Page 1

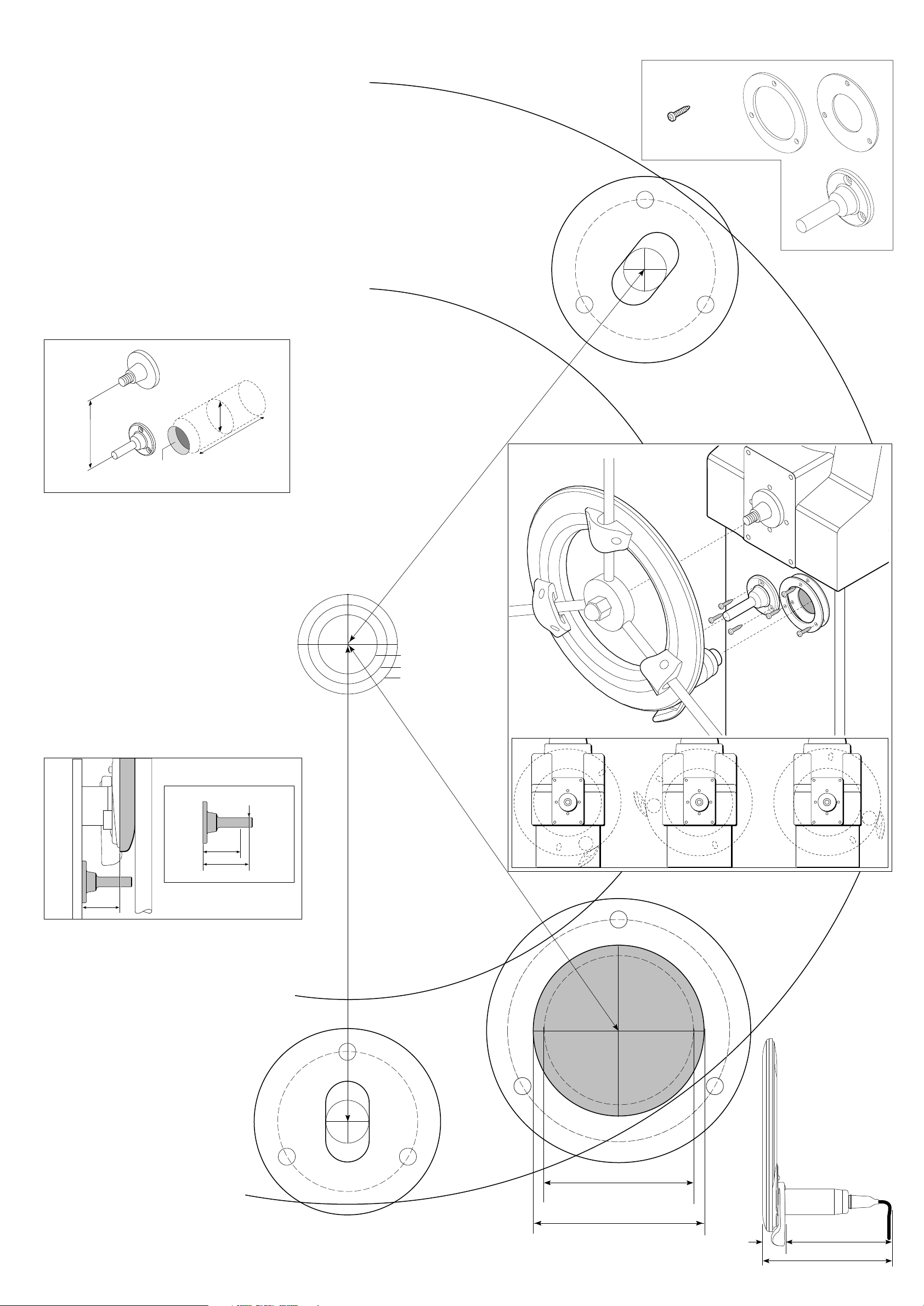

Raymarine 4000 mk2 Wheel Drive - Bulkhead/Box Pedestal Fitting Kit (E15017)

Installation Template and Instructions

Instructions

Note: Before following these instructions, attach the wheel drive to the wheel (refer to the

ST4000+ Owner's Handbook for details).

Preparation

1. Cut out the appropriate 'wheel spindle' circle (at the center of this template), so you

can place the template over your wheel spindle.

2. Rotate the template to determine suitable locations for the motor tube and bracket:

• You may be able to orientate the wheel drive so the motor tube runs alongside the

pedestal. In this case, proceed to 'Cutting the bracket'.

• There are two alternative slots for the bracket in the back cover of the wheel drive

(Slot 1 and Slot 2).

• Locate the motor tube where:

• a 55 mm (21/8 in) hole can be cut in the bulkhead/pedestal (if required)

• the seal and ring can be secured around the motor tube

• there is sufficient space behind the mounting location to allow at least 10 mm

(0.4 in) clearance around the motor (see diagram below)

CAUTION:

Mount the drive so the motor tube is as far as possible from the boat's

compass to reduce the risk of deviation.

3. Use the template to mark the locations of the bracket and motor tube.

Parts Supplied

No 10 x 3/4 in

self-tapping screw (x 6)

Slot 2

Bracket location

(alternative)

Metal

ring

Rubber

seal

Bracket

68 mm (2.7 in)

minimum clearance diameter:

154 mm

(6.1 in)

required depth:

1

8

/

55 mm (2

diameter hole

in)

up to 190 mm (7.5 in)

Cutting the motor tube hole

1. Drill a small pilot hole at the center of the intended motor tube location so you can

check there is sufficient clearance behind the mounting location.

CAUTION:

Before you cut the motor tube hole, check behind the intended

location for any steering mechanisms, cables or obstructions.

2. Cut a 55 mm (21/8 in) diameter hole at the motor tube location and smooth any

sharp edges.

3. Assemble the ring/seal onto the motor tube:

• fit the metal ring first

• then fit the rubber seal: the seal will self-center on the tube

4. Temporarily mount the wheel and drive onto the spindle, allowing

the motor tube to pass through the hole.

5. Press the seal against the bulkhead/pedestal, orientate the seal as

required, then mark the centers of its mounting holes.

Cutting the bracket

1. With the wheel still in place, hold the bracket under the wheel

drive so you can mark dimension A – the distance between the

mounting surface and the rear edge of the wheel drive front cover.

Note:If the wheel is bent or not running true, dimension A will

change. Measure the shortest distance.

Typical installation

154 mm (6.1 in)

Wheel spindle

19 mm (3/4 in) diameter

25 mm (1 in) diameter

32 mm (11/4 in) diameter

Alternative positions

Cut here

A

A + 10 mm

A

2. Use a hacksaw to cut the pin 10 mm (0.4 in) LONGER than

dimension A. Remove any sharp edges with a file or sandpaper.

3. Position the bracket so the pin is in the middle of the relevant slot.

Note: the center of the bracket pin should be 154 mm (6.1 in) from

the center of the wheel spindle.

4. Mark the center of the bracket's mounting holes then remove the

wheel and drive.

Attaching the bracket and ring/seal

1. Drill 4 mm (5/32

ring/seal mounting screws.

2. Attach the bracket using three self tapping screws

(No 10 x

need to replace the mounting screws with suitable

nuts, bolts and washers.

3. Remove the ring/seal from the motor tube, then use

three self tapping screws (No 10 x

them to the mounting surface.

Note: make sure the rubber seal is closest to the

surface (i.e. with the metal ring on top).

in) diameter pilot holes for the bracket and

3

/4

in). Note: on fiber-glass surfaces you may

3

/4

in) to attach

Final assembly

1. Attach the drive cable to the socket on the motor

tube, then secure the cable so it is clear of any

moving parts.

2. Fit the wheel and drive back onto the wheel spindle

and fully tighten the wheel nut.

3. Route the cable to the control unit, bearing in mind

the EMC guidelines in the ST4000+ Handbook.

Document number: 84092-1

154 mm (6.1 in)

Slot 1

Bracket location

152 mm (6.0 in)

Motor tube

48 mm (1.9 in) diameter

Motor tube hole

55 mm (21/8 in) diameter

Motor tube seal

45 mm (1.8 in)

min. clearance:

D5603-1

190 mm (7.5 in)

235 mm (9.3 in)

Loading...

Loading...