Page 1

MF 70 cnc-ready

Manual

Page 2

4

8

7

3

5

11

6

9

1210

2

1

-4-

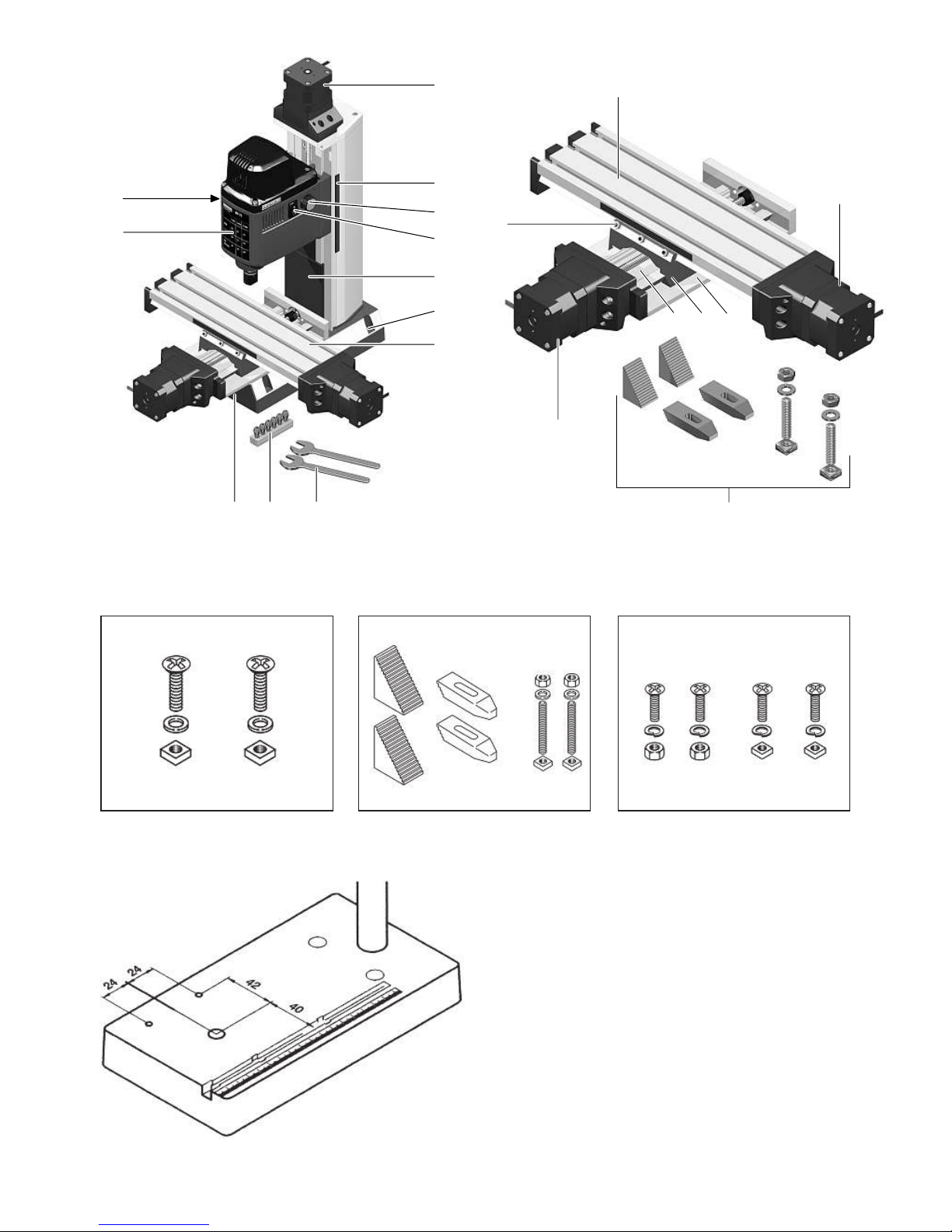

Fig. 1a

7

1

6

8

2

3

45

Fig. 1b

abc

M4 x15M4x40 M4 x15

Fig. 2

Fig. 3

Page 3

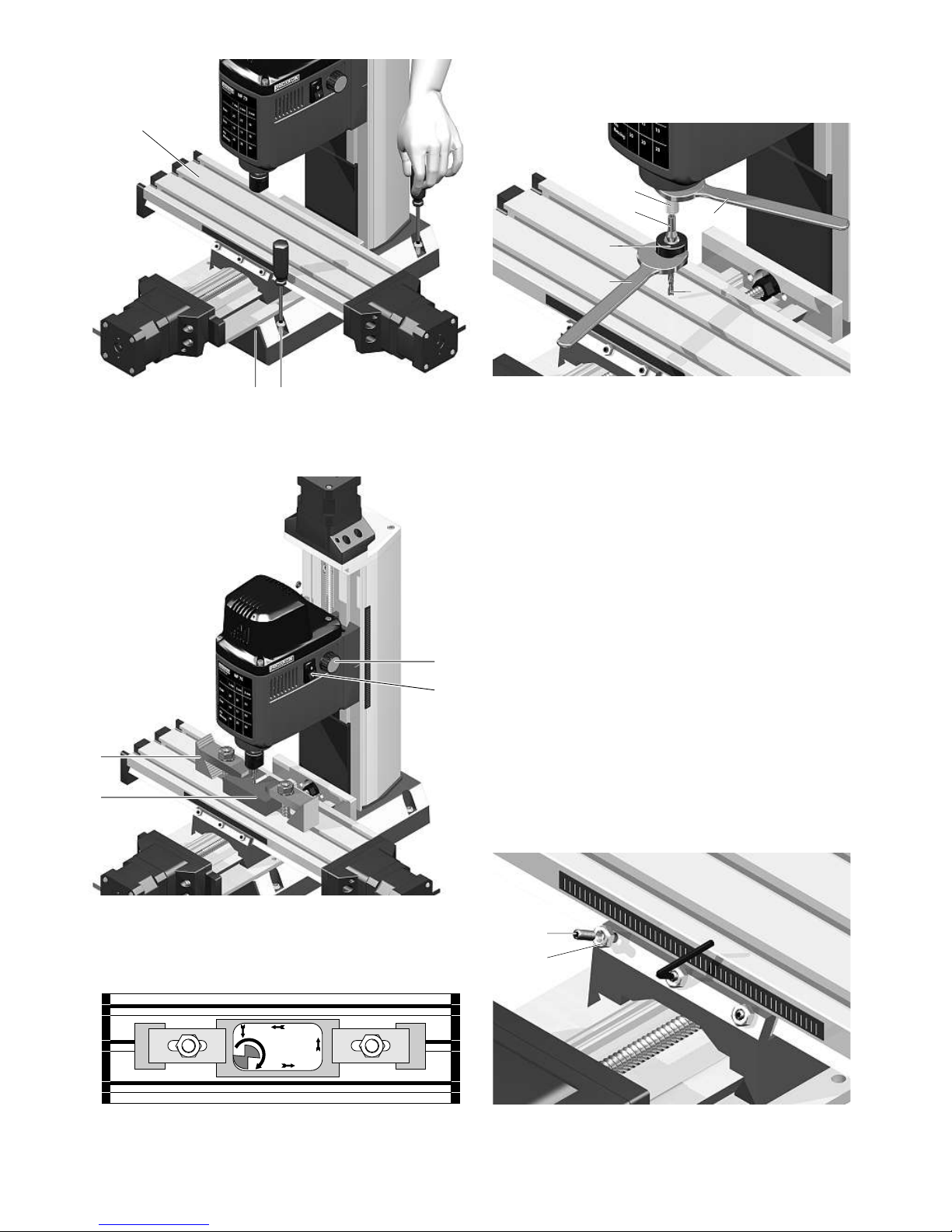

2

4

3

1

2

1

-5-

1

3

2

1

4

3

2

2

5

Fig. 6

Fig. 4

Fig. 5

Fig. 8

Fig. 7

Page 4

-10-

Translation of the Original Operating

Instructions Micro miller MF 70 CNCreadyand compound table KT 70 CNCready

Dear customer!

Regardless of whether you have purchased aMicro miller

MF 70 CNC-ready or the compoundtableKT70CNCready, you have carefullydesigned and manufactured

equipment for all fine, precision milling operationsinvolving

metal, plastics or wood at your disposal.

Designed on the basis of our proven Micro miller MF 70

and compoundtableKT70models, the CNC-readyversions

of both products offer the same features in each case, but

are fitted with stepping motors instead of the familiar

handwheels.

These take charge of traversing of the compoundtable

carriageand the milling headduring milling operations.

ACNC controlsystem (not included in the scope of

delivery) is responsible forsupplying the stepping motors,

thus enabling traversing in all three axes.

Thecolumn and compoundtableconsistofhigh-precision,

surface-compacted aluminiumand areequipped with

adjustabledovetail guides whichare free of play.The

stable basis of the Micro millerMF70CNC-ready is providedbyaheavy machine base made of greycast iron.

An extremely low-vibration,carefully balanced 24-pole

high-performance DC motor ensures thatthe Micro miller

MF 70 CNC-ready exhibits quiet and uniform running characteristics,and electronic controlateveryspeedfrom

5000 to 20000revolutionsper minute provides adequate

power whichenablesaccurate machining with even the

smallest milling cutter diameters!

The clamping jawset included ensures thatthe workpieces

to be machined aresecured safelyand reliably.

In addition, the scope of deliveryofthe millerincludes a

colletset with sixclamping jaws with apractical selection

of diameters of 1.0 -1.5 -2.0 -2.4 -3.0 and 3.2 mm held

in an orderlyfashion in acollet block. Carefullyselected

material and targeted hardening contribute to along

servicelife,while the triple slotting ensures maximum precision.

Our comprehensiveand carefully compiled accessory

range providesyou with alarge selection of machining

tools of everykind. These can be found in our equipment

brochure or on the internetatwww.proxxon.com.

We are confident thatyou will be impressed by the successfulmachiningresults achieved and we hopeyou enjoy

using our compound table KT 70 CNC-ready or the

completemiller MF 70 CNC-ready!

1 Micro miller MF 70 CNC-ready(Article 2712,

Fig. 1a):

1.1 Key to general view

1. On/Off switch

2. Speed controlknob

3. Scale forZ-axis

4. Motor for Z-axisspindle drive

5. Spindle cover

6. Compound table KT 70 CNC-ready

7. Adjusting screws

8. Table forspindle speeds

9. Collets

10. Machine base

11. Hole forbase fixing

12.Wrenches

1.2 Technicaldata:

Miller

Voltage: 230 Volt, 50/60 Hz

Capacity: 100 Watt

Spindle speed 5,000 –20,000/min

Overall height (approx.): 400 mm

Z-axis traversing path (approx.): 70 mm

Mass: 7kg

Noise generation70dB(A)

Vibration 2.5 m/s2

Please notethatthe sound and vibration measurementsin

particularhavebeen performed with Proxxon bits and cutters. When usingthird-party brands we cannotguarantee

compliance with the statements givenhere!

1.3 Scope of delivery:

•Miller spindle with Z-column and robust base,stepping

motor and connectingcable

•Compound tableKT70CNC-ready with stepping

motors, mounting parts and connecting cable

•

Colletblock (colletØ1.0, 1.5,2.0, 2.4,3.0 and 3.2 mm)

•Operating tools

•Operating and safetyinstructions

2 Compound table KT 70 CNC-ready

(Article 27114, Fig. 1b):

2.1 Key to general view

1. T-slot table

2. X-axis drivemotor

3. Baseplate

4. Support

6. Y-axis drive motor

7. Adjustingscrews

8. Clamping jawset incl.mountingparts

GB

Page 5

-11-

2.2 Compoundtable KT 70 CNC-ready (Fig. 1b):

Table size 250 x70mm

Traversing paths (approx.):

X-axis 150mm

Y-axis 70 mm

T-slot dimensions 12 x6x5mm

T-slot spacing 25 mm

Mass: 2kg

2.3 Scope of delivery:

•Compound tableKT70CNC-ready with stepping

motors and connecting cable

•Mountingparts

Fig. 2a Screws/nutsfor clamping the machinevice MS

4

Fig. 2b Clamping jaws

Fig. 2c Mounting parts forfixing the coordinate table

•Flexible spiralhose

•Operating and safetyinstructions

Use only in dryrooms

Pleasedonot dispose of thiselectrical

machine in the household waste!

Foryour safety,always wear hearing

protection whileworking!

3 Mounting the Micro coordinate table KT 70

CNC-readyonthe PROXXON drill stand MB

200, MB 140 or PROXXON table drilling

machine TBM 220 (Fig. 3)

TheMicro coordinate table KT 70 CNC-ready is ideally suitable foruse in combinationwith the PROXXON drill stand

MB 200, the MB 140 or the PROXXON table drilling

machine TBM 220. It is, forexample, perfectfor semi-automatic coordinatedrilling!

Aconventional MF 70 can alsoberetrofitted with this

device, althoughautomatic operationofthe Z-axis is then,

naturally enough, no longeranoptioninthis configuration.

The existing compound table can be simply replacedfor

thispurpose. TwoM4threads should first be cut in the

worktop as depicted in Fig. 3for usewith the PROXXON

drill stand or the PROXXON table drilling machine TBM 220.

1. Pilotdrillthe threaded holeswith adrillbit (ø 3.3 mm)

and countersink the holes. Then cut the threads with

an M4 tap.

2. The Micro coordinate table KT 70 CNC-ready can now

be fixed to the drill stand base with the aid of the M4

threaded holesand the mounting parts providedwith

the device.

4 Miller setup (Fig. 4):

Caution:

Pleaseensure thatthe mains plug is pulled out of the

socket during all assembly,setup or adjustingwork! A

failure to do thismay result in the inadvertentstartingof

the machine, damage and injury.

Caution:

Themiller should be screwed securely to astablesupporting surface foroperation! Four holesare provided in the

device basefor thispurpose with which the millercan be

screwed to an appropriate supporting surface using suitable

bolts(3)!

The compound table (Fig. 4) can thenbefixedtothe base

using the 4M4Allen screws provided. The compound table

carriage mayneed to be traversed for thispurpose in order

to move the carriage and worktabletoensure access to

the screwholes.

Caution: No control system shouldbeconnected to the

machineifthe spindles arerotated manuallytotraverse

the carriage!

Following connectionofthe plug connectors to the control

system,the wiring should be sheathedinthe spiralhose

provided.

5 Fitting the collets (Fig. 5):

Caution:

Pullout the mains plug priortoany adjusting, setupor

assemblywork, as there is otherwisearisk of injuryor

possible damagetothe device!

Alwaysinsertasuitable tool in the collettotightenthe

union nut! Tightening the union nut without an appropriate

shaftwill damagethe collet!

All operational tools should be clamped as short as

possible! Shafts protruding too far will vibrate and result in

poor milling results.

1. Hold the spindle1firmly on the flats with one of the

wrenches 2provided and releaseand remove the

union nut 3.

2. Insertthe desired collet4into the spindle and tighten

the union nut 3slightly by hand.

3. Insertthe desired tool 5into the collet. Caution:

Ensure thatthe tool shaftdiameter corresponds to the

inside diameter of the collet!

4. Hold the spindle firmly with the wrench and tighten

the union nut firmly with the second wrench.

Page 6

-12-

6 Selecting the spindle speed

Themiller is equippedwith an electronic speedcontrol

system. This enables the continuousadjustment of the

spindle speedwithin arangefrom 5000-20000rpm to suit

different materials, tool feed speeds, infeeds and milling

cutter diameters. Optimum adaptationofthe milling parameters is therefore possible to suit all operating conditions

encounteredunder practicalcircumstances.

Fundamentally speaking, the following apply:

Higherspeeds Smallermilling cutter diameters

High feed

High infeed

Lower speeds Greatermilling cutter diameters

Lower feed

Reducedinfeed

The table on the front of the millerprovides assistance

when selecting the right spindlespeed.

7 Working with the miller (Fig. 6)

Caution:

Wear protective goggles when milling.Itisimperative that

the safety instructions included be observed!

TheMicro millerMF70CNC-ready and compoundtableKT

70 CNC-ready weredesigned for fine, precision work.

Decisive milling parameters such as infeed or feed should

therefore be adapted in the software you are using.

Pleasenote that, in addition to negatively influencing the

working results, mechanicalorelectricaloverloadingofthe

machinealso strikingly increasesmachinewear,particularly

on the drive, bearingsand guides.

1. The workpiece 1should be fixed reliably and safely

using either the clamping jaws 2provided or another

appropriate clamping medium.

2. Realisethe milling process. Ensure thatthe switch 3is

in the “On” position. The motorshould be activated

manually if the CNC controlsystem does not support

automatic activation and deactivation of the spindle

drive.

3. Set the appropriate speedwith the knob4ifnecessary.

4. Ensure thatthe feed speedand infeed depthare

appropriate!The milling cutter should operate during

counter rotationasillustrated in the diagram in Fig. 7.

This means thatthe motionofthe milling cutter

cutting edge should alwaysbecounter to the feed

direction!

8 Maintenance and care

Thedeviceismaintenance-free, apart from the necessity

for regular cleaning and,whererequired,readjustment and

lubrication of the guides. Thetasks necessaryinthis

respect aredescribed below.

8.1 Adjustmentofplay in the dovetail guides (Fig. 8)

Caution:

Pullout the millermainsplug priortoany adjusting, setup

or assemblywork, as there is otherwisearisk of injuryor

possible damagetothe device!

Boththe millerand the compound table areequipped with

adjustable dovetail guides. These provide an option for

counteracting mechanicalwear whichoccurs naturally

when working with the millerorcompound table. The

guides can be readjusted simplyifthe play becomestoo

greatafter asufficiently long period of use. Please note

thatthe procedurefor the miller and compoundtableisthe

same.

1. Loosenthe hexagonal nuts 1.

2. Screw in the setscrews2slightly with asuitable Allen

key. The setting is correct if play is minimal, but the

guide still works smoothly.

Please note:

Excessive tightening of the setscrews results in increased

wearand maydamage the guide!

3. Following successful adjustment, hold the setscrews

in the correct position with an Allenkey and counter

lockbytightening the hexagonal nuts.

Accessories

Formore detailed information on accessories,please

request our device catalogue from the address specified on

the last page in the warranty information.

Please noteingeneral:

Proxxonbits and cuttershavebeen designed to work with

our machines, whichmakes them optimal for theiruse.

We will not assumeany liabilitywhatsoever forthe safe

and proper function of our devices when using third-party

bits and cutters!

8.2 Cleaning

Caution:

Alwayspull out the millermainsplug priortomaintenance,

cleaning and repairs. Inadvertentactivation mayresult in

injury!

Page 7

-13-

To ensure along servicelife,the machine should be

cleaned with asoft cloth, handbrushorpaintbrush after

each use. Useofavacuum cleaner is alsorecommended

here.

Theoutside of the housing can thenbecleaned with asoft

cloth, dampened if necessary. It is possible to use mild

soaporanother suitable cleaning agent. Solvents or cleaning agents containingalcohol(e.g. petrol,cleaning alcohols,

etc.) shouldbeavoided, sincethese can attack the plastic

parts.

It is besttoapply adrop of machineoil to moving parts

occasionally.The milling headguides and compound table

should be lubricatedatregular intervals.

8.3 Repairs:

Caution:

Always pull out the mainsplug beforemaintenance, cleaningand repairs. Inadvertent activationmay result in injury!

Repairs should only be realisedbyqualified skilledpersonnel or,better still,bythe PROXXON CentralService! Never

repairelectricalparts, butalways replace them with

original PROXXON spare parts!

9 Disposal

Pleasedonot dispose of thismachineinhouseholdwaste!

Thedevicecontains valuablematerialswhich can be recycled. If you have anyquestions in this respect,please contact your localdisposalcompanyorother relevantcommunal facilities.

10 EC Declaration of Conformity

Name and address:

PROXXON S.A.

6-10, Härebierg

L-6868 Wecker

Product designation: MF 70 CNC-ready

Article No.: 27112

We hereby declareonour sole responsibilitythatthis

product conforms to the following directives and normativedocuments:

EU EMC Directive 2014/30/EC

DINEN55014-1/05.2012

DIN EN 55014-2/02.2016

DIN EN 61000-3-2/03.2015

DIN EN 61000-3-3/03.2014

EU MachineryDirective 2006/42/EC

DINEN61029-1 /01.2010

Date:31.08.2016

Dipl.-Ing. JörgWagner

PROXXON S.A.

Appliance Safety Division

The CE document authorizedagent is identical to the

signatory.

Page 8

-54-

Page 9

MF 70 cnc-ready

-55-

Page 10

-56-

Page 11

27114 - 01 Work table

27114 - 02 Support

27114 - 03 Base plate

27114 - 04 Nut

27114 - 06 Holding plate

27114 - 07 Limit stop, cpl.

27114 - 08 Screw

27114 - 09 Coupling

27114 - 10 Screw

27114 - 11 Holder for Motor

27114 - 12 Screw

27114 - 13 Step motor

27114 - 14 Screw

27114 - 15 Nut

27114 - 16 Holding plate for

bearing y-axle

27114 - 17 Rolling bearing

ET-Nr.: Description ET-Nr.: Description

27114 18 Screw

27114 19 Screw

27114 - 20 Nut

27114 - 21 Y spindle

27114 - 22a Spindle nut

27114 - 22b Spindle nut

27114 - 23 Holder plate

27114 - 24 Holding plate for

bearing x-axle

27114 - 25 x spindle

27114 - 26 Adjustment plate

27114 - 27 Nut

27114 - 28 Set screw

27114 - 29 Adjustment plate

27114 - 30 Terminal

27114 - 31 Wiring

KT 70 CNC-ready

-57-

Page 12

12 Motors and Wiring:

12.1 Technicaldata of the Motors:

Type Bipolar-Type

Current 1,8 A/Phase

Holdingtorque0,5 Nm

Step angle 1,8°

Mass0,34 kg

Rotor inertia 66,5 gcm2

Resistance/Phase 1,75Ohm

Inductance/Phase 3,3 mH

12.2 Pin-Content oft theSubD-Plug

Endswitch

Coil 1a

Coil 1b

Coil 2a

Coil 2b

12.3 Colour of wires axle-specificwiring oft the

motors:

SubD-Pin MotorColour

of wire

1Coil 1a black

2Coil 1b browne

4Coil 2a red

5Coil 2b orange

7End switch black

8End switch browne

Directionoft rotoa-

tion oft spindle

whiledriving in

positive Direction

Flanklead

Pin-Content in the Molex-Plug:

12 3456

xbrowne black orange redCWRH

ybrowne black redorangeCCW LH

z browne black orange redCWLH

Axle

-58-

Page 13

GB Service note

All PROXXON products are thoroughly inspected after production. Should a defect

occur nevertheless, please contact the dealer from whom you purchased the

product. Only the dealer is responsible for handling all legal warranty claims

which refer exclusively to material and manufacturer error.

Improper use, such as capacity overload, damage due to outside influences

and normal wear are excluded from the warranty.

Youwill find further notes regarding "Service and Spare Parts Management" at

www.proxxon.com.

Art.-Nr.27112-99 PR 7087167005 J

Loading...

Loading...