Page 1

PLX™ Series

▲▲

▲ PLX 1202

▲▲

▲▲

▲ PLX 1602

▲▲

▲▲

▲ PLX 2402

▲▲

▲▲

▲ PLX 3002

▲▲

Technical Service Manual

TD-000078-00

TD-000078-00

Page 2

+ PLX

+

PLX 1602

+

PLX 2402

1202

+

PLX 3002

Page 3

PLX SERIES

SERVICE MANUAL

PLX

1202

PLX 1602

PLX 2402

PLX 3002

QSC Technical Services

Wats: I

Local:

Fax: 1-714-754-6173

QSC Technical Support BBS

QSC Audio Products, Inc.

1675 MacArthur Blvd.

Costa Mesa,

-%OO-772-2034

1-714-957-7150

I -714-668-7567

1-800-856-6003

CA

92626

http://www.qscaudio.com

Page 4

Table of Contents

PLX Product Specifications ................................................................

Introduction ........................................................................................

Test and Calibration ............................................................................

Troubleshooting PLX ...........................................................................

PLX Parts List

PLX 1202 PCB Assembly (120V) 23

PLX 1202 PCB Assembly (230V) 25

PLX 1202 Chassis Assembly (120V) 28

PLX 1202 Chassis Assembly (230V) 28

PLX 1602 PCB Assembly (120V) 28

PLX 1602 PCB Assembly (230V) 31

PLX 1602 Chassis Assembly (120V) 34

PLX 1602 Chassis Assembly (230V) 34

PLX 2402 PCB Assembly (120V) 35

PLX 2402 PCB Assembly (230V) 38

PLX 2402 Chassis Assembly (120V) 41

PLX 2402 Chassis Assembly (230V) 41

.....................................................

.....................................................

................................................

................................................

.....................................................

.....................................................

................................................

................................................

.....................................................

.....................................................

................................................

................................................

1

2

3

13

PLX 3002 PCB Assembly (120V) 42

PLX 3002 PCB Assembly (230V) 45

PLX 3002 Chassis Assembly (120V) 48

PLX 3002 Chassis Assembly (230V) 49

.....................................................

.....................................................

................................................

................................................

PLX Semiconductors ..............................................................................

Chassis Drawings ...................................................................................

Schematics

PLX 1202 Main PCB Schematics 57

PLX 1602 Main PCB Schematics 62

PLX 2402 Main PCB Schematics 67

PLX 3002 Main PCB Schematics 72

.....................................................

.....................................................

.....................................................

.....................................................

PLX Series PCB Circut Board Drawings .................................................

50

53

73

Page 5

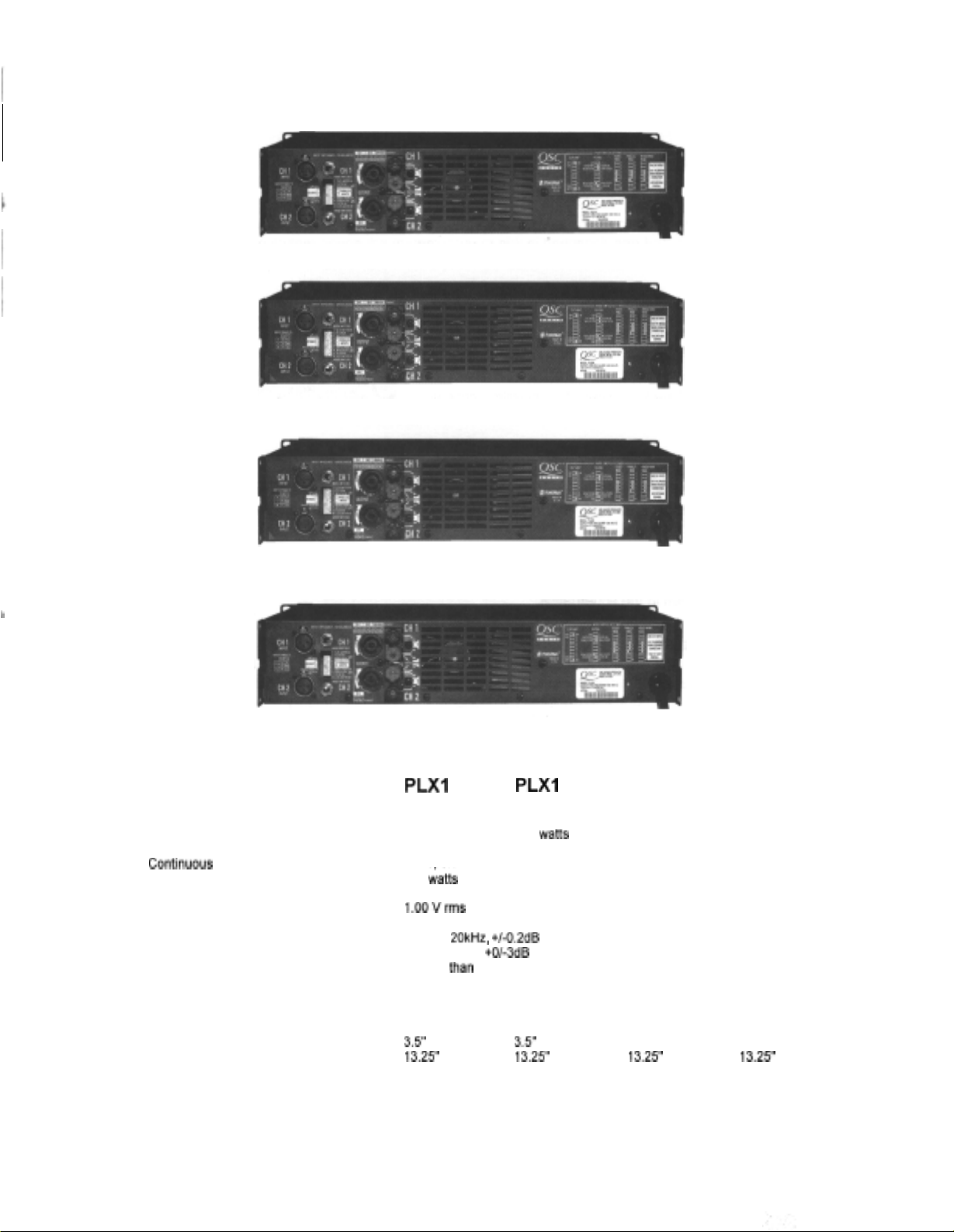

PLX

1202

PLX 1602

PLX 2402

PLX Product Specifications

PLX

3002

Output

Power (per channel):

Continuous Average

8

ohms,

ohms,

Impedance

2OHz-2OkHz,

2OHz-2OkHz,

Average

2OHz - 2OkHz,

4

Con0nuous

8 ohms,

Voltage Gain (dB)

Sensitivity (for rated power @ 8 ohms)

Distortion

Frequency Response (LF Switched Off)

Damping Factor (1

Noise

Input

Dimensions

Faceplate Width

Faceplate Height

Chassis Depth

Weight

Net, Lbs/kg

Output

Power both channels driven:

0.03%

THD

0.05%

Output

kHz

THD

Power bridged mono

0.1% THD

and Below)

PLXI

PLXI

202

200watts

325

watts

ooeration:

700

iatts

32

1.00vrms

SMPTE-IM

2OHz to 2OkHz,

8Hz to 5OkHz, +Ol-3dB

Greater

106dB

6k unbalanced,

Standard 19” Rack Mounting

3.Y

13.2Y

2119.5 2119.5

Less

than

+I-0.2dB

than

500

below rated output (20 Hz to 20 kHz)

12k

balanced

602

300

waKs

500

watts

1100

watts 1500 watts

32

1.20 Vrms

0.01%

3.r

13.2v

PLX2402

425watts 550

700

watts 900watts

32

1.50 Vrms

3.5” 3.Y

13.2Y 13.2Y

2119.5

PLX3002

2000 watts

32

1.70

2119.5

watts

vrms

Page 6

Introduction

This manual is prepared to assist service personnel with the repair and calibration of PLX power

amplifiers

and sophisticated audio test equipment.

Documentation

This manual contains schematics, printed circuit board (PCB) drawings, parts lists, and

mechanical assembly drawings. This information should be used in conjunction with the

test and troubleshooting guide.

The electrical and electronic components are identified by circuit identification numbers on

the schematics and the parts list. The test

designations shown in the schematics.

.

The procedures described in this manual require advanced technical experience

CAUTION: To reduce the risk of electric shock,

do not remove the cover. No user-serviceable

parts inside. Refer servicing to qualified

personnel.

WARNING: To prevent fire or electric shock, do

not expose this equipment to rain or moisture.

&

troubleshooting sections refer to

CAUTION

Equivalent Parts

Although many of the electronic components used in this product may be available from

WC.

electronic suppliers, some components are specially tested and approved by

product repaired with

Repairs performed using non-QSC parts may void the product warranty.

you may contact

Parts orders to QSC should include the product model number, the part description, and

the QSC part number (from the parts list in this manual). Parts will be shipped via UPS,

F.O.B. Costa Mesa, California. Shipping, handling and COD charges may be added to

the cost of the parts.

non-WC

QSC

Technical Services for assistance.

supplied components may not meet factory specifications.

men

A

in doubt,

Factory Repair

It may become necessary to return a product to the factory for repair. Call QSC Technical

Services for return instructions. QSC Technical Services may be reached at (800)

772-2834.

Test and Troubleshooting Equipment

-Audio

-

Distortion Analyzer capable of 0.01% THD+N

-

High Power Load Bank

-

Function Generator 8 Digital Multimeter

-

2OMHz

Oscilloscope

-

Variac (0-140

VAC, 30-40A)

(8,4,8

2

ohms)

Precision - System One

+

Thermometer

2

Page 7

Test & Calibration

PLX 1202 Test Procedure

.

SET-UP

1.

Connect a test load to the output terminals of the amplifier.

-

2. Make sure Mode Switches 1

3. Connect a distortion analyzer with a resolution of

output terminals of the amplifier. Enable the

4. Connect a dual-channel oscilloscope to the following test points:

Chl

-

a

IOX

(vertical sensitivity -

Ch2

-

a IX scope probe (vertical sensitivity -

output.

5.

Set amp gain pots fully clockwise and turn on power switch.

6. Connect the output of the signal generator to the input terminals of the amplifier and

select an output of 1.30

7. Plug the amplifier into a variac and set up an AC line current monitor.

. POWER UP 8 MUTE DELAY TEST

CAUTION: To avoid damage to the main printed circuit board, place a 50 ohm

240VAC) in series with the high

supply has a shorted device at initial power up, this AC resistor pad will help prevent undue damage. After

the amplifier has been fully powered up via the variac, confirm that the amplifier has achieved

stable operation during idle. Remove AC power from the amplifier and disconnect the series

resistor for normal operation. Continue with the test

10 are in the default position (1 on, 10 on, all others off).

O.Ol%, 20-2OkHz

8OkHz

low pass filter.

2V/cm)

scope probe to the channel speaker output.

O.lV/cm)

VRMS,

1

kHz

sine wave.

(+)

lead on the AC cable during variac ramp up. If the switching power

&

calibration process.

to the distortion analyzer

(or better) to the

225W

resistor (100 ohm,

I. Slowly raise the variac voltage and watch for excessive current draw (line current

greater than

0.5A

a.c. at 60 Volts). This is slightly less for 240V.

Pause at

(2OOVAC European) for three seconds until the mute I protect circuit disengages.

Continue to

12OVAC

(240V European).

2. Verify that the fan is operating at low speed.

3. Turn the power switch off and on a few times to verify the 3 second power-up muting

delay.

l CHANNEL OUTPUT

I. Look for amplified signal on the scope for channel 1. Switch the input signal and scope

/

to channel 2 and repeat output test. Check for noisy

contaminated gain pots by

observing general instability on the distortion waveform while adjusting the gain control

levels.

2. Select an 8 ohm load and confirm that this amplifier is producing 200 watts at 1 kHz just

below the point of clipping. Check both channels.

l BRIDGE MODE

1. Turn the power switch off.

#7

2. Set Mode Switch

on CH2 are disabled with Mode Switch

3.

Set load to both red output binding posts

4. Apply a 1.30

in the on position. The gain control, limiter, and filter switch positions

#7

on.

(CHI

positive and CH2 negative).

VRMS,

1

kHz

sinewave input to channel I of the amplifier. Check the power

and verify that the output does not immediately collapse. Check for 700 watts at 8 ohms.

9OVAC

Page 8

5.

Turn power off and place the amplifier back into the Stereo mode with output

loads connected to each channel.

. BIAS

1. Let the amplifier cool down to room temperature.

2. With an input amplitude of

1.3OVrms

input signal 20dB (80%) from full output. Adjust the crossover

VR166 (CH2) for about a

4OOmVpk-pk

increase the input frequency to

trimpot

2OkHz.

VR43

crossover spike protruding from the noise trace

on the oscilloscope. It will be necessary to have the oscilloscope measure unfiltered

distortion from the amplifier in order to see the crossover spike. It is necessary to

disable the 80kHz

lowpass

filter on the analyzer for this test.

Further trim so that

the total distortion for that channel is less than 0.1% THD+N.

3. With the trim settings achieved, and with no signal plugged into the amplifier and with an

8 ohm load, verify that the AC idle current from the AC service is no more than 1 .O

amperes.

4. Let the amplifier cool down and check channel 2.

. SHORT CIRCUIT CURRENT

1.

Select a 2 ohm load and apply a

of the amplifier.

Ensure that power is on and that the gain controls are fully up.

1.3Vrms

sinewave (1

kHz)

input signal to both channels

2. While the amplifier is producing power into the loads, apply a short to the output binding

posts of each channel. In other words, apply a jumper between the red and black

binding posts of each channel. Once this is done, combined AC line current draw for

both channels should be no greater than

13A ac.

This is with a 120 volt AC service to

the amplifier. Current may be lower if AC line voltage is lower.

3. Remove the short from each channel and verify that the channels recover in to 2 ohm

loads. The output should not experience any hang up and a full

sinewave

should be

present just as it was before a short was applied for this test.

4. If the amplifier does not pass any of the above steps, troubleshoot the current limit

section of the amplifier. If steps 2, 3, and 4 above pass, continue to the next test

FREQUENCY RESPONSE.

Reduce the

(CHl)

and

l FREQUENCY RESPONSE

1,

Set load to 8 ohms and scale the input generator to gain 1 watt of power from the

amplifier on each channel. Gain controls on the amplifier should be fully up.

2.

Check frequency response from

2OHz

to 20kHz

(+I- 0.2OdB)

by sweeping random

frequencies between these extremes. This is done by verifying the same voltage

amplitude at each of the frequencies selected (within

2OHz

to

2OkHz).

Check both

channels.

l POWER vs. DISTORTION TEST

I. Check to ensure that both channels will produce rated power at

2OHz, 2KHz,

into an 8 ohm load.

2. While verifying rated power, check that at all frequencies the distortion measurement is

less than or equal to 0.03% THD.

l THERMAL TEST

1. Set input frequency to 1 KHz and short both channels while they are producing power into

a load.

2. Apply a short to the output of each channel.

3. AC line current draw should be about 11 - 13.5 amperes for both channels. As the

amplifier gets hot, there will be some current drift upwards and the fan speed will

increase. This is not a problem as long as the case temperature on the output

transistors does not exceed

105

degrees C.

and 20kHz.

4

Page 9

4.

Verify that the NTC circuit causes thermal shutdown after an extended period.

5. When thermal shutdown occurs, verify AC idle current of less that 0.90 amperes

l CM TEST

1. Select an 8 ohm load and confirm that this amplifier is producing rated power.

2. Check the Common Mode of the amplifier by inserting a

channel and observe about 6

dB

of output voltage reduction. There will also be a 180

1/4”

input jack halfway into each

degree phase inversion at the output of the channel under test.

l OUTPUT NOISE

1. Set the amplifier gain controls all the way up, with a 1

kHz 1.3OVrms sinewave

signal. Note the output level at full power just below clipping. Adjust gain if needed.

2. Remove the input signal connector from the amplifier and measure the residual noise

level produced into the load by the amplifier. The noise signal should be 107

from the full output power point measured. A signal to noise ratio should be better than

or equal to

l FINAL CHECK

107dB.

Check both channels.

This completes the amplifier test procedure for this model.Inspect the amplifier for

mechanical defects. Inspect the solder connections. Reassemble the amplifier and verify

the amplifier’s operation before returning the product to service.

input

dB

down

PLX 1602 Test Procedure

.

SET-UP

1.

Connect a test load to the output terminals of the amplifier.

2.

Make sure Mode Switches 1

Connect a distortion analyzer with a resolution of

3.

output terminals of the amplifier.Enable the 80kHz low pass filter.

4.

Connect a dual-channel oscilloscope to the following test points:

Chl -

a 1 OX (vertical sensitivity -

Ch2

-

a IX scope probe (vertical sensitivity -

output.

5.

Set amp gain pots fully clockwise and turn on power switch.

Connect the output of the signal generator to the input terminals of the amplifier and

6.

select an output of 1.30

Plug the amplifier into a variac and set up an AC line current monitor.

7.

l POWER UP 8 MUTE DELAY TEST

CAUTION: To avoid damage to the main printed circuit board, place a 50 ohm 225W resistor (100 ohm,

240VAC) in series with the high

supply has a shorted device at initial power up, this AC resistor pad will help prevent undue damage. After

the amplifier has been fully powered up via the variac, confirm that the amplifier has achieved

stable operation during idle. Remove AC power from the amplifier and disconnect the series

resistor for normal operation. Continue with the test

Slowly raise the variac voltage and watch for excessive current draw (line current

greater than

(2OOVAC

European) for three seconds until the mute I protect circuit disengages.

Continue to

0.5A a.c

12OVAC (24OV

at 60 Volts).

Verify that the fan is operating at low speed.

-

10 are in the default position (1 on, 10 on, all others off)

VRMS,

1

(+)

lead on the AC cable during variac ramp up. If the switching power

European).

O.Ol%, 20-20kHz

2V/cm)

scope probe to the channel speaker output.

O.lV/cm)

kHz

sine wave.

&

calibration process.

T/I;s is s/;ghf/y less

to the distortion analyzer

for 240V. Pause at

(or better) to the

9OVAC

Page 10

3. Turn the power switch off and on a few times to verify the 3 second power-up muting

delay.

. CHANNEL OUTPUT

1. Look for amplified signal on the scope for channel 1. Switch the input signal and scope

to channel 2 and repeat output test. Check for noisy

/

contaminated gain pots by

observing general instability on the distortion waveform while adjusting the gain control

levels.

2. Select an 8 ohm load and confirm that this amplifier is producing 300 watts at 1 kHz just

below the point of clipping. Check both channels.

. BRIDGE MODE

1. Turn the power switch off.

2. Set Mode Switch

on CH2 are disabled with Mode Switch

3. Set load to both red output binding posts

4. Apply a 1.30

#7

in the on position. The gain control, limiter, and filter switch positions

#7

on.

(CHI

positive and CH2 negative).

VRMS,

1

kHz

sinewave input to channel 1 of the amplifier. Check the power

and verify that the output does not immediately collapse. Check for 1000 watts at 8

ohms.

5.

Turn power off and place the amplifier under test back into the Stereo mode with output

loads connected to each channel.

l BIAS

I. Let the amplifier cool down to room temperature.

2. With an input amplitude of

input signal 20dB (80%) from full output. Adjust the crossover

VR166 (CH2) for about a

1.3OVrms

increase the input frequency to 20kHz. Reduce the

4OOmVpk-pk

trimpot

VR43

crossover spike protruding from the noise trace

on the oscilloscope. It will be necessary to have the oscilloscope measure unfiltered

distortion from the amplifier in order to see the crossover spike.

disable the 80kHz

lowpass

filter on the analyzer for this test. Further trim so that

It is necessary to

the total distortion for that channel is less than 0.1% THD+N.

3. With the trim settings achieved, and with no signal plugged into the amplifier and with an

8 ohm load, verify that the AC idle current from the AC service is no more than 1 .O

amperes.

4. Let the amplifier cool down and check channel 2.

(CHl)

and

l SHORT CIRCUIT CURRENT

1.

Select a 2 ohm load and apply a

of the amplifier.Ensure that power is on and that the gain controls are fully up.

2. While the amplifier is producing power into the loads, apply a short to the output binding

posts of each channel.

binding posts of each channel. Once this is done, combined AC line current draw for

both channels should be no greater than

the amplifier. Current may be lower if AC line voltage is lower.

3. Remove the short from each channel and verify that the channels recover in to 2 ohm

loads. The output should not experience any hang up and a full

present just as it was before a short was applied for this test.

4. If the amplifier does not pass any of the above steps, troubleshoot the current limit

section of the amplifier. If steps 2, 3, and 4 above pass, continue to the next test

FREQUENCY RESPONSE.

6

1.3Vrms

sinewave (1

kHz)

input signal to both channels

In other words, apply a jumper between the red and black

13A

ac. This is with a 120 volt AC service to

sinewave

should be

Page 11

l FREQUENCY RESPONSE

I.

Set load to 8 ohms and scale the input generator to gain 1 watt of power from the

amplifier on each channel. Gain controls on the amplifier should be fully up.

2. Check frequency response from

2OHz

to 20kHz

(+I- 0.2OdB)

by sweeping random

frequencies between these extremes. This is done by verifying the same voltage

2OHz

amplitude at each of the frequencies selected (within

to 20kHz). Check both

channels.

l POWER vs. DISTORTION TEST

1. Check to ensure that both channels will produce rated power at

2OHz, 2KHz,

into an 8 ohm load.

2.

While verifying rated power, check that at all frequencies the distortion measurement is

less than or equal to 0.03% THD.

l THERMAL TEST

1.

Set input frequency to 1 KHz and short both channels while they are producing power into

a load.

2. Apply a short to the output of each channel.

3. AC line current draw should be about

II -

13.5 amperes for both channels. As the

amplifier gets hot, there will be some current drift upwards and the fan speed will

increase. This is not a problem as long as the case temperature on the output

transistors does not exceed 105 degrees

C.

4. Verify that the NTC circuit causes thermal shutdown after an extended period.

5. When thermal shutdown occurs, verify AC idle current of less that 0.90 amperes.

and 20kHz.

l CM TEST

1. Select an 8 ohm load and confirm that this amplifier is producing rated power.

2. Check the Common Mode of the amplifier by inserting a

dB

channel and observe about 6

of output voltage reduction. There will also be a 180

1/4”

input jack halfway into each

degree phase inversion at the output of the channel under test.

l OUTPUT NOISE

I. Set the amplifier gain controls all the way up, with a 1

signal.

Note the output level at full power just below clipping. Adjust gain if needed.

kHz 1.3OVrms sinewave

2. Remove the input signal connector from the amplifier and measure the residual noise

level produced into the load by the amplifier. The noise signal should be 107

from the full output power point measured. A signal to noise ratio should be better than

107dB.

or equal to

l FINAL CHECK

This completes the amplifier test procedure for this model.

Check both channels.

Inspect the amplifier for

mechanical defects. inspect the solder connections. Reassemble the amplifier and

the amplifier’s operation before returning the product to service.

PLX 2402 Test Procedure

l SET-UP

1. Connect a test load to the output terminals of the amplifier.

2. Make sure Mode Switches 1

- 10

are in the default position (1 on, 10 on, all others off).

input

dB

down

veri@

Page 12

3. Connect a distortion analyzer with a resolution of

O.Ol%, 20-20kHz

(or better) to the

output terminals of the amplifier. Enable the 80kHz low pass filter.

4. Connect a dual-channel oscilloscope to the following test points:

Chl

-

a

1OX

(vertical sensitivity - 2V/cm) scope probe to the channel speaker output.

Ch2

-

a IX scope probe (vertical sensitivity - 0.

IV/cm)

to the distortion analyzer

output.

5. Set amp gain pots fully clockwise and turn on power switch.

6. Connect the output of the signal generator to the input terminals of the amplifier and

select an output of 1.50

VRMS

1

kHz

sine wave.

7. Plug the amplifier into a variac and set up an AC line current monitor.

l POWER UP

&

MUTE DELAY TEST

CAUTION: To avoid damage to the main printed circuit board, place a 50 ohm

240VAC) in series with the high

supply has a shorted device at initial power up, this AC resistor pad will help prevent undue damage. After

the amplifier has been fully powered up via the variac, confirm that the amplifier has achieved

stable operation during idle. Remove AC power from the amplifier and disconnect the series

resistor for normal operation. Continue with the test

(+)

lead on the AC cable during variac ramp up. if the switching power

&

calibration process.

225W

resistor (100 ohm,

1. Slowly raise the variac voltage and watch for excessive current draw (line current

greater than

(2OOVAC

European) for three seconds until the mute / protect circuit disengages.

Continue to

0.5A a.c

at 60 Volts).

12OVAC (24OV

This

European).

is

slight/y /ess fof

24OV.

Pause at

2. Verify that the fan is operating at low speed.

3.

Turn the power switch off and on a few times to verify the 3 second power-up muting

delay.

l CHANNEL OUTPUT

I. Look for amplified signal on the scope for channel

to channel 2 and repeat output test. Check for noisy

1.

Switch the input signal and scope

/

contaminated gain pots by

observing general instability on the distortion waveform while adjusting the gain control

levels.

2. Select an 8 ohm load and confirm that this amplifier is producing 425 watts at 1 kHz just

below the point of clipping. Check both channels.

l BRIDGE MODE

1. Turn the power switch off.

2. Set Mode Switch

on CH2 are disabled with Mode Switch

3. Set load to both red output binding posts

4. Apply a 1.30

#7

in the on position. The gain control, limiter, and filter switch positions

#7

on.

(CHI

positive and CH2 negative).

VRMS,

1

kHz sinewave

input to channel 1 of the amplifier. Check the power

and verify that the output does not immediately collapse. Check for 1500 watts at 8

ohms.

5. Turn power off and place the amplifier under test back into the Stereo mode with output

loads connected to each channel.

l BIAS

1.

Let the amplifier cool down to room temperature.

2. With an input amplitude of

input signal 20dB (80%) from full output. Adjust the crossover

VR166 (CH2) for about a

1.5OVrms,

increase the input frequency to

4OOmVpk-pk

2OkHz.

trimpot

VR43

crossover spike protruding from the noise trace

on the oscilloscope. It will be necessary to have the oscilloscope measure unfiltered

distortion from the amplifier in order to see the crossover spike.

It is necessary to

9OVAC

Reduce the

(CHl)

and

Page 13

disable the 80kHz

the total distortion for that channel is less than 0.1%

lowpass

filter on the analyzer for this test.Further trim so that

THD+N,

3. With the trim settings achieved, and with no signal plugged into the amplifier and with an

8 ohm load, verify that the AC idle current from the AC service is no more than 1 .O

amperes.

4. Let the amplifier cool down and check channel

l SHORT CIRCUIT CURRENT

1.

Select a 2 ohm load and apply a

1.3Vrms

2.

sinewave (1

kHz)

input signal to both channels

of the amplifier.Ensure that power is on and that the gain controls are fully up.

2. While the amplifier is producing power into the loads, apply a short to the output binding

posts of each channel. In other words, apply a jumper between the red and black

binding posts of each channel. Once this is done, combined AC line current draw for

both channels should be no greater than

13A

ac. This is with a 120 volt AC service to

the amplifier. Current may be lower if AC line voltage is lower.

3. Remove the short from each channel and verify that the channels recover in to 2 ohm

loads. The output should not experience any hang up and a full

sinewave

should be

present just as it was before a short was applied for this test,

4. If the amplifier does not pass any of the above steps, troubleshoot the current limit

section of the amplifier. If steps 2, 3, and 4 above pass, continue to the next test

FREQUENCY RESPONSE.

l FREQUENCY RESPONSE

1. Set load to 8 ohms and scale the input generator to gain 1 watt of power from the

amplifier on each channel. Gain controls on the amplifier should be fully up.

2. Check frequency response from

2OHz

to 20kHz

(+/- 0.2OdB)

by sweeping random

frequencies between these extremes. This is done by verifying the same voltage

amplitude at each of the frequencies selected (within

2OHz

to 20kHz). Check both

channels.

l POWER vs. DISTORTION TEST

1. Check to ensure that both channels will produce rated power at

2OHz, 2KHz,

into an 8 ohm load.

2. While verifying rated power, check that at all frequencies the distortion measurement is

less than or equal to 0.03%

l THERMAL TEST

THD.

1. Set input frequency to 1 KHz and short both channels while they are producing power into

a load.

2. Apply a short to the output of each channel.

11

-

3. AC line current draw should be about

13.5 amperes for both channels. As the

amplifier gets hot, there will be some current drift upwards and the fan speed will

increase, This is not a problem as long as the case temperature on the output

transistors does not exceed 105 degrees C.

4. Verify that the NTC circuit causes thermal shutdown after an extended period.

5,

When thermal shutdown occurs, verify AC idle current of less that 0.90 amperes.

l CM TEST

I. Select an 8 ohm load and confirm that this amplifier is producing rated power.

2. Check the Common Mode of the amplifier by inserting a

114”

input jack halfway into each

channel and observe about 6 dB of output voltage reduction. There will also be a 180

degree phase inversion at the output of the channel under test.

and 20kHz.

9

Page 14

l OUTPUT NOISE

1. Set the amplifier gain controls all the way up, with a I

signal.

Note the output level at full power just below clipping. Adjust gain if needed.

kHz 1.5OVrms sinewave

2. Remove the input signal connector from the amplifier and measure the residual noise

level produced into the load by the amplifier. The noise signal should be 107

from the full output power point measured. A signal to noise ratio should be better than

or equal to

l FINAL CHECK

107dB.

Check both channels.

This completes the amplifier test procedure for this model.Inspect the amplifier for

mechanical defects. Inspect the solder connections. Reassemble the amplifier and verify

the amplifier’s operation before returning the product to service,

PLX 3002 Test Procedure

l SET-UP

1. Connect a test load to the output terminals of the amplifier.

2. Make sure Mode Switches 1 - 10 are in the default position (1 on, 10 on, all others off).

3.

Connect a distortion analyzer with a resolution of

output terminals of the amplifier. Enable the 80kHz low pass filter.

4. Connect a dual-channel oscilloscope to the following test points:

-

a

1OX

Chl

Ch2

(vertical sensitivity -

-

a 1X scope probe (vertical sensitivity -

2V/cm)

scope probe to the channel speaker output.

output.

5.

Set amp gain pots fully clockwise and turn on power switch.

6. Connect the output of the signal generator to the input terminals of the amplifier and

select an output of 1.70

VRMS,

1

kHz

sine wave.

7. Plug the amplifier into a variac and set up an AC line current monitor.

O.Ol%,

O.lV/cm)

20-20kHz

(or better) to the

to the distortion analyzer

input

dB

down

. POWER UP 8 MUTE DELAY TEST

CAUTION: To avoid damage to the main printed circuit board, place a 50 ohm 225W resistor (100 ohm,

240VAC) in series with the high

supply has a shorted device at initial power up, this AC resistor pad will help prevent undue damage. After

the amplifier has been fully powered up via the variac, confirm that the amplifier has achieved

stable operation during idle. Remove AC power from the amplifier and disconnect the series

resistor for normal operation. Continue with the test

1.

Slowly raise the variac voltage and watch for excessive current draw (line current

greater than

(2UOVAC

Continue to

0.5A

a.c. at 60 Volts).

European) for three seconds until the mute / protect circuit disengages.

12OVAC

(+)

lead on the AC cable during variac ramp up. If the switching power

TIG.s is s/ight/y

(240V European).,

&

calibration process.

less for

24UV.

Pause at

2. Verify that the fan is operating at low speed.

3. Turn the power switch off and on a few times to verify the 3 second power-up muting

delay.

l CHANNEL OUTPUT

1.

Look for amplified signal on the scope for channel 1. Switch the input signal and scope

to channel 2 and repeat output test. Check for noisy I contaminated gain pots by

observing general instability on the distortion waveform while adjusting the gain control

levels.

9OVAC

10

Page 15

2. Select an 8 ohm load and confirm that this amplifier is producing

550

watts at 1 kHz just

below the point of clipping. Check both channels.

l BRIDGE MODE

1. Turn the power switch off.

2. Set Mode Switch

on CH2 are disabled with Mode Switch

3. Set load to both red output binding posts

4. Apply a 1.30

#7

in the on position. The gain control, limiter, and filter switch positions

#

7 on.

(CHI

positive and CH2 negative).

VRMS,

1

kHz

sinewave input to channel 1 of the amplifier. Check the power

and verify that the output does not immediately collapse. Check for 2000 watts at 8

ohms.

5. Turn power off and place the amplifier under test back into the Stereo mode with output

loads connected to each channel.

l BIAS

1.

Let the amplifier cool down to room temperature.

2. With an input amplitude of

input signal 20dB

VRl66

(CH2) for about a

(80°h)

1.7OVrms

increase the input frequency to 20kHz. Reduce the

from full output. Adjust the crossover

4OOmVpk-pk

crossover spike protruding from the noise trace

trimpot

VR43

on the oscilloscope. It will be necessary to have the oscilloscope measure unfiltered

distortion from the amplifier in order to see the crossover spike. It is necessary to

disable the 80kHz

lowpass

filter on the analyzer for this test.Further trim so that

the total distortion for that channel is less than 0.1% THD+N.

3,

With the trim settings achieved, and with no signal plugged into the amplifier and with an

8 ohm load, verify that the AC idle current from the AC service is no more than 1 .O

amperes.

4. Let the amplifier cool down and check channel

2.

(CHI)

and

l SHORT CIRCUIT CURRENT

1.

Select a 2 ohm load and apply a

1.3Vrms

sinewave (1

kHz)

input signal to both channels

of the amplifier.Ensure that power is on and that the gain controls are fully up.

2,

While the amplifier is producing power into the loads, apply a short to the output binding

posts of each channel. In other words, apply a jumper between the red and black

binding posts of each channel. Once this is done, combined AC line current draw for

both channels should be no greater than

13A

ac. This is with a 120 volt AC service to

the amplifier. Current may be lower if AC line voltage is lower.

3. Remove the short from each channel and verify that the channels recover in to 2 ohm

loads. The output should not experience any hang up and a full

sinewave

present just as it was before a short was applied for this test.

4. If the amplifier does not pass any of the above steps, troubleshoot the current limit

section of the amplifier. If steps 2, 3, and 4 above pass, continue to the next test

FREQUENCY RESPONSE.

l FREQUENCY RESPONSE

1. Set load to 8 ohms and scale the input generator to gain I watt of power from the

amplifier on each channel. Gain controlson the amplifier should be fully up.

2. Check frequency response from

to 20kHz

(+I- 0.2OdB)

by sweeping random

2OHz

frequencies between these extremes. This is done by verifying the same voltage

amplitude at each of the frequencies selected (within

2OHz

to 20kHz). Check both

channels.

should be

11

Page 16

l POWER vs. DISTORTION TEST

1.

Check to ensure that both channels will produce rated power at

2OH2, 2KHz,

into an 8 ohm load.

2. While verifying rated power, check that at all frequencies the distortion measurement is

less than or equal to 0.03% THD.

l THERMAL TEST

I. Set input frequency to

1 KHz and short both channels while they are producing power into

a load.

2. Apply a short to the output of each channel.

3. AC line current draw should be about 11

-

13.5 amperes for both channels. As the

amplifier gets hot, there will be some current drift upwards and the fan speed will

increase. This is not a problem as long as the case temperature on the output

transistors does not exceed 105 degrees

C.

4. Verify that the NTC circuit causes thermal shutdown after an extended period.

5. When thermal shutdown occurs, verify AC idle current of less that 0.90 amperes.

l CM TEST

1. Select an 8 ohm load and confirm that this amplifier is producing rated power.

2. Check the Common Mode of the amplifier by inserting a

channel and observe about 6 dB of output voltage reduction. There

114”

input jack halfway into each

will

also be a 180

degree phase inversion at the output of the channel under test.

l OUTPUT NOISE

1. Set the amplifier gain controls all the way up, with a 1

signal.

Note the output level at full power just below clipping. Adjust gain if needed.

kHz 1.7OVrms sinewave

2. Remove the input signal connector from the amplifier and measure the residual noise

level produced into the load by the amplifier. The noise signal should be 107

from the full output power point measured. A signal to noise ratio should be better than

or equal to

107dB.

Check both channels.

and 20kHz.

input

dB

down

l FINAL CHECK

This completes the amplifier test procedure for this model.

Inspect the amplifier for

mechanical defects. Inspect the solder connections. Reassemble the amplifier and verify

the amplifier’s operation before returning the product to service.

12

Page 17

T r o ubleshooting

PLX 1202 l PLX 1602 l PLX 2402 l PLX 3002

Power Supply -

In order to improve

are driven by an active, direct coupled integrated circuit, rather than a gate drive transformer.

driver failure should be rare (when correctly assembled) but when the

following parts:

CHECKLIST AFTER BLOWN

Q96, Q97,

D78, D79,

Ul8, lR2110

also typically damage the gate coupling parts noted above.

Ul9,

SOMETIMES

RARELY

PROBABLE CAUSES OF MASSIVE

SHORTS IN CONTROL CIRCUIT.

The parts operate well within their ratings and should hold up well in the field. The usual cause of failure is

when both

signal to one part to remain on when the other part is supposed to turn on. Shorts from solder or debris are

one obvious cause.

SHORTS IN THE LOAD.

Although there is peak current shutdown, shorts in the power amplifier transistors or secondary-side supply

components can cause currents to increase too quickly to prevent damage.

(IGBT’s

R358, R359,

high-side gate driver, Fault current when low-side

3525 controller, Blows from currents shorted

Ul3,

IGBT’s

EMI

performance, reduce cost, and increase current capacity, the PLX

generally fail in pairs)

gate drive coupling

Ul4, 556,

which has fairly high supply voltage ratings.

powered from 5V output of 3525, which may fail high when 3525 fails.

turn on at once, shorting Pri-Hi to Pri-Lo. This occurs when something causes the drive

Replacing Blown

-

IGBT’S

IGBT

comonents,

FAULTS

check after removing blown

thru Ul8,

IGBTs.

IGBTs

IGBT

or

IGBT’s

blow, it usually damages the

IGBT’s.

IGBT

shorts to upper rail. Such currents

or possibly by overvoltage on the supply rail

OVERVOLTAGE ON THE BIAS SUPPLY.

If the TOP-210 bias supply fails to operate, no harm occurs, the unit simply does not operate.

However, open circuit (missing part) in several key components can cause the Bias supply voltage to be

much too high, This blows the 2110 and thus the

QUICK TEST OF BIAS SUPPLY.

Ramp the AC voltage up slowly to 25% of regular voltage (30V for

normally, the green “power” LED should come on between 30 and

start-up level. If the LED comes on at

until you have measured the bias voltage. The switching will not start until you reach

the

IGBT’s

from blowing.

Confirm that bias voltage at Cl38 is

feedback to U16 and cause overvoltage.

2OV,

18-19V.

IGBT’s.

or not until

Open or missing

5OV,

12OV

unit). If the bias supply is working

35Vz

with its usual, steady

or blinks, DO NOT RAISE VOLTAGE PAST 60V

9OV,

D63,

64, 65, 66, 67 or R349 will break the

“half-brighr

so you can save

13

Page 18

Troubleshooting “TOP-210” Bias Supply.

QUICK TEST OF BIAS SUPPLY.

Ramp the AC voltage up slowly to 25% of regular voltage (30V for

normally, the green “power” LED should come on between 30 and

start-up level.

CAUTION: if the LED comes on at

until you have measured the bias voltage. The switching will not start until you reach

the

IGBT’s

from blowing.

Confirm that bias voltage at Cl38 is

BIAS SUPPLY VOLTAGE MUCH TOO HIGH

D63,64,65,66,67

NO BIAS SUPPLY VOLTAGE

U16 missing or blown.

Tl missing, reversed, or open primary

D62 open or missing.

BIAS VOLTAGE ERRORS

The exact voltage is controlled by the feedback through

Cl38 is the

D63,

Cl39 , is the

D66,

R349 subtracts about

Ul6

uses this feedback to adjust the “on” time at pin 5, in order

charging Cl38 and thus maintain regulation of the

C142,

“hunting”.

Q99

and associated R374 reduce the voltage of the Bias supply by 33% when the AC voltage is turned off.

This prevents the Power LED from showing at half brightness after turn-off, since U16 continues to run

from the main filters for some time after shut down R375 and 376 sense the output of

AC” comparator, and cause

AC is turned on.

“+18V’

64, 65 each subtract a diode drop

a

IOV zener

R356,

or R349 open or missing -- breaks feedback to U16

rail with about

“+16V”

rail with about

diode , plus diode

0.5V,

bringing the net voltage at

and R349 form a closed-loop stability circuit which prevents the regulated voltage from

18.8V

Q99

to turn on. If

2OV,

or not until

18-19V.

typical.

(0.7V)

16.6V typcial.

D67,

subtract about 1 IV from

5OV,

from Cl38.

+16V

Q99

is shorted, the bias voltages will remain 33% low when

or blinks, DO NOT RAISE VOLTAGE PAST 60V

D63, 64_

Ul6,

feedback pin 4, to about

and

12OV

unit). If the bias supply is working

35V,

with its usual, steady

9OV,

65, 66, 67 and R349 as follows:

+16.6V.

5.lV.

toraise

+18V

or lower the

supplies

flyback

Ul3:3,

“half-brighf’

so you can save

voltage

the “Loss of

14

REPLACING BLOWN TOP-210.

If U16 has blown, check T-l for continuity after removing

measure about 15 ohms

Ul6.

Its primary may be open. Pins I-2 It should

Replacing Blown Output Transistors

OUTPUT TRANSISTOR SHORTED

Stmrk

in one device tend to cause the opposing device to blow as

If an output transistor shorts:

Drive transistor will be shorted

CXNne

transistors will short in pairs (Q39 &

The rest will short in fours

IGBT’s

8 their associated components may

(Q26, Q27, Q71,

(Q28, Q29,

Q34 &

Q72)

Q40,

Q36 &

Q35; Q73, Q74, Q79 8, Q80)

fail

well,

Q37, Q84

8

Q85, Q81 8, Q82)

Page 19

CHECK EMITTER AND BASE RESISTORS WHILE DEVICES ARE REMOVED,

Each output transistor has an associatated pair of 0.47 ohm resistors in parallel.

Each BANK of output transistors has a 15 ohm resistor from base to rail (emitter bus).

Audio Outputs, Troubleshooting Current Limit

WEAK CURRENT LIMIT -- PREMATURE CLIPPING.

The usual symptom of weak output current is premature clipping of one or more peaks of the audio voltage.

This could be caused by missing step, weak current limit, or dead output section.

PREMATURE CLIPPING at 60% VOLTAGE, SIMILAR AT ALL IMPEDANCES:

This points to a step problem (2402, 3002 only). See Step Troubleshooting.

If the amplifier reaches full voltage at 8 ohms, but prematurely clips at 4 ohms or 2 ohms, we can assume

the step is OK but the output current is too low (see below).

NO OUTPUT AT ALL ON ONE POLARITY.

This indicates complete failure (open circuit) in the circuit leading to the dead output polarity. Check the

series components in the current splitter for missing or open:

Ch 1:

Ch 2:

CONSTANT, PREMATURE CLIPPING, WORSE AT LOW IMPEDANCES.

First, check the clamping voltages on

table below. At idle, all four voltages should all be similar. If one is out, check parts according to the

following table

Positive,

Positive,

Ql9, R381, Q20, R70, DIO,

Q64, R383, Q65, Rl93, D35,

C21

(Ch

D14. Negative:

D39. Negative:

I+),

C22 (Ch I-),

Q22, R382, Q21, R71,

Q67, R384, Q66, Rl94, D36,

C56

(Ch

2+), C57

(Ch

Dl I, D12

2-),

as shown in

D37

CLAMPING VOLTAGES ARE WRONG AT IDLE

I+

CHANNEL-POLARITY

Measure voltage on:

3002 and 2402, about

1602, about

1202 about

Voltage too high: missing resistor:

Voltage

Voltage

Voltage wrong: wrong value

The exact voltage varies with temperature. Look for the mismatching value on the weak cell.

A too-low voltage causes early clamping of that output section, as explained in the previous several pages.

If the voltage is correct and current is still low, also check for missing - unsoldered output device, or emitter

resistors.

4,6V,

4.9V.

or missing transistor:

0-0.3V:

or missing resistor

0.7V,

missing resistor:

6V.

shorted transistor

CH

c21

R60

Q14

Ql4,24

R

51,

72

R59

R59,60

CH

l-

c22

R61

Ql5

Ql5,

25

R53,

75

R62

R62,61

2+

CH

C56

RI83

Q59

Q59,69

Rl74,

RI82

Rl82,

195

183

2-

CH

c57

RI84

Q60

Q60,70

Rl76,

198

RI85

Rl85,184

15

Page 20

Audio Power Stage, Current Limit Troubleshooting

CURRENT LIMITS WHICH COLLAPSE PREMATURELY.

An immediate collapse of ALL current limits at full power could be premature triggering of “Power Supply

Cutback”, which is described in the section below. Cutback after several seconds of full power operation at

two ohms is normal.

Cutback of one or more output sections, at full temperature, while approaching full power into two ohms is

also normal. However, cutbacks at 4 ohms, or when cold into two ohms, indicate problems with the

transistor power measuring circuitry.

CLAMPING VOLTAGES COLLAPSE TOO SOON.

CH

CHANNEL-POLARITY

Measure voltage on:

Cuts back too easily: low value,

or high value: R 51,

or missing diode:

CLAMPING VOLTAGES ARE CORRECT, CURRENT STILL WEAK.

Shorted diode

Missing-unsoldered output device or emitter resistor.

TROUBLESHOOTING “POWER SUPPLY CUTBACK”.

As noted in the section on Power Supply, the amplifier’s current limit cuts back when necessary to protect

the power supply. Because the Observed effect is a reduced output voltage, in response to prolonged

operation above the long-term current limit, we commonly refer to this behavior as “power supply cutback”,

but we must remember that it is actually

from the power supply. Full power operation into 2 ohms (both channels) should produce a 50% cutback of

current after several seconds.

If both channels of the amplifier fail to cut back after about 3 seconds, 2-ohms, both channels driven, the

cutback signal is probably missing. CAUTION: Prolonged operation under these conditions could blow

IGBT

or burn out

Check the output (secondary side) pins of U17 (sh 4). Confirm presence of

normally be at about

If

Ul7-pin

4 does not go high, check U17 itself. If it appears OK, trace the circuitry driving U17 (PRIMARY

SIDE, CAUTION). Check for continuity through

R347,

all of which drive optocoupler U17. A short in R346 or Cl31 will also prevent drive to U17.

If

Ul7-pin

4 goes high on schedule, and BOTH channels fail to cut back, trace voltage on

R273 (sh

(sh 2). If only ONE channel fails to cut back, look for missing

(sh 2).

Cl31 controls the speed of cutback.. If missing, the amplifier current limits will enter cutback almost

immediately at or above full power, 4 ohms.

Cl44.

Test for 6-10 seconds maximum.

OV,

and go high (I-5V) after 3 seconds at full power,

3),

which connects to “MUTE+” bus. Continue tracing voltage on MUTE+ to

I+

c21

R67,

73

72

D9

DIO, 14

amp/Tier

CH

l-

c22

R68,

74

R53,

75

D8

Dll,

12

current

L6:2

hmifhg

in response to an overload signal sent

to Pri-Lo, check missing or open

Ql6,

CH

2+

C56

Rl90,

Rl74,

D34

D35,

39

+6V

R 65,

Ql7

CH

2-

c57

196

195

on pin 5. Pin 4 should

(sh I) or

Rl91,

197

Rl76,

198

D33

D36,

37

R343, D61, Q95,

“PS_OL”

Ql6

(sh I) and

Q61, Rl88, Q62

bus to

Q61

16

SHORT CIRCUIT CURRENT DOESN’T CUT BACK.

CAUTION: DO NOT MAINTAIN A SHORTED LOAD IF CUTBACK FAILS TO OCCUR WITHIN 1 SECOND.

It will be necessary to measure the output current with a DC current probe, or by noting the voltage across

a low value resistance with a DC scope, in order to determine which output cell is failing to cut back.

Failure to cut back could indicate either lack of clamping, or lack of voltage cutback. Measure the voltage

on the respective clamp capacitor. If the voltage decreases, but current limiting does not cut back, check

the clamping transistor.

:

Page 21

CLAMPING VOLTAGE DECREASES, BUT NO CURRENT CUTBACK

CHANNEL-POLARITY CH

Measure voltage on:

Check clamp transistor

If the measured voltage on the clamp capacitor is not decreasing to about 50% during the short, check the

circuitry which measures the current during short circuit,

CLAMPING VOLTAGE DOES NOT DECREASE TO 50% DURING SHORT.

CHANNEL-POLARITY

Measure voltage on:

Missing cutback transistor, resistor

Missing voltage sense resistor,

Shorted or low value shunt resistor R72

I+

c21

Q18

CH

I+

c21

Q24,

R67

R 73 R 74

CH

c22

Q23

CH

c22

Q25,

R75

l-

l-

R68

CH

2+

C56

Q63 Q68

CH

2+

C56

Q69,

RI90

RI96 RI97

RI95

CH

C5?

CH

c57

Q70,

RI98

2-

2-

RI91

Troubleshooting Thermal Tracking

MOUNTING PROBLEMS WITH IOK SENSING NTC.

The thermal sensing for fan and bias tracking depends on a 1 OK NTC which is mounted in a hole in the

heat sink. The hole is filled with thermal grease to improve coupling. If the NTC is not straight while

mounting the heat sink, it may short out against the side of its hole. It is mounted on a standoff which

protrudes into the hole, so this should not occur if care is taken while installing the heatsink.

If shorted to the heat sink, the amplifier output voltage is coupled to the NTC. If the short is to the grounded

lead of the

which will probably damage it.

SHORT FROM “LIVE” END OF NTC TO HEAT SINK:

Replace affected NTC

BE AWARE! This can short (relatively) quietly and then appear to be operating normally. Poor bias

tracking can indicate this problem. Sometimes this short will not happen until the amplifier is driven past IV

input.

NTC BENT OVER AND SHORTED TO DRIVER TRANSISTORS.

May touch

This causes severe overcurrent to the affected output cell, possibly damaging the parts in series with the

shorted transistor. It may also blow the power supply.

Replace affected

NTC,

it may not damage anything. If to the other end, a large voltage is put across the NTC

Ql9, Q26,

Ch 1:

Ch 2:

or

Q64, Q71.

NTC,

drive transistors, check components in series with drive transistor

Ql9

shorted, check,

Q26 shorted, check ALL outputs and opposing driver transistor on this channel.

Q64 shorted, check

Q71

shorted, check ALL outputs and opposing driver transistor on this channel.

R381, Q20, R70, DIO,

R383, Q65, Rl93, D35, D39.

D14.

17

Page 22

Audio Output, Troubleshooting Stability Feedback

HIGH FREQUENCY OSCILLATIONS

SEVERE-DRAWS CURRENT-GROSS DISTORTION

C27 (62) missing or wrong, or series R367 (368)

C 25, 26 (60, 61) missing

Secondary filter capacitors missing or open (unlikely that ALL are defective).

SEVERE, BUT DOES NOT DRAW LARGE CURRENT

R22 (146) open.

MARGINAL -- MAY APPEAR ONLY AS EXCESS DISTORTION

Cl4 (49) missing

Cl 6 (50) missing or too large

C28 (63) missing

C 25 or 26 (60 or 61) missing or too large

Cl95 or 196 missing (input board).

EXCESSIVE OSCILLATION JUST BELOW CLIPPING, 2-4 ohms

Cl 7 (52) missing

NOTE: about 0.1% oscillation right below clipping at 2 ohms is normal.

EXCESSIVE SWITCHING INTERFERENCE.

Switching interference may LOOK like an instability, however it is at a much lower frequency

most instabilities. It will be more visible at low frequencies

Missing jumper at

Missing

Grounds not connected to chassis at output board and front chassis mounting screw.

Cl29,

R224.

134 on output board.

(2OOHz)

and at lower impedances.

(1lOkH.z)

than

FEEDBACK PROBLEMS: GAIN INCORRECT

Gain of output stage set by

Gain of Ch 1 volume control buffer stage set by RI 1, 16.

Gain of Ch 2 volume control buffer stage set by

at Q48 should not affect gain. Check RI 32 (drives Q48).

Gain of balanced input is set by 4 matched resistors

of balanced input are working. Check

R23,

31 (147, 153)

R5,

6 (123, 124).

Rl37,

139. Make sure

R9,

8, 12, 13 (129, 130, 135, 136). Confirm both sides

Q48

is turned on - grounding

Audio Output, Troubleshooting Clipping, Limiting

EXCESS STICKING (TOO MUCH DISTORTION DURING CLIP LIMITING)

Cl4 (49) much too large (also causes increased high frequency distortion).

R38 (161) missing.

R38-39

(161-162) have wrong values.

Q9,

10 (54, 55) missing

R34 (157) or

Q8

(53) missing

R35

(158) missing

RI37

18

Page 23

CLIP LIMITING DOESN’T WORK:

BOTH CHANNELS:

Check U3 missing,

Check U3 supply voltages, +I

ONLY ONE CHANNEL BAD:

Probe output of U2

R38 (161) missing.

R38-39 (161-162)

Q9,

10 (54, 55) missing.

R34 (157) or

Q8 (53) missing

(7),

pin 7 while clipping. If output exceeds 4V during clipping, check

have wrong values.

R35

(158) missing

3VCL, -13VCL,

on

C73*

74

:

If output at pin 7 clamps at

R32 (154) missing

Q7 (52) missing

R28 (151) missing

Q6 (51) missing

RI8

(141) missing

RI9 (142) missing

SW I:1 (1:lO) not making contact

Check each pin on U3

CLIP LIMITING OSCILLATES:

Cl 3 (48) missing.

R21,

27 (144, 150) missing

3.5.4V

as expected, check parts surrounding U3:

Troubleshooting Step Problems

EXCESSIVE STEP DISTORTION (STEP GLITCH)

Close scrutiny of the distortion trace, and scope probing of the switched waveform, will help determine the

cause of excess step distortion, The step should switch when the output voltage is within IO-12 volts of its

respective rail, This switching margin should be fairly constant from

should be a fairly uniform up and down ramp, moving at about 25 volts/us, therefore taking about

complete its transition.

Step Switching Too Close to

This will cause increased step glitch, especially at low impedances. If present at all frequencies,

check the reference voltages:

Negref: 17.5 volts above its intermediate rail:

PosRef:

20V below its intermediate rails:

the

Rail:

D88, R276-7-8.

D87, R256,

257,

20-

20kHz. The switching event itself

D53.

2us

to

Confirm correct values in output voltage divider: R48 loaded by

only at high frequencies, check the value of the speed up capacitor

or look for slow switching (see below).

R49-50 (Rl71,

C20 (C55)

and

Rl72-173).

in the output voltage divider,

If present

19

Page 24

Step Chattering.

If the step repeatedly switches on and off, usually at a low frequency, it creates an oscillation burst

which increases step glitch at low frequency. The tendency is usually worse at low impedances

and low frequencies. 2-3 “false trials” at very low frequency, 2 ohms, is normal, but prolonged

bursts of maximum frequency chattering may cause FET failure.

Positive step: check hysteresis resistor R66 (RI 89)

Negative step: check hysteresis resistor R69 (RI 92) and capacitor Cl 87 (Cl 93).

Slow or Fast Switching.

Slow switching reduces step glitch but puts more strain on the FET. Fast switching increases step

glitch. The usable limit is

If both slopes are equally off speed, check the slope capacitors:

Positive,

If only one slope is slow, check the resistors and buffer transistors:

Positive step:

Negative step:

Step FET Oscillation.

Certain FET types oscillate at extremely high frequency while ramping up and down. This injects

interference into the amplifier which increases the step glitch. Such problems are supposed to be

found while

know.

STEP WON’T TURN ON (Premature Clipping)

If the step refuses to switch high, the amp will clip prematurely, at the intermediate rail, at any load. Make

sure the clipping is not

and intermediate rail voltages to confirm clip point and lack of step action. Trace the circuit from the step

FET back via gate drive to drive circuit to locate cracks, missing part etc. Check DC power on step driver

(14V

on EACH positive step drivers,

+65V

rail) or Negref

ladders.

C30 (C65)

R78,

R83,

(dis)qualifying

acually

(17.5V

above

17-27

volts/us,

and Negative, C29 (C64).

79,

Dl5, Q30-31 (R201,

84,

Dl7, Q32-33 (R206,

specific FET types. If they crop up in production, Engineering needs to

current cutback, usually evident only at 2 ohms. Probe the output voltage

12V

on BOTH negative drivers). Check voltage of

-65V

rail). Look for severe mismatches of the comparator resistor

202,

207,

D40, Q7576)

D42, Q77-78).

PosRef

(20V below

STEP STUCK ON (Switched Rail Voltage Stuck On Full)

If the positive step is stuck on, (evidenced by permanent high voltage on switched rail) the FET is probably

bad, since the positive gate drive cannot sustain DC turn-on due to the bootstrapping. If the negative step

is stuck on, it could be a bad

confirmed by measuring the gate voltage. Malfunctioning gate drive circuitry should be checked as noted

above under “Won’t Turn On”.

REPEATED FET FAILURE.

Repeated failure of step

region). The actual failure usually occurs at 2 ohms, where the dissipation is highest. After replacing the

FET,

the step waveform should be monitored, starting at light load to avoid repeated failure, and advancing

briefly to heavier loads while closely watching the waveform. You will need to use an isolated scope probe

which allows voltage readings to be taken with respect to the intermediate rails, or to FET sources.

FET Does Not Fully Turn On:

Generally causes problems at low frequency, 2 ohms.

Confirm that the step FET remains fully on for the entire cycle

drive and determine cause.

Weak positive drive: check voltage on C32

missing D18

Weak negative drive: check voltage on

FET,

or the gate drive circuit could be holding the FET on, which will easily be

FET’s

is usually caused by failure to fully switch ON or OFF (lingering in the linear

(2OHz).

If not, confirm weak gate

(C51)

for

14V.

(Dl48).

Check

R78, Dl5, Q30 (R201, D40,

C67, 12V.

Check

Check

Q75).

R83, Dl7,

C31 (C66),

Q32

(R206, D42,

low RIO4

(R227),

Q77).

20

Page 25

FET Turns On or Off Very Slowly:

Generally causes problems at high frequency, 2 ohms.

If both slopes are equally slow, check the slope capacitors:

Positive,

If only one slope is slow, check the resistors and buffer transistors:

Positive step:

Negative step:

Severe Step Oscillation.

Generally observed at low frequency, low impedance, right at threshold.

Positive step: check hysteresis resistor

Negative step: check hysteresis resistor

C30 (035)

R78,

R83,

and Negative, C29 (034).

79,

Dl5, Q30-31 (R201,

84,

Dl7, Q32-33 (R206,

R66

R69

202,

(RI 89)

D40, Q75-76)

207,

D42, Q77-78).

(RI 92) and capacitor Cl 87 (Cl 93)

Troubleshooting DC Fault Shutdown

NORMAL BEHAVIOR OF THE CIRCUIT.

Any amplifier fault which causes a non-symmetrical output, such as premature clipping of one polarity, a

missing step,

TRACING THE CAUSE OF FALSE TRIGGERS.

If amplifier is shutting down for no apparent cause, the source of the false signal must be found. Be sure the

output is checked with a DC coupled scope in order to confirm absence of an actual DC offset. The circuit

will trip on DC offsets exceeding about

etc,

may trigger DC fault shutdown. This indicates normal operation of the circuit

4V.

The optocoupler’s input can be safely disabled by shorted

triggering is before or after

The output of

signal.

SHUTDOWN OCCURS AS SOON AS SWITCHING STARTS.

Disable

series with AC line to limit fault current in case of shorted outputs.

If amplifier output looks OK, check UlO:l output. If low, check voltage on pins 2 and 3

UlO:l,

UlO:l,

Check R348 at Ul.5.

SHUTDOWN OCCURS ABOVE ABOUT 4V OUTPUT:

Q87, C7, R240

Confirm D48 is pulled low

NOTE: this control voltage responds to the Br Mono switch, pole

Check R348 at

Bad connection at step diodes

UlO:l,

Ul5

as noted above, determine if there is a DC fault condition. CAUTION: use

pin 2: should be zero (no signal)

pin 31 should be about

or D48 missing.

Ul5.

Ul5.

pin 1 should be monitored. If it goes low during DC shutdown, it is sending the false

2V!

set by

(-13V),

holding Q87 on. If not, check RI 17, 118, Q42

(D21, D22, D46, D47)

R243,

244, 245.

Ul5,

pins I-2 together. This will indicate if false

7.

50-ohm

resistor in

21

Page 26

Fan Speed Troubleshooting

FAN STUCK HIGH:

Q88

or Q89 failed

R30

or

Rl55,

Thermal Sense

R266 or

FAN DOESN’T RUN

Check fan voltage, should be 1 IV when cold, 29V when hot.

Voltage OK -- replace fan.

No Voltage: check

R271

missing.

Q91,

NTC,

shorted to

89, 90, R264 and 265 missing. Confirm that

heatsink

+/-15V

is reaching circuit.

22

Page 27

PLX 1202 PCB ASSEMBLY

(12OV)

PLX 1202 PCB ASSEMBLY

(12OV)

Cont’d

Part Number

CA-01 0002-30

CA-01

5002-10

CA-I 10002-30

CA-I 33001-10CAP SM 330PF 5% 500V

CA-I 47003-30CAP 470PF 5%

CA-168003-30CAP CER 68OPF 5%

CA-21

0005-30

CA-222001-00CAP CER Y

CA-227001-30CAP CER .0027UF 10%

CA-233001-10 CAP MYLAR

CA-233002-00CAP CER Y

CA-322001-10 CAP MYLAR

CA-410001-00 CAP MET POLY

CA-410002-10 CAP MYLAR

CA-410003-10 CAP MET POLY

CA-410006-30CAP CER

CA-410011-00 CAP MMYL

CA-422001-10 CAP MYLAR

CA-447001 -00 CAP MET POLY

CA-447003-00 CAP POLYP

CA-51 0005-30

CA-510006-00 CAP MPOLY X

CA-61 0002-10 1 OUF,35V,2O%,RADlAL

CA-647001 -10

CA-647002-1 0

CA-71 0002-10

CA-71 0004-10

CA-747001 -10

CA-747004-00 CAP LYTIC RL 47OUF 20%

Description Reference

CAP 1 OPF 5% 50V 0805 SMT

CAP CER

CAP CER 1 OOPF 5%

CAP ,001

CAP LYTIC 1 UF 20%

CAP LYTIC RL 47UF 10% 1 OV NP

CAP LYTIC RL 47UF 20%

CAP LYTIC RL 1 OOUF 20%

CAP LYTIC RL

CAP LYTIC RL 47OUF 20%

15PF

10%

5OOV

5OV

5OV

1206 SMT

5OV

LJF

5%

5OV

1206 SMT

.0022UF

20%

.0033UF

10%

.0033UF

20%

.022UF

10%

X.lUF

.lUF

5%

IOOV

.lUF

10% 250V

.lUF

10% 5OVX7R SMT

.lUF

10% 400V

.22UF

5%

X.47UF

.47UF

10% 400V

5OV

IUF

20% 25OVAC Cl 10,112

IOOUF

20%

IOOV

20% 250V Cl26

5OV

20% 250 Cl 17

ELECT

c14,49

0805

25V

25V

16V

1OOV

Cl6,50

C40,41,43,

C5,6,9,18,

c53

Cl45,146

Cl,2,4,17,

c119,121,

Cl48,181,

Cl82,186,

Cl88

C26,36,37,

C52,61,

Cl20,124,

Cl95,196

C75,81,85,

ClO8,109,

Cl28

C20,23,24,

C55,58,59,

Cl13

Cl 15,118

C27,62

c47

C8,12,44,

Cl29,134,

Cl56,157

C28,63,

Cll6,125,

c135,155,

Cl62,163,

Cl79,180,

Cl83,185,

Cl89,190,

c19,39,54,

Cl91

ClO7,123

c10,45

Cl44

Cl3,48,184

Cl92

C3,38,80,

C86,114,

C46,71

C7,11~42~

C21,22,56,

C57,89

c139,142,

Cl43

Cl5*33,72!

C78,79,

Cl38,149,

Cl50

C73374>763

c77,131

Cl52,153,

Cl59,160,

SL

NPO SM

NPO SM C25,60

125VAC Cl22,127

IOOV

125VAC

IOOV

SMT

5OV

Part Number Description

CA-822200-AE CAP LYTIC RL 22OOUF 20% 200V Cl 32,133

CH-000102-00 HEATSINK, AUDIO, PLX

CH-000103-00 SPRING, CLAMP, 2 HOLE

CH-000104-00

CH-0001 1 I-00

CH-000114-00 CLAMP, 2 FINGER PLX

CO-000036-CO SPEAKONS, PC MOUNT J7,8

CO-000148-00 CONN XLR F VERT PCB

CO-000155-00 HEADER PCB ,100 2-POSITION

CO-000162-00 BNDG POST A, DUAL SLOT, PLX

CO-000163-00 BNDG POST

CO-3001

HW-OOOOOI-FC FUSE CLIPS

IC-000024-00

IC-000047-30 IC

IC-000048-30 IC

IC-000051-00 IC

IC-000053-30 IC

IC-000054-30 IC

IC-000073-30 IC

IC-000134-00 IC CMOS HV DRVR

IC-000135-00 IC

IC-005532-OPIC

MS-000048-HS

MS-0001 12-00 FUSE

PC-000531-00 PCB MAIN PLX

PL-000114-00

PL-000726-00 SPRING, SEAT, PLX

PL-000128-00 SPACER, LED,

PL-000135-00 INSULATOR, MICA 1.25” X 1.75”

PL-905156-SP

PT-125000-AT RES VAR IT 250 20%

PT-310000-CR

QD-000014-QD

QD-000042-00 DIODE RECT ULTRAFAST 400V 3

QD-000052-00 LED GRN T-l

QD-000053-00

QD-000054-00 LED RED T-l

QD-000062-10 XISTOR NPN TO-92 40V 0.2A 1.5 Q20,65

QD-000063-10 XISTOR PNP TO-92 40V 0.2A 1.5

QD-000076-00 XISTOR NPN TO-220 250V

QD-000077-00 XISTOR PNP TO-220

QD-000102-30 DIODE SW IN4148 SMT

QD-000103-30 XISTOR NPN SMT 40V

HEATSINK

BRACKT,OUTPUT

12-PJ

JACK

IC

REG PWM 40V O.lA

OPTO-IS0 MOC8101

HEAT SINK,

INSUIATOR, IGBTIRECT HS,

SPACER,ROUND,NYLON,#6,0.155 REF:Ll,2

RES VAR IT

DIODE TO220 ULTRAFAST 200V

LED YEL T-l

PS PLX

PCB PLC PLATFORM

B,

DUAL SLOT, PLX

1/4”

PHONE DBLOPEN CKT

SG3525A Ul9

LIN

DUAL COMP LM393 SO-8

LIN

DUAL OP AMP MC33078

LIN

SMT DUAL TIMER

LIN

SMT QUAD COMP LM339A

LIN

DUAL OP AMP

LIN

PWM SWITCH TOP 210

LIN

DUAL OP AMP 5532

ISOL

TO-220

25A 125V

3AG FAST CER Fl

,276”

IOK

20%

LM556

LMI

3600

lR2110

0.15W

0.2W

25OV

75V 75M Dl-5,8,9,

.2A .2W

Reference

Cl65,166,

Cl69,170

J2,lO

J13

Jl,9

REF: Fl

UIO

Ul,6

u1517

Ul4

Ul3

U3

Ul8

Ul6

EXIMP U2,7

REF:

PLX

LD2-LDI

REl55,LDl,

REF:R30,

REF:Q96,97

CAR

VR43,166

W/DE

VR2,121

D74,75,80,

D81

D70,71

LD2,3,4,7,

LD8,9,11

LDI ,6

LD5,lO

Q21,66

Q27,72

Q26,71

DIO-12,14,

D23-30,33,

D34-37?39_

D48-51,55,

D59,63,

D64,65,67,

D69,89,90,

D91

Ql3,15;18,

Q25,49,50,

Q91

Q5,7,&%

Q52?53,54?

Q58,60,63,

1

23

Page 28

PLX 1202 PCB ASSEMBLY

(12OV)

Cont’d PLX 1202 PCB ASSEMBLY

(12OV)

Cont’d

Part Number

QD-000104-30 XISTOR PNP SMT 40V

QD-000105-30

QD-000106-30

QD-000108-30

QD-0001 lo-30

QD-000113-30

QD-00011530 DIODE SMT RECT 600V IA

QD-000116-30

QD-000154-00 XISTOR NPN TO-220 230V

QD-000155-00

QD-000156-00 XISTOR PNP TO-220

QD-000162-00

QD-000170-00

QD-001302-PN XISTOR PNP TO-3P 200V

QD-003281-NP XISTOR NPN TO-3P 200V

QD-004744.ZA

QD-005402-DX DIODE RECT DO27 200V 3A

RE-.04703-10 RES MOFP

RE-

56002-10 RES MOFP 5.6 5% 2W MINI

RE-000210-NR

RE-000230-NR

RE-001003-30 RES SMT 10 OHM 5%

RE-001502-10

RE-003921-30 RES SMT 39.2 OHM 1%

RE-005606-10RES MOFP 56 5% 2W MINI

RE-007502-30

RE-010002-30 RES SMT 100 1%

Description

.2A .2W

XISTOR NPN SMT 300V

XISTOR PNP SMT 300V

DIODE SMT SWITCH 200V

DIODE ZNR 6.2V 5%

DIODE ZNR

DIODE RECT SMT 200V IA

XISTOR PNP TO-220 230V

XlSTOR,lGBT 2OAI6OOV

DIODE BRIDGE RECT 600V

DIODE ZNR

THERMISTOR NTC

THERMISTOR NTC

RES MOFP 15 5% 2W MINI

RES SMT 75 1%

IOV

5%

15V

5% 1 W 1

.47

5% 2W MINI

l/l

.2A .2W

.2A .2W

.3W

SMT

.3W

SMT

1OOV

15A

15A

N4744A D53,54

15A

CUR

IOK

5%

1/8W

1/8W

OW 1 OOV

IIIOW IOOV

.2A

3A 40

5OA

1206

50

LIM

120

Reference

Q70,89,90,

Q92,93,95

Ql-4,6,10,

Ql2,14,23,

Q24>42143,

Q44-48,51,

Q55,57,59,

Q68,69,87,

Q88,94,98,

Q99

Ql6,61

Ql7,62

Dl3,16,38,

D41,61,68,

D78,79

D56

D66

D58,60,86

D62*76,77j

D82,83

Ql9,64

Q22,67

Q91

Q96,97

BRI

Q28,36,39,

Q73181,84

Q29,37,40,

Q74,82va5

Dl9,20,44,

D45

RlO3,107,

R108,111,

RI

12-114,

R211,212,

R214,215,

R225,226,

R230,231,

R234-237

Raasa9,91

R92,102,

R203,221,

R354,355,

R373

R80,98,

R324

R30,155

R353,356,

R358,359

R209,210,

R213,216,

R367,368

R85-87,90,

R93,208,

R246-249,

R349,357

R372

RI24

R5,6,123,

Rl50,193,

RI 94,334,

~

Part Number Description Reference

R21,27,70,

R364,381,

R382-384

R71,144?

RE-027401-30

RE-038301-30

RE-047001-10

RE-047502.30RES SMT 475 1%

RE-053602-30

RE-063402-30

RE-110006-30

RE-115002-30

RE-120002-30

RE-122103-30 RES

RE-139002-10

RE-147502-30

RE-156001-10 RES

RE-159002-30

RE-175002-30

RE-178701-30

RE-190902-30

RE-210003-30

RE-212702-30

RES SMT 274 1%

RES SMT 383 1%

RES MOFP 470 5% 2W MINI

RES SMT 536 1%

RES

SMT

RES SMT 1 .OOK 1%

RES SMT

RES SMT

SMT2.2lK

RES MOFP

RES SMT

5.6OK .I% 1/4W

RES SMT

RES SMT

RES SMT

RES SMT

RES SMT

RES SMT

l/l

OW 1 OOV

l/lOW IOOV

l/lOW IOOV

l/l

OW 1 OOV

6341%1/8W

1.5OK

1%

l/lOW