Radio Shack TRS-80, TRS-80 4P Gate Array, 26-1080 Service Manual

•

ervlce

CUSTOM MANUFACTURED IN U.S.A. BY RADIO SHACK, A DIVISION OF TANDY CORPORATION

TRS-80"' Model 4Pi4P Gate Array Service Manual

Copyright" 1984 Tandy Corporation

All Rights Reserved.

Reproduction or use, without express written permission from Tandy Corporation. of any

in

portion of this manual is prohibited. While reasonable efforts have been taken

preparation of this manual to assure its accuracy, Tandy Corporation assumes no liability

resulting from any errors or omissions

contained herein.

in

this manual, or from the use of the information

the

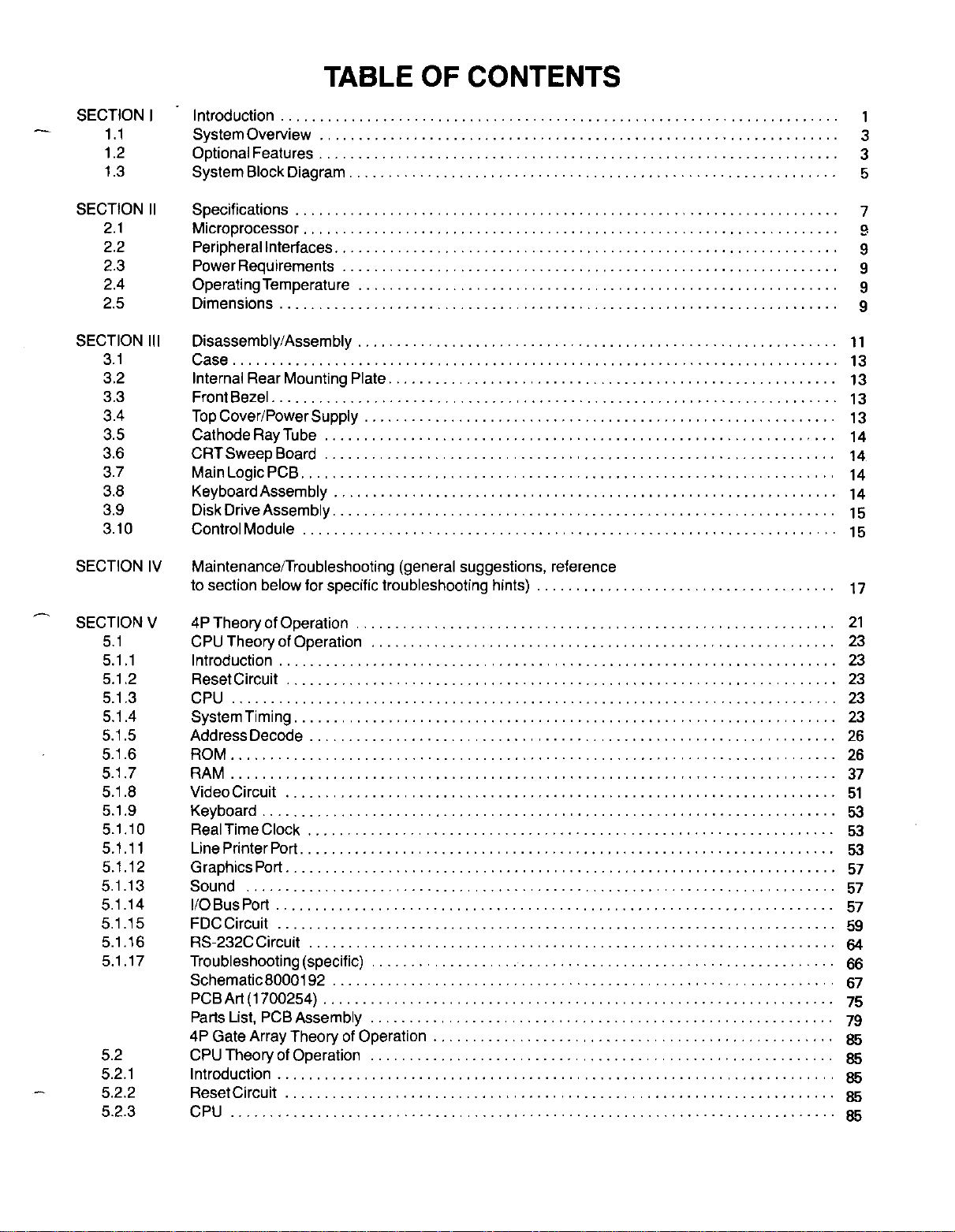

TABLE OF CONTENTS

SECTION I

1.1

1.2

1.3

SECTION

2.1

2.2

2.3

2.4

2.5

SECTION

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

3.9

3.10

SECTION

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SystemOverview

Optionai Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . 3

System BlockDiagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

II

Specifications . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Microprocessor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . . .. . . .. . . . . . . . . . . . . . .

Peripheral Interfaces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

PowerRequirements 9

OperatingTemperature 9

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Disassembly/Assembly

III

Case

Internal Rear Mounting Plate.... . . . . . . . . . . . . . . . . . . . . . . .... . . . . . . . . . . . . . . . . . . . . . . . . ...13

FrontBezel. . . . . .

Top

Cover/Power

CathodeRayTube

CRTSweepBoard

Main Logic PCB. .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...14

KeyboardAssembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...14

DiskDriveAssembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .... . . . .

Control Module .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

IV

Maintenance/Troubleshooting (general suggestions, reference

to section below for specific troubleshooting hints) . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . .

..

.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

..

.. . . . .... . . . . . . . . . . . . . . . . . . . . . . .....

Supply....

. . . . . .... . . . . .... . . . . . . .... . . . . . . . . . . . . .... . . . . . . . . .....

. . . . . . . . . . . . . .

.. ..

.. ......

.. ..... . . . . ...13

. .

.. ..

11

13

13

14

14

. . . . . ...15

..

17

9

SECTION V

5.1

5.1.1

5.1.2

5.1.3

5.1.4

5.1.5

5.1.6

5.1.7

5.1.8

5.1.9

5.1.10

5.1.11

5.1.12

5.1.13

5.1.14

5.1.15

5.1.16

5.1.17

5.2

5.2.1

5.2.2

5.2.3

4P

Theory of Operation . . . . . . .... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPU Theory ofOperation

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...23

ResetCircuit .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...23

CPU............................................................................

SystemTiming. . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

AddressDecode . . . . . . . . . . .... . . . . . . . . . . . . . . . . . . . . ..... . . . . . . . . . ..... . . .. . . . . . . .

ROM.......................................................................

RAM

VideoCircuit

Keyboard... . . . . . . . . . . . . . . . . . . . . . . . . . . .... . . . . . . . . . . . . . . ..... . . . . . . . . . . . . . . . . . . .

Real Time Clock . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . .... . . . . .

LinePrinterPort. . . . . .... . . . . . . .... . . . . . . . . . . . . ..... . . . .... . . . . . . . . . . . . . . . . . . . . . . .

GraphicsPort. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...57

Sound

I/OBusPort

FDCCircuit 59

RS-232CCircuit 64

Troubleshooting (specific)

Schematic8000192 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PCBArt(1700254)

Parts List, PCB Assembly .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...79

4P Gate Array Theory of Operation . . . . .... . . .... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CPU Theory of Operation

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ResetCircuit .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...85

C~

.. ..

. . . . . . . . . . . . . . . . . . . . . .

····

.. ..

. . . . . ...21

...

..

..

..

.. ..

·····85

23

23

23

26

26

37

51

53

53

53

57

57

66

67

75

85

85

85

5.2.4

5.2.5

5.2.6

5.2.7

5.2.8

5.2.9

5.2.10

5.2.11

5.2.12

5.2.13

5.2.14

5.2.15

5.2.16

5.2.17

5.3

5.4

5.4.1

5.4.2

5.4.3

5.4.4

5.4.5

5.4.6

5.4.7

5.5

5.5.1

5.5.2

5.5.3

5.6

5.6.1

SystemTiming. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

_AddressDecode . . . . . . .... . . . . . . .... . . . . .... . . . . . . .... . . . . . . . . . . . . . . . . . . . . . . . . . . 87

ROM 87

RAM 98

VideoCircuit 112

Keyboard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

..

RealTime Clock . . . . . . . . .

Line PrinterPort

GraphicsPort 118

. . . . . . . . . . . . . . . . . . . . . . . . . .... . . . . . . . . . . . . . .... . . . . . . . ...114

_.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.. ..

..

85

..

114

. ...114

Sound 118

110

Bus Port 118

FDCCircuit 120

RS-232CCircuit 124

Troubleshooting(specific) 126

Schematic8000192

Art (1700254) _ 134

PCB

Parts List, PCB Assembly . . . . .

Mini-Disk Drives

PowerSupplyAssembly 143

PowerSupplyDescription .. . . . . . . . . . . . . . . . .

Technical Specifications 147

Theoryof Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TroubleshootingChart

Testingand Adjustments

Schematic 8000164, 65W Power Supply 8790049

Component Layout, 65W Power Supply 8790049 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...163

Circuit Trace, 65W Power Supply 8790049 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Parts List, 65W Power Supply 8790049

CRTDisplay

Specifications

Adjustmentprocedures

Theoryof Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...174

Schematic 23533 (BIW) and 23757 (Green) 179

Parts list 8790612 (BIW) and 8790613 (Green)

Options 189

GraphicsBoard 189

(Tan

_ 127

..

. . . . .... . . . . . . . . . . . . . . . . . . . . . . . . ......137

don TM-50) 143

..

. . . .... . . . . . . . . . . . . . . . . . . . . . . . . . . ......143

..

148

_.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...158

_ " 159

161

..

164

_ " 165

_........

_

. _ 169

_ 169

171

181

SECTION

ADDENDA

A.

VI

Exploded View/Parts

CaseAssembly . 202

Main ChassisAssembly

DiskDriveAssembly 206

KeyboardAssembly

Tandon Operating and Service Manual,

Lists.

. . . . . . . . 199

_ _ _ 204

_. . _ 208

TM50-1 and TM50-2 5-1/4" Flexible Disk Drives

MODEL 4P/4P GATE ARRAY

HARDWARE

SECTION I

INTRODUCTION

INTRODUCTION

1.1

SYSTEM OVERVIEW

The

TRS-SO

tained portable (transportable) version of the popular

Model 4 Microcomputer.Itprovides a carrying/protective case

which

which protects the CRT and disk drives and serves as a base

when in the portable configuration, and self-contained key-

board

Power cord, floppy disk and manual storage are provided in-

side

the

equipment are made at the rear of the Model 4P and optional

feature

Proper care and handling must be observed to prevent damage

to

the

Model4P

hasarecessed

conveniently

removable

connections

computer.

Microcomputerisa complete, self-con-

carrying

stowed

cover/base.

are

handle,

awayina

madebyremovingarear

removable

recessinthe

All

connectionstoperipheral

front

main

cover

TRS-SO

cover

case.

plate.

The Model 4Pis100% compatible with all Model

4 disk software. System capability for Model III compatibility includes:

emulate ROM

keyboard, memory-mapped video with 64-character by 16-line

display, and full

compatibility includes:

mapped keyboard

upper memory with SO-character by 24-line display, standard

64K

of the Model4P which were options on the Model

4 are built-in FDC Circuit with two

an

ZSOA

CPU, 2 MHz operation, programmable RAM to

lor

BASIC operating system, memory-mapped

4SK

Random Access Memory (RAM). Model 4

ZSOA

CPU, 4 MHz operation, memory-

in

upper memory, memory-mapped video in

RAM

expandable to 12SK RAM. Other standard teatures

lS4K

Floppy Disk Drives and

RS-232-C Serial Communications Interface Circuit.

III

and Model

III

and Model

1.2 OPTIONAL FEATURES

Optional features available on the Model 4P include: 640 by

240 pixel High Resolution graphics Board, Direct-connect,

auto-dial, auto-answer 300 bps Modem Board. The Model 4P

does not support cassette operation

Drive.

or

external Floppy Disk

3

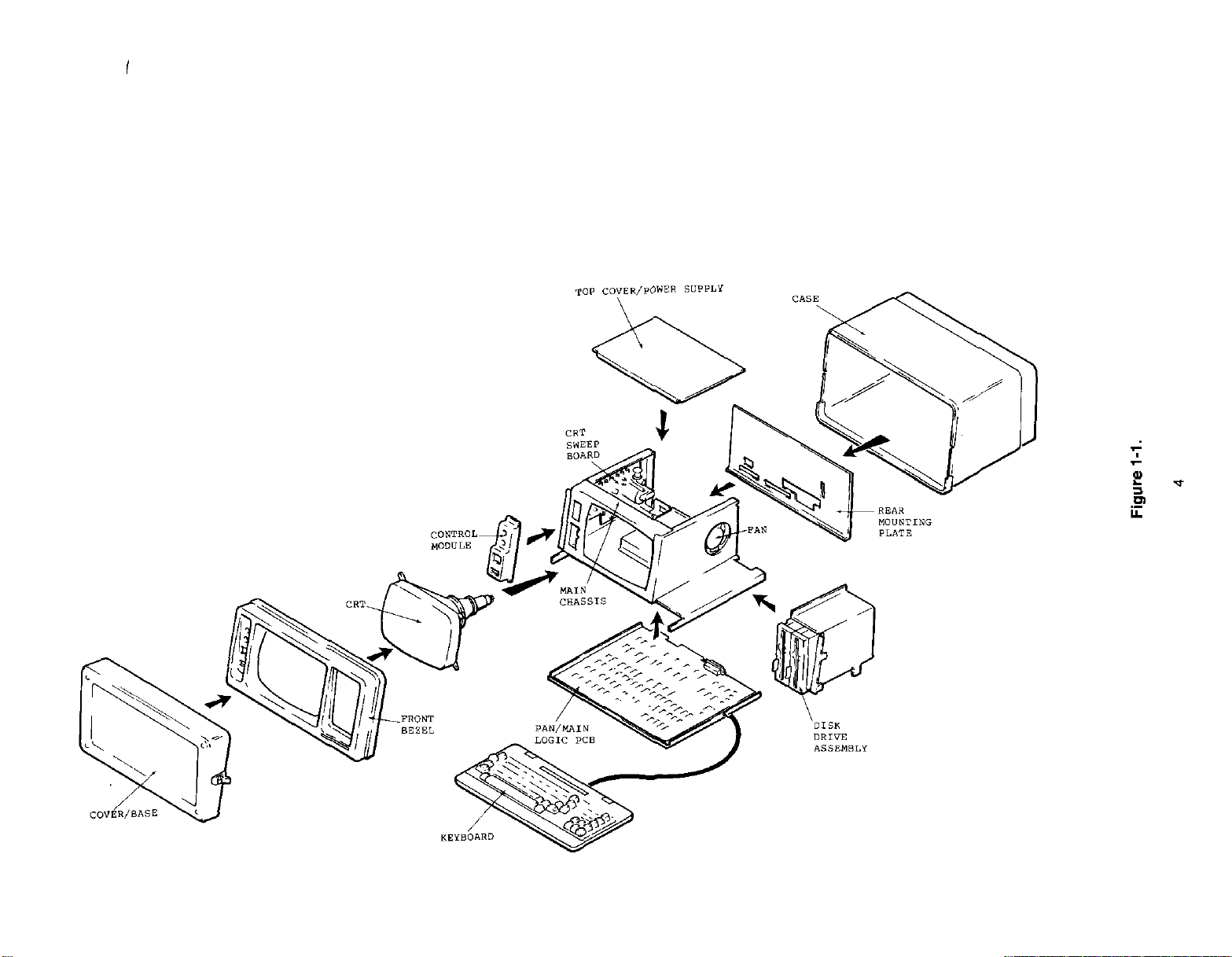

TOP

COVER/POWER

,~

SUPPLY

CASE

~"

COVER/BASE

CONTROL

MODULE

,"

~~j'"

1>1

11

~~MAIN

FRONT

BEZEL

KEYBOARD

CRT

SWEEP

BOARD

1'l/$

lJ

Uo

CHASSIS

PAN/MAIN

LOGIC

PCB

~

DISK

DRIVE

ASSEMBLY

REAR

MOUNTING

PLATE

~

~

ii:

,

l!!

:::>

Dl

"

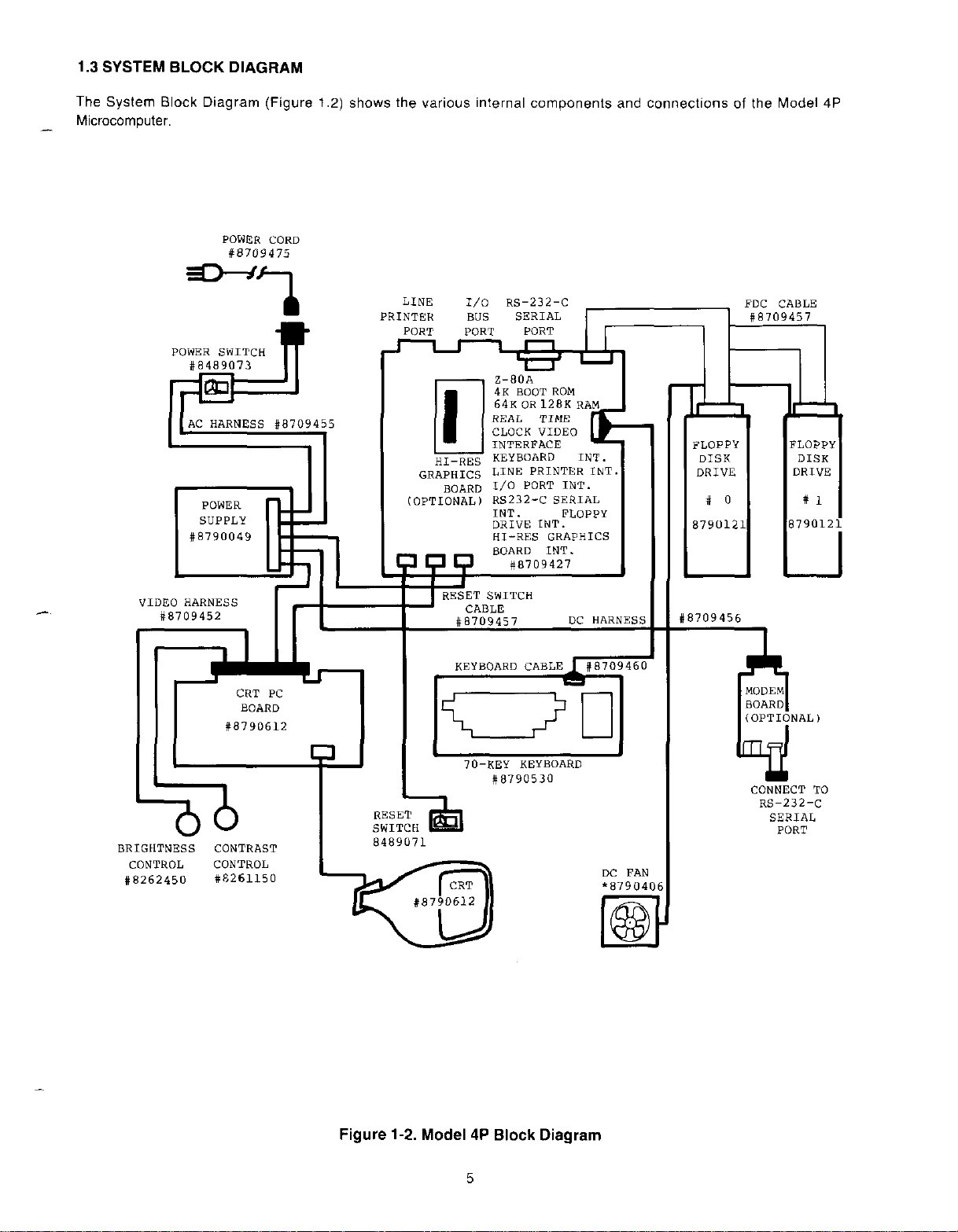

1.3 SYSTEM BLOCK DIAGRAM

The System Block Diagram (Figure 1.2) shows the various internal components and connections of the Model 4P

Microcomputer.

POWER

CORD

#8709475

50---4'

#8709455

POWER

SUPPLY

#8790049

VIDEO HARNESS

#8709452

CRT

PC

BOARD

iB790612

LINE

PRINTER

PORT

GRAPHICS

(OPTIONAL)

I/O

BUS

PORT

~~8~~OT

64KOR128K

REAL

[J

HI

BOARD

RESET

CLOCK

INTERFACE

- RES KEYBOARD

LINE

r/o

RS232-c

INT.

DRIVE

HI-RES

BOARD

SWITCH

CABLE

#8709457

KEYBOARD

RS-232-C

SERIAL

PORT

TIME

VIDEO

PRINTER

PORT

INT.

INT.

#8709427

CABLE

ROM

RAM

INT.

INT.

INT.

SERIAL

FLOPPY

GRAPHICS

DC

HARNESS

#8709460

FOC

CABLE

#8709457

..

__

..

FLOPPY

DISK

DRIVE

# 0

8790121

#8709456

FLOPPY

DISK

DRIVE

# 1

8790121

BRIGHTNESS

CONTROL

#8262450

CONTRAST

CONTROL

#8261150

RESET

SWITCH

8489071

#87D

70-KEY

E1

KEYBOARD

iB790530

Figure 1-2. Model4PBlock

5

Diagram

DC

FAN

*8790406

CONNECT

RS-232-c

SERIAL

PORT

TO

SECTION

II

SPECIFICATIONS

7

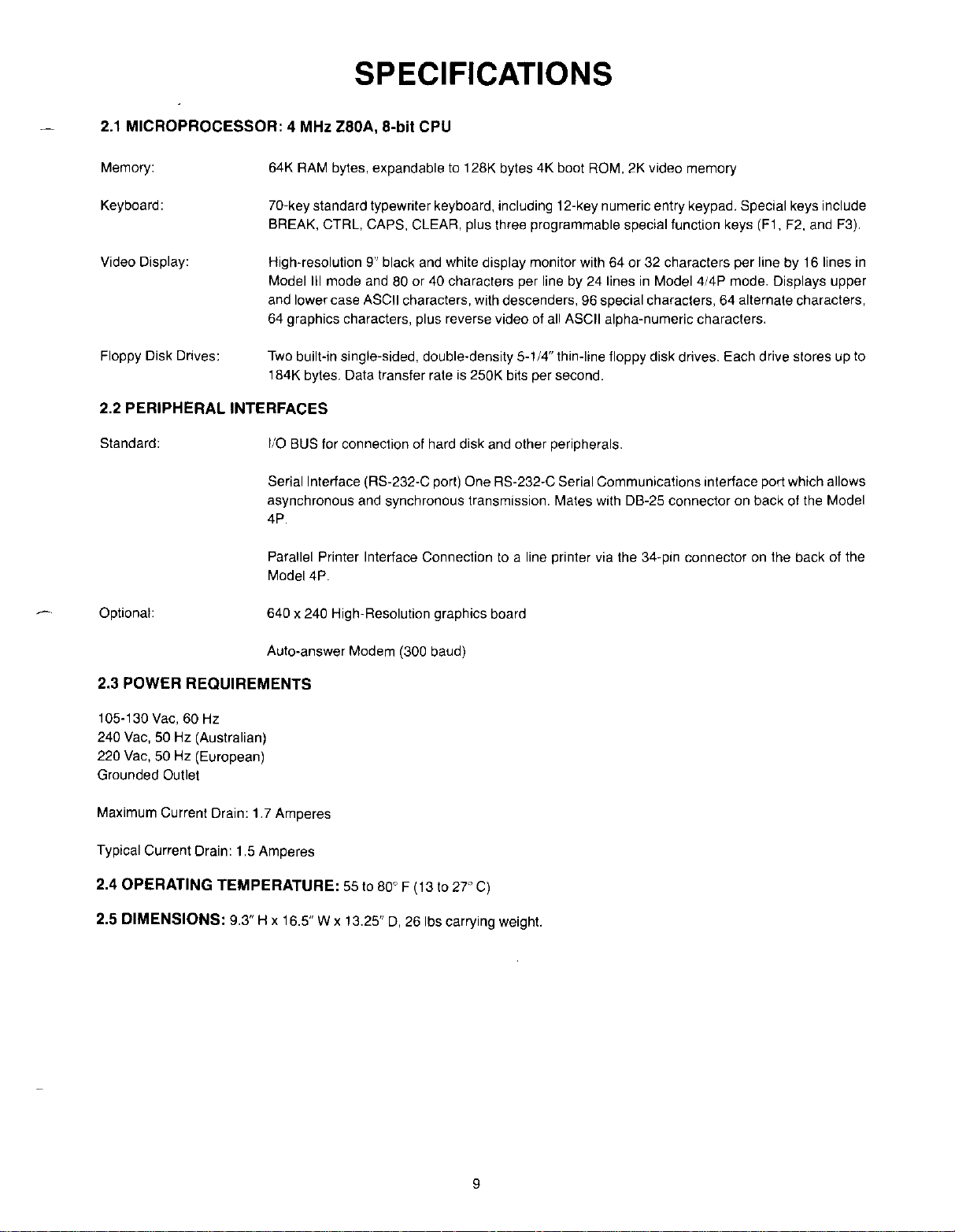

SPECIFICATIONS

2.1

MICROPROCESSOR: 4 MHz Z80A, 8-bit CPU

Memory:

Keyboard:

Video Display:

Floppy Disk Drives:

64K RAM bytes, expandable

70-key standard typewnter keyboard, including 12-key numeric entry keypad. Special keys include

BREAK, CTRL, CAPS, CLEAR, plus three programmable special function keys (F1, F2, and F3).

High-resolution

Model

III

and lower case ASCII characters, with descenders, 96 special characters, 64 alternate characters,

64 graphics characters, plus reverse video of

Two built-in single-sided, double-density

184K bytes. Data transfer rate

2.2 PERIPHERAL INTERFACES

Standard:

Optional:

I/O BUS for connection of hard disk and other peripherals.

Serial Interface (RS-232-C port) One RS-232-C Serial Communications

asynchronous

4P.

Parallel

Model4P.

640 x 240 High-Resolution graphics board

to

128K bytes 4K boot ROM, 2K video memory

9"

black and white display monitor with 64 or 32 characters per line by 16 lines

mode and 80 or 40 characters per line by 24 linesinModel 4/4P mode. Displays upper

all

ASCII alpha-numeric characters.

5-114"

thin-line floppy disk drives. Each drive stores up to

is

250K bits per second.

Interface port which allows

and

Printer

synchronous

Interface

transmission.

Connectiontoa

line

Mates

printer

with

via

08-25

the

connectoronbackofthe

34-pin

connectoronthe

Model

backofthe

in

Auto-answer Modem (300 baud)

2.3 POWER REQUIREMENTS

105-130 Vac, 60 Hz

240 Vac, 50 Hz (Australian)

220 Vac, 50 Hz (European)

Grounded Outlet

Maximum

Typical Current Drain: 1.5 Amperes

Current

Drain:

1.7

Amperes

2.4 OPERATING TEMPERATURE: 55 to 80

2.5 DIMENSIONS: 9.3" H x 16.5" W x 13.25"

0

F (13 to2TC)

D,

261bs carrying weight.

9

SECTION III

DISASSEMBLY/ASSEMBLY

11

DISASSEMBLY/ASSEMBLY

3.1

OVERVIEW AND CASE

The

Model4Pismodularinconstructioninthatitcanbedisas-

sembledinmajor

cover. These major component blocks include the disk drives,

the power supply, main CPU board, the CRT display, and the

monitor

additional diskettes, and operating manual can be stored

convenient recessesinthe removable

cover/base provides protection for the CRT and disk drives during

sitionofthe

The cover/baseisheld in place with snap locksoneach side.

These

vent

unsnap the lock and release the catch from the main assembly

latch. The following procedures are noted in sequential order

requiredtoprovide

parts

are

instructions.

1.

board.

transport.Italso serves as the baseinthe non-operating po-

locks

accidental

removal

noted.

The main

cover

which

removed.

These include theACpower cord, printer cable, I/O port

connector, and RS-232-C connector. The printer cable and

I/O port connectors are edge card type connectors

ercise

component

Accessory

computer.

are

positive

openingofthe

accesstosomeofthe

does

not

require

For

reassemblyofunit,

assembiy

allows

accesstoall

Remove

careintheir

removal.

blocks

after

removalofthe

components

action

cover/base.Toremove,

previous

of the Model 4P has a removable

all

connectionstothe

suchasthe

front

cover/base. This

withaprotective

components.

steps.

Those

reverse

orderofdisassembly

internal

components

rearofthe

power

bosstopre-

merely

which

case

cord,

Some

do

when

unit.

- ex-

side of the unit. With the rear of the unit toward you, two of

in

these screws are located at the left just

Drive Assembly and accessibie from the left side of the

chassis

the rear of the chassis assembly.

3.

in

Six other screws are located around the outside edges of

the rear mounting plate. Remove the plate and set

for reassembly.

assembly.

The

twoonthe

right

front of the Disk

are

accessible

it

from

aside

3.3 FRONT BEZEL

1.

The

front

bezel

canberemoved

and

rear

mounting

Paragraphs

2.

Pull the brightness and contrast knobs off the pots from the

front.

3.

The

rear

mounting

bezel·mounting

flanges of the metal chassis. The other two screws are located to the right of the metal partition separating the Disk

Drives from the CRT section of the unit. Access to these

two screws is with a long shank 1/4" nutdriver above and

below the fan assembly.

4.

Once

these

six

setitaside

prevent

for

scratchingormarring

plate

3.1

and 3.2.

plate

screws.

screws

are

reassembly. Exercise

have

removal

Four

screws

removed,

the

from

the

unit

been

removedasnoted

allows

accesstothe

attachtothe

remove

careinhandling

surface.

after

the

the

outside

bezel

case

in

six

and

to

2.

Place the unit Bezel/CRT face-downona soft surtace to

prevent damage to the CRT.

3.

The

caseisheldinplace

screws

from

either

sideofthe

To

gain

accesstothe

end of the carrying handle and then lift the handle from its

recess.

under the handle assembly. These two screws attach the

handle assembly as well

4.

scratching or damaging the cover.

The

final

two

mounting plate.

After removing all six screws, lift the cover off the computer

and

setitaside

for

with

last

two

case

mounting

as

the case to the ',nternal rear

reassembly.

six

screws.

caseatthe

screws,

press

screws

Exercise

Remove

frontofthe

downonone

are

caretoprevent

3.2 INTERNAL REAR MOUNTING PLATE

1.

Remove the case from the unitasnotedinParagraph

2.

The

rear

mounting

case carrying handle and protection for the CRT. There are

ten

mounting

metal chassis of the computer. Four screws (Item53on

exploded viewp.144, twooneach side) mount the handle

support (Item

plate

servestoprovide

screws

16) and are accessible from the

which

attach

this

platetothe

mounting

two

unit.

accessible

3.1

for

the

main

LH

and

RH

3.4 TOP COVER/POWER SUPPLY

1.

The Power Supply for the Model 4P is locatedonthe un-

dersideofthe

minal plate as notedinParagraphs

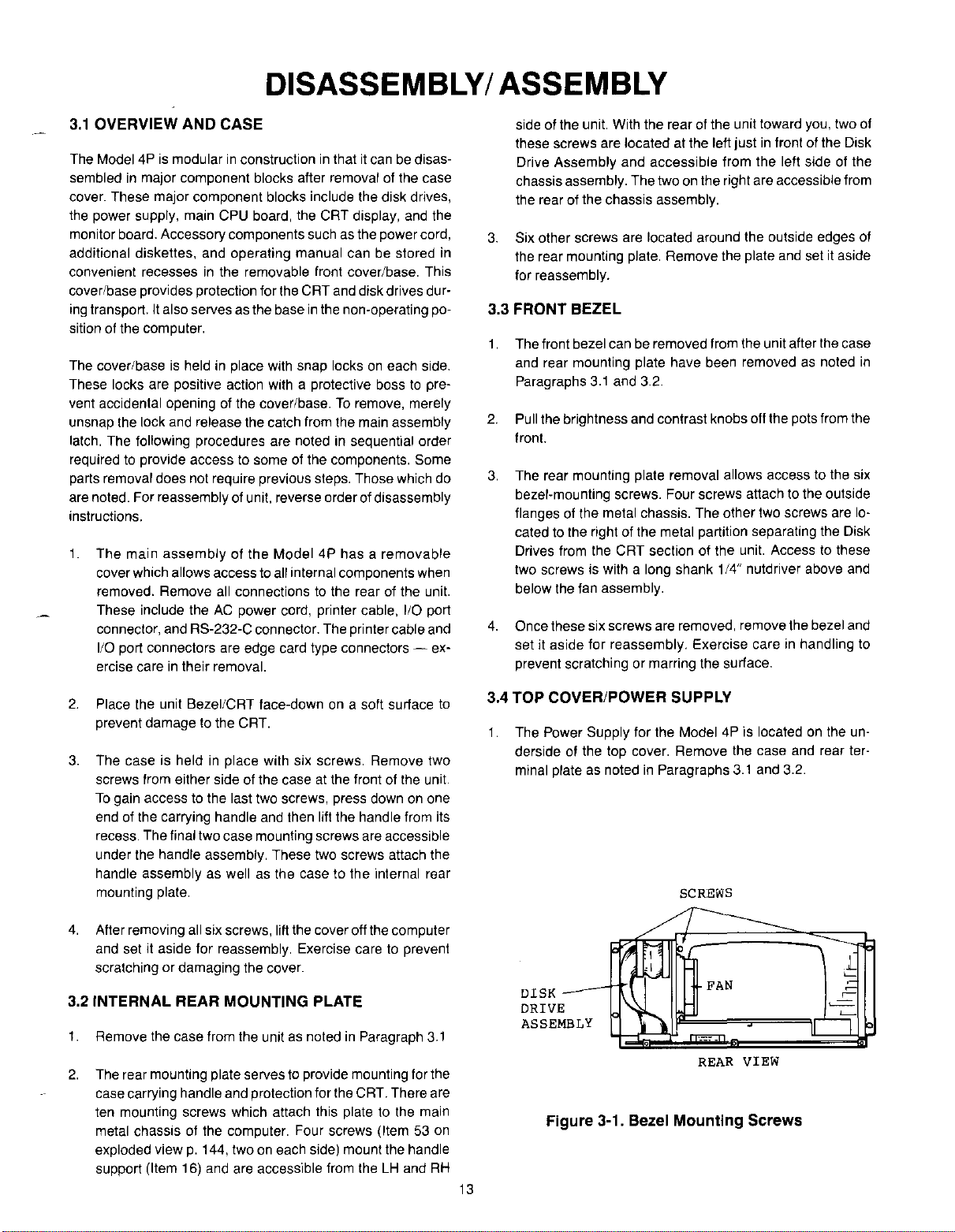

DISK

_-----rTI

top

cover.

DRIVE

ASSEMBLY

Figure 3-1. Bezel Mounting Screws

13

Remove

SCREWS

FAN

REAR

the

3.1

VIEW

case

and

and 3.2.

rear

ter-

2.

The

coverisattachedtothe

Remove these screws and then flip the cover to the right.

A

convenient

supply while workingonother modulesisto reattach the

cover/power

ing the assembly to rest above the disk drive assembly.

3.

The power supply is attached to the top cover with four

screws.

supply at the left and then four screws to remove the supply

completely from the unit.

arrangement

supplytothe

Remove

the

metal

for

chassis

connectors

chassis

storing

with

the

two

with

screws,

attachedtothe

cover/power

six

screws.

allow-

power

6.

Remove

CRT which attachitto the metal chassis. Carefully slide the

CRT out of the chassis through the front.

the

four

screws

and

washer

from

the

frontofthe

3.6 SWEEP BOARD

The CRT Sweep Boardisaccessible after the Ci;lT IS removed

from the unit.

with four screws.

and

the

reassembly.

Itismounted to the left side of the metal chassis

An

insulated plate is located between the PCB

metal chassis. Make

sure

this

plateisin

place

on

4.

When reassembling, ensure that the mylar insulatorispositioned between the power supply and the top cover to

provide

3.5 CATHODE

The CRT is mechanically attached to the metal chassis with

four

screws

1.

Remove

supply as notedinParagraphs 3.1, 3.2, 3.3, and 3.4. This

allows access to the connections

2.

Disconnect the deflection yoke cable from the CRT

board.

3.

Disconnect the connectoronthe rear of the CRT neck

which

The anode of the CRT may have a high voitage charge.

Before removing the high voltage (anode) iead, discharge

the CRT as follows to prevent a serious shock. Connect

one end of a wire to a known good ground and the other

end of the wire to the metal shaft of

screwdriver.

cup and touch it to the clip holding the high voltage lead.

4.

Disconnect the high voltage lead by inserting a grounded

screwdriver

press the clip and pull the wire tree.

5.

Disconnect fhe ground wire (fastenedatthe splice) to the

CRT neck connector PCB.

proper

insulation.

RAY

TUBE

which

are

accessible

the

case

rear

is

attached to a smallPCboard.

Insert

the

under

the

from

terminal

cover,

WARNING

screwdriver

cup.

Use

the

frontofthe

and

top

cover/power

on

the CRT.

an

insulated-handle

blade

under

the

the

screwdrivertocom-

unit.

PC

suction

3.7 MAIN LOGIC PCB

The main logic PCB is a large board nested inside a metal pan

at

the

bottomofthe

assembly, remove unit parts as notedinParagraphs

3.2.

Itisnot necessary to remove the power supply assembly,

or the CRT and associated PCB. Remove

rear of the unit. These include the Modem connector, I/O port

edge-card connector, printer edge-card connector, and floppy

disk edge-card connector.

1.

There

are

mounting pan which attach the pan to the metal chassis.

Remove

movedasa

2.

At

the front of the board, remove the four connectorsatthe

left front of the board. These include the reset, video,

power

connectors,

3.

Nine screws attach the main logic PCB to the metal pan.

The board is spaced away from the pan with raised bosses

stamped into the pan.

main

four

screws

these

screws

sUbassembly

metal

chassis.Togain

on each

and

the

board

from

the

andagrounding

accesstothis

all

connectorsatthe

side

of the metal PCB

and

pan

chassis.

wire.

3.1

and

canbere-

and

3.8 KEYBOARD ASSEMBLY

1.

The keyboard assembly is attached to the Main Logic PCB

with a connector located at the right rear of the board. The

PCB must be removed from the pan to allow this connector

to be removed. Therefore, disassembly procedures for the

main PCB must be followed.

2.

The keyboard assemblyisdisassembled by removing the

7 mounting screws from the underside of the assembly.

Oneofthese

should be takeninremoving this strip so thatitis

or punctured.

screwsisunderacork

non-skid

strip

not ripped

and

care

CAUTION:

If

the CRT is dropped,itmay implode.Toavoid this kind of

accident, carefully support the CRT when removing

the chassis. Do not handle the CRT by the neck

may cause the tube to break and cause

perso"al injury.

it

as

from

this

14

3.

Remove the top cover, lift the keyboard PCB from its positioning

bosses,

and

then

remove

the

connector.

keyboard

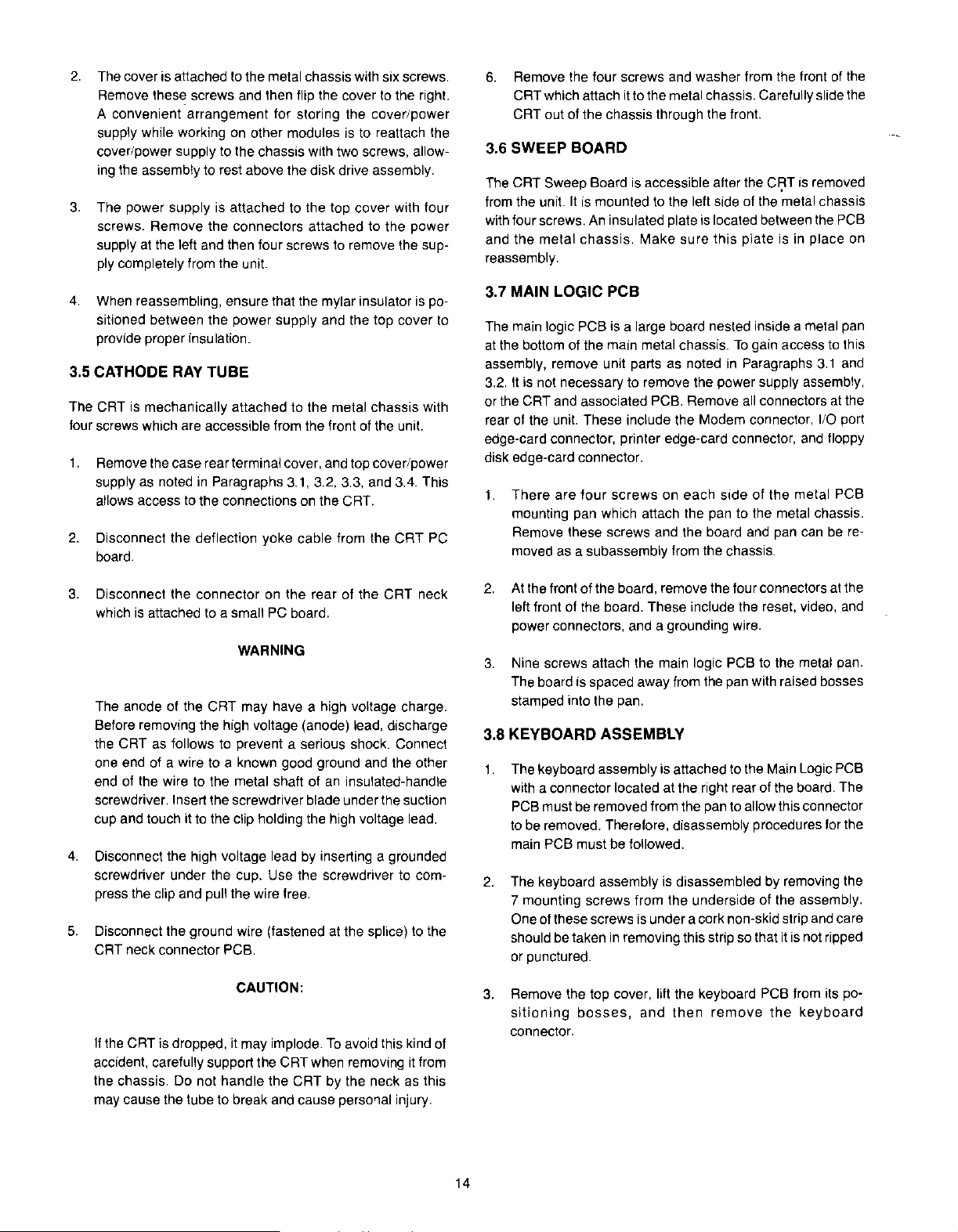

4.Ifthe cable assembly requires replacement, feed the connector through the opening

stall a tiewrap around the cable just before the insulation

sleeve.

This

servesasa

keyboard is reassembled. Ensure that this t',ewrap is in the

recess

between

bosses on the bottom of the case.

the

openinginthe

in

the keyboard base, then in-

strain

relief

for

the

cable

case

and

the

when

the

clamping

MOUNTING

SCREWS

DISK DRIVE

SU

BASSEMBLY

5.

Also ensure thatonreassembly the PCBisproperly positioned on the bosses of the base before attaching the top

cover.

Figure 3·2, Keyboard Cable Strain Relief

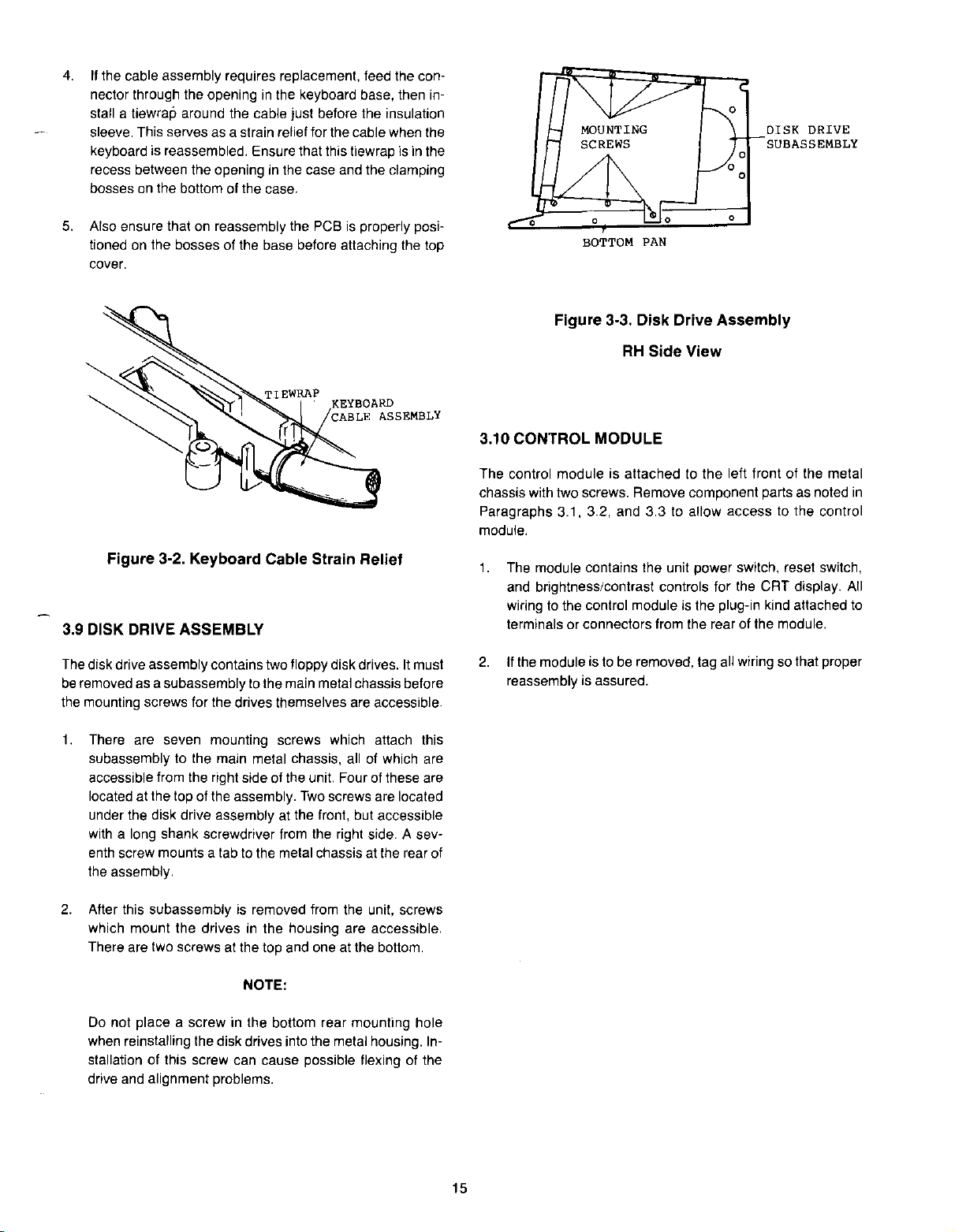

3,9

DISK DRIVE ASSEMBLY

The

disk drive assembly contains two floppy disk drives. it must

be

removed as asubassembly to the main metal chassis before

the

mounting

screws

for

the

drives

themselves

are

accessible.

•

o 0

BOTTOM PAN

o

Figure 3·3, Disk Drive Assembly

RH

Side View

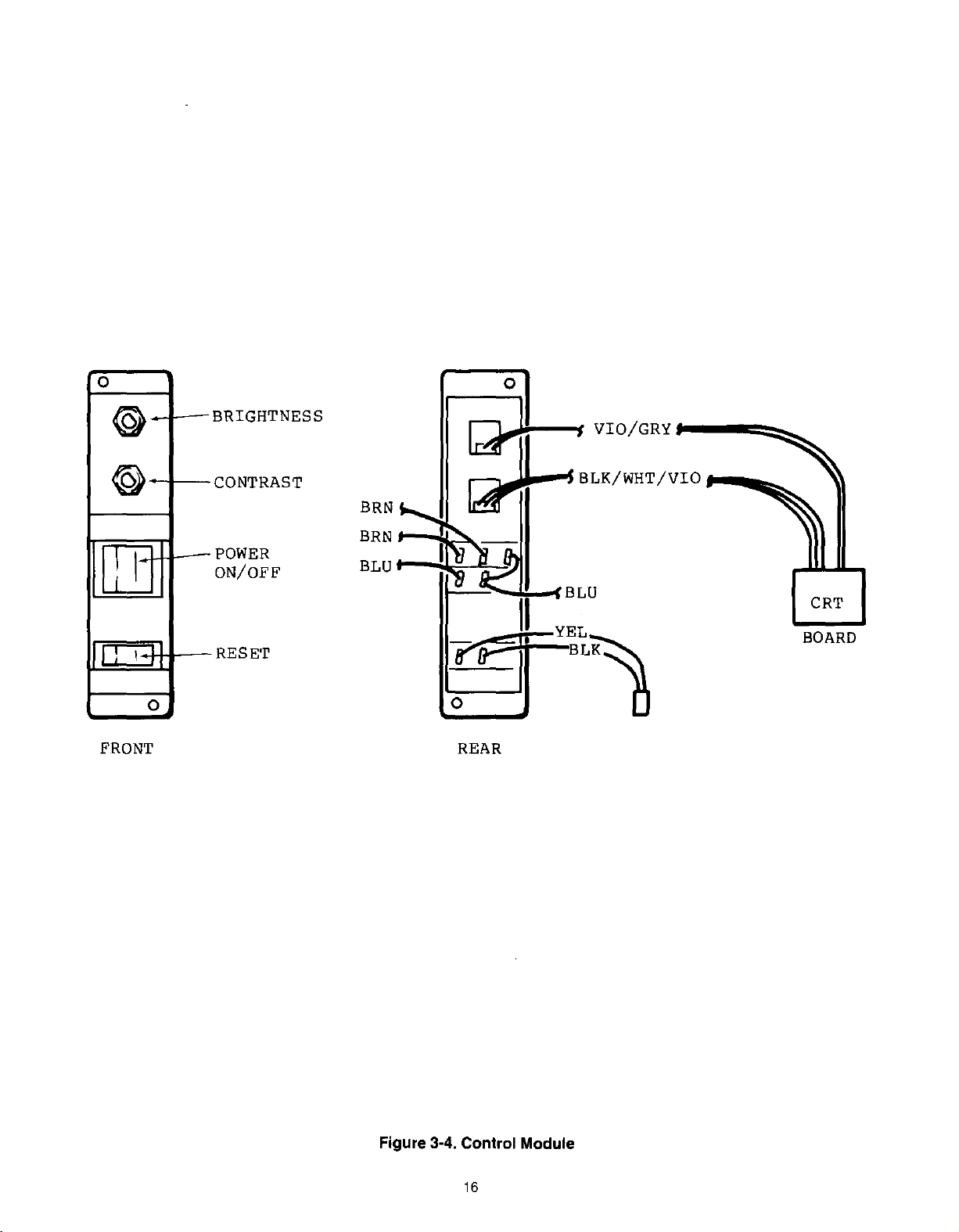

3,10 CONTROL MODULE

The control module is attached to the left front of the metal

chassis

Paragraphs 3.1, 3.2, and 3.3 to allow access to the control

module.

1.

2.Ifthe module is to be removed, tag all wiring so that proper

with

two

screws.

The module contains the unit power switch, reset switch,

and brightness/contrast controls for the CRT display. All

wiring to the control module is the plug-in kind attached to

terminalsorconnectors

Remove

from

component

the

rearofthe

partsasnoted

module.

reassemblyisassured.

in

1.

There are seven mounting screws

subassembly to the main metal chassis, all of which are

accessible from the right side of the unit. Four of these are

located at the top of the assembly.

under the disk drive assembly at the front, but accessible

with a long shank screwdriver from the right side. A

enth screw mounts a tab to the metal chassis at the rear of

the assembly.

2.

After this subassembly is removed from the unit, screws

which

mount the drivesinthe housing are accessible.

There are two screws at the top and one at the bottom.

NOTE:

Do not place a screw in the bottom rear mounting hole

when reinstalling the disk drives into the metai housing. installation of this screw can cause possible flexing of the

drive and alignment problems.

which

Two

screws are located

attach

this

sev-

15

0

o

@

@

II

I !

Irr

0

FRONT REAR

BRIGHTNESS

CONTRAST

POWER

ON/OFF

RESE'r

BRN

BRN

.....

-I.L~

BLU

t-~~~-'9I

Ii-=:-':~~-e

~BLK

o

--ft--,Y

II

B

LU

YlEL.'1

CRT

BOARD

Figure 3-4. Control Module

16

SECTION IV

MAINTENANCE/TROUBLESHOOTING

17

4.1

INTRODUCTION

MAINTENANCE/TROUBLESHOOTING

This sectionisa general guide for use by service personnel.

contains the Maintenance and Troubleshooting procedures

necessary to help isolate the problem area to a faulty board or

sUbsystem. After board or subsystem has been identified, refer

to

specific

section

for

more

detailed

troubleshooting

information.

Refer to the schematics and the theory of operation during

maintenance and troubleshooting for specific checkpoints and

testing.

4.2 MAINTENANCE

The oniy part of the Model 4P that requires maintenanceisthe

two Floppy Disk Drives. Periodical cleaning of the Read/Write

Heads

are

recommendedtoassure

other maintenanceoralignments required, refer to Section 5.3

Mini-Disk Drives Maintenance Checks and Adjustments.

error-free

operation.

For

4.3 TROUBLESHOOTING

Please be sure that the powercord is properly connected to

power before starting troubleshooting.

1.

Turn

Model 4P

light indicator

2.

RecheckACpower and power cord.Ifokay go to3,if bad

"ON"

by toggling power switch.Ifpower

is

on then go to4,if not, go to

2.

AC

replaceorrepair.

3.

Checkpower switch and bulb.Ifokay go to 1,ifbad repiace

power switch or bulb.

4.

Wait a few seconds for CRT to warm

and contrast at the front of consoie.

on go to

5.

Check p'Jwer switch.Ifokay go to6,if bad replace.

9,

if not go to

5.

up.

Adjust brightness

If

video display comes

all

It

10.

Does message "Close the Floppy Drive Door And Try

Again" appear?

11. Does message "The Floppy Disk Drive

appear?

12.

Does message "CRC Error,

Disk" appear?

13.

Does message "Seek Error, Try Again Or Use Another

Disk" appear?

14.

Does any other message appear?Ifyes then refer to Appendix B Startup Error Messages in Introduction to Your

Disk System TRS-80 Model 4P, if not then go to

15.

Insert Write Protected Diskette with TRSDOS

into Drive

4P boot up to TRSDOS Logo and prompt for date?

then go to 18, if not then go to 16.

16. Does message "The Floppy Disk Drive

appear?

Try

17.

18.

19. This indicates a hardware failure of Floppy Disk intertace

to boot again or use another diskette.Ifokay go to 18.

if still same message then go to 19.

pears, go to

This indicates that the problem area existsonthe Main

Logic CPU Board. Refer to Section 5.1.17

Board TroUbleshooting for more detailed troubleshooting

procedures.

or Floppy Disk Drive. Refer to Section 5.1.17 or 5.2.17

CPU

Board Troubleshooting or Section 5.3 Mini-Disk Drive

Maintenance Checks or Adjustments.

If

yes, go to 17, if not go to 11.

Is

If

yes then go to 19, if not go to 12.

Try

Again Or Use Another

If

yes then go to 19,ifnot go to 13.

If

yes then go to 19, if not go to 14.

0,

close door and toggle RESET Switch. Does

Is

If

yes then go to 17, if not then go to 10.

If

anothermessage ap-

9.

Not Available"

5.

6.1.1

or later

If

yes

Not Ready" still

or

5.2.17 CPU

6.

Check forACpower at input to power supply.Ifokay go to

7,

if bad replaceorrepairACwiring harness.

7.

Check power supply for correct output voltages. (Refer to

Power Supply Section 5.4.)

Power Supply Troubleshooting 5.3.4.

8.

Check for video and sync signais from Main Logic Board

J9. (Refer to CPU Board Section and Schematic.)Ifokay

refer to CRT Display Adjustment Section 5.5.2, if bad refer

to CPU Board Troubleshooting Section 5.1.17 or 5.2.17.

9.

Does message "The Floppy Disk DriveIsNot Ready" appear?

If

yes go to 15, if not go to 10.

If

okay go to8,if bad refer to

at

19

SECTION V

4P THEORY OF OPERATION

21

4P THEORY OF OPERATION

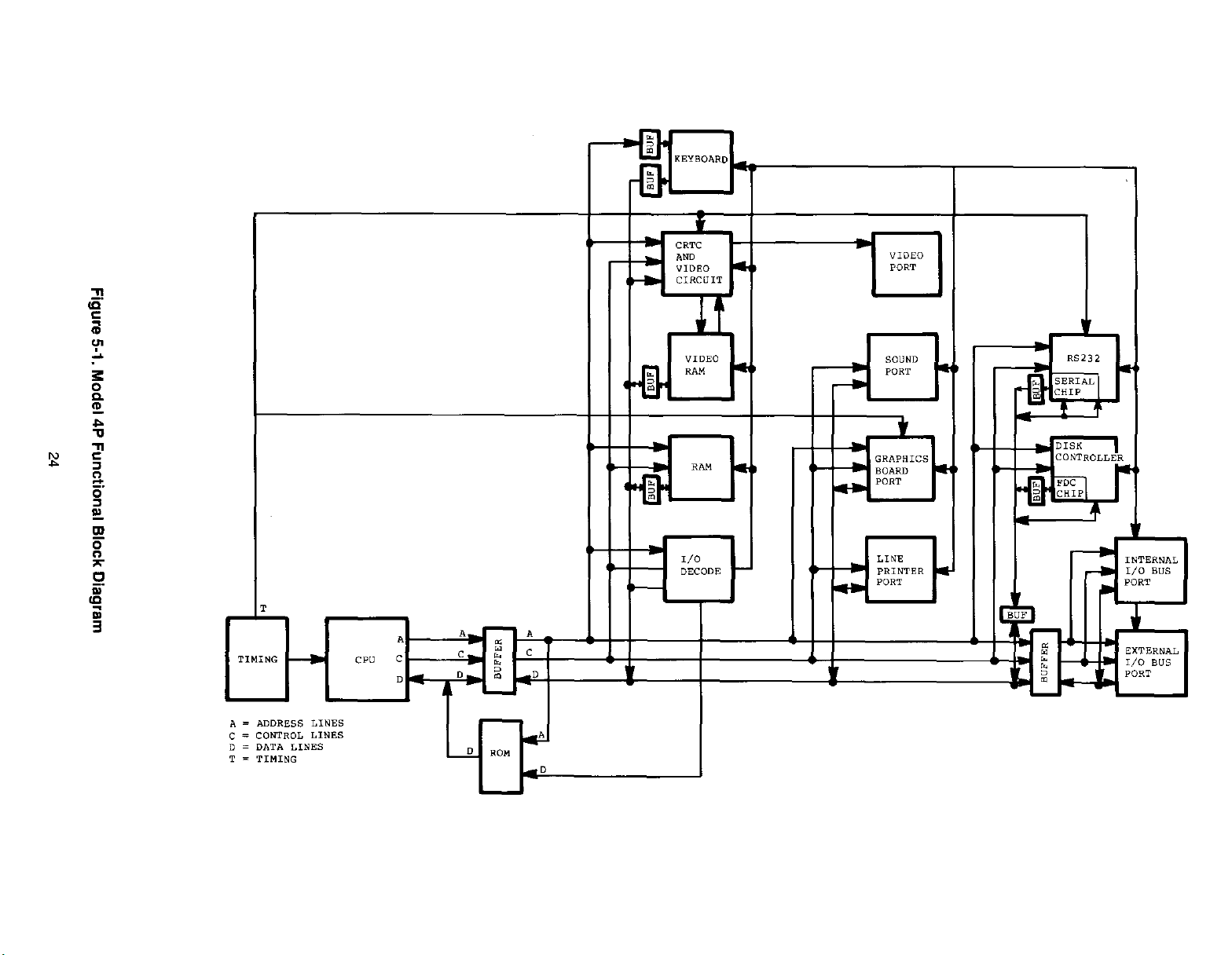

5.1

CPU THEORY OF OPERATION

5.1.1

Introduction

Containedinthe following paragraphsisa description of the

component parts of the Model4P CPU.

ical

operational

locatedonthe Main CPU board inside the case housing. Refer

to

Section 3 for disassembly/assembly procedures.

functionsofthe

5.1.2 Reset Circuit

Itisdivided into the log-

computer.

All

components

are

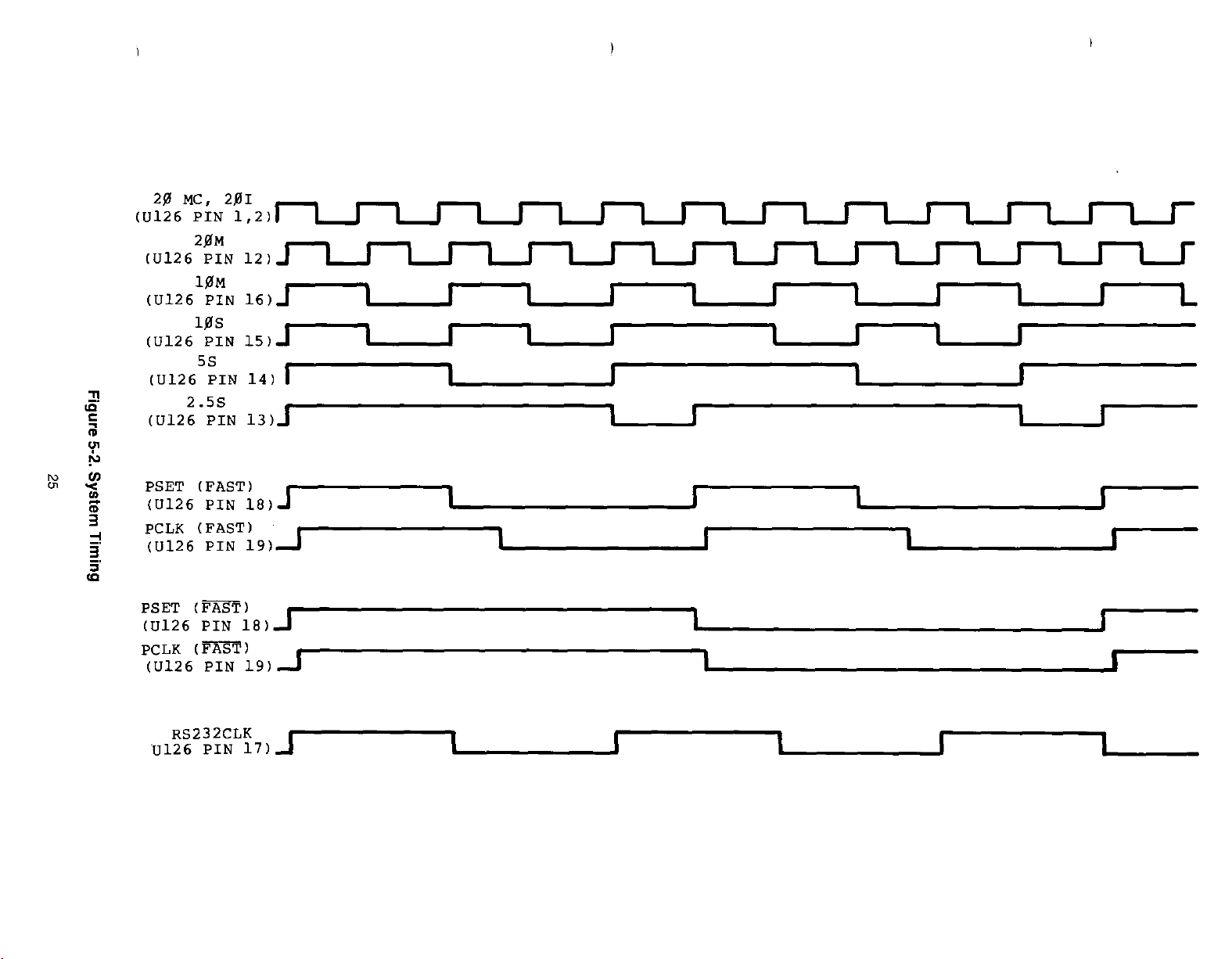

(pin 9 of U126).IfFASTisa logic low, the 20.2752 MHzisdivided by 10 which generates a 2.2752 MHz signal

logic high, the 20.2752 MHz

4.05504 MHz signal. The CPU clock (PCLK)

active

pull-up

circuit

which

rise and fall times required by the Z80A. U126. the 16R6A

generates

low the PCLK output to short cycle or generate a low or high

pulse

RefertoSystem Timing Fig. 5-2.

under

all

symmetrical

110

nanoseconds

is

divided by 5 which generates a

generates a

output

signals

which

ful15-volt

and

the

ZaOA

If

is

fed through

swing

also

does

also

FASTisa

an

with

fast

PAL.

not

al-

requires.

The Model 4P reset circuit provides the neccessary reset

pulsestoall

and C218 provide a time constant which holds the input of

low during power-up. This allows power to be stable to

cuits before the

C218 charges to a logic high, the output of

input of a retriggerable one-shot mullivibrator

a pulse with

reset switch is pressed on the front panel, this discharges C218

and

holds the input of

release of the switch, C218 again charges up, triggering

andU1to

circuits

during

powerupand

RESEr

an

approximate width of70microsecs. When the

reset

the

and RESET signals are applied. When

U121

low until the switch is released.

microcomputer.

reset

operations.

U121

(Ul).Uloutputs

R25

U121

all

cir-

triggers the

On

U121

5.1.3 CPU

The central processing unit (CPU) of the Model 4P microcomputer

is

a Z80A microprocessor. The Z80A is capaqle of run-

ning in either 2 MHz

functionsofthe

(AO-A

15), data lines

/RO,

/WR, /MREQ, and /RFSH). The address lines

are

buffered to other ICs through two 74LS244s (U68 and U26)

which are enabled all the time with their enables pulled to GNO.

The control lines are buffered to other ICs through a 74F04

(U86). The data lines

tionaI74LS245 (U71) which

rection

is

controlled by BUSOIW.

or

4 MHz mode. The CPU controls all

microcomputer

(00-07),

(00-07)

is

through

and control lines

are buffered through a bi-direcenabled by BUSEW and the di-

useofits

address

(lMl,

lines

/IOREQ,

(AO-A

15)

5.1.4 System Timing

The

main

timing

referenceofthe

ception of the FOC circuit, comes from a 20.2752 MHz Crystal

Oscillator (Y1). This reference

ating all necessary timing for the CPU, video circuit, and

232-C circuit. The output of the crystal oscillatorisfiltered by a

ferrifte bead (FB5), 470 ohm resistor (R46), and a

pacitor (C242). After being filtered,

PAL

(Programmable Array Logic), whereitis divided by 2 to

generate a 10.1376 MHz signal (10M) for the

play. U126 divides the 20.2752 MHz

MHz signal (RS232CLK) for the baud rate generator

232-C circuit. The

can

be

either 2 or 4 MHz dependingonthe state of

CPU

clockisalso generated by U126 which

microcomputer,

is

divided and used for gener-

itisfed into U126, a 16R6A

by

4 to generate a 5.0688

64X16

with

the

68pfca-

video dis-

in

the RS-

FAST

ex-

RS-

input

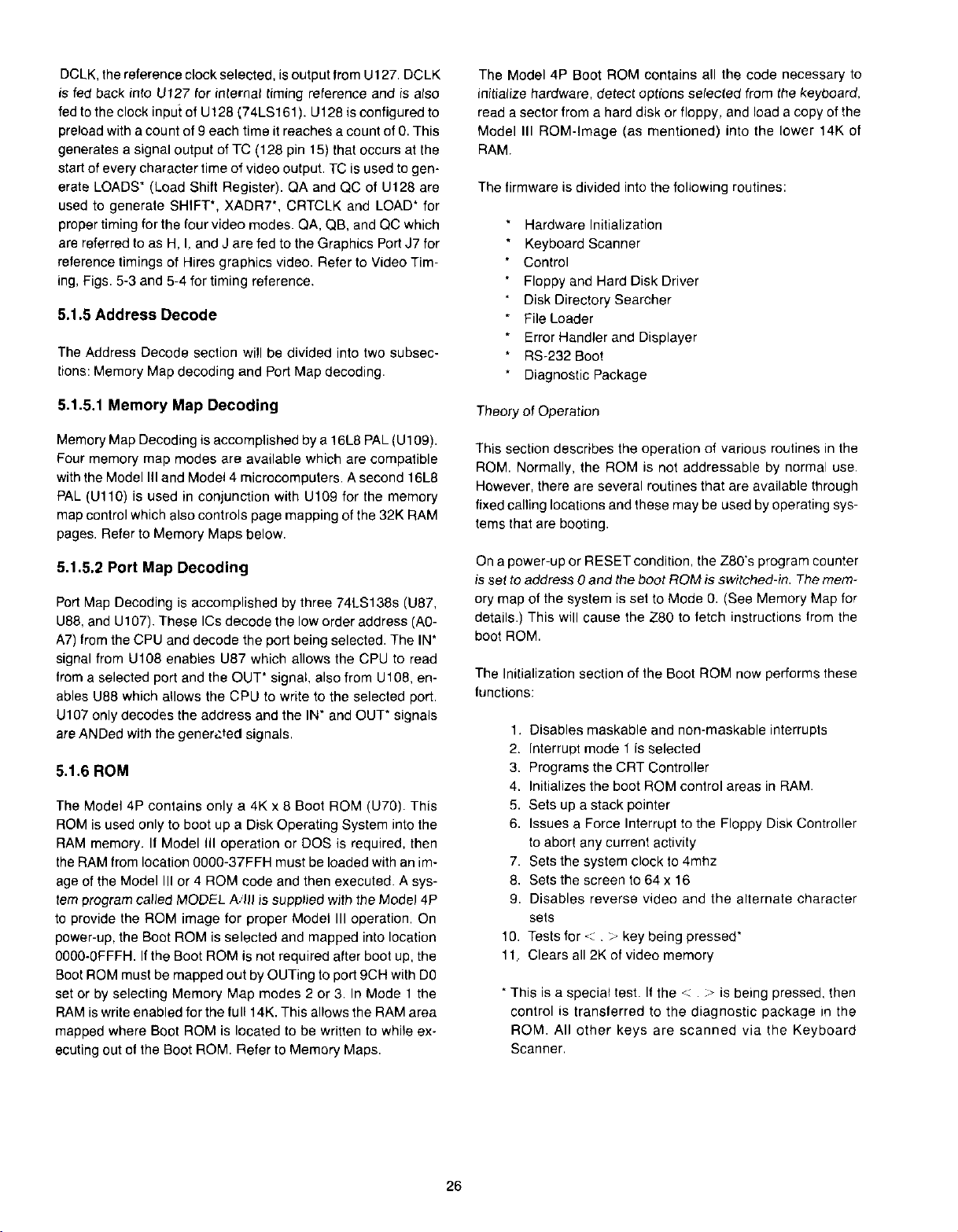

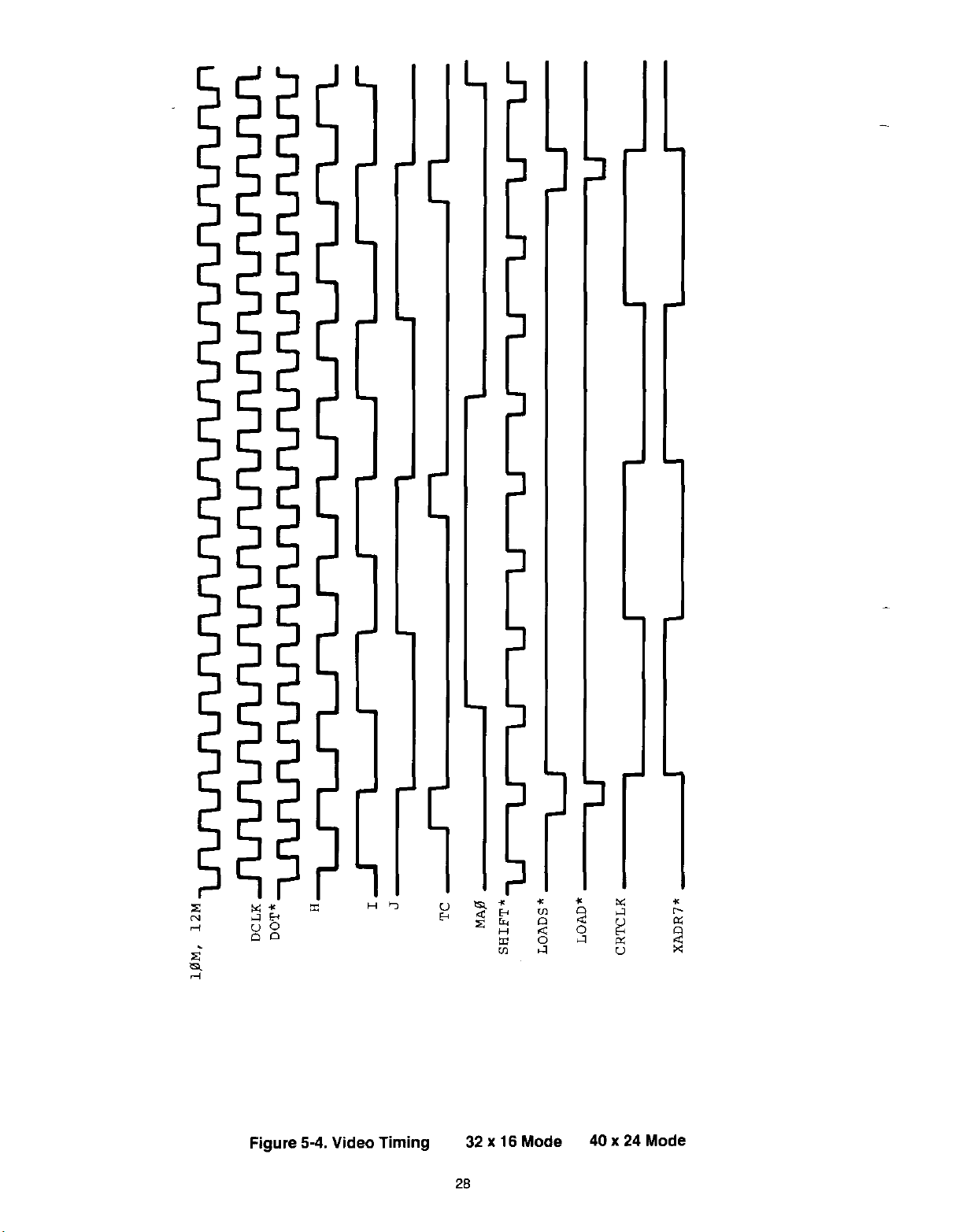

5.1.4.1 Video Timing

The video timing is controlled by a 1

bit synchronous counter U128 (74LS161). These two ICs generate all the necessary timing signals for the four video modes:

64x16,

nals

clock, the 10.1376 MHz signal (10M),isgeneratedbyU126 and

is

ence clock

a Phase Locked Loop (PLL) circuit and

and 40 x24modes. The PLL circuit consists of U147 (74LS93),

U148 (NE564 PLL), and U149 (74LS90). The original 20.2752

MHz clock

1.2672 MHz signal. The output of U147 is reduced

by

coupledtothe reference input of U148 by C227.

The PLL (NE564)isadjusted to oscillate at 12.672 MHz by the

luning capacitor C231. This 12.672 MHz clock

by

whioh is fed to a second input of U148. The two 1.2672 MHz

signals

12.672 MHz output soitis

clock.

MOOSEL and

video mode.

U127 and MOOSEL controls the single or double character

width mode. Refer to the following chart for selecting each

video

32 x 16,80x 24, and 40 x 24.

are

required

used by the64x 16 and32x 16 modes. The second refer-

is

the voltage divider network R27 and R28 and the output

10 through U149 to generate a second 1.2672 MHz signal

are

mode.

8064'

for

the

four

a 12.672 MHz (12M) signal whichisgenerated by

is

divided by16through U147 which generates a

compared

8064'

internallytothe

synchronized with the 20.2752 MHz

8064'

signals are used to select the desired

controls which reference clockisused by

MOOSEL

o

o

1

1

'This

is the state to be wriften to latch U89. Signalisinverted

before being input to U127.

OL8

PAL

(U127) and a four-

Two

reference clock sig-

video modes. One reference

is

usedbythe 80 x

in

is

then divided

PLL

whereitcorrects

Video Mode

o

1

o

1

64 x 16

32 x 16

80

x24

40

x 24

amplitude

the

24

is

23

...

'"

cEo

"

c:

~

CD

'!'

-

;;:

0

Co

!2.

...

"tI

c:

"

:::l

"

-

0"

:::l

!!!.

III

0"

,..

"

9-

..

IC

~

..

3

T

TIMING

-

A = ADDRESS

C::CONTROL

D::DATA

T

'"

TIMING

LINES

LINES

LINES

CPU

~

...

-

*'

~

CRTC

AND

VIDEO

CIRCUIT

~

VIDEO

PORT

f

RS232

SERIAL

~

CHIP

• t

DISK

:::TROLLE~

a:

CHIP

~

..

"t

INTERNAL

I/a

BUS

~

-A

~

~

~

~

~

~

-

EXTERNAL

*

I/O

BUS

PORT

~

VIDEO

RAM

..

-

SOUND

PORT

•

rti

t

..

GRAPHICS

BOARD

PORT

I-

~

RAM

..

Kt

I/O

DECODE

f-

..--

r--

A

C

0

C

0

........E..

~

~

~

~

~

~

.....

r--

ROM

A

C

0

~

0

LINE

•

PRINTER

PORT PORT

...

i-

Qm

2jJ MC,

<0126

<0126

(U126

<0126

(U

"T1

.co

c:

~

U1

~

1Il

"

~

'"

co

-

3

-i

3°

oj'

lC

126

<012~·~~N

PSET

(U126

PCLK

<0126

2jJI

PIN

2jJM

PIN

1jJM

PIN

1jJS

PIN

5S

PIN

(FAST)

PIN

(FAST)

PIN

1,2)

12)

16)

J I 1 I 1 I 1 I I I , L

15)J

14)

I I 1 I I

13>J

J I

IS)

..Jr--------...,

19)

I I I I I I I I

I I I

1~

----'1

....11

I I

I I

I~---

PSET

<0126

PCLK

(U126

RS232CLK

U126

(FAST)

PIN

(FAST)

PIN

PIN

lS)J

19)

-l

J-----....,

17)

I

I

I

.......JI

~

I 1 _

Ir----

I~---

DCLK, the reference clock selected,isoutput from U127. DCLK

is

fed

back

info

U127

tor

internal

fedtothe clock inpui of U128 (74LS161). U128 is configured to

preload with a count of g each time

generates a signal output of TC (128 pin 15) that occurs at the

every character time of video output.

start of

erate LOADS' (Load Shift Register). QA and QC of U128 are

used to generate

proper timing for the four video modes. QA, QB, and

are referred to as

reference

ing, Figs. 5-3 and 5-4 for timing reference.

timingsofHires

SHIFr,

H,I,and J are fed to the Graphics Port J7 for

graphics

riming

reference

it

reaches a count ofO.This

XADR7", CRTCLK and LOAD' for

video.

RefertoVideo

andisalso

TCisusedtogen-

QC

which

Tim-

5.1.5 Address Decode

The Address Decode section will be divided into two subsections: Memory Map decoding and Port Map decoding.

The Model 4P Boot ROM contains all the code necessary to

initialize hardware, detect options selecled from

read a sector from a hard disk or floppy, and load a copy of the

Model III ROM-Image (as mentioned) into the lower 14K of

RAM.

The

firmwareisdivided

Hardware

Keyboard Scanner

Control

Floppy and Hard Disk

Disk Directory Searcher

File Loader

Error Handler and Displayer

RS-232 Boot

Diagnostic Package

into

Initialization

the

Driver

following

the keyboard.

routines:

5.1.5.1 Memory Map Decoding

Memory Map Decoding is accomplished by a 16L8

Four

memory

with the Model

PAL

(U110)isusedinconjunction with U109 for the memory

map control which also controls page mapping of the 32K RAM

pages. Refer to Memory Maps below.

map

modes

are

available

III

and Model 4 microcomputers. A second 16L8

which

PAL

are

compatible

(U1

09).

5.1.5.2 Port Map Decoding

Port Map Decodingisaccomplished by three 74LS138s (U87,

U88,

and U107). These ICs decode the low order address

A7)

from the CPU and decode the port being selected. The

signal from U108 enables U87 which allows the CPU to read

our

from a selected port and the

ables U88 which allows the CPU to write to the selected port.

U1

07 only decodes the address and the IN" and

are ANDed with the

gener~ted

signal, also from U108, en-

our

signals.

(AO-

IN'

signals

5.1.6 ROM

The Model 4P contains only a 4K x 8 Boot ROM (U70). This

ROMisused only to boot up a Disk Operating System into the

RAM

memory.IfModel III operation or DOS is required, then

RAM

the

age of the Model

tem program called MODEL A/III is supplied with the Madej 4P

to

power-up, the Boot ROMisselected and mapped into location

OOOO-OFFFH.

Boot ROM must be mapped out by OUTing to port 9CH with

set orbyselecting Memory Map modes 2 or3.In

RAMiswrite enabled for the

mapped where Boot ROM

ecuting out

from location 0000-37FFH must be loaded with an im-

III

or 4 ROM code and then executed. A sys-

provide the ROM image for proper Model

If the Boot ROM is not required after boot

fuII14K. This allows the RAM area

is

located to be writtentowhile ex-

of

the Boot ROM. Refer to Memory Maps.

III

operation. On

up,

the

DO

Mode 1 the

Theory of Operation

This

section

ROM. Normally, the ROM is not addressable by normal use.

However,

fixed calling locations and these may be used by operating systems that are booting.

On

a power-up or RESET condition, the Z80's program counter

is set to address 0

ory map of the systemisset to ModeO.(See Memory Map for

details.) This will cause the Z80 to fetch instructions trom the

boot ROM.

The Initialization section of the Boot ROM now performs these

describes

there

are

several

and

the

operationofvarious

the

routines

boot

that

ROM

routinesinthe

are

available

through

issWitched-in. The mem-

functions:

1.

Disables maskable and non-maskable interrupts

2.

Interrupt mode 1isselected

3.

Programs the CRT Controller

4.

Initializes the boot ROM control areasinRAM.

5.

Sets up a stack pointer

6.

Issues a Force Interrupt to the Floppy Disk Controller

to

abort

any

current

7.

Sets the system clock to 4mhz

8.

Sets the screen to 64 x 16

9,

Disables reverse video and the alternate character

sets

10.

Tests for < . > key being

11.

Clears all 2K of video memory

* This

is

a special test.Ifthe

is

control

ROM. All

Scanner.

transferredtothe diagnostic packageinthe

other

keys

activity

<'

are

scanned

pressed'

:>

is

being pressed, then

via

the

Keyboard

26

:>:

N

.-i

lSt

.-i

:>:

:<:

-<

U

Q

"

E-<

0

Q

"

"

r..

""'

H

p::

til

0

til

Q

<t:

-<

p::

,.,

H

""'

~

lSt

U

"

~

0

-<

~

-<

U

E-<

cr;

u

"

r-

cr;

~

:><

Figure 5·3. Video Timing 64 x16Mode

27

80x24

Mode

:E

N H

H

:E

H

""

r,

'"

uO

Q Q

~

Eo<

'"

H

Figure 5-4. Video Timing

U

Eo<

<l:

""

:E

32x16

28

~

Eo<

0<

H

Ul H

'"

Mode

~

~

Q

(JJ

Q

<l:

0

<l:

0

H

40x

H

'"

U

Eo<

~

U

24 Mode

~

r-

~

Q

<l:

><

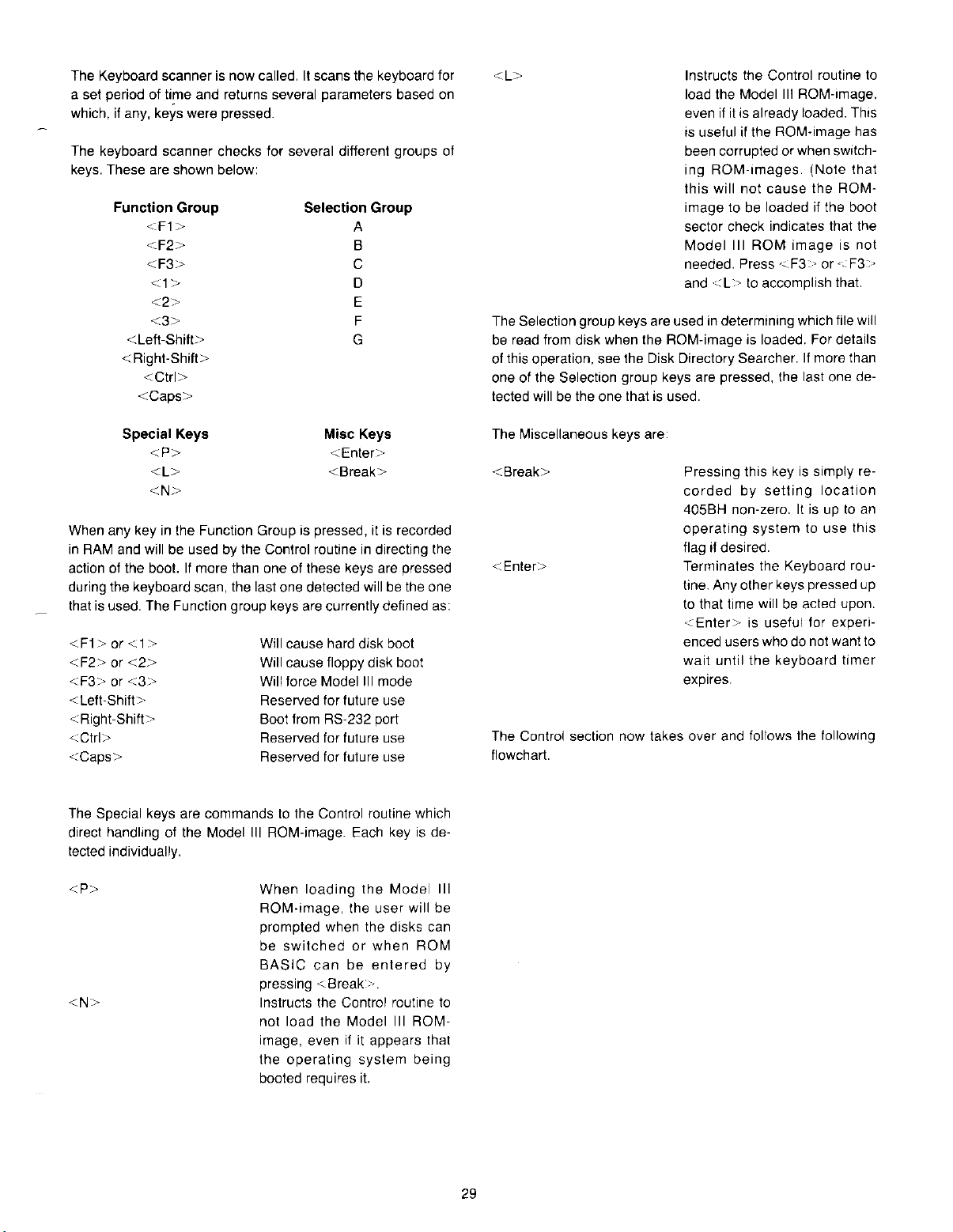

The Keyboard scannerisnow called. It scans the keyboard for

a set period of

which,

if

The keyboard scanner checks for several different groups of

keys. These are shown below:

Function

ti:ne and returns several parameters based on

any, keys were pressed.

Group

<F1>

Selection

A

<F2>

<F3>

<1>

C

D

<2>

<3>

<Left-Shift>

<Right-Shift>

G

Group

B

E

F

<Gtrl>

<Caps>

<L>

The Selection group keys are used in determining which file will

be

read from disk when the ROM-image is loaded. For details

of this operation, see the Disk Directory Searcher. If more than

one of the Selection group keys are pressed, the last one detected will

be

the one that is used.

Instructs the Control routine to

load the Model

even if it is already loaded.

IS

useful if the ROM-image has

been corrupted or when switching

ROM-Images.

this

will

image to be loaded if the boot

sector check indicates that the

Model

needed. Press

and

III

<L>

III

ROM-Image,

(Note that

not

cause

the ROM-

ROM

imageisnot

<F3>or<F3'

to accomplish that.

ThiS

Special

When any key

in

RAM and will be used by the Control routineindirecting the

action of the boot.

during the keyboard scan, the last one detected will be the one

that

is

used. The Function group keys are currently defined as:

<F1>or<1>

<F2>or<2>

<F3>or<3>

<Left-Shift>

<Right-Shift>

<Gtrl>

<Caps>

The Special keys are commands

direct handling of the Model

tected individually.

<p>

<N>

Keys

<p>

<L>

<N>

in

the Function Group is pressed, itisrecorded

If

more than one of these keys are pressed

Will cause hard disk boot

Will cause floppy disk boot

Will force Model

Reserved for future use

Boot from RS-232 port

Reserved for future use

Reserved for future use

III

ROM-image. Each keyisde-

When

ROM-image,

prompted when the disks can

be

BASIC

pressing

Instructs the Control routine to

not

image, even

the

booted requires it.

Misc

Keys

<Enter>

<Break>

III

mode

to

the Control routine which

loading

switched

can

load

operating

the

the

user

or

when

be

entered

<Break--,

the

Model III ROM-

if

it appears that

system

Model

will be

ROM

being

III

by

The Miscellaneous keys are:

is

<Break>

<Enter>

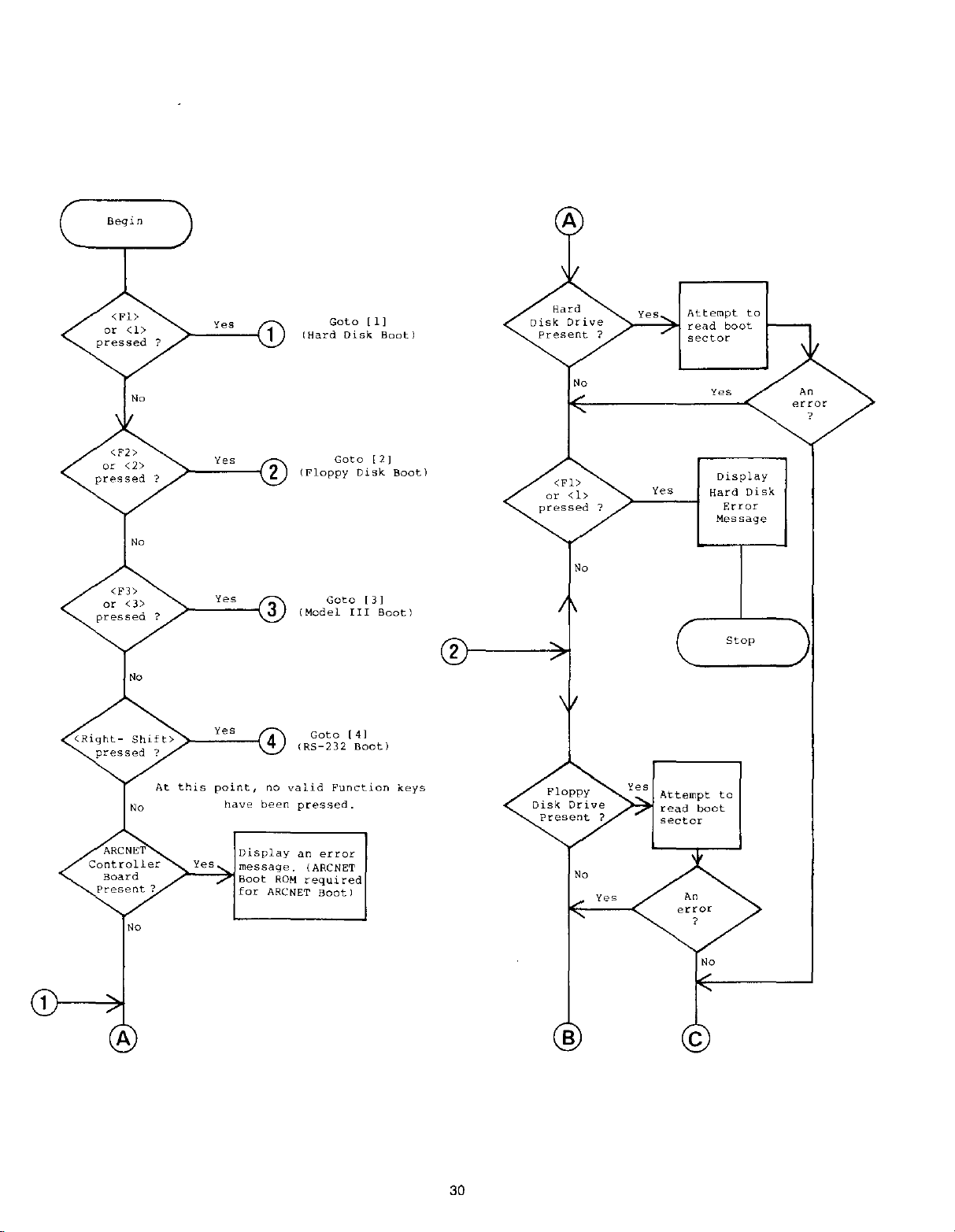

The Control section now takes over and follows the following

flowchart.

Pressing this key

corded

405BH non-zero.Itis

operating

flag If desired.

Terminates the Keyboard rou·

tine. Any other keys pressed up

to that time will

<Enter>

enced users who do not want to

wait

expires.

by

setting

systemtouse

is useful for experi-

until

the

simply re-

location

up to an

be

acted upon.

keyboard

this

timer

29

Begin

A

1

A

30

B

B

c

D

<F2>

or

<2>

pressed?

Yes

Display

Floppy

Error

Message

<N>

pressed

?

No

Stop

Disk

No

Yes

256

and

Sector

no

Model

ROM

bytes,

ref.s

?

Yes

III

Note:

Set

Transfer

Address

3~l5H

Note:

Attempt

locate

ROM

on

Floppy

Note:

Found

Note:

Write-enable

~-37FFH

(Mode

1

Load

Image

Note:

Image

ROM

Image

to

Disk

4

No

?

4

Yes

1)

ROM

5

to

2

F

No

D

Set

Transfer

<L>

pressed

?

Address

43~~H

Note:

2

®

to

Errors

while

ROM

Set

Transfer

Address

of

ROM

(Normally

Note:

loading

Image

at

Image

2

?

end

3~15H)

Yes

Display

Error

Message

Stop

No

~

Yes

":"::':""

__

---.J

E

G

31

G

ROM

Image

Present

~

boot

Switch

out

of

No

?

ROM

Memory

<p>

pressed

?

Display

II

ROM

Image

is

loaded

message

Waitfor

<ENTER>

<BREAK>

be

pressed

Yes

Jump

to

.....

,

tiali

6

foe

Determine

Correct

Baud

Rate

Address

ze

Port

Detect

Transfer

7

II

or

to

Ini

RS-232

Note:

Wait

Carrier

Write-protect

memory

Set

to

CPU

2MHz

(Mode

H

speed

0)

Transmit

Rate

Message

Detect

Baud

I

32

Wait

Sync

(FFH)

for

Byte

Packages that do not reference the Model III ROMinthe

boot sector can still cause the Model

loaded by coding a

It

does not have to be executable.Atthe same time, Model

4 packages

CDxxOO

must

take care that thereisno

somewhereinthe boot sector.

III ROM image to be

sequence

bytesinthe boot sector that could be mis-interpreted to be

a reference to the Boot ROM. An example of this would be

sequence

06CDOEOO,

which is a LD B,OCDH and a LD

C,O.Ifthe boot sector cannot be changed, then the user

must press the

to inform the ROM that the disk contains a Model

age which needs the Model

<F3>

key each time the systemisstarted

III

ROM-image.

III

pack-

of

Load

program

from

RS-232

Notes:

An

error

Transfer

control

to

address

recei

?

ved

Yes

Display

transmit

and

error

(1)Ifthe boot sector was not 256 bytesinlength, thenitis

sumed to be a Model III package, and the ROM-image will

be needed. If the sector is 256 bytes

sector

is

scanned for the sequence

the first byte of a

ZBO

unconditional subroutine call. The

in

length, then the

CDxxOOH.

TheCDis

next byte can have any value. The third byte is tested

against a zero. What this check does is test for any references

to

the first 256 bytes of memory. All Radio Shack

Model

III

operating systems, and many other packages all

reference the ROM at some point during the boot sector.

Most boot sectors will display a message

not be loaded.Tosave

Model

III

ROM calls to display the message. Several

space, these routines use the

if

the system can-

calls have their entry pointsinthe first 256 bytes of memory, and these references are detected by the boot ROM.

as-

ROM

(2)Ifyou are loading a Model 4 operating system, then the

boot ROM will always transfer control to the first byte of the

boot sector, which is

III

operating system or about to use Model

at

4300H.Ifyou are loading a Model

III

ROM BASIC,

then the transfer address is 3015H. This is the address of

ajump

vectorinthe

"C"

ROM of the Model III ROM image,

and this will cause the system to behave exactly like a

Model III.

If

the ROM-image file that is loaded has a differ-

ent transfer address, then that address will be used when

loading

is

complete.Ifthe imageisalready present,itwill

use 3015H.

(3)

Two

different tests are done to insure that the Model III

ROM image

is

present. The first test is to check ever third

location starting at 3000H for a C3H. This is done for 1010-

cations.Ifanyofthese locations does not contain a C3H,

then the ROM image is considered to be

The next test is to check two bytes at location

these addresses contain

E9E1H,then the ROM image is

"not

present".

OOOBH.

considered to be "present".

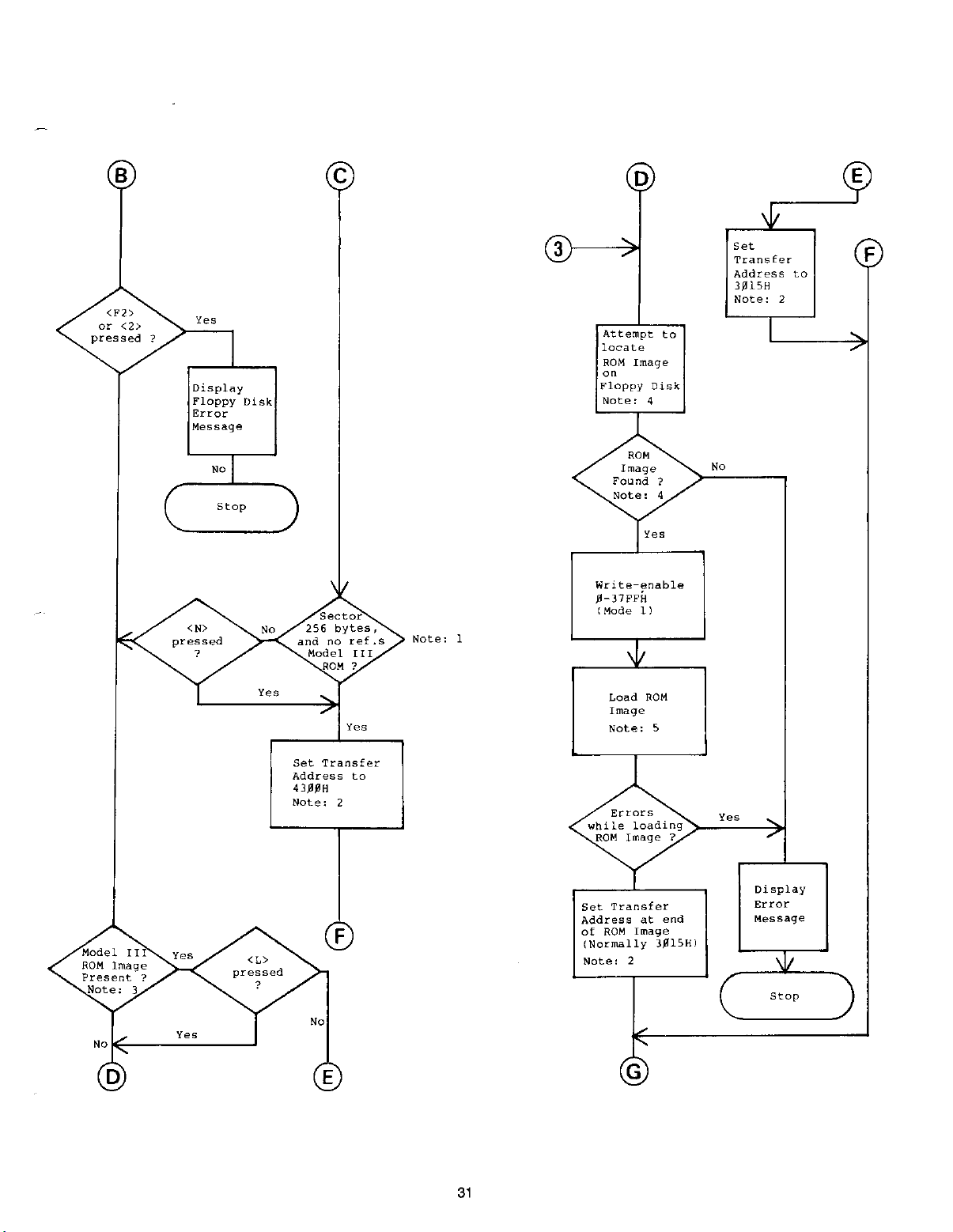

(4)

See Disk Director Searcher for more information.

(5)

See File Loader for more information.

(6)

The RS-232 loaderisdescribed under RS-232 Boot.

Disk Directory

When the Model

from the floppy

Searcher

III

ROM image

in

drive

O.

isto

be loaded,itis

always read

Before the operation begins, some checks are made. First, the

boot sector is read in from the

checked to make sure

itiseither a

floppy

and the first byte is

OOH

or a FEH.Ifthe byte

contains some other value, no attempt will be made to read the

ROM

image from that disk. The location of the directory cylinder

is

then taken from the boot sector and the type of disk is deter-

mined. This

is

done by examining the Data Address Mark that

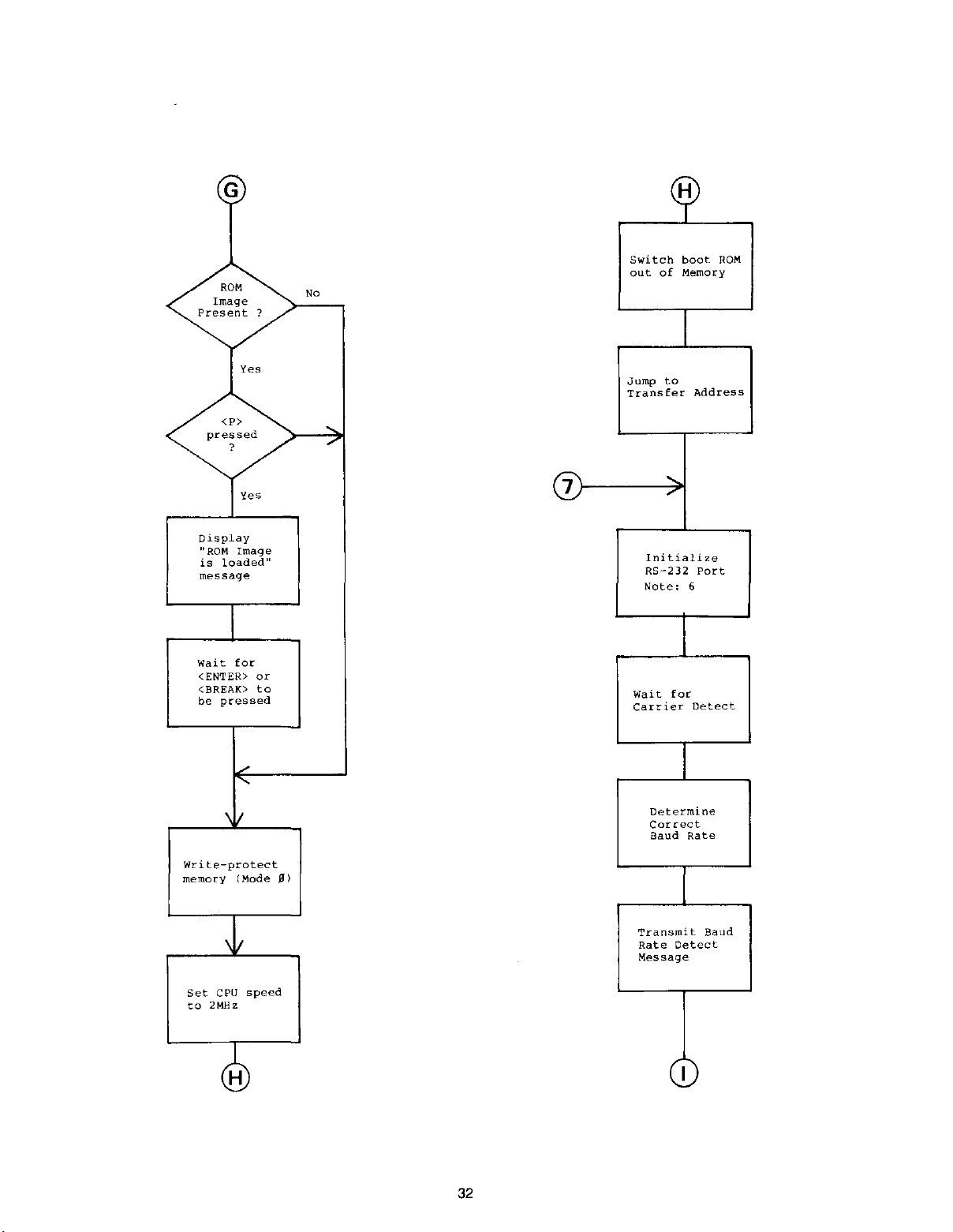

If

33

was picked up by the Floppy Disk Controller (FDC) during the

1,

read of the sector. II the DAM equals

1.x style disk. Ifthe DAM equals

TRSDOS 6 style disk. This

0,

is

important since TRSDOS 1.x

the diskisa TRSDOS

then the diskisa LDOS 5.1/

disks number sectors starting with 1 and LDOS style disks

number sectors starting with

Once

the

disk

type

has

if

the diskisa LDOS style disk. This test reads the Granule Al-

O.

been

determined,anextra

t8St

is

made

location Table (GAT)todetermine if the disk is single sided or

double sided.

Floppy

The

disk

and

drivers

Hard

Disk Driver

are

entered

via

RSTBHand

will

readasector

anywhere on a floppy disk and anywhere on head 1 (top-head'

in

a hard disk drive. Either 256 or 512 byte sectors are readable

by

these

size.

and the

routines

The'11ard

WD1010controllers. The floppy disk driveriswritten for

and

they

make

the

determinationofthe

sector

disk driver is compatible with both'the WD1000

the WD1793 controller.

Loader

Serial

The

directoryisthen

read

one

recordata

time

andacompare

is made againsf the pattern 'MODEL% ' for the filename and

'III'

for

the extension. The

'%'

means that any character

will

match this position. II the user pressed one of the selection

keys (A-G) during the keyboard scan, then that character is

substituted

piace of the

'%'

character. For example,ifyou

in

pressed 'D', then the search would be for the file 'MODELD "

with the extension

it

finds the entry or it reaches the end of the directory.

'Ill'. The searching algorithm searches until

Once the entry has been found, the extent information for that

fileiscopied

File

Loader

intoacontrol

block

for

later

use.

The file loaderisactually two modules - the actual loader and

a set of routines to fetch bytes from the file on disk. The loader

is

invoked via a RST 28H. The byte fetcher is called by the

loaderusing RST 20H. Since restart vectors can be re-directed,

the same loader is used by the RS-232 boot. The difference

that the RST 20Hisredirected to point to the RS-232 data re-

ceiving

routine.

The loader

reads

standard

loader

records

and

acts upon two types:

01

Data Load

1 byte with length of block, including address

1 word with address to load the data

n bytes of data, where n

+2 equals the length specified

02 Transfer Address

1 byte with the value of 02

1

word

with

the

addresstostart

execution

at.

Any other loader code is treated as a comment block andisignored. Once an 02 record has been found, the loader stops

if

reading, even

thereisadditional data, sobesure to place the

02 recordatthe end of the file.

Invoking

the

serial

loaderissimilartoforcingaboot

disk or floppy.Inthis case the right shift key must be pressed

some

time

during

the

first

three

gram

does

not

careifthe

venienttoconnect

seconds

keyispressed

pins8and10of

the

after

forever,

keyboard

a shorting plug for bench testing of boards. This assumes that

the object program being loaded does not care about the key

closure.

Upon entry, the program first asserts DTR (J4

4)

(J4 pin

of

true. Next, "Not Ready"isprinted on the topmost line

the video display. Modem status line CD (J4 pin8)is

sampled. The program loops until it finds CD asserted true.

that time the message "Ready"isdisplayed. Then the program

sets

about

To

determine

determining

the

the

baud

rate

from

the

baud rate, the program compares data

ceived by the UART to a test byte equal to '55' hex. The receive

is

first set to 19200baud.Iften bytes are received which are not

is

equal

is

repeated

to

the test byte, the baud rateisreduced. This sequence

untilavalid

test

byteisreceived.Iften

at50baud, the entire process begins againat19200 baud.Ifa

valid

test

rive

before

rate.Ifat

byteisreceived,

concluding

this

timeanimproper

the

program

thatithas

byteisreceivedora

waits

determined

for

ror (overrun, framing, or parity)isintercepted, the task begins

again at 19200 baud.

In

order to get to this point, the host or the modem must assert

CD true. The host must transmit a sequence of test bytes equal

to

'55' hex with 8 data bits, odd parity, and 1 or 2 stop bits. The

test bytes should be separated by approximately

avoid

overrun

errors.

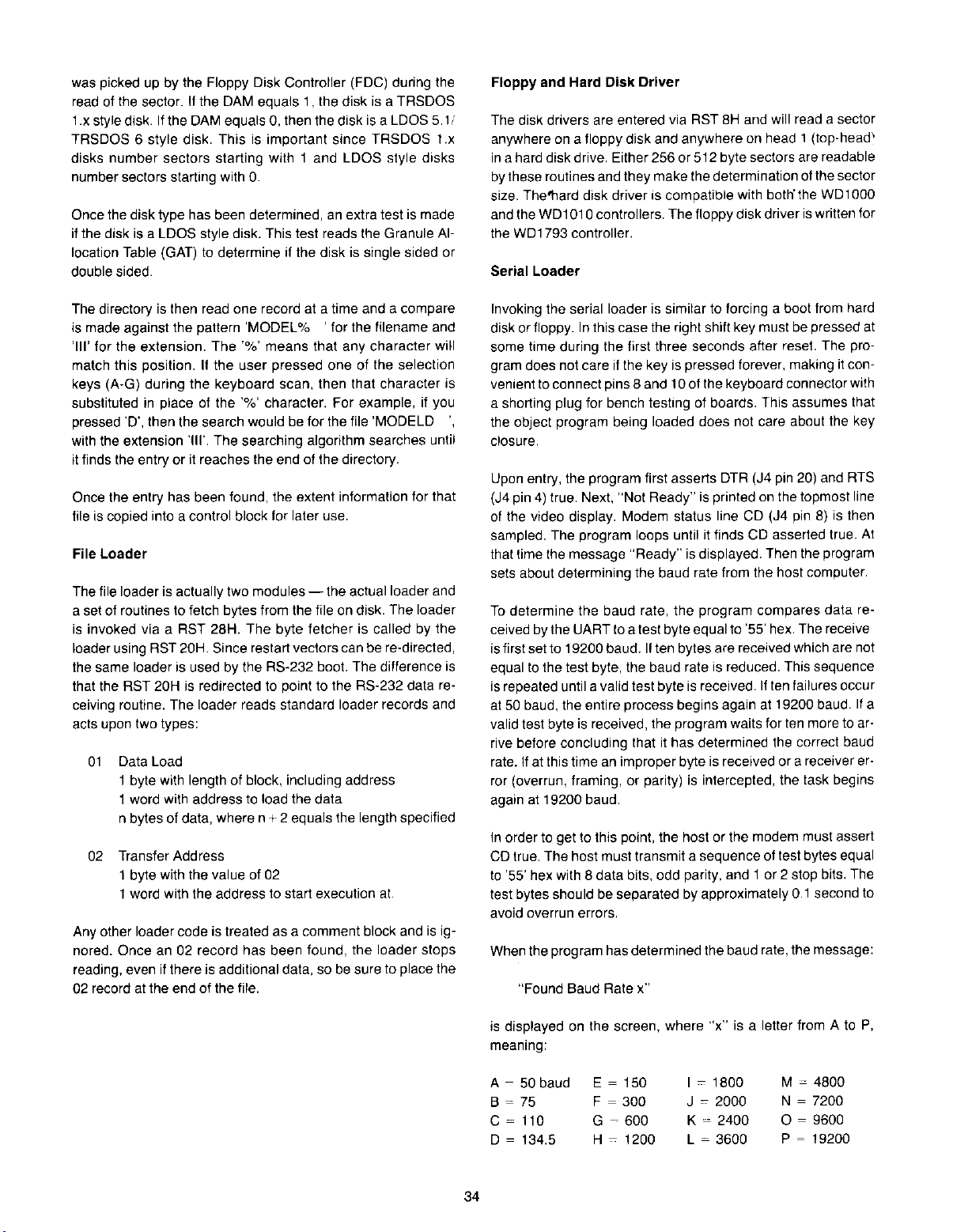

When the program has determined the baud rate, the message:

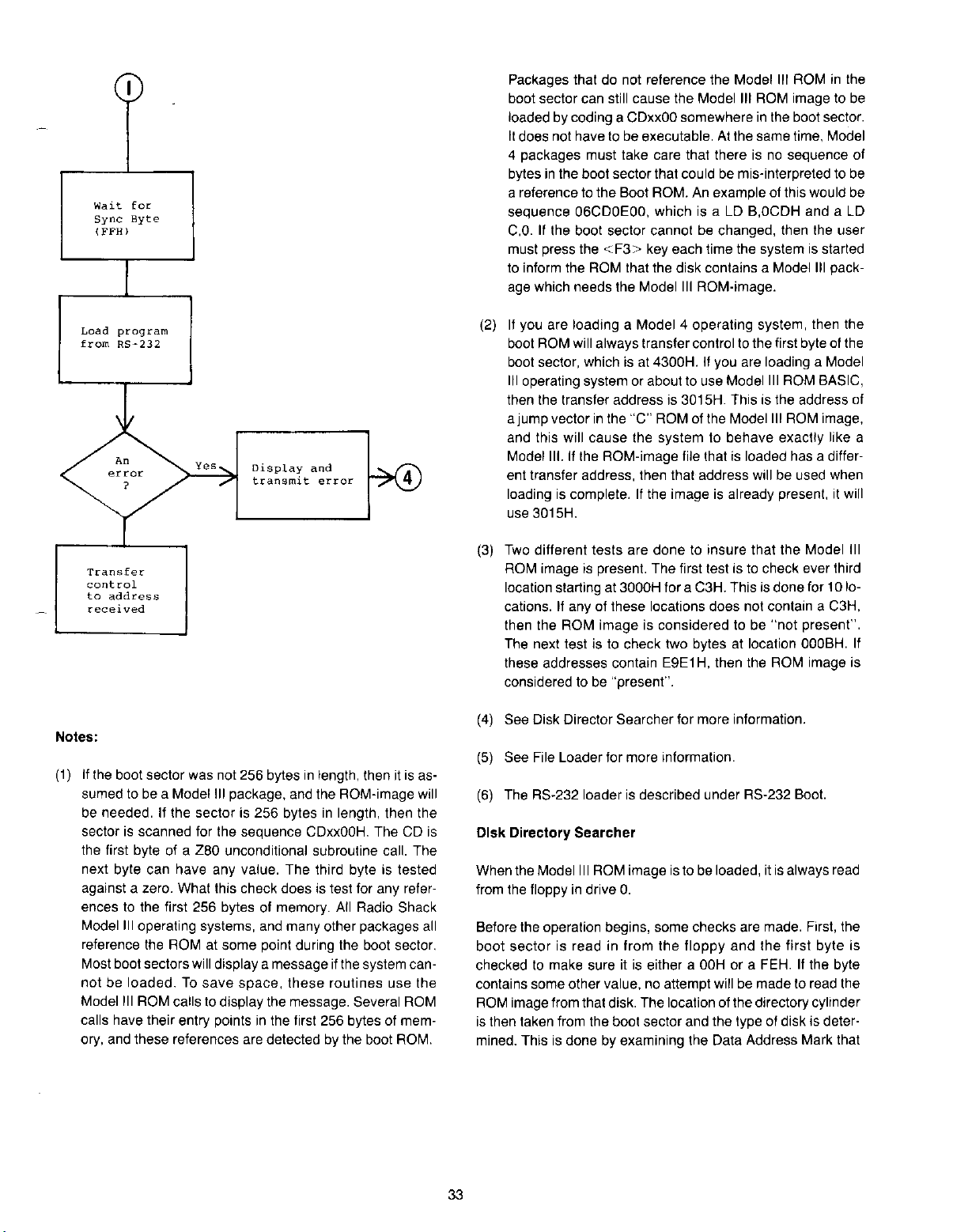

"Found Baud Rate x"

from

reset.

The

makingitcon-

connector

pin

20) and RTS

host

computer.

failures

ten

moretoar-

the

correct

receiver

0.1

second to

hard

at

pro-

with

then

At

re~

occur

baud

er-

is

displayedonthe

meaning:

A

~

B

~

C~110

~

D

34

50 baud

75

134.5

screen, where

~

150

E

~

300

F

~

600

G

~

1200

H

I

~

J

K

L

"x"isa

1800

~

2000

~

2400

~

3600

letter

fromAto

~

M

~

N

o

~

P

~

19200

P,

4800

7200

9600

Loading...

Loading...