Page 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scorpion 24 DDS-3 Tape Drive

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STD124000N

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STD224000N

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STD624000N

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 2

h

Page 3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scorpion 24 DDS-3 Tape Drive

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STD124000N

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STD224000N

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STD624000N

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

© 1997 Seagate Technology, Inc. All rights reserved

Publication Number: 10004436-002, Rev. B, May, 1998

Seagate, Seagate Technology, the Seagate logo, Scorpion and the Scorpion logo

are trademarks or registered trademarks of Seagate Technology, Inc. Other product

names are trademarks or registered trademarks of their owners.

Seagate reserves the right to change, without notice, product offerings or

specifications. No part of this publication may be reproduced in any form without

written permission from Seagate Technology, Inc.

Page 5

FCC Notice

This equipment generates and uses radio frequency energy and, if not installed and

used properly—that is, in strict accordance with the manufacturer’s instructions—

may cause interference to radio communications or radio and television reception. It

has been tested and found to comply with the limits for a Class B computing device

in accordance with the specifications in Part 15 of FCC Rules, which are designed to

provide reasonable protection against such interference in a residential installation.

However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause interference to radio or television

reception, which can be determined by turning the equipment on and off, you are

encouraged to try to correct the interference by one or more of the following

measures:

z

Reorient the receiving antenna.

z

Relocate the computer with respect to the receiver.

z

Move the computer into a different outlet so that the computer and receiver are

on different branch circuits.

If necessary, you should consult the dealer or an experienced radio/television

technician for additional suggestions. You may find the following booklet prepared

by the Federal Communications Commission helpful:

How to Identify and Resolve Radio-TV Interference Problems

This booklet (Stock No. 004-000-00345-4) is available from the U.S. Government

Printing Office, Washington, DC 20402.

Warning. Changes or modifications made to this equipment which have not been

expressly approved by Seagate Technology may cause radio and

television interference problems that could void the user’s authority to

operate the equipment.

Further, this equipment complies with the limits for a Class B digital apparatus in

accordance with Canadian Radio Interference Regulations.

Cet appareil numérique de la classe B est conforme au Règlement sur brouillage

radioélectrique, C. R. C., ch. 1374.

The external device drive described in this manual requires shielded interface cables

to comply with FCC emission limits.

Additional Warnings:

z

To prevent fire or electrical shock hazard, do not expose the unit to rain or

moisture.

z

To avoid electrical shock, do not open the cabinet.

z

Refer servicing to qualified personnel.

Product Manual Page iii

Page 6

About This Manual

All information contained in or disclosed by this document is considered proprietary

by Seagate Technology. By accepting this material, the recipient agrees that this

material and the information contained therein are held in confidence and in trust

and will not be used, reproduced in whole or in part, nor its contents revealed to

others, except to meet the purpose for which it was delivered. It is understood that

no right is conveyed to reproduce or translate any item herein disclosed without

express written permission from Seagate Technology.

Seagate Technology provides this manual “as is,” without warranty of any kind,

either expressed or implied, including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose. Seagate Technology reserves

the right to change, without notification, the specifications contained in this manual.

Seagate Technology assumes no responsibility for the accuracy, completeness,

sufficiency, or usefulness of this manual, nor for any problem that may arise from

the use of the information in this manual.

Following are brief descriptions of the sections in this manual.

Chapter 1, “Introduction” on page 1 provides general specifications, features and

an overview on DAT technology.

Chapter 2, “Specifications” on page 9 contains physical, performance,

environmental, power, drive tape handling and DAT cartridge specification tables.

Chapter 3, “Installation” on page 15 provides cautions, unpacking tips, inspection

information and installation/connection steps, including cabling requirements and

connector pinouts.

Chapter 4, “Drive Operations” on page 33 explains the simple operation of drives.

Chapter 5, “SCSI Interface” on page 43 lists general information about the SCSI-2

interface.

Chapter 6, “DDS-3 Tape Format” on page 47 explains the DDS, DDS-DC, DDS-2

and DDS-3 tape formats.

Chapter 7, “Data Compression” on page 61 describes the data compression

algorithm and explains pertinent information for effective use of data compression.

Chapter 8, “Theory of Operations” on page 71 details the functional operation of

various assemblies of the drives.

Chapter 9, “Maintenance and Reliability” on page 83 presents maintenance

procedures and reliability information.

Appendix A, “Acronyms and Measurements” on page 87 lists the acronyms and

measurements used in the manual.

Appendix B, “Vendor-Unique SCSI Information” on page 91 provides specific

SCSI information for programming and retrieving configuration data.

The glossary on page 95 defines key terms.

Page iv DAT Drives

Page 7

Contents

1 Introduction.......................................................................1

Overview..............................................................................................1

DDS Format Standard Compatibility 1

Scorpion 24 Capacity and Transfer Rates 2

Features ..............................................................................................3

Models.................................................................................................4

DAT Technology Overview...................................................................6

Helical Scan Recording..................................................................6

Recording Formats ........................................................................7

DDS-3 Recording Format ........................................................7

DDS-2 Recording Format ........................................................7

DDS Recording Format ...........................................................7

DDS-DC Recording Format.....................................................8

2 Specifications.................................................................... 9

Overview..............................................................................................9

Physical Specifications.........................................................................9

Power Specifications..........................................................................11

Drive Performance Specifications....................................................... 12

Environmental Requirements .............................................................13

DDS Cartridge Specifications.............................................................13

Regulatory Compliance......................................................................14

3 Installation.......................................................................15

Introduction........................................................................................15

Guidelines and Cautions (Internal Models) .........................................15

Unpacking and Inspection..................................................................16

Cabling and Connectors.....................................................................16

Cabling Considerations................................................................16

Electrical Characteristics..............................................................16

SCSI Connector—Internal Models ...............................................18

SCSI Connector—External Models ..............................................19

Installing Internal Drives.....................................................................20

Configuring Options.....................................................................20

Setting the Switchbank Parameters .............................................20

SCSI Device Address (S1, S2, S3) .......................................22

Media Recognition System (MRS) (S4) .................................22

Product Manual Page v

Page 8

Contents

Parity Check Enable/Disable (S5)..........................................23

DDS Pass-Through Mode Enable/Disable (S6)......................23

Inquiry String (S7)..................................................................23

Power-on Self-Test Mode Enable/Disable (S8) ......................23

Switches 9 and 10.................................................................23

Setting the Jumpers...............................................................24

SCSI Device Address Jumpers.............................................. 25

Hardware Data Compression.................................................26

Active Terminator.................................................................. 26

Terminator Power..................................................................26

Mounting the Drive.......................................................................27

Completing the Power and Interface Connections........................29

Installing External Drives....................................................................29

Selecting the SCSI Address.........................................................30

Completing the Interface Connection ...........................................30

Connecting the Power Cord......................................................... 31

4 Drive Operations .............................................................33

Introduction........................................................................................33

Data Compression Operation.............................................................33

Front Panel LED Operation................................................................34

Loading/Unloading the Cartridge........................................................ 37

Loading/Unloading a Cartridge (Normal Operation)......................37

Unloading a Cartridge (Manual Operation)................................... 38

Using a Blank Cartridge .....................................................................39

Using a Cartridge Containing Data ..................................................... 40

Loading Revised Firmware Using Seagate Firmware Cartridges......... 40

Flash Memory....................................................................................40

Firmware Download Process.............................................................. 41

5 SCSI Interface..................................................................43

Introduction........................................................................................43

SCSI-2 Interface................................................................................ 43

ANSI X3.131, 199x Conformance Statement (SCSI-2).......................45

General Features...............................................................................45

Typical System Configurations...........................................................46

6 DDS-3 Tape Format.........................................................47

Introduction to DDS Recording Format Standards..............................47

DDS-3 Tape Format...........................................................................47

Basic Groups...............................................................................48

Entities ........................................................................................49

Subgroups...................................................................................49

Basic Group Transformation Summary ........................................49

Subcode Information....................................................................49

Page vi DAT Drives

Page 9

Contents

Subcode Location........................................................................49

DDS-3 Track Geometry ...............................................................50

Recorded Patterns.......................................................................51

Format of a Track........................................................................51

Positioning Accuracy....................................................................52

Timing Tracking...........................................................................52

Tape Layouts in the DDS-3 Standard.................................................53

Layout of a Single Data Space Tape (Single Partition)........................53

Device Area................................................................................. 54

Reference Area............................................................................54

System Area................................................................................55

Data Area....................................................................................55

Appending to Tape.......................................................................55

EOD Area....................................................................................57

Early Warning Point (EWP).......................................................... 57

Initialization..................................................................................57

Layout of a Partitioned Tape ..............................................................58

Partition 1....................................................................................59

Partition 0....................................................................................59

Initialization of Partitioned Tapes..................................................59

Housekeeping Frames.......................................................................60

DDS-3 Recording Format Standard—Further Reference....................60

7 Data Compression .......................................................... 61

Introduction........................................................................................ 61

Data Compression—General..............................................................61

Data Compression Considerations...............................................62

Hardware Compression ...............................................................63

Data Integrity...............................................................................63

DCLZ Algorithm .................................................................................64

DCLZ Algorithm...........................................................................64

Simplified Compression Operation............................................... 64

Dictionary ....................................................................................65

Simplified Decompression Operation............................................66

SCSI/Data-Compression Chip............................................................68

Overview .....................................................................................68

Features......................................................................................68

8 Theory of Operations...................................................... 71

Overview............................................................................................71

The STD124000N Drive...............................................................72

Motors and Control Circuits..........................................................73

SCSI Controller............................................................................ 74

Helical Scan Recording—Four-Head Design................................75

Motors and Control Circuits................................................................ 76

Read and Write LSI .....................................................................77

Timing Tracking Circuitry .............................................................77

SCSI Controller............................................................................ 77

Product Manual Page vii

Page 10

Contents

Flash Memory.................................................................................... 77

Sensors .............................................................................................78

Read-After-Write................................................................................78

Media Recognition System (MRS)...................................................... 79

DDS Data Cartridge...........................................................................79

9 Maintenance and Reliability...........................................83

Maintenance...................................................................................... 83

Head Cleaning.............................................................................83

Automatic Drive Spin-Down and Write ......................................... 84

Guidelines for High Temperature or Humidity Conditions

(Outside the Specified Operating Environment)................... 84

Reliability ...........................................................................................85

Mean Time Between Failures.......................................................85

Mean Time To Repair.................................................................. 85

A Acronyms and Measurements .......................................87

Acronyms and Abbreviations..............................................................87

Measurements...................................................................................89

B Vendor-Unique SCSI Information ..................................91

Overview............................................................................................91

MODE SELECT Flash Memory Configuration Page (30

MODE SENSE Flash Memory Configuration Page (30

)...................92

H

).....................93

H

Glossary......................................................................................95

Page viii DAT Drives

Page 11

Figures

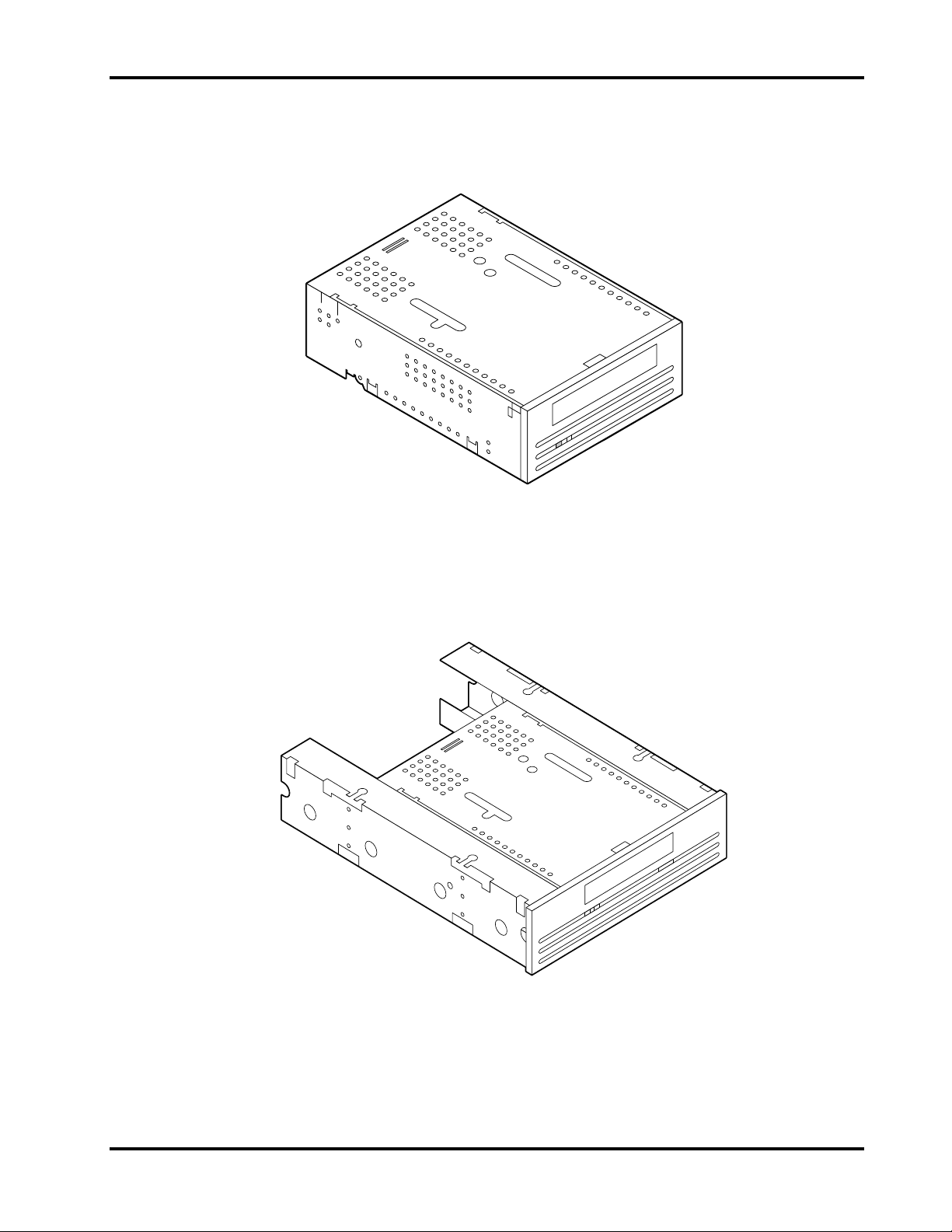

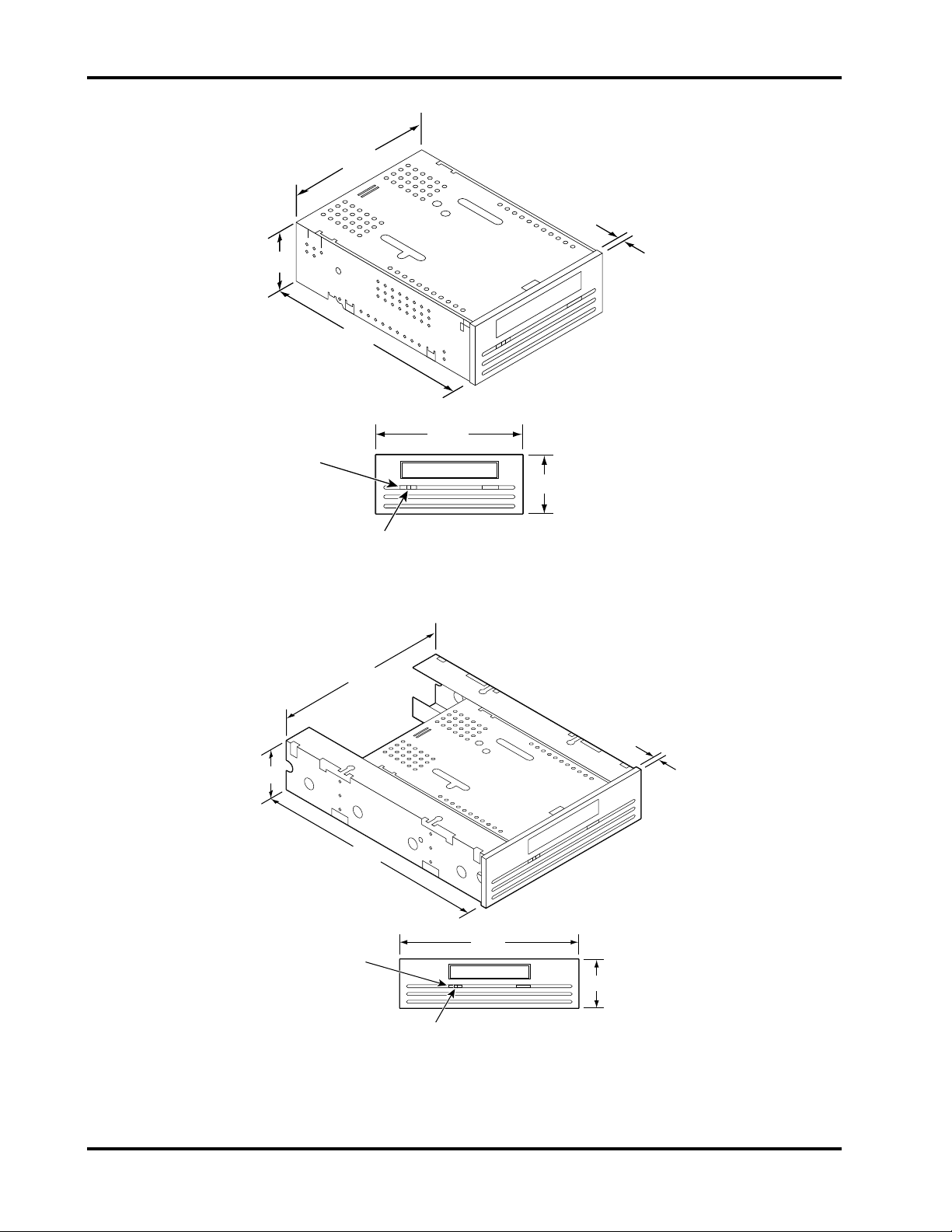

Figure 1. 3.5-inch Internal DDS Drive...................................................5

Figure 2. 5.25-Inch Internal DDS Drive.................................................5

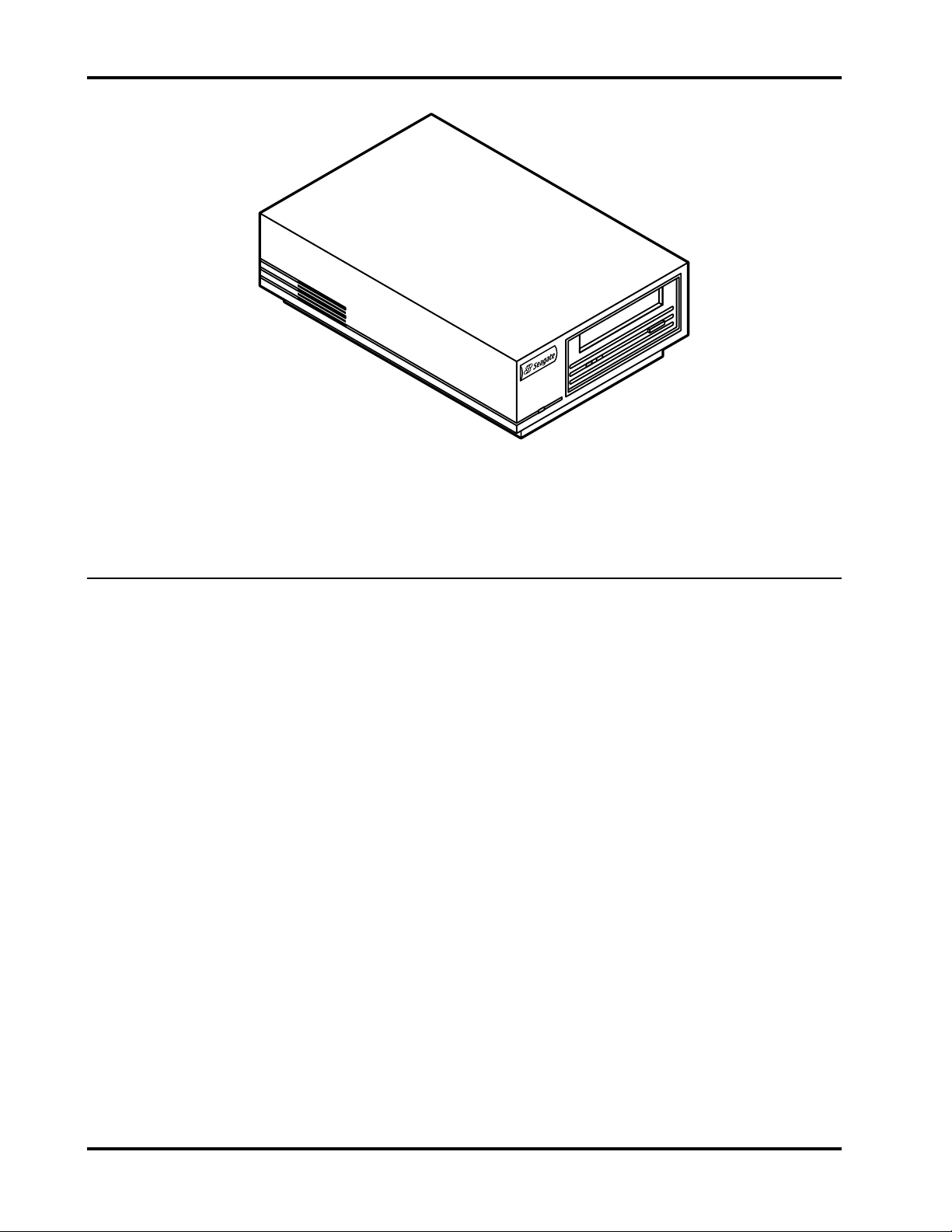

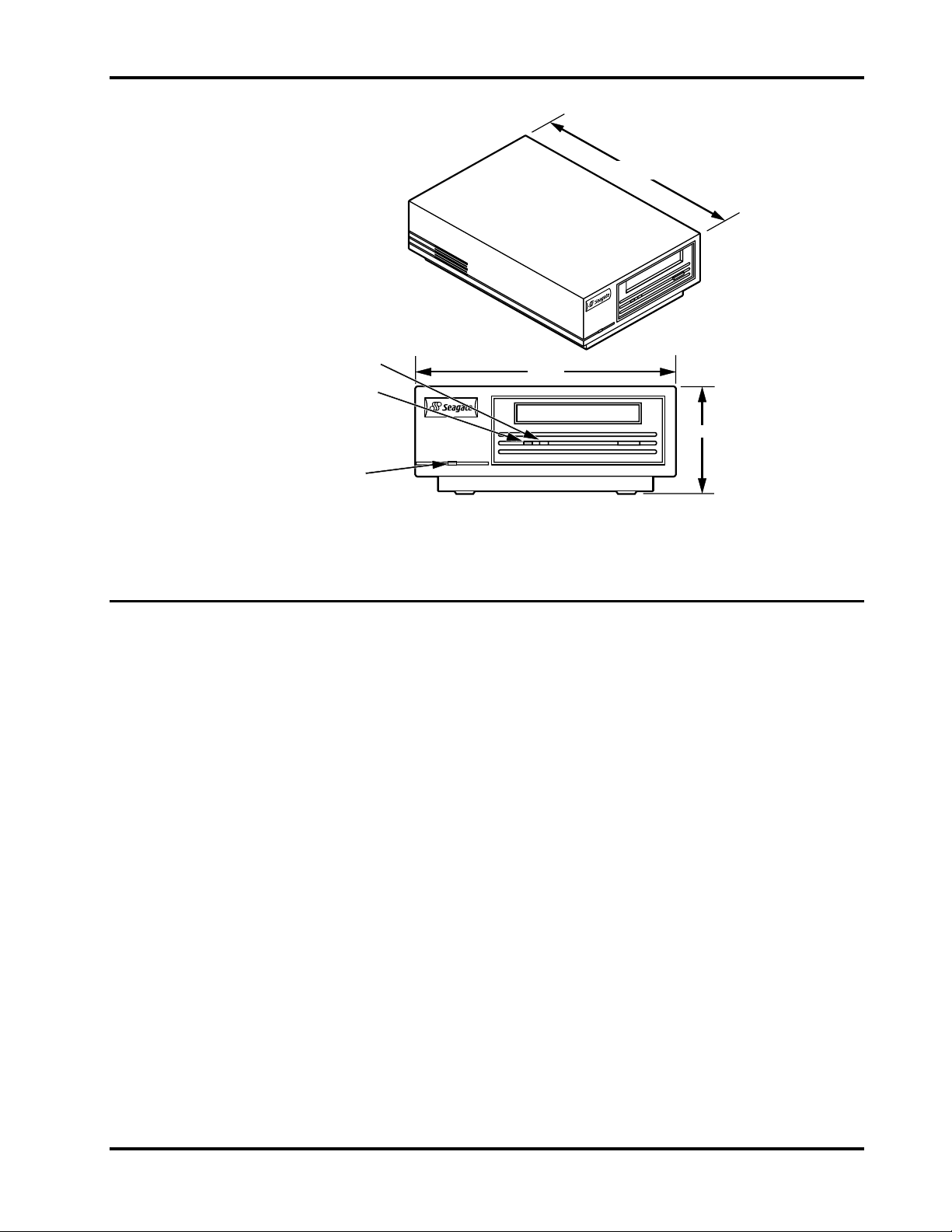

Figure 3. External DDS Drive...............................................................6

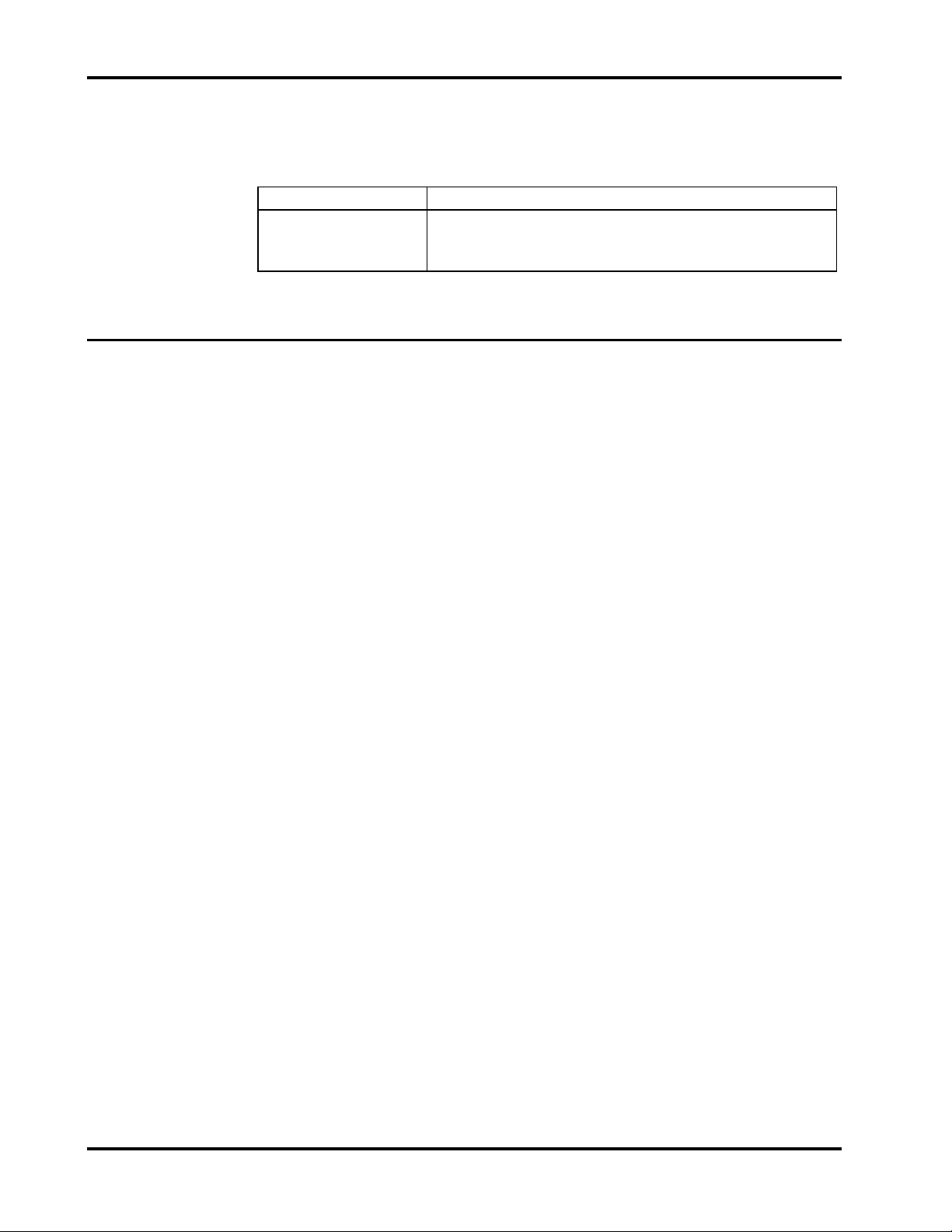

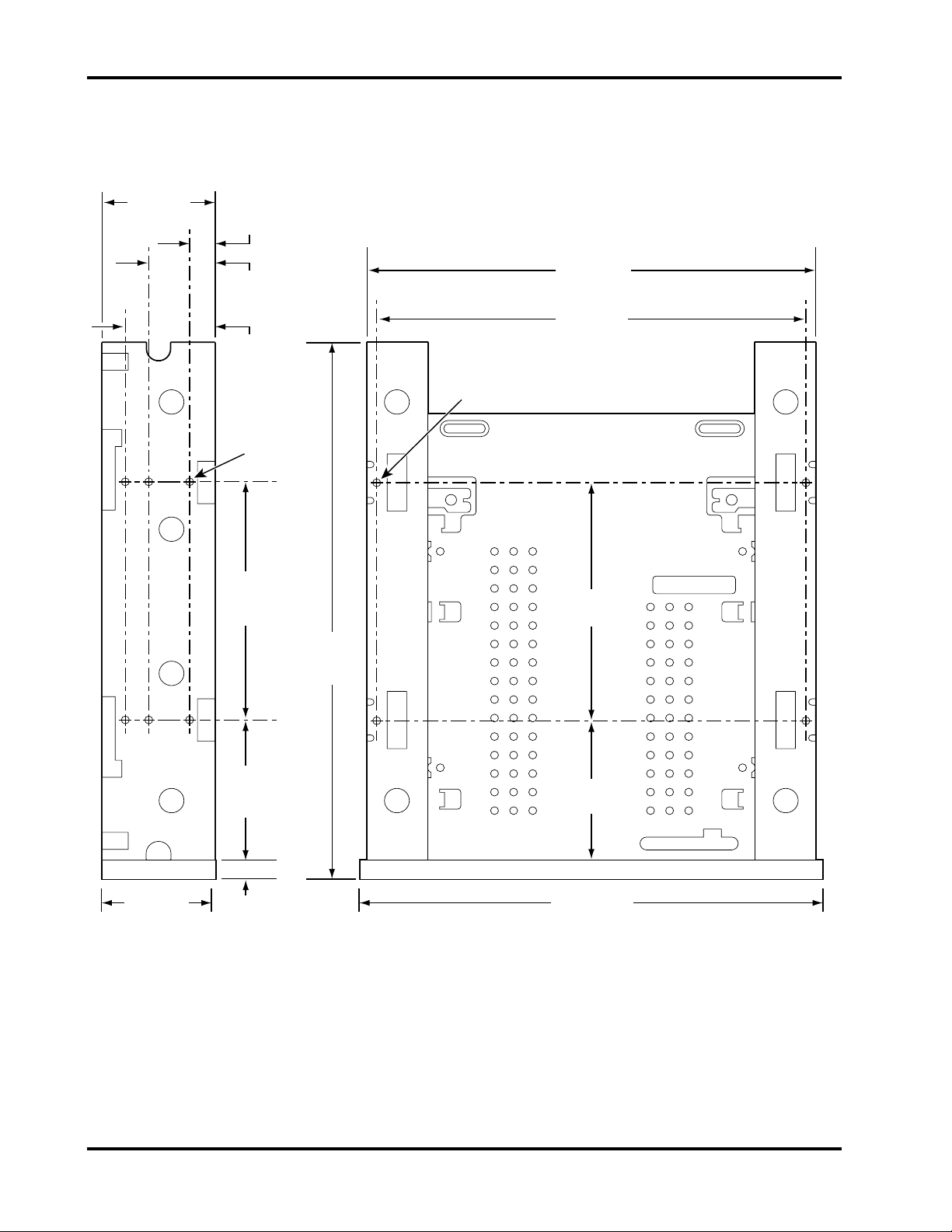

Figure 4. Internal DDS Drive—General Dimensions ...........................10

Figure 5. Internal DDS Drive with Rails—General Dimensions............10

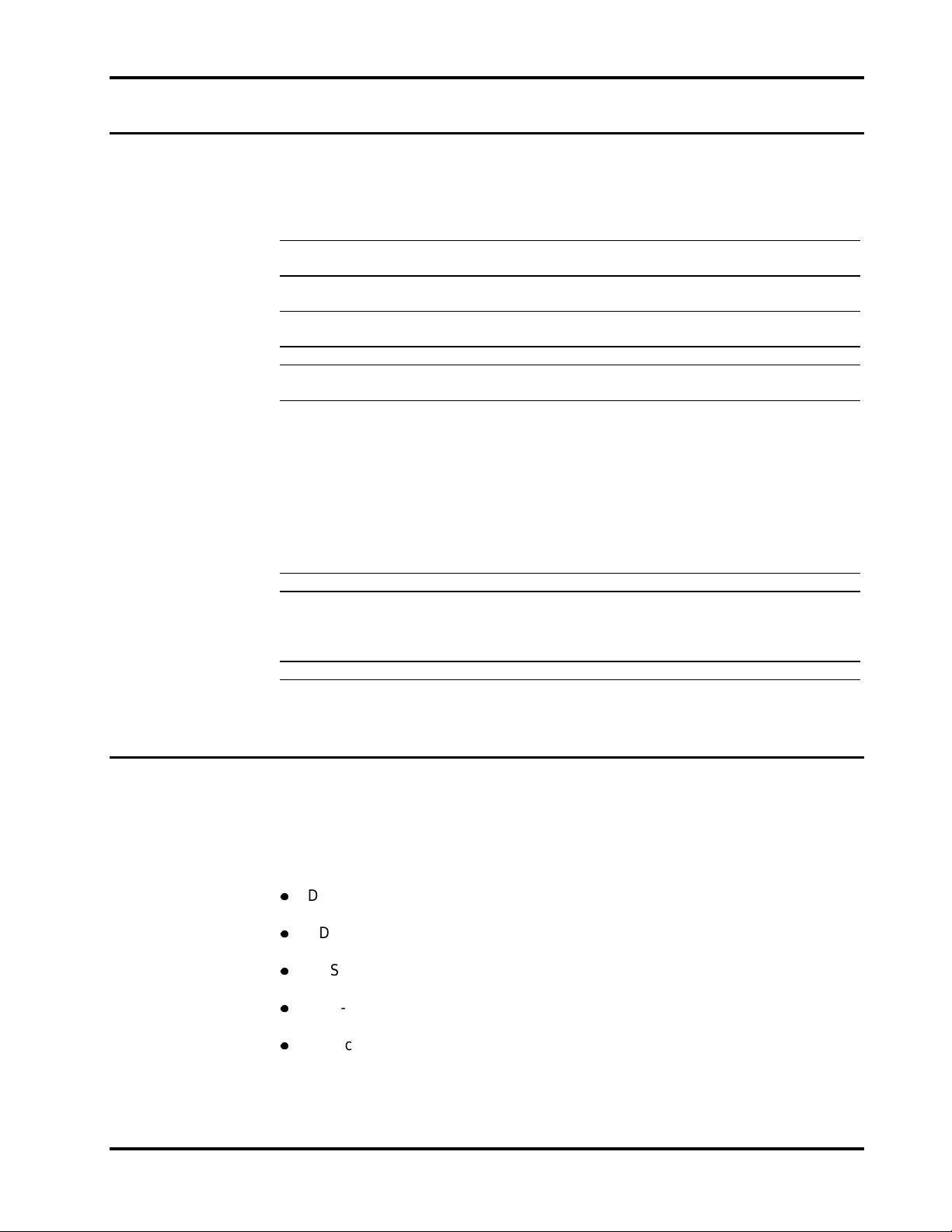

Figure 6. External Subsystem—General Dimensions .........................11

Figure 7. Switchbank Access—3.5-Inch Internal Model ......................20

Figure 8. Switchbank Access—5.25-Inch Internal Model ....................21

Figure 9. Dip Switch Default Settings .................................................22

Figure 10. Location of Jumpers for Internal Model..............................24

Figure 11. Location of Jumpers for Internal Model with Rails..............24

Figure 12. Jumper Configurations.......................................................25

Figure 13. Mounting Hole Locations (Internal Drive without Rails).......27

Figure 14. Mounting Hole Locations (Internal Drive with Rails) ...........28

Figure 15. Rear Panel (External Model)..............................................30

Figure 16. Daisy Chain Diagram.........................................................31

Figure 17. Front Panel—Internal Model..............................................35

Figure 18. Front Panel—Internal Model with Rails..............................36

Figure 19. Front Panel—External Subsytem.......................................36

Figure 20. Cartridge Loading (Internal DAT Drive)..............................37

Figure 21. Locations on Drive.............................................................38

Figure 22. SCSI System Sample Configurations.................................46

Figure 23. Structure of a Basic Group................................................48

Figure 24. Track Configuration...........................................................50

Figure 25. Timing Tracking.................................................................53

Figure 26. Layout of a Single Data Space Tape..................................54

Figure 27. Appending Rules...............................................................55

Figure 28. Tolerance on Seamless Appending ...................................56

Figure 29. Layout of a Partitioned Tape..............................................58

Figure 30. Layout of SCSI/Data Compression Device.........................69

Figure 31. Simplified Block Diagram—Scorpion 24 DDS-3 Drive ........73

Figure 32. Block Diagram—SCSI Controller DAT Models...................74

Figure 33. Four-Head Design.............................................................75

Figure 34. Alternate Azimuth Angles ..................................................76

Figure 35. DDS Cartridge...................................................................80

Figure 36. Cartridge Design Features.................................................81

Figure 37. Write-Protect Tab on the DDS Cartridge............................81

Product Manual Page ix

Page 12

Figures

Page DAT Drives

x

Page 13

Introduction

Overview

1

®

The Seagate

computer environments that require high-performance, high-capacity data storage.

Based on a 3.5-inch mechanism, the internal and external Scorpion 24 models

provide 12 Gbytes of data-storage capacity, 24 Gbytes compressed, with a native

transfer rate of 1.1 Mbytes per second, 2.2 Mbytes per second compressed.

The Scorpion 24 drive combines established DAT technology, high-density

recording and hardware data-compression capability along with Seagate’s proven

computer grade design to provide unmatched reliability and performance

characteristics among DDS products. The Scorpion 24 is ideal for workstation,

server and network/enterprise applications such as:

z

Backup of high-capacity fixed discs

z

Data interchange between systems

z

Network server

z

Loader products

z

Online data collection

z

Near-line secondary storage for text, graphics or multimedia information of all

types

Scorpion

®

24 digital data storage (DDS) drive is designed for

z

Archival storage

DDS Format Standard Compatibility

The Scorpion 24 drive supports the DDS-3, DDS-2 and DDS recording formats.

Compatibility with each of these standards ensures complete write and read

interchange of recorded digital data between all compliant drive and media vendors.

Additionally, the Scorpion 24 drive supports DDS-DC, the DDS data compression

standard, effectively doubling storage capacity and transfer rates.

Product Manual Page 1

Page 14

Chapter 1 Introduction

The Scorpion 24 drive complies with:

z

The DDS recording format standard,

ANSI/ECMA-139, 3,81mm Wide Magnetic

Tape Cartridge for Information Interchange - Helical Scan Recording - DDS

Format.

z

The DDS-DC recording format standard,

ANSI/ECMA-150, 3,81mm Wide

Magnetic Tape Cartridge for Information Interchange - Helical Scan Recording DDS-DC Format using 60 m and 90 m Length Tapes.

z

The DDS-2 recording format standard,

ANSI/ECMA-198, 3,81mm Wide

Magnetic Tape Cartridge for Information Interchange - Helical Scan Recording DDS-2 Format using 120 m Length Tapes.

z

The DDS-3 recording format standard,

ANSI/ECMA-236, 3,81mm Wide

Magnetic Tape Cartridge for Information Interchange - Helical Scan Recording DDS-3 Format using 125 m Length Tapes.

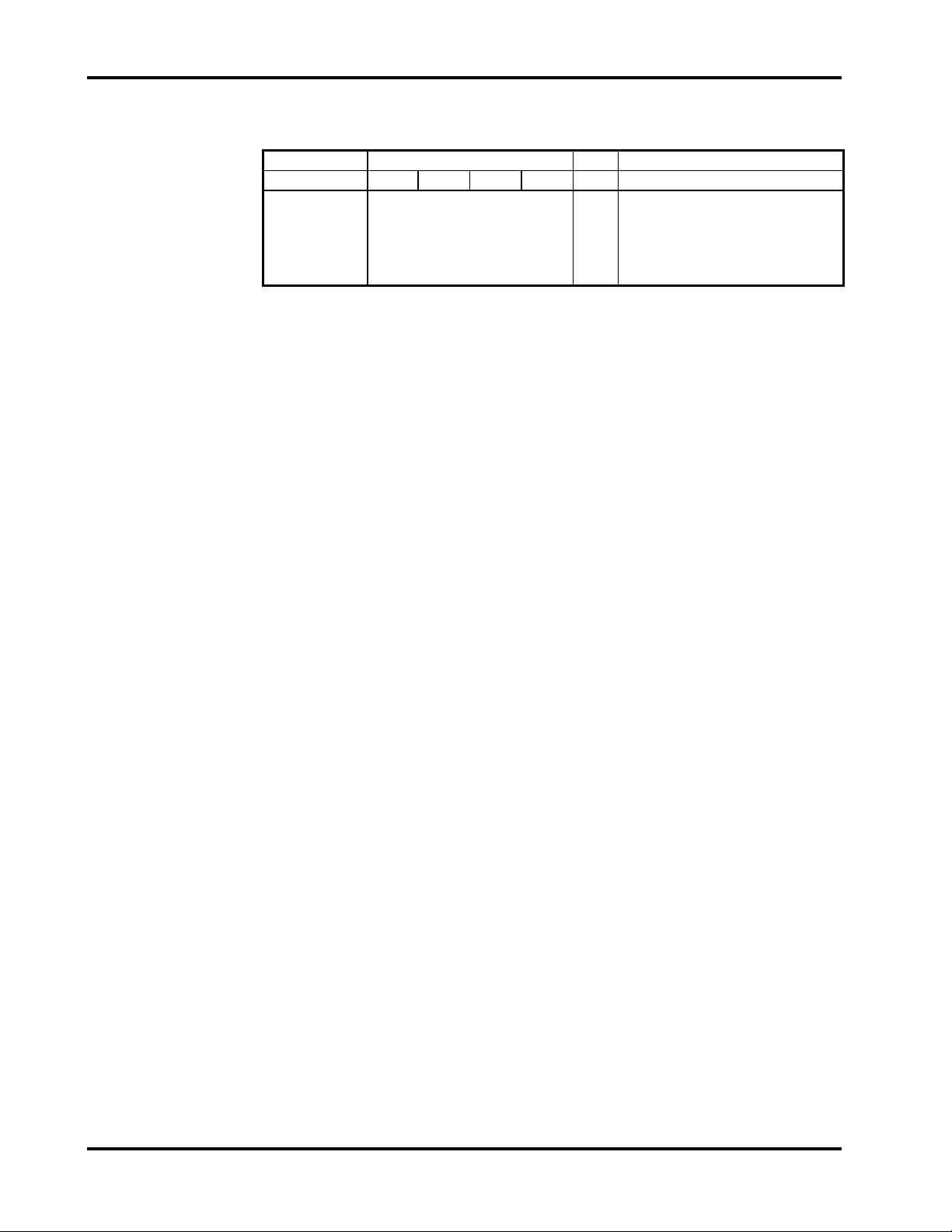

Scorpion 24 Capacity and Transfer Rates

The Scorpion 24 provides the following capacities and transfer rates, depending on

recording mode and tape length:

Recording Mode

DDS DDS-DC DDS-2 DDS-3

Tape length 60 meter 90 meter 120 meter 125 meter

Capacity (native) 1.3 Gbytes 2.0 Gbytes 4.0 Gbytes 12.0 Gbytes

Capacity (compressed) N/A 4.0 Gbytes 8.0 Gbytes 24.0 Gbytes

Transfer rate (native) 780

Kbytes/sec

780

Kbytes/sec

780

Kbytes/sec

1.1

Mbytes/sec

In data-compression mode, the Seagate Scorpion 24 drive typically doubles the

storage capacity and transfer rate of the native uncompressed operation. Tape

capacity and sustained data-transfer rate are also dependent upon the

characteristics of the files being compressed, along with other system parameters,

including the speed of the host, the operating system and the application software

used.

The Scorpion 24 drive also offers synchronous or asynchronous SCSI transfers with

a high-speed burst data-transfer rate of 10 Mbytes per second.

The Scorpion 24 provides unmatched reliability through three levels of errorcorrection code (ECC) and the four-head design, which provides for read-after-write

(RAW) error detection and correction. The Scorpion 24 also contains an onboard

serial port that provides the capability for extensive testing of the drives.

Page 2 DAT Drives

Page 15

Introduction Chapter 1

Features

The Scorpion 24 DDS drive represents Seagate’s commitment to engineering

reliable and durable tape drive products that implement leading-edge technology.

Key features of the drive include:

z

Platform based on 3.5-inch DDS drive components

z

3.5-inch internal form-factor for installation in a 3.5-inch half-height space

(model STD124000N)

z

3.5-inch drive with factory-installed 5.25-inch mounting rails and bezel for

installation in a 5.25-inch half-height space (model STD224000N)

z

External subsystem with built-in, auto-sensing, worldwide power supply (model

STD624000N)

z

Capability to write and read DDS-3, DDS-2, DDS-DC and DDS cartridges

z

Advanced onboard DDS-DC hardware using Data Compression Lempel-Ziv

(DCLZ) data-compression algorithm

z

ANSI/ECMA DDS-3, DDS-2, DDS-DC and DDS tape format compliance for

compatibility and interchange

z

High-speed random access of 20 seconds (average) to any file on a 60 m tape;

30 seconds for a 90 m tape; 40 seconds on a 120 m tape; and 40 seconds on a

125 m tape

z

High-speed transfer rates for fast backups:

– 1.1 Mbytes per second (66 Mbytes per min) typical—uncompressed data

– 2.2 Kbytes per second (132 Mbytes per min) typical—compressed data

z

High-performance SCSI burst transfer rate of 7 Mbytes per second

asynchronous and 10 Mbytes per second synchronous

z

Flash memory to store setup parameters

z

Four-head design with RAW error detection and rewrites

z

Three levels of ECC to ensure data integrity

z

Uncorrectable error rate of less than 1 in 1015 bits

z

Flash memory to enable field firmware upgrades

z

Custom Seagate-designed LSI circuitry to reduce component count and boost

drive reliability

z

Advanced, single-chip, DDS formatter LSI

z

Low power consumption—less than 5.5 watts (typical) for internal drives

Product Manual Page 3

Page 16

Chapter 1 Introduction

z

Single-ended SCSI connection with these features:

– Embedded full LSI, high-speed SCSI-2 controller

– Software selectable synchronous or asynchronous SCSI data transfer

– Onboard output jack on internal models for configuring the SCSI

address if repackaged in an external box

z

Automatic power-on self-tests available

z

Manual emergency cartridge ejection procedure

z

Support for TapeAlert™ Certified Solutions

Models

The Scorpion 24 3.5-inch and 5.25-inch internal drive form-factors are tailored for

easy installation in today’s computers, and the full-featured embedded SCSI

controller facilitates easy integration into a variety of systems.

Scorpion 24 Model Names

Capacity 24.0 Gbytes*

3.5-in internal STD124000N

5.25-in internal STD224000N

External STD624000N

*Typical with data compression

Scorpion 24 models include:

z

A 3.5-inch, half-height DDS-3 drive that mounts internally (model

STD124000N).

z

A 5.25-inch, half-height DDS-3 drive that consists of a 3.5-inch drive with 5.25inch mounting rails and bezel that mounts internally in a 5.25-inch, half-height

space (model STD224000N).

z

A complete external subsystem that contains the 3.5-inch DDS-3 drive and

built-in worldwide power supply (model STD624000N).

Page 4 DAT Drives

Page 17

Introduction Chapter 1

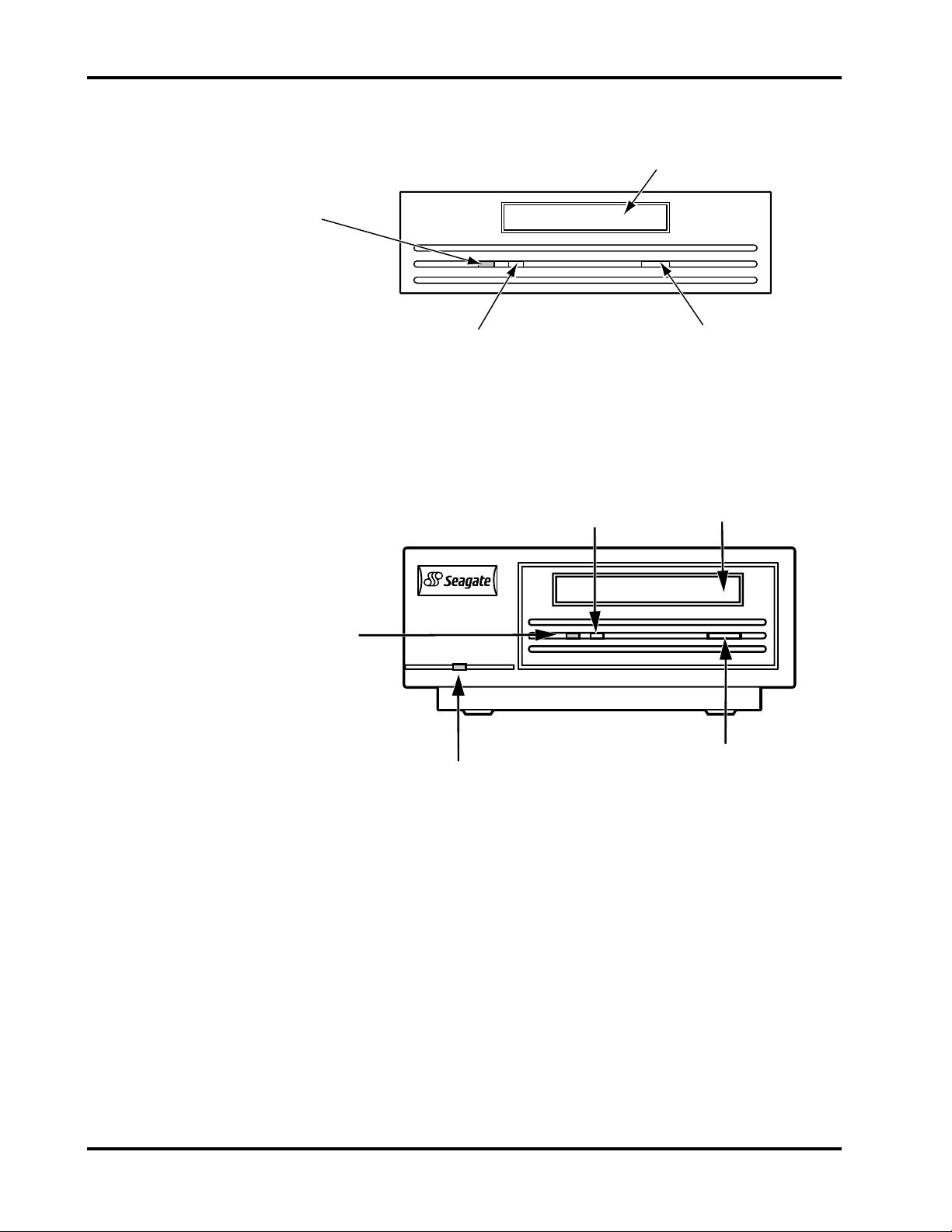

Figures 1, 2 and 3 illustrate the internal, internal with rails and external drives,

respectively.

Figure 1. 3.5-Inch Internal DDS Drive

Figure 2. 5.25-Inch Internal DDS Drive

Product Manual Page 5

Page 18

Chapter 1 Introduction

Figure 3. External DDS Drive

DAT Technology Overview

Developed for the audio electronics market, DAT technology was first applied in

computer peripherals in the late 1980s. Unlike traditional magnetic tape audio

cartridge products, DAT technology proves inherently reliable through the

scan recording method,

error rate. All DAT products, including computer implementations, use the helical

scan recording method. This recording method has been used in professional video

tape recorders (VTRs) since 1956 and in home video cartridge recorders (VCRs)

since 1974. In 1986, DAT products that used helical scan technology were first

developed for audio applications. DAT consumer products are specifically designed

for digital audio recording and playback.

Helical Scan Recording

Helical scan recording was originally developed as a method of efficiently recording

high-quality television signals on a relatively slow moving tape. It requires that both

the tape and the recording head move simultaneously. This recording method

results in an extremely high recording density, far higher than can be achieved with

stationary-head devices such as 1/2-inch open-reel or 1/4-inch cartridge tapes. (See

chapter 8, “Helical Scan Recording—Four-Head Design” for additional information.)

In helical scan recording, both the read and write heads are located on a rapidly

rotating cylinder or drum. The cylinder is tilted at an angle in relation to the vertical

axis of the tape. As the tape moves horizontally, it wraps around the part of the

circumference of the cylinder (102°) so that the head enters at one edge of the tape

and exits at the other edge before the tape unwraps.

helical

which provides a high recording density with a very low

Page 6 DAT Drives

Page 19

Introduction Chapter 1

The horizontal movement of the tape in combination with the angular movement of

the cylinder causes the track to be recorded diagonally across the tape rather than

straight down its length. The resulting recorded track, nearly one inch, is

approximately eight times longer than the width of the tape.

Recording Formats

The Seagate Scorpion 24 DDS drive is designed to comply with the industrystandard DDS-3, DDS-2, DDS-DC and DDS recording formats. These formats are

summarized in the following text.

DDS-3 Recording Format

The DDS-3 recording format provides for writing data in helical tracks that are the

same width as DDS-2. The significant capacity increase associated with DDS-3 is

achieved by: 1) doubling linear recording density from 61 Kbpi (DDS-2) to 122 Kbpi

along with the use of PRM L enc oding; 2) increasing tape length to 125 meters and

3) using the timing tracking system, which eliminates the need for dedicated top and

bottom servo burst information associated with the previous ATF system.

DDS-2 Recording Format

DDS Recording Format

The DDS-2 or narrow track recording format provides for writing data in helical

tracks that are narrower than the previous DDS track width. This format doubles

capacity by increasing track density one and a half times, along with a 33% increase

in tape length; the higher output MP+ media associated with the 120-m DDS-2

cartridges ensures reliable data integrity given the decrease in track widths from

13.6 µm with DDS and DDS-DC to 9 µm with DDS-2.

This standard format was codeveloped by DDS manufacturers to support DAT

devices as computer peripherals. The objectives of DDS are to maximize storage

capacity and performance, facilitate data interchange, provide compatibility with

existing tape storage command sets and provide extremely fast random access.

The DDS format also takes advantage of the helical scan recording method and the

inherent error correction capability of the DAT technology to augment error detection

and correction.

The format consists of a finite sequence of data groups where each data group is a

fixed-length recording area. A data group is made up of 22 data frames and 1 ECC

frame; each frame is made up of two helical scan tracks. The advantages of the

fixed-length data group is that ECC is easily generated, and buffering requirements

are simplified. (See Chapter 6, “Tape Formats,” for additional information.)

Although data groups are fixed-length and always contain 22 data frames, the DDS

format is designed such that variable-length computer records can be stored in the

fixed-length data groups.

Product Manual Page 7

Page 20

Chapter 1 Introduction

DDS-DC Recording Format

A superset of the basic DDS format, DDS-DC drives can write compressed and

uncompressed data to the same cartridge. Because DDS-DC is based on the DDS

format, backward-compatibility is maintained.

Introduced by the DDS Manufacturers Group and approved by ANSI and ECMA,

DDS-DC is a

lossless

compression algorithms based on substitution—such as those of the

record compression

industry-standard format that provides support for

Lempel-Ziv family.

This format supports compressed and uncompressed records. A recorded DDS

cartridge may contain compressed records, uncompressed records, filemarks and

setmarks. Compressed records exist within recorded objects called

entities

. Entities

and uncompressed records are collected into groups.

Many aspects of the DDS-DC format are identical to those of the DDS format:

z

The series of transformations (randomizing, interleaving, generation and

inclusion of two Reed-Solomon error-correction codes) applied to a group

before recording

z

The tape layout

z

The third group-based level of Reed-Solomon error-correction codes (C3)

The only differences between the DDS and DDS-DC formats are in the contents of

the groups.

Page 8 DAT Drives

Page 21

Specifications

Overview

This chapter includes technical specifications for the internal and external SCSI

drives. This information covers the following specifications and requirements:

z

z

z

z

z

z

2

Physical specifications

Power requirements

Drive performance specifications

Environmental requirements

DAT cartridge specifications

Regulatory compliance

Physical Specifications

The physical specifications of the Scorpion 24 internal and external models are

listed in the following table:

Specification Internal Internal with rails External

Height 1.6 in/41.2 mm 1.6 in/41.2 mm 2.7 in/69 mm

Width 4.0 in/101.6 mm 5.7 in/146.0 mm 6.1 in/155.0 mm

Length 5.7 in/146.0 mm 6.9 in/175.0 mm 9.3 in/236.0 mm

Weight 2.0 lb/0.85 kg 2.4 lb/1.1 kg 4.1 lb/1.8 kg

Figures 4, 5 and 6 illustrate the general dimensions of the internal and external drive

models. Drive dimensions are in millimeters.

Product Manual Page 9

Page 22

Chapter 2 Specifications

101.6

6

41.3

146

Cassette

104.1

in Place (Green)

41.2

Drive Busy (Yellow)

Figure 4. Internal DDS Drive—General Dimensions

146

41.4

174.6

6

Cassette

in Place (Green)

Drive Busy (Yellow)

149.1

41.2

Figure 5. Internal DDS Drive with Rails—General Dimensions

Page 10 DAT Drives

Page 23

Specifications Chapter 2

236

Drive Busy

(Yellow)

Cassette in Place

(Green)

Power On

(Green)

155

69

Figure 6. External Subsystem—General Dimensions

Power Specifications

The following table lists the power specifications for the internal Scorpion 24 drives.

DC Voltage +12 VDC +5 VDC

Voltage Tolerance + or – 10% + or – 7%

Operational Current 250 milliamps 600 milliamps

Standby Current 50 milliamps 550 milliamps

Peak 600 milliamps 800 milliamps

Ripple (peak-to-peak)

Power dissipation

(Standby)

Power dissipation

(Operating)

The following table lists pin assignments of the power connector for the internal

models.

Pin Assignment

1 +12 VDC

2 +12 return

3 +5 return

4 +5 VDC

≤

100 mV

≤

100 mV

< 3.3 watts < 2.2 watts

< 5.5 watts < 5.5 watts

Product Manual Page 11

Page 24

Chapter 2 Specifications

The external drives have a built-in power supply that senses the incoming voltage

and automatically adapts to voltages within the range of 100 to 240 volts, 50 to 60

Hz. The following table lists its power specifications.

Specification AC Input Voltage

100 (Japan) 120 (US) 240 (European)

AC Input Current 100 milliamps 85 milliamps 170 milliamps

AC Input Power 10.0 watts 10.0 watts 10.0 watts

Drive Performance Specifications

The following table lists the specifications for the Scorpion 24 drive.

Capacity

60 m MP

90 m MP

120 m MP+

125 m MP++

2.6 Gbytes

4.0 Gbytes

8.0 Gbytes

24.0 Gbytes

Recording density 122,000 bpi

Flux density 152,400 ftpi

Track density 2,804 tpi

Error recovery Read-after-write

Reed Solomon ECC (C3 - 3 levels)

Recording unrecoverable errors < 1 in 10

Tape drive type Computer grade 4DD mechanism

Head configuration 2 read heads, 2 write heads

Recording format DDS-3

Recording method Helical scan (R-DAT)

Cartridge 2.9 in × 2.1 in × 0.4 in

Transfer rate (sustained) 2,200 Kbytes per sec DC ON

Synchronous transfer rate (burst) 10 Mbytes per sec max

Asynchronous transfer rate (burst) 7 Mbytes per sec max

Search speed 200 X normal speed

Average access time

60 m cartridge

90 m cartridge

120 m cartridge

125 m cartridge

Drum rotation speed 4,000 RPM (DDS-3 mode)

Tape speed 0.43 in per sec

Head-to-tape speed 246.94 in per sec

<20 sec

<30 sec

<40 sec

<40 sec

8,000 RPM (DDS-2, DDS modes)

15

data bits

Page 12 DAT Drives

Page 25

Specifications Chapter 2

Environmental Requirements

The following table lists the environmental specifications for DDS drives. You can

mount internal DDS drives either vertically (drive left side up or right side up) or

horizontally.

Specification Operational Nonoperational

Temperature +41o to +113oF

(+ 5o to + 45oC)

Thermal gradient 2oC per minute

(no condensation)

Relative humidity 20% to 80%

noncondensing

Maximum wet bulb temperature 78.8oF (26oC) No condensation

Altitude –100 to +4,575 meters –300 to +15,200

Vibration — 1.5 g (5 to 500 Hz)

Sweep Test 1.20 mm peak-to-peak

(5–17 HZ)

0.73 G peak (17 to 150 Hz)

0.50 G peak (150–500 Hz)

Sweep Rate 8 decades per hour —

Dwell Test (15 min) 0.90 mm peak-to-peak

(5–17 Hz)

0.55 G peak (17–150 Hz)

0.25 G peak (150–500 Hz)

Acoustic level idling (A-wt sum) 45 dBA maximum —

Acoustic level operational

(A-wt sum)

Shock (1/2 sine wave) 10 Gs peak, 11 msec 50 Gs peak, 11 msec

50 dBA maximum

(measured in suitable

enclosure at 3-ft distance

and operator height)

1

1

o

–40

to +149oF

(–40o to + 65oC)

Below condensation

0% to 90%

noncondensing

meters (power off)

—

—

—

—

—

—

—

2

2

1. Mechanism and media 2. Mechanism

DDS Cartridge Specifications

DDS drives provide maximum data integrity and reliability when Seagate-qualified

DDS cartridges are used as the recording media. Seagate maintains an ongoing

program to qualify manufacturers of DDS cartridges.

The following cartridges are recommended:

z

DDS data cartridge: model M31300, 60-meter tape

z

DDS data cartridge: model M32000, 90-meter tape

z

DDS-2 data cartridge: model M34000, 120-meter tape

z

DDS-3 data cartridge: model M312000, 125-meter tape

z

DDS cleaning cartridge: model M91301

Contact your Seagate sales representative for information on qualified DDS data

and cleaning cartridge manufacturers and models.

Product Manual Page 13

Page 26

Chapter 2 Specifications

Regulatory Compliance

These DDS drives comply with the regulations listed in the following table.

Agency Regulation

CSA C22.2, No. 950-M89

TUV-RHEINLAND EN 60 950

UL 1950

FCC Class A and Class B

CE CE compliance

1. Required compliance for external model; verification on file for internal models.

Use these drives only in equipment where the combination has been determined to

be suitable by an appropriate certification organization (for example, Underwriters

Laboratories Inc. or the Canadian Standards Association in North America). You

should also consider the following safety points:

Install the drive in an enclosure that limits the user’s access to live parts, gives

adequate system stability and provides the necessary grounding for the drive.

1

Provide the correct voltages (+5 VDC and +12 VDC) based on the regulation

applied—Extra Low Voltage (SEC) for UL and CSA and Safety Extra Low

Voltage for BSI and VDE (if applicable).

Page 14 DAT Drives

Page 27

Installation

Introduction

3

This chapter explains how to install the Scorpion 24 drive. Some of the information

relates to all models; other information is specifically aimed at either the internal or

external models. The following paragraphs briefly outline the organization of this

chapter.

Guidelines and Cautions: lists guidelines for handling the internal drive.

z

Unpacking and Inspection: contains general information that you should read

z

before installation.

Cabling and Connectors: gives specific cabling requirements and connector

z

pinouts for the drive.

Installing the Internal Drives: describes installing the 3.5-inch internal drive

z

and the 3.5-inch drive with 5.25-inch mounting rails and bezel.

Installing the External Drive: describes installing the external subsystem.

z

Guidelines and Cautions (Internal Models)

The following guidelines and cautions apply to handling and installing the Scorpion

24 internal drive. Keep them in mind as you install the drive.

z

Internal drives contain some exposed components that are sensitive to static

electricity. To reduce the possibility of damage from static discharge, the drives

are shipped in a protective antistatic bag.

z

Do not remove the drive from the antistatic bag until you are ready to install it.

z

Before you remove the drive from the antistatic bag, touch a metal or grounded

surface to discharge any static electricity buildup from your body.

z

Hold the drive by its edges only, and avoid direct contact with any exposed

parts of the printed circuit board (PCB).

z

While not installed, always lay the drive either on top of the antistatic bag or

place it inside of the bag to reduce the chance of damage from static discharge.

Product Manual Page 15

Page 28

Chapter 3 Installation

Unpacking and Inspection

Although drives are inspected and carefully packaged at the factory, damage may

occur during shipping. Follow these steps for unpacking the drive.

1. Visually inspect the shipping containers and notify your carrier immediately of

any damage.

2. Place shipping containers on a flat, clean, stable surface; then carefully remove

and verify the contents against the packing list.

If parts are missing or the equipment is damaged, notify your Seagate

representative.

3. Always save the containers and packing materials for any future reshipment.

Cabling and Connectors

The Scorpion 24 drive provides a standard single-ended SCSI interface. ANSI SCSI

standards specify the technical requirements for correctly cabling and connecting

single-ended devices. This section provides some basic information about SCSI

cabling and connectors for the drives.

Cabling Considerations

You can use either a 50-pin flat cable or a 25-signal twisted-pair cable with a

maximum length of 6 meters (19 feet) to connect the drives to the SCSI host

adapter output. If twisted-pair cabling is used, connect the twisted pairs to physically

opposing contacts on the connector.

A stub length no greater than 0.1 meter should be used off the mainline connection

within any connected equipment.

The cable characteristic impedance should be between 90 ohms and 140 ohms. A

cable characteristic impedance of greater than 100 ohms is recommended.

To minimize noise and ensure even distribution of terminator power, the minimum

recommended conductor size is 28 AWG (0.08042 mm

Electrical Characteristics

This section lists measurements of various electrical signals in relation to the singleended SCSI connection. For these measurements, SCSI bus termination is

assumed to be external to the SCSI device.

2

).

Page 16 DAT Drives

Page 29

Installation Chapter 3

All signals except GROUND and TEMPWR must be terminated at both ends of the

cable. Each signal termination consists of 220 ohms (± 5%) to TEMPWR and 330

ohms (± 5%) to GROUND and must meet the following specifications or

requirements:

z

Terminators must supply a characteristic impedance of 100 to 132 ohms.

z

External terminators must be powered by the TEMPWR line, and units that

provide terminator power to the cable must have:

V

= 4.25 to 5.25 VDC

TERM

900 milliamps minimum source drive capability

The external drive normally supplies terminator power to the SCSI bus.

z

When TEMPWR matches the above values, the voltage of released signal lines

must be at least 2.5 VDC.

z

When a driver asserts a line and pulls it to 0.5 VDC, the current available to the

signal line driver may not exceed 48 milliamps. The first two terminators may

only supply 44.8 milliamps of this current.

z

When at least one device supplies TEMPWR, these conditions may be met by

any valid configuration of targets and initiators.

All signals use open-collector drivers. The output characteristics (measured at the

connector of the drive) of signals driven by the drive are:

z

Signal assertion (low-level output voltage): 0.0 to 0.5 VDC at 48 milliamps

sinking

z

Signal negation (high-level output voltage): 2.5 to 5.25 VDC

Signals received by the drive have the following characteristics.

z

Signal assertion (low-level input voltage): 0.0 to 0.8 VDC

z

Signal negation (high-level input voltage): 2.0 to 5.25 VDC

z

Maximum input load (low-level input current): –0.4 at 0.5 VDC

z

Minimum input hysteresis: 0.2 VDC

Product Manual Page 17

Page 30

Chapter 3 Installation

SCSI Connector—Internal Models

The internal drive provides a 50-pin, right-angle, dual-row connector on the main

PCB at the rear of the drive. The pin assignments for this single-ended connector

are listed in the following table.

Note. All odd pins, except pin 25, are connected to signal ground at the drive. Pin

25 is left open. A signal name or abbreviation preceded by a dash indicates

that the signal is active-low.

Pin Assignment

2 –DB(0)

4 –DB(1)

6 –DB(2)

8 –DB(3)

10 –DB(4)

12 –DB(5)

14 –DB(6)

16 –DB(7)

18 –DB(P)

20 GROUND

22 GROUND

24 GROUND

26 TERMINATOR POWER

28 GROUND

30 GROUND

32 –ATN

34 GROUND

36 –BSY

38 –ACK

2

–

40

RST

42 –MSG

44 –SEL

46 –C/D

48 –REQ

50 –I/O

1

1. The +5V drive supply is available on the SCSI connector as a terminator power

option. This pin is connected to the +5V through a diode. The option is selected

by a jumper at the rear of internal drives. Terminator power disabled is the

factory default.

2. ANSI defines –RST as a bidirectional pin. On the drive, –RST is input only.

Page 18 DAT Drives

Page 31

Installation Chapter 3

SCSI Connector—External Models

The external drive provides two 50-pin, shielded connectors (ANSI Alternative 2) on

the rear panel of the drive. These connectors consist of two rows of ribbon contacts

spaced 2.16 mm (0.085 in) apart.

These two connectors facilitate adding the drive to a daisy-chain configuration.

Either connector is a SCSI IN connection; the other is a SCSI OUT connection.

When the drive is the last device in the chain (or the only device), an external

terminator is plugged in the SCSI OUT connector.

The pin assignments for these single-ended connectors are listed in the following

table.

Note. Pins 1 through 12 and 14 through 25 are connected to ground. Pin 13 is

open. A signal name or abbreviation preceded by a dash indicates that the

signal is active-low.

Pin Assignment

26 –DB(0)

27 –DB(1)

28 –DB(2)

29 –DB(3)

30 –DB(4)

31 –DB(5)

32 –DB(6)

33 –DB(7)

34 –DB(P)

35 GROUND

36 GROUND

37 GROUND

38 TERMINATOR POWER

39 GROUND

40 GROUND

41 –ATN

42 GROUND

43 –BSY

44 –ACK

–

45

46 –MSG

47 –SEL

48 –C/D

49 –REQ

50 –I/O

RST

Product Manual Page 19

Page 32

Chapter 3 Installation

Installing Internal Drives

The two internal models are a 3.5-inch drive that mounts internal to the computer in

a 3.5-inch, half-height space and a 3.5-inch drive with mounting rails and bezel for

internal installation in a 5.25-inch, half-height space.

Installing these two models consists of a few easy steps:

1. Configure the switchbank parameters and set the jumpers.

2. Mount the drive unit.

3. Complete the power and interface connections.

The installation procedure is the same for both models except physically mounting

the unit in the computer. The following text explains the installation steps for both

models.

Configuring Options

You can configure various operational options on the Scorpion 24 by setting the

switches on a switchbank at the base of the drive or by setting jumpers on a jumper

block at the rear of the drive. The directions for setting both switches and jumpers

are given in the following subsections.

Setting the Switchbank Parameters

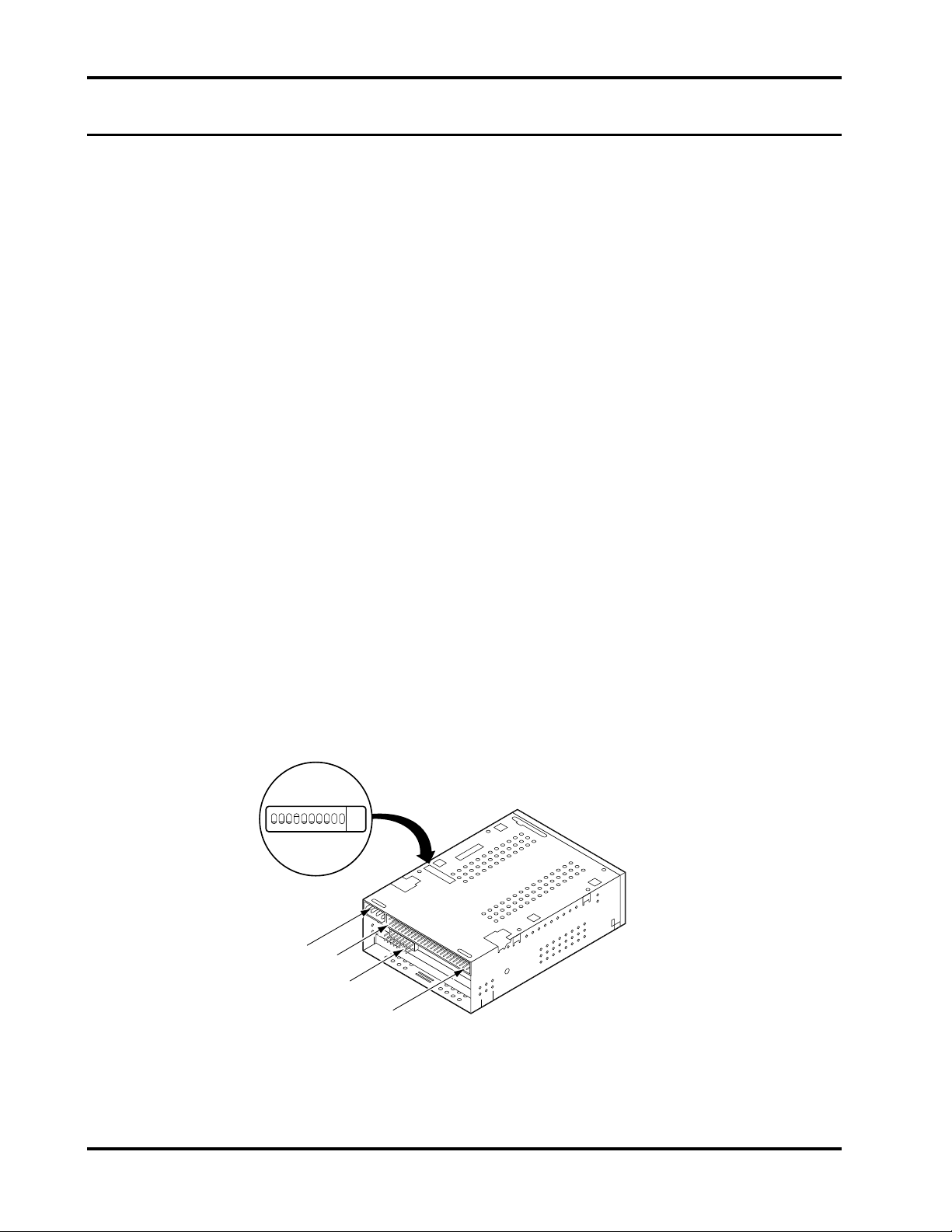

Set the switches before you install the drive in the computer. Figure 7 illustrates the

switchbank location for the 3.5-inch internal drive (bottom of the drive is shown).

123456789

F

F

O

Power

Connector

10

Pin 1

Jumper

Block

SCSI

Connector

Figure 7. Switchbank Access—3.5-Inch Internal Model

Page 20 DAT Drives

Page 33

Installation Chapter 3

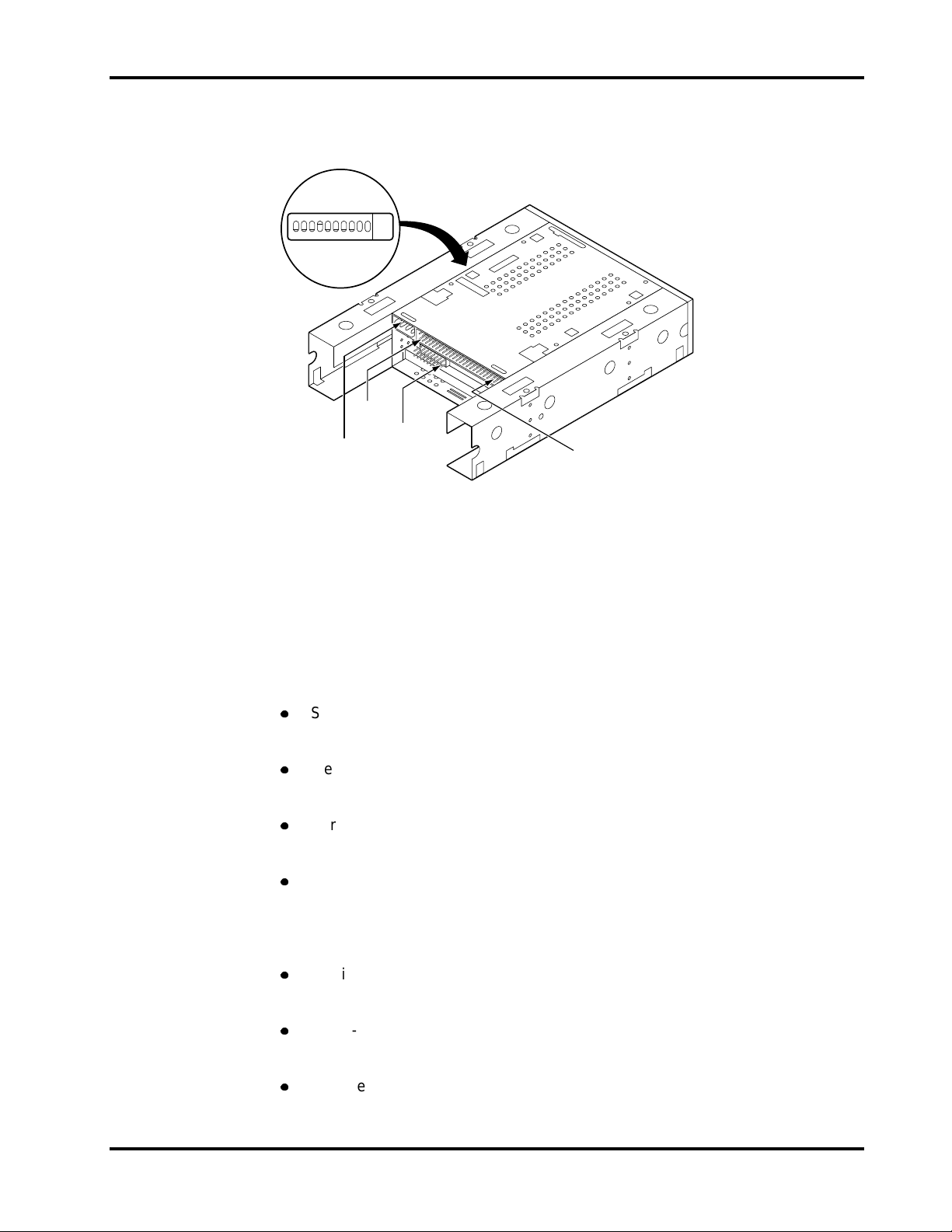

Figure 8 illustrates the switchbank location for the 5.25-inch internal drive (bottom of

the drive is shown).

123456789

F

F

O

Connector

Power

10

Pin 1

Jumper

Block

SCSI

Connector

Figure 8. Switchbank Access—5.25-Inch Internal Model

The Scorpion 24 switc hbank allows y ou to configure the S CS I device address,

media-recognition system (MRS) mode, parity check, DDS pass-through mode

(data-compress ion m ode) , Seagate’s selectable inquiry string and power- on s elf-test

(POST).

Following are brief descriptions of the various positions and with their def ault values.

z

SCSI device address (S1, S2, S3):

Default: SCSI ID = 0 (S1= OFF, S2 = OFF, S3 = OFF)

z

Media-recognition system (MRS) mode (S4):

Default: MRS check disabled (S4 = ON)

z

Parity check enable/disable (S5):

Default: Parity disabled (S5 = OFF)

z

DDS pass-through mode enable/disable (S6):

Default: Pass-through mode disabled (S6 = OFF)

When S6 is OFF, data compression is enabled.

When S6 is ON, data compression is disabled.

z

Inquiry string selection (S7):

Default: Seagate inquiry string (S7 = ON)

z

Power-on self-test enable/disable (S8):

Default: Power-on self-test disabled (S8 = OFF)

z

Reserved (S9 and S10):

Do not use these switches.

Product Manual Page 21

Page 34

Chapter 3 Installation

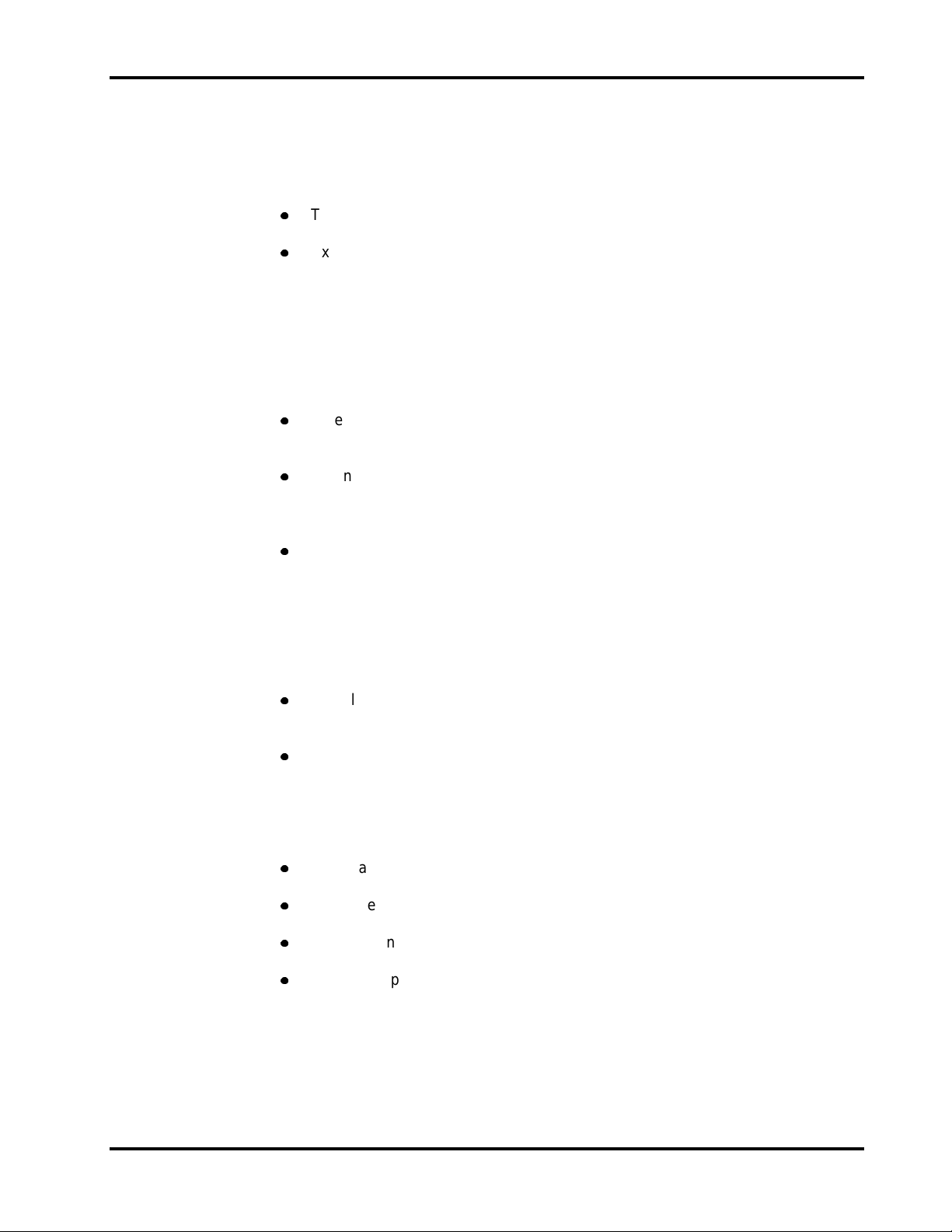

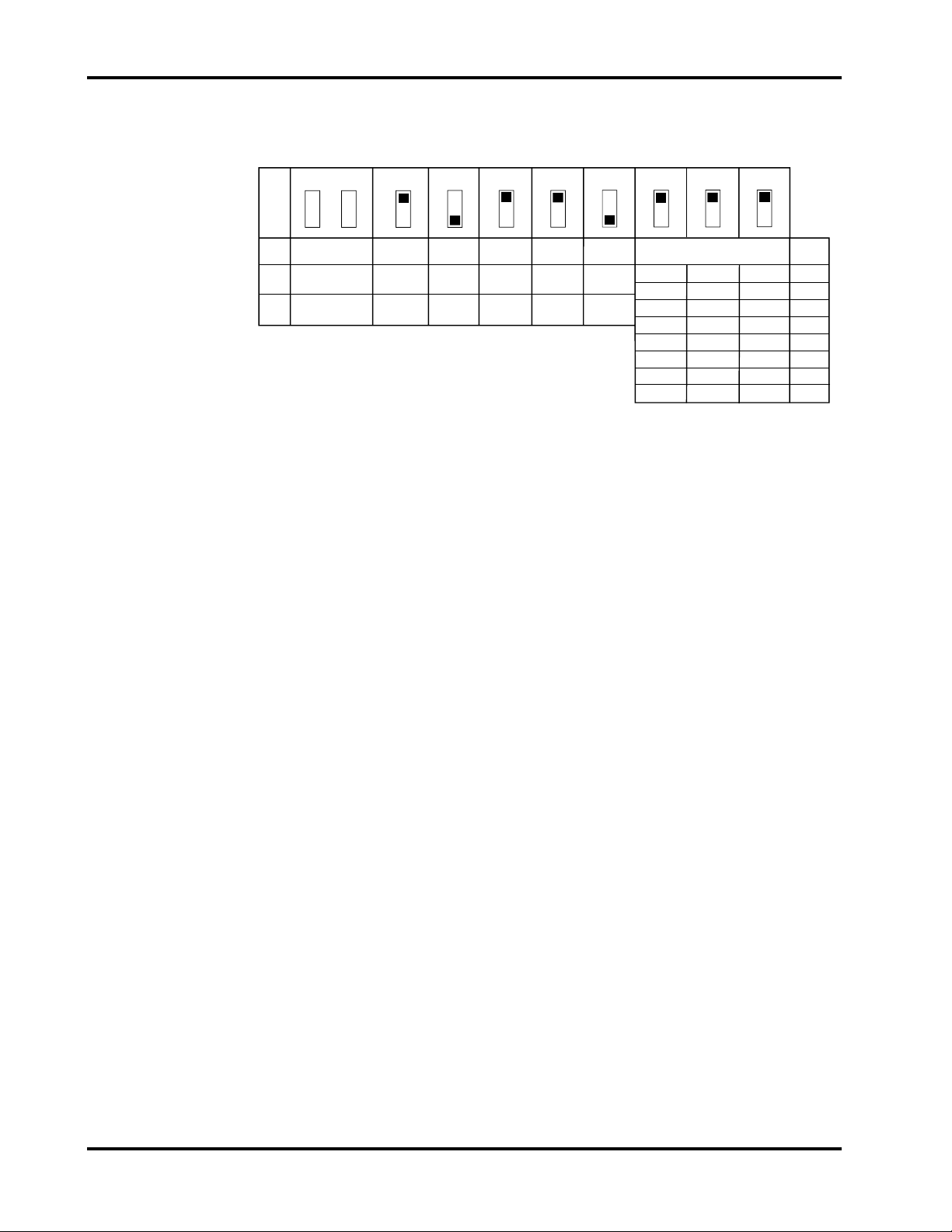

Figure 9 shows the default switch settings.

OFF

ON

OFF

ON

S9

S10

Reserved

(do not use)

S8

Self-test

Disable

Enable

S7

Inquiry

String

Archive

Seagate

DDS Pass-

through

DDS-DC

DDS

Parity

Disable

Enable

MRS

Mode

MRS

All

S2S3S4S5S6

SCSI ID Selection

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

ON

ON

OFF

OFF

ON

ON

S1

OFF

ON

OFF

ON

OFF

ON

OFF

ON

SCSI ID

0

1

2

3

4

5

6

7

Figure 9. Dip Switch Default Settings

If you need to change any of the factory-default settings, you must first power-cycle

the drive by turning it off and then on again, or a SCSI Bus Reset command must be

received for the new switch settings to take effect.

If the default settings are correct for your system,

go to: “Mounting the Drive” on page 27.

Otherwise, refer to the appropriate following section, make the changes, then go to:

“Mounting the Drive” on page 27.

SCSI Device Address (S1, S2, S3)

The three switches S1, S2 and S3 correspond to the SCSI device address

identification bits 0 (LSB) through 2 (MSB), respectively.

The default setting is SCSI device address 0 (S1 through S3 = OFF).

Be sure that no other device on the SCSI bus has the same SCSI address.

Media Recognition System (MRS) (S4)

S4 = ON disables the MRS check

S4 = OFF enables the MRS check

The default is MRS disabled (S4 = ON).

If S4 is ON, the drive writes or reads both MRS and non-MRS 4-mm media. If S4 is

OFF, the drive only writes to MRS media. The drive reports a check condition if the

media is nondata grade. The Sense Key is 07, Data Protect. The additional Sense

Code and qualifier is 30/00, incompatible media installed.

Page 22 DAT Drives

Page 35

Installation Chapter 3

Parity Check Enable/Disable (S5)

The S5 switch enables or disables parity checking for the SCSI bus.

The default is parity disabled (S5 = OFF).

S5 = ON enables parity checking

S5 = OFF disables parity checking

DDS Pass-Through Mode Enable/Disable (S6)

The S6 switch enables or disables DDS pass-through mode. The default is DDS

pass-through mode disabled (S6=OFF).

S6 = ON enables DDS pass-through mode

S6 = OFF disables DDS pass-through mode

If you are using the DIP switches to set the DDS pass-through mode, move the

DDS pass-through jumpers on the jumper block to the OFF position.

When S6 is OFF, DDS-DC data compression is ENABLED during writing.

When S6 is ON, DDS-DC data compression is DISABLED. During a read operation,

compressed data is always decompressed, regardless of the position of S6.

The function of the S6 switch can be overridden by the proper SCSI

command issued from the host computer. Regardless of the position of S6, the

Mode Select command can independently enable or disable data compression.

Inquiry String (S7)

The S7 switch is used to select the SCSI inquiry string. The default setting (S7=ON)

enables the Seagate inquiry string. You can set it to Archive to provide compatibility

with older backup software.

S7 = ON enables Seagate inquiry string

S7 = OFF enables Archive inquiry string

Power-on Self-Test Mode Enable/Disable (S8)

The S8 switch enables or disables execution of power-on self-test (POST)

diagnostics when the drive is first powered on. When ON, the drive responds to

SCSI commands only after successful completion of the test (about 5 seconds).

The default is power-on self-test mode disabled (S8 = OFF).

Mode Select

S8 = ON enables power-on self-test mode

S8 = OFF disables power-on self-test mode

Switches 9 and 10

These switches are reserved and should not be used.

Product Manual Page 23

Page 36

Chapter 3 Installation

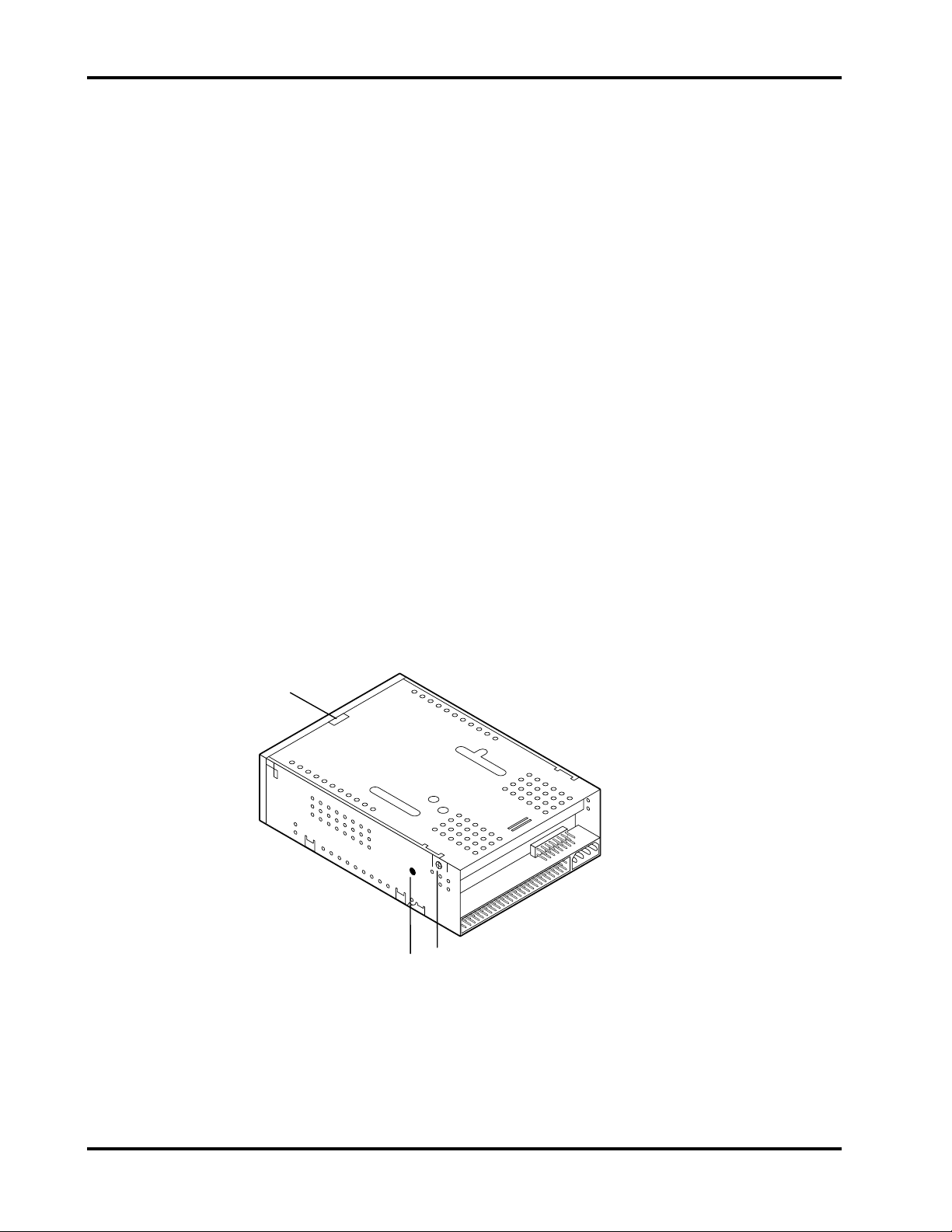

Setting the Jumpers

The jumper block on the Scorpion 24 provides additional access to settings for SCSI

ID, hardware data compression (HDC), enabling of the active terminator and

termination power.

For the SCSI ID jumper block settings to take effect, switches S1, S2 and S3 on the

switchbank must be in the OFF position.

Figures 10 and 11 illustrate the location of the jumper block for internal drives.

Jumper

Block

Pin 1

SCSI

Access for Manual

Cartidge Unload

Connector

Figure 10. Location of Jumpers for Internal Model

Pin 1

SCSI

Connector

Power

Connector

Jumper

Block

Power

Connector

Figure 11. Location of Jumpers for Internal Model with Rails

Page 24 DAT Drives

Page 37

Installation Chapter 3

Figure 12 shows the jumper configurations for the various SCSI device addresses

(IDs) and for the other options.

9 7654321

11

13

15

8

10

12

14

16

Pins

3, 4

Jumper OFF

SCSI

Pins

1, 2

ID

SCSI ID

HDC Disabled

(Jumper on pins 9 and 10)

Active Terminator Enabled

(Jumper on pins 11 and 12)

Not Connected (NC)

Termination Power ON

(Jumper on pins 15 and 16)

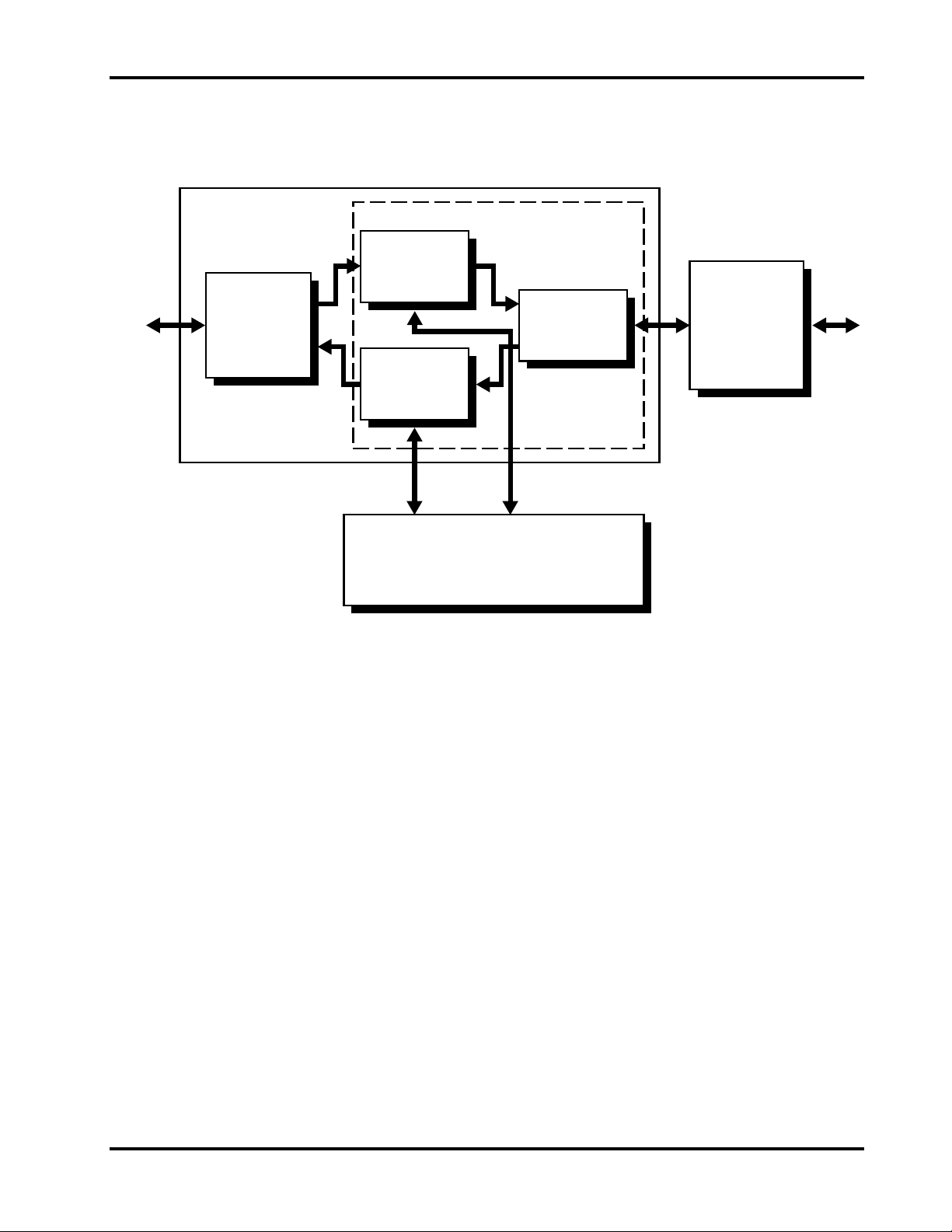

Jumper ON

Pins

5, 6

OFF OFF 0OFF

OFF OFF 1ON

OFF ON 2OFF

OFF ON 3ON

ON OFF 4OFF

ON OFF 5ON

ON ON 6OFF

ON ON 7ON

Figure 12. Jumper Configurations

If you need to change any of the factory-default settings, you must first power-cycle

the drive by turning it off and then on again, or a SCSI Bus Reset command must be

received for the new switch settings to take effect.

If the default address setting ID = 0 is correct for your system and you do not want

to change any other options, go to “Mounting the Drive” on page 27.

Otherwise, refer to Figure 9 on page 22 and the appropriate following section, make

the changes and then go to “Mounting the Drive.”

SCSI Device Address Jumpers

The three jumper locations for ID = 0, ID = 1 and ID = 2 correspond to the SCSI

device address identification bits 0 (LSB) through 2 (MSB), respectively.

The default setting is SCSI device address = 0.

Be sure that no other device on the SCSI bus has the same SCSI address.

Product Manual Page 25

Page 38

Chapter 3 Installation

Hardware Data Compression

Hardware data compression (HDC) is set by either using Switch S6 on the

switchbank or by using the jumper block.

The default setting is HDC enabled (no jumper on pins 9 and 10). Placing a jumper

on pins 9 and 10 overrides the switchbank setting and disables HDC.

As stated earlier, HDC can also be selected by the proper SCSI Mode Select

command issued by the host computer.

Active Terminator

The Scorpion 24 drive provides a jumper-selectable active terminator feature as a

substitute for terminator resistor packs. Termination is required if the drive is the

only device on the SCSI bus or in the event that the drive is the last device on the

bus.

The active terminator option is disabled as the factory-default.

If you need to have an active terminator for the drive, place a jumper across pins 11

and 12.

Terminator Power

The Scorpion 24 drive also provides jumper-selectable terminator power. You can

enable +5-volt terminator power if needed for terminators or other SCSI devices

through a jumper placement.

The factory-default for the Scorpion 24 drive is with terminator power disabled.

To enable terminator power, place the jumper shunt across pin 15 and 16 as shown

in Figure 12 on page 25.

Be sure the jumper is firmly in place.

!

Caution.

The Scorpion 24 also contains a terminator power fuse to prevent damage to drive

components in case the terminator power is shorted. The terminator power fuse is

located beside the terminator power jumper.

If the jumper is installed, be careful not to short the TERMPWR

signal to ground.

In the event that the fuse has blown to prevent damage to the drive, please return

the drive to the nearest Seagate authorized repair facility for replacement.

Page 26 DAT Drives

Page 39

Installation Chapter 3

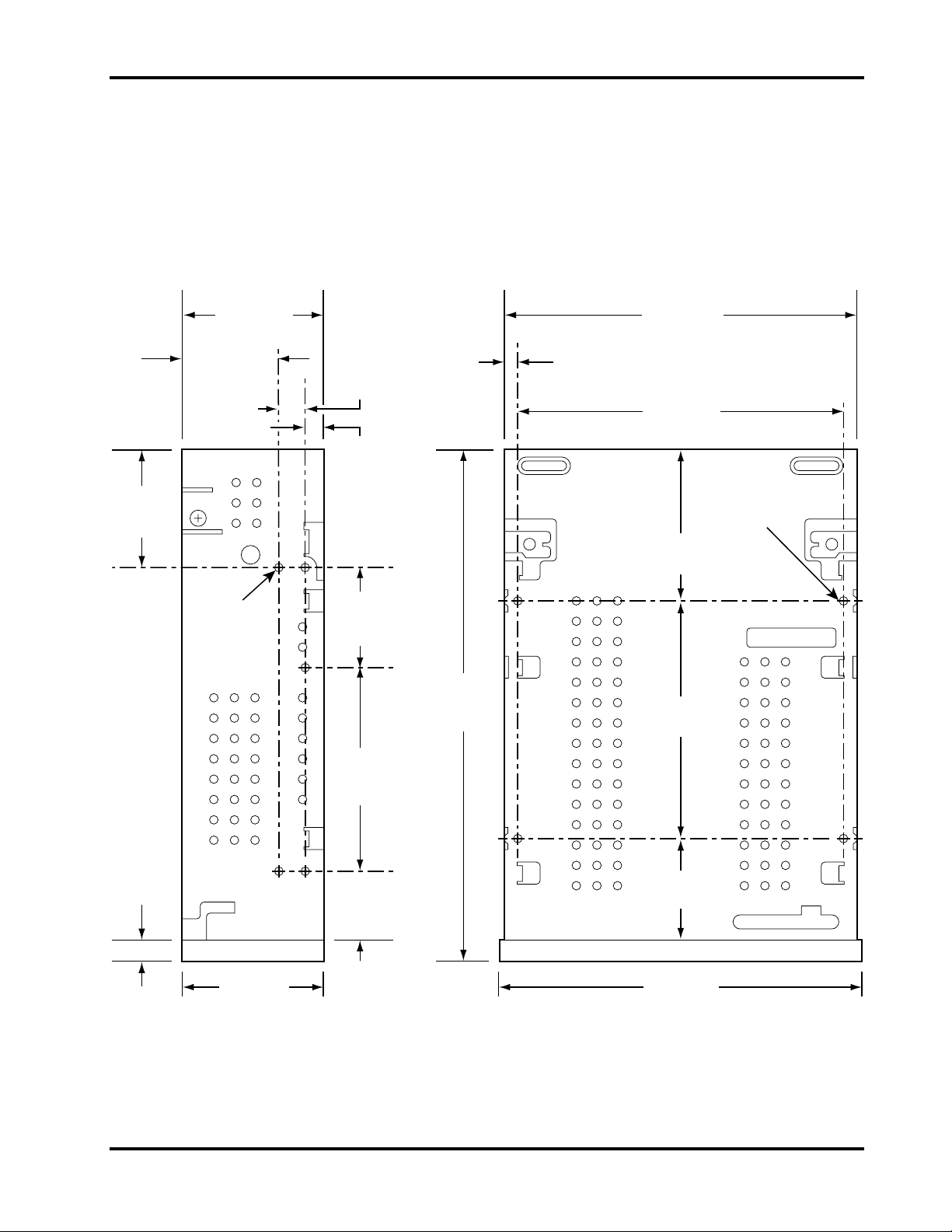

Mounting the Drive

You can install the internal drives in three different orientations: one horizontal (eject

button right) and two vertical (eject button up or eject button down).

The internal drive chassis contains threaded mounting holes for M3.0 metric screws.

The maximum length for the M3.0 metric screws is 4 mm. Four are located on the

bottom and five are on each side of the frame. See Figure 13 for details.

35.0 mm

(1.38 in)

2 Places

41.3 mm

(1.63 in)

28.3 mm

(1.11 in)

2 Places

M3.0 X

4 Deep Min.

10 Places

8.0 mm

(0.31 in)

2 Places

5.0 mm

(0.20 in)

2 Places

30.0 mm

(1.18 in)

2 Places

60.0 mm

(2.36 in)

2 Places

152 mm

(5.98 in)

2 Places

101.6 mm

(4.00 in)

3.8 mm

(0.15 in)

2 Places

94.0 mm

(3.70 in)

M3.0 X

4 Deep Min.

4 Places

45.0 mm

(1.77 in)

70.0 mm

(2.76 in)

6.0 mm

(0.24 in)

2 Places

21.0 mm

(0.83 in)

31.0 mm

(1.22 in)

2 Places

41.2 mm

(1.62 in)

104.1 mm

(4.10 in)

Side Bottom

Figure 13. Mounting Hole Locations (Internal Drive without Rails)

Product Manual Page 27

Page 40

Chapter 3 Installation

The chassis for the internal drive with rails contains threaded mounting holes for

M3.0 metric screws. The maximum length for the M3.0 screws is 4 mm. Four are

located on the bottom and six are on each side of the frame. See Figure 14.

41.3 mm

(1.63 in)

9.9 mm

(0.39 in)

2 Places

21.8 mm

(0.86 in)

2 Places

31.5 mm

(1.24 in)

2 Places

M3.0 X

4 Deep Min.

12 Places

79.4 mm

(3.13 in)

2 Places

146 mm

(5.74 in)

139.7 mm

(5.50 in)

M3.0 X

4 Deep Min.

4 Places

79.4 mm

(3.13 in)

180.6 mm

(7.11 in)

2 Places

41.2 mm

(1.62 in)

47.6 mm

(1.87 in)

2 Places

6.0 mm

(0.24 in)

2 Places

47.6 mm

(1.87 in)

148.5 mm

(5.84 in)

Side Bottom

Figure 14. Mounting Hole Locations (Internal Drive with Rails)

Page 28 DAT Drives

Page 41

Installation Chapter 3

Completing the Power and Interface Connections

The power and interface connectors for the internal models are located at the back

of the drive unit.

Figure 10 illustrates these connections for the 3.5-inch internal drive. Figure 11

illustrates these connections for the 5.25-inch internal drive with rails.

Note. Turn off all power before inserting connectors.

1. Connect the SCSI cable to the SCSI connector at the rear of the drive. Pin 1

on the SCSI connector is to your right as you look at the back of the drive.

(See Figures 10 and 11.) Your SCSI cable should be color-coded with Pin 1

highlighted by a color strip.

2. Make sure you connect Pin 1 on the cable to Pin 1 on the drive. Failure to do

so may make the drive inoperative.

3. Connect a power cable from the host system to the power connector on the

drive.

The recommended

with AMP 60617-1 pins or equivalent.

Installing External Drives

The compact external drive connects as a turnkey subsystem to the computer. The

drive is operational in either a vertical or horizontal orientation.

The following configuration is the standard default setup:

z

The drive writes or reads both MRS and non-MRS 4-mm media.

z

Parity is disabled.

z

DDS-DC data compression is enabled.

z

The power-on self-test (POST) diagnostics of the drive are disabled.

z

Terminator power is supplied to the SCSI bus.

Installing the external unit consists of a few easy steps:

power mating connector

requires an AMP 1-48024-0 housing

1. Select the SCSI address.

2. Complete the interface connection.

3. Complete the power cord connection.

Product Manual Page 29

Page 42

Chapter 3 Installation

Selecting the SCSI Address

The rear panel of the external drive contains the SCSI address selection push

switch, the two interface connectors, the ON/OFF switch and the power cord

connection. Figure 15 illustrates the rear panel.

Push

Switch

ON/OFF

Switch

6

Power

Connector

Figure 15. Rear Panel (External Model)

Locate the SCSI address push switch. Select the SCSI address for the drive by

pressing the (+) or (–) button until the desired address (0 through 7) appears in the

window.

If you need to change any of the factory-default settings, you must first power-cycle

the drive by turning it off and then on again, or a SCSI Bus Reset command must be

received for the new switch settings to take effect.

Completing the Interface Connection

The external drive provides two SCSI connectors to allow daisy-chain connections.

(See Figure 16.) Either connector can connect to the host computer or to any other

SCSI device in the daisy chain.

Turn off all power before connecting cables and the terminator.

Note.

z

When the drive is either the only drive in the chain or the last drive in the chain,

a single interface cable is attached to one connector, and a terminating plug is

installed in the other connector. (Seagate part number 38-9-74000000)

SCSI

Connectors

z

When the drive is within the chain, the interface cable from the preceding

device is connected in one connector, and an interface cable is also connected

from the other connector to the following device. In this case, no termination is

required.

Page 30 DAT Drives

Page 43

Installation Chapter 3

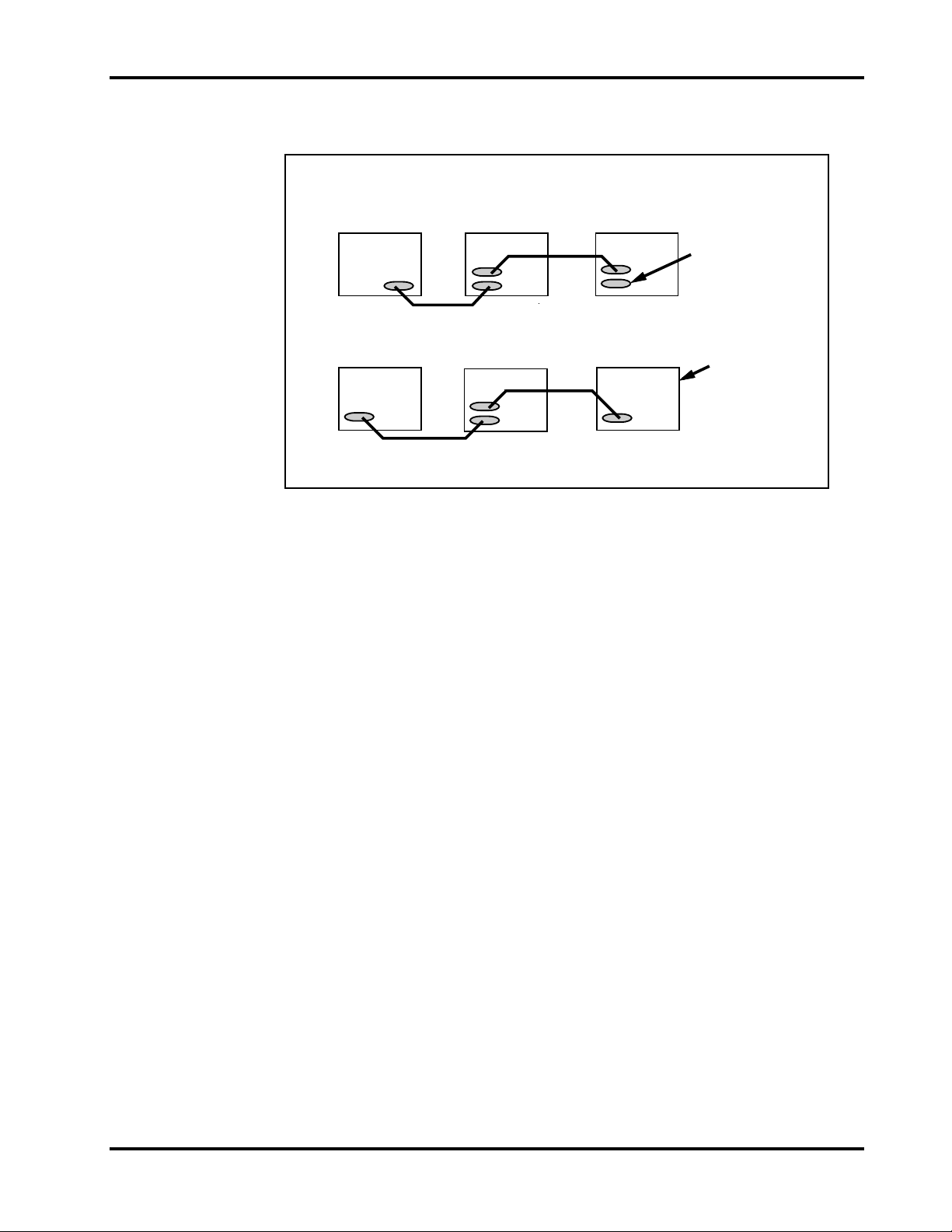

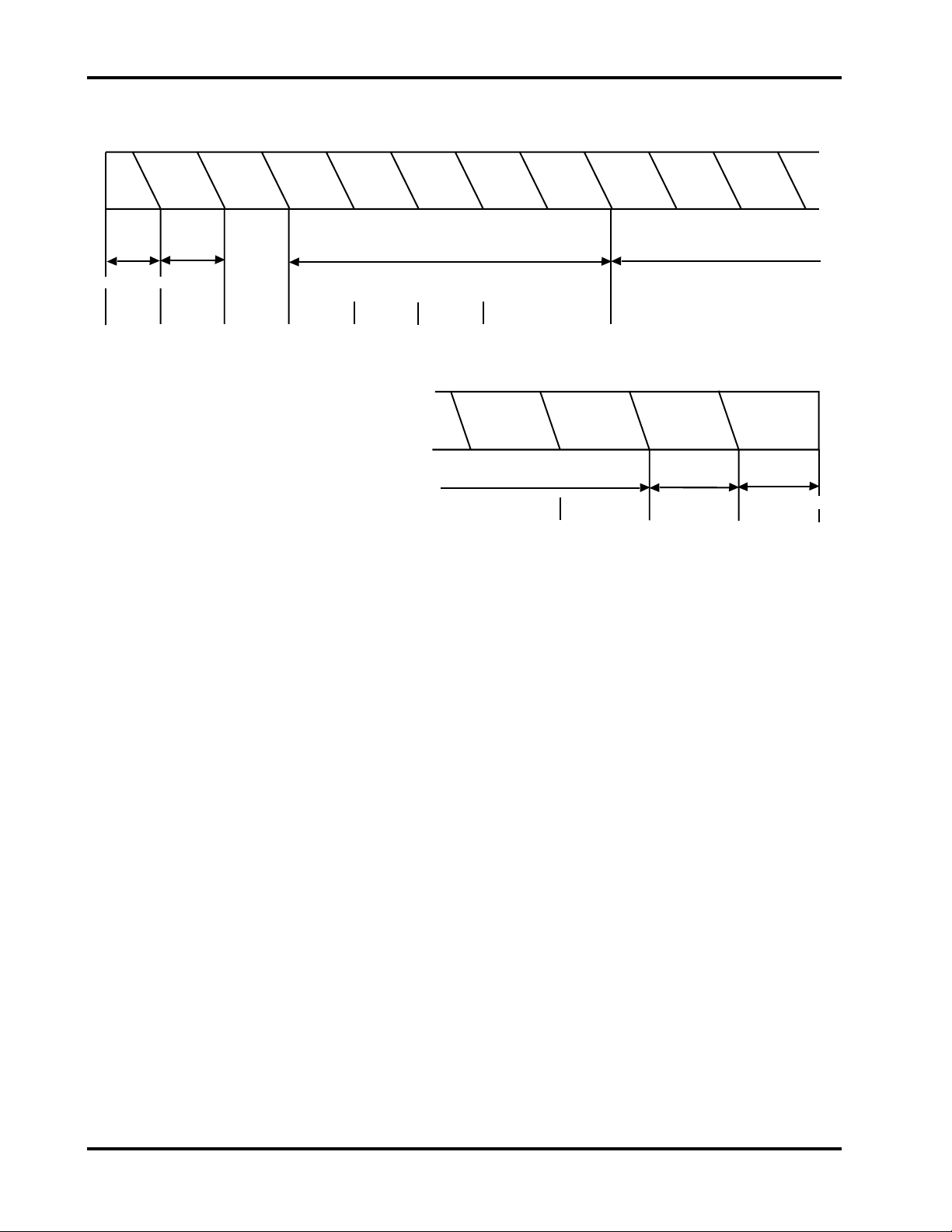

Figure 16 illustrates these daisy-chain connections

DAT DRIVE AS THE FINAL DEVICE

DAT DRIVE WITHIN A CHAIN

Figure 16. Daisy Chain Diagram

The same type of mating connector is used for either of the daisy-chain

connections. The mating interface connector for the external drive is a single-ended

connector as described earlier in this chapter.

Connecting the Power Cord

See Figure 15 for the location of the power cord connector.

DAT DRIVE

DAT DRIVE

TERMINATOR

FINAL

DEVICE

MUST HAVE

TERMINATOR

Insert the power cord mating connector into the connector on the rear panel. Be

sure the connection is secure. Plug the other end of the power cord into an electrical

outlet power strip, a continuous power supply or a wall receptacle.

Product Manual Page 31

Page 44

Chapter 3 Installation

Page 32 DAT Drives

Page 45

Drive Operations

4

Introduction

This chapter describes important operational procedures for the Scorpion 24 drive. It

covers the following topics:

z

Data compression operation

z

Front panel LED operation

z

Loading and unloading a cartridge

z

Using a blank cartridge

z

Using a cartridge that contains data

z

Loading revised firmware through Seagate firmware cartridges

Data Compression Operation

Default operation for the Scorpion 24 drive is to have data compression enabled—

the drive automatically compresses all data written to tape and decompresses all

compressed data read from tape.

The degree of compression varies due to the type of data being processed.

Data with high degrees of redundancy, such as structured database files or graphics

files, can be compressed most efficiently, often at a ratio of 2:1 or more. Data with

little redundancy, such as executable programs, can be compressed the least.

The SCSI

uncompressed mode for writing data regardless of the position of the jumper

position. When reading, the drive automatically selects compressed or

uncompressed mode, depending on the data that is read.

On internal models, a jumper on the rear panel can also be used to enable or

disable data compression. See Chapter 3 for more information.

Mode Select

command can switch the drive into compressed or

Product Manual Page 33

Page 46

Chapter 4 Drive Operations

Front Panel LED Operation

The front panel of the Scorpion 24 drive contains two rectangular LEDs. The yellow

rectangular LED indicates the drive status, and the green rectangular LED indicates

the cartridge status. These two indicators provide operating information for normal

conditions and error conditions.

The

drive status LED

z

When ON (lit), the drive is reading or writing the tape. (SCSI or drive activity is

present.)

z

When flashing rapidly, a hardware fault has occurred. If this situation occurs

immediately after power-on and you have enabled the power-on self-test

through a jumper setting, the power-on self-test may have failed. In that case,

the drive will not operate.

Note. During a SCSI Prevent Media Removal command, the LED is always ON.

Note. Do not push the eject button while the yellow drive status LED is ON. If you

do, the operation in progress is aborted and the cartridge ejected, possibly

causing a loss of data.

indicates the following conditions:

The

cartridge status LED

z

When ON (lit), a cartridge is inserted and the drive is operating normally.

z

When flashing slowly, a cartridge is inserted but is generating excessive media

indicates the following conditions:

errors beyond a predefined error threshold. This signal is a warning only and

does not indicate a loss of data.

Whenever the cartridge status LED flashes slowly to warn of excessive media

errors, the operator should clean the drive heads using an approved cleaning

cartridge (such as the Seagate Model M7301).

If the LED continues to flash or flashes while ejecting a cartridge, use a new

cartridge for future writes as a precaution.

Note. As routine maintenance, the drive heads should be cleaned after every 25

hours of operation. Even though the Scorpion 24 drive has an internal

cleaning mechanism, a regular cleaning routine helps reduce errors due to

environmental contaminants such as dust, carpet fibers or airborne debris.

z

When flashing rapidly, the drive could not write the tape correctly (maximum

rewrite count exceeded). The

WRITE

operation failed.

First, clean the drive heads using an approved cleaning cartridge, such as the

Seagate Model M7301. If the LED continues flashing, use a new cartridge for

future writes.

Page 34 DAT Drives

Page 47

Drive Operations Chapter 4

Audio Mode Indicator

The cartridge status LED flashing in conjunction with the drive status LED indicates

that a prerecorded audio cartridge is inserted and is playing automatically.

External Power LED

The round, green LED on the external drive illuminates when power is applied to the

drive.

The following table summarizes the operation of the front-panel LEDs. See the

previous explanations to remedy fault conditions.

LED Action Meaning

Yellow ON (lit) The drive is reading or writing the tape.

Yellow Flashing rapidly A hardware fault occurred.

Green ON (lit)

Green Flashing slowly

Green

Green Flashing rapidly

Green, round

(External

drives)

Flashing slowly

(with yellow LED

flashing)

ON (lit) The external drive is powered on.

A cartridge is inserted and does

excess errors.

A cartridge is inserted but generates excessive

errors beyond a predefined error threshold.

(Warning only)