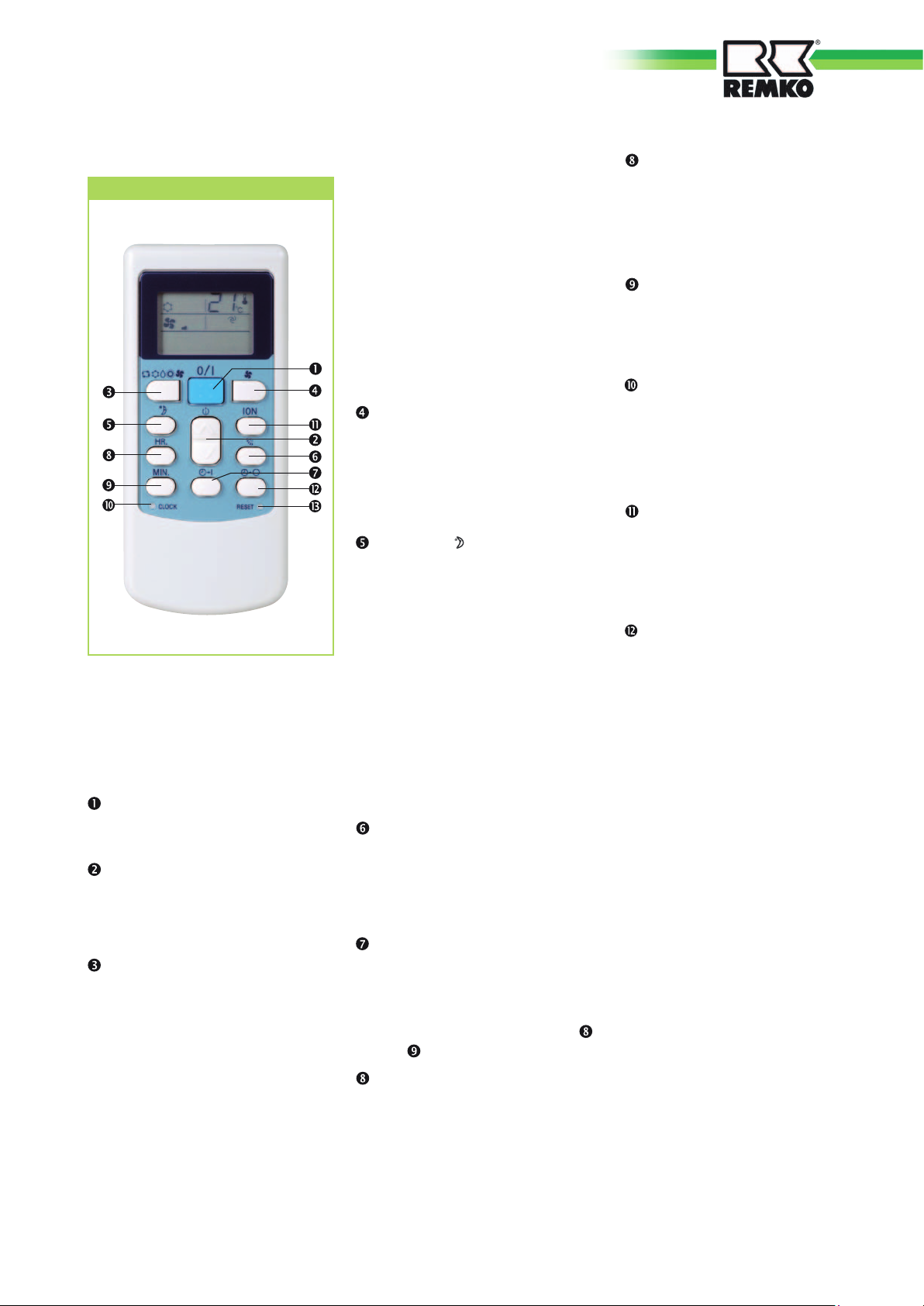

Buttons on the remote control

3. Heating mode In this mode,

the warm air in the room

is warmed to the desired

temperature.

4

. Air circulation mode

In this mode, the air in the room

is recirculated.

"MIN."button

This button increases the

minute value for time and timer

programming.

Buttons on the remote control

"ON/OFF" Button

Press this button

to start the unit.

" "button

This button is used to set

the desired temperature

between 18°C and 30°C.

"MODE"button

Use this button to select the

operating mode. The indoor unit

has 5 modes:

1. Automatic mode

In this mode, the unit works in

cooling or in heating mode.

2. Cooling mode

In this mode the cold air in the

room is cooled to the desired

temperature.

5

. Dehumidification mode

In this mode the room is mainly

dehumidified and the adjusted

temperature is maintained.

"FAN" button

Press this button to set the

desired fan speed. 4 speeds

are available: Automatic, high,

medium and low fan speed.

"(SLEEP)" button

After pressing this button,

the Sleep mode is activated

and in cooling operation, the

nominal temperature increases

automatically by 1 °C within

an hour, in heating operation,

the nominal temperature is

lowered by 1 °C within an

hour. After the second hour,

the temperature is increased/

lowered by 2°C. After 6 hours,

the function is switched off.

"(SWING)"button

This button directly activates

the oscillating function of the

fins for better air distribution

in the room.

"TIMER ON"button

This button is used to

activate the automatic on and/

or off time of the unit and

is programmed with buttons

and at intervals of 10

minutes.

"HR"button

This button increases the

hour value for time and timer

programming.

"CLOCK"button(recessed)

By pressing this button, the

time setting is activated.

"ION" button

By pressing this button, the ion

generator and turbo mode are

activated.

"TIMER OFF" button

This button serves to program

the automatic switch-off time

for the unit within the next 24

hours.

"RESET" button

(recessed)

This button resets the remote

control to its factory default

configuration.

7

REMKO ATY

Button functions

A symbol is shown on the display to indicate that the settings are being transferred.

ON/OFF Button

/ Button

By pressing the ON / OFF button, you can activate or deactivate your

unit. The programmed settings and adjustment values before the unit

was turned off will appear on the display.

ON/OFF ON/OFF

The remote control has its own temperature display. If buttons / are

pressed alternately, the display changes to . The button can be used

to reduce the desired nominal temperature, the button can be used

to increase it. This adjustment is only possible in coolingand heating

mode. In automatic mode, the fixed temperature of 24°C is preset.

The current setting is shown next to the temperature display.

In dehumidification mode, no temperature adjustment can be made.

MODE Button

Cooling /

mode

heating

Use the MODE button to select between the individual operating modes.

5 modes are available:

1. Automatic automatic selection of cooling or heating operation

2. Cooling predominantly summer operating mode

3. Dehumidification Summer or winter operating mode

4. Heating predominantly winter operating mode

5. Air circulation only for circulation of air

Automatic Cooling

MODE

Dehumidifying

MODE MODE MODE MODE

Heating

Air circulation

8

AUTOMATIC MODE

In automatic mode, the controller autonomously selects between heating

and cooling operation when the unit is first turned on. A nominal

temperature of 24 °C is preset.

Cooling MODE

MODE

AUTOMATIC

In cooling mode, the air in the room is cooled down to the set nominal

temperature. The desired room temperature is set with the ▲/▼buttons

in 1 °C increments. If the room temperature is 1 °C above the selected

nominal temperature, the indoor unit starts to cool the air in the room.

The inverter controller checks the difference between the adjusted

nominal temperature and the actual room temperature. If there is a large

difference, the cooling output is very high. If the difference is smaller,

a lower cooling output is produced. This serves to maintain the air

discharge temperature and the room temperature.

If the adjusted room temperature is lower than approx. 2 °C, then the

control system turns the cooling function off. To protect the compressor,

the controller only turns the cooling on again after a waiting period

of 3 minutes.

MODE

COOLING OPERATION

Functional diagram

Nominal temperature

Nominal temperature -2°C

Compressor operation AT

Fan operation AT

Fan operation IT

Actual temperature

> 6 Min.

> 6 Min.> 3 Min.

30 sec. 30 sec.

Start cooling mode

Cooling mode

Stop cooling mode

Operation

Stop

9

REMKO ATY

Heating MODE

In the heating mode, you can heat the room in spring or fall. The desired

room temperature is set with buttons / in 1 °C increments. If the

room temperature is 1 °C below the selected nominal temperature, then

the indoor unit starts to warm up the air in the room. If the adjusted

room temperature is exceeded by approx. 0.5°C, then the controller

turns the heater function off. To protect the compressor, the controller

will not switch the heating on again until

it has waited for 3 minutes.

MODE MODE

HEATING

OPERATION

Functional diagram

Nominal temperature +5

Nominal temperature +2

Compressor operation AT

Fan operation AT

Fan operation IT

Reverse flow valve

Actual temperature

°C

°C

> 6 Min.

> 6 Min.> 3 Min.

30 sec. 30 sec.

30 sec. 30 sec.

Stop heating operation

Heating mode

Start heating mode

Operation

Stop

Air circulation MODE

During the defrosting cycle, the indoor unit vaporiser fan and

the outdoor unit condenser fan are switched off.

After the cycle is concluded, the fans are switched to their previous

settings.

Reverse flow valve

Compressor operation AT

Fan operation AT

Fan operation IT

Defrost period

30 sec.

< 7 Min.

15 sec.

30 sec.

60 sec.

30 sec.

3 Min.

Operation

Stop

In the air circulation mode, the air in the room is only circulated.

The room temperature cannot be changed in this mode. The cooling

or heating operation is not activated. The fan has four speeds. Neither

the ion generator nor turbo mode can be selected in this mode.

MODE

AIR CIRCULATION

10

Dehumidification MODE

In dehumidification mode, the room temperature cannot be set. Due

to the low temperature of the refrigerant, the dew point of the air at the

condenser is undercut. The excess moisture in the air is condensed on the

condenser, the room is dehumidified. The fan has four speeds. Neither

the ion generator nor turbo mode can be selected in this mode.

FAN Button

MODE

DEHUMIFICATION

MODE

Functional diagram

Nominal temperature

Nominal temperature -2°C

Compressor operation AT

Fan operation AT

Fan operation IT

Actual temperature

Low fan speed

Start

Dehumidifying mode

Dehumidifying mode

Stop

Dehumidifying mode

30 sec.

Operation

Stop

The fan speed can be adjusted with this button. A selection can be made

between low, medium, high and automatic fan speed.

FANFANFAN FAN

CLOCK Button (recessed)

NOTE

The speed change is achieved with a phase control. When switching

between individual speeds, virtually no audible difference is

noticeable.

The time can be programmed by pressing the CLOCK button. The time

blinks in the display and the current time can be set using the HR. and

MIN. button. Programming is completed by pressing the CLOCK button,

the display will stop blinking.

CLOCK

HR./MIN.

CLOCK

11

REMKO ATY

SWING Button (covered)

SLEEP Button

The oscillating function of the air discharge fins can be adjusted with this

butto. This makes it possible to switch directly between a fixed position

and the oscillating function. The air distribution in the room is improved

using the swing function.

This button activates a programming function, which causes the

nominal temperature in cooling mode to increase after one hour by 1°C

and after two hours by 2 °C. In heating mode, the nominal temperature

is decreased after one hour by 1°C and after 2 hours by 2°C . In this

function, the fan is in automatic mode.

SLEEP

TIMER Button

Functional diagram

1st

hour

2nd

Nominal temperature +2

Nominal temperature +1°C

unit operation

Nominal temperature -1

Nominal temperature -2

°C

°C

°C

hour

1st hour 2nd hour 6th hour

6th

hour

Opera

Stop

tion

The turn on and turn off time can be programmed with this button.

By pressing the TIMER button several times, the turn on, the turn

off and the combined turn on and off timer is activated. The turn on

or turn off time blinks. The timer display on the indoor unit illuminates.

The desired turn on or turn off time is set by pressing the buttons HR.

and MIN. After completed adjustment, the timer symbol will continue

to blink for approximately 15 seconds. When the programmed time

has been reached, the unit automatically switches on or off. If the unit

is automatically switched on, the mode, temperature and fan speed for

the last setting are activated. The prior deletion of the on and off time

is made by pressing the corresponding timer button. The timer display

on the indoor unit goes out.

12

PROGRAMMINGTIMER ON

The controller turns the unit on after programming. During operation,

all settings can be seen on the display. Out of operation, only the timer

settings are visible.

PROGRAMMING TIMER OFF

PROGRAMMING TIMER ON/OFF

Timer on

HR/MIN

30 sec.

The controller turns the unit off after programming. During operation,

all settings can be seen on the display. Out of operation, only the timer

settings are visible.

Timer off HR/MIN 30 sec.

The controller turns the unit on or off after programming. In operation,

all settings are visible on the display. Out of operation, only the timer

settings are visible.

Unit On Unit Off

Example:

The controller turns on at 10:20.

The unit is in operation until 05:00.

13

REMKO ATY

INDOOR UNIT DISPLAY

SET

TURBO

C

By pressing the "ION" button several times, the "ION" function,

the "Turbo" function, or both can be set at the same time.

Ion function

The unit is equipped with an ion generator to generate negative ions.

A high concentration of negative ions is found for example in mountains,

near waterfalls and in forests and people perceive this inhaled air as

"clean". Only a slight ion concentration is found in interior rooms. In this

case, the ion generator can enhance the ions to the oxygen molecules

of the surrounding air and can increase the feeling of well-being. In

addition, atmospheric particles and dust particles in the air are bound,

naturally cleaning the air. Any dust can settle on smooth surfaced due

to the ionization and can be removed manually. Weekly cleaning of the

housing and the filter should be observed when using the ionization

feature. The function is available in all operating modes.

Turbo function

With this button, the air volume flow in cooling and heating operation

is increased for 30 minutes. This makes it possible to cool off or warm

up a room quicker. The ventilation and dehumidification mode cannot

be obtained, the system changes to automatic mode.

After 30 minutes, the controller returns to the last programmed settings.

SET

TURBO

C

14

Shutdown

Care and maintenance

Temporary

Shutdown

1. Allow the indoor unit to run for 2

to 3 hours in air circulation

mode or in cooling mode at the

maximum temperature setting

in order to remove any residual

moisture from the unit.

2. Shut down the unit using the

remote control.

3. Switch off the voltage supply

to the unit.

4. Check the unit for visible

signs of damage and clean as

described in the chapter "Care

and maintenance".

Permanent

Shutdown

Ensure that equipment and

components are disposed

of in accordance with local

regulations, e.g. using certified

firms and recycling specialists or

at collection points.

REMKO GmbH & Co. KG or your

contractual partner will be pleased

to provide a list of certified firms

near you.

Regular care and maintenance

serves to ensure trouble-free

operation and long service life

of the unit.

CAUTION

Prior to performing any work,

ensure the equipment is

disconnected from the voltage

supply and secured to prevent

accidental switch-on!

Care

■

Ensure the indoor unit and

outdoor component are

protected against dirt, mould

and other deposits.

■

Clean the equipment using

a damp cloth. Do not use any

caustic, abrasive or solventbased cleaning products. Do

not use a jet of water.

■

Before an extended shut down

period, clean the fins on the

outdoor unit and cover the

outdoor unit with plastic to

avoid infiltration of dirt into

the unit.

Maintenance

■

We recommend concluding

a maintenance contract

with annual service from an

appropriate specialty company.

NOTE

This ensures the operational

reliability of your system!

NOTE

Statutory regulations require

an annual leak test for the

refrigerant circuit in relation to

the refrigerant filling capacity.

Inspection and documentation

is to be carried out by

specialty technicians.

Cleaning the housing

of the indoor unit

1. Disconnect the supply voltage

to the equipment.

2. Clean the unit with a soft damp

cloth.

3.

Switch the supply voltage back on.

CAUTION

Care and maintenance work

may only be carried out if the

unit is disconnected.

Air filter for indoor unit

Clean the air filter at intervals of

no more than 2 weeks. Reduce this

interval in case of heavily soiled air.

Cleaning the filter on

the indoor unit

The indoor unit is equipped with

a filter with antibacterial coating.

The filter cleans the air of dust and

thereby reduces the distribution of

bacteria.

15

REMKO ATY

1. Switch the indoor unit via the

remote control to air circulation

(the front cover of the air inlet

must be open!) (Figure 2).

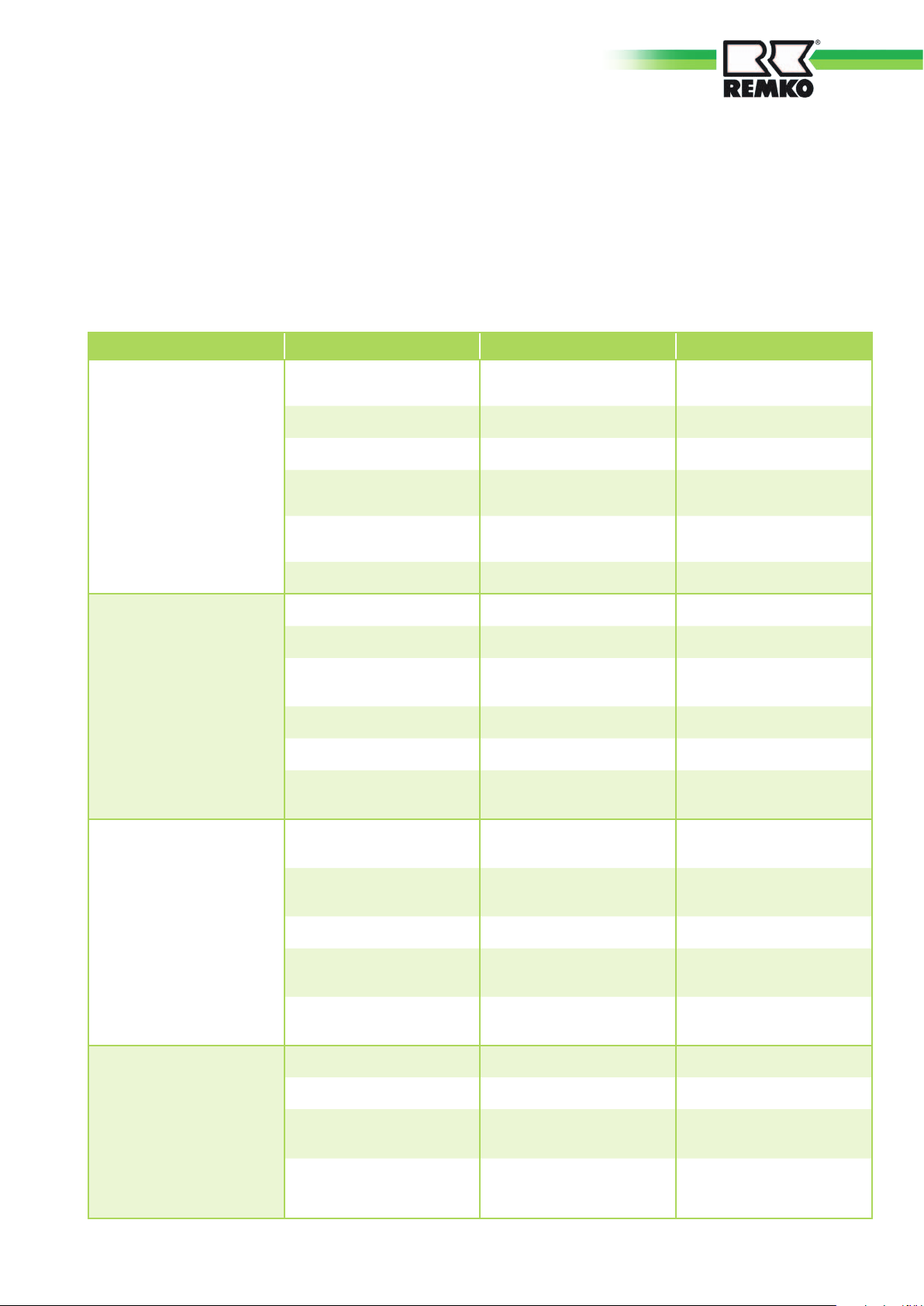

Type of task

Checks/Maintenance/Inspections

2. Open the lower display cover

on the front side of the unit

by pressing both latches

and carefully fold the cover

downward and remove it from

the bracket (figure 3).

3. Push the clips on the filter up

and pull it out on the clips

(figure 4).

4. Clean the filter with a standard

vacuum cleaner. Turn the dirty

side upward (figure 5).

5. Carefully clean off any dirt in

lukewarm water and with mild

cleaner. Turn the dirty side

downwards (figure 6).

6. If water is used, let the filter dry

out air before replacing it in the

unit.

General

Measure voltage and current

Check function of compressor

Check fan function

Contamination of evaporator fins

Check refrigerant fill quantity

Check condensation drain

Test insulation

Check moving parts

Sealing test for refrigerant circuit

1) see note S.15

2 Open front cover

Commissioning

Monthly

Six-monthly

Yearly

• •

• •

• •

• •

• •

• •

• •

• •

• •

• •

Cleaning the condensation

pump (accessories)

An optional integrated or separate

condensation pump may be included

with the indoor unit, which pumps

out any accumulated condensation

into higher positioned drains.

Observe the care and maintenance

instructions given in the separate

operating instruction manual.

1)

7. Carefully insert the filter. Make

sure it is seated correctly.

8. Close the display cover as

described above but in reverse

order.

9. Set the desired operating mode.

4 Pull out the filter

5 Cleaning using a vacuum cleaner 3 Remove the display cover

6

Cleaning with lukewarm water

16

Troubleshooting and customer service

The equipment and components are manufactured using state-of-the-art production methods and tested several times

to verify their correct function. If malfunctions should occur, please check the functions as detailed in the list below. Please

inform your dealer if the unit is still not working correctly after all the functional checks have been performed!

Fault

Fault Possible cause Checks Remedial measures

The unit does not start

or switches itself off

continually.

The unit does not respond

to the remote control

Power failure, low voltage, main

fuse defective / main switch

turned off.

Power line damaged.

Waiting time after turn on too

short.

Operating temperature fallen

below / exceeded.

Power surge due to thunderstorm.

Problem of external condensation

pump.

Transmission distance too large /

receiving problem.

Remote control is defective.

Receiver and transmitter are

exposed to too much sun exposure.

Electromagnetic fields disrupt the

transmission.

Button of remote control stuck /

dual button control.

Are all other electrical installations

functioning correctly?

Are all other electrical installations

functioning correctly?

Have approx. 5 minutes

elapsed since the restart?

Are the fans in the indoor unit

and outdoor component working

correctly?

Have there been lightning strikes

in the area recently?

Did the pump shut down due to

a fault?

Does the indoor unit beep when

pressing a button?

Is the unit running in manual

mode?

Does it function correctly in the

shade?

Does it function after removing

potential fault sources?

Does the "Send” symbol appear

on the display?

Check voltage if necessary wait

until turned on again.

Repair by a certified service centre.

Schedule longer waiting periods.

Observe temperature ranges of

indoor unit and outdoor unit.

Switch off the mains breaker and

switch it back on. Inspection by

certified service centre.

Check or clean the pump, if

necessary.

Reduce the distance to less than

6 m and change location.

Replace remote control.

Shade the transmitter and receiver.

Signal is not transmitted when

interference sources are operational.

Release the button / press only

one button.

The unit is running with

reduced or without

cooling output.

Condensation discharge

on unit.

Batteries of remote control are

discharged.

Filter is dirty / air inlet / outlet

opening is blocked by debris.

Windows and doors open.

Heating/cooling loads increased.

No cooling operation is set.

Fins of the outdoor unit are

blocked by foreign matter.

Leaks in refrigerant circuit.

Drain pipe of collector reservoir

plugged / damaged.

External condensation pump or

floater defective.

Non-discharged condensation is in

the condensation line.

Condensation cannot be

discharged.

Have new batteries been inserted?

Is the display incomplete?

Have the filters been cleaned? Clean filters.

Have there been any

constructional / applicationrelated changes?

Is the cooling symbol activated

in the display?

Is the fan on the outdoor component

running outdoor component. Are the

evaporator fins clear?

Is frost formation visible on connections

of the outdoor unit?

Is unrestricted condensation discharge

ensured?

Is the collection tray full of water

and the pump not running?

Has the condensation pipe been

laid on a slope and is not blocked?

Are the condensation lines

unblocked and laid on a slope? Are

the condensation pump and float

switch functioning correctly?

Insert new batteries.

Close windows and doors / install

additional systems.

Correct the settings for the unit .

Check fan or winter regulation,

reduce air resistance.

Repair by certified service centre.

Cleaning of drain pipe and

collector reservoir.

Have pump replaced by certified

service centre.

Route the condensation line

downward or clean it.

The condensation line must have

a fall. If necessary, clean the pipe.

A faulty condensation pump and

float switch should be replaced.

17

REMKO ATY

Problem display by blinker code

LED in AT

No.

No.

Display

16

red

yellow

ER01 flashes - - -

ER02 flashes - - -

ER03 flashes - - -

ER04 flashes - - -

ER05 flashes - - -

ER06 flashes - - -

ER07 flashes - - -

ER08 flashes

ER09 flashes

ER10 flashes

ER11 flashes

ER12 flashes

ER13 flashes

ER14 flashes

ER15 flashes

ER16 flashes

ER18 flashes

ER19 flashes

ER20 flashes

O • •

• O •

O O •

O • O

• O O

× • •

• • ×

O • ×

× O •

× O O

× × ×

× × •

17

No.

Fault description Checks Remedial measures

18

green

Air circulation sensor on

indoor unit is defective /

triggered

Indoor unit power supply

defective

Frost protection sensor on

indoor unit faulty/tripped

Vaporiser fan motor speed

too low / defective

EEPROM indoor unit control

board error

Communication error

between IT and AT

Refrigerant fill quantity

incorrect

AT condenser sensor faulty /

tripped

Communication error

between IT and AT

Compressor speed too low

Over-current error

PFC error

Inverter-control board

communication error

Inverter board safety shut-off

Indoor unit outdoor air sensor

defective

Compressor temperature too

high

EEPROM Outdoor unit

control board error

Compressor start error

Outdoor unit system error

Check resistance (see p. 19) Replace defective sensor

Check power supply Repair power supply

Check resistance (see p. 19) Replace defective sensor

Check fan motor, fan blade Replace motor or blade

Check refrigerant pressure.

Check resistance (see p. 19) Replace defective sensor

Check wiring and connections

Check cable connections, pipe connections,

shut-off valves, compressor

Check voltage, cable connections,

refrigerant pressure, ambient conditions

Check cable connections, pipe connections,

shut-off valves, compressor

Check cable connections, pipe connections,

shut-off valves, compressor

Check cable connections, pipe connections,

shut-off valves, compressor

Check resistance (see p. 19) Replace defective sensor

Check condenser for dirt, check refrigerant

pressure Check fan

Check cable connections, pipe connections,

shut-off valves, compressor

HL

OT

OP

OD

OH

• × ×

O × •

× × O

× • O

× O ×

O × ×

Incorrect setting type for unit Contact specialist firm

Power supply fault

Ambient temperature too

high

Liquid temperature too high

Hot gas temperature too high

Inverter board overheat

• = Off O = On × = flashes

18

Check voltage, cable connections,

refrigerant pressure, ambient conditions

Switch unit off, switch unit back on when

ambient temperature is lower

Check condenser for dirt, check refrigerant

pressure Check fan

Check condenser for dirt, check refrigerant

pressure Check fan

Controller, safety controller and resistance

Hot gas sensor, IPM AT sensor

Temp.

0 160.73 kΩ

5 125.57 kΩ

10 98.78 kΩ

15 78.23 kΩ

20 62.35 kΩ

25 50.00 kΩ

30 40.33 kΩ

Resistance

AT condenser sensor, AT ambient temperature sensor

IT vaporiser sensor, IT circulation sensor

Temp.

0 27.42 kΩ

5 22.15kΩ

10 18.00 kΩ

15 14.72 kΩ

20 12.10 kΩ

25 10.00 kΩ

30 8.31 kΩ

Resistance

AT compressor

Temp.

Resistance

20 0.71 Ω

Measuring

point

U-V

V-W

U-W

Compressor control by via gas temperature Compressor control via vaporiser temperature

Hot gas tempera-

ture

< 87°C

93°C - 97°C no change to frequency

97°C - 110°C

> 110°C

Normal operating condition

decrease in frequency 1Hz/3sec.

Controller

control via IT

Switch off compressor

IT surface tempera-

ture

> 6°C

< 6°C no change to frequency

< 4°C decrease in frequency 1Hz/3sec.

< 1°C Switch off compressor

Cooling regulation

Normal operating condition

control via IT

Compressor control via ambient temperature

Ambient temperature

> 53°C Frequency 32Hz

47°C - 53°C Frequency 50 Hz

39°C - 47°C Frequency 70Hz.

15°C - 39°C

< 15°C Frequency 32Hz

Cooling mode regulation

Normal operating condition

control via IT

Compressor control via ambient temperature

Ambient temperature

> 23°C Frequency 32Hz

19°C - 23°C Frequency 50 Hz

12°C - 19°C Frequency 70Hz.

< 12°C

<-25°C or >+70°C Switch off compressor

Heating mode regulation

Normal operating condition

control via IT

Compressor control via vaporiser temperature

IT surface tempera-

ture

< 51°C

51°C - 55°C no change to frequency

55°C - 65°C decrease in frequency 1Hz/3sec.

> 65°C Switch off compressor

Heating regulation

Normal operating condition

control via IT

Compressor control via power consumption

Power consumption

> 6.1 A no change to frequency

6.2 - 6.7A decrease in frequency 1Hz/3sec.

6,7-7,5 Switch off compressor

Cooling / heating regulation

19

REMKO ATY

Installation instructions for qualified personnel

Important notes prior to

installation

NOTE

The assembly and installation

of the units and components

may only be carried out by

especially trained technicians.

■

Transport the unit in its original

packaging as close as possible

to the installation location.

You avoid transport damages

by doing so.

■

Check the contents of the

packaging for completeness

and check the unit for visible

transport damage. Report any

damage immediately to your

contractual partner and the

shipping company.

■

Lift the unit at the corners

and not by the refrigerant or

condensation connections.

■

The refrigerant pipes

(injection and suction line),

valves and connections must

be insulated against vapour

diffusion. If necessary, also

insulate the condensation pipe.

■

Select an installation location

which allows air to freely

flow through the inlet and

outlet. (See section "Minimum

clearances").

devices with intensive thermal

radiation. Installation near

sources of thermal radiation

reduces the output of the unit.

■

Only open the shut-off valves

of the refrigerant lines after

the installation is complete.

■

Before connecting the injection

line, remove the valve core

in the indoor unit connection

ports.

■

Seal off open refrigerant lines

with suitable caps or adhesive

strips to avoid infiltration of

moisture and never kink or

compress the refrigerant lines.

■

Avoid unnecessary bends.

In doing so, you minimise loss

of pressure in the refrigerant

lines and ensure clear return

flow of the compressor oil.

■

Take special precautions with

regard to the oil return if the

exterior component is located

above the indoor unit. (See

section "Oil return flow

measures").

■

If the basic length of the

refrigerant line exceeds

5 metres, add refrigerant.

The quantity of additional

refrigerant is provided in

the chapter "Add refrigerant".

■

Only use the union nuts for the

refrigerant pipes included in the

delivery, and remove them only

shortly before connecting the

refrigerant lines.

■

Make electrical connections

in accordance with the effective

DIN and VDE standards.

■

Always fasten electric cables

properly to the electrical

terminals. Otherwise a fire

could result.

■

Do not install the unit in

the immediate vicinity of

20

Wall openings

Selection of the installation location

Wind

■ A wall opening of at least

70 mm diameter and 10 mm

slope from the inside to the

outside must be made for each

indoor unit.

■ We recommend that the inside

of the opening is padded or

lined, e.g. using a PVC pipe,

to prevent the lines being

damaged.

■ After installation, the wall

opening should be closed off

with a suitable sealant. Do not

use materials containing cement

or lime!

Lines in the wall throughput

Control line

The indoor unit is designed for

horizontal wall installation in the

upper wall area (at least 1.75

m from the upper edge - floor).

However, it can also be used in the

upperwall area above doors.

The outdoor component is

designed for horizontal installation

on a base in outdoor areas. It

should be placed on level, flat and

firm surface. The unit should also

be secured to prevent toppling.

The outdoor unit can be set up

outside as well as inside a building.

For external installation, please

observe the following notes to

protect the unit from weather

conditions.

Rain

If the unit is being installed in

windy areas, ensure that the

warm outlet air discharges in the

main wind direction. If this is not

the case it may be necessary to

install a windbreak (provided by

the customer). Ensure that the

windbreak does not adversely

affect the air intake to the unit.

Windbreak

Wind

PVC tube

Suction line

Condensation line

Injection line

Installation material

The indoor unit is attached with

4 screws on the building side,

through the back wall of the unit.

The outdoor unit is attached with

4 screws via a wall bracket on

the wall or a floor bracket on the

ground.

NOTE

Install the outdoor unit

with appropriate anchors,

depending on the type of wall.

The unit should be at least 10 cm

off the ground when mounted on

the roof or ground. A pedestal is

available as an accessory.

Sun

The evaporator fins (condenser)

of the outdoor unit are the

heat discharge components in

cooling operation. Exposure to

direct sunlight further increases

the temperature of the fins and

so reduces the heat released by

the finned heat exchanger. The

outdoor component should be

installed on to the north side of

the building whenever possible.

If necessary, take measures

to provide sufficient shade

(responsibility of customer).

This could be a small roof.

However, the discharging warm air

flow may not be affected by the

measures.

Snow

The unit should be wall-mounted

in areas of heavy snowfall.

Installation should then be at least

20 cm above the expected level

of snow to prevent snow from

entering the outdoor component.

An optional wall bracket is

available as an accessory.

Minimum clearance to snow

Snow

20 cm

21

REMKO ATY

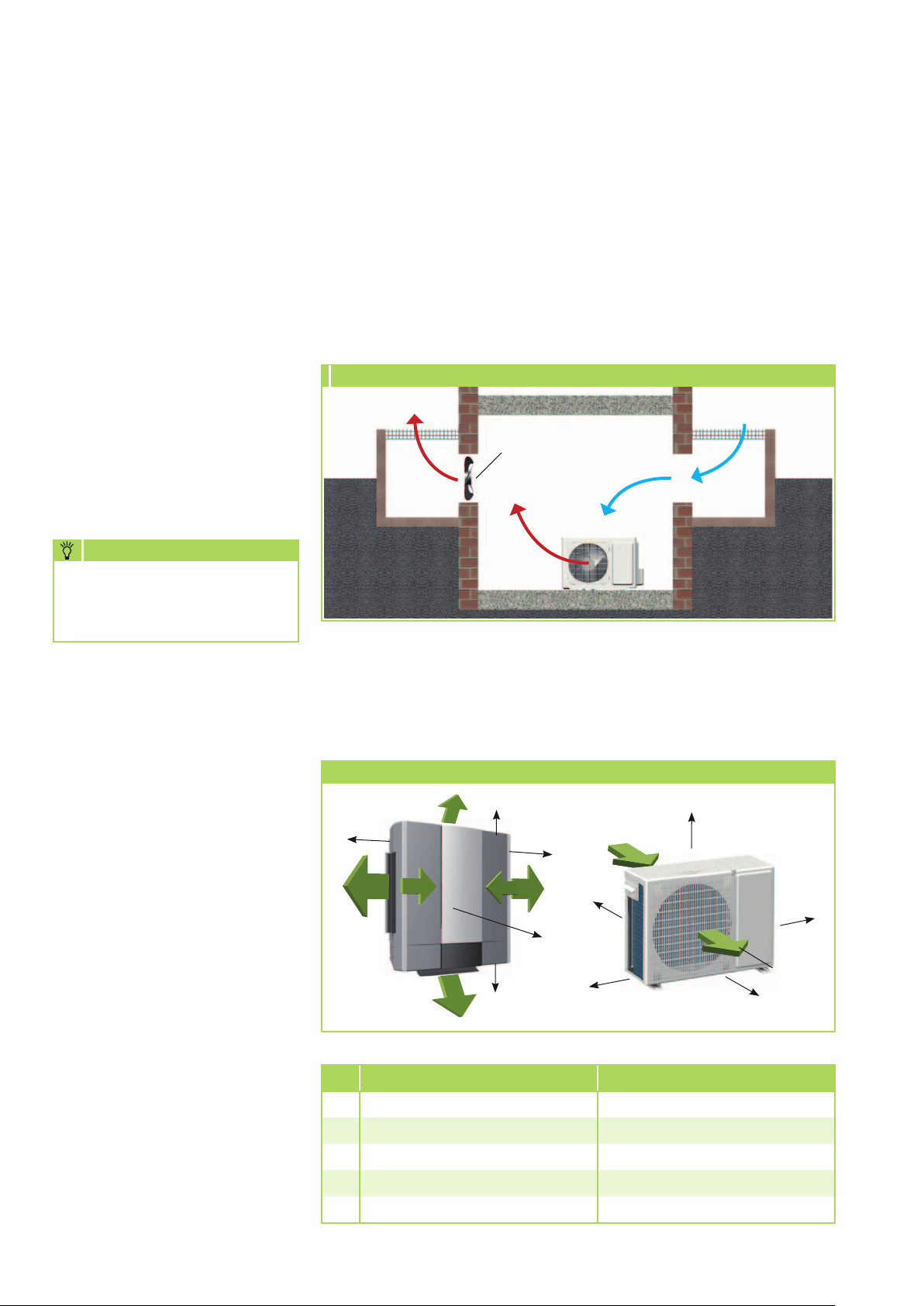

Installation inside buildings

■

Ensure that heat can dissipate

adequately when placing the

outdoor component in cellars,

attics, adjoining rooms or halls

(figure 7).

■

Install an additional fan with

a rated flow comparative to

that of the outdoor component

being installed in the room.

This is used in conjunction with

ventilation ducts to compensate

any pressure losses (figure 7)

NOTE

■

Ensure a continuous and

unobstructed air flow from

outside, preferably using

sufficiently large air intakes

placed opposite each other

(figure 7).

7 Installation inside buildings

Warm air

Additional

fan

Light

well

Warm air

■

Comply with any regulations

and conditions affecting the

structure of the building.

If necessary, fit acoustic

installation.

Outdoor component

Cold

Fresh air

Light

well

In heating mode, condensation

formation may occur due to

cold surfaces.

Minimum clearances

Observe the minimum clearances

to allow access for maintenance

and repair work and facilitate

optimum air distribution.

Minimum clearances

1000

300

1000

1000

1000

Air intake

D

A

E

C

Air

discharge

B

22

ATY 261 DC AT ATY 351 DC AT

A 100 mm 100 mm

B 700 mm 700 mm

C 400 mm 400 mm

D 100 mm 100 mm

E 300 mm 300 mm

Installation

Oil return measures

If the outdoor unit is installed at

a higher level than the indoor unit,

we recommend that suitable oil

return measures are taken. Usually

an oil pump bend is installed

for every 2.5 metres of height

difference.

Oil return measures

Outdoor component

Oil pump bend

in suction pipe to

outdoor component

1 x every 2.5 metres

of rise in the line

max. 5 m

NOTE

Installation may only be

performed by authorised

specialists.

Unit installation

When attaching the indoor unit,

pay attention to the lower, upper

and side area air discharge.

1. Use the dimensions of the

unit to mark the fixing points

on structural parts approved

to support the static load.

2. Open the display cover(figure 8)

and remove the two screws from

underneath the filter (figure 9).

8

Open display cover

9

Remove screws

Radius:

50 mm

Outdoor component

Connection variations

of indoor unit

Connection variations

1

2

1 Outlet on the wall, right

2 Outlet through the wall, right

3 Outlet through the wall, left

4 Outlet on the wall, left

View from the rear

3. Remove the front of the unit

by lifting the front in the lower

area from the body approx.

10 cm and folding it upward

(figure 10).

4. Pull the plugs of the front cover

from the circuit board (figure 11).

5. Remove the housing's break

out opening if necessary.

6. nstall the unit on the wall.

Ensure undistorted installation.

7. Connect the refrigerant

4

3

lines, electrical cables and

condensation line to the indoor

unit as described below.

8. Check that the unit is level.

9. Re-assemble the unit.

10

R

elease unit front

11

Remove the plug

Installation of the indoor unit

The wall bracket for the unit must

be attached with suitable screws

and anchors.

23

REMKO ATY

Connecting the

refrigerant lines

The on-site connection of the

refrigerant lines is undertaken

inside the unit.

It may be necessary to fit a reducer

or flared adapter to the indoor

unit. These fittings are included

with the indoor unit as an

accessory kit. Once installed, the

connections should be sealed to

prevent vapour diffusion.

CAUTION

The units are factory filled with

dry nitrogen to check for leaks.

The pressurised nitrogen is

released when the union nuts

are loosened.

The following instructions describe

the installation of the refrigerant

circuit and the assembly of the indoor

unit and the outdoor component.

1.

Check the "Technical Data"

chart for the required pipe

diameters and connect the

refrigerant line.

2. To bend the copper tubing, use

the appropriate bending tool to

prevent kinks in the tubing.

3. Observe the permitted bending

radius for the refrigerant pipes

during installation. Never bend

a pipe twice in the same place.

Brittleness and cracking can

result.

4. Lay the refrigerant lines from

the indoor unit to the outdoor

component. Ensure that the

fastenings are adequate and if

necessary, take appropriate oil

return measures!

5. Use the wall or floor brackets

to fit the outdoor component

against structural parts

approved to support the static

load (refer to the installation

instructions for the brackets).

6. Ensure that structure-borne

sound is not transferred to parts

of the building. Use vibration

dampers to reduce the effects

of structure-borne sound!

7. Remove the factory-fitted

protective caps and the union

nuts from the blocking valve

connections and use them for

further installation.

8. Before flanging the refrigerant

lines, ensure that the union nut

is on the pipe.

9. Prepare the refrigerant lines as

shown below

(figure 12+13, page 23).

10.

Check if the flange has the

correct shape

(figure 14, page 23).

11 Before connecting the injection

line, remove the valve core

in the indoor unit connection

ports.

12.

First connect and hand-tighten

the refrigerant connections

to ensure they are correctly

seated.

13.

Now fully tighten the fittings

using 2 suitably sized openended spanners.

Use one spanner to counter

the force when tightening the

fitting (figure 15, page 23).

14.

Apply appropriate heat

insulation to both installed

refrigerant lines, including

connector.

15.

Only use insulating hoses

suitable and diffusion-safe or

the temperature range.

NOTE

Use only tools which are

approved for use in an HVAC

environment. Pipe cutter,

deburrer, bending pliers and

flanging tool.

Supplementary information

for Installation

■

When combining the outdoor

component with some indoor

units, the connection of the

refrigerant pipes may differ.

In that case, install the provided

reducer or expansion fittings to

the indoor unit.

■

If the basic length of the

refrigerant line exceeds

5 m, add refrigerant when

commissioning the system for

the first time. (See chapter

"Add refrigerant").

24

Monitoring for leaks

12 Deburring the refrigerant line

Refrigerant line

Deburrer

13 Flanging the refrigerant line

Flanging tool

14 Correct flange shape

Once all the connections have

been established, the pressure

gauge station is attached as

follows to the Schrader valve

(if fitted):

red = small valve

= injection pressure

blue = large valve

= suction pressure

After completed connection, the

leakage test is carried out with dry

nitrogen.

CAUTION

Before the leakage test, the

pipe connections must be

checked.

The tightness test involves

spraying a leak detection spray

onto the connections. If bubbles

are visible, the connections have

not been properly made. Tighten

the connection or prepare a new

flange.

The time required to generate

the vacuum is dependent on

the pipework volume of the

indoor unit and the length of the

refrigerant lines. The process will

always take at least 60 minutes.

Once any foreign gases and

moisture have been completely

extracted from the system, the

valves on the pressure gauge

station will be closed and the

valves on the outdoor component

will be opened as described in the

chapter on "Commissioning".

15 Tighten fittings

Tighten 1st Spanner

Counter

2nd Spanner

Tightening

torque:

“

12 - 16 Nm

“

28 - 32 Nm

“

40 - 44 Nm

“

64 - 68 Nm

After successful leakage test, the

excess pressure in the refrigerant

lines is removed and a vacuum

pump with the absolute final

partial pressure of min. 0.01 mbar

is used to remove all the air and

empty the lines. Any moisture

present in the pipes will also be

removed.

NOTE

A vacuum of min. 0.05 mbar

must be created!

25

REMKO ATY

Condensate drain

Due to the dew point shortfall

on the vaporiser, condensation is

created on the indoor unit during

the cooling operation and on the

outdoor unit during the heating

operation.

Below the vaporiser is a collection

tray, which must be connected to

a drain.

■

The condensation line is to

be installed with a minimum

slope of 2 %. (figure 11).

If necessary, fit vapour diffusion

tight insulation.

■

Lead the condensation line

freely to the run-off line. If

the condensation runs directly

into a sewer pipe, fit a trap to

prevent any unpleasant odours.

■

When operating the unit at

outdoor temperatures below

0°C, ensure the condensation

pipe is laid to protect it

against frost. If necessary, fit

supplementary pipe heating.

■

After completed installation,

check for unobstructed

condensation run off and

ensure that a permanent seal

is provided.

The condensation hose is designed

to be installed on the right and the

left side (view from front). Remove

the plug at the corresponding

connection.

Indoor unit condensation connection

50

65

40

45

Condensate drain

right or left

Electrical connection

Mains cable must be installed as

voltage supply to the indoor unit

and a control cable to the outdoor

component, with appropriate

safeguards.

■

We recommend installing a

main / repair switch on the

building near to the indoor unit.

■

Power is supplied to the

indoor unit, the outdoor unit

is supplied via a control line

from the indoor unit.

■

The terminal blocks for making

the connections are located

behind the cover on the

outdoor component.

■

If an optionally available

condensation pump is used

on the unit, then an additional

relay for the shut-off contact

of the pump will be needed to

increase the switching power

to shut off the compressor.

■

Control cables should be

screened if laid in areas exposed

to strong magnetic fields.

16

Slope of the condensation line

26

at least

2% fall

Condensation connection - outdoor component

Opening for

Condensate drain

Condensation tray

for the outdoor unit.

NOTE

A condensation pump cannot

be installed within the units.

■

Electrical protection is provided

in accordance with the technical

data.

CAUTION

All electrical installation work

is to be performed by specialty

companies. Disconnect the

voltage supply when connecting

the electrical terminals.

Connecting the indoor unit Figure 17

Connecting the outdoor

component

Proceed as follows to connect the

cable:

1. Remove the cover from the

unit.

2. Remove the side panel next to

the terminals.

Terminal bar /

control bar

Mains cable

Before connecting the refrigerant

piping, the valve core must be

removed from the injection line.

3. Feed the cables through the

ferrite core supplied in the

delivery (figure 17+18).

4. Feed the cable through the

edge protection ring of the

fixed connection plate.

5. Connect the cable as shown

on the electrical connection

diagram.

6. Anchor the cable in the strain

relief and re-assemble the unit.

Check all plugged and clamped

terminals to verify they are seated

correctly and make a permanent

contact. Tighten as required.

Figure 18

Connecting the indoor unit

Make the connection as follows:

1. Remove the front of the unit,

as described in chapter "Unit

installation" .

2. Select the cable cross-section

according to the relevant

standards.

Electrical connection diagram

ATY 261 DC / ATY 351 DC

Outdoor

component

Exterior conductor

A

B

Neutral conductor

C

Control conductor

D

PE

Earth conductor

the indoor unit

Exterior conductor

L

1N

Earth conductor

PE

1

2

3

4

PE

Mains cable

L1

N

PE

230 V~,

50 Hz,

L1 / N

/ PE

3. Connect the unit to the mains

cable and control cable on the

outdoor component.

(See electrical connection

diagram).

4. Re-assemble the unit.

27

U

V

W

U

V

W

REMKO ATY

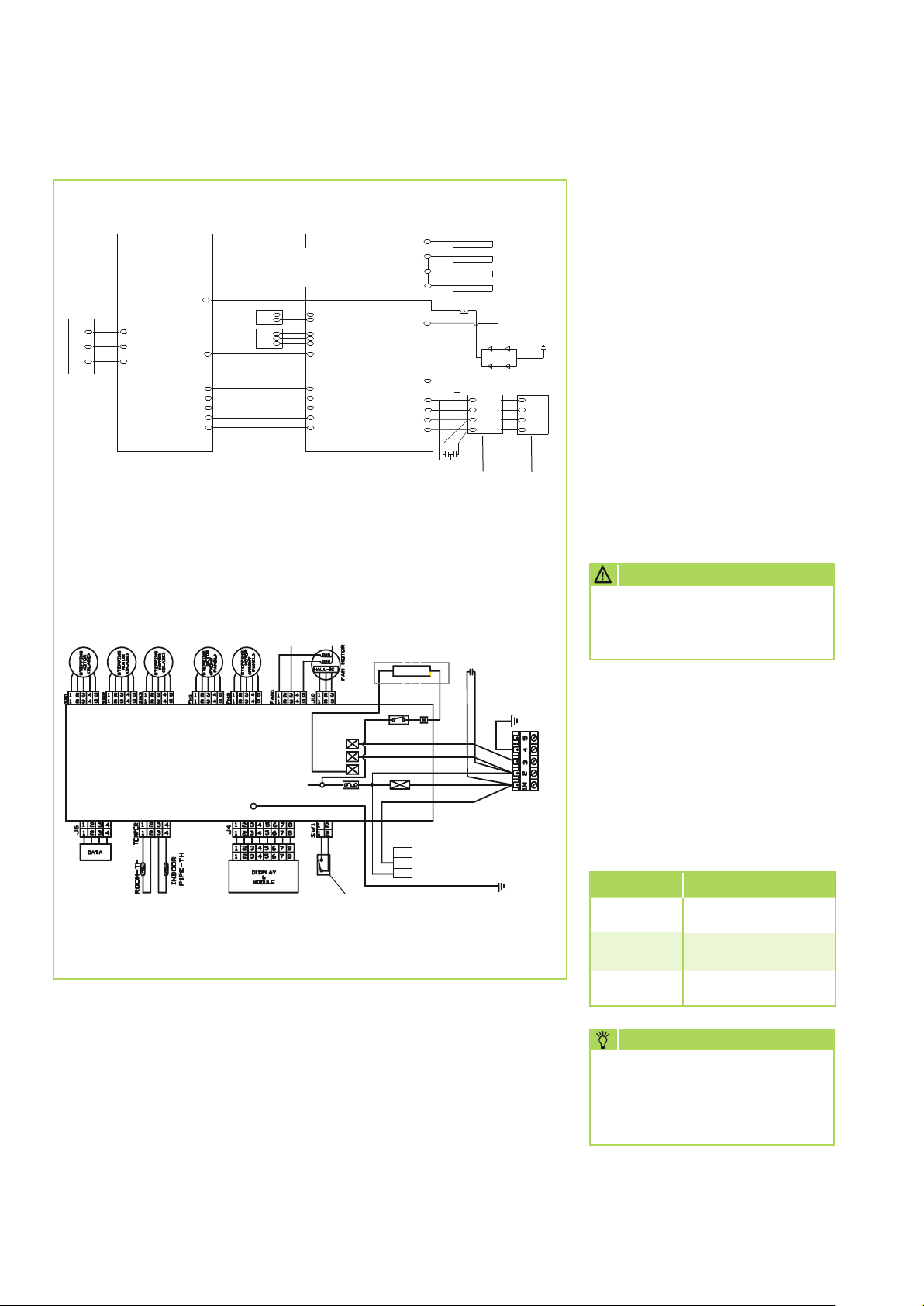

Electrical circuit diagram

ATY 261 DC AT / ATY 351 DC AT

■

Check the refrigerant lines and

insulation for damage.

L in

W

U

Compressor

W

VV

U

A = Reverse flow valve

B = Condenser fan

IPM

Sensor

IPM inverter power drive

N out

P out

A

B

J1

P

N

ATY 261 DC IT / ATY 351 DC IT

Swing motors

Lift motors

L

N

N

L

C

J4

N out

P out

P

N

Vaporiser

fan

J2

J1

N-Out

L-Out

Control board

E

COMM

AC N In

AC L In

Condenser

Ion generator

LDC

Pe

D

S

C

N

B

L

A

Terminal strip

Outdoor

component

Condenser

Test

Air-intake sensor

Condenser sensor

Hot gas sensor

AC N

AC L

4

3

2

1

Terminal strip

the indoor

unit

■

Check the electrical connection

between the indoor unit and

the outdoor unit for correct

polarity.

■

Check that all fastenings,

mountings etc. are firm and

at the correct level.

Add refrigerant

CAUTION

Wear protective clothing when

handling refrigerant.

Display

Air circulation sensor

Antifreeze sensor

Before commissioning

After successful leakage test, the

vacuum pump must be connected

using the pressure gauge station

to the valve connections of

the outdoor unit (see chapter

"Leakage test") to create

a vacuum.

Perform the following checks

prior to commissioning the

unit for the first time and after

Display

Pe

Mains cable

N

230/1Ph/50Hz

L

Button

manual operation

any interventions affecting the

refrigerant circuit. Record the

results in the commissioning

report:

■

Check all refrigerant lines and

valves with leak detection spray

or soapy water for leaks and for

inadvertent mix up of suction

and injection line. Perform this

check when the unit is not

running.

The equipment contains a

basic quantity of refrigerant.

Furthermore, for refrigerant line

lengths of more than 5 metres

per circuit, an additional amount

of refrigerant must be added,

Control line

in accordance with the following

chart:

ATY 261 DC

ATY 351 DC

Basic

line length

Additional fill quantity

Up to and

incl.

0 g/m

5 m

5 m to

max. 15 m

20 g/m

NOTE

Ensure that the refrigerant in

use is always replenished in

liquid form!

28

Commissioning

NOTE

Commissioning is only to be

performed and documented

by specially trained personnel.

Once all the components have

been connected and tested, the

system can be commissioned

. A functional check should be

performed to verify its correct

function and identify any unusual

operational behaviour prior to

handing it over to the operator.

Function test and

test run

Check the following points:

■

Leak tightness of refrigerant

lines.

■

Compressor and fan running

smoothly.

Function test of Cooling

operating mode

1. Remove the caps

from the valves.

2. Begin the commissioning

process by briefly opening the

shut-off valves of the external

unit until the manometer

displays a pressure of approx.

2 bar.

3. Use leak detection spray or

suitable devices to check that all

the connections are tight.

4. If no leaks are found, open

the stop valves by turning them

anti-clockwise as far as they will

turn using a hexagon spanner.

If leaks are found, draw off

the refrigerant and rework

the defective connection. It is

imperative that the vacuum

creation and drying steps are

repeated!

5. Switch on the mains switch

or circuit breaker.

9. Check the correct function

of the condensation line by

pouring distilled water into the

condensation tray.

A bottle with a spout is

recommended for pouring the

water into the condensation

tray.

10.

Switch the indoor unit to

cooling mode.

NOTE

Due to the turn on delay, the

compressor will start up a few

minutes later.

11.

Check the correct function and

settings of all control and safety

devices during the test run.

12.

Check the control system

in the indoor unit using the

functions described in the

operating manual.

(Timer, temperature settings

and all mode settings).

■

In cooling mode, cold air

output by the indoor unit, and

warm air output by the outdoor

component.

■

Functional test of the indoor

unit and all program sequences.

■

Check of the surface

temperature of the suction

pipe and determination of

vaporiser overheating. To

measure the temperature, hold

the thermometer to the suction

pipe and subtract the boiling

point temperature reading on

the pressure gauge from the

measured temperature.

■

Documentation of the

measured temperatures in the

commissioning report.

6. Use the remote control to

switch on the unit and select

the cooling mode, maximum

fan speed and lowest nominal

temperature.

7. Measure and record all

the required values in the

commissioning report and

check the safety functions.

8. Check the control system

for the unit using the

functions described in the

chapter "Operation". Timer,

temperature setting, fan speeds

and switching to circulating or

dehumidifying mode.

13.

Check the overheating,

outdoor, indoor, outlet and

vaporisation temperatures and

record the measured values

in the commissioning report.

14.

Remove the pressure gauge

and fit the sealing caps.

NOTE

Then, check the blocking

valves for leaks.

Final tasks

■

Reassemble all disassembled

parts.

■

Familiarise the operator with

the system.

29

REMKO ATY

Unit dimensions

ATY 261 DC AT / ATY 351 DC AT

623

265

ATY 261 DC IT / ATY 351 DC IT

148

720

567

245

532

All values in mm

470

567

47

45

396

25

All values in mm

We reserve the right to modify the dimensions and constructional design as part of the ongoing technical development process.

30

495

Technical data

Series ATY 261 DC ATY 351 DC

Operational mode Inverter-wall room air conditioner combination for cooling and heating

Nominal cooling output

Nominal heating output

Energy efficiency class, cooling EER

Energy efficiency class, heating COP

Energy efficiency ratio EER

Coefficient of performance COP

Power consumption, annual, (500h) K / H kWh 365 495

Operating range (room volume), approx. m³ 80 110

Refrigerant R 410A

Operating pressure, max. per cooling circuit kPa 3800/1200 3800/1200

Power supply V/Hz 230/1~/50 230/1~/50

Nom. electrical power consumption, cooling

Nom. electrical power consumption, heating

Elec. nominal power consumption cooling

Elec. nominal power consumption heating

Elec. starting current, max. A 20 25

Refrigerant connection - injection line

Coolant connection - suction line

Data specific to indoor unit

Operating range °C/ %r.F +16 to +32 / 80% +16 to +32 / 80%

Adjustment range - Cooling °C +18 to +30 +18 to +30

Adjustment range - Heating °C +16 to +28 +16 to +28

Air flow volume per speed setting m³/h 360/390/420 380/410/440

Protection class IP X0 X0

Sound pressure level per speed setting

Dimensions - height mm 567 567

Width mm 567 567

Depth mm 148 148

Weight kg 12,0 12,0

Corresponding outdoor component

Operating range - cooling °C +15 to +45 +15 to +45

Operating range - heating °C -7 to +24 -7 to +24

Air volume flow, max. K/H m³/h 1340 1890

Protection class IP X4 X4

Sound pressure level, max.

Refrigerant, basic quantity

Refrigerant, additional quantity > 5 m g/m 20 20

Refrigerant line, max. length m 15 15

Refrigerant line, max. height m 5 5

Dimensions - height mm 532 532

Width mm 720 720

Depth mm 245 245

Weight kg 37,0 38,0

Serial number 937... 938...

EDP no. 1624261 1624351

1) Air inlet temperature TK 27°C / FK 19°C, outdoor temperature TK 35°C, FK 24°C, max. air flow volume, 5m line length, according to DIN EN14511

2) Air inlet temperature TK 20°C, outdoor temperature TK 7°C / FK 6°C, max. air flow volume, 5m line length, according to DIN EN14511

3) Distance 1 m free field

4) Contains greenhouse gas according to Kyoto protocol

1)

2)

1)

2)

1)

2)

kW 2,69 (1,00-2,93) 3,52 (1,2-3,87)

kW 2,93 (1,00-3,20) 3,87 (1,20-4,10)

A A

A B

3,68 3,56

3,64 3,49

4)

1)

kW 0,75 0,99

2)

kW 0,81 1,11

1)

A 3,48 4,62

2)

A 4,00 5,21

Inches (mm)

Inches (mm)

1/4 (6,35) 1/4 (6,35)

3/8 (9,52) 1/2 (12,7)

R 410A

4)

ATY 261 DC IT ATY 351 DC IT

3)

dB(A) 33/36/40 35/37/41

ATY 261 DC AT ATY 351 DC AT

3)

4)

dB(A) 45 49

kg 410 A / 0.63 410 A / 0.83

31

REMKO ATY

Exploded view ATY 261 DC IT / ATY 351 DC IT

3

17

15

1

5

7

14

6

7

We reserve the right to modify

the dimensions and constructional design

as part of the ongoing technical

development process.

13

5

14

8

7

4

11

10

2

12

Spare parts list

No. Designation ATY 261 DC IT ATY 351 DC IT

1 Cover - air inlet 1107400 1107400

2 Cover - display 1107401 1107401

3 Air filter 1107402 1107402

4 Display board 1107470 1107470

5 Lift motor, set 1107404 1107404

6 Swing motor 1107405 1107405

7 Air outlet fins, set 1107406 1107406

8 Condensation tray 1107439 1107439

9 Fin vaporiser 1107409 1107486

10 Fan wheel, vaporiser 1107410 1107410

11 Fan motor, vaporiser 1107471 1107471

12 Control board 1107472 1107473

13 Ion generator 1107415 1107415

14 Housing angle, set (right & left) 1107416 1107416

15 Mounting clip - cover, set 1107417 1107417

16 Antifreeze sensor / air circulation sensor 1107418 1107418

17 IR remote control 1107474 1107474

16

9

When ordering spare parts, please state the computerised part no., unit number and type (see identification plate) !

32

Exploded view ATY 261 DC AT / ATY 351 DC AT

14

1

9

4

15

16

6

13

10

11

12

5

8

7

3

14

14

2

We reserve the right to modify

the dimensions and constructional design as part of the ongoing technical development process.

Spare parts list

No. Designation ATY 261 DC AT ATY 351 DC AT

1 Front panel 1107421 1107421

2 Fan blade, condenser 1107422 1107422

3 Fan motor, condenser 1107449 1107424

4 Ribbed condenser 1107444 1107426

5 Side panel, right 1107475 1107475

6 Compressor, cpl. 1107476 1107477

7 Stop valve, suction line 1107434 1107435

8 Stop valve, injection line 1107436 1107436

9 Side section, left 1107438 1107438

10 Reverse flow valve 1107437 1107437

11 Reverse flow valve coil 1107478 1107478

12 Control board 1107479 1107480

13 IPM inverter power drive 1107481 1107482

14 Hot gas, condenser, air-intake sensor set 1107483 1107483

15 Compressor sensor 1107484 1107484

When ordering spare parts, please state the computerised part no., unit number and type (see identification plate) !

33

REMKO ATY

34

Notes

35

REMKO ACROSS EUROPE

… and also right in your neighbourhood!

Make use of our experience and advice

REMKO GmbH & Co. KG

Air conditioning and heating technology

Im Seelenkamp 12 · 32791 Lage

PO Box 1827 · 32777 Lage

Telephone +49 5232 606-0

Telefax +49 52 32 6 06-260

E-mail info@remko.de

Website www.remko.de

Hotline

Air conditioning and heating technology

+49 5232 606-0

Export

+49 5232 606-130

Consultation

Thanks to intensive training,

our consultants are always

completely up-to-date in terms

of technical knowledge. This has

given us the reputation of being

more than just an excellent,

reliable supplier:

REMKO, a partner helping you

find solutions to your problems.

Distribution

REMKO offers not just a well

established sales network both

nationally and internationally,

but also has exceptionally highly

qualified sales specialists.

REMKO field staff are more than

just sales representatives: they

must primarily act as advisers

in air conditioning and heating

technology for our customers.

SFlbCustomer service

Our equipment operates

precisely and reliably. However,

in the event of a fault, REMKO

customer service is quickly at

the scene. Our comprehensive

network of experienced dealers

always guarantees quick and

reliable service.

Subject to technical modifications, no liability assumed!

Loading...

Loading...