Page 1

Owner’s Manual

Installation and service of this appliance should be performed by

qualified personnel. Hearth & Home Technologies recommends

HHT Factory Trained or NFI certified professionals.

R

Operation & Care

INSTALLER: Leave this manual with party responsible for use and operation.

OWNER: Retain this manual for future reference.

Contact your dealer with questions on installation, operation, or service.

NOTICE: DO NOT DISCARD THIS MANUAL

PELLET BURNING STOVE

MODEL NUMBER:

CAB50-C

WARNING

If the information in these instructions is

not followed exactly, a re could result

causing property damage, personal injury,

or death.

• Do not store or use gasoline or other ammable

vapors and liquids in the vicinity of this or any

other appliance.

• Do not over re - If appliance or chimney connector

glows, you are over ring. Over ring will void

your warranty.

• Comply with all minimum clearances to combustibles

as specied.

Failure to comply may cause house re.

WARNING

HOT SURFACES!

Glass and other surfaces are hot during

operation AND cool down.

Hot glass will cause burns.

• Do not touch glass until it is cooled

• NEVER allow children to touch glass

• Keep children away

• CAREFULLY SUPERVISE children in same room

as replace.

• Alert children and adults to hazards of high

temperatures

• High temperatures may ignite clothing or other

ammable materials.

• Keep clothing, furniture, draperies and other

ammable materials away.

CAUTION

Tested and approved for wood pellets, Burning of any

other type of fuel voids your warranty.

1 04/217074-804F

CAUTION

Check building codes prior to installation.

• Installation MUST comply with local, regional, state

and national codes and regulations.

• Consult local building, re ocials or authorities

having jurisdiction about restrictions, installation

inspection, and permits.

NOTE: To obtain a French translation of this

manual, please contact your dealer or visit

www.quadrare.com.

REMARQUE : Pour obtenir une traduction française de

ce manuel, s’il vous plaît contacter votre

revendeur ou visitez www.quadrare.com.

Page 2

BARCODE LABEL

MINIMUM CLEARANCES TO COMBUSTIBLE MATERIALS /

ESPACES LIBRES MINIMUM DES MATÉRIAUX COMBUSTIBLES:

DO NOT REMOVE THIS LABEL / NE PAS ENLEVER L'ÉTIQUETTE

7074-805A

Made in U.S.A. of US and imported parts. / Fabriqué aux États-Unis-d’Amérique par des pièces d’origine américaine et pièces importées.

A

B

C

C

D

E

F

C

C

USA

G = 2 in

H* = 2 in

I = 6 in

CANADA

G = 203 mm

H* = 51 mm

I = 152 mm

G

H

I

G

U.S. ENVIRONMENTAL PROTECTION AGENCY

Certified to comply with 2020 particulate emission standards at 1.0 g/hr EPA method 28R and ASTM 2779 using premium wood pellets.

This wood heater needs periodic inspection and repair for proper operation. Consult the owner’s manual for further information. It is against federal regulations to operate this wood

heater in a manner inconsistent with the operating instructions in the owner’s manual.

2020

2021

2022 JAN FEB MAR APR MAY JUN

JUL AUG SEP OCT NOV DEC

C# 4001508

Manufactured by: Fabriqué par:

352 Mountain House Road

Halifax, Pa 17032

www.quadrafire.com

CAB50-C

Serial No.

N° de série

HF

0061PS085E

CAUTION

:

HOT WHILE IN OPERATION DO NOT TOUCH, KEEP CHILDREN AND

CLOTHING AWAY. CONTACT MAY CAUSE SKIN BURNS.

CHAUD LORS DE L'OPÉRATION. NE PAS TOUCHER. GARDEZ LES ENFANTS ET LES VÊTEMENTS

LOIN DE L'ESPACE DÉSIGNÉ DE L'INSTALLATION. LE CONTACT PEUT CAUSER

DES BRÛLURES À LA PEAU. GARDEZ LES MEUBLES ET LES MATÉRIAUX COMBUSTIBLES LOIN DE

L'ESPACE DÉSIGNÉ DE L'APPAREIL. VOIR L'ÉTIQUETTE ET LES INSTRUCTIONS.

ATTENTION:

KEEP FURNISHINGS AND OTHER COMBUSTIBLE MATERIAL FAR AWAY FROM

THE APPLIANCE. SEE NAMEPLATE AND INSTRUCTIONS

*

Non-combustible floor protection must extend 2 inches (51mm) beneath

the flue pipe when installed with horizontal venting or under the Top Vent

Adapter with vertical installation. RECOMMENDED IN USA; REQUIRED

IN CANADA.

*Un protecteur incombustible de plancher doit s'étendre 2 inches (51mm) sous le

conduit de cheminée pour une installation de ventilation horizontale ou sous un

adapteur de ventilation de dessus pour une installation verticale.

ÉTATS-UNIS -

RECOMMANDÉ; CANADA - REQUIRENT.

Floor protector must be non-combustible material, extending beneath

heater and to the front/sides/rear as indicated. Measure front distance (I)

from the surface of the glass door.

Le poêle doit être placé sur une assise non combustible s’étendant tout autour de lui,

comme les schémas l’indiquent. Mesurez la distance du devant (I) de la surface de

la porte vitrée.

FLOOR PROTECTION / PROTECTION DU SOL

NOTE 1:

In residential installations, when using Parts TPVNT-5, (3" - 3" Top Vent Adapter) and

812-3570 (3" - 6" Offset Adapter) or 811-0720 (3” - 4” Offset Adapter), 24 gauge 6" single wall flue

connector may be used. /

REMARQUE 1 : Dans les installations résidentielles, lorsque les pièces

TPVNT-5, (dessus de l'adapteur de ventilation 3 po - 3 po) et 812-3570 (le ressaut de l'adapteur 3

po - 6 po) ou 811-0720 (le ressaut de l'adapteur 3 po - 4 po), un tuyau connecteur de 6 po pour mur

simple de calibre 24 peut être utilisé.

NOTE 2: In manufactured home installation, when using Part TPVNT-5, (3" - 3" Top Vent Adapter)

and 812-3570 (3" - 6" Offset Adapter)

or 811-0720 (3” - 4” Offset Adapter)

, use listed double wall

flue connector. An Outside Air Kit (Part 811-0872), must be used with manufactured home

installation. / REMARQUE 2 : Pour l'installation dans les maisons préfabriquées, lorsque les pièces

TPVNT-5, (dessus de l'adapteur de ventilation 3 po - 3 po) et 812-3570 (le ressaut de l'adapteur 3

po - 6 po) ou 811-0720 (le ressaut de l'adapteur 3 po - 4 po), utilisez un tuyau connecteur

enregistré pour mur double. Un assemblage d'air extérieur (Part 811-0872), doit être utilisé pour

l'installation dans les maisons préfabriquées.

A Back Wall / Mur Arrière 2 in [51mm]

B Side Wall / Mur De Côté 14 in [356mm]

CORNER INSTALLATION / NSTALLATION DU COIN :

C Side Wall / Mur De Côté 2 in [51mm]

VERTICAL 3 in. - 3 in. ADAPTER KIT (PART TPVNT-5) INSTALLATION:

UN ASSEMBLAGE POUR ADAPTEUR 3- 3 in (76-76mm) (PIÈCE TPVNT-5) POUR INSTALLATION VERTICALE:

D Pipe to Back Wall / Un Tuyau Mur Arrière 1 in [25mm]

E Side Wall / Mur De Côté 14 in [356mm]

F Back Wall / Mur Arrière 6.25 in [159mm]

CORNER INSTALLATION WITH VERTICAL ADAPTER KIT:

INSTALLATION DU COIN AVEC UN ASSEMBLAGE D'ADAPTEUR VERTICAL

:

G Side Wall / Mur De Côté 2 in [51mm]

ALCOVE INSTALLATION /

INSTALLATION DE L' ALCÔVE

:

Min. Alcove Height: /

Une hauteur minimum de l'alcôve

56.75 in [

1441mm]

Min. Alcove Side Wall: /

Une hauteur minimum m

ur de côté

de l'alcôve

14 in [356mm]

Min. Alcove Width /

Une épaisseur minimum m

ur de côté

de l'alcôve

53 in [1346mm]

Max. Alcove Depth: /

La profondeur maximum de l'alcôve

48 in [1219mm]

Max. Mantle Depth: /

Profondeur maximum de la manteau de cheminée 36 in [914mm]

Top of Unit to Combustibles: / Vue du haut des matériaux combustibles 21 in [533mm]

Listed Solid Fuel Room Heater/Pellet Type.

Also suitable for Mobile Home Installation. This appliance

has been tested and listed for use in Manufactured Homes in accordance with OAR 814-23-9000

through 814-23-909.

Certified to: ASTM STD E1509, Certified to: ULC STD S627 Room Heating Pellet BurningType, (UM)

84-HUD FOR USE

ONLY WITH PELLETIZED WOOD.

Do not use any other type of fuel. Intertek-Test

Laboratories has determined that this appliance complies with Canadian Standards Association (CSA)

B415.1 and Title 40 of the U.S. Code of Federal Regulations, Part 60, SubPart AAA.

Input Rating: 49,869 Btu's/hr. Electrical Rating: 115 VAC, 60 Hz, Start 5.1 Amps, Run 3.0 AMPS.

Route power cord away from unit. Do not route cord under or in front of appliance. Do not obstruct the

space beneath the heater.

DANGER:

Risk of electrical shock. Disconnect power supply before servicing. Replace glass only with

5mm ceramic available from your dealer. To start, set thermostat above room temperature, the stove will

light automatically. To shutdown, set thermostat to below room temperature. For further instruction refer to

owner's manual.

Keep viewing and ash removal doors tightly closed during operation.

PRÉVENTION DES FEUX DE MAISON

I

nstallez et utilisez en accord avec les instructions d'installation et d'opération du fabricant. Contactez le bureau de la

construction ou le bureau des incendies au sujet des restrictions et des inspections d'installation dans votre voisinage. Ne pas

obstruez l'espace en dessous de l'appareil.

A

VIS - Pour Les Maisons Mobiles : Ne pas installer dans une chambre à coucher. Un tuyau extérieur de combustion d'air

doit être installé et ne doit pas être obstrué lorsque l'appareil est en usage. La structure intégrale du plancher, du plafond et des

murs de la maison mobile doit être

maintenue intacte.

Référez vous aux instructions du fabricant et des codes locaux pour les précautions requises pour passer une cheminée à

travers un mur ou un plafond combustibles, et les compensations maximums.

Inspectez et nettoyez la cheminée fréquemment. Ne pas connecter cet appareil à une cheminée servant un autre appareil.

Utilisez systèm de ventilation "L" ou "P" diamètre 76mm ou 102mm

Certifié à : ASTM E1509, Certifié à : ULC S627 Room Heating. Pellet Burning Type, (UM) 84-HUD POUR USAGE AVEC

LES BOULETTES DE BOIS. N’utiliser aucun autre genre de combustible.

Intertek Test Laboratories a déterminé que cet

appareil se conforme avec la norme de l’Association Canadienne de normalisation (CSA) B415.1 ainsi que le Titre 40

du Code Fédéral de Régulations des États-Unis, partie 60, sous-partie AAA.

Puissance de Rendement : 49,869 Btu's/hr. Puissance Électrique : 115 VAC, 60 Hz, Début 5.1 Amps, Courir 3.0 Amps,

Éloignez le fil électrique de l'appareil. Ne pas faire passer le fil électrique au dessus ou en dessous de l'appareil. Ne pas bloquer

l’espace au dessous de l’appareil.

DANGER : Il y a risque de décharge électrique. Déconnectez le fil électrique de la prise de contact avant le service.

Remplacez la vitre seulement avec une vitre céramique de 5 mm disponible chez votre fournisseur.

Pour allumer, monter la température du thermostat au dessus de la température de la pièce, le poêle s'allumera automatiquement.

Pour éteindre, descendre la température du thermostat en dessous de la température de la pièce. Pour des instructions

supplémentaires, référez vous au manuel du propriétaire. Gardez la porte d'ouverture et la porte des cendres fermées

hermétiquement durant l'opération.

Appareil de chauffage de combustible solide/de type de boulettes.

Accepté dans l'installation dans les maisons mobiles. Cet appareil a été testé et enregistré pour l'usage dans les

Maisons Mobiles en accord avec OAR 814-23-9000 jusqu'à 814-23-909.

PREVENT HOUSE FIRES

Install and use only in accordance with manufacturer's installation and operating instructions. Contact local

building or fire officials about restrictions and inspection in our area.

WARNING - FOR MOBILE HOMES: Do not install appliance in a sleeping room. An outside combustion

air inlet must be provided. The structural integrity of the mobile home floor, ceiling and walls must be

maintained.

Refer to manufacturer's instructions and local codes for precautions required for passing chimney

through a combustible wall or ceiling. Inspect and clean vent system frequently in accordance with

manufacturer's instructions.

DO NOT CONNECT THIS UNIT TO A CHIMNEY SERVING ANOTHER APPLIANCE.

Use a 3" or 4" diameter type "L" or "PL" venting system.

Refer to the Intertek Directory of Building Products (https://bpdirectory.intertek.com) for detailed information.

Reportez-vous au répertoire des produits de construction d'Intertek (https://bpdirectory.intertek.com) pour obtenir des informations détaillées.

R

NOTE: Clearances may only be reduced by means approved by the regulatory

authority having jurisdiction

A. Sample of Serial Number / Safety Label

LOCATION: Back of appliance

Test Lab

and Report

Number

2 04/217074-804F

and Welcome to the Quadra-Fire Family!

Model Name

SAMPLE

Serial Number

Manufacturer

Date

Page 3

Safety Alert Key:

• DANGER! Indicates a hazardous situation which, if not avoided will result in death or serious injury.

• WARNING! Indicates a hazardous situation which, if not avoided could result in death or serious injury.

• CAUTION! Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

• NOTICE: Indicates practices which may cause damage to the appliance or to property.

TABLE OF CONTENTS

A. Sample of Serial Number / Safety Label ........... 2

B. Warranty Policy ..............................4

C. Quick Start Guide............................. 6

1 Listing and Code Approvals

A. Appliance Safety Certication ...................7

B. Appliance Emissions Certication ................7

C. BTU & Eciency Specications.................. 7

D. Glass Specications........................... 8

E. Electrical Rating (on high) ...................... 8

F. Mobile Home Approved ........................8

G. Sleeping Room .............................. 8

H. California - Prop65............................ 8

2 Operating Instructions

A. Fire Safety .................................. 9

B. Non-Combustible Materials ..................... 9

C. Combustible Materials .........................9

D. Fuel Material and Fuel Storage . . . . . . . . . . . . . . . . . . 9

E. General Operating Information.................. 10

F. Before Your First Fire ......................... 10

G. Hopper Lid and Hopper Switch ................. 11

H. Starting Your First Fire ........................ 11

I. Fire Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

J. Feed Rate Adjustment Instructions............... 12

K. Ignition Cycles .............................. 12

L. Clear Space ................................ 13

M. Thermostat Operation ........................ 13

N. Frequently Asked Questions ...................14

3 Maintenance and Service

A. Proper Shutdown Procedure ................... 15

B. Quick Reference Maintenance Chart............. 15

C. General Maintenance......................... 16

D. High Ash Fuel Content Maintenance ............. 20

E. Soot or Creosote Fire......................... 20

4 Troubleshooting Guide....................... 21

5 Service Parts Replacement

A. Side Curtain Replacement ..................... 24

B. Convection Blower Replacement................ 24

C. Exhaust Blower Replacement .................. 25

D. Snap Disc #1, #2, #3 Replacement ..............25

E. Igniter Replacement.......................... 26

F. Bae Replacement .......................... 26

G. Glass Replacement ..........................27

6 Reference Materials

A. Component Functions ........................ 28

B. Component Locations ........................ 30

C. Maintenance and Service Log ..................31

D. Service Parts List............................ 35

= Contains updated information

Quadra-Fire is a registered trademark of Hearth & Home Technologies.

3 04/217074-804F

Page 4

B. Warranty Policy

Igniters, Auger Motors, Electronic Components, and

See condi�ons, exclusions and limita�ons on the next page

Hearth & Home Technologies

LIMITED LIFETIME WARRANTY

Hearth & Home Technologies, on behalf of its hearth brands (“HHT”), extends the following warranty for HHT gas, wood, pellet and

electric hearth appliances that are purchased from an HHT authorized dealer.

WARRANTY COVERAGE:

WARRANTY PERIOD:

distributor, whichever occurs earlier. However, the warranty shall commence no later than 24 months following the date of product

is produced in the following table.

Warranty Period HHT Manufactured Appliances and Venting

Parts Labor Gas Pellet Wood Electric Venting Components Covered

X1 Year X X X X

X X

2 years

3 years X

5 years 1 year

6 years 3 years

7 years 3 years X X Manifold tubes, HHT Chimney and Terminations

10 years 1 year

Limited

Lifetime

3 years

X

X X

X

X X

X

X

X X X

All parts including handles, external enamaled

components and other material except as covered by

Conditions, Exclusions, and Limitations listed

Glass

Electrical components limited to modules, remotes/wall

switches, valves, pilots, blowers, junction boxes, wire

harnesses, transformers and lights (excluding light bulbs)

Molded Refractory Panels, Glass Liners

Firepots, burnpots, mechanical feeders/auger

assemblies

Vent Free Burners, Vent Free Logs

Castings, Medallions and Baffles

Catalyst - Limitations Listed

Burners, logs and refractory

Firebox and heat exchanger, FlexBurn® System

(engine, inner cover,access cover and fireback)

1 Year

4021-645K 1/20

4 04/217074-804F

None

X X X X X All replacement parts beyond warranty period

Page 1 of 2

Page 5

WARRANTY CONDITIONS:

• This warranty only covers HHT appliances that are purchased through an HHT authorized dealer or distributor. A list of HHT

authorized dealers is available on the HHT branded websites.

•

• This warranty is only valid in the country in which the HHT authorized dealer or distributor that sold the appliance resides.

• Contact your installing dealer for warranty service. If the installing dealer or distributor is unable to provide necessary parts,

a dealer other than the dealer from whom you originally purchased the product.

• Check with your dealer in advance for any costs to you when arranging a warranty call. Travel and shipping charges for parts are not

covered by this warranty.

• Limited Catalyst Warranty

o For wood burning products containing a catalyst, the catalyst will be warranted for a six-year period to the original purchaser at

catalyst.

WARRANTY EXCLUSIONS:

This warranty does not cover the following:

•

•

• Repair or replacement of parts that are subject to normal wear and tear during the warranty period are not covered. These parts

•

noise are not covered by this warranty.

•

•

•

•

This warranty is void if:

•

•

• There is any damage to the appliance or other components due to water or weather damage which is the result of, but not limited

LIMITATIONS OF LIABILITY

•

have other rights, which vary from state to state. EXCEPT TO THE EXTENT PROVIDED BY LAW, HHT MAKES NO EXPRESS WARRANTIES

OTHER THAN THE WARRANTY SPECIFICED HEREIN. THE DURATION OF ANY IMPLIED WARRANTY IS LIMITED TO DURATION OF THE

EXPRESSED WARRANTY SPECIFIED ABOVE.

4021-645K 1/20

Page 2 of 2

5 04/217074-804F

Page 6

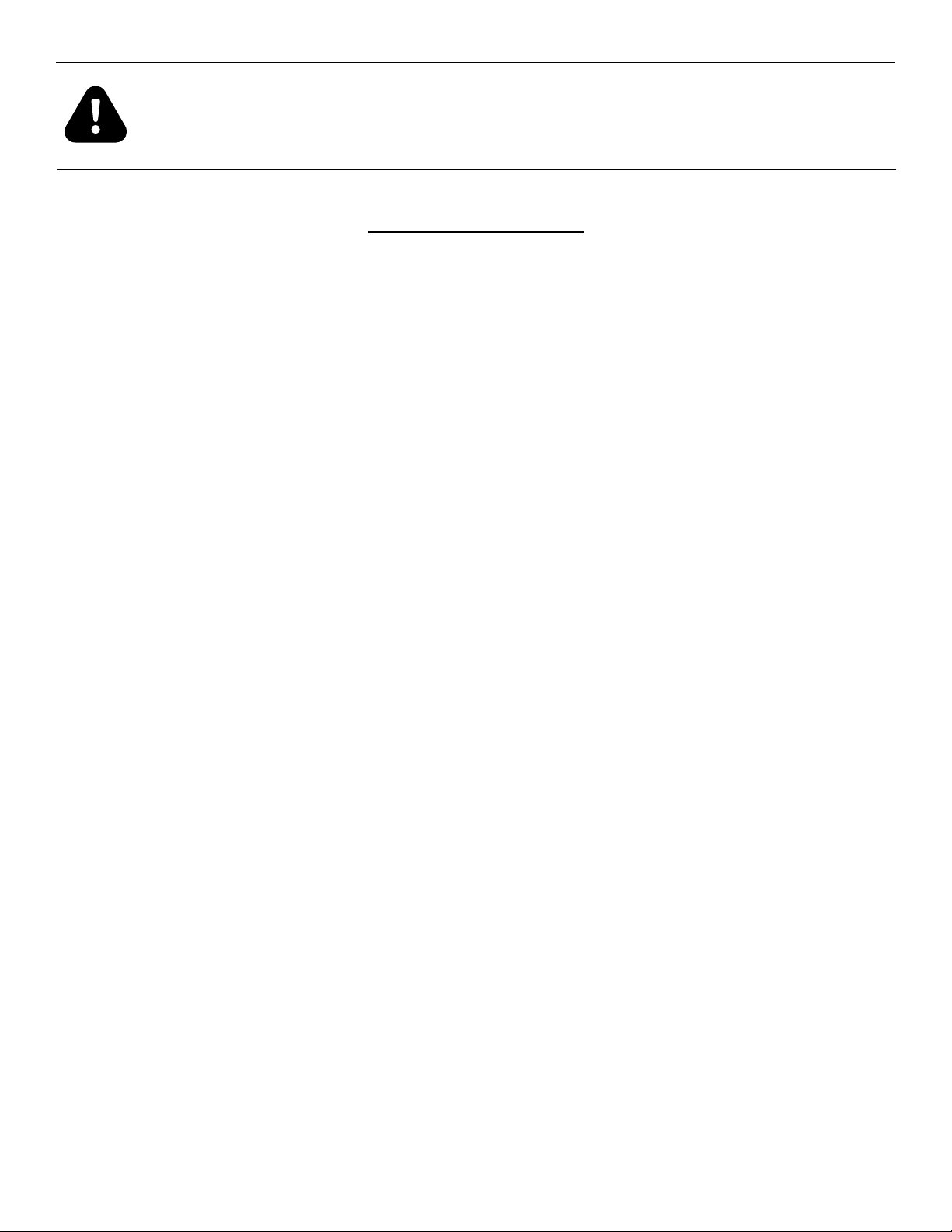

C. Quick Start Guide

Remove hang tags from the door glass. Clean the glass. Remove the hardware pack and desiccant

QUICK START GUIDE

*Before you plug in this appliance, follow these instructions*

bag from the rebox area before your rst re.

Turn the thermostat to o .

1

If the feed tube is empty

or this is the rst re, add

a handful of pellets to the

re pot.

*Do not add extra fuel to

the re pot if the feed tube

has already been primed.

Over lling the re pot will

cause smoky start-ups.

Add pellets to the hopper and

close the lid.

2

Close the rebox door and

plug the power cord into the

wall receptacle.

Open the rebox door and

make sure the ba es are

in place.

3

Turn the thermostat on.

4 5 6

The stove will feed pellets

for a minute and stop. Once

a re starts, the feed cycle

will resume.

NOTE: Allow 5 minutes for

ignition to take place.

7

After 30 minutes have passed, turn the thermostat o and allow the unit to cool completely. Open the door

and clean the re pot according to the cleaning instructions found inside the hopper lid or owners manual.

Close the door and set the thermostat to a desired temperature. Unit is now ready to resume

10

6 04/217074-804F

normal operation.

If the re dies out after a few

minutes of operation it will be

necessary to push the reset

button to add more fuel.

8

Once a re has been

established in the unit, leave

the unit burning on the “high”

setting for 30 minutes to allow

the paint to cure.

NOTE: Odors and vapors

will be released during

this process.

*Open windows in the room

for ventilation*

9

Page 7

1 Listing and Code Approvals

A. Appliance Safety Certication

Model CAB50-C

Laboratory: Intertek

Report

Number:

Type:

Standard:

100358108PRT-005

Solid Fuel Room Heater/Pellet Fuel

Burning Type

ASTM E1509-04 and ULC S627-00

Room Heater Pellet Fuel Burning type

and (UM) 84-HUD,

Mobile Home Approved.

B. Appliance Emissions Certication

Model: CAB50-C

Laboratory: OMNI Test Laboratories, Inc.

Report

Number:

Standard:

Can be found at:

www.quadrare.com/about-us/epa-certication

0061PS085E

Method 28R, ASTM E1509-04 and

ASTM 2779

C. BTU & Eciency Specications

EPA Certication

Number:

EPA Certied

Emissions:

*LHV Tested Eciency: 69.5%

**HHV Tested Eciency: 65.1%

***EPA BTU Output: 7,500 to 36,600 / hr.

****BTU Input: 13,100 to 49,900 / hr.

Vent Size: 3” or 4” Type “L” or “PL”

Hopper Capacity: 120 lbs.

Fuel: Premium Wood Pellets

* Weighted average LHV (Low Heating Value) eciency

using data collected during EPA emissions tests in

accordance with the requirements of CSA B415.1.

** Weighted average HHV (High Heating Value) eciency

using data collected during EPA emissions tests in

accordance with the requirements of CSA B415.1.

*** A range of BTU outputs calculated using HHV

eciency and the burn rates from the EPA tests.

**** Based on the maximum feed rate per hour multiplied

by approximately 8600 BTU’s which is the average BTU’s

from a pound of pellets.

Number: N/A

1.0 grams per hour

The CAB50-C is Certied to

comply with 2020 particulate

emission standards.

This pellet heater needs periodic inspection and repair for proper operation. It is against federal regulations to operate this

pellet heater in a manner inconsistent with operating instructions in this manual.

NOTICE: This installation must conform with local codes. In the absence of local codes you must comply with the

ASTM E1509-04, ULC S627-00 and (UM) 84-HUD.

7 04/217074-804F

Page 8

D. Glass Specications

This appliance is equipped with 5mm ceramic glass.

Replace glass only with 5mm ceramic glass. Please

contact your dealer for replacement glass.

E. Electrical Rating (on high)

115 VAC, 60 Hz, Start 5.1 Amps, Run 3.0 Amps

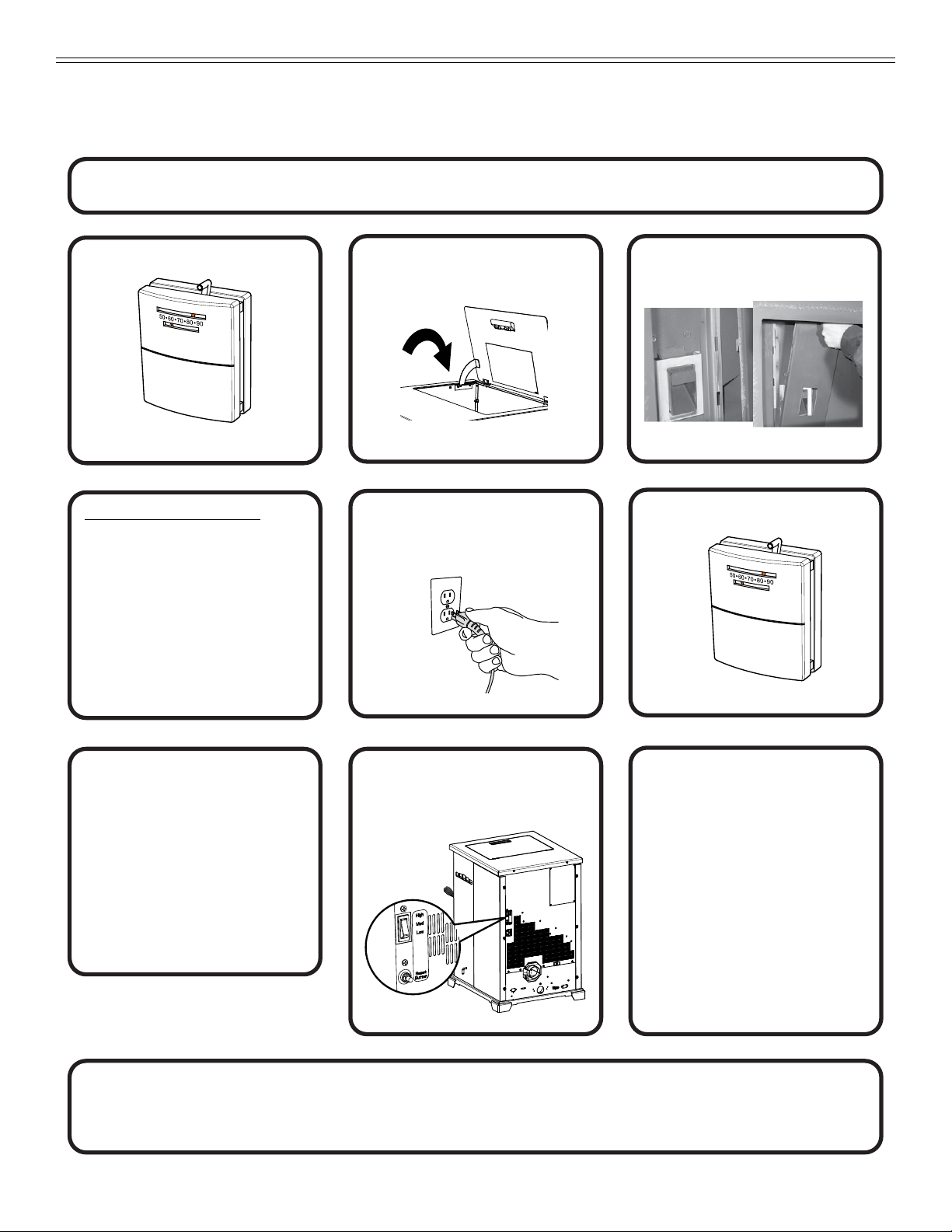

WARNING

Fire Risk

Hearth & Home Technologies disclaims any

responsibility for, and the warranty will be

voided by, the following actions:

F. Mobile Home Approved

• This appliance is approved for mobile home

installations when not installed in a sleeping room and

when an outside combustion air inlet is provided.

• The structural integrity of the mobile home oor, ceiling,

and walls must be maintained.

• The appliance must be properly grounded to the frame

of the mobile home with #8 copper ground wire, and

use only listed double-wall connector pipe.

• Outside Air Kit, part 811-0872 or OAK-3 must be

installed in a mobile home installation.

• Appliance must be secured to mobile home structure.

G. Sleeping Room

When installed in a sleeping room it is recommended that

3ft of vertical be installed prior to horizontally exiting the

room and a smoke/CO alarm be installed in the bedroom;

The size of the room must be at least 50ft³ per 1,000 Btu/hr

stove input, if the stove exceeds the room size, outside air

must be installed.

H. California - Prop65

WARNING

This product and the fuels used to operate this product (wood), and

the products of combustion of such fuels, can expose you to

chemicals including carbon black, which is known to the State of

California to cause cancer, and carbon monoxide, which is known to

the State of California to cause birth defects or other reproductive

harm. For more information go to: WWW.P65Warnings.ca.gov

• Installation and use of any damaged appliance.

• Modication of the appliance.

• Installation other than as instructed by Hearth &

Home Technologies.

• Installation and/or use of any component part not

approved by Hearth & Home Technologies.

• Operating appliance without fully assembling all

components.

• Operating appliance without legs attached (if

supplied with appliance).

• Do NOT Over re - If appliance or chimney connector

glows, you are over ring.

Any such action that may cause a re hazard.

Improper installation, adjustment, alteration, service or

maintenance can cause injury or property damage.

For assistance or additional information, consult a qualied

installer, service agency or your dealer.

NOTE: Hearth & Home Technologies, manufacturer

of this appliance, reserves the right to alter

its products, their specications and/or price

without notice.

Hearth & Home Technologies WILL NOT warranty

appliances that exhibit evidence of over-ring. Evidence

of over-ring includes, but is not limited to:

• Warped air tube

• Deteriorated refractory brick retainers

• Deteriorated bae and other interior components

8 04/217074-804F

Page 9

2 Operating Instructions

User Guide

WARNING

Fire Risk.

• Do not operate appliance before reading

and understanding operating instructions.

• Failure to operate appliance properly may

cause a house re.

Visit www.quadrare.com/shopping-tools/videos to view

product and use & care videos.

A. Fire Safety

To provide reasonable re safety, the following should be

given serious consideration:

• Install at least one smoke detector and CO monitor on

each oor of your home.

• Locate detectors away from the heating appliance and

close to the sleeping areas.

• Follow the detector’s manufacturer’s placement and

installation instructions and maintain regularly.

• A CO detector should be installed in the room with

the appliance.

• Conveniently locate a Class A re extinguisher to

contend with small res.

• In the event of a hopper re:

• Evacuate the house immediately.

• Notify re department.

B. Non-Combustible Materials

Material which will not ignite and burn, composed of any

combination of the following:

- Steel

- Plaster

- Brick

- Iron

- Concrete

- Tile

- Glass

- Slate

Materials reported as passing ASTM E 136, Standard

Test Method for Behavior of Metals, in a Vertical Tube

Furnace of 750° C.

C. Combustible Materials

Material made of/or surfaced with any of the

following materials:

- Wood

- Compressed Paper

- Plant Fibers

- Plastic

- Plywood/OSB

- Sheet Rock (drywall)

Any material that can ignite and burn: ame proofed or not,

plastered or non-plastered.

D. Fuel Material and Fuel Storage

Pellet fuel quality can greatly uctuate. This appliance has

been designed to burn a wide variety of fuels, giving you

the choice to use the fuel that is most economical in your

region.

Hearth & Home Technologies strongly recommends only

using Pellet Fuel Institute (PFI) certied fuel.

Fuel Material

• Made from sawdust or wood by-products

• Depending on the source material it may have a high

or low ash content.

Higher Ash Content Material

• Hardwoods with a high mineral content

• Fuel that contains bark

• Standard grade pellets, high ash pellets

Lower Ash Content Material

• Softwoods

• Fuels with low mineral content

• Premium grade pellets

CAUTION

Do not burn fuel that contains an additive; (such as

soybean oil).

• May cause hopper res

• Damage to product may result

Read the ingredients list on the package. If you are

buying corn the only ingredient that should be listed

is corn.

Clinkers

Minerals and other non-combustible materials such as

sand will turn into a hard, glass-like substance called a

clinker when heated in the re pot.

Trees from dierent areas will vary in mineral content. That

is why some fuels produce more clinkers than others.

9 04/217074-804F

Page 10

Moisture

Always burn dry fuel. Burning fuel with high moisture

content takes heat from the fuel and tends to cool the

appliance, robbing heat from your home. Damp pellet fuel

can clog the feed system.

Size

• Pellets are either 1/4 inch or 5/16 inch (6-8mm)

in diameter

• Length should be no more that 1-1/2 inches (38mm)

• Pellet lengths can vary from lot to lot from the

same manufacturer

• Due to length variations, the ame height (feed rate)

may need adjusting occasionally. Refer to the section

on Feed Rate Adjustment Instructions found on

page 12.

Performance

• Higher ash content requires the ash drawer to be

emptied more frequently

• Hardwoods require more air to burn properly

• Set wall control to “Utility Pellet” if the re pot and ash

pan are lling quickly. This will cause the auto-clean

system to empty the re pot more often.

• Premium wood pellets produce the highest heat output.

• Burning pellets longer than 1-1/2 inches (38mm)

can cause an inconsistent fuel feed rate and/or

missed ignitions.

We recommend that you buy fuel in multi-ton lots whenever

possible. However, we do recommend trying various

brands before purchasing multi-ton lots to ensure your

satisfaction.

E. General Operating Information

1. Thermostat Calls For Heat

The appliance is like most modern furnaces; when the

thermostat calls for heat, your appliance will automatically

light and deliver heat. When the room is up to temperature

and the thermostat is satised, the red call light will shut

o and the appliance will shut down. The red call light is

located behind the left access panel.

2. Heat Output Controls

This appliance is equipped with a heat output control switch

that has three settings or burn rates; low, medium and high

(Figure 10.1). The appliance will turn on and o as the

thermostat demands. When the thermostat calls for heat,

the appliance will always start up on High. After burning

approximately 4 minutes, the appliance will then burn at the

rate at which it was originally set. If the appliance is set at

one of the lower settings, it will run quieter but takes longer

to heat up an area than if it were set at a higher burn rate.

Regardless of the burn rate, when the area is warm enough

to satisfy the thermostat, the appliance will shut o.

Changing to Dierent Fuel Type

• Empty the hopper of the previous fuel

• Thoroughly vacuum hopper before lling with the

new fuel

• Select the appropriate setting on the

FUEL SELECTION screen on the thermostat

wall control

The burn rate, BTU content and heat output will all vary

depending on the fuel selected.

CAUTION

Tested and approved for wood pellets. Burning of any

other type of fuel voids your warranty.

Storage

• Wood pellets should be left in their original sealed bag

until using to prevent moisture absorption.

• This will also prevent rodents from becoming

a problem.

• Do not store any pellet fuel within the clearance

requirements or in an area that would hinder routine

cleaning and maintenance.

Figure 10.1

F. Before Your First Fire

1. First, make sure your appliance has been properly

installed and that all safety requirements have been

met. Pay particular attention to the re protection,

venting and thermostat installation instructions.

2. Double check that the ash drawer and rebox

are empty!

3. Check that cleaning rod is in the fully closed position.

4. Close and latch the door.

CAUTION

Tip of thermocouple must be in contact with the inside

end of the thermocouple cover.

• Missed ignitions can occur.

CAUTION

HOT WHILE IN OPERATION. KEEP CHILDREN,

CLOTHING AND FURNITURE AWAY. CONTACT MAY

CAUSE SKIN BURNS.

10 04/217074-804F

Page 11

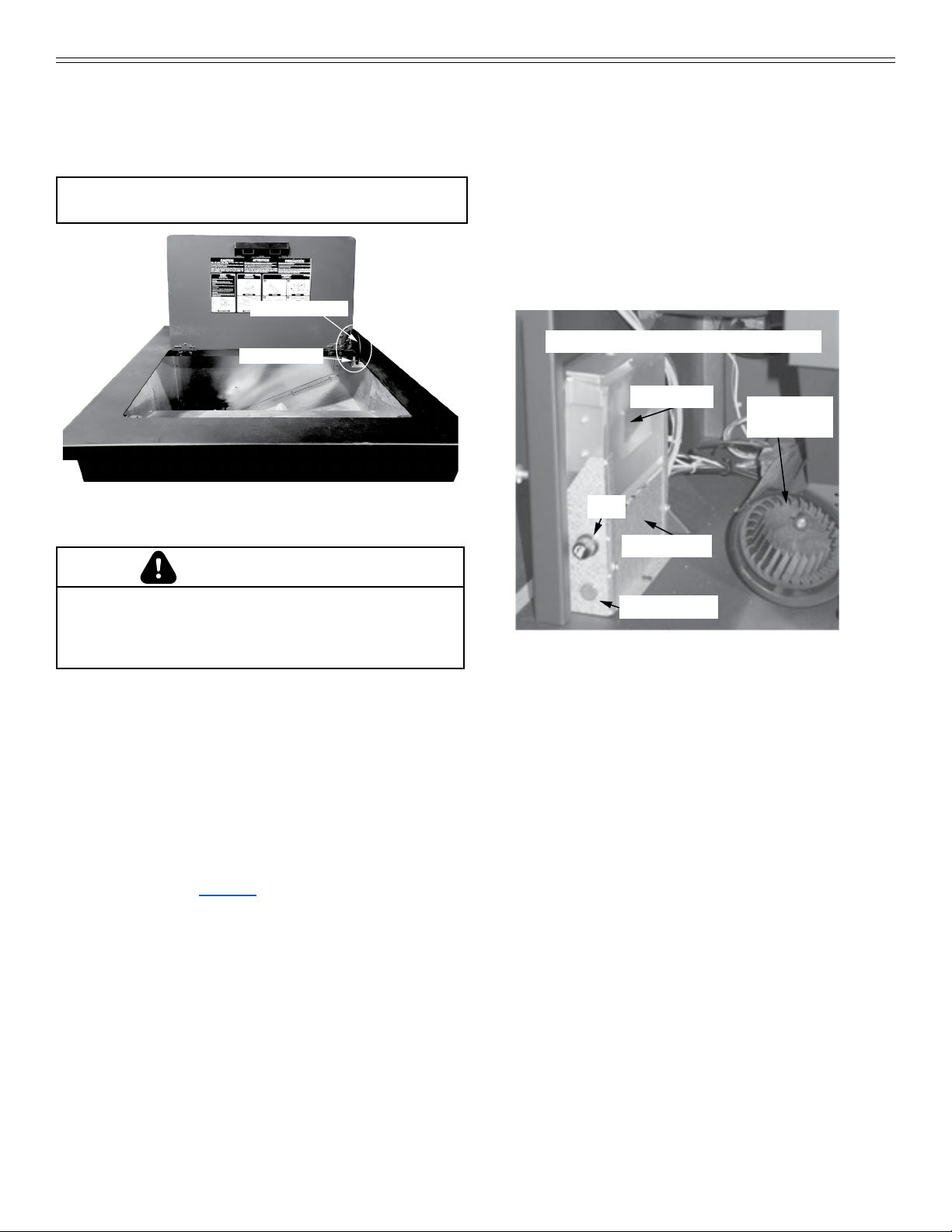

G. Hopper Lid and Hopper Switch

Hopper Lid LatchHopper Lid Latch

Hopper Switch

Hopper Switch

Control Box

Junction Box

Red Call Light

Fuse

Convection

Blower

LOCATED BEHIND LEFT SIDE PANELS

1. Lift up the hopper lid; now you can ll the hopper

with fuel.

2. The hopper switch is designed to shut down the feed

motor when the hopper lid is open. Leaving the lid open

too long can cause the re to go out (Figure 11.1).

NOTE: The hopper switch is activated by a magnet

attached to the Hopper Lid.

Figure 11.1

6. The fuel feed system and the igniter should now be on.

7. For your rst re it will be necessary to press the reset

button once approximately 2 minutes after start up

and again in 5 minutes. Reset as needed or every 60

seconds until pellets begin to drop into re pot. This will

ll the feed system and allow the appliance to begin

dropping pellets. Or you can put a handful of pellets

in the re pot to speed up the process. The appliance

will continue to run as long as the thermostat is calling

for heat.

8. Once the appliance has ignited, let it burn for

approximately 15 minutes, then set the thermostat to

the desired room temperature. Adjust the heat output

control switch to the desired setting.

H. Starting Your First Fire

CAUTION

Odors and vapors released during initial operation.

• Curing of high temperature paint.

• Open windows for air circulation.

Odors may be irritating to sensitive individuals.

1. A thermostat is required for proper operation of this

appliance. If you have to adjust the feed rate after

you have started the re, most of the pellets in the

hopper will need to be removed so start out with lling

the hopper approximately 1/4 full at this time. Set the

thermostat to its lowest setting and plug the power cord

into nearby outlet.

2. The exhaust blower will stay on for approximately 18

minutes even though the thermostat is not calling for

heat. This is normal.

3. Locate the heat output control switch mounted on

the back of the appliance in the upper left corner

(Figure 10.1 on page 10).

4. Turn it to the “high” setting by pushing the top of the

control switch in and then adjust the thermostat to its

highest setting.

5. Look through the hole in the left lower side panel and

you will see the red call light on the control box will

be on (Figure 11.2). This indicates the thermostat is

calling for heat.

Figure 11.2

11 04/217074-804F

Page 12

I. Fire Characteristics

A properly adjusted re with the heat output control

switch set on “high” has a short active ame pattern

that extends out of the repot approximately

4 to 8 inches (102 to 203mm).

If the re has tall ames with black tails and seems

somewhat lazy, the feed rate will need to be reduced. This

is done by sliding the fuel adjustment control rod down,

which will reduce the feed (Figure 12.2).

If the re is not 4 to 8 inches (102 to 203mm) tall, slide

the fuel adjustment control rod up to increase the feed. A

medium and low setting will give a shorter ame. The ame

will rise and fall somewhat. This is normal.

J. Feed Rate Adjustment Instructions

1. Loosen the thumb screw.

2. Pull the feed adjustment control rod up to increase the

feed rate and ame height or push down to decrease

the feed rate and ame height.

3. Re-tighten the thumb screw. A new stove has a break

in period. The re characteristics should be checked

again after 5 bags of pellets and adjustments made

if necessary.

K. Ignition Cycles

1. At the beginning of each ignition cycle, it is normal to

see some smoke in the rebox. The smoke will stop

once the re starts.

2. The convection blower will automatically turn on after

your appliance has been burning for approximately

10 minutes.

This blower transfers heat from your appliance into

the room, and will continue to run after the thermostat

has stopped calling for heat until the appliance has

cooled down.

3. Occasionally the appliance may run out of fuel and shut

itself down. When this happens, the red call light will be

on (Figure 11.2 on page 11).

- To restart it, ll the hopper and press the reset

button. When you press the reset button the red

call light will go out. Release the button and the

light will come back on. Continue pushing the

button once a minute until pellets begin to fall into

the re pot.

- You should see a re shortly. If not, follow the

instructions, for Starting Your First Fire on

page 11.

Figure 12.1

Figure 12.2

Feed Adjustment Rod located

inside Hopper at Front

Bottom of Hopper

Push Down

to Decrease

Pull Up to

Increase

Loosen Thumb

Screw

12 04/217074-804F

Page 13

L. Clear Space

Mantel:

Avoid placing candles and other heat-sensitive objects

on mantel or hearth. Heat may damage these objects.

NOTICE: Clearances may only be reduced by means

approved by the regulatory authority

having jurisdiction.

WARNING

Fire Risk.

Do NOT place combustible objects in front of

the appliance. High temperatures may ignite

clothing, furniture or draperies. Maintain a

minimum clearance of 3 feet (914mm) in front

of appliance.

WARNING

Fire Risk.

Keep combustible materials, gasoline and

other ammable vapors and liquids clear of

appliance.

• Do NOT store ammable materials in the

appliance’s vicinity.

• DO NOT USE GASOLINE, LANTERN FUEL,

KEROSENE, CHARCOAL LIGHTER FLUID OR

SIMILAR LIQUIDS TO START OR “FRESHEN UP”

A FIRE IN THIS Appliance.

• DO NOT BURN GARBAGE OR FLAMMABLE

FLUIDS SUCH AS GASOLINE, NAPHTHA OR

ENGINE OIL.

• DO NOT USE CHEMICALS OR FLUIDS TO START

THE FIRE.

• Keep all such liquids well away from the appliance

while it is in use.

• Combustible materials may ignite.

M. Thermostat Operation

For accurate temperature control and comfort, correct

location is very important. On new installations, the

guidelines listed in the installation manual under

Thermostat Installation should be followed as closely

as possible.

To operate thermostat simply slide the Slide Control that

is located at top of thermostat, left or right to adjust the

temperature of the room (Figure 13.1).

Slide Control

Figure 13.1

NOTE: A thermostat can only control temperature near it.

If you nd that it is uncomfortable some distance

away from the thermostat, change the setting in

order to compensate for this.

13 04/217074-804F

Page 14

N. Frequently Asked Questions

What causes my glass to become dirty?

If the glass has white ash build up it is normal and the glass should be cleaned. If it is a black soot build up airow through the unit may be

restricted. The most often cause is overdue maintenance and cleaning. See “Maintaining and Servicing Appliance” in the owner’s manual.

How can I get more heat out of the appliance?

The most often cause of diminished heat output is overdue maintenance and cleaning. See “Maintaining and Servicing Appliance” in the

owner’s manual. If this still does not help, verify the correct settings for maximum heat output. See “Feed Rate Adjustment” under “Operating

Instructions” in the owner’s manual.

What should I

do if I smell smoke or there is ash/soot coming from the appliance?

Seal exhaust venting system to the unit with High Temp silicone. Secure the venting system to the unit with at least (3) screws. All pellet

vent pipe must be secured together either by means provided by the pipe manufacturer or by (3) screws at each joint.

Why would my appliance run ne last winter but not start this fall?

It is possible that the stove was not properly prepared for the Non-burn season. See “Trouble shooting” in the owner’s manual.

Why would the metal on the inside of the appliance begin to ake?

There are some pellet mills that get their raw materials from lumber mills that purchase logs that are transported in sea water. These pellets can

have a higher salt content and cause the metals in the unit to corrode prematurely and deteriorate. If you are seeing any components inside the

rebox deteriorate it is recommended to change pellet brands immediately.

Why does only the exhaust blower run when I unplug and plug back in my appliance?

This is a Safety feature to prevent the unit from operating in an unsafe condition. Allow the unit to run and it will return to normal operation.

Is there a place to lubricate the blowers to quiet them down?

The most often cause of noisy blowers is from the impellers becoming dirty over time. See “General Maintenance & Cleaning” under

“Maintaining & Servicing Appliance” in the owner’s manual. No form of lubrication should ever need applied to the blowers.

Why are dierent components cycling on and o in my appliance at random?

The selector switch on control box may be on the wrong setting. Refer to the Reference Materials section of our owner’s manual for details.

What is the metal object with the bend in it for that came inside the plastic bag?

It is a clean-out tool used to help clean the re pot and remove any jams in the rare event they occur in the feed tube.

Why is there a black residue building up on the outside of my home?

Wind can cause this to happen. If the appliance is operating correctly very little soot should ever exit the termination cap. Also check to be sure

the venting is installed per the owner’s manual and local codes.

Do I need an outside air kit?

Outside air is required for mobile home installs and in some jurisdictions. Refer to “Listing & Code Approvals”,“ Mobile Home Installation” and “

Appliance Set-up” owner’s manual. Also refer to local building codes.

I am seeing sparks coming out of my pipe (termination cap) outside is this safe?

This is normal. As long as clearances to combustibles were followed this is safe.

My unit sounds like a freight train at times what can be done to eliminate this?

This is referred to as Rumbling. Maintenance may be needed see “Maintaining and Servicing appliance” in the owner’s manual. Decrease fuel

ow see “Feed rate adjustment” under Operating Instructions”.

Why does my unit run ne on high, but shuts down on low and medium?

Maintenance may be needed see “Maintaining and Servicing Appliance” See also “Trouble Shooting”.

Can I use another brand of wall thermostat or remote system?

Yes, any remote/wall thermostat system that does not require power from the appliance should work.

I have no power to anything. Does this unit have a circuit breaker or fuse or a reset button?

This unit has one serviceable fuse in the junction box and a reset button for the thermostat circuit.

Can I burn corn in my unit?

Corn is not an approved fuel for the CAB50-C.

I’m thinking about going green (solar power) and need to know what the power consumption is on my Unit.

CAB50 115 VAC, 60 Hz, Start 5.1 Amps, Run 3.0 Amps

Where is the serial # of my unit is located?

The serial # is located on the back of the stove.

CONTACT YOUR DEALER for additional information regarding operation and troubleshooting.

Visit www.quadrare.com to nd a dealer.

14 04/217074-804F

Page 15

3 Maintenance and Service

When properly maintained, your replace will give

you many years of trouble-free service. Contact your

dealer to answer question regarding proper operation,

troubleshooting and service for your appliance. Visit

www.quadrare.com/owner-resources to view basic

troubleshooting, FAQs, use & care videos. We recommend

annual service by a qualied service technician.

A. Proper Shutdown Procedure

Turn o the thermostat.

This pellet heater has a manufacturer-set minimum low

burn rate that must not be altered. It is against federal

regulations to alter this setting or otherwise operate this

pellet heater in a manner inconsistent with operating

instructions in this manual.

Follow the detailed instructions found in this section for each step listed as referenced in the chart below.

Shock and Smoke Hazard

• Turn down thermostat, let appliance

• Smoke spillage into room can occur if

• Risk of shock if appliance not unplugged

CAUTION

completely cool and exhaust blower must

be o. Now you can unplug appliance

before servicing.

appliance is not cool before unplugging.

before servicing appliance.

B. Quick Reference Maintenance Chart

Cleaning or Inspection

Ash Pan - Burning Wood Pellets Every 5 bags of fuel OR X

Ash Pan - Burning Alternate

Fuels

Ash Removal from Firebox

Every 1 bag of fuel OR X

More frequently depending

on the fuel type or ash build-upOR X

Frequency Daily Weekly

Every 2

Weeks

Monthly Yearly

Blower, Combustion (Exhaust)

Blower, Convection

Door Latch Inspection Prior to heating season OR X

Firebox - Prepare for Non-Burn

Season

Fire pot - Burning Softwood

Pellets

Fire pot - Burning Hardwood

Pellets

Glass

Heat Exchanger & Drop Tube Every 1 ton of fuel OR X

Hopper

Top Vent Adapter

Venting System

Table 15.1

More frequently depending

on the fuel type

More frequently depending

on the operating environment

At end of heating season OR X

Every 5 bags OR X

Every 3 bags OR X

When clear view of re pot

becomes obscured

Every 1 ton of fuel or when

changing fuel types

More frequently depending

on ash build-up

More frequently depending

on the fuel type

OR X

OR X

OR X

OR X

OR X

OR X

NOTICE: These are recommendations. Clean more frequently if you encounter heavy build-up of ash at

the recommended interval or you see soot coming from the vent. Not properly cleaning your

appliance on a regular basis will void your warranty.

15 04/217074-804F

Page 16

Firepot Cleaning Rod

C. General Maintenance

Clinker

1. Types of Fuel

Depending on the type of fuel you are burning will dictate

how often you have to clean your re pot.

If the fuel you are burning has a high dirt or ash content,

it may be necessary to clean the re pot more than once

a day.

OPEN position: light

color painted area visible

Dirty fuel will cause clinkers to form in the re pot. A clinker

is formed when dirt, ash or a non-burnable substance is

heated to 2000°F (1093°C) and becomes glass-like. See

section on High Ash Fuel Content Maintenance on

page 20 in this section for more details on fuels with high

ash content.

Figure 16.1 - Clinker

2. Cleaning Fire pot with Cleaning Rod & Fire pot

Clean-Out Tool;

• Frequency: Daily or more often as needed

• By: Homeowner

a. The appliance must be in complete shutdown and

cool and the exhaust blower o. If you are just

cleaning the re pot, there is no need to unplug

the appliance.

b. Locate the re pot cleaning rod on the right side

of the appliance (Figure 16.2). When you pull the

cleaning rod straight out it will slide open the repot

oor to allow the ashes to be deposited in the ash

drawer. You will see the light color painted area on

the cleaning rod to let you know the rod is in OPEN

position (Figure 16.3).

c. Pull the re pot cleaning rod OUT and IN a couple

of times to help shake debris loose. If the rod is

hard to pull, it may be necessary to use your re

pot clean-out tool to chip away material that has

built up on the bottom plate of the re pot and to

push out any clinkers while in the open position.

d. To close the re pot oor: slightly raise the cleaning

rod and then push it back into place. If you have

closed the cleaning rod properly (pushed all the

way in) you will not see any of the light color

painted area (Figure 16.3).

e. Always have the ash drawer in place before pulling

the re pot cleaning rod, otherwise the ashes will

fall down and ll the outside air opening and the

appliance will produce soot out of the exhaust and

will aect eciency.

Lift up and push closed

CLOSED position: no

light color paint is visible

Figure 16.2 Figure 16.3

WARNING

Fire Risk

• NEVER pull repot cleaning rod out when

appliance is operating.

• Cleaning Rod MUST be completely

pushed in before operating appliance.

• Hot pellets may fall into ash pan and start

a re or mis-starts due to lack of vacuum.

3. Ash Removal from Firebox

• Frequency: Weekly or more frequently depending on

ash build-up.

• By: Homeowner

a. There must not be any hot ashes in the rebox

during cleaning so allow the appliance to

completely cool. The rebox ash should be

removed every time the exhaust path is cleaned.

Frequent cleaning of the ash in the rebox will

help slow down the build-up of ash in the exhaust

blower and vent system.

b. Vacuum out the rebox thoroughly on both sides

of the rebox and the oor and ceiling. The ash

drawer should be emptied every time you clean the

rebox. Remember to place the ash and debris into

a metal or non-combustible container (See section

on Disposal of Ashes on page 17).

c. Always have the ash drawer in place before pulling

the re pot cleaning rod, otherwise the ashes will

fall down and ll the outside air opening and the

appliance will produce soot out of the exhaust and

will aect eciency.

WARNING

Burn Risk

• NEVER remove ash drawer while

appliance is operating.

16 04/217074-804F

Page 17

Pull out Ash Drawer and

dispose of ashes in

non-combustible container

Ash Drawer

4. Cleaning Ash Drawer

• Frequency: Weekly or every 5 bags of fuel

• By: Homeowner

a. There must not be any hot ashes in the ash drawer

when you empty it, so allow the appliance to

completely cool.

b. Locate the ash drawer underneath the re pot.

Slide the ash drawer straight out. Empty into a

non-combustible container and re-install the ash

drawer. See section on Disposal of Ashes on

page 17.

c. Always have the ash drawer in place before pulling

the re pot cleaning rod, otherwise the ashes will

fall down and ll the outside air opening and the

appliance will produce soot out of the exhaust and

will aect eciency.

6. Cleaning the Exhaust Path, Baes & Drop Tube

• Frequency: Monthly or every 25 bags or more

frequently depending on ash build-up.

• By: Homeowner

a. Appliance must be completely cool.

b. Open the door and remove the center bae rst

and then the right and left baes. See section

on Bae Replacement instructions on page 26.

Thoroughly vacuum the exhaust path and drop

tube and continue throughout the rest of the

rebox. Also vacuum the front and back of the

baes.

c. Also vacuum the combustion blower impellers or

use a soft brush to remove any ash build-up.

Replace the right and left baes and then the center bae

and close and latch the door.

Baffles Removed

Baffles Removed

Figure 17.1

5. Disposal of Ashes

• Frequency: As needed

• By: Homeowner

Ashes should be placed in a metal container with a tight-

tting lid. The closed container of ashes should be placed

on a non-combustible oor or on the ground, well away

from all combustible materials, pending nal disposal.

If the ashes are disposed of by burial in soil or otherwise

locally dispersed, they should be retained in the closed

container until all cinders have been thoroughly cooled.

WARNING

Disposal of Ashes

• Ashes should be placed in metal container

with tight tting lid.

• Ashes should be retained in closed

container until all cinders have thoroughly

cooled.

Exhaust Path and

Drop Tube

Drop Tube

Figure 17.2

Exhaust Path and

Blower Impellers

Blower Impellers

7. Cleaning the Hopper

• Frequency: Monthly or after burning 50 bags of fuel

• By: Homeowner

After burning approximately 50 bags of fuel you will need to

clean the hopper to prevent sawdust build-up.

A combination of sawdust and pellets on the bottom end of

the auger reduces the amount of fuel supply to the re pot.

This can result in nuisance shutdowns and mis-starts.

a. The appliance must be in complete shutdown.

Allow the appliance to completely run out of pellets

and cool down.

b. Empty the hopper of any remaining pellets.

c. Vacuum the hopper and feed tube.

NOTE: Hearth & Home Technologies recommends to

use a heavy duty vacuum cleaners specically

designed for solid fuel appliance cleaning.

17 04/217074-804F

Page 18

8. Soot and Fly Ash: Formation & Need for Removal in

Locknut

Door Cross Section

(example)

Latch Cam

Spacing

Washers

Square Key

Door Handle

Spring

Handle

Exhaust Venting System.

• Frequency: Yearly or more frequently depending on

ash build-up.

• By: Qualied Service Technician/Homeowner

Be sure the appliance is allowed to cool, has been

unplugged and the exhaust blower is o.

The products of combustion will contain small particles

of y ash. The y ash will collect in the exhaust venting

system and restrict the ow of the ue gases.

At start-up if there is incomplete combustion, or if there is

a shutdown or incorrect operation of the appliance it will

lead to some soot formation. This will collect in the exhaust

venting system.

The venting (chimney) system may need to be cleaned at

least once a year or more often depending upon the quality

of your fuel or if there are any horizontal pipe sections.

Ash will build up more quickly in the horizontal sections

and elbows.

9. Door Handle Inspection

• Frequency: Monthly or prior to heating season

• By: Homeowner

The gasket between the glass and rebox should be

inspected periodically to make sure there is a good seal.

Check door handle for smooth cam operation.

10. Cleaning the Glass

• Frequency: When clear view of the re pot becomes

obscure

• By: Homeowner

a. Appliance must be completely cool before

cleaning glass.

b. Vacuum y ash from glass and door rope.

c. Use a damp paper towel or any non-abrasive glass

cleaner. Wipe o with dry towel.

CAUTION

Handle glass assembly with care.

When cleaning glass:

• Avoid striking, scratching or

slamming glass.

• Do NOT clean glass when hot.

• Do NOT use abrasive cleaners.

• Refer to maintenance instructions.

WARNING

Handle glass with care.

• Inspect the gasket to ensure it

is undamaged.

• Do NOT strike, slam or scratch glass.

• Do NOT operate appliance with glass

assembly removed.

Figure 18.1

11. Cleaning Exhaust Blower - Requires No Lubrication

• Frequency: Yearly or more frequently depending on

ash build-up

• By: Homeowner or Qualied Service Technician

a. Be sure the appliance is allowed to cool, has been

unplugged and the exhaust blower is o.

b. Follow the directions for cleaning the exhaust path

found on page 17.

c. If unable to thoroughly clean the blower through

this access, follow section on Side Curtain

Replacement on page 24 to remove right side

from the appliance obtain direct access to the

exhaust blower.

d. Vacuum the blower’s impellers. Use care not to

bend or damage the blower ns.

NOTE: Hearth & Home Technologies recommends to

use a heavy duty vacuum cleaners specically

designed for solid fuel appliance cleaning.

18 04/217074-804F

Page 19

Clean-Out

Cover

12. Cleaning Convection Blower - Requires No

Lubrication

• Frequency: Yearly or more frequently depending on

Dust/Dirt build-up

• By: Homeowner or Qualied Service Technician

a. Be sure the appliance is allowed to cool and has

been unplugged.

b. Follow section on Side Curtain Replacement on

page 24 to remove left side from the appliance to

obtain direct access to the convection blower.

c. Sweep or vacuum out any build-up. Use a brush or

compressed air to loosen dirt if needed.

13. Cleaning the Top Vent Adapter

• Frequency: Yearly or more frequently depending on

ash build-up

• By: Homeowner

a. The appliance must be in complete shutdown

and the exhaust blower should be o. Allow the

appliance to completely cool down.

b. Open the clean-out cover (Figure 19.1).

c. Sweep or vacuum out any ash build-up.

14. Preparing Firebox for Non-Burn Season

• Frequency: Yearly

• By: Homeowner

a. Be sure the appliance is allowed to cool, has been

unplugged and the exhaust blower is o.

b. Remove all ash from the rebox and

vacuum thoroughly.

c. Paint all exposed steel, including cast-iron.

— Purchase paint from your local dealer.

— Must use a high-temperature paint made

specically for heating appliances.

Figure 19.1

19 04/217074-804F

Page 20

D. High Ash Fuel Content Maintenance

• Frequency: As needed

• By: Homeowner

Poor quality pellet fuel, or lack of maintenance, can create

conditions that make the re pot ll quickly with ashes

and clinkers.

This condition makes the appliance susceptible to

overlling the re pot with pellets which may result in

smoking, sooting and possible hopper res. Figure 20.1

shows an example where the re pot overlls, pellets

back up into the feed tube and ash has accumulated in

the rebox.

An inecient and non-economical method of burning of fuel

caused by poor quality pellet fuel is shown in Figure 20.2.

Incorrect Flame Height

Tall, Lazy Flame

Tall, Lazy Flame

Orange in Color

Orange in Color

The correct ame size when good quality, premium pellet

fuel is burned is shown in Figure 20.3.

If the ash buildup exceeds the half way point in the re pot

IMMEDIATE ATTENTION AND CLEANING IS REQUIRED.

WARNING

Fire Risk

• High ash fuels, or lack of maintenance,

can cause the re pot to overll. Follow

proper shutdown procedure if ash buildup

exceeds halfway point in re pot.

• Failure to do could result in smoking,

sooting and possible hopper res.

Pellets Back-up in Feed Tube

Pellets Back-up in Feed Tube

Firepot Overfills

Firepot Overfills

Ash build-up in FireboxAsh build-up in Firebox

Figure 20.1

Figure 20.2

Correct Flame Height

Yellow/White in Color

Figure 20.3

E. Soot or Creosote Fire

Establish a routine for the fuel, wood burner and ring

technique. Check daily for creosote build-up until

experience shows how often you need to clean to be

safe. Be aware that the hotter the re the less creosote

is deposited, and weekly cleaning may be necessary in

the mild weather even though monthly cleaning may be

enough in the coldest months. Contact your local municipal

or provincial re authority for information on how to handle

a chimney re.

In the event of a soot or creosote re, close the rebox

door, exit the building immediately and contact the

proper re authorities.

DO NOT under any circumstances re-enter

the building.

20 04/217074-804F

Page 21

4 Troubleshooting Guide

With proper installation, operation, and maintenance your appliance will provide years of trouble-free service. If you do

experience a problem, this troubleshooting guide will assist a qualied service person in the diagnosis of a problem and the

corrective action to be taken. This troubleshooting guide can only be used by a qualied service technician.

Symptom Possible Cause Corrective Action

Plug in appliance No response.

Call light on. No re.

No fuel in re pot.

Call light on. No re.

Partially burned fuel in

re pot.

Call light on. No re.

Unburned pellets in

re pot.

Slow or smoky start-up.

Table 21.1

No current to outlet.

7 amp fuse defective.

#3 snap disc tripped or defective.

Control box defective.

Out of fuel.

#2 snap disc may be defective.

Vacuum switch not closing, no vacuum.

Control box defective.

Fire pot clean-out plate not closed.

Fire pot is dirty (missed ignition).

Fire pot clean-out plate not closed.

Fire pot is dirty.

Ignition hole blocked.

Igniter not working.

Control box defective.

Fire pot clean-out plate not closed.

Fire pot is dirty.

Excessive amount of fuel at start-up.

Check circuit breaker at service panel.

Replace fuse.

Reset or replace snap disc.

Replace control box.

Check hopper. Fill with fuel.

Replace snap disc.

Check exhaust blower is plugged in

and operating.

Check vacuum switch is plugged in.

Check vacuum hose is in good condition,

clear and connected at both ends.

Check thermocouple is in good condition

and plugged in properly.

Make sure venting system is clean.

Make sure front door is closed.

Replace control box.

Check that re pot clean-out plate is fully

closed.

Clean re pot. Make sure there is no clinker

in the re pot.

Clinkers may have to be broken up with re

pot scraper tool or other means.

Check that re pot clean-out plate is

fully closed.

Clean re pot. Make sure there is not a

clinker in the re pot. Clinkers may have

to be pushed out of re pot with re pot

scraper tool or other means.

Scrape with solid piece of wire.

Remove ash pan to see if igniter is glowing

red on start-up.

Check igniter wires for good connection.

Replace igniter using 1/4 inch male /female

spade connectors.

Replace control box.

Check that re pot clean-out is fully closed.

Clean re pot. Make sure there is not a

clinker in the re pot. Clinkers may have to

pushed out of re pot with re pot scraper

tool or other means.

Reduce feed rate using feed rate adjustment

control rod located inside hopper.

21 04/217074-804F

Page 22

Symptom Possible Cause Corrective Action

Slow or smoky start-

up (Cont’d)

Feed system fails

to start.

No call light. Appliance

does not begin

start sequence.

Dirty exhaust and/or venting system.

Out of fuel.

#2 snap disc may be defective.

Vacuum switch not closing. No vacuum.

Feed system jammed or blocked.

Feed spring not turning with feed motor.

Feed motor defective or not plugged in.

Thermostat not set to a high enough

temperature.

Snap Disc #3 tripped.

No power.

Fuse blown.

Connections at thermostat and/or appliance not

making proper contact.

Defective thermostat or thermostat wiring.

Check for ash build up in appliance,

including behind rear panels, rebox, heat

exchanger, exhaust blower and venting.

Check hopper, ll with fuel.

Replace snap disc. Firebox door must be

closed securely.

Check exhaust blower is plugged in and

operating.

Check vacuum switch is plugged in. Check

vacuum hose is in good condition, clear and

connected at both ends.

Check thermocouple is in good condition

and plugged in properly.

Make sure venting system is clean.

NOTE: High winds blowing into the venting

system can pressurize the rebox

causing loss of vacuum.

Empty hopper of fuel. Use a wet/dry vacuum

cleaner to remove remaining fuel, from

hopper, including feed tube.

Check feed chute for obstructions.

Loosen 2 screws and jiggle feed assembly.

Check that set screw is tight on feed spring

shaft at end of feed motor.

Check connections on feed motor, replace if

defective.

Adjust thermostat above room temperature.

Reset snap disc.

Connect to power.

Replace fuse.

Check connections at thermostat

and appliance.

Replace thermostat or wiring.

NOTE: To test thermostat and wiring, use

a jumper wire at the thermostat

block on the appliance to by-pass

thermostat and wiring.

Control box defective.

Appliance fails to

shut o.

Table 22.1

Call light on.

22 04/217074-804F

Replace control box.

Turn thermostat o.

If call light does not go out, disconnect

thermostat wires from appliance. If call

light does go out, thermostat or wires

are defective.

Page 23

Symptom Possible Cause Corrective Action

No call light.

Defective control box.

Convection blower fails to

start.

Exhaust blower fails to

start or does not shut o.

Large, lazy ame, orange

color. Black ash on glass.

#1 snap disc defective.

Blower not plugged in.

Blower is defective.

Control box is defective.

Blower not plugged in.

Blower is clogged with ash.

Blower is defective.

Control box is defective.

Dirty appliance.

Poor fuel quality, high ash content.

Fire pot clean-out plate not

completely closed.

Excessive amount of fuel.

Low ame.

Replace snap disc.

Check that blower is plugged into

wire harness.

Replace blower.

Replace control box.

Check that blower is plugged into wire

harness.

Clean exhaust system.

Replace blower.

Replace control box.

Clean appliance, including re pot, heat

exchangers and venting system. Remove

stainless steel bae from rebox to clean

ash from on top of bae. Clean behind rear

brick panels. Change fuel brand to premium.

Check that re pot clean-out plate is

fully closed.

Reduce feed rate using feed rate adjustment

control rod located inside hopper.

Increase feed by opening feed rate

adjustment control rod located inside

hopper.

Nuisance shutdowns.

Appliance calls for heat.

Call light illuminates.

Exhaust blower starts.

No feed or igniter.

Table 23.1

Sawdust buildup in hopper.

Feed motor is reversing.

Defective thermocouple.

Defective control box.

Fire pot more than 1/2 full

Thermocouple is defective or not properly

plugged in.

Defective control box

Clean hopper, see page 17.

Check for good connections between feed

motor and wire harness.

Replace thermocouple.

Replace control box.

See page 20 for detailed instructions for

“High Ash Fuel Content Maintenance”.

Check connections on thermocouple or

replace if defective.

A ashing yellow light on the control box

indicates a problem with the thermocouple.

Replace control box.

23 04/217074-804F

Page 24

5 Service Parts Replacement

Loosen Screws,

Do Not Remove.

Nylon Wire Retainer

Wing Screw

Hold Down Bracket

Spade

Connectors

Locating Tab

A. Side Curtain Replacement

1. Using a #2 Phillip Head screwdriver, a 3/8 inch wrench

or a 3/8 Inch socket, loosen the three (3) bolts from the

back side of the appliance (Figure 24.1).

2. Remove side curtain by lifting up and out of the slots

(Figure 24.2).

NOTE: If conducting other service part replacements, do

it at this time:

- Right side: Feed motor, vacuum switch, and

combustion blower (Figure 30.3 on page 30).

- Left side: Control box, convection blower,

fuse, junction box, and red call light

(Figure 30.2 on page 30).

3. Add new side curtain in reverse order.

B. Convection Blower Replacement

1. Turn down the thermostat, let appliance completely

cool and then unplug appliance before servicing.

2. The convection blower is located on the oor at the

rear of the appliance.

3. Follow section on Side Curtain Replacement on

page 24 to remove left side from the appliance.

4. Release blower wires from the nylon wire retainer if

applicable. This appliance has 1 black and 1 white wire

coming from the blower.

5. Remove the wing bolt and move the blower and hold-

down bracket toward the back of the appliance to

release the locating tab (Figure 24.3). Pull the blower

out from under the convection plenum. Slide the blower

out of the appliance. Disconnect the wires from the

spade connectors at this time (Figure 24.4).

6. Return wires to nylon wire retainer. Make sure wires

do not contact any moving parts or touch any surfaces

that may become hot (Figure 24.4).

Figure 24.1

Left Panel

Figure 24.2

Figure 24.3

Lift Up and

Out of Slots

Figure 24.4

24 04/217074-804F

Page 25

C. Exhaust Blower Replacement

Exhaust Blower

Snap Disc #1

Snap Disc #3

Snap Disc #2

Remove ScrewRemove Screw

Snap Disc Bracket

Snap Disc Bracket

1. Turn down the thermostat, let appliance completely

cool and then unplug appliance before servicing.

2. Follow section of Side Curtain Replacement on

page 24 to remove right side from the appliance.

3. Disconnect two (2) white wires from the white and blue

wires of the exhaust blower.

4. There is a removable plate on the exhaust blower.

Depending on the model, use a 1/4 inch socket, or

1/4 inch Nut Driver or #2 Phillips Head screw driver to

loosen the six (6) screws in the keyhole shaped holes

and rotate the plate. It is only necessary to loosen

screws (Figure 25.1).

5. Remove the exhaust blower and gasket.

6. Check for degradation on the gasket and replace if

necessary using the gasket included in the kit.

7. Re-install in reverse order.

Snap Disc #2 - Fuel Delivery Interrupt

1. Turn down thermostat, let appliance cool completely if

running. Then unplug appliance before servicing.

2. Follow section on Side Curtain Replacement on

page 24 to remove right side from the appliance.

3. Snap disc #2 is located on the convection plenum

in the center of the appliance above the convection

blower (Figure 25.2).

4. It has a black wire and an orange wire attached to it

with 1/4 inch female spade terminals.

5. Disconnect the two wires from the snap disc. Using

a #2 Phillips screwdriver, remove the two screws

securing the snap disc to the appliance.

6. Re-install in reverse.

Snap Disc #3 - Feed Motor - Manual Reset

1. Turn down thermostat, let appliance cool completely if

running. Then unplug appliance before servicing.

2. Follow section on Side Curtain Replacement on

page 24 to remove right side from the appliance.

3. Snap disc #3 is located on the bracket on the feed tube

near the feed motor (Figure 25.2).

4. It has a two gray wires attached to it with 1/4 inch

female spade terminals.

5. The locating bracket is attached to the feed tube with

an 8 X 32 inch wing nut. Remove the wing nut to

detach the bracket from the feed tube.

6. Disconnect the two wires from the snap disc.

7. Using a #2 Phillips screwdriver, remove the screw

securing the snap disc to the bracket (Figure 25.3).

8. Re-install in reverse.

Figure 25.1

D. Snap Disc #1, #2, #3 Replacement

Snap Disc #1 - Convection Blower

1. Turn down thermostat, let appliance cool completely if

running. Then unplug appliance before servicing.

2. Follow section on Side Curtain Replacement on

page 24 to remove right side from the appliance.

3. Snap disc #1 is located on the convection plenum

below the feed motor (Figure 25.2).

4. It has two purple wires attached to it with 1/4 inch

female spade terminals.

5. Disconnect the two wires from the snap disc. Using

a #2 Phillips screwdriver, remove the two screws

securing the snap disc to the appliance.

6. Re-install in reverse.

Figure 25.2

25 04/217074-804F

Figure 25.3

Page 26

E. Igniter Replacement

Firepot

Igniter

Igniter

Chamber

Thermocouple &

Thermocouple Cover

Thumb

Screw

Firepot Cleaning Rod

Igniter Wires

MUST BE ROUTED

Through Wire Retainer Hook

Use handle at top

of center baffle to

pull up and then

towards you.

Lift up to

remove hooks

from slots

Remove left baffle

Remove right baffle

Lift up to remove

hooks from slots

1. Shut down the appliance by turning down the

thermostat and let the appliance completely cool down.

After the appliance has cooled down, unplug it and

remove the ash drawer.

2. The wire leads to the igniter are connected to the wire

harness with 1/4 inch male / female spade connectors.

3. Follow section on Side Curtain Replacement on

page 24 to remove right side from the appliance to

expose the spade connectors.

4. Disconnect the spade connectors and remove the

igniter from the chamber. Loosen thumb screw and

slide igniter out.

5. Install new igniter into the chamber and tighten thumb

screw. The wires MUST route through the wire retainer

hook and then re-connect the wires to the two (2) leads

with the spade connectors (Figure 26.1).