Remeha Quinta Pro Brochure

The NEW Remeha

QUINTA PRO

Selection, Design and Installation

of Flue and Fluecade Systems

REMEHA QUINTA PRO | SELECTION, DESIGN AND INSTALLATION OF FLUE SYSTEMS

HIGH EFFICIENCY

108.9% NCV

PREMIX BURNER

CLEAN COMBUSTION

High efficiency wall hung condensing boiler

with ultra low NOx emission

QUINTA PRO RANGE OUTPUTS

QP30: 8.0 - 31.4 kW

QP45: 8.0 - 43.0 kW

QP65: 12.0 - 65.0 kW

QP90: 14.1 - 89.5 kW

QP115: 16.6 - 114.0 kW

FULLY MODULATING

BOILER CONTROL

ULTRA LOW NOx

BREEAM EXCELLENT

RECYCLABLE

MATERIALS

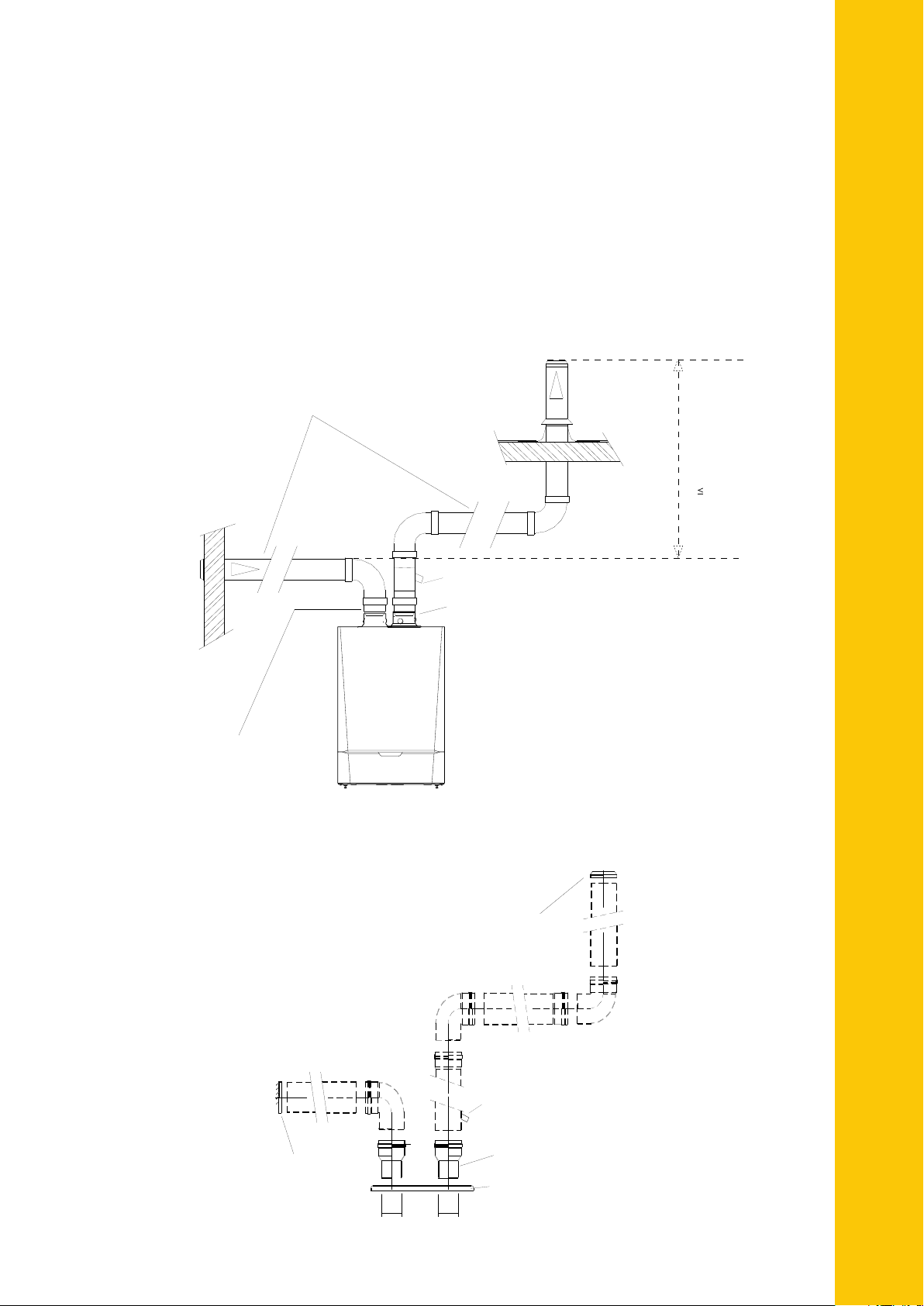

Quinta Pro Series flue options

The Quinta Pro series of boilers have fan assisted flues and are supplied as

standard with a ‘concentric’ flue outlet/air inlet which is used for room sealed

operation or for open flue (room ventilated) applications. An optional twin pipe

fitting is available for the room sealed ‘CLV’ system.

The concentric system can be supplied for individual boilers for horizontal or

vertical installation. Because of the excess fan capacity of the boiler, most flue

lengths can be accommodated (depending on boiler model and actual route taken),

which enables the installer to position the boiler almost anywhere in the building.

Open flue or room ventilated systems can be installed as individual or combined

flues and should discharge vertically with the flue terminating in a optional tapered

cone complete with bird guard.

Care should be taken when siting the actual discharge point as a vapour plume will

be visible when the boiler is operating (maximum flue gas exit temperature will be

less than 75°C) and it is possible for water to drip to the ground from the terminal

on horizontal installations, which could turn to ice in freezing conditions.

Recommendations

Refer to latest relevant British Standards

(Ref BS 5440 – 2: Specification for installation and maintenance of ventilation for

gas appliances not exceeding 70kW) (1st, 2nd and 3rd family gases)

(Ref BS 5440 – 1: Specification for installation of gas appliances to chimneys and for

maintenance of chimneys not exceeding 70kW) (1st, 2nd and 3rd family gases)

(Ref BS 6644: Specification for installation of gas-fired hot water boilers of rated

inputs between 70kW to 1.8 MW)(net)(2nd and 3rd family gases)

(Ref IGE/UP/10) Installation of flued gas appliences in industrial and commercial

premises.

It is the responsibility of the installer to install the flue and Flucade to comply with

the current regulations and standards.

IMPORTANT NOTE: All flue terminals and CLV kits are now supplied with a

condensate drain/adaptor. We would advise the fitting of this component if

installations are over 2 metres in length both vertically and horizontally and also if

the flue consists of dissimilar materials. Installations taken directly from the top of

the boiler horizontally through an outside wall do not require the condensate drain.

On flue components supplied by others, ensure in line condensate drains are fitted

in the correct positions.

Further details regarding flue with dissimilar metals can be found in

BS6644 – 2011 Section 6.10.4

Flue components are constructed from a white painted metal outer and plastic inner.

Flue terminals are painted as detailed in the terminal diagrams.

Plume kit external components are aluminium or plastic and are painted black.

All flue components are CE approved.

2

FLUE GAS

FLUE GAS

AIR IN

REMEHA QUINTA PRO | SELECTION, DESIGN AND INSTALLATION OF FLUE SYSTEMS

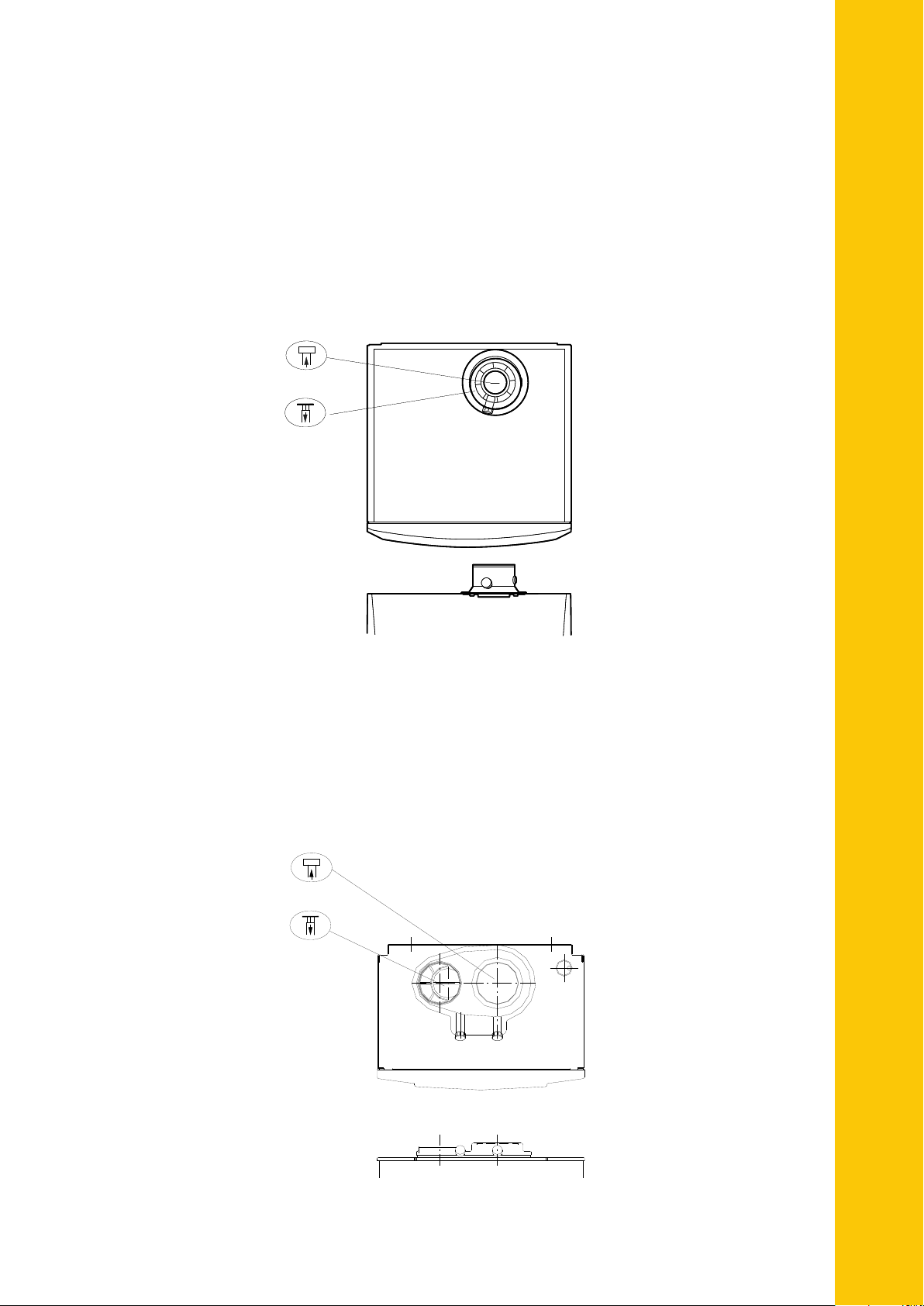

Quinta Pro Series Flue outlet / Air inlet details

The Quinta Pro Series boilers are supplied as standard with a Concentric Flue

outlet / Air inlet connection which can be used for:

1. Room sealed operation using the concentric flue system (Flue within air duct)

2. Conventional/Open flue operation using single skin flue system connected to the

inner concentric connection with the air supply taken from the boiler house via

the outer concentric connection.

AIR IN

This shows the optional Twin pipe Flue outlet / Air inlet connection and is used for

Room sealed operation using the CLV flue system (air inlet and flue gas discharge

from two pressure zones).

Using single skin, water and gas tight flue system with single skin air tight

air inlet system.

FLUE GAS

AIR IN

3

240mm

Sq.

4 x 5mm

Holes

204 Sq

Centre line of

Terminal 180mm

Clearance hole for

Terminal through

wall 130mm

Note:140mm diameter recess

15mm deep required from the

face of the i nside wall face to

allow clearance for the bend

Cut Terminal on site

to suit wall thickness

Max 1000mm

Min 150mm

Wall closure plate should be fitted

to terminal before passing

through hole in wall to ensure

correct positioning

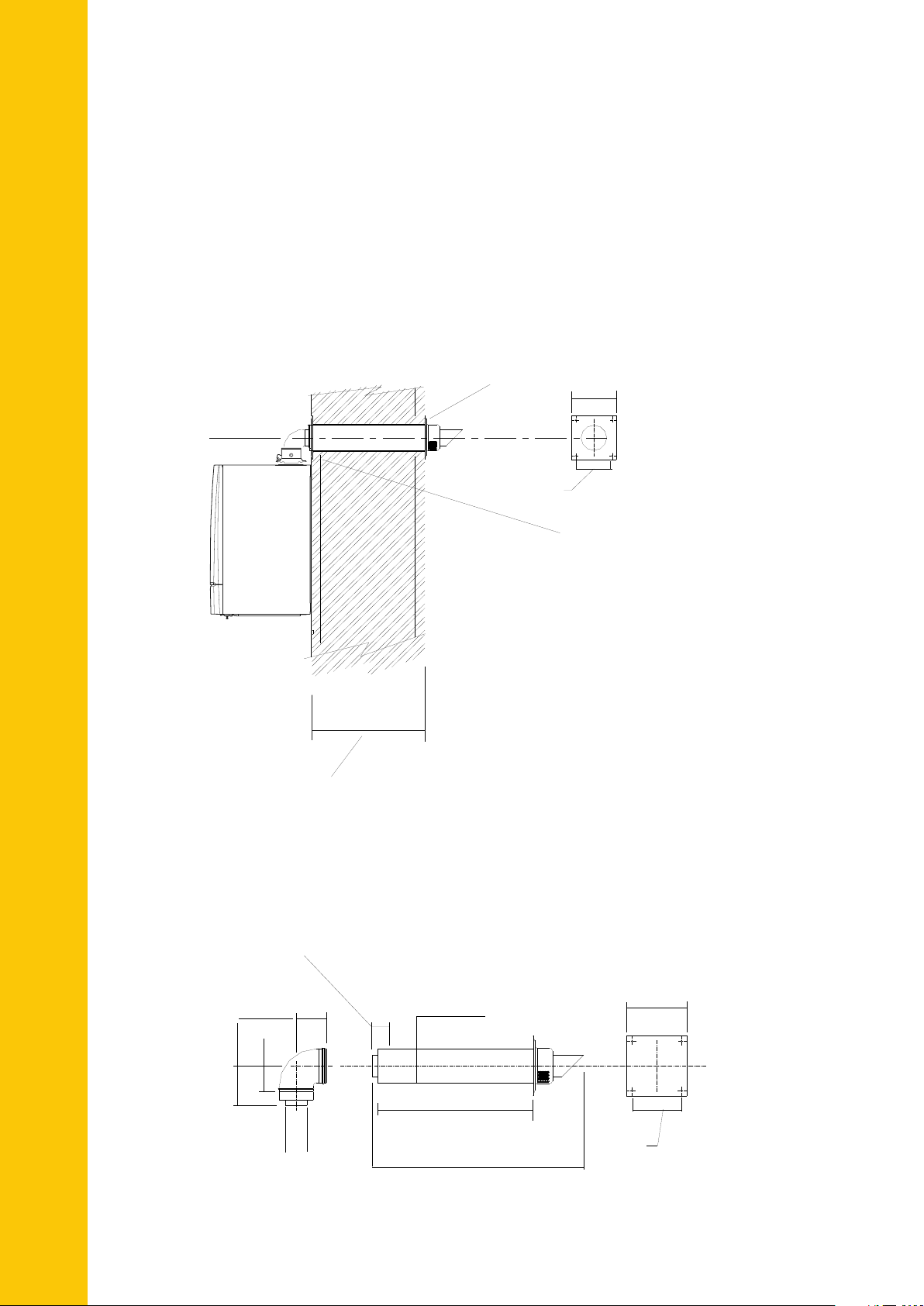

Quinta Pro 30 and 45 – Room Sealed, 80/125mm

Horizontal Concentric Flue Kit Option QP01

(For use when the boiler/s are mounted on and flued through a rear outside wall.)

Typical single boiler installation – can also be used for multiple boilers but each

must have its own flue system at a minimum of 530mm centres and never installed

immediately above another. For two boilers only it is also possible to install the

external terminal wall plates touching each other.

Wall closure plate should be fitted

to terminal before passing

through hole in wall to ensure

correct positioning

4 x 5mm

Holes

204 Sq

240mm

Sq.

Centre line of

Terminal 180mm

Kit Parts – KT00307

(max wall thickness 500mm)

Clearance hole for

Terminal through

wall 130mm

Note:140mm diameter recess

15mm deep required from the

face of the i nside wall face to

allow clearance for the bend

1 x Terminal – MG410082982

1 x Condensate drain – MG410084472

Cut Terminal on site

to suit wall thickness

Max 1000mm

Min 150mm

(Boiler bend/wall plate are included)

Kit Parts – KT00340 (Extended version

max wall thickness 1000mm)

1 x Terminal – MG410081940

1 x Condensate drain – MG410084472

(Boiler bend/wall plate are included)

Detail of the Horizontal 80/125mm Concentric Flue Kit Option QP01

(Part No KT00307/KT00340)

50mm insertion length

into mating socket

240mm

Sq.

4 x 5mm

holes

204 Sq

145mm

95mm

110mm

80mm o/d

BS RAL

Colour 9016 7021/

125mm o/d

600/1000mm

740/1135mm

HRS Room sealed terminal (80/125mm)

MG410082982 & MG410081940

4

QP3 0/45/65/90/115 =100mm

Dn80

Dn125

1350mm

755mm

RAL - 7021

Ral - 9016

(300mm)

Quinta Pro 30 and 45 – Room Sealed, 80/125mm

QP3 0/45/65/90/115 =100mm

o

)

Condense

Drain

'L'

101 i/d

100 o/d

Standard length

'L'= 1000mm Part No. MG87062

'L'= 500mm Part No. MG87061

'L'= 250mm Part No. MG86060

105

105

90° Bend

Part No. MG87113

45° Bend

Part No. MG87103

76

76

125

101 i/d

80 o/d

Reducer 80 spigot to 100 socket

Part No. MG87127

Mus

connection to adapt to 100mm

system

Silicon seal ring

Part No. MG87183

50

Mountng Bracket

Part No. MG87 193

8mm x 45mm

S

crew thread

25-55 mm

Note:

s will off dneb °54 x 2

set to 71mm centres

101 i/d

95

30

20

Flue terminal c/w bird guard

Part No. PU001

Air Inlet guard

Part No. PU002

10

10

200

60

101 i/d

Top

600mm X 500mm

Cut down to suit dia.

of Flue in use a nd seal

with silicone supplied

80 approx

t be used on the QP30/45 flue

Detail of Standard weathering plate for

100mm to 150mm flue (Part No VE001)

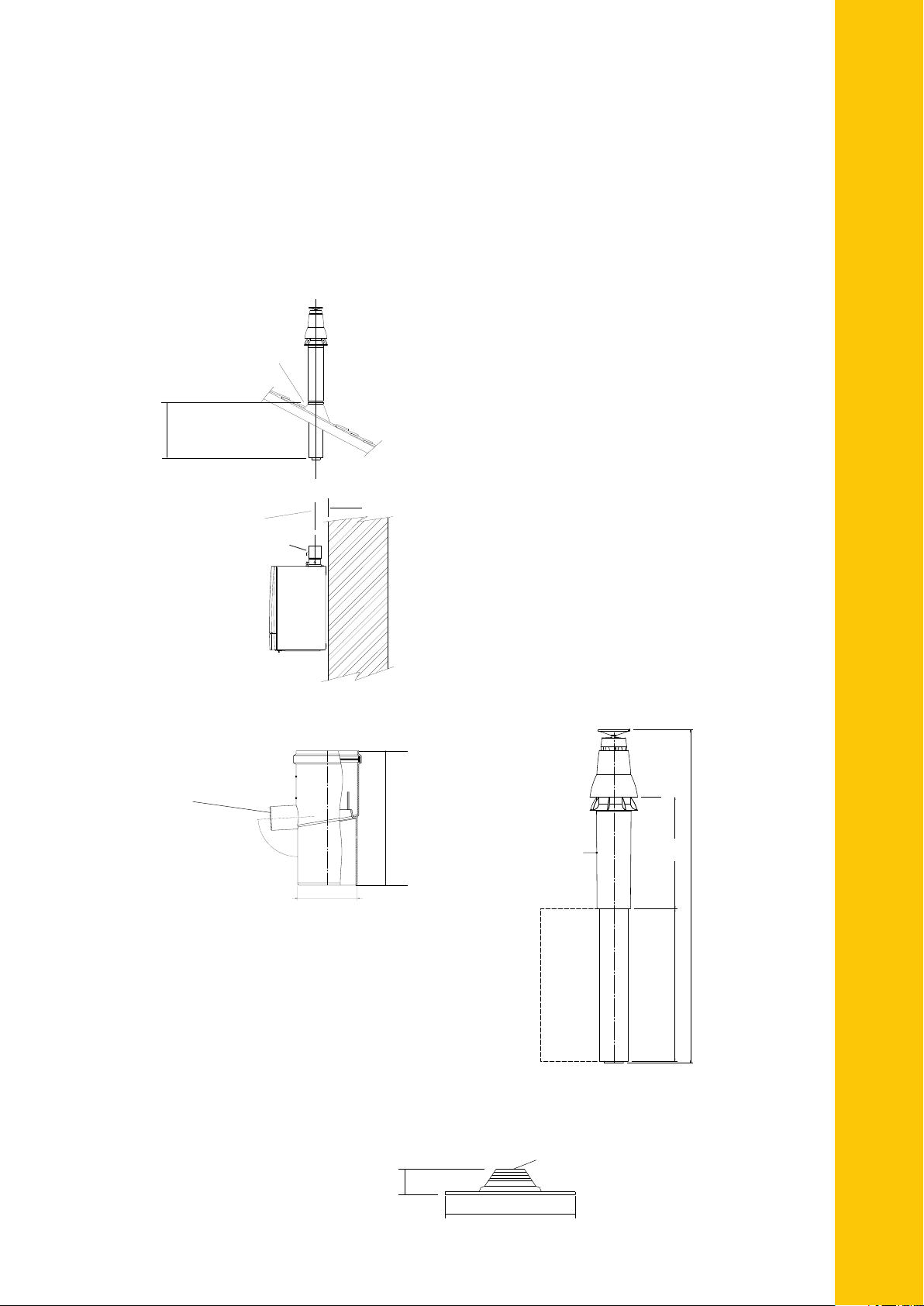

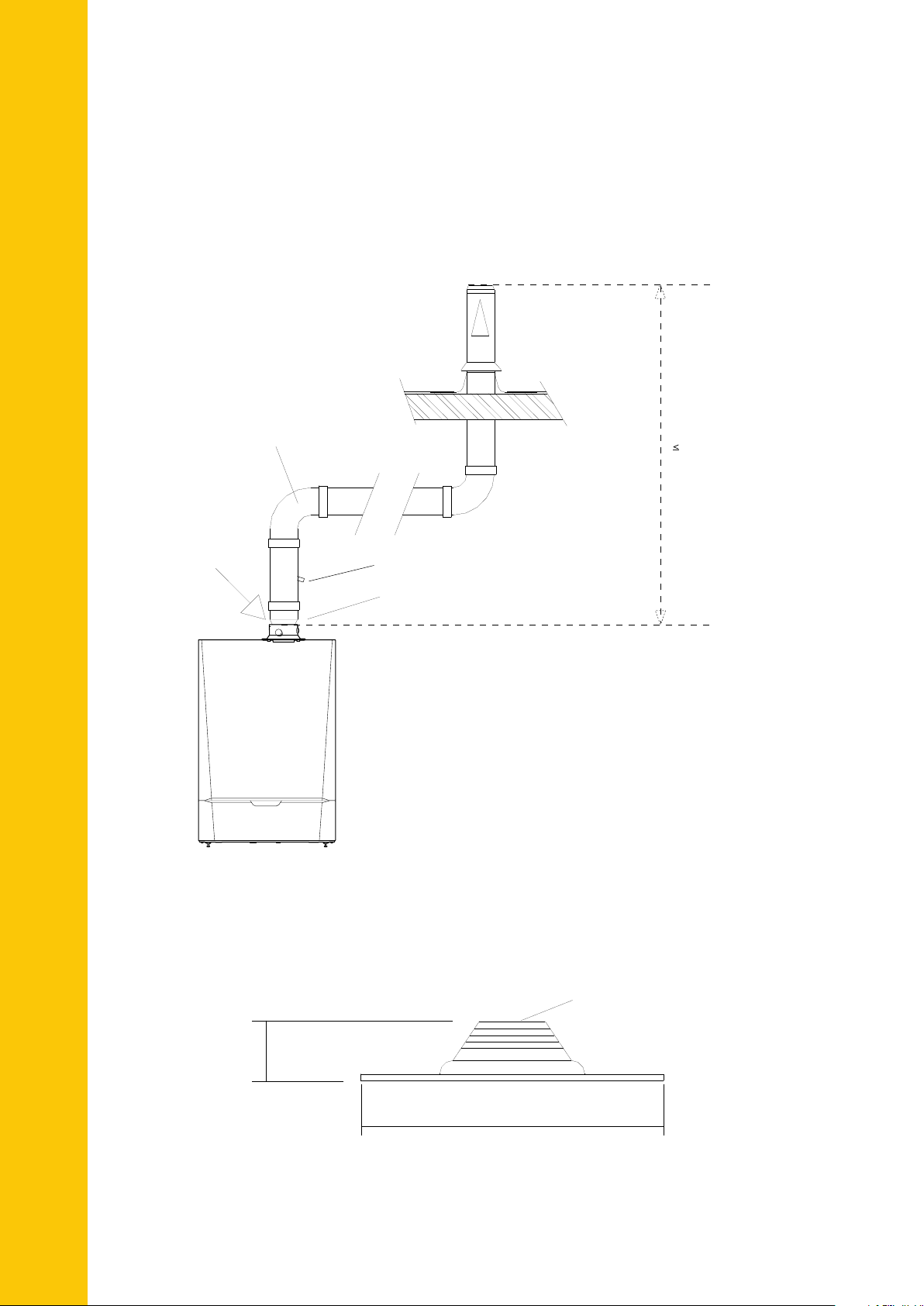

Vertical Concentric Flue Kit Option QP03

(For use when the flue is discharged vertically through the roof)

Typical single boiler installation – can also be used for multiple boilers, but each

must have its own flue system and terminals sparated a min of 300mm if at the

same height. Refer to the relevant British Standard if this is not the case.

Weathering Slate

Suitable for flat or

pitched roof (60

o

)

REMEHA QUINTA PRO | SELECTION, DESIGN AND INSTALLATION OF FLUE SYSTEMS

QP30/45 - 495mm

Additional components

required to suit site

details (within boiler

constraints)

Condense

Drain

QP3 0/45/65/90/115 =100mm

Kit Parts – KT00308

1 x Vertical Terminal – MG410086864

Detail of the Vertical 80/125mm Concentric Flue Kit Option QP03 (Part No KT00308)

25mm ID/32mmO/D

100mm

Condensate Drain

Part No. MG410085130

180mm

Can be cut down on site

to a minimum of 150mm

Retain the difference

between inner and outer

1 x Universal Roof seal Pack – VE001

1 x Condensate drain – MG410084472

RAL - 7021

Ral - 9016

Dn80

Dn125

(300mm)

755mm

1350mm

Detail of Standard weathering plate for 100mm to 150mm flue (Part No VE001)

flat or pitch roofs up to 60º

80mm approx

600mm X 500mm

Cut down to suit dia.

of Terminal in use

5

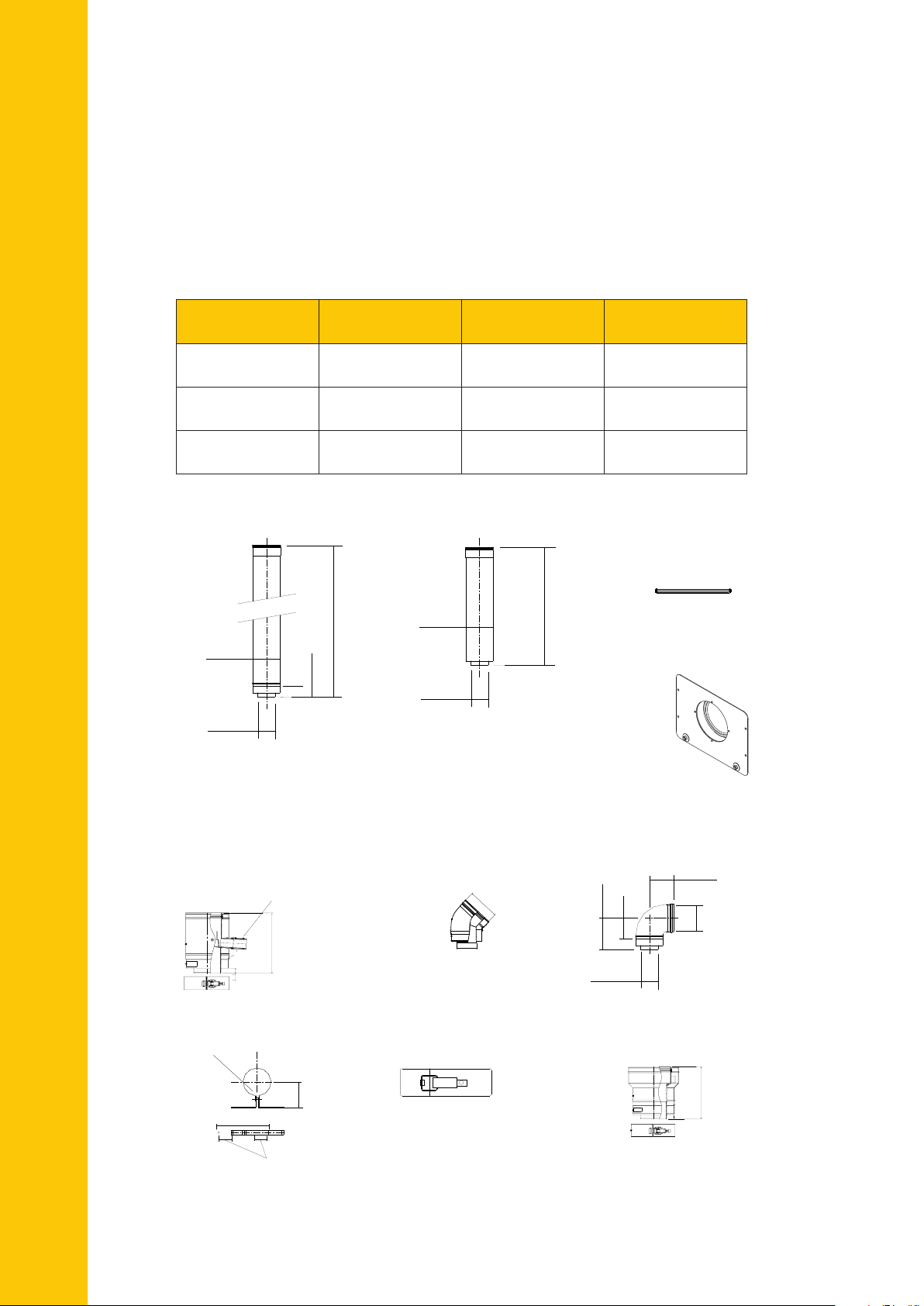

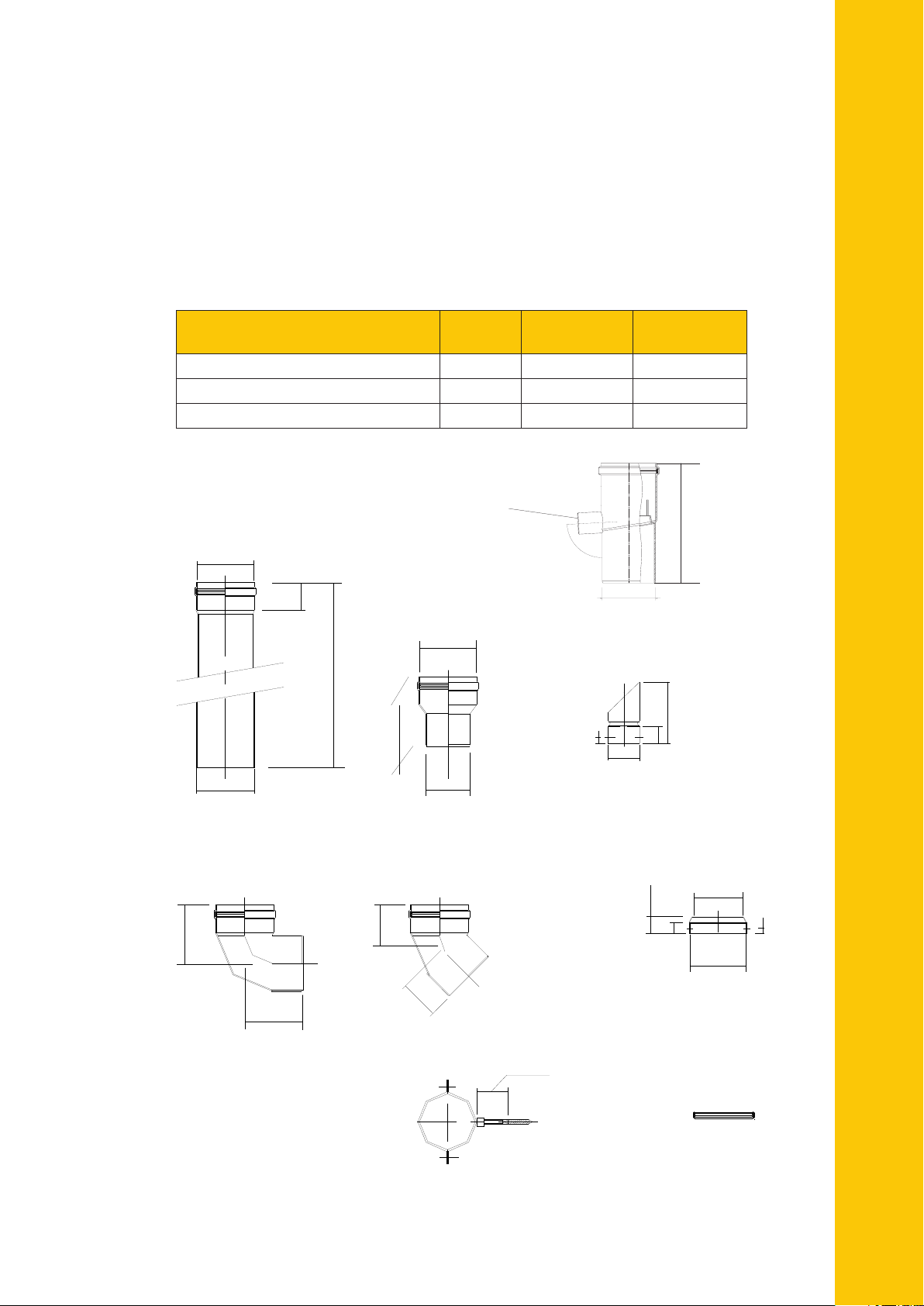

Quinta Pro 30 and 45 – 80/125mm Room

Sealed Calculated data to determine

maximum flue runs

(Calculation data based on flue products supplied by Remeha Commercial)

Table 1

Room Sealed

Calculation Data

Maximum overall

Quinta Pro 30

80/125mm

Metres 20 16

Quinta Pro 45

80/125mm

flue run

Reduction Length

Metres 1 1

for each 45° bend

Reduction Length

Metres 2 2

for each 90° bend

80/125mm Concentric Flue System Components for Room Sealed Operation

125 o/d

'L'

125 o/d

‘L’

Internal Seal (80mm)

Part No MG410027355

50

80 o/d

80 o/d

Standard length (cannot be cut)

'L' = 1000mm Part No MG410084486

'L' = 500mm Part No MG410084485

Standard length (cuttable length)

‘L’ = 1000mm Part No MG410082314

‘L’ = 500mm Part No MG410082313

Internal wall plate

Part No. MG410081302

110

25mm I/D - 32mm O/D

180mm

o

CE

Condensate drain Part No MG410084472

87-90

10

80mm o/d

45 Bend

Part No MG410084461

CE

125 i/d

95

145

125 i/d

80 o/d

o

90

Boiler short bend Part No MG41008410

o

90 Bend Part No MG410084460

126 i/d

210

115

Wall bracket

Part No MG410087863

PLEASE NOTE: All dimensions are in mm.

6

60 ctrs

Clamp band

Part No MG410087654

(one supplied with

each component

except MG410084810)

80/125mm -100/150mm

Concentric adaptor

Part No. MG410084475

158mm

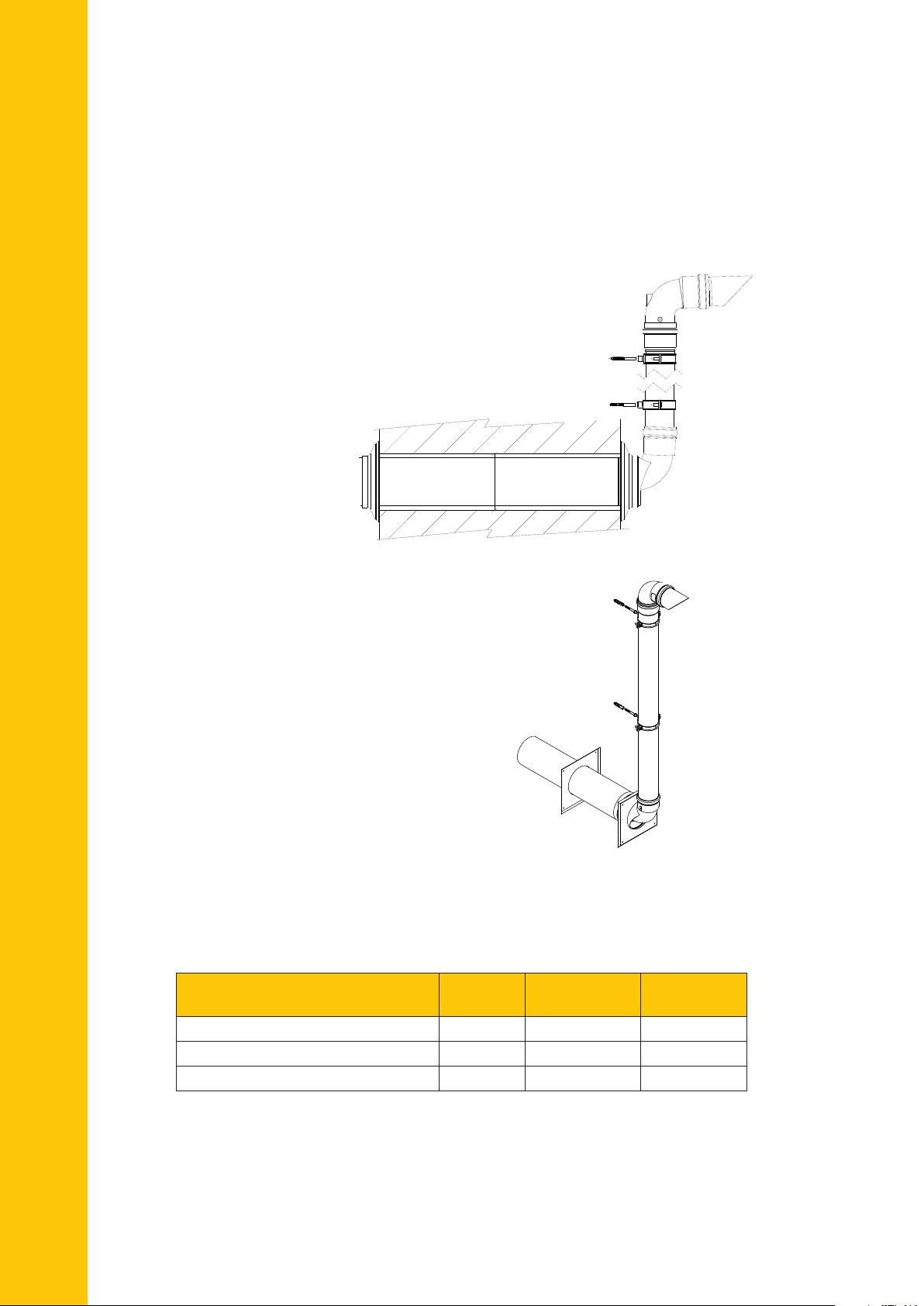

Fall to boiler T 36m

Fall from boiler

Flue outlet

Quinta Pro 30/45 two pipe adaptor plate is

required to replace standard concentric fitting

(maximum

height)

Condensate drain

Quinta Pro 30 and 45 – Room Sealed,

100mm Two zone CLV Flue Kit Option QP04

(For use when the air inlet is drawn from low level and flue outlet discharged

vertically in a different pressure zone).

Typical single boiler installation – can also be used for multiple boilers, but each

must have its own flue system.

Please contact our technical department or refer to the Quinta Pro Installation

and Service Booklet for details on maximum flue lengths allowed when using

CLV installations.

REMEHA QUINTA PRO | SELECTION, DESIGN AND INSTALLATION OF FLUE SYSTEMS

100mm Aluminium single wall

flue and air inlet system

Air

inlet

100 / 80mm Reducers to adapt

boiler to suit 100mm system

if required.

Fall from boiler

Flue outlet

Fall to boiler T 36m

Condensate drain

Quinta Pro 30/45 two pipe adaptor plate is

required to replace standard concentric fitting

Kit Parts – KT032

1 x Flue connection – S100250

2 x Flue adaptor 80/100 – MG87127

1 x Flue terminal – PU001

1 x Air inlet – PU002

1 x Condensate drain – MG410085130

(maximum

height)

Detail of the 100mm Two Zone CLV Flue Kit Option QP04 (Part No KT032)

Flue terminal

Only parts named are in the kit

additional 100mm single wall pipe

and bends, shown dotted will be

needed to suit site requirements

(overall length to be within boiler

constraints)

Air inlet Guard

80mm

c/w bird guard

80mm

Condensate drain

100-80 mm Reducer x2

Two pipe adaptor

plate

7

Quinta Pro 30 and 45 100mm Conventional

Fall to boiler

100 /

80mm Reducer to adapt

boiler to suit 100mm system

Flue outlet

T Max 36m

Condensate drain

(Maximum

height)

or Open Flue Systems

Typical single boiler installation – can also be used for multiple boilers with each

boiler having its own flue system. Please ensure that the overall route does not

exceed the maximum values in the table on page 9.

Flue outlet

100mm Aluminium single wall

flue system.

Air from

plant room

Fall to boiler

Condensate drain

100 /

boiler to suit 100mm system

80mm Reducer to adapt

T Max 36m

(Maximum

height)

Detail of Standard weathering plate for 100mm to 150mm flue (Part No VE001)

flat or pitch roofs up to 60º

Cut down to suit dia.

of flue.

80mm appox

600mm X 500mm

8

Quinta Pro 30 and 45 – 100mm Conventional

'L'

101 i/d

100 o/d

Standard length

'L'= 1000mm Part No. MG87062

'L'= 500mm Part No. MG87061

'L'= 250mm Part No. MG86060

105

105

90o Bend

Part No. MG87113

45o Bend

Part No. MG87103

76

76

125

101 i/d

80 o/d

Reducer 80mm spigot to 100mm

Part No. MG87127

Must be used on the QP30/45 flue socket

connection to adapt to 100mm

system

Silicon seal ring

Part No. MG87186

50

Mountng Bracket

Part No. MG87193

8mm x 45mm

Screw thread

25-55 mm

Note:

2 x 45° bends will off

set to 71mm centres

10 /d

95

30

20

Flue terminal c/w bird guard

Part No. PU001

Air Inlet guard

Part No. PU0 02

10

10

200

60

101 i/d

Top

1 i

101 i/d

95

Air Inlet guard

Part No. PU002

10

10

200

60

101 i/d

Top

or Open Flue Systems

(As the Boiler is fan assisted it makes no difference if the run is horizontal or

vertical but should terminate vertically as shown on page 8).

(Calculation data based on flue products supplied by Remeha).

Table 2

REMEHA QUINTA PRO | SELECTION, DESIGN AND INSTALLATION OF FLUE SYSTEMS

Open Flue Data Quinta Pro 30

Maximum overall flue run Metres 40 40

Reduction Length for each 45° bend Metres 1.4 1.4

Reduction Length for each 90° bend Metres 4.9 4.9

Quinta Pro 45

100mm

25mm ID/32mmO/D

100mm

180mm

100mm

Condensate Drain

Part No. MG410085130

PLEASE NOTE: All dimensions are in mm.

Silicon seal ring

Part No. MG87183

9

Min 150mm

Note: Can be extended with extra parts

see table.

Remeha Quinta Pro 30 & 45 Plume Kits

80/125mm Flue Kit Option QP05

(Calculations based on products supplied by Remeha Commercial)

Wall Depth – Max 500mm – Min 150mm

Terminal inner and outer can be cut to suit.

Note 1: 140mm diameter recess 15mm deep required

from the face of the inside wall face to allow if

clearance for the bend.

Note 2: Both the air intake and flue outlet

termination postions must comply with

current regulations and British Standards.

Flue can be taken directly

through rear outside wall

or discharged through

a side wall left or right.

Both must be within

the constraints in the

table below.

80/125mm Plume Management Kits

QP05 Part No. KT00335

PMK-Horizontal Terminal Kit

1. PMK Wall terminal

2. Boiler bend – not illustrated

3. Wall plates

4. 1000mm flue extension (80mm)

5. Support bracket (80mm)

6. 90° bend (80mm)

7. Flue outlet (80mm)

8. Bird guard

Core Drill Wall - 130mm Dia.

6

5

5

1

Note: Can be extended with extra parts

Min 150mm

see table.

8

7

4

Note: The horizontal terminal unit must be

installed with the outlet pointing vertically

upwards. External components are

constructed of black PP (plastic).

Horzontial terminal kit installed

3

3

80/125mm Plume Management details

Table 3

Quinta Pro 30

80/125mm

Quinta Pro 45

80/125mm

Maximum overall flue run Metres 37 23

Reduction Length for each 45° bend Metres 1.96 1.96

Reduction Length for each 90° bend Metres 2.25 2.25

The table shows the maximum lengths allowed which includes both the internal

concentric 80/125mm and the external 80mm. The bend from the top of the boiler

and the external 80mm bend have already been taken into account. Any bends

used must be taken from the total using the table above, this applies to the internal

80/125mm and the external 80mm.

The maximum horizontal run is 6 metres.

10

Loading...

Loading...