Page 1

POWERMATIC DDS-225/DDS-237 Dual Drum

Sander

The POWERMATIC DDS-237 Dual Drum Sander is a

production class machine that is loaded with features and

available in configurations to suit your needs. The

#1791321 (DDS-237, 37” drums) is equipped with a

10HP, 230/460V (prewired 230V), 3 PH motor. Also

available are the #1791320 (DDS-237 37”-drums) with a

7.5HP, 230V, 1Ph motor and the #1791290 (DDS-225,

25”-drums) powered by a 5HP, 230V, 1Ph motor. All

POWERMATIC Dual Drum Sanders are protected with a

full magnetic On-Off switch. Aside from the 25” drum

length of the DDS-225, the features remain similar.

The POWERMATIC DDS-237 Dual Drum

Sander is a very capable solution for your

sanding needs.

Size and Capacity

Despite the compact 60”-wide x 45”-deep x 45”tall overall size, (DDS-237 model) the

POWERMATIC Dual Drum Sanders have the

capacity to handle a huge range of jobs from

small to large. With a minimum board length of

just 9”, a minimum thickness of 1/32” and

maximum thickness of 5-1/4”, these sanders offer

expansive job coverage.

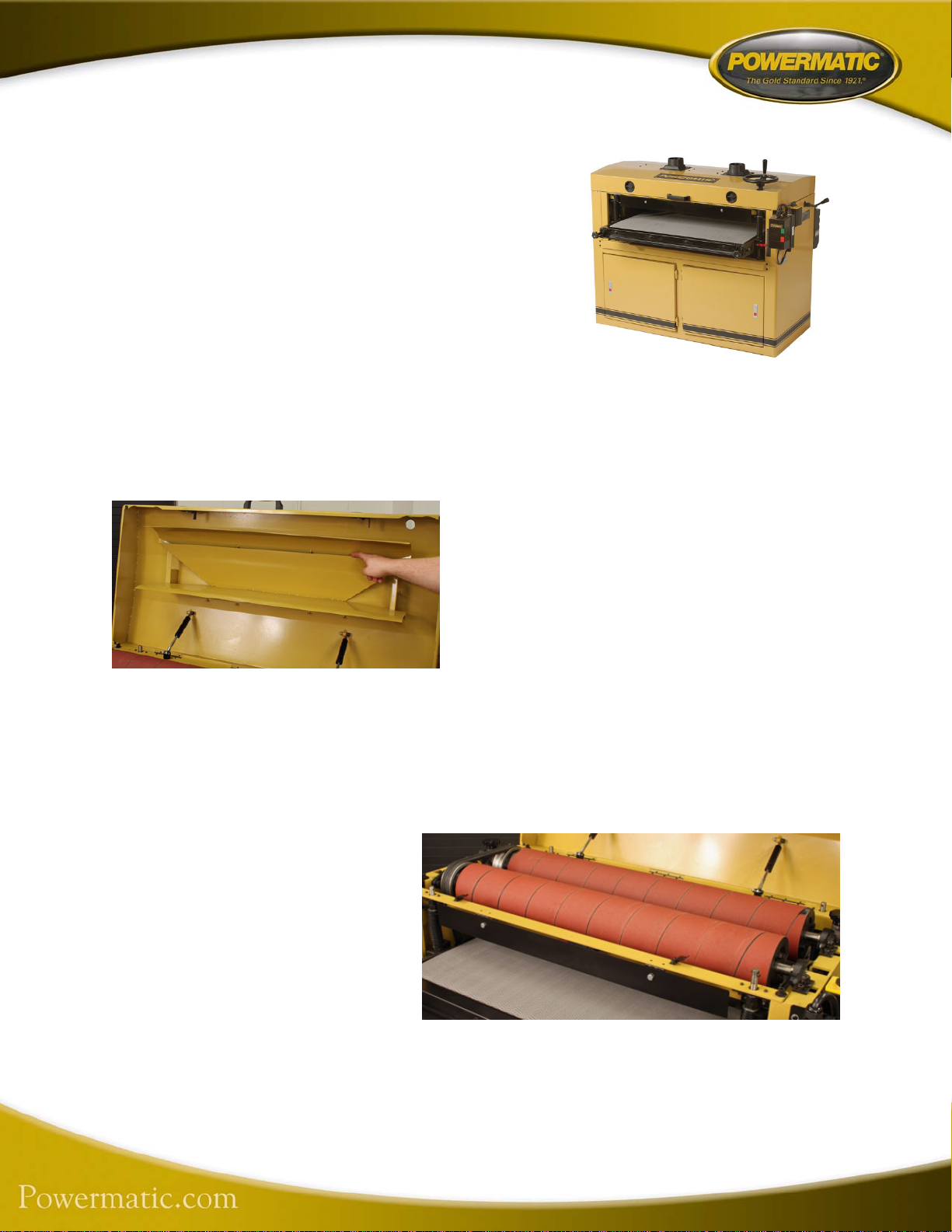

The top of the cabinet opens for easy access to the drums

and shows the special dust system that helps keep this

machine performing.

Spacious Cabinet

The POWERMATIC Dual Drum Sanders are enclosed in an all-steel cabinet. Compartments

with latching doors at the bottom enclose the motor, drive systems and provide spacious storage.

Removable panels provide good access to important systems when needed.

The full-width, hinged steel top opens

to make working with the drums and

roller systems easy. Built into the top

are a pair of 4”-diameter dust ports.

These ports connect to specially

designed directional baffles within the

top that enhance the effectiveness of

the dust evacuation. For maximum

efficiency, a dust collector system

with a minimum 1200-CFM (cubic

feet per minute) capacity should be

The rubber-covered steel drums enhance accuracy and consistency.

used.

Page 2

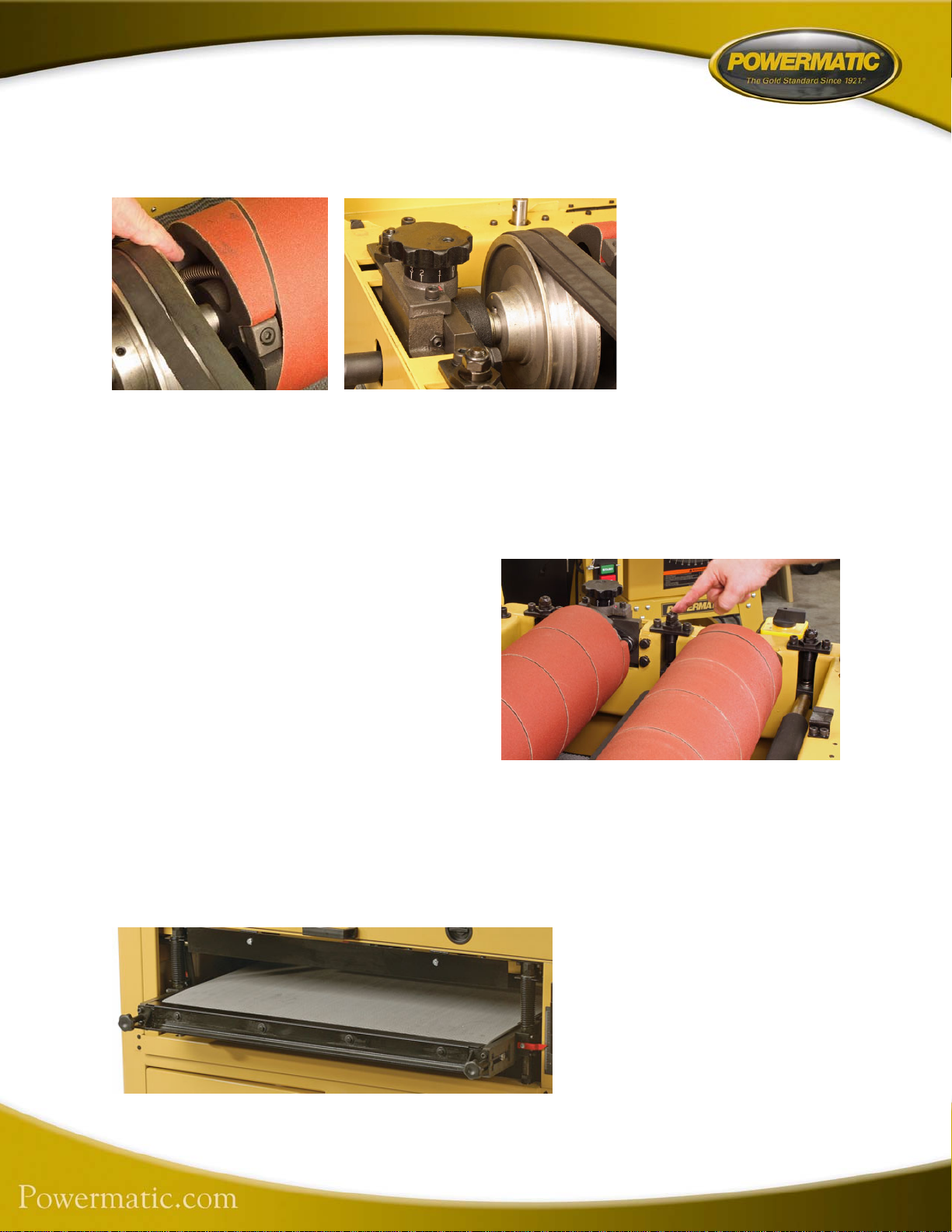

Steel Drums

The POWERMATIC

Dual Drum Sanders

feature dual steel drums

spinning at a consistent

1700-RPM that are

precisely machined and

then given a hard

durometer rubber coating

Installing abrasive strips (left) is easy and secure with the wedge retainers. The rear drum

is adjustable (right) using this knob to compensate when using different abrasive grits

than on the front drum.

that ensures a flat, nonmarring surface. These

6”-diameter steel drums

have the strength to resist

flex during sanding for

maximum accuracy and consistency.

The rear drum is independently adjustable, which allows fine-tuning, especially when it is

equipped with a different grit paper than is on

the front drum. A special graduated knob at

either end of the rear drum makes setting this

height for the abrasive grit being used easy and

accurate. We include a handy chart on the

cabinet below the adjustment that shows the

correct settings for the various grits.

The abrasive strips can be purchased ready to

cut or can be cut in your shop. The strips are

secured to the drums using simple but very

tough and highly effective wedges. Tuck the end

The pressure rollers are easily adjusted with these tough but

simple mechanisms located up top for easy access.

of the paper in, insert the wedge and tighten the

retaining bolt.

The pressure rollers are also fully adjustable. The easy to use adjusters are located on top at

either end of the rollers for easy access. These adjusters are designed to be rugged and to hold

their adjustment during long periods of use. The full adjustment procedure is described in the

instruction manual.

Conveyor Table and Belt

A heavy cast iron table has been

precisely machined to insure

flatness. The table is raised and

The conveyor belt runs on a precision cast iron table for flatness and

consistency.

Page 3

lowered on four jackscrews turned simultaneously by a slip-free chain

drive. That chain drive also

keeps the table level at all

heights. The chain drive has

an automatic tensioning

system built in to reduce

setup and adjustment. The

table height system is

operated by a large cast iron

handwheel at the top of the

POWERMATIC Dual

Drum Sanders. An easy-toread depth gauge next to the

table makes presetting table

The conveyor is driven by a two-speed gearbox (left) that is shifted while the belt is

running. Each side of the conveyor has an easy adjuster (right) for belt tracking and

tension

for specific material

thicknesses easy.

The heavy-duty poly conveyor belt provides a positive grip on the material being sanded. The

high-quality conveyor belt has tracking adjusters at either end of the table. These adjusters also

control belt tension.

The 1/4HP feed motor drives the conveyor belt and is

controlled by a two-speed forward/reverse gearbox that

produces feed rates of 8 and 12 SFPM (surface feet per

minute). The gearbox can only be shifted between the low

and high feed rates while the machine is running. The

conveyor belt can also be reversed, using a separate threeposition switch with forward, off and reverse positions.

Reversing can be handy in the event that a problem

develops, the belt can be reversed to safely bring the piece

back out. That lets you correct the problem more easily.

The POWERMATIC Dual Drum Sanders are designed with

the industrial environment in mind. They are tough, easy to

Industrial-tough controls, including a full

magnetic switch protect the

POWERMATIC Dual Drum Sanders.

use and easy to maintain. Their wide capacity ranges mean

one machine handles more jobs, making the P

OWERMATIC

Dual Drum Sanders a very cost-effective investment.

Loading...

Loading...