Remeha Quinta Pro Schematics

QUINTA PRO RANGE

Suggested Schematics with Control

and Power Wiring Details

REMEHA QUINTA PRO RANGE - SUGGESTED SCHEMATICS WITH CONTROL AND POWER WIRING DETAILS

HIGH EFFICIENCY

108.9% NCV ∆T 50/30°C

High efficiency wall hung condensing boiler

with ultra low NOx emissions

QUINTA PRO RANGE OUTPUTS

QP30: 8.0 - 31.4 kW

QP45: 8.0 - 43.0 kW

QP65: 12.0 - 65.0 kW

QP90: 14.1 - 89.5 kW

QP115: 16.6 - 114.0 kW

FULLY MODULATING

BOILER CONTROL

PREMIX BURNER

CLEAN COMBUSTION

ULTRA LOW NOx

BREEAM EXCELLENT

RECYCLABLE

MATERIALS

Schematics with Control Page

Control Options for the Quinta Pro Series of Boilers p3

External controls by others

Simple Quinta Pro boiler domestic installation - p4-5

Typical ‘S’ plan, heating and hot water

Single Quinta Pro boiler, heating only p6-7

Single Quinta Pro boiler, heating only with low loss header p8-9

Single Quinta Pro boiler, heating and priority hot water using a low loss header p10-13

and pump or valve kit

Remeha supplied controls

Single Quinta Pro boiler, heating only using the iSense controller p14-16

(room/weather compensation)

Single Quinta Pro boiler, heating and Priority DHW using the iSense controller p17-19

(room or outside compensation)

Multiple Quinta Pro boilers HTG only using a low loss header with the Celcia MC4 p20-21

and iSense (room or outside compensation)

Multiple Quinta Pro boilers HTG and Priority DHW using a low loss header with p22-24

the Celcia MC4 and iSense (room or outside compensation)

Multiple boilers, heating and hot water using a low loss header with the p25-30

iSense Pro controller (optimising/weather compensated control for dual

heating zone and hot water from all or single boilers)

Connecting multiple boilers with external control interlocks and alarm p31

and run signals

Quinta Pro nominal flow rates and boiler resistances p31

Note: We supply the Grundfoss 25/80 (Part No. S101621) as standard for the full Quinta Pro

range. This will alter due to changes in EU regulations. The Quinta Pro 30 will operate on speed

1, the 45 and 65 will operate on speed 2, and the 90 and 115 will operate on speed 3. They are

intended to act as a shunt pump. In the layouts illustrated, they are designed to operate on a

20ºC Delta TΔ. If using a pump without a low loss header, please take into account both the

boiler and system resistance and also when being used in conjunction with a calorifier and low

loss header. Contact our sales or technical departments for further assistance.

The hydraulic and control layouts illustrated in this brochure are for guidance only and must be

used in conjunction with the Quinta Pro and iSense Pro installation and service manuals. They

do not constitute a full system design. Remeha Commercial accept no liability for any loss or

damage rising from any errors or omissions that may be inadvertently contained in this booklet.

When connecting a control cable to the OT terminals on the main control PCB, disconnect and

remove the factory fitted lead connected to the IF- 01 PCB.

Some earths and neutrals are omitted for clarity.

All systems, mechanical and electrical, must be installed to the current regulations by a suitably

qualified engineer.

2

Control Options for the Quinta Pro 30 / 45 / 65 / 90 and 115 series

The Remeha range of Quinta Pro boilers are supplied as standard with an “Open Therm”

control interface which enables direct weather compensation using Remeha single and

multi boiler controls. The customer can choose to use external control options supplied

by others without affecting boiler performance.

Supplied by others

On/off control:

• Boiler requires a permanent 230v supply and is enabled using a volt free switch/relay.

The boiler will modulate its output to maintain the flow temperature setpoint,

normally 80ºC, but can be adjusted on the boiler between 20ºC and 90ºC

0-10 volt control:

• Boiler requires a permanent 230v supply and is enabled and modulated using a 0-10

volt signal from a Building Management System or quality panel mounted optimiser/

compensator. The control can be flow temperature or percentage output based

• Temperature based example: if 56ºC ow is required from the boiler, the control will need to

supply 5.6v. The output will be modulated to maintain a flow temperature of 56ºC

• Percentage based example: if the control logic requires that a boiler should be running

at 33%, the control will need to supply 3.3v to the boiler. The boiler will run at 33% output

with a variable flow temperature

• Applications - domestic/commercial and industrial installations, with a variety of heat

emitters, DHW via calorifiers or plate heat exchangers, and installations where a variety

of different temperature zones are required at the same time

Supplied by Remeha Commercial as optional extras

iSense Controller - Single/multi boiler weather compensating controller

• A simple to operate room/boiler mounted thermostat/timer which can be used with a

combination of outside/room and flow temperature sensors to vary the boiler output

(flow temp) to suit weather conditions. The iSense can be installed in a reference room

and can also be mounted in a boiler when used in weather compensated mode.

It has a 7 day timer with multiple on/off and night setback periods, holiday function,

frost protection and manual override

Celcia MC4

• Multiple boiler weather compensating controller with step control (up to 4 boilers)

to be used in conjunction with the iSense controller

• The iSense can be mounted in a reference room, in the plant room or on the boiler

• The MC4 is mounted adjacent to the boiler group

iSense Pro - Multiple boiler weather compensating controller with sequence control (up to 8 boilers)

• Optimiser compensator which can provide 2 timed heating zones and uses a combination

of outside, flow and room temperature to vary the boiler output (flow temp) to suit weather

conditions. Can also provide time control to DHW circuit. The iSense Pro controller is mounted

in a wall box when used with the Quinta Pro and is complete with timer, night setback, frost

protection and pump cycling protection. The iSense Pro controller will sequence and rotate

the lead boiler on multiple installations. This controller also has the ability to accept remote

extension timers, supplied as an optional extra, which will allow the heating system to run

on daytime compensation outside the normal timed settings without need for access or

interference to the boiler or controller. Ideal for school lettings/night classes etc.

Note: We do not advise using a combination of external and built-in controls as in most cases

there can be no interface between them; it is likely they will ‘conflict’ with each other

and neither will work properly. The exception to this is when using the iSense Pro kit KT1154

in conjunction with a Remote BMS controller (see page 31).

3

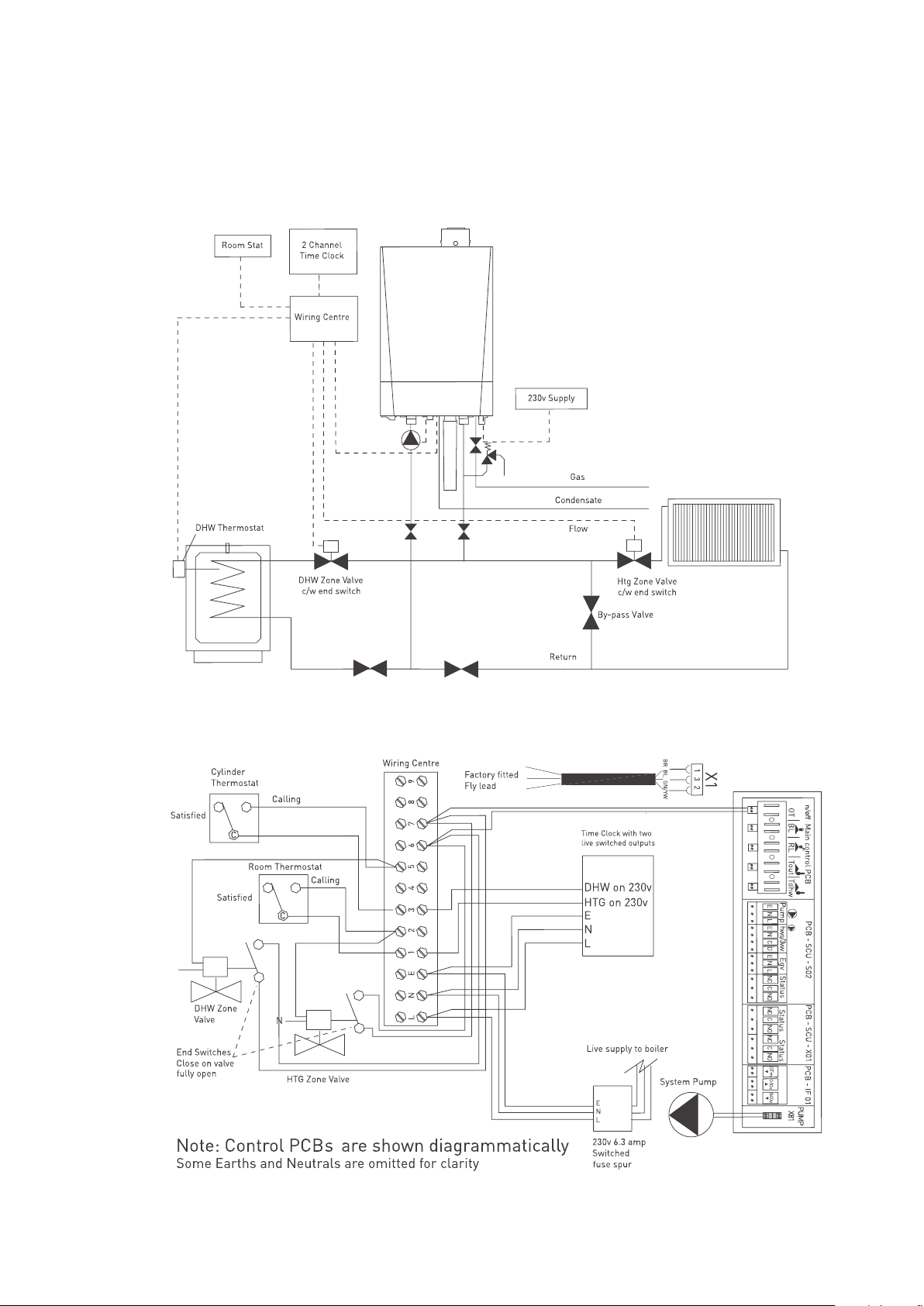

Simple Quinta Pro boiler domestic installation

Typical ‘S’ plan, heating and hot water

(Time and temperature control by others)

Power Supply

• Boiler requires a permanent 230v single phase supply fused at 6.3 amps connected

to the factory fitted fly lead

Boiler Control Settings

(see 5.7.2 in technical documentation)

• Set boiler code P1 to the required ow temp i.e. 80 = 80ºC (system design requirements)

• Boiler will recognise the control being used

• Use the zone valve end switches to provide the volt free switch pair on OT on the main

control PCB to enable the boiler

• Boiler output will vary between 18% part load set point and 100% full load set point

to achieve the boiler flow set point (code P1)

System Components

(not supplied)

• Simple two channel time clock providing 230v switched supplies to control

heating and domestic hot water

• System pump

• Cylinder thermostat

• Room thermostat

• HTG and DHW zone valves c/w a single end switch (closes on valve fully open)

• Wiring centre

Note:

1. Maintain polarity on all connections

2. Some Neutral and Earth connections have been omitted for clarity

3. The schematic is for guidance only and does not constitute a design

4. Heating and hot water can be operated independently or simultaneously

with this layout provided the control selected will allow it

4

Quinta Pro single boiler heating and domestic hot water, using a

simple ‘S’ Plan

QP 001S

Quinta Pro single boiler heating and domestic hot water, using a

simple ‘S’ Plan

Single Quinta Pro boiler, heating and domestic hot water,

using a simple ‘S’ Plan

QP 001S

O

Shunt

QP 001SA

5

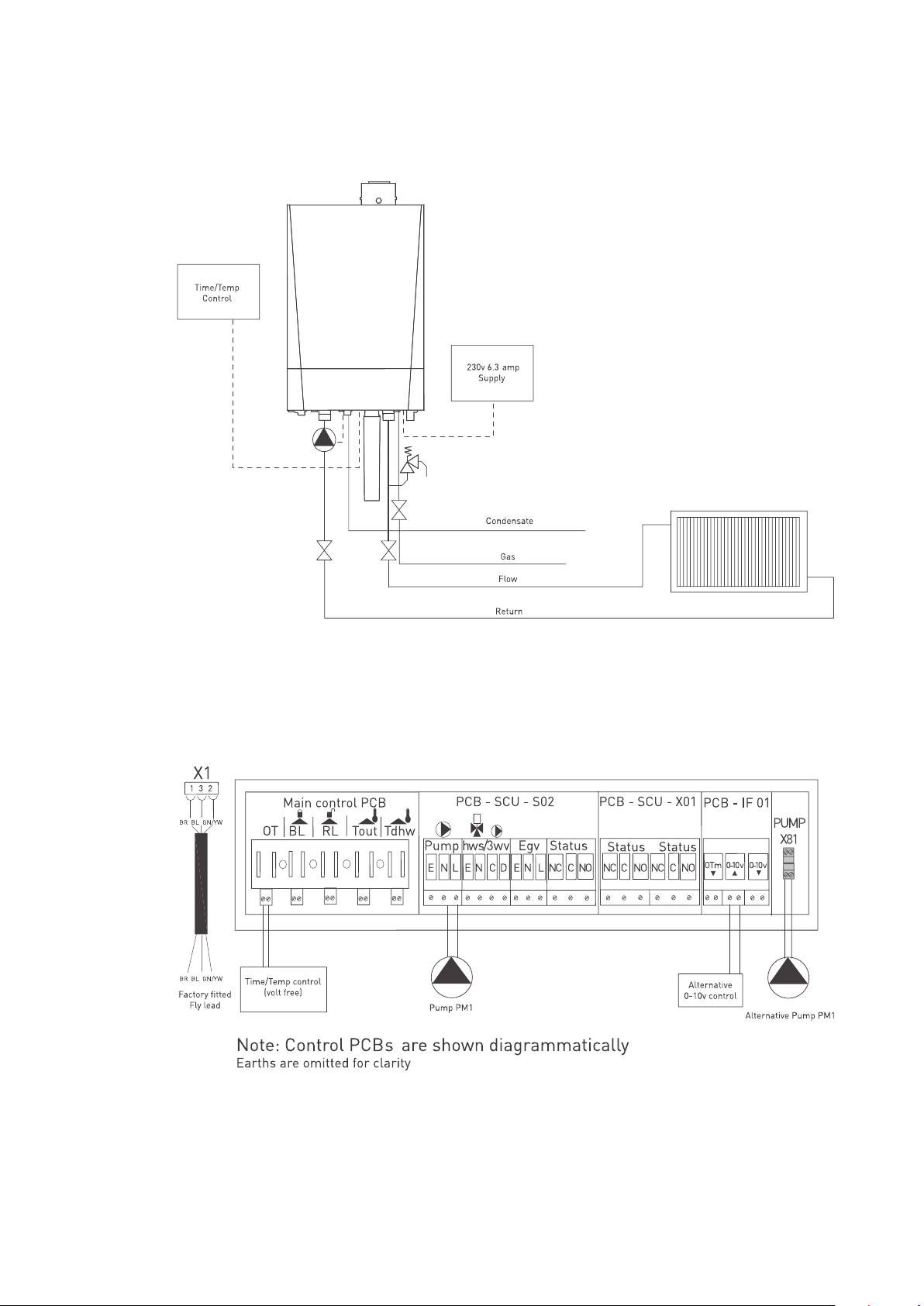

Single Quinta Pro boiler, heating only

(Time and temperature control by others)

Power Supply

• Boiler requires a permanent 230v single phase supply fused at 6.3 amps connected to the

factory fitted fly lead

Boiler Interlocks

(for pressure switches etc.)

• Safety Interlock - remove the existing link and t volt free switch pair to BL on the main

control PCB. If the circuit is open the boiler will go to a shut down mode displaying code

9 and will restart when the circuit is closed

Indication Controls

(to report actual function)

• Common Alarm - volt free relay on SCU-X01 (see boiler manual for full details)

• Boiler Run - volt free relay on SCU-X01 (see boiler manual for full details)

Boiler Control Settings

(see 5.7.2 in technical documentation)

• Connect the external controls (volt free) to the OT terminals on the main control PCB (on/off).

Boiler will modulate to the set point set in P1 or the 0 -10v terminals on the IF-01.

Control option based on temperature or output can be adjusted on the jumper on the IF-01.

(See installation manual for full details)

• Boiler will recognise the type of control being used

• Set boiler code P1 to the required ow temp i.e. 80 = 80ºC (system design requirements)

• Pump: connect the heating pump to terminals shown on the PCB SCU - S02 max 400Va

(1.5 amp). Alternatively, pump can be connected to the fly lead supplied with the boiler

to plug X81; this a max duty of 200w (0.8 amp)

6

Quinta Pro single boiler heating only

QP 002

Quinta Pro single boiler heating only

Single Quinta Pro boiler, heating only

QP 002

QP 002A

7

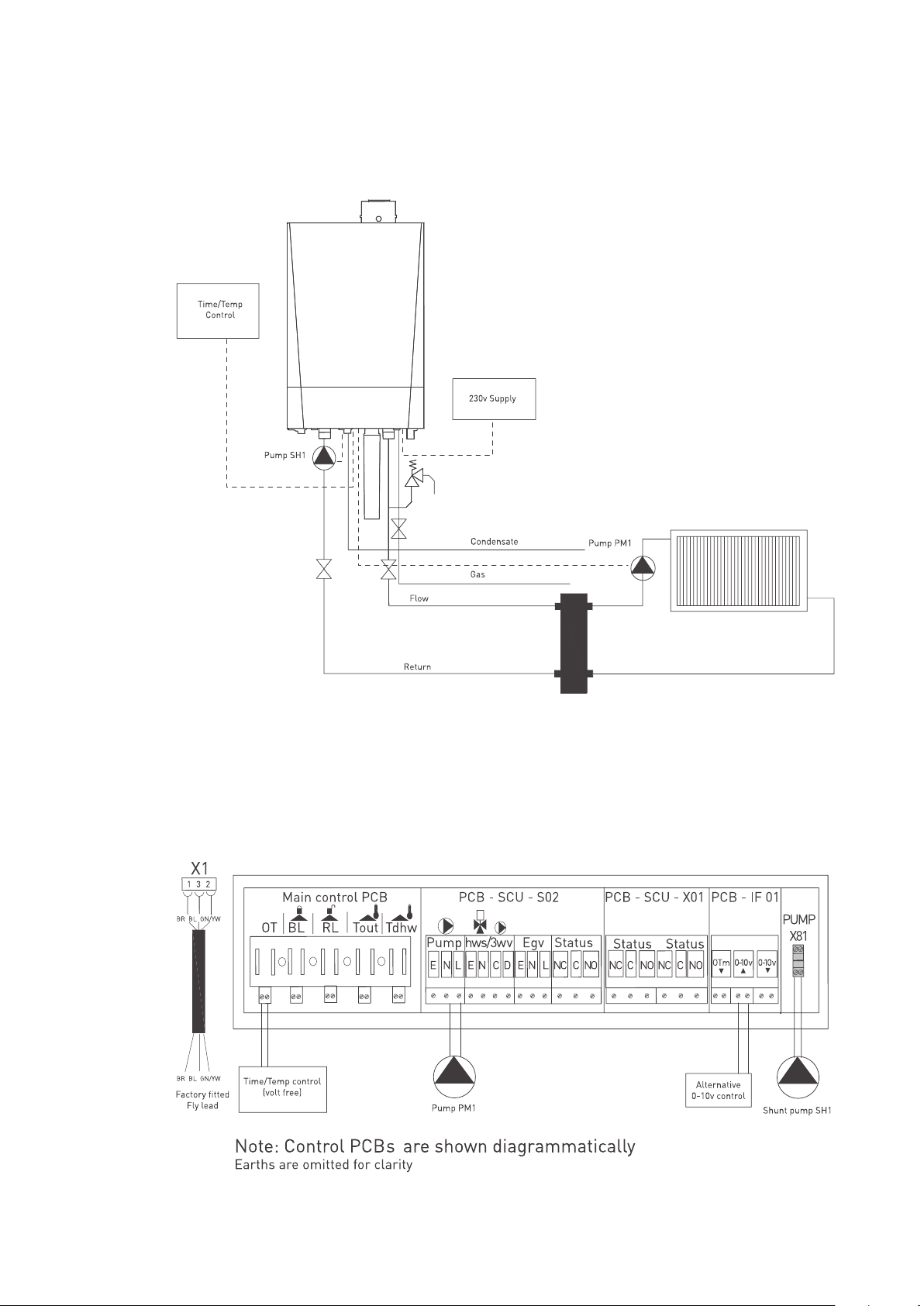

Single Quinta Pro boiler, heating only with low loss header

(Time and temperature control by others)

Power Supply

• Boiler requires a permanent 230v single phase supply fused at 6.3 amps connected

to the factory fitted fly lead

Boiler Interlocks

(for pressure switches etc.)

• Safety Interlock - remove the existing link and t volt free switch pair to BL on the main

control PCB. If the circuit is open the boiler will go to a shut down mode displaying code

9 and will restart when the circuit is closed

Indication Controls

(to report actual function)

• Common Alarm - volt free relay on SCU-X01 (see boiler manual for full details)

• Boiler Run - volt free relay on SCU-X01 (see boiler manual for full details)

Boiler Control Settings

(see 5.7.2 in technical documentation)

• Boiler will recognise the type of control being used

• Set boiler code P1 to the required ow temp i.e. 80 = 80ºC (system design requirements)

• Connect the external controls (volt free) to the OT terminals on the main control PCB

(on/off). Boiler will modulate to the set point set in P1 or the 0 -10v terminals on the IF- 01.

Control option based on temperature or output can be adjusted on the jumper on the IF- 01.

(See installation manual for full details)

• Pumps: connect pump PM1 to the heating pump terminals shown on the PCB SCU - S02

max 400Va (1.5 amp). Connect the shunt pump SH1 to the pump y lead supplied with the

boiler to plug X81

8

Quinta Pro single boiler heating only with loss heading

QP 003

Quinta Pro single boiler heating only with loss heading

Single Quinta Pro boiler, heating only with low loss header

QP 003

QP 003A

9

Single Quinta Pro boiler, heating with priority hot water

using a low loss header and pump or valve kit

(Time and temperature control by others)

Power Supply

• Boiler requires a permanent 230v single phase supply fused at 6.3 amps connected

to the factory fitted fly lead

Boiler Interlocks

(for pressure switches etc.)

• Safety Interlock - remove the existing link and t volt free switch pair to BL on the main

control PCB. If the circuit is open the boiler will go to a shut down mode displaying code

9 and will restart when the circuit is closed

Indication Controls

(to report actual function)

• Common Alarm - volt free relay on SCU-X01 (see boiler manual for full details)

• Boiler Run - volt free relay on SCU-X01 (see boiler manual for full details)

Boiler Control Settings

(see 5.7.2 in technical documentation)

• Boiler will recognise the type of control being used

• Set boiler code P1 to the required ow temp i.e. 80 = 80ºC (system design requirements)

• Connect the external controls (volt free) to the OT terminals on the main control PCB

(on/off). Boiler will modulate to the set point set in P1

• Pumps: connect pump PM1 to the heating pump terminals shown on the PCB SCU - S02 max

400Va (1.5 amp). Connect the shunt pump SH1 to the y lead supplied with the boiler to plug

X81 max 200w (0.8 amp). On pump installations, connect the shunt pump to the terminals

shown; a contactor or relay will be required if loading exceeds 1.5 amps

• 3-way valve: on the 3-way valve option, connect the valve to the terminals shown on the PCB

SCU – S02

Important:

When using the Remeha supplied low loss header and pump kit and the DHW diverting valve or

primary pump kit, the calorifier must be sited within 3M of the boiler. In both cases, the DHW

cylinder must be a high recovery unit capable of accepting the full or adjusted DHW output of the

boiler being used (reference parameter P18).

10

Loading...

Loading...