Page 1

HEAR THE POWER OF TECHNOLOGY.

PowerLight™ Series

Two-Channel Power Amplifiers

TECHNICAL SERVICE MANUAL

▲▲

▲ PowerLight 6.0 II

▲▲

▲▲

▲ PowerLight 6.0

▲▲

▲▲

▲ PowerLight 9.0

▲▲

PFC

PFC

22 22

1 -CHANNEL- 2

24 24

ON

OFF

PROTECT

STANDBY

POWER

1 CHANNEL 2

POWERLIGHT 9.0

PFC

9000 WATT POWER FACTOR CORRECTED PROFESSIONAL AMPLIFIER

20 20

18 18

14 14

88

-00 -00

CLIP

26 26

-10dB

28 28

-20dB

30 30

SIGNAL

32 32

CLIP LIMITER

dB

dB

*TD-000083-00*

TD-000083-00

Rev. Prelim.

Page 2

Page 3

PowerLight Series

Technical Service Manual

▲▲

▲ PowerLight 6.0 II

▲▲

▲▲

▲ PowerLight 6.0

▲▲

▲▲

▲ PowerLight 9.0

▲▲

IMPORTANT NOTICE:

This document contains proprietary information that is the property

of QSC Audio Products, Inc, and may not be disclosed, reproduced or

used without express or written consent from QSC Audio Products.

QSC Audio Products, Inc.

Technical Services Group

Phone: 1-800 QSC AUDIO (1-800-772-2834) USA only

+1 (714) 957-7150

Fax: +1 (714) 754-6173

Postal: 1665 MacArthur Blvd.

Costa Mesa, California 92626 USA

E-mail: tech_support@qscaudio.com

Web: http://www.qscaudio.com (product information and support)

http://www.qscstore.com (parts and accessory sales)

PFC

PFC

Copyright 2004 QSC Audio Products, Inc. All rights reserved.

Document # TD-000083-00, Preliminary Rev. Released November 2004.

Technical Service Manual 1

PowerLight 6.0 II, PowerLight 6.0

PFC

, and PowerLight 9.0

PFC

Page 4

PowerLight 9.0

PFC

PowerLight 6.0

PFC

PowerLight 9.0 II

2 QSC Audio Products, Inc.

TD-000083-00

Page 5

Table of Contents

Performance Specifications ............................................................................................................................................................................................... 4

1. Introduction ..................................................................................................................................................................................................... 5

1.1 Service bulletins.............................................................................................................................................................................................................. 5

1.2 The well-equipped service bench ............................................................................................................................................................................... 5

1.3 Working with surface-mount components................................................................................................................................................................. 5

T wo-terminal components (resistors, capacitors, diodes, etc.)............................................................................................................................................................. 5

Multi-pin components (ICs, etc.) ........................................................................................................................................................................................................ 6

Three-terminal components (transistors, etc.) .................................................................................................................................................................................... 6

1.4 Series description ........................................................................................................................................................................................................... 6

1.5 Technical descriptions and theory of operation........................................................................................................................................................ 7

Power supplies ................................................................................................................................................................................................................................. 7

Audio circuitry................................................................................................................................................................................................................................... 7

2. Servicing the amplifier .................................................................................................................................................................................. 8

2.1 Mechanical disassembly and reassembly ................................................................................................................................................................. 8

Introduction...................................................................................................................................................................................................................................... 8

T ools and materials needed .............................................................................................................................................................................................................. 8

Disassembly ..................................................................................................................................................................................................................................... 8

Reassembly.................................................................................................................................................................................................................................... 11

2.2 The display board.......................................................................................................................................................................................................... 13

2.3 AC line filter ................................................................................................................................................................................................................... 13

2.4 Power supply servicing................................................................................................................................................................................................ 15

Bench testing power supply modules .............................................................................................................................................................................................. 15

Replacing switching MOSFET s in PFC models.................................................................................................................................................................................. 15

Suggestions for troubleshooting..................................................................................................................................................................................................... 17

Adjusting and calibrating the power supply module......................................................................................................................................................................... 18

2.5 AC voltage conversions................................................................................................................................................................................................ 22

2.6 Bias adjustments ........................................................................................................................................................................................................... 22

3. Troubleshooting ............................................................................................................................................................................................ 23

3.1 Initial check ................................................................................................................................................................................................................... 23

3.2 Preliminary troubleshooting........................................................................................................................................................................................ 23

3.3 Further troubleshooting ................................................................................................................................................................................................ 24

4. Parts ................................................................................................................................................................................................................. 25

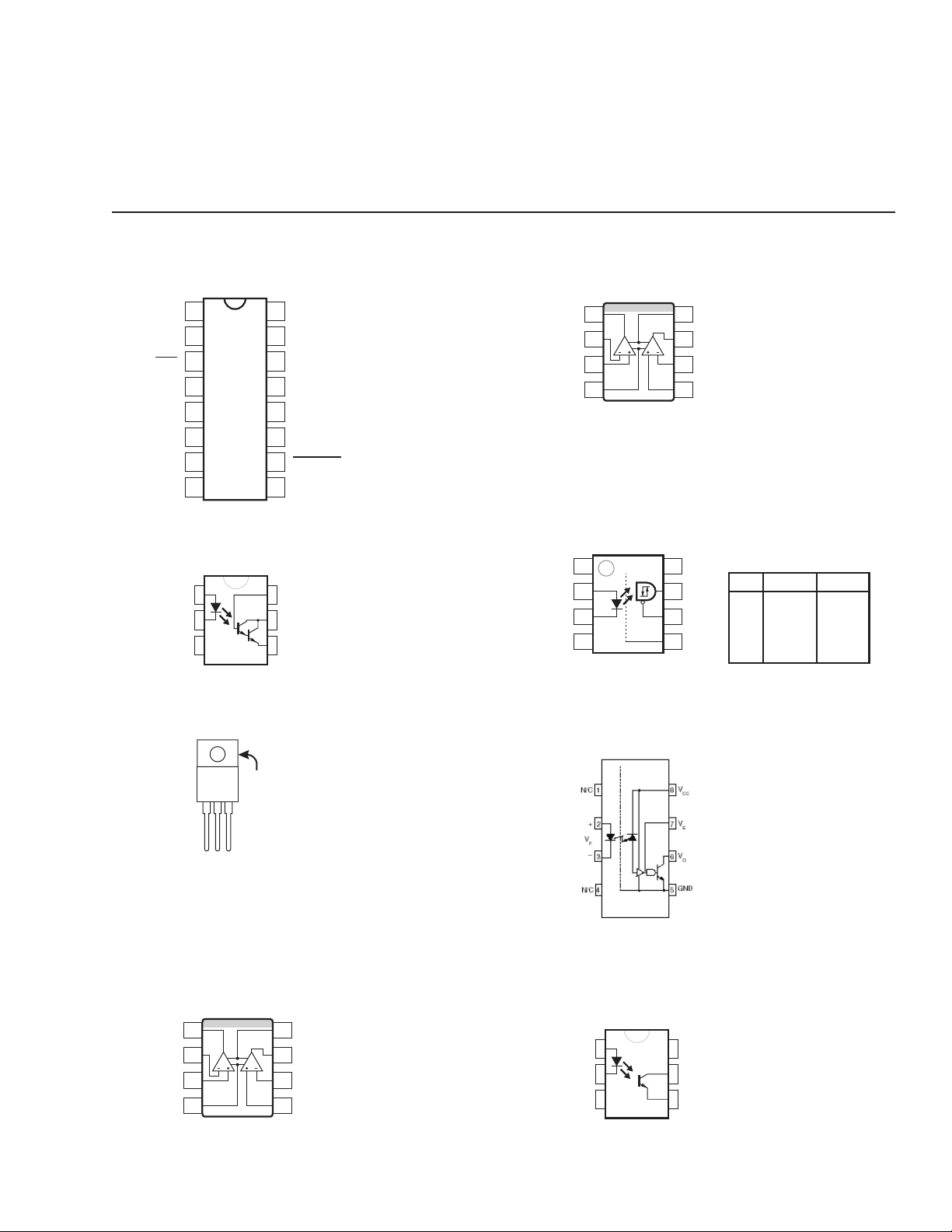

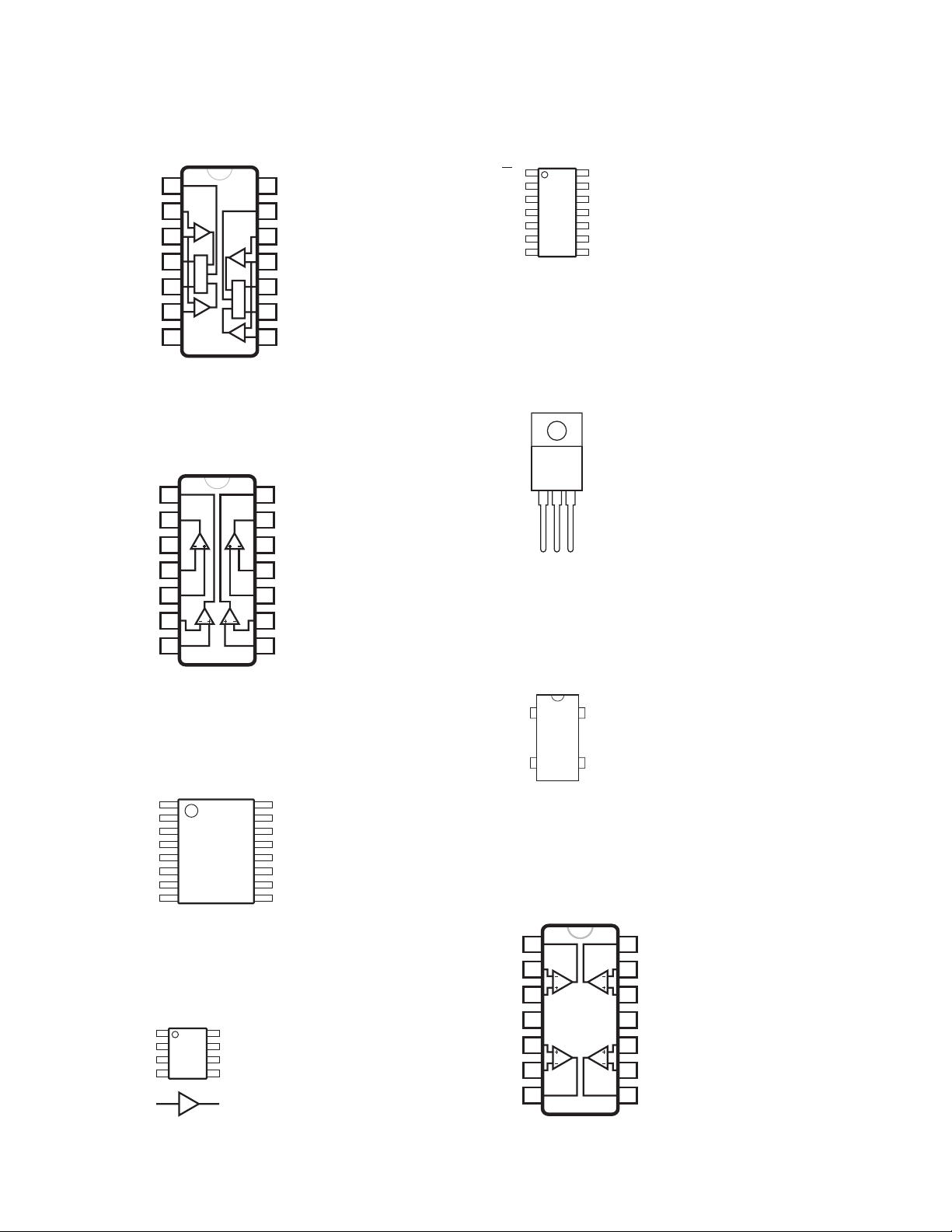

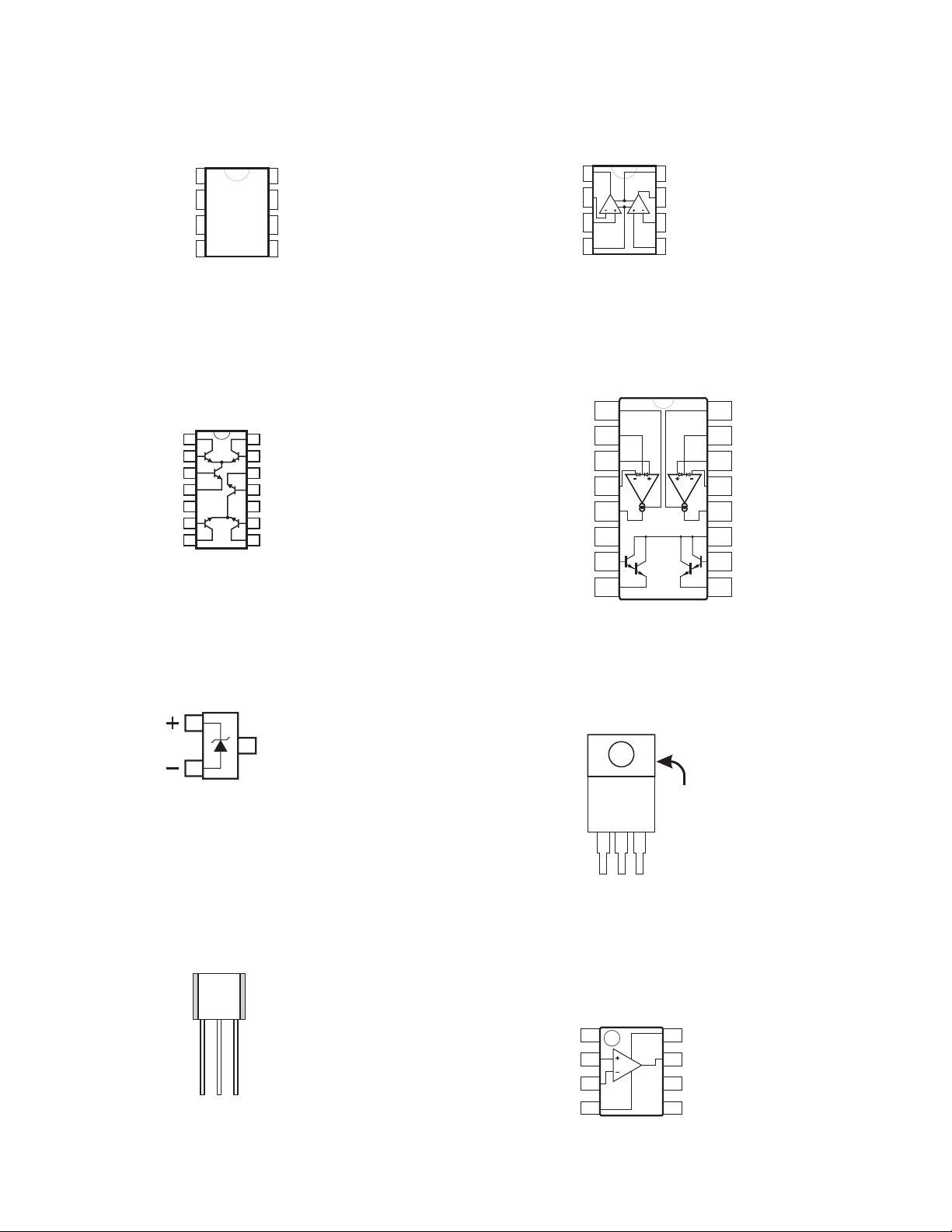

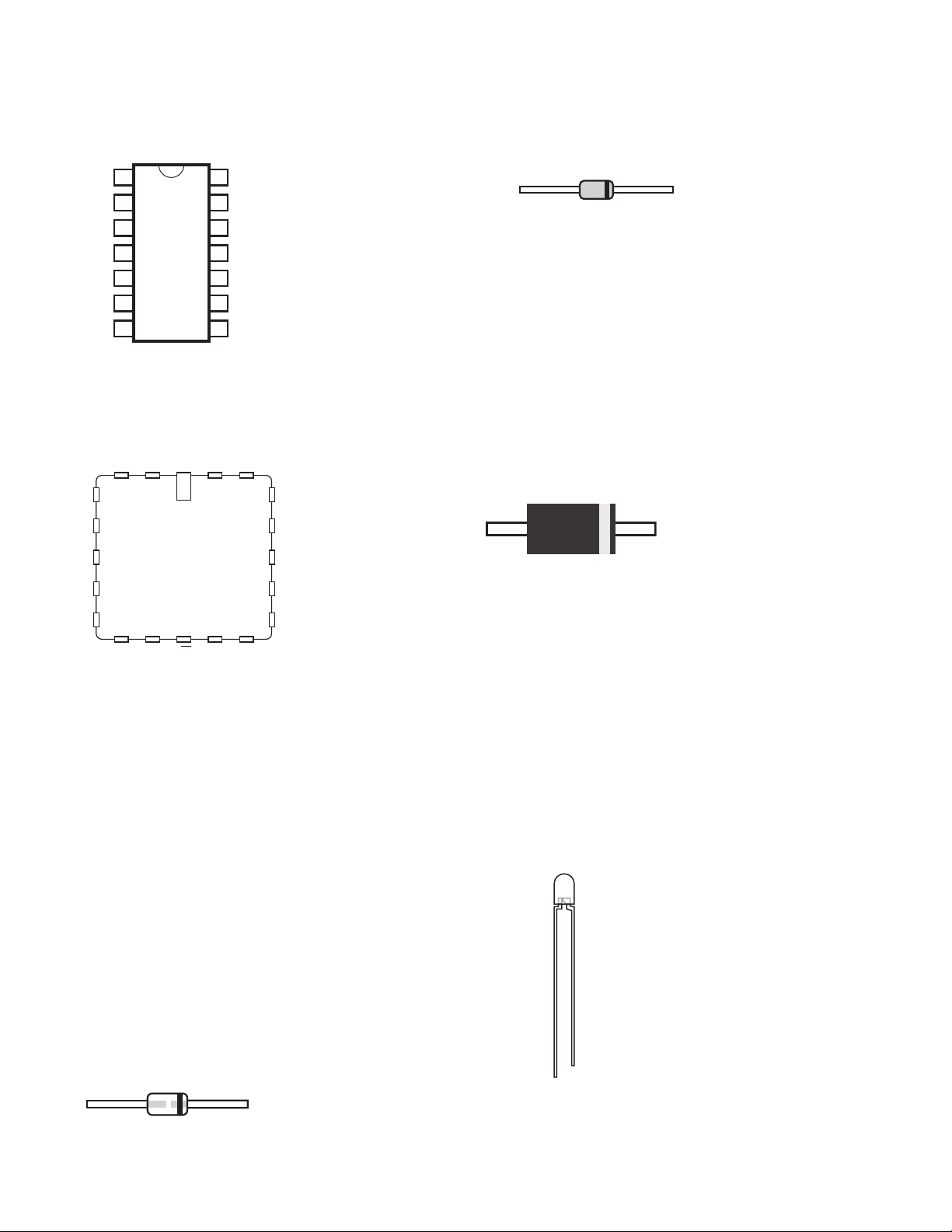

4.1 Semiconductor package descriptions and pinouts ................................................................................................................................................ 25

4.2 Parts lists ........................................................................................................................................................................................................................ 33

Chassis Assembly (QSC part #WP-000268-00) ................................................................................................................................................................................ 33

Chassis Assembly (QSC part # WP-000268-02) ............................................................................................................................................................................... 34

Chassis Assembly (QSC part # WP-000260-00) ............................................................................................................................................................................... 35

Chassis Assembly (QSC part # WP-000260-02) ............................................................................................................................................................................... 36

Chassis Assembly (QSC part # WP-000170-00) ............................................................................................................................................................................... 37

Chassis Assembly (QSC part # WP-000170-02) ............................................................................................................................................................................... 38

Chassis Assembly, Rear (QSC part # WP-000271-00)....................................................................................................................................................................... 39

Chassis Assembly, Rear (QSC part # WP-000264-00)....................................................................................................................................................................... 39

Chassis Assembly, Rear (QSC Part # WP-000172-00)....................................................................................................................................................................... 40

Output PCB Assembly (QSC part # WP-000179-00) ......................................................................................................................................................................... 40

Input PCB Assembly (QSC part # WP-000272-00)............................................................................................................................................................................ 40

Input PCB Assembly (QSC part # WP-000265-00)............................................................................................................................................................................ 41

Input PCB Assembly (QSC part # WP-000175-00)............................................................................................................................................................................ 41

Input Daughterboard Assembly (QSC part # WP-000178-00)........................................................................................................................................................... 42

Audio Channel Module Assembly (QSC part number WP-000276-00)............................................................................................................................................. 42

Audio Channel Module Assembly (QSC part # WP-000182-00) ....................................................................................................................................................... 46

Power Supply Assembly (QSC part # WP-000266-00)...................................................................................................................................................................... 50

Power Supply Assembly (QSC part # WP-000266-02)...................................................................................................................................................................... 52

Power Supply Assembly (QSC part # WP-000262-00)...................................................................................................................................................................... 55

Power Supply Assembly (QSC part # WP-000262-02)...................................................................................................................................................................... 56

Power Supply Controller Assembly (QSC part # WP-000263-00)...................................................................................................................................................... 58

Power Supply Assembly (QSC part # WP-000173-00)...................................................................................................................................................................... 60

Power Supply Assembly (QSC part # WP-000180-00)...................................................................................................................................................................... 61

Power Supply Controller Assembly (QSC part # WP-000174-00)...................................................................................................................................................... 63

Display PCB Assembly (QSC part number WP-000176-00)............................................................................................................................................................... 64

Line Filter Assembly (QSC part number WP-000177-00)................................................................................................................................................................... 66

Line Filter Assembly (QSC part number WP-000181-00)................................................................................................................................................................... 66

Matched FET s................................................................................................................................................................................................................................. 67

5. Schematic diagrams .................................................................................................................................................................................... 68

Technical Service Manual 3

PowerLight 6.0 II, PowerLight 6.0

PFC

, and PowerLight 9.0

PFC

Page 6

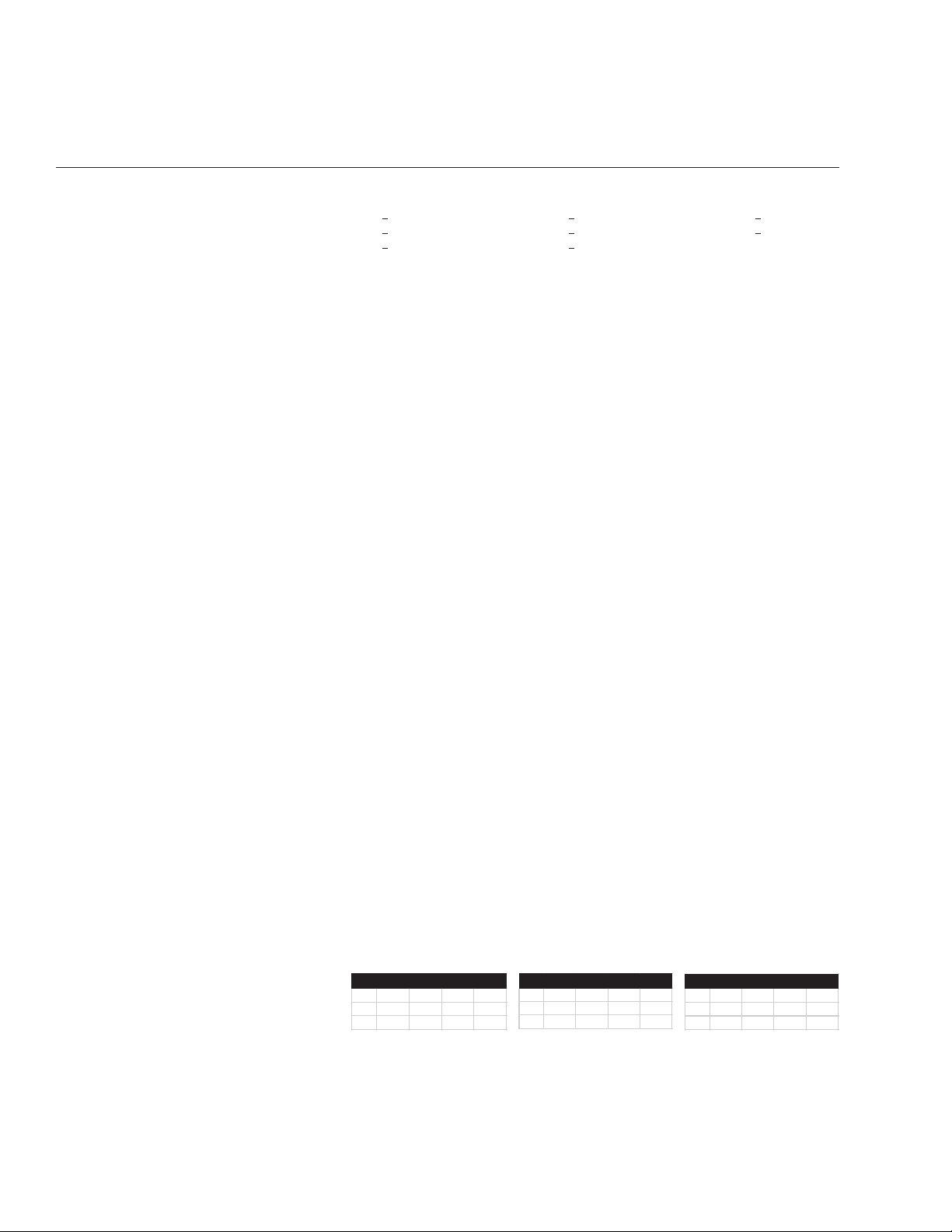

Performance Specifications

PowerLight 6.0 II PowerLight 6.0

PFC

PowerLight 9.0

PFC

OUTPUT POWER

in watts

FTC: 20 Hz–20 kHz, both channels driven

8Ω per channel 1150 (< 0.1% THD) 1400 (< 0.1% THD) 1800 (< 0.2% THD)

4Ω per channel 2050 (< 0.1% THD) 2500 (< 0.1% THD) 3200 (< 0.2% THD)

2Ω per channel 3250 (< 0.1% THD) 3250 (< 0.1% THD)

EIA: 1 kHz @ 1% THD, both channels driven

8Ω per channel 1300 1600 1950

4Ω per channel 2200 2800 3400

2Ω per channel 3500 3500 4500

Bridge Mono:

16Ω, 1 kHz, 1% THD 2600 3200 3900

8Ω, 1 kHz, 1% THD 4400 5600 6800

4Ω, 1 kHz, 1% THD 7000 7000 9000

DYNAMIC HEADROOM 0.77 dB @ 4Ω

DISTORTION

THD: 20 Hz–20 kHz (8, 4, & 2Ω @ 10 dB below rated power) < 0.06% < 0.15%

(8 & 4Ω @ FTC rated power) < 0.1% (20 Hz–20 kHz) < 0.02% (20 Hz–2 kHz) < 0.03% (20 Hz–2 kHz)

20 Hz–2 kHz (2Ω) < 0.1% (20 Hz–20 kHz @ 3250 W) < 0.02% (@ 3250 W) < 0.05% (@ 4500 W)

SMPTE-IM: < 0.02% < 0.02% < 0.02%

FREQUENCY RESPONSE 20 Hz–20 kHz, ±0.15 dB

(at 10 dB below rated output power) -3 dB points: 2 Hz and 50 kHz

DAMPING FACTOR > 2000 @ 8Ω, at 1 kHz and below

NOISE (unweighted 20 Hz to 20 kHz, below rated output) 107 dB 107 dB 107 dB

VOLTAGE GAIN 40× (32 dB)

INPUT SENSITIVITY, V RMS

full rated power @ 8Ω 2.4 v (+9.8 dBu) 2.6 v (+10.6 dBu) 3.0 v (+11.8 dBu)

full rated power @ 4Ω 2.3 v (+9.5 dBu) 2.5 v (+10.2 dBu) 3.8 v (+11.2 dBu)

INPUT IMPEDANCE 10 kΩ unbalanced

20 kΩ balanced

CONTROLS Front: AC switch, Ch. 1 and Ch. 2 gain, Ch. 1 and Ch. 2 clip limiter switches

Rear: Parallel/Stereo/Bridge switch, remote power supply enable terminals

INDICATORS each channel PROTECT: Red LED CLIP: Red LED

STANDBY: Yellow LED -10 dB: Yellow LED

POWER: Green LED -20 dB: Yellow LED

SIGNAL: Green LED

CONNECTORS Input: Active balanced; “Euro-style” terminal block; Neutrik “Combo” XLR

and ¼" (6.3 mm) TRS, tip and pin 2 positive

Output: “Touch-Proof” binding posts (60A rated) and Neutrik Speakon™ (1 per channel)

DataPort: HD 15 female connector for use with QSControl, Basis, or accessories

COOLING Four continuously variable speed fans, back-to-front air flow

AMPLIFIER PROTECTION Full short circuit, open circuit, thermal, ultrasonic, and RF protection

Stable into reactive or mismatched loads

LOAD PROTECTION Turn-on/turn-off muting,

OUTPUT CIRCUIT TYPE H: Full-bridge current cell vertical N-channel MOSFET linear output with Class H 4-step high efficiency circuit

DIMENSIONS 19.0" (48.3 cm) wide, 3.5" (8.9 cm) tall (2 rack spaces)

17.9" (45.5 cm) rack mounting to rear support ears; 19.5” (49.5 cm) overall

WEIGHT Shipping: 59 lb. (26.8 kg) 65 lb. (29.5 kg) 65 lb. (29.5 kg)

Net: 53 lb. (24.1 kg) 59 lb. (26.8 kg) 59 lb. (26.8 kg)

POWER REQUIREMENTS Available for 120 or 220–240 VAC, 50/60 Hz

POWER CONSUMPTION

(both channels driven)

Multiply currents by 0.5 for 230V units

@ 120 VAC

Typical

1

Full2Max

Idle

8Ω

2.5 A 10.3 A 19.3 A 39.3 A

4Ω

2.5 A 15.5 A 35.1 A 67.5 A

2Ω

2.5 A 23.8 A 47.4 A 104.7 A

1

Pink noise at 1/8 of full power; analogous to typical program with occasional clipping.

2

Pink noise at 1/3 of full power; analogous to typical program with heavy clipping.

3

Continuous sine wave at threshold of clipping (1% THD).

3

Idle

8Ω

2.5 A 10.3 A 19.3 A 39.3 A

4Ω

2.5 A 15.5 A 35.1 A 67.5 A

2Ω

2.5 A 23.8 A 47.4 A 104.7 A

Typical

1

Full2Max

3

Idle

8Ω

2.5 A 10.3A 19.3 A 39.3 A

4Ω

2.5 A 15.5A 35.1 A 67.5 A

2Ω

2.5 A 23.8A 47.4 A 104.7A

Typical

1

Full2Max

US patents pending

SPECIFICATIONS SUBJECT TO CHANGE WITHOUT NOTICE

3

4 QSC Audio Products, Inc.

TD-000083-00

Page 7

1. Introduction

1.1 Service bulletins

Contact QSC Technical Services to make sure you have the most

up-to-date service bulletins for PowerLight Series amplifiers.

Service bulletins may be distributed in hard copy, via fax, and

electronically (Adobe Acrobat PDF) via CD-ROMs, FTP from the QSC

web site (www.qscaudio.com), and e-mail.

These service bulletins had been issued at the time this manual

was printed: PFC0001, “PFC MOSFET Replacement” (PowerLight

PFC

6.0

and PowerLight 9.0

Replacement Guidelines” (PowerLight 6.0

only); and PFC0003, “Amplifier Goes Into Protect When Turned On”

(all three models).

PFC

only); PFC0002, “PFC Power Supply

PFC

and PowerLight 9.0

PFC

1.2 The well-equipped service

bench

To properly service QSC amplifiers, a technician needs the right

tools. The technician’s service bench should have the following

equipment:

• Digital multimeter with RMS AC voltage and current

• Digital clamp-on ammeter

• Dual-trace oscilloscope

• Audio distortion analyzer

• Non-inductive load resistors, configurable as 8 ohms (min. 1800

watts capacity), as 4 ohms (min. 3200 watts capacity), and as

2 ohms (min. 4500 watts capacity)

• Variable AC voltage source, such as a Variac or Powerstat

variable transformer, with a rated current capacity of up to 50A

(for 120V models) or 25A (for 230V models)

• Low-distortion audio sine wave generator

• Philips and flat screwdrivers

• Soldering iron with a fine tip (25–60W recommended)

• Rosin-core solder (60/40 or 63/37)

• Long-nose pliers

• Diagonal cutters

• Wire strippers

Automated test equipment, such as an Audio Precision worksta-

tion, is very useful for servicing PowerLight amplifiers. Contact

QSC Technical Services to obtain applicable AP test files.

Servicing power supply modules will require some additional

special-built equipment:

• Power supply remote controller

• PFC power supply fixture (for PFC modules only)

• CMP box

Becauseof the complexity of the PFC power supplies, QSC

recommends they be serviced only by QSC.

1.3 Working with surface-mount

components

PowerLight amplifiers, like many modern electronic products, use

surface-mount technology (SMT) components where appropriate in

order to make high-density circuitry that is reliable and economical

to manufacture.

SMT components in the PowerLight amps are used in the smallsignal and control circuits, so they do not handle significant

amounts of power; therefore, they are subject to very little stress

and should seldom fail. Sometimes they do fail, or they require

replacement for a performance upgrade or modification. Thus, it is

important to know how to work with SMT components.

Specialized tools and equipment exist for soldering, unsoldering,

and removing SMT components quickly and efficiently, but they are

often expensive. Most SMT repairs, though, can be handled reasonably well with common tools and equipment, such as tweezers,

solder braid, and fine-tip soldering irons.

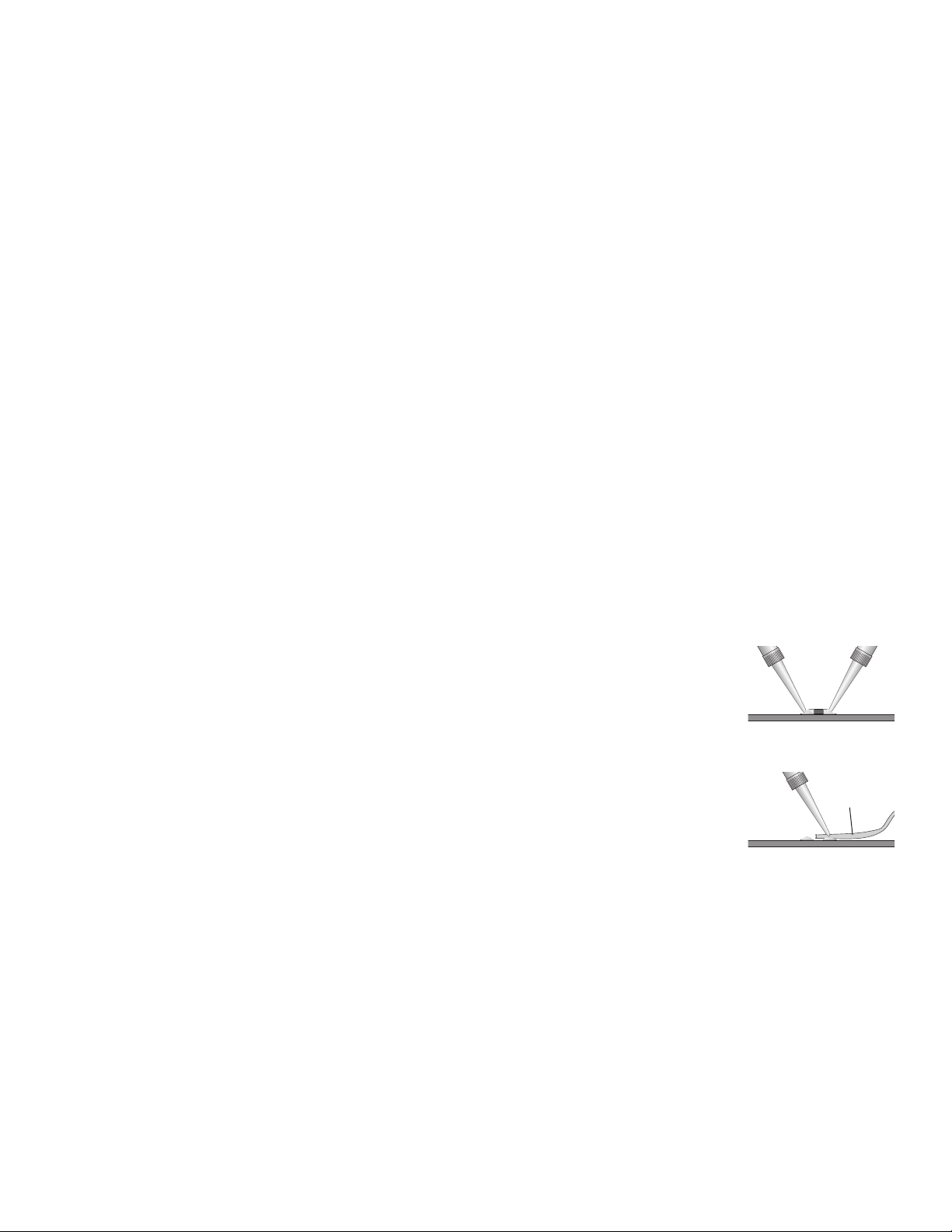

T wo-terminal components (resistors, capacitors,

diodes, etc.)

Removal

1. Use two soldering irons, prefer-

ably about 25 to 40 watts, with

fine tips.

2. With a soldering iron in each

hand, hold one tip on the solder at

one end of the component and the

other tip on the other end (Figure

1.1).

3. Once the solder melts on both

ends, grip the component

between the two tips and lift it

from the circuit board.

4. Use solder braid and a soldering

iron to remove the solder from the

two pads (Figure 1.2).

Insertion

1. With a soldering iron and 60/40 or 63/37 eutectic-type solder,

melt just enough solder onto one pad to create a small mound

(Figure 1.3).

2. Grasp the component in the middle with tweezers. Melt the

small mound of solder with the iron and place the component

across the two pads (in the correct orientation, if the component is sensitive to direction) and press it flat against the circuit

board, with one end of the component immersed in the melted

solder (Figure 1.4).

3. Hold the component in place and take the soldering iron away.

Figure 1.1.

Solder braid

Figure 1.2.

Technical Service Manual 5

PowerLight 6.0 II, PowerLight 6.0

PFC

, and PowerLight 9.0

PFC

Page 8

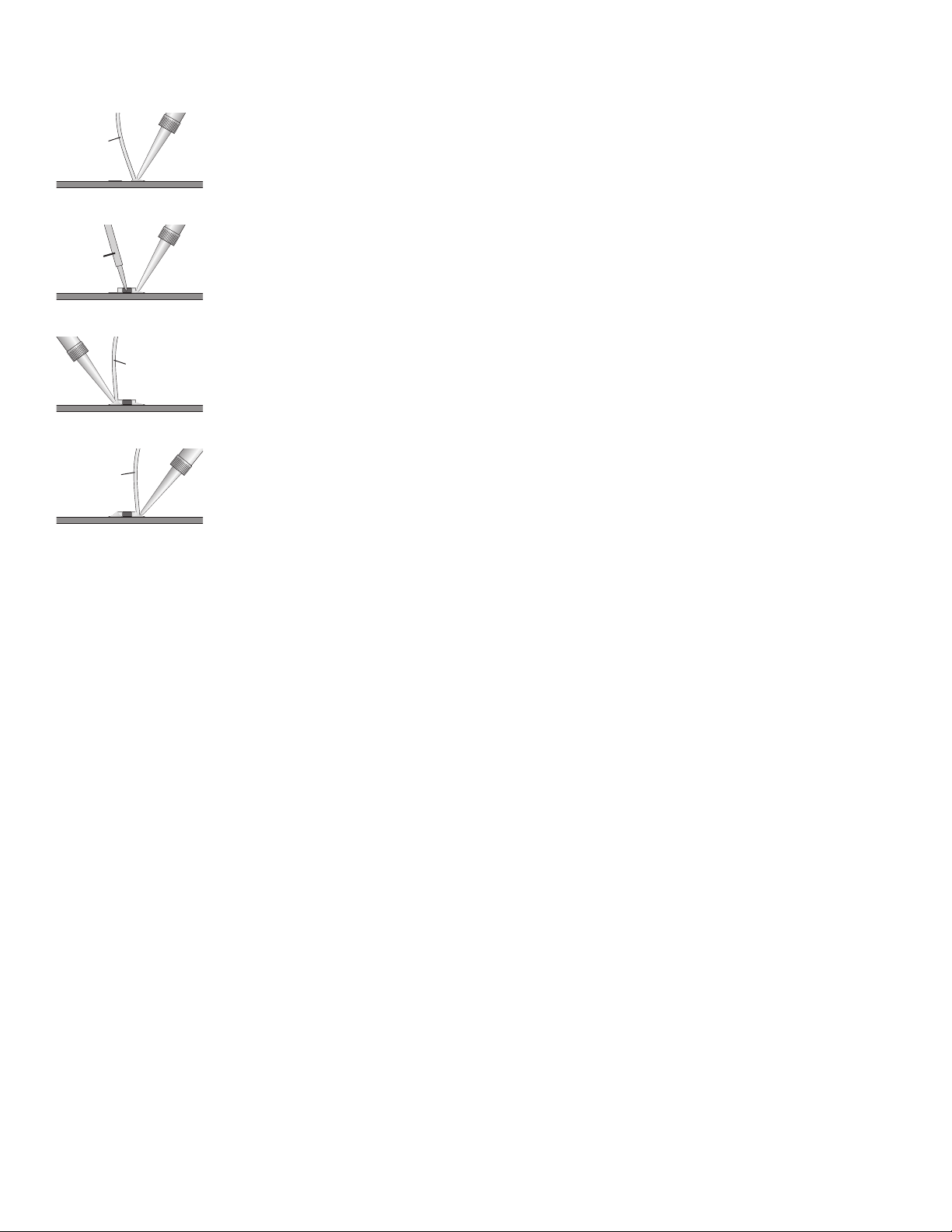

Solder

Figure 1.3.

Tweezers

Figure 1.4.

Figure 1.5.

Solder

Figure 1.6.

Solder

Let the solder harden to tack the

component in place.

4. Fully solder the other end of the

component to its pad. Let the

solder harden (Figure 1.5).

5. Fully solder the tacked end of

the component to its pad (Figure

1.6).

Three-terminal

components (transistors,

etc.)

Removal

1. With a soldering iron and solder

braid, remove as much solder as

possible from the middle

terminal of the component.

2. With a soldering iron in each

hand, hold one tip on the solder

at the terminal at one end of the

component and the other tip on

the terminal at the other end.

3. When the solder on both ends

2. With fine tweezers, carefully try to lift each pin to see if it’s

free. If it’s not, touch it with the tip of the soldering iron and if

necessary, use the solder braid to remove the remaining solder.

3. Repeat the process until all the pins are free and you can

remove the component.

Insertion

1. With a soldering iron and 60/40 or 63/37 eutectic-type solder,

melt just enough solder onto one pad to create a small mound

of solder. It is usually easiest to use a pad that corresponds to

one of the end or corner pins of the component.

2. Grasp the component with tweezers. Melt the small mound of

solder with the iron and place the component in the correct

orientation upon its pads and gently press it flat against the

circuit board, with the appropriate terminal of the component

pressed into the melted solder.

3. Hold the component in place and take the soldering iron away.

Let the solder harden to tack the component in place.

4. Fully solder the other terminals of the component to their pads.

Let the solder harden.

5. Fully solder the tacked terminal of the component to its pad.

melts, grip the component between the two tips and lift it from

the circuit board. You might need to quickly touch the pad on

the middle terminal with a soldering iron to melt any remaining

solder that might be holding the component down.

4. Use solder braid and a soldering iron to remove the solder from

the three pads.

Insertion

1. With a soldering iron and 60/40 or 63/37 eutectic-type solder,

melt just enough solder onto one pad to create a small mound

of solder.

2. Grasp the component with tweezers. Melt the small mound of

solder with the iron and place the component in the correct

orientation across the three pads and press it flat against the

circuit board, with one terminal of the component pressed into

the melted solder.

3. Hold the component in place and take the soldering iron away.

Let the solder harden to tack the component in place.

4. Fully solder the other terminals of the component to their pads.

Let the solder harden.

5. Fully solder the tacked terminal of the component to its pad.

Multi-pin components (ICs, etc.)

Removal

Removing a multi-pin SMT component is a delicate procedure.

Ideally, you should use a soldering iron with an attachment that

allows you to heat all the pins simultaneously.

If such a soldering device is not available, use this procedure:

1. Use a soldering iron and solder braid to remove as much solder

as possible from the pins of the component.

1.4 Series description

QSC’s PowerLight Series amplifiers are high-performance

professional audio products, designed primarily for live and touring

sound and large-scale installations.

This service manual covers the three most powerful models

developed for the PowerLight Series: the PowerLight 6.0 II, the

PowerLight 6.0

audio channels and is three rack spaces tall. See page 2 for

complete specifications.

The PowerLight 6.0

supplies with power factor correction, which reduces peak current

demand by drawing power throughout the AC voltage waveform.

The PowerLight 6.0 II has power supplies that don’t have PFC but

are simpler and less expensive to manufacture.

The first four digits of the amplifier’s serial number indicate the

month and year of manufacture in MMYY formay. For example,

0701xxxxx = July 2001). A serial number that starts with “13”

indicates the amplifier was made during the model’s beta

production. The PowerLight 9.0

The PowerLight 6.0

PowerLight 6.0 II, in August 2002. Many PowerLight 6.0

amplifiers, however, have been converted by QSC Technical

Services into PowerLight 6.0 II amplifiers, so you may encounter

PowerLight 6.0 II amplifiers with serial number date codes that

precede the model’s actual release date.

The PowerLight 6.0

March 2004.

PFC

, and the PowerLight 9.0

PFC

and PowerLight 9.0

PFC

PFC

followed in March 1999, and the

PFC

and PowerLight 9.0

entered production in May 1998.

PFC

. Each one has two

PFC

feature power

PFC

PFC

ceased production in

6 QSC Audio Products, Inc.

TD-000083-00

Page 9

1.5 Technical descriptions and

theory of operation

Power supplies

QSC PowerLight amplifiers feature high-frequency switch-mode

power supplies that help reduce noise, increase electrical

efficiency, and lower weight. Two models, the PowerLight 9.0

and the PowerLight 6.0

the peak current demand from

the AC mains. They accomplished this by drawing current

throughout the AC voltage

waveform, instead of just at

the peaks, as most amplifiers

and other electronic equipment

do. The PowerLight 6.0 II was

developed later, and its power

supplies do not have power

factor correction.

All three models have a fourtier class H system of multiple

rail voltages to boost efficiency.

A power amplifier is most efficient at or near full power, yet the

dynamic nature of music and other typical audio requires much less

than full power most of the time. Thus, this class H scheme creates

essentially four different “full-power” levels within the amplifier

Figure 1.8. An amplifier with PFC

draws current throughout the

AC voltage waveform.

PFC

, had power factor correction to reduce

Figure 1.7. Amplifiers without

PFC draw current only at the

peaks of the AC voltage

waveform.

channel. The amplifier circuitry

automatically and instantaneously switches to the lowest

rail voltage that will allow the

reproduction of the audio

signal without discontinuity.

Each amplifier channel has its

own power supply. In addition,

each has a small “housekeeping” supply that manages the

turn-on functions before the

main power supply starts up.

PFC

susceptible to RF interference,

high-frequency oscillations, etc.

The audio signal passes through

a pre-clipper, which prevents

the audio signal from driving

the output section itself into

actual clipping. This maintains

damping on the channel output

even during clipping so that it

continues to tightly control the

loudspeaker motion, which is

something most amplifiers

cannot do. A defeatable clip

limiter on each channel reduces

signal level when clipping occurs; it does not prevent clipping, but

reduces the amount of distortion to inaudible or barely audible

levels.

An all-pass filter uses group delay to slow the audio signal by 4 µs,

but the class H steps are controlled by the undelayed signal. This

reduces IM distortion by ensuring that the steps are executed

before the audio signal in the output section reaches the transition

thresholds.

The audio signal voltage is converted into current by transistors

Q87 and Q89, to be precisely bifurcated into positive and negative

halves by the current steering circuitry. These current signals are

the controls for the output devices.

Figure 1.10. Most amps lose

feedback during clipping,

resulting in loss of damping and

in “clip sticking.”

Figure 1.9. The rail voltages of

the output section switch

among four tiers to reproduce

the signal faithfully while

maximizing efficiency.

The output devices are vertical

MOSFETs, which are commonly

used for very high power

switching because of their

power handling capability and

general nonlinearity. Using

them for linear audio amplification requires an unorthodox

approach. In these three

PowerLight amplifier models,

each channel has eight MOSFET

devices arranged in a full bridge

configuration. Each one has a

Audio circuitry

The audio inputs are balanced to offer a high amount of commonmode noise rejection. The input balancing is done using an

instrumentation amplifier arrangement, which uses a single op

amp, arranged as a voltage follower or buffer, on each leg of the

balanced input, driving a single op amp differential amplifier. The

degree of common-mode rejection is dependent on the close

matching of the impedance between each leg and ground and

around the differential amplifier. The circuitry uses 1% precision

resistors to ensure at least 40 dB of common-mode rejection.

The differential amplifier circuitry includes a first-order highfrequency roll-off, down 3 dB at 280 kHz (nearly four octaves above

the high end of the audio spectrum). This makes the amplifier less

Technical Service Manual 7

PowerLight 6.0 II, PowerLight 6.0

PFC

, and PowerLight 9.0

PFC

local management circuit called

a current cell that controls and

linearizes the device by

providing the necessary

compensation to make the

MOSFET’s conductivity track the

signal current.

Figure 1.11. The pre-clipping

scheme in the PowerLight 6.0

PFC

9.0

, and 6.0 II keeps the

output signal clean despite the

flat-topping of the waveform.

PFC

,

Page 10

2. Servicing the amplifier

2.1 Mechanical disassembly and reassembly

Introduction

Replacing components will usually require removing the affected

modules from the amplifier chassis. The two channels each have

their own power supply module and audio module, and they share

the line filter assembly and the input, output, and display board

assemblies.

Within the chassis, the power supply modules are on the bottom,

and the audio modules are on top. Getting at a power supply

module requires removal of its audio module first.

The following instructions describe the procedure for removing

both audio and both power supply modules. However, if you only

need to work on one channel, you do not need to remove the

modules from the other.

Tools and materials needed

• Philips screwdriver

• Diagonal cutters

• Tie wraps

• Needle-nose pliers

• Adhesive rubber foot (one per channel), QSC part # QQQQQQQQ-QQ or equivalent

• 5/64” hex (Allen) key

• 11/32” nutdriver or socket wrench

• Isopropyl alcohol and a small brush

Disassembly

Removing the top cover

1. Disconnect the amplifier from AC power and allow at least 10

minutes for internal voltages to bleed down.

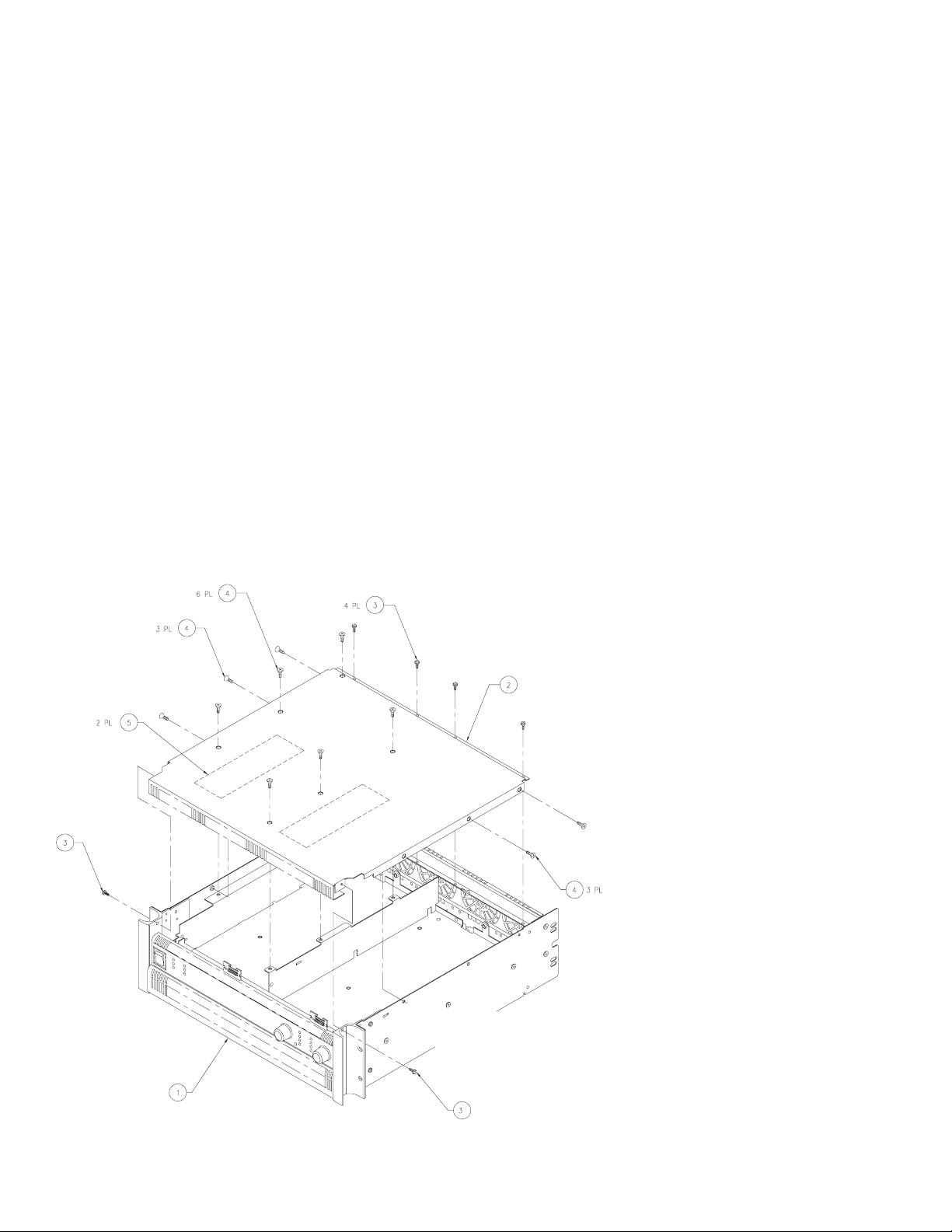

2. A total of 18 screws—six with pan heads and twelve with flat

heads—hold the top cover to the chassis. Using a Philips

screwdriver, remove them and set them aside. See Figure 2.1.

3. Lift the top cover up at the front until it clears the side rack ear

pieces, then lift it off the chassis. If the front of the cover is

bent or dented, make sure the front edge clears the two

display board headers.

Figure 2.1. Removing or installing

the top cover.

Key QSC Part Description Qty.

1

WP-000170-XX Chassis assy., PL 9.0 1

2

CH-000079-00 Top cover 1

3

SC-082051-PL Screw, #8-32 × 5/16”, pan head 6

4

SC-080051-PU Screw, #8-32 × 5/16”, flat head 12

5

PL-000104-00 Insulator, high volt. 2

8 QSC Audio Products, Inc.

TD-000083-00

Page 11

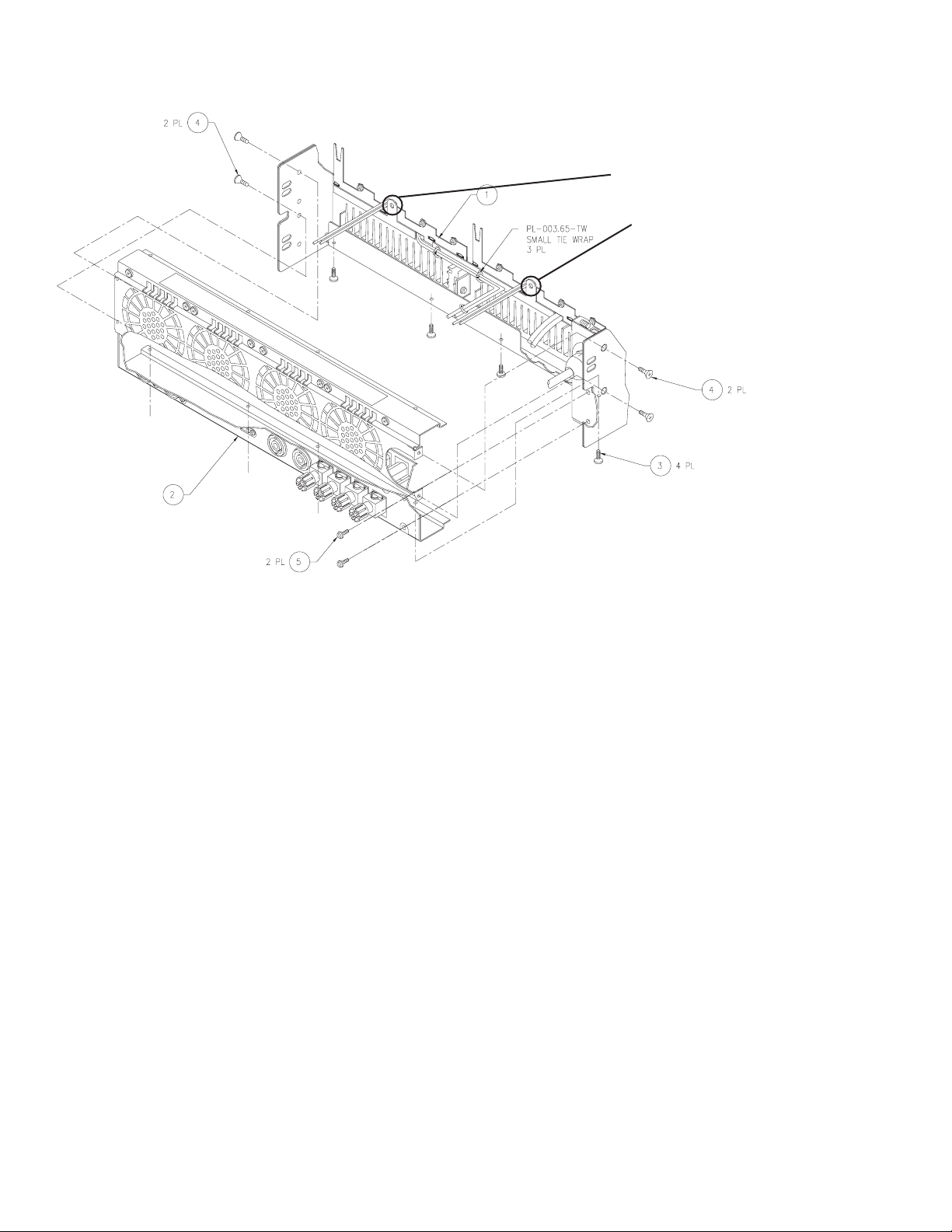

(2 bundles)

Figure 2.2. Seven tie wraps.

Preparing the audio modules for removal

4. There are two fishpaper insulators on each audio module.

Remove them by lifting them straight up off the heat sinks. Do

not slide them forward or backward.

5. Cut the tie wraps in the seven locations shown in Figure 2.2.

6. Disconnect the display board header in front of each module.

7. Using needle-nose pliers, grasp one of the housekeeping

supply connectors and disconnect it from the modules (see

Figure X.X). Repeat for the other(s).

8. Disconnect the fan connections (two on each module).

9. Spread open the latches on the power

supply control interface connections and

disconnect the headers from the

modules.

10. Remove the two screws that secure the

audio module to the chassis partition.

One screw is at the corner near the

power supply connections, and the other

is about 6 cm (2.5 inches) behind the

housekeeping supply connections.

11. Locate the power supply connections, the

five screw terminals at the front of each

module. Loosen them and remove the

wires.

Figure 2.3. The connections to

Power supply

control (8-pin

header)

Power supply

(wires 0 through 4)

the audio module.

Fan (4-pin header;

2 pins per fan)

12. There may be an adhesive rubber foot

wedged in front of each module circuit board.

Grasp it with the needle-nose pliers and pull

it out.

Removing the chassis rear panel

13. Remove the four screws on the rear panel

(see Figure 2.4).

14. Tip the amplifier up on its right side (the side

opposite the power cord). There are three flat

head screws in a line along the center of the

side panel. Remove them.

15. Remove the two pan head screws on the rear

rack tab.

16. Set the amp back down and remove the two

pan head screws from the other rear rack tab.

17. Remove the two screws under the power

cord.

18. Tip the chassis rear panel back and disconnect the header from the input board.

19. Lift the fan wires clear of the heat sinks on

the audio modules.

From input

board

(detachable

latching header)

Housekeeping

supply

Display

board

(via multiconductor

ribbon cable)

Technical Service Manual 9

PowerLight 6.0 II, PowerLight 6.0

PFC

, and PowerLight 9.0

PFC

Page 12

Figure 2.4. Removing or installing the

chassis rear panel.

Locations of

ground screws

for audio modules

Key QSC Part Description Qty.

1

CH-000078-00 Chassis, PL 9.0 1

2

WP-000172-00 Rear chassis assembly 1

3

SC-082051-PL Screw, #8 × 5/16”, pan head 4

4

SC-080051-PU Screw, #8-32 × 5/16”, flat head 4

5

SC-082051-PL Screw, #8 × 5/16”, pan head 2

20. Remove the chassis rear panel from the main chassis.

21. Cut and remove the tie wraps that secure the output wires to

the rear panel.

Removing the audio modules

22. There is a ground screw at the back of each audio module

(see Figure 2.4). Remove it.

23. Slide the audio module toward the front of the chassis so that

its keyed mounting holes are clear of the standoffs.

24. Lift up the back of the audio module slightly, then lift the

entire module clear of the chassis.

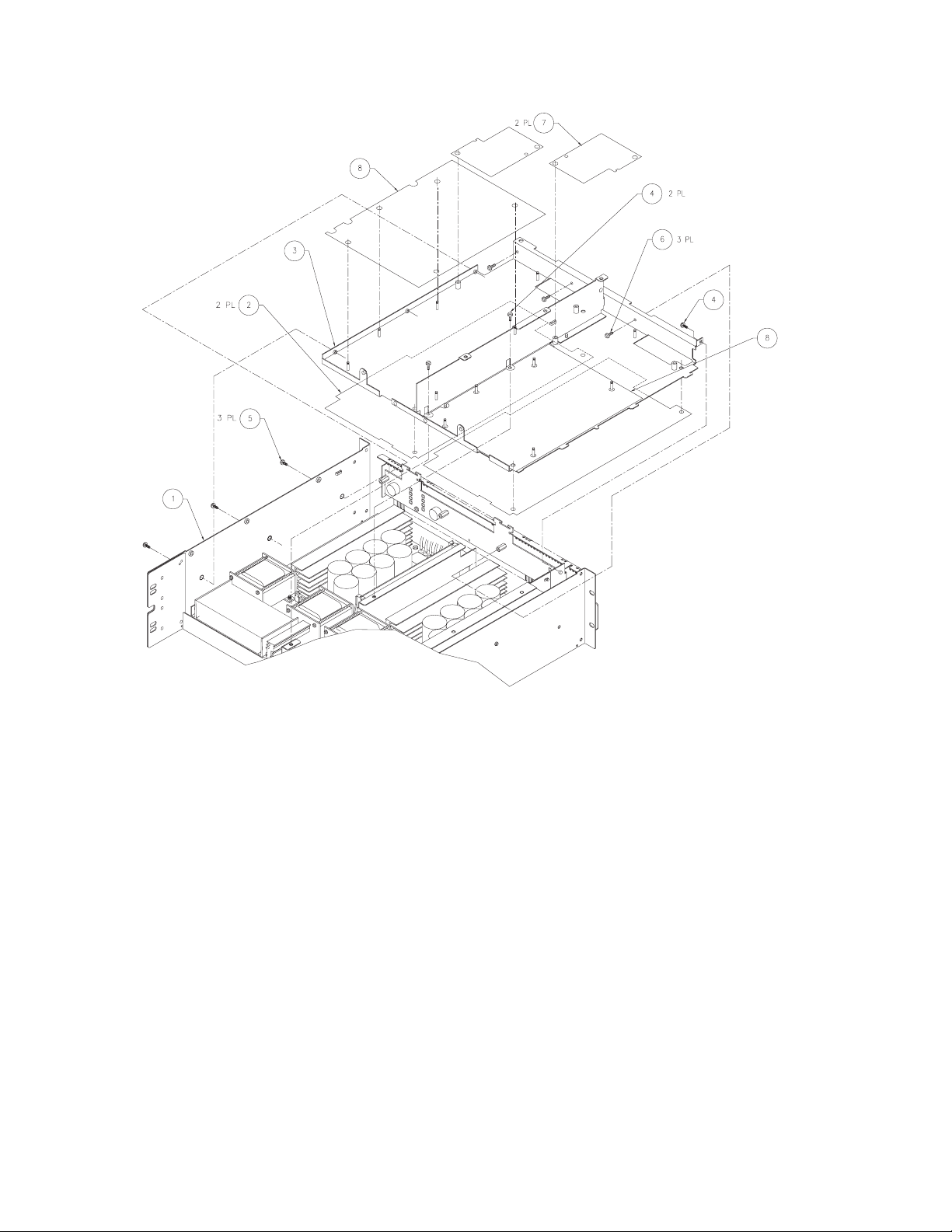

Removing the power supply modules

25. If you need to remove one or both power supply modules, you

will need to remove both audio modules. Invert one audio

module and set it on top of the other channel’s audio module,

then set them aside.

26. Straighten the five power supply wires on each channel.

27. Remove the three screws from the front of the chassis

partition.

28. Remove the side-facing screw from the front of the partition

on channel 1’s side.

29. Remove two black pan head screws from the center line of

the chassis partition.

30. Slide the chassis partition back, then lift up on the channel 2

side of it. Press down on the back of the partition, then lift it

clear of the chassis.

31. Remove the two screws at the front of the power supply

module.

32. Use a 5/64” hex (Allen) key to remove the screw at the rear of

the power supply module.

33. Use an 11/32” nutdriver or socket wrench to remove the two

nuts on the AC connection (a white and a black wire).

34. Slide the power supply module toward the rear of the chassis,

then lift it up and out of the amplifier.

Inspecting the power supply modules

35. Visually inspect the power supply module. Check the leads of

diodes D1 and D12, because they sometimes crack due to

flexing of the circuit board.

36. Using isopropyl alcohol and a brush, clean any dirty or charred

parts of the circuit board. Look for burned-off circuit board

traces, especially around the switching MOSFETs; missing or

damaged ones can be repaired using a trace repair kit. If the

10 QSC Audio Products, Inc.

TD-000083-00

Page 13

Key QSC Part Description Qty.

1

CH-000078-00 Chassis, PL 9.0 1

2

PL-000107-00 Heatsink insulator 2

3

CH-000080-00 Chassis horiz. partition 1

4

SC-080051-PS Screw, #8-32 × 5/16”, SEMS 3

5

SC-082051-PU Screw, #8-32 × 5/16”, pan head 3

6

SC-060042-PP Screw, #6-32 × 1/4”, SEMS 3

PL-000109-00 Insulator, mega platform 2

7

8

PL-000137-00 2

Insulator, amp rear bottom

Figure 2.5. Removing or installing the chassis partition.

circuit board is burned into the fiber layers or badly damaged,

replace the entire module.

See instructions for servicing the power supply module

elsewhere in this chapter.

4. Insert and tighten the two screws at the front of the module.

5. Install the chassis partition.

6. Insert and tighten the two screws along the center line of the

chassis partition.

7. Insert and tighten the side-facing screw at the front of the

Reassembly

Reassembling the amplifier chassis is essentially reversing the

order of the disassembly process.

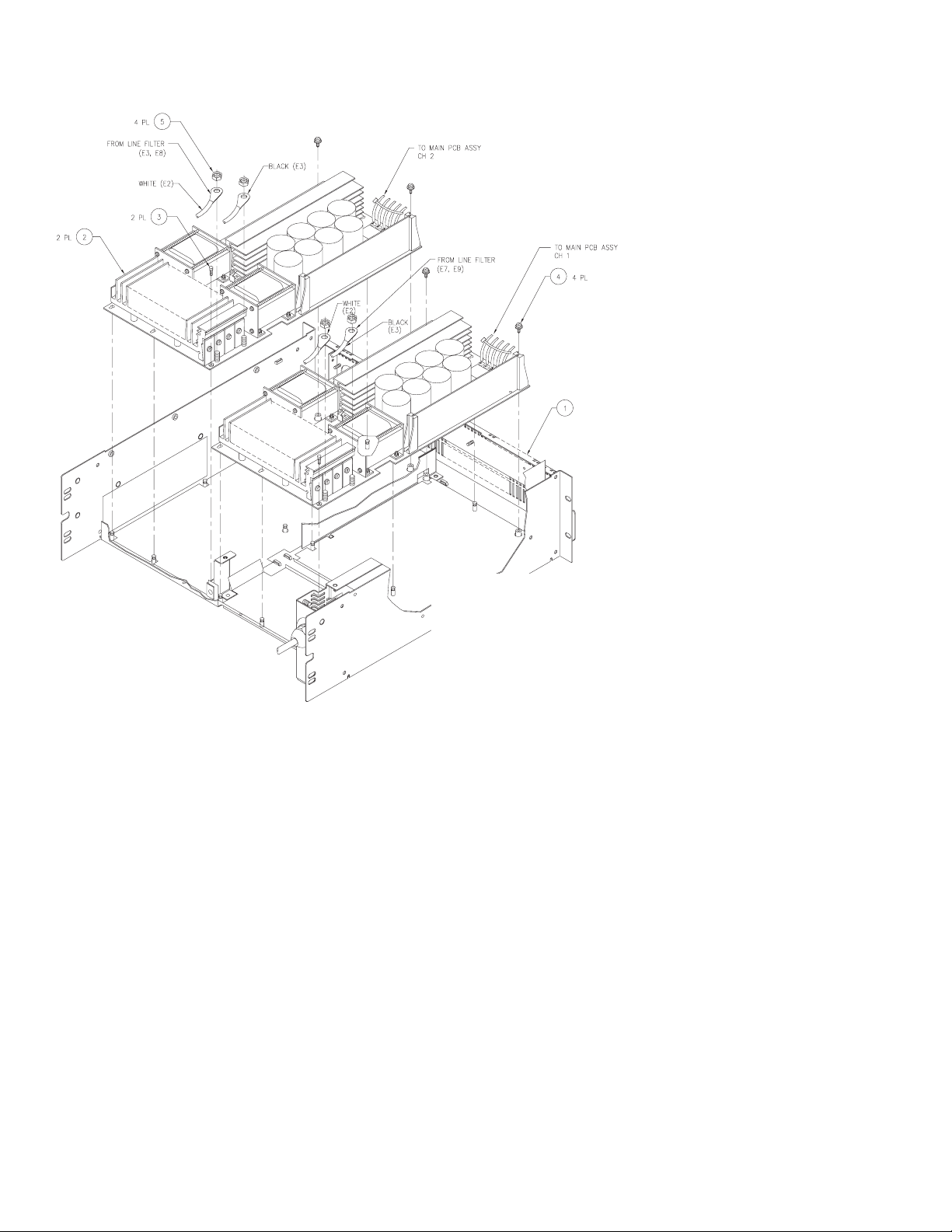

Installing the power supply module

1. Align the keyed slots in the power supply module circuit board

with the chassis standoffs. Watch out for the fish paper

insulators, which may get caught underneath. Drop the

module into place on the standoffs and slide it forward.

2. Using the 11/32” nutdriver or socket wrench, attach the AC

wires to the module. The black wire attaches in front (closer

to the front of the amplifier chassis) of the white one.

3. Using the 5/64” hex (Allen) key, insert and tighten the screw

at the rear of the power supply module.

Technical Service Manual 11

PowerLight 6.0 II, PowerLight 6.0

PFC

, and PowerLight 9.0

PFC

chassis partition on the channel 1 side.

8. Insert and tighten the three screws at the front of the chassis

partition.

Installing the audio modules

9. Place the audio modules in position.

10. Insert and tighten the ground screw at the back of each

module (see Figure 2.4).

11. With new tie wraps, secure the output wires to the chassis

rear panel.

12. Loosely insert one screw on each end of the chassis rear

panel, then tighten them both.

13. Insert and tighten the other two screws.

Page 14

Figure 2.6. Removing or installing the

power supply modules.

Key QSC Part Description Qty.

1

CH-000078-00 Chassis, PL 9.0 1

2

WP-000173-00 Power supply PCB assy. (120V) 2

WP-000180-00

3

SC-040155-00 Screw, #4-40 shoulder hex head 2

4

SC-060042-PP Screw, #6-32 × 1/4”, SEMS 4

5

NW-080500-KP Keps nut, #8-32 4

Power supply PCB assy. (230V) 2

14. Insert and tighten the two screws under the power cord.

15. On each audio module, tuck the two fan wires into one or two

slots of the heat sink. Reconnect both to the four-pin header

on the audio module.

16. Reconnect the input headers to the audio module.

17. Tip the amplifier up on its right side (the side opposite the

power cord). Insert and tighten the three flat head screws in a

line along the center of the side panel.

18. Set the amp back down. Reconnect the five power supply

20. Reconnect the housekeeping supply wires at the front of the

module.

21. Using five new tie wraps, secure the wire bundles to the

chassis partition at or near the front of the amplifier. Each

secures one bundle, except for the one at the center, which

secures two.

22. Using two new tie wraps, re-connect and secure the two

headers to the display board.

23. Re-install the top cover of the amplifier.

wires, 0 through 4, to their respective screw terminals at the

front of the module. Make sure they are placed in the proper

sequence—from left to right, as viewed from the front of the

amplifier:.0, 1, 2, 3, and 4.

19. Reconnect the power supply control interface. Make sure the

latching wings of the board-mounted connector are up all the

way.

12 QSC Audio Products, Inc.

TD-000083-00

Page 15

Key QSC Part Description Qty.

1

CH-000078-00 Chassis, PL 9.0 1

2

HW-000079-00 Hex standoff #6-32 x 9/16” 5

3

WP-000176-00 Display PCB assy. 1

4

SC-060042-PP Screw, #6-32 × 1/4”, SEMS 2

5

HW-060080-HW Hex standoff #6-32 x 1/2” 3

6

PL-000054-00 Knob fab. 2

Figure 5.7. Removing or installing the display board.

2.2 The display board

The display board contains the signal metering, clip, power, and

status LEDs. It also holds the two gain potentiometers. LED failures

are very rare, but you will need to remove the board if the gain

pots become damaged or badly contaminated. See Figure 2.7.

2.3 AC line filter

The AC line filter is an important part of the amplifier because it

reduces noise and interference from the internal switching

circuitry to prevent its radiation into the AC wiring. It also contains

part of the housekeeping supplies for the two audio modules;

without the housekeeping supplies, the amplifier’s power supply

modules will not start up even if they are in working order.

The line filters are the same among the three amplifier models,

but the 120-volt and 230-volt versions are not interchangeable.

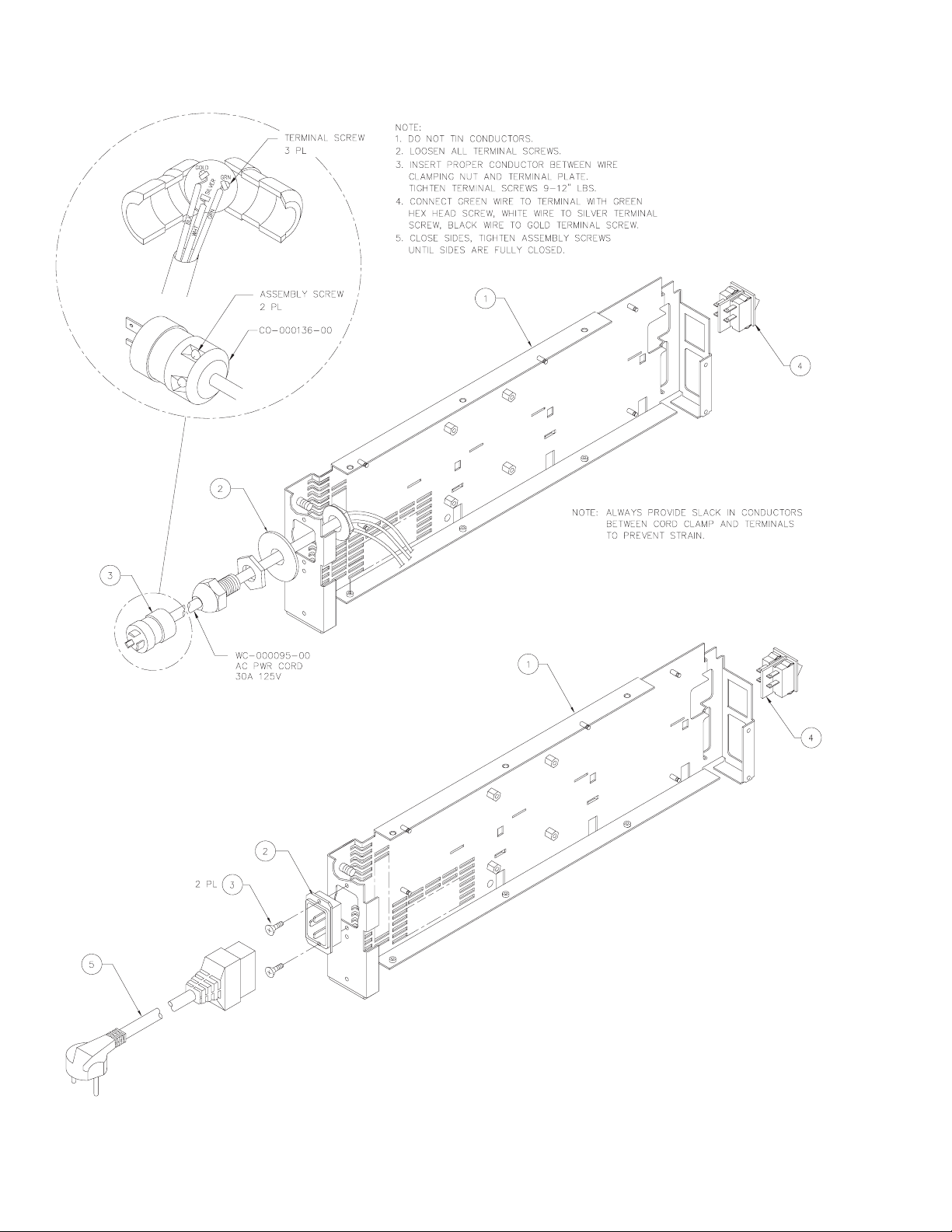

See Figure 2.8.

Technical Service Manual 13

PowerLight 6.0 II, PowerLight 6.0

PFC

, and PowerLight 9.0

PFC

Page 16

120V version

230V version

Key QSC Part Description Qty.

1

WP-000177-00 Line filter PCB assy. 1

2

NW-000021-03 Flat Washer 1

3

WP-000042-00 AC power cord assy., 30A 125V 1

4

SW-000027-SW Switch AC 1

Key QSC Part Description Qty.

1

WP-000181-00 Line filter PCB assy. (230V) 1

2

C0-000099-00 Connector line side flange 1

3

SC-083061-PU Screw, #8-18 × 3/8”, flat head 2

4

SW-000027-SW Switch AC 1

5

WC-000022-00 Cord set 3 cond. 16A 250 VAC 1

Figure 2.8. Assembly details of the AC line filter.

14 QSC Audio Products, Inc.

TD-000083-00

Page 17

2.4 Power supply servicing

Bench testing power supply modules

The housekeeping supplies provide electrical power to certain

control circuitry in their respective audio channel modules. The

control circuitry in turn enables the power supply module to

operate. Thus, a power supply module normally will not operate

when it is not connected to an audio channel.

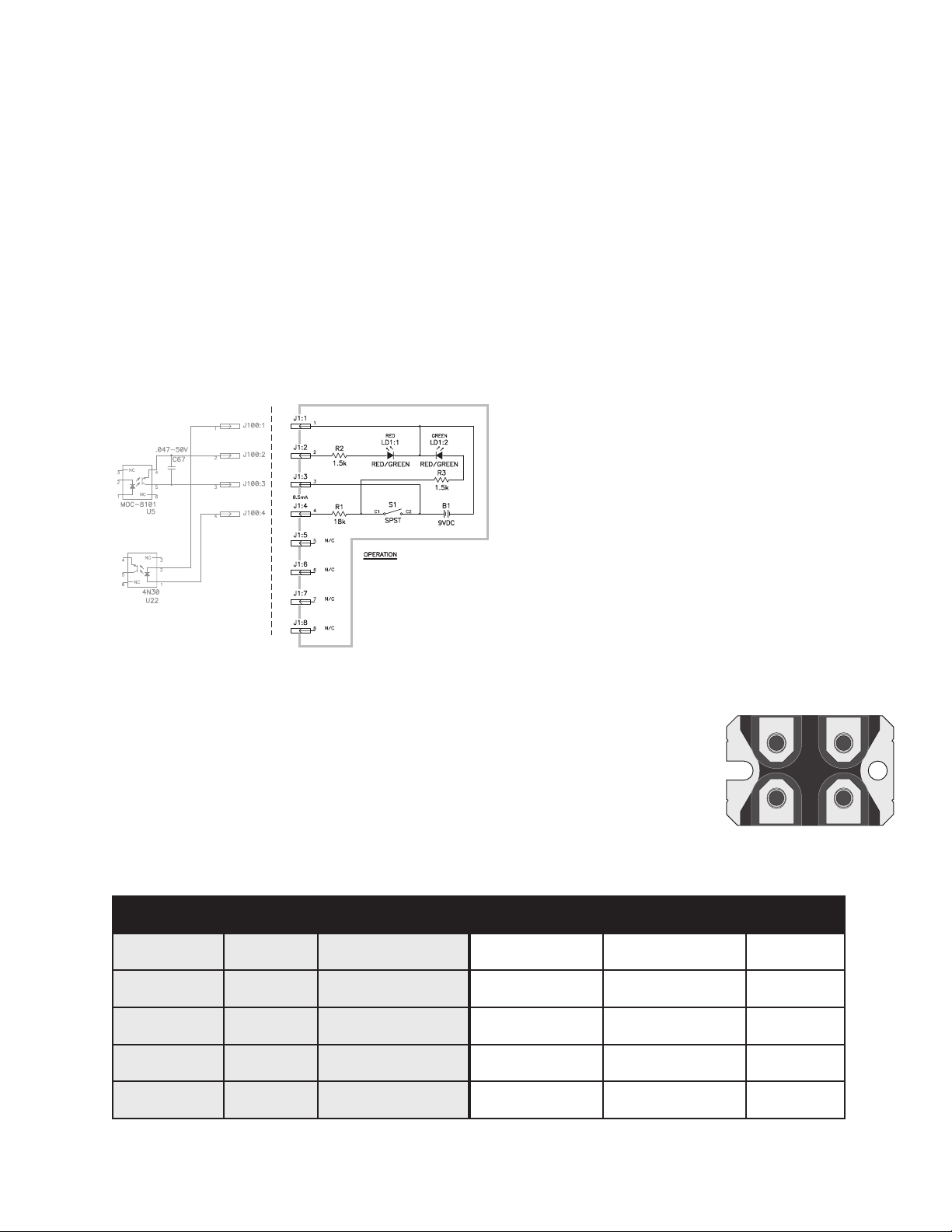

The remote control circuit shown in Figure 2.9 allows the power

supply module to operate without an audio channel module

connected. This is useful for verifying the power supply’s operation

independently of other amplifier circuitry.

POWER SUPPLY TEST

REMOTE CONTROLLER

THIS REMOTE CONTROL IS USED TO TURN ON THE

PFC POWER SUPPLY VIA J100 ON THE CONTROLLER

BOARD.

CLOSING POWER SWITCH S1 ENABLES THE POWER

SUPPLY, AND LED LD1:2 WILL GLOW GREEN.

THE AC INPUT VOLTAGE APPLIED TO THE PS

POWER SUPPLY

CONTROLLER BOARD

MODULE REACHES THE TURN-ON THRESHOLD (65

VAC FOR 120V UNIT OR 130 VAC FOR 230V UNIT),

LED1:1 WILL ALSO LIGHT, AND THE RESULTING

COLOR WILL BE YELLOW-ORANGE.

Figure 2.9. Remote controller for power supply testing.

Parts list

• 8-pin header (J1)

• 9-volt battery (B1)

• SPST switch (S1)

• Three-lead tri-color LED (LD1)

• 18 kΩ resistor (R1)

• Two 1.5 kΩ resistors (R2 and R3)

Replacement parts

WHEN

Replacing switching MOSFETs in PFC models

Replacing the power MOSFETs and their associated components

requires that the power supply modules be removed from the

amplifier.

T ools and materials required:

• Soldering iron

• Rosin-core solder (60/40 or 63/37 eutectic type)

• Long-nose pliers

• #1 and #2 Philips screwdrivers

• Thermal grease (heat sink compound)

• Small diagonal cutters

• Desoldering equipment or solder braid

• Micro-torque wrench with 9/64” Allen (hex) and #1 Philips bits

If fuse F1 on the power supply module’s printed circuit board (PCB)

is blown, you will also need a 1A 250V 5×20 mm slow-blow fuse

(QSC part # MS-000113-00) to replace it with. Also, the alumina

insulator between the diodes and the heat sink is very fragile and

often breaks when the diodes are removed; replace it with QSC

part # PL-000085-00.

To ensure that the devices will share power equally, the four

MOSFETs must have similar V

. For a set of four matched

DSS

MOSFETs, as pre-sorted by QSC production, order QSC part #

WP-000056-00.

Procedure: replacing Q1, Q2, Q3, and Q4

1. Remove the heat sink assembly to which the MOSFETs are

attached.

To do this, remove the clamps on the four diodes (D1, D2, D7,

and D8) to free them from the heat sink. Keep the two mica

insulators (from between the

diodes and clamps) and set

them aside for when you

reassemble the heat sink and

diodes later; they are fragile,

so be careful handling them

but replace any that are

damaged. The QSC part

number is PL-000059-00.

Remove the alumina insulator

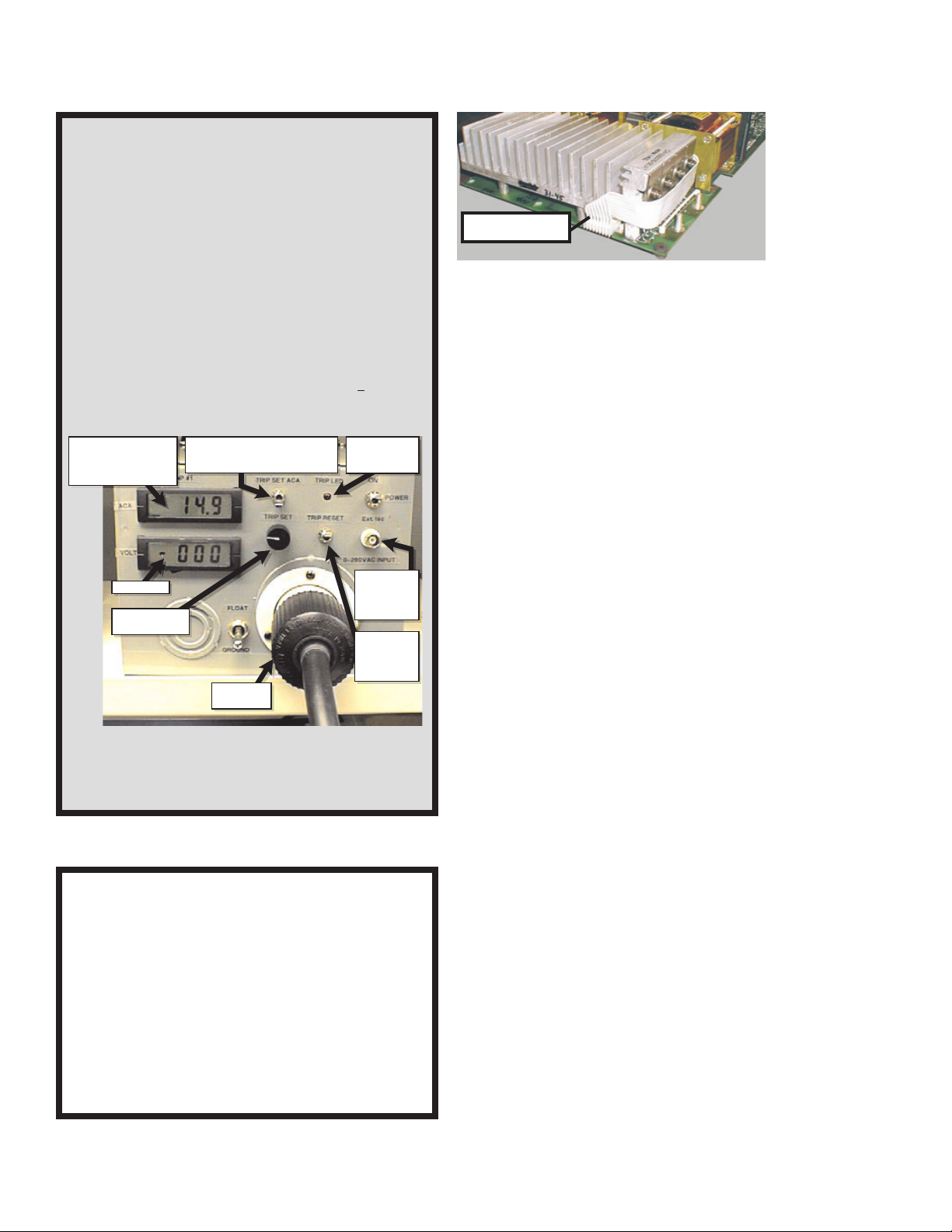

Figure 2.10. Bottom view of a

MOSFET

ecnerefertraP #trapweN noitpircseD #trapdlosecalper… noitpircseD ?sledomhcihW

4Q&,3Q,2Q,1Q

8R&,7R,6R,5R

8D&,7D,2D,1D

8D&,7D,2D,1D

02C

00-881000-DQ TEFSOMA5505N55FXI

01-10574.-ER 57.4 ΩΩΩΩΩ rotsiserttaw-¼

00-381000-DQ edoid80SPE06

00-281000-DQ edoid21SPE06

00-900014-AC roticapacV052Fµ1.0

00-911000-DQTEFSOMA8405N84FXI

01-20001.-ER1Ω rotsiserttaw-¼

00-621000-DQedoidA60-06IESD

00-761000-DQedoid21-06IESD

00-004743-ACroticapacV004Fµ740.0

sledomllA

sledomllA

ylnosledomV021

ylnosledomV032

sledomllA

Technical Service Manual 15

PowerLight 6.0 II, PowerLight 6.0

PFC

, and PowerLight 9.0

PFC

Page 18

“Diode”

end of

heat sink

Figure 2.10: The heat sink assembly, with all four MOSFETs

attached. The “diode” end of the heat sink is at right; the slots in

the MOSFETs would face to the left.

(from between the diodes and the heat sink); it is extremely

fragile, so it is best to replace it during reassembly with a

new one.

Then remove the 16 screws that attach the MOSFETs to the

printed circuit board (PCB); if the MOSFETs are blown, some

of the mounting screws may be melted or damaged. The new

MOSFETs come with new mounting screws with captive

washers, so there is no need to save old ones for reuse.

Remove the other four mounting screws so that the heat sink

assembly is free from the circuit board. Set the hardware

aside.

Find where the twisted wire lead from the heat sink’s thermal

sensor attaches to a pair of pins on the board, and unplug it.

Detach the gate drive cable, which is an 8-conductor ribbon

cable that plugs into an 8-pin header. Lift the heat sink and

MOSFET assembly from the board. If the strip of fishpaper

(Figure 2.11) remains stuck to the PCB, leave it there; if it

comes loose, set it aside for re-assembly later.

Figure 2.11. The silk screen on the circuit board shows the

correct orientation of the MOSFETs. This photo also shows

the four resistors (R5–R8) to be replaced.

2. Remove the MOSFETs from the heat sink. Thoroughly clean the

old thermal grease off the heat sink. Apply fresh thermal

grease to the new MOSFETs (QSC part # QD-000188-00) and

attach them to the heat sink.

Make sure the new MOSFETs are correctly oriented. One end

of each MOSFET has a mounting hole, while the other has an

open-ended slot (see Figure 2.9). Each MOSFET must be

away

mounted so the slot end faces

from the diode end of the

heat sink (see Figure 5.11). Try to get the MOSFETs evenly

spaced and as close to perfectly in line as you can. The silk

screen print on the circuit board (see Figure 5.12) shows the

correct orientation.

Tighten the MOSFET mounting screws to 32–35 lb-in (3.6–4.0

N-m) torque. Do not over-torque them.

3. Remove the four diodes on the circuit board (D1, D2, D7, and

D8). See Figure 2.12.

4. Check the value and rating labeled on capacitor C20 (see

Figure 2.13). If it is not a 0.1 µF 250V capacitor (early modules

will have the original 0.047 µF 400V component instead),

replace it with QSC part # CA-410009-00.

5. Remove resistors R5 through R8 (see Figure 2.11) and replace

them with 4.75Ω ¼-watt resistors (QSC part # RE-.47501-10).

6. Set the MOSFET and heat sink assembly upside-down and

place the PCB on top of it. Make sure all the threaded holes in

the heat sink and the MOSFETs line up exactly with the holes

in the board. If any MOSFETs don’t line up, reposition them so

they do because misaligned mounting screws can damage

them when tightened.

Make sure the fishpaper strip is in place, and then reattach

the MOSFET and heat sink assembly to the PCB. Make sure

you use the correct screws and washers in each location.

Tighten the four heat sink screws to 32–35 lb-in (3.6–4.0 N-m)

torque and the MOSFET mounting screws to 12 lb-in (1.4 Nm). Do not over-torque them.

CAUTION: Overtightening its mounting screws will destroy a

MOSFET. When tightening a screw, use the split lockwasher

as a visual guide; as soon as it is flattened, the screw is tight

enough.

Plug the thermal sensor lead onto its two pins on the circuit

board.

7. Clear any solder from the circuit board holes for the four diodes.

Apply a thin coating of new thermal grease to both sides of

the alumina strip and set it in place on the heat sink.

Insert the four new diodes (120V models: QSC part #

QD-000183-00; 230V models: QSC part # QD-000182-00) into

their holes in the PCB, but do not solder them in place yet.

Then set the two mica insulators in place over the diodes

(they will overlap in the middle), and clamp and fasten the

diodes to the heat sink; tighten the screws to 32–35 lb-in

(3.6–4.0 N-m) torque. Do not over-torque them. As you do

16 QSC Audio Products, Inc.

TD-000083-00

Page 19

Figure 2.12. These four diodes need to be replaced.

this, make sure the diodes are straight and evenly spaced, and

reposition them if necessary.

8. Solder the four diodes to the circuit board.

9. Reattach the gate drive cable.

10. Check the fuse (see Figure 2.14). If it is blown, replace it with

a slow-blow 1A 250V 5×20 mm fuse (QSC part #

MS-000113-00).

11. Repeat the procedure for the other channel’s power supply

board if it also has failed or is to be updated.

Capacitor C20

Figure 2.13. Capacitor C20 may also need

replacement. See the text.

Fuse F1

Figure 2.14. Fuse F1 may need replacing.

Suggestions for troubleshooting

If you are repairing a failed power supply module and not simply

upgrading a working one, you should determine whether other

components have also failed.

Typical collateral failures around PFC power supply module failures

include:

Blown high rail diodes: Check D12 and D14 for sooty or

blackened thermal grease around their edges or for any other

signs of damage. If you suspect that they might be damaged,

remove them from the circuit board and check them with the

diode test function on a DMM. Replace them if necessary

(QSC part # QD-000126-00). These diodes are clamped onto

the other heat sink, at the end next to the power transformer.

If you remove the diodes, thoroughly clean away the old

thermal grease from that portion of the heat sink and from

the mica insulators; apply fresh thermal grease when you

reassemble or replace them.

Blown driver ICs: The two MIC4452BN MOSFET driver ICs, U1

and U3, are under the MOSFET heat sink. Frequently, when

MOSFETs fail, the driver IC associated with the transistor(s)

fails, too. The IC’s QSC part # is IC-000064-00.

Fuses: Conditions that cause the MOSFETs to fail also frequently

cause the fuses on the AC line filter to blow. The filter circuit

board runs along the side of the amplifier between the AC power

cable and the AC power switch. Each channel has two fast-blow

ceramic AC fuses, for a total of four (120V models: 125V 25A,

QSC part # MS-000112-00; 230V models: 250V 15A, QSC part #

MS-150250-FU). Check them and replace any that are blown.

Also on the AC line filter board are the housekeeping supplies

for each channel; if they do not work, the channels will not

start even if the power supply modules are in perfect working

order. The housekeeping supplies each use a 250V 1A slowblow fuse (QSC part # MS-000113-00).

Technical Service Manual 17

PowerLight 6.0 II, PowerLight 6.0

PFC

, and PowerLight 9.0

PFC

Page 20

Adjusting and calibrating the power supply

module

Adjusting and calibrating the power supply card will help ensure

the success of the repair; this portion of the service bulletin

describes a series of five procedures for doing so. Because of the

specialized nature of the power supply fixture required for these

procedures, it can only be performed at the QSC factory by trained

personnel. Follow these procedures exactly and in order.

There are four trimpots, VR1–VR4 (see Figure 2.14), on the

controller card that must be adjusted correctly before reinstalling

the power supply in the amplifier:

VR1 On the PL 9.0

sets V

OUT

/26.6.

PFC

, this trimpot sets V

/32; on the PL 6.0

OUT

PFC

, it

VR2 This trimpot is for balancing the transformer to the PFC circuitry.

VR3 This trimpot sets the maximum 2-ohm output power. For the

PFC

PL 9.0

, it will be set for 4500 watts @ 2 ohms at 2 kHz; for

the PL 6.0

PFC

, it will be set for 3600 watts @ 2 ohms at 2 kHz.

VR4 This trimpot sets the power supply’s idle voltage. For the PL

PFC

9.0

, it will be set for 191.3 volts DC; for the PL 6.0

PFC

it will

be 166.5 volts DC.

VR4

VR3

VR1

VR2

Figure 2.15. The locations of the four trimpots, VR1–VR4

Tools and materials needed:

• PFC power supply fixture with external power supply and CMP

(Control-Monitor-Power) box

• Two digital multimeters (DMM #1 and #2) with clip-on leads

• Digital multimeter (DMM #3) with clamp-on AC current probe

• 0–240 VAC Variac™, Powerstat™, or similar variable AC

transformer; 60 amperes or higher rating, with RMS voltage

and current metering

• 120 VAC power (for the fixture’s housekeeping supply)

• Four-channel oscilloscope with ×1/×10 probes

• Oscilloscope with differential probe

step 10 of the V

procedure)

OUT

• Small pocket-type flat-blade screwdriver

• Grounded anti-static work surface

• Audio Precision (AP) workstation with PFC test

procedure files* and 2-ohm load resistor banks

(mimimum power handling capacity: 1250 watts per

8-ohm resistor; 5000 watts total in 2-ohm configuration).

*The four AP test procedure files are available on the QSC Technical

Support CD-ROM: Pfcxf.tst; Pfcpwr2k.tst; Pfcpwr20.tst; and

Pfctherm.tst.

(optional; see

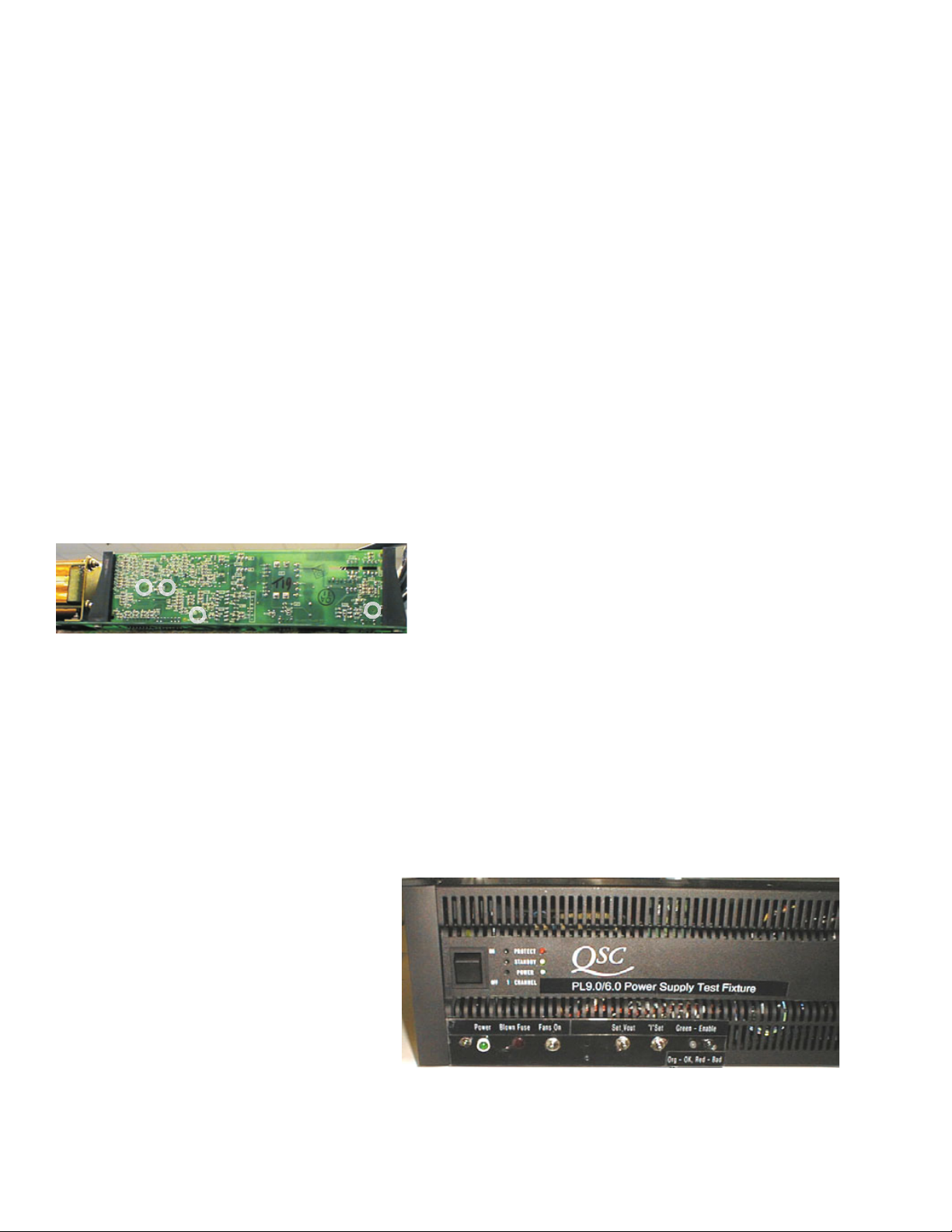

Figure 2.16. The front of the fixture. The amplifier channel’s gain control is

to the right, out of the picture

The PFC power supply fixture

The PFC power supply fixture is a special test bed for PowerLight 6.0

and 9.0 supply modules. It has the necessary connections and

indicators for adjusting, calibrating, and testing the modules. It

also contains one audio channel of a PowerLight 9.0 to allow

testing of the module’s capability to power an actual amplifier

channel. The fixture is custom built by QSC.

Front panel switches and indicators

From left to right (Figure 2.14):

• Power switch. For the AC lines to the power supply module

being tested.

• Power indicator. It lights when the fixture is connected to AC

power and is turned on.

• Blown fuse indicator. Connected across the large fuse under

the door in the top of the fixture chassis, this indicator will light

if the fuse blows. The fuse, however, is merely a backup in case

the CMP box’s solid-state electronic fuse malfunctions.

• Protect, Standby, and Power indicators. In the portions of

the test that use the amplifier channel, these LEDs function just

as they do on a regular amplifier.

• Fan switch. Some portions of these procedures require the

module fans running, and others need them off.

• “Set V

• “I

for checking the module’s I

• “I

module’s I

Rear panel switches and attachments

From left to right (Figure 2.15):

• Audio input. This is where to connect the signal output from

the AP workstation.

• DC high rail outputs. These are two pairs of red and black

binding posts, and they carry the DC output of the supply

module’s high rails. Connect DMM #1 to one of these sets of

binding posts.

• Audio output. This Neutrik Speakon connector carries the

audio output of the fixture’s amplifier channel. Connect this

” switch. This switch is used for the first procedure.

OUT

” switch. This switch also is used in the first procedure

SET

” indicator. This tri-color LED indicates the status of the

SET

circuit.

SET

circuit.

SET

18 QSC Audio Products, Inc.

TD-000083-00

Page 21

Audio signal input

from Audio Precision

workstation

DC high rail outputs: for

PFC PFC

PL 9.0 ; for PL 6.0

Red = +; Black = -

The two sets of binding posts are

in parallel. Connect DMM #1 to

191.3 V

166.5 V

one set.

Audio signal output

to Audio Precision

workstation and load

resistors

Figure 2.17. The fixture’s rear panel.

Transformer flux sample

for balancing procedure.

Connect to oscilloscope

using ×1 probe.

(Do not connect to Variac!)

Connect to external DC

supply. Watch polarity:

Red = +; Black = -

120 VAC for fixture's

housekeeping supply

Power switch for

housekeeping

supply.

• Upper barrier strip. Connect the

DC rail wires to the upper barrier

strip for the other procedures.

• Control connection. Above the

barrier strips is a multiconductor

cable that connects to the 8-pin

header on the controller card of the

power supply module under test.

• AC wires. Located at the top of the

front panel, these two wires connect

to points E2 and E3 on the supply

module.

output to the AP workstation and to the load resistors.

• Transformer flux sample. Connect the tip of an oscilloscope’s

×1 probe to the exposed conductor at the tip of this attachment, and connect the probe’s reference clip to the loop. This is

used in the transformer balancing, the third procedure in the

supply module adjustment and calibration.

• DC supply input. This dual binding post set is for connecting

the fixture to the external power supply.

• 120 VAC power cord. This connects to a regular AC outlet and

provides power for the fixture’s “housekeeping” supply, which

powers the various circuits and indicators.

• Housekeeping supply power switch. This small rocker

switch lets you turn off the housekeeping supply when the

fixture is not in use.

• Fixture power cord. This large power cord connects to the

Variac and provides AC power for the power supply module

under test.

Other attachments

See Figure 2.17.

• Lower barrier strip. Connect the supply module’s five black

DC rail wires to the lower barrier strip’s terminals for the first

procedure, setting V

OUT

.

Procedure 1 of 5: Setting V

OUT

1 Turn off all power to the fixture and turn the Variac all the

way down. Set the power supply module in place atop the

fixture, as shown in Figure 2.18.

2 On the test fixture, set switches V

/32 and I

OUT

SET

in the

up

position. Turn off the fan switch.

3. On the power supply module, disconnect the gate drive cable

(Figure 13).

4. Connect the two AC line wires to the stud terminals on the

PCB: white to E2 on the left, black to E3 on the right. Use the

long insulated threaded posts to secure the wires to the

terminals.

5. Connect the power supply module’s five black DC output

wires, labeled 0 through 4, to the screw terminals on the

lower

barrier strip (Figure 10). Keep them in order; do not

cross any of them.

6. The external power supply has two dual banana sockets—one

is labeled

dual banana plug to the external power supply’s

active

and the other,

dummy

. Connect the fixture’s

active

socket.

7. Plug the AC lines for both the external DC supply and the

fixture into the Variac.

8. Set the CMP boxe’s electronic fuse to a trip threshold of 5

amperes.

Switches and

LED indicators

Figure 2.18. The two barrier strips. Use the lower

one for the first adjustment (setting V

/32 or V

OUT

OUT

Ext. DC

AC connection

supply

Solid-

/

state fuse

26.6), and the upper one for the other adjustments. Figure 2.19. The power supply module loaded onto the test fixture.

Technical Service Manual 19

PowerLight 6.0 II, PowerLight 6.0

PFC

, and PowerLight 9.0

PFC

Page 22

The CMP box

The CMP box has two digital panel meters that monitor AC

voltage and current and a solid-state electronic AC fuse that

can be set to trip specific current levels from 0 to 100

amperes.

To set the current trip level, flip the trip set switch down;

the AC ammeter will then read the trip current setting. Use

the trip set knob to adjust the desired trip point, then flip

the switch up.

The BNC jack provides an AC voltage proportional to the AC

current: 100 mV RMS = 1.0 ampere RMS. This is useful in

the transformer balancing procedure because it allows the

use of an external voltmeter with finer resolution (>3 decimal

places) than the panel ammeter has.

Trip set switch up:

reads AC current;

Trip set switch down:

reads trip current setting

AC voltage

Adjusts trip current

of solid state fuse

Trip set switch:

for normal solid state fuse function;

UP

to set solid state fuse trip

DOWN

0–280 VAC in

from Variac

Figure 2.20. The CMP box. The variable AC outlet for

the test fixture is on the back of the box.

Indicates that the

solid state fuse

circuit has tripped

AC current

sample for

external DMM

100 mV = 1.0 A

Press switch

down and back

up to reset the

solid state fuse.

Gate drive cable

Figure 2.21. The gate drive cable for the MOSFETs.

Disconnect it here for the V

9. Connect DMM #1 to one set of the parallel DC V

procedure.

OUT

terminals

OUT

on the back of the fixture. Connect DMM #2 to the controller

card, with the ground or reference lead on the tab of U8, a

+12V regulator, and the hot lead on the left leg of capacitor

C34. On the board, this point is labeled “VOUT/32.”

10.

Note: this step is optional because the replacement diodes

specified in this bulletin do not have the leakage problems

that many of the original fast diodes had.

Through a differential probe, connect an oscilloscope input between resistor R31

(labeled “OSC”) and ground; this will allow you to view the

output of the diodes to see if any are leaky.

11. Turn the fixture power switch on. Turn up the Variac gradually

until DMM #1 reads 190 volts DC (for the PL 9.0) or 166 volts

(for the PL 6.0). You don’t need to measure the AC voltage

from the Variac yet.

12. Adjust VR1 to obtain a reading on DMM #2 of 5.94 volts DC

(for the PL 9.0) or 6.20 volts DC (for the PL 6.0).

13. Flip the I

switch lights green or orange, I

switch down. If the LED indicator next to the

SET

is good; if red, it is bad and

SET

should be rejected for controller board replacement or repair.

14. Turn down the Variac all the way. Turn off the fixture’s AC

switch. Unplug the external supply’s AC line from the Variac.

15. Set the I

SET

and V

/32 switches

OUT

down

. Remove DMM #2’s

leads from the controller card.

16. Wait a few seconds for the capacitors to discharge and DMM

#1’s voltage reading to drop to 60 volts or less.

Important note about repaired PFC power

supply modules

After repairing a failed power supply module that had

already been calibrated before its failure, either in production or in Technical Services, the VOUT/32 and VOUT @

idle voltages in Procedure 1 only need to be checked and

not fully adjusted, unless the measured high rail voltage is

not 191.3 volts, ±1.5 volts, for the PL 9.0 or 166.5 volts, ±1.5

volts, for the PL 6.0. If the high rail voltages are outside this

range, then the module will require full adjustment and

calibration.

Procedure 2 of 5: Adjusting idle voltage

1. Re-attach the gate drive cable on the power supply module.

Also, disconnect the five DC rail output wires on the right end

of the module from the lower barrier strip and attach them to

the corresponding screw terminals on the upper barrier strip.

Make sure the screw connections are tight and secure.

2. Turn the fixture’s AC switch on and turn the Variac up to the

appropriate AC voltage: 120 volts AC for a 120V module, or

230 volts AC for a 230V module. The power supply will turn

on and begin to draw current when the AC voltage reaches

about the halfway point.

3. Adjust VR4 to obtain the a reading of 191.3 volts DC (for the

PL 9.0) or 166.5 volts DC (for the PL 9.0) on DMM #1.

20 QSC Audio Products, Inc.

TD-000083-00

Page 23

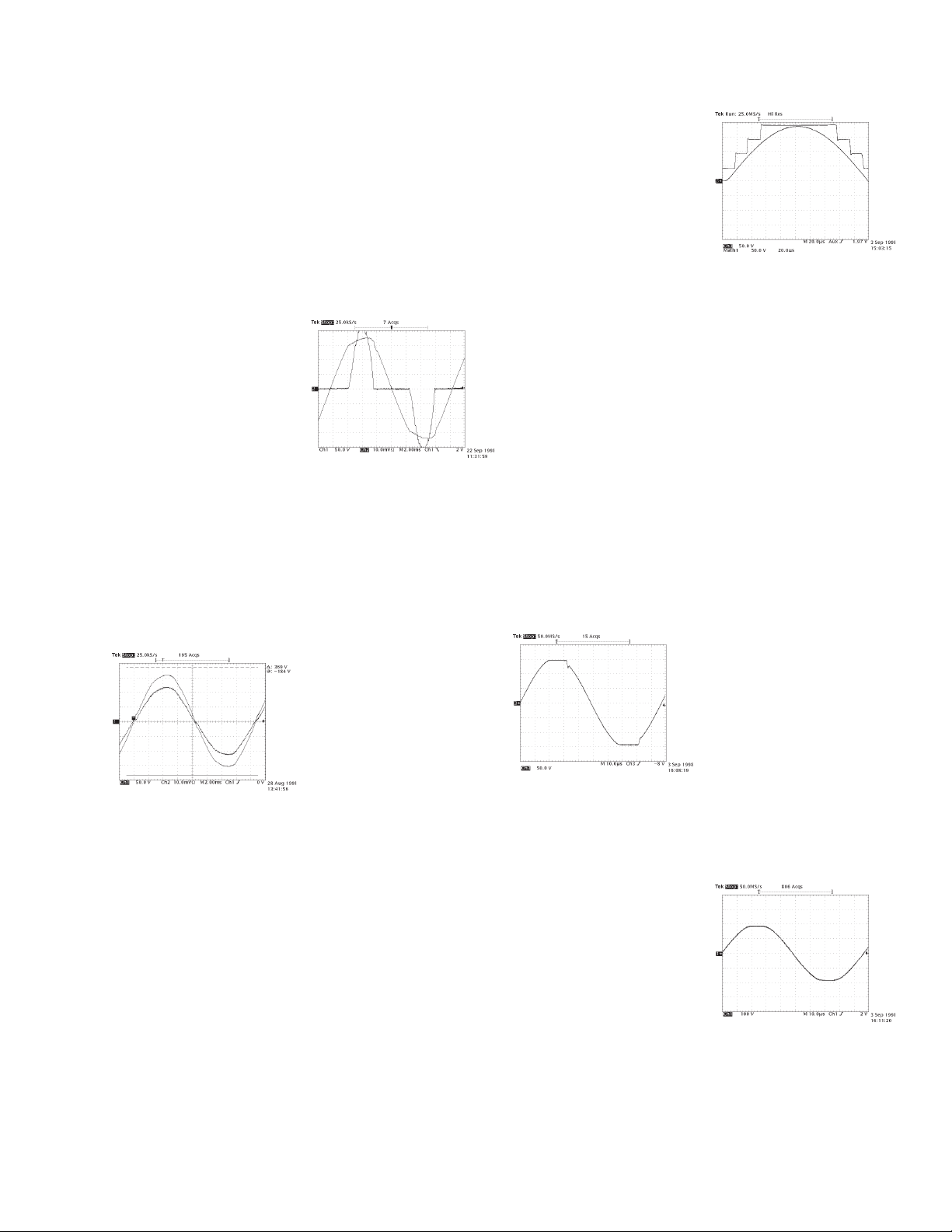

Procedure 3 of 5: Adjusting transformer balance

This is done in three stages. In the first two, watch the transformer flux “bubble” waveform on the oscilloscope, and on the

third, adjust the AC current to a minimum. To prevent overcurrent

cutback due to undervoltage, adjust the Variac to 130 volts for

120-volt modules or 260 volts for 230-volt modules.

1. Set the CMP box’s electronic fuse to a trip threshold of 20

amperes (for a 120V module) or 10 amperes (for a 230V

module) and turn on the fans.

2. Start the PFC test file (Pfcxf.tst) on the AP workstation. It will

put out a 2 kHz sine wave at 0.1 volt RMS and will switch the

load resistance to 2 ohms. Turn the fixture’s gain control all

the way up.

3. Step the signal level up in 0.1 volt increments and watch the

transformer flux “bubble” signal on the oscilloscope (vertical

scale: 20 or 50 V/div; horizontal scale: 1 or 2 ms/div; ×1 scale).

At each step, adjust VR2 to get a smooth, balanced signal.

See Figure 14. There should be no spurious oscillations or

noise visible.

4. When the audio signal reaches a particular level, the CMP box’s

electronic fuse will trip. Set the audio signal back to 0.1 volt.

5. Reset the trip point to 40 amperes (for a 120V module) or 20

amperes (for a 230V module) and repeat steps 2 and 3. The

electronic fuse should trip at about 2.8 kW of output

(measured on the AP)

,

with approximately 1.4 volts input.

6. Reduce the AP’s signal level to 0.1 volt. Reset the electronic

fuse and increase the signal level so that the output is about

2.5 kW. Gently adjust VR2 to null the AC current on DMM #3

to a minimum.

7. Turn the Variac down to zero and set the electronic fuse to 60

amperes.

Procedure 4 of 5: Adjusting 2-ohm limits

1. If this is a brand new module (not a repair), set VR3 to

approximately 4 o’clock. If it is a repair or has otherwise

already been calibrated at some time, leave VR3 alone until

after the first power sweep.

2. Set the Variac to 130 volts (for 120V modules) or 260 volts

(for 230V modules).

3. Run the AP test file (Pfcpwr2k.tst) for a 2-ohm power sweep

test at 2 kHz.

4. Watch the power sweep on the AP monitor and see where

the power cutback occurs. The target output power level at

2 kHz is about 4.6 to 4.7 kW for the PL 9.0 or 3.6 to 3.7 kW for

the PL 6.0. If the cutback point is not in the target range,

carefully adjust VR3 and then repeat the power sweep. It may

take more than two or three tries to get the right setting.

CAUTION: During the power sweep, keep a finger on the

reset switch of the CMP box. If anything abnormal happens,

such as power cutback at a low level, or audible noise from

the supply module’s transformers,

switch

down

and hit F1 on the AP computer keyboard to abort

immediately

flip the reset

the sweep test.

If you stopped the test due to transformer noise, go back and

start over at the transformer balancing procedure. If you had

not aborted the power sweep, in a short time you would have

destroyed the MOSFETs.

If you stopped the test for any other abnormality, you must

troubleshoot and repair the supply module before continuing.

5. Load the AP test file Pfcpwr20.tst, which will change the

signal frequency to 20 kHz, and repeat step 4. This time, verify

that the power cutback does not occur until approximately 4.5

kW for the PL 9.0 or 3.6 kW for the PL 6.0.

6. After competing the power sweeps, press F1 on the AP

computer keyboard.

Procedure 5 of 5: Thermal test

1. On the AP workstation, load the thermal test file

Pfctherm.tst. It should select the Pseudo (pink noise)