Page 1

DNPM

ProLinx Gateway

DNP 3.0 Master

September 30, 2009

DRIVER MANUAL

Page 2

Important Installation Instructions

Power, Input, and Output (I/O) wiring must be in accordance with Class I, Division 2 wiring methods, Article 501-4 (b)

of the National Electrical Code, NFPA 70 for installation in the U.S., or as specified in Section 18-1J2 of the Canadian

Electrical Code for installations in Canada, and in accordance with the authority having jurisdiction. The following

warnings must be heeded:

A WARNING - EXPLOSION HAZARD - SUBSTITUTION OF COMPONENTS MAY IMPAIR SUITABILITY FOR

CLASS I, DIV. 2;

B WARNING - EXPLOSION HAZARD - WHEN IN HAZARDOUS LOCATIONS, TURN OFF POWER BEFORE

REPLACING OR WIRING MODULES

C WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NONHAZARDOUS.

D THIS DEVICE SHALL BE POWERED BY CLASS 2 OUTPUTS ONLY.

All ProLinx® Products

WARNING – EXPLOSION HAZARD – DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

AVERTISSEMENT – RISQUE D'EXPLOSION – AVANT DE DÉCONNECTER L'EQUIPMENT, COUPER LE

COURANT OU S'ASSURER QUE L'EMPLACEMENT EST DÉSIGNÉ NON DANGEREUX.

Markings

UL/cUL ISA 12.12.01 Class I, Div 2 Groups A, B, C, D

cUL C22.2 No. 213-M1987

243333 183151

CL I Div 2 GPs A, B, C, D

Temp Code T5

II 3 G

Ex nA nL IIC T5 X

0° C <= Ta <= 60° C

II – Equipment intended for above ground use (not for use in mines).

3 – Category 3 equipment, investigated for normal operation only.

G – Equipment protected against explosive gasses.

ProLinx Gateways with Ethernet Ports

Series C ProLinx™ Gateways with Ethernet ports do NOT include the HTML Web Server. The HTML Web Server

must be ordered as an option. This option requires a factory-installed hardware addition. The HTML Web Server now

supports:

8 MB file storage for HTML files and associated graphics files (previously limited to 384K)

32K maximum HTML page size (previously limited to 16K)

To upgrade a previously purchased Series C model:

Contact your ProSoft Technology distributor to order the upgrade and obtain a Returned Mercha ndise Authorization

(RMA) to return the unit to ProSoft Technology.

Page 3

To Order a ProLinx Plus gateway with the -WEB option:

Add -WEB to the standard ProLinx part number. For example, 5201-MNET-MCM-WEB.

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions, comments,

compliments or complaints about the product, documentation, or support, please write or call us.

ProSoft Technology

5201 Truxtun Ave., 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

www.prosoft-technology.com

support@prosoft-technology.com

Copyright © ProSoft Technology, Inc. 2009. All Rights Reserved.

DNPM Driver Manual

September 30, 2009

ProSoft Technology

Technology, Inc. All other brand or product names are or may be trademarks of, and are used to identify products

and services of, their respective owners.

®

, ProLinx ®, inRAx ®, ProTalk®, and RadioLinx ® are Registered Trademarks of ProSoft

ProSoft Technology® Product Documentation

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product shipments.

User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are provide d on the enclosed CD-ROM,

and are available at no charge from our web site: www.prosoft-technology.com

Printed documentation is available for purchase. Contact ProSoft Technology for pricing and availability.

North America: +1.661.716.5100

Asia Pacific: +603.7724.2080

Europe, Middle East, Africa: +33 (0) 5.3436.87.20

Latin America: +1.281.298.9109

Page 4

Page 5

Contents DNPM ♦ ProLinx Gateway

Driver Manual DNP 3.0 Master

Contents

Important Installation Instructions.......................................................................................................2

Your Feedback Please........................................................................................................................3

ProSoft Technology® Product Documentation....................................................................................3

1 Functional Overview 7

1.1 Module Internal Database.........................................................................................8

1.2 DNP Master Database Layout ..................................................................................8

1.3 DNP Master Driver Data Flow...................................................................................9

2 Port Physical and Protocol Specifications 11

2.1 DNP 3.0 Master Port Specifications........................................................................11

2.2 Serial Port Specifications ........................................................................................11

3 DNPM Protocol Configuration 13

3.1 [DNP Master]...........................................................................................................13

3.2 [DNP Master Database] ..........................................................................................14

3.3 [DNP Master Slave List]..........................................................................................15

3.4 [DNP Master Commands] .......................................................................................16

4 Communication Port Cables 25

4.1 DNP 3.0 Master Port...............................................................................................25

4.2 Port 0, 1, 2, 3: RS-232 - Null Modem (DTE with Hardware Handshaking).............26

4.3 Port 0, 1, 2, 3: RS-232 - Null Modem (DTE without Hardware Handshaking)........27

4.4 Port 0, 1, 2, 3: RS-232 - DTE to DCE Modem Connection.....................................27

4.5 Collision Avoidance (DNP modules only)................................................................28

4.6 Port 0, 1, 2, 3: RS-422 Interface Connections ........................................................29

4.7 Port 0, 1, 2, 3: RS-485 Interface Connections ........................................................29

5 LED Indicators 31

5.1 Common module LEDs...........................................................................................31

5.2 LEDs for Port 0 Serial Port......................................................................................32

5.3 4101 Series LEDs ...................................................................................................32

6 Reference 33

6.1 Error Codes.............................................................................................................33

6.2 Device Profile..........................................................................................................37

6.3 Subset Definition.....................................................................................................39

6.4 Command List Entry Form......................................................................................45

ProSoft Technology, Inc. Page 5 of 56

September 30, 2009

Page 6

DNPM ♦ ProLinx Gateway Contents

DNP 3.0 Master Driver Manual

7

Support, Service & Warranty 49

7.1 How to Contact Us: Technical Support................................................................... 49

7.2 Return Material Authorization (RMA) Policies and Conditions............................... 50

7.3 LIMITED WARRANTY............................................................................................ 51

Index 55

Page 6 of 56 ProSoft Technology, Inc.

September 30, 2009

Page 7

Functional Overview DNPM ♦ ProLinx Gateway Driver Manual DNP 3.0 Master

1 Functional Overview

In This Chapter

Module Internal Database .......................................................................8

DNP Master Database Layout.................................................................8

DNP Master Driver Data Flow.................................................................9

The DNP 3.0 Master protocol driver exists in a single port (DNPM)

implementation only. The DNPM port operates in a Master mode only, supporting

the DNP 3.0 protocol in a Level 2 implementation.

The DNP Master driver is implemented in ProLinx communication modules to

interface DNP slave units with a variety of communication protocols and

interfaces. This driver supports DNP version 3.0, subset level 2. The Reference

chapter of this documentation contains the Device Profile for the driver. The

Reference chapter contains the subset definition for the driver. This document

serves as the base for understanding the DNP Master driver functionality and

configuration. The discussion is general in nature deferring specifics to the

individual product documents.

Before attempting to use this or any other DNP protocol device, verify that you

have a copy of the DNP Basic 4 document and other information available

through the DNP User Group. It is very important that these documents be

understood for successful application of the protocol in a user’s solution. If you

are a member of the user group, you can download these documents from the

http://www.dnp.org (

All data in the module’s database configured as DNP data points is available to

the remote devices for read and write requests. This permits other devices

connected to the ProLinx unit to monitor and control DNP slave devices

connected to the master port.

http://www.dnp.org) web site.

ProSoft Technology, Inc. Page 7 of 56

September 30, 2009

Page 8

DNPM ♦ ProLinx Gateway Functional Overview

DNP 3.0 Master Driver Manual

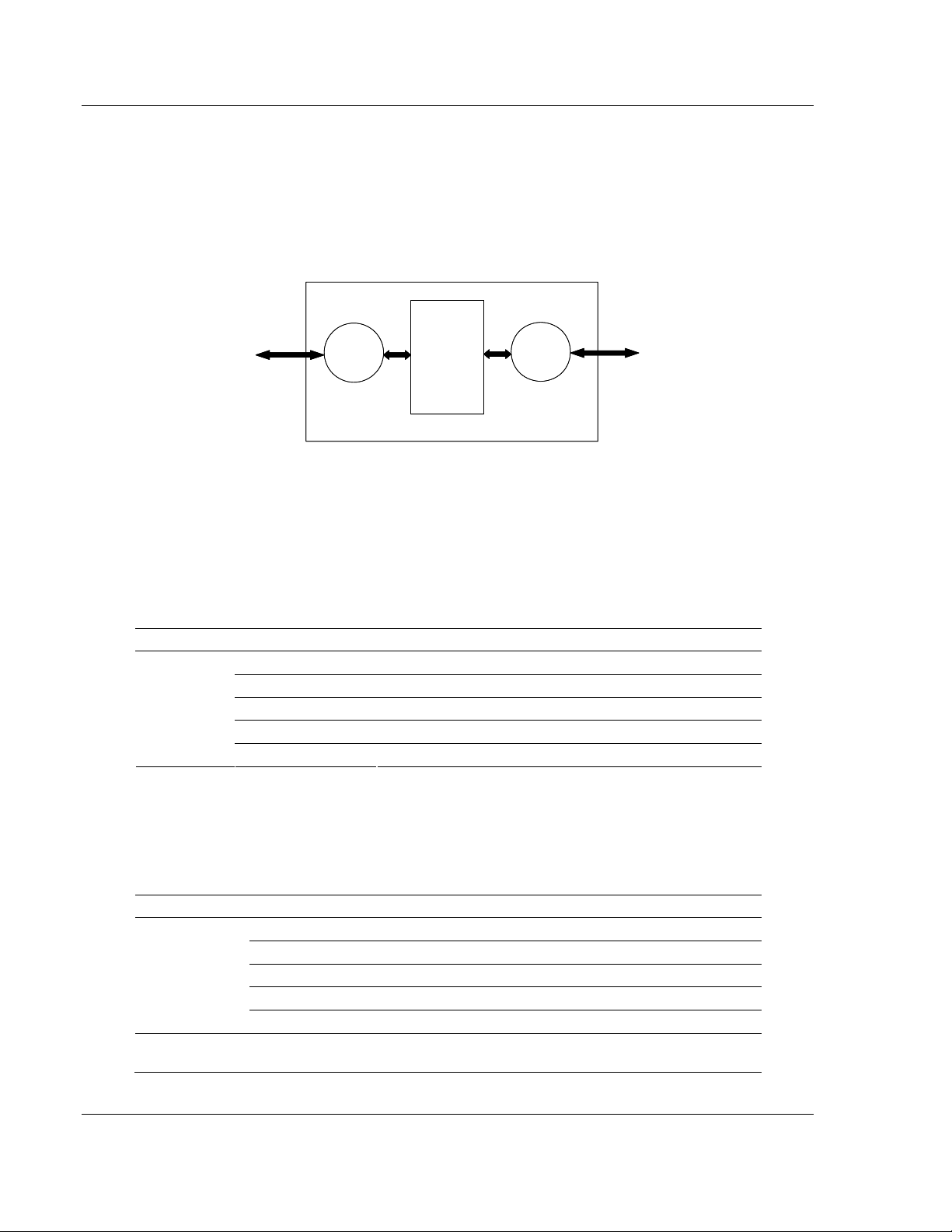

1.1 Module Internal Database

The internal database is central to the functionality of the module. This database

is shared between all the ports on the module and is used as a conduit to pass

information from one device on one network to one or more devices on another

network. This permits data from devices on one communication port/network to

be viewed and controlled by devices on another port/network.

ProLinx

ProLinx

Communication

Communication

Gateways

Other ProLinx

Other ProLinx

Protocol

Protocol

Driver

Driver

Gateways

Internal

Internal

Database

Database

(Up to 4000 regs)

regs)

DNPM

Driver

Driver

1.2 DNP Master Database Layout

Central to the functionality of the DNP driver is the database. This database is

used as the interface between remote DNP devices and the other protocol

implemented on a module. The content and structure of the user data area of the

database is completely user defined. The following illustration shows the general

format of the module’s database:

DATA AREA DATA SIZE

DNP DATA

BINARY INPUTS 1 WORD PER 16 POINTS

ANALOG INPUTS 1 WORD PER POINT

COUNTER DATA 2 WORDS PER POINT

BINARY OUTPUTS 1 WORD PER 16 POINTS

ANALOG OUTPUTS 1 WORD PER POINT

The first word of the module’s database contains the first 16 points of binary input

data (if defined). It is important to understand how the data is mapped to the

database so that it can be accessed by the other protocol. Each DNP data type

has a fixed size. This size is used in conjunction with the number of points

configured for the type to determine the size and location in the database. The

following is an example of a user database with a defined set of point counts:

DATA AREA REGISTERS CFG VALUES

DNP DATA

USER DATA

BINARY INPUTS 0 TO 1 2

ANALOG INPUTS 2 TO 51 50

COUNTER DATA 52 TO 71 10

BINARY OUTPUTS 72 TO 73 2

ANALOG OUTPUTS 74 TO 113 40

REMAINING DATA

114 TO 3999

AREA

Page 8 of 56 ProSoft Technology, Inc.

September 30, 2009

Page 9

Functional Overview DNPM ♦ ProLinx Gateway

p

Driver Manual DNP 3.0 Master

Note that the order of the data types is fixed by the driver. In order to access the

binary input data read from a slave device, registers 0 to 1 are used. To set

analog output data to pass to the driver for remote slaves, registers 74 to 113 are

used. Register 74 contains the value for analog output point 0, and register 113

contains the value for analog output point 39.

The other protocol on the ProLinx module should place data in the binary and

analog output data areas. Values set will be passed by the master driver to slave

units on the network.

The other protocol on the ProLinx module should retrieve the data for the binary

and analog inputs and counters as these are obtained by the master driver from

slave units. This monitored data area should not be altered by the other protocol

on the module.

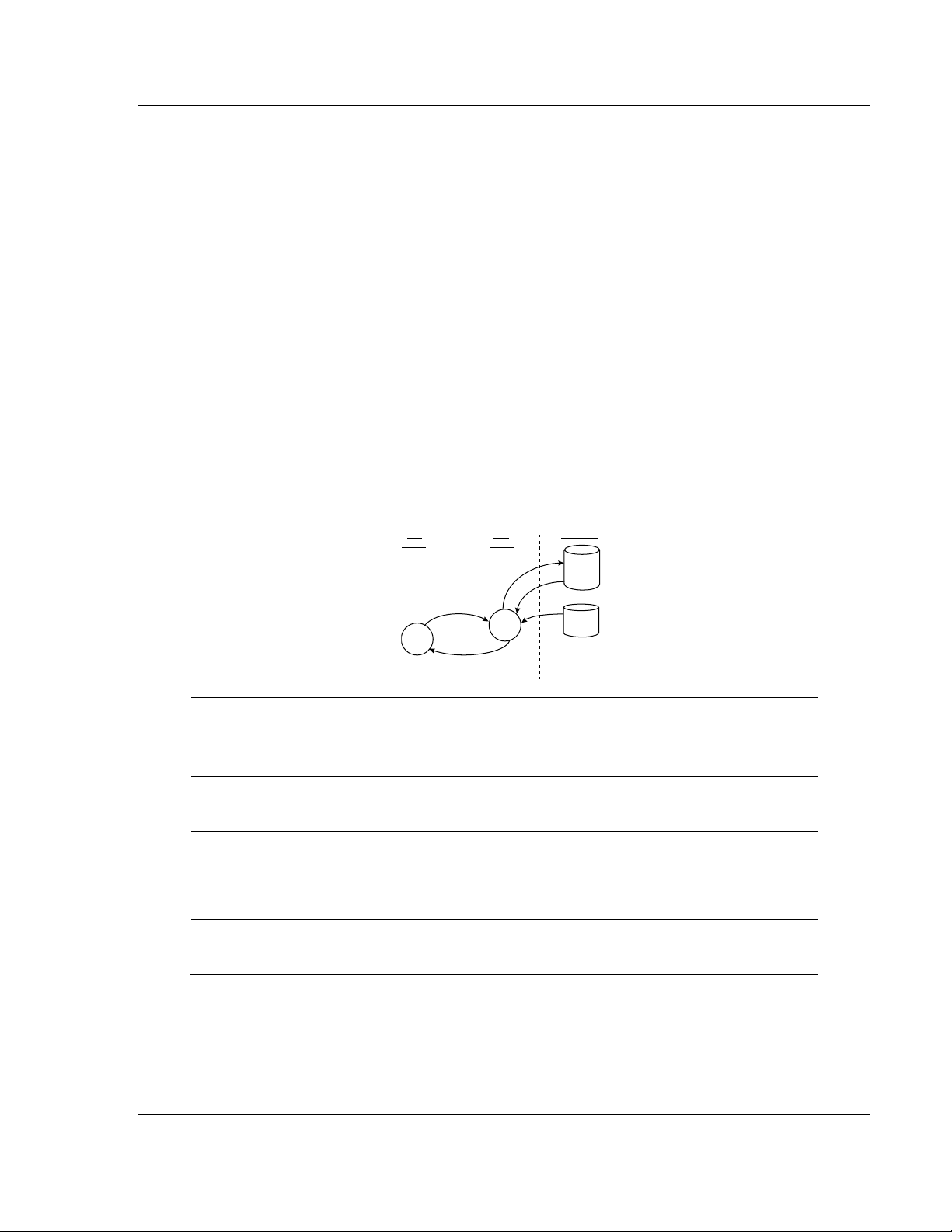

1.3 DNP Master Driver Data Flow

The DNP Master Driver allows the module to generate read and write commands

issued to slave units on the DNP network. The following flow chart and

associated table describe the flow of data into and out of the module.

Step Description

1

The DNP Master driver receives the configuration information from the Flash memory in

the module. This information configures the serial port and define the Master node

characteristics.

2

The Master Driver issues a read or write command to the DNP Slave’s node address.

The Slave device qualifies the message then issues a response containing the

information requested by the master..

3

After the module accepts the response, the data is immediately transferred to or from the

internal database in the module. If the command is a read command (binary input,

analog input, counter, event, and so on), the data is written to the module database. If

the command is a write command (binary output or analog output), the data is read

directly from the database.

4

Error/Status data are available in a Status Block that can be placed anywhere in the

module’s database. This area can be accessed by the other protocol on the module

using the correct database offset.

DNP

Slaves

Unsolicited

Messages or

Res

Slave

Device

onses

Master

Wri te for DNP Read

Function

Master

Driver

Request

DatabasesDNP

Read for DNP

Write Function

Read

Virtual

Database

Command

List

ProSoft Technology, Inc. Page 9 of 56

September 30, 2009

Page 10

DNPM ♦ ProLinx Gateway Functional Overview

DNP 3.0 Master Driver Manual

Page 10 of 56 ProSoft Technology, Inc.

September 30, 2009

Page 11

Port Physical and Protocol Specifications DNPM ♦ ProLinx Gateway

Driver Manual DNP 3.0 Master

2 Port Physical and Protocol Specifications

In This Chapter

DNP 3.0 Master Port Specifications......................................................11

Serial Port Specifications.......................................................................11

2.1 DNP 3.0 Master Port Specifications

Type Specifications

General Parameters

Internal Database Binary Inputs: 0 to 500 word count

Analog Inputs: 0 to 500 points of analog inpu t data

Counters: 0 to 250 points of counter data

Binary Outputs: 0 to 500 word count

Analog Outputs: 0 to 500 points of analog output

Communication parameters Port 0: Baud Rate: 110 to 115,200 baud

Stop Bits: 1

Data Size: 8 bits

Parity: None

RTS Timing delays: 0 to 65535 milliseconds

DNP Mode DNP 3.0 Master - Level 2

DNP Object Support See Reference chapter for full Object Definition document

DNP Master

Node address 0 to 65534 (software selectable)

Slave count The module supports the definition of up to 40 slave devices

Command count

The module supports the definition of up to 300 user defined

commands to interface with remote slave devices

2.2 Serial Port Specifications

Type Specifications

Serial Ports

Serial Port Cables (DB-9M

Connector)

Port 0 RS-232/422/485: jumper selectable

ProSoft Technology, Inc. Page 11 of 56

September 30, 2009

One DIN to DB-9M cable included per configurable serial port

DB-9M connector

Hardware Handshaking: RTS,CTS,DTR,DSR,DCD

Page 12

DNPM ♦ ProLinx Gateway Port Physical and Protocol Specifications

DNP 3.0 Master Driver Manual

Type Specifications

Serial Port Isolation 2500V RMS port-to-port isolation per

UL 1577.

3000V DC min. port to ground and port to logic power isolation.

Serial Port Protection

Collision Avoidance

RS-485/422 port interface lines TVS diode protected at +/- 27V

standoff voltage.

RS-232 port interface lines fault protected to +/- 36V power on,

+/- 40V power off.

The DNP collision avoidance scheme can be enabled for the

port when more than one slave device is present on the

network and unsolicited messaging is supported.

Page 12 of 56 ProSoft Technology, Inc.

September 30, 2009

Page 13

DNPM Protocol Configuration DNPM ♦ ProLinx Gateway

Driver Manual DNP 3.0 Master

3 DNPM Protocol Configuration

In This Chapter

[DNP Master] .........................................................................................13

[DNP Master Database].........................................................................14

[DNP Master Slave List] ........................................................................15

[DNP Master Commands]......................................................................16

The following topics are excerpted from a configuration file showing typical

examples of the DNPM Port of a CFG file for a DNPM port. Shipped with each

unit (or available from the web) is a default configuration file that can easily form

the basis for a working solution. This file can either be downloaded from the

ProSoft web site at www.prosoft-technology.com, or transferred from the module.

Refer to the ProLinx Reference Guide for information on configuring and

downloading .CFG files to ProLinx modules.

3.1 [DNP Master]

The [DNP Master] section of the CFG file sets the DNP 3.0 port communication

parameters and the protocol specific parameters. The following example and

table lists the parameters defined in this section:

[DNP Master]

Internal ID : 1 #0-65534 identification code for this unit

DNP Database Offset : 2000 #0-3999 Start of DNP data in internal DB

Baud Rate : 19200 #Baud rate for port 110-115200

RTS On : 0 #0-65535 milliseconds before message

RTS Off : 0 #0-65535 milliseconds after message

Min Response Delay : 10 #0-65535 milliseconds before response sent

# Collision Avoidance parameters

Collision Avoidance : N #Use Collision Avoidance (Yes or No)

CD Idle Time : 10 #0-32000 mSec min idle time before transmit

CD Time Before Receive : 12 #0-65535 milliseconds before receive

Variable Name Data Range Description

[DNP Master]

Internal Master ID: 0 to 65534

DNP Database Offset 0 to 3999

Baud Rate:

Baud Rate

from Table

This section header defines the start of the DNP Master

parameter set.

This is the DNP address for the module. All messages

assigned to this address from the master are processed by

the module.

Offset in which to place DNP data. Specifies the start of DNP

data in the internal database.

Port Baud Rate: 300, 600, 1200, 2400, 4800, 9600, 19200,

384 (38400), 576 (57600), 115 (115200)

ProSoft Technology, Inc. Page 13 of 56

September 30, 2009

Page 14

DNPM ♦ ProLinx Gateway DNPM Protocol Configuration

DNP 3.0 Master Driver Manual

Variable Name Data Range Description

RTS On: 0 to 65535

RTS Off: 0 to 65535

Min Response Delay: 0 to 65535

Collision Avoidance Parameters

Collision Avoidance: Yes or No

CD Idle Time: 0 to 32000

CD Time Before

Receive:

0 to 65535

This value represents the number of 1 ms increments to be

inserted between asserting the RTS modem line and the

actual transmission of the data.

This value represents the number of 1 ms increments to be

inserted after the last character of data is transmitted before

the RTS modem line is dropped.

Minimum time between receiving a request and transmitting a

response. Allows master time to disable transmitter on an

RS-485 network.

This parameter defines if the collision avoidance functionality

is to be applied to the port. If the parameter is set to No,

collision avoidance is not used. It will be used if set to Yes. If

collision avoidance is used, it requires a special cable.

Defines the minimum number of milliseconds to wait before

transmitting a message after the CD signal is recognized as

low.

Defines the number of milliseconds to wait before receiving

characters after the CD signal is recognized as high.

3.2 [DNP Master Database]

The [DNP Master Database] section of the CFG file sets the size of each data

type utilized by the module in order to define the database. The example and

following table lists the parameters defined in this section:

[DNP Master Database]

Binary Inputs : 2 #0-500 word count to hold BI data

Analog Inputs : 50 #0-500 points of analog input data

Counters : 10 #0-250 points of counter data

Binary Outputs : 2 #0-500 word count to hold BO data

Analog Outputs : 40 #0-500 points of analog output data

Variable Name Data Range Description

[DNP Master Database]

Binary Inputs: 0 to 500

Analog Inputs: 0 to 500

Counters: 0 to 250

Binary Outputs: 0 to 500

Analog Outputs: 0 to 500

This section defines the database for the module

Number of words for digital input points to configure in the

DNP Master device. Each word contains 16 binary input

points.

Number of analog input points to configure in the DNP

Master device. Each point will occupy a one-word area in the

module memory.

Number of counter points to configure in the DNP Master

device. Each point will occupy a two-word area in the module

memory. This number corresponds to the number of frozen

counters. The application maps the counters to the frozen

counters directly.

Number of words for digital output points to configure in the

DNP Master device. Each word contains 16 binary output

points.

Number of analog output points to configure in the DNP

Master device. Each point will occupy a one word area in the

module memory.

Page 14 of 56 ProSoft Technology, Inc.

September 30, 2009

Page 15

DNPM Protocol Configuration DNPM ♦ ProLinx Gateway

Driver Manual DNP 3.0 Master

3.3 [DNP Master Slave List]

The DNP Master Slave List defines information about each slave that will be

used by the master port. Up to 40 devices can be defined for the master driver.

Each node must have an entry. The following example and tables define the data

required for each node:

[DNP Master Slave List]

# This section is used to store information about each slave to be

# used by the master port. There must be an entry in this table for each

# node to be used in the command list. Two of the parameters in this list

# are coded values:

# Conf Mode ==> 0=Never, 1=Sometimes and 2=Always (select 0).

# Flags is bit coded as follows:

# Bit 0 (decimal 1) ==> Enable the slave

# Bit 1 (decimal 2) ==> Use Unsolicited messaging with this slave

# Bit 2 (decimal 4) ==> Use delay measurement with this slave

# Bit 3 (decimal 8) ==> Auto time synchronization enabled

#

START

# Node DL Conf Conf Conf App Rsp

# Address Mode Timeout Retry Timeout Flags

2 0 1000 0 2000 9

END

Two parameters in the list contain coded values as shown in the example.

Variable Name Value Description

Node Address Node address for slave being defined

Conf Mode 0, 1, or 2 0=Never, 1=Sometimes, 2=Always (Select 0)

Conf Timeout Data Link Layer Confirmation timeout

Conf Retry Data Link Layer Confirmation retry count

App Resp Timeout Application layer timeout

Flags Bit 0 (decimal 1) = Enable the slave

Bit 1 (decimal 2) = Use unsolicited messaging with this slave

Bit 2 (decimal 4) = Use delay measurement with this slave

Bit 3 (decimal 8) = Auto time synchronization enabled

The following table describes the information required for each column of each

record in the slave list section. A record is required for each slave device to be

interfaced with by the module.

Column

1

2

3

Variable

Name

DNP Slave

Address

Data Link

Confirm

Mode

Data Link

Confirm

Timeout

Data Range Description

0 to 65534

Coded Value (0=Never,

1=Sometimes,

2=Always).

1 to 65535 milliseconds

This is the slave address for the unit to

override the default values.

This value specifies if data link frames sent

to the remote device require a data link

confirm. This parameter should be set to

zero for almost all applications.

This parameter specifies the time to wait for

a data link confirm from the remote device

before a retry is attempted.

ProSoft Technology, Inc. Page 15 of 56

September 30, 2009

Page 16

DNPM ♦ ProLinx Gateway DNPM Protocol Configuration

DNP 3.0 Master Driver Manual

Column

4

5

6 Slave Mode

Variable

Name

Maximum

Retries for

Data Link

Confirm

Application

Layer

Response

Timeout

Data Range Description

0 to 255 retries

1 to 65535 milliseconds

Coded Value (Bit 0 =

Enable, Bit 1 = Unsol

Msg, Bit 2 = Use DM, Bit

3 = Auto Time Sync).

Maximum number of retries at the Data Link

level to obtain a confirmation. If this value is

set to 0, retries are disabled at the data link

level of the protocol. This parameter is only

used if the frame is sent with confirmation

requested.

Time-out period the master will wait for each

response message fragment. If data link

confirms are enabled, make sure the timeout

period is set long enough to permit all data

confirm retries.

This word contains bits that define the slave

mode. The slave mode defines the

functionality of the slave device and can be

combined in any combination. The fields

have the following definition: Enable:

determines if this slave will be used. Unsol

Msg: causes an enabled unsolicited

response message to be sent to the slave

when its RESTART IIN bit is set. This

parameter is also required for unsolicited

message reporting by the IED unit. Use DM:

uses delay measurement. Auto Time Sync:

time synchronization used when NEED TIME

IIN bit set.

3.4 [DNP Master Commands]

The DNP Master Commands section contains the list of commands to process

on the master port. Up to 300 commands can be defined in this section to

monitor and control all the slave devices on the network. Node addresses in the

command list must contain an entry in the [DNP Slave List]. The following

example and table define the data required for each command:

[DNP Master Commands]

# This section contains the list of commands to process on the master port.

# Node addresses present in the command list must have an entry in the

# [DNP Slave List]. Commands with nodes not present in the list will not be

# executed.

#

START

# 1 2 3 4 5 6 7 8 9

#Flags/ Node Data Data Cmd Device Point IED DB Poll

#Enable Address Object Variation Func Address Count Address Interval

6 2 1 0 1 0 -32 0 0

6 2 -12 257 3 0 2000 0 10

6 2 20 0 1 0 5 0 0

6 2 30 0 1 0 -50 0 0

6 2 41 2 5 0 4 0 0

END

Page 16 of 56 ProSoft Technology, Inc.

September 30, 2009

Page 17

DNPM Protocol Configuration DNPM ♦ ProLinx Gateway

Driver Manual DNP 3.0 Master

Variable Name Value Description

Flags Enable See discussion that follows

Node Address

Data Object

Data Variation This is the DNP data variation for the command

Cmd Func

Device Address

Point Count

IED DB Address

Poll Interval

Specifies the node address of the slave unit for which the

command is to be sent

This is the DNP data object code for the command (For

issuing a CROB command refer to the following discussion).

This is the DNP command code to be used when forming the

command request

This is the starting address in the device (point address) for

the command

This field defines the number of points to request from the

slave device. If the parameter is set to a negative number

(-n), the module will only process the first -n number of

points. For example, if this field is set to -3, only the first 3

points will be accepted into the database.

This field defines the internal address in the master driver's

database to be associated with the command. If the

command is a read command, the data read will be placed at

this address. If the command is a write command, the data to

be written will be sourced from this address.

This field specifies the minimum number of seconds to wait

between the issuance of the command.

The value for the Flags/Enable and point count are dependent on the type of

function (input or output) being executed by the module. The two diagrams

display this relationship:

Inputs:

Port/Flags

Bits

0 Not Used

1 Communication Port (1=DNP Master Port) 2

2 Enable/Disable Command (1=Enable, 0=Disable) 4

3 to 7 Not Used

If # of Points < 0, then use Qual 06h (all points, packaged & -Points = # of points to consider)

If Address in Slave = 0 & # of Points > 0, then use Qual 00h or 01h (points 0 to # of points -1)

If Address in Slave > 0 & # of Points > 0, then use Qual 00h or 01h (address to address+# of

points-1)

Description

Decimal

Equivalent

Outputs:

Port/Flags

Bits

0 Not Used

1 Communication Port (1=DNP Master Port) 2

2 Enable/Disable Command (1=Enable, 0=Disable) 4

3 Poll Type (0=Poll, 1=Exception) 8

4 to 7 Not Used

Description

Decimal

Equivalent

ProSoft Technology, Inc. Page 17 of 56

September 30, 2009

Page 18

DNPM ♦ ProLinx Gateway DNPM Protocol Configuration

DNP 3.0 Master Driver Manual

Port/Flags

Description

Bits

If Address in Slave = 0 & # of Points > 0, then use Qual 17h or 28h (# of points specified starting at

point 0)

If Address in Slave > 0 & # of Points > 0, then use Qual 17h or 28h (points from address to

address+# of points-1)

If # of Points <= 0, then ignore because this is illegal for outputs.

Decimal

Equivalent

Other rules that must be observed when constructing commands are as follows:

Address in Slave: This value must be >= 0. If it is set to a value < 0, the

command will be ignored.

Point Count: This value must be set to a value other than 0. If the value is set to

0, the command will be ignored.

Poll Interval: 0=Continuous, >0=Number of seconds between polls. If exception

processing is used for output commands, this parameter is ignored, and the

command will only be issued when data changes.

The following two examples of commands display the interrelationship of the

parameters used to construct a command:

BINARY INPUT COMMAND EXAMPLES:

WORD 012345678

VALUE 6 21010 32 00

Address Address

Port/Flg Slave Object Var Func Addr Pnt Cnt IED DB Poll Int

Command for DNP Master Port, Enabled.

IED #15 IED BI's

00

31 31

IED Unit 2 is to be polled.

Object type is 1 (Binary Input).

Variation of 0 (default variation).

Function 1 is for a read.

Point address 0 Is starting address in IED device

Point count of 32 indicates points 0-31 to be

polled.

IED DB address of 0 is where first data point is

placed. (within BI database)

Poll command as soon as possible.

BINARY OUTPUT COMMAND EXAMPLES:

WORD 0 1 2 3 4 5 6 7 8

VALUE 14

Address Address

Port/Flg Slave Object Var Func Addr Pnt Cnt IED DB Poll Int

2

IED #15 IED BO's

0

15

12 1 5 0 16 25 0

Command for Port 2, Enabled, only operate on

point change.

IED Unit 2 is to be controlled.

0

15

Object type is 12 (Binary Output Control).

Variation of 1 (Control Relay Output

Block).

Function 5 is for direct operate.

Slave address of 0 is starting point in IED.

16 points are transferred.

IED DB address of 0 is first source point.

Command not a polled command.

Write only on change of data in BO database.

Page 18 of 56 ProSoft Technology, Inc.

September 30, 2009

Page 19

DNPM Protocol Configuration DNPM ♦ ProLinx Gateway

Driver Manual DNP 3.0 Master

Note: CROB commands (object 12) exceeding a count of 16 are not recommended. Many IEDs

only support one transport layer and a count > 16 may cause the IED device to not accept the new

data value being written by the ProLinx module.

The following table aids in defining the command list as it displays the values

required for certain DNP data types:

Digital input Digital input Events Digital Output Counter

0 Port/Flags Port/Flags Port/Flags Port/Flags

1 Slave Address Slave Address Slave Address Slave Address

2 1 2 12 20

3 0, 1 or 2 0, 1, 2 or 3 1* 0, 5 or 6

4 1* 1* 3, [4], 5 or 6 1, 7, 8, 9 or 10

5 Address in Slave Address in Sla v e Address in Slave Address in Slave

6 # of Points # of Points # of Points # of Points

7 IED DB Address IED DB Address IED DB Address

8 Poll Interval Poll Interval Poll Interval Poll Interval

Frozen Counter Analog Input Analog Input Events Analog Output

0 Port/Flags Port/Flags Port/Flags Port/Flags

1 Slave Address Slave Address Slave Address Slave Address

2 21 30 32 41

3 0, 9 or 10 0, 1, 2, 3 or 4 0, 1, 2, 3 or 4 2*

4 1* 1* 1* 3, [4], 5 or 6

5 Address in Slave Address in Slave Address in Slave Address in Slave

6 # of Points # of Points # of Points # of Points

7 IED DB Address IED DB Address IED DB Address

8 Poll Interval Poll Interval Poll Interval Poll Interval

Time and Date Class 0 Class 1 Class 2

0 Port/Flags Port/Flags Port/Flags Port/Flags

1 Slave Address Slave Address Slave Address Slave Address

2 50 60 60 60

3 1* 1 2 3

4 2*

5

6 1 1 1 1

7

8 Poll Interval Poll Interval Poll Interval Poll Interval

ProSoft Technology, Inc. Page 19 of 56

September 30, 2009

Page 20

DNPM ♦ ProLinx Gateway DNPM Protocol Configuration

DNP 3.0 Master Driver Manual

Class 3 Cls 1, 2 & 3 Cls 0, 1, 2 & 3 [Clear Restart Bit]

0 Port/Flags Port/Flags Port/Flags Port/Flags

1 Slave Address Slave Address Slave Address Slave Address

2 60 60 60 80

3 4 5 6 1

4 2

5 7

6 1 1 1 1

7

8 Poll Interval Poll Interval Poll Interval

Cold Restart Warm Restart Enable Unsol. Msg Disable Unsol. Msg

0 Port/Flags Port/Flags Port/Flags Port/Flags

1 Slave Address Slave Address Slave Address Slave Address

2 0 0 0 0

3

4 13 14 20 21

5

6 1 1 1 1

7

8

Word Offset Definitions

* Value Assumed 0 Port/Flags

[ ] Automatically implemented 1 Slave Address

2 Object

3 Variation

4 Function

5 Address in Slave

6 Point Count

7 IED DB Address

8 Poll Interval

Page 20 of 56 ProSoft Technology, Inc.

September 30, 2009

Page 21

DNPM Protocol Configuration DNPM ♦ ProLinx Gateway

Driver Manual DNP 3.0 Master

A special data type is added to the module in order to generate CROB

commands to control binary outputs. The following table shows the format to be

utilized when this command is desired:

Column Definitions Description

1 Port/Flags Set this parameter to 6 to enable the command in the list.

2 Slave Address

3 Object Object type always -12

4 CROB Image (L)

Pulse Count (H)

5 Function

6 Address in Slave Point in IED to consider with the CROB.

7 Pulse Time

8 DB Address

9 Poll Interval

This is the IED node address for the slave to consider on the

network.

The CROB Image parameter contains the CROB image for

the command. Refer to the following table for the definition of

this block.

The pulse count parameter specifies the number of pulses to

generate for pulse output control. This parameter has a range

of 0 to 255 as the value is a byte parameter in the CROB. If a

value of zero is entered, the operation will not execute.

Function codes 3, 5 and 6 supported. Function code 4 is

automatically sent after a successful function 3.

This parameter sets the on and off time to use if the pulse

operation is to associate with this command.

This is address in the module's internal database to use as a

trigger for the command. If a value other than 0 is found in the

register, the command will be executed. The database register

will be set to 0 after the command is placed in the command

queue.

This field specifies the minimum number of seconds to wait

between the issuance of the command.

The value for the CROB image is that specified in the DNP specification. The

following table lists the bits that comprise this value:

Bits Definitions Description

0 to 3 Code

4 Queue

5 Clear

6 to 7 Trip/Close

These bits determine the control operation to be performed by

the command: 0=No operation, 1=Pulse on, 2=Pulse off,

3=Latch on and 4=Latch off. All other values are undefined in

the DNP protocol.

0=Normal (execute once), 1=Requeue (place at end of queue

after operation).

This parameter clears the queue. If the value is set to zero,

the queue is not affected. If the value is set to 1, the queue will

be cleared.

These two bits select the trip or close relay. For close relay

control, set the bits to 01. For trip relay control, set the bits to

10. A value of 00 for the bits is used for single point control of

normal digital output points.

ProSoft Technology, Inc. Page 21 of 56

September 30, 2009

Page 22

DNPM ♦ ProLinx Gateway DNPM Protocol Configuration

DNP 3.0 Master Driver Manual

Example 1 – Digital Output

No CROB Control - Does not allow full control of Control Operation, Queue,

Clear, Trip/Close, and Pulse count. Only Latch On/Off supported and count is set

1, on and off time set to zero, 1 and status set to zero.

1

2

3 12

4

5

6

7

8

9 Low byte of parameter value is used as Pol l Interval

Example 2 – Digital Output

For Select (and implied operate).

With CROB control - Allows full control of Control Operation, Queue, Clear,

Trip/Close and Pulse count.

1

2

3 -12

4 Lo byte of parameter value is object variation

5 3, [4]

6

7

8

9 Low byte of parameter value is used as Pol l Interval

Example 3 – Digital Output

For Direct Operate (with/without rack).

With CROB control - Allows full control of Control Operation, Queue, Clear,

Trip/Close, and Pulse/count.

1

2

3 -12

4 Low byte is object variation. High byte = Pulse count = 1

5 Low byte = Function (5 or 6)

6

7

8

9 Not used.

Page 22 of 56 ProSoft Technology, Inc.

September 30, 2009

Page 23

DNPM Protocol Configuration DNPM ♦ ProLinx Gateway

Driver Manual DNP 3.0 Master

Besides issuing commands to slave devices, the command list is also used to

map data received in event messages to the proper database locations. For

example, Slave 1 and Slave 1 both possess binary point 0. When an event from

each slave is received, the data entered into the command list is utilized to place

the data for the two events in the correct database location. When the command

list is read by the module is forms lists for each slave relating the address in the

device to that in internal database of the module. The following illustration shows

how the module stores this data:

SLAVE LIST

Address Address Address

DNP Data DNP Data DNP Data

Comm Data Comm Data Comm Data

Next Ptr Next Ptr Next Ptr Null

DI | AI | C DI | AI | C DI | AI | C

DI Pnts Null Cntr Pnts DI Pnts Null Cntr Pnts DI Pnts AI Pnts Null

DI Pnts Cntr Pnts DI Pnts Null DI Pnts AI Pnts

Null Cntr Pnts DI Pnts Null AI Pnts

Null Null Null

DI Pnts are generated for each command with an object type of 1.

AI Pnts are generated for each command with an object type of 30.

Cntr Pnts are generated for each command with an object type of 20 or 21.

The point lists are used by the module to determine the destination of all data

read by the module from the IED's. When the master receives a poll response or

an unsolicited response message, the points in the message are mapped to the

IED database using the point lists. For example, when the master receives a

value for binary input point 10 from slave unit 14, the following steps are

performed by the module:

1 First the module searches the slave list to make sure slave 14 is valid for the

module. If the slave not found the message is ignored. If the slave is found,

the module saves the pointer to the binary input point list.

2 Point number 10 is searched for in the binary input point list. If the point is

found in the DNP point list, the new value is stored at the correct offset in the

BI database. If the point is found in the IED point list, the new value is stored

at the correct offset in the IED database. If the point is not found in either

point list, it is ignored.

Each node in the point lists contain the start-stop IED point ranges and the IED

database offset values. These values are read by the module from the command

list each time the module performs the restart operation. If the database address

value is set to -1, the database is not used for the specified point range.

When the lists are formed by the module, the enable/flag field is ignored.

Therefore, you can place commands that will not be executed in the command

list and are only used for data mapping.

ProSoft Technology, Inc. Page 23 of 56

September 30, 2009

Page 24

DNPM ♦ ProLinx Gateway DNPM Protocol Configuration

DNP 3.0 Master Driver Manual

Page 24 of 56 ProSoft Technology, Inc.

September 30, 2009

Page 25

Communication Port Cables DNPM ♦ ProLinx Gateway

Driver Manual DNP 3.0 Master

4 Communication Port Cables

In This Chapter

DNP 3.0 Master Port .............................................................................25

Port 0, 1, 2, 3: RS-232 - Null Modem (DTE with Hardware Handshaking)26

Port 0, 1, 2, 3: RS-232 - Null Modem (DTE without Hardware

Handshaking)........................................................................................

Port 0, 1, 2, 3: RS-232 - DTE to DCE Modem Connection....................27

Collision Avoidance (DNP modules only)..............................................28

Port 0, 1, 2, 3: RS-422 Interface Connections.......................................29

Port 0, 1, 2, 3: RS-485 Interface Connections.......................................29

This section contains information on the cable and pin assignments for the

ProLinx module's serial ports (RS-232/422/485). The ProLinx module will come

with one to five serial ports, depending on the configuration purchased. In all

cases, the protocol serial ports will have the same pinouts.

27

Example: The 5202-MNET-MCM4 module contains five serial communication ports; four

configurable protocol application ports and one Configuration/ Debug port.

The 5201-MNET-MCM module contains two serial communication ports; one configurable protocol

application port and one Configuration/Debug port.

Each physical serial port has an eight-pin Mini-DIN jack connector. A six-inch

Mini-DIN-8Male to DB-9Male adapter cable is provided for each serial port. The

DB-9M provides connections for RS-232, wired as Data Terminal Equipment

(DTE), RS-422 and RS-485. The diagrams in the following topics detail the pin

assignments for several possible electrical interface connections.

4.1 DNP 3.0 Master Port

ProSoft Technology, Inc. Page 25 of 56

September 30, 2009

Page 26

DNPM ♦ ProLinx Gateway Communication Port Cables

DNP 3.0 Master Driver Manual

The ProLinx module supports the DNP 3.0 protocol as a Master on one port. This

port is fully configurable.

The relationship between the port labeling on the front of the ProLinx module and

the application is as follows:

Port Label Function

Debug Debug/Configuration

Port 0 DNP Master Port

Following ports only exist on multiple port units

Port 1 Not available to DNP Driver

Port 2 Not available to DNP Driver

Port 3 Not available to DNP Driver

The DNP Master port can be used to continuously interface with a DNP slave

devices over a serial communication interface (RS-232, RS-422 or RS-485).

4.2 Port 0, 1, 2, 3: RS-232 - Null Modem (DTE with Hardware Handshaking)

This type of connection is used when the device connected to the module

requires hardware handshaking (control and monitoring of modem signal lines;

Use CTS parameter set to Y

ES).

Page 26 of 56 ProSoft Technology, Inc.

September 30, 2009

Page 27

Communication Port Cables DNPM ♦ ProLinx Gateway

Driver Manual DNP 3.0 Master

4.3 Port 0, 1, 2, 3: RS-232 - Null Modem (DTE without Hardware

Handshaking)

This type of connection can be used to connect the module to a computer or field

device communication port.

Note: If the port is configured with the Use CTS set to YES, then a jumper is required between the

RTS and the CTS line on the module connection.

4.4 Port 0, 1, 2, 3: RS-232 - DTE to DCE Modem Connection

This type of connection is required between the module and a modem or other

communication device.

The Use CTS Line parameter for the port configuration should be set to Y

most modem applications.

ProSoft Technology, Inc. Page 27 of 56

September 30, 2009

ES for

Page 28

DNPM ♦ ProLinx Gateway Communication Port Cables

DNP 3.0 Master Driver Manual

4.5 Collision Avoidance (DNP modules only)

The RTS line is controlled by the RTS on and off parameters set for the port. If

the CTS line is used (usually only required for half-duplex modems and not

defined for use in the DNPS specification), the RTS and CTS lines must either be

connected together or connected to the modem. The following illustration shows

the cable required when connecting the port to a modem.

If collision avoidance is used in a point-to-point connection on the RS-232

interface, the following cable should be used.

Page 28 of 56 ProSoft Technology, Inc.

September 30, 2009

Page 29

Communication Port Cables DNPM ♦ ProLinx Gateway

Driver Manual DNP 3.0 Master

4.6 Port 0, 1, 2, 3: RS-422 Interface Connections

The following illustration applies when the RS-422 interface is selected.

4.7 Port 0, 1, 2, 3: RS-485 Interface Connections

The following illustration applies when the RS-485 interface is selected.

NOTE: This type of connection is commonly called a RS-485 half-duplex, 2-wire connection. If you

have RS-485 4-wire, full-duplex devices, they can be connected to the module's serial ports by

wiring together the TxD+and RxD+ from the two pins of the full-duplex device to Pin 1 on the

module and wiring together the TxD- and RxD- from the two pins of the full-duplex device to Pin 8

on the module. As an alternative, you could try setting the module to use the RS-422 interface and

and connect the full-duplex device according to the RS-422 wiring diagram (page 29). For

additional assistance, please contact ProSoft Technical Support.

ProSoft Technology, Inc. Page 29 of 56

September 30, 2009

Page 30

DNPM ♦ ProLinx Gateway Communication Port Cables

DNP 3.0 Master Driver Manual

Page 30 of 56 ProSoft Technology, Inc.

September 30, 2009

Page 31

LED Indicators DNPM ♦ ProLinx Gateway Driver Manual DNP 3.0 Master

5 LED Indicators

In This Chapter

Common module LEDs .........................................................................31

LEDs for Port 0 Serial Port....................................................................31

4101 Series LEDs .................................................................................32

Troubleshooting the operation of the DNP Master port can be performed using

several methods.

The first and quickest is to scan the LEDs on the module to determine the

existence and possibly the cause of a problem. This section provides insight into

the operation of the Serial Port status LEDs. Information on the module’s other

LEDs can be found in the ProLinx Reference Guide.

5.1 Common module LEDs

LED State Description

Power

Err

Off

Green Solid

Off Normal operation. Fault

Red Solid

Off Normal operation. Cfg

Amber Solid

Off Normal operation.

Flashing

Solid Red

Power is not connected to the power terminals or source is insufficient

to properly power the module (800mA at 24vdc minimum required)

Power is connected to the power terminals. Verify that the other LEDs

for operational and functional status come on briefly after power-up

(check for burned-out LEDs).

A critical error has occurred. Program executable has failed or has

been user-terminated and is no longer running. Press Reset p/b or

cycle power to clear error. If not, use the Debug procedures described

later in this manual.

The unit is in configuration mode. The configuration file is currently

being downloaded or, after power-up, is being read, the unit is

implementing the configuration values, and initializing the hard ware.

This will occur during power cycle, or after pressing the reset button. It

also occurs after a cold/warm boot command is received.

An error condition has been detected and is occurring on one of the

application ports. Check configuration and troubleshoot for

communication errors.

This error flag is cleared at the start of each command attempt

(master/client) or on each receipt of data (slave/adapter/server); so, if

this condition exists, it indicates a large number of errors are occurring

in the application (due to bad configuration) or on one or more ports

(network communication failures).

ProSoft Technology, Inc. Page 31 of 56

September 30, 2009

Page 32

DNPM ♦ ProLinx Gateway LED Indicators

DNP 3.0 Master Driver Manual

5.2 LEDs for Port 0 Serial Port

Some ProLinx modules have three extra serial ports. Each of these serial ports

has two LEDs indicating status.

LED Color Description

Off No activit y on the port. Port 0 - ACT

Green Flash The port is either actively transmitting or receiving data

Port 0 - ERR

Off

Red On or Flashing

Normal state. When off and Port Active led is indicating

activity, there are no communication errors

Activity on this led indicates some communication error

was detected, either during transmit or receive

5.3 4101 Series LEDs

LED State Description

Off Power is not connected to the power terminals. Power

Green Solid

Off Normal operation. Fault

Red Solid

Off Normal operation. CFG

Amber Solid

ERR

Off Normal operation.

Flashing

Solid Red

Power is connected to the power terminals. Verify that the other LEDs

for operational and functional status light.

The Debug/Configuration mode is active (applies to modules that

support pass-through on Debug port - such as DFCM units).

If CFG LED is not on, a critical error has occurred. Program executable

has failed or has been user-terminated and is no longer running. Press

Reset p/b or cycle power to clear error. If not, use the Debug

procedures described later in this manual.

If Fault LED is on, the Debug/Configuration Mode is active (if the

module supports pass-through on the Debug port - such as DFCM

units).

If the Fault LED is off, the unit is in the configuration mode. The

configuration file is being read and the unit is implementing the

configuration values and initializing the hardware. This will occur during

power cycle, or after pressing reset button. It also occurs after a

cold/warm boot command is received.

An error condition has been detected and is occurring. Check

configuration.

This condition is indicative of a large number of errors in the application

interface communications. The module's error flag is cleared at the

start of each command (master/client) or receipt of data

(slave/adapter/server).

Page 32 of 56 ProSoft Technology, Inc.

September 30, 2009

Page 33

Reference DNPM ♦ ProLinx Gateway

Driver Manual DNP 3.0 Master

6 Reference

In This Chapter

Error Codes...........................................................................................33

Device Profile........................................................................................37

Subset Definition...................................................................................39

Command List Entry Form.....................................................................45

6.1 Error Codes

6.1.1 Module Error Codes

These error codes are generated by the module in response to communication

problems on an emulated slave port or configuration errors. Review the error list

to view the last set of 60 errors generated by the module. The error codes are

listed in the following tables:

Slave Port Communication Errors

Error Code Name Description

0 OK

10

11

12

13

14

15

16

17

18

19

DNP synchronization error

(Physical Layer Error)

DNP overrun error (Physical

Layer Error)

DNP length error (Physical

Layer Error)

DNP bad CRC error (Data

Link Layer Error)

DNP user data overflow

error (Transport Layer Error)

DNP sequence error

(Transport Layer Error)

DNP address error

(Transport Layer Error)

DNP bad function code

error (Application Layer

Error)

DNP object unknown error

(Application Layer Error)

DNP out of range error

(Application Layer Error)

The module is operating correctly and there are no

errors.

Extra bytes are received before the start bytes (0x05

and 0x64).

Mainline Data Link Layer routine could not read data

received on DNP port before it was overwritten.

Length of message does not match length value in

message.

Computed CRC value for message does not match

that received in message.

Application layer received a message fragment buffer

which is too small.

Sequence numbers of multi-frame request fragments

do not increment correctly.

Source addresses contained in multi-frame request

fragments do not match.

Function code received from DNP master is not

supported for selected object/variation.

Slave does not have the specified objects or there are

no objects assigned to the requested class.

Qualifier, range or data fields are not valid or out of

range for the selected object/variation.

ProSoft Technology, Inc. Page 33 of 56

September 30, 2009

Page 34

DNPM ♦ ProLinx Gateway Reference

DNP 3.0 Master Driver Manual

Error Code Name Description

20

21

System Configuration Errors

Error Code Name Description

100

101

102 Too many counter points

103

104

105

106

107

108 Not enough memory

109

110 File count invalid The file count must be in the range of 0 to 6.

111 Invalid file record size The file record size must be in the range of 1 to 120.

112

DNP Port Configuration Errors

Error Code Name Description

212 Invalid DNP address

213 Invalid DNP port baud rate

219

220

222

223

224

DNP message overflow

error (Application Layer

Error)

DNP master multi-frame

message error (Application

Layer Error)

Too many binary input

points

Too many binary output

points

Too many analog input

points

Too many analog input

points

Too many binary input

events

Too many analog input

events

Invalid analog input

deadband

Invalid block transfer delay

for blocks 251 and 252

(error/status blocks)

Invalid block identification

code for file

Invalid DNP data link layer

confirm mode

Invalid DNP data link

confirm time-out

Invalid DNP select/operate

arm time duration

Invalid DNP application

layer confirm time-out

Invalid DNP write time

interval

Application response buffer overflow condition. The

response message from the slave is too long to

transmit.

Received a multi-frame message from the DNP

master. This application does not support multi-frame

messages from the master.

Too many binary input points are configured for the

module. Maximum value is 15360.

Too many binary output points are configured for the

module. Maximum value is 15360.

Too many counter points are configured for the

module. Maximum value is 480.

Too many analog input points are configured for the

module. Maximum value is 960.

Too many analog output points are configured for the

module. Maximum value is 960.

Too many binary input events are configured for the

module. Maximum value is 400.

Too many analog input events are configured for the

module. Maximum value is 400.

Deadband value for analog input events is out of

range. Value must be in the range of 0 to 32767.

There is not enough memory in the module to

configure the module as specified.

Block transfer delay value specified is too low.

The file block transfer code must be in the range of

100 to 120.

The DNP address specified in the configuration is not

valid (0 to 65534).

The baud rate code specified in the configuration is

not valid.

The data link confirmation mode code is not valid in

the configuration.

The data link time-out period specified in the

configuration is 0. It must be an integer in the range of

1 to 65535.

The select/operate arm timer is set to 0. It must be an

integer in the range of 1 to 65535.

The application layer confirm time-out value is set to 0.

It must be an integer in the range of 1 to 65535.

The write time interval is not in the data range in the

configuration. The value must be in the range of 0 to

1440.

Page 34 of 56 ProSoft Technology, Inc.

September 30, 2009

Page 35

Reference DNPM ♦ ProLinx Gateway

Driver Manual DNP 3.0 Master

Error Code Name Description

225

226

227

228

230

Invalid DNP unsolicited

response mode

Invalid DNP unsolicited

response minimum quantity

for Class 1

Invalid DNP unsolicited

response minimum quantity

for Class 2

Invalid DNP unsolicited

response minimum quantity

for Class 3

Invalid DNP unsolicited

response destination

address

The unsolicited response mode code is not valid in the

configuration.

The unsolicited response minimum quantity for Class

1 is not valid in the configuration. Value must be an

integer in the range of 1 to 255.

The unsolicited response minimum quantity for Class

2 is not valid in the configuration. Value must be an

integer in the range of 1 to 255.

The unsolicited response minimum quantity for Class

3 is not valid in the configuration. Value must be an

integer in the range of 1 to 255.

The unsolicited response destination address is not

valid in the configuration. Value must be in the range

of 1 to 65534.

6.1.2 Command Error Codes

Command error codes are generated by the module's program. These errors are

generated when an error occurs when issuing a request or processing a

response of a command list function. The following tables list the command error

codes used in the module:

General Command Errors

Error Code Name Description

1 Device not defined

2 Invalid command

3 Object not supported

4

10

11

20

30

31

40

50

51

Command function not

supported

Invalid binary input poll

command

Invalid binary input event

poll command

Invalid binary output

command function

Invalid counter poll

command function

Invalid counter poll

command

Invalid frozen counter poll

command

Invalid analog input poll

command

Invalid analog input event

poll command

The IED slave address referenced in the command is

not defined in the module. Check to make sure there is

an entry in the slave table for each slave device

referenced in the command list.

This command is not valid. Check to make sure the

slave address parameter is greater than or equal to

zero and that the point count is not set to zero.

The data object in the command is not supported by

the module. Refer to the DNP subset for the Master

Port.

The function specified in the command is not

supported for the object type selected. Refer to the

DNP subset for the Master Port.

This binary input object command is not valid.

This binary input event object poll command is not

valid.

This binary output command function is not valid.

The counter object poll command contains an invalid

function code.

This counter object poll command is not valid.

This frozen counter object poll command is not valid.

This analog input poll command is not valid.

This analog input event poll command is not valid.

ProSoft Technology, Inc. Page 35 of 56

September 30, 2009

Page 36

DNPM ♦ ProLinx Gateway Reference

DNP 3.0 Master Driver Manual

Error Code Name Description

60

61

70

80 Invalid event poll command This event poll command is not valid.

Application Layer Errors

Error Code Name Description

1000 Device index invalid

1001

1002

1003 Sequence number error

1004

1005

1006

1007

1008

1009

1010

Invalid analog output poll

command function

Invalid analog output poll

command

Invalid time/date poll

command

Duplicate request in

application layer queue

COM port device removed

from system

Response to select before

operate does not match

Response does not contain

date/time object

Time-out condition on

response

Function code in application

layer message not

supported

Read operation not

supported for

object/variation

Operate function not

supported for the

object/variation

Write operation not

supported for the

object/variation

This analog output poll command contains an invalid

function code.

This analog output poll command is not valid.

This time/date object poll command is not valid.

The device index in the request or response message

is not found in the slave list.

The newly submitted message to the application layer

already exists in the queue. The message is ignored.

The communication port for the message has been

uninstalled on the system. This error should never

occur as the communication ports are only uninstalled

when the module's program is terminated.

The application sequence number in the response

message does not match that based on the last

request message. This indicates application layer

messages are received out of order.

The select response message received from the slave

module is not that expected from the last select

request. This indicates a synchronization problem

between the master and slave devices.

The response message from the slave device does

not contain a date/time object. The master expects this

object for the response message.

The slave device did not respond to the last request

message from the master within the time-out set for

the IED device. The application layer time-out value is

specified for each IED unit in the slave configuration

table in the module. This table is established each

time the module performs the restart operation.

The function code returned in the response message

is not valid for the application layer or not supported by

the module.

The application layer response message contains an

object that does not support the read function.

The application layer response message contains an

object that does not support the operate function.

The application layer response message contains an

object that does not support the write function.

Use the error codes returned for each command in the list to determine the

success or failure of the command. If the command fails, use the error code to

determine the cause of failure.

Page 36 of 56 ProSoft Technology, Inc.

September 30, 2009

Page 37

Reference DNPM ♦ ProLinx Gateway

Driver Manual DNP 3.0 Master

6.2 Device Profile

DNP V3.00

DEVICE PROFILE DOCUMENT

Vendor Name: ProSoft Technology, Inc.

Device Name: DNP MASTER (VERSION 2.20)

Highest DNP Level Supported : Device Function:

For Request: L2 Master

For Responses: L2

Notable objects, functions, and/or qualifiers supported in addition to the highest DNP level stated above (see

attached table for complete list):

The following features are configurable on the module: Collision avoidance

Maximum Data Link Frame Size (octets): Maximum Application Fragment Size (octets):

Transmitted : 292 Transmitted : 2048

Received : 292 Received : 2048

Maximum Data Link Re-tries: Maximum Application Layer Re-tries:

Configurable from 0 - 255 None

Requires Data Link Layer Confirmation:

Configurable at module start-up (never, sometimes, & always)

Requires Application Layer Confirmation:

ProSoft Technology, Inc. Page 37 of 56

September 30, 2009

Page 38

DNPM ♦ ProLinx Gateway Reference

DNP 3.0 Master Driver Manual

Page 38 of 56 ProSoft Technology, Inc.

September 30, 2009

Page 39

Reference DNPM ♦ ProLinx Gateway

Driver Manual DNP 3.0 Master

6.3 Subset Definition

OBJECT REQUEST RESPONSE

Obj Var Description Func

Codes

1 0 Binary Input: All

Variations

1 Binary Input 1 06 129,

2 Binary Input with

Status

2 0 Binary Input

Change: All

Variations

1 Binary Input

Change Without

Time

2 Binary Input

Change With Time

3 Binary Input

Change With

Relative Time

10 0 Binary Output: All

Variations

1 Binary Output

2 Binary Output

Status

12 0 Control Block: All

Variations

1 Control Relay

Output Block

2 Pattern Control

Block

3 Pattern Mask

20 0 Binary Counter: All

Variations

1 32-Bit Binary

Counter

2 16-Bit Binary

Counter

3 32-Bit Delta

Counter

4 16-Bit Delta

Counter

5 32-Bit Binary

Counter Without

Flag

1 06

1 06 129,

1 06, 07, 08

1 06, 07, 08

1 06, 07, 08 129,

1 06, 07, 08 129,

1 06

3, 4, 5, 6 17, 28 129 Echo of

1, 7, 8,

9, 10

1, 7, 8,

9, 10

Qual

Codes

(hex)

129,

06

129,

129,

129,

129,

06 129,

Func

Codes

130

130

129,

130

130

130

130

130

130

130

130

130

Qual

Codes

(hex)

1 Master will generate this variation

00, 01 1 Master will generate and process this

00, 01 8 Master will generate and process this

56 Master will generate this variation

17, 28 8 Master will generate and process this

17, 28 56 Master will generate and process this

17, 28 24 Master will generate and process this

8

1

00, 01 8

88

request

88

16

32 Master will generate this variation

00, 01 40 Master will process this variation.

00, 01 24 Master will process this variation

00, 01 40 Master will process this variation.

00, 01 24 Master will process this variation

00, 01 32 Master will generate and process this

Data

NOTES

Size

(bits)

variation

variation. Status flags are discarded.

variation. Status flags are discarded.

variation. Status flags and time stamp

are discarded.

variation. Status flags and relative

time are discarded.

Master does not use this object type

and will not generate a message or

process this type

88 Master will generate this variation

and parse the response

Status flags are discarded.

Status flags are discarded.

variation

ProSoft Technology, Inc. Page 39 of 56

September 30, 2009

Page 40

DNPM ♦ ProLinx Gateway Reference

DNP 3.0 Master Driver Manual

OBJECT REQUEST RESPONSE

Obj Var Description Func

Codes

6 16-Bit Binary

Counter Without

Flag

7 32-Bit Delta

Counter Without

Flag

8 16-Bit Delta

Counter Without

Flag

21 0 Frozen Counter: All

Variations

1 32-Bit Frozen

Counter

2 16-Bit Frozen

Counter

3 32-Bit Frozen Delta

Counter

4 16-Bit Frozen Delta

Counter

5 32-Bit Frozen

Counter With Time

Of Freeze

6 16-Bit Frozen

Counter With Time

Of Freeze

7 32-Bit Frozen Delta

Counter With Time

Of Freeze

8 16-Bit Frozen Delta

Counter With Time

Of Freeze

9 32-Bit Frozen

Counter Without

Flag

10 16-Bit Frozen

Counter Without

Flag

11 32-Bit Frozen Delta

Counter Without

Flag

12 16-Bit Frozen Delta

Counter Without

Flag

22 0 Counter Change

Event: All

Variations

1, 7, 8,

9, 10

1 06

1 06 129,

1 06 129,

1 06, 07, 08

Qual

Codes

(hex)

06 129,

129,

129,

129,

129,

Func

Codes

130

130

130

130

130

130

130

Qual

Codes

(hex)

00, 01 16 Master will generate and process this

00, 01 32 Master will process this variation

00, 01 16 Master will process this variation

32 Master will generate this variation

00, 01 40 Master will process this variation.

00, 01 24 Master will process this variation.

40

24

88

72

88

72

00, 01 32 Master will generate and process this

00, 01 16 Master will generate and process this

32

16

NOTES

Data

Size

(bits)

variation

Status flags are discarded.

Status flags are discarded.

variation

variation

Master will not generate a request for

this variation

Page 40 of 56 ProSoft Technology, Inc.

September 30, 2009

Page 41

Reference DNPM ♦ ProLinx Gateway

Driver Manual DNP 3.0 Master

OBJECT REQUEST RESPONSE

Obj Var Description Func

Codes

1 32-Bit Counter

Change Event

Without Time

2 16-Bit Counter

Change Event

Without Time

3 32-Bit Delta

Counter Change

Event Without Time

4 16-Bit Delta

Counter Change

Event Without Time

5 32-Bit Counter

Change Event With

Time

6 16-Bit Counter

Change Event With

Time

7 32-Bit Delta

Counter Change

Event With Time

8 16-Bit Delta

Counter Change

Event With Time

23 0 Frozen Counter

Event: All

Variations

1 32-Bit Frozen

Counter Event

Without Time

2 16-Bit Frozen

Counter Event

Without Time

3 32-Bit Frozen Delta

Counter Event

Without Time

4 16-Bit Frozen Delta

Counter Event

Without Time

5 32-Bit Frozen

Counter Event With

Time

6 16-Bit Frozen

Counter Event With

Time

7 32-Bit Frozen Delta

Counter Event With

Time

Qual

Codes

(hex)

129,

129,

Func

Codes

130

130

Qual

Codes

(hex)

17, 28 40 Master will process this variation.

17, 28 24 Master will process this variation.

40

24

88

72

88

72

40

24

40

24

88

72

88

NOTES

Data

Size

(bits)

Status flags are discarded.

Status flags are discarded.

ProSoft Technology, Inc. Page 41 of 56

September 30, 2009

Page 42

DNPM ♦ ProLinx Gateway Reference

DNP 3.0 Master Driver Manual

OBJECT REQUEST RESPONSE

Obj Var Description Func

Codes

8 16-Bit Frozen Delta

Counter Event With

Time

30 0 Analog Input: All

Variations

1 32-Bit Analog Input 1 06 129,

2 16-Bit Analog Input

3 32-Bit Analog Input

Without Flag

4 16-Bit Analog Input

Without Flag

31 0 Frozen Analog

Input: All Variations

1 32-Bit Frozen

Analog Input

2 16-Bit Frozen

Analog Input

3 32-Bit Frozen

Analog Input With

Time To Freeze

4 16-Bit Frozen

Analog Input With

Time To Freeze

5 32-Bit Frozen

Analog Input

Without Flag

6 16-Bit Frozen

Analog Input

Without Flag

32 0 Analog Change

Event: All

Variations

1 32-Bit Analog

Change Event

Without Time

2 16-Bit Analog

Change Event

Without Time

1 06

1 06 129,

1 06 129,

1 06 129,

1 06, 07, 08

1 06, 07, 08 129,

1 06, 07, 08 129,

Qual

Codes

(hex)

Func

Codes

130

130

130

130

130

130

Qual

Codes

(hex)

72

16 Master will generate this variation

00, 01 40 Master will generate and process this

00, 01 24 Master will generate and process this

00, 01 32 Master will generate and process this