Page 1

IEC-101 Slave

ProLinx Communication Gateway

IEC 60870-5-101 v3 Slave

(Firmware version 3.xx)

August 6, 2010

PROTOCOL MANUAL

Page 2

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions, comments,

compliments or complaints about our products, documentation, or support, please write or call us.

ProSoft Technology

5201 Truxtun Ave., 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

www.prosoft-technology.com

support@prosoft-technology.com

Copyright © 2010 ProSoft Technology, Inc., all rights reserved.

101S v3 Protocol Manual

8/5/2010

ProSoft Technology

Technology, Inc. All other brand or product names are or may be trademarks of, and are used to identify products

and services of, their respective owners.

®

, ProLinx ®, inRAx ®, ProTalk®, and RadioLinx ® are Registered Trademarks of ProSoft

ProSoft Technology® Product Documentation

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product shipments.

User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are provided on the enclosed CD-ROM,

and are available at no charge from our web site: www.prosoft-technology.com

Printed documentation is available for purchase. Contact ProSoft Technology for pricing and availability.

North America: +1.661.716.5100

Asia Pacific: +603.7724.2080

Europe, Middle East, Africa: +33 (0) 5.3436.87.20

Latin America: +1.281.298.9109

Page 3

Important Installation Instructions

Power, Input, and Output (I/O) wiring must be in accordance with Class I, Division 2 wiring methods, Article 501-4 (b)

of the National Electrical Code, NFPA 70 for installation in the U.S., or as specified in Section 18-1J2 of the Canadian

Electrical Code for installations in Canada, and in accordance with the authority having jurisdiction. The following

warnings must be heeded:

A WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR

CLASS I, DIV. 2;

B WARNING - EXPLOSION HAZARD - WHEN IN HAZARDOUS LOCATIONS, TURN OFF POWER BEFORE

REPLACING OR WIRING MODULES

C WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

D THIS DEVICE SHALL BE POWERED BY CLASS 2 OUTPUTS ONLY.

All ProLinx® Products

WARNING – EXPLOSION HAZARD – DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

AVERTISSEMENT – RISQUE D'EXPLOSION – AVANT DE DÉCONNECTER L'EQUIPMENT, COUPER LE

COURANT OU S'ASSURER QUE L'EMPLACEMENT EST DÉSIGNÉ NON DANGEREUX.

Markings

UL/cUL ISA 12.12.01 Class I, Div 2 Groups A, B, C, D

cUL C22.2 No. 213-M1987

183151

CL I Div 2 GPs A, B, C, D

II 3 G

Ex nA nL IIC X

0°C <= Ta <= 60°C

II – Equipment intended for above ground use (not for use in mines).

3 – Category 3 equipment, investigated for normal operation only.

G – Equipment protected against explosive gasses.

ProLinx Gateways with Ethernet Ports

Series C ProLinx™ Gateways with Ethernet ports do NOT include the HTML Web Server. The HTML Web Server

must be ordered as an option. This option requires a factory-installed hardware addition. The HTML Web Server now

supports:

8 MB file storage for HTML files and associated graphics files (previously limited to 384K)

32K maximum HTML page size (previously limited to 16K)

To upgrade a previously purchased Series C model:

Contact your ProSoft Technology distributor to order the upgrade and obtain a Returned Merchandise Authorization

(RMA) to return the unit to ProSoft Technology.

To order a ProLinx Plus gateway with the -WEB option

Add -WEB to the standard ProLinx part number. For example, 5201-MNET-MCM-WEB.

Page 4

Page 5

IEC-101 Slave ♦ ProLinx Communication Gateway Contents

IEC 60870-5-101 v3 Slave (Firmware version 3.xx) Protocol Manual

Contents

Your Feedback Please ........................................................................................................................ 2

ProSoft Technology® Product Documentation .................................................................................... 2

Important Installation Instructions ....................................................................................................... 3

All ProLinx® Products .......................................................................................................................... 3

ProLinx Gateways with Ethernet Ports ............................................................................................... 3

To upgrade a previously purchased Series C model: .................................................................... 3

To order a ProLinx Plus gateway with the -WEB option ................................................................ 3

Guide to the 101S v3 Protocol Manual 9

1 Start Here 11

1.1 What's New ............................................................................................................. 11

1.2 ProLinx Reference Guide ........................................................................................ 11

1.3 Installing ProSoft Configuration Builder Software ................................................... 12

1.3.1 Using the Online Help ............................................................................................. 12

1.4 Using ProSoft Configuration Builder ....................................................................... 13

1.4.1 Setting Up the Project ............................................................................................. 13

1.4.2 Renaming PCB Objects .......................................................................................... 15

1.4.3 Configuring Module Parameters ............................................................................. 15

1.4.4 Creating Optional Comment Entries ....................................................................... 16

1.4.5 Printing a Configuration File .................................................................................... 16

1.4.6 Using the CommonNet Data Map ........................................................................... 17

1.4.7 Downloading the Project to the Module .................................................................. 21

2 101S Protocol Configuration 23

2.1 [IEC-870-5-101 Port 0] ............................................................................................ 24

2.1.1 Enabled ................................................................................................................... 24

2.1.2 Time DB Offset ........................................................................................................ 24

2.1.3 Disable Time Sync Events ...................................................................................... 25

2.1.4 Data Link Address Value ......................................................................................... 25

2.1.5 Data link address length .......................................................................................... 25

2.1.6 Common Address of ASDU Val .............................................................................. 25

2.1.7 Common Address of ASDU Len ............................................................................. 25

2.1.8 Inform. Object Address Len..................................................................................... 26

2.1.9 Cyclic Data Transmission ........................................................................................ 26

2.1.10 Select/Operate Timeout .......................................................................................... 26

2.1.11 Use ACTTERM with Set Point ................................................................................ 26

2.1.12 Use ACTTERM with Step ........................................................................................ 26

2.1.13 Single char ACK F0, 1 or 3...................................................................................... 26

2.1.14 Single char ACK C1 or C2....................................................................................... 27

2.1.15 Maximum ASDU Resp Len ..................................................................................... 27

2.1.16 Cause of Trans(mission) Octets .............................................................................. 27

2.1.17 Freeze Start Type .................................................................................................... 27

2.1.18 Interval for Freeze ................................................................................................... 29

2.1.19 Set Priority Queues ................................................................................................. 30

2.1.20 Event Priority ........................................................................................................... 31

2.1.21 Cyclic Set IV Time - PLX 101S ............................................................................... 31

ProSoft Technology, Inc. Page 5 of 159

August 6, 2010

Page 6

Contents IEC-101 Slave ♦ ProLinx Communication Gateway

Protocol Manual IEC 60870-5-101 v3 Slave (Firmware version 3.xx)

2.1.22 IV Check Delay Time .............................................................................................. 33

2.1.23 IV Fail Count ........................................................................................................... 33

2.1.24 Event Scan Delay ................................................................................................... 33

2.1.25 Scan Events ............................................................................................................ 34

2.1.26 Time Type ............................................................................................................... 35

2.1.27 Use Balanced Mode ............................................................................................... 35

2.1.28 Retry Count ............................................................................................................. 35

2.1.29 Response Timeout .................................................................................................. 36

2.1.30 Baud Rate ............................................................................................................... 36

2.1.31 Parity ....................................................................................................................... 36

2.1.32 RTS On ................................................................................................................... 36

2.1.33 RTS Off ................................................................................................................... 36

2.1.34 Minimum Delay ....................................................................................................... 36

2.1.35 Receive Timeout ..................................................................................................... 37

2.1.36 Hardware Handshaking .......................................................................................... 37

2.2 [IEC-870-5-101 Database] ...................................................................................... 38

2.2.1 Short Pulse Time .................................................................................................... 38

2.2.2 Long Pulse Time ..................................................................................................... 38

2.2.3 Point Count ............................................................................................................. 39

2.2.4 Sequence Flag ........................................................................................................ 40

2.2.5 Parameter Offset .................................................................................................... 41

2.3 [M_SP_NA_1] ......................................................................................................... 42

2.4 [M_DP_NA_1] ......................................................................................................... 42

2.5 [M_ST_NA_1] ......................................................................................................... 43

2.6 [M_BO_NA_1 104] .................................................................................................. 43

2.7 [M_ME_NA_1]......................................................................................................... 44

2.8 [M_ME_NB_1]......................................................................................................... 44

2.9 [M_ME_NC_1] ........................................................................................................ 45

2.10 [M_IT_NA_1] ........................................................................................................... 45

2.11 [C_SC_NA_1] ......................................................................................................... 46

2.12 [C_DC_NA_1] ......................................................................................................... 46

2.13 [C_RC_NA_1] ......................................................................................................... 47

2.14 [C_BO_NA_1 104] .................................................................................................. 47

2.15 [C_SE_NA_1].......................................................................................................... 48

2.16 [C_SE_NB_1].......................................................................................................... 48

2.17 [C_SE_NC_1] ......................................................................................................... 49

2.18 Group Codes........................................................................................................... 50

3 Module Communication Ports 51

3.1 Serial Port Cable Connections: Config/Debug and Port 0 ...................................... 51

3.2 RS-232 Configuration/Debug Port .......................................................................... 52

3.3 Application Serial Port(s) ........................................................................................ 53

3.3.1 RS-232: Modem Connection (Hardware Handshaking Required) ......................... 53

3.3.2 RS-232: Null Modem Connection (Hardware Handshaking) .................................. 53

3.3.3 RS-232: Null Modem Connection (No Hardware Handshaking) ............................ 54

3.3.4 RS-422 .................................................................................................................... 55

3.3.5 RS-485 Application Port(s) ..................................................................................... 55

3.3.6 RS-485 and RS-422 Tip ......................................................................................... 55

Page 6 of 159 ProSoft Technology, Inc.

August 6, 2010

Page 7

IEC-101 Slave ♦ ProLinx Communication Gateway Contents

IEC 60870-5-101 v3 Slave (Firmware version 3.xx) Protocol Manual

4 Diagnostics and Troubleshooting 57

4.1 LED Indicators ......................................................................................................... 57

4.1.1 Base Module LEDs .................................................................................................. 57

4.1.2 Mini-DIN8 Serial Port .............................................................................................. 58

4.2 Using ProSoft Configuration Builder (PCB) for Diagnostics.................................... 59

4.2.1 Using the Diagnostic Window in ProSoft Configuration Builder .............................. 59

4.2.2 Navigation ............................................................................................................... 61

4.2.3 Keystrokes ............................................................................................................... 61

5 Reference 63

5.1 Product Specifications ............................................................................................. 63

5.1.1 General Specifications ............................................................................................ 63

5.1.2 Functional Specifications - IEC 60870-5-101 Slave ................................................ 64

5.1.3 Internal Database .................................................................................................... 64

5.1.4 Hardware Specifications.......................................................................................... 66

5.2 IEC-60870-5-101 Slave Protocol Implementation ................................................... 67

5.2.1 Data Flow Between the Module and External Host ................................................ 68

5.2.2 General Parameter Configuration ........................................................................... 72

5.2.3 Monitor Direction and Control Direction .................................................................. 80

5.2.4 Using Monitor Points ............................................................................................... 81

5.2.5 Using Control (Command) Points ........................................................................... 88

5.2.6 Events...................................................................................................................... 99

5.2.7 Command Block Functionality ............................................................................... 113

5.2.8 Slave Error and Status .......................................................................................... 128

6 IEC 60870-5-101 Slave Interoperability Statement 129

6.1 System or Device .................................................................................................. 130

6.2 Network Configuration ........................................................................................... 130

6.3 Physical Layer ....................................................................................................... 130

6.3.1 Transmission Speed (Control Direction) ............................................................... 130

6.3.2 Transmission Speed (Monitor Direction) ............................................................... 130

6.4 Link Layer .............................................................................................................. 131

6.5 Application Layer ................................................................................................... 131

6.5.1 Transmission Mode for Application Data .............................................................. 131

6.5.2 Common Address of ASDU - 101S ....................................................................... 131

6.5.3 Information Object Address ................................................................................... 131

6.5.4 Cause of Transmission .......................................................................................... 131

6.5.5 Length of APDU - 101S ......................................................................................... 131

6.6 Selection of Standard ASDUs ............................................................................... 132

6.6.1 Process Information in Monitor Direction .............................................................. 132

6.6.2 Process Information in Control Direction ............................................................... 133

6.6.3 System Information in Monitor Direction ............................................................... 134

6.6.4 System Information in Control Direction ................................................................ 134

6.6.5 Parameter in Control Direction .............................................................................. 134

6.6.6 File Transfer .......................................................................................................... 134

6.7 Type Identifier and Cause of Transmission Assignments ..................................... 135

6.8 Basic Application Functions .................................................................................. 137

6.8.1 Station Initialization ............................................................................................... 137

6.8.2 Cyclic Data Transmission ...................................................................................... 137

6.8.3 Read Procedure .................................................................................................... 137

ProSoft Technology, Inc. Page 7 of 159

August 6, 2010

Page 8

Contents IEC-101 Slave ♦ ProLinx Communication Gateway

Protocol Manual IEC 60870-5-101 v3 Slave (Firmware version 3.xx)

6.8.4 Spontaneous Transmission .................................................................................. 137

6.8.5 Double Transmission of Information Objects ........................................................ 138

6.8.6 Station Interrogation ............................................................................................. 138

6.8.7 Clock Synchronization .......................................................................................... 138

6.8.8 Command Transmission ....................................................................................... 139

6.8.9 Transmission of Integrated Totals ........................................................................ 139

6.8.10 Parameter Loading ............................................................................................... 140

6.8.11 Parameter Activation ............................................................................................ 140

6.8.12 Test Procedure ..................................................................................................... 140

6.8.13 File Transfer .......................................................................................................... 140

6.8.14 Background Scan ................................................................................................. 141

6.8.15 Aquisition of transmission delay ........................................................................... 141

7 101S v3 Database Design Forms 143

7.1 M_SP_NA, M_DP_NA, M_ST_NA, M_BO_NA, and M_IT_NA Form .................. 144

7.2 M_ME_NA and M_ME_NB Form .......................................................................... 145

7.3 Form for All C_ (Command) Data Types, Except C_RC_NA ............................... 146

7.4 C_RC_NA Form .................................................................................................... 147

8 Support, Service & Warranty 149

8.1 How to Contact Us: Technical Support ................................................................. 149

8.2 Return Material Authorization (RMA) Policies and Conditions ............................. 150

8.2.1 All Product Returns: .............................................................................................. 150

8.2.2 Procedures for Return of Units Under Warranty: .................................................. 151

8.2.3 Procedures for Return of Units Out of Warranty: .................................................. 151

8.3 LIMITED WARRANTY .......................................................................................... 152

8.3.1 What Is Covered By This Warranty ...................................................................... 152

8.3.2 What Is Not Covered By This Warranty ................................................................ 153

8.3.3 Disclaimer Regarding High Risk Activities ............................................................ 153

8.3.4 Intellectual Property Indemnity ............................................................................. 154

8.3.5 Disclaimer of all Other Warranties ........................................................................ 154

8.3.6 Limitation of Remedies ** ..................................................................................... 155

8.3.7 Time Limit for Bringing Suit ................................................................................... 155

8.3.8 No Other Warranties ............................................................................................. 155

8.3.9 Allocation of Risks ................................................................................................ 155

8.3.10 Controlling Law and Severability .......................................................................... 156

Index 157

Page 8 of 159 ProSoft Technology, Inc.

August 6, 2010

Page 9

IEC-101 Slave ♦ ProLinx Communication Gateway Start Here

system requirements, hardware installation, and

associated with this product, Specifications, and

IEC 60870-5-101 v3 Slave (Firmware version 3.xx) Protocol Manual

Guide to the 101S v3 Protocol Manual

Function

Introduction

(Must Do)

Diagnostic and

Troubleshooting

Reference

Product Specifications

Functional Overview

Support, Service, and

Warranty

Index

Section to Read Details

Start Here (page 11) This section introduces the customer to the

→

Diagnostics and

→

Troubleshooting

(page 57)

Reference (page 63)

→

Product

Specifications (page

63)

Functional Overview

(page 67)

Support, Service

→

and Warranty (page

149)

Index

gateway. Included are: package contents,

basic configuration.

This section describes Diagnostic and

Troubleshooting procedures.

These sections contain general references

the Functional Overview.

This section contains Support, Service and

Warranty information.

Index of chapters.

ProSoft Technology, Inc. Page 9 of 159

August 6, 2010

Page 10

Start Here IEC-101 Slave ♦ ProLinx Communication Gateway

Protocol Manual IEC 60870-5-101 v3 Slave (Firmware version 3.xx)

Page 10 of 159 ProSoft Technology, Inc.

August 6, 2010

Page 11

IEC-101 Slave ♦ ProLinx Communication Gateway Start Here

IEC 60870-5-101 v3 Slave (Firmware version 3.xx) Protocol Manual

1 Start Here

In This Chapter

What's New ........................................................................................... 11

ProLinx Reference Guide ...................................................................... 11

Installing ProSoft Configuration Builder Software .................................. 12

Using ProSoft Configuration Builder ...................................................... 13

For most applications, the installation and configuration steps described in this

section will work without additional programming. ProSoft Technology strongly

recommends that you complete the steps in this chapter before developing a

custom application.

1.1 What's New

This new and enhanced version 3 of ProSoft Technology's IEC 60870-5-101

Slave implementation includes several new features not found on previous

versions. Version 3 now supports 32-bit bitstring data types. Version 3 also

supports more Causes of Transmission than previous versions. For additional

details, please see the Interoperability Statement (page 129).

1.2 ProLinx Reference Guide

The ProLinx Reference Guide on the ProSoft Solutions CD-ROM provides

detailed information on the entire range of ProLinx gateways. If you have any

questions that are not answered in the 101S Protocol Manual, please refer to the

ProLinx Reference Guide.

ProSoft Technology, Inc. Page 11 of 159

August 6, 2010

Page 12

Start Here IEC-101 Slave ♦ ProLinx Communication Gateway

Protocol Manual IEC 60870-5-101 v3 Slave (Firmware version 3.xx)

1.3 Installing ProSoft Configuration Builder Software

You must install the ProSoft Configuration Builder (PCB) software to configure

the gateway. You can always get the newest version of ProSoft Configuration

Builder from the ProSoft Technology website.

To install ProSoft Configuration Builder from the ProSoft website

1 Open your web browser and navigate to http://www.prosoft-

technology.com/pcb

2 Click the D

Configuration Builder.

3 Choose S

4 Save the file to your Windows Desktop, so that you can find it easily when

you have finished downloading.

5 When the download is complete, locate and open the file, and then follow the

instructions on your screen to install the program.

If you do not have access to the Internet, you can install ProSoft Configuration

Builder from the ProSoft Solutions Product CD-ROM, included in the package

with your gateway.

To install ProSoft Configuration Builder from the Product CD-ROM

1 Insert the ProSoft Solutions Product CD-ROM into the CD-ROM drive of your

PC. Wait for the startup screen to appear.

2 On the startup screen, click P

Windows Explorer file tree window.

3 Click to open the U

and files you will need to set up and configure your gateway.

4 Double-click the S

PCB_*.

software on your PC. The information represented by the "*" character in the

file name is the PCB version number and, therefore, subject to change as

new versions of PCB are released.

OWNLOAD HERE link to download the latest version of ProSoft

AVE or SAVE FILE when prompted.

RODUCT DOCUMENTATION. This action opens a

TILITIES folder. This folder contains all of the applications

ETUP CONFIGURATION TOOL folder, double-click the

EXE file and follow the instructions on your screen to install the

Note: Many of the configuration and maintenance procedures use files and other utilities on the

CD-ROM. You may wish to copy the files from the Utilities folder on the CD-ROM to a convenient

location on your hard drive.

1.3.1 Using the Online Help

Most of the information needed to help you use ProSoft Configuration Builder is

provided in a Help System that is always available whenever you are running

ProSoft Configuration Builder. The Help System does not require an Internet

connection.

To view the help pages, start ProSoft Configuration Builder, open the H

menu, and then choose CONTENTS.

Page 12 of 159 ProSoft Technology, Inc.

August 6, 2010

ELP

Page 13

IEC-101 Slave ♦ ProLinx Communication Gateway Start Here

IEC 60870-5-101 v3 Slave (Firmware version 3.xx) Protocol Manual

1.4 Using ProSoft Configuration Builder

ProSoft Configuration Builder (PCB) provides a quick and easy way to manage

gateway configuration files customized to meet your application needs. PCB is

not only a powerful solution for new configuration files, but also allows you to

import information from previously installed (known working) configurations to

new projects.

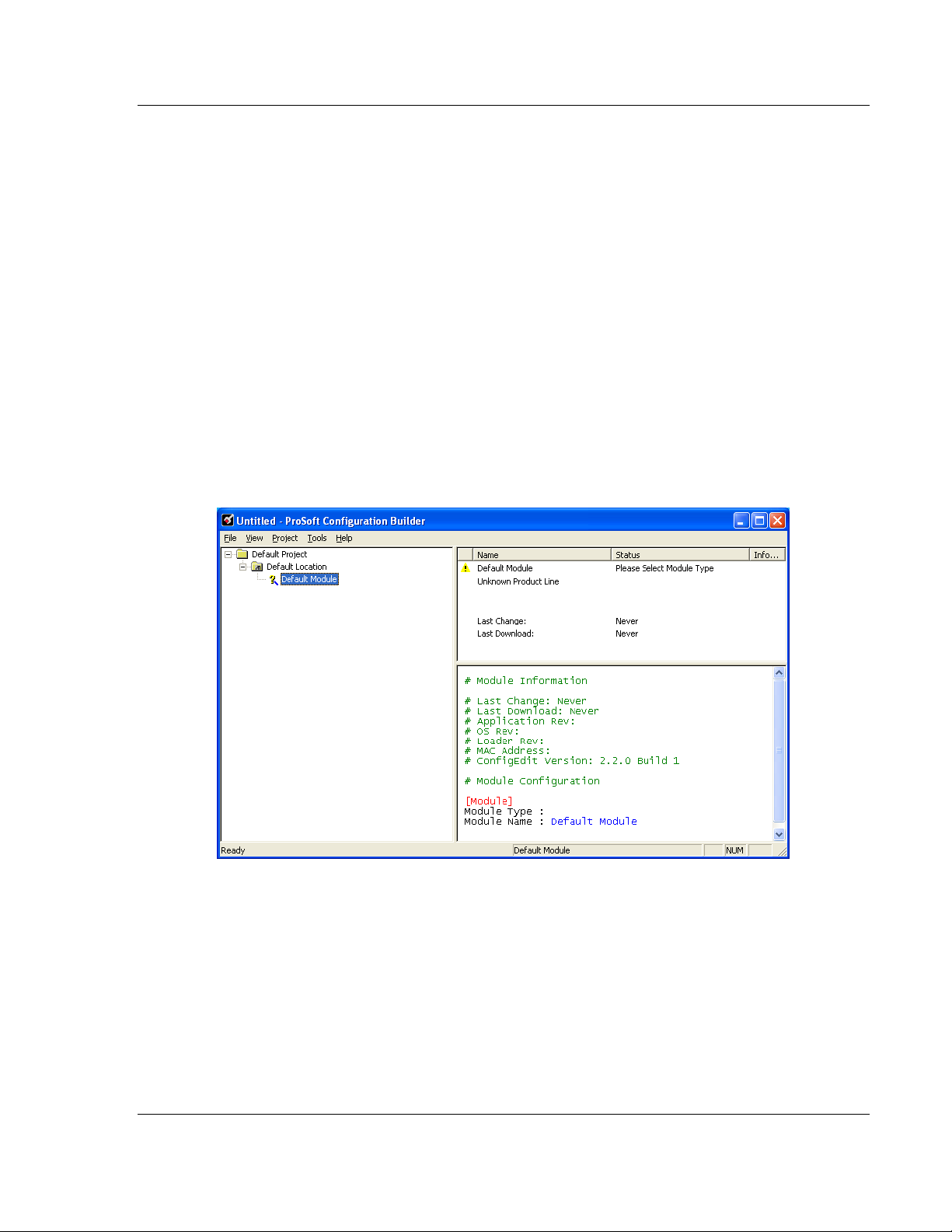

1.4.1 Setting Up the Project

To begin, start ProSoft Configuration Builder (PCB). If you have used other

Windows configuration tools before, you will find the screen layout familiar.

ProSoft Configuration Builder’s (PCB's) window consists of a tree view on the

left, an information pane, and a configuration pane on the right side of the

window. When you first start PCB, the tree view consists of folders for Default

Project and Default Location, with a Default Module in the Default Location

folder. The following illustration shows the PCB window with a new project.

ProSoft Technology, Inc. Page 13 of 159

August 6, 2010

Page 14

Start Here IEC-101 Slave ♦ ProLinx Communication Gateway

Protocol Manual IEC 60870-5-101 v3 Slave (Firmware version 3.xx)

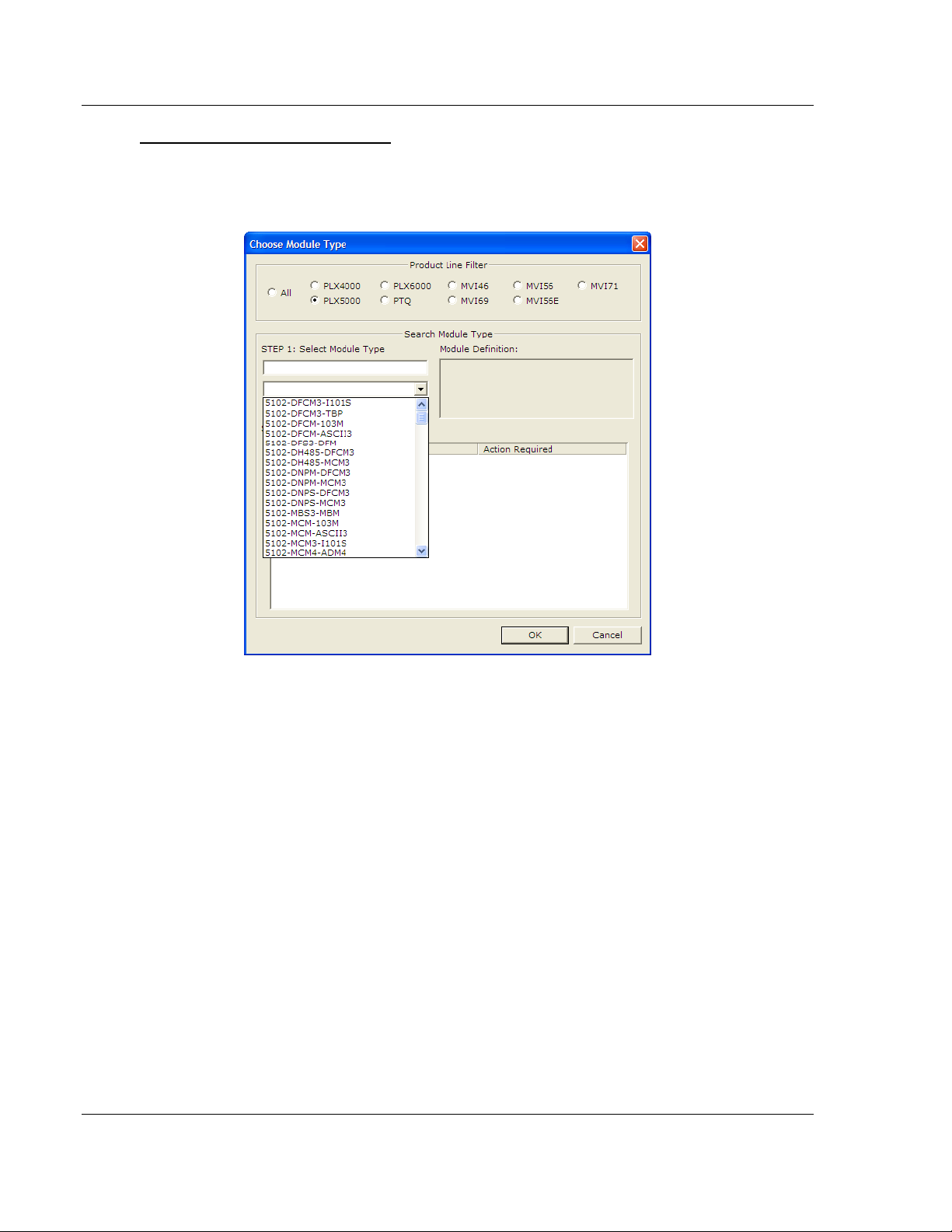

To add the gateway to the project

1 Use the mouse to select DEFAULT MODULE in the tree view, and then click the

right mouse button to open a shortcut menu.

2 On the shortcut menu, choose C

Choose Module Type

dialog box.

HOOSE MODULE TYPE. This action opens the

3 In the Product Line Filter area of the dialog box, select the appropriate

product type radio button.

4

In the STEP 1: Select Module Type dropdown list, select the model number

that matches your gateway, and then click OK

return to the

PCB Main window.

to save your settings and

Page 14 of 159 ProSoft Technology, Inc.

August 6, 2010

Page 15

IEC-101 Slave ♦ ProLinx Communication Gateway Start Here

IEC 60870-5-101 v3 Slave (Firmware version 3.xx) Protocol Manual

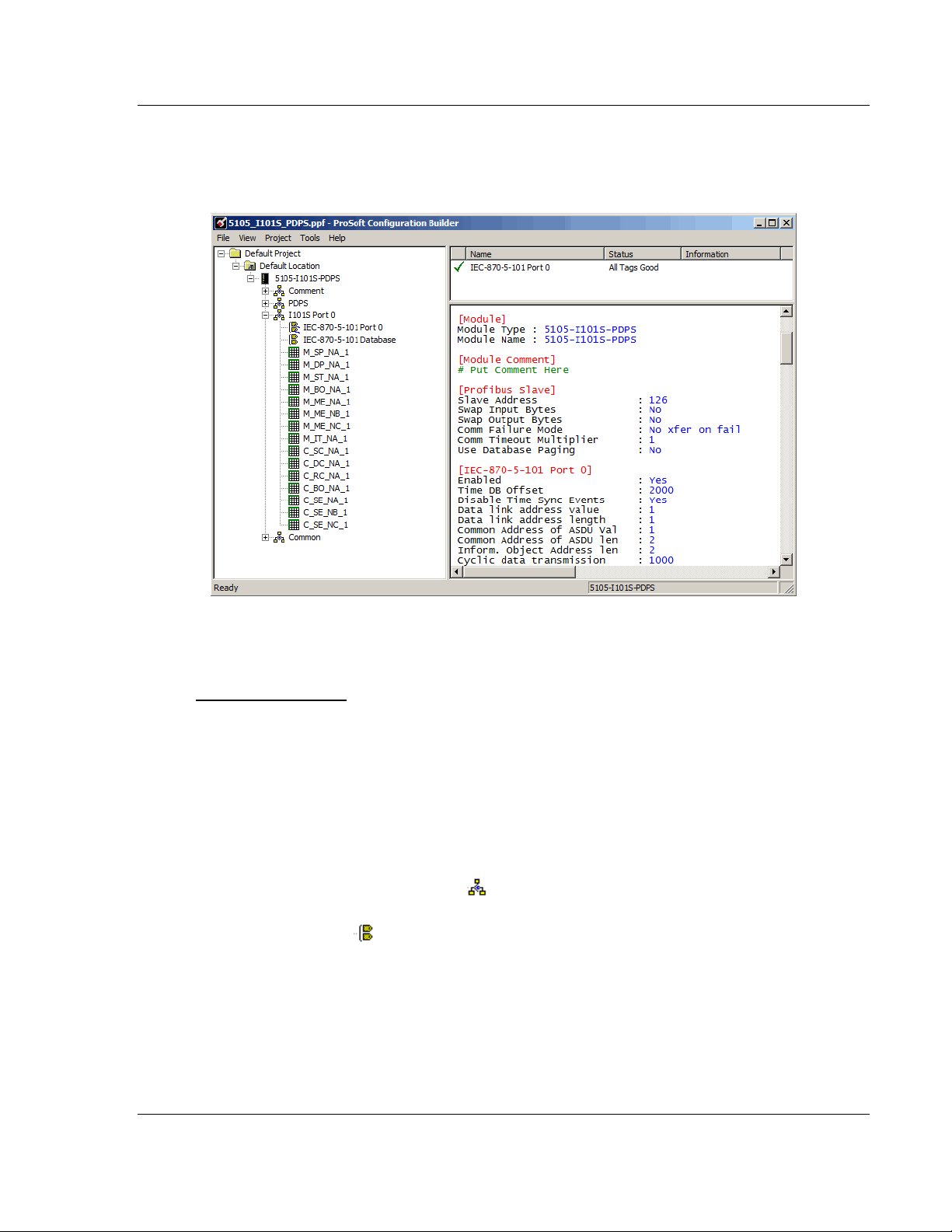

1.4.2 Renaming PCB Objects

Notice that the contents of the information pane and the configuration pane

changed when you added the gateway to the project.

At this time, you may wish to rename the Default Project and Default Location

folders in the tree view.

To rename an object

1 Select the object, and then click the right mouse button to open a shortcut

menu. From the shortcut menu, choose R

ENAME.

2 Type the name to assign to the object.

3 Click away from the object to save the new name.

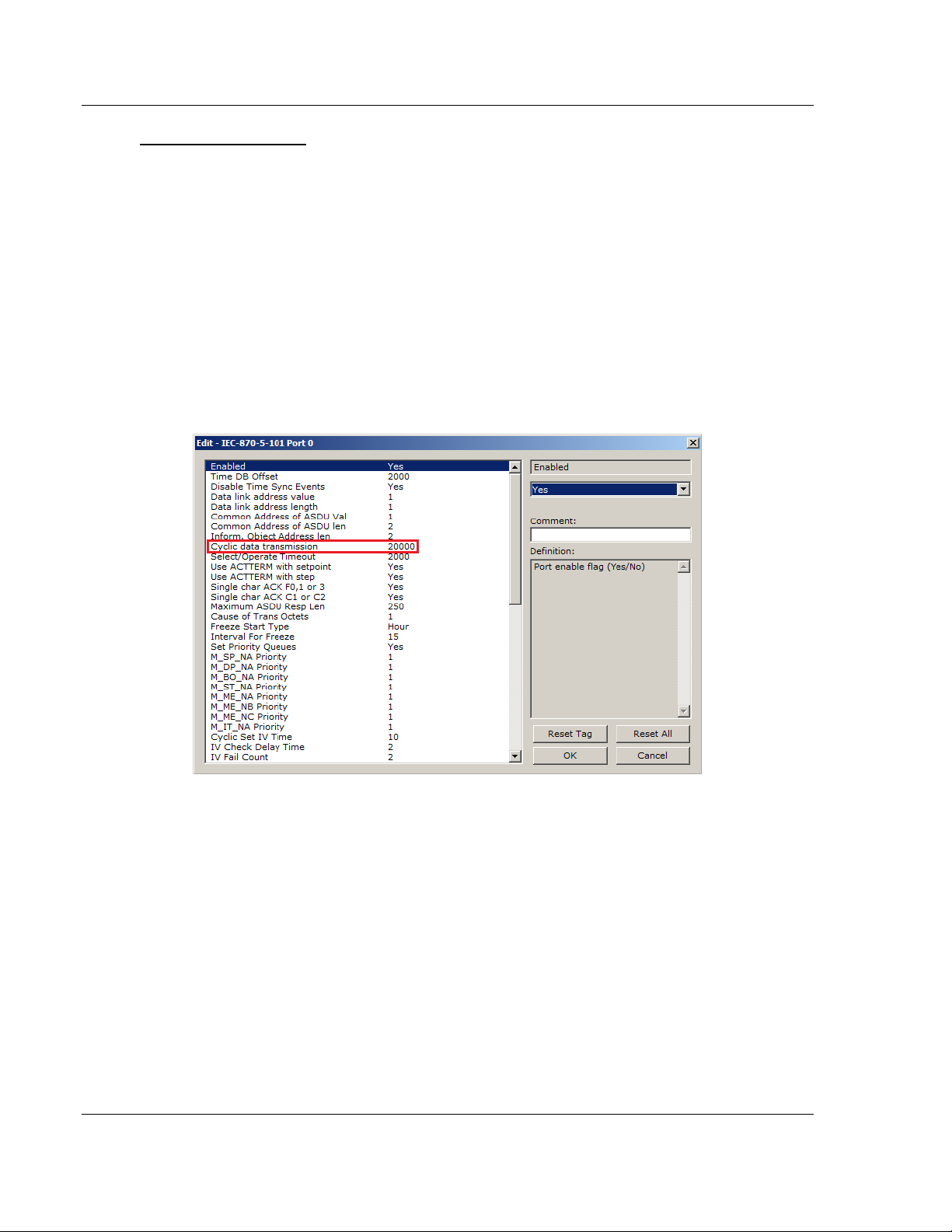

1.4.3 Configuring Module Parameters

1 Click on the [+] sign next to the gateway icon to expand gateway information.

2 Click on the

configuration options.

3 Double-click any

4 To edit a parameter, select the parameter in the left pane and make your

changes in the right pane.

5 Click OK

[+] sign next to any icon to view gateway information and

icon to open an Edit dialog box.

to save your changes.

ProSoft Technology, Inc. Page 15 of 159

August 6, 2010

Page 16

Start Here IEC-101 Slave ♦ ProLinx Communication Gateway

Protocol Manual IEC 60870-5-101 v3 Slave (Firmware version 3.xx)

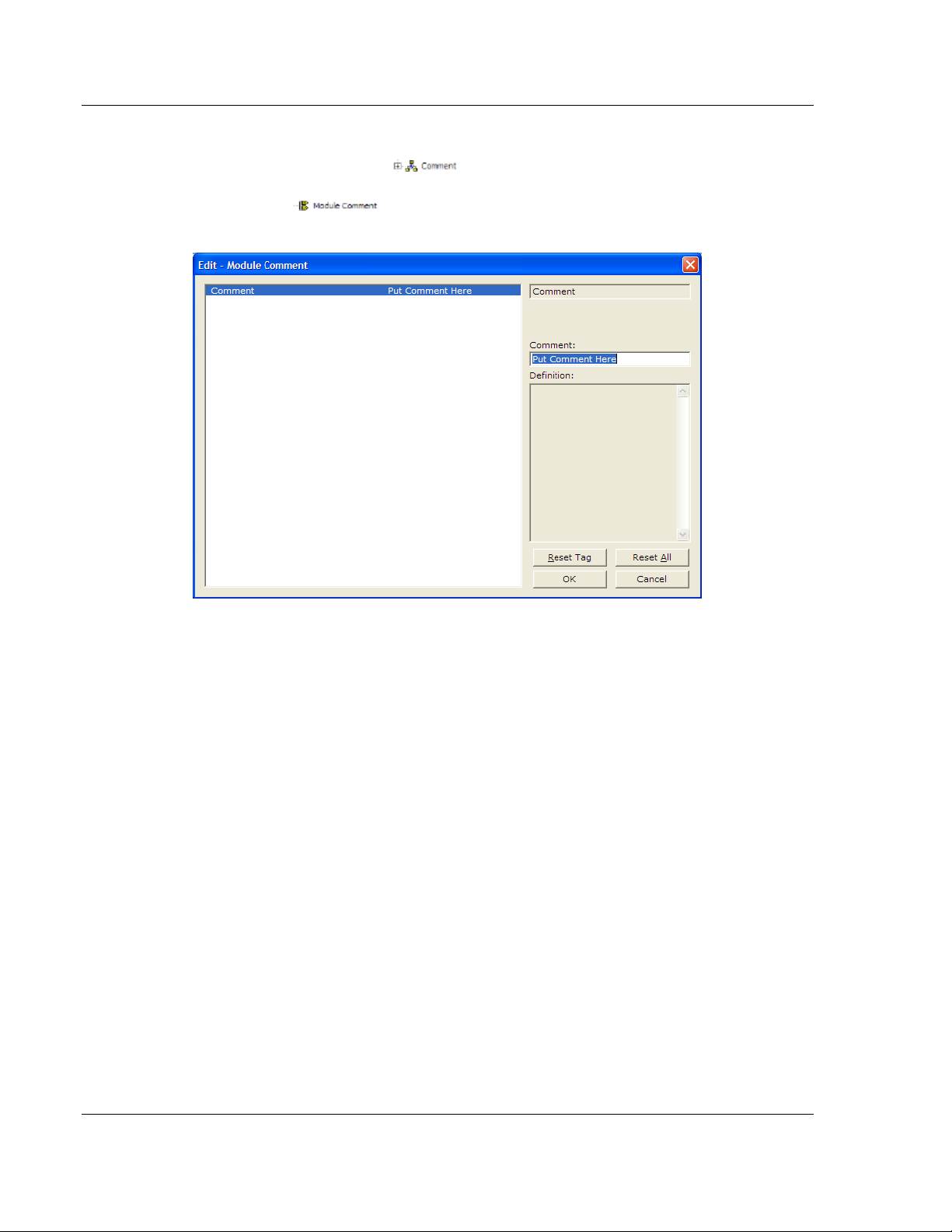

1.4.4 Creating Optional Comment Entries

1 Click the [+] to the left of the icon to expand the module

comments.

2 Double-click the

appears.

icon. The Edit - Module Comment dialog box

3 Enter your comment and click OK

to save your changes.

1.4.5 Printing a Configuration File

1 Select the gateway icon, and then click the right mouse button to open a

shortcut menu.

2 On the

View Configuration window.

3 On the View Configuration window, open the F

This action opens the Print dialog box.

4 On the Print dialog box, choose the printer to use from the drop-down list,

select printing options, and then click OK.

shortcut menu, choose VIEW CONFIGURATION. This action opens the

ILE menu, and choose PRINT.

Page 16 of 159 ProSoft Technology, Inc.

August 6, 2010

Page 17

IEC-101 Slave ♦ ProLinx Communication Gateway Start Here

IEC 60870-5-101 v3 Slave (Firmware version 3.xx) Protocol Manual

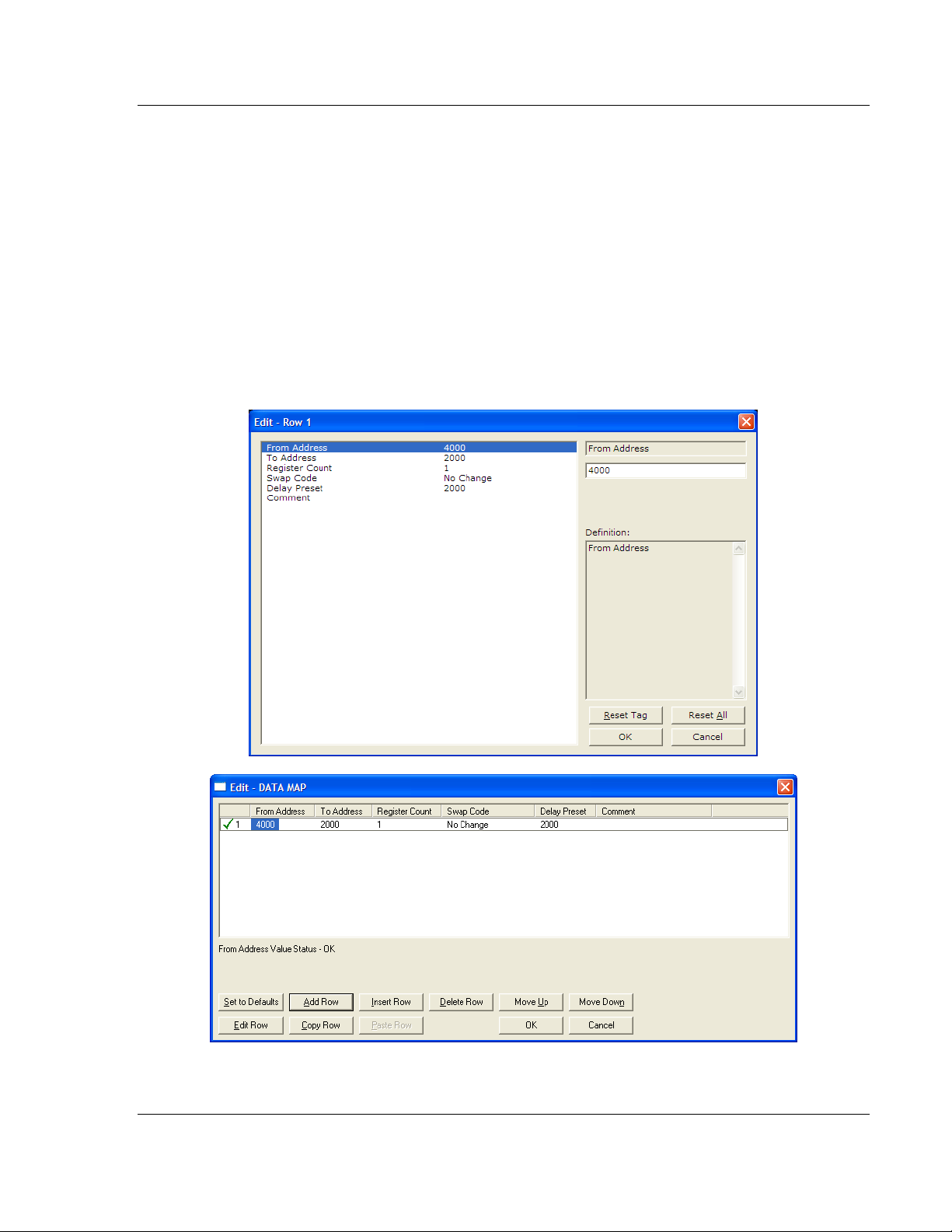

1.4.6 Using the CommonNet Data Map

The Data Map section allows you to copy data between areas in the gateway's

internal database.

You can copy a maximum of 100 registers per Data Map command, and you can

configure a maximum of 200 separate copy commands.

You can copy data from the error or status tables in upper memory to internal

database registers in the User Data memory area.

You can rearrange the byte and/or word order during the copy process. For

example, by rearranging byte or word order, you can convert floating-point values

to the correct format for a different protocol.

You can also use the Data Map to condense widely dispersed data into one

contiguous data block, making it easier to access.

ProSoft Technology, Inc. Page 17 of 159

August 6, 2010

Page 18

Start Here IEC-101 Slave ♦ ProLinx Communication Gateway

Protocol Manual IEC 60870-5-101 v3 Slave (Firmware version 3.xx)

From Address

0 to highest Status Data address

This field specifies the beginning internal database register address for the copy

operation. This address can be any valid address in the User Data Area or the

Status Data Area of the gateway.

To Address

0 to 3999

This parameter specifies the beginning destination register address for the copy

operation. This address must always be within the User Data registers area.

Take care to specify a destination address that will not overwrite data that has

been stored in memory by one of the communication protocols running on the

gateway.

Register Count

1 to 100

This parameter specifies the number of registers to copy.

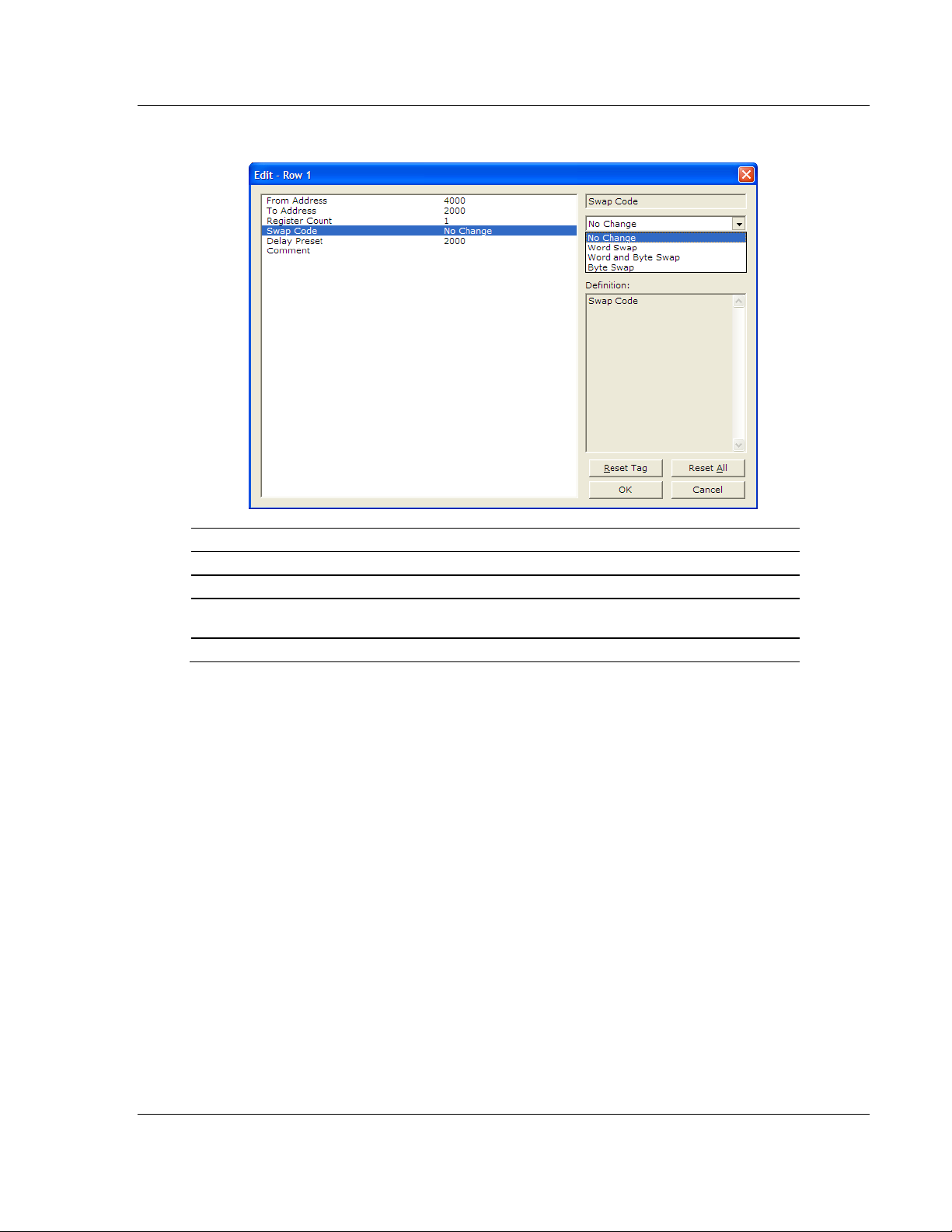

Swap Code

NO CHANGE, WORD SWAP, WORD AND BYTE SWAP, BYTE SWAP

You may need to swap the order of the bytes in the registers during the copy

process in order to change the alignment of bytes between dissimilar protocols.

This parameter is helpful when dealing with floating-point or other multi-register

values, as there is no standard method of storage of these data types in slave

devices.

Page 18 of 159 ProSoft Technology, Inc.

August 6, 2010

Page 19

IEC-101 Slave ♦ ProLinx Communication Gateway Start Here

IEC 60870-5-101 v3 Slave (Firmware version 3.xx) Protocol Manual

The following table defines the values and their associated operations:

Swap Code Description

No Swap No change is made in the byte ordering (1234 = 1234)

Word Swap The words are swapped (1234=3412)

Word and

Byte Swap

Bytes The bytes in each word are swapped (1234=2143)

The words are swapped, then the bytes in each word are swapped (1234=4321)

ProSoft Technology, Inc. Page 19 of 159

August 6, 2010

Page 20

Start Here IEC-101 Slave ♦ ProLinx Communication Gateway

Protocol Manual IEC 60870-5-101 v3 Slave (Firmware version 3.xx)

Delay Preset

This parameter sets an interval for each Data Map copy operation. The value you

put for the Delay Preset is not a fixed amount of time. It is the number of firmware

scans that must transpire between copy operations.

The firmware scan cycle can take a variable amount of time, depending on the

level of activity of the protocol drivers running on the ProLinx gateway and the

level of activity on the gateway's communication ports. Each firmware scan can

take from 1 to several milliseconds to complete. Therefore, Data Map copy

operations cannot be expected to happen at regular intervals.

If multiple copy operations (several rows in the Data map section) happen too

frequently or all happen in the same update interval, they could delay the process

scan of the gateway protocols, which could result in slow data updates or missed

data on communication ports. To avoid these potential problems, you should set

the Delay Preset to different values for each row in the Data Map section and set

them to higher, rather than lower, numbers.

For example, Delay Preset values below 1000 could begin to cause a noticeable

delay in data updates through the communication ports. And you should not set

all Delay Presets to the same value. Instead, use different values for each row in

the Data Map such as 1000, 1001, and 1002 or any other different Delay Preset

values you like. This will prevent the copies from happening concurrently and

prevent possible process scan delays.

Page 20 of 159 ProSoft Technology, Inc.

August 6, 2010

Page 21

IEC-101 Slave ♦ ProLinx Communication Gateway Start Here

IEC 60870-5-101 v3 Slave (Firmware version 3.xx) Protocol Manual

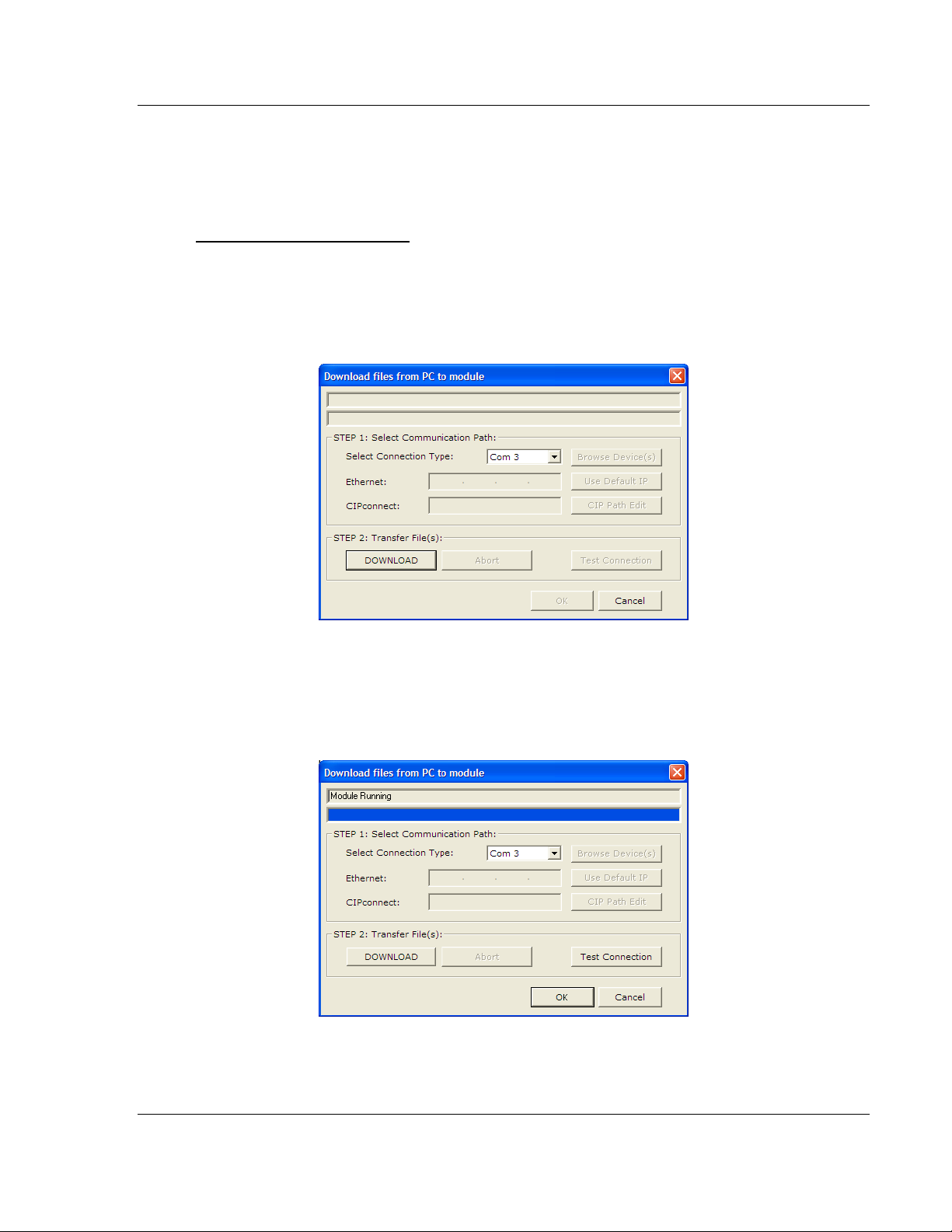

1.4.7 Downloading the Project to the Module

For the gateway to use the settings you configured, you must download (copy)

the updated Project file from your PC to the gateway.

To Download the Project File

1 In the tree view in ProSoft Configuration Builder, click once to select the

gateway.

2 Open the P

program will scan your PC for a valid com port (this may take a few seconds).

When PCB has found a valid COM port, the Download

ROJECT menu, and then choose MODULE/DOWNLOAD. The

dialog box will open.

3 Choose the COM port to use from the

D

OWNLOAD button.

dropdown list, and then click the

The gateway will perform a platform check to read and load its new settings.

When the platform check is complete, the status bar in the Download

box will display the message Module Running.

dialog

ProSoft Technology, Inc. Page 21 of 159

August 6, 2010

Page 22

Start Here IEC-101 Slave ♦ ProLinx Communication Gateway

Protocol Manual IEC 60870-5-101 v3 Slave (Firmware version 3.xx)

Page 22 of 159 ProSoft Technology, Inc.

August 6, 2010

Page 23

IEC-101 Slave ♦ ProLinx Communication Gateway 101S Protocol Configuration

IEC 60870-5-101 v3 Slave (Firmware version 3.xx) Protocol Manual

2 101S Protocol Configuration

In This Chapter

[IEC-870-5-101 Port 0] .......................................................................... 24

[IEC-870-5-101 Database]..................................................................... 38

[M_SP_NA_1] ........................................................................................ 42

[M_DP_NA_1] ....................................................................................... 42

[M_ST_NA_1] ........................................................................................ 43

[M_BO_NA_1 104] ................................................................................ 43

[M_ME_NA_1] ....................................................................................... 44

[M_ME_NB_1] ....................................................................................... 44

[M_ME_NC_1] ....................................................................................... 45

[M_IT_NA_1] ......................................................................................... 45

[C_SC_NA_1] ........................................................................................ 46

[C_DC_NA_1] ........................................................................................ 46

[C_RC_NA_1] ........................................................................................ 47

[C_BO_NA_1 104] ................................................................................. 47

[C_SE_NA_1] ........................................................................................ 48

[C_SE_NB_1] ........................................................................................ 48

[C_SE_NC_1] ........................................................................................ 49

Group Codes ......................................................................................... 50

ProSoft Technology, Inc. Page 23 of 159

August 6, 2010

Page 24

101S Protocol Configuration IEC-101 Slave ♦ ProLinx Communication Gateway

Protocol Manual IEC 60870-5-101 v3 Slave (Firmware version 3.xx)

2.1 [IEC-870-5-101 Port 0]

This section provides information required to configure a slave application with

the gateway.

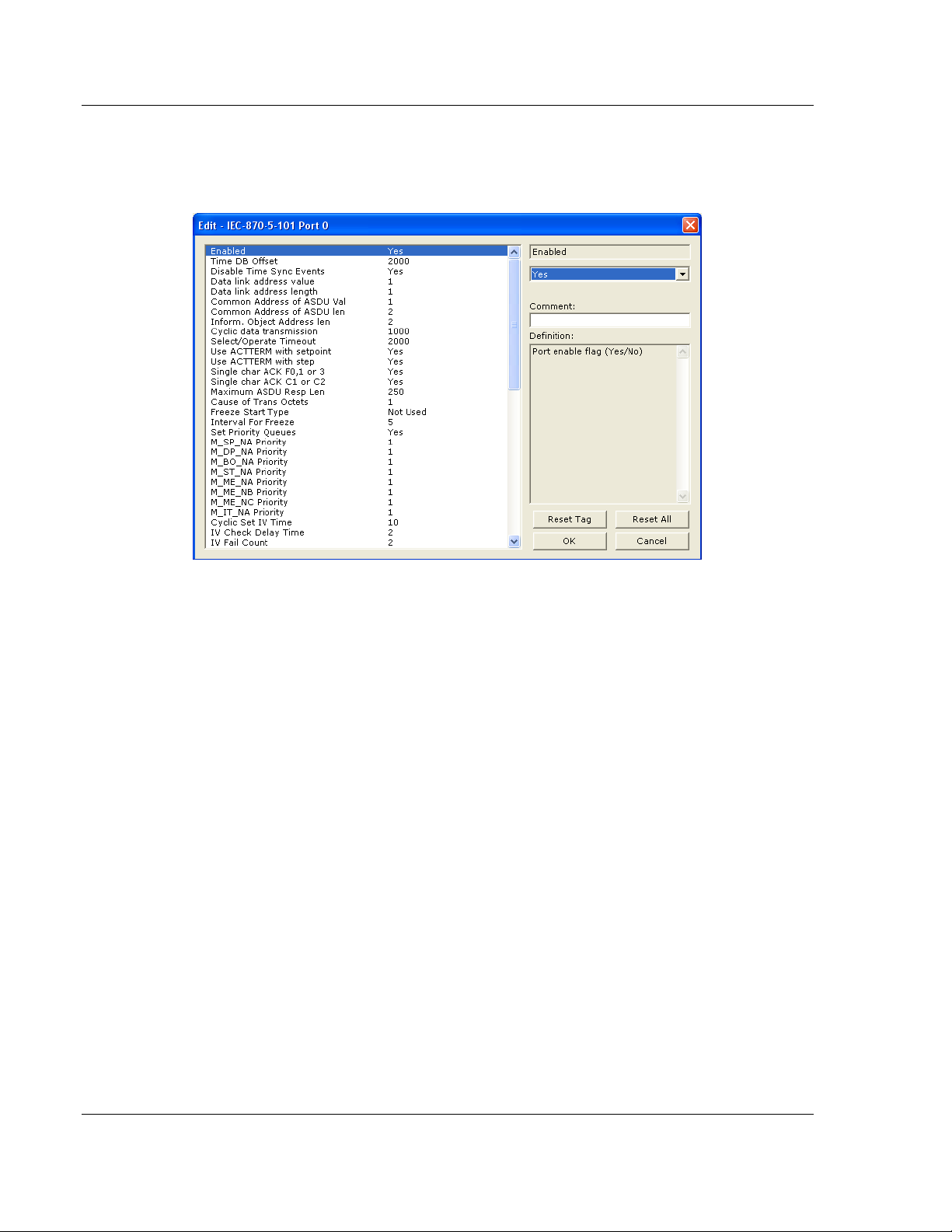

2.1.1 Enabled

YES or NO

Enables or disables the primary port. If the port is not enabled (No), then the

gateway will not use the port. If the port is enabled (Yes), the gateway will

emulate an IEC 60870-101 slave device on the port.

2.1.2 Time DB Offset

-1, or 0 to 3994

This parameter defines the location in the database where the time maintained

for the IEC protocol is copied. This time is updated whenever a time

synchronization command is received from the host and continually as the

program runs. If the parameter is set to -1, the time will not be placed in the

database.

Page 24 of 159 ProSoft Technology, Inc.

August 6, 2010

Page 25

IEC-101 Slave ♦ ProLinx Communication Gateway 101S Protocol Configuration

IEC 60870-5-101 v3 Slave (Firmware version 3.xx) Protocol Manual

2.1.3 Disable Time Sync Events

YES or NO

This feature can be used when the Master receives the event timestamp with

only minutes and milliseconds information for each event message (CP24 time

type). If the parameter is set to N, the spontaneous time sync events will be

generated to indicate the change of hour. If this parameter is set to Y, then the

spontaneous time sync event messages are not generated to indicate the

change of hour.

2.1.4 Data Link Address Value

0 to 65535

This parameter defines the Data Link Address for the emulated device on the

gateway. This address identifies the gateway on the network along with the

common address of ASDU.

2.1.5 Data link address length

0, 1, or 2

This parameter specifies the number of octets used for the data link address.

This parameter must be set the same for all devices on the network. A value of 0

is only valid when the balanced mode is used. If unbalanced mode is used, a

value of 1 or 2 must be used.

2.1.6 Common Address of ASDU Val

0 to 65535

This parameter specifies the common address of the ASDU (section address) for

access to data in the gateway. There is only one value entered for access to all

data in the gateway.

Refer to ASDU Configuration for more information on Application Service Data

Unit configuration.

2.1.7 Common Address of ASDU Len

1 or 2

This parameter specifies the number of octets used for the common address of

ASDU. This parameter must be set the same for all devices on the network.

ProSoft Technology, Inc. Page 25 of 159

August 6, 2010

Page 26

101S Protocol Configuration IEC-101 Slave ♦ ProLinx Communication Gateway

Protocol Manual IEC 60870-5-101 v3 Slave (Firmware version 3.xx)

2.1.8 Inform. Object Address Len

1, 2, or 3

This parameter specifies the number of octets used to define the address of an

information object (point address).

2.1.9 Cyclic Data Transmission

0 to 4,294,967,296 (2 raised to the power of 32) milliseconds

This parameter defines the number of milliseconds between cyclic updates. The

range of values allow for update times between 1 millisecond and 49.7 days. Set

this parameter to 0 to disable cyclic data reporting.

2.1.10 Select/Operate Timeout

0 to 4,294,967,296 (2 raised to the power of 32) milliseconds

This parameter sets the number of milliseconds to wait for a valid Execute

command after receiving a Select command. The range of values allows for

update times between 1 millisecond and 49.7 days. Set this parameter to 0 to

disable this feature.

2.1.11 Use ACTTERM with Set Point

Y - YES or N - NO

This parameter determines if an ACTTERM will be sent. If the parameter is set to

Y

ES, then set point commands will issue an ACTTERM when the command is

complete. If the parameter is set to N

O, ACTCON is the last response to a set

point command.

2.1.12 Use ACTTERM with Step

Y - YES or N - NO

This parameter determines if an ACTTERM will be sent. If the parameter is set to

Y

ES, then step commands will issue an ACTTERM when the command is

complete. If the parameter is set to N

O, ACTCON is the last response to a step

command.

2.1.13 Single char ACK F0, 1 or 3

Y - YES or N - NO

If set to Yes, a single character ACK (0xE5) will be sent instead of a fixed length

ACK (secondary function code 0) in response to a primary link function code 0, 1

or 3 if there is no access demand for class 1 data (ACD=1). If set to No, the fixed

length ACK will be sent.

Page 26 of 159 ProSoft Technology, Inc.

August 6, 2010

Page 27

IEC-101 Slave ♦ ProLinx Communication Gateway 101S Protocol Configuration

IEC 60870-5-101 v3 Slave (Firmware version 3.xx) Protocol Manual

2.1.14 Single char ACK C1 or C2

Y -YES or N - NO

If set to Yes, a single character ACK (0xE5) will be sent instead of a fixed length

NACK (secondary function code 9) when no response user data is available. If

set to No, the fixed length NACK will be sent.

2.1.15 Maximum ASDU Resp Len

25 to 252

Sets the maximum ASDU response message length (usually 252).

2.1.16 Cause of Trans(mission) Octets

1 or 2

Specifies the number of COT octets (1 or 2)

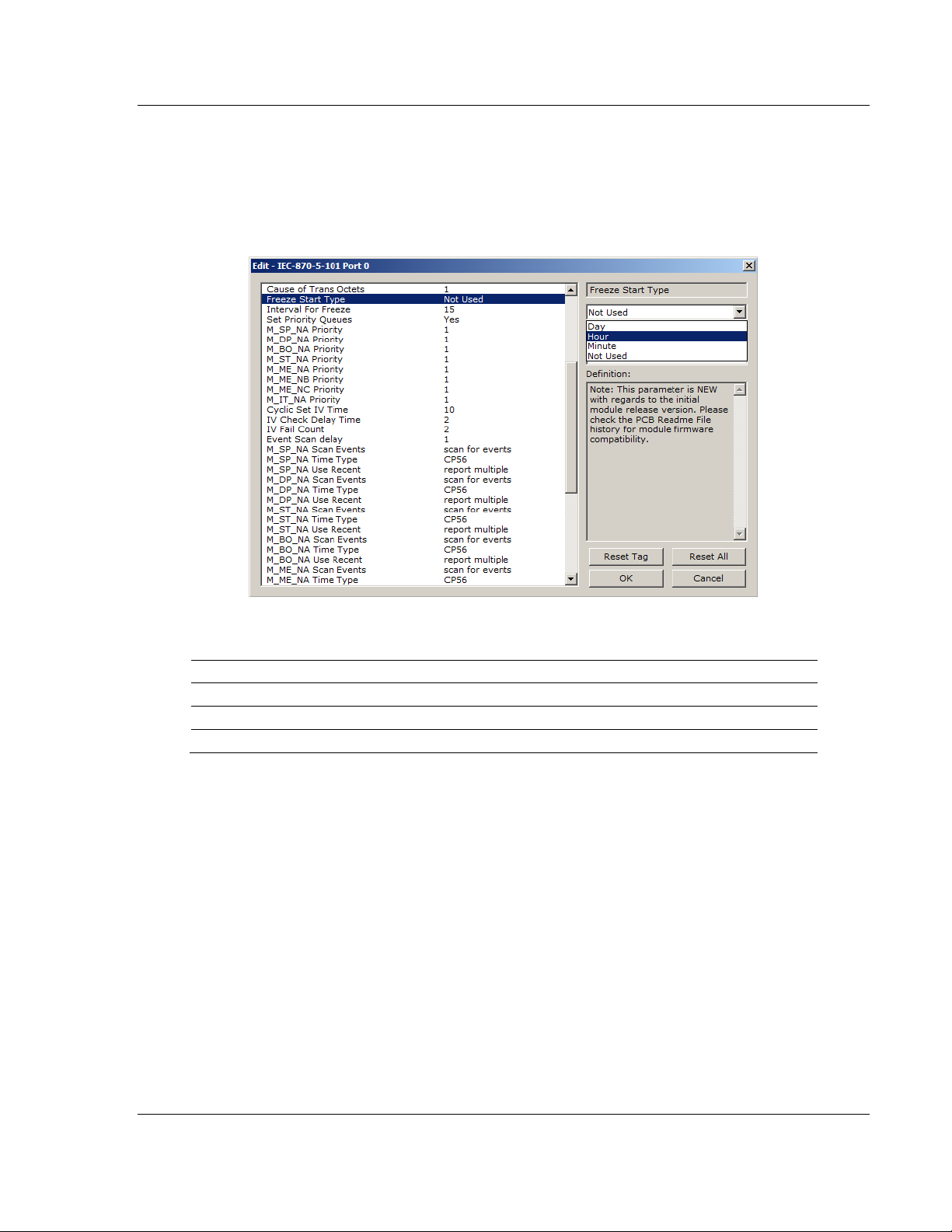

2.1.17 Freeze Start Type

D = DAY, H = HOUR, M = MINUTE, N = NOT USED The Freeze Start Type parameter defines when the gateway starts sending the

M_IT messages.

ProSoft Technology, Inc. Page 27 of 159

August 6, 2010

Page 28

101S Protocol Configuration IEC-101 Slave ♦ ProLinx Communication Gateway

Protocol Manual IEC 60870-5-101 v3 Slave (Firmware version 3.xx)

Example I - Freeze Start Type

If the gateway should send the counter points on the hourly turn around time and

also 45 minutes later, the Mode A parameters should be configured as follows:

So the gateway would send events as follows (Hours:Minutes:Seconds):

17:00:00

17:45:00

18:00:00

18:45:00

19:00:00

19:45:00

…

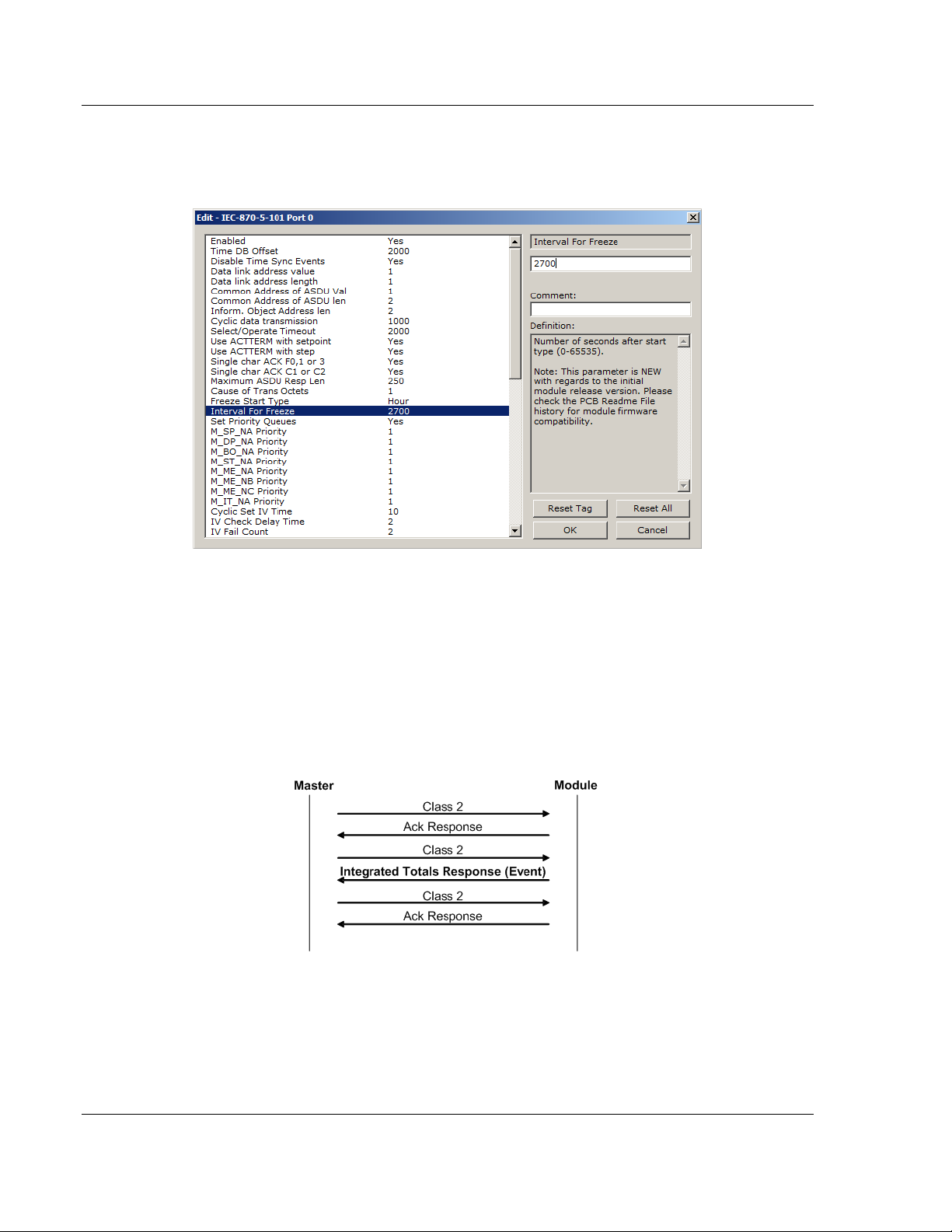

The following illustration shows a typical communication example when the Mode

A is selected during unbalanced mode operation:

Page 28 of 159 ProSoft Technology, Inc.

August 6, 2010

Page 29

IEC-101 Slave ♦ ProLinx Communication Gateway 101S Protocol Configuration

IEC 60870-5-101 v3 Slave (Firmware version 3.xx) Protocol Manual

Example II - Freeze Start Type

If the gateway powers up with the following date and time settings on its internal

clock:

03/25/2004 18:07:42

And if you configure the Interval For Freeze parameter to 15 seconds, as follows:

The Freeze Start Type parameter determines when the gateway will begin

sending these messages, as follows:

If the Freeze Start Type is set to: Then Messages will start being sent at:

D 03/26/2004 00:00:00 and every 15 seconds thereafter

H 03/25/2004 19:00:00 and every 15 seconds thereafter

M 03/25/2004 18:08:00 and every 15 seconds thereafter

Once message transmission begins, the gateway will freeze and transmit counter values at whatever interval has been configured using the Interval For Freeze parameter. In this example, that would be every 15-seconds.

2.1.18 Interval for Freeze

0 to 65535 seconds

Freeze Start Type and Interval for Freeze are used if Mode A operation is to be

used for the counter freeze operation. If they are not used, the gateway will

operate in Mode D.

ProSoft Technology, Inc. Page 29 of 159

August 6, 2010

Page 30

101S Protocol Configuration IEC-101 Slave ♦ ProLinx Communication Gateway

Protocol Manual IEC 60870-5-101 v3 Slave (Firmware version 3.xx)

2.1.19 Set Priority Queues

YES or NO

This section defines priority queues for the gateway. You can assign priorities to

data types that return events so that events of some data types will be returned

before events of other data types. If this feature is utilized, each data type must

be assigned a unique index from 0 to 7. The lower the index, the higher the

priority (0=highest priority, 7=lowest priority).

Events of ASDUs with lower numbers will be reported before events from other

ASDUs with higher numbers.

Note: In some configurations, depending on the total number of events generated for all data

types, setting priorities may cause some events to be lost, as the event buffers for low priority

queues may overflow before their events can be reported.

For more information, refer to Event Priority (page 31).

Page 30 of 159 ProSoft Technology, Inc.

August 6, 2010

Page 31

IEC-101 Slave ♦ ProLinx Communication Gateway 101S Protocol Configuration

IEC 60870-5-101 v3 Slave (Firmware version 3.xx) Protocol Manual

2.1.20 Event Priority

Event Priority permits the user to set reporting priorities for data change events

generated for each data type. The configuration file contains the following

parameters to support this feature:

The Set Priority Queues parameter must be enabled for this feature to be used.

Each of the Monitored Point ASDUs must be assigned a unique priority index

from 0 to 7. When events of the ASDU with a lower priority number are present,

they will always be reported before events from any other ASDUs with higher

priority numbers.

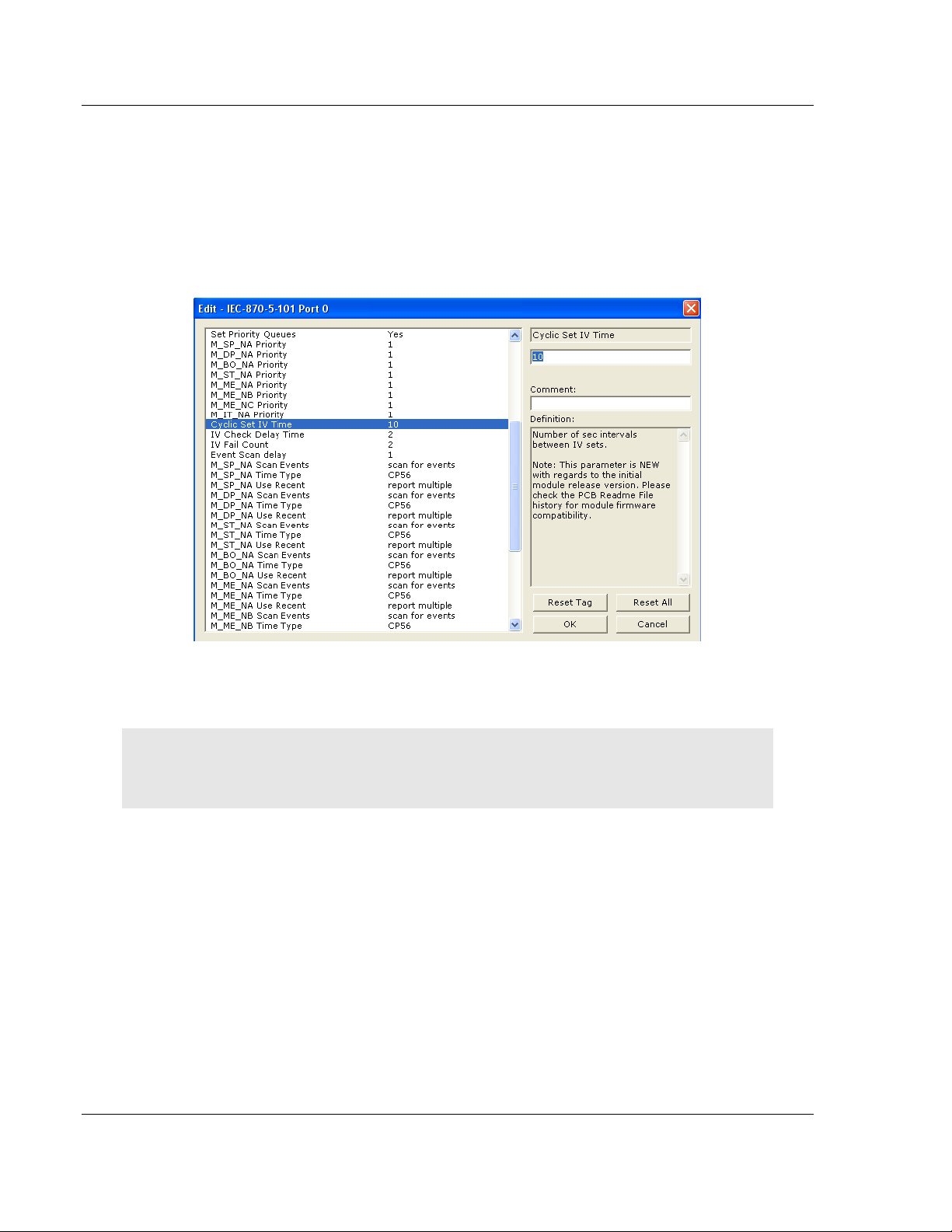

2.1.21 Cyclic Set IV Time - PLX 101S

1 to 65535 seconds, or 0 to disable Invalid Bit Monitoring

The parameter should be set to a value significantly greater than the value of the

IV Check Delay Time parameter, multiplied by the value of the IV Fail Count

parameter. Example:

If, IV Check Delay = 3;

And, IV Fail Count = 5;

Then set Cyclic Set IV Time significantly greater than 15; preferably some

multiple of this value, like 30, 45, 60,

The Cyclic Set IV Time parameter is one of three parameters needed to establish

a fail-safe data validation system for this protocol implementation. This

parameter is used with the IV Check Delay Time and the IV Fail Count

parameters to create a way to alert the remote IEC-101 Master to situations

where data being sent by the gateway might be invalid.

or more.

ProSoft Technology, Inc. Page 31 of 159

August 6, 2010

Page 32

101S Protocol Configuration IEC-101 Slave ♦ ProLinx Communication Gateway

Protocol Manual IEC 60870-5-101 v3 Slave (Firmware version 3.xx)

The gateway will automatically set ON (set to one) the IV Bits of all IEC database

Monitor Points (M_xx_xx point) that have been configured to use invalid bit

monitoring. This means that all IEC database Monitor Points configured with IV

Bit addresses greater than zero (0) will have their IV Bit addresses in the

gateway database set to a value of one (1) by the gateway firmware in a timed,

periodic cycle, based on the number of seconds entered in Cyclic Set IV Time.

The IV Bits are checked at the interval specified by the IV Check Delay Time

parameter. At the end of each check delay interval, if an IV Bit for any IEC

database point is ON, an IV Bit Check Fail accumulator for that point will be

incremented. If the value in any IV Bit Check Fail accumulator becomes equal to

the value of the IV Fail Count parameter, the gateway will consider the data value

of that point invalid and will report the invalid status of that point to the Master

along with the data value.

If the IV Bit is cleared (reset, set OFF, set to zero) before the IV Bit Check Fail

accumulator value becomes equal to the value of the IV Fail Count parameter,

the IV Bit Check Fail accumulator will be reset to 0. The gateway will consider the

data value of that point valid and will report the valid status of that point to the

Master along with data value.

To properly use data validity checking with a ProLinx Gateway, the application

that communicates to the gateway through the other gateway protocol (Modbus,

EtherNet/IP, etc.) must be programmed to provide data validity information, as

well as the actual data to be transferred. This other application must write bit

values of zero (0) or one (1) to the proper gateway database addresses along

with the data for each IEC database point.

This means the other protocol application will be responsible for clearing the IV

Bits for data points which contain valid data at a time interval less than the

amount of time required to accumulate the required number of IV Bit Check

failures. If the other protocol application does not clear the IV Bits, then those

IEC database monitor point values will be reported to the Master as invalid.

NOTE: If one or more of the Cyclic Set IV Time, the IV Check Delay Time, or the IV Fail Count

parameters are set to zero, the data validity checking feature will be disabled for all points in the

IEC database and the data reported to the remote Master will always be reported as valid data. If

you wish to have actual data validity information relayed to the Master, be sure the Cyclic Set IV

Time, the IV Check Delay Time, and the IV Fail Count parameters are set to non-zero values and

be sure the application has been programmed to properly manipulate the IV Bit addresses in the

gateway database. Once data validity checking has been enabled, you can still turn off validity

checking on a point-by-point basis by setting the IV Bit Address to zero (0) for any point you wish to

exclude from data validity checking and reporting.

For more information on the data validity features of this protocol implementation,

refer to Invalid Bit Monitoring.

Page 32 of 159 ProSoft Technology, Inc.

August 6, 2010

Page 33

IEC-101 Slave ♦ ProLinx Communication Gateway 101S Protocol Configuration

IEC 60870-5-101 v3 Slave (Firmware version 3.xx) Protocol Manual

2.1.22 IV Check Delay Time

1 to 65535 seconds, or 0 to disable Invalid Bit Monitoring

This parameter sets the number of seconds between IV Bit value checks. Every

IEC database Monitor information object which has an IV Bit address set greater

than 0 will have that bit address checked at the interval specified by this

parameter.

Setting this parameter to zero (0) will disable data validity checking.

2.1.23 IV Fail Count

1 to 65535 seconds, or 0 to disable Invalid Bit Monitoring

This parameter sets the number of successive IV Bit check failures which must

occur before the data from an IEC database Monitor information object will be

reported to the remote Client as invalid data.

An IV Bit Check Failure occurs when the IV Bit value in the gateway database is set ON {when it contains a value of one (1)} at the time an IV Bit Check is performed. IV Bit Check failures are counted and held in separate IV Bit Check Failure accumulators for each IEC Monitor information object configured for validity checking. If the value in any point's failure accumulator becomes equal to the value set in this IV Fail Count parameter, the gateway will consider data from this point as invalid and report to the Client this invalid status, along with the point's data value.

Setting this parameter to zero (0) will disable data validity checking.

2.1.24 Event Scan Delay

1 to 65535 milliseconds, or 0 to disable

If set to 0, the feature will be disabled and the gateway will not generate any

events. If set from 1 to 65535, the parameter represents the number of

milliseconds between event scanning. This parameter defines how often the

program will scan for new events in the databases.

NOTE: The lower you set this value, the more negative effect it will have on overall gateway data

update and transfer performance. Scanning for new events causes an interrupt of other data

manipulation functions. The more often these scan interrupts occur, the less processor time the

gateway will have available for other data operations. When choosing a value for this parameter,

you should consider such factors as how often events might be generated by your application and

how often you need to recognize and respond to such events. This will allow you to set this value

as high as it can be set and still maintain your overall event capturing and reporting strategy.

Doing so can reduce the amount of interrupts, prevent excessive event scanning, and maximize

data update and transmission rates.

ProSoft Technology, Inc. Page 33 of 159

August 6, 2010

Page 34

101S Protocol Configuration IEC-101 Slave ♦ ProLinx Communication Gateway

Protocol Manual IEC 60870-5-101 v3 Slave (Firmware version 3.xx)

2.1.25 Scan Events

[0] = NO SCANNING or [1] = SCAN FOR EVENTS

Separate parameters exist for each monitored point type and define whether or

not events of that particular point type will be generated by the gateway. If the Scan Events parameter is set to zero generated. If this parameter is set to [1] or S scanned and generated on data change.

[0] or NO SCANNING, then events will not be

CAN FOR EVENTS, events will be

Page 34 of 159 ProSoft Technology, Inc.

August 6, 2010

Page 35

IEC-101 Slave ♦ ProLinx Communication Gateway 101S Protocol Configuration

IEC 60870-5-101 v3 Slave (Firmware version 3.xx) Protocol Manual

2.1.26 Time Type

[0] = None, [1] = CP24, or [2] = CP56

Separate parameters exist for multiple point types. This parameter defines the

time format used with data events.

2.1.27 Use Balanced Mode

Y - YES or N - NO

This parameter specifies if the port will use balanced mode. If balanced mode is

used, only one controlled station will be permitted on the port. If unbalanced

mode is used, multiple controlled stations can be used on a port.

Refer to gateway Initialization for more information on these modes.

2.1.28 Retry Count

0 to 255

In balanced mode, this parameter specifies the number of retries (0 to 255) if a

response is not received. In unbalanced mode, this parameter is ignored.

ProSoft Technology, Inc. Page 35 of 159

August 6, 2010

Page 36

101S Protocol Configuration IEC-101 Slave ♦ ProLinx Communication Gateway

Protocol Manual IEC 60870-5-101 v3 Slave (Firmware version 3.xx)

2.1.29 Response Timeout

0 to 65535 milliseconds

This parameter specifies the minimum number of milliseconds to wait for a

response to a primary message. Do not set this parameter too small or timeout

conditions may prevent successful data transmission. If the timeout is

recognized, the message will be retransmitted up to the number of times

specified in the Retry Count parameter. This parameter is only used in balance

mode.

2.1.30 Baud Rate

300, 600, 1200, 2400, 4800, 9600, 19200, or 38400

This parameter specifies the baud rate for the primary port on the gateway. Baud

rates from 300 to 38400 are supported on the gateway.

2.1.31 Parity

None, Odd, Even

Parity is a simple error checking algorithm used in serial communication. This

parameter specifies the type of parity checking to use.

All devices communicating through this port must use the same parity setting.

2.1.32 RTS On

0 to 65535 milliseconds

This parameter sets the number of milliseconds to delay after Ready To Send

(RTS) is asserted before data will be transmitted.

2.1.33 RTS Off

0 to 65535 milliseconds

This parameter sets the number of milliseconds to delay after the last byte of

data is sent before the RTS modem signal will be set low.

2.1.34 Minimum Delay

0 to 65535 milliseconds

This parameter defines the minimum number of milliseconds to wait before a

response is sent from the unit.

Page 36 of 159 ProSoft Technology, Inc.

August 6, 2010

Page 37

IEC-101 Slave ♦ ProLinx Communication Gateway 101S Protocol Configuration

IEC 60870-5-101 v3 Slave (Firmware version 3.xx) Protocol Manual

2.1.35 Receive Timeout

0 to 65535 milliseconds

This parameter specifies the minimum number of milliseconds to wait after the

first byte of a frame is received before a timeout condition is set. Be careful not to

set this parameter too small. If the timeout condition is set, all bytes in the frame

received will be discarded.

2.1.36 Hardware Handshaking

NONE, RTS/CTS, DTR/DSR, MODEM

Selects the hardware handshaking type. RTS/CTS, DTR/DSR and M

options are most commonly used for older telephone line modems. RTS/CTS

and DTR/DSR are also commonly used with leased-line data modems. The

M

ODEM option is also commonly used with dial-up modems. When the messages

must go out if the modem is not connected, the gateway will assert the DTR line

which will cause the modem to dial the number in the modem’s configuration.

The gateway does not have the functionality to dial the number to be called for

the modem. The gateway reconnects after 30 seconds of inactivity.

ODEM

ProSoft Technology, Inc. Page 37 of 159

August 6, 2010

Page 38

101S Protocol Configuration IEC-101 Slave ♦ ProLinx Communication Gateway

Protocol Manual IEC 60870-5-101 v3 Slave (Firmware version 3.xx)

2.2 [IEC-870-5-101 Database]

This section configures the IEC-870-5-101 Database.

2.2.1 Short Pulse Time

0 to 2,147,483,647 (2 raised to the power of 31, minus 1) milliseconds

This parameter defines the number of milliseconds to be associated with a short

pulse command.

2.2.2 Long Pulse Time

0 to 2,147,483,647 (2 raised to the power of 31, minus 1) milliseconds

This parameter defines the number of milliseconds to be associated with a long

pulse command.

Page 38 of 159 ProSoft Technology, Inc.

August 6, 2010

Page 39

IEC-101 Slave ♦ ProLinx Communication Gateway 101S Protocol Configuration

IEC 60870-5-101 v3 Slave (Firmware version 3.xx) Protocol Manual

2.2.3 Point Count

Point Count configuration ranges in the following configuration items are based

on the assumption that you will be using only one of the available data types for

your application. The number of point counts you configure will have an effect on

gateway performance, in particular, the accuracy of the gateway’s internal clock.

Parameter Description Range

M_SP_NA point count The number of point values assigned in monitored

single-point database.

M_DP_NA point count The number of point values assigned in monitored

double-point database.

M_ST_NA point count The number of point values assigned in monitored

step-point database.

M_BO_NA point count The number of 32-bit values assigned in monitored

bitstring database

M_ME_NA point count The number of point values assigned in monitored

normalized-point database.

M_ME_NB point count The number of point values assigned in monitored

scaled-point database.

M_ME_NC point count The number of point values assigned in monitored

scaled short-float point database.

M_IT_NA point count The number of point values assigned in monitored

counter-point database.

C_SC_NA point count The number of point values assigned in command

single-point database.

C_DC_NA point count The number of point values assigned in command

dual-point database.

0 to 1000

0 to 1000

0 to 1000

0 to 1000

0 to 1000

0 to 1000

0 to 50

0 to 99

0 to 1000

0 to 1000

ProSoft Technology, Inc. Page 39 of 159

August 6, 2010

Page 40

101S Protocol Configuration IEC-101 Slave ♦ ProLinx Communication Gateway

Protocol Manual IEC 60870-5-101 v3 Slave (Firmware version 3.xx)

Parameter Description Range

C_RC_NA point count The number of point values assigned in command

step-point database.

C_BO_NA point count The number of 32-bit values assigned in command

bitstring database

C_SE_NA point count The number of point values assigned in command

normalized-point database.

C_SE_NB point count The number of point values assigned in command

scaled-point database.

C_SE_NC point count The number of point values assigned in command

short-float point database.

0 to 1000

0 to 1000

0 to 1000

0 to 1000

0 to 50

2.2.4 Sequence Flag

In order to save bandwidth, you can configure the gateway to use the Sequence

Flag feature. If this feature is not selected, the gateway will send the Information

Object Address (IOA) and the data value for every Monitor information object in

a poll response to the Master. If this parameter is enabled, the gateway will turn

on the Sequence Flag bit in a Monitor response; send the Informaiton Object

Address of only the first object in the response, along with its data value; and

send only the data values for all the other information objects in the response.

The Master assumes that all other points use IOAs in a contiguous order (using

the first point as the starting reference address). Since the IOAs are omitted for

all but the first point, this feature allows each message packet to contain more

process data, which improves network throughput and optimizes bandwidth

utilization.

Page 40 of 159 ProSoft Technology, Inc.

August 6, 2010

Page 41

IEC-101 Slave ♦ ProLinx Communication Gateway 101S Protocol Configuration

IEC 60870-5-101 v3 Slave (Firmware version 3.xx) Protocol Manual

2.2.5 Parameter Offset

This parameter specifies the IOA (Information Object Address) offset to the

parameter data for the normalized parameter data. The value entered is added to

the Information Object address for the associated point to compute the

parameter IOA address.

The Master may send a "Parameter of Measured Normalized" or "Parameter of

Measured Scaled" command using the parameter IOA in order to change the

deadband values for specific points.

Note: The Low Limit and High Limit values are always calculated based on the deadband value as

described in the following table.

Point Value

Threshold Determined by the deadband set in the configuration file or altered by the write

command.

Low Last reported event value - threshold.

High Last reported event value + threshold.

For example, if the configuration sets two M_ME_NA points with IOA (Point #) of

600 and 601 and an M_ME_NA Parameter Offset value of 3000, it would result in

the parameter points shown in the table.

ProSoft Technology, Inc. Page 41 of 159

August 6, 2010

Page 42

101S Protocol Configuration IEC-101 Slave ♦ ProLinx Communication Gateway

Protocol Manual IEC 60870-5-101 v3 Slave (Firmware version 3.xx)

2.3 [M_SP_NA_1]

This section defines the monitored single-point database. This information is

sourced from the database and is transferred to the remote Master unit.

This section takes the following parameters:

P

OINT #

DB

G

IV

ADDRESS

ROUPS (page 50)

DB BIT

Each point consumes one bit (1 = On, 0 = Off state). The DB

corresponds to the bit offset address in the database.

The DB

ADDRESS should be located in a database area that is being constantly

moved from the gateway to the Master.

For additional information on how to set these parameters, see the Reference

chapter of this manual.

2.4 [M_DP_NA_1]

This section defines the monitored dual-point database. This information is

sourced from the database and is transferred to the remote Master unit.

This section takes the following parameters:

P

OINT #

DB

G

IV

Each point consumes two bits (00 = intermediate, 01 = off, 10 = on and 11 =

intermediate). The DB

the database.

The DB

moved from the gateway to the Master.

For additional information on how to set these parameters, see the Reference

chapter of this manual.

ADDRESS

ROUPS (page 50)

DB BIT

ADDRESS should be located in a database area that is being constantly

ADDRESS VALUE

ADDRESS value corresponds to the bit offset address in

Page 42 of 159 ProSoft Technology, Inc.

August 6, 2010

Page 43

IEC-101 Slave ♦ ProLinx Communication Gateway 101S Protocol Configuration

IEC 60870-5-101 v3 Slave (Firmware version 3.xx) Protocol Manual

2.5 [M_ST_NA_1]

This section defines the monitored step database. This information is sourced

from the database and is transferred to the remote Master unit.

This section takes the following parameters:

P

OINT #

DB

G

IV

ADDRESS

ROUPS (page 50)

DB BIT

Each point consumes one, 8-bit byte. The

byte offset address in the database.

The DB

ADDRESS should be located in a database area that is being constantly

moved from the gateway to the Master.

For additional information on how to set these parameters, see the Reference

chapter of this manual.

2.6 [M_BO_NA_1 104]

This section defines the Monitored 32-bit Bitstring Data Point database. This

information is sourced from the database and is transferred to the remote Master

unit.

This section takes the following parameters:

Point #

DB Address

Groups (page 50)

IV DB Bit

Each point is four 8-bit bytes (two 16-bit words) and the DB Address value

corresponds to the double word offset in the gateway memory database.

The DB address should be located in a database area that is being constantly

moved from the gateway to the Master.

For additional information on how to set these parameters, see the Reference

chapter of this manual.

DB ADDRESS value corresponds to the

ProSoft Technology, Inc. Page 43 of 159

August 6, 2010

Page 44

101S Protocol Configuration IEC-101 Slave ♦ ProLinx Communication Gateway

Protocol Manual IEC 60870-5-101 v3 Slave (Firmware version 3.xx)

2.7 [M_ME_NA_1]

This section defines the monitored measured value, normalized database. This

information is sourced from the database and is transferred to the remote Master

unit.

To determine the IOA (Information Object Address) for each object, add the

P

OINT # in the following section to the value of the M_ME_NA parameter offset

parameter set in the previous section.

This section takes the following parameters:

P

OINT #

DB

G

D

IV

Each point consumes one, 16-bit word. The DB

the word offset address in the database.

The DB

moved from the gateway to the Master.

For additional information on how to set these parameters, see the Reference

chapter of this manual.

ADDRESS

ROUPS (page 50)

EFAULT DEADBAND

DB BIT

ADDRESS should be located in a database area that is being constantly

ADDRESS value corresponds to

2.8 [M_ME_NB_1]

This section defines the monitored measured value, scaled database. This

information is sourced from the database and is transferred to the remote Master

unit.

To determine the IOA (Information Object Address) for each object, add the

P

OINT # in the following section to the value of the M_ME_NB parameter offset

parameter set in the previous section.

This section takes the following parameters:

P

OINT #

DB

G

D

IV

Each point consumes one, 16-bit word. The DB

the word offset address in the database.

The DB

moved from the gateway to the Master.

For additional information on how to set these parameters, see the Reference

chapter of this manual.

ADDRESS

ROUPS (page 50)

EFAULT DEADBAND

DB BIT

ADDRESS should be located in a database area that is being constantly

ADDRESS value corresponds to

Page 44 of 159 ProSoft Technology, Inc.

August 6, 2010

Page 45

IEC-101 Slave ♦ ProLinx Communication Gateway 101S Protocol Configuration

IEC 60870-5-101 v3 Slave (Firmware version 3.xx) Protocol Manual

2.9 [M_ME_NC_1]

This section defines the monitored short-float point database. This information is

sourced from the database and is transferred to the remote Master unit.

To determine the IOA (Information Object Address) for each object, add the

P

OINT # in the following section to the value of the M_ME_NC Parameter Offset

parameter set in the previous section.

This section takes the following parameters:

P

OINT #

DB

G

D

IV

Each point consumes four 8-bit bytes (two 16-bit words). The DB

corresponds to the double-word offset address in the database.

The DB

moved from the gateway to the Master.

For additional information on how to set these parameters, see the Reference

chapter of this manual.

ADDRESS

ROUPS (page 50)

EFAULT DEADBAND

DB BIT

ADDRESS value

ADDRESS should be located in a database area that is being constantly

2.10 [M_IT_NA_1]