Page 1

PDPMV1

ProLinx Gateway

PROFIBUS DPV1 Master

March 23, 2011

PROTOCOL MANUAL

Page 2

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions, comments,

compliments or complaints about our products, documentation, or support, please write or call us.

How to Contact Us

ProSoft Technology

5201 Truxtun Ave., 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

www.prosoft-technology.com

support@prosoft-technology.com

Copyright © 2011 ProSoft Technology, Inc., all rights reserved.

PDPMV1 Protocol Manual

March 23, 2011

ProSoft Technology ®, ProLinx ®, inRAx ®, ProTalk ®, and RadioLinx ® are Registered Trademarks of ProSoft

Technology, Inc. All other brand or product names are or may be trademarks of, and are used to identify products

and services of, their respective owners.

ProSoft Technology® Product Documentation

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product shipments.

User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are provided on the enclosed CD-ROM in

Adobe® Acrobat Reader file format (.PDFs). These product documentation files may also be freely downloaded from

our web site: www.prosoft-technology.com

Page 3

Important Installation Instructions

Power, Input, and Output (I/O) wiring must be in accordance with Class I, Division 2 wiring methods, Article 501-4 (b)

of the National Electrical Code, NFPA 70 for installation in the U.S., or as specified in Section 18-1J2 of the Canadian

Electrical Code for installations in Canada, and in accordance with the authority having jurisdiction. The following

warnings must be heeded:

WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR CLASS

I, DIV. 2;

WARNING - EXPLOSION HAZARD - WHEN IN HAZARDOUS LOCATIONS, TURN OFF POWER BEFORE

REPLACING OR WIRING MODULES

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

THIS DEVICE SHALL BE POWERED BY CLASS 2 OUTPUTS ONLY.

ProLinx® Products Warnings

WARNING – EXPLOSION HAZARD – DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

AVERTISSEMENT – RISQUE D'EXPLOSION – AVANT DE DÉCONNECTER L'EQUIPMENT, COUPER LE

COURANT OU S'ASSURER QUE L'EMPLACEMENT EST DÉSIGNÉ NON DANGEREUX.

ProLinx Gateways with Ethernet Ports

Series C ProLinx™ Gateways with Ethernet ports do NOT include the HTML Web Server. The HTML Web Server

must be ordered as an option. This option requires a factory-installed hardware addition. The HTML Web Server now

supports:

8 MB file storage for HTML files and associated graphics files (previously limited to 384K)

32K maximum HTML page size (previously limited to 16K)

To upgrade a previously purchased Series C model

Contact your ProSoft Technology distributor to order the upgrade and obtain a Returned Merchandise Authorization

(RMA) to return the unit to ProSoft Technology.

Page 4

Page 5

PDPMV1 ♦ ProLinx Gateway Contents

PROFIBUS DPV1 Master Protocol Manual

Contents

Your Feedback Please ........................................................................................................................ 2

How to Contact Us .............................................................................................................................. 2

ProSoft Technology® Product Documentation .................................................................................... 2

Important Installation Instructions ....................................................................................................... 3

ProLinx® Products Warnings ............................................................................................................... 3

ProLinx Gateways with Ethernet Ports ............................................................................................... 3

To upgrade a previously purchased Series C model ..................................................................... 3

1 Functional Overview 9

1.1

1.2

1.3

1.4

1.5

1.6

1.3.1

1.3.2

1.3.3

1.3.4

About the PROFIBUS Protocol ............................................................................... 10

Compatibility Note ................................................................................................... 11

PROFIBUS DP Architecture .................................................................................... 12

How Cable Length Affects Communication Rate .................................................... 12

Bus Access .............................................................................................................. 12

Token Passing ......................................................................................................... 13

Master/Slave Polling ................................................................................................ 13

Communication Types ............................................................................................. 14

Master/Slave Communication Phases .................................................................... 15

Gateway Internal Database ..................................................................................... 16

2 Configuration 17

2.1

2.2

2.3

2.4

2.5

2.1.1

2.1.2

2.1.3

2.2.1

2.2.2

2.2.3

2.2.4

2.2.5

2.2.6

2.2.7

2.2.8

2.2.9

2.2.10

2.2.11

2.2.12

2.2.13

2.2.14

2.2.15

2.4.1

2.4.2

2.4.3

2.4.4

Configuring the Gateway ......................................................................................... 18

Installing ProSoft Configuration Builder Software ................................................... 18

Setting Up the Project ............................................................................................. 22

Setting Gateway Parameters .................................................................................. 24

PROFIBUS Master DPV1........................................................................................ 26

Input Start Register ................................................................................................. 26

Input Data Size ........................................................................................................ 26

Output Start Register ............................................................................................... 26

Output Data Size ..................................................................................................... 26

Input Byte Swap ...................................................................................................... 27

Output Byte Swap ................................................................................................... 27

Mailbox Register ...................................................................................................... 28

Slave Diagnostics Register ..................................................................................... 29

Alarm Register ......................................................................................................... 29

Status Data Register ............................................................................................... 29

Minimum Command Delay ...................................................................................... 29

Response Timeout .................................................................................................. 29

Watchdog Register .................................................................................................. 29

Watchdog Timeout .................................................................................................. 30

Watchdog Reset Value ............................................................................................ 30

PROFIBUS Master Commands .............................................................................. 31

Example Mailbox Commands ................................................................................. 33

Set Operating Mode ................................................................................................ 33

Get Live List ............................................................................................................ 38

Start/Stop Slaves ..................................................................................................... 43

Other Mailbox Commands....................................................................................... 49

Configuring the PROFIBUS DP Network ................................................................ 52

ProSoft Technology, Inc. Page 5 of 157

March 23, 2011

Page 6

Contents PDPMV1 ♦ ProLinx Gateway

Protocol Manual PROFIBUS DPV1 Master

2.5.1

2.6

2.7

2.5.2

2.5.3

Installing the GSD Files .......................................................................................... 52

Configuring the PROFIBUS Slaves ........................................................................ 53

Printing the ProLinx Memory Map .......................................................................... 69

Downloading the Project to the Gateway ............................................................... 71

Backing Up the Project ........................................................................................... 72

3 Mailbox Messaging 75

3.1

3.2

3.3

3.1.1

3.2.1

3.2.2

3.2.3

3.2.4

3.2.5

3.2.6

3.2.7

3.2.8

3.2.9

3.2.10

3.3.1

3.3.2

3.3.3

3.3.4

3.3.5

Mailbox Message Queuing ..................................................................................... 76

Queue Timeouts ..................................................................................................... 76

Special Function Mailbox Messaging Commands .................................................. 77

Mailbox Message: Set Operating Mode ................................................................. 78

Mailbox Message: Set Slave Mode ........................................................................ 80

Mailbox Message: Get Slave Diagnostics .............................................................. 83

Mailbox Message: Get Slave Configuration ........................................................... 86

Mailbox Message: Get Database Information ........................................................ 87

Mailbox Message: Get Live List .............................................................................. 89

Mailbox Message: Acyclic Data Read: Class 1 ...................................................... 91

Mailbox Message: Acyclic Data Write: Class 1 ...................................................... 93

Mailbox Message: Start Slave ................................................................................ 95

Mailbox Message: Stop Slave ................................................................................ 96

Mailbox Messaging Error Codes............................................................................. 99

Acyclic Message Status Word ................................................................................ 99

Return Codes ........................................................................................................ 100

Error Codes ........................................................................................................... 101

DP-V1 Error Codes ............................................................................................... 102

Command Error Codes ......................................................................................... 103

4 Diagnostics and Troubleshooting 105

4.1

4.2

4.3

4.4

4.5

4.6

4.7

4.3.1

4.3.2

4.5.1

4.5.2

4.6.1

4.6.2

4.6.3

4.6.4

4.6.5

4.6.6

4.7.1

Required Hardware ............................................................................................... 106

Basic Troubleshooting Steps ................................................................................ 107

PROFIBUS DP-V1 (PDPMV1 Driver) Master LED Indicators .............................. 108

PROFIBUS Master Indicators ............................................................................... 108

Examples .............................................................................................................. 109

Viewing the Online Status of the PROFIBUS Network ......................................... 110

Using ProSoft Configuration Builder (PCB) for Diagnostics ................................. 112

Using the Diagnostic Window in ProSoft Configuration Builder - PLX ................. 112

Main Menu ............................................................................................................ 115

Standard PROFIBUS Slave Diagnostic Bytes ...................................................... 117

Byte 0 - Station Status 1 Bits ................................................................................ 117

Byte 1 - Station Status 2 Bits ................................................................................ 117

Byte 2 - Station Status 3 Bits ................................................................................ 118

Byte 3 - Master Address ....................................................................................... 118

Byte 4 - Ident Number High .................................................................................. 118

Byte 5 - Ident Number Low ................................................................................... 118

Status and Status Mapping ................................................................................... 119

PDPMV1 Command Status Data Area ................................................................. 120

5 Reference 121

5.1

5.1.1

PROFIBUS comDTM ............................................................................................ 122

ProSoft Technology Product Availability ............................................................... 122

Page 6 of 157 ProSoft Technology, Inc.

March 23, 2011

Page 7

PDPMV1 ♦ ProLinx Gateway Contents

PROFIBUS DPV1 Master Protocol Manual

5.1.2

5.2

5.3

5.4

5.5

5.6

5.1.3

5.1.4

5.1.5

5.1.6

Introduction to PROFIBUS comDTM .................................................................... 123

System Requirements ........................................................................................... 126

Installation ............................................................................................................. 127

Quick Start ............................................................................................................. 128

Verifying the comDTM Version and comDTM Install Version ............................... 133

RS-232 Configuration/Debug Port ........................................................................ 139

DB9 to Mini-DIN Adaptor (Cable 09) ..................................................................... 140

PROFIBUS Master Port ........................................................................................ 141

Supported PROFIBUS Services ........................................................................... 142

Constructing a Bus Cable for PROFIBUS DP ....................................................... 143

6 Support, Service & Warranty 147

Contacting Technical Support ......................................................................................................... 147

6.1

6.2

6.1.1

6.1.2

6.1.3

6.2.1

6.2.2

6.2.3

6.2.4

6.2.5

6.2.6

6.2.7

6.2.8

6.2.9

6.2.10

Return Material Authorization (RMA) Policies and Conditions.............................. 149

Returning Any Product .......................................................................................... 149

Returning Units Under Warranty ........................................................................... 150

Returning Units Out of Warranty ........................................................................... 150

LIMITED WARRANTY ........................................................................................... 151

What Is Covered By This Warranty ....................................................................... 151

What Is Not Covered By This Warranty ................................................................ 152

Disclaimer Regarding High Risk Activities ............................................................ 152

Intellectual Property Indemnity .............................................................................. 153

Disclaimer of all Other Warranties ........................................................................ 153

Limitation of Remedies ** ...................................................................................... 154

Time Limit for Bringing Suit ................................................................................... 154

No Other Warranties ............................................................................................. 154

Allocation of Risks ................................................................................................. 154

Controlling Law and Severability ........................................................................... 154

Index 155

ProSoft Technology, Inc. Page 7 of 157

March 23, 2011

Page 8

Contents PDPMV1 ♦ ProLinx Gateway

Protocol Manual PROFIBUS DPV1 Master

Page 8 of 157 ProSoft Technology, Inc.

March 23, 2011

Page 9

PDPMV1 ♦ ProLinx Gateway Functional Overview

PROFIBUS DPV1 Master Protocol Manual

1 Functional Overview

In This Chapter

About the PROFIBUS Protocol .............................................................. 10

Compatibility Note ................................................................................. 11

PROFIBUS DP Architecture .................................................................. 12

Communication Types ........................................................................... 14

Master/Slave Communication Phases ................................................... 15

Gateway Internal Database ................................................................... 16

The PROFIBUS Master protocol driver exists as a single port implementation.

The driver can be configured as a Class 1 and Class 2 PROFIBUS Master to

interface with other PROFIBUS slave devices. The unit is also used for

configuration of the nodes on the PROFIBUS network. It provides access to

standard and extended diagnostic information, as well as freeze/sync capability,

Acyclic Communication (DPV1, Class 1 and 2), and Alarm Handling (DPV1). The

PROFIBUS Master port can be used to continuously interface with PROFIBUS

slave devices over a serial communication interface (RS-485).

ProSoft Technology, Inc. Page 9 of 157

March 23, 2011

Page 10

Functional Overview PDPMV1 ♦ ProLinx Gateway

Protocol Manual PROFIBUS DPV1 Master

1.1 About the PROFIBUS Protocol

PROFIBUS (Process Field Bus) is a widely used, open-standards protocol

created by a consortium of European factory automation suppliers in 1989.

PROFIBUS is a Master/slave protocol. The Master establishes a connection to

the remote slave. When the connection is established, the Master sends the

PROFIBUS commands to the slave.

The ProLinx PDPMV1 gateway unit acts as an input/output module between

devices on a PROFIBUS DP network and any other communication protocol. The

gateway uses an internal database to send data and mailbox requests and

responses to all PROFIBUS slaves on the PROFIBUS DP network.

PROFIBUS supports a variety of network types. The network type supported by

the PLX-PDPMV1 gateway is PROFIBUS DP version 1.0, which is designed for

remote I/O systems, motor control centers, and variable speed drives.

Page 10 of 157 ProSoft Technology, Inc.

March 23, 2011

Page 11

PDPMV1 ♦ ProLinx Gateway Functional Overview

PROFIBUS DPV1 Master Protocol Manual

1.2 Compatibility Note

The PDPMV1 product is not backward-compatible with the PDPM product due to

new enhancements and command structure. The PDPMV1 PROFIBUS DP-V1

Master gateway provides enhanced features beyond the PDPM DP-V0 gateway

as follows:

1 Increased Cyclic I/O. The PDPMV1 provides 768 Words of Input and 768

Words of Output.

2 ProSoft Configuration Builder (PCB) complete support. The PCB provides

module-level configuration and integrated PROFIBUS Master network

configuration support.

3 The PDPMV1 Master supports DP-V1 Class 1 or Class 2 DPV1 features such

as acyclic communication with slaves for parameterization and other slave

settings, alarm handling, extended diagnostics.

ProSoft Technology, Inc. Page 11 of 157

March 23, 2011

Page 12

Functional Overview PDPMV1 ♦ ProLinx Gateway

Protocol Manual PROFIBUS DPV1 Master

1.3 PROFIBUS DP Architecture

The PROFIBUS DP-V1 Master network supports multiple Master systems with

several slaves.

The following table shows the most important features of PROFIBUS DP-V1

Master:

Standard EIN 501 70

DIN 19245

Transmission equipment (Physical) EIA RS-485

IEC 1158-2 (through link or coupler)

Fiber Optic Cable (not available)

Transfer procedure Half-duplex

Bus topology Linear bus with active bus termination

Bus cable type Shielded twisted pair conductors

Connector 9-pin D-Sub

Number of nodes on the bus Max: 32 with no repeaters

Max: 125 with 3 repeaters in 4 segments

1.3.1 How Cable Length Affects Communication Rate

Max Bus Cable Length Per Segment Baud Rates (for 12 Mbps cable)

1.2 km 9.6 kbit/sec

1.2 km 19.2 kbit/sec

1.2 km 93.75 kbit/sec

1.0 km 187.5 kbit/sec

0.5 km 500 kbit/sec

0.2 km 1.5 Mbit/sec

0.1 km 3 Mbit/sec

0.1 km 8 Mbit/sec

0.1 km 12 Mbit/sec

1.3.2 Bus Access

Two different bus access procedures handle the various communication

requirements for the PROFIBUS DP-V1 Master topology:

Token Passing

Polling

Page 12 of 157 ProSoft Technology, Inc.

March 23, 2011

Page 13

PDPMV1 ♦ ProLinx Gateway Functional Overview

PROFIBUS DPV1 Master Protocol Manual

1.3.3 Token Passing

Token passing ring is the basis for communication between the more complex,

active stations. All stations have the same rights in that a token is passed from

station to station in a logical ring. The token is passed to each station with a

maximum, definable token cycle time. A station is given transmission rights for

the duration of time that it has the token.

1.3.4 Master/Slave Polling

Master/slave polling guarantees a cyclic, real-time based data exchange

between the station with transmission rights, the active station, and its

subordinates, the passive stations. In this case, the Master is able to pass data to

the slave and/or receive data. The services in layer 2 (field-bus data link in ISOOSI reference model) organize this communication.

ProSoft Technology, Inc. Page 13 of 157

March 23, 2011

Page 14

Functional Overview PDPMV1 ♦ ProLinx Gateway

Protocol Manual PROFIBUS DPV1 Master

1.4 Communication Types

In addition to point-to-point data transfer, the PROFIBUS protocol can also

handle the following types of communication.

Broadcast communication: An active node sends an unacknowledged

message to all other nodes (Master and slaves)

Multicast communication (control instructions): An active node sends an

unacknowledged message to a group of nodes (Master and slaves)

Page 14 of 157 ProSoft Technology, Inc.

March 23, 2011

Page 15

PDPMV1 ♦ ProLinx Gateway Functional Overview

PROFIBUS DPV1 Master Protocol Manual

1.5 Master/Slave Communication Phases

The communication between the Master and the slaves takes place in the

following phases:

Parameterization and configuration phase

Usable data transfer phase

Before a DP slave can be integrated into the usable data transfer phase, the

parameterization and configuration phase runs a device identification test that

verifies that the planned configuration matches the actual device configuration for

each slave in the PROFIBUS network. The test verifies that:

The device is actually there

It is the right type of device

The station address set on the device matches the station address in the bus

configuration

The formats, telegram length information, and bus parameters are correct

and

The number of configured inputs and outputs is correct

ProSoft Technology, Inc. Page 15 of 157

March 23, 2011

Page 16

Functional Overview PDPMV1 ♦ ProLinx Gateway

Protocol Manual PROFIBUS DPV1 Master

1.6 Gateway Internal Database

The internal database is central to the functionality of the gateway. This database

is shared between all the ports on the gateway and is used as a conduit to pass

information from one device on one network to one or more devices on either

connected network. This permits data from devices on one communication port

or network to be viewed and controlled by devices on another port or network.

In addition to data from the Master and slave ports, status and error information

generated by the gateway can also be mapped into the internal database.

Page 16 of 157 ProSoft Technology, Inc.

March 23, 2011

Page 17

PDPMV1 ♦ ProLinx Gateway Configuration

PROFIBUS DPV1 Master Protocol Manual

2 Configuration

In This Chapter

Configuring the Gateway ....................................................................... 18

PROFIBUS Master DPV1 ...................................................................... 26

PROFIBUS Master Commands ............................................................. 31

Example Mailbox Commands ................................................................ 33

Configuring the PROFIBUS DP Network ............................................... 52

Downloading the Project to the Gateway .............................................. 71

Backing Up the Project .......................................................................... 72

ProSoft Technology, Inc. Page 17 of 157

March 23, 2011

Page 18

Configuration PDPMV1 ♦ ProLinx Gateway

Protocol Manual PROFIBUS DPV1 Master

2.1 Configuring the Gateway

Because the task of configuring the PROFIBUS network can be challenging,

ProSoft Technology has provided a configuration tool called ProSoft

Configuration Builder (PCB) that will help you with the following tasks:

Creating a configuration project (page 22)

Setting gateway parameters (page 24)

Configuring the PROFIBUS network (page 52) (Master and slaves)

Downloading the project to the gateway (page 71)

The following topics of this chapter explain each task step-by-step.

2.1.1 Installing ProSoft Configuration Builder Software

You must install the ProSoft Configuration Builder (PCB) software to configure

the gateway. You can always get the newest version of ProSoft Configuration

Builder from the ProSoft Technology website.

To install ProSoft Configuration Builder from the ProSoft Technology website

1 Open your web browser and navigate to http://www.prosoft-

technology.com/pcb

2 Click the D

Configuration Builder.

3 Choose S

4 Save the file to your Windows Desktop, so that you can find it easily when

you have finished downloading.

5 When the download is complete, locate and open the file, and then follow the

instructions on your screen to install the program.

If you do not have access to the Internet, you can install ProSoft Configuration

Builder from the ProSoft Solutions Product CD-ROM, included in the package

with your gateway.

OWNLOAD HERE

AVE

or S

AVE FILE

link to download the latest version of ProSoft

when prompted.

Page 18 of 157 ProSoft Technology, Inc.

March 23, 2011

Page 19

PDPMV1 ♦ ProLinx Gateway Configuration

PROFIBUS DPV1 Master Protocol Manual

To install ProSoft Configuration Builder from the Product CD-ROM

1 Insert the ProSoft Solutions Product CD-ROM into the CD-ROM drive of your

PC. Wait for the startup screen to appear.

2 On the startup screen, click P

RODUCT DOCUMENTATION

. This action opens a

Windows Explorer file tree window.

3 Click to open the U

TILITIES

folder. This folder contains all of the applications

and files you will need to set up and configure your gateway.

4 Double-click the S

PCB_*.

EXE

file and follow the instructions on your screen to install the

ETUP CONFIGURATION TOOL

folder, double-click the

software on your PC. The information represented by the "*" character in the

file name is the PCB version number and, therefore, subject to change as

new versions of PCB are released.

Note: Many of the configuration and maintenance procedures use files and other utilities on the

CD-ROM. You may wish to copy the files from the Utilities folder on the CD-ROM to a convenient

location on your hard drive.

Using the Online Help

Most of the information needed to help you use ProSoft Configuration Builder is

provided in a Help System that is always available whenever you are running

ProSoft Configuration Builder. The Help System does not require an Internet

connection.

To view the help pages, start ProSoft Configuration Builder, open the H

menu, and then choose C

ONTENTS

.

ELP

Adding a Location to an Existing Project File

1 Right-click the P

ROJECT

icon and select A

DD LOCATION

. A new Location icon

appears.

or

Select the P

2 Choose P

ROJECT

ROJECT

icon.

from the P

ROJECT

menu, and then choose A

DD LOCATION

.

A new Location icon appears.

or

If the Default Location has not been named (is not already an existing

project), right-click the folder and choose R

3 Type in the Location name.

ENAME

.

Adding a Project to an Existing Project File

1 Select the D

2 Open the P

This action opens a new Project folder.

EFAULT PROJECT

ROJECT

menu, choose P

icon.

ROJECT,

and then choose A

DD PROJECT

.

ProSoft Technology, Inc. Page 19 of 157

March 23, 2011

Page 20

Configuration PDPMV1 ♦ ProLinx Gateway

Protocol Manual PROFIBUS DPV1 Master

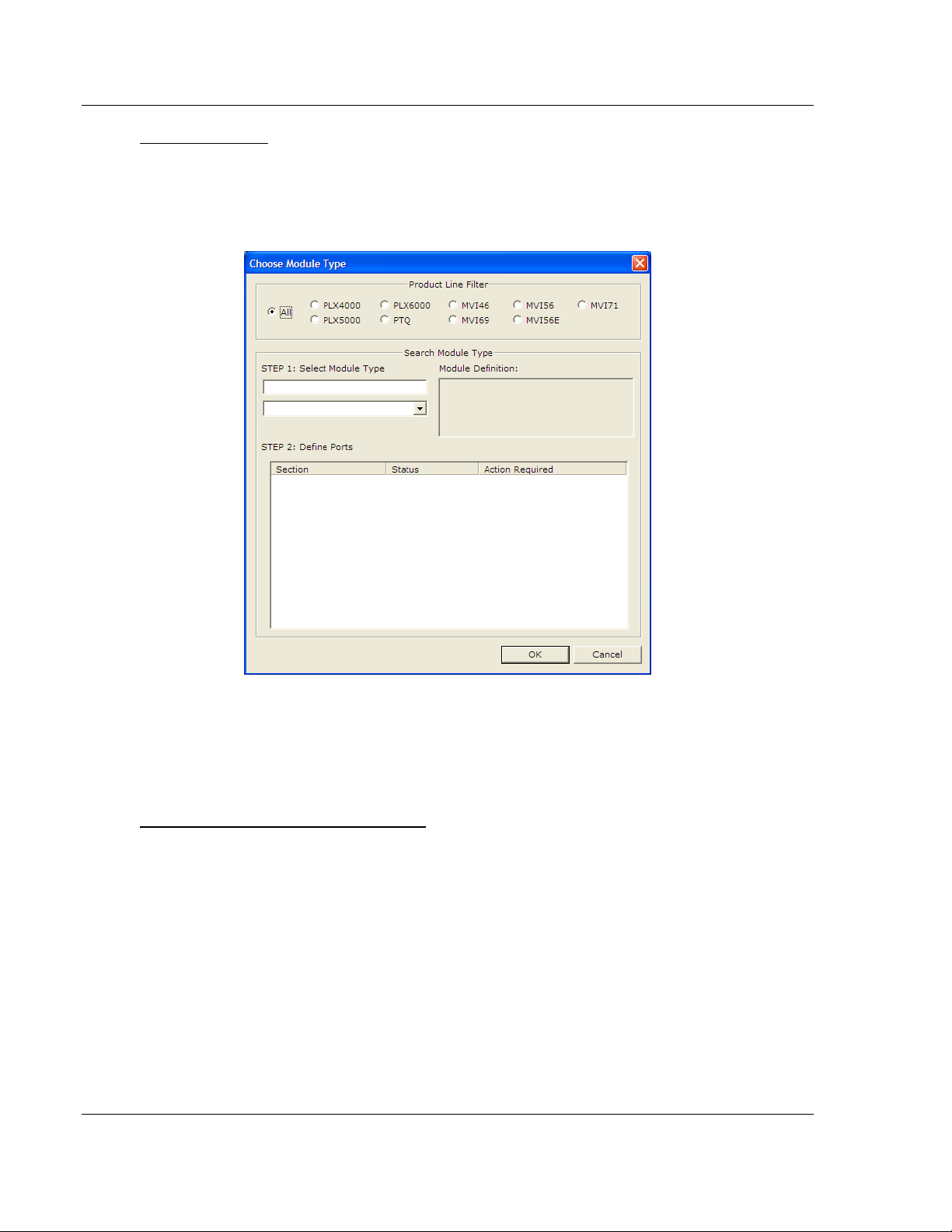

Adding a Module

Begin the process of creating your custom application configuration by selecting

the module type of your ProLinx gateway.

1 Double-click the D

EFAULT MODULE

icon to open the Choose Module Type

dialog box.

2 In the Choose Module Type dialog box, select the M

ODULE

type.

Or

1 Open the P

2 On the L

ROJECT

OCATION

menu and choose L

menu, choose A

DD MODULE

OCATION.

.

To add a module to a different location

1 Right-click the L

OCATION

folder and choose A

DD MODULE

. A new Module icon

appears.

Or

1 Select the L

2 From the P

OCATION

ROJECT

icon.

menu, select L

OCATION

, and then select A

DD MODULE

.

Page 20 of 157 ProSoft Technology, Inc.

March 23, 2011

Page 21

PDPMV1 ♦ ProLinx Gateway Configuration

PROFIBUS DPV1 Master Protocol Manual

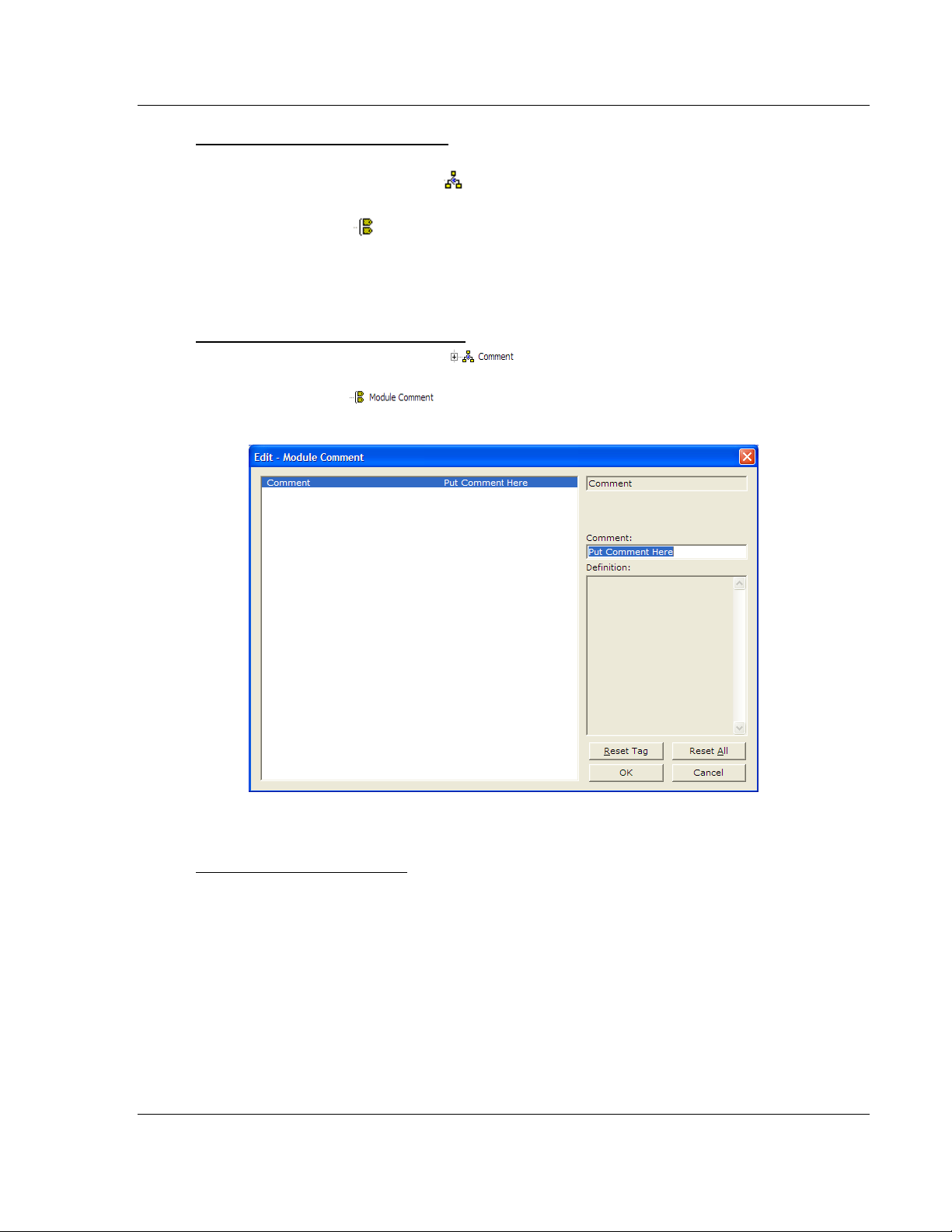

Configuring Gateway Parameters

1 Click the [+] sign next to the module icon to expand gateway information.

2 Click the [+] sign next to any icon to view gateway information and

configuration options.

3 Double-click any icon to open an Edit dialog box.

4 To edit a parameter, select the parameter in the left pane and make your

changes in the right pane.

5 Click OK to save your changes.

Creating Optional Comment Entries

1 Click the [+] to the left of the icon to expand the module

comments.

2 Double-click the icon. The Edit - Module Comment dialog box

appears.

3 Enter your comment and click OK to save your changes.

Printing a Configuration File

1 Select the module icon, and then click the right mouse button to open a

shortcut menu.

2 On the shortcut menu, choose V

IEW CONFIGURATION

. This action opens the

View Configuration window.

3 In the View Configuration window, open the F

ILE

menu, and choose P

RINT.

This action opens the Print dialog box.

4 In the Print dialog box, choose the printer to use from the drop-down list,

select printing options, and then click OK.

ProSoft Technology, Inc. Page 21 of 157

March 23, 2011

Page 22

Configuration PDPMV1 ♦ ProLinx Gateway

Protocol Manual PROFIBUS DPV1 Master

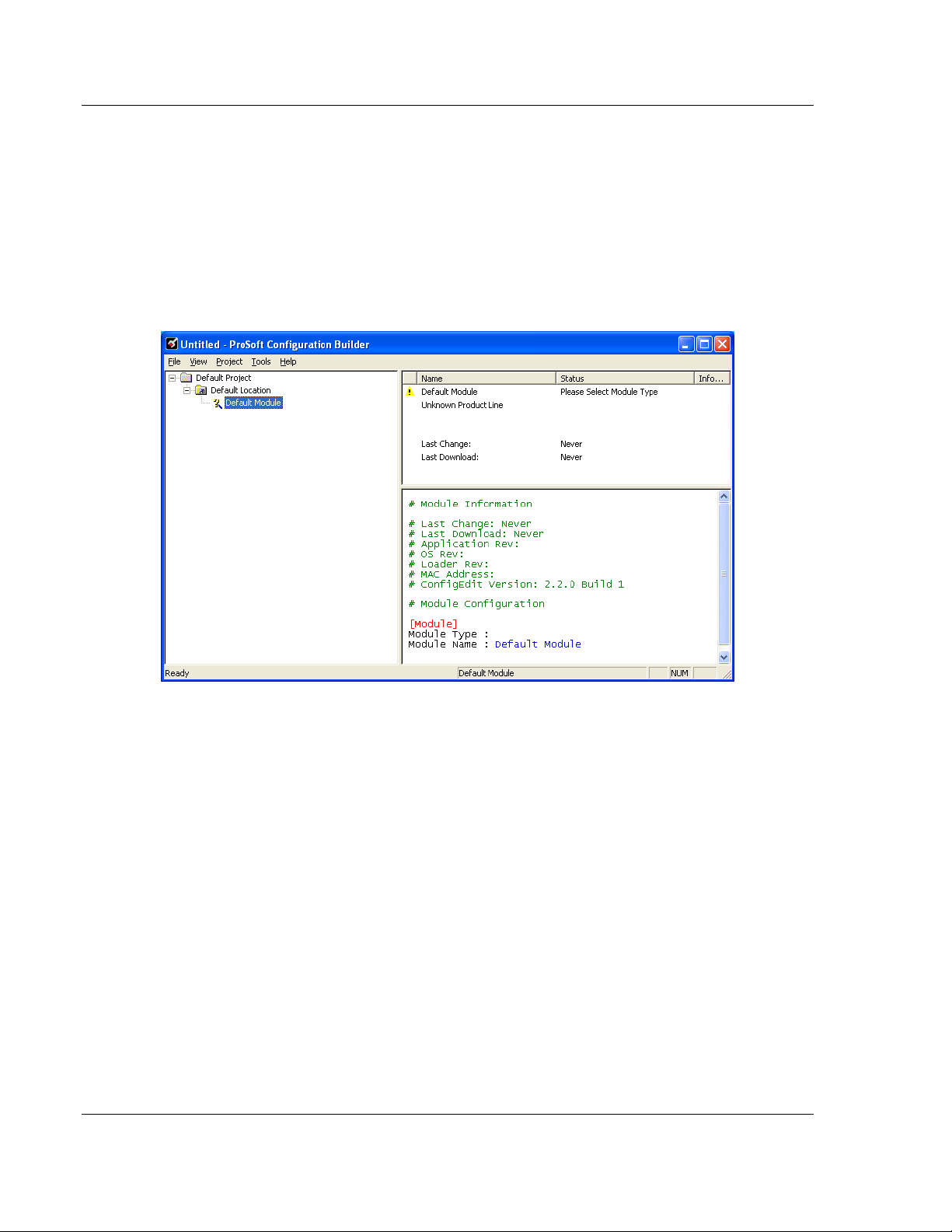

2.1.2 Setting Up the Project

To begin, start ProSoft Configuration Builder. If you have used other Windows

configuration tools before, you will find the screen layout familiar. ProSoft

Configuration Builder’s window consists of a tree view on the left, an information

pane and a configuration pane on the right side of the window. When you first

start ProSoft Configuration Builder, the tree view consists of folders for Default

Project and Default Location, with a Default Module in the Default Location

folder. The following illustration shows the ProSoft Configuration Builder window

with a new project.

Your first task is to add the PDPMV1 gateway to the project.

1 Use the mouse to select D

EFAULT MODULE

in the tree view, and then click the

right mouse button to open a shortcut menu.

Page 22 of 157 ProSoft Technology, Inc.

March 23, 2011

Page 23

PDPMV1 ♦ ProLinx Gateway Configuration

PROFIBUS DPV1 Master Protocol Manual

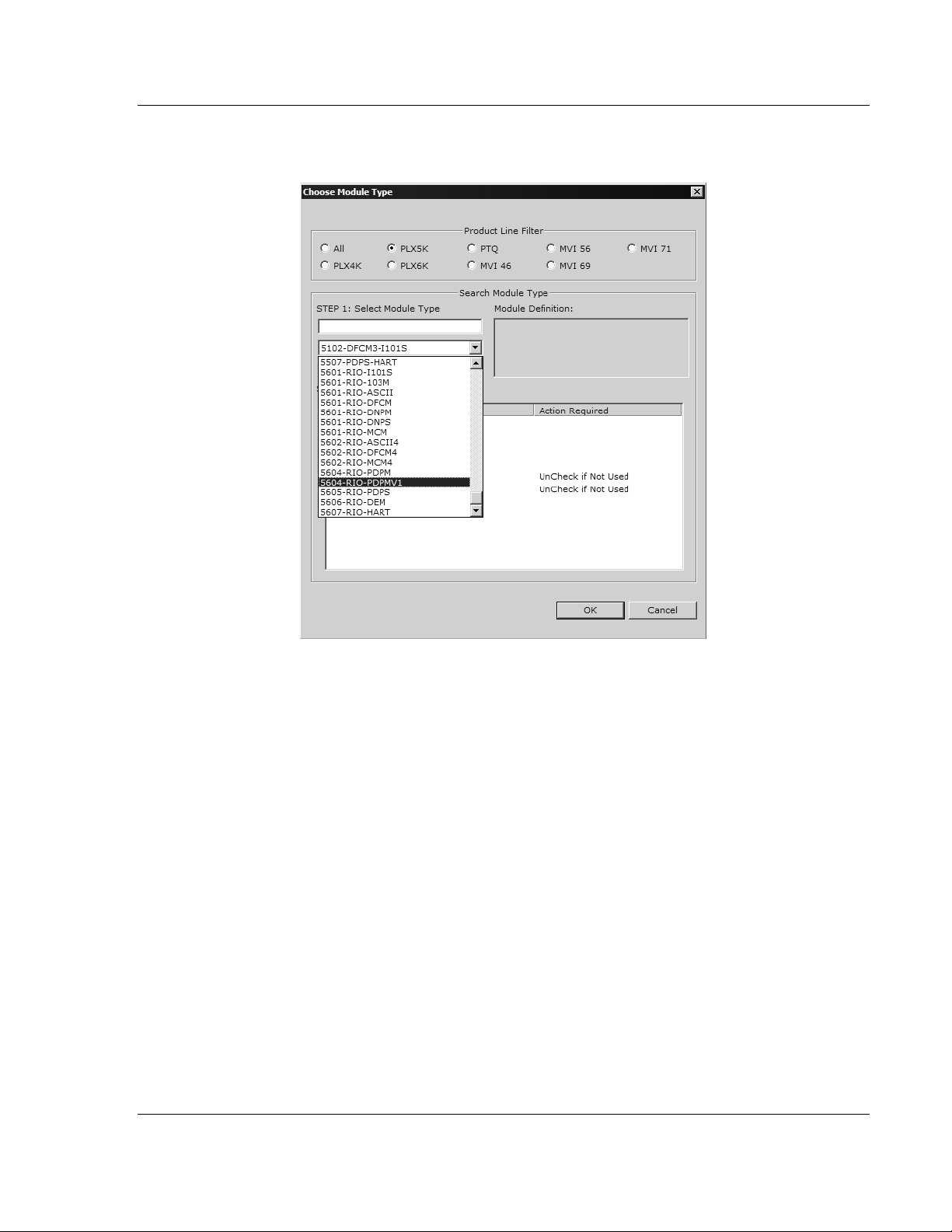

2 On the shortcut menu, select C

HOOSE MODULE TYPE

. This action opens the

Choose Module Type dialog box.

3 In the Product Line Filter area of the dialog box, select the gateway series

(PLX5K for wired gateways, or PLX6K for wireless gateways). In the Select

Module Type dropdown list, select the model number for your gateway (for

example, 5204-MNET-PDPMV1), and then click OK to save your settings and

return to the ProSoft Configuration Builder window.

The next task is to set the gateway parameters.

ProSoft Technology, Inc. Page 23 of 157

March 23, 2011

Page 24

Configuration PDPMV1 ♦ ProLinx Gateway

Protocol Manual PROFIBUS DPV1 Master

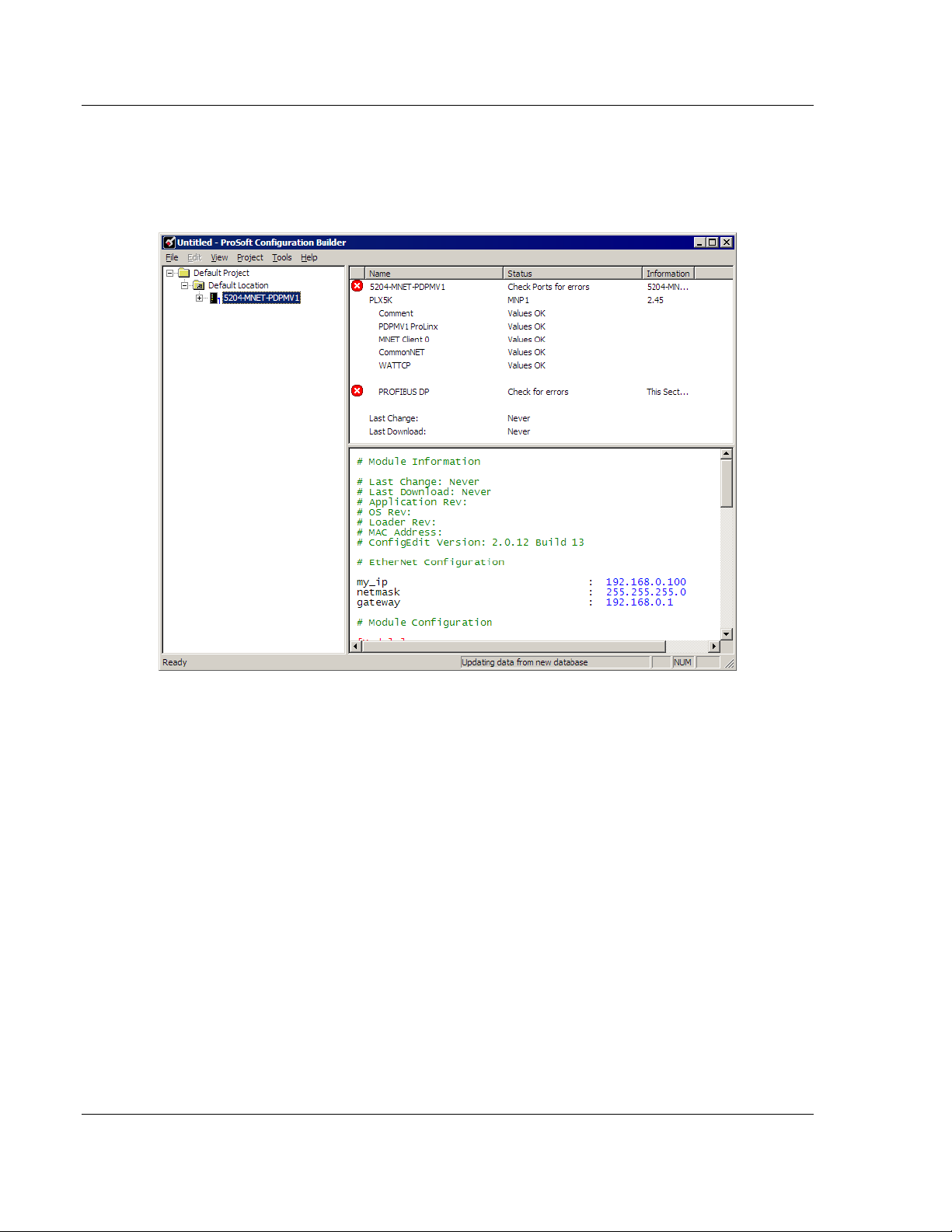

2.1.3 Setting Gateway Parameters

Notice that the contents of the information pane and the configuration pane

changed when you added the PDPMV1 gateway to the project. The red "X" icon

indicates that the gateway’s configuration is incomplete.

1 Click the plus sign [+] next to the module icon to expand the module tree, and

then expand the PLX PDPM-V1 tree.

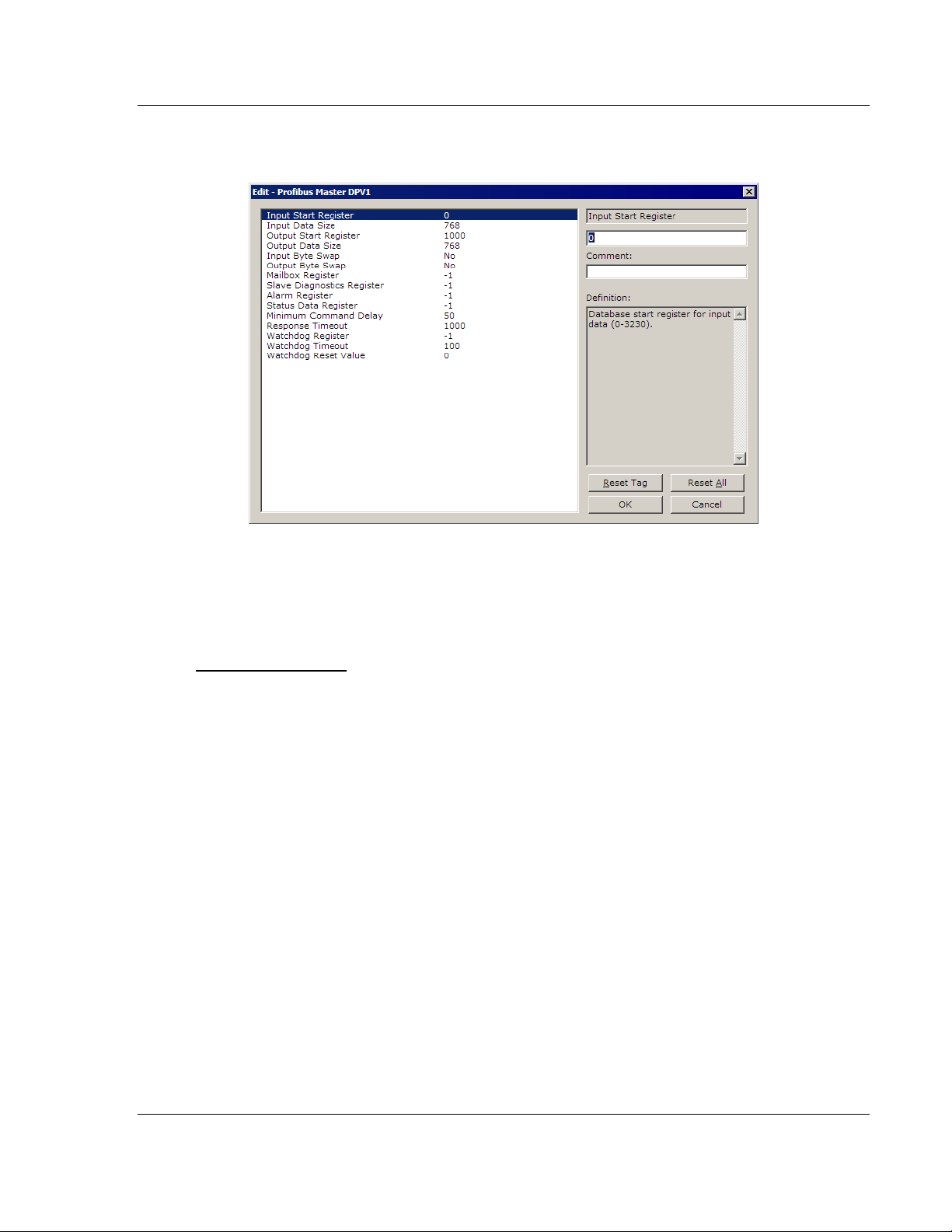

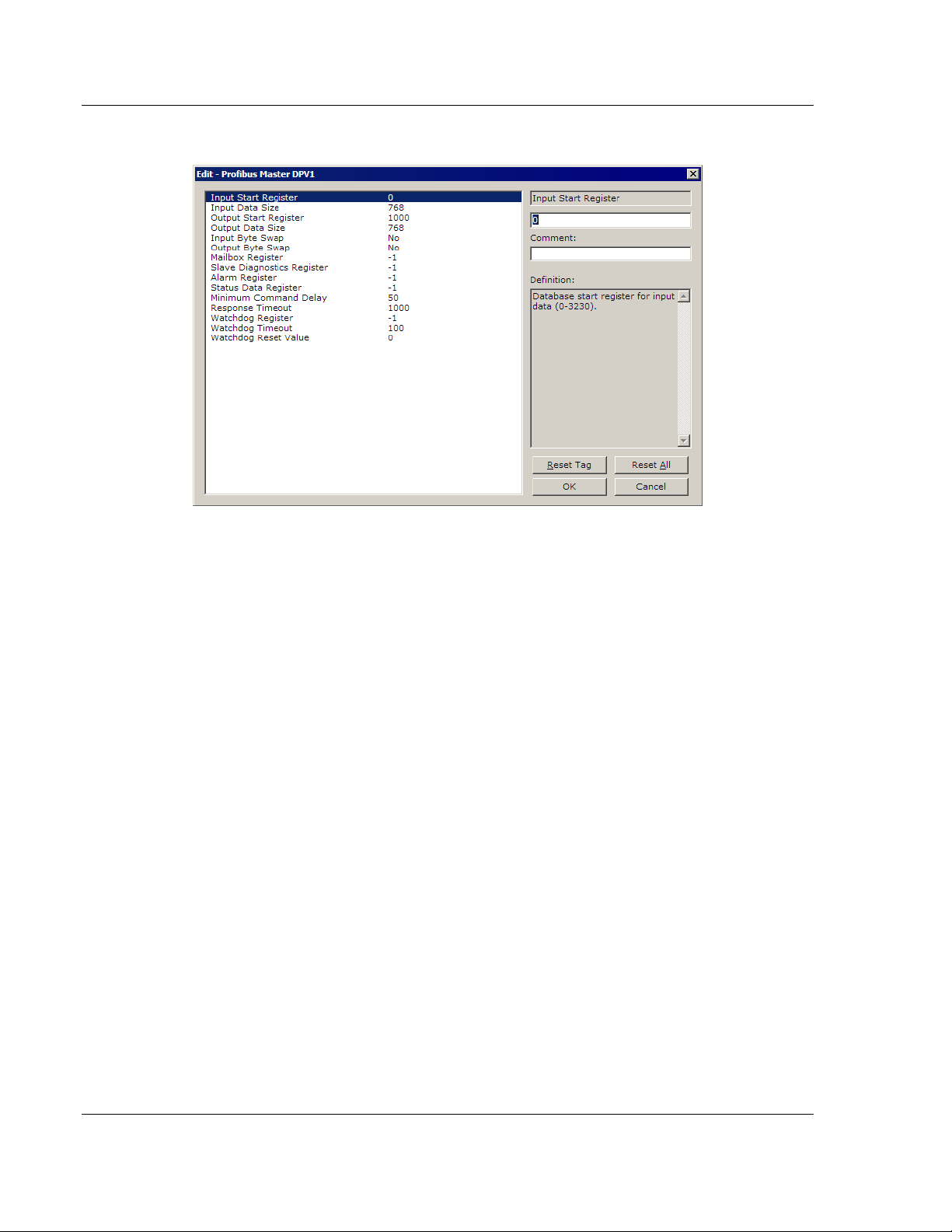

2 Double-click the PROFIBUS M

ASTER

DPV1 object. This action opens the Edit

dialog box.

3 In the Edit dialog box, enter the values for Input Data Size and Output Data

Size (PROFIBUS input and output point words) to match the values required

by your application. To change a value, select the parameter to modify in the

left pane, and then type the new value in the edit field in the right pane.

Page 24 of 157 ProSoft Technology, Inc.

March 23, 2011

Page 25

PDPMV1 ♦ ProLinx Gateway Configuration

PROFIBUS DPV1 Master Protocol Manual

For the sample application, the input and output data size values are fixed to

a value of 768.

4 Click OK to save your settings and return to the ProSoft Configuration Builder

window.

At this time, you may wish to rename the Default Project and Default Location

folders in the tree view.

To rename an object

1 Select the object, and then click the right mouse button to open a shortcut

menu. From the shortcut menu, choose R

ENAME

.

2 Type the name to assign to the object.

3 Click away from the object to save the new name.

ProSoft Technology, Inc. Page 25 of 157

March 23, 2011

Page 26

Configuration PDPMV1 ♦ ProLinx Gateway

Protocol Manual PROFIBUS DPV1 Master

2.2 PROFIBUS Master DPV1

2.2.1 Input Start Register

0 to 3230

Database start register for input data.

2.2.2 Input Data Size

0 to 768

Total number of PROFIBUS Input Words (one word equals two bytes) from all

PROFIBUS slaves. These Input Words will be the data received from slave

devices on the PROFIBUS network.

2.2.3 Output Start Register

0 to 3230

Database start register for output data.

2.2.4 Output Data Size

0 to 768

Total number of PROFIBUS Output Words (one word equals two bytes) to be

sent to all PROFIBUS slaves. These Output Words will be the data sent to slave

devices on the PROFIBUS network.

Page 26 of 157 ProSoft Technology, Inc.

March 23, 2011

Page 27

PDPMV1 ♦ ProLinx Gateway Configuration

PROFIBUS DPV1 Master Protocol Manual

2.2.5 Input Byte Swap

YES or NO

This parameter determines if the bytes in the PROFIBUS Input Data area are

swapped before being stored in the gateway memory database. If the parameter

is set to NO, no swapping will be applied. If the parameter is set to YES, the order

of bytes in each word will be swapped before being stored in memory.

Example:

With Input Byte Swap set to NO, incoming order is unchanged - ABCDEF

With Input Byte Swap set to YES, each byte pair is swapped - BADCFE

2.2.6 Output Byte Swap

YES or NO

This parameter determines if the bytes in the PROFIBUS Output Data area are

swapped before being transmitted to slaves on the PROFIBUS network. If the

parameter is set to NO, no swapping will be applied. If the parameter is set to

YES, the order of bytes in each word will be swapped before being transmitted.

Example:

With Output Byte Swap set to NO, outgoing output order is unchanged -

ABCDEF

With Output Byte Swap set to YES, each output byte pair is swapped -

BADCFE

ProSoft Technology, Inc. Page 27 of 157

March 23, 2011

Page 28

Configuration PDPMV1 ♦ ProLinx Gateway

Protocol Manual PROFIBUS DPV1 Master

2.2.7 Mailbox Register

0 to 3700, -1 to disable

Enter the database register for DPV1 mailbox messages, or -1 to disable mailbox

messages.

Mailbox messages can be sent through the database to the PROFIBUS Master.

This functionality requires 290 registers of the database. The map of the

database area utilized for this purpose is as follows.

Offset Description

0 This is the handshake word used to tell the PROFIBUS driver when a new acyclic

message is ready to send. If the value at this location is zero (0), no message will be

sent. If the value is not zero, then the PROFIBUS driver will send an acyclic

message using the contents of words 1 through 144. This handshake word should

be set to a non-zero value only after the complete acyclic message is stored in

offsets 1 to 144. After the PROFIBUS driver has added the acyclic message to the

queue, this register will be set to zero (0), so that the message is not repeated and to

indicate that a new acyclic message may be prepared.

NOTE: It would be a good practice to check the value of word 145 to be sure it is set

to zero (indicating that no acyclic messages are awaiting processing) before setting

this word to a non-zero value, triggering an acyclic message. This will help avoid

acyclic data collisions and data loss.

1 to 144 This area holds the acyclic message bytes to send. Please refer to Mailbox

Messaging (page 75) for the format of this data area.

NOTE: The header words (first 32 bytes) are stored in little-endian format and the

gateway will change the order to big-endian format before sending.

145 This handshake word indicates when a new acyclic response message has been

received by the PROFIBUS driver. If the value is zero (0), no response message has

been received. If the value is non-zero, a response message has been received and

stored in words 146 to 289. This data should be transferred by the other gateway

protocol for external processing. After the acyclic message has been externally

processed, a message should be returned through the other protocol that sets this

address to zero, to indicate readiness to receive and process a new acyclic response

message.

146 to 289 This area holds the acyclic message response bytes. Please refer to Mailbox

Messaging (page 75) for the format of this data area. The header words (first 32

bytes) are stored in little-endian format to make it easier to use.

Alarm acyclic messages are sent from the PROFIBUS driver to the database if

this feature is enabled by entering a valid database register in the configuration

file. This feature requires 145 database registers. The format of the data area is

as follows.

Offset Description

0 This is the alarm handshake word. If the value is not zero (0), alarm data is present

in the words 1 through 144. This register should be set to zero after the alarm is

process, so another alarm can be passed through the database. If this register is

zero (0), the database area is ready to receive a new alarm message.

1 to 144 This area holds the alarm acyclic message received by the PROFIBUS Master

device. Please refer to Mailbox Messaging (page 75) for a description of this acyclic

message. The header (first 32 bytes) of the message is stored in little-endian format

Page 28 of 157 ProSoft Technology, Inc.

March 23, 2011

to make it easier to process.

Page 29

PDPMV1 ♦ ProLinx Gateway Configuration

PROFIBUS DPV1 Master Protocol Manual

2.2.8 Slave Diagnostics Register

0 to 3600, -1 to disable

Enter the database register start location for DPV1 slave diagnostics messages,

or -1 to disable slave diagnostics.

When this register is enabled, the gateway will automatically place 378 words of

collected slave diagnostic data into the specified database start register.

Each slave requires 3 words of data. Data is gathered for slaves 0 to 125. The

application will poll for a new slave every 100 milliseconds.

2.2.9 Alarm Register

0 to 3900, -1 to disable

Enter the database register for DPV1 alarm messages, or -1 to disable alarm

messages.

2.2.10 Status Data Register

0 to 3900, -1 to disable

Enter the gateway memory database register for DP-V1 status data messages,

or -1 to disable status data messages.

2.2.11 Minimum Command Delay

0 to 32767

Minimum number of milliseconds between each command.

2.2.12 Response Timeout

0 to 5000 milliseconds

Number of milliseconds to wait for response to command. The value is set

depending upon the communication network used and the expected response

time of the slowest device on the network.

2.2.13 Watchdog Register

The Watchdog function allows the gateway to monitor a database register, the

Watchdog Register, to check for loss of communication with the non-PROFIBUS

communication protocol. If this function is used, the other gateway protocol is

expected to change the value in the Watchdog Register at an interval less than

the amount of time specified in the Watchdog Timeout parameter. If the value in

the Watchdog Register does not change within this amount of time, a

communication loss is assumed and the Watchdog function will set the

PROFIBUS outputs to the default value specified in the Watchdog Reset Value

parameter. To disable this function, set this parameter to a value of -1.

ProSoft Technology, Inc. Page 29 of 157

March 23, 2011

Page 30

Configuration PDPMV1 ♦ ProLinx Gateway

Protocol Manual PROFIBUS DPV1 Master

2.2.14 Watchdog Timeout

Sets the period of time (in 0.1s increments) for the gateway to wait for

communication loss detection. For example, set this parameter to 100 to set a

waiting period of 10 seconds. To disable this function, set this parameter to a

value of -1.

2.2.15 Watchdog Reset Value

Sets the value that will be sent to the PROFIBUS output byte registers upon

communication loss as detected by the Watchdog function. To disable this

function, set this parameter to a value of -1.

Page 30 of 157 ProSoft Technology, Inc.

March 23, 2011

Page 31

PDPMV1 ♦ ProLinx Gateway Configuration

PROFIBUS DPV1 Master Protocol Manual

2.3 PROFIBUS Master Commands

Type

Disabled: command will not be executed.

Enabled Continuous: command will be executed as frequently as set by Poll

Interval parameter.

Enabled Conditional: command will only be executed if the values at the

database at address set by Database Register parameter changes.

Enabled With Trigger: command will be executed if database trigger value

(set by Database Trigger parameter) is different from 0. After the command is

executed then the database trigger value is automatically set to 0 (zero).

Database Register

Database location for the operate mode if the count is set to 0 (zero).

Count

If Count is equal to zero, operate mode for command is derived from the

Database Register parameter in the gateway database. If the count is non-

zero, then the value in the Operation Mode field is used with the command.

Poll Interval

Sets how frequently in seconds the command will be executed if type is

configured as Enabled Continuous.

Swap

On requests used only for Function Code 33 (Acyclic Write).

On responses used for Function Code 4, 23, 24 and 32.

Database Trigger

This functionality requires the type parameter to be set as Enabled With

Trigger. The command will be executed if the database value set by this

parameter is non-zero. After the command is executed this value will be

automatically set to zero.

Function

Set Operate Mode (FC-2)

Set Slave Mode ( FC-3)

Get Slave Diagnostic Data (FC-4)

Get Slave Configuration (FC-5)

Start/Stop Slaves Dynamically (FC-11/FC-12)

Get Database Information (FC-23) (should be viewed in ASCII for CRC

Values)

Get Live List (FC-24)

Acyclic Read (FC-32)

Acyclic Write (FC-33)

ProSoft Technology, Inc. Page 31 of 157

March 23, 2011

Page 32

Configuration PDPMV1 ♦ ProLinx Gateway

Protocol Manual PROFIBUS DPV1 Master

Operation Mode

This field is required if the count field is set to 1 and represents the new

operation mode as follows:

o

64=Stop

o

128=Clear

o

192=Operate

Page 32 of 157 ProSoft Technology, Inc.

March 23, 2011

Page 33

PDPMV1 ♦ ProLinx Gateway Configuration

PROFIBUS DPV1 Master Protocol Manual

2.4 Example Mailbox Commands

The following examples show how to issue mailbox commands for Set Operating

Mode, Get Live List and Start/Stop Slaves. The rest of the supported mailbox

commands are configured the same way.

2.4.1 Set Operating Mode

1 In ProSoft Configuration Builder (PCB), expand the PLX PDPM-V1 section.

2 Select P

mouse button, and then choose C

ROFIBUS MASTER COMMANDS SET OPERATE MODE

ONFIGURE

, click the right

.

ProSoft Technology, Inc. Page 33 of 157

March 23, 2011

Page 34

Configuration PDPMV1 ♦ ProLinx Gateway

Protocol Manual PROFIBUS DPV1 Master

This action opens the Edit - Profibus Master Commands dialog box. This

dialog box allows you to add commands, one row at a time, with all the

necessary parameters.

3 To add a command, click A

DD ROW

. This action adds a command to the list,

populated with the default values for the command.

Page 34 of 157 ProSoft Technology, Inc.

March 23, 2011

Page 35

PDPMV1 ♦ ProLinx Gateway Configuration

PROFIBUS DPV1 Master Protocol Manual

4 To change the settings for the command, select the row, and then click E

DIT

ROW. This action opens the Edit - Row 1 dialog box.

Command Layout for Set Operating Mode

Column Value Description

Type 0 to 3

DB_Reg If the count is set to 0, this is the database location for the operate mode. Place a value of

Count If Count is equal to 0, operate mode for command is derived from the DB_Reg in the

Poll_Int Only if type = 1

Swap Not used

DB_Trigger This functionality requires the type parameter to be set as Enabled With Trigger. The

Func 2 Set Operate Mode.

Param_1 64, 128 or

192

0 Command Disabled

1 Command Enabled, use poll interval

2 Command executed when database changes (Func 2, 3, 11, 12 or 33 only)

3 Command executed when database trigger set Not equal to 0

64 or 128 or 192 in parameter 1 for description.

gateway database. If the count is not equal to 0, then the value in the Param_1 field is

used with the command.

command will be executed if the database value set by this parameter is nonzero. After

the command is executed this value will be automatically set to zero.

This field is required if the count field is set to 1 and represents the new operation mode

as follows: 64=Stop, 128=Clear and 192=Operate.

ProSoft Technology, Inc. Page 35 of 157

March 23, 2011

Page 36

Configuration PDPMV1 ♦ ProLinx Gateway

Protocol Manual PROFIBUS DPV1 Master

For this example, the command will stop the Master using database trigger

register 3200. Any nonzero value placed in this register will trigger the command

to execute. When the command has executed, the database register will be reset

to zero.

The following illustration shows the parameters that execute this command.

In the following illustration, from the Diagnostics window in ProSoft Configuration

Builder, the Master's operation state is Operate (C0 hex). To see this screen,

press [2] from the Main menu.

Page 36 of 157 ProSoft Technology, Inc.

March 23, 2011

Page 37

PDPMV1 ♦ ProLinx Gateway Configuration

PROFIBUS DPV1 Master Protocol Manual

When you download the configuration containing this mailbox command to the

gateway, and then return to the Diagnostics window, press [F] at the Main menu,

and then press [S] to view the command list. The following illustration shows the

command list. Notice that the first command matches the settings you made in

the Edit - Profibus Master Commands dialog box.

Press [M] to return to the Main menu, and then press [2] to view the Fieldbus

Data again. Notice that the Operation State has changed to Stop (40 hex).

ProSoft Technology, Inc. Page 37 of 157

March 23, 2011

Page 38

Configuration PDPMV1 ♦ ProLinx Gateway

Protocol Manual PROFIBUS DPV1 Master

2.4.2 Get Live List

1 In ProSoft Configuration Builder (PCB), expand the PLX PDPM-V1 section.

2 Select P

button, and then choose C

ROFIBUS MASTER COMMANDS GET LIVE LIST

ONFIGURE

.

, click the right mouse

This action opens the Edit - Profibus Master Commands dialog box. This

dialog box allows you to add commands, one row at a time, with all the

necessary parameters.

Page 38 of 157 ProSoft Technology, Inc.

March 23, 2011

Page 39

PDPMV1 ♦ ProLinx Gateway Configuration

PROFIBUS DPV1 Master Protocol Manual

3 To add a command, click A

DD ROW

. This action adds a command to the list,

populated with the default values for the command.

4 To change the settings for the command, select the row, and then click E

ROW. This action opens the Edit - Row 1 dialog box.

DIT

ProSoft Technology, Inc. Page 39 of 157

March 23, 2011

Page 40

Configuration PDPMV1 ♦ ProLinx Gateway

Protocol Manual PROFIBUS DPV1 Master

Command Layout for Get Live List

Column Value Description

Type 0, 1 or 3

DB_Reg Location where the results from the command are placed.

Count This parameter specifies the number of word registers in the reply to place in the

Poll_Int Only if type = 1

Swap Utilized on response message

DB_Trigger This functionality requires the type parameter to be set as Enabled With Trigger. The

Func 24 Get Live List

Type 0 Command Disabled

1 Command Enabled, use poll interval

3 Command executed when database trigger set != 0

database.

command will be executed if the database value set by this parameter is nonzero.

After the command is executed this value will be automatically set to zero.

For this example, the command will retrieve the list of Masters and slaves using

database trigger register 3201. Any nonzero value placed in this register will

trigger the command to execute. When the command has executed, the

database register will be reset to zero. Data from the response will be placed at

database address 3300, with a length of 128 words.

The following illustration shows the parameters that execute this command.

Page 40 of 157 ProSoft Technology, Inc.

March 23, 2011

Page 41

PDPMV1 ♦ ProLinx Gateway Configuration

PROFIBUS DPV1 Master Protocol Manual

When you download the configuration containing this mailbox command to the

gateway, and then return to the Diagnostics window, press [F] at the Main menu,

and then press [S] to view the command list. The following illustration shows the

command list. Notice that the first command matches the settings you made in

the Edit - Profibus Master Commands dialog box.

ProSoft Technology, Inc. Page 41 of 157

March 23, 2011

Page 42

Configuration PDPMV1 ♦ ProLinx Gateway

Protocol Manual PROFIBUS DPV1 Master

Any nonzero value placed in register 3201 issues mailbox command Get Live

List. The results of this command are placed in the database starting at register

3300.

A value of 03 HEX indicates this is the Master address which is in this case is

01.

A value of 04 HEX indicates the slave is not configured and not connected.

A value of 00 HEX means this slave is configured and connected. In this case

Slave #2 and Slave #6 are connected to the Master and are exchanging

cyclic data.

Page 42 of 157 ProSoft Technology, Inc.

March 23, 2011

Page 43

PDPMV1 ♦ ProLinx Gateway Configuration

PROFIBUS DPV1 Master Protocol Manual

2.4.3 Start/Stop Slaves

1 In ProSoft Configuration Builder (PCB), expand the PLX PDPM-V1 section.

2 Select P

mouse button, and then choose C

Profibus Master Commands dialog box. This dialog box allows you to add

commands, one row at a time, with all the necessary parameters.

ROFIBUS MASTER COMMANDS START/STOP SLAVE

ONFIGURE

. This action opens the Edit -

, click the right

ProSoft Technology, Inc. Page 43 of 157

March 23, 2011

Page 44

Configuration PDPMV1 ♦ ProLinx Gateway

Protocol Manual PROFIBUS DPV1 Master

3 To add a command, click A

DD ROW

. This action adds a command to the list,

populated with the default values for the command.

4 To change the settings for the command, select the row, and then click E

ROW. This action opens the Edit - Row 1 dialog box.

DIT

Page 44 of 157 ProSoft Technology, Inc.

March 23, 2011

Page 45

PDPMV1 ♦ ProLinx Gateway Configuration

PROFIBUS DPV1 Master Protocol Manual

Command Layout for Start/Stop Slaves

Column Value Description

Type 0 to 3

DB_Reg This is the database location where the 126 bytes of data for the message to be constructed

Count This field is not used as the message is always 63-words in length

Poll_Int Only if type = 1

Swap Utilized on request and response message

DB_Trigger Used if type is 3

Func 11

12

Param_1 This field contains the database address where the 63-words of response data from the

Type 0 Command Disabled

1 Command Enabled, use poll interval

2 Command executed when database changes

(Func 2, 3, 11, 12 or 33 only)

3 Command executed when database trigger set

Not equal to 0

for the mailbox command is present.

Start Slave(s)

Stop Slave(s)

mailbox is written. Set to -1, if the data is not to be written to the database.

For this example, the command will stop and start the specified slave(s) using

Database trigger register 3199 (stop) and 3198 (start). Any nonzero value placed

in either register will trigger the command to execute. When the command has

executed, the database register will be reset to zero. Data will be read from

database register 3200 for a count of 63 words. The response will be placed at

Database address 3500 with a length of 63 words.

The following illustration shows the parameters that execute this command.

ProSoft Technology, Inc. Page 45 of 157

March 23, 2011

Page 46

Configuration PDPMV1 ♦ ProLinx Gateway

Protocol Manual PROFIBUS DPV1 Master

When you download the configuration containing this mailbox command to the

gateway, and then return to the Diagnostics window, press [F] at the Main menu,

and then press [S] to view the command list. The following illustration shows the

command list. Notice that the first two commands match the settings you made in

the Edit - Profibus Master Commands dialog box.

When you place any value at database register 3199, this will issue the

command for the mailbox Stop slave(s). Slaves that are required to stop

communicating with the master will show RED. This is a byte map value entered

at database address 3200-3263. A decimal value of 257 in database register

3205 will stop slaves 10 and 11.

Page 46 of 157 ProSoft Technology, Inc.

March 23, 2011

Page 47

PDPMV1 ♦ ProLinx Gateway Configuration

PROFIBUS DPV1 Master Protocol Manual

The Monitor/Modify Slave screen in ProSoft Configuration Builder for PROFIBUS

will show that the slave is working properly.

Double-click on Slave 10.

ProSoft Technology, Inc. Page 47 of 157

March 23, 2011

Page 48

Configuration PDPMV1 ♦ ProLinx Gateway

Protocol Manual PROFIBUS DPV1 Master

The Diagnostic tab contains the following information for Slave 10, indicating that

the slave has stopped exchanging cyclic data.

To start the slaves again, place any value in database register 3198.

Important Note: Values in DB register are byte mapped values of 1 and 257. Use decimal values

only. There are 126 byte for 126 allowed PROFIBUS addresses. To stop slave address 100, place

a value of 1 in DB 50 of the 63. To stop slave address 10 and 11, place a value of 257 at Database

address 5 of the 63. If the Database start address is 3200, place a value of 257 at Database

address 3205.

Refer to Mailbox Message: Start Slave (page 95) and Mailbox Message: Stop Slave (page 96) for

more information on these commands.

DB_register and Param_1 should be same for both function codes 11 and 12. If you stop a certain

slave address, you must restart the same address.

Page 48 of 157 ProSoft Technology, Inc.

March 23, 2011

Page 49

PDPMV1 ♦ ProLinx Gateway Configuration

PROFIBUS DPV1 Master Protocol Manual

2.4.4 Other Mailbox Commands

3 - Set Slave Mode

Field Value Description

Type 0 to 3

DB_Reg Database location for the three values used by the

command.

Count If count == 0, the three values for the command are derived

from the database. If count != 0, the three parameters for the

command are present in the command list.

Poll_Int Only if type = 1

Swap Not used

DB_Trigger

Func 3

Param_1 0 to 125 or 127 This field represents the slave address for the command.

Address 127 is used for multicast address.

Param_2 Group Select Refer to Mailbox Message: Set Slave Mode (page 80)

Param_3 Control Command Refer to Mailbox Message: Set Slave Mode (page 80)

4 - Get Slave Diagnostic Data

Field Value Description

Type 0, 1 or 3

DB_Reg This is the database location where the results of the

command will be placed

Count This parameter specifies the number of words in the

response message to place in the database.

Poll_Int Only if type = 1

Swap Utilized on response message

DB_Trigger

Func 4

Param_1 0 to 125 This field represents the slave address for the command.

Param_2 Type of Req If 0, internal database used. If 1, data polled on network.

This last option is used if the slave is not controlled by this

Master.

ProSoft Technology, Inc. Page 49 of 157

March 23, 2011

Page 50

Configuration PDPMV1 ♦ ProLinx Gateway

Protocol Manual PROFIBUS DPV1 Master

5 - Get Slave Configuration

Field Value Description

Type 0, 1 or 3

DB_Reg This is the database location where the results of the

command will be placed

Count This parameter specifies the number of words in the

response message to place in the database.

Poll_Int Only if type = 1

Swap Utilized on response message

DB_Trigger

Func 5

Param_1 1 to 125 This field represents the slave address for the command.

23 - Get Database Information

Field Value Description

Type 0, 1 or 3

DB_Reg Location of the 4 words received in the response to this

request.

Count This field is not used as the message is always 4-words in

length

Poll_Int Only if type = 1

Swap Utilized on response message

DB_Trigger

Func 23

32 - Acyclic Read

Field Value Description

Type 0, 1 or 3

DB_Reg Database location where read data placed

Count Number of words in response message to write to the

database.

Poll_Int Only if type = 1

Swap Applied to data in response message

DB_Trigger

Func 32

Param_1 Slave Addr Slave address to read data from

Param_2 Slot Slot in slave to access

Param_3 Index Index in slave to access

Param_4 Len Length in bytes of data to be sent from the slave.

Page 50 of 157 ProSoft Technology, Inc.

March 23, 2011

Page 51

PDPMV1 ♦ ProLinx Gateway Configuration

PROFIBUS DPV1 Master Protocol Manual

33 - Acyclic Write

Field Value Description

Type 0 to 3

DB_Reg Starting database location of the write data.

Count Number of word registers to read from the database into the

command.

Poll_Int Only if type = 1

Swap Applied to data in request message

DB_Trigger

Func 33

Param_1 Slave Addr Slave address to write to with data

Param_2 Slot Slot in slave to access

Param_3 Index Index in slave to access

Param_4 Len Length in bytes of data to be sent to the slave.

ProSoft Technology, Inc. Page 51 of 157

March 23, 2011

Page 52

Configuration PDPMV1 ♦ ProLinx Gateway

Protocol Manual PROFIBUS DPV1 Master

2.5 Configuring the PROFIBUS DP Network

To configure your PROFIBUS DP network you must perform four tasks:

1 Install any PROFIBUS slave-specific device configuration files, typically

called .GSD files (page 52).

2 Configure the ProLinx PROFIBUS DP Master (page 52).

3 Configure the PROFIBUS slaves.

4 Print the Unity Passthru Memory Map.

2.5.1 Installing the GSD Files

ProSoft Configuration Builder (PCB) uses PROFIBUS slave device definition files

(GSD files) to obtain basic configuration information about the PROFIBUS slaves

you add to the network. The GSD configuration files identify the slave’s

capabilities so that the PDPMV1 can communicate with it correctly. Slave device

manufacturers provide the GSD files for the equipment they make. Slave device

files sometimes come in various languages. When a manufacturer provides slave

device files in several languages, it is a common practice to use the third letter of

the file extension to indicate the language used in the file. For instance:

o

.GSD is the most commonly used file extension and will usually be in

either English or German

o

.GSE will usually be in English

o

.GSS will usually be in Spanish

o

.GSF will usually be in French

o

other combinations may also be seen, as well as other languages using

the letters indicated above

Follow these steps to install the GSD file or files for your slave device or devices.

Tip: GSD configuration files for popular PROFIBUS slaves and ProSoft Technology solutions are

included with PCB. Before installing GSD files, browse the list of available slaves in the Tree View

window to see if GSD files for your slave are already installed.

GSD files are often both model number specific as well as model revision specific. Just because

you may have an older GSD file from a manufacturer for the particular make and model of your

slave device does not guarantee it will work for a newer revision of that device. Be sure you obtain

from the device manufacturer the correct GSD file or files for your PROFIBUS slave or slaves.

Page 52 of 157 ProSoft Technology, Inc.

March 23, 2011

Page 53

PDPMV1 ♦ ProLinx Gateway Configuration

PROFIBUS DPV1 Master Protocol Manual

To install GSD files manually

1 In ProSoft Configuration Builder tree view, click [+] to expand the module

tree, and then double-click the PROFIBUS DP icon. This action opens the

PDPMV1 PROFIBUS Master Setup dialog box.

2 Click the C

ONFIGURE

PROFIBUS button. This action opens the ProSoft

Configuration Builder for PROFIBUS application.

3 Open the T

OOLS

menu, and then choose I

NSTALL NEW

GS*

FILE

. This action

opens a dialog box that allows you to browse for the location of the GSD

configuration files to install. (Depending on the device and language used in

the file, the actual extension may be ".GSD", ".GSE", ".GSS", or other

combinations; hence the generic reference to ".GS*" files, where "*" is a

wildcard that stands for any letter.)

4 Choose the file to install, and then click O

PEN

. If the file already exists in the

configuration file path, you will be prompted to overwrite the file.

5 You will be prompted to associate the GSD configuration file with a bitmap

image of the slave device. Use the F

ILE / OPEN

dialog box to browse for the

location of the image file to use. If you have no device-specific bitmap file,

you may C

the Bus Configuration window for this slave device.

ANCEL

the bitmap upload, and a generic device icon will be used in

2.5.2 Configuring the PROFIBUS Slaves

There are two essential steps to configuring a slave:

1 Add the slave in ProSoft Configuration Builder (PCB) as a device connected

to the PROFIBUS Master, specifying the slave address and any necessary

input and output configuration. Download the PROFIBUS Master

configuration to the PDPMV1 module.

2 Configure the slave (using PCB or the configuration tool supplied by the

manufacturer, for some PROFIBUS slaves). Verify that the slave address

configured in the slave module matches the slave address configured in PCB.

Download the PROFIBUS Slave configuration to the slave module.

Scanning for Slaves Manually

Important: The GSD file for this example is not included on the ProLinx Solutions CD-ROM, and is

used for illustrative purposes only. You can download a variety of example GSD files from the

PROFIBUS Trade Organization website at www.profibus.org, or from the manufacturer's website

for your PROFIBUS slaves.

The following steps describe how to add and configure a Siemens EM 277 I/O

chassis to the PROFIBUS network. The configuration information (.GSD file) for

this device must be installed according to the procedure found in Install the GSD

Files (page 52). Most other PROFIBUS slaves can be configured in a similar

manner.

1 In ProSoft Configuration Builder for PROFIBUS, click the plus sign [+] to

expand the PROFIBUS DP tree.

ProSoft Technology, Inc. Page 53 of 157

March 23, 2011

Page 54

Configuration PDPMV1 ♦ ProLinx Gateway

Protocol Manual PROFIBUS DPV1 Master

2 Navigate to the folder containing the type of slave device to add

(PLCS/S

IEMENS

/EM 277, in this example), and then click the plus sign [+] to

expand the folder.

3 Click the EM 277 PROFIBUS-DP icon in the tree view and drag and drop the

icon into the Bus Configuration view. This action adds the slave device and

connects it to the Master in a network relationship.

Page 54 of 157 ProSoft Technology, Inc.

March 23, 2011

Page 55

PDPMV1 ♦ ProLinx Gateway Configuration

PROFIBUS DPV1 Master Protocol Manual

4 In the tree view, click the plus sign [+] to expand the slave device you added.

This action opens a list of device configuration values. The following

illustration shows the possible input/output configuration values for a Siemens

EM 277. The selections available for other devices may be different, so you

should review the specifications for the product you are installing in order to

determine the correct values to use.

5 Drag the input and output parameters to the slot location grid (Subscriber

List) below the Bus Configuration window. The slot view displays the slot

number, configuration data, and input and output addresses. The PROFIBUS

DP Master uses this information to identify and communicate with individual

slaves on the network.

ProSoft Technology, Inc. Page 55 of 157

March 23, 2011

Page 56

Configuration PDPMV1 ♦ ProLinx Gateway

Protocol Manual PROFIBUS DPV1 Master

For this example, we will configure 8 words of input and 32 words of output.

These input and output words are assigned to addresses within the

gateway's internal database.

For each new slave added to the PROFIBUS network, ProSoft Configuration

Builder automatically converts the input/output byte addresses to word

input/output addresses.

Tip: To make it easier to view the data from individual slaves, you can create a spreadsheet with

all added slaves and input and output data offsets, or you can view and print the data map.

Page 56 of 157 ProSoft Technology, Inc.

March 23, 2011

Page 57

PDPMV1 ♦ ProLinx Gateway Configuration

PROFIBUS DPV1 Master Protocol Manual

6 Double-click the S

LAVE

icon to view the Slave properties dialog box.

ProSoft Configuration Builder automatically assigns a PROFIBUS address to

each new slave. The slave address assignment begins at address 3 for the

first slave added to the network (addresses 0, 1, and 2 are reserved for use

with PROFIBUS Masters), and is incremented by 1 for each new slave added

to the network. You may, however, assign any address, 0-125 to any Master

or slave node as long as you do not assign the same address to more than

one device. You can change the address in the C

OMMON

tab of the Slave

properties dialog box. ProSoft Configuration Builder will not allow you to

assign a PROFIBUS address that is already in use by another device on this

network.

Leave the remaining settings unchanged for now, and click OK to close the

Slave properties dialog box.

7 Repeat steps 2 through 6 for all slaves you intend to place on the network.

8 When you are finished adding slaves, open the P

E

XIT.

Click Y

ES

to save the project and return to the PROFIBUS Master Setup

ROJECT

menu and choose

dialog box.

ProSoft Technology, Inc. Page 57 of 157

March 23, 2011

Page 58

Configuration PDPMV1 ♦ ProLinx Gateway

Protocol Manual PROFIBUS DPV1 Master

Using The Autoscan Feature

The concept of Automatic network scanning means that the user can instruct the

Bus Configuration window to automatically gather information about slaves that

are connected to the network. When the scan is completed the user can adopt

the detected slaves to the bus configuration and download to the Master.

This is a quick way to get a network up and running. However, one should be

aware that it is not guaranteed that any particular slave will enter data exchange

since the user parameter data might not match. This is especially obvious if no

associated GSD-file is found during the network scan, this means that no user

parameter data would be sent to the slave.

N

ETWORK SCAN

down menu for the M

is selectable from the Online menu as well as from the drop-

ASTER

icon.

Page 58 of 157 ProSoft Technology, Inc.

March 23, 2011

Page 59

PDPMV1 ♦ ProLinx Gateway Configuration

PROFIBUS DPV1 Master Protocol Manual

When the download is completed, the PROFIBUS Master Configuration window

will initialize the Master to operate as a Class 2 Master only. In this mode it is

possible to initialize the Master even if the database does not contain any slaves.

After successful initialization, the PROFIBUS Master Configuration window will

issue the following mailboxes in order to gather information about the connected

slaves:

1 1. Send FB_APPL_GET_LIVE_LIST in order to detect connected slaves,

2 2. Send FB_APPL_GET_SLAVE_DIAG (external request) to all devices

identified as slaves according to the Live list.

3 3. Send FB_APPL_GET_SLAVE_CONFIG to all devices identified as slaves

according to the Live list.

When the information is collected the PROFIBUS Master Configuration window

will find a matching GSD-file and extract information from it. Refer to the

flowchart below for this sequence:

ProSoft Technology, Inc. Page 59 of 157

March 23, 2011

Page 60

Configuration PDPMV1 ♦ ProLinx Gateway

Protocol Manual PROFIBUS DPV1 Master

GSD Selection Algorithm

If two or more matching GSD-files are found, the first one found should be

selected. The other compatible files should be stored so that the user can select

one of them instead. If the user selects another GSD-file, the PROFIBUS Master

Configuration window will run through the Module Selection Algorithm (described

below) again.

Module Selection Algorithm

The algorithm used to find modules in the GSD based on the Identifier byte(s) is

as follows:

Select the module that matches the largest number of Identifier bytes. If the GSD

contains two or more modules with the exact set of Identifier bytes, use the first

module found.

Example:

If a slave responds with identifier bytes: 0x11, 0x21, 0x31 and that the associated

GSD-file contains five modules: “A” = 0x11, “B” = 0x21, “C” = 0x31, “AB” = 0x11,

0x21 and “BC” = 0x21, 0x31. The PROFIBUS Master Configuration window will