Page 1

User’s Manual

TM

SL/T5R Energy Star

RFID Smart Label and Thermal Printers

Page 2

Page 3

Printronix makes no representations or warranties of any kind regarding this

material, including, but not limited to, implied warranties of merchantability

and fitness for a particular purpose. Printronix shall not be held responsible

for errors contained herein or any omissions from this material or for any

damages, whether direct, indirect, incidental or consequential, in connection

with the furnishing, distribution, performance or use of this material. The

information in this manual is subject to change without notice.

This document contains proprietary information protected by copyright. No

part of this document may be reproduced, copied, translated or incorporated

in any other material in any form or by any means, whether manual, graphic,

electronic, mechanical or otherwise, without the prior written consent of

Printronix.

COPYRIGHT © 2005, 2013 PRINTRONIX, INC. All rights reserved.

T rademark Acknowledgements

Printronix, IGP, Auto Label Mapping, LinePrinter Plus, PGL, and PrintNet are

registered trademarks of Printronix, Inc.

SL/T5R Energy Star and Thermaline are trademarks of Printronix, Inc.

HP is a registered trademark of Hewlett-Packard Company.

Code V is a trademark of QMS, Inc.

QMS is a registered trademark of Quality Micro Systems, Inc.

IBM is registered trademark of International Business Machines Corp.

Monarch is a registered trademark of Paxar Corporation.

MS-DOS and Windows are registered trademarks of Microsoft Corporation.

Centronics is a registered trademark of Genicom Corporation.

IEEE is a registered service mark of the Institute of Electrical and Electronic

Engineers, Inc.

ANSI is a registered trademark of American National Standards Institute, Inc.

EIA is a registered service mark of Electronic Industries Association.

ZPL, ZPL II, and Zebra are registered trademarks of Zebra Technologies

Corporation.

TEC is a registered trademark of the Toshiba TEC Corporation.

Intermec is a registered trademark of the Intermec Technologies Corporation.

SATO is a registered trademark of SATO America, Inc.

DPL is a trademark and Datamax is a registered trademark of Datamax

Technologies Corporation.

IER is a registered trademark of IER Siège

Page 4

Page 5

Table of Contents

1 Introduction ......................................................... 11

The SL/T5R Energy Star ™ Family of Printers.................................... 11

Standard Features ........................................................................ 12

Optional Features.......................................................................... 13

Thermal Printer Technology ................................................................ 14

The Printing Process ..................................................................... 14

Dynamic Print Control ................................................................... 15

Warnings and Special Information....................................................... 15

Manual Conventions ............................................................................ 15

Thermal Consumables......................................................................... 16

Media Selection............................................................................. 16

Ribbons ......................................................................................... 17

Setting Up the Printer .......................................................................... 17

Unpacking the Printer.................................................................... 17

Installation ..................................................................................... 19

2 Operation ............................................................ 23

Controls and Indicators ........................................................................ 23

Power Switch ................................................................................ 23

Control Panel ................................................................................ 23

Powering On the Printer ................................................................ 27

Operating Modes........................................................................... 27

Media Handling Modes ........................................................................ 27

Loading Media and Ribbon.................................................................. 28

Loading Roll Media ....................................................................... 29

Loading Fanfold Media.................................................................. 36

Loading Ribbon ............................................................................. 40

Using the Optional Internal Rewinder .................................................. 43

Batch Rewind Mode ...................................................................... 43

Label Peel-Off ............................................................................... 48

Removing the Paper Path ............................................................. 51

Printing Adjustments ............................................................................ 52

Printhead Pressure Adjustment..................................................... 52

Printhead Pressure Block Adjustments ......................................... 53

Positioning the Media Sensors...................................................... 54

Sensing Different Media Types ..................................................... 59

Page 6

Table of Contents

Running Auto Calibrate ................................................................. 60

Running Media Profile ................................................................... 62

Running Manual Calibrate............................................................. 66

Cleaning............................................................................................... 68

Exterior Cleaning........................................................................... 68

Interior Cleaning ............................................................................ 68

Cleaning the Printhead, Platen Roller, Media Sensors and

Media Damper............................................................................... 69

3 Configuring The Printer ....................................... 73

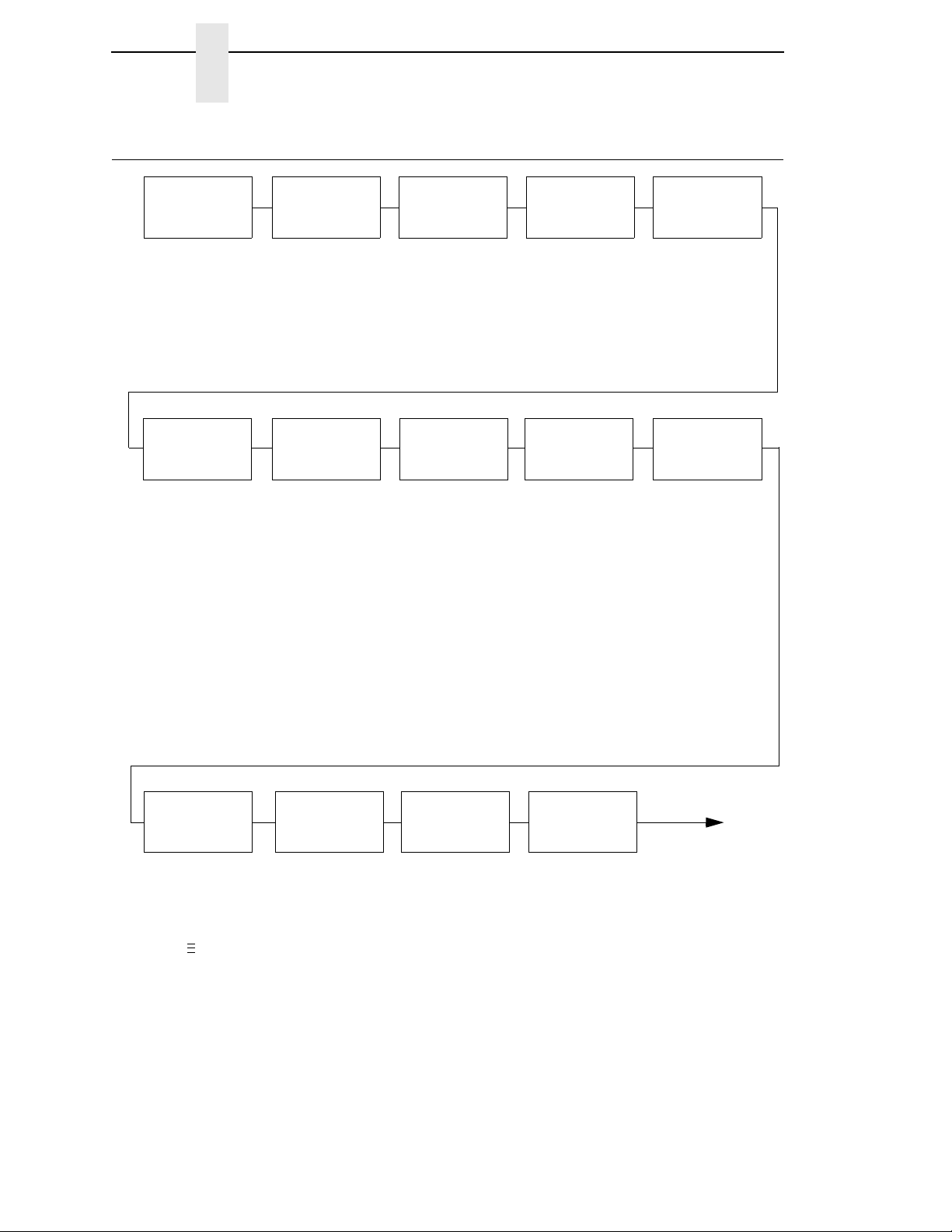

Overview.............................................................................................. 73

Setting Printer Configuration Parameters ..................................... 73

Moving within the Configuration Menu .......................................... 73

Selecting a Menu Option............................................................... 74

Changing Printer Settings ............................................................. 75

Saving a Configuration .................................................................. 76

Auto Save Configuration ............................................................... 77

Specifying a Power-Up Configuration ........................................... 78

Modifying a Saved Configuration .................................................. 79

Printing a Configuration................................................................. 81

Loading A Saved Configuration .................................................... 81

Menu Overview.................................................................................... 82

Main Menu ........................................................................................... 84

QUICK SETUP .................................................................................... 95

QUICK SETUP Submenus............................................................ 96

CONFIG. CONTROL ......................................................................... 104

CONFIG. CONTROL Submenus ................................................ 105

MEDIA CONTROL............................................................................. 107

MEDIA CONTROL Submenus .................................................... 108

CALIBRATE CTRL ............................................................................ 127

CALIBRATE CTRL Submenus.................................................... 128

PRINTER CONTROL ........................................................................ 135

PRINTER CONTROL Submenus................................................ 137

EMULATIONS ................................................................................... 149

Overview ..................................................................................... 149

COAX SETUP.................................................................................... 153

TWINAX SETUP................................................................................ 156

SPC COAX SETUP ........................................................................... 158

SPC TWINAX SETUP ....................................................................... 159

IPDS SETUP ..................................................................................... 160

TN3270 SETUP ................................................................................. 164

TN5250 SETUP ................................................................................. 166

Page 7

Table of Contents

PGL SETUP....................................................................................... 168

VGL SETUP....................................................................................... 170

P-SERIES SETUP ............................................................................. 172

P-SER XQ SETUP............................................................................. 174

SERIAL MATRIX SETUP .................................................................. 176

PROPRINTER XL SETUP................................................................. 178

EPSON FX SETUP............................................................................ 180

Emulation Submenus .................................................................. 182

DIAGNOSTICS .................................................................................. 225

DIAGNOSTICS Submenus ......................................................... 226

PARALLEL PORT.............................................................................. 229

PARALLEL PORT Submenus ..................................................... 230

SERIAL PORT ................................................................................... 233

SERIAL PORT Submenus .......................................................... 234

C/T PORT .......................................................................................... 241

C/T PORT Submenus ................................................................. 241

USB PORT ........................................................................................ 242

USB Port Submenu ..................................................................... 242

ETHERNET PORT ............................................................................ 243

ETHERNET PORT Submenu...................................................... 243

ETHERNET ADDRESS ..................................................................... 244

ETHERNET ADDRESS Submenus ............................................ 245

ETHERNET PARAMS ....................................................................... 246

ETHERNET PARAMS Submenus............................................... 247

WLAN ADDRESS .............................................................................. 249

WLAN ADDRESS Submenus ..................................................... 250

WLAN PARAMS ................................................................................ 251

WLAN PARAMS Submenus........................................................ 253

KERBEROS PARAMS....................................................................... 257

KERBEROS PARAMS Submenus.............................................. 257

WLAN EAP ........................................................................................ 260

WLAN EAP Submenus ............................................................... 260

PRINTER MGMT ............................................................................... 262

PRINTER MGMT Submenus ...................................................... 262

DATE ................................................................................................. 263

Date Submenus .......................................................................... 263

Page 8

Table of Contents

4 Downloading Software ...................................... 265

Loading Flash Memory ...................................................................... 265

Downloading Software with the Firmware Download Utility............... 266

Downloading Software through the Parallel Port ............................... 267

Downloading Software through the NIC ............................................ 269

Downloading Software through the NIC using FTP ........................... 270

Downloading Software through the USB Port.................................... 272

Downloading Software through the Printronix Windows Driver ......... 273

Downloading Software if Flash Contains Only Boot or

Corrupt Code ..................................................................................... 274

Using TrueType Fonts ....................................................................... 275

Downloading TrueType Fonts............................................................ 275

Printronix Windows Driver........................................................... 276

PGL Emulation (Online) .............................................................. 276

Download Mode .......................................................................... 277

PTX_SETUP ............................................................................... 279

Labeling Applications .................................................................. 279

Filename Extensions Not Shown in Menus ....................................... 279

Select and Print Downloaded TrueType Fonts .................................. 280

5 Interfaces .......................................................... 281

Overview............................................................................................ 281

Auto Switching ................................................................................... 281

Centronics Parallel Interface.............................................................. 282

Centronics Parallel Interface Signals .......................................... 283

IEEE 1284 Parallel Interface.............................................................. 284

Compatibility Mode...................................................................... 284

Nibble Mode ................................................................................ 284

Byte Mode ................................................................................... 284

Signals ........................................................................................ 285

RS-232 and Optional RS-422 Serial Interfaces ................................. 287

RS-232 ........................................................................................ 287

RS-422 ........................................................................................ 288

USB ................................................................................................... 289

Ethernet and Wireless ....................................................................... 289

Page 9

Table of Contents

6 Diagnostics and Troubleshooting...................... 291

Printer Tests ...................................................................................... 291

Troubleshooting Common Situations................................................. 291

Improving Processing Time......................................................... 292

Data Exchange............................................................................ 292

Controlling Print Quality............................................................... 294

Determining Printhead Wear ....................................................... 295

Replacing the Printhead .................................................................... 296

Restore the Printer to Operation........................................................ 298

Diagnostics for E0xx, Bad NVM, or ILL NVM Errors.......................... 299

Solving other Printer Problems.................................................... 300

Printer Alarms ............................................................................. 308

Fault Messages ........................................................................... 308

A Specifications.................................................... 333

Print Method ................................................................................ 333

Media .......................................................................................... 334

Ribbon ......................................................................................... 336

Indicators and Switches .............................................................. 336

Memory ....................................................................................... 336

Media Cutter Option .................................................................... 337

Host Interfaces ............................................................................ 338

Power .......................................................................................... 338

Environmental ............................................................................. 339

Physical ....................................................................................... 339

Acoustic Specifications ............................................................... 339

Maximum Page Length ............................................................... 340

B Printer Options .................................................. 341

Hardware Options.............................................................................. 341

Interface Options ......................................................................... 342

Supplies and Accessories.................................................................. 343

Genuine Printronix Thermal Transfer Ribbons............................ 344

Genuine Printronix Media............................................................ 345

Accessories ................................................................................. 347

C ASCII Control Codes......................................... 349

Page 10

Table of Contents

D Media Cutter Installation ................................... 351

Prepare the Printer ............................................................................ 351

Installing the Cutter............................................................................ 352

Restore the Printer To Operation ................................................ 353

Removing the Media Cutter ............................................................... 353

E Media Cutter Tray Installation ........................... 355

Assembling the Media Cutter Tray .................................................... 355

Installing the Media Cutter Tray......................................................... 356

F Selecting Supported RFID Tag Types .............. 359

Read this First.................................................................................... 359

Selecting RFID Tag Types................................................................. 359

G PTX_SETUP Commands .................................. 361

Overview............................................................................................ 361

The PTX_SETUP Commands ........................................................... 361

General Commands .................................................................... 362

Thermal Commands.................................................................... 369

H Customer Support ............................................. 371

Printronix Customer Support Center.................................................. 371

Printronix Supplies Department .................................................. 371

Corporate Offices ........................................................................ 372

I Glossary ............................................................ 373

J Communication Notices and Warranties........... 379

Communication Notices..................................................................... 382

Software License Agreement............................................................. 385

Warranty Information ......................................................................... 393

Page 11

1

Introduction

The SL/T5R Energy St ar ™ Family of Printers

NOTE: As used in this manual, the terms “T5R” and “printer” refer to all

models within the series. “SL” refers to all SmartLine RFID models.

The SL/T5R Energy Star series consists of a family of high quality, direct

thermal and thermal transfer printers specifically designed for printing labels

and tags from any MS-DOS

Twinax option) based compatible computer.

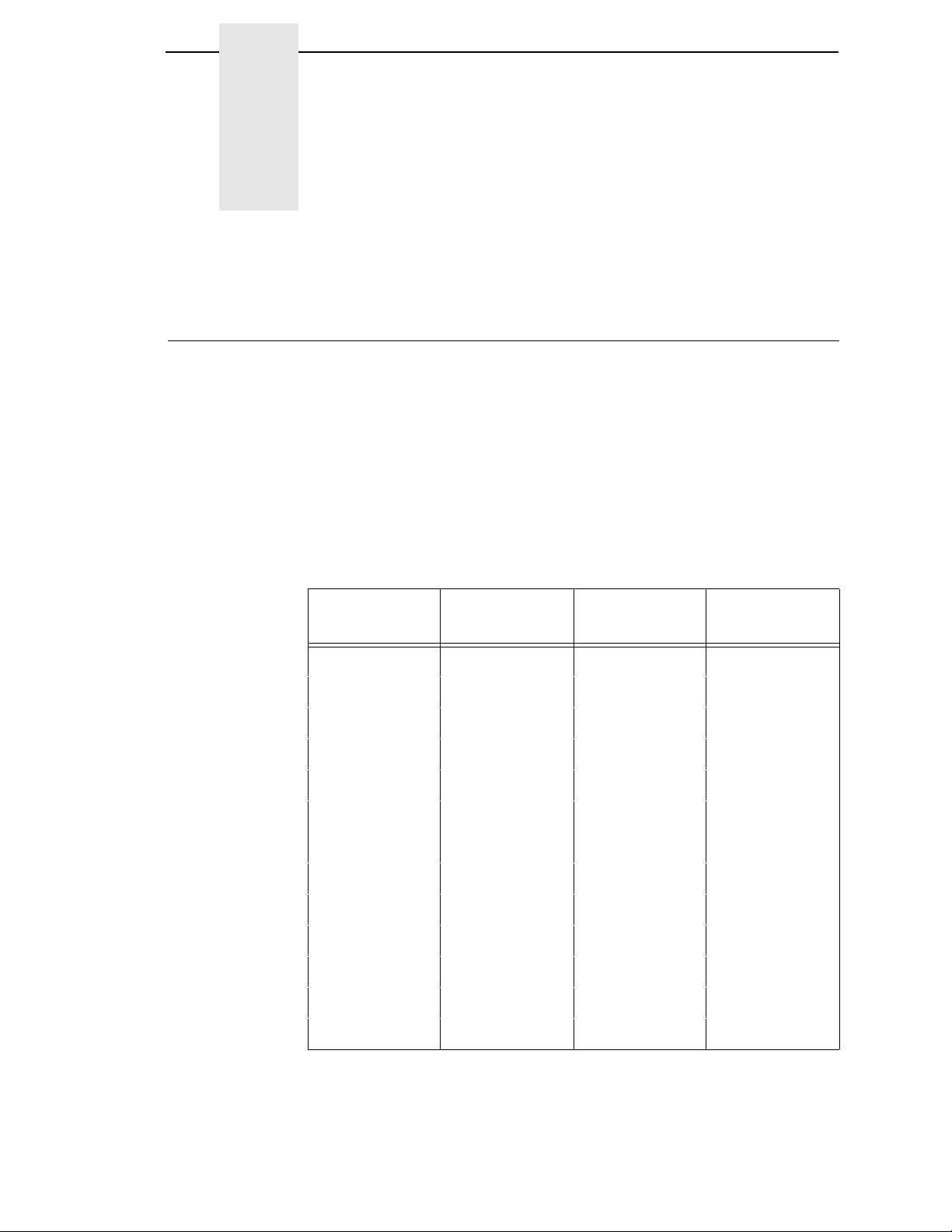

The T5R, Smart Ready, and SmartLine series are comprised of the products

detailed in

NOTE: All 4” models are Smart Ready.

Table 1.

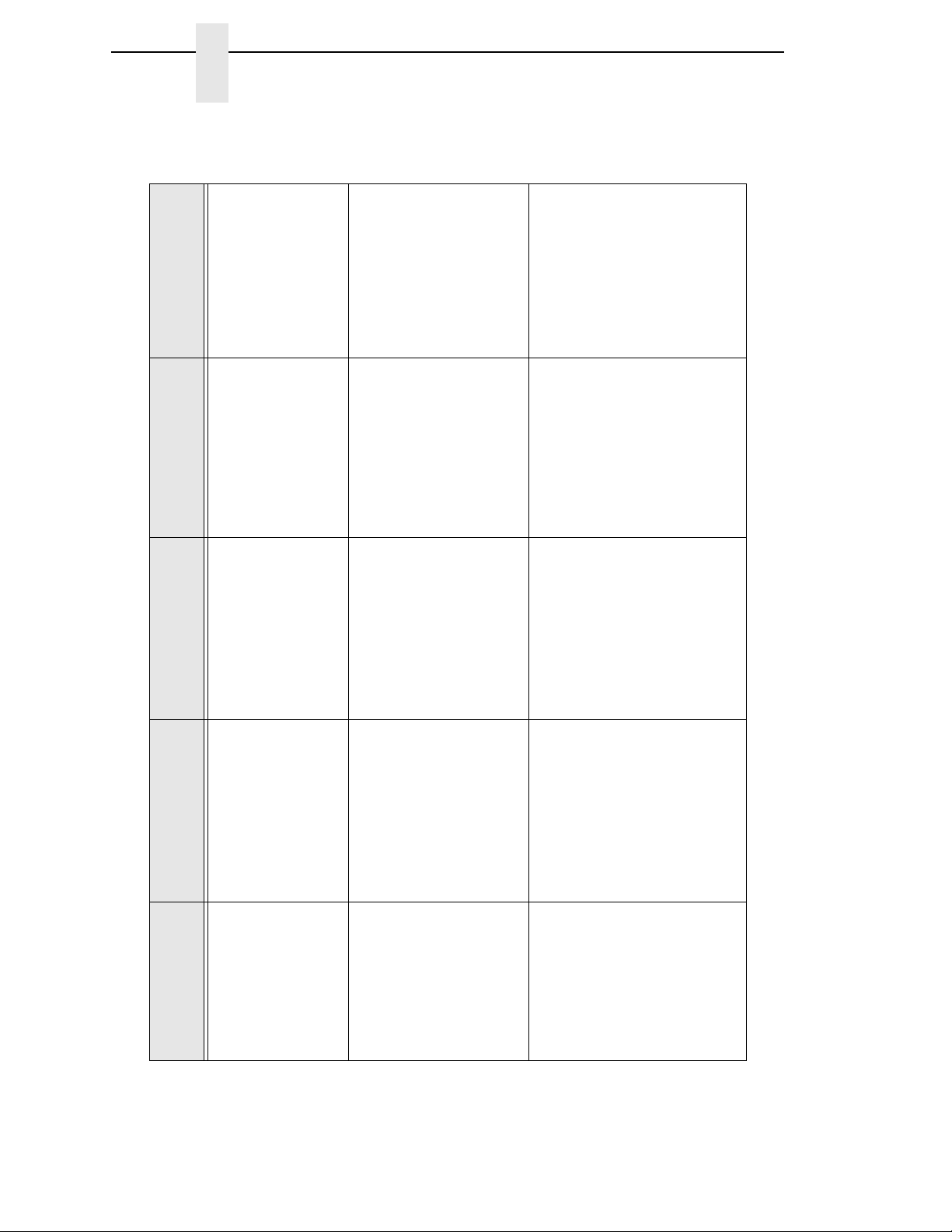

Table 1. The T5R, Smart Ready, and SmartLine Series

®

, Windows®, ASCII, or EBCDIC (with the Coax/

Version

T5204R 10 203 4.1

T5204R DT* 10 203 4.1

SL5204R 10 203 4.1

T5304R 8 300 4.1

T5304R DT* 8 300 4.1

SL5304R 8 300 4.1

SL5304R 8 300 4.1

T5206R 10 203 6.6

SL5206R 10 203 6.6

T5306R 8 300 6.6

SL5306R 8 300 6.6

T5208R 8 203 8.5

T5308R 6 300 8.5

Max Print

Speed ( ips)

Printing

Density (dpi)

Max Print

Width (inches)

* Direct Thermal only 4 inch models (no ribbon transfer support)

11

Page 12

Chapter 1

The SL/T5R Energy Star ™ Family of Printers

St andard Fea tures

•

64MB DRAM memory (fixed).

•

16MB Flash memory (fixed).

•

Auto Label Mapping®: For compatibility with programs written for

Printronix line matrix printers.

•

Bar Codes: Supports over 20 types of bar codes.

•

Download: Fonts, forms, and graphics to printer memory.

•

Emulations:

•

Printronix LinePrinter Plus® (LP+). Provides direct compatibility with

Printronix P-Series printers, Epson FX-1050, Proprinter IIIXL, and

Serial Matrix Printers.

•

Printronix PGL®. Provides printer system commands for text,

barcodes, graphics, lines, and boxes.

•

Printronix VGL. Emulates the QMS Code V™ Version II programming

language to produce on-line forms, bar codes, and alphanumeric text

generation in both normal and high resolution.

•

ZGL, TGL, IGL, STGL, DGL, MGL, and IEGL Interpreters:

ZGL (Zebra®), TGL (TEC®), IGL (Intermec®), STGL (SATO®),

DGL (Datamax®), MGL (Monarch®), and IEGL (IER®) interpreters are

powerful integration tools that allow the SL/T5R to function in virtually

®

all legacy ZPL, TEC, IPL, SATO, DPL™, MPCL II

application environments without requiring modification to host data

stream.

•

High Resolution Printhead: For sharp graphics and text.

•

Label Taken Sensor: Detects removal of labels in Tear-Off mode (and in

Peel-Off mode when optional rewinder is installed).

•

Resident Fonts: Letter Gothic Bold (#93779), Courier Bold (#93952),

CG Triumvirate Bold Condensed (#92250), OCR-A (#90993),

OCR-B (#91409), CG Triumvirate (#92244), CG Triumvirate Bold

(#92248), and CG Times New Roman (#92500).

•

Standard Interfaces:

•

10/100Base Ethernet

•

Network Interface Port: This interface allows you to attach the printer

to a LAN (Local Area Network) rather than attaching it directly to a

host computer. The port is visible on the back panel. The ethernet

port is a 10/100Base and supports data transfer rates up to 100

Mbps. The PrintNet Enterprise Suite (PNE) remote management

software is included with the package. The option is enabled by a

security key.

, and IER

®

12

•

Parallel: Centronics®-compatible parallel, IEEE® 1284 compliant

parallel

Page 13

Optional Features

•

Serial: RS-232

•

USB 2.0 Universal Serial Bus

NOTE: The interface cable needed to connect the printer to the host device is

supplied by the user.

•

Tear-Off Mode: Positions the label at the tear-off position and detects its

removal before printing the next label.

•

Tear-Off Strip Mode: Prints a specified number of labels and positions

the last label at the tear-off position.

•

Thermal Transfer and Direct Thermal Printing: On all printers (except

DT models, which print only in direct thermal mode).

•

Ventless System: For operation in environments with airborne

particulate matter without compromising performance.

Optional Features

Ask your authorized representative about the following enhancement options:

•

Coax/Twinax Host Interface: Provides connection to a host computer

system using a coaxial or twinaxial interface.

•

Fonts: A selection of purchasable fonts can be loaded from the host

computer into printer memory.

•

GPIO (General Purpose Input/Output): Enables a T5R printer to

interface with an external device such as a label applicator system. GPIO

is available as a factory option or field installable kit that also includes a

mating connector for field interface, installation instructions, and operation

manual.

•

Internal Label Rewinder: In label peel-off mode, peels off labels one at a

time before printing the next label and rewinds the liner into a discardable

roll. In batch rewind mode, rewinds printed labels into a removable roll.

•

IPDS: Available for coax/twinax, a NIC, or a combination of both. The

printer may be ordered with this option installed and the required

hardware to support it, or it can be field installed by an authorized service

representative at a later date. The printer must have a coax/twinax

interface or NIC, and 300 dpi printhead installed to support this field

installed option.

NOTE: RFID is not supported in IPDS applications.

•

Media Cutter: Automatically cuts printed media when the media exits the

printer. Available for 4, 6, and 8 inch printers.

•

Media Cutter Tray: Used with the media cutter option to catch and collect

the cut media in a bin.

•

NIC, Wireless: This card provides wireless 802.11b/g connectivity

without expensive cabling and reconfigurations required from a wired

network. PNE is standard with this option.

13

Page 14

Chapter 1

Thermal Printer Technology

•

Online Barcode Validator: Analyzes each bar code to ensure it meets

stringent scanning standards. This inspection validates the symbology

specifications of both linear and PDF417 bar code images. Bad bar code

labels are cancelled and good replacement labels are printed

automatically.

•

RFID MP2 Encoder: The RFID (Radio Frequency Identification) UHF

encoder reads and writes information to smart labels (with embedded

RFID tags) with a pitch typically two to six inches. These labels are used

on shipping cartons and pallets.

NOTE: The RFID encoder is standard on the SL5R, and optional for the T5R.

•

RS-422: Serial interface option.

•

TN5250/TN3270: Enables your printer to communicate with an IBM host

through a network interface using the 5250/3270 datastream. This feature

allows you to use an application generated for the coax/twinax emulation

to be printed through the network interface.

NOTE: RFID is not supported by TN5250/3270 applications.

For more information about printer options, see Appendix B.

Thermal Printer T echnology

Quiet and fast, with excellent print quality, your multifunction thermal printer

uses an inline thermal printhead. The thermal printer operates differently from

a line matrix or laser printer, because the thermal printer uses a printhead with

heating elements and special paper or ribbon.

The Printing Process

The thermal printhead allows two modes of operation:

•

Direct Thermal

During direct thermal printing, the thermal printhead selectively heats

small, rectangular thermal dots. When these contact the coated thermal

paper, the dyes and developers in the coating react to the heat and

develop an image. This mode of printing is generally used for short-term

labeling applications.

•

Thermal Transfer

During thermal transfer printing, the heated thermal dots contact a

thermal ribbon. The heat reacts with the ribbon and bonds the image to

the paper. This method is used especially for abrasive, long-storage

applications and for specialized applications, such as in extreme

environmental conditions or where tamper-proofing is required.

NOTE: Thermal transfer is not supported on 4 inch DT model printers.

14

Page 15

Dynamic Print Control

Dynamic print control is a unique feature of your thermal printer that provides

excellent print quality by preventing unevenness of print density.

Print quality largely depends on how the thermal paper or the thermal ribbon

and thermal transfer paper responds to the heat of the thermal printhead.

During printing, the thermal printhead must reach a set temperature in the

shortest possible time. Then it must cool down to the original temperature in

the shortest possible time after printing. Thus print quality is dependent on the

precise control of the energy supplied to the thermal dots.

The dynamic print control is a method for predicting the quantity of heat

required to print dots based on the results of the previous printing. This

prevents unevenness of print density and results in the printing of narrowladder bar codes or vertical grid lines that are straight from the microscopic

viewpoint.

W arnings and Special Information

Dynamic Print Control

For your safety and to protect valuable equipment, read and comply with all

information highlighted under special headings:

WARNING

WARNING

WARNING

WARNING

WARNING

CAUTION

IMPORTANT

Conditions that could harm you and damage the equipment.

Achten Sie auf folgendes, um keine Personen in Gefahr zu bringen bzw.

das Gerät zu beschädigen.

Condiciones que pueden causar daños a personas y equipos.

Conditions à respecter pour éviter tout danger corporel et dommage

matériel.

Condizioni che possono arrecare danni alle persone e alle

apparecchiature.

Conditions that could damage the printer or related equipment.

Information vital to proper operation of the printer.

NOTE: Information and helpful tips about printer operation.

Manual Conventions

•

Operator panel keys are printed in uppercase letters.

Example: Press the PAUSE key and then press ENTER.

•

Operator panel keys are often shown by their symbol or icon (located on

the control panel directly below the key).

Example: Press the

•

Liquid Crystal Display (LCD) messages are printed in uppercase letters

inside quotation marks ( “ ” ).

↵

key for ENTER.

15

Page 16

Chapter 1

Thermal Consumables

Example: When “OFFLINE” appears on the LCD, you may release the

PAUSE key.

•

LCD fault messages display the specific fault in uppercase letters on the

top line. A corrective action in upper and lowercase letters displays on the

bottom line.

Example: PAPER OUT

•

Key combinations are indicated by the + (plus) symbol.

Example: Press ↑ + ↓ means Press the Up ↑ key and the Down ↓ key at

the same time.

Thermal Consumables

Media Selection

Since there are two print modes of operation, there are two kinds of thermal

media:

Load Paper

•

Direct thermal media

•

Thermal transfer media

Direct thermal media is paper coated with special chemicals that act as an

accelerator, acceptor dye, and binder. During direct thermal mode, the heat

from the thermal printhead contacts the paper and causes a chemical

reaction.

Thermal transfer media requires ribbon. A wide range of Printronix thermal

transfer media is available, such as film or synthetic paper substitutes. Most

of these media options can be die-cut for easy label applications. The wide

selection of media sizes and face stocks have been tested with Printronix

ribbons for print quality and usage. Consult your Genuine Printronix Supplies

Catalog, call the Printronix Customer Support Center (see

access the Printronix web page at www.printronix.com.

NOTE: The term “media” used in this manual refers to all the different kinds

of paper or tag stock that can be used in the printer.

See “Genuine Printronix Media” on page 345 for more information.

page 371), or

16

Page 17

Ribbons

183380a

Tape Strips (2)

Foam Pads (2)

Media Cover

Frame

Printronix offers a wide range of ribbons specifically engineered to enhance

printing capabilities and to prevent premature printhead wear. Therefore, you

should use a Genuine Printronix Thermal Ribbon in your printer.

See “Genuine Printronix Thermal Transfer Ribbons” on page 344 for more

information.

Setting Up the Printer

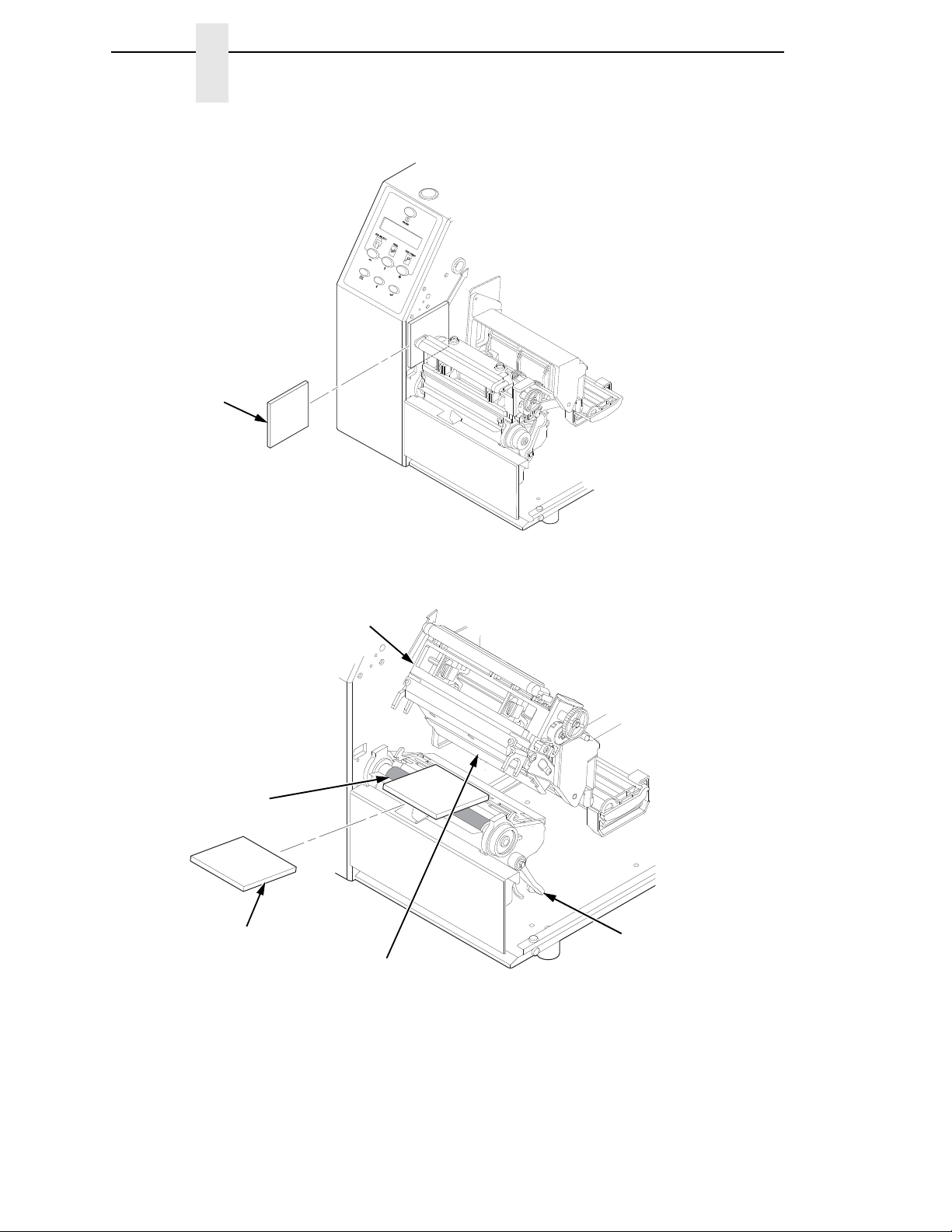

Unpa cking t he Prin ter

The printer is shipped in a carton and protective bag. The top lid of the carton

has instructions for removing the internal packing material. Keep all packing

material in case repacking is required.

Ribbons

CAUTION

CAUTION

Avoid touching the electrical connectors to prevent electrostatic

discharge damage while setting up the printer. The discharge of

accumulated electrostatic energy can damage or destroy the printhead

or electronic components used in this device.

Do not place the printer on its backside during unpacking or handling,

because you may damage the printer interface connector.

1. Remove the tape strips from the media cover. Lift open the media cover.

2. Remove the tape securing the foam pad to the inside of the media cover.

3. Remove the foam pad between the front door and the frame.

17

Page 18

Chapter 1

183381a

Foam

183382a

Foam Pad

Deck Lock

Lever

Pivoting Deck

Platen

Printhead

Setting Up the Printer

4. Remove the foam pad between the pivoting deck and the frame.

5. Open the pivoting deck by rotating the blue deck lock lever fully

clockwise.

6. Remove the foam pad from between the printhead and the platen (rubber

roller).

7. Close the pivoting deck and media cover.

18

Page 19

Installation

Installation

The following sections will guide you through the printer installation process.

1. Place the printer on a flat level surface that allows easy access to all sides

of the printer.

CAUTION

WARNING

CAUTION

Never operate the printer while it is resting on its side or upside down.

2. Check that the printer power switch is in the OFF (O) position.

Failure to properly ground the printer may result in electric shock to the

operator.

In compliance with international safety standards, this printer has been

equipped with a three-pronged power cord. When inserted in a correctly

wired power outlet, the ground conductor will ensure that the printer

chassis is at ground (earth) potential. Do not use adapter plugs or

remove the grounding prong from the cable plug. If an extension cord is

required, ensure that a three-wire cable with a prope rly grounded plug is

used.

3. Attach the AC power cord to the AC power receptacle in the back of the

printer.

Verify the required voltage on the printer’s model number label on the

rear of the printer.

4. Attach the AC power cord to a grounded (three prong) electrical outlet of

the proper voltage.

19

Page 20

Chapter 1

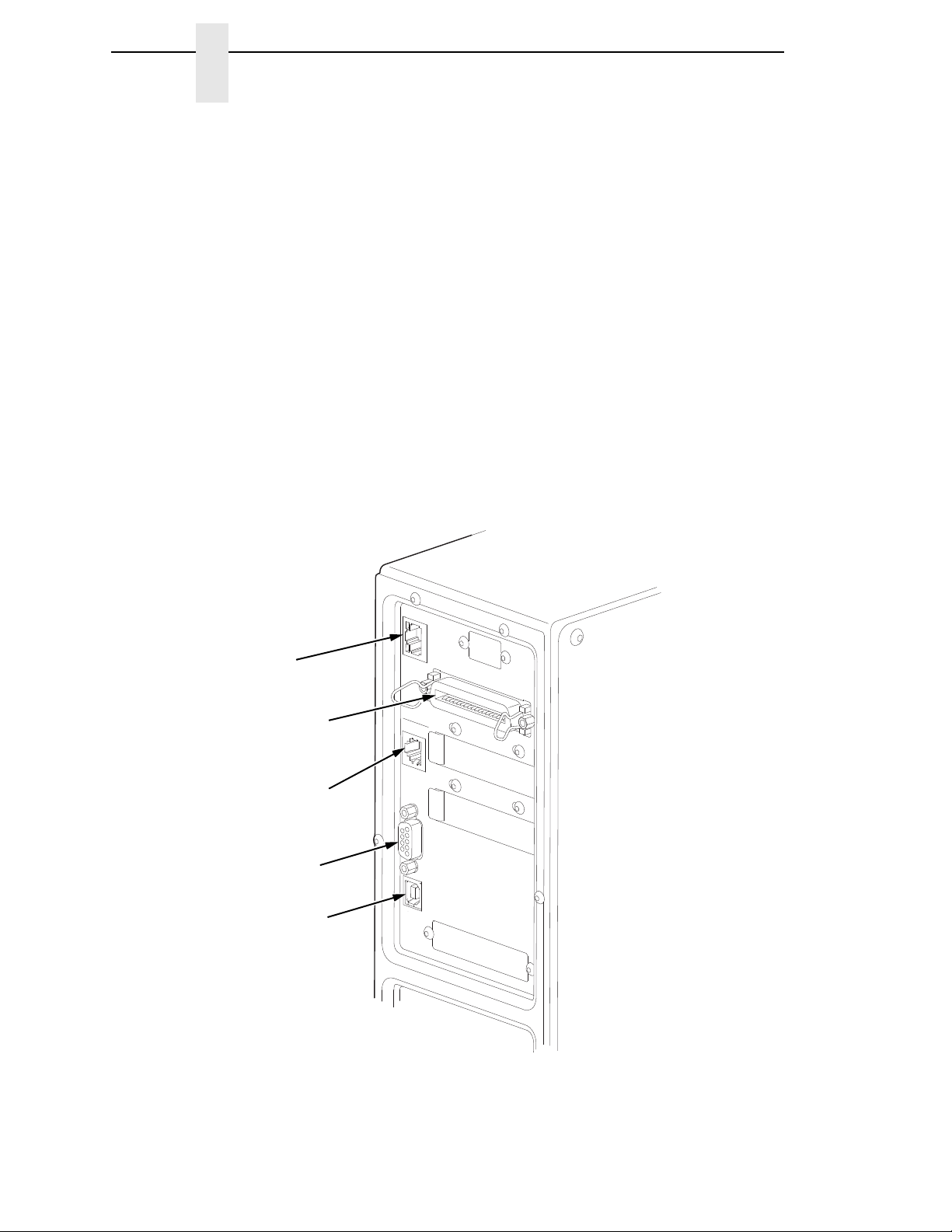

183383a

STATUS

DEBUG

PARA

LLEL

ETHERNET

RS232

GP

I0

USB

Parallel Interface

Serial Interface

Debug Interface

Standard Interface Panel

USB Connection

Ethernet Port

Setting Up the Printer

5. Attach Interface:

a. Parallel Interface

Attach a suitable parallel printer cable from the computer to the

Centronics/IEEE 1284 interface connector at the back of the printer.

Snap the bail locks to the Centronics connector to secure the

interface cable to the printer.

b. Serial Interface

Attach a suitable serial printer cable from the computer to the DB-9

RS-232 serial interface connector at the back of the printer. For

additional information on serial cable wiring, refer to

“Diagnostics and

Troubleshooting” on page 291.

NOTE: The printer supports simultaneous connection of the parallel, serial,

ethernet, and USB interfaces using the Auto Switching feature. Auto

Switching is described on

page 281.

20

Page 21

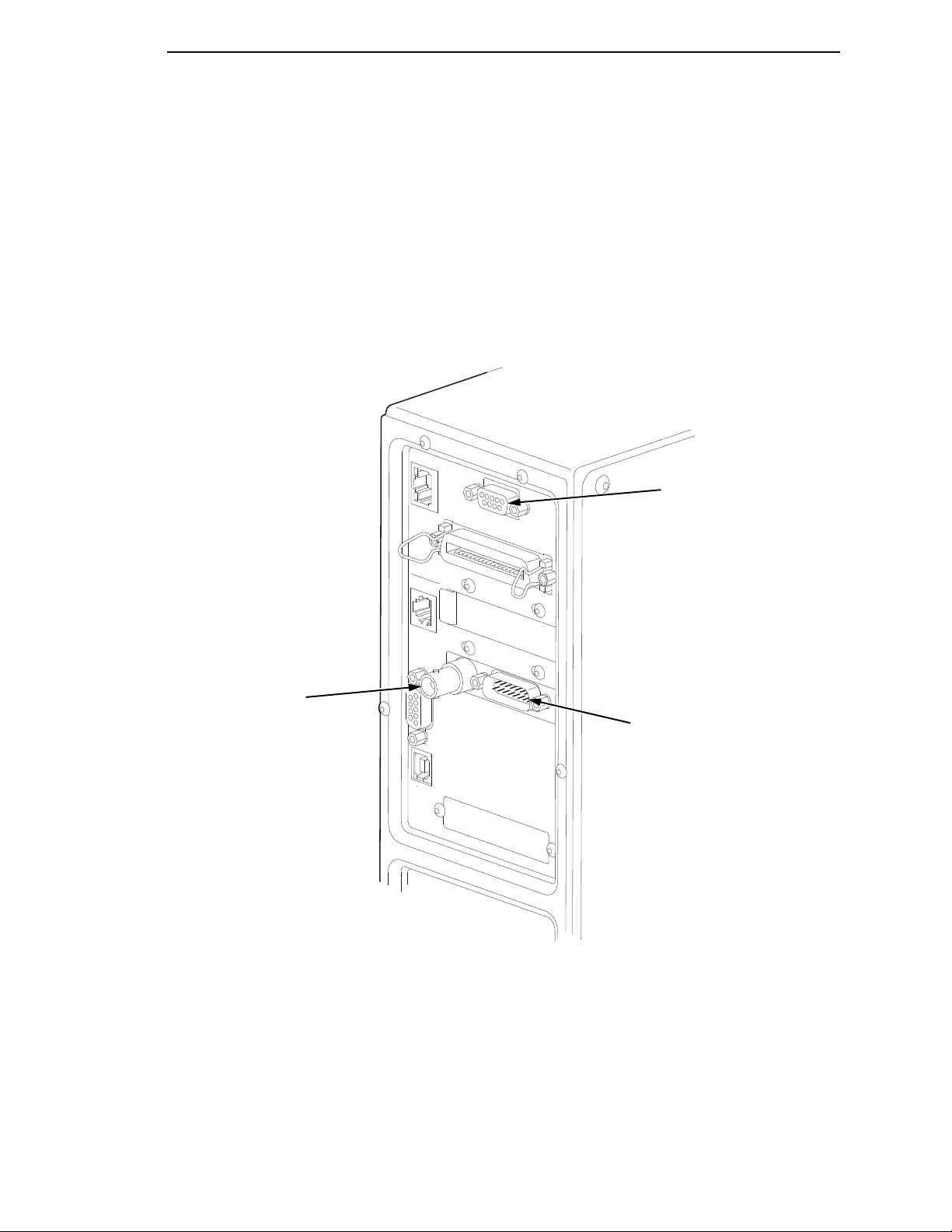

Installation

183384a

STATUS

DEBUG

PARA

LLEL

ETHERNET

RS232

GP

I0

USB

RS-422

Coax Connection

Coax/Twinax and RS-422 Panel

Twinax Connection

If your printer is equipped with the optional Coax/Twinax, and/or optional

RS-422, the rear I/O panel will appear as illustrated below.

NOTE: Autoswitching does not support simultaneous switching between

coax and twinax interfaces. However, autoswitching supports all

interfaces including coax or twinax. Auto Switching is described on

page 281.

21

Page 22

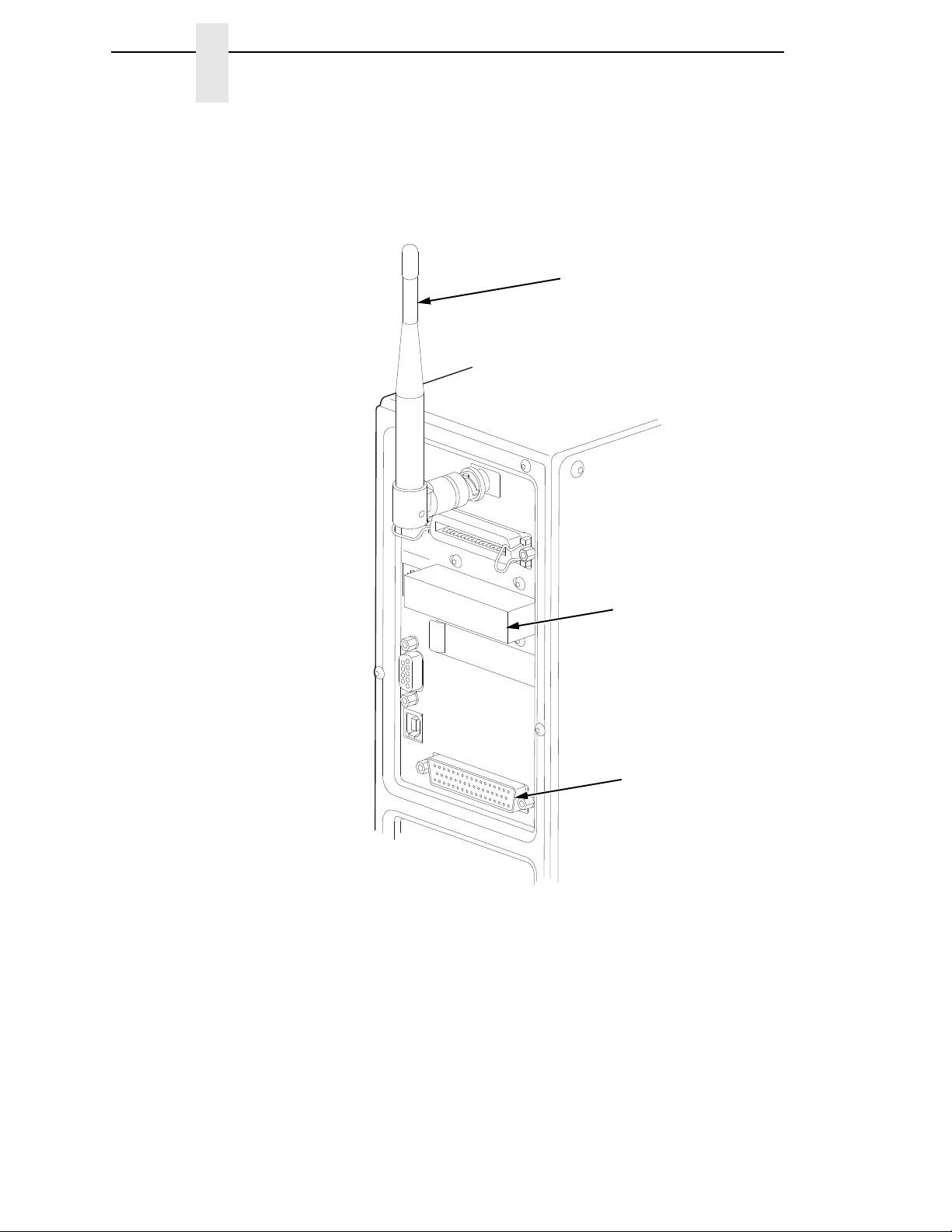

Chapter 1

183385a

STATUS

DEBUG

PARA

LLEL

RS232

GP

I0

USB

Wireless And GPIO Interface Panel

Wireless

Antenna

Wireless

Interface

GPIO

Connection

Setting Up the Printer

If your printer is equipped with the optional Wireless and Optional GPIO it

will appear as illustrated below.

c. Coax Connection

Attach a suitable coaxial cable from the computer to the coax

connector located in the I/O plate in the back of the printer.

d. Twinax Connection

22

Attach a suitable twinax cable from the computer to the twinax

connector located in the I/O plate in the back of the printer.

e. NIC Connection

Insert a suitable NIC cable from your hub or switch to the NIC

connector located in the I/O panel in the rear of your printer.

Page 23

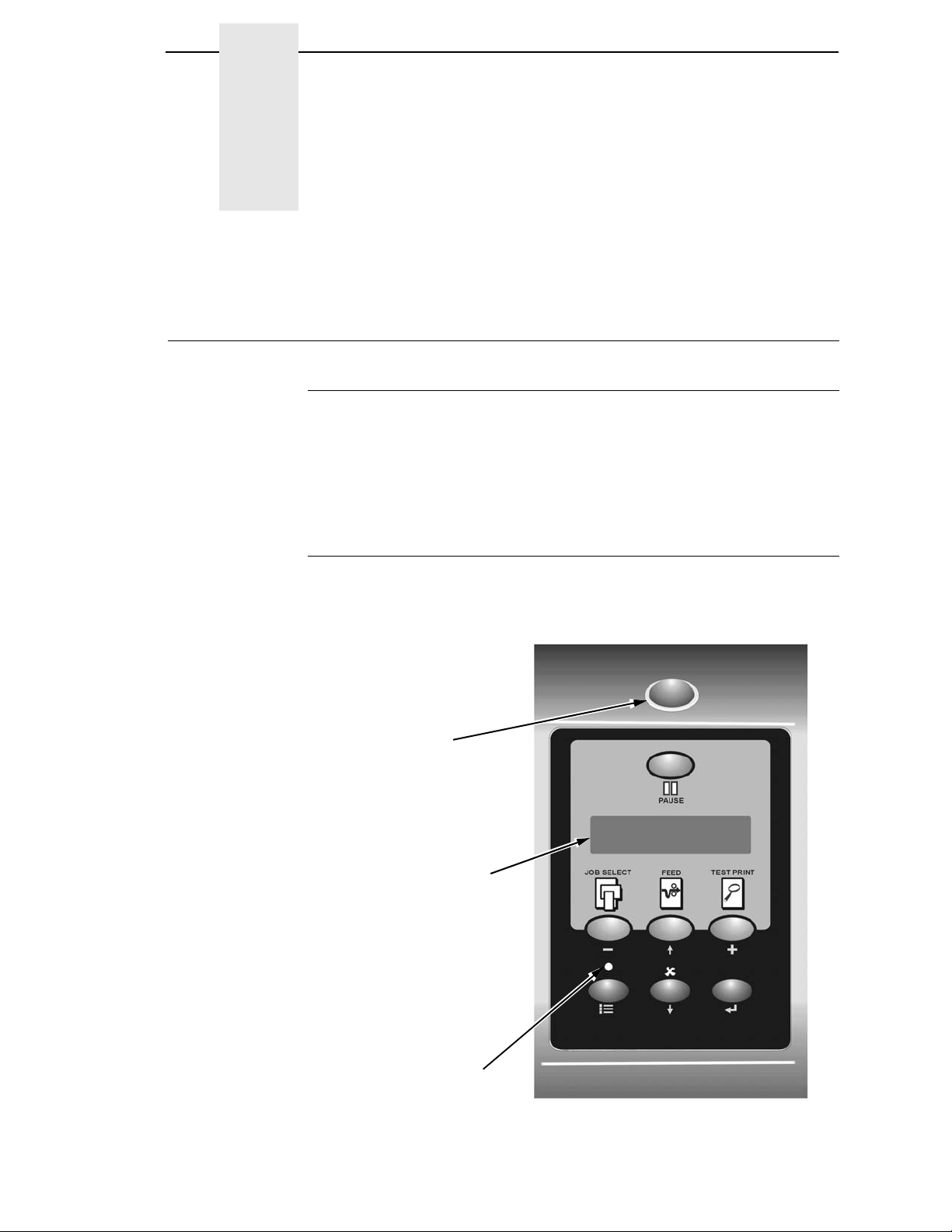

2

OFFLINE

Liquid Crystal

Display (LCD)

Online Status

Indicator

Job In Process

Indicator

Operation

Controls and Indicators

Power Switch

The power switch is located on the bottom back panel of the printer. To apply

power, place the switch in the | (ON) position. When you first power on the

printer, a series of initialization messages will appear on the Liquid Crystal

Display (LCD) on the control panel.

To remove power, place the power switch in the O (OFF) position.

Control Panel

The control panel is located on the front of the printer and includes an LCD,

indicators, and control keys (buttons). These are described in the following

tables. (Also refer to Chapter

3.)

23

Page 24

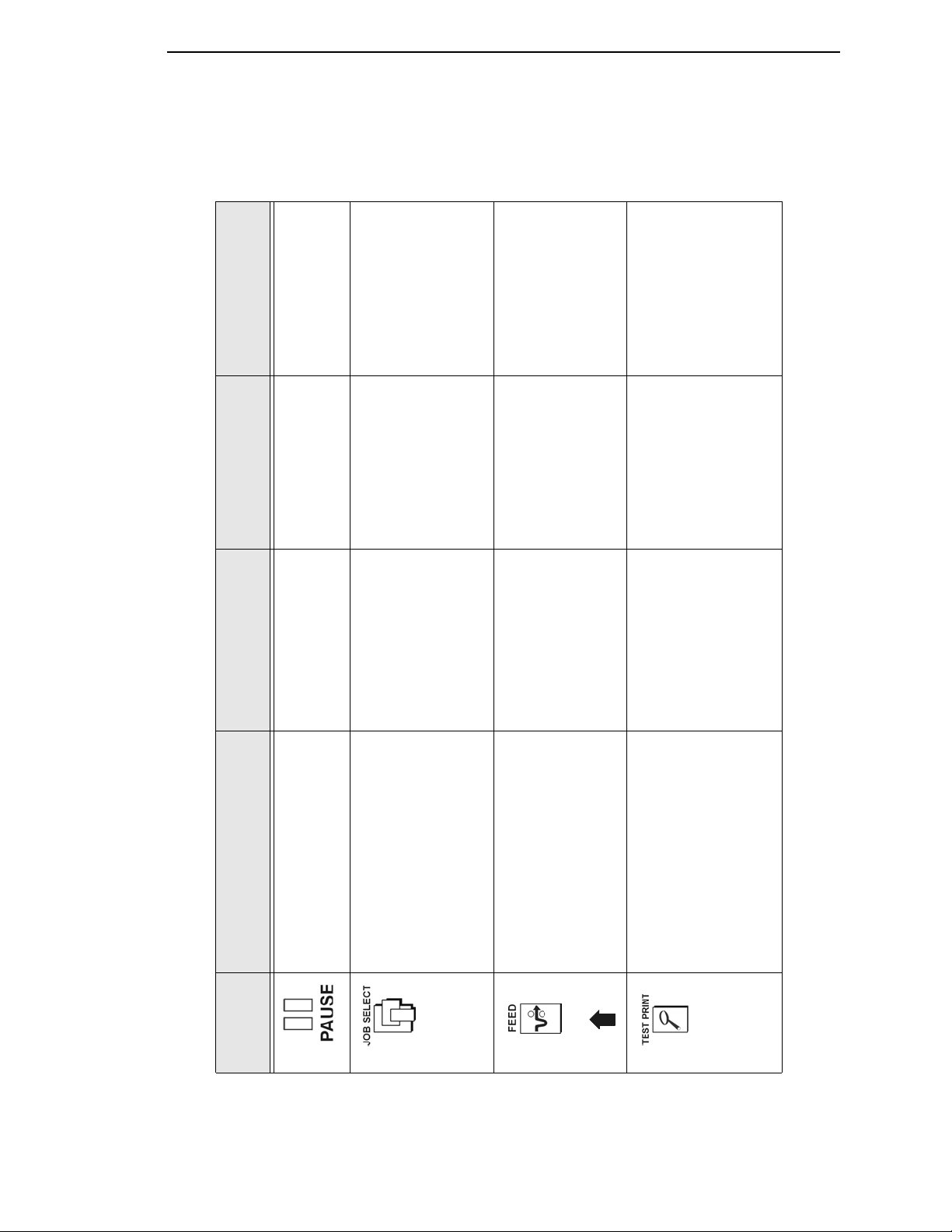

Indicator Description

Function in

Online Mode

Function in

Offline Mode

Function in

Menu Mode

Online Status Indicates when the

printer is online, offline,

or when there is a fault

condition.

Stays lit when the

printer is online, ready

to print, and accept

data from the host.

Flashes during a fault

condition.

Off when the printer is

offline.

Flashes during a fault

condition.

Off.

Flashes during a fault

condition.

Liquid Crystal

Display (LCD)

A backlighted liquid

crystal display with two

rows of 16 characters

each.

Displays “ONLINE,” the

interface type, and

emulation in use.

During a fault condition,

displays the specific

fault message and the

corrective action.

Displays “OFFLINE.”

During a fault

condition, displays the

specific fault message

and the corrective

action.

Displays main menu,

submenu, or option.

During a fault

condition, displays the

specific fault message

and the corrective

action.

Job In Process Indicates when the

printer is receiving or

processing data.

Flashes when receiving

data. Stays lit when data has

been processed and is

waiting to be printed.

Off when no data is

being received or when

no data remains in the

buffer.

Flashes when

receiving data. Stays lit when data has

been processed and is

waiting to be printed.

Off when no data is

being received or when

no data remains in the

buffer.

None

Chapter 2

Controls and Indicators

Sta tus and Display Indicators

24

Page 25

Button Description

Function in

Online Mode

Function in

Offline Mode

Function in

Menu Mode

PAUSE Key

Toggles the printer between

Online and Offline Modes.

Sets printer to Offline

Mode.

Sets printer to Online

Mode.

Sets printer to Offline

Mode.

JOB SELECT Key None Displays the name

and number of the last

loaded configuration

and allows you to load

the factory and/or

pre-stored printer

configurations.

Scrolls left through

main menus.

Decrements option

values within

submenus.

-

DECREMENT Key in

Menu Mode

FEED Key

UP Key in Menu Mode

Advances the media

one label length.

Advances the media

one label length.

Scrolls the current

menu selection one

level up.

TEST PRINT Key

Pressing the ↵ (ENTER) key

with a Diagnostic Test displayed

initiates the test. Pressing ↵

again terminates the test.

None Selects the Printer

Tests menu and

scrolls through the

Test Print patterns.

See “Printer Tests” on

page 226.

Scrolls right through

main menus.

Increments option

values within

submenus.

+

INCREMENT Key in

Menu Mode

Control Panel

Control Panel Keys

25

Page 26

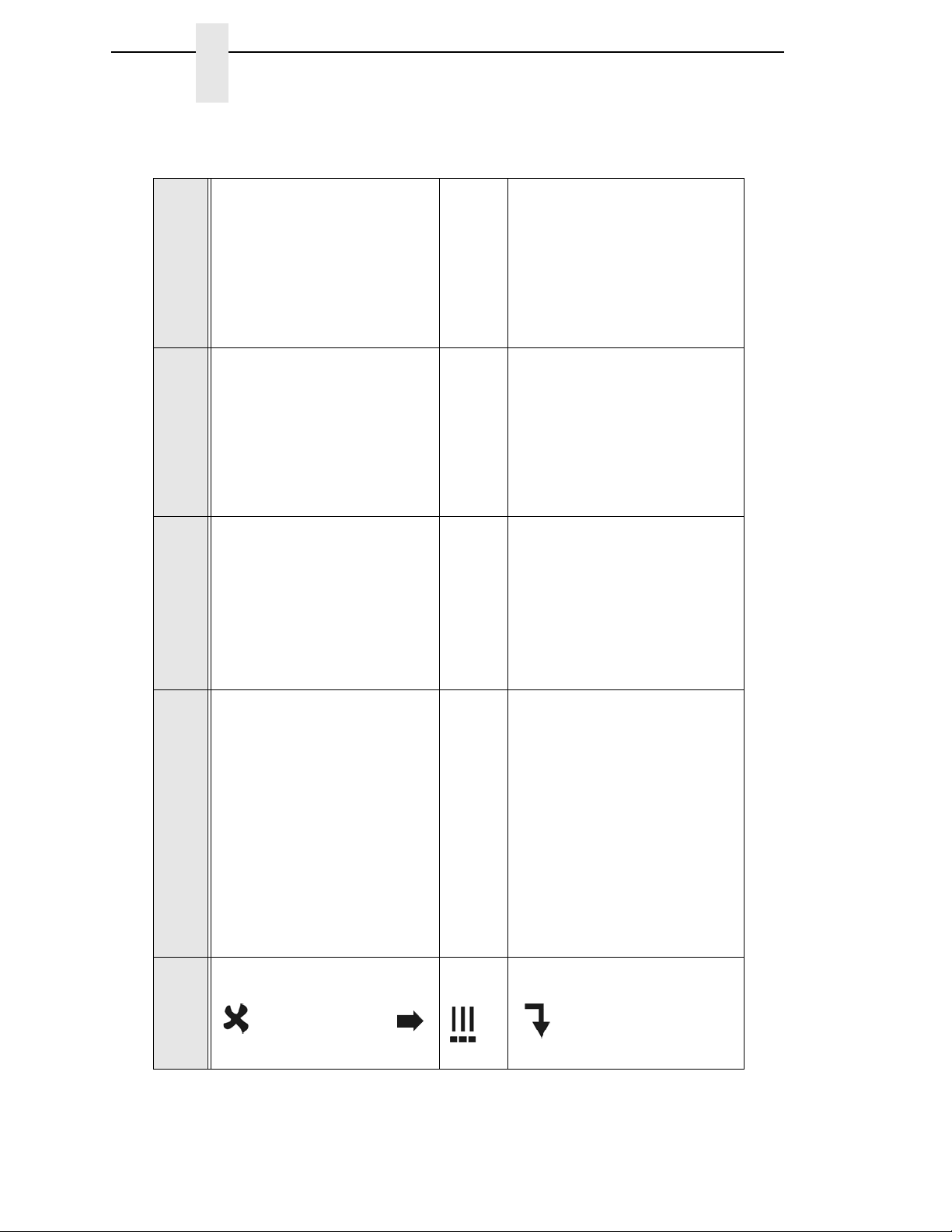

Button Description

Function in

Online Mode

Function in

Offline Mode

Function in

Menu Mode

CANCEL Key

When the CANCEL key is enabled,

pressing it will clear all data in the

printer buffer and prevent printing of

that data.

Note: The factory default = Disable.

However, when the Coax/Twinax

Interface option is installed, the

factory default = Enable.

DOWN Key in Menu Mode

None Clears all data in the

printer data buffer

when enabled.

Scrolls the current

menu selection one

level down.

MENU Key Takes the printer

Offline and selects the

Menu Mode.

Selects the Menu

Mode.

Scrolls between main

menu selections.

ENTER Key

Pressing the ↵ (ENTER) key in

Menu Mode selects the displayed

option or value. An asterisk then

appears next to the option or value

indicating it has been selected.

Note: If the ENTER key is locked,

“ENTER SWITCH LOCKED”

displays on the LCD for one second.

Press the (DOWN) and

↵ (ENTER) keys at the same time to

unlock the ENTER key.

None None Selects the current

menu value and

displays an asterisk

(*) next to the value.

Chapter 2

Controls and Indicators

Control Panel Keys (co nt.)

26

Page 27

Powering On the Printer

Powering On the Printer

When you power on the printer, it executes a self-test. During the self-test, the

LCD momentarily displays the DPI resolution (203 or 300 DPI) of the installed

printhead. The default power-on state is online. Once the printer has

successfully initialized, the ONLINE status indicator light illuminates, and the

LCD indicates the communication interface selected and the emulation

selected.

If there is a fault during the self-test, the ONLINE status indicator flashes, and

a fault message appears on the display. The alarm may also sound, if

configured to do so.

Operating Modes

The current operating mode can be selected through the control panel keys or

can result from routine operations such as powering on the printer.

Online: In online mode, the printer can receive and print data sent from the

host. Pressing the PAUSE key toggles the printer between the online and

offline modes. The ONLINE status indicator is lit in online mode.

Offline: In offline mode, you can perform operator functions such as loading

media or changing ribbon. Pressing the PAUSE key toggles the printer from

offline to online mode. The ONLINE status indicator is not illuminated in offline

mode.

Menu: Pressing the MENU key takes the printer offline and into Menu mode.

In this mode, you can navigate through all configuration and status menus

and change the printer configuration.

Fault: In fault mode, a fault condition exists that must be cleared before

printing can continue. The ONLINE status indicator flashes, the alarm beeps

(if configured to do so), and a descriptive fault message displays.

Before normal printing can continue, the fault must be corrected, the message

cleared by pressing the PAUSE key, and the printer placed online.

Media Handling Modes

Before you load media, you must decide which media handling mode to use:

•

Continuous. Prints on the media and sends it out the front of the printer.

When the optional internal rewinder is installed, use “Continuous” for

Batch Rewind mode (see

•

Tear-Off Strip. Prints on the media and sends it out the front until the

print buffer is empty then positions the last label over the tear bar for

removal.

•

Tear-Off. After each label is printed, the printer positions the label over

the tear bar and waits for you to tear off the label before printing the next

label (on-demand printing). A “Remove Label” message will display to

remind you to remove the label before the next one can be printed.

page 43).

27

Page 28

Chapter 2

Loading Media and Ribbon

•

Peel-Off. When the optional internal rewinder is installed, the printer

prints and peels die-cut labels from the liner without user assistance. The

label liner is wound on the rewinder. The printer waits for you to take

away the label before printing the next one (on-demand printing). A

“Remove Label” message will display to remind you to remove the label

before the next one can be printed. For Label Peel-off information, see

page 48.

•

Cut. When the optional media cutter is installed, the printer automatically

cuts media after each label is printed or can cut the media after a

specified number of labels have been printed using a software cut

command.

Once you have decided on the mode, configure the printer. See Chapter 3 for

more information.

Loading Media and Ribbon

NOTE: This section describes the procedures for loading various types of

media and ribbon. You can also refer to instructions on the printer

itself, on a label on the inside of the media cover.

CAUTION

CAUTION

IMPORTANT

The term “media” in this manual refers to all the different kinds of paper, label,

or tag stock material that can be printed on by the printer. Your thermal printer

can print on continuous paper, adhesive backed labels, or non-adhesive tags

packaged in roll or fanfold form.

DO NOT TOUCH the printhead or the electronic components under the

printhead assembly. The discharge of electrostatic energy that

accumulates on the surface of the human body or other surfaces can

damage or destroy the printhead or electronic components used in this

device.

Do not close the pivoting deck without label stock installed between the

printhead and the platen, because debris on the platen may damage the

printhead.

Adhesive backed labels that DO NOT lay flat on the liner can jam the

printer. This can cause the label to peel off the liner. The exposed edges

can stick to the label guides and rollers inside the printer.

If you run out of labels while printing, do not turn off the printer while

reloading labels, because you can lose data.

28

Page 29

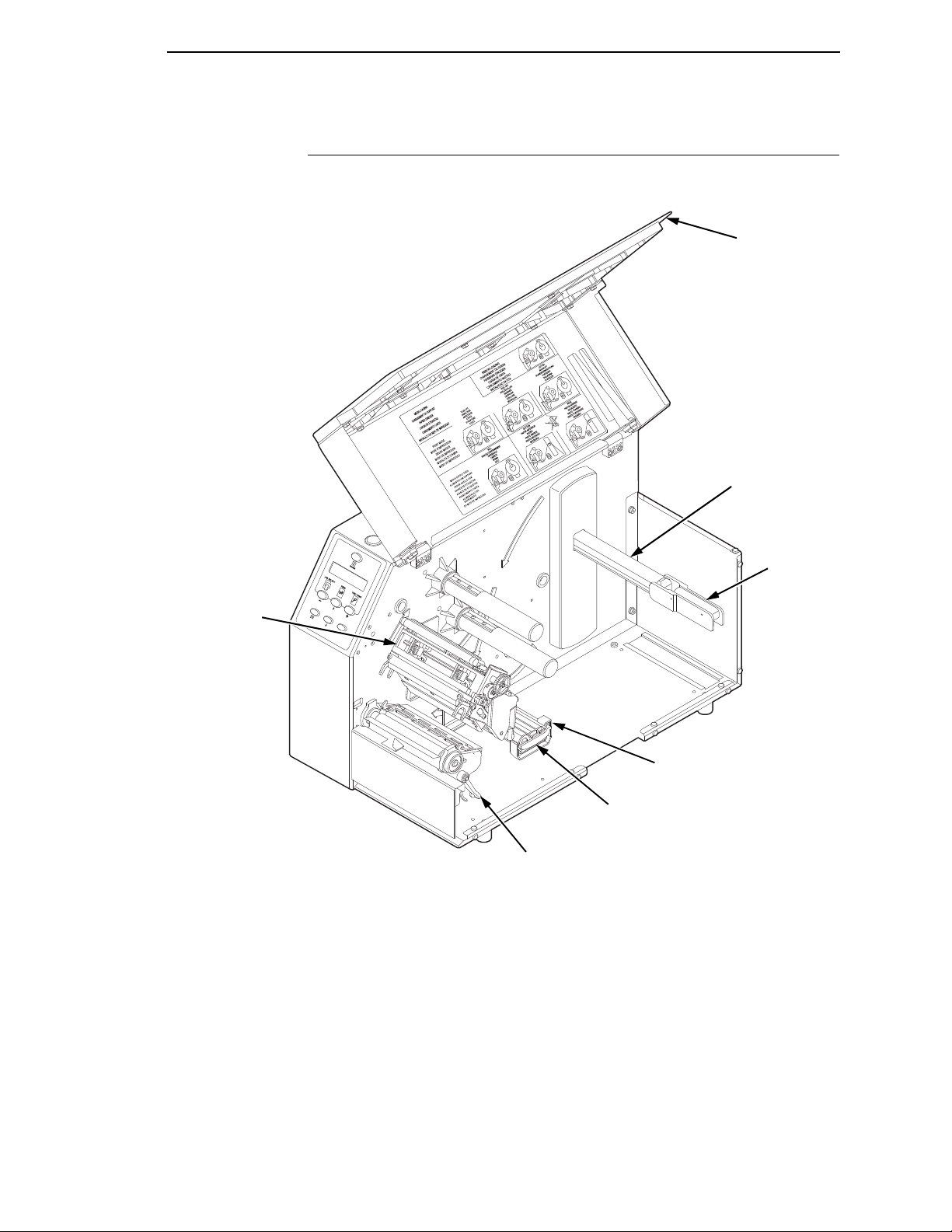

Loading Roll Media

183386a

Media Hanger

Media

Hanger

Guide

Media Width

Guide

Deck Lock Lever

Pivoting

Deck

Media Cover

Media Damper

Loading Roll Media

1. Open the media cover.

2. Slide the blue media hanger guide outward to the end of the media

hanger, and flip it up horizontally.

3. Open the pivoting deck by rotating the blue deck lock lever fully

clockwise.

4. Slide the blue media width guide close to the outside end of the media

damper.

29

Page 30

Chapter 2

183387a

Media Roll

Media Hanger

Guide

Media Hanger

Loading Media and Ribbon

30

5. Slide a roll of media onto and towards the back of the media hanger. The

media feeds from the top of the roll and towards the front of the printer.

6. Place the media hanger guide under the media hanger and against the

lower part of the label core at a 45 degree angle (as shown). This position

provides the required tension for a new label roll and the desired drag for

a partial label roll.

Page 31

Loading Roll Media

183388a

Media Damper

Printhead

Platen (Rubber

Drive Roller)

Media and

Ribbon Loading

Instruction

Media

7. Thread the media under the media damper and then between the platen

(rubber drive roller) and the printhead.

You can also refer to the arrows on the printer frame or to the label inside

the media cover for media loading instructions.

31

Page 32

Chapter 2

183389a

Media Sensor

Handle

Media Guard

Lower Media

Sensor

Fixed Guide

Media Damper

Media Width

Guide

Loading Media and Ribbon

8. Verify that the left (inside) edge of the media is against the fixed guide on

the bottom of the media damper.

9. Push the blue media width guide in until it is flush with the outer edge of

the media.

10. Check the horizontal position of the lower media sensor (located under

the media guard), and refer to

“Positioning the Media Sensors” on

page 54.

32

Page 33

Loading Roll Media

183390a

Upper

Sensor

Visible Red Beam

Lower Sensor

Upper Sensor

Handle

Media Guard

Opening

183391a

Guide Notch

Media

(left edge)

11. Slide the upper sensor directly over the lower sensor.

12. Align the left (inside) edge of the media with the guide notch located on

the front edge of the tear bar.

33

Page 34

Chapter 2

183392a

Deck Lock Lever

Pivoting

Deck

Loading Media and Ribbon

IMPORTANT

13. Close the pivoting deck and rotate the deck lock lever fully

counterclockwise. This locks the pivoting deck and printhead assembly

into the printing position.

Ensure the pivoting deck is down and locked before attempting to

advance media or print. Failure to do so will cause the “PRINTHEAD UP”

fault message to display.

14. Verify that Print Mode in the printer configuration menu is set for the

media type installed (Direct or Transfer). The Print Mode submenu is

located in the QUICK SETUP menu. See

“Main Menu” on page 84 for

details.

15. Verify the printhead pressure is properly set. See “Printhead Pressure

Adjustment” on page 52.

16. Verify the pressure blocks are properly positioned. See “Printhead

Pressure Block Adjustments” on page 53.

17. Verify the Gap/Mark Sensor selection matches the type of media

installed. See

“Sensing Different Media Types” on page 59.

34

Page 35

Loading Roll Media

For direct thermal operation (no ribbon required):

•

If you have not run an Auto Calibrate, do so now. See “Running Auto

Calibrate” on page 60.

•

If you have already run an Auto Calibrate, complete the following

steps:

a. Close the media cover.

b. Press the FEED key once to verify that the media advances.

c. Press the PAUSE key to place the printer online.

For thermal transfer operation (which uses a ribbon):

Complete the ribbon loading procedure (see “Loading Ribbon” on

page 40).

35

Page 36

Chapter 2

183393a

Media

Hanger

Fanfold

Media

Media

Hanger

Guide

Fanfold

Tension

Arm

Deck Lock Lever

Pivoting

Deck

Media Cover

Bottom Panel

Opening

Loading Media and Ribbon

Loading Fanfold Media

CAUTION

36

1. Open the media cover.

2. Slide the media hanger guide outward to the end of the media hanger and

rotate it upward to a horizontal position to remove any roll media.

3. Place the fanfold media either behind or beneath the printer, depending

on the desired fanfold supply location. Insert the first few labels through

either the rear or bottom panel opening.

4. Place the media over the media hanger, flush against the back of the

printer.

5. Flip up the media hanger guide and slide it in against the outer edge of

the fanfold media.

6. Flip the fanfold tension arm down by pushing on it through the opening at

the top of the media hanger guide.

Do not allow the tension arm to snap down on the media hanger, this

could cause the tension arm to break. Instead, gradually lower the

tension arm onto the media hanger.

7. Open the pivoting deck by rotating the deck lock lever fully clockwise until

the deck swings upward.

Page 37

Loading Fanfold Media

183389a

Media Sensor

Handle

Media Guard

Lower Media

Sensor

Fixed Guide

Media Damper

Media Width

Guide

8. Slide the media width guide outward to the end of the media damper.

9. Thread the media under the media damper and then between the platen

(rubber drive roller) and the printhead. You can also refer to the arrows on

the printer frame or to the label inside the media cover for media loading

instructions.

Verify that the left (inside) edge of the media is against the fixed guide on

the bottom of the media damper.

10. Slide the media width guide inward against the outer edge of the media.

11. Check the horizontal position of the lower media sensor (located under

the media guard), and refer to

“Positioning the Media Sensors” on

page 54.

37

Page 38

Chapter 2

183391a

Guide Notch

Media

(left edge)

183392a

Deck Lock Lever

Pivoting

Deck

Loading Media and Ribbon

12. Align the left (inside) edge of the media with the guide notch located on

the front edge of the tear bar.

IMPORTANT

38

13. Close the pivoting deck and rotate the deck lock lever fully

counterclockwise. This locks the pivoting deck and printhead assembly

into the printing position.

Ensure the pivoting deck is down and locked before attempting to

advance media or print. Failure to do so will cause the “PRINTHEAD UP”

fault message to display.

14. Verify that Print Mode submenu is set for the media type installed (direct

or transfer). The Print Mode submenu is located in the QUICK SETUP

menu. See

“Main Menu” on page 84 for more information. Also, if thermal

transfer media is installed, see “Loading Ribbon” on page 40.

Page 39

Loading Fanfold Media

15. Verify the printhead pressure is properly set. See “Printhead Pressure

Adjustment” on page 52.

16. Verify the pressure blocks are properly positioned. See “Printhead

Pressure Block Adjustments” on page 53.

17. Verify the Gap/Mark Sensor selection matches the type of media

installed. See

For direct thermal operation (no ribbon required):

•

If you have not run an Auto Calibrate, do so now. See “Running Auto

Calibrate” on page 60.

•

If you have already run an Auto Calibrate, complete the following

steps:

a. Close the media cover.

b. Press the FEED key once to verify that the media advances.

c. Press the PAUSE key to place the printer online.

For thermal transfer operation (which uses a ribbon):

“Sensing Different Media Types” on page 59.

Complete the ribbon loading procedure (see “Loading Ribbon” on

page 40).

39

Page 40

Chapter 2

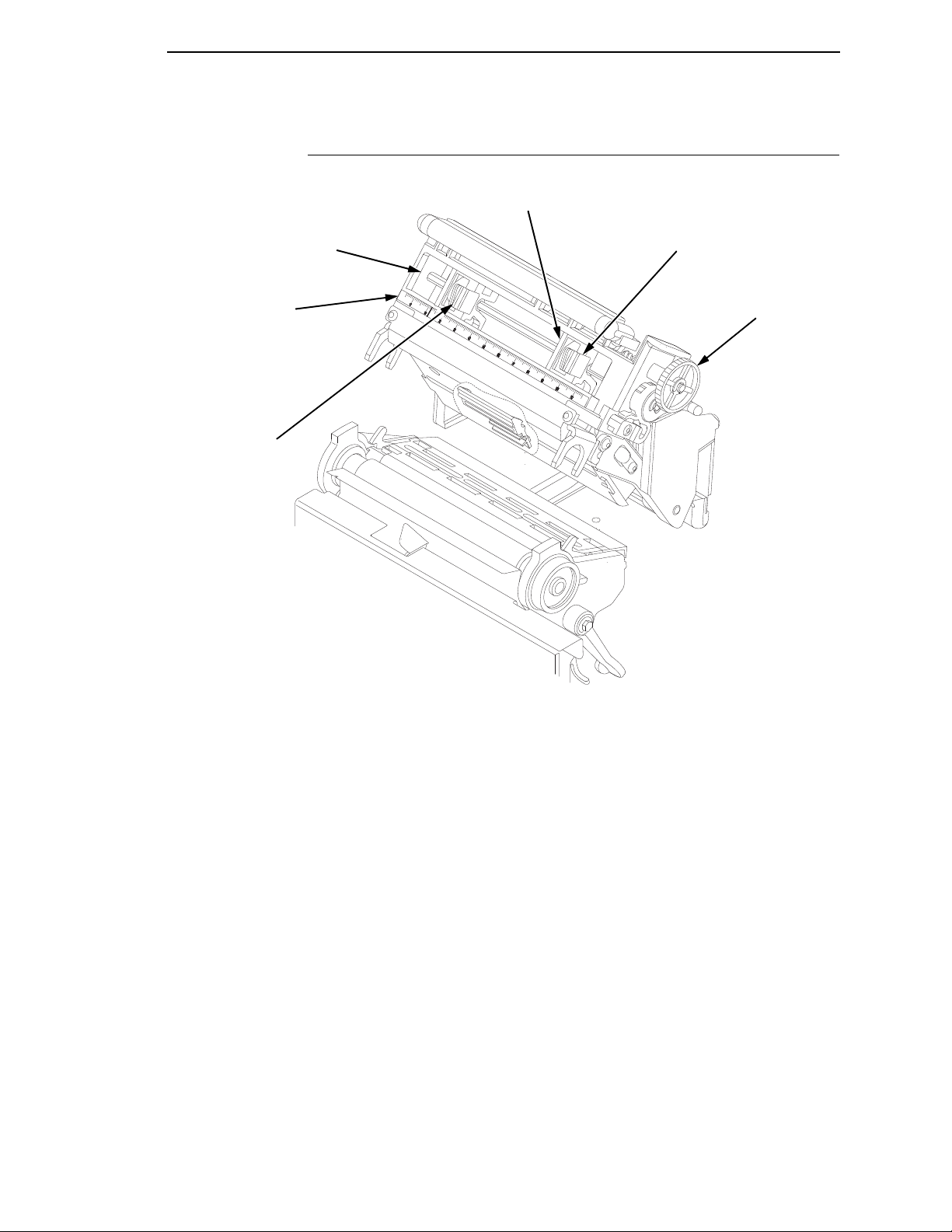

183394a

Ribbon Roll

Ribbon Supply

Spindle

Deck Lock

Lever

Pivoting

Deck

Ribbon

Take-Up Core

Ribbon

Take-up

Spindle

Loading Media and Ribbon

Loading Ribbon

Skip this section for 4 inch DT models or when using direct

thermal printing.

1. Install the ribbon take-up core on the ribbon take-up spindle.

NOTE: The first ribbon take-up core comes with the printer. Thereafter, use

the core from the old (used up) ribbon.

2. Slide the ribbon roll onto the ribbon supply spindle until it stops against

the spindle flange.

3. Open the pivoting deck by rotating the deck lock lever fully clockwise until

the deck swings upward.

40

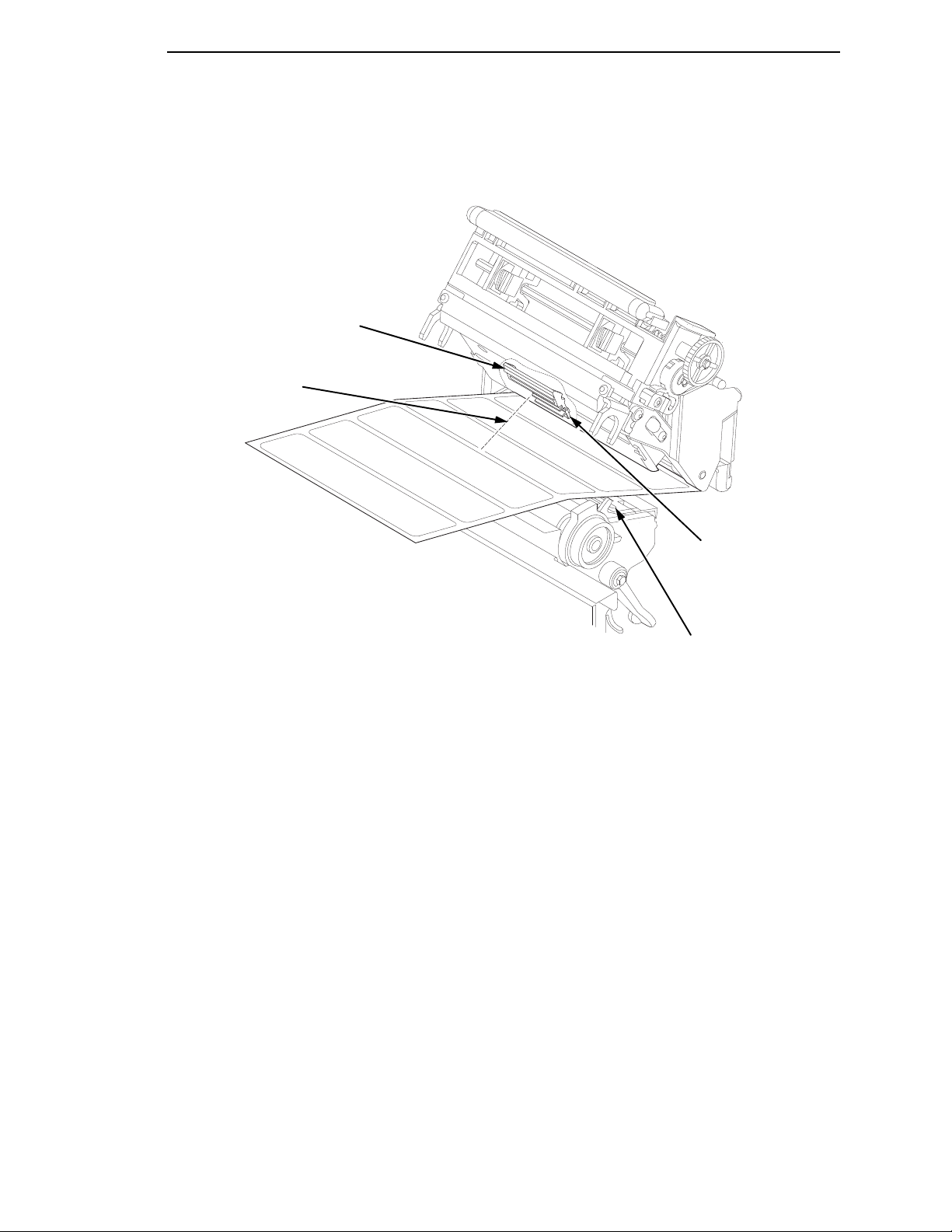

Page 41

Loading Ribbon

183395 REV

183395a

Media

Printhead

Rear Ribbon Guide Roller

Ribbon

4. Thread the end of the ribbon under the rear ribbon guide roller, then

between the platen and the printhead.

You can also refer to the arrows on the printer frame or to the upper-right

corner of the label inside the media cover for ribbon loading instructions.

41

Page 42

Chapter 2

183396a

Ribbon

Take-up Spindle

Ribbon

Take-up Core

Media Cover

Media and Ribbon

Loading Instructions

Loading Media and Ribbon

IMPORTANT

Do not attach the ribbon to the ribbon take-up spindle without a

fiberboard take-up core installed.

5. Attach the ribbon to the ribbon take-up core on the ribbon take-up spindle

using the adhesive on the ribbon leader.

6. Manually rotate the spindle clockwise until the clear leader has passed

the printhead.

7. Close the pivoting deck and rotate the deck lock lever fully

counterclockwise.

8. Verify that Print Mode (in the QUICK SETUP menu) is set for Transfer.

See

“QUICK SETUP” on page 95 for more information.

9. If you have not run an Auto Calibrate with this media and ribbon, do so

now. See

“Running Auto Calibrate” on page 60.

10. Press the FEED key once to verify that the media and ribbon advance.

11. Press the PAUSE key to place the printer online.

12. Close the printer media cover if the rewinder is not needed.

42

Page 43

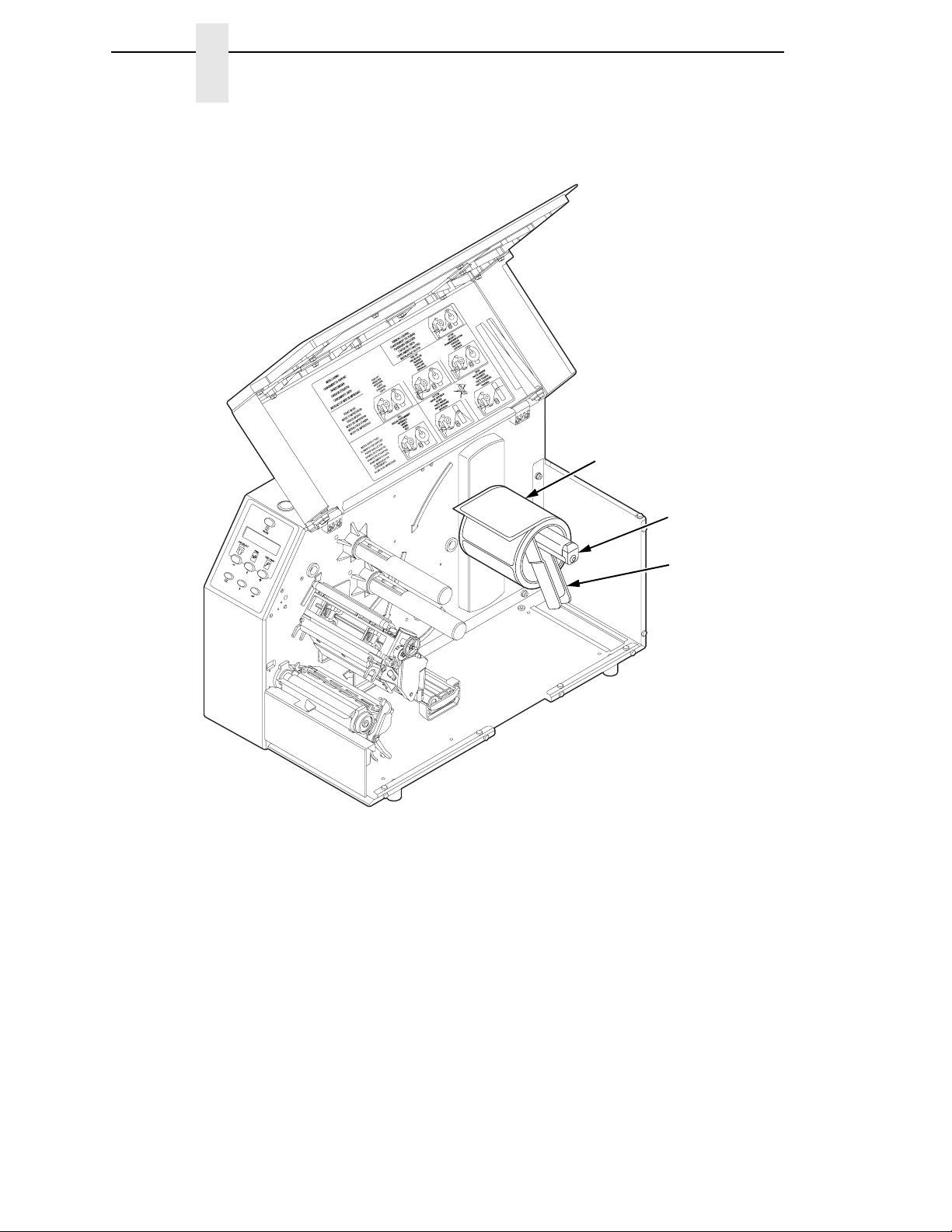

Using the Optional Internal Rewinder

183397a

Paper

Path

Groove

Hook

Front Door

The printer can be set up to rewind labels after they have been printed (Batch

Rewind Mode) or to automatically peel labels from their backing and dispense

them one at a time while rewinding the liner (Peel-Off Mode). Both modes

require an internal rewinder, which is available as a factory installed or a field

unit option.

Batch Rewind Mode

Batch Rewind allows you to automatically rewind printed labels into a roll

using the optional internal rewinder.

Configuring the Printer Menu

1. Set Media Handling to “Continuous” under the QUICK SETUP menu.

(See Chapter

2. Press the PAUSE key until “OFFLINE” displays.

3, “Configuring The Printer” for more information.)

Batch Rewind Mode

Installing the Paper Path

The paper path must be installed when using Batch Rewind mode.

To install the paper path:

1. Open the front door by pulling it upwards, then forward.

43

Page 44

Chapter 2

183398a

Rewinder

Rewinder

Release Lever

Using the Optional Internal Rewinder

2. The bottom of the plastic paper path is shaped like a hook and the top has

a groove:

a. Hook the bottom of the paper path under the bottom edge of the front

door.

b. Snap the groove on the paper path to the top edge of the front door.

3. Close the front door.

Loading Media

44

1. To load media, refer to “Loading Roll Media” on page 29 and complete

steps 1 through 10.

Page 45

Batch Rewind Mode

183399a

Rewinder Release Lever

Slot

Paper

Path

Media

183400a

Back Flange

Raised Ridge

Slot

Rewinder Release

Lever

Media or Liner

IMPORTANT

2. Thread the media over the front of the paper path and through the

opening under the front door toward the internal rewinder.

If you do not complete the following step, it will be extremely difficult to

remove the printed labels from the rewinder.

3. Turn the release lever on the rewinder counterclockwise and lock it in

place. This forms a raised ridge along the width of the rewinder.

4. Insert the leading edge of the media into the closest slot of the rewinder,

5. Hold the media edge in the slot and manually rotate the rewinder one full

and slide the media against the back flange.

revolution counterclockwise until the media is taut.

45

Page 46

Chapter 2

183401a

Deck Lock Lever

Media Cover

Using the Optional Internal Rewinder

IMPORTANT

6. Press down on both sides of the pivoting deck and rotate the deck lock

lever counterclockwise against its stop to place the printhead assembly

into the printing position.

7. Press the FEED key to advance the media to the next TOF (Top-of-Form)

position.

8. Press the PAUSE key until “ONLINE” displays.

9. Close the media cover.

The rewinder supports a maximum diameter of five inches of printed

labels. Exceeding this diameter can cause printed labels to rub on the

bottom pan.

46

Page 47

Removing Printed Media from the Rewinder

183401a

Printhead

Release

Lever

Rewinder

Batch Rewind Mode

1. Open the media cover.

2. Press the FEED key to advance the last printed label past the printhead,

and tear the liner from behind the last printed label.

3. Manually rewind the remaining printed labels onto the rewinder by turning

the rewinder counterclockwise.

4. Turn the release lever on the rewinder clockwise.

5. Slide the roll of printed labels off the rewinder.

47

Page 48

Chapter 2

183402a

Pivoting

Deck

Deck Lock

Lever

Bottom Roller

Tear Bar

Paper Path

Using the Optional Internal Rewinder

Label Peel-Off

You can set up the printer to automatically peel die-cut labels off their liner

(backing) and dispense them one at a time while rewinding the liner.

You can install the paper path to prevent long labels from accidentally

adhering to the front door assembly, but it is normally not needed when using

labels less than two inches long (see

Configuring the Printer Menu

1. Set Media Handling to “Peel-Off” under the QUICK SETUP menu. (See

Chapter

2. Press the PAUSE key until “OFFLINE” displays.

3, “Configuring The Printer” for more information.)

Loading Media

1. If you want to install the paper path to print long labels, do so now by

completing the steps listed in

2. Open the media cover and refer to the Label Peel-Off illustration on the

Ribbon and Media Loading instruction label on the inside of the cover.

“Installing the Paper Path” on page 43).

“Installing the Paper Path” on page 43.

48

3. Open the front door by pulling it upward, then forward.

4. Open the pivoting deck by rotating the deck lock lever clockwise until the

deck swings upward.

5. Thread the media (label and liner) over the tear bar and around the

bottom roller, then through the opening at the bottom of the front door and

into the printer.

Page 49

Label Peel-Off

183400a

Back Flange

Raised Ridge

Slot

Rewinder Release

Lever

Liner

183403a

IMPORTANT

If you do not complete the following step, it will be difficult to remove

the liner from the rewinder.

6. Turn the release lever on the rewinder counterclockwise and lock it in

place. This forms a raised ridge along the width of the rewinder.

7. Insert the leading edge of the media into the closest slot of the rewinder,

and slide the media against the back flange.

8. Hold the media in the slot and rotate the rewinder one full revolution

counterclockwise until the media is taut.

9. Remove labels from the liner so that behind the tear bar the liner is void of

labels for about 1.5 inches and below the tear bar for about 2 inches.

10. Close the front door.

11. Complete the media routing as shown above.

49

Page 50

Chapter 2

183404a

Deck Lock Lever

Media Cover

Using the Optional Internal Rewinder

IMPORTANT

12. Press down on both sides of the pivoting deck and rotate the deck lock

lever fully counterclockwise.

13. Press the FEED key. The label advances to the peel-off position, and

“Remove Label” displays on the LCD.

14. Manually remove the peeled label from the printer.

15. Press the PAUSE key until “ONLINE” displays.

16. Close the media cover.

The rewinder supports a maximum diameter of 5 inches of liner.

Exceeding this diameter can cause the liner to rub on the bottom pan.

The rewinder is designed to support the full amount of liner from a

standard 8 inch diameter media roll.

50

Page 51

Removing the Paper Path

183405a

Paper

Path

Groove

Hook

Front Door

Tear Bar

Removing Label Liner from the Rewinder

1. Open the media cover.

2. Open the front door.

3. Tear the liner at the tear bar.

4. Manually rewind the remaining liner onto the rewinder by turning the

rewinder counterclockwise.

5. Turn the release lever on the rewinder clockwise.

6. Slide the roll of label liner off the rewinder and discard.

Removing the Paper Path

Remove the paper path from the front door when using Tear-Off or Tear-Off

Strip media handling, because you will need to tear the label downward

against the tear bar.

1. Open the front door by pulling it upward, then forward.

2. Grasp the upper right corner of the paper path and pry it off of the top of

the front door.

3. After removing the paper path, close the front door.

4. Open the pivoting deck and load paper and ribbon normally (see “Loading

Media and Ribbon” on page 28).

51

Page 52

Chapter 2

183406a

Printhead Pressure

Adjustment Dial

Active Pressure

Setting

Printing Adjustments

Printing Adjustments

Printhead Pressu re Ad jus tme nt

52

Sometimes you will need to adjust printhead pressure because of variations in

media thickness and width. The printhead pressure adjustment dial is shown

above. The value shown at the bottom of the dial is the active setting.

In general, adjust printhead pressure to the lowest value which produces the

desired print quality. Die cut labels usually require a setting of 4, while heavy

stock requires a setting of 6 to max. The numbers on the printhead pressure

adjustment lever are relative only and do not indicate a specific printhead

pressure or media thickness. By following this procedure, you will minimize

printhead wear.

Page 53

Printhead Pressure Block Adjust ment s

183406a

Lead Screw

Knob

Right Pressure

Block Pointer

Pressure Block

Adjustment Scale

Left Pressure

Block

Left Pressure

Block Handle

Right Pressure Block

Printhead Pressure Bloc k Adjus tments

Printhead pressure block adjustments are used to obtain a uniform print

density across the width of the installed media under a variety of media and

ribbon conditions.

Left Pressure Block

Under normal printing conditions, the left block should be set with its handle

aligned with the bold mark on the pressure block adjustment scale. When

using media or ribbon widths less than one-third the printer’s maximum

printing width, you may need to manually slide the left pressure block further

to the left.

Right Pressure Block

The right pressure block should be positioned with its pointer (handle on

4 inch printer models) near the right edge of the media or ribbon in use. Turn

the lead screw knob clockwise to move the block right or counterclockwise to

move it left.

Check the pressure block positioning by printing the Grey test pattern:

1. Press the PAUSE key until “OFFLINE” appears on the LCD.

2. Press the TEST PRINT key until “Printer Tests/Grey” displays.

53

Page 54

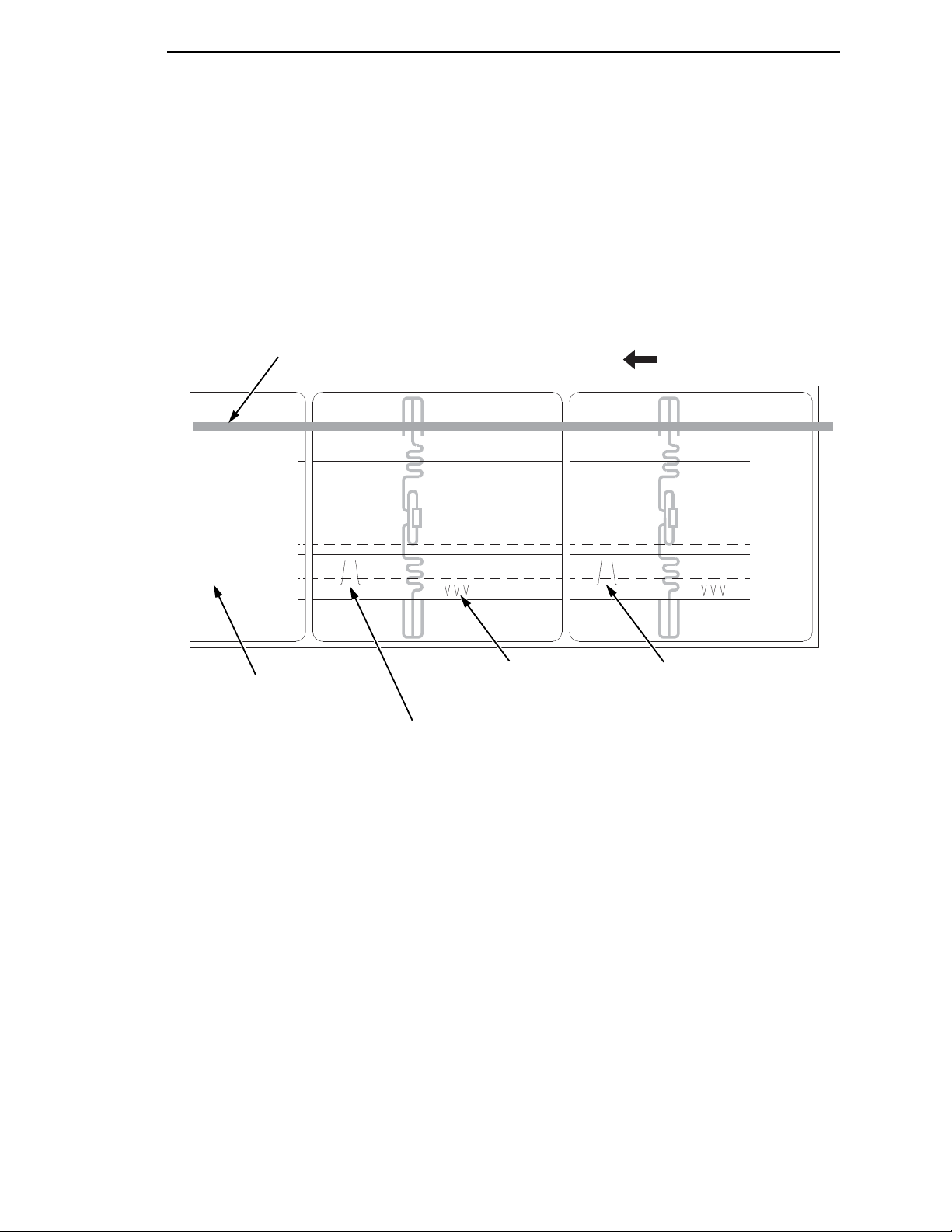

Chapter 2

183407a

Vertical Gap and

Rounded Die-cut

Label Corners

Extraneous

Cut-out

Dark

Pre-printing

Position the

media sensors

in either of the

grey shaded

areas.

Printing Adjustments

3. Press the ↵ key to start the Grey test pattern. The pattern will start and

continue to print.

4. Press ↵ again to stop printing.

5. Check the test pattern. If necessary reposition the pressure blocks to

obtain a uniform print density across the media width. In most cases, only

the right pressure block may need to be adjusted.

6. Whenever you reposition a pressure block, run the Grey test pattern to

verify the print pattern is acceptable.

Positioning the Media Sensor s

Your printer is equipped with upper and lower media sensors that detect the

top-of-form position on media with label length indicators (gaps, notches,

holes, or black marks). These sensors also detect when a Paper Out

condition exists.

The media sensors should not be placed in the path of media features that

could cause false gap detection or paper out faults. Such features are dark

pre-printing, rounded die-cut label corners, vertical gaps associated with

side-by-side labels, and extraneous cut-outs, as shown below.

54

Page 55

Positioning the Media Sensors

183408a

Lower Sensor

Media Guard

Opening

Black Mark

(underside

of media)

Sensor Handle

Visible Red Beam

from Lower Sensor

Sensing Media with Horizontal Black Marks (Mark) or

Media with No Label Length Indicators (Disable)

Sensing Media with Horizontal B lack Ma rks

Position the lower media sensor for detecting horizontal black marks located

on the underside of media, and position the upper sensor above the lower

sensor to provide a consistent background.

1. Check the position of the sensor by looking through the long, narrow

2. Use the sensor handle to manually position the sensor to the center of the

3. Select “Mark” in the Gap/Mark Sensor submenu under the CALIBRATE

4. Perform an Auto Calibrate. See “Running Auto Calibrate” on page 60.

Sensing Media with No Label Length Indicators

1. When using media without label length indicators (no gaps, notches,

2. Select “Disable” in the Gap/Mark Sensor submenu under CALIBRATE

3. Perform an Auto Calibrate. See “Running Auto Calibrate” on page 60.

opening in the media guard. Use the visible red light emitting from the

lower sensor as a reference pointer.

black mark on the media.

CTRL menu. See

“Sensing Different Media Types” on page 59.

holes, or marks) or when you want to ignore all existing length indicators,

place the lower sensor in the center of the media so it can detect when a

Paper Out condition exists. Also set the upper sensor above it.

CTRL. See

“Sensing Different Media Types” on page 59.

55

Page 56

Chapter 2

183409a

Media Guard

Opening

Visible Red Beam

from Lower Sensor

Upper Sensor

Printing Adjustments

Sensing Media with Gaps, Notches, or Holes (Gap)

Position the lower media sensor for detecting gaps, notches, or holes in

media with a white background. If using direct thermal media, position the

upper sensor away from the lower sensor.

NOTE: The 4 inch SL/T5R media guard is divided into three open sensor

areas. Make sure the media sensor is placed in an open area.

1. Position the lower sensor directly under the center of the gap, notch, or

hole.

2. Check the position of the lower sensor by looking through the long,

narrow opening in the media guard. Use the visible red light emitting from

the lower sensor as a reference pointer.

3. Use the sensor handle to manually position the sensor to the center of the

gap, notch, or hole in the media.

4. Select “Gap” in the Gap/Mark Sensor submenu under the CALIBRATE

CTRL menu. See

5. Perform an Auto Calibrate. See “Running Auto Calibrate” on page 60.

“Sensing Different Media Types” on page 59.

56

Page 57

Positioning the Media Sensors

183410a

Upper Sensor

Handle

Media Guard

Opening

Visible Red Beam

Lower Sensor

Upper Sensor

Sensing Media with Dark Background Labels with Gap s

(Advanced Gap)

NOTE: Ribbon is not displayed in this illustration. The upper and lower

sensors are designed to function with or without ribbon installed.

The upper sensor and lower sensor are used together to detect liner gaps

between die cut labels that have a black or dark background on white or clear

liner.

1. Position the lower sensor directly under the center of the gap, and then

place the upper sensor directly over the lower sensor.

2. Check the position of the lower sensor by looking through the long,