Page 1

User’s Manual

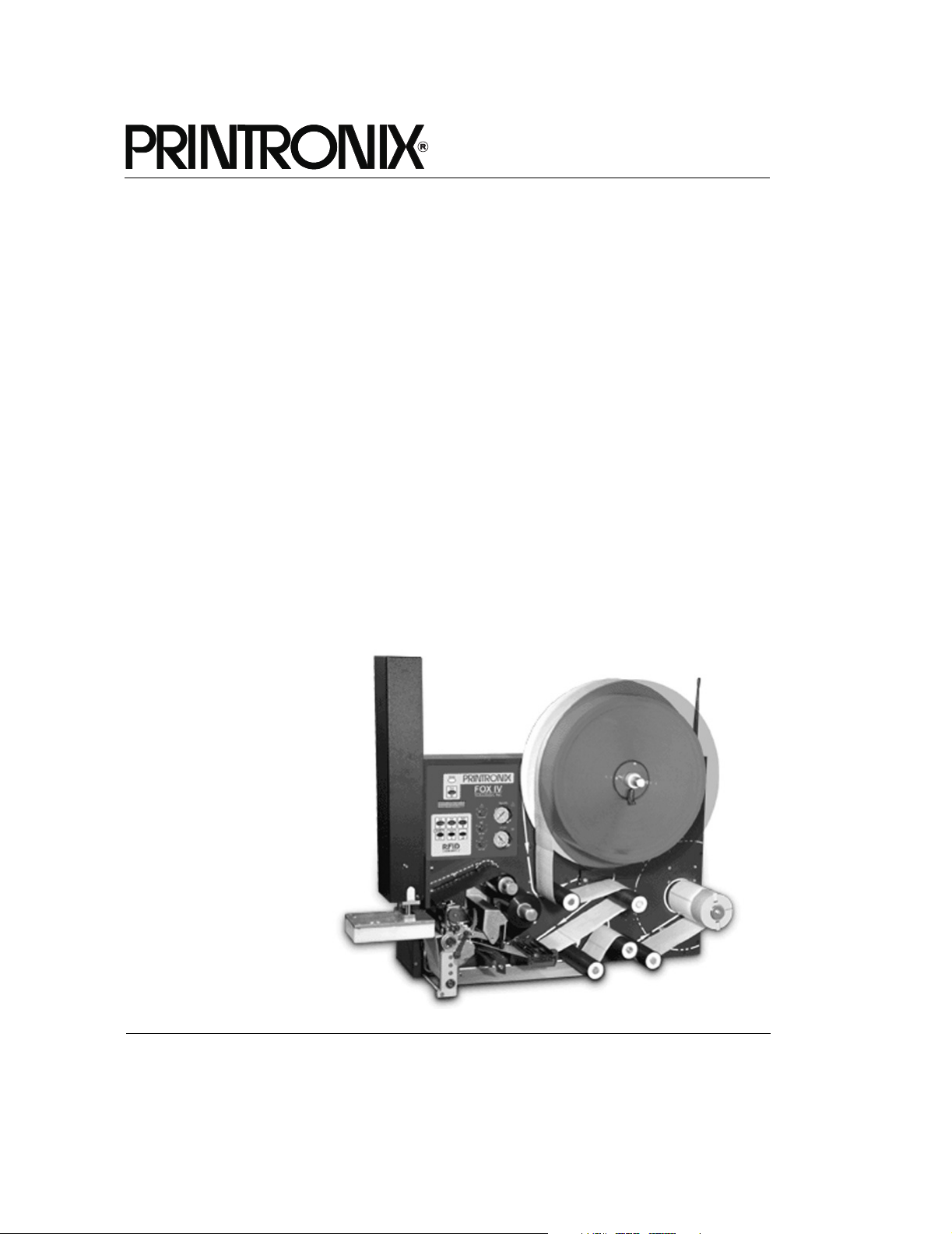

SLPA7000e Smart Label Printer Applicator

Page 2

Page 3

User’s Manual

SLPA7000e Smart Label Printer Applicator

Page 4

IMPORTANT WARRANTY INFORMATION

PRINTER WARRANTY

Printronix warrants to purchaser that under normal use and service, this printer (excluding the

thermal printhead) purchased hereunder shall be free from defects in material and workmanship

for a period of ninety (90) days from the date of shipment from Printronix.

Consumable items such as media and ribbons are not covered under this warranty. This warranty

does not cover equipment or parts that have been misused, altered, or used for purposes other

than those for which they were manufactured. This warranty also does not cover loss, shipping

damage, damage resulting from accident or damages resulting from unauthorized service.

THERMAL PRINTHEAD

Printronix warrants the printhead for a period of one hundred eighty (180) days, or 1,000,000 linear

inches for direct thermal use, or 2,000,000 linear inches for thermal transfer use, whichever comes

first. The warranty does not cover printheads that have been misused, damaged due to improper

cleaning, or damaged due to use of improper ribbons or media.

SUPPLIES

For the nearest Printronix full-service distributor that carries Printronix genuine supplies, please

call (800) 733-1900 or fax (714) 368-2354. Supplies design, specification, and selection are

integral to the development of any computer imaging system. Printronix’s extensive manufacturing

and research capabilities, along with years of experience in the design of printers and their

applications, assures that you will receive the exact materials that you require to maximize the

performance of your Printronix printer. For more information, call the Printronix Customer

Solutions Center at (714) 368-2686 or access the Printronix website at http://www.printronix.com.

ON-SITE MAINTENANCE SERVICE

Printronix offers on-site support services in the United States. Please contact the Printronix

Maintenance Contracts Group at (714) 368-2798 for detailed service agreement information.

Page 5

Model ____________ Setup Values

Software Version ___________________________

Touch-Blo Control ___________________________

Print Mode ___________________________

Apply Mode ___________________________

Print Darkness ___________________________

Machine Type ___________________________

Pinch Roller ___________________________

Random Stroke Delay ___________________________

Cycle Time Delay ___________________________

Cylinder Extend Time ___________________________

Vacuum Delay Time ___________________________

CPU Dip Switch Settings __________________________

Printer Serial Number ___________________________

Page 6

Communication Notices

Federal Communications Commission (FCC) Statement: This equipment has been tested and

found to comply with the limits for a Class A digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provided reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can

radiate radio frequency energy and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference, in which case the user will be required to

correct the interference at his own expense.

Properly shielded and grounded cables and connectors must be used in order to meet FCC

emission limits. Printronix is not responsible for any radio or television interference caused by

using other than recommended cables and connectors or by any unauthorized changes or

modifications to this equipment. Unauthorized changes or modifications could void the user’s

authority to operate the equipment.

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two

conditions: (1) this device may not cause harmful interference, and (2) this device must accept any

interference received, including interference that may cause undesired operation.

Canadian Department of Communications Compliance Statement: This Class A digital

apparatus complies with Canadian ICES-003.

Avis de conformite aux normes du ministere des Communcations du Canada: Cet appareil

numerique de la classe A est conform á norme NMB-003 du Canada.

European Community (EC) Conformity Statement:

This product is in conformity with the protection requirements of EC Council Directive 89/336/EEC

on the approximation of the laws of the Member States relating to electromagnetic compatibility.

Printronix cannot accept responsibility for any failure to satisfy the protection requirements

resulting from a non-recommended modification of the product, including the fitting of nonPrintronix option cards.

German Conformity Statement:

Zulassungsbescheinigung Gesetz über die elektromagnetische Verträglichkeit von Geraten

(EMVG) vom 30. August 1995

Dieses Gerät ist berechtigt in Übereinstimmung mit dem deutschen das EG-Konformitätszelchen CE - zu führen.

Der Außteller der Konformitätserklärung ist die Printronix......(1)

Informationen in Hinsicht EMVG Paragraph 3 Abs. (2) 2:

Das Gerät erfüllt die Schutzanforderungen nach EN 55022 und EN 55024

Klasse A.

Page 7

EN 55022 Klasse A Geräte bedürfen folgender Hinweise:

Nach dem EMVG: “Geräte dürfen an Orten, für die sie nicht asreichend entstört sind, nur mit

besonderer Genehmigung des Bundesminesters für Post und Telekommunikation oder des

Bundesamtes für Post und Telekommunikation betrieben werden. Die Genehmigung wird erteilt,

wenn keine elektromagnetischen Störungen zu erwarten sind.” (Auszug aus dem EMVG,

Paragraph 3, Abs. 4) Dieses Genehmigungsverfahren ist nach Paragraph 9 EMVG in Verbindung

mit der entsprechenden Kostenverordnung (Amtsblatt 14/93) kostenpflichtig.

EN 55022: Dieses ist eine Kategorie A Vorrichtung. Betrieb in den Wohnbereichen kann

elektrische Störung verursachen. Es ist die Verantwortlichkeit des Benutzers, passende

Gegenmaßnahmen zu ergreifen.

EN 55024: Begrenzung Werte für Gebrauch in bevölkerten Bereiche, kommerziellen und

Industriegebieten sind innen Übereinstimmung mit den spezifizierten Anforderungen Hinsichtlich

Störfreiheit.Anmerkung: Um die Einhaltung des EMVG sicherzustellen sind die Geräte, wie in den

Handbüchern angegeben, zu installieren und zu betreiben.

This product has been tested and found to comply with the limits for Class A Information

Technology Equipment according to European Standard EN 55022. The limits for Class A

equipment were derived for commercial and industrial environments to provide reasonable

protection against interference with licensed communication equipment.

Warning

This is a Class A product. In a domestic

environment this product may cause radio

interference in which case the user may be

required to take adequate measures.

Page 8

Trademark Acknowledgements

Compatibility Software Copyright © 1989 Phoenix Technologies Ltd., All Rights Reserved.

Alien and Alien Technology are registered trademarks of Alien Technology Corporation.

Code V is a trademark of Quality Micro Systems, Inc.

EIA is a registered service mark of the Electronic Industries Association.

Epson is a registered trademark of Seiko Epson Corporation.

HP is a registered trademark of Hewlett-Packard Company.

IBM is a registered trademark of International Business Machines Corporation.

IGP, LinePrinter Plus, PGL, Printronix, and PSA are registered trademarks of Printronix, Inc.

IPDS is a trademark of International Business Machines Corporation.

LaserJet is a registered trademark of Hewlett-Packard Company.

Microsoft, MS-DOS, and Windows are registered trademarks of Microsoft Corporation.

PCL is a registered trademark of Hewlett-Packard Company.

PhoenixPage PCL 5 is a registered trademark of Phoenix Technologies Ltd.

PostScript is a registered trademark of Adobe Systems.

PPI1, PPI2, SLPA7000e are trademarks of Printronix, Inc.

Proprinter is a registered trademark of International Business Machines Corporation.

QMS is a registered trademark of Quality Micro Systems, Inc.

TEC is a registered trademark of the Toshiba TEC Corporation.

Zebra is a registered trademark of Zebra Technologies Corporation.

Copyright 2004, 2005, Printronix, Inc.

Page 9

Table Of Contents

1 Introduction ......................................................... 15

Printronix Customer Support Center.................................................... 15

To Replace Parts .......................................................................... 15

To Order Parts .............................................................................. 16

Notes And Notices ........................................................................ 16

Manual Conventions ..................................................................... 17

Related Manuals ........................................................................... 17

Overview.............................................................................................. 18

General Operation......................................................................... 18

Operating Specifications ............................................................... 19

Storage, Shipping, & Handling ...................................................... 20

Safety................................................................................................... 21

Warnings And Cautions ................................................................ 21

Operating Precautions .................................................................. 22

Operational Safety ........................................................................ 22

The T5000e Series Label Printer......................................................... 23

Standard Features ........................................................................ 23

Optional Features.......................................................................... 24

Thermal Printer Media................................................................... 25

Ribbons ......................................................................................... 25

Thermal Printer Technology.......................................................... 25

Installing The SLPA ............................................................................. 28

Unpacking Your SLPA .................................................................. 28

Mounting The SLPA ...................................................................... 28

Optional Mounting Accessories..................................................... 29

Mounting The Beacon ................................................................... 29

Air, Power, And Communications Connections............................. 30

Adjusting The Voltage ................................................................... 33

2 Operation ............................................................ 35

Control Panel ....................................................................................... 35

LCD ............................................................................................... 36

Keypad .......................................................................................... 36

Key and Indicator Descriptions...................................................... 38

Pneumatic Control Valves And Gauges ........................................ 40

9

Page 10

Table of Contents

Setup ................................................................................................... 41

Removing Label Backing .............................................................. 41

Threading The Label Roll .............................................................. 41

Loading Ribbon ............................................................................. 49

Positioning The Air Jets ................................................................ 52

RFID System Configuration Parameters ............................................. 53

System Adjustments ............................................................................ 55

Printhead Pressure Adjustment .................................................... 55

Printhead Pressure Block Adjustments ......................................... 56

Positioning The Media Sensors .................................................... 56

Sensing Different Media Types ..................................................... 58

Calibrating The Media Sensors..................................................... 63

Printing And Applying Labels............................................................... 68

Label Application (Positioning) Adjustments ................................. 68

Adjusting The Cylinder Extend Time ............................................. 70

The Print And Apply Process ........................................................ 71

3 Configuring The SLPA ........................................ 73

Setting Printer Configuration Parameters ............................................ 73

Moving Within The Configuration Menu............................................... 73

Selecting A Menu Option .............................................................. 74

Changing Printer Settings ............................................................. 74

Saving A Configuration ................................................................. 75

Specifying A Power-Up Configuration ........................................... 76

Modifying A Saved Configuration.................................................. 77

Printing A Configuration ................................................................ 78

Main Menus ......................................................................................... 82

QUICK SETUP Menu .......................................................................... 87

QUICK SETUP Submenus............................................................ 88

RFID CONTROL Menu........................................................................ 95

RFID CONTROL Submenus ......................................................... 96

Admin User Submenus ................................................................. 99

CONFIG. CONTROL Menu ............................................................... 102

CONFIG. CONTROL Submenus ................................................ 103

MEDIA CONTROL Menu................................................................... 105

MEDIA CONTROL Submenus .................................................... 107

CALIBRATE CTRL Menu .................................................................. 121

CALIBRATE CTRL Submenus.................................................... 122

PRINTER CONTROL Menu .............................................................. 127

PRINTER CONTROL Submenus................................................ 130

DIAGNOSTICS Menu ........................................................................ 140

DIAGNOSTICS Submenus ......................................................... 141

10

Page 11

Table of Contents

ETHERNET ADDRESS Menu ........................................................... 144

ETHERNET ADDRESS Submenus ............................................ 145

ETHERNET PARAMS Menu ............................................................. 146

ETHERNET PARAMS Submenus............................................... 147

GPIO CONTROL Menu ..................................................................... 149

GPIO CONTROL Submenus....................................................... 150

Applicator Delay Menu....................................................................... 152

4 Preventive Maintenance ................................... 153

Cleaning............................................................................................. 153

General Cleaning ........................................................................ 153

Cleaning The Printhead, Platen Roller And Media Sensors........ 155

Cleaning Procedure .................................................................... 155

Cleaning The Applicator Pad ...................................................... 156

Cleaning/Replacing The Vacuum Generator............................... 157

Cleaning Schedule ...................................................................... 158

5 Troubleshooting ................................................ 159

Introduction ........................................................................................ 159

What You Should Know About Print Quality ............................... 159

How To Maximize Printhead Life................................................. 159

Troubleshooting At A Glance ...................................................... 160

Start Here .......................................................................................... 161

How To Troubleshoot ........................................................................ 162

Printer Tests ................................................................................ 163

To Print A Test Label .................................................................. 163

Troubleshooting Display Messages................................................... 164

List Of Messages ........................................................................ 165

Troubleshooting Other Symptoms ..................................................... 198

General Symptom List................................................................. 198

Communications Failures .................................................................. 218

Troubleshooting A New Installation ................................................... 221

Printer Configuration ................................................................... 221

GAP NOT DETECTED................................................................ 221

PRINT HEAD UP......................................................................... 221

Ribbon......................................................................................... 221

Documentation ............................................................................ 221

11

Page 12

Table of Contents

6 Replacing Parts................................................. 223

About This Chapter............................................................................ 223

Preparing The Printer For Maintenance ...................................... 223

Restoring The Printer To Operation ............................................ 224

Removal And Replacement Procedures............................................ 225

Access Panels............................................................................. 226

Control Panel Assembly.............................................................. 227

Controller PCBA (Printed Circuit Board Assembly)..................... 228

Damper, Media............................................................................ 230

Drive Belt, Platten Rollers ........................................................... 231

Gear, Ribbon Drive, Final............................................................ 232

Gear, Ribbon Drive, Intermediate ............................................... 233

Head Pressure Block Assembly.................................................. 234

Media Sensor Assembly, Lower.................................................. 237

Memory Modules, Flash And DRAM........................................... 239

Motor, DC Ribbon Drive .............................................................. 242

Motor, Stepper ............................................................................ 243

NIC Assembly ............................................................................. 244

Platen .......................................................................................... 248

Power Supply Assembly ............................................................. 249

Printhead Assembly .................................................................... 250

Printhead Cover/Upper Media Sensor ........................................ 252

Resistors, Terminating ................................................................ 253

Rewind (Label Liner Take-Up) Assembly.................................... 255

Security PAL ............................................................................... 256

Sensor, Head Up......................................................................... 258

Spindle Assembly, Ribbon Supply Or Take-Up .......................... 259

Support Assembly, Lower ........................................................... 260

Support Assembly, Upper ........................................................... 261

12

7 Illustrated Parts Breakdown .............................. 263

Organization Of This Chapter............................................................ 263

Illustrated Parts Breakdown............................................................... 263

Hardware Kit ............................................................................... 316

A Specifications .................................................... 319

Applicator Orientation ........................................................................ 319

Product Distance Variation ................................................................ 319

Application Rate................................................................................. 319

Placement Accuracy .......................................................................... 319

Printing............................................................................................... 320

Media ................................................................................................. 320

Page 13

Table of Contents

Ribbon ............................................................................................... 322

Electrical ............................................................................................ 322

Pneumatic.......................................................................................... 322

Environmental.................................................................................... 323

Physical ............................................................................................. 323

Connections....................................................................................... 324

Communications Interface................................................................. 324

B Options.............................................................. 325

Expansion Modules ........................................................................... 325

Beacon Package Options .................................................................. 325

Fault/Warning Beacon Package.................................................. 326

Pneumatic Monitor Package ....................................................... 326

Fault/Warning Beacon Package With Interface Module.............. 326

Pneumatic Monitor Package With Interface Module ................... 326

Mounting The Beacon ................................................................. 327

Mounting Accessories........................................................................ 328

U-Arm And Accessories .............................................................. 328

Mounting Stand ........................................................................... 329

Low Label Sensor .............................................................................. 330

Product Sensor .................................................................................. 331

Application Options............................................................................ 333

Cylinder Stroke Lengths .............................................................. 333

Soft Pad ...................................................................................... 333

Random Stroke Sensor ............................................................... 333

C Wire Data .......................................................... 335

Circuit Board And Cable Pinouts ....................................................... 335

D Downloading Software ...................................... 351

Flash Memory .................................................................................... 351

Downloading Software Through the Serial or Parallel Port ......... 352

Downloading Software Through the NIC..................................... 355

Downloading Optional Fonts to Flash Memory ........................... 358

E Dual NIC Wireless Interface.............................. 361

Installation and Removal ................................................................... 361

Install The Dual NIC Wireless Interface ...................................... 362

Install The Radio Card, Protective Cover, And Antenna ............. 365

Spare Parts........................................................................................ 367

13

Page 14

Table of Contents

F RFID Encoder and Antenna Assemblies........... 369

Installation And Removal................................................................... 369

Prepare The Printer ........................................................................... 369

Replace The RFID Antenna And Encoder Assemblies ..................... 370

Remove the RFID Encoder Assembly ........................................ 370

Replace The RFID Antenna Assembly ....................................... 372

Install The RFID Encoder Assembly ........................................... 375

Route The Data And Power Cables ............................................ 377

Finish The Installation........................................................................ 378

Error Messages ................................................................................. 379

Troubleshooting ................................................................................. 380

Spare Parts........................................................................................ 381

14

Page 15

1 Introduction

CAUTION

Thoroughly review this manual before attempting to install, set up, and

operate the SLPA.

Printronix Customer Support Center

The Printronix Customer Support Center offers technical support with:

• Installation

• Configuration and setup

• Operation and supplies loading

• Specifications of the proper print media and ribbon

• Answers to post-sale service support questions

Call the Printronix Customer Support Center at:

(714) 368-2686 in the Americas

(31) 24 6489 489 in Europe, Middle East, and Africa

(65) 654 84114 in Asia Pacific

or visit the Printronix web page at www.printronix.com

http://www.printronix.com/public/servicesupport/default.aspx

To Replace Parts

1. Go to Chapter 6, page 223.

2. Find the removal procedure for the part.

3. Read the entire procedure

understand all notes and notices, which are defined on page 16.

4. Gather the tools you will need.

5. Do the procedure.

before

you start and make sure you

15

Page 16

Chapter 1 Printronix Customer Support Center

To Order Parts

Go to the Illustrated Parts Breakdown (IPB) on page 263, which contains

drawings of all printer assemblies. Next to each illustration is a list of the parts

shown and their part numbers. When locating parts, note the following:

• If a part number is listed you can order that part or assembly. If a

component is part of a field kit, order the kit.

• Parts marked “Ref” (reference) are not spared or are part of another

assembly.

• Part numbers are not listed for common fasteners.

• In illustrations, magnified details are shown with locator arrows and

letters:

WARNING

This arrow points to an area . . .

the same page or a

subsequent page.

A

A

• Assemblies you can order as kits are shown in the following manner:

80

that is magnified here, on

To get item 80, 85, or 87, for

example, order item 90, which

is a kit containing all these

parts.

Notes And Notices

For your safety and to protect valuable equipment, always read and comply

with information highlighted under the following special headings:

A warning describes conditions that can harm you as well as damage

the equipment.

85

87

90

CAUTION

IMPORTANT

16

A caution describes conditions that can damage the printer or related

equipment.

Information vital to proper operation of the printer.

NOTE: Helpful and timesaving tips about printer operation and maintenance.

Page 17

Manual Conventions

Manual Conventions

• Control panel keys are printed in bold, uppercase letters.

Example: Press the PAUSE key to take the printer offline.

• Control panel keys are often shown by their symbol or icon (located on

the control panel directly below the key).

Example: Press the

• Liquid Crystal Display (LCD) messages are printed in uppercase letters

inside quotation marks ( “ ” ).

Example: When “OFFLINE” appears on the LCD, you may release the

PAUSE key.

• LCD fault messages display the specific fault in uppercase letters on the

top line. A corrective action in upper and lowercase letters displays on the

bottom line.

Example: PAPER OUT

Load Paper

↵ to select it.

• Key combinations (pressing keys at the same time) are indicated by the

+ (plus) symbol.

Example: Press ↓ +

↵ to unlock the ↵ key.

Related Manuals

This manual does not explain how to install, operate, configure the printer, or

how to program application software for operation with the printer. That

information is in the following manuals, available online at www.printronix.com:

• T5000 Thermal Printer User’s Manual

• T5000 Quick Reference Manual

• T5000 Maintenance Manual

• Network Interface Card User’s Manual

• Online Data Validator User’s Manual

• IGP

• IGP

• IPDS™ Programmer’s Reference Manual

• LinePrinter Plus

• Printer Protocol Interpreter 1.0 (PPI1™) Programmer’s Reference Manual

• Printer Protocol Interpreter 2.0 (PPI2™) Programmer’s Reference Manual

®

/PGL Emulation Programmer’s Reference Manual

®

/VGL Emulation Programmer’s Reference Manual

®

Emulation Programmer’s Reference Manual

17

Page 18

Chapter 1 Overview

Overview

General Operation

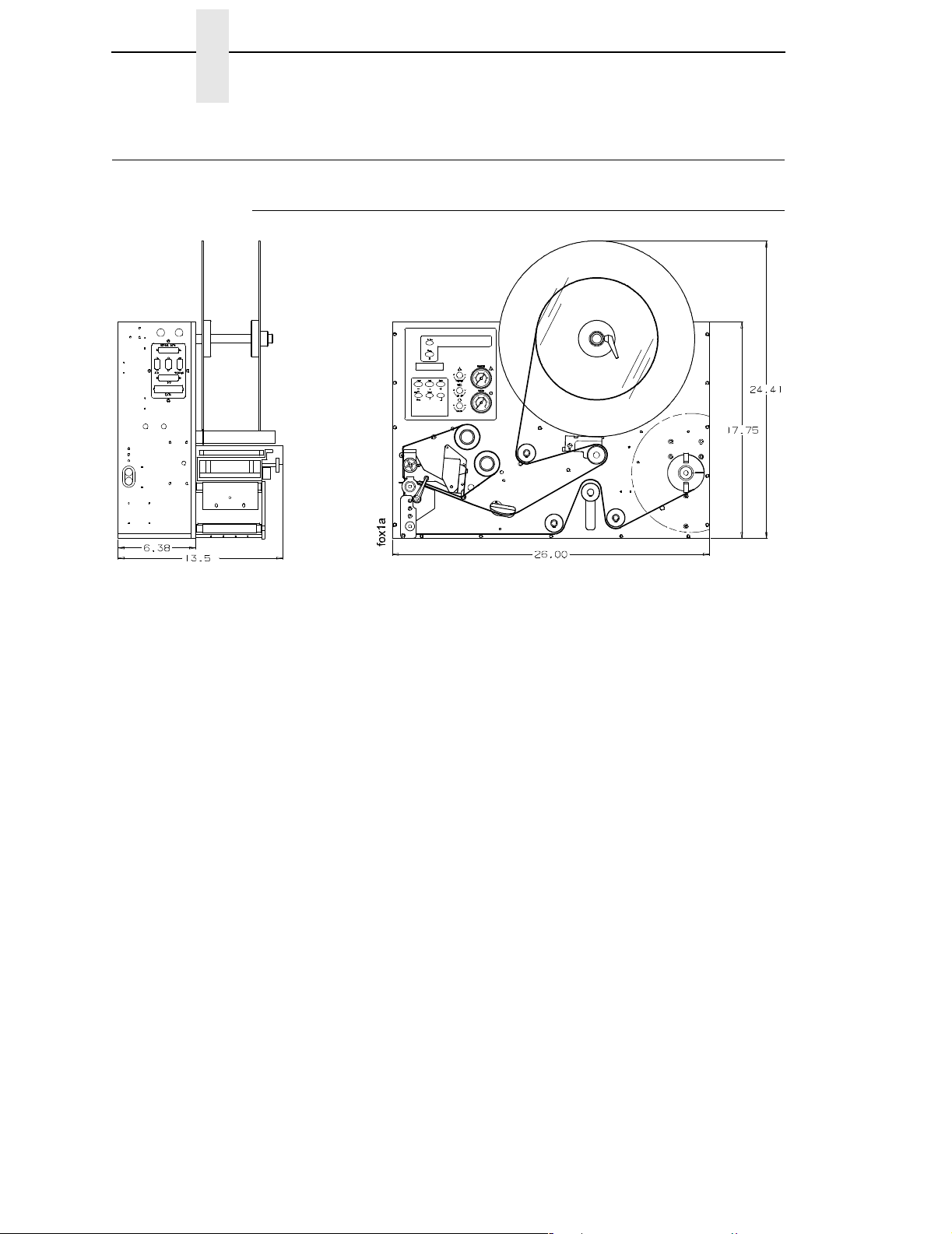

Figure 1. SLPA Dimensions

This document contains information and instructions for the Printronix Smart

Label Printer Applicator (SLPA). The SLPA can print label patterns up to 4.1

inches (104 mm) wide and applies them by means of a pneumatic applicator

system, although optional methods of applying the label are available by

design. The

menu configurations, as well as adjustments and basic maintenance

procedures the operator can perform.

The SLPA is both a direct thermal and thermal transfer label printer. The

SLPA can be positioned for top, side, or bottom applications and mounted

using the mounting holes in either the base or sides.

NOTE: Specify the orientation of the SLPA when ordering. If the system is to

The SLPA is an integrated unit composed of the following modules:

User’s Manual

be used for bottom applications, custom work may be needed.

contains information on setup, operation, and

• Label printer engine

• Label apply system

• GPIO control system

• Control panel (comprised of air controls, Liquid Crystal Display (LCD),

touch keypad/display, and air pressure gauges)

• Label supply

• Backing rewind system

18

These systems are packaged into a metal frame with an aluminum cover

enclosing the rest of the system. The metal frame is used for component

mounting, and all system controls are located on this frame.

Page 19

Operating Specifications

Operating Specifications

Operating Environment

The SLPA is designed for general use in warehouse and industrial

environments. It should not be exposed to liquids or damaging chemical

vapors, and will function properly in environments with an ambient

temperature between 40

exposure to dirt and dust is also recommended.

NOTE: Optional enclosures may be purchased to protect the products in

unusually harsh environments.

Power Requirements

A properly grounded, dedicated line supplying either:

115 VAC +

or

230 VAC +

10%, single phase @ 50 - 60 Hz

10%, single phase @ 50 - 60 Hz.

o

to 100o F (4o to 38o C). Minimizing unnecessary

CAUTION

CAUTION

It is recommended that you isolate the SLPA from its power supply by

means of a surge suppressor to minimize any potential damage to the

equipment.

A suppressor which limits voltage to 400V and has a response time of

1-5ns is highly recommended.

Air Supply

The applicator system works with a regulated 80 to 100 psi (550 to 690 kPa)

air supply that is dust and oil free. A filter is provided that is equipped with a

mist separator to remove any condensation that builds in the line.

The pneumatic supply line should also be dedicated to maintain the

appropriate pressure range, thereby providing relief against excess

pressure. Providing such protection should prevent the supply pressure

from exceeding 135 psi (931 kPA).

19

Page 20

Chapter 1 Overview

Storage, Shipping, & Handling

Storage

• Store the SLPA in a clean dry area.

• Storage temperatures should be between -40

• Do not store the SLPA with labels or printing ribbon installed.

• Store the SLPA in its original packaging if possible.

Shipping

• Observe storage conditions when shipping. Retain the shipping materials

if the SLPA is intended to be moved from site to site.

• If the original packing is not available, ensure sufficient padding/

protection for the printhead, applicator, label rollers, and rear cover.

• Carefully inspect the SLPA packaging upon receipt. If damage from

dropping, crushing, or punctures occurred, contact the carrier directly and

specify the nature of the damage.

o

to 150o F (-40o to 65o C).

Handling

• When handling the SLPA, do not rest or pivot it such that pressure may

be applied to the printhead assembly.

• Do not lift or pull the SLPA by gripping the applicator pad, the pneumatic

tubing, the printhead assembly, or any of the rollers which are located on

the front of the it.

NOTE: It is possible to manually position the applicator pad. Ensure that the

applicator pad is in the full up position to prevent any damage from

occurring when the SLPA is moved.

20

Page 21

Safety

Warnings And Cautions

Warnings And Cautions

WARNING

WARNING

WARNING

WARNING

CAUTION

Printronix has provided the necessary guards and warnings within the

confines of the SLPA, but cannot anticipate each customer’s individual

installation and operational environments. It is the customer’s

responsibility to provide in-house safety guards to provide adequate

worker safety for their respective production settings.

An input signal from the product sensor activates the SLPA when it is

powered on. Make certain that protective guards are properly secured

and that materials are clear of the applicator pad/printhead assembly

before powering on the SLPA.

This manual includes instructions on basic operation and preventative

maintenance only. Only qualified technicians should perform service

procedures, i.e, procedures requiring access to the rear compartment or

power entry module of the SLPA.

Both surge protection for the electrical supply and pressure relief for

the pneumatic supply are strongly recommended. Failure to properly

protect against extreme fluctuations in the supply sources could result

in operator injury or damage to equipment.

Power off the SLPA and disconnect both the power source and the air

supply prior to doing any maintenance, adjustments, and/or parts

replacement which do not require these systems to be powered on.

CAUTION

CAUTION

CAUTION

Read and become familiar with all of the instructions in this manual

before proceeding to operate the SLPA.

Any external communications cables to be used with the SLPA must be

properly shielded and grounded. Failure to provide proper shielding or

grounding for these cables could result in malfunctioning or damage to

the SLPA.

When handling the SLPA, do not rest or pivot it such that pressure may

be applied to the printhead assembly.

21

Page 22

Chapter 1 Safety

Operating Precautions

Proper operation of the SLPA depends upon timely maintenance and

appropriate operation. Always observe the following precautions:

• Use label stock which is designed for use with the SLPA. Printronix

• Ensure that a regulated air supply is used for the pneumatic system. Use

• Secure all protective guards, covers, and enclosures prior to operating

• Do not attempt to operate an SLPA from a power source other than that

• Use only Printronix replacement parts for maintenance and repair.

• You must have this manual to perform any maintenance. Use only the

• Do not use objects other than a finger to operate buttons on the keypad.

supplied replacement stock is recommended.

the appropriate filters for the removal of dirt, oil, and excessive moisture.

the SLPA. Ensure proper mounting of the SLPA prior to use.

for which it was designed. Do not use any of the SLPA’s components to

power or operate any equipment except those they are intended to

operate.

appropriate tools and ensure that maintenance workers are properly

grounded if work is being performed on the circuitry.

WARNING

WARNING

• Sound pressure levels indicated a maximum reading of 81 ±1dB(A).

Sound levels were determined based on printers of similar design and

assembled with a 3 x 4 inch applicator pad. Readings were taken in a low

noise environment, at approximately 1.0 meter.

NOTE: Sound levels may vary depending upon the mounting of the SLPA,

the surface to which a label is applied, and the environment in which it

is used. The size of the applicator pad can also affect sound levels, in

that larger pads can produce greater noise when applying labels.

Operational Safety

The addition of custom safety guards in the vicinity of the label

applicator is essential to the safe operation of the SLPA. Due to the

variety of potential assembly line setups, Printronix cannot provide

sufficient guarding in a standard package. The addition of such guards

is the responsibility of the buyer.

The SLPA should be powered off during any operation in which a

worker may be exposed to a hazardous zone. If it is necessary that the

SLPA remain powered on, make certain that the Pause button is pressed

and the product sensor is disconnected.

22

Page 23

The T5000e Series Label Printer

Standard Features

The T5000 Series is a family of direct thermal and thermal transfer printers

designed to print labels and tags from any MS-DOS

based computer.

Printronix Dynamic Print Control provides exceptional print quality. A circuit

monitors the data to be printed and automatically adjusts the energy applied

to the thermal printhead for maximum performance.

The printer can communicate with the host computer via RS-232 and RS-422

serial, Centronics

(optionally) coax/twinax, ethernet 10/100Base-T, or wireless ethernet host

connections. The interface cable needed to connect the printer to the host

device is supplied by the user.

®

-compatible parallel, IEEE® 1284 compliant parallel, and

®

, Windows®, or ASCII-

Standard Features

• Emulations:

• Printronix LinePrinter Plus (LP+). Provides direct compatibility with

Printronix P-series printers.

• Epson FX-1050, Proprinter IIIXL, and Serial Matrix printers.

• Printronix IGP/PGL and IGP/VGL. Provides printer system

commands for text, barcodes, graphics, lines, and boxes.

• Thermal Transfer and Direct Thermal Printing: On all printers

(except -DT models, which print only in direct thermal mode)

• Bar Codes: Support for over 20 types of bar codes

• Resident Fonts: OCRA, OCRB, Courier, Letter Gothic, and

CG Triumvirate Bold Condensed

• Download: Forms, fonts, and graphics into printer memory

• High Resolution Printhead: For sharp graphics and text

• Label Taken Sensor: For detecting removal of labels in Tear-Off mode

(and in Peel-Off mode when optional rewinder is installed)

• Tear-Off Mode: For positioning the label at the tear off position and

detecting its removal before printing the next label

• Tear-Off Strip Mode: For printing a specified number of labels and

positioning the last label at the tear off position

• 8MB DRAM memory

• 4MB Flash memory

• Auto Label Mapping

Printronix line matrix printers.

®

: For compatibility with programs written for

• Ventless System: For operation in environments with airborne

particulate matter without compromising performance

23

Page 24

Chapter 1 The T5000e Series Label Printer

Optional Features

The following options are also available:

• PPI1 and PPI2 Interpreters: PPI1 (Zebra

interpreters are powerful integration tools that allow the SLPA to function

in virtually all legacy ZPL and TEC application environments without

requiring modifications to the host data stream. PPI1 (Zebra) enables you

to print files formatted for Zebra printers to the Printronix SLPA. PPI2

(TEC) prints files formatted for TEC printers to the Printronix SLPA.

• Fonts: A selection of fonts can be loaded from the host computer into

printer memory. Once loaded, these fonts are accessed in the same way

as the resident fonts. See Table 17 on page 358 for a list of optional fonts.

• Memory Expansion (for non-IPDS printers only):

• 16MB DRAM SIMM (single in-line memory module): Provides

additional memory to accommodate long label formats.

• 10MB Flash SIMM: Provides additional memory for forms, logos, and

fonts.

• Heavy Duty Media Cutter: Automatically cuts up to 0.010” thick printed

tag stock as the media exits the printer. Available for 4, 6, and 8 inch

printers.

®

) and PPI2 (TEC®)

• Standard Duty Media Cutter: Automatically cuts up to 0.008” thick

printed tag stock as the media exits the printer. Available for 4 inch

printers only.

• Twinax/Coax Host Interface: Provides connection to a host computer

system using a coaxial or twinaxial interface.

• Dual NIC (10/100Base-T & 802.11b wireless): The Dual NIC (network

interface card) provides both 10/100Base-T or 802.11b wireless

connectivity in one. The card provides wireless connectivity without the

expansive cabling and reconfigurations required from a wired network. It

also provides 10/100Base-T for wired network and wireless back up. The

remote management software, a powerful printer management tool, is

standard with the Dual NIC (10/100Base-T & 802.11b wireless).

• NIC (10/100Base-T) Internal or External: The NIC 10/100Base-T

connectivity option provides wired networks in either an internal or

external option that allows you to attach the printer to a LAN (local area

network) instead of directly to a host computer. The remote management

software is standard with this option.

• IPDS: Available for coax/twinax, a NIC, or a combination of both. The

printer may be ordered with this option installed and the required

hardware to support it, or it can be field installed by an authorized service

representative at a later date. The printer must have a coax/twinax

interface or NIC, 300 dpi printhead, 16 MB DRAM, and 10 MB flash

memory installed to support this field-installed option.

• TN5250/TN3270: Enables your printer to communicate with an IBM host

through a NIC using the 5250/3270 datastream. This feature allows you

to use an application generated for the twinax/coax emulation to be

printed through the NIC.

24

Page 25

Thermal Printer Media

Thermal Printer Media

Because there are two modes of operation, there are two kinds of thermal

printer paper:

• Direct thermal paper: This paper is coated with chemicals that act as

accelerators, ink, and ink binders. In direct thermal mode, the heat from

the thermal printhead contacts the paper and causes a chemical reaction

on the surface of the paper.

• Thermal transfer paper: This film or synthetic paper substitute is

designed to accept transferred images well and to resist scratching. Most

thermal transfer papers can be die-cut for easy label applications.

Printronix offers a selection of thermal transfer paper sizes and face

stocks, which ensures high print quality and long life when used with

Printronix ribbons.

Ribbons

Use only Printronix Genuine Thermal Ribbons in this printer. Printronix

thermal ribbons are engineered to enhance thermal printing capabilities and

to prevent premature wear of the printhead.

Thermal Printer Technology

Unlike a dot matrix, laser, or LED printhead printer, a thermal printer has a

printhead containing heating elements that are used with paper or a ribbon

specially designed for use with a heated printhead. The SLPA uses an inline

thermal printhead, which produces high resolution output quickly and

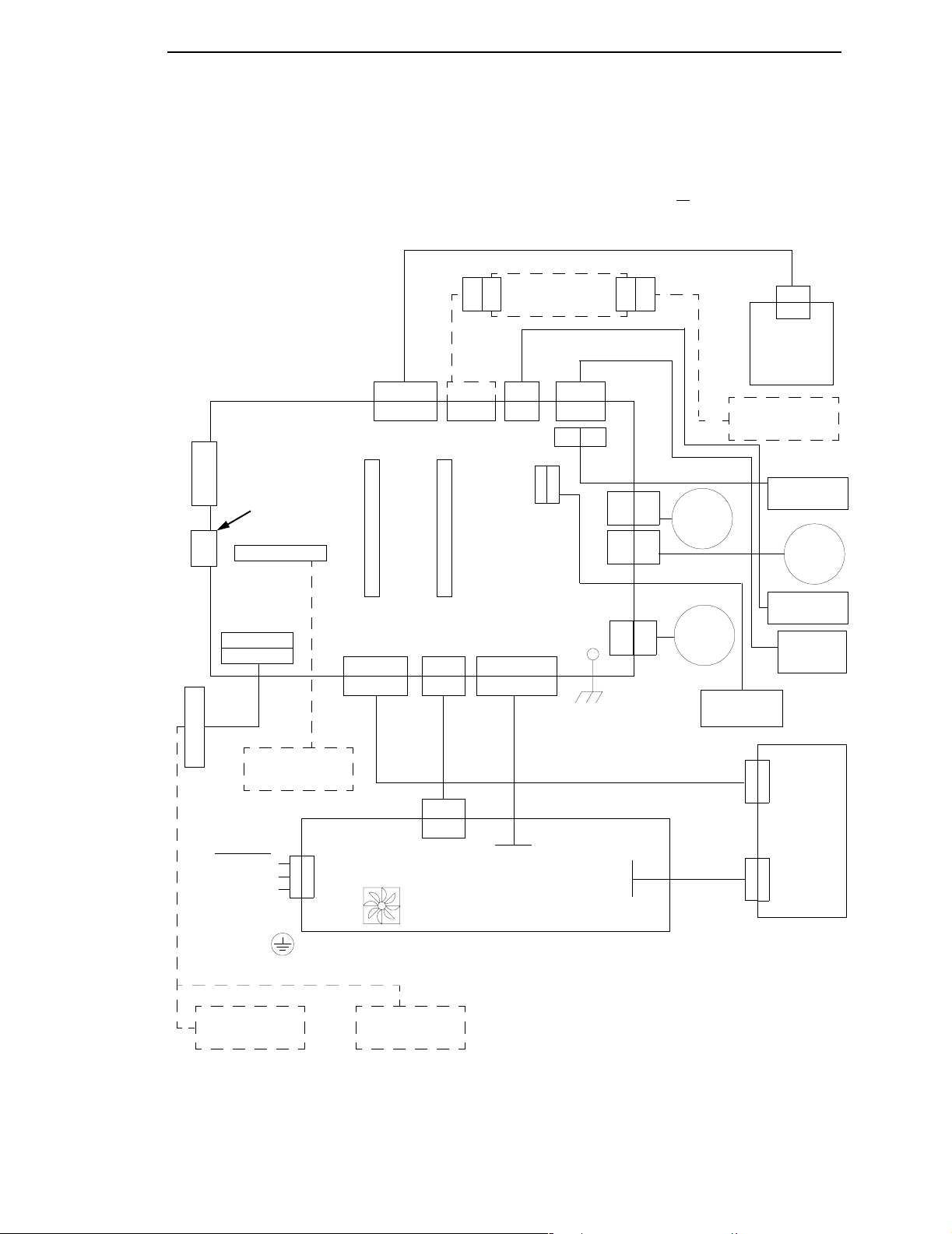

efficiently. The architecture of the SLPA is shown in Figure 2.

The Printing Process

The thermal printhead allows two modes of operation:

• Direct Thermal Mode: The thermal printhead selectively heats tiny

rectangular

coated thermal paper, the dyes and developers in the coating react to the

heat and develop an image. This mode of printing is often used for shortterm labeling applications.

• Thermal Transfer Mode: The heated dots contact a thermal ribbon; the

thermal ribbon reacts to the heat by bonding the image to the paper. This

method is especially suitable for print applications requiring long-term

storage, abrasion resistance, durability in extreme environmental

conditions, and resistance to tampering. (Models designated -DT do not

print in this mode.)

dots on its surface. When the heated dots contact specially

25

Page 26

Chapter 1 The T5000e Series Label Printer

Dynamic Print Control

Print quality in thermal printers depends on how well the thermal ribbon and

thermal transfer paper respond to the heat of the thermal printhead. The

thermal printhead must reach a specific temperature to print, then must cool

down in the shortest possible time after printing. Print quality therefore

depends on precise control of the energy supplied to the thermal dots. If

uneven print density occurs, it is usually caused by the stored heat from dots

printed previously.

The SLPA uses Dynamic Print Control technology to ensure even print

density. Dynamic Print Control is printer software that monitors and adjusts

printhead temperatures. Based on stored results of previously printed dots,

the printer predicts the amount of heat required to print subsequent dots and

regulates the electrical energy applied to the printhead. This prevents uneven

print density and permits the printing of narrow-ladder bar codes and vertical

grid lines that are absolutely straight.

26

Page 27

Thermal Printer Technology

J2

J3

J203

Parallel

Serial

Port

DB25

Port

Diagnostic Port

DB9

Expansion Port

J4

J112

P112

P13

J13

J38 J33

Flash DRAM

SIMM SIMM

J6

P6

J5

P5

J2P2

P9

J9

Controller

Cutter

PCBA Option

P11

J11

J

P

1

1

5

5

J17

P17

J21

P18

J18

P21

J16

J14

J8

P1J1

P8,

16

P14

P8,

16

Ribbon

Supply

Motor

Ribbon

Take-up

Motor

Lower Media

P301

J301

Control

Panel

Cutter Option

Upper Media

Sensor

Stepper

Head Up

Sensor

Label

Taken

Sensor

Sensor

Motor

Expansion-CT

AC Power

Line 1

Line 2/neutral

Ground (green/

yellow wire)

Ethernet NIC

Option

Option

J201

P403

CN403

Fan

Wireless Dual

NIC Option

Power Supply

Figure 2. Functional Block Diagram

P401

P402

J401

Thermal

Print

Head

J402

27

Page 28

Chapter 1 Installing The SLPA

Installing The SLPA

Unpacking Your SLPA

The SLPA has been securely packaged for protection during transportation.

Once received, follow the steps outlined below to ensure that the SLPA is not

damaged.

1. Remove the top layer of protective paper from the SLPA.

2. Lift the SLPA from the protective bottom layer of the box.

CAUTION

Do not lift or pull the SLPA by gripping the applicator pad, the

pneumatic tubing, the printhead assembly or any rollers which are

located on the front of it.

3. Save the shipping container and protective layers of paper to ensure

proper return shipping to Printronix, if necessary.

4. Organize all items as they are unpacked from their containers. Carefully

inspect each item for signs of damage. Make certain that all parts

(options) requested are received with the order.

5. Consult the enclosed packing slip for contact information if any item is

missing or broken.

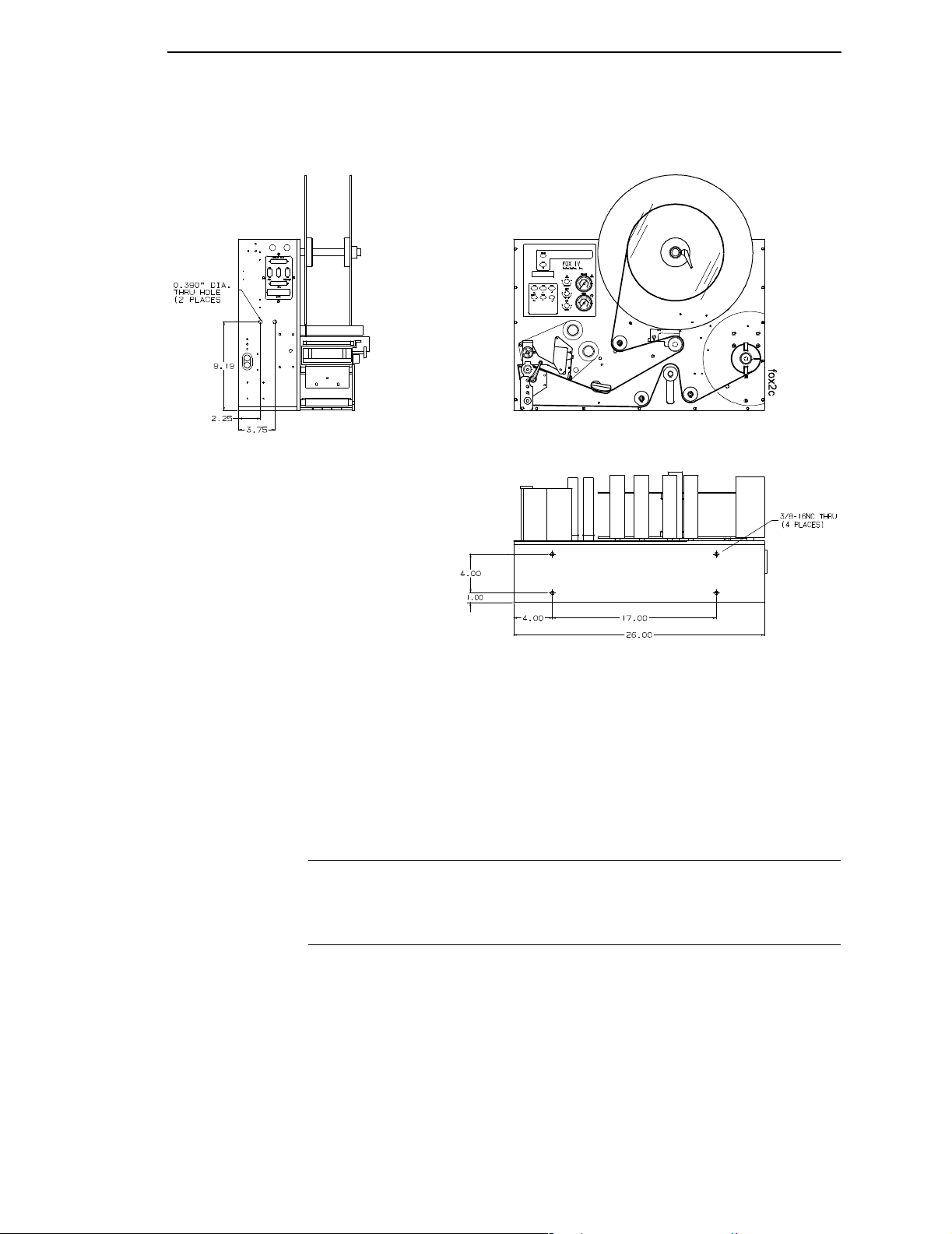

Mounting The SLPA

The mounting method for the SLPA allows for side, top, or bottom

applications.

NOTE: Specify the orientation of the SLPA when ordering. If the system is to

be used for bottom applications, custom work may be needed.

If the bottom base plate is used, the SLPA can easily be mounted to any flat

surface using the four 3/8 - 16 UNC holes provided. If the SLPA is mounted

using the 0.39 inch diameter holes provided on the side panels, special

fixturing may be needed to prevent potential damage to the connectors and

cabling in those areas.

28

To facilitate access to the control panel, the SLPA should be mounted at a

height between 2.0 feet (0.6 m) to 6.2 feet (1.9 m) above service level.

Page 29

Optional Mounting Accessories

CAUTION

IMPORTANT

Figure 3. Mounting Hole Configuration

The mounting plates of the SLPA are 0.375 inches (9.25 mm) thick.

When mounting the SLPA, use screws that will secure the assembly into

place but will not penetrate deeper than 1/2 inch (12.7 mm) in the SLPA.

Retain cap screws in mounting holes that are not to be utilized.

Optional Mounting Accessories

See “Mounting Accessories” on page 328.

Mounting The Beacon

See “Mounting The Beacon” on page 327.

29

Page 30

Chapter 1 Installing The SLPA

Air, Power, And Communications Connections

CAUTION

Any external communications cables to be used with the SLPA must be

properly shielded and grounded. Failure to provide proper shielding or

grounding for these cables could result in malfunctioning or damage to

the SLPA.

After mounting the SLPA, connect the system as follows:

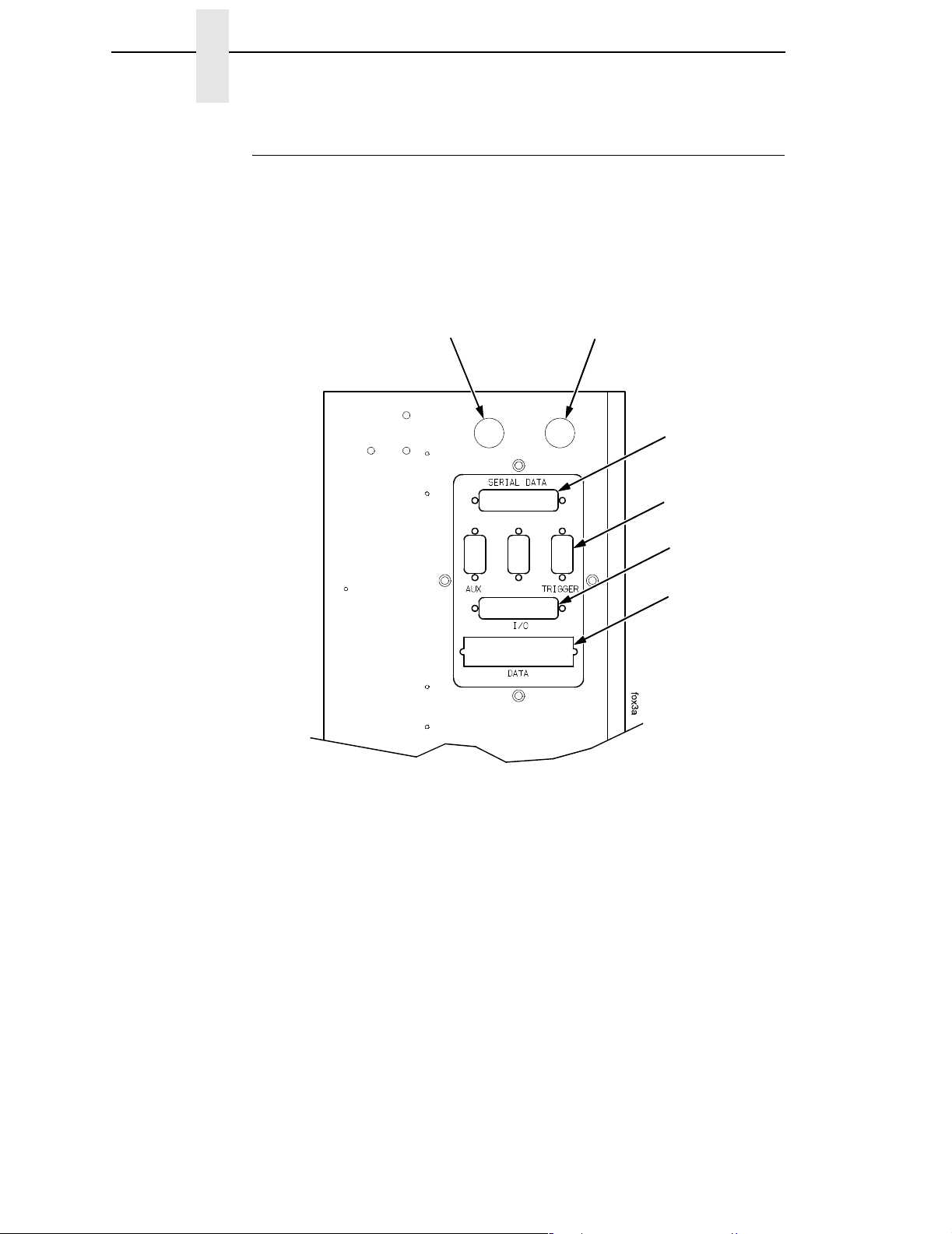

Beacon

Port

Pad Home

Port

Serial Data

Port

Trigger Port

I/O Port

Data Port

30

Figure 4. Interface Panel

1. Connect the pad home sensors mounted on the air cylinder to the pad

home port on the interface side panel. (Figure 4.)

2. Connect the interface cable to the serial data port.

3. Connect the opposite end of the interface cable to the serial

communications port of the host which will provide data.

4. Connect the product sensor connector to the trigger port.

NOTE: The I/O port is used to communicate with the SLPA’s GPIO inputs

and outputs if the optional fault/warning applicator control package is

installed.

5. If you have the IEEE-1284 parallel communications cable option, attach it

to the data port.

Page 31

Air, Power, And Communications Connections

Air Pressure

Adjustment Knob

Air Pressure

Gauge

To Air

Supply

Hose

IN

Air Supply

Connector

Air Hose to

SLPA

OUT

Quick

Connect

Air Fitting

Figure 5. Air Filter

6. If you have a fault warning beacon, connect it to the beacon port.

(Figure 4.)

The fault warning beacon can also be mounted remotely from the SLPA.

(An optional 12 feet cable extension is available.)

7. Mount the air filter according to requirements.

NOTE: Customer must provide the necessary mounting for the air filter

supplied with the system.

8. Connect the air supply hose to the air supply connector marked IN.

(Figure 5.)

9. Connect the air hose to the quick connect air fitting marked OUT.

31

Page 32

Chapter 1 Installing The SLPA

Quick

Connect

Air Fitting

Power Switch

AC Power

Receptacle

Figure 6. Power Panel

10. Connect the opposite end of the air hose to the quick connect air fitting on

the power panel. (Figure 6.)

NOTE: Make certain that all communication port parameters have been

configured according to purchase order requirements. Print

parameters must be programmed correctly to achieve the best

possible print quality. The factory settings are sufficient for most

applications. Refer to “Configuring The SLPA” on page 73 to

customize printing setup.

11. Adjust the air pressure to 90 ±10 psi using the air pressure adjustment

knob and the air pressure gauge (Figure 5): pull up the knob, then rotate it

clockwise to increase pressure or counterclockwise to decrease pressure.

Push in the knob when you have set the pressure.

12. If necessary, adjust the voltage (page 33).

13. Plug the AC power cord into the AC power receptacle. (Figure 6.)

14. Plug the SLPA and computer AC power cords into a grounded (three

prong) electrical outlet of the proper voltage.

32

15. Set the power switch to | (On) to power on the SLPA.

Page 33

AC Power

Receptacle

Selected

Voltage

Adjusting The Voltage

Facing

Arrows

Adjusting The Voltage

Power

Switch

Slot

Fuse Holder

Assembly

The facing arrows indicate the selected voltage setting. (Figure 7.). If the

setting is incorrect, adjust the voltage as follows:

1. Set the power switch to O (Off).

2. Insert the tip of a flat tip screwdriver into the slot above the fuse holder

3. Flip over the fuse holder assembly and make sure the fuse is in the active

NOTE: Refer to “Electrical” on page 322 for fuse electrical specifications.

Active Fuse

Figure 7. Adjusting the Voltage

assembly, and twist to remove the assembly.

fuse location.

4. Reinsert the fuse holder assembly. Make sure the facing arrows are

aligned properly.

33

Page 34

Chapter 1 Installing The SLPA

34

Page 35

2 Operation

Control Panel

The operation and system status of the SLPA are provided on the control

panel. Information concerning the SLPA is displayed on the liquid crystal

display (LCD), while commands are given to the SLPA through the control

panel keypad. Control valves are provided for refined adjustments to the

pneumatic system.

IMPORTANT

Online

Status

Indicator

Liquid

Crystal

Display

(LCD)

Data

Indicator

It is important to become familiar with all of the operations, readouts,

and components of the control panel. Inappropriate settings may impair

the SLPA’s functionality.

Figure 8. Control Panel

35

Page 36

Chapter 2 Control Panel

LCD

The LCD is a 2 line by 16 character per line reflective display with a light

emitting diode (LED) backlight. The LCD displays system information on the

SLPA when performing system set-up procedures, print batch status during

operation, and system information in a fault condition.

Keypad

The keypad is used to place the SLPA in operation, to perform calibration or

testing, or to modify the systems operating parameters.

The keypad functions as two key groups: SLPA control when the SLPA is

online, and menu option setting when the SLPA is offline. The use of one key

group will not interfere with the use of the other key group. The function of

each indicator and key is defined in Table 1.

Table 1. Control Panel Keys

Indicator or

Key

Online Status

indicator

Liquid Crystal

Display (LCD)

Description Online Mode Offline Mode Menu Mode

Indicates when

SLPA is online,

offline, or in fault

condition.

A 2 line by 16

character per

line reflective

display with a

light emitting

diode (LED)

backlight.

Light is on when

online, ready to

print, and accept

data from host.

Flashes during

fault condition.

Displays

ONLINE, the

interface type,

and emulation in

use.

During a fault

condition,

displays specific

fault message

and required

action.

Light is off when

SLPA is offline.

Flashes during

fault condition.

OFFLINE

During a fault

condition,

displays specific

fault message

and required

action.

Light is off.

Flashes during

fault condition.

Displays

OFFLINE, a

Main menu and

submenu, or

option.

During a fault

condition,

displays a

specific fault

message and

required action.

Pause key Switches the

SLPA between

online and

offline modes.

36

Pressing this

key when the

SLPA is online

takes the SLPA

offline.

Pressing this

key when the

SLPA is offline

places the SLPA

online.

Takes the SLPA

offline.

Page 37

Table 1. Control Panel Keys

Keypad

Indicator or

Key

Description Online Mode Offline Mode Menu Mode

Print key Print key

– (decrease) key

in Menu mode.

Feed key Feed key

↑ (up arrow) key

in Menu mode.

Apply key Apply key

+ (increase) key

in Menu mode.

Menu key

Data indicator

Menu key

Data indicator is

green when data

is in the system.

Prints the next

label in the

buffer.

Advances the

media one label

length.

Manually applies

the label.

Takes the SLPA

offline and

selects Menu

mode.

None Scrolls left

through current

menu options.

Decreases

option values in

submenus.

None Scrolls current

menu selection

up one level.

Selects the

Printer Tests

menu, and then

Scrolls right

through current

menu options.

scrolls through

the options.

Increases option

values in

submenus.

Enters Menu

mode.

Scrolls through

the Main menu

selections.

Cancel key Pressing the

Cancel key will

enable the key

and clears all

data from the

print buffer and

prevent printing

of that data.

1

↓ (down arrow)

key in Menu

mode.

↵ (Enter) key Pressing the ↵

(Enter) key in

Menu mode

selects the

displayed option

or value.

1

Cancel Key must be set to Enable in the PRINTER CONTROL menu to use

the Cancel key. The default is Disable.

None Clears all data in

the print buffer.

Selects the

Applicator Delay

menu

(page 152).

When in the

Printer Tests

menu, runs the

selected test.

Scrolls the

current menu

selection down

one level.

Selects the

current menu

value.

37

Page 38

Chapter 2 Control Panel

Key and Indicator Descriptions

For the locations of these keys and indicators, refer to Figure 8 on page 35.

Online Status Indicator

The SLPA is online when the Online status indicator light is on. When the

SLPA is offline, the light is off.

Pause Key

When the SLPA is online or in Menu mode, the Pause key takes the SLPA

offline (offline mode) and suspends all SLPA operations, but operations do

not cease until the current print or apply cycles have been completed. When

the SLPA is offline, the operator may make mechanical adjustments to the

SLPA, clear assembly line jams, etc., without powering off the system.

When the SLPA is offline, the Pause key places the SLPA back online (online

mode).

NOTE: The SLPA may automatically take itself offline in several situations

(e.g., out of labels, after recovering from a fault, etc.).

Print Key

When the SLPA is online, the Print key prints a label and feeds it to the

applicator pad if there is a label configuration in the SLPA’s print buffer. If no

label pattern exists in the buffer, it will not function.

In Menu mode, the – (decrease) key scrolls left through current menu options

or decreases option values in submenus.

NOTE: The Print key has no effect when the SLPA is offline.

Feed Key

When the SLPA is online, the Feed key advances the media one label length.

if the print buffer is currently empty. If the system is printing labels from the

buffer, this key will not function until the batch is done printing.

In Menu mode, the ↑ (up arrow) key scrolls the current menu selection one

level up.

NOTE: The Feed key has no effect when the SLPA is offline.

Apply Key

When the SLPA is online, the Apply key cycles the applicator as though the

SLPA was triggered by the product sensor. The cylinder extends to place the

label and a new label prints and is placed on the pad upon its return to the

home position.

In Menu mode, the + (increase) key scrolls right through current menu options

or increases option values in submenus.

38

Page 39

Key and Indicator Descriptions

Menu Key and Data Indicator Light

When the SLPA is either online or offline, the Menu key takes the SLPA

offline and into Menu mode.

In Menu mode, the Menu key scrolls through the Main menu of the SLPA’s

operating system. It permits the operator to set or change various operating

parameters.

The Data indicator light on the Menu key is green when data is in the system.

This data refers to the information printed on the label. If the green light is off,

there is no data in the system. There is no manual operation of this indicator.

Cancel Key

NOTE: Cancel Key must be set to Enable in the PRINTER CONTROL menu

to use the Cancel key. The default is Disable.

When the SLPA is offline, the Cancel key clears the current print pattern and

all printing programs currently in the print buffer.

After clearing the print buffer, the SLPA automatically takes itself offline. The

SLPA may then have a new label pattern downloaded to the print buffer.

Press the Pause key to place the SLPA back online.

In Menu mode, the ↓ (down arrow) key scrolls the current menu selection one

level down.

NOTE: The Print key has no effect when the SLPA is online.

↵

(Enter Key)

When the SLPA is online, the ↵ (Enter) key selects the Applicator Display

Menu (page 152).

When the SLPA is offline, the

or parameter value within the submenus. Press

parameter.

In Menu mode, the

↵ (Enter) key selects the current value.

↵ (Enter) key is used to select a menu option,

↵ to select a menu option or

39

Page 40

Chapter 2 Control Panel

Pneumatic Control Valves And Gauges

Air Cylinder Regulator

NOTE: You may also adjust the cylinder delay time through the Applicator

Delay menu. See “Applicator Delay Menu” on page 152.

The air cylinder regulator (CYLINDER valve) is used to regulate the air to the

applicator cylinder. The regulator setting affects how quickly the applicator

pad will extend (apply stroke) and return (return stroke) during the apply

cycle. This adjustment determines the force with which the applicator pad will

contact the product. If set too high, the applicator pad could contact the

product with enough force to cause damage. If set too low, the applicator pad

may not contact the product. The air pressure delivered for the apply stroke

and the return stroke is equal.

Monitor the setting of the air cylinder regulator using the PRESSURE gauge.

Air Jet Adjustment

The air jet adjustment (AIR JET) controls the air supply to the air jet tube. Air

is forced out the air jet tube allowing the labels to properly transfer over the

peel bar then to the applicator pad. If the adjustment is too low, the labels will

not properly transfer from the printer to the applicator pad. If set too high, the

label edge will be incorrectly positioned. The air jet is factory preset. Adjust

the air jet pressure by turning the AIR JET control clockwise to increase the

flow, counterclockwise to decrease the flow. See “Positioning The Air Jets” on

page 52.

Vacuum Adjustment

NOTE: You may also adjust the vacuum delay time through the Applicator

Delay Menu. See “Applicator Delay Menu” on page 152.

The vacuum adjustment (VACUUM) controls the amount of air flow through

the vacuum generator, thus determining the amount of vacuum holding the

label onto the applicator pad. A weak vacuum will cause labels to fall off of the

applicator pad prematurely. A vacuum that is too strong, however, can cause

difficulty when transferring the label onto the applicator pad and the product.

Vacuum is increased by rotating the valve clockwise and decreased by

rotating the valve counterclockwise.

NOTE: To get a vacuum on every label, every hole on the applicator pad

must be covered by the label surface.

Monitor the setting of the vacuum adjustment using the VACUUM gauge.

40

Page 41

Setup

Removing Label Backing

Removing Label Backing

If the media rewind spool needs to be unloaded during operation, proceed as

follows:

1. Press the Pause key to take the SLPA offline. Disable the product sensor

if necessary.

2. Tear the label backing near the media rewind hub, then reach around the

rewound backing, placing your fingers behind the hub of the media rewind

spool.

3. Pull the rewind spool away from the centerwall plate until the rewind

release bars collapse toward the center of the hub, then pull off the used

label backing. The rewind hub will snap back into position near the

centerwall once the used label backing is removed.

4. Feed a few blank labels by inserting the new edge of the label backing

into the slit on the rewind spool and manually rotate the spool at least one

turn counterclockwise.

5. Press the Pause key to place the SLPA online then enable the product

sensor to continue operation.

Threading The Label Roll

Pivoting Deck

Deck Lock Lever

Figure 9. The Printhead Assembly

41

Page 42

Chapter 2 Setup

1. Press the Pause key to take the SLPA offline.

2. Open the pivoting deck by rotating the deck lock lever fully clockwise.

Label Roll Hub

Label Roll Core

Label Roll

Retainer

Label Roll Hub

Collar

Cam Lock

Figure 10. Mounting Label Media

3. Loosen the cam lock located on the collar of the label roll hub.

4. Slide the label roll retainer off the label roll hub.

5. Remove the empty label roll core, if necessary, from the label roll hub.

42

Page 43

Label

Threading The Label Roll

Label Roll

Back Stop

Label Roll

Spindle

Label Roll

Retainer

Collar

Label Roll

Cam Lock

Figure 11. Loading Label Media

6. Slide the new label roll onto the label roll hub (unwinding

counterclockwise) and against the label roll back stop.

7. Angle the flat edge of the collar so that it aligns with the flat edge of the

label roll spindle.

8. Place the label roll retainer onto the label roll spindle until it is flush with

the label roll, then tighten the black cam lock.

NOTE: If necessary, loosen the set screw on the collar and adjust the core

blade so that it cuts into the label core.

43

Page 44

Chapter 2 Setup

Label Roll

Retainer

Label Roll

Brake

Assembly

Printhead

Platen

Label

Media Damper

Backing (Liner) Path

Figure 12. Loading Labels

9. Unwind approximately 3.0 feet (91cm) of media from the label roll. If your

label roll does not have a leader, remove the labels from the backing. The

empty backing (leader) will act as a leader to thread the media through

the SLPA components.

10. Pull the brake assembly away from the label roll back stop (behind the

label roll retainer) to release the tension.

11. Thread the leader around the rollers and toward the media damper using

the solid white arrow threading diagram etched on the front center wall

plate.

44

Page 45

Media Guard

Threading The Label Roll

Lower Media

Sensor

Leader

Fixed Guide

Media Sensor

Handle

Media Damper

Media Width

Guide

Figure 13. Threading Media Through the Printhead Assembly

12. Slide the media width guide close to the outside end of the media

damper.

13. Thread the leader under the media damper and then between the platen

(rubber drive roller) and the printhead.

14. Verify that the inside edge of the leader is against the fixed guide on the

bottom of the media damper.

15. Push the media width guide in until it is flush with the outer edge of the

media.

NOTE: Do not wrinkle the leader by pushing the media width guide too close

to the SLPA panel.

16. Check the horizontal position of the lower media sensor (located under

the media guard). See “Positioning The Media Sensors” on page 56.

45

Page 46

Chapter 2 Setup

Printhead

Assembly

Upper Media

Sensor

Visible Red Beam

Lower Sensor

Upper Sensor

Handle

Platen Roller

Figure 14. Threading the Leader

17. Slide the upper sensor directly over the lower sensor.

18. Thread the leader between the printhead assembly and across the top of

the platen roller.

46

Page 47

Peel Bar

Threading The Label Roll

Media Edge

Platen

Figure 15. Aligning Media

19. Align the inside edge of the media with the inside edge of the peel bar.

20. Thread the leader over the peel bar, then between the lower platen roller

and the air jet.

21. Follow the label guide arrows from the printhead, around the rollers to the

media rewind spool.

22. Fold the leading edge of the leader and insert it into the slit on the rewind

spool. Make sure the leader lines up closely to the SLPA panel.

23. Manually rotate the spool at least one turn counterclockwise.

NOTE: Hold the leader down while rotating the rewind spool to keep the

leader in place.

24. If the SLPA is being used in Thermal Transfer mode, it may be necessary

to load ribbon. See “Loading Ribbon” on page 49, otherwise proceed as

follows.

47

Page 48

Chapter 2 Setup

Pivoting Deck

Deck Lock

Lever

IMPORTANT

Figure 16. Locking the Pivoting Deck

25. Ensure that the label path is clear of obstructions, then close the pivoting

deck and rotate the deck lock lever fully counterclockwise. This locks the

pivoting deck and printhead assembly into the printing position.

Ensure the pivoting deck is down and locked before attempting to

advance media or print. Failure to do so will cause the PRINTHEAD UP

fault message to display.

26. Press the Pause key to place the SLPA online, and send a label format

via the host.

48

Page 49

Pivoting Deck

Loading Ribbon

Loading Ribbon

Ribbon Take-Up Core

Ribbon Take-Up

Spindle

Ribbon Supply

Spindle

Ribbon Roll

Deck Lock Lever

Figure 17. Loading Ribbon

1. Press the Pause key to take the SLPA offline.

2. Install the ribbon take-up core on the ribbon take-up spindle.

NOTE: The first ribbon take-up fiberboard core comes with the SLPA.

Thereafter, use the fiberboard core from the old (used up) ribbon.

3. Slide the ribbon roll onto the ribbon supply spindle until it stops against

the spindle flange.

4. Open the pivoting deck by rotating the deck lock lever fully clockwise until

the deck swings upward.

49

Page 50

Chapter 2 Setup

Printhead

Ribbon

Rear Ribbon

Guide Roller

Figure 18. Threading Ribbon Through the Printhead Assembly

5. Thread the end of the ribbon under the rear ribbon guide roller, then

between the platen and the printhead using the dotted line etched on the

front center wall plate.

50

Page 51

Ribbon

Loading Ribbon

Ribbon

Take-up Core

Ribbon

Take-up Spindle

IMPORTANT

Figure 19. Attaching the Ribbon to the Take-up Core

6. Wrap the ribbon from the front of the printhead assembly to the top of the

ribbon take-up spindle. Attach the ribbon to the take-up core on the ribbon

take-up spindle with tape.

When installing a new roll of ribbon, attach the ribbon leader adhesive

strip to the ribbon take-up core. Manually rotate the spindle clockwise to

feed the unusable portion of the ribbon leader around the take-up spindle.

Do not attach the ribbon to the ribbon take-up spindle without a ribbon

take-up core installed.

7. Close the pivoting deck and rotate the deck lock lever fully

counterclockwise.

8. Press the Feed key once to verify that the media and ribbon advance.

9. Press the Pause key to place the SLPA online, then send a label format

via the host.

51

Page 52

Chapter 2 Setup

Positioning The Air Jets

When a printed label is being fed from the SLPA onto the applicator pad, it