prototrak XYZ Operating Manual

XYZ TURRET MILL

PROTOTRAK SMX CNC

Safety, Programming, Operating, & Care Manual

COVERS MODELS: |

|

• XYZ TURRET MILL WITH 2-AXIS CNC |

|

SMX SLV SMX2 |

|

SMX 1500 SMX2 |

DOCUMENT: 25049 |

SMX 2000 SMX2 |

VERSION: 042913 |

|

|

SMX 3000 SMX2 |

|

• XYZ TURRET MILL WITH 3-AXIS CNC |

|

SMX SLV SMX3 |

|

SMX 1500 SMX3 |

|

SMX 2000 SMX3 |

|

SMX 3000 SMX3 |

|

SOUTHWESTERN INDUSTRIES, INC.

2615 Homestead Place

Rancho Dominguez, CA 90220-5610 USA T | 310.608.4422 | F | 310. 764.2668 Service Department: 800.367.3165

e-mail: sales@southwesternindustries.com | service@southwesternindustries.com | web: southwesternindustries.com

Copyright © 2013 XYZ Machine Tools, Ltd. All rights are reserved. No part of this publication may be reproduced, stored in a retrieval system, or transmitted, in any form or by any means, mechanical, photocopying, recording or otherwise, without the prior written permission of XYZ Machine Tools, Ltd.

While every effort has been made to include all the information required for the purposes of this guide, XYZ Machine Tools assumes no responsibility for inaccuracies or omission and accepts no liability for damages resulting from the use of the information contained in this guide.

All brand names and products are trademarks or registered trademarks of their respective holders.

XYZ Machine Tools

Woodlands Business Park

Burlescombe, Nr Tiverton

Devon, EX16 7LL

Service Department

Tel: 01823 674214

Fax: 01823 674201

Table of Contents

1.0 |

Introduction |

1 |

1.1Conditions of This Manual

1.2Manual Organization

2.0 |

Safety Specifications & |

2 |

|

Lubrication |

|

2.1Health and Safety Directives

2.2Danger, Warning Labels & Notes

2.3Safety Precautions

3.0 |

Description |

12 |

3.1Control Specifications

3.2Display Pendant

3.3Machine Specifications

3.4Auto Lube System

3.5Servo Motors

3.6Ballscrews

3.7Electrical Cabinet

3.8Z Scale

3.9Auxillary Functions

3.10Work Light

3.11Coolant Pump

3.12Chip Pan/Splash Shield

3.13Table Guard

3.14Z Ballscrew and Motor Assy

3.15Limit Switch

3.16Optional Equipment

4.0 |

Basic Operation |

27 |

4.1Basic Control Operation

4.2Basic Machine Operation

5.0Definition, Terms & Concepts 37

5.1ProtoTRAK Axis Conventions

5.2Part Geometry & Tool Path Prog

5.3Planes and Vertical Planes

5.4Absolute and Incremental Refs

5.5Referenced & Non Ref Data

5.6Incremental Ref Position and Prog

5.7Tool Diameter Compensation

5.8“ “ When Contouring in Z

5.9Connective Events

5.10Conrad

5.11Memory and Storage

6.0 DRO Mode |

43 |

6.1Enter DRO Mode

6.2DRO Functions

6.3Jog

6.4Power Feed

6.5Do One

6.6Go To

6.7Teach

6.8Return Abs Zero

6.9Tool #

7.0 Program Mode |

47 |

7.1Programming Overview

7.2Enter Program Mode

7.3Program Header Screen

7.4Auxillary Funtions

7.5Multiple Fixtures

7.6Assumed Inputs

7.7Z Rapid Positioning

7.8Softkeys within Events

7.9Programming Events

7.10Editing Data while Programming

7.11Look

7.12Finish Cuts

7.132 vs. 3 axis Programming

8.0 |

Program Mode |

57 |

|

Part Two: Programming Events |

|

8.1Position Drill

8.2Bolt Hole Events

8.3Mill Events

8.4Arc Events

8.5Pocket Events

8.6Islands Events

8.7Profile Events

8.8Engrave Events

8.9Subroutine Event

8.10Copy Event

8.11Finish Teach Event

9.0Three Axis Program Events 70

9.1Position Events

8.2Drill Events

8.3Bolt Hole Events

8.4Mill Events

8.5Arc Events

8.6Pocket Events

8.7Islands Events

8.8Profile Events

8.9Helix Events

8.10Subroutine Event

8.11Copy Event

8.12Thread Mill Event

8.13Pause Event

8.14Engrave Event

8.15Finish Teach Event

10.0 AGE Programming |

91 |

10.1Starting the AGE

10.2AGE Mill Prompts

10.3AGE Arc Prompts

10.4Skipping Over Prompts

10.5The OK/Not OK Flag

10.6Ending AGE

10.7Guessing Data

10.8Look and Guess

10.9Calculated Data

10.10Arcs and Conrads

10.11Tangency

11.0 Edit Mode |

97 |

i

XYZ Machine Tools, Ltd.

XYZ Turret Mill, ProtoTRAK SMX CNC Safety, Programming, Operating and Care Manual

11.1Delete Events

11.2Spreadsheet Editing

11.3Erase Program

11.4Clipboard

11.5G Code Editing

12.0 Set-Up Mode |

104 |

12.1The Tool Table

12.2Tool Path

12.3Reference Position

12.4Fixture Offsets

12.5Verify Part

12.6Service Codes

13.0 Run Mode |

116 |

13.1Run Mode Screen

13.22 vs. 3 axis Programming

13.3Starting a Run

13.4Program Run

13.5TRAKing

13.6Program Run Messages

13.7Stop

13.8Feedrate and Speed Override

13.9Trial Run

13.10Data Errors

13.11Fault Messages

14.0 Program In/Out Mode |

120 |

14.1Softkey Selections

14.2Basic Navigation of Screens

14.3Opening a File

14.4Saving Programs

14.5Copying Programs

14.6Deleting Programs

14.7Renaming Programs

14.8Backing Up Programs

14.9Converters

14.10Compatibility with other Models

14.11Running G Code Files

14.12Networking

14.13Cad/Cam Post Processor

15.0 Sample Program |

147 |

15.1Sample Program #1

15.2Sample Program #2

ii

XYZ Machine Tools, Ltd.

XYZ Turret Mill, ProtoTRAK SMX CNC Safety, Programming, Operating and Care Manual

1.0 Introduction

Congratulations! Your new XYZ Turret Mill with the ProtoTRAK SMX CNC is an excellent allaround addition to your shop. The ProtoTRAK SMX has an easy-to-use interface and dozens of features that maximize your productivity for any small-lot production job.

Manual Machining is always available and made easier with features like power feed, 2500 mm per minute rapids, tool offsets and all the best features of sophisticated DRO’s.

Two-Axis Machining is available at the touch of a button for the prototyping and moderately complex, low volume work that is typically done on knee mills.

Three-Axis CNC Machining is also available for models with the ProtoTRAK SMX3. Programs may be entered at the control or imported from other applications such as CAD/CAM.

The operation of the ProtoTRAK SMX CNC has been painstakingly refined to bring you the best in technology while retaining the ease of use that has made ProtoTRAK the top brand in controls for low volume production.

The ProtoTRAK SMX CNC allows you to chose the CNC configuration that is right for you. The base system is a powerful CNC for toolroom work. You may add options for additional features and capabilities.

This manual will describe the operation of all basic and optional features in the appropriate context. Where optional features are discussed, a note will explain in which option the particular feature is found.

1.1Conditions Of This Manual

All details contained in this manual are accurate at the time of going to press E & OA, but please be aware that XYZ Machine Tools has a policy of continuous development, and because of this some details are subject to change without prior notice. Please be sure to confirm any important specifications and details prior to ordering.

1.2Manual Organization Notes

This manual covers the operation of all XYZ Turret Mill products that use the ProtoTRAK SMX CNC.

Some Sections do not apply to all users. For example, if you own a ProtoTRAK SMX 2-axis machine, you should skip Section 9, Three-axis program events.

Sections that may not apply to all users contain a note to inform you of this fact.

Section 2 of this manual provides important safety information. It is highly recommended that all operators of this product review this safety information carefully.

1

XYZ Machine Tools Ltd.

XYZ Turret Mill & ProtoTRAK SMX CNC Retrofit Safety, Programming, Operating & Care Manual

.

2.0 Safety

The safe operation of your turret mill depends on its proper use and the precautions taken by each operator.

Read and study this manual. Be certain every operator understands the operation and safety requirements of this machine before its use.

Always wear safety glasses and safety shoes.

Always stop the spindle and check to ensure the CNC control is in the stop mode before changing or adjusting the tool or workpiece.

Never wear gloves, rings, watches, long sleeves, neckties, jewellery, or other loose items when operating or around the machine.

Use adequate point of operation safeguarding. It is the responsibility of the employer to provide and ensure point of operation safeguarding.

2.1Health and Safety Directives and Standards

XYZ Milling Machines are certified to comply with the following Directives and Standards.

EC Machinery Directive 98/37EC

EMC Directive 89/336/EEC

Low Voltage Directive 73/23/EEC

BS EN 13128 Safety of machine toolsMilling machines (including boring machines). BS EN 1837 Safety of machinery-Integral lighting of machines.

BS EN 60204 Safety of machinery-Electrical equipment of machines.

BS EN 954-1 Safety of machinery Safety related parts of control systems

BS EN 292-2 Safety of machines Basic concepts, general principles for design. BS EN 1050 Safety of machinery, Principles for risk assessment.

BS EN 953 Safety of machinery. Guards, general requirements for the design and construction of fixed and movable guards.

BS EN 60529 Degrees of protection provided by enclosures.

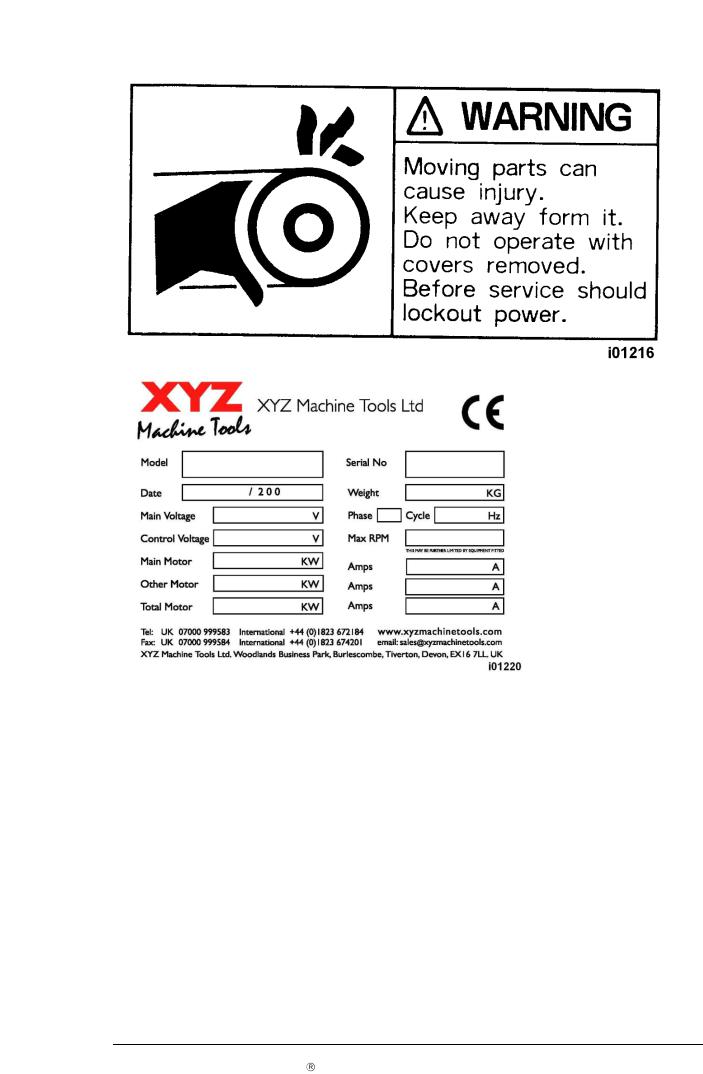

2.2Danger, Warning, Caution, and Note Labels and Notices As Used In This Manual

DANGER - Immediate hazards that will result in severe personal injury or death. Danger labels on the machine are red in color.

WARNING - Hazards or unsafe practices that could result in severe personal injury and/or damage to the equipment. Warning labels on the machine are orange in color.

CAUTION - Hazards or unsafe practices that could result in minor personal injury or equipment/product damage. Caution labels on the machine are yellow in color.

NOTE - Call attention to specific issues requiring special attention or understanding.

2

XYZ Machine Tools, Ltd.

XYZ Turret Mill & ProtoTRAK SMX CNC Retrofit Safety, Programming, Operating & Care Manual

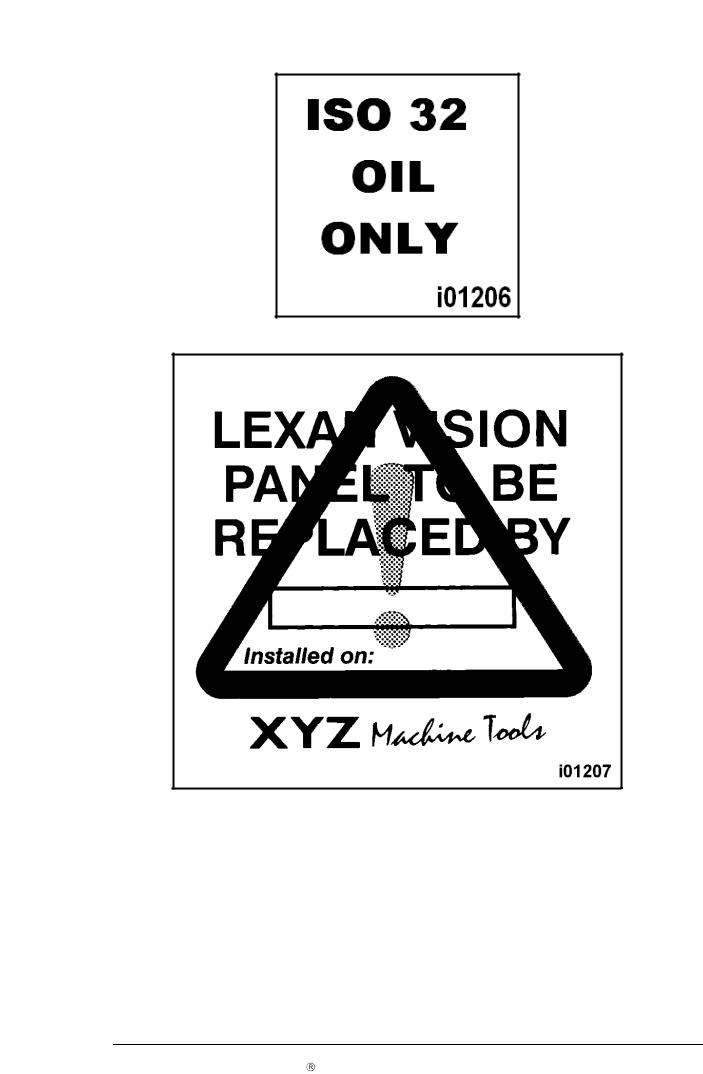

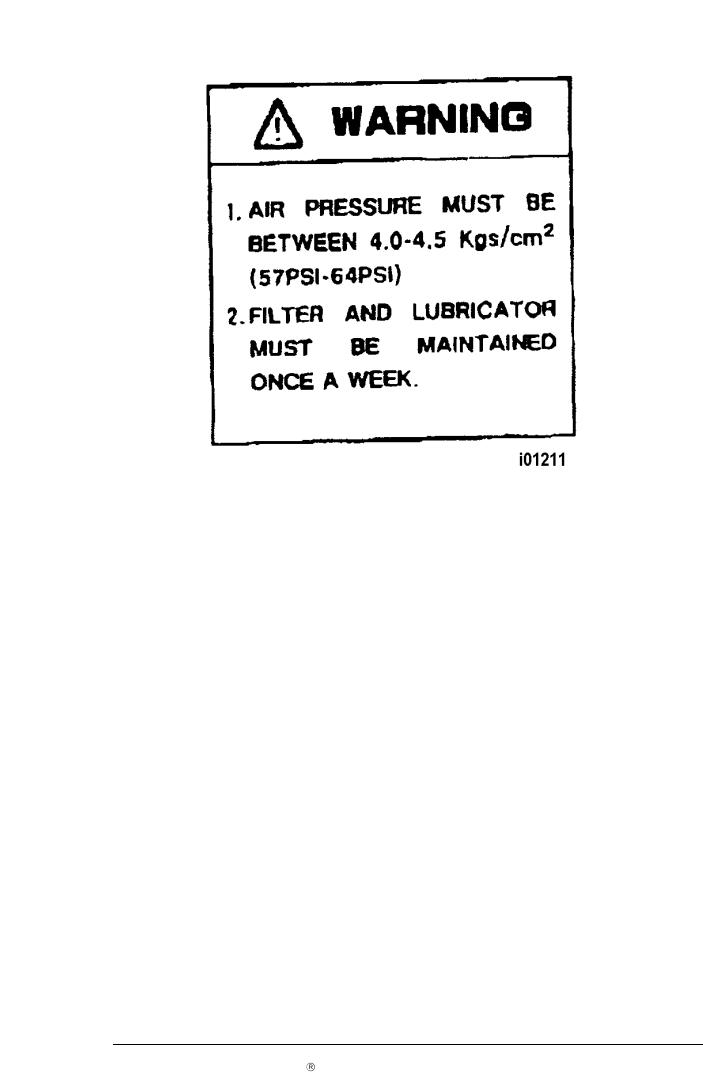

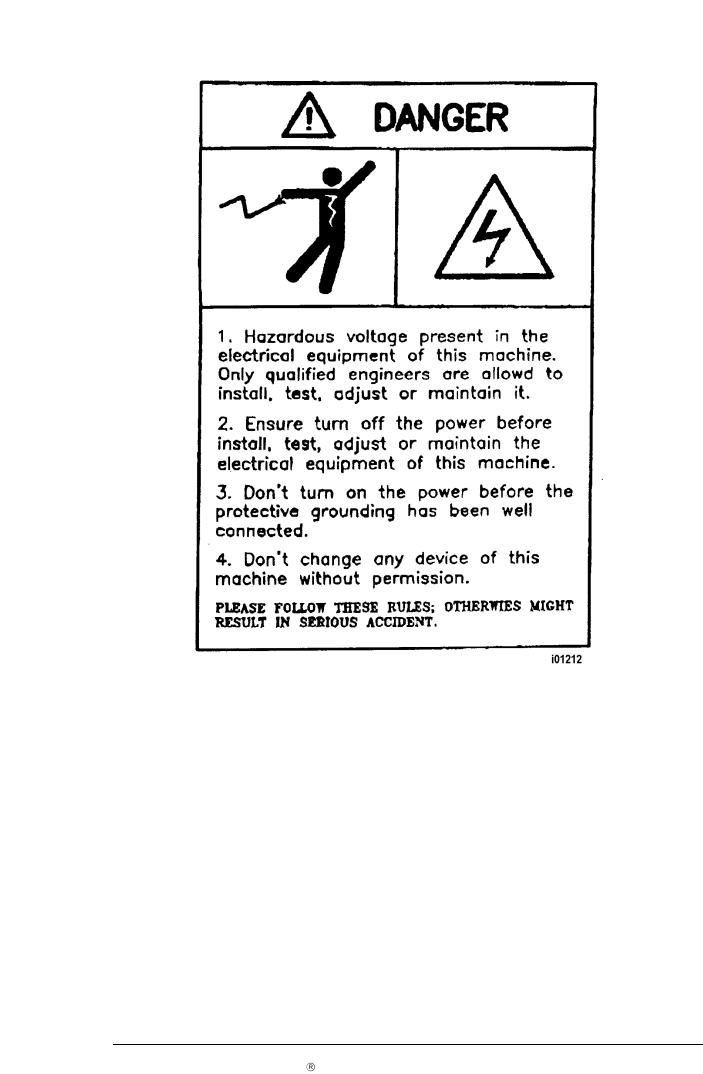

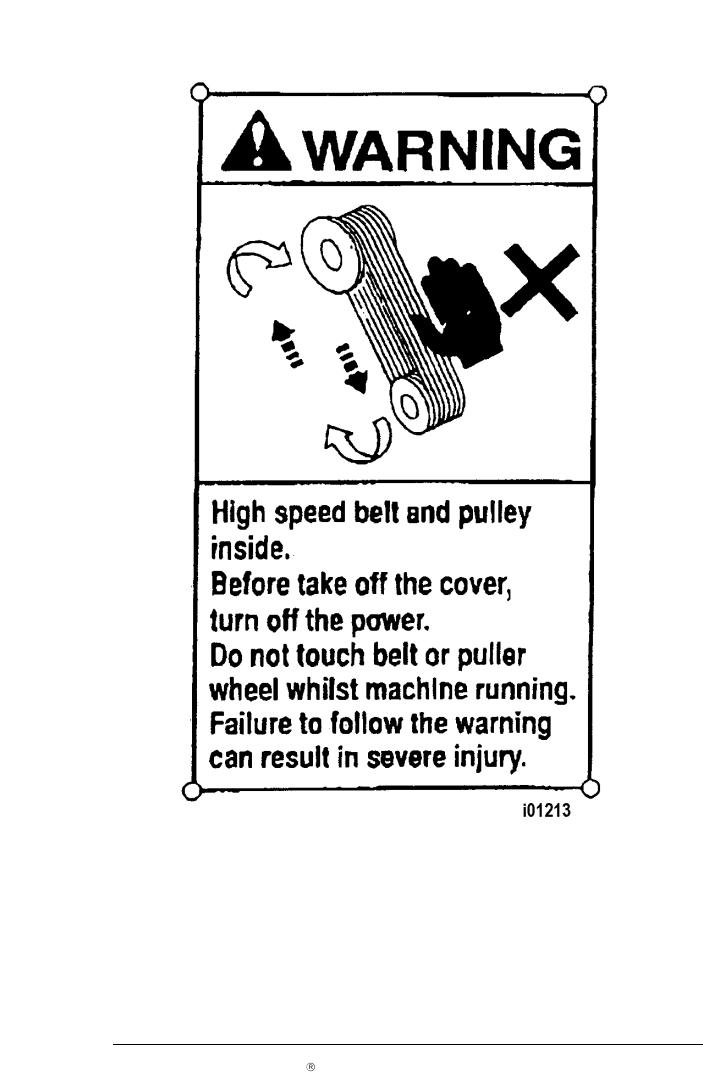

Safety & Information Labels Used On The

XYZ Turret Mills

It is forbidden by law to deface, destroy or remove any of these labels

3

XYZ Machine Tools, Ltd.

XYZ Turret Mill & ProtoTRAK SMX CNC Retrofit Safety, Programming, Operating & Care Manual

Safety & Information Labels Used On The

XYZ Turret Mills

It is forbidden by law to deface, destroy or remove any of these labels

4

XYZ Machine Tools, Ltd.

XYZ Turret Mill & ProtoTRAK SMX CNC Retrofit Safety, Programming, Operating & Care Manual

Safety & Information Labels Used On The

XYZ Turret Mills

It is forbidden by law to deface, destroy or remove any of these labels

5

XYZ Machine Tools, Ltd.

XYZ Turret Mill & ProtoTRAK SMX CNC Retrofit Safety, Programming, Operating & Care Manual

Safety & Information Labels Used On The

XYZ Turret Mills

It is forbidden by law to deface, destroy or remove any of these labels

6

XYZ Machine Tools, Ltd.

XYZ Turret Mill & ProtoTRAK SMX CNC Retrofit Safety, Programming, Operating & Care Manual

Safety & Information Labels Used On The

XYZ Turret Mills

It is forbidden by law to deface, destroy or remove any of these labels

7

XYZ Machine Tools, Ltd.

XYZ Turret Mill & ProtoTRAK SMX CNC Retrofit Safety, Programming, Operating & Care Manual

Safety & Information Labels Used On The

XYZ Turret Mills

It is forbidden by law to deface, destroy or remove any of these labels

8

XYZ Machine Tools, Ltd.

XYZ Turret Mill & ProtoTRAK SMX CNC Retrofit Safety, Programming, Operating & Care Manual

415 VOLTS

Safety & Information Labels Used On The

ProtoTRAK SMX CNC

It is forbidden by law to deface, destroy or remove any of these labels

9

XYZ Machine Tools, Ltd.

XYZ Turret Mill & ProtoTRAK SMX CNC Retrofit Safety, Programming, Operating & Care Manual

2.3Safety Precautions

1.Do not operate this machine before the ProtoTRAK SMX CNC Safety, Installation, Maintenance, Service and Parts List Manual, and the Safety, Programming, Operating & Care Manual have been studied and understood.

2.Do not run this machine without knowing the function of every control key, button, knob, or handle. Ask your supervisor or a qualified instructor for help when needed.

3.Protect your eyes. Wear approved safety glasses (with side shields) at all times.

4.Don't get caught in moving parts. Before operating this machine remove all jewellery including watches and rings, neckties, and any loose-fitting clothing.

5.Keep your hair away from moving parts. Wear adequate safety headgear.

6.Protect your feet. Wear safety shoes with oil-resistant, anti-skid soles, and steel toes.

7.Take off gloves before you start the machine. Gloves are easily caught in moving parts.

8.Remove all tools (wrenches, check keys, etc.) from the machine before you start. Loose items can become dangerous flying projectiles.

9.Never operate a milling machine after consuming alcoholic beverages, or taking strong medication, or while using non-prescription drugs.

10.Protect your hands. Stop the machine spindle and ensure that the CNC control is in the stop mode:

Before changing tools Before changing parts

Before you clear away the chips, oil or coolant. Always use a chip scraper or brush

Before you make an adjustment to the part, fixture, coolant nozzle or

take measurements

Before you open safeguards (protective shields, etc.). Never reach for the part, tool, or fixture around a safeguard.

11.Protect your eyes and the machine as well. Don't use a compressed air hose to remove the chips or clean the machine (oil, coolant, etc.).

12.Stop and disconnect the machine before you change belts, pulley, gears.

13.Keep work area well lighted. Ask for additional light if needed.

14.Do not lean on the machine while it is running.

15.Prevent slippage. Keep the work area dry and clean. Remove the chips, oil, coolant and obstacles of any kind around the machine.

10

XYZ Machine Tools, Ltd.

XYZ Turret Mill & ProtoTRAK SMX CNC Retrofit Safety, Programming, Operating & Care Manual

16.Avoid getting pinched in places where the table, saddle or spindle head create "pinch points" while in motion.

17.Securely clamp and properly locate the workpiece in the vise, on the table, or in the fixture. Use stop blocks to prevent objects from flying loose. Use proper holding clamping attachments and position them clear of the tool path.

18.Use correct cutting parameters (speed, feed, depth, and width of cut) in order to prevent tool breakage.

19.Use proper cutting tools for the job. Pay attention to the rotation of the spindle: Left hand tool for counterclockwise rotation of spindle, and right hand tool for clockwise rotation of spindle.

20.Prevent damage to the workpiece or the cutting tool. Never start the machine (including the rotation of the spindle) if the tool is in contact with the part.

21.Check the direction (+ or -) of movement of the table when using the jog or power feed.

22.Don't use dull or damaged cutting tools. They break easily and become airborne. Inspect the sharpness of the edges, and the integrity of cutting tools and their holders. Use proper length for the tool.

23.Large overhang on cutting tools when not required result in accidents and damaged parts.

24.Prevent fires. When machining certain materials (magnesium, etc.) the chips and dust are highly flammable. Obtain special instruction from your supervisor before machining these materials.

25.Prevent fires. Keep flammable materials and fluids away from the machine and hot, flying chips.

26.When working in manual mode (not CNC) make sure the computer control is switched to DRO or OFF.

11

XYZ Machine Tools, Ltd.

XYZ Turret Mill & ProtoTRAK SMX CNC Retrofit Safety, Programming, Operating & Care Manual

3.0Description

3.1ProtoTRAK SMX CNC Specifications

In its base form, the ProtoTRAK SMX CNC is powerful and easy to use. For turret mill applications, the two-axis CNC is usually preferred because of its simplicity and ease of use. When three-axis CNC is required, a ballscrew and motor is mounted to the head to drive the quill.

The list below summarizes the features and specifications. Each feature is described in more detail in the appropriate section of the manual.

3.1.1Basic System Specifications

Control Hardware

2 or 3-axis CNC, 3-axis DRO

Real handwheels for manual operation

10.4” color active-matrix screen Industrial-grade Intel processor 256 Mb Ram

P/S 2 Keyboard connector 2 USB connectors

Override of program feedrate LED status lights built into display TEAC floppy drive

Software Features – General Operation

Clear, uncluttered screen display Prompted data inputs

English language – no codes Soft keys - change within context Windows® operating system

Selectable two or three-axis CNC (three-axis CNC models) Color graphics with adjustable views

Inch/mm selectable Convenient modes of operation

DRO Mode Features for Manual Machining

Incremental and absolute dimensions Jog at rapid with override

Powerfeed X, Y (or Z for three-axis CNC models) Do One CNC canned cycle

Teach-in of manual moves Servo return to 0 absolute Tool offsets from library

Z Go To (three-axis CNC models only)

Program Mode Features

Geometry-based programming Incremental and absolute dimensions Automatic diameter cutter comp Circular interpolation

Linear interpolation

Look –graphics with a single button push

List step – graphics with programmed events displayed Alphanumeric program names

Program data editing Canned cycles

o |

Position |

o |

Drill |

o |

Bolt Hole |

o |

Mill |

o |

Arc |

o |

Circle pocket |

|

12 |

|

XYZ Machine Tools, Ltd. |

XYZ Turret Mill & ProtoTRAK SMX CNC Retrofit Safety, Programming, Operating & Care Manual

o Rectangular pocket o Circular profile

o Rectangular profile Program pause

Conrad – automatic corner radius Math helps with graphical interface Auto load of math solutions

Tool step over adjustable for pocket routines Pocket bottom finish pass (three-axis CNC models)

Selectable ramp or plunge cutter entry (three-axis CNC models) Subroutine repeat of programmed events

Nesting

Rotate about Z axis for skewing data (three-axis CNC models)

Edit Mode Features

Delete events

Erase program

Set Up Mode Features

Program diagnostics Advanced tool library Tool names

Tool length offset with modifiers(three-axis CNC models) Advanced diagnostic routines

Software travel limits

Tool path graphics with adjustable views

Run Mode Features

Trial run at rapid

3D CAM file program run (three-axis CNC models)

3D G code file run with tool comp (three-axis CNC models) Real time run graphics with tool icon

Z Go To (for two-axis run on three-axis CNC models)

Program In/Out Mode Features

Simple program storage to floppy CAM program converter

Converter for prior-generation ProtoTRAK programs

3.1.2 Advanced Features Option

The Advanced Features Option may be purchased with the original order or purchased later. Note, the Advanced Features Option is included in the ProtoTRAK Offline Software, but must be purchased separately for each ProtoTRAK SMX CNC.

It is easy to tell if you have the Advanced Features Option. If you have the Advanced Features Option, the features listed below will be active. If you do not, the features listed below will not be active and any Softkey for that feature will be grayed out. For example, in the Program Mode, under Pocket, check the Softkey labeled IRREG PCKT.

If the words “IRREG PCKT” are black, the Advanced Feature Option is active. If they are gray, the Advanced Feature Option is not active.

The other way to tell if the Advanced Features Option is active is to go to Service Code 318. The Advanced Features Option is active if the letters are in black, inactive if they are in gray.

With the Advanced Features Option, you get the following:

Auto Geometry Engine ™ (see Section 9.0)

3-axis conversational programming (three-axis CNC models) Additional Canned Cycles:

-Irregular Pocket (8.6.3)

-Face Mill (8.6.8)

-Circle Island (8.7.1)

13

XYZ Machine Tools Ltd.

XYZ Turret Mill & ProtoTRAK SMX CNC Retrofit Safety, Programming, Operating & Care Manual

-Rectangular Island (8.7.2)

-Irregular Island (8.7.3)

-Irregular Profile (8.8.3)

-Helix (three-axis CNC models) (8.9)

-Thread milling (three-axis CNC models) (8.12)

-Engrave (8.14)

-Tapping (8.15)

G-Code editor

Countdown clock to next pause or tool change Total program time estimator

Spreadsheet editing Global data change Scaling of print data Multiple fixture offsets Event comments

Tool path conversational programming Mirror of programmed events

Copy with or without offsets Copy Rotate

Copy Mirror Copy Drill to Tap

Clipboard to copy events between programs

If the Advanced Features Option is not active you may purchase it easily. The Advanced Features Option is a software option so it is simply a matter of entering the Activation Password into the ProtoTRAK.

To obtain the Password, see the instructions in section 3.1.8 below.

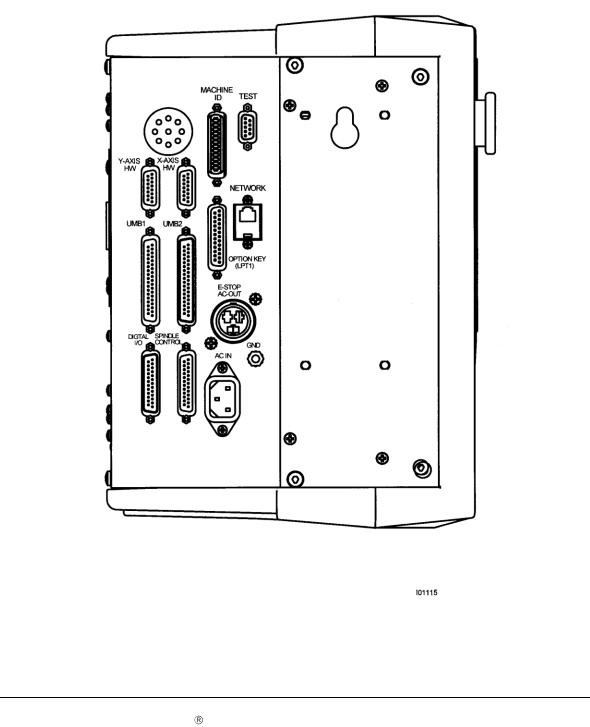

3.1.3 Networking Option

The Networking Option gives you powerful choices in program storage and handling. This option may be ordered with your machine or at any time after it is installed in your shop. A RJ45 port is found on each pendant to hook up your networking cable. See figure 3.2.2 below for the location of this port.

3.1.4 Installing and using the USB Thumb Drive Flash Memory

The first time you install the USB Thumb Drive, we recommend that you install it after the ProtoTRAK SMX has booted up. Once it is installed, the memory will be accessible on Drive D. If you want to buy additional thumb drives, these are readily available in computer stores. We recommend SanDisk® brand, 128MB or higher. Other brands may require the installation of separate drivers.

3.1.5The DXF File Converter Option

The DXF File Converter Option gives you powerful capability for quickly and easily translating DXF and DWG files into ProtoTRAK SMX programs. If you work with CAD drawings, we highly recommend that you get a demo of the DXF file converter.

Import and convert CAD data into ProtoTRAK programs DXF or DWG files

Chaining

Automatic Gap Closing Layer control

Easy, prompted process you can do right at the machine

To tell if the DXF File Converter is active on your ProtoTRAK SMX CNC, go to the options screen using Service Code #318. If the AutoCAD DXF option is in black letters, it is activated. If it is in gray letters, you will need to purchase the option to activate it.

14

XYZ Machine Tools, Ltd.

XYZ Turret Mill & ProtoTRAK SMX CNC Retrofit Safety, Programming, Operating & Care Manual

The DXF Option Consists of additional software and an Activation Password. The software can be shipped to you. See Section 3.1.8 below for instructions on ordering and obtaining your Activation Password.

The DXF Option has its own manual which is shipped with the software.

3.1.6Converter Options

Optional converters are available for running programs created on other CNCs on the ProtoTRAK and vice versa.

See section 13.9 for instructions on using converters.

If the converter you want is not active you may purchase it easily. Converters are software options so it is simply a matter of entering the correct Activation Password into the ProtoTRAK.

To obtain the Password, see the instructions in section 3.1.8 below.

3.1.7TRAKing/Electronic Handwheels Option

The TRAKing/Electronic Handwheels Option extends the power of the ProtoTRAK SMX CNC beyond the ordinary by combining the electronic handwheels with software routines in the DRO and RUN Modes. If you did not buy this option with the original machine, you may add it later.

The option includes:

Electronic Handwheels on X and Y (replaces the mechanical handwheels, see Section 3.4.1).

TRAKing of programs during program run (see Section 12.5) Go To Dimensions (see Section 6.6)

Selectable Fine/Coarse handwheel resolution (see Section 3.4.1)

If you order this option, do not activate the software for the TRAKing/Electronic Handwheels Option until the electronic handwheels are installed on the machine. Contact XYZ Machine Tools on 01823 674200 or contact your Area Sales Manager to make arrangements for an authorized technician to install the electronic handwheels. For three-axis CNC models, the Go To dimensions for the Z axis are a part of the base product even if this option is not ordered. You do not need this option for Z-axis Go To dimensions.

3.1.8How To Buy Software Options

If you did not buy the software options described above with your machine, you may purchase them later. In order to use these options, a Software Activation Password is required. These passwords are unique to your ProtoTRAK SMX CNC.

Software Options are not free. You may call XYZ Machine Tools on 01823 674200 or contact your Area Sales Manager for a price quotation.

1.We recommend that you install the latest version of the ProtoTRAK SMX master software before installing the newest option.

2.Go to the ProtoTRAK SMX CNC on which the option is to be installed, use Service Code 318 to go to the Software Options Screen.

3.Highlight the option you wish to install (for example, “A: Advanced Features”) and press the softkey labeled INSTALL.

4.A screen will appear that advises you how to purchase the option. Near the bottom of the screen there will be a Hardware Key Serial Number and an Option Serial Number. Write down both of these numbers.

5.Call XYZ Machine Tools on 01823 674200 or contact your Area Sales Manager with your purchase order number and the numbers you wrote down in step 4 above.

15

XYZ Machine Tools Ltd.

XYZ Turret Mill & ProtoTRAK SMX CNC Retrofit Safety, Programming, Operating & Care Manual

6.When you receive your Password Activation Number, input it into the ProtoTRAK where indicated on the screen obtained in step 2 above. Some options require you to reboot the ProtoTRAK to activate.

7.Refer to the appropriate section of this manual for instructions on using your new features.

3.2Display Pendant

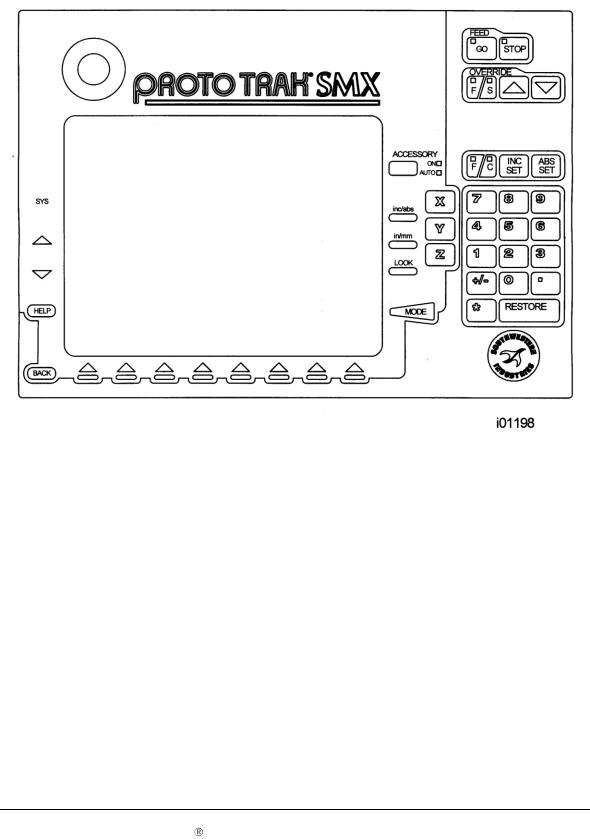

3.2.1Front

Figure 3.2.1 The ProtoTRAK SMX CNC front panel

Keyboard Hard Keys

Feed Keys:

GO: initiates motion in Run. The green LED on the GO key will be lit when the servomotors are moving the machine either in jog or when the program run has been initiated by the GO key.

STOP: halts motion during Run. The red LED on the STOP key will be lit when the servos motors are not moving the machine.

Override Keys:

F/S: selects the function for the override operation. F is for feedrate. When the LED above the F is lit, arrow presses will increase or decrease axis feedrate. S is for spindle RPM. When the LED above the S is lit, arrow presses will increase or decrease the spindle RPM. Note: the spindle override is active only when the Programmable Electronic Head Option is installed.

16

XYZ Machine Tools, Ltd.

XYZ Turret Mill & ProtoTRAK SMX CNC Retrofit Safety, Programming, Operating & Care Manual

: Feedrate Override to increase feedrate or spindle rpm up to 150%.

: Feedrate Override to decrease feedrate or spindle rpm down to 10%.

Each button push Modifies the feedrate in 10% increments and the spindle speed in 5% increments.

ACCESSORY: When the switch is in the On position, the flood coolant pump (or spray coolant) will come on and stay on during machining operations. In the Auto mode, the coolant pump or spray coolant will be controlled as programmed by the Auxiliary functions. To get to the Auto operation, press and hold the Accessory key. If neither light is on, the coolant pump or spray coolant will not operate.

F/C: Selects between fine and course resolution for the X and Y handwheels when the TRAKing/Electronic Handwheels Option is installed. The LED above the letter indicates which feed is active. Fine feed moves the axis 5mm (.200 inches) per revolution. Course feed moves 20mm (.800 inches) per revolution.

INC SET: loads incremental dimensions and general data

ABS SET: loads absolute dimensions and general data

INC/ABS: switches all or one axis from incremental to absolute or absolute to incremental

IN/MM: causes Inch to Metric or Metric to Inch conversion of displayed data

LOOK: part graphics in Program mode

X, Y, Z: selects axis for subsequent commands

RESTORE: clears an entry, aborts a keying procedure

0-9, +/-, . : inputs numeric data with floating point format. Data is automatically + unless +/- key is pressed. All input data is automatically rounded to the system's resolution.

MODE: to change from one mode of operation to another

SYS: To shut down the ProtoTRAK SMX CNC, change from 2-axis to 3-axis, or 3-axis to 2-axis operation, and other functions.

:reinstates a window

:eliminates a window

HELP: displays help information, math help or additional functions. Active for additional functions when the help symbol (a blue question mark) is displayed on the screen next to the HELP key.

Soft Keys:

Beneath the display are 8 keys that are labeled with arrows. These keys are called software programmable or soft keys. A description of the function or use of each of these keys will be shown at the bottom of the display directly above each key. If, at any time, there is no description above a key, that key will not operate.

Sometimes the description or function of the key is visible but grayed out. This indicates that the particular function is not available because of some other condition. For example, if there is no program in the current memory, the EDIT Mode softkey will be grayed out because there is no program to edit.

17

XYZ Machine Tools Ltd.

XYZ Turret Mill & ProtoTRAK SMX CNC Retrofit Safety, Programming, Operating & Care Manual

Emergency Stop Switch

The emergency stop (E-stop) switch kills all power to the spindle and ProtoTRAK's servomotors. The computer and pendant remain powered. If the Emergency Stop switch is pushed, it will be necessary to press the Reset Button on the right side of the pendant (see Section 3.2.3 below) to reenergize the relay.

The Liquid Crystal Display (LCD)

The display of the ProtoTRAK SMX CNC is a 10.4" active-matrix color LCD. The very top is the Status Line that shows the overall status of the ProtoTRAK SMX CNC. This includes the current Mode, the current program part number, the current tool number, 2 or 3-axis mode and whether the X, Y and Z dimensions are in inch or millimeter (mm).

Just above the soft keys is a data input line that appears when an input is required.

3.2.2 Pendant Left Side (See Figure 3.2.2)

FIGURE 3.2.2 The ProtoTRAK SMX CNC left side with connectors labeled

18

XYZ Machine Tools, Ltd.

XYZ Turret Mill & ProtoTRAK SMX CNC Retrofit Safety, Programming, Operating & Care Manual

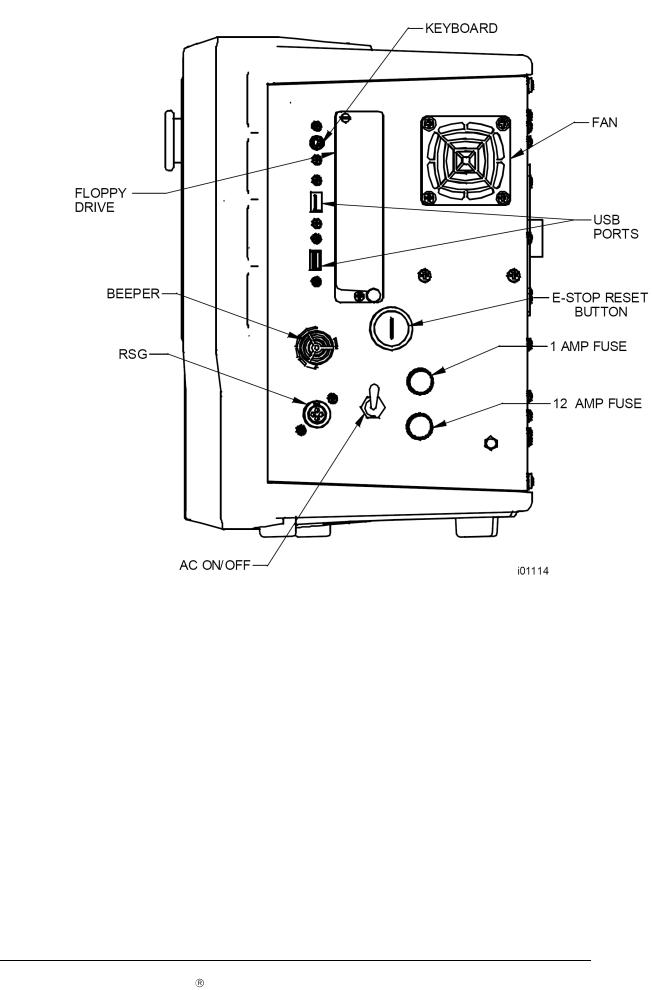

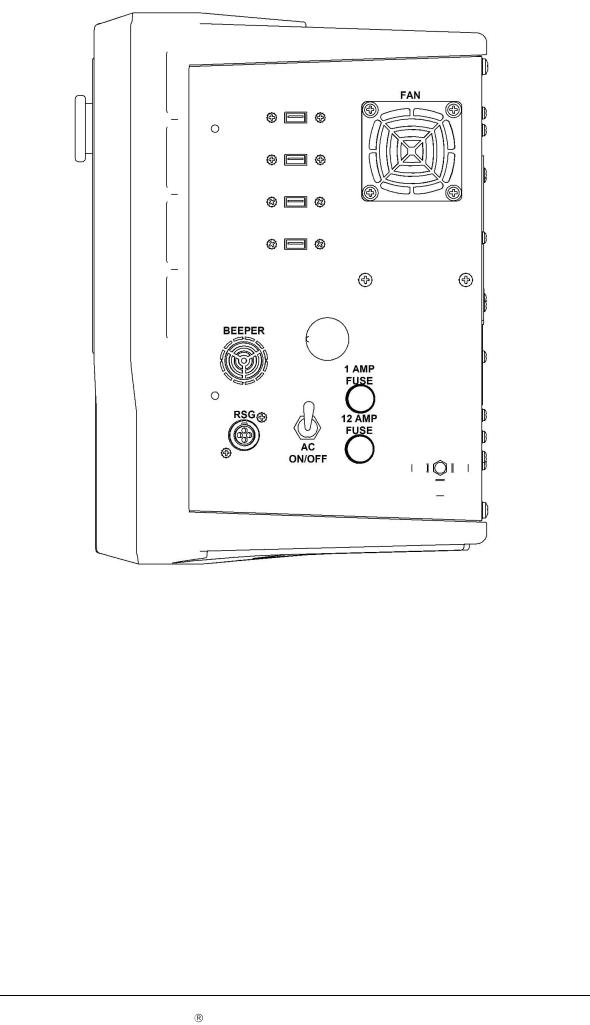

3.2.3 Pendant Right Side (See Figure 3.2.3)

FIGURE 3.2.3 The ProtoTRAK SMX CNC right side

19

XYZ Machine Tools Ltd.

XYZ Turret Mill & ProtoTRAK SMX CNC Retrofit Safety, Programming, Operating & Care Manual

Pendant Right Side with USB Ports

Keyboard P/S2 port. This port is for the keyboard only. If this port is used, the connection must be made before the ProtoTRAK is turned on. If the ProtoTRAK is already on, it will not recognize the keyboard until it is rebooted with the keyboard plugged in. You may also plug the keyboard into one of the USB ports.

USB Ports. The USB ports are the only ports available for plugging in a mouse. They may also be used for a keyboard or for plugging in the USB Thumb Drive flash memory. Items used by USB ports will be recognized even if they are plugged in after the ProtoTRAK is turned on.

If you need more than two USB ports, we recommend that you install a USB hub.

If you use the USB Thumb Drive to store a G-code (.gcd) program file, you must leave the Thumb Drive plugged into the USB port the entire time the program is in current memory. If you unplug the thumb drive with the program still in current memory, the ProtoTRAK will display an error message.

Drivers for most major brands of mouse and keyboard are already in the ProtoTRAK SMX. If a mouse or keyboard is not recognized by the ProtoTRAK, it means that the driver is not

20

XYZ Machine Tools, Ltd.

XYZ Turret Mill & ProtoTRAK SMX CNC Retrofit Safety, Programming, Operating & Care Manual

available. Loading a new driver is not difficult for a qualified computer administrator who can access the start menu on the ProtoTRAK with a keyboard plugged in (see the Catch 22?). However, most users would be happier to simply go get a keyboard and mouse that are already supported. We recommend Microsoft, Logitech and Belkin brand products.

AC on/off. The ProtoTRAK should be shut down properly before turning off (Sections 4.1 and 4.2).

Reset. The reset button re-energizes the relay that is tripped when the E-Stop button is pressed. To reset the system after an E-Stop press, first reset the E-Stop button by rotating it until it returns to its out position. After the E-Stop is reset, press and release the Reset button on the right side of the pendant.

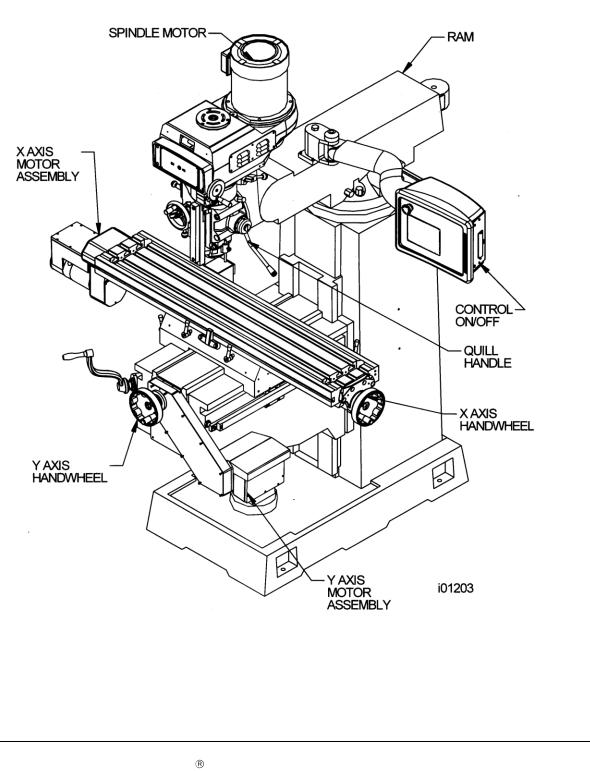

3.3 Mill Specifications (See Figures 3.3.1 and 3.3.2)

Note: Machine shown above is in the two-axis CNC configuration.

21

XYZ Machine Tools Ltd.

XYZ Turret Mill & ProtoTRAK SMX CNC Retrofit Safety, Programming, Operating & Care Manual

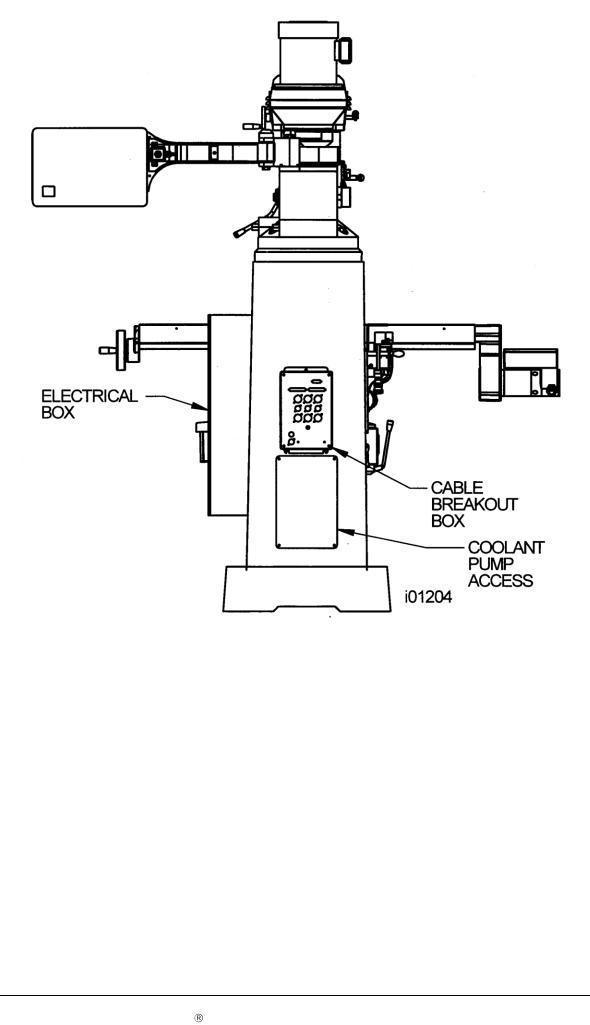

FIGURE 3.3.2 The XYZ Turret Mill back view

Twoand three-axis CNC Turret Mill Specifications

|

SMX 1500 SMX2 |

SMX 2000 SMX2 |

SMX 3000 SMX2 |

SMX SLV SMX2 |

|

2-Axis CNC, |

2-Axis CNC, |

2-Axis CNC, |

2-Axis CNC, |

|

3-Axis DRO |

3-Axis DRO |

3-Axis DRO |

3-Axis DRO |

|

|

|

|

|

|

SMX1500 SMX3 |

SMX2000 SMX3 |

SMX3000 SMX3 |

SMX SLV SMX3 |

|

3-Axis CNC, |

3-Axis CNC, |

3-Axis CNC, |

3-Axis CNC, |

|

3-Axis DRO |

3-Axis DRO |

3-Axis DRO |

3-Axis DRO |

Table Size |

1066 x 228 |

1270 x 254 |

1371 x 305 |

1473 x 305 |

T-Slots |

3 |

3 |

3 |

3 |

Table Travel |

660 |

762 |

813 |

1016 |

Saddle Travel |

330 |

406 |

431 |

431 |

Knee Travel |

406 |

406 |

406 |

406 |

Ram Travel |

330 |

450 |

450 |

450 |

22

XYZ Machine Tools, Ltd.

XYZ Turret Mill & ProtoTRAK SMX CNC Retrofit Safety, Programming, Operating & Care Manual

Maximum Quill Travel, |

127 |

127 |

127 |

127 |

2-axis CNC |

|

|

|

|

Maximum Quill Travel, |

115 |

115 |

115 |

115 |

3-axis CNC |

|

|

|

|

Quill Diameter |

86 |

86 |

105 |

105 |

Spindle Taper |

R8 |

R8 |

40 ISO |

40 ISO |

Spindle Speed |

75 - 4200 |

75 - 4200 |

70 – 3600 |

70 - 3600 |

Head Tilt fore & aft |

45 - 45 |

45 - 45 |

45 – 45 |

45 - 45 |

Head Tilt left - right |

90 - 90 |

90 - 90 |

90 - 90 |

90 - 90 |

Spindle Motor Power |

3 HP |

3 HP |

5 HP |

5 HP |

Power requirements, |

16 Amp |

16 Amp |

20 Amp |

20 Amp |

machine |

|

|

|

|

Maximum Weight on |

350 Kg |

350 Kg |

550 Kg |

580 Kg |

Table |

|

|

|

|

Machine Weight |

1100 Kg |

1250 Kg |

1650 Kg |

1850 Kg |

Machine dims l, w, h |

3220 x 2520 x |

3220 x 2580 x |

3670 x 2690 x |

4000 x 2690 x |

|

2200 |

2180 |

2340 |

2340 |

Max rapid feed X,Y |

2500 |

2500 |

2500 |

3800 |

Max rapid feed, Z CNC |

2500 |

2500 |

2500 |

2500 |

Way surface type |

Hard chrome V |

Hard chrome V |

Hardened Box |

Hardened Box |

|

way |

way |

way |

Way |

Precision 7207 CP4 spindle bearings

Chrome hardened and ground quill

Meehanite castings

Slide ways are Turcite coated

Wide way surfaces are hardened and ground

3.4 Auto Lubrication System

The way and ballscrew lubrication are supplied by a pump located on the side of the machine body. The interval and discharge time of the pump are set by XYZ Machine Tools and should not be changed or altered otherwise your warranty will become invalid.

After periods of non-operation of the machine we recommended that before you operate the machine you first press the pump button located on the pump itself. This will ensure that adequate lubrication is supplied to key parts of the machine before you start .

Factory Default Values

Interval Time – 50 min

Discharge Time – 5 sec

Discharge Pressure – Approximately 100 – 150psi

CAUTION!

Failure to properly lubricate the mill will result in the premature failure of bearings and sliding surfaces.

CAUTION!

Failure to manually activate the pump at the beginning of each day, or allowing the Auto Lube to run dry may cause severe damage to the mill’s way surfaces and ballscrews.

23

XYZ Machine Tools Ltd.

XYZ Turret Mill & ProtoTRAK SMX CNC Retrofit Safety, Programming, Operating & Care Manual

Head Lubrication

Once Each Week:

1.Fill the oil cup on the front of the head with ISO 32 oil. This oil lubricates the Hi/Lo range shifter.

2.Fill the ball oiler located in the front lower right corner of the speed hanger housing. This oil lubricates the speed changer shaft.

3.Extend the quill fully and apply a coating of ISO 32 oil to the outside diameter of the quill.

Every Four Months:

Apply a good grade of general-purpose grease through the grease fittings on the back of the head and on the left side of the head. The grease lubricates the low range gear set and the feed change gears respectively.

3.5 Servo Motors

The servo motors on the table and saddle are 2 newton-meters of torque. Integrated into each motor is an encoder with 0.000924mm underlying resolution for models 1500, 2000 and 3000 and .00075mm for model SLV.

3.6 Ballscrews

Precision ground ballscrews are installed in the table and saddle to ensure smooth traverse and positive control for manual and CNC machining.

3.7 Electrical Cabinet

XYZ Turret Mills require a 415V power supply into the electrical cabinet.

3.8 Z Axis Feedback Scale

For two-axis CNC models, a Z-axis feedback scale is mounted either to the quill or the knee in order to provide digital readout of the Z axis position.

3.9 Auxiliary Functions (Three-Axis CNC Models Only)

Auxiliary functions are controlled through the ProtoTRAK SMX CNC either in the program or with the accessory key on the front panel. The Auxiliary functions consist of the following:

Spindle off command.

An air solenoid to control spray coolant or other pneumatically activated peripheral equipment. Shop air should not exceed 125 psi.

Switched and fused 120 VAC 8 Amp outlet for coolant pumps, automatic oilers, etc.

INPUT/OUTPUT to interface with programmable indexers, dividing heads, etc.

oOutput from ProtoTRAK SMX CNC is .3-second actuation of a solid-state relay between pin 3 (plus), and pin 4 (minus).

oInput to the ProtoTRAK SMX CNC is .3-second actuation of a solid-state relay between pin 1 (plus), and pin 2 (minus).

o Note: Pin 1 is on top, 2 on right, 3 on left, 4 on bottom.

24

XYZ Machine Tools, Ltd.

XYZ Turret Mill & ProtoTRAK SMX CNC Retrofit Safety, Programming, Operating & Care Manual

3.10 Work Light

An halogen work light is supplied with the machine. It mounts to the left side (facing) of the column and plugs into a 110v outlet in the electrical cabinet.

3.11 Coolant Pump

The coolant pump is mounted in the back of the machine column. It is plugged into the electrical cabinet and is configured to operate as commanded by the accessory key.

3.12 Chip Pan

The Chip Pan fits around the base of the mill to collect coolant and chips.

3.13 Table Guard

The Table guard provides an enclosed workspace mounted on the table. The doors are switched to prevent the machine spindle starting in any mode if they are open. It also prevents the operation of the CNC in Run mode with the door open. While it will aid in the control of chips and coolant, it is not a full, waterproof enclosure. Removal of these guards is prohibited by law. They are fitted for the benefit of the machine operator and to comply with the current legislation, removal means you are breaking the law.

3.14 Z-Axis Ballscrew and Motor Assembly

For three-axis CNC models, a Z-axis ballscrew and motor assembly is mounted on the head using two tramming bolts and the fine feed boss.

In manual and CNC operations, the quill is moved by a servo motor connected by a belt to a ballscrew. The ball nut of the ballscrew is attached to fork that engages the quill in the threaded hole previously used by the quill stop knob.

In CNC operations, the motor is controlled by the CNC program.

In manual operations, the motor is controlled by jog commands from the user and by the operation of the electronic handwheel.

A limit switch in the assembly prevents damage from over travel. Z-axis traverse is limited to 115mm.

3.15 Limit Switches

Limit switches are mounted for the saddle and table travel.

3.16 Optional Equipment

3.16.1 Electronic Handwheels

When ordered as part of the TRAKing/Electronic Handwheels Option (see Section 3.1.7) the electronic handwheels replace the standard mechanical handwheels for table and saddle traverse. The electronic handwheels will operate when the ProtoTRAK SMX CNC is in a Mode where the machinist controls the motion of the table and saddle. This includes the DRO Mode, the Set-Up Mode and the TRAKing operation in the Run Mode. The electronic handwheels will not operate during other functions, such as when the “Select a Mode” message appears on the screen.

Handwheel resolution is determined by the F/C key on the display. Fine feed moves 5mm (0.200 inches) per revolution, Course feed moves 20mm (0.800 inches) per revolution.

25

XYZ Machine Tools Ltd.

XYZ Turret Mill & ProtoTRAK SMX CNC Retrofit Safety, Programming, Operating & Care Manual

3.16.2 Linear Scales

The ProtoTRAK SMX CNC may be configured to run either with or without Linear Scales for X and Y travel. Linear scales have a feedback resolution of 5 Microns.

3.16.3 Power Draw Bar

A manual draw bar comes standard with the machine. A power draw bar option may be ordered. For the SMX 3000, and SMX SLV machines, the draw bar included in the option may be M16 or 5/8 UNC.

The standard type of power draw bar is of the appropriate length to fit tool holders that have a threaded tang on the top ( ISO 40). BT40 and CAT 40 tool holders have a different arrangement at the small tapered end so a longer drawbar is required to thread into the tool holder when the retention knob is removed. These longer drawbars can be provided on request please talk to your Area Sales Manager or XYZ Machine Tools parts department.

3.16.4 Remote Stop Go Switch

For the convenience of operation while running the program, a Remote Stop/Go switch may be purchased. This switch is on a ten-foot cable and operates like the FEED Stop and Go keys on the display.

26

XYZ Machine Tools, Ltd.

XYZ Turret Mill & ProtoTRAK SMX CNC Retrofit Safety, Programming, Operating & Care Manual

Loading...

Loading...