Page 1

Distributed by

Any reference to Raytheon or

RTN in this manual should be

interpreted as Raymarine.

The names Raytheon and RTN

are owned by the

Raytheon Company.

Page 2

Page 3

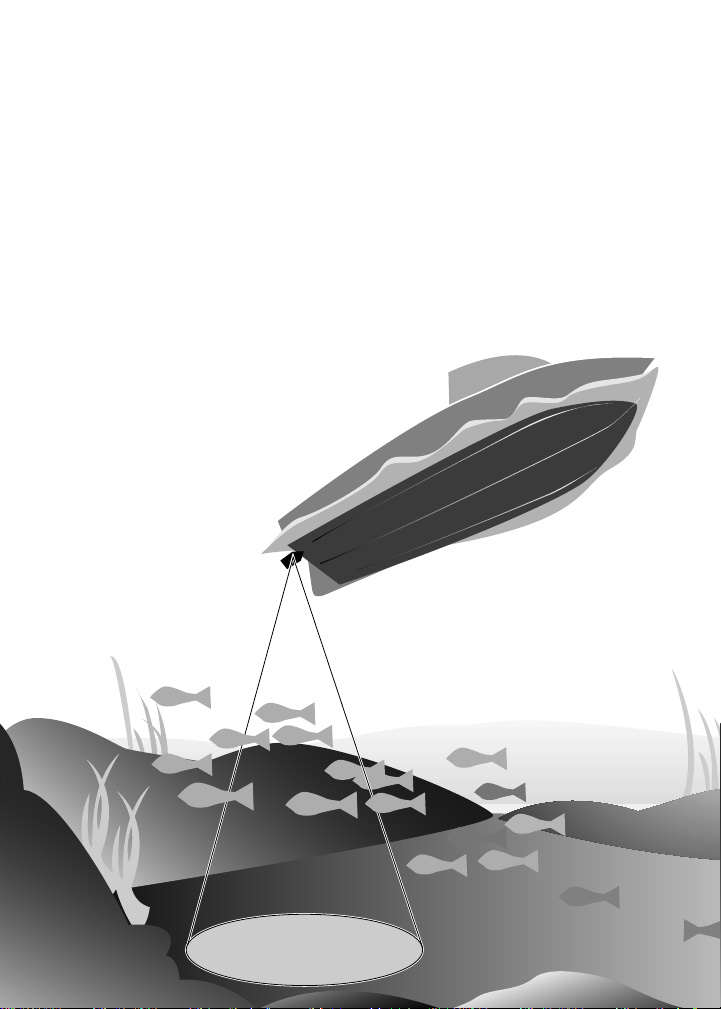

Echo Sounding

How it Works

◆ Your eyes underwater

An “echo sounder” or “sonar” unit sends high-frequency sound waves do wn into the

water below a boat. These sounds hit the bottom of the lake or sea and bounce bac k.

The display unit measures the time delay as the signal goes out and returns. The

FishFinder uses this information to display a graphic image of the bottom conditions.

The system also uses this same principle to detect fish or other objects in the water,

and display their size and location. This display is like a “window” which allows you to

look into the underwater world.

◆ About the transducer

The transducer transmits the sound waves do wn into the

water. It also receives the waves as they return. One

type of transducer can be mounted on the transom

of the boat, as shown here. Other types of

transducers can be installed through a hole in

the hull, or mounted inside the hull.

◆ The Sidelooker

transducer

The optional Sidelooker is a

special type of transducer

which allows the FishFinder to detect fish beside

the boat. The Sidelooker

produces two powerful horizontal beams which extend to either side, just

below the surface of the

water.

The Sidelooker transducer uses a

special plastic material called “PVDF,”

which was developed by Raytheon

Naval Systems. This allows the Sidelooker to give you the clearest possible

picture of conditions underwater.

Page 4

FishFinder 465

“Out of the box” operation

Because of a number of automatic features, the FishFinder 465 unit is ready to

operate “right out of the box.” This unit includes automatic settings for the most

important controls – range, sensitivity, and

zoom. Because these settings are

automatic, the FishFinder will provide useful displays right from the start. Once you

become more comfortable with the

operation of the unit, you can adjust these

settings.

Excellent ability to find fish

T o a sonar unit lik e the FishFinder, the

water includes a lot of background “noise.”

There are many conditions which could

confuse a sonar unit – bubbles and wakes

in the water, temperature diff erences between water layers, and so on. It can be

difficult for a sonar unit to detect fish

against this background of noise.

Because of its advanced circuitry , the 465

is especially good at telling the difference.

Dual frequency operation

“Frequency” is a measure of ho w fast the

sound waves change or “vibrate.” The

FishFinder uses sound waves with two

different frequencies – 50 kHz and 200

kHz. The 50 kHz frequency scans a wide

area, and penetrates the water well. This

frequency is best for use in deep water .

The 200 kHz frequency scans a narrower

area but produces a more detailed view .

This frequency is best for seeing fish near

the bottom, or fish which are close

together. The FishFinder can also use

both frequencies at the same time. This

provides good depth penetration and good

detail in the display .

Features and functions

465

PWR

SETUP

ZOOM

BOT

LOCK

CLEAR

A-SCP

FISHFINDER

Fish symbols and alarms

The unit provides fast, positive identification of fish in the water. It e ven indicates

the size of a fish using eight different fish

symbols. The 465 includes alarms f or

shallow warning, deep warning and fish

warning.

Clear LCD display

The FishFinder display produces continuous pictures of bottom conditions and fish

in the water. The displa y unit may be

turned or tilted to the best viewing angle.

The FishFinder unit can be easily

removed from the boat for storage in a

safe place.

Totally waterproof

The FishFinder 465 meets U.S. Coast

Guard specifications for waterproofing, so

it can stand up to the hard service

required on small boats. The rugged

construction and sophisticated sealing

methods used in this unit will ensure

many years of reliable service.

Page 5

Before you begin

This manual contains very important information on the installation and

operation of your FishFinder 465. For best results as you use this unit,

please take the time to read this manual thoroughly.

IMPORTANT NOTICE

THIS DEVICE IS ONLY AN AID TO NAVIGATION. ITS ACCURACY CAN

BE AFFECTED BY MANY FACTORS, INCLUDING EQUIPMENT

FAILURE, DEFECTS, ENVIRONMENTAL CONDITIONS AND IMPROPER HANDLING OR USE.

IT IS THE USER’S RESPONSIBILITY TO EXERCISE COMMON PRUDENCE AND NAVIGATIONAL JUDGMENT. THIS DEVICE SHOULD

NOT BE RELIED UPON AS A SUBSTITUTE FOR SUCH PRUDENCE

AND JUDGMENT.

Warranty card

Before you go any further, please take a few minutes to fill out the

warranty card. It is very important that you return the warranty card soon

after your purchase. This will ensure that you receive the full benefits

offered by the warranty.

Service information

In the unlikely event that your unit is ever in need of service, please refer

to the section on “Maintenance and Troubleshooting” at the back of this

manual. See the information on “How to Contact Apelco.”

Special terms

In this manual, we will use some special terms which have to do with

boats and boating. These are explained in a Glossary at the end of the

manual. If you do not recognize a word which appears in this manual,

check the Glossary.

ii

Page 6

FishFinder 465

Instruction Manual

Page 7

Contents

Echo sounding – How it works (inside front cover)

FishFinder 465 – Features and functions i

For information and service ii

1 Introduction 1

About the FishFinder 465 1

System Components 2

Standard Equipment 2

Standard Transducers 2

Optional Accessories 2

2 Installation 4

About the Transducer 4

Selecting the Correct Type of Transducer 5

Assembling the Transducer Bracket 6

Positioning the Transom-Mount Transducer 6

Mounting the Transom-Mount Transducer 9

Mounting the Optional Sidelooker Transducer 10

Installation Notes – Thru-Hull Transducer 10

Installation Notes – In-Hull Transducer 12

Installation Notes – Trolling Motor Transducer 12

Installation Notes –

Transducer for Speed and Temperature Only 13

EMC Installation Guidelines 13

Mounting the Display Unit – Standard Mount 15

Mounting the Display Unit – Flush Mount 17

Installing the Transducer Cable 18

Installing the Transducer Cable – Sidelooker Option 20

Installing the Transducer Cable –

Separate Speed and Temperature Sensors 20

Making the DC Power Connections 21

Calibrating the Sensors 23

3 Operating Instructions 25

Controls on Display Unit 25

Tur ning the Power On and Off 27

Setup Memory 27

Lamp/Contrast Display 28

iv

Page 8

Operating Pages 29

FishFinder Page 31

Choosing a Frequency 36

Fish Indications 37

Bottom Indications 38

Window Page 40

Sidelooker Page 42

Digital Page 46

Performance Modes 49

Zoom Mode 49

A-Scope (Bottom Coverage) Mode 51

Bottom Lock Mode 53

4 Setup Instructions 55

The Setup Menu 55

Range Setting 56

Sensitivity Setting 57

Chart Speed Setting 59

Frequency Setting 60

Resetting the Log 62

System Setup Menu 63

Simulator 64

Language 64

Fish Symbol 64

White Line 64

VRM 65

Sidelooker 65

Speed Cal 65

Temp Cal 66

Depth Digits 66

Shallow Alarm 66

Deep Alarm 67

Fish Alarm 67

Buzzer 68

Depth Units 69

Speed Units 69

Temp Units 69

Speed 69

Log 69

Temp 69

Setup Menus for Zoom Mode 70

Zoom Select Menu 70

Zoom Screen Split/Full Menu Item 71

Setup Menus for Bottom Lock Mode 72

Bottom Lock Range Menu Item 72

Bottom Lock Split/Full Menu Item 73

Setup Menu for Window and Digital Pages 74

Resetting from the Digital Page 75

Setup Instructions for Sidelooker 75

Sidelooker Range Menu Item 76

v

Page 9

Sidelooker Sensitivity Menu Item 77

Sidelooker Chart Speed Menu Item 77

Sidelooker View Menu item 78

Combining Displays 79

Resetting the Unit to Factory Defaults 80

Default Settings 81

5 Maintenance and Troubleshooting 82

Cleaning Instructions 82

Troubleshooting Suggestions 82

Servicing a Thru-Hull Transducer 86

How to Contact Apelco 86

6 Specifications 89

General Information 89

FishFinder Functions 90

Connector Diagrams 91

Glossary of Terms 92

vi

Page 10

List of Figures

Figure Page

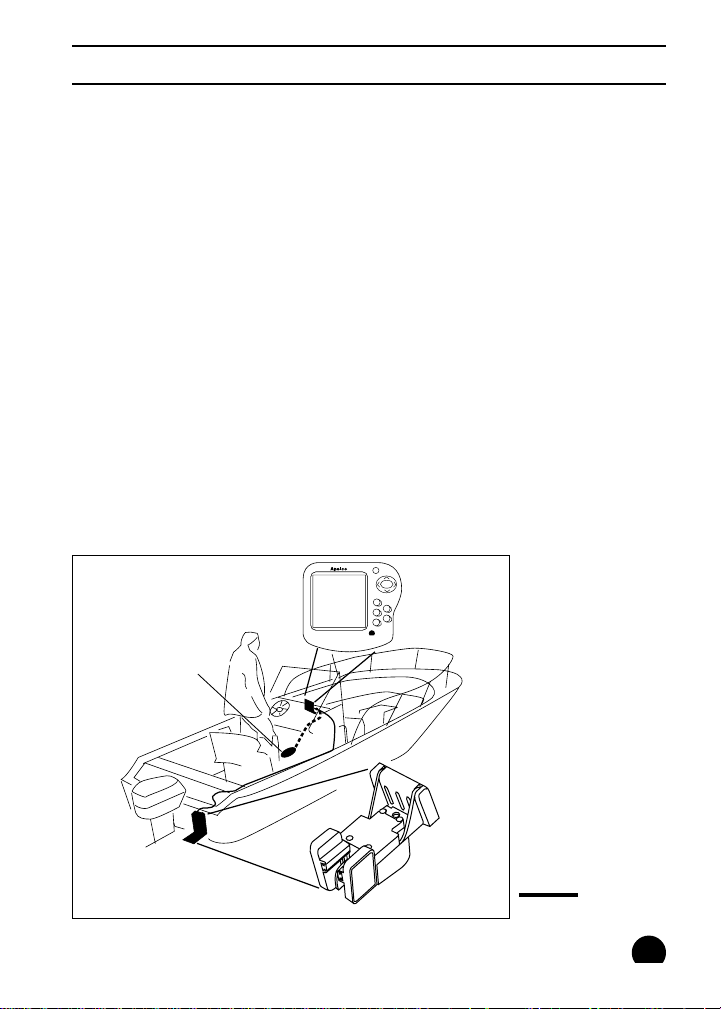

Unit in Use Inside front cover

Front Panel i

1-1 Typical Installation 1

2-1 Transducer Types 5

2-2 Assembling the Transducer Bracket 6

2-3 Transducer Mounted on Transom 7

2-4 Transducer Bracket, Side View 7

2-5 Correct Mounting Position 8

2-6 Mounting the Transducer 8

2-7 Installing the Sidelooker Transducer 10

2-8 Suppression Ferrites 14

2-9 Installation on Bracket 15

2-10 Dimensions 16

2-11 Flush-Mount Installation 17

2-12 Disassembling from Bracket 18

2-13 Installing Cable on Transom 19

2-14 Cable for Sidelooker Transducer 20

2-15 Cable for Speed and Temperature Sensor 21

2-16 DC Power Connections 22

3-1 Display Panel 25

3-2 Lamp/Contrast Menu 28

3-3 Operating Pages 30

3-4 FishFinder Mode Page 31

3-5 Fish Indications 37

3-6 Bottom Conditions 39

3-7 Window Page 40

3-8 Options for Window Page 41

3-9 Sidelooker Feature 42

3-10 Sidelooker Page 43

3-11 Digital Page 46

3-12 Performance Modes 48

3-13 Zoom Mode 49

3-14 A-Scope Mode 51

3-15 Bottom Lock Mode 53

4-1 Setup Menu Items 55

4-2 Range Menu Item 56

4-3 Sensitivity Menu Item 57

4-4 Changing the Chart Speed Setting 59

4-5 Chart Speed Menu Item 60

4-6 Frequency Menu Item 60

4-7 Log Reset Menu Item 62

vii

Page 11

4-8 Reaching the System Setup Menu 63

4-9 System Setup Menu 63

4-10 Zoom Select Menu Item 70

4-11 Zoom Screen Split/Full Menu Item 71

4-12 Bottom Lock Range Menu Item 72

4-13 Bottom Lock Split/Full Menu Item 73

4-14 Digital Setup Menu Item 74

4-15 Sidelooker Range Menu item 76

4-16 Sidelooker Sensitivity Menu Item 77

4-17 Sidelooker Chart Speed Menu Item 77

4-18 Sidelooker View Menu Item 78

4-19 Split FishFinder Page with A-Scope Mode 79

4-20 Window Page with Option G Selected

and Zoom Enabled 80

5-1 Sample Mailing Label 88

6-1 Connector Diagrams 91

viii

Page 12

1 – Introduction

About the FishFinder 465

The FishFinder 465 is a system that uses sound waves (“sonar”) to

detect fish and show the bottom of a lake or sea. The system includes a

transducer and a display unit, connected by a cable. The transducer

sends high-frequency sound waves down into the water. These sounds

strike fish, the bottom, or other objects in the water, and return as

echoes. The FishFinder then interprets these echoes and presents a

display.

The FishFinder 465 can handle many different jobs:

• detect the presence of fish below the boat

• trigger an alarm when fish are found

• measure the depth of the water

• set alarms for minimum and maximum depth

• show the shape of the bottom

• determine whether the seabed is hard or soft

• measure the speed of the boat and the distance traveled

• show the water temperature

We are sure you will find the FishFinder 465 to be one of the most useful

devices on your boat.

PWR

FISHFINDER

Optional Thru Hull

Transducer

FishFinder 465

Display Unit

SETUP

CLEAR

ZOOM

A-SCP

BOT

LOCK

465

Transducer mounted

in quick release

transom bracket

Introduction

Fig. 1-1

T ypical Installation

1

Page 13

System Components

The FishFinder 465 consists of a compact display unit connected to a

transducer. The transducer is attached to the boat and extends into the

water.

Standard Equipment

When you unpack your FishFinder 465, you should find the following

standard equipment in the carton. If any items are missing, please notify

your Apelco dealer immediately, or contact the Customer Ser vice

Department at Apelco at 1-800-539-5539, ext. 2120. Please provide the

serial number of the FishFinder when reporting any missing items.

Description Part No.

FishFinder 465 display unit M78954

Quick-release swivel-mount br acket

(with mounting hardware) G623996-1

DC power cable M99-146

Instruction manual 81146-1

Four #10 x 3/4” ss mounting screws —

Standard Transducers

Depending on which model of the 465 you have purchased, the box will

include one of the transducers listed below:

Description Part No.

T ransom-mount transducer (with speed

and temperature sensors, including

mounting bracket and hardware) M78898

Bronze thru-hull transducer (with

speed and temperature sensors) M78923

Optional Accessories

Optional accessories and parts can be purchased directly from Apelco

Marine. For prices and ordering information, please call the Parts

Department at (800) 539-5539 ext. 2120.

2

Introduction

Page 14

Description Part No.

Sidelooker transom-mount transducer M78930

Sidelooker transducer for trolling motor

(all-in-one unit senses depth below boat,

with Sidelooker and temperature sensor ,

including mounting hardware) M78929

Extension for transducer cable (15 ft., 5 m) M99-140

Extension for transducer cable,

for Sidelooker transducer (15 ft., 5 m) M99-139

Flush-mounting kit (with hardware and

mounting template) M99-138

Fairing bloc k for M78923 thru-hull

transducer (Lexan®) M99-142

Low profile plastic thru-hull transducer

(Valo x® plastic, sensor for depth only) M78922

Bronze thru-hull transducer

(sensor for depth only) M78921

In-hull/trolling motor transducer (for installation in

fiberglass hull only , or mounting on trolling motor,

including hardware for either installation) M78928

Angled in-hull transducer (for installation

in fiberglass hull only , where deadrise

angle is 10° to 22°) M78946

Plastic thru-hull transducer (Valo x® plastic, with

speed and temperature sensors, used with depthonly transducers M78922, M78928, M78946) M78937

T ransom-mount speed and temperature

sensor (used with depth-only transducers

M78922, M78928, M78946) M78936

Replacement transom transducer

mounting bracket kit M99-148

T ransducer s witch box (select between tw o 465

FishFinder displays, using one transducer) M99-136

Replacement paddle wheel kit (for transommount transducer) M99-143

Replacement paddle wheel kit

(for thru-hull transducer) D234

Replacement paddle wheel kit

(for bronze thru-hull transducer) D144

Introduction

3

Page 15

2 – Installation

The installation process has four parts:

• Mounting the transducer

• Mounting the display unit

• Connecting the cables for the transducer and power supply

• Calibrating the display unit

About the Transducer

Several different kinds of transducers can be used with this unit. The

transom-mount type is used most often. Other types are shown in Fig. 2-

1.

Most transducer types can measure the water depth. Some of the

transducers also have two other sensors: a paddle wheel which detects

the speed of the boat, and a sensor for the water temperature. The

display unit uses the speed information to calculate the distance the boat

has traveled.

The transducer is very important to the operation of the FishFinder. It is

also important that you mount the transducer correctly. The transducer

will give the most reliable readings if it looks into water which is smooth

and undisturbed. If you place the transducer so bubbles or turbulence

flow across the face of the unit, the system may give inaccurate readings.

There are three important rules for placing any type of transducer:

• The transducer should be continuously covered by water when the

boat is moving. (If the transducer is mounted near the side of the

boat, it may be exposed when the boat is turning.)

• The transducer should be placed where turbulence or bubbles will

not pass directly over the face of the unit. Don’t place the transducer

behind any running strakes, intakes, or thru-hull fittings which create

turbulence.

• The transducer should be mounted where it will not be affected by

the wash from the propeller(s).

4

Installation

Page 16

Transom-mount

transducer

Thru-hull

transducer

Fairing for

thru-hull transducer

In-hull

transducer

Sidelooker

transducer

Fig. 2-1

Transducer

Types

Selecting the Correct Type of Transducer

Before you begin the installation, double-check to be sure you have the

correct type of transducer. Each kind of transducer is designed for a

particular type of use. In this manual we will include detailed mounting

instructions for the transom-mount transducer. We will also include some

general information on the other types. For detailed information on these

other transducers, see the instructions which are packaged with the unit.

Use a transom-mount transducer if –

your boat has an outboard or inboard-outboard engine(s) only. This type

of transducer must be mounted ahead of or beside the propeller(s). Don’t

use this type of transducer on a boat with a straight-shaft inboard engine.

Use a thru-hull transducer if –

your boat has a straight-shaft inboard engine. This type of transducer is

installed in a hole drilled through the hull.

Use an in-hull transducer if –

you have a high-speed boat or if, for some reason, you cannot use a

transom-mount or thru-hull transducer. The hull may be no more than 1"

thick.

Installation

5

Page 17

Use a trolling motor transducer if –

you want to attach the transducer to a trolling motor.

Use a Sidelooker transducer if –

you need a way of searching for fish on either side of the boat. This type

of transducer is attached to the bracket of the transom-mount transducer.

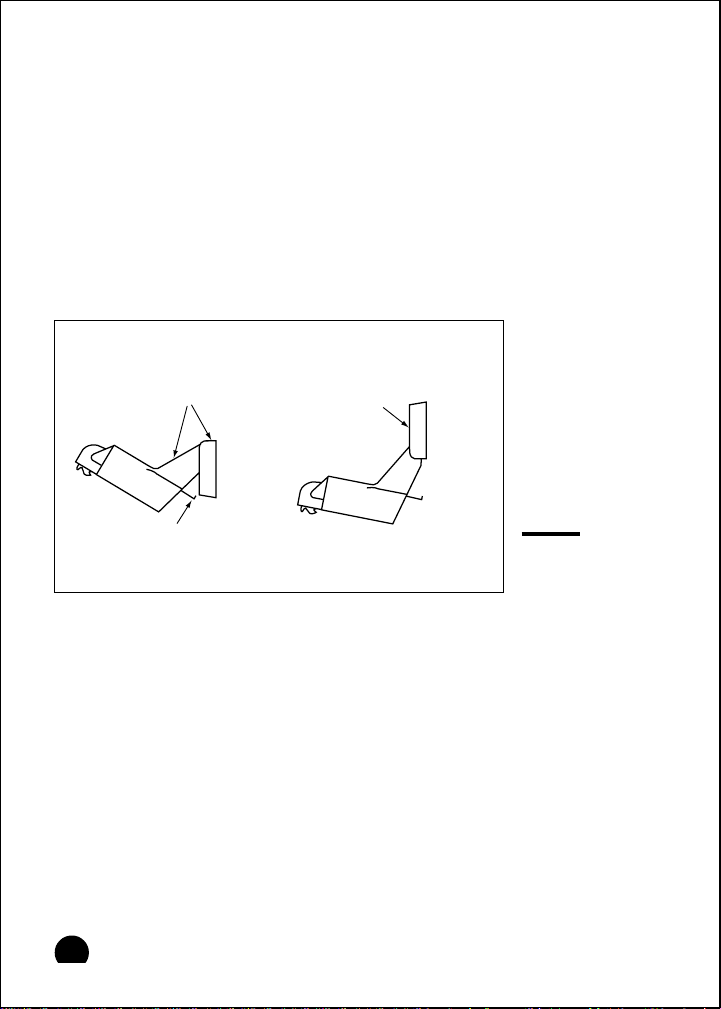

Assembling the Transducer Bracket

Fit together the two parts of the transducer bracket as shown in Fig. 2-2.

When the installation is complete, the parts snap together as shown.

NOT THIS!LIKE THIS!

Attach the

two parts

Bracket is installed

upside down

Lower the transducer

and snap in the

release clip

Fig. 2-2

Assembling

the T ransducer

Bracket

Positioning the Transom-Mount Transducer

Begin by finding the best location for the mounting bracket. Here are the

rules:

• If your boat has one propeller (outboard or inboard-outboard), mount

the transducer about 18” (455 mm) to the side of the centerline of

the boat. See Fig. 2-3. Choose the side that is on the downstroke of

the propeller. (This is usually the starboard side of the boat.) This

will reduce any interference caused by air bubbles.

• If your boat has twin propellers (outboard or inboard-outboard),

place the transducer near the centerline of the boat.

• If the propeller can be turned to steer the boat, allow at least 2" (50

mm) beyond the swing radius of the propeller. This will prevent the

6

Installation

Page 18

Fig. 2-3

Transducer

Mounted on

T ransom

Allow a clearance

of at least 10

inches (254 mm)

10"

(254 mm)

Transducer in

released position

Fig. 2-4

Transducer

Bracket,

Side View

propeller from damaging the transducer when it is turned.

•

Do not

mount the transducer behind any hull fittings, intakes, or

other parts which extend from the hull. These may cause turbulence

or air bubbles.

• The bracket has a quick-release mechanism. This prevents damage

by allowing the transducer to flip up if it hits any debris or the bottom.

See Fig. 2-4. Allow enough clearance above the transducer so that it

can swing upward completely. This is about 10" (254 mm) measured

from the bottom of the transom.

Installation

7

Page 19

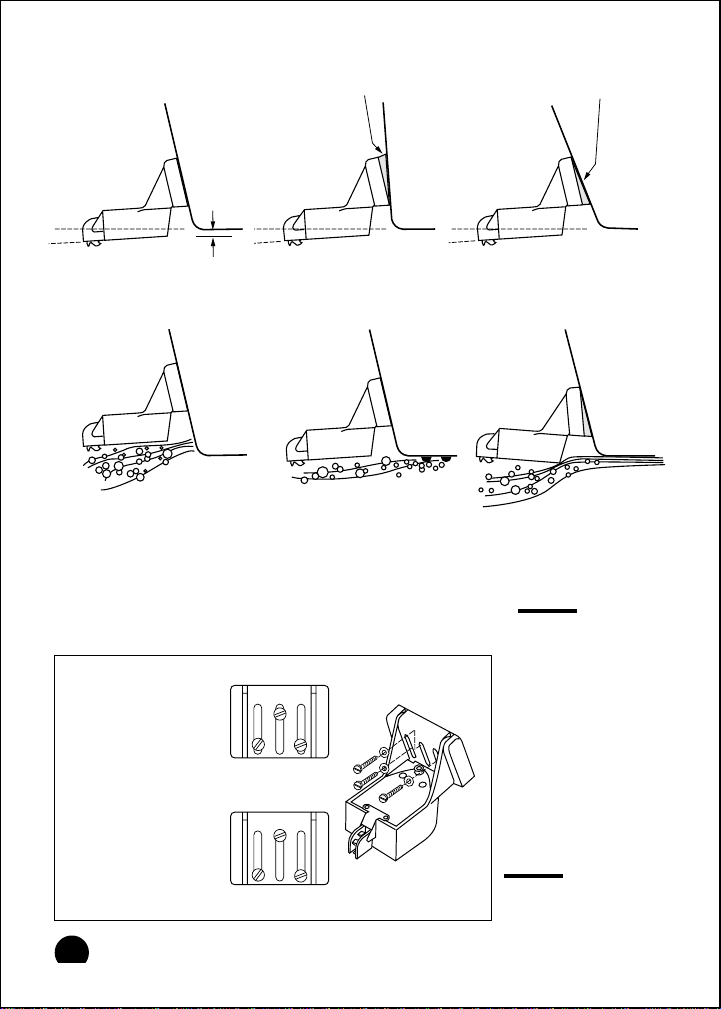

Average transom angle–

no wedge necessary

Vertical transom –

place wedge this way

Sloping transom–

place wedge this way

2° to 5°

2° to 5° 2° to 5°

For fiberglass hull – 1/8" to 1/4" (3.2 to 6 mm)

For aluminum hull – 1/4" to 3/8" (6 to 9 mm)

No! No! No!

The bow of the transducer

is above the bottom of the

transom, creating

cavitation.

Insert screws 1 and 3

1/4" from the bottom of

slots, and screw 2

1/4" from the top of the

slot to allow room for

adjustment.

Rivets on the hull are

creating bubbles.

Lower the transducer

a bit.

123

Correct

alignment

The rear of the transducer

is too high, creating

cavitation.

Fig. 2-5

Correct Mounting

Position

If screws are inserted

this way, it won’t be

possible to make the

height adjustment.

8

Incorrect

alignment

Fig. 2-6

Mounting

the T ransducer

Installation

Page 20

• If the boat will be carried on a trailer, be sure the transducer will not

hit any rollers, bunks or fittings on the trailer.

Mounting the Transom-Mount Transducer

1. On a boat with a fiberglass hull, the leading edge of the transducer

should extend 1/8" (3.2 mm) to 1/4" (6 mm) below the bottom edge

of the hull. See Fig. 2-5. On an aluminum hull, the transducer should

extend a bit more – 1/4" (6 mm) to 3/8" (9 mm). If the boat will be

operated at high speeds, the transducer may be mounted closer to

the centerline of the hull.

2. The lower surface of the transducer should tilt down toward the rear

at a slight angle (2° to 5°). The mounting bracket includes a wedge.

Depending on the angle of the transom on your boat, you may need

this wedge to get the correct angle for the bottom of the transducer.

3. Looking at the rear of the boat, be sure the bracket is vertical

(perpendicular to the water line).

4. Hold the bracket (and the wedge, if used) against the transom and

trace the positions of the screw slots.

5. Remove the bracket. See Fig. 2-6. The screws in the outer slots

should be placed about 1/4" (6 mm) up from the bottom of each slot.

The screw in the center slot should be placed 1/4” (6 mm) down from

the top. (This will allow you to adjust the bracket up or down a bit.)

Drill pilot holes 3/4" (19.1 mm) deep. Use a 9/64" (3.6 mm) drill bit.

To prevent drilling too deeply, wrap masking tape around the drill bit

about 7/8" (22 mm) from the tip. Drill in only as far as the tape

marker.

If you are attaching the bracket to a fiberglass hull, you can minimize

any surface cracking of the gel coat. Before drilling each pilot hole,

drill a shallow hole (chamfer) at each location about 1/16" (1.5 mm)

deep. Use a 1/4" (6 mm) dr ill bit.

6. Attach the bracket to the hull using the panhead screws with flat

washers. Before you tighten the screws, apply a good-quality marine

sealant to the pilot holes. This will protect the hull from water

penetration.

7. Move the bracket up or down so that the leading edge of the

transducer has the clearance shown in Fig. 2-5.

8. Once the bracket is in the correct position, you can tighten the screws.

Do not tighten the screws completely yet.

Installation

9

Page 21

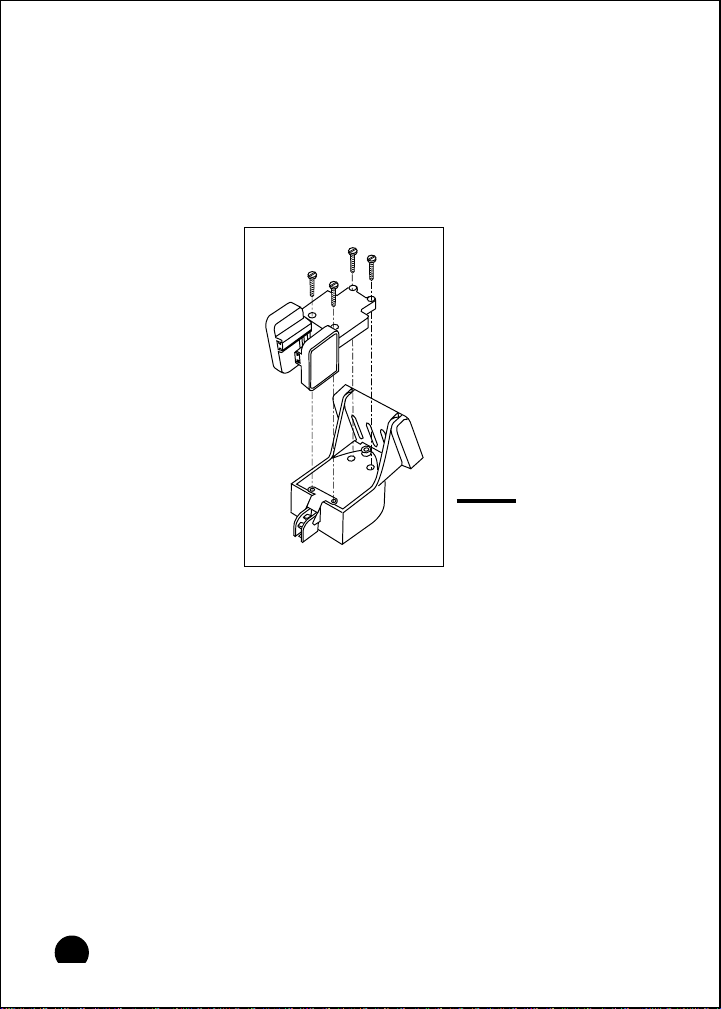

Mounting the Optional Sidelooker Transducer

1. The Sidelooker transducer allows the display unit to check the water

to either side of the boat. This is helpful when you are looking for fish

near river banks, or under docks or piers.

2. The Sidelooker transducer is attached to the same mounting bracket

used with the transom-mount transducer. See Fig. 2-7. Begin by

installing the transom-mount bracket as described earlier.

Fig. 2-7

Installing the

Sidelooker

T ransducer

3. Attach the Sidelooker transducer to the top of the transom mounting

bracket. Use the four panhead screws supplied. The fit should be

snug, but do not overtighten the screws.

4. If you are installing the optional Sidelooker transducer, there will be

two

transducer cables. Run the second cable beside the cable for

the transom-mount transducer.

Installation Notes – Thru-Hull Transducer

Detailed instructions for this installation will be included with the transducer. In this section, we will note just a few important points.

1. Earlier we listed three general rules for placing transducers. All of

these rules apply when you are mounting a thru-hull transducer.

Here are some other rules for selecting the best mounting location:

10

Installation

Page 22

For planing hulls – Install in the flat planing area near the stern.

Always install forward of the propeller(s) and shaft(s).

For small displacement hulls – Install near the centerline of the

hull and 1/3 of the way forward from the stern. Always install forward

of the propeller(s) and shaft(s).

For large displacement hulls – Install near the centerline of the hull

and 1/3 of the way aft from the bow. Always install forward of the

propeller(s) and shaft(s).

For sailboats – Install forward of the leading edge of the keel, to

one side and near the centerline of the hull.

2. Choose a location where you can easily reach the transducer from

inside the boat. This will allow you to service the unit. Allow at least

6" (152 mm) of headroom above the transducer.

3. When choosing a mounting location, drill a small pilot hole (1/8" or

3.2 mm) from the inside of the hull. Before you drill the hole, be sure

you will be able to reach the large nut on the top of the unit, and that

there will be enough clearance for the cable. If there is a strake or

other feature on the hull, drill from the outside of the hull instead.

(This small hole can be filled easily if the mounting location is not

suitable.)

4. The position of the transducer is especially critical on high speed

boats (capable of more than 20 knots). Check the locations of the

transducers on similar boats before installing the transducer in your

own boat. Choose the location which will offer the best performance.

5. If the bottom of the hull at the mounting location is flat, you can

mount the transducer directly through the hull. If the hull rises at an

angle (the “deadrise angle”) of more than 10°, you must include a

mounting block or “fairing.” The transducer must be mounted in a

vertical position. Attach the fairing block to the hull as firmly as

possible. This fairing block must be able to resist the drag of the

water against the hull, and must also be completely waterproof.

6. If the hull of the boat has a core-type hull, you will need to follow

special mounting procedures. The core material must be protected

from any water which may leak from the inside of the boat. (If the

core material is remains wet, it may rot and weaken the hull.)

7. When working with the transducer, support it by holding the body of

the unit or the rings. Do not hang the transducer from the cable.

Installation

11

Page 23

8. It is very important to seal the opening around the transducer using

a high-quality marine sealant suitable for underwater use. After

installation, do not leave your boat in the water for any amount of

time without checking for leaks.

Installation Notes – In-Hull Transducer

Detailed instructions for this installation will be included with the transducer. In this section, we will note just a few important points.

1. Choose the best mounting location:

For outboard powerboats – Install as far aft as possible

For inboard/outboard powerboats – Install close to the engine(s)

For inboard powerboats – Install forward of the propeller(s) and

shaft(s)

For sailboats – Install near the centerline of the hull and forward of

the leading edge of the keel

2. An in-hull transducer may only be installed in a fiberglass hull which

is no more than 1" (25 mm) thick. The in-hull transducer may not be

installed in wood or aluminum hulls.

3. Use the standard in-hull transducer if it will be installed in a flat part

of the hull, or a section with no more than 10° of deadrise. Use the

angled in-hull transducer if the mounting location has up to a 22° of

deadrise.

4. Do not try to compensate for the angle of the hull by fairing the

epoxy adhesive on the face of the transducer.

5. Use the epoxy supplied with the in-hull transducer, or an equivalent

epoxy glue. Do not use any other type of adhesive, including silicone

or RTV adhesive.

Installation Notes – Trolling Motor Transducer

Detailed instructions for this installation will be included with the transducer. This type of transducer is attached to the horizontal gear case of

the trolling motor. The installation is simple, but is important to keep the

transducer away from the wash from the propeller, and from turbulence

caused by parts of the hull.

12

Installation

Page 24

Installation Notes – Transducer for Speed and

Temperature Only

This type of transducer may be used with a thru-hull transducer which

reads depth only. The speed/temperature transducer is attached to the

transom of the boat. Detailed instructions for this installation will be

included with the transducer. The cable for this transducer uses a “Y”

connector. See the notes on “Installing the Transducer Cable.”

EMC Installation Guidelines

When different types of marine electronic equipment are mounted closely

together in a tight space, they may interfere with each other. The design

and manufacture of this unit follow industry standards for

“Electromagnetic Compatibility” (EMC). However, it is important to install

the unit correctly to ensure the best possible performance. Below is a list

of some of the factors which could affect the operation of the product.

Some of these factors may affect the way you install the FishFinder and

the wiring cables.

• Place the display unit and the power and signal cables at least 3 ft.

(1m) from any equipment transmitting radio signals, or any cables

carrying radio signals. This includes VHF radios, cables and antennas. In the case of SSB radios, the distance should be increased to 7

ft. (2m).

• Allow a space of at least 7 ft. (2m) from the path of a radar beam.

Normally, a radar beam will spread about 20° above and below the

radiating element.

• The power for the display unit should be supplied from a different

battery than the one used to start the engine. If the voltage to the

FishFinder unit drops below +10.8 V DC, this could cause the unit to

reset. This will not damage the equipment, but it may cause the loss

of some information, and it can change the operating mode.

Avoid running the FishFinder power wires near the power wiring for any

radar, radio, or Loran-C units. If possible, wire the FishFinder power wires

to a separate circuit breaker.

• If the transducer cable runs near another electrical wire, it may pick

up electrical interference or “noise.” To reduce this, try to keep the

transducer cable separated as far as possible from all other wires.

Installation

13

Page 25

This is especially important with wiring for the boat’s ignition,

alternator, or tachometer. It is also helpful to keep the transducer

cable away from the FishFinder power cable. If it is necessar y to run

the transducer cable across any wires, make the crossing at a right

angle.

• Use only genuine Raytheon cables. During the installation, do not cut

the transducer cable or remove the connector. Do not try to shorten

or splice the cable. The transducer cable includes several wires,

along with shielding and insulation. If the cable is cut, it cannot be

repaired. (Cutting the cable will also void the warranty.) During

installation, if you need to drill any holes for the cable, they must be

large enough to accept the connector. This will allow you to make the

installation without cutting the wire.

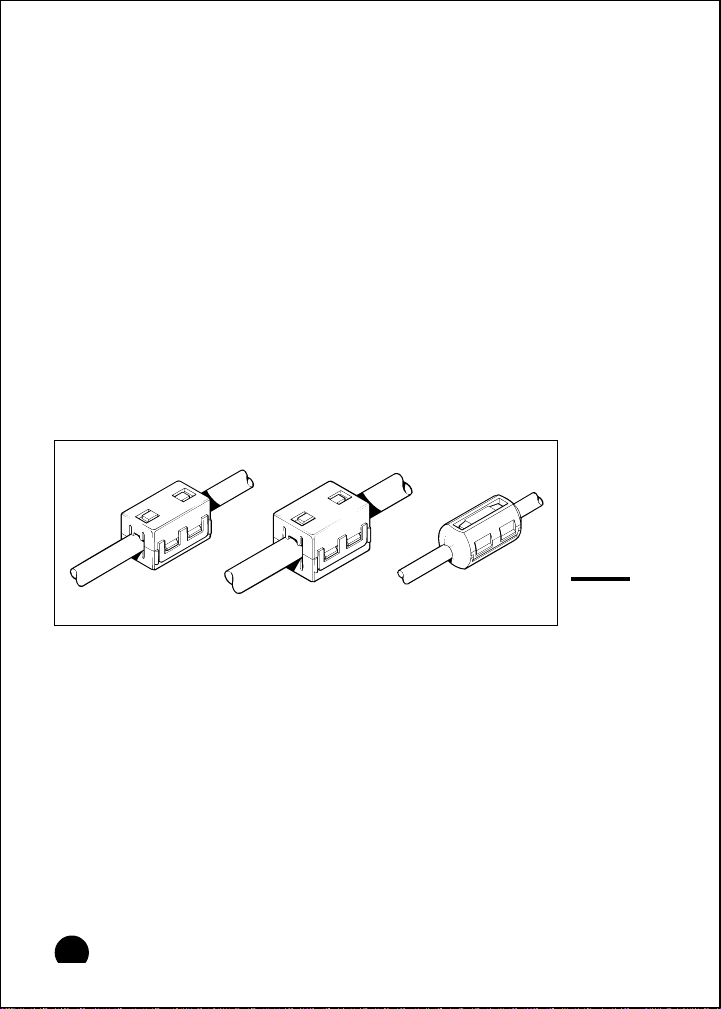

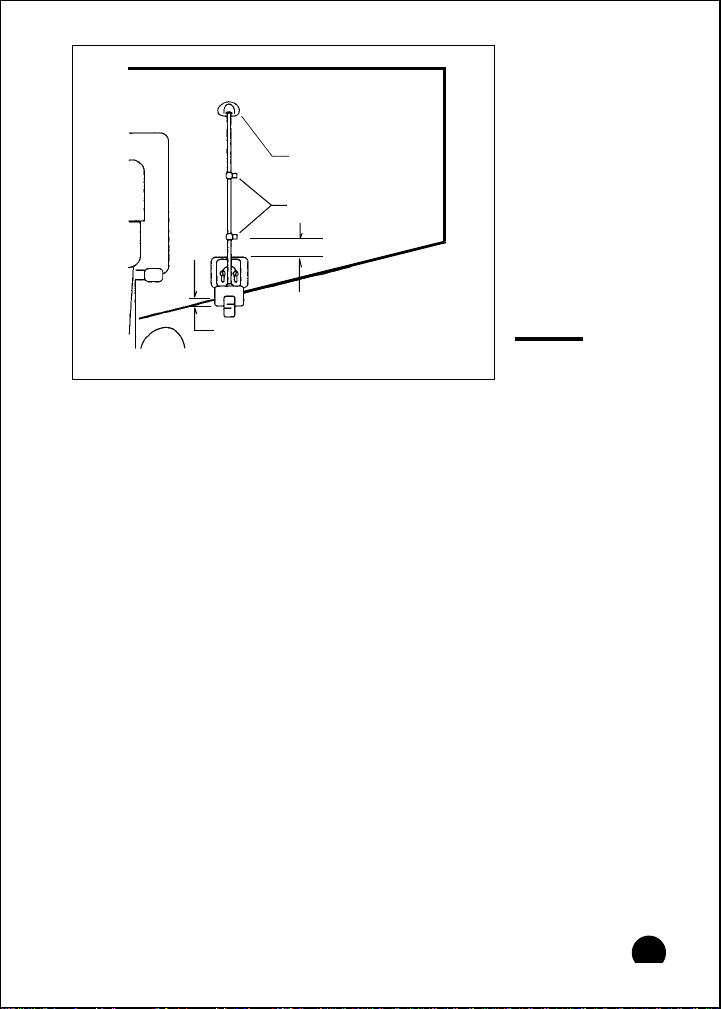

• A “suppression ferrite” may be attached to one of the cables. See

Fig. 2-8. If you must remove the ferrite during installation, be sure to

reassemble it in the same position.

Fig. 2-8

Suppression

Ferrites

14

Installation

Page 26

PWR

SETUP

CLEAR

ZOOM

A-SCP

BOT

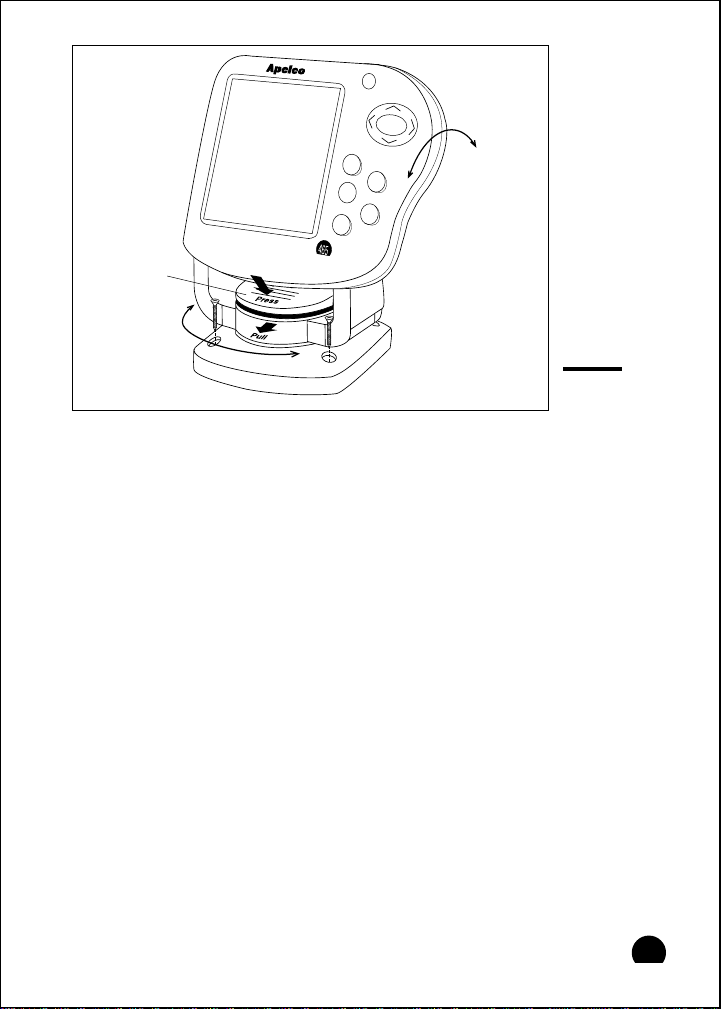

To release the

display from

the base,

press here.

The display can

be turned from

side to side.

LOCK

The angle of

the display

can be changed.

Fig. 2-9

Installation

on Bracket

Mounting the Display Unit – Standard Mount

You may mount the display unit on any flat surface using the bracket

supplied. See Fig. 2-9. (There is also an optional kit which allows you to

flush-mount the display in a flat panel or dashboard). Follow these

instructions if you are using the standard mounting bracket:

1. The “LCD” type display used on this unit is easier to see from certain

angles. Before selecting a permanent mounting location, make

temporary power connections and turn on the unit. This will allow you

to test the visibility of the display from several different angles.

2. Remove the display unit from the bracket by pressing on the large

button in the center of the bracket. See Fig. 2-9.

3. Mount the base of the bracket using the supplied screws.

4. Slide the display unit back into the bracket.

5. Adjust the display unit for the best viewing angle. You can turn the

display from side to side, and tilt it up or down.

Installation

15

Page 27

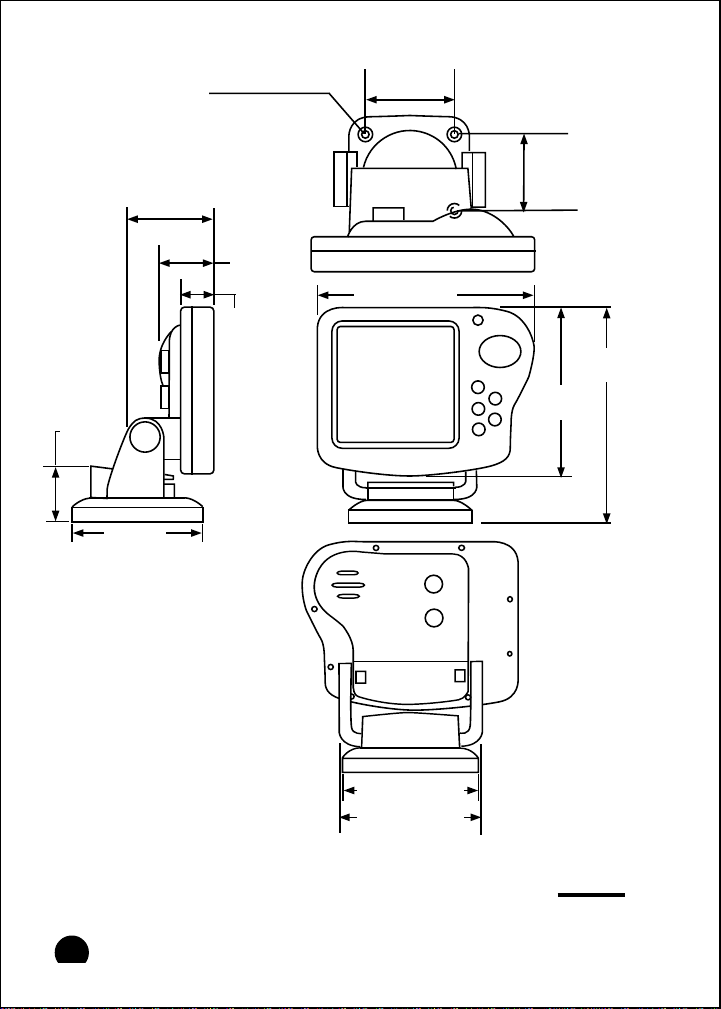

1-3/4"

(44 mm)

2-27/32"

(72 mm)

4-9/32"

(109 mm)

Hole 3/16" (5 mm)

1-3/4"

(45 mm)

1-15/32"

(37 mm)

2-25/32"

(70 mm)

2-21/32"

(67 mm)

6-5/8" (169 mm)

8-1/4"

(210 mm)

5-13/16"

(147 mm)

16

3-29/32"(99 mm)

4-7/32"(107 mm)

Fig. 2-10

Dimensions

Installation

Page 28

Mounting the Display Unit – Flush Mount

In order to do this installation, you will need the optional flush mounting

kit (part no. M99-138). See Fig. 2-11.

1. Select a mounting location on the dashboard or control panel.

Choose a clear, flat area at least 7" x 7" (180 mm x 180 mm). Be

sure you will also have at least 6" (152 mm) of clearance behind the

area where the display unit will be mounted. It is a good idea to drill a

small pilot hole in the center of the mounting area. Be sure there are

no hidden electrical wires or other items behind the point where you

plan to mount the display unit.

2. A mounting template is supplied with the flush mounting kit. Tape this

over the selected location on the panel and trace around the edges.

3. Make the cutout for the display. Drill a series of 1/2" (13 mm) holes

at the points shown around the edges of the cutout area.

4. Drill the two small holes for the threaded studs as shown on the

mounting template. Use a 7/32" (5.5 mm) drill bit.

5. Remove the template and draw straight lines between the 1/2" holes.

Cut along each of the lines with a small saw.

Gasket

Mounting hole

cut according to

template

Screw holes

Installation

Fasten with

threaded studs

and wing nuts

Fig. 2-11

Flush-mount

Installation

17

Page 29

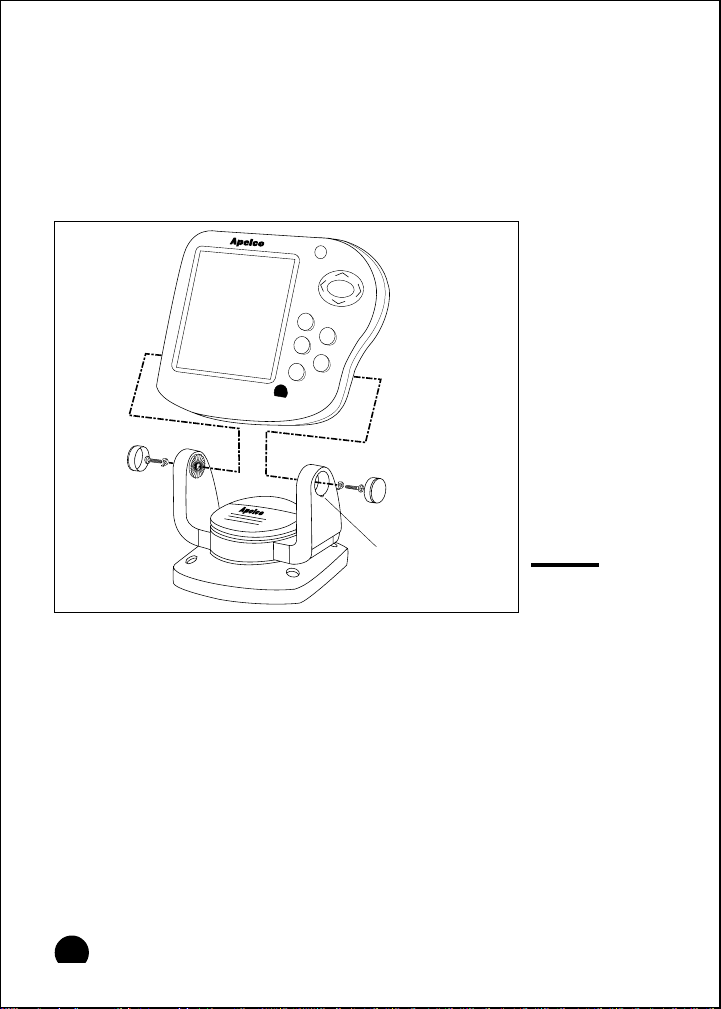

6. Separate the display unit from the mounting bracket. (See Fig. 2-12.)

Press the large button in the center of the bracket to separate the

bracket arms. The display unit is attached to the arms by two screws.

Each screw is covered by a cap. Locate the small slot beside each

cap and pry upward using a small screwdriver. Remove the caps,

then the two screws and the two wave washers. Save these parts in

case you ever want to use the mounting bracket.

PWR

SETUP

CLEAR

ZOOM

A-SCP

BOT

LOCK

465

To pry up the cap,

insert a small screwdriver here.

Fig. 2-12

Disassembling

from Bracket

7. Screw the threaded studs into the holes on the rear of the display unit.

8. Set the display unit into place to be sure that it will fit correctly.

Thread the wing-nuts onto the threaded studs to hold the display unit

in place temporarily.

9. Once the DC wiring is complete, finish the installation. Hold the

gasket in place around the opening. Fit the display into the cutout

again. From the rear, screw the thumbscrews securely onto the

threaded studs to hold the unit in place.

Installing the Transducer Cable

A 20 foot length of cable, with the connector attached, is supplied with

the transducer.

18

Installation

Page 30

Cable feed-thru

cap

Cable clamp

1" (25 mm)

Hull projections

Fiberglass: 1/4" (6mm)

Aluminum: 1/2" (13 mm)

Fig. 2-13

Installing Cable

on T ransom

1. Route the cable up and over the top edge of the transom. See Fig.

2-13. Secure the cable using cable clamps. (These clamps are

available from your local marine equipment supplier.)

If you do not want to expose the cable on the deck, you may drill a

new hole (3/4" or 19 mm) through the transom for the cable.

(Remember–this hole must be large enough to accept the cable with

the connector attached. Do not cut the cable!) To seal the opening,

use a feed-thru cap where the cable passes through the transom.

2. Run the cable through the interior of the boat. If the transducer cable

runs near another electrical wire, it may pick up electrical

interference or “noise.” To reduce this, try to keep the transducer

cable separated as far as possible from all other wires. This is

especially important with wiring for the boat’s ignition, alternator, or

tachometer. Also tr y to keep the transducer cable away from the

antenna and power cables for VHF or FM radios. It is also helpful to

keep the transducer cable away from the FishFinder power cable. If it

is necessary to run the transducer cable across any wires, make the

crossing at a right angle.

3. Be careful not to tear the cable jacket when passing it through

bulkheads and other parts of your boat. Secure the cables using

tywraps or lacing twine. Coil the extra cable and tie it out of the way.

4. If the 20 foot transducer cable is not long enough, a 15 foot extension cable (5M) is available from your Apelco dealer (PN: M99-140).

Installation

19

Page 31

When you attach the extension cable, be sure that the connections

are tight and watertight. Use Dow Corning DC-4 or an equivalent

sealing compound to protect the connector assemblies.

5. At the rear of the display unit, plug in the transducer cable using the

keyed connector.

Installing the Transducer Cable – Sidelooker Option

1. If the installation includes the optional Sidelooker transducer, there

will be two transducer cables. See Fig. 2-14. The cable from the

Sidelooker includes a “Y” connector.

2. Plug the cable from the depth transducer into the open end of the “Y”

connector.

Sidelooker

transducer

Depth

transducer

Fig. 2-14

Cable for

Sidelooker

T ransducer

Installing the Transducer Cable –

Installation with Separate Speed and Temperature Sensors

1. Optional depth-only and speed- and temperature-only transducers

are available for the FishFinder 465. In this optional configuration the

separate transducers are connected via a “Y” type receptacle cable

located on the optional speed- and temperature-only transducer cable.

20

Installation

Page 32

2. Plug the cable from the depth-only transducer into the receptacle

connector on the optional speed- and temperature-only transducer.

The speed- and temperature-only transducer then connects at the

transducer receptacle of the FishFinder 465. This is shown below in

Fig. 2-15.

Sensor for

speed and

temperature

Sensor for

depth only

Fig. 2-15

Cable for Speed

and T emperature

Sensor

Making the DC Power Connections

1. The display unit is designed for use on boats with 12V DC power

systems. (The unit can operate as long as the actual voltage is

between 10.8 and 16V DC.) The display unit can be wired to a

negative-ground system, or both the negative and positive supply

lines may be “floating” above ground.

use on boats with positive ground.

2. The 6-foot power cable supplied with the display unit should reach

the source of DC power. On a small boat, connect the power leads

directly to the main battery isolation switch or breaker. On a larger

boat, route the power leads to the DC power distribution panel.

3. It is very important that you connect the power leads correctly. See

Fig. 2-16. At the power source, connect the

Installation

This unit is not intended for

red

wire to the

positive

21

Page 33

RED

DC 12V

BLACK

RF ground

DC 12V

connector

to battery

T/D

connector

to transducer

Fig. 2-16

DC Power

Connections

terminal (+), and the

black

wire to the

negative

terminal (-). The

negative terminal may also be called “ground” or “ear th.” (The display

unit is internally protected if you accidentally reverse the polarity of

the power wires.)

4. Attach the red or positive wire to a 5 amp circuit breaker. If the unit is

connected directly to the boat’s battery, include a 2 amp in-line fuse.

(In-line fuses are available at most marine supply stores.)

5. The power cable includes a smaller “shield” wire. Connect this to a

good ground.

6. If you need to extend the power wiring by more than 10 feet, use a

larger wire size. This will allow the wires to deliver the correct voltage

in spite of the longer wire distance. For runs of 20 to 35 feet, use #14

AWG.

If you extend the power wiring, be sure all electrical connections are

solid and durable. Soldering is the best way to make these connections. Insulate all connections using heat-shrink tubing or electrical

tape. You may also use crimp connectors or a terminal strip, but be

sure to use good-quality marine-grade parts.

7. At the rear of the display unit, plug in the power cable using the

keyed connector.

22

Installation

Page 34

Note –

Press firmly when inserting the power cable and transducer cable to

ensure a tight seal.

8. When you press the

the unit will not turn on and you suspect that you may have reversed

the power connections, check the DC power lines all the way back to

the battery. If the polarity is not correct, reconnect the leads properly

and try again.

PWR

button, the display unit should turn on. If

Calibrating the Sensors

The transducer most often used with this unit includes sensors for boat

speed and water temperature. These sensors are normally very accurate,

but you may want to calibrate them.

The speed indication on your FishFinder is usually very accurate.

However, there are some special cases where the speed reading may be

high or low. This means that the speed of the water past the transducer

may not be the same speed that your boat moves through the water. The

hull of the boat may have a shape which channels water past the

transducer at a speed which is faster or slower than normal.

1. To calibrate the speed sensor, set up a course between two known

points. As markers you can use buoys, range markers, or landmarks.

Measure the time the boat takes to cover a known distance.

2. You may also use locations indicated by a G.P.S. or Loran unit. (If

you choose this method, remember that these devices measure

“speed over ground” or “speed over the bottom.” Tides, currents, or

winds can create a difference between the FishFinder’s “speed

through water” measurement and the boat’s “speed over ground.”

Before calibrating using a G.P.S. or Loran unit, wait for still water or

slack tide conditions.

3. If the display unit is reading high or low, you can correct for this using

the entry for “Speed Cal.” (To reach Speed Cal, go to the System

Setup Menu. This is described in Section 4.) The entry for Speed

Cal is a percentage. An entry of “100” equals 100%, meaning that

low

there is no correction. If the display unit is producing a

use a

higher

value for Speed Cal. If the display unit is reading

reading,

high

,

Installation

23

Page 35

use a

smaller

between 75 and 125.

4. The temperature sensor is usually very accurate, but you can adjust

the calibration using the entry for “Temp Cal.”

Final note: After you finish the installation, please remember to fill out the

Warranty Card included with this manual.

number for Speed Cal. You may enter any value

24

Installation

Page 36

3 – Operating Instructions

In this section of the manual, we will explain how to operate the unit.

(Setup instructions are included in the next section.) Below is a drawing

of the display unit.

Display

area

FISHFINDER

465

PWR

SETUP

ZOOM

BOT

LOCK

CLEAR

A-SCP

Controls on Display Panel

The FishFinder is designed to be easy to use while the boat is moving.

You can steady your hand by gripping the right side of the display with

the fingers of your right hand. This will allow you to use your right thumb

to press the buttons on the display.

Notice that some of the buttons can be used in two ways. They do one

job during a normal display, and a different job when you are setting up

the unit. In this section, we will use symbols like this –

to indicate the buttons on the front of the unit.

PWR

This button turns the power on and off.

To turn on the power

– Press once to turn the power on.

To enter the Lamp/Contrast Menu

Lamp/Contrast Menu in any operating mode, press the

PWR

key for a moment, then release it.

To turn off the power –

the display will say “Powering Off.” If you hold the button for

more than 3 seconds, the display unit will switch off.

Power button

Page control

pad

Setup button

Clear button

Zoom button

A-Scope button

Bottom Lock

button

Fig. 3-1

Display

Panel

PWR

and

SETUP

–

– To bring up the

If you press and hold the button,

Operating Instructions

25

Page 37

Page Control

Pad

SETUP

Up and down arrows –

During setup

– Use these controls to call up a choice or

( and )

move to the next line on a menu.

If the Zoom display is turned on

– If the manual zoom

feature is turned on, these will move the zoom display up

or down.

Left and right arrows –

During normal display

(< and >)

– Use these buttons to go to the

next display.

During setup

– Use these arrows to make a choice within a

line on the menu.

To enter the Setup Menu –

To go to the System Setup Menu –

Press

SETUP

at any time.

Press this button

twice in all normal displays. If the sidelooker split screen

(Window Page options F, G, or H) is enabled, this button

must be pressed three times.

During setup

– Once you make a change, press

SETUP

to

save the change and go back to the normal display.

CLEAR

During normal display –

CLEAR

use

to turn off the buzzer. (The alarm will continue

When an alarm is triggered,

to be indicated on the display.)

During setup –

Once you make a change, press

CLEAR

save the change and go back to the normal display.

When the unit is first turned on, it will present the normal FishFinder

Page. You can reach the Zoom, A-Scope and Bottom Lock Modes by

pressing buttons on the control panel. See Fig. 3-12.

ZOOM

A-SCP

26

The “Zoom” Mode shows a magnified view of a section of

the display area.

The “A-Scope” Mode shows a “real time” view of the area

directly under the transducer.

Operating Instructions

to

Page 38

BOT

PWR

LOCK

The “Bottom Lock” Mode shows a “bottom-up” view. The

bottom is used as a reference, and all depths are

measured from the bottom up.

For more information, see the section on “Performance Modes” on page

49.

Turning the Power On and Off

Press the

Lamp/Contrast Menu will appear and the panel light will flash on and off.

The light will allow you to see in order to set up the display in the dark.

After the screen flashes three times, the unit will go to the display page

which was used last (unless this is the first time the unit is powered up).

The first time power is supplied to the unit, you will be asked to select the

language used by the displays. English is the default language. You may

also select any of six other languages. (You can change this setting at

any time using the System Setup Menu.)

To tur n the power off, press and hold the

seconds.

PWR

button once to turn on the power. For a few seconds, the

button for more than 3

Setup Memory

When you first turn on the power, the unit will be prepared to operate

using a number of preset values. These “default” values are stored in the

unit at the factory. (The default values are listed in Section 4.)

This unit has a memory for some of the settings—range, sensitivity,

zoom, and frequency. (We will explain these in a moment.) When you

turn off the power, any changes you make to these settings will be saved.

You can return all of the settings to the factory default values, and reset

the trip log to zero. To reset the unit, confirm that the unit is off. Press and

CLEAR

hold the

button, then press the

unit powers up, release the

CLEAR

PWR

button.

button for a moment. After the

Operating Instructions

27

Page 39

Adjust lamp

brightness

Adjust

contrast

Fig. 3-2

Lamp/Contrast

Menu

Lamp/Contrast Menu

PWR

Press

Adjust lamp

brightness The 465 FishFinder has a backlit display and keypad.

Adjust contrast You can also adjust the “contrast” of the display. This is a

The Lamp/Contrast Menu appears when you first press

PWR

the

button and turn on the power. (You will be able

to see part of the main FishFinder Page behind the

Lamp/Contrast menu.)

You can press the

PWR

button a second time to exit from

the Lamp/Contrast Menu and go directly to the

FishFinder Page. (If you do not make any changes to the

settings within 7 seconds, the unit automatically exits

from the Lamp/Contrast Menu anyway.)

You can also enter the Lamp/Contrast Menu from any of

the other displays by pressing the

PWR

button for a

moment.

This feature allows you to use the unit at night. The

backlight for the display is adjustable to five levels of

brightness. To turn the lamp on or adjust the brightness,

use the < or > controls on the Page Control Pad.

measure of how light or dark the display appears. Use

control to move from the line for “Lamp” to the line

the

for “Contrast.” Use the < or > controls to adjust the

contrast. (The FishFinder unit has a feature which adjusts

the contrast automatically to compensate for changes in

air temperature.)

28

Operating Instructions

Page 40

Save settings When the settings on this display are correct, press the

CLEAR

button to save the settings and go to the

FishFinder Page.

Operating Pages

The 465 FishFinder has four “pages,” or normal displays. These can be

used to show different kinds of information. Here is a list of the pages:

Mode Function See page

FishFinder Page Standard operating mode page 31

Window Pa ge Right half of the display operates the

Sidelooker Page View of either side of centerline

(using optional of boat (used only with Sidelooker

Sidelooker transducer) transducer). page 42

Digital Page Numerical display of depth, speed,

You can step from one of these pages to another using the < and >

arrows of the Page Control Pad.

same as the FishFinder Page. Left

half of the display is a user-selectable

window showing digital information

or sidelooker information (when the

optional Sidelooker transducer is used). page 40

distance traveled, battery voltage,

elapsed time, and water temperature

graph. page 46

Operating Instructions

29

Page 41

Lamp/Contrast Menu

FishFinder Page

PWR

Window Page

Digital Page

CLEAR

Sidelooker Page

(Only if Sidelooker feature

is turned on)

30

Return to

FishFinder

Page

Fig. 3-3

Operating

Pages

Operating Instructions

Page 42

FishFinder Page

Fish alarm set

Shallow alarm set

Deep alarm set

Buzzer symbol

Auto

features on

Speed

Log/distance

Water

temperature

Auto range on

Auto sensitivity on

Auto zoom on

Fish symbol on

Auto frequency on

T ransducer frequency

Boat symbol

Water surface

Depth markers

Bottom

indication

Bottom depth

Fish depth

Fish symbol

Range

Fig. 3-4

FishFinder

Page

Figure 3-4 shows a typical FishFinder display. (The FishFinder Page is

also called the “chart” or “bottom graph” display.) As time passes, this

display scrolls from right to left. The scrolling image becomes a record of

the echoes and the bottom seen by the FishFinder as your boat moves.

The images at the right side of the display show the most recent echoes.

Some of these echoes indicate fish, and others show the bottom. As new

echoes are received, the FishFinder “draws” a graph of the bottom. The

bottom graph helps you to tell whether the bottom is rising or falling. It

also allows you to identify the shape or “structure” of the bottom. This can

indicate a reef or shipwreck.

Notice that the scrolling speed of the display does not necessarily match

the speed of the boat. The scrolling speed of the display is called the

Operating Instructions

31

Page 43

“chart speed.” You can adjust this using the “Setup Menu.” (See Section 4.)

Many of the items on this display appear in the other display pages.

Since you are likely to use the FishFinder Page most often, we will

explain all of these items here.

Top of display

Buzzer symbol

This symbol shows whether any of the alarms will use the

buzzer. There are three kinds of alarms: shallow, deep, and

fish. If one of these alarms is triggered, the unit will

present a flashing symbol on the display. The Buzzer

symbol shows whether, in addition to the flashing symbol,

the alarms will also use the buzzer.

If the Buzzer setting in the System Setup Menu is on

(indicating that the buzzer is enabled for all of the alarms),

this symbol will appear filled.

If the Buzzer setting is off (indicating that the buzzer is

disabled for all of the alarms), this symbol will be empty.

Shallow alarm set

You can set an alarm to go off if the boat moves into water

which is shallower than a certain depth. If you set this type

of alarm, the “S” indicator will appear on the display. If the

alarm is triggered, the “S” symbol will flash. If the buzzer

has been turned on (in the System Setup Menu), the

buzzer will also sound. To stop the buzzer, press the

CLEAR

button. The “S” symbol will continue to flash until you move

into deeper water.

Deep alarm set

You can set a different alarm to go off if the boat moves

into water which is deeper than a certain depth. When this

alarm is set, the “D” symbol will appear. If the alarm is

triggered, the “D” symbol will flash. If the buzzer has been

turned on (in the System Setup Menu), the buzzer will also

CLEAR

sound. To stop the buzzer, press the

button. The

“D” symbol will continue to flash until you move into

shallower water.

32

Operating Instructions

Page 44

Fish alarm set

The FishFinder also has an alarm which will sound

whenever it detects a fish. When this alarm is set, the fish

symbol appears at the top of the display. If the alarm is

triggered and the buzzer has been turned on (in the

System Setup Menu), the buzzer will sound for a moment.

Auto features on (AUTO)

any

of the automatic features are turned on, the “Auto”

If

indication will appear here. (These include the automatic

range, auto sensitivity, and auto zoom features.)

Auto range on (R)

The “range” is the maximum depth the unit is set to

measure. When the auto range feature is on, the

FishFinder chooses the correct range setting automatically.

Auto sensitivity on (S)

The “sensitivity” controls the ability of the unit to tell the

difference between echoes of different strengths. A higher

sensitivity setting makes it easier to see smaller fish, but

also may pick up background noise. When auto sensitivity

is on, the FishFinder chooses the correct sensitivity setting

automatically.

Auto zoom on (Z)

The “zoom” is used to magnify the image from a small

section of the water below the boat. (This is used with the

Zoom Mode, which we will describe in a moment.) When

the auto zoom feature is on, the FishFinder automatically

moves the zoom window up or down to track the bottom.

Fish symbol on

When the FishFinder sees a fish, it can show this by

displaying a fish symbol. When the fish symbol feature is

turned off, the FishFinder indicates a fish as an archshaped line on the display. For more information, see the

section on “Fish Indications.”

Transducer frequency

The transducer can use two frequencies – 50 kHz for wide

coverage, or 200 kHz for a detailed view. You can also set

Operating Instructions

33

Page 45

the unit to use both frequencies at the same time (“dual

frequency”), or even display both frequencies at once (“split

screen”).

Auto frequency on (A)

An “A” indication here shows that the unit is choosing the

frequency automatically. (For more on this, see “Choosing

the Frequency.”)

Boat symbol This symbol is always turned on. It indicates that the new

information appears at the right edge of the display, and

the older information moves toward the left.

Center of display

Water surface This symbol (“0”) shows the depth indicated by the top

of the display. Usually, this is the level of the surface of

the water. (If Zoom Mode is turned on, this will show the

depth of the top of the zoom area.) The depth is shown

using the same units as the rest of the display. This can

be feet (FT), fathoms (FA), or meters (M), depending on

the setting you make in the System Setup Menu.

Depth markers

These markers show depths between the surface and the

full depth range. In this example, the unit is set for a depth

range of 100 feet. This means that each of the depth

markers shows an interval of 20 feet.

Speed This entry shows the speed of the boat through the water.

From the System Setup Menu, you can turn this item off or

change the units used for this display.

Log/distance This shows how far the boat has traveled since the log was

last reset. From the System Setup Menu, you can turn this

item off or change the units used for this display.

Water temperature

This entry shows the current water temperature at the

surface of the water. (The reading for water temperature

can be helpful for finding fish. A par ticular type of fish

will often prefer water in a narrow temperature range.)

34

Operating Instructions

Page 46

From the System Setup Menu, you can turn this item off

or change the units used for this display.

Fish symbol This indicates that the FishFinder sees a fish. Generally,

the larger the fish symbol appears, the larger the fish.

(The size of the fish symbol actually depends on a number

of factors. See the section on “Fish Indications.”)

If the fish is detected using the narrow 200 kHz beam, the

display will show a filled-in symbol. If the fish is detected by

the wide 50 kHz beam, the display will use a hollow

symbol. (For more on this, see “Choosing the Frequency.”)

Fish depth This indicates the depth of the fish shown by the fish

symbol. This number will be shown using the same depth

units (feet, fathoms, or meters) you have selected on the

System Setup Menu. The fish depth indicator is tur ned off

when the fish symbol function is off.

Bottom of display

Bottom indication

This shows the bottom of the lake or sea. You can

compare this to the range depth shown in the lower righthand corner. (In this example, the checkered pattern

shows the unit is getting a strong echo return from the

bottom. See the information on the White Line feature in

the Setup Instructions.)

Range The “range” is the maximum depth the unit is set to

measure. In this example, this is 100 feet. You can set the

range manually, or the FishFinder can do it automatically.

Bottom depth This is the depth of the bottom shown on the display. You

can select FT (feet), FA (fathoms), or M (meters) using the

System Setup Menu. If the FishFinder can’t tell how deep

the water is, the last known depth flashes on the display.

This will continue until the unit can see the bottom again.

Before we explain the other pages, there are some general things you

should know about the operation of the FishFinder.

Operating Instructions

35

Page 47

Choosing a Frequency

We said that the FishFinder uses sound waves to “see” through the water

under the boat. The “frequency” is a measure of how fast the sound

waves change or “vibrate.” The FishFinder uses sound waves with two

different frequencies – 50 kHz and 200 kHz. Apelco uses these two

frequencies because each is better for a particular purpose:

50 kHz frequency

• Scans a wide area

• Penetrates water well, good for deep water

200 kHz frequency

• Scans a narrower area, but produces a more detailed view

• Good for seeing fish near the bottom or fish close together

• Better for use in very shallow water

“Dual” frequency (both 50 kHz and 200 kHz at once)

• Has the advantages of both frequencies

• Good depth penetration

• Good detail in display

• Using the “Dual 50 kHz” setting, the display is produced using the

signal from the 50 kHz beam, with additional information from the

200 kHz beam.

• Using the “Dual 200 kHz” setting, the display is produced using the

signal from the 200 kHz beam, with additional information from the

50 kHz beam.

If you are using one of the dual frequency settings, you can get some

useful information from the fish symbols. If the fish is spotted by the

narrow 200 kHz beam, the fish symbol will be black or filled-in. If a fish is

detected by the wide 50 kHz beam, the symbol will be hollow.

When the unit is first turned on, it is set to use the Auto frequency

feature. When set this way, the unit begins by using the 200 kHz

frequency. If the bottom depth increases to more than 250 feet (or 50

fathoms or 80 meters), the unit will automatically switch to the 50 kHz

frequency. If the unit cannot find the bottom, it will try both the 200 kHz

and the 50 kHz frequencies. The unit will then use the frequency which

finds the bottom first.

36

Operating Instructions

Page 48

Fish Indications

Even using advanced sonar technology, it is sometimes hard to detect a

fish in the water. The body of a fish is just a little more dense than the

surrounding water. There is really nothing very solid for the sound waves

to bounce off of. The FishFinder 465 is very good at telling the difference

between a fish and the surrounding water. In fact, Apelco is the leader in

this technology.

When the FishFinder detects a fish, it can be indicated by a fish symbol

on the display. In general, a larger symbol means a larger fish. This rule is

not always true, though. Let’s say that there are two fish of the same size:

one is close to the surface, and the other is near the bottom. The fish

which is close to the surface will have a larger symbol. This is because

the fish which is closer returns more of the sound waves back to the

FishFinder.

Actually, the sound waves are usually reflected by the air sac near the

center of the fish, and not by the body of the fish. The size of this air sac

is different for different kinds of fish. This can also affect the size of the

An arch-shaped image indicates a fish.

The same fish appears differently

50 kHz

200 kHz

when shown by the 50 kHz or 200 kHz

transducer beams.

This indicates a group of small fish.

This shows a fish detected in

sidelooker mode.

A shallow arch or horizontal line is

generated when the boat is moving

slowly or stopped.

When the boat is moving very fast,

a fish appears as a single vertical line.

Operating Instructions

Fig. 3-5

Fish

Indications

37

Page 49

fish symbols on the display. A fish with a large air sac will produce a large

fish symbol, while a fish with a small sac will produce a small symbol.

The symbol also indicates which of the two frequencies was used to

locate the fish. If the fish was spotted by the wide 50 kHz beam, the

symbol will appear to be hollow. If the fish was detected by the narrow

200 kHz beam, the symbol will be solid.

If the fish symbol feature is turned off, the FishFinder indicates fish in a

different way. See Fig. 3-5. An arch-shaped mark on the display usually

indicates a fish. Again, a larger arch usually indicates a larger fish.

Several arches together show a school of fish.

The return from a fish will have a different appearance, depending on the

frequency used. If a fish is spotted by the wide 50 kHZ beam, the arch

will be broad. When using the narrower 200 kHz beam, the same fish will

produce a narrower arch.

The shape of the arch is also affected by the speed of the boat. If you are

moving slowly, the arches tend to be longer. If the boat is moving more

quickly, the arches are shor t and peaked. If the boat is moving very fast,

a fish may be indicated by a single vertical line.

You can select the frequency from the Setup Menu.

Bottom Indications

The bottom usually produces a strong echo, so it is easy for the FishFinder

to see a lot of detail. The FishFinder can indicate many different kinds of

bottom conditions. See Fig. 3-6. A hard bottom appears as a thin line. A

softer bottom or a bottom covered with seaweed will produce a wide line,

as the sound waves reflect from different layers of the bottom. An uneven

bottom which is covered with rocks or coral produces a complex display

like that shown in the last part of Fig. 3-6. The bottom image is irregular,

with long “tails” pointing upward. A wreck produces a similar image.

When the White Line feature is turned on, the unit can display even more

information about the bottom. In Fig. 3-4, the FishFinder is getting a good

echo from the bottom, so the upper layer of the bottom is shown in a

checkerboard pattern. Notice that the lower layer of the bottom is shown

as a solid display. This indicates a weaker echo. Sometimes this means

that the upper layer of the bottom is soft. Some of the sound waves may

38

Operating Instructions

Page 50

Hard

(Sand)

Soft

(Mud)

Rocks

Fig. 3-6

Bottom

Conditions

reach through this layer, and may be reflected by a more solid layer

below. It is also possible that the sound waves are making

two

complete

trips – hitting the seabed, bouncing off of the bottom of the boat, then

reflecting off the seabed again. This can happen if the water is shallow,

the seabed is hard, or the sensitivity is set to a high value.

Operating Instructions

39

Page 51

Window Page

Fig. 3-7

Window Page

The Window Page is a flexible feature which allows you to combine

several different kinds of information on the display of the unit. See

Fig. 3-7.

The right side of the Window Page is a half-screen version of the FishFinder Page. All of the features of the full-screen FishFinder Page are available, including Zoom, A-Scope, and Bottom Lock. The fishfinder features of

the Window page operate identically to those in the FishFinder Page.

On the left side of the Window Page is one of eight selectable

each of which shows a portion of the Digital Page or the Sidelooker Page.

You select which window to display using the Window option in the Setup

menu. The eight Window selections are designated A through H, and are

illustrated in Fig. 3-8.

Window Contents

A Large Depth, small Speed, Log, Temperature

B Large Speed, small Log, Temperature, Depth

C Large Depth, large Speed, 30-minute temperature graph

D Small Depth, Speed, Log, and 30-minute T emperature graph

E Small Depth, Speed, Log, Temperature, and Battery voltage

F Left Sidelooker

G Both left and right Sidelooker

H Right Sidelooker

windows

,

40

Operating Instructions

Page 52

Option A Option B

Option C Option D

Option E Option F

Option G Option H

Operating Instructions

Fig. 3-8

Options

for Window

Page

41

Page 53

The digital displays in Window options A, B, C, D, and E all behave

identically to the corresponding ones in the full-screen Digital Page (see

page 46).

The sidelooker displays in Window options F, G, and H all behave

identically to those in the full-screen Sidelooker Page (see page 43).

These options will only be displayed if the Sidelooker feature is enabled.

Sidelooker Page

Rock

Boat

31° beam

11° beam aimed

down at 4° angle

Rock

Fig. 3-9

Sidelooker

Feature

Fish

Fish

Sidelooker

transducer

(This feature will only work if the optional Sidelooker transducer has been

installed, and if the Sidelooker feature has been turned on in the System

Setup Menu.) The optional Sidelooker feature is very helpful for certain

kinds of fishing. It allows you to check along the sides of a stream or river.

You can also look under the edge of a bank or pier, or into a snag or

shallow spot.

42

Operating Instructions

Page 54

The optional Sidelooker transducer transmits two acoustic beams-one to

the port side of the boat, and one to the starboard. These are displayed

on the left and right halves of the Sidelooker Page. See Fig. 3-9.

Once the Sidelooker feature has been turned on, you can reach the

Sidelooker page easily. Press the < or > buttons on the Page Control Pad

until the Sidelooker Page appears. The unit will present a display similar

to Fig. 3-10.

Boat

symbol

Dashed

vertical

line

Side

range

Bottom/

shore

indication

Fish

indication

Fig. 3-10

Depth

Sidelooker

Page

The Sidelooker Page, like the FishFinder Page, displays a graph or chart.

The scrolling vertical dashed line represents the centerline of the boat.

As new Sidelooker echoes are received, the new information appears at

the top of the display, and older information moves towards the bottom.

There is no relationship between the chart speed of the FishFinder and

the speed of the boat. (The speed at which the display moves is set by

the entry for “chart speed” in the Setup Menu.)

When the Fish Symbol feature is turned off, any fish detected will appear

as long, vertical lines. These will be slightly arched towards the center of

the display. The unit can also be set to display fish symbols, but the fish

arches are usually more helpful. The Sidelooker transducer transmits at

the 200 kHz frequency. If the unit spots any fish while the Fish Symbol

feature is on, they will be indicated by solid fish symbols. (You can turn the

Fish Symbol feature on or off from the System Setup Menu. See Section

4.)

Operating Instructions

43

Page 55

Underwater objects such as tree stumps or rocks can also be detected

by the Sidelooker transducer. These objects usually appear as thicker

vertical targets. The Sidelooker sounding beam is transmitted very close

to the surface of the water. In rough or choppy water this turbulence may

appear on the Sidelooker display as “noise” or “clutter.” The Sidelooker

also displays noise or clutter when your boat travels at high speeds. For

best results, use the Sidelooker at idle or slow trolling speeds.

On the Sidelooker Page, you may select one of three views using the

Sidelooker View option in the Setup menu. These are labeled F, G, and H

to match the three Window options which include Sidelooker views.

View F looks only to the port (left) side of your boat. The boat symbol

appears at the top of the display and the dashed vertical line appear

on the right side of the screen.

View G looks to both sides of your boat. The boat symbol appears at

the top of the display and the dashed vertical line appears in the

center of the screen.

View H looks only to the starboard (right) side of your boat. The boat

symbol appears at the top of the display and the dashed vertical line