Page 1

i

FROM QUANTUM CORPORATION

Quantum

®

DLTtape™Handbook

Your Complete Guide to Today’s

Hottest Storage Technology

Eighth Edition

Page 2

Notice

Editor

Peter McGowan

g•m marketing

communications

Associate Editor

Stephen Weekley

Quantum Corporation

Senior Wr iter

Hank Giles

g•m marketing

communications

Art Director

Christine Koch

Knockout Graphics

Illustrator

Steve Hussey

Copyright ©1997, 1998, 2000,2001 Quantum Corporation

QUANTUM CORPORATION

501 Sycamore Drive

Milpitas, CA 95035

1-800-624-5545

www.quantum.com orwww.DLTtape.com

Quantum and the Quantum logo are trademarks of Quantum Corporation, registered in the U.S.A.

and other countries. DLTtape, the DLTtape logo,Super DLTtape, and the Super DLTtape logo are

trademarks of Quantum Corporation. Products mentioned herein are for identification purposes

only and may be trademarks or registered trademarks of their respective companies.Quantum is not

responsible for typographical, editorial, or pictorial errors in this publication.Product specifications

and technical information are subject to change without notice.

ii

Page 3

Foreword

The world of data storage has changed a great deal since we published the first Quantum DLTtape

™

Handbook in 1997.In just this

short time, the role of storage has evolved dramatically.It has

become clear that effective storage strategies are fundamental to

the success of virtually any information technology strateg y,

whether it’s in re-energized smokestack industries or e-commerce.

Since the first Quantum DLTtape Handbook,we now have published a total of eight editions, plus two editions in Japanese and

one in Chinese.And, while the roles of storage and DLTtape technology have changed and evolved with incredible speed, the

objective of the handbook is stil l much the same as it was originally: to educate our various audiences by providing an in-depth look

at DLTtape system technology and a comprehensive overview of

DLTtape products and solutions. The book will also g ive you a

context for understanding how storage technology has evolved into

such an integral part of enterprise IT str ategy, and the role

DLTtape technology plays.

The most notable change in the content of this eig hth edition is

the inclusion of extensive information on the new Super DLTtape

™

technology,the next generation of DLTtape technology.Super

DLTtape technology delivers dramatic increases in DLTtape speed

and capacity,while continuing the DLTtape commitment to compatibility with previous generations of drives and media.

Incorporating a number of important technology innovations,

Super DLTtape technology promises to broaden the role of the

QUANTUM DLTtape HANDBOOK

iii

Page 4

DLTtape system as the dominant tape technology for backup,

recovery, archiving, vaulting, near on-line storage, and multimedia storage hierarchies.

Because Super DLTtape technology is the newest development in

DLTtape systems, we have included in this edition of the handbook

a great deal of new information specific to Super DLTtape technology.However,it is important to emphasize that, while Super DLTtape

technology includes a number of breakthrough innovations,it is

not a “new”technology : it is an extension of all the concepts that

have made the DLTtape systems so successful since the original

linear tape technology was introduced in 1985.So when we use the

term “DLTtape systems”or “DLTtape technology”throughout this

book, we refer to all DLTtape technology,including Super DLTtape

technology,and the entire DLTtape family of products,including

the newest Super DLTtape drives and media.

Welcome to the eighth edition of the Quantum DLTtape

Handbook,and to the exciting possibilities of a whole new

generation of Super DLTtape systems.

FOREWORD

iv

Page 5

Contents

Chapter

— Introduction

— 1. The Evolving Tape Storage Market

— 2.What is the DLTtape System?

— 3. History of DLTtap e Technology

— 4.Why Customers Want the DLTtape System

— 5. Reliability: The Heart of the DLTtape System

— 6. Demystifying Tape Drive Specs

— 7. DLTtape Media

— 8.Automation

— 9. Horizontal Applications

— 10.Vertical Market Applications

— 11. DLTtape System Technology Compared

— 12. Evaluating the Cost of a DLTtape Backup Solution

— 13. Platform Connectivity & Software Compatibility

— 14. Storage Management Software

— 15. Firmware

— 16. Using the DLTtape System

— 17. Super DLTtape: The Future of DLTtape Technology

— Appendix A: Super DLTtape System Products

and DLTtape System Products

— Glossary

— Index

Page

vii

1.1

2.1

3.1

4.1

5.1

6.1

7.1

8.1

9.1

10.1

11.1

12.1

13.1

14.1

15.1

16.1

17.1

A.1

G.1

I.1

QUANTUM DLTtape HANDBOOK v

Page 6

vi

Page 7

Introduction

This handbook will introduce you to one of the dominant forces in

mid-range storage technology – the DLTtape systems, including the

new Super DLTtape systems.These systems are the acknowledged

market-share leaders in mid-range tape backup and archiving, thanks

to their remarkable performance,reliabilit y,and storage capacity.

Convergence Emergence

Why has a seemingly mundane topic like backup and archiving

become such a hot subject in recent years? There are several

answers.A number of trends are converg ing to create a new and

seemingly limitless hunger for faster, higher capacity storage backup systems. These trends include:

•

The growth of Internet, Intranet, and e-commerce

applications, many of which require constant backup of ver y

large databases.

•

The popularity of storage-intensive applications like multi-

media, data warehousing, v ideo editing, medical imaging,

financial analysis, and engineering .

•

Centralized backup management of distributed,

networked systems.

•

Exponential increases in hard disk capacity and performance.

QUANTUM DLTtape HANDBOOK

vii

Page 8

•

A shrinking “window”for backup and archiving.

•

The emergence of enterprise level storage management

strategies, including Storage Area Networks.

In this handbook,we will show you why DLTtape and Super DLTtape

drives and media are the best storage solutions for these and many of

the other storage challenges you may face.We will also help you evaluate your DLTtape storage options and pick the solution that’s right

for you.

We’ve Got You Covered

To help you understand DLTtape technology and how it fits into

your IS backup picture,we’ve included chapters that cover everything from the history of DLTtape drives and media to a detailed

comparison of competitive backup solutions.Here’s a sample of

what we’ll cover:

•

What is the DLTtape system?

• What is Super DLTtape technology?

•

Why customers want DLTtape drives and media – the

DLTtape system.

•

Applications for the DLTtape system.

•

What makes the DLTtape system so reliable?

•

Why the DLTtape system is perfect for autoloaders,librar ies,

and Storage Area Networks (SANs).

•

What makes DLTtape cartridges special.

•

Platform connectivity considerations.

•

The br i g h t f ut ure o f Super DLTtape technology.

Welcome to the new world of storage management.Welcome to

the world of the DLTtape and Super DLTtape systems from

Quantum Corporation.

INTRODUCTION

viii

Page 9

The Evolving

Tape Storage Market

QUANTUM DLTtape HANDBOOK

1

1.1

Before we plunge into the story of the DLTtape system, we need

some context. Who’s buying DLTtape drives and media? And,more

importantly,WHY? In this chapter, we’ll walk you through some of

the market forces that are impacting the industry, including:

•

Trends in computing systems: moving away from centralized

computing, toward a client/server model.

•

Moving to centralized management of dist ributed systems.

•

Growth of mission critical, leading edge applications.

•

Dramatic advances in tape technology for backup.

Market Si ze

The market for tape drives is projected at $6 billion a year for the

next few years,with unit shipments holding steady at about 4 million per year, worldwide. Almost all of those 4 million units are going

to be used for backup.

But,while unit shipments will remain steady, the amount of data that

needs to be backed up is growing rapidly. For example, it is estimated

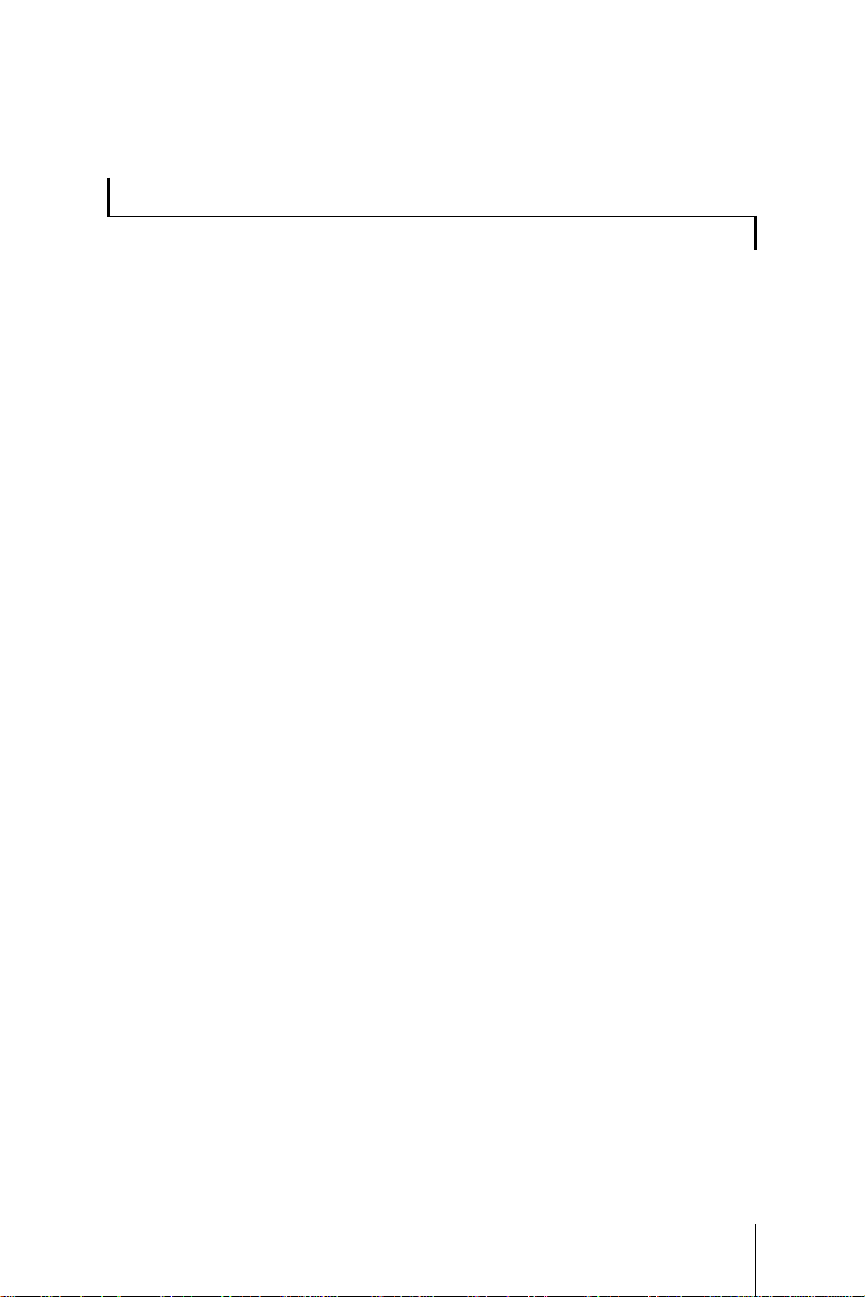

that in 1999 worldwide server capacity,one important category of data

that needs to be backed up,was less than 500 petabytes (Figure 1.1). By

2004,that figure will have multiplied to over 4,300 petabytes!

Page 10

THE EVOLVING TAPE STORAGE MARKET1.2

With the projected amount ofdata that needs to be backed up climbing at a rapid rate,and the projected growth in tape drive units shipped

staying relatively flat,each of those backup tape drive units must deliver more capacity than ever before.Analysts project that there may be

the potential for a melt-down if the backup technology does not keep

up with that sharply rising demand curve.The continual evolution of

DLTtape technology and the dramatic increase in capacity and performance delivered by Super DLTtape technology are a direct response to

this need.What factors are driving this rising demand for backup

capacity? Let’s start with computer systems trends.

From Mainframe to Client/Server

The deployment of client/server systems is accelerating.From 1994

to 1996,the percentage of organizations that said they were actually

using client/server systems grew from 25 to 44 percent.Today,

client/server is the dominant mainstream approach to enterprise

0

500

1,500

1,000

2,000

2,500

3,000

3,500

4,000

4,500

1999 2000 2001 2002 2003 2004

Centralized

Network

Centralized

Administration

Distributed

Workgroups

SOHO

Networks

Worldwide Server Capacity (in Petabytes)

Source: Strategic Research Corp., Network Demographics, 2000

Figure 1-1 Worldwide Server Capacity is one measure of data to be

backed up. The figure is climbing at a much steeper rate than the rate of

tape shipments. Backup capacity must increase to match increased storage

demands in this and other categories.

Page 11

QUANTUM DLTtape HANDBOOK 1.3

computing.For storage and backup,this means a shift away from the

high-end products used in mainframe environments (reel-to-reel

tape),and away from low-end,PC-oriented products (4mm DAT),

and toward the mid-range (8mm and half-inch DLTtape systems).

New Storage Strategies

New storage strategies are also driving the market for DLTtape technology.Two good examples are Storage Area Networks and Network

Attached Storage.A Storage Area Network (SAN) is a high-speed,

special-purpose local network that provides a large pool of storage

resources and makes it easily available to the enterprise network.

SANs are usually deployed to support applications that require large

amounts of storage, and to support large, enterprise-le vel networks.

Most SANs depend on large DLTtape-based libraries to back up disk

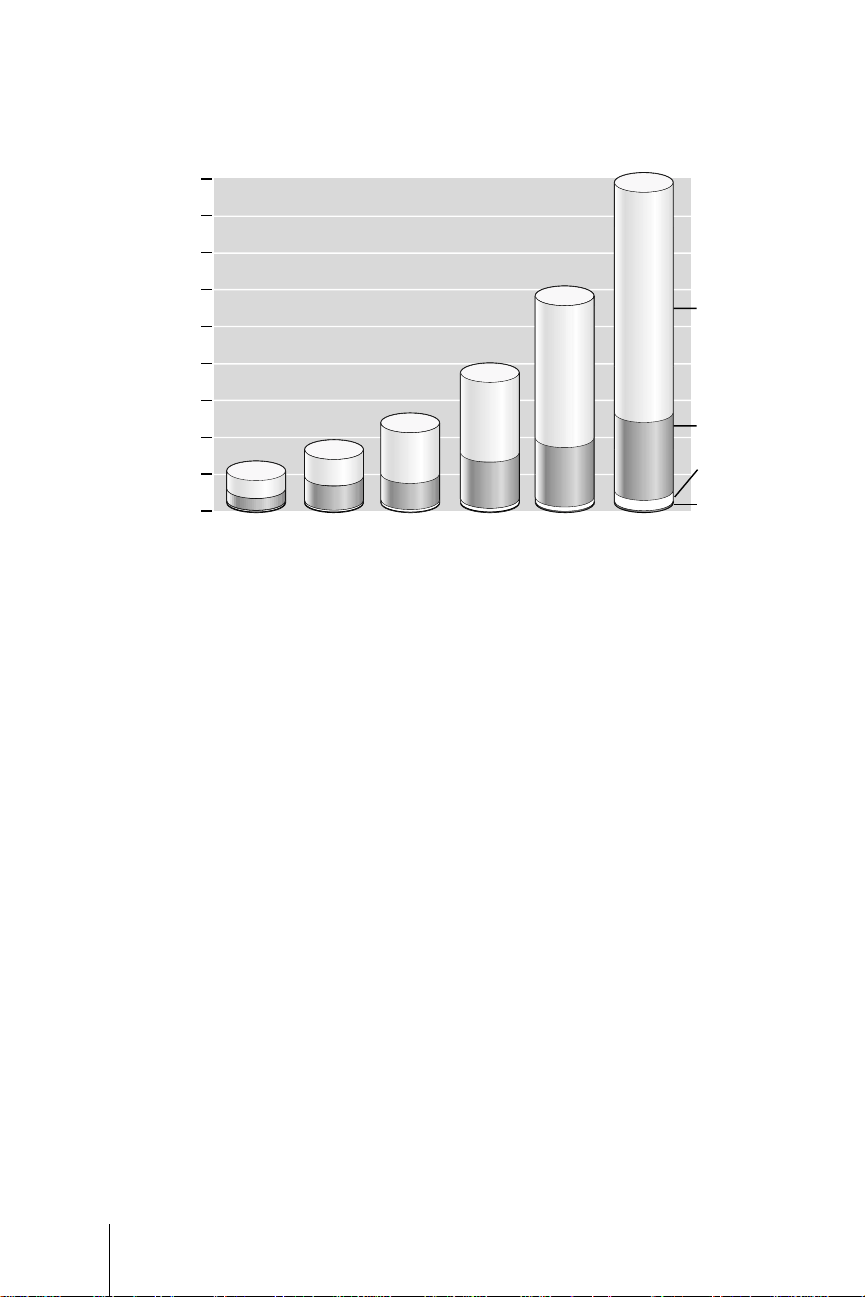

storage. SAN revenues are expected to grow from under $4 bil lion in

1999 to over $20 billion in 2004,according to IDC.(See Figure 1-2.)

Another indicator of the size of this market opportunity for DLTtape

0

20

16

12

8

4

1999 2000 2001 2002 2003 2004

Source: IDC December 2000

SAN

NAS

Worldwide SAN and NAS Revenues in $ Billions

Figure 1-2 SAN and NAS Disk Shipment Revenues will continue to grow

quickly as these storage concepts are implemented widely.

Page 12

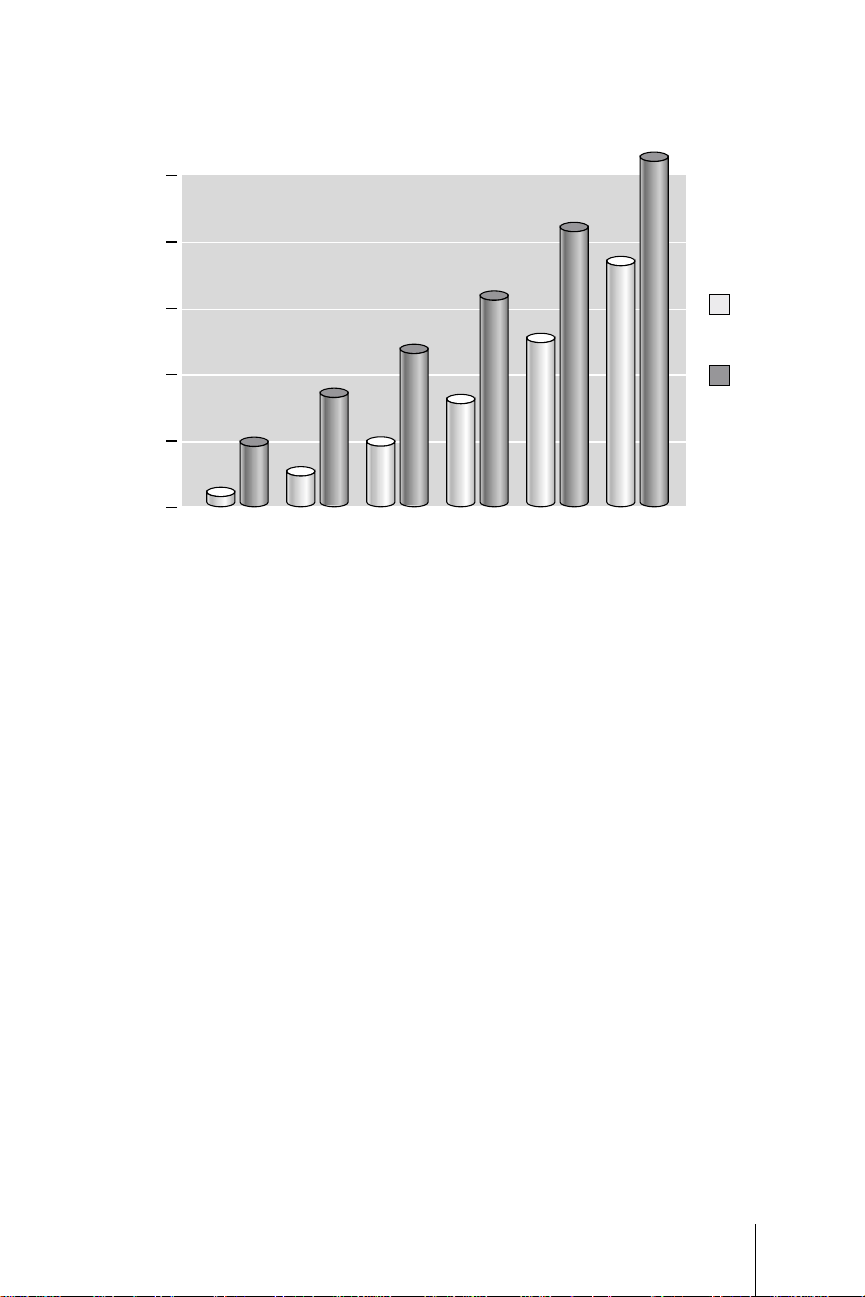

0

1997 1998

3,000

2,000

2,500

1,000

1,500

500

1999 2000 2001 2002 2003

Worldwide F ibre Channel Hub and Switch Rev enue ($M)

Source: IDC April 2000

Figure 1-3 Worldwide Fibre Channel Hub and Switch Revenues.

Storage Area Networks (SANs) incorporating Fibre Channel technology will

grow as the preferred enterprise storage strategy, as evidenced by the projected growth in Fibre Channel network hardware revenues. DLTtape technology

plays an important role in the consolidation of backup to these large storage

networks.

technology is the rapid growth in Fibre Channel hub and switch revenues.(See Figure 1-3.)

Network Attached Storage (NAS) is simply storage that is deployed

independently on a Local Area Network.NAS products feature a pluggable Ethernet connection for easy installation.Target market applications include file server,desktop,remote office installations,software

distribution, and emerging applications such as audio,video,and

Internet storage.DLTtape is a perfect complement to the growing

storage needs NAS solves.A user can easily grow their storage requirements and still back up the network through a DLTtape solution. IDC

projects that NAS revenues will grow from under $1 billion in 1999 to

nearly $15 billion in 2004.(See Figure 1-2.)

THE EVOLVING TAPE STORAGE MARKET1.4

Page 13

Centralized Management

The management of information resources has been evolving from

the totally centralized “glass house”systems of the 1970s and 1980s

(see Figure 1-4).In the late 1980s and into the 1990s,the client/

server model emerged. Computers were distributed, storage was

distributed, and the management of distr ibuted resources was itself

distributed. To some extent, the mainframe-or iented management

structure was weakened.

However, without centralized, professional management,decentralized

computing systems are in danger of reducing system reliability,data

integrity,and security.Now, at the beginning of the 21st century,the

trend is for information resources to contin ue to be distributed,but for

resource management – including storage management – to become

more centralized,under a professional management team, using highlevel,highly integrated management tools,and more and more

automation.

Centralized management of storage resources has a powerful impact

on backup systems,creating a demand for universal backup strate-

QUANTUM DLTtape HANDBOOK 1.5

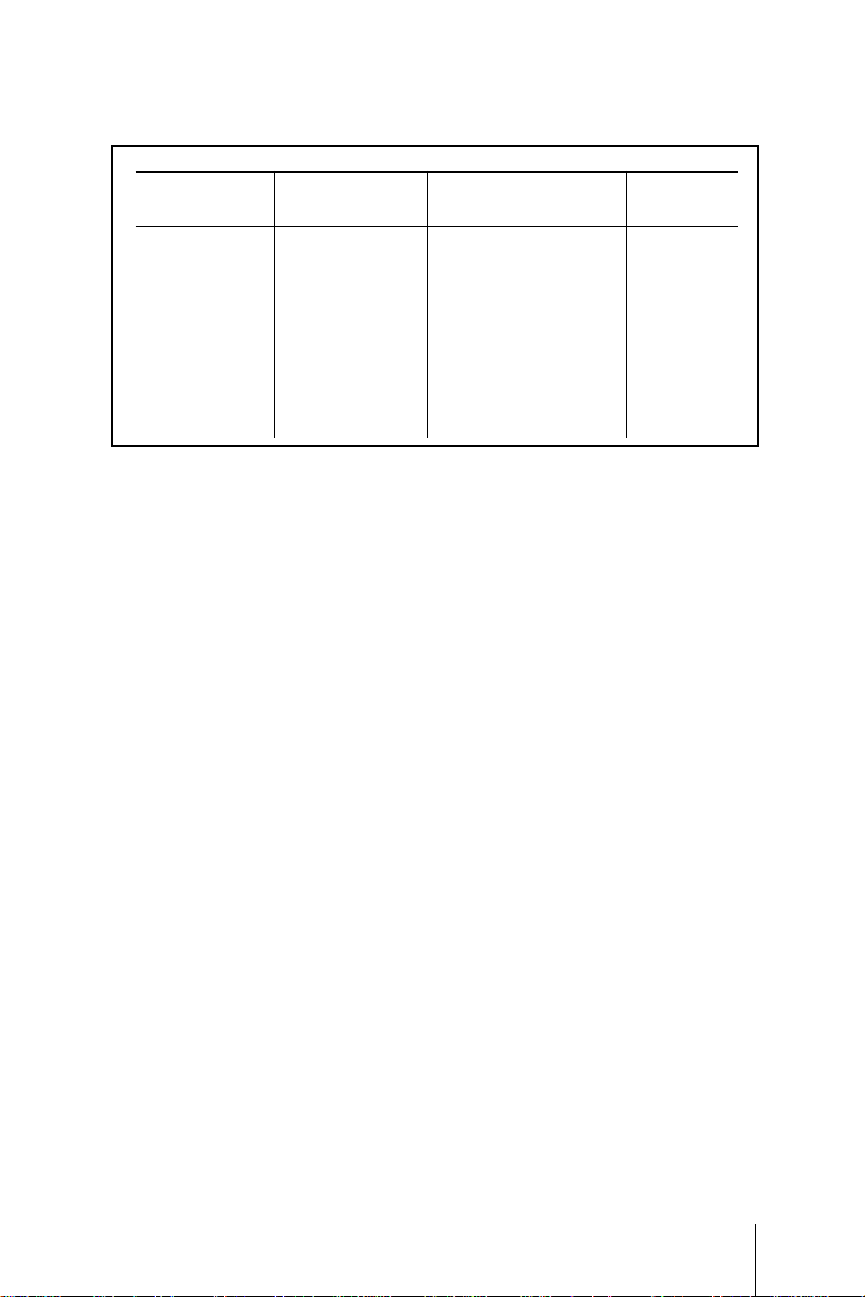

Figure 1-4 The Storage Management Evolution shows a transition to re-

centralized storage management and a continuation of distributed data resources.

Time

Regime

Early 1980s

Late 80s–90s

Late 90s

Early 2000s

Glass House

Client/Server

Professionally

Managed

Automated

Central

Distributed

Central

Central and

Distributed

Central

Distributed

Distributed

Central and

Distributed

System

Management

Location

of Data

Location of

Data Management

Page 14

gies. There is a greater demand for standard solutions, and robust,

highly reliable systems for mission critical applications. Large, g lobal

enterprises demand global backup and disaster recovery plans.

The system-level trends we’ve been talking about – the move to

client/server,the emergence of Storage Area Networks, and the

strong trend toward centralized management of distributed storage

resources – are increasing the demand for bigger,smarter tape

backup systems.And that’s where the DLTtape system fits.

Now let’s look at another set of trends that are having a major

impact on tape backup issues. Namely, trends in applications.

Mission Critical Applications

Yesterday’s mission-critical applications were back office tasks like

payroll,accounts receivable,and accounts payable.They were mission

critical because the business needed them to function.Today’s mission critical applications must run 7x24, and they are often very customer-oriented,highly visible, and strategic. E-commerce applications like on-line banking,ticketless airline reservations,or on-line

stock transactions are prime examples.Almost by definition, these

customer-interfacing applications are client/server applications, so

they have to run outside the protection of the old “glass-house”

mainframe environment.

This means that there is intense pressure to keep these applications

aggressively backed up, and within a shrinking window of time. If

the application is up on a 7x24 schedule, when can you do backups? Solutions to this problem include more frequent backups,

more servers with their own dedicated backup systems, and bigger,

faster systems to fit backup into the shrinking backup window.

Clearly, the introduction of new high perfor mance, hig h capacity

Super DLTtape systems has a major impact on backup capability.

THE EVOLVING TAPE STORAGE MARKET1.6

Page 15

Vertical Markets

Growth in specific vertical markets is pushing the demand for better

backup solutions. Internet/Intranet applications are growing at a

very fast rate. They are driving the sales of servers,and they are also

driving the sale of a large amount of storage capacity.An increase in

storage capacity always drives the need for more backup capacity.

Internet and Intranet applications, impose heavy backup demands

for several reasons.They run around the clock, so the backup window is always under pressure, they change constantly,they tend to

grow in size,and their content is increasingly graphical and therefore

storage intensive.Ver tical markets driving the demand for DLTtape

backup include:

• E-commerce.

• Internet/Intranet.

• Archiving.

• Disaster recovery.

• Data mining .

• Medical imaging.

• Graphic ar ts.

• CAE/CAD/CAM.

• Multimedia.

• Publishing.

• Data acquisition.

•Video-on-demand.

• Dig ital nonlinear video editing .

•Video distribution.

• Storage Ser v ice Providers (SSPs).

• Application Service Providers (ASPs).

In Chapter 10,we will go into more detail on the special backup

needs of various vertical applications.

QUANTUM DLTtape HANDBOOK 1.7

Page 16

Content is Everything

Another trend driving the DLTtape system market is the shift in

application content.When images, color,full motion video,and

audio are added to the content mix,storage requirements explode.

This growth is generating demand for high capacity storage, and

for backup.

Applications that use non-traditional content have other requirements beyond just size.For instance,these applications often

involve distribution of content (for example, programming for

video-on-demand applications). It is important to have durable,

reliable media that can stand up to the abuse of shipping, frequent

use, and storage in hostile environments.

Tape Technolog y Trends

Trends at the system level and in applications are driving changes

in the tape backup market.Another factor in the evolving tape

market is the changing tape technology itself.

One of the most important trends in the tape environment is the continuing proliferation of incompatible tape formats. New tape formats

are being introduced,not by newcomers and start ups, but by some of

the biggest names in the technology world.A review of available tape

technologies would include 4mm DAT,8mm,quarter-inch (QIC),and

half-inch,including the DLTtape system.There have always been

options available,and new options keep coming. There are quarter

inch cartridge (QIC) drives that use quarter-inch tape,and there is

quarter-inch tape that is actually .315 inches wide.There are three different types of 4mm DAT tape: DDS-2, DDS-3, and DDS-4.

Fortunately, the latest and the highest capacity DDS-4 tapes are backward compatible with the earlier versions.That isn’t always true as

THE EVOLVING TAPE STORAGE MARKET1.8

Page 17

new technologies come out.For example, Sony’s 8mm tape (AIT) and

Ecrix’s VXA are not compatible with other 8mm tapes on the market.

It appears that there are more formats available than the market

can possibly use. To a certain extent, the formats sor t themselves

out naturally.QIC and 4mm products are designed for low end

applications, primarily for PC and small network backup, while

8mm and DLTtape system half-inch products are flourishing in the

mid- and high-end ranges.

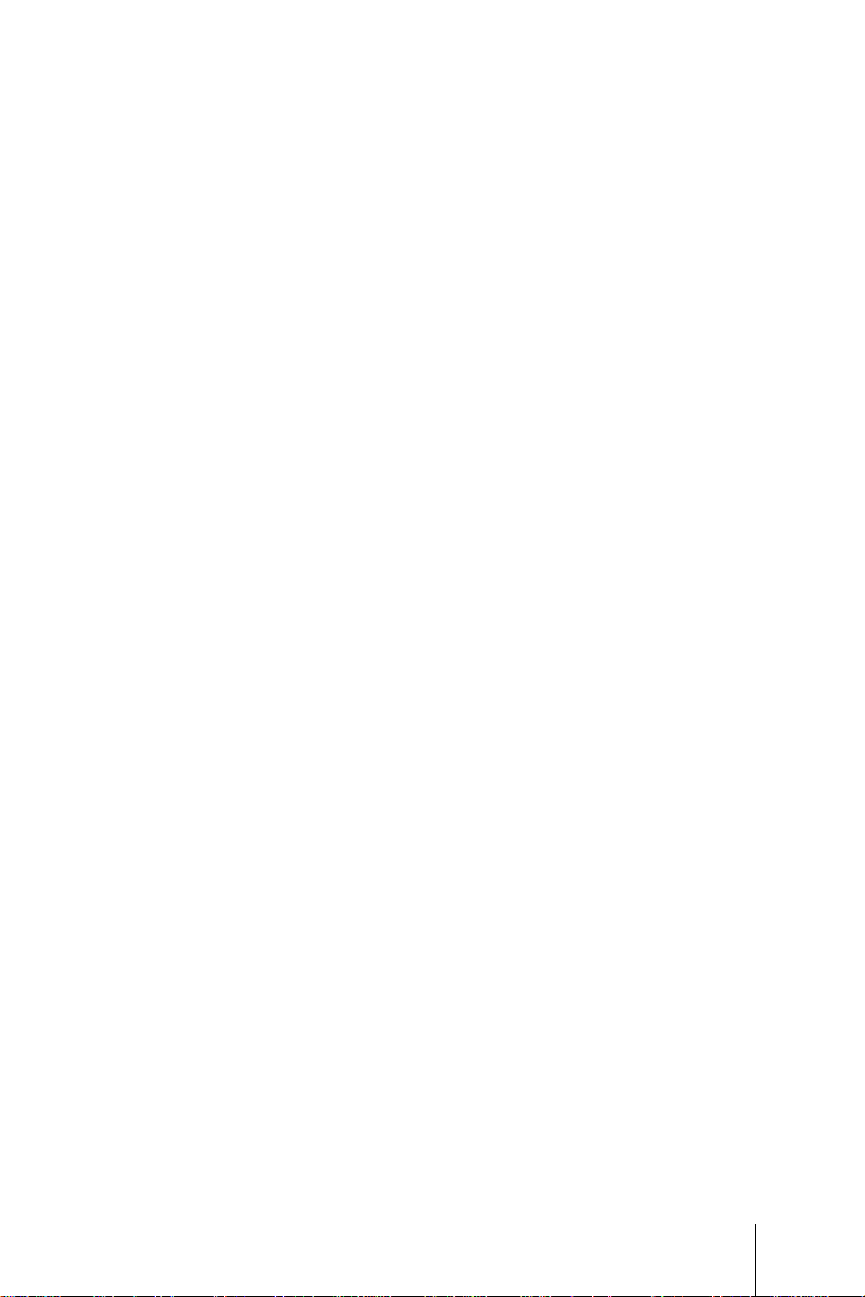

Figure 1-5 DLTtape System Product Family includes the DLT 4000 drive,

the DLT 8000 drive, the DLT1 drive and the SDLT 220 drive, as well as the DLTtape III,

DLTtape IIIXT, DLTtape IV, and Super DLTtape I cartridges. DLTtape drives are available in desktop and system-installable units.

QUANTUM DLTtape HANDBOOK 1.9

DLT 4000

drive

DLT 8000

drive

SDLT 220

drive

DLT1

drive

DLTtape IV

DLTtape III

DLTtape IIIXT

Super DLTtape I

Page 18

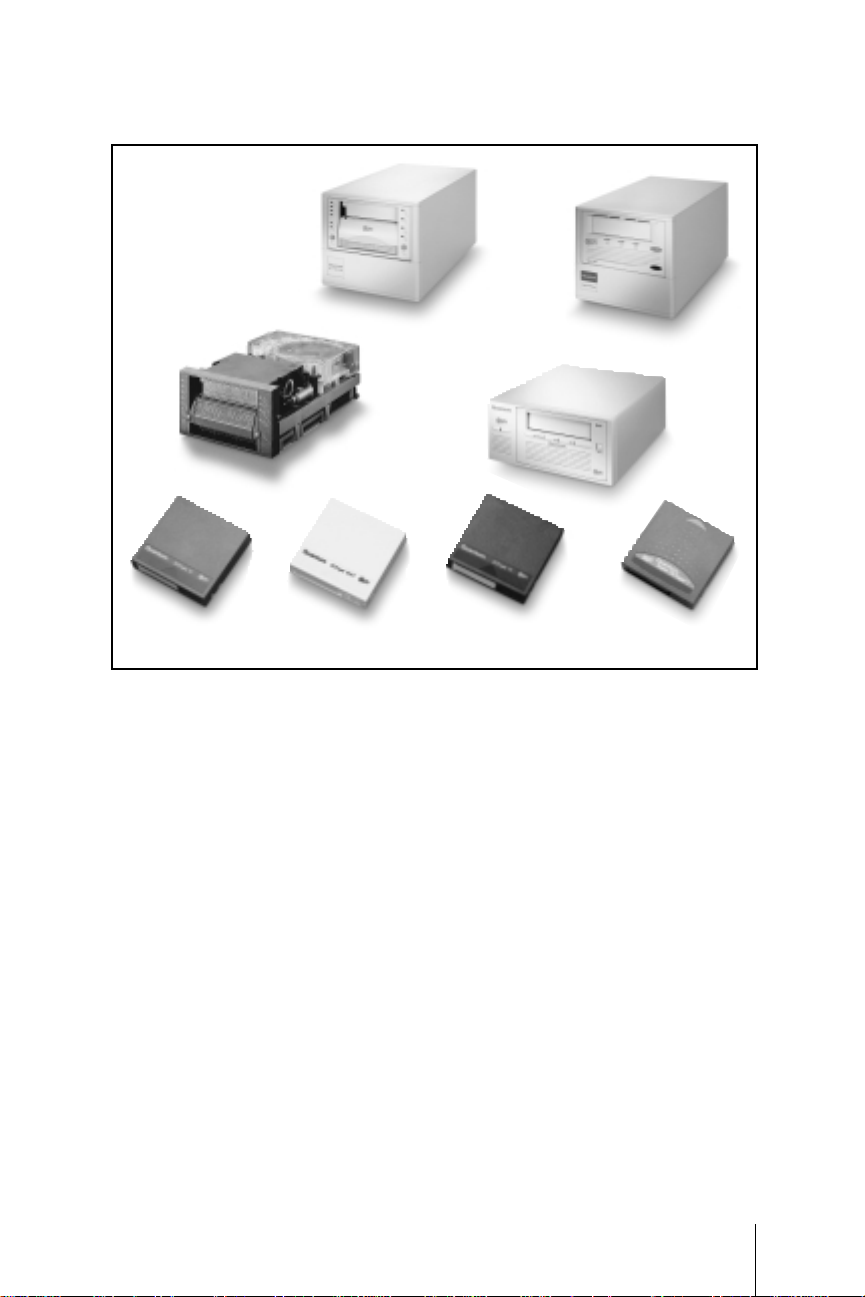

Capacity

(GB, native)

Data Rate

(MB/s, native)

Bit Density

(Kbpi)

Track Density

(tpi)

Media Type

Media Length

Recording

Channels

Hardware Data

Compression

Interface

20

1.5

82.5

256

MP-2

1,800‘

2

Yes

SCSI-2/F

SE/HVD

DLT

4000

40

6.0

98.0

416

MP-2

1,800‘

4

Yes

SCSI-2/FW

LVD/HVD

DLT

8000

35

5.0

86.0

416

MP-2

1,800‘

4

Yes

SCSI-2/FW

LVD/HVD

DLT

7000

40

3.0

123.0

336

MP-2

1,800‘

2

Yes

SCSI-2/FW

LVD

DLT1

110

11.0

131.0

896

AMP

1,800‘

8

Yes

SCSI-2/FW

LVD/HVD

SDLT

220

Is there room for more new tape technologies? It seems unlikely. No

matter how well designed and well engineered a new tape technology

might be, it will require a significant new value proposition in order to

gain a foothold in the market.A new format would have to offer far

greater capacity or two to three times the speed of Quantum’s

DLTtape system in order to have a big impact.In reality,the new technologies challenge DLTtape technology in some areas, but not in all.

DLTtape technology also has a huge amount of “head room”in terms

of scalability and an extremely well defined technology road map.So

even if a new technology offers a short-term performance benefit

today, in all likelihood that advantage will disappear as the DLTtape

system continues to evolve.The new generation of DLTtape systems,

Figure 1-6 DLTtape Drive Comparison Chart shows some of the important speci-

fications for DLTtape systems, including the industry-leading Super DLTtape system.

THE EVOLVING TAPE STORAGE MARKET1.10

Page 19

the Super DLTtape systems,leapfrog current and proposed competitive technologies,with first generation Super DLTtape products offering transfer rates of 11MB/s and capacity of 110GB,advancing to at

least one terabyte (uncompressed) over multiple generations (see

Chapter 17 for a product roadmap).

The biggest barrier to adoption of new tape formats is that users are

very reluctant to change backup technologies unless the benefits are

overwhelming and compelling.The pain involved in converting

archive tapes,for example, seems to be so acute that most people

don’t want to try it. So any new technology that is not backward/forward compatible can face an uphill battle to be widely accepted.

Today, DLTtape technology has a huge installed base,with over 1.5

million drives and over 55 million media cartridges shipped to customers.These facts,combined with a clear technology growth path

and a proven commitment to generation-to-generation compatibility,add up to an island of stability in a world of changing technology.

Range of Products

Another trend in the tape environment is user demand for a range

of compatible products that will address different performance,

functionality,and pr ice requirements. Users want a single solution

that works at many levels,not a different solution for every situation. Today,the DLTtap e system offers a very broad range of choices, ranging from stand-alone drives, to single-drive, multi-car tridge

autoloaders, to very large, enterprise-class libr aries w ith multiple

drives,multiple ports, and hundreds of cart ridges, all sharing compatible media, drives, and storage management software.

Ease of Use

Customers also want backup systems that are easier to use. In

response,the providers of backup solutions are starting to offer

bundled hardware/software solutions,w hich should lead to a

QUANTUM DLTtape HANDBOOK 1.11

Page 20

happier “out of the box”experience for users. There is also a trend

toward providing more user-friendly graphical displays that show

the user exactly what’s going on w ith backup, where the process

stands at the moment, and what and where a hangup is occurring.

Application Diversity

Over time,the range of applications for tape is diversifying, and

that trend will probably continue.Tape, especial ly the DLTtap e

system,is not just about backup anymore.Tape applications also

include archiving, disaster recovery, hierarchical storage management, real-time backup,distribution (especially distribution of

video programs and graphics files), near on-line storage,and a host

of others.As these applications mature and become better defined,

you may see the emergence of different products to fit different sets

THE EVOLVING TAPE STORAGE MARKET1.12

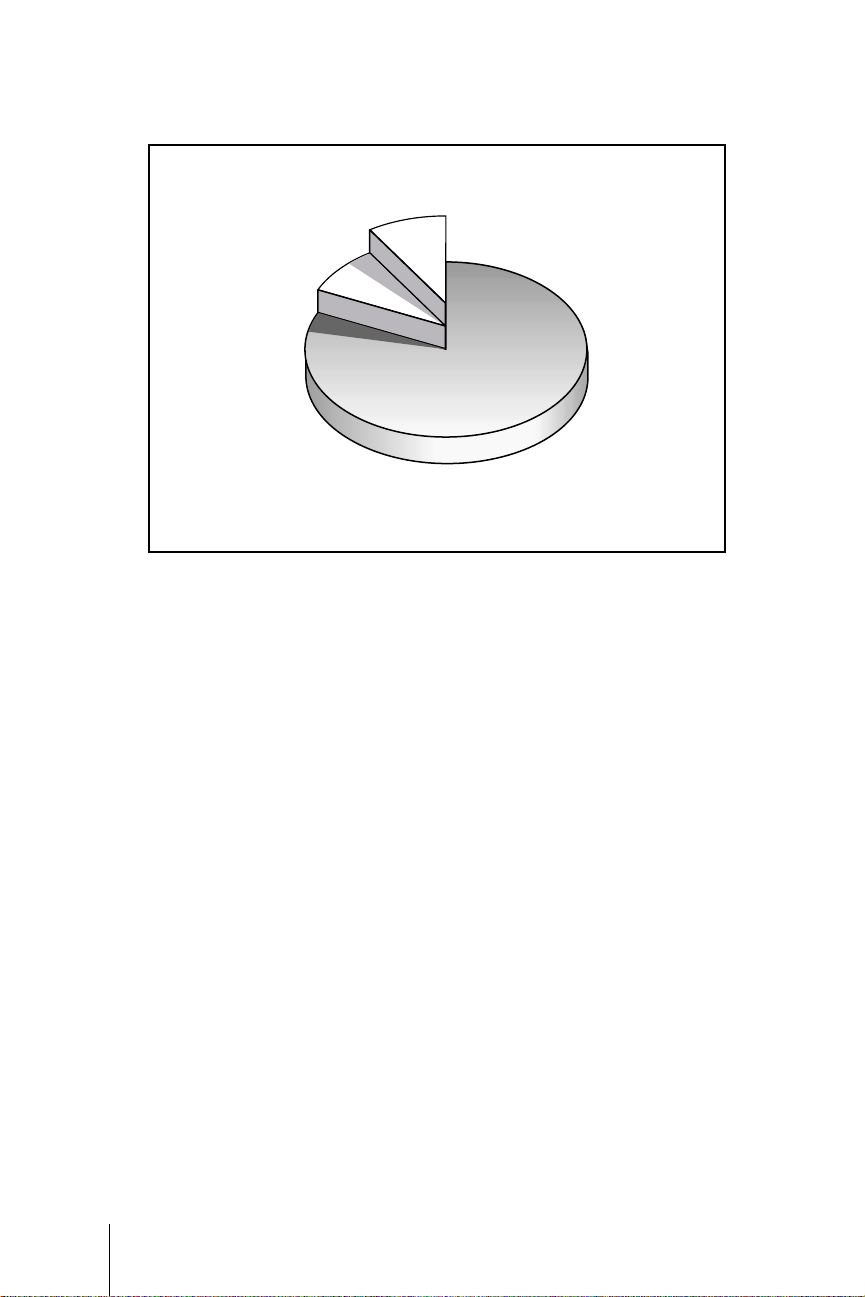

Worldwide Re venue Market Share, 2000

Source: Dataquest, Preliminary Mar ch 2001

Exabyte 11

%

Sony 11

%

Quantum 78

%

Figure 1-7 The DLTtape System Is the Overwhelming Choice

among high-performance tape systems.

Page 21

of needs. For example, we may see the emergence of a distinct class

of “desktop” DLTtape libr aries aimed at v ideo and g raphic ar ts

applications, while a class of mid-range to very large librar ies may

be targeted for Storage Area Network (SAN) applications.

The Last Word

In any discussion of the mar ket for DLTtape technology,the

bottom line has to be market share (see Figure 1-7).In 2000, the

total number of DLTtape drives in use g lobally was about ten times

what it was only four years earlier, and DLTtape dominates its

market space,with a market share of nearly 80%.

Next,we’ll look at what makes the DLTtape system uniquely

superior to other drive technolog ies.

QUANTUM DLTtape HANDBOOK 1.13

Page 22

What Is the

DLTtapeSystem?

QUANTUM DLTtape HANDBOOK

2

2.1

In later chapters we will cover a great deal of technical information

about exactly how DLTtape system technology works. In this chapter

we focus on what it is about the DLTtape and Super DLTtape systems that makes them unique.When you examine the details,there

are dozens of differences between the DLTtape system and other

tape systems. In this chapter we stick to the major points.Some are

obvious, and some are invisible, buried inside the product.

Speed, Capacity,Reliability

From a performance point of v iew, the characteristics that distinguish the DLTtape system from other tape storage technologies are

speed, capacity,and reliability.When compared to other technologies (see Chapter 11 for a detailed analysis), current DLTtape and

Super DLTtape drives offer very fast transfer rates (11MB/s native),

DLTtape cartridges store large amounts of data (110GB on a sing le

Super DLTtape I cartridge), and DLTtape drives can run longer,

under more demanding duty cycles,than any competitive technologies. Or,as one DLTtape sytem user put it,“You take the specs

for the 8mm solutions we used previously and multiply by about

4x, and that gives you the DLTtape technology spec.”

Page 23

WHAT IS THE DLTtape SYSTEM?2.2

Half-Inch Tape

The DLTtape system uses half-inch wide tape. That is the

widest tape available. The half-inch format was orig inally used in

mainframe products and was adopted by Digital Equipment

Corporation when they designed the ancestors of the DLTtape

system.What is important about the half-inch format is very

straightforward – it’s bigger than the other widely used technologies, such as quarter-inch, 4mm, and 8mm tape. Half-inch tape is

60 percent wider than 8mm tape. Therefore, you can put more

information on half-inch tape than you can on smaller-format tape.

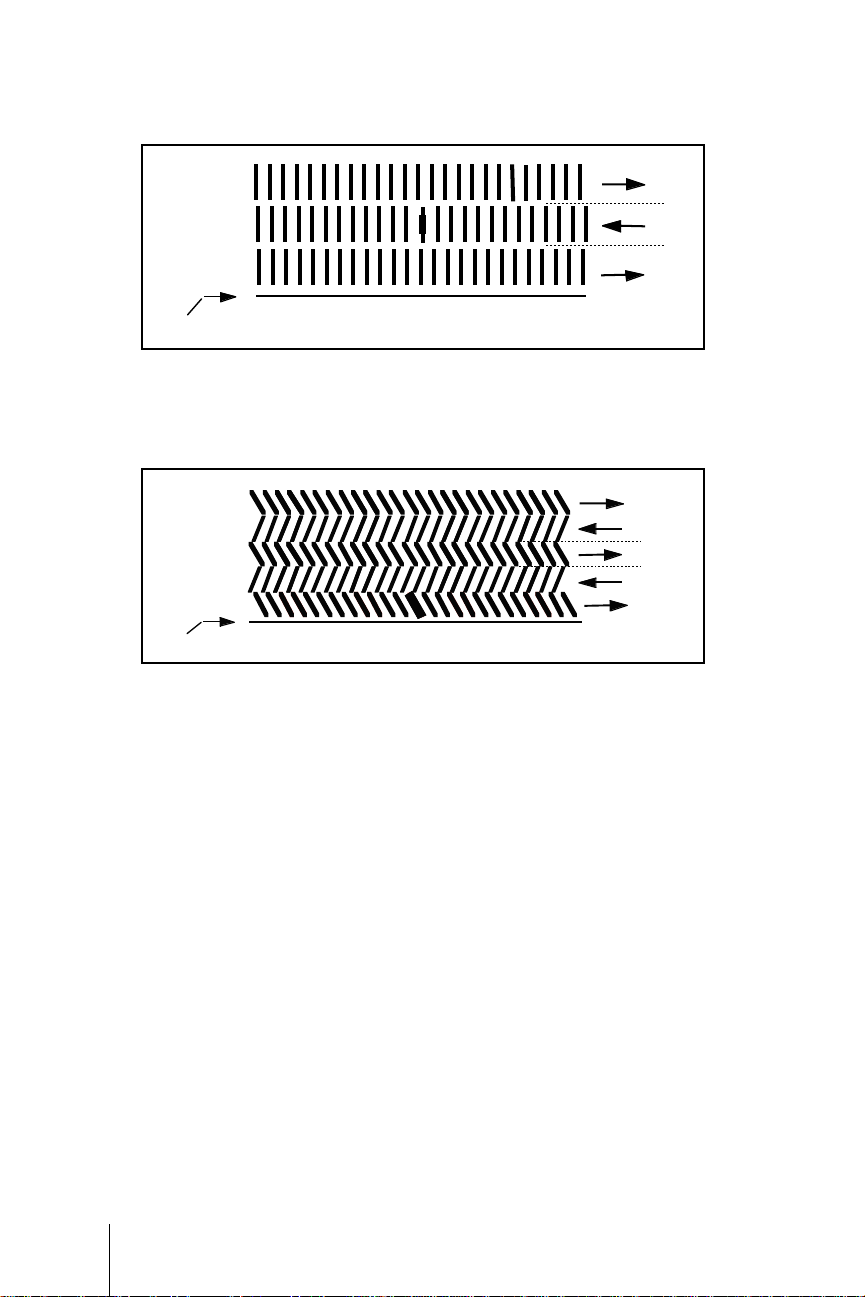

Linear Recording,Versus Helical Scan

DLTtape drives read and write data in a linear pattern on the tape

(see Figure 2-2).That is, each data track goes the entire length of

the tape (about 1,800 feet for DLTtape IV and Super DLTtape I

media, for example). When data is being recorded,the first set of

tracks is recorded on the whole length of the tape. When the end

Cartridge

Head

Take-up reel

Head guide

assembly

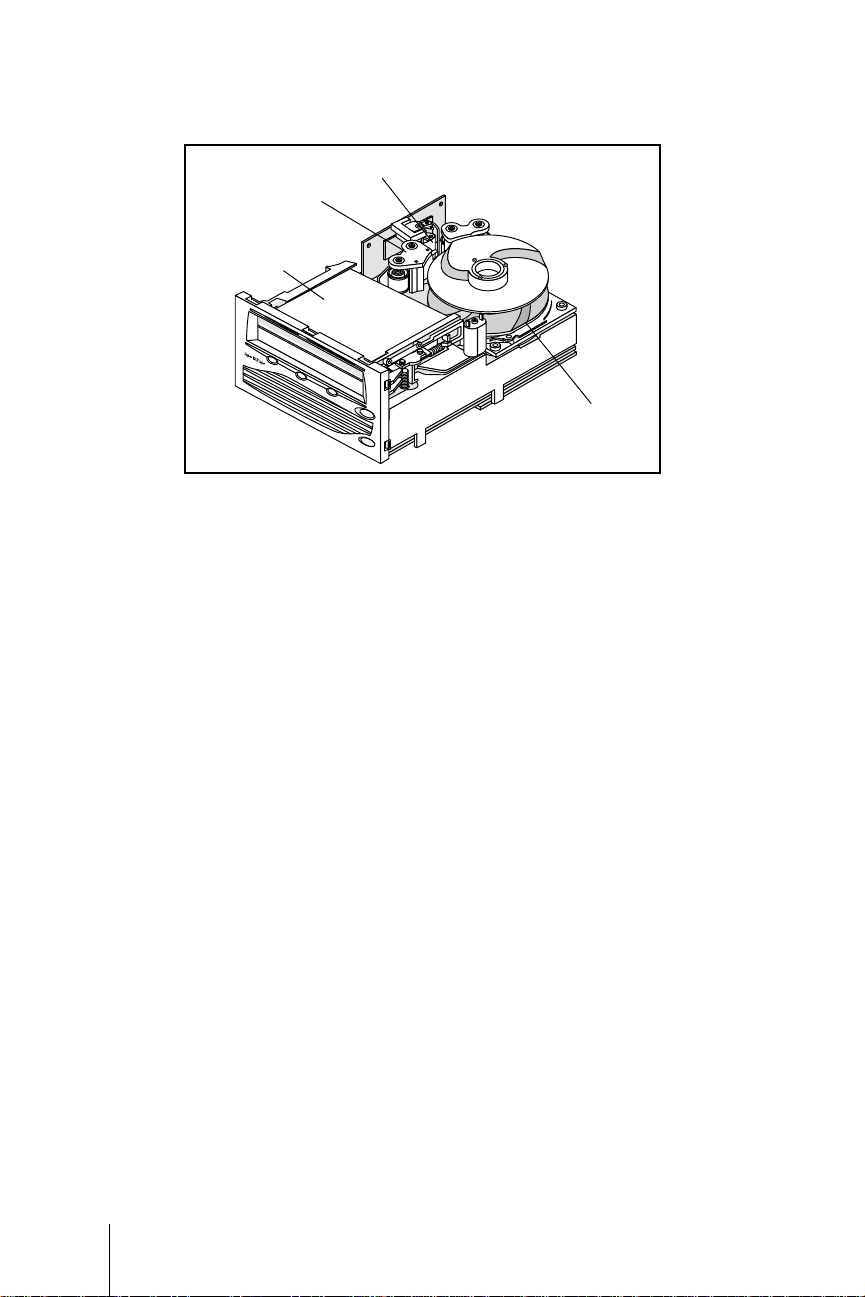

Figure 2-1 Super DLTtape Drive delivers industry-leading

capacity, reliability, and data transfer rate in a 5.25" form factor.

Page 24

QUANTUM DLTtape HANDBOOK 2.3

of the tape is reached, the heads are repositioned to record a new

set of tracks, and the tape is again recorded on its whole length,

this time in the opposite direction.That process continues,back

and forth, until the tape is full. Current DLTtape drives record

either 128 tracks (DLT 4000 drives), 168 tracks (DLT1 dr ives), 208

tracks (DLT 7000 and DLT 8000 drives), or 448 tracks (Super

DLTtape drives) on half-inch tape.

By contrast, helical scan systems record data in diagonal stripes

across the tape. This diagonal pattern allows data tracks to be overlapped for very high data density.One of the drawbacks of such

high density is the increasing difficulty it introduces in error detection and correction.Even a very small defect on a helical-scan tape

will probably corrupt the data, because such a large amount of

data is squeezed into a very small linear space.With DLTtape

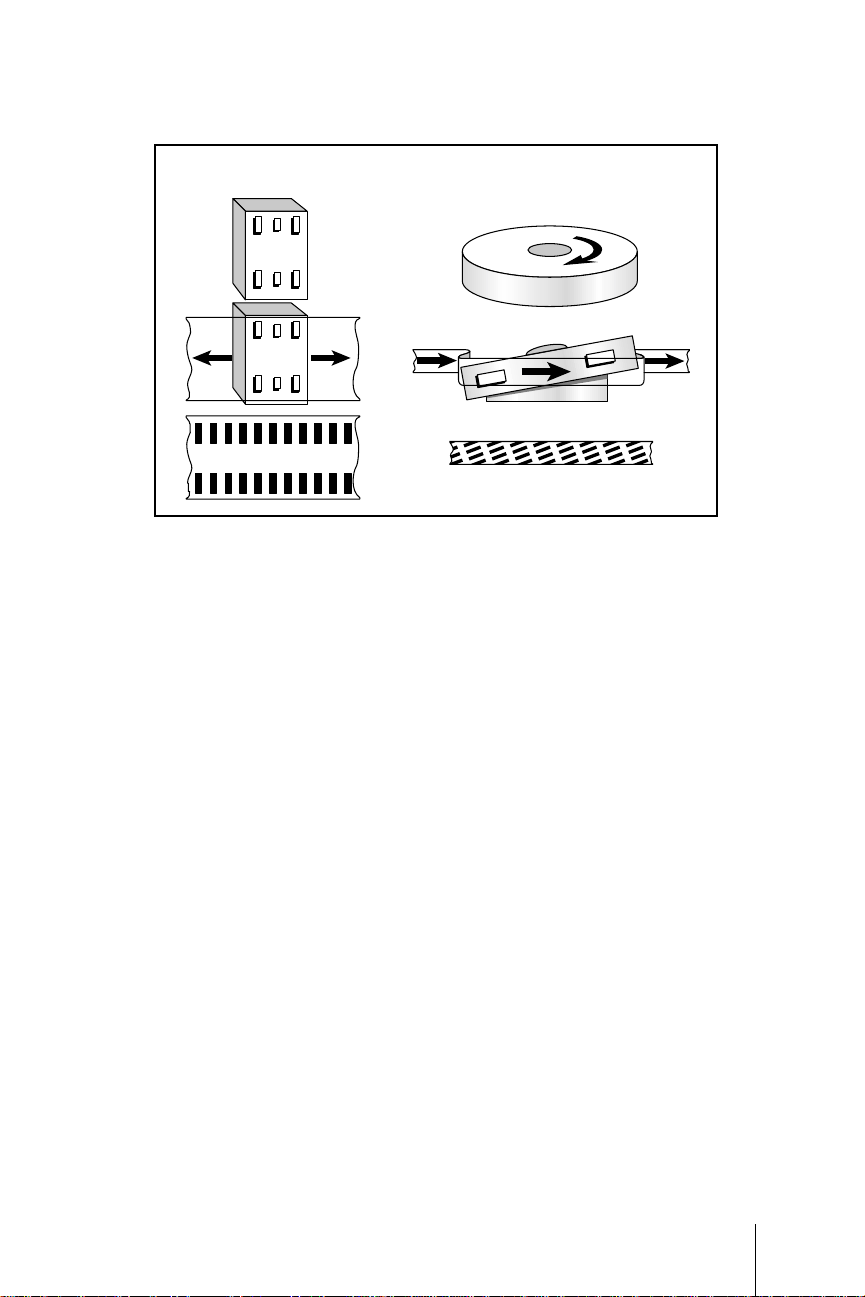

Figure 2-2 The DLTtape System’s Linear Serpentine Recording

pattern writes data along tracks from one end of the DLTtape cartridge to

the other. Helical scan systems use read/write heads on a rotating drum to

record data in angled stripes across the tape.

Helical scan recordingDLTtape drive recording

Page 25

media, however, a defect on the tape – say a scratch – could be as

long as an inch without causing an unrecoverable error. That’s

because the parallel channel architecture used in DLTtape drives

enables the system to automatically rewrite bad blocks to parallel

channels.

Maintaining Compatibility

Figure 2-3 shows the linear-serpentine recording pattern used in

DLTtape drives through the DLT 4000 model. The vertically-or iented pattern requires guard bands between tracks to prevent crosstrack interference.In the DLT 7000 and DLT 8000 drives (see Figure

2-4), data density was increased by angling the data pattern on

WHAT IS THE DLTtape SYSTEM?2.4

3mils

Track 0

Track 1

Track 2

Bottom edge of tape

Tape Direction

Figure 2-3 DLT 4000 Drive writes data on two channels simultaneously

in linear tracks that run the length of the tape. The system has a capacity of

20GB native and 40GB compressed.

1.75mils

Bottom Edge of Tape

Track 3

Track 2

Track 1

Track 0

Track 4

Tape Direction

Figure 2-4 DLT 7000 and DLT 8000 Drives’ Symmetric Phase

Recording

™

writes data in an angled pattern, allowing higher data

density, with per cartridge capacity of 40GB native and 80GB compressed.

Page 26

QUANTUM DLTtape HANDBOOK 2.5

Head Motion

Write Heads Write Heads

Read Heads

Figure 2-6 DLT 7000 and DLT 8000 Read/Write Head features 4

channels for a data transfer rate of up to 6MB/s (native). Center row of read

elements provides read-after-write data accuracy.

Figure 2-7 Super DLTtape Read/Write Head features 8 channels.

Very small Magneto-Resistive Cluster (MRC) Heads yield data transfer rates

as high as 11MB/s (native).

Head Motion

Write Heads Write Heads

Read Heads

Figure 2-5 DLT 4000 Read/Write Head writes data with the tape

running either forward or backward, and performs a read-after-write in

either direction to ensure accuracy.

Page 27

WHAT IS THE DLTtape SYSTEM?2.6

adjacent tracks. This data recording technique is called Symmetric

Phase Recording™(SPR). SPR’s her r ingbone pattern eliminates the

need for guard bands and thus allows greater track density.

Figures 2-5 and 2-6 show the arrangement of read/write elements on

the two-channel DLT 4000 heads and the four-channel DLT 7000 and

DLT 8000 heads.When reading DLTtape cartridges recorded on earlier

models,the DLT 7000 and DLT 8000 read/write heads automatically

shift to a vertical orientation.This feature provides backward compatibility and protects the end user’s investment in the DLTtape system.

Figure 2-7 shows the read-write head assembly for the Super DLTtape

drive.Super DLTtape drives incorporate newly designed MagnetoResistive Cluster (MRC) heads. This design features clusters of very

small,cost-effective magneto resistive tape heads,densely packed in a

small area on the head.MRC heads deliver higher data transfer rates

and greater data density than traditional heads of similar size.They are

also less susceptible to negative effects due t o environmental (temperature and humidity) conditions.

Simpler Tape Path

The design of the head guide assembly (HGA) is at the heart of what

makes DLTtape technology superior (see Figure 2-8).More than any

other characteristic,it is what makes a DLTtape drive a DLTtape drive.

It is a patented design,and it is one of the keys to the success of the

DLTtape system.

The head guide assembly positions the tape in front of the selfcalibrating read/write heads. The DLTtape system HGA is different

from competing technologies.On 4mm and 8mm helical scan systems (see Figure 2-12),the head guide systems are designed to

move.These systems must reach out,hook the tape, wrap it

around the rotating read/write drum,hold it in position, and then

move the tape back into its cassette.(See Figure 2-12.)

Page 28

QUANTUM DLTtape HANDBOOK 2.7

Drive

Leader

Head

Take-up

Reel

Tach

Assembly

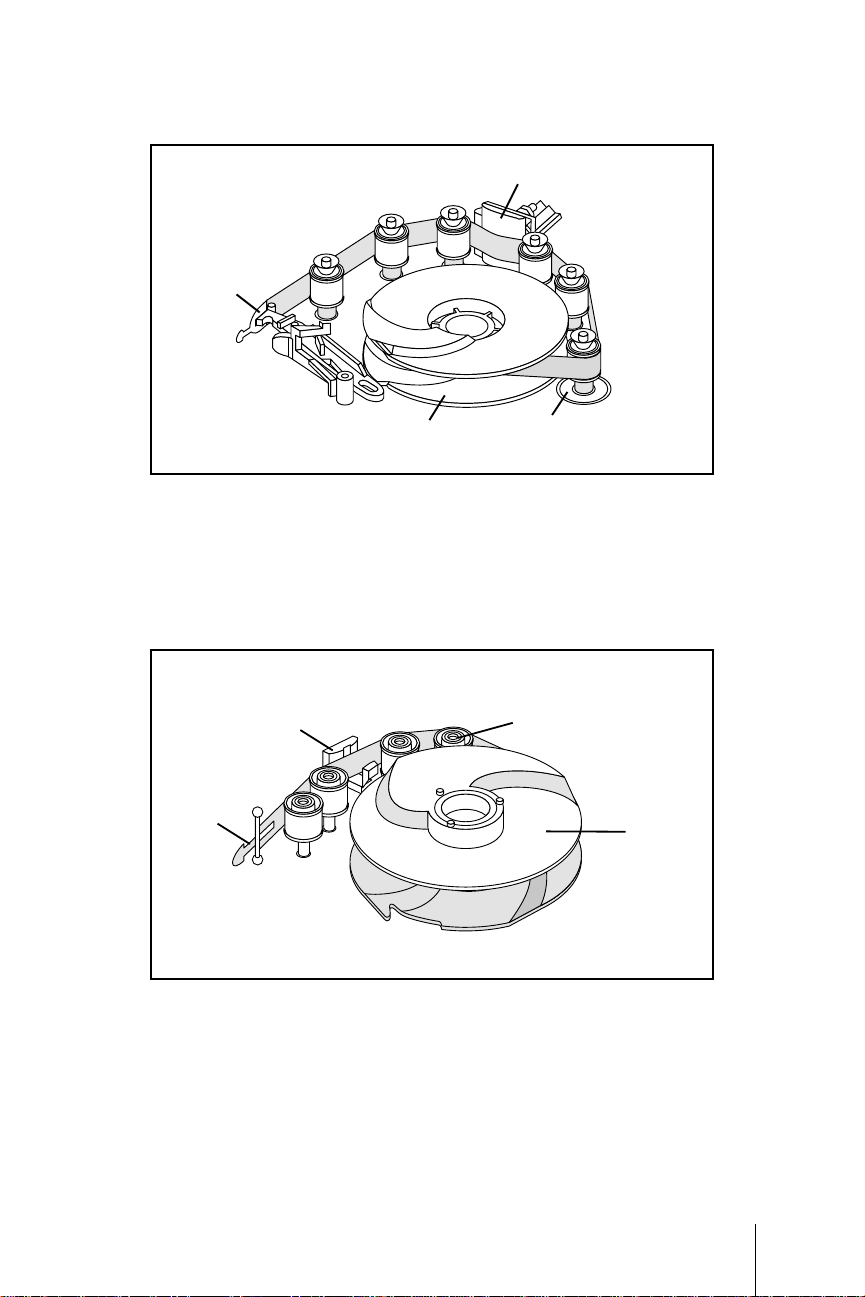

Figure 2-8 The Patented DLTtape Head Guide Assembly, first

incorporated in the TF85 drive, is one of the keys to DLTtape reliability.

Six precision rollers provide a gentle tape path for long tape life.

Take-up

Reel

Head Guide Rollers

Head

Drive

Leader

Figure 2-9 The Super DLTtape Head Guide Assembly is a refined

version of the DLTtape Head Guide Assembly. It incorporates only four

rollers, further reducing contact and tape wear.

Page 29

WHAT IS THE DLTtape SYSTEM?2.8

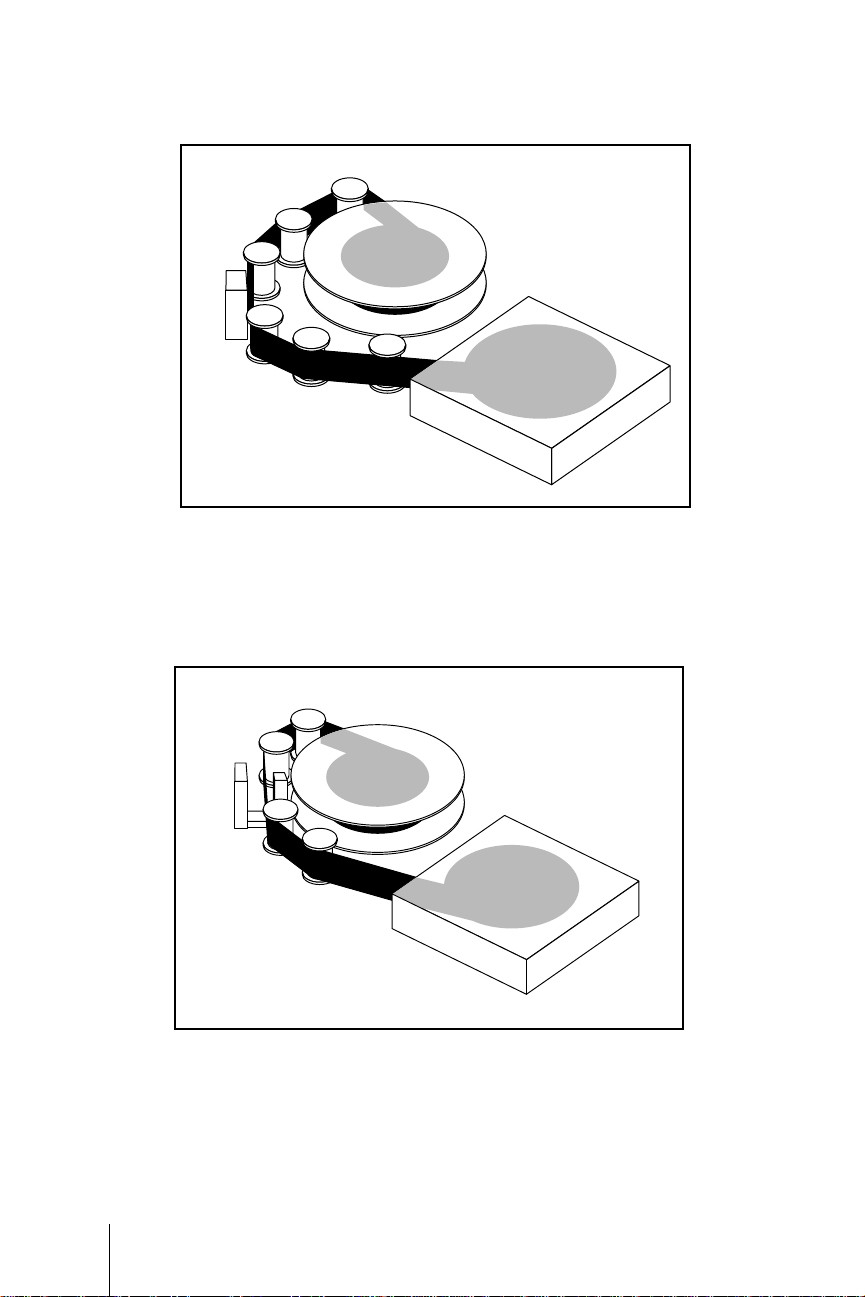

Figure 2-11 Super DLTtape System Tape Path is even sim-

pler than that of the DLTtape drive, requiring only four precision

rollers to guide the tape.

Figure 2-10 DLTtape System Tape Path Is Key reason for

the industry-leading reliability, long life, and accuracy of DLTtape

technology. Six precision rollers guide tape to internal take-up reel.

Page 30

QUANTUM DLTtape HANDBOOK 2.9

Figure 2-12 Helical Scan Tape System must pull tape out of

the cartridge and around a spinning read/write head. Acute wrap

angles and recording-side contact reduce tape life.

By contrast,the DLTtape head guide assembly is entirely different. It

remains stationary.It consists of a series of six precision rollers.

Instead of grabbing the tape in the middle and pulling it into place,

as with helical scan systems, the DLTtape guide system links a leader

strip on the end of the tape and pulls it out of the car t ridge, guides it

around the head guide assembly in a smooth arc,and gently wraps it

around the take-up reel in the drive.The rollers guide, but do not

pull the tape. The wr ap ang les around the guide rollers are gentle.

Contact between tape and guide is minimized.The recorded side of

the tape never touches the guides,minimizing tape wear.The head

guide assembly in the Super DLTtape drives is a refined design that

incorporates only four rollers,reducing even further the amount of

contact with the tape.

Page 31

WHAT IS THE DLTtape SYSTEM?2.10

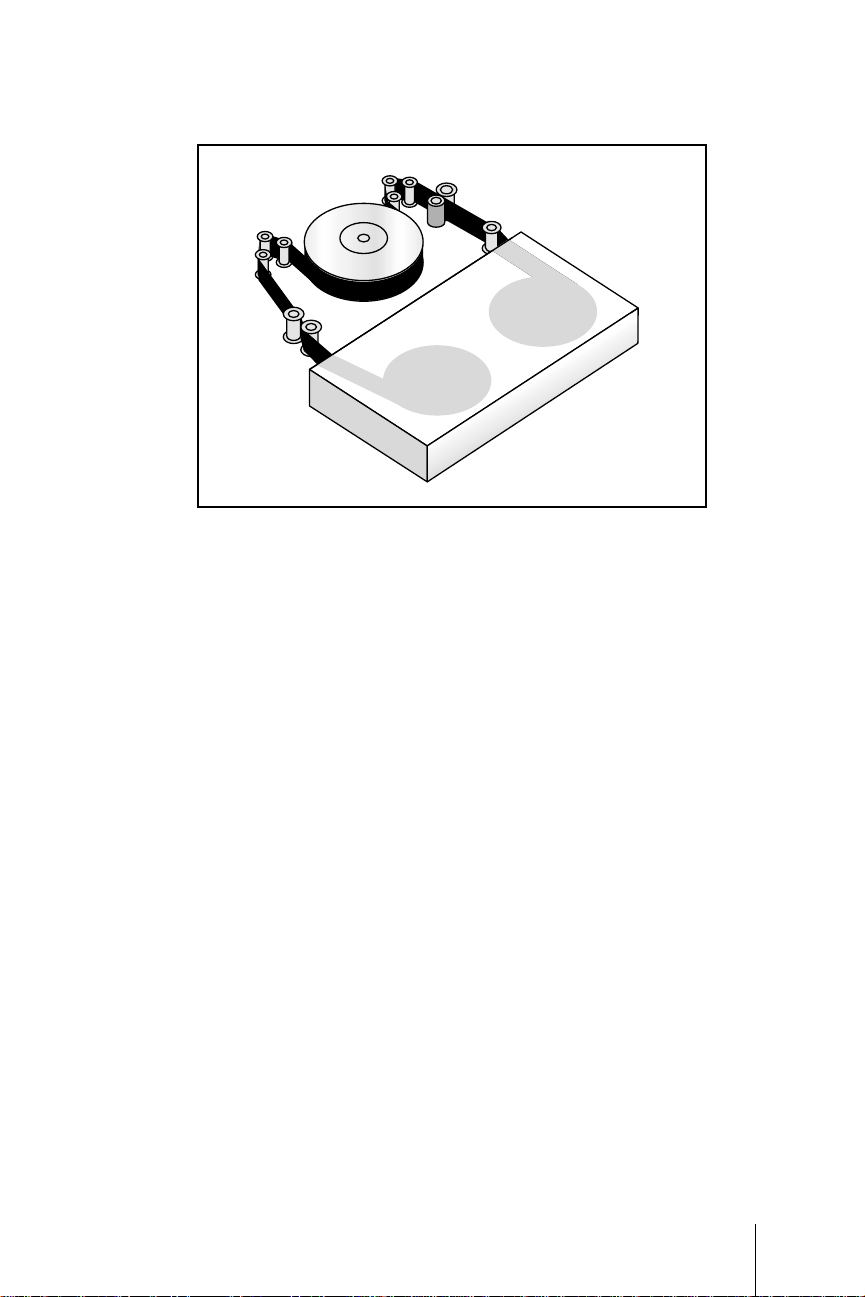

Single Reel Design

The DLTtape media cartridge is unique in the midr ange system

market, in that it has only one reel. The take-up reel – the second

reel – is in the DLTtape drive itself.This single-reel design leaves a

great deal more space for tape inside the cartridge. (See Figure 2-13

and 2-14.)

Most tape cassettes have two reels – a feed reel and a take-up reel.

The tape is pulled across the read/write heads between the two

reels, kept in alignment by the moving head guide assembly

described earlier.So, the par t of the tape that needs to be accurately aligned with the read/write heads is actually suspended between

two moving points, held in place by a series of movable guides. All

that motion makes it hard to maintain perfect alignment.

On the other hand, the DLTtape media is attached at one end to a

fixed point,the take up reel,w hich is mounted within the drive

Figure 2-13 DLTtape Cartridge provides low-cost-per-giga-

byte, high density data storage. Single-reel design eliminates

wasted space.

Access door Leader Supply reel

Write

Protect

switch

Tape

Drive access

Page 32

itself, and it is guided by the stationary HGA. It is inherently more

stable, because much less movement is possible.

When you look at a conventional two-reel 8mm cassette, it is obvious that the two reels take up a great deal of space, leaving less

space for tape. Not only can you see the difference, you can feel it.

A DLTtape cartridge, with only one reel, is packed full with tape.

Just pick up a DLTtape cartridge, and you realize that it is heavy,

because it is all storage, and very little empty spaces.

These characteristics – half-inch format, linear recording, patented

tape guide, and the DLTtape car tr idge – are some of the keys that

make DLTtape technology clearly superior.

Next,we look at the history of the DLTtape technology.

QUANTUM DLTtape HANDBOOK 2.11

Figure 2-14 The Super DLTtape I Cartridge is a ruggedized

design that includes an internal circular wall and ribbing, along

with new wear-resistant materials to reduce the generation of

debris.

Page 33

History of

DLTtape Technology

QUANTUM DLTtape HANDBOOK

3

3.1

In 1984, the Berlin Wall was still standing, and the real estate bust,

Black Monday, recession, and the collapse of the minicomputer

market were still years away. At home, Commodore 64 and Atari

computers were selling well.On the IS front, the Apple Macintosh

and the 80286 PC/AT were introduced and began to complicate life

in the glass house.

In 1984,Digital Equipment Corporation was on a roll,capturing

midrange and mainframe market share with its networked minicomputers.Digital’s MicroVAX II workstation system was nearly ready for

release,but it needed a backup system.A group of Digital storage engineers,led by consulting engineer Fred Hertrick, worked day and night

to come up with a drive that could match the M icroVAX performance.

With time short and the pressure on,the group decided to use off-theshelf half-inch magnetic tape,the same kind of stock used in mainframe-class reel-to-reel systems.Hertrick and his team devised a drive

that combined the qualities of reel-to-reel and cartridge tape systems.

No Take-Up Reel

The new system used a square cartridge that contained tape, but

no take-up reel.The take-up reel was built into the drive itself.

This design eliminated the wasted space typically associated with

cassette and cartridge drives such as the QIC, 8mm, and v ideo cas-

Page 34

HISTORY OF DLTtape TECHNOLOGY3.2

sette systems (DAT wasn’t out yet).Of course,the drive itself had

to be made somewhat larger than most to accommodate the internal take-up reel.Dubbed the TK50, the new tape drive was capable

of storing 94MB per cartridge.

Using a ferrite read/write head,the TK50 recorded data in linear

blocks along 22 tracks using two channels.The TK50’s read/write

head actually contained two sets of read/write elements. One set

was used when reading and writing forward and the other reading

and writing backward. The TK50 started recording at the beginning of the tape, recording on one track.When it reached the end,

the system recorded back to the beginning along a new track. After

every two tracks were written, the system moved the head up the

width of one track and began the process again. The read-afterwrite capability of the system ensured basic data accuracy.

The TK50 was introduced with the MicroVAX II in 1985.The drive

fit into a full height, 5.25" drive bay in the MicroVAX.Compared

to the DLTtape drive of today, the TK50 was like Neanderthal Man

– it walked upright and used tools, but it still had a long way to go.

The TK line of drives used only two guide rollers to hold the

streaming tape against the read/write head. This was okay for the

low data densities of these early systems, but would never work at

the extreme densities we’ve come to expect today.

In 1987,the year of the first IBM 80386-based PCs and Windows

2.0, Digital rolled out the TK70. This new tape drive offered 294MB

of storage on the same square tape cartridge, a 3x improvement

over the TK50.This was accomplished by upping the number of

tracks to 48 and increasing density on the same half-inch tape.

Millions of PCs were in use and had become a permanent part of

corporate America.Popular PC applications included desktop publishing, word processing, spreadsheet, and database management.

Page 35

QUANTUM DLTtape HANDBOOK 3.3

Macintosh and its GUI operating system were growing in popularity,having entered through the back door of corporate gr aphics

departments and in-house advertising groups.

Need for Precision

The TK70 wasn’t enough to quench the thirst for greater storage

capacity and faster throughput speed in tape backup systems.Disk

drive capacity was steadily increasing.Industry was becoming

more dependent than ever on information systems technology.

Databases swelled to overflowing, and tape dr ives lagged behind

the growing wave.

The storage systems engineers knew that, in order to push the

envelope,the y’d have to improve the precision of the tape guide.

Unless the tape was held rock solid in front of the read/write head,

there was little hope of achieving the quantum leap that was needed in tape capacity.

By 1988,digital audio tape (DAT) was about to cross over from the

music world to become the smallest entry in data storage subsystems.However, though small in size, these systems were projected to

store at least a gigabyte (GB) or more.Eight millimeter and VHS

video/data systems were already offering storage capacities of 2GB or

more.Clearly the engineers had some serious work to do.

And, they did it. In 1989, Digital introduced the TF85,the first true

DLT system. The TF85 (later to be dubbed the DLT 260) incorporated a host of new features that enabled the system to pack

2.6GB onto a 1,200 foot tape (CompacTape

™

III, now known as

DLTtape III). Less than two years after the introduction of the

294MB TK70, the engineers had increased storage capacity nearly

tenfold and made a breakthrough in tape drive performance that

we now call DLTtape technology.

Page 36

Head Guide Assembly

Probably the most important new feature introduced with the

TF85 was the patented six-roller head guide assembly (HGA).This

mechanism provides a gentle,solid path to precisely move the tape

past the read/write head. This boomerang-shaped assembly consists of a forged aluminum base with six precision rollers fixed to

it. The new HGA enabled the engineers to safely increase track

density from 48 tracks to 128 tracks across the half-inch wide tape.

The six-roller head guide assembly (see Figure 3-1) gave the TF85

a much shorter tape path than helical scan systems like the 8mm

drive,which meant less wear and tear on the tape.The rock solid

platform of the HGA also provided the industry’s most accurate

tape path. Helical scan systems have to draw tape around a spinning read/write drum, which requires a moving tape path with

many more parts and points of tape wear.

Write/Read/Write

Another innovation in the TF85 resulted in high performance data

transfer speed and improved error correction.The read/wr ite head

was equipped with an additional write element. The elements now

were arranged in a write/read/write pattern, allowing continuous

accuracy checking. This pattern enabled the TF85 to read after

writing on two channels and in both forward and reverse.Multichannel serpentine recording was born.

Seven-Cartridge Autoloader

To meet the need for unattended backup of large databases, Digital

also introduced a seven-cartridge autoloader,designated the TF857.

This system used a single TF85 drive, a seven-cartridge magazine,

and an elevator mechanism. Tape loaders and librar ies minimized or

eliminated operator involvement and simplified tape management.

HISTORY OF DLTtape TECHNOLOGY3.4

Page 37

In 1991,Windows 3.1 became a standard for PCs.“Mini”manufacturers industry-wide felt the pressure as companies discovered that

a string of inexpensive PCs could be networked to do the same

work that had once been the province of the minicomputer.

Meanwhile,Dig ital’s storage group kept advancing DLT technology.In 1991, the company introduced the TF86 (later dubbed

the DLT 600), which offered 6GB of storage on the same 1,200'

DLTtape III (known at the time as CompacTape III) cartr idge.

This new drive was read/write compatible with the TF85, preserving customer investment in drives and media.

Two years later, the company introduced the TZ87,now known as

the DLT 2000 tape drive. This advanced system offered 10GB of

native capacity on a single CompacTape III cartridge (now known

as DLTtape III), 2MB of read/write data cache memory,and a data

transfer rate of 1.25MB/s. In 1993,Digital also introduced a compact five-cartridge tape loader (now known as the DLT 2500) that

Drive

Leader

Head

Take-up

Reel

Tach

Assembly

Figure 3-1 The Patented DLTtape Head Guide Assembly, first

incorporated in the TF85 drive, is one of the keys to DLTtape reliability.

Six precision rollers provide a gentle tape path for long tape life.

QUANTUM DLTtape HANDBOOK 3.5

Page 38

could store up to 50GB of uncompressed data using the

DLT 2000 drive and eventually up to 100GB of uncompressed

data using the DLT 4000 drive.

Early in 1994, Digital began to gear up to sell DLT tape drives outside its normal user base. The SCSI-2 interface used by DLT drives

was an industry standard that would allow almost any computer to

work with the drives.At about this time,Digital renamed its disk

and tape subsystem group Avastor.

Quantum Enters the Picture

By 1994,Quantum Corporation, a Milpitas, California-base d maker

of high performance disk drives since 1980, had built a healthy $2.1

billion business. The company was the leading supplier of 3.5-inch

hard drives for PCs and the third leading supplier of hig h-capacit y

drives (2GB and up).In DLT technology,Quantum saw the opportunity to acquire advanced technology that could ensure the company’s leadership position and op en new markets for it. Quantum

acquired Digital’s disk and tape divisions and, within them, DLT

technology .

Potential for Success

Quantum recognized the undeveloped potential that DLT technology represented.This technology was the perfect complement to

their established disk drive business.Almost immediately,Quantum

announced new tape drives based on the acquired technology. In

late 1994,Quantum rolled out the DLT 4000 drive and leapt to the

head of the line in performance, capacity and reliability.

By increasing areal density (bits per inch) from 62,500 to 82,000

and tape length by 600 additional feet (to 1,800 feet),Quantum’s

storage engineers were able to up the capacity of the DLT 4000 system to 20GB (40GB compressed) on a single half-inch DLTtape IV

HISTORY OF DLTtape TECHNOLOGY3.6

Page 39

cartridge. The new DLTtape system provided data transfer at

1.5MB/s (3MB/s compressed) and was fully read/write compatible

with previous generations of DLTtape drives.Again,customer

investments in DLTtape drives and media were preserved.

Sales Growth

Quantum sales rose to $3.5 billion for FY’95 on strong growth on all

fronts.Quantum had evolved from its role as only a disk drive maker

to a provider of mass-storage solutions. The r apid r ise of multimedia,

data warehousing,data mining, large network storage servers,

Internet/Intranet growth,and 7x24 information system operations

meant the need for fast,high capacity backup systems was exploding,

and Quantum had the products that the market wanted.

In 1995,Quantum introduced an improved DLT 2000 system,

dubbed the DLT 2000XT for “extended tape.”The new system provided an additional 5GB over the capacity of the DLT 2000 drive for

a total of 15GB native capacity. Quantum was able to achieve this

improvement through firmware changes (see Chapter 15),and by

increasing the length of the tape used from 1,200 to 1,800 feet

(DLTtape IIIXT).As usual,the DLT 2000XT was fully backward compatible with all previous DLTtape drives.

Others Playing Catch-up

Quantum enjoyed a time-to-market gap that had manufacturers of

8mm, DAT, and QIC tap e drives scrambling to tr y to match

DLTtape system capacity and performance. Just when it seemed

they might come close, Quantum introduced the DLT 7000 drive in

1996. This new drive offered a total storage capacity of 35GB native

(70GB compressed) on the 1,800 foot DLTtape IV cartridge.

Thanks to the DLT 7000 drive’s new 4-channel head, it could

transfer data at the rate of 5MB/s in native mode. Other tape

QUANTUM DLTtape HANDBOOK 3.7

Page 40

drive makers were left far behind. Demand for the drive quickly

outstripped supply as OEMs and resellers flocked to take it on.

Library manufacturers wanted the drive in order to up total

library capacities into the multi-terabyte range. Unix Review

magazine named the DLT 7000 drive one of its Outstanding

Products for 1996.Press accounts began by stating the DLT 7000

drive’s technical dominance at the high end of the midrange tape

backup market.

DLT 8000 Drive

In 1999, Quantum introduced the DLT 8000 drive, a significant

step up in performance and capacity over the market-leading

DLT 7000 drive. The DLT 8000 system delivered a 15% increase in

storage capacity (from 35GB to 40GB native),a 20% increase in

transfer rate (from 5MB/s to 6MB/s), and an important improvement in reliability (from 200,000 hours MTBF to 250,000 hours).

And, of course, the DLT 8000 system delivered another important

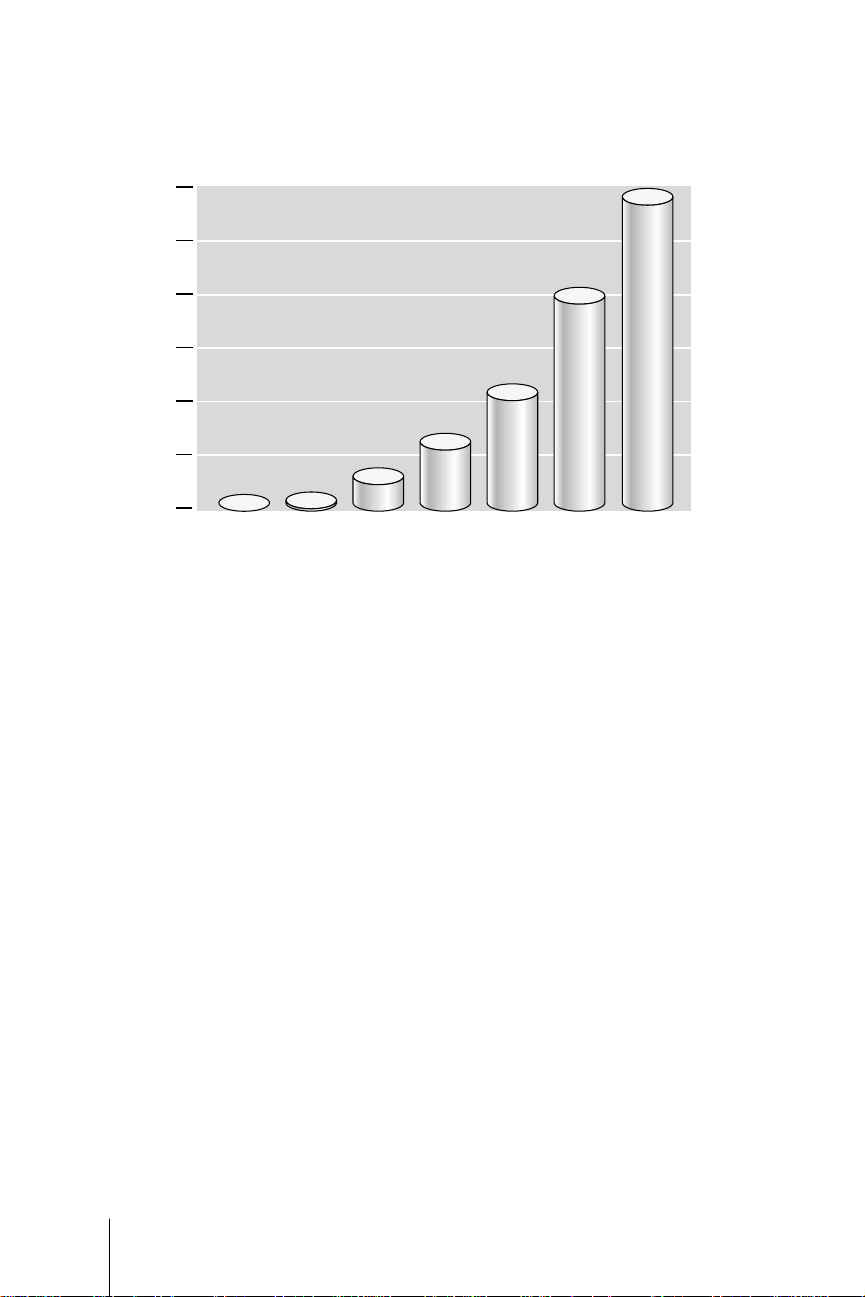

0

200,000

400,000

600,000

800,000

1,000,000

1,400,000

1,200,000

1,800,000

1,600,000

70,000,000

60,000,000

50,000,000

40,000,000

30,000,000

20,000,000

10,000,000

0

FY 97 FY 98 FY 99 FY 00 Q3FY 01

Source: Quantum Corporation

Units, Drives Installed Units, Media Shipped

Figure 3-2 The Installed Base of DLTtape systems has grown dramatically,

with a projected total of over 1.5 million drives installed and over 55 million cartridges shipped to customers by the end of Q3, FY01.

HISTORY OF DLTtape TECHNOLOGY3.8

Page 41

benefit – investment protection: the DLT 8000 drive,which uses

the same DLTtape IV tape cartridges as the DLT 7000 drive,is

compatible with a very large percentage of all of the DLTtape

media ever sold (some 55 million cartridges).

DLTtape System Sales Growth

At the end of FY '99,sales of DLTtape products hit $1.4 billion, and

DLTtape products accounted for nearly 30 percent of Quantum’s

sales.According to Quantum CEO Michael Brown,“The move to

enterprise servers, the proliferation of Internet servers, and the

increase in mission-critical content stored on these servers have

dramatically increased the demand for backup and archival storage.

Quantum’s DLTtape drives use advanced linear recording technology and a highly accurate tape guide system to provide exceptionally

reliable,scalable data backup and archival storage for mid-range

and high-end systems. These drives, which have become the industry’s de facto standard, provide a strong foundation for market

acceptance of our next generation products.”

The Next Generation: Super DLTtape Technology

Early in 1998, Quantum had also revealed plans from the most

important development in the history of DLTtap e technology:

Super DLTtape technology,the next generation of DLTtape technology.It incorporates dramatic advances in virtual ly ever y impor tant

area,from mechanical packaging through head design, tape guidance,and media properties.Yet the Super DLTtape system is also

unmistakably a DLTtape product, providing a smooth growth path

from today's market leading technology to a new technology that

will deliver order-of-magnitude advances in capability.

By mid-2000, Quantum announced plans to deliver a family of

competitively priced tape drive products based on Super DLTtape

QUANTUM DLTtape HANDBOOK 3.9

Page 42

technology.Volume production and first customer shipments began

in Q1, 2001. These products address the individual storage needs of

low-,mid-, and high-end customers in the mid-range data storage

market.These new products include drives that deliver capacities of

110GB (uncompressed),and transfer rates of 11MB/s (uncompressed).They are the first products based on the Super DLTtape

technology, a technology that Quantum will continue to evolve,

with coming generations planned to deliver over 1 terabyte of

storage (uncompressed) on a single cartridge. And, of course, the

Super DLTtape system delivers another and continuing benefit –

investment protection.The Super DLTtape system is backward read

compatible with DLTtape IV cartr idges wr itten on DLT 4000,

DLT1, DLT 7000, and DLT 8000 drives.

DLT1 Drive

Early in 2001, Quantum introduced the DLT1 drive. Delivering

40GB per cartridge native capacity (80GB compressed), along with

a native transfer rate of 3MB/s (6MB/s compressed),the DLT1 drive

is an exceptionally cost-effective backup solution for a wide range

of applications. The DLT1 can back up most small- and mediumsize storage servers and workstations on a single cartridge. Available

for both internal installation and as a free-standing, table-top unit,

DLT1 is designed primarily for stand-alone applications. It uses the

same DLTtape IV cartr idge that is standard for the DLT 4000 drive,

allowing users of small and medium-size storage devices and workstations a simple migration path and the ability to make an initial

investment in their future storage strategy using the DLTtape products.

Next,we’ll take a look at the advantages that make the DLTtape

system the most sought after backup solution on the mar ket today.

HISTORY OF DLTtape TECHNOLOGY3.10

Page 43

Why Customers

Want DLTtape Systems

QUANTUM DLTtape HANDBOOK

4

4.1

When Quantum bought DLT technology in 1994, sales of DLT

products were running a modest 20,000 units per year. In just six

years, DLTtape drive sales climbed to over 500,000 units a year.

Why are so many people buying DLTtape systems? Some of the

reasons have to do with big industry trends. Others have more to

do with the basics of DLTtape technology itself. In this chapter,

we’re going to look at the forces that are driving customer

demand for DLTtape system b ackup solutions.

The Server Boom

One of the industry trends driving the demand for DLTtape systems is the growth in the population of midrange servers. Not

many years ago, 8mm and 4mm DAT (digital audio tape) dominated the backup world.There was no reason to think that wouldn’t

continue.Many people probably assumed they would keep using

DAT for backup until optical disk technology eventually took over.

And, in the desktop computer world,that scenario is holding up

pretty well. People are still buying 4mm DAT drives by the tens and

hundreds of thousands, and optical – in one form or another – is

coming up over the horizon.

The midrange field, however, offers a whole different scenario.

Instead of the “death of the minicomputer industry,”we have seen

Page 44

WHY CUSTOMERS WANT DLTtape SYSTEMS4.2

the “birth of the ser ver industry.”Of course, today’s servers look a

great deal like yesterday’s minicomputers,and, instead of disappearing, this class of computers is growing very rapidly.

These midrange servers support much larger disk storage than

desktop systems.That means you need more backup capability –

more capacity, more speed, and greater reliability.These backup

needs are the strengths of the DLTtape system. It’s no accident that

the growth in popularity of the DLTtape system closely parallels

the boom in server use.

The “Mission Critical”Boom

Much of the growth in the midrange market is fueled by a new

class of mission critical applications, such as Internet servers,

enterprise wide email servers, v ideo editing, electronic commerce,

and so on. These applications demand bigger disks, more capacity,

and, of course, better backup solutions. This is where DLTtape

technology really shines.

Customers are buying DLTtape systems because these mission critical applications need backup solutions that offer more speed,

capacity,and reliability: exactly what DLTtape system backup delivers. Don’t forget that DAT (digital audio tape) and 8mm are really

consumer entertainment technologies,adapted for industrial use.

DLTtape technology is industrial-strength from the start. It just

takes one failure of a mission cr itical application to make people

understand that what they really need is industrial strength backup.

A Proven Technology

“Leading edge”technologies sometimes end up on the “bleeding

edge.”In this case,however, DLTtape technology is growing so fast

because it has been proven.People want DLTtape technology

because they know it works.Today,there are over 1.5 million

Page 45

QUANTUM DLTtape HANDBOOK 4.3

DLTtape drives installed,and over 55 million DLTtape cartridges in

use worldwide.In the understated words of one user,“DLTtape

technology is a well understood way to get a lot of data backed up.”

Widely Available

DLTtape systems are available from many sources.The list of

OEMs who put DLTtape drives in their systems is impressive and

growing. Almost all the leading vendors of mid-range computer

systems or workstations sell DLTtape products, including Compaq,

Dell, Hewlett-Packard,IBM, and Sun.Every one of these manufacturers offers DLTtape systems as factory installed backup systems

and libraries for their high-performance ser vers.

DLTtape technology is also available from the leading manufacturers of tape storage libraries and autoloaders. DLTtape products are

available through major industrial distributors, and from valueadded resellers,many of whom serve specialized markets.A good

example is Avid Technolog y,the leader in special effects editing

systems for film and video; DLTtape drives come as standard

equipment with Av id systems.

Speed Is Critical

Industry trends and good history have created the conditions for

success of DLTtape technology.However,trends don’t mean much

if the technology doesn’t deliver performance.Customers want

DLTtape technology because it offers blazing performance.

DLTtape dr ives are very fast: from 1.5MB/s to 11MB/s in “native”

or uncompressed mode (see Figure 4-1).That’s nearly hard disk

drive speed. If you are running a network in a large engineering

department, and all the ser vers must be backed up between midnight and 6 a.m., speed is your best friend. Or, if you’re putting the

finishing touches on special effects for a TV commercial,and the

Page 46

clock is running out, you don’t want to have to face the long, slow

process of putting the ad on tape before you can ship it to the

client.You want DLTtap e system speed.

Bigger Is Better

Users want DLTtape technology because bigger is much better.You can

put much more information on half-inch-wide tape than you can on

8mm or 4mm tape.Currently, an SDLT 220 drive can store 110GB on

a single Super DLTtape I cartridge.Add compression of 2-to-1 and

you’ve got 220GB on one four-inch-square cartridge (not to mention

22MB/s throughput).That’s enough capacity to store multiple fulllength feature films,and you can look for greater capacity in the future

(see Chapter 17 for details on Super DLTtape technology).For the typ-

WHY CUSTOMERS WANT DLTtape SYSTEMS4.4

Figure 4-1 DLTtape Drive Comparison Chart shows some of the important

specifications for DLTtape systems, including the industry-leading Super DLTtape system.

Capacity

(GB, native)

Data Rate

(MB/s, native)

Bit Density

(Kbpi)

Track Density

(tpi)

Media Type

Media Length

Recording

Channels

Hardware Data

Compression

Interface

20

1.5

82.5

256

MP-2

1,800‘

2

Yes

SCSI-2/F

SE/HVD

DLT

4000

40

6.0

98

416

MP-2

1,800‘

4

Yes

SCSI-2/FW

LVD/HVD

DLT

8000

35

5.0

86

416

MP-2

1,800‘

4

Yes

SCSI-2/FW

LVD/HVD

DLT

7000

40

3.0

123

336

MP-2

1,800‘

2

Yes

SCSI-2/FW

LVD

DLT1

110

11.0

131

896

AMP

1,800‘

8

Yes

SCSI-2/FW

LVD/HVD

SDLT

220

Page 47

ical system administrator running a network backup application,more

capacity per cartridge means less need to swap cartridges.

More Reliable

While we were researching this book,we talked to end users and

network managers. Over and over again,they told us that they had

switched to DLTtape backup because the systems they had been

using just weren’t reliable enough anymore. Under the pressure of

backing up big networks,4mm and 8mm solutions just don’t cut it.

This from the people whose necks are on the line when systems fail.

They say things like “too many midnight calls,” or “ever y once in

a while an 8mm drive would go bang,”or “our old 4mm drives

could not handle it.”So,customers want DLTtape technology

because it is more reliable than any other backup technology.

Heavy Duty

Most drive makers base their performance and reliability figures on

drive utilization (duty cycle) as low as 10 percent.That means that

in a 7x24 operation, other drive makers base reliability figures on as

little as 2.5 hours of use during every 24-hour period. At Quantum,

we have traditionally calculated our reliability figures based on 100

percent usage.In fact,even at 100 percent duty-cycle,DLTtape drives are rated at up to 250,000 hours Mean Time Between Failures

(MTBF). Even when compared to a competing drive offering the

same MTBF, DLTtap e drives are the clear winner,because we have

calculated MTBF assuming 100 percent usage.In practice,few drives will actually be subjected to non-stop operation. But, it’s nice to

know you could run your DLTtap e drive continuously if you had

to,w ithout the worry of premature failure or data loss.(See

Chapter 5 for a complete discussion of DLTtape system reliability.)

Economy

Because DLTtape technology star ted life as a proprietary technology,and because its market is primarily in the midr ange and high-

QUANTUM DLTtape HANDBOOK 4.5

Page 48

end server arena, some people mistakenly characterize DLTtape

technology as expensive.That is simply not the case.

One of the great things about the free market is that buyers usually

figure out the best deals pretty quickly.Users want DLTtape technology because, as it turns out, in many applications, not only does it

offer superior performance, but it’s also the least expensive way to

get the job done.

DLTtape technology isn’t the cheapest backup for desktop applications – yet. That’s still 4mm DAT. But once you jump to UNIX

workstations or enterprise networks, it’s a whole different story.

For starters,you need to factor in capacity. At 40GB uncompressed, for example, the DLT 8000 drive compares favorably in

price with competitive units of lesser capacity.

The cost equation changes when you factor in performance.If you’ve

got all night and you only need to backup a few files,slow is fine. But,

if you’re try ing to back up a large, constantly changing database, and

the only time you can do it is from 2 a.m.to 5 a.m., then speed is

money.For more and more applications,with growing storage needs

and shrinking backup windows,the critical issues are: Can you complete this backup in the available time,w ith minimum operator

involvement, and provide maximum dependability? With its 110GB

capacity and 11MB/s native transfer rate,the SDLT 220 drive is the

value leader in these increasingly common circumstances.

Comparing media cost is a similar story.If your total system storage

capacity is only one or two GB,smaller capacity,lower-initial-cost

tape cassettes may be fine.As soon as you jump up a class and have 5,

10,30GB or even terabytes to back up,dollars-per-gigabyte becomes

the meaningful measure of the cost of media. Gener ally,the larger

your backups are,the more cost-effective it becomes to use DLTtape

WHY CUSTOMERS WANT DLTtape SYSTEMS4.6

Page 49

technology.No other tape drive system packs as much data in a single

cartridge as the DLTtape system; up to 110GB in native mode on a

single Super DLTtape I cartridge.

True Cost

The true cost of backup isn ’t in the drives and the media at all – it’s in

the people and time it takes to meet your backup goals.If files are small

and the windows of time are wide open,administrative costs probably

aren ’t even worth measuring.In these rare situations,the lowest initial

cost solution works.As soon as you crank up the volume,however,

administrative costs can soar. If you’ve got 4mm cassettes filling up constantly,just swapping tapes can become a time sink.And if you’re really

pushing the limits of speed,capacity ,and duty cycle of your backup

solution,failure rates start climbing. That means serious interruptions

and delays as you scramble to replace bad drives. In other words,

administrative costs quickly get out of control.One user told us he used

to spend 35 hours a week to support 4mm DAT backup for critical

client files.When he moved to DLTtape backup,that cost virtually disappeared.That’s another reason why people want DLTtape technology.

Scalability

One of the primary reasons people want DLTtape technology is scalability.Scalability means DLTtape system customers solve the backup problem once,and then keep applying the same solutions as

needs grow.You can go from a DLT 4000 dr ive with uncompressed

capacity of 20GB, to an SDLT 220 drive with uncompressed capacity

of 110GB.Beyond that, you can move up to one of many available

automated DLTtape libraries with capacities r anging from “a terabyte on a desktop”to many terabytes or even petabytes on the floor.

Room t o Gr ow

One of your goals should be to pick a backup technology that has

a future.While helical scan technologies,for example, are pushing

QUANTUM DLTtape HANDBOOK 4.7

Page 50

the upper limits of their potential,DLTtape technology is just hitting its stride, w ith plenty of room to grow.

Half-inch tape simply offers more growth capacity than the much

smaller 4mm or 8mm formats (see Figure 4-2).Where 8mm and 4mm

are pushing their density limits,half-inch DLTtape technology isn’t even

close to maxing out.For example, the DLT 4000 drive uses 128 recording tracks.The DLT 8000 drive uses the Symmetric Phase Recording

™

pattern,allowing it to lay down 208 tracks on the same half-inch tape.

The next generation of Super DLTtape systems increased track density

yet again,by a factor of more than 2X, to 448 tracks.

Track density is just one parameter.Another is the underlying tape

technology.Today, DLTtape IV cartridges use metal particle (MP)

media.Super DLTtape I cartridges use state-of-the-art Advanced

Metal Powder (AMP) media. AMP media offers increased media

capacity,ease-of-use, and lower cost of ownership.Designed to meet

the needs of multiple generations of Super DLTtape drives,AMP

DAT QI C-MC QIC-DC 8mm Half-inch DLTtape

0

2,000

4,000

6,000

8,000

10,000

DAT QIC-MC QIC-DC 8mm

Media Recording

Area (square inches)

Figure 4-2 Half-inch DLTtape Media leaves plenty of room

for capacity growth for future DLTtape drives. A single DLTtape

cartridge has a tape area of over 10,000 square inches.

WHY CUSTOMERS WANT DLTtape SYSTEMS4.8

Page 51

media ensures the highest track density available today. AMP uses

durable metal powder technology for recording at very high densities.

The back side of the AMP media contains specially formulated backcoating to receive the optical servo tracks,so customers can reserve

the entire data-bearing side of the media for recording data and eliminate the need for pre-formatting.

DLTtape System Compatibility

In most cases,IS managers are reluctant to change backup technology.

You may have dozens,hundreds,or even thousands of old backup

QUANTUM DLTtape HANDBOOK 4.9

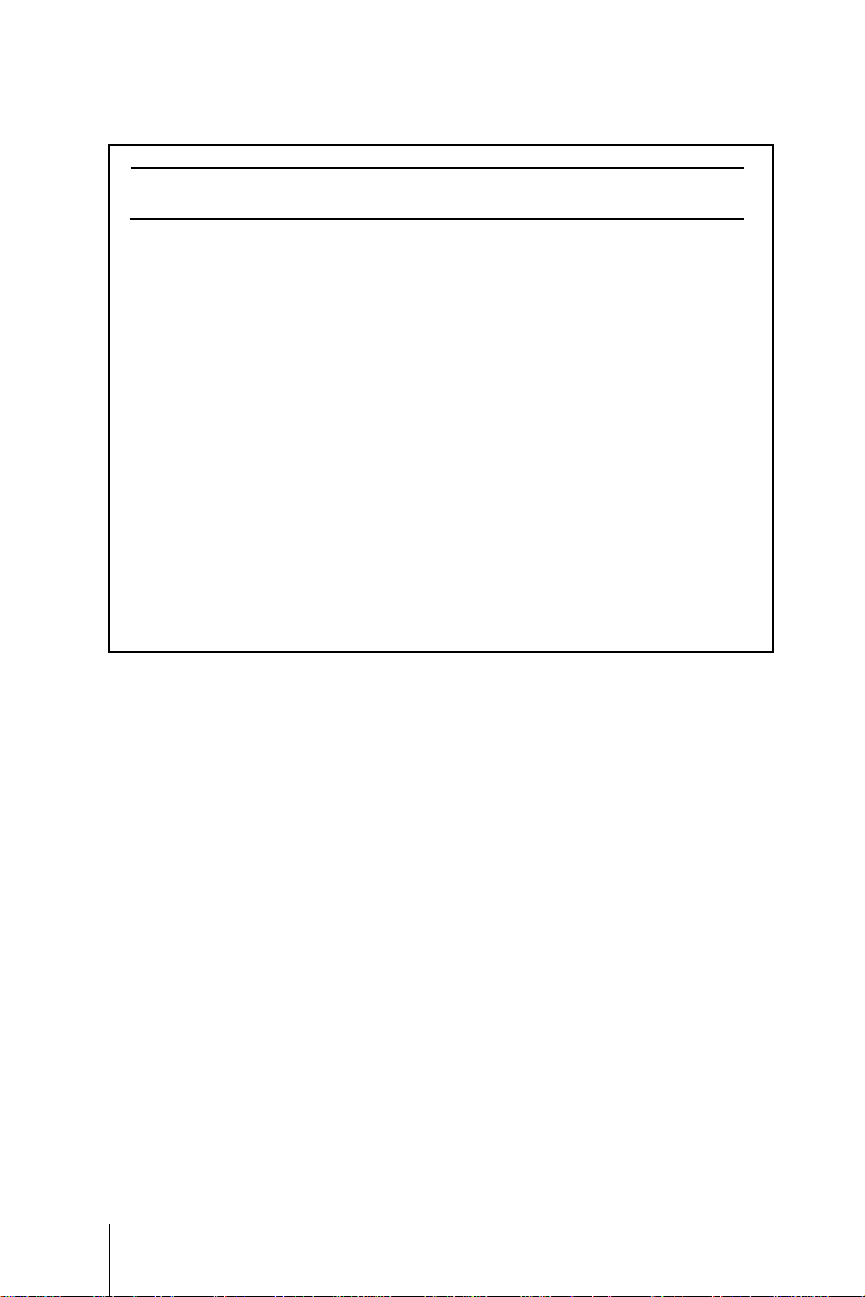

Figure 4-3 Backward Compatibility is maintained throughout the DLTtape media

family .

Tape Type

(recorded on

drive type)

DLTtape IIIXT

(recorded on

DLT 2000XT)

DLTtape IV

(recorded on

DLT 4000)

DLTtape IV

(recorded on

DLT 7000)

DLTtape IV

(recorded on

DLT1)

DLTtape IV

(recorded on

DLT 8000)

Super DLTtape I

(recorded on

SDLT 220)

15GB

20GB

35GB

40GB

40GB

110GB

1.5MB/s

1.5MB/s

1.5MB/s

1.5MB/s

1.5MB/s

NA

Native

Capacity

Native

Transfer

Rate

(read

on DLT

4000)

Native

Transfer

Rate

(read

on DLT

7000)

Native

Transfer

Rate

(read

on DLT1)

Native

Transfer

Rate

(read

on DLT

8000)

Native

Transfer

Rate

(read

on SDLT

220)

1.5MB/s

1.5MB/s

5MB/s

NA

5MB/s

NA

NA

1.5MB/s

NA

3MB/s

NA

NA

1.5MB/s

1.5MB/s

5MB/s

NA

6MB/s

NA

NA

1.5MB/s

3.5MB/s

3MB/s

4MB/s

11MB/s

NA=Tape format is not compatible with the tape drive.

Page 52

tapes.You w il l never need most of them. But if you do need some old

tapes from last year, or 5 years ago, or just last week,you would have

a major problem if you had changed backup platforms. That is generally not the case with DLTtape technology.A cartr idge recorded on

a DLT 2000 drive three or four years ago can be read on a DLT 4000

drive today.You can put a DLTtape IV cartridge in a DLT 4000 drive

today, fill it w ith data, and two years from now you will be able to

read it on a DLT 8000 drive (see Figures 4-5 and 4-6).All DLTtape

drives up to the DLT 4000 drive use a similar head design and recording pattern that makes possible compatibility among drives.

However, the DLT 7000 and DLT 8000 drives use a new recording

pattern,Symmetric Phase Recording.T he read/wr ite head of the

DLT 7000 and DLT 8000 drives tilt forward and back (see Figure 4-5)

to achieve higher track density.When a DLTtape cartridge that has

been recorded on a DLT 4000 drive,for example, is inserted in a

DLT 8000 drive,the drive automatically detects the difference in

recording pattern.The DLT 8000 drive then automatically adjusts its

read/write head (Figure 4-6) to a vertical position that enables it to

read the older DLTtape cartridge.

WHY CUSTOMERS WANT DLTtape SYSTEMS4.10

Forward

Write Cores

Reverse

Write Cores

Reader Cores

Figure 4-4 DLT 7000/DLT 8000 Read/Write Head tilts

back and forth to record at highest data density, yet it can still read

older formats by assuming vertical position shown here.

Page 53

QUANTUM DLTtape HANDBOOK 4.11

Figure 4-5 Symmetric Phase Recording (SPR), used in

DLT 7000 and DLT 8000 drives, angles recording tracks to prevent

cross-track interference and increase data density.

Figure 4-6 DLT 7000/8000 Head Positioned to read

DLTtape cartridge recorded on an older DLTtape drive, providing compatibility and data interchange.

Forward Tape Direction

Reverse Tape Direction

Forward Tape Direction

Reverse Tape Direction

Page 54

WHY CUSTOMERS WANT DLTtape SYSTEMS4.12

The DLT1 drive uses DLTtape IV media, so DLT1 drives can read

any DLTtape IV cartridges recorded on DLT 4000 drives.And,of

course,DLTtape IV cartr idges recorded on DLT1 drives can be read

by DLT 4000 drives and by SDLT 220 drives.

Super DLTtape I Media Compatibility

Super DLTtape I media provides backward read compatibility

with DLT 4000, DLT1, DLT 7000, and DLT 8000 drives using

DLTtape IV cartridges. To read DLTtape IV cartridges recorded

on a DLT 4000 drive or DLT1 drive, the Super DLTtape Backward

Read Compatible head remains in an upright position. To read

DLTtape IV cartridges recorded on a DLT 7000 or DLT 8000 dr ive,

the Super DLTtape head tilts to read data recorded using Sy mmetr ic

Phase Recording (SPR).(See Figure 4-7.) That means data wr itten

on any DLTtape IV cartridge using any DLT 4000, DLT1, DLT 7000,

or DLT 8000 drive can be read on a Super DLTtape drive.That