Page 1

This .pdf document is bookmarked

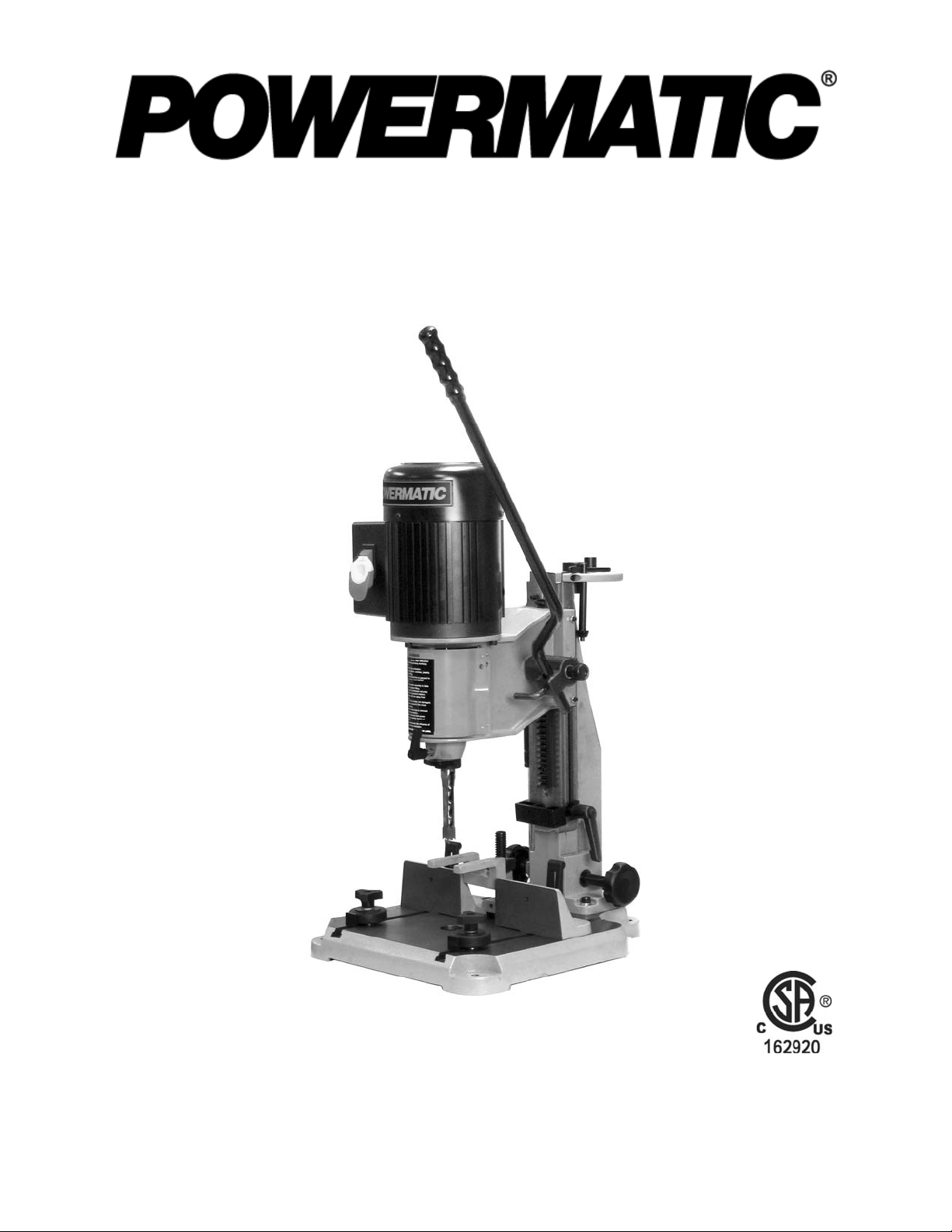

Operating Instructions and Parts Manual

Deluxe Bench-top Mortiser

Model: 701

WALTER M EIE R (Manufac turing) Inc.

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-1791310

Ph.: 800-274-6848 Revision B1 02/2012

www.powermati c.c om Copyright © 2012 Walter Meier (Manufacturi ng) Inc .

Page 2

Warranty and Service

Walter Meier (Manufacturing) Inc., warrants every product it sells. If one of our tools needs service or repair, one of our

Authorized Service Centers located t hroughout the United States can give you quick service. In most cases, any of t hese W alter

Meier Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or perform routine maintenance

and major repair on your POWERMATIC

MORE INFORMATION

Walter Meier is consistently adding new products to the line. For complete, up-to-date product information, check with your local

Walter Meier distributor, or visit powermatic.com.

WARRANTY

POWERMATIC products carry a limited warranty which varies in duration based upon the product.

®

tools. For the name of an Authorized Service Center in your area call 1-800-274-6848.

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the exceptions stated below. Cutting tools, abrasives

and other consumables are excluded from warranty coverage.

WHO IS COVERED?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The general POWERMATIC warranty lasts for the time period specified in the product literature of each product.

WHAT IS NOT COVERED?

The Five Year Warranty does not cover products used for commercial, industri al or educational purposes. Products with a Five

Year Warranty that are used for commercial, industrial or education purposes revert to a One Year Warranty. This warranty does

not cover defects due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear, improper repair or

alterations, or lack of maintenance.

HOW TO GE T SERVICE

The product or part must be returned for examination, postage prepaid, t o a location designated by us. For the name of the

location nearest you, please call 1-800-274-6848.

You must provide proof of initial purchase dat e and an explanation of the complaint must accompany the merchandise. If our

inspection discloses a defect, we will repair or replace the product, or refund the purchase price, at our option.

We will return the repaired product or replacement at our expense unless it is determined by us that there is no defect, or that the

defect resulted from causes not within the scope of our warranty in which case we will, at your direction, dispose of or return the

product. In the event you choose t o have the product returned, you w ill be responsible for the handling and shi ppi ng cost s of the

return.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.

LIMITATIONS ON THIS WARRANTY

WALTER MEIER (MANUFACTURING) INC., LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED

WARRANTY FOR EACH PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTABILITY

AND FITNESS ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY

LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

WALTER MEIER SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR PRODUCTS.

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO

THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Walter Meier sells through distributors only. The specifications in Walter Meier catalogs are given as

general inf ormation and are not bindi ng. Members of Walter M eier reserve the right to eff ect at any time,

without prior notice, those alterat ions to parts, fit tings, and accessory equipm ent which they m ay deem

necessary for any reason whatsoever.

2

Page 3

Table of Contents

Warranty and Servic e .............................................................................................................................. 2

Table of Contents .................................................................................................................................... 3

Warnings ................................................................................................................................................. 4

Introduction ............................................................................................................................................. 6

Specifica tions .......................................................................................................................................... 6

Unpac king ............................................................................................................................................... 7

Contents of the Mortiser Carton ............................................................................................................ 7

Assembly ................................................................................................................................................ 7

Gib Screw s .......................................................................................................................................... 7

Operating Handle ................................................................................................................................. 8

Gib Adjustment .................................................................................................................................... 8

Overview – Chuck Ext ensi on ................................................................................................................ 9

Installing the Chuck Extension.............................................................................................................. 9

Installing Chisel and Auger ................................................................................................................. 10

Securing Mortiser to Work Bench ....................................................................................................... 11

Tool Holder ........................................................................................................................................ 11

Diamond Sharpeni ng Cone ................................................................................................................ 11

Electrical ............................................................................................................................................... 11

115V/230V Operati on ......................................................................................................................... 11

Power Connection .............................................................................................................................. 11

Grounding Instr uc tions ....................................................................................................................... 12

Operating Controls ................................................................................................................................ 12

Start/Stop Switch ............................................................................................................................... 1 2

Adjustments .......................................................................................................................................... 1 2

Depth Stop Adjustment ...................................................................................................................... 12

Chisel Parall el to W orkpiece ............................................................................................................... 13

Fence and Clamp ............................................................................................................................... 14

Fence Adjustm ent ........................................................................................................................... 14

Hold-down Clamp ........................................................................................................................... 1 4

Operation .............................................................................................................................................. 1 5

Rotating Column ................................................................................................................................ 15

Maintenance .......................................................................................................................................... 16

General .............................................................................................................................................. 16

Sharpening Chisel and A uger ............................................................................................................. 16

Auger ............................................................................................................................................. 16

Chisel ............................................................................................................................................. 16

Handle Position Adjustment ............................................................................................................... 12

Lubrication............................................................................................................................................. 16

Parts List ............................................................................................................................................... 17

Assembly Drawing ................................................................................................................................. 19

Wiring Diagram ...................................................................................................................................... 20

Optional Accessories ............................................................................................................................. 20

Ordering Replacement Parts.................................................................................................................. 20

3

Page 4

Warnings

1. Read and understand the entire owner's manual bef or e att em pting assembly or operation.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Failur e to comply wit h

any of these warnings may c ause serious i njury.

3. Replace the warning labels if they become obscured or removed.

4. This mortiser is designed and i ntended f or use by properly trai ned and experi enced personnel onl y. If

you are not f amiliar wit h the proper and safe operat ion of a mortiser, do not use unti l proper t raining

and knowledge have been obtained.

5. Do not use this mortiser f or other than its intended use. If used for other purposes, W alter Meier

(Manufactur ing) Inc., di sclaims any real or implied warranty and hol ds itself harmless from any injur y

that may result from that use.

6. Always wear approved safety glasses/face shields while using this mortiser. Everyday eyeglasses

only have impact resi stant lenses; they are not safety glasses.

7. Before operating this morti ser, remove tie, rings, watc hes and other jewelry, and roll sleev es up past

the elbows. Rem ove all l oose clothing and confine long hair . Non-slip footwear or anti- skid floor strips

are recommended. Do not wear gloves.

8. Wear ear protector s (plugs or muffs) during extended peri ods of oper ation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemi cals known to cause cancer , birt h defects or other repr oductiv e harm. Some examples

of these chemic als are:

• Lead from lead based paint.

• Crystalline sil ic a from bricks, cement and other m asonry pr oduc ts.

• Arsenic and chromium from chemically treated lumber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not operate this machi ne while tired or under the influence of drugs, al c ohol or any m edic ation.

11. M ak e c er tain the switch is in the OFF position before connecting the machine to the power supply.

12. M ak e c er tain the machine is properly grounded.

13. M ak e all machine adjustments or maintenance with the machine unplugged f r om the power source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

15. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use ext r eme caution and replace the guards imm ediately.

16. M ak e sure t he m or tiser is firmly secured to the fl oor or bench bef or e use.

17. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Check for alignment of moving part s, binding of moving parts, break age of parts, mounting

and any other condi ti ons that m ay affect its operati on. A guard or ot her part that i s damaged should

be properly repaired or replaced.

18. P r ov ide for adequate space surroundi ng work area and non-glare, ov er head lighting.

19. K eep the floor around the machi ne cl ean and free of scrap material, oil and grease.

20. K eep v isitors a safe distance from the work area. Keep children away.

4

Page 5

21. M ak e y our workshop chi ld proof with padlock s, m aster swit c hes or by r em ov ing starter keys.

22. Giv e your work undivided attention. Looking around, carrying on a conversation and “horse-play” are

careless acts that can result in serious injury.

23. Maint ain a balanced stance at all times so that you do not fall or lean agai nst the chisel and dril l bits

or other moving parts. Do not overreach or use excessive forc e to perform any machine operation.

24. Use the ri ght t ool at the corr ect speed and f eed rat e. Do not force a t ool or attac hment to do a j ob for

which it was not designed. T he ri ght tool will do the job better and safer.

25. Use recom mended accessories; improper accessories m ay be hazardous.

26. Maintain tools with care. Keep chisel and drill bits sharp and clean for the best and safest

perform anc e. Foll ow instr uc tions for lubricati ng and c hanging ac c essories.

27. Make sure the work pi ece is securely attached or cl amped to the table. Nev er use your hand to hol d

the work piece.

28. Turn off the m ac hine before cleaning. Use a brush or compressed air to rem ov e c hips or debris — do

not use your hands.

29. Do not stand on the machine. Seri ous i njur y c ould oc c ur if the mac hine tips over.

30. Never leave the mac hine r unning unattended. Turn t he power off and do not leave the machine until it

comes to a complete stop.

31. Remove loose items and unnecessary work pieces from the area bef or e start ing the machine.

Familiarize you rself with the following safety no tices used in this manual:

This means that if precautions are not heeded, it may result i n mi nor i njur y and/or

possible machine damage.

This means that if precautions are not heeded, it may result i n serious injury or possibly

even death.

- - SAVE THESE INSTRUCTIONS - -

5

Page 6

Introduction

This manual is provided by Walter Meier (Manufacturing) Inc., covering the safe operation and

maintenance pr ocedures for a M odel 701 Delux e Bench-top Mor tiser. Thi s manual contai ns instructions

on installation, safety precautions, general operating procedures, maintenance instructions and parts

breakdown. This machine has been desi gned and constr uc ted to provide y ear s of trouble free oper ation if

used in accordance to instructions set forth in this manual. If there are any questions or comments,

please contact eit her your local supplier or Walter Meier. Walt er Meier can also be reached at our web

site: www.walte rm eier.com.

Specifications

Model No. ............................................................................................................................................ 701

Stock No. .....................................................................................................................................1791310

Chisel shank capacity, maximum ......................................................................................................... 3/4"

Chuck capacity, maximum ................................................................................................................... 1/2"

Chisel stroke, maximum.................................................................................................................... 5-1/2"

Chise l cente r to fenc e d is ta n c e ......................................................................................................... 4-3/8"

Bushing sizes provided ................................................................................................................ 5/8", 3/4"

Fence size ......................................................................................................................... 12-1 /2" x 2-5/8"

Base size ...................................................................................................................... 16-5/16" x 13-3/4"

Capacity under hold- down ...................................................................................................................... 5"

Spindle speed............................................................................................................................ 1725 RPM

Motor (TEFC) ....................................................................... 3/4 HP, 1 PH, 4P, 115V/230, Pre-wired 115V

Weight (net/shippi ng) ................................................................................................................. 93 / 100 lb

The above specifications were current at the time t his manual was published, but because of our policy of

continuous improvement, Walter M eier reserves the right to change specifications at any time and without

prior notice, wit hout incurring obligati ons.

6

Page 7

Unpacking

Remove content s from the shippi ng carton. Check

for damage and ensure all parts are intact. Any

damage should be reported immediately to your

distributor and shipping agent. Read the manual

thoroughly to familiarize yourself with the correct

assembly and maintenance procedur es and proper

safety precautions.

Contents of the Mortiser Carton

1 ea – Mortiser (not shown)

1 ea – 3/4" Chisel Bushing (A )

1 ea – Chuck Extension Adaptor ( B )

1 ea – Chuck Key (C)

1 ea – Operating Handle (D)

Assembly

Do not connect th e machine to

power source until completely

assembled. Read and understand the entire

manual.

Gib Screws

The Powermatic Model 701 Deluxe Bench-top

Mortiser is packaged with the head locked to

prevent movement during shipment and is in the

down position.

Referring to Figur e 1:

1. Using a 10mm wrench loosen three lock nuts.

Contents of the Mortiser Car ton

2. With a 3mm hex wrench loosen three gib

screws the same amount. Loosen enough to

permit the head to move freely on the column.

Do not tighten. The gib adjustment will be done

later.

Figure 1

Page 8

Operating Handle

Referring to Figur e 2:

The operating handle can be mounted on either

the left- or right-hand side of the mortiser. The

handle hub (D) comes mounted on the right-hand

side from the factory. If right-hand operation is

desired skip steps 1– 3 and proceed to step 4. F or

left-hand operati on the hub must be moved t o the

left side as follows:

1. Unscrew and remove the hub lock knob (A),

flat washer (B), spring (C) and hub (D) from

the pinion shaft (E).

2. Remove the protective sleeve from the gear

shaft on the left side of the m or ti ser.

3. Install the hub (D), spring (C) and flat washer

(B) on the left-side pinion shaft and secure the

assembly with t he hub loc k knob (A).

Referring to Figur e 3:

4. Loosen the lock handle (F) located on the

hub (H).

5. Insert the operating handl e int o the bracket on

the hub. Positi on the upper part of the handle

away from the m ortiser allowing it to clear t he

switch box duri ng operat ion.

Figure 2

Note: If handle is mounted on the right side,

also position t he handle so the upper port ion is

away from the mortiser

Note: The handle assembly is spring-loaded

permitti ng the operating handle t o be repositioned

by pulling out the hub (H) and repositioning it in 36º

increment s (t en posi tions total) on the pinion shaft.

Gib Adjustment

Now that the operati ng handle has been install ed,

the gib screws that were previously loosened

should be adjusted.

Alternat ely raise and lower the mort iser head with

the operating handl e, then adj ust each of t he three

set screws (Figur e 1) with a 3mm hex wrench the

same number of turns.

Tighten the set screws to remove play from the

column but do not over tighten such that it is

difficult t o rai se and l ower the oper ating handle.

When adjustm ent is complete, tighten the loc k nut

with a 10mm wrench while maint aini ng the positi on

of the setscrew with t he 3 mm hex wrench.

Figure 3

8

Page 9

Overview – Chuck Extension

Do you need it

The 701 Mortiser comes with the chuck already

assembled at the f actory, intended to be used with

augers havi ng long shanks. Augers come with long

or short shanks (Figure 4) depending on the

manufacturer.

Long shank augers

If you plan to install an auger with a long shank,

you can skip this section and proceed to the

Installing Chisel and Auger sect ion on page 10.

Short shank augers

If you plan to i nstall an auger with a short shank,

proceed to Installing the Chuc k E x tension section.

Figure 4

Installing the Chuck Extension

Referring t o Figure 4, remove the chuc k from the

motor shaft as follows:

1. Open door (A).

2. Unscrew and remove the chuck (B) from the

motor shaft (C) using a 12mm wrench pl aced

on the flat indents of the shaft (C) and the

chuck key in the chuck (B).

3. Thread the chuck extens ion (D) ont o the motor

shaft (C).

4. Tighten using 12mm and 14mm wrenches

respectiv ely on flat sides of the motor shaft (C)

and chuck ext ens ion (D).

5. Thread the chuck (B) onto the chuck

extension (D).

6. Ti ghten using a 14mm wrench on flat sides of

the chuck extension (D) and the chuc k key in

the chuck (B).

Figure 5

9

Page 10

Installing Chisel and Auger

Referring to Figur e 6:

1. Open door (A).

2. Swing two bushing spacers (B) away from the

head (C).

3. Loosen the lock screw (D).

4. Insert the chi sel bushing* (E) into the head (C),

lining up the hole (F) with the lock screw (D).

5. Set the lock screw (D) so the threaded end

extends into the hole (F) of the bushing (E),

holding it in place. The bushing should still

have about 1/4" of vertical travel margin.

The chis el to a uger cle aranc e (see F igure 5) is the

vertical cl ear anc e between the auger and chisel.

When assembled, the proper chisel to auger

clearance i s dependant on the chisel size and t he

position of the chisel (adjustable) with respect to

the auger (which is fixed). The position of the

chisel is set with spacers described in the foll owing

steps.

6. Position spacers (B) so they rest against the

bushing above the lip (J).

Number of spacers to use:

For chisels 1/2" or less – use the

upper spacer only

For chisels greater than 1/2" – use

both spacers

Chisels are extremely sharp.

Use extreme care when handling to prevent

perso nal inju r y .

7. Insert the auger (K) into the chisel (L). Then

insert the assembly through the bushing (E).

Using gloves or a bl ock of wood, press up on

the auger as far as it will go. The shank should

slide into the opening in the bottom of the

chuck (M).

8. Using t he chuck key, tight en the chuck (M) to

secure the auger (K).

9. Move the spacers (B) away from the

bushing (E), push the chisel and bushing up

against the head (C); then tighten the lock

screw (D).

Hint: S et the slot i n the side of the chisel to the left

or right if the workpiece is to be moved laterally

and front or back if it is to be moved from front t o

back. The workpi ece should be mov ed so that the

slot in the c hisel is rel easing chips into t he already

cut part of the workpiece (see Fi gur e 13) .

*

Only if c hanging bus hings. Th e 701 Mortis er comes wit h the

5/8" bushi ng already ins talled.

Figure 6

Note: Thi s would be a good time to make sure that

the chisel is parallel to the workpiece. See the

Chisel Parallel to Wor k piec e sect ion.

10

Page 11

Securing Mortiser to Work Bench

It is highly recommended t o secure the mor tiser to

the workbench to prev ent the possibil ity of tipping,

sliding or "walking" during operation.

Secure the mortiser to the bench with fasteners

(not supplied) through four holes located in the

base (Figure 7).

Tool Holder

Referring to Figur e 8:

The 701 Bench-top M ortiser has a tool holder (A)

that is installed at the factory and requires no

assembly. I t can be used to stor e the extra bushing

(B), chuck key (C), extension (D) as well as any

additional c hisel s and acces sories.

Diamond Sharpening Cone

Referring to Figur e 8:

1. From hardware kit insert the diamond

sharpening cone (E) into the opening (F) at the

top of the column.

2. Secure with the setscrew (G). The threaded

opening is located behind the tool holder (A)

which needs to be rai sed to ac c ess.

Electrical

115V/230V Operation

The Powermatic 701 Mortiser comes pre-wired

from the fact ory to operate at 115V . The motor can

be rewired to operate at 230V (see Wiring

Diagram) which will also requir e a 230V plug and

electrical outlet. If unsure, consult a qualified

electrician.

Figure 7

Figure 8

Power Connection

Do not operate this machin e in

damp locations.

A separate electri c al circuit should be used for your

machines. This circuit should be protected with a

15 Amp time lag fuse. If an extensi on cord is used,

use only 3-wire extension cords which have

3-prong grounding type plugs and matching

receptacle, which will accept the machine’s plug.

Before connecting the machine to the power line,

make sure the switch is in the Off position and be

sure that the electric current is of the same

characteri stic s as indicated on the machine. All line

connections should make good contact. Running

on low voltage will damage the machine.

Figure 9

11

Page 12

Grounding Instructions

This machine must be

grounded whi le in use to pro tect the u ser from

shock

In the event of a malfunction or breakdown,

grounding provides a path of least resistance for

electric curr ent to r educ e t he ri sk of electric shock.

If you are not sure whet her your outlet i s properly

grounded, consult a qualified electrician.

Referring t o Figure 9: As rec eiv ed from the factory ,

your morti ser is ready t o run at 115-v olt operati on.

This mortiser is intended for use on a circuit that

has an outlet and a plug that looks like the one

illustrat ed in (A). A temporary adaptor , which looks

like the adaptor shown in (B), may be used to

connect this plug to a two-pole receptacle if a

properly grounded outlet is not available. The

temporary adaptor should only be used until a

properly grounded outlet can be installed by a

qualified elec trician. This adaptor i s not applicable

in Canada. The green c olor ed rigi d ear, lug, or tab,

extending fr om the adaptor, m ust be connected to

a permanent gr ound such as a properly grounded

outlet box.

Figure 10

Operating Controls

Start/St op Switch

Referring to Figur e 10:

The Start/Stop switch is located to the left of the

motor. Flip the switch out to start; flip in to stop.

The yellow insert is a switch lock which prev ents

the mortiser fr om bei ng star ted when removed.

Adjustments

Depth Stop Adjustment

Referring to Figur e 11:

A depth stop is provided to limit the depth, or

downward travel, of the chisel. This enables the

operator to make repeated boring operations

without the need to m easure eac h bor e. To adjust:

1. Loosen the lock handle (A) and bring the depth

stop (B) to rest at the bottom of the column.

2. With the operating handle (C) lower the

head (D) until the chisel (E) is at the desired

depth.

3. Bring the depth stop (B) up until it comes to

rest against the bottom of the head (D).

4. Tighten the lock handle (A).

Figure 11

Handle Position Adjustment

Referring to Figur e 11:

The handle assembly is spring-loaded permitting

the operating handle (C) to be repositioned by

pulling out the hub (F) and repositioning it (G) in

36º increments on the pi nion shaf t for a t otal of t en

available positions.

12

Page 13

Chisel Parallel to Workpiece

Referring to Figur e 12:

The chisel can be adjusted parallel to the

workpiece as follows:

1. Loosen the two clamps (A) that secure the

fence (B).

2. With the adjust knob (C), mov e the fence back

far enough to insert the workpiece (D) between

the chisel (F) and fence (B). Raise the

workpiece hold-down clamp (E) if necessary.

3. With the operating handle (G) bring the head

down until the chi sel points are almost at the

table level.

4. Bring the fence (B) forward with the adjust

knob (C) until the front edge of the

workpiece (D) r ests agai nst the back surface of

the chisel (F), but do not f orce.

5. Loosen the chisel lock handle (H). This will

allow the chisel to rotate.

Further adjust t he c hisel by hand if needed.

6. Tighten the lock handle (H) while making sure

the bushing maintains contact with the head

casting to preserve the clearance setting..

Figure 12

13

Page 14

Fence and Clamp

Referring to Figur e 13:

The 701 Mortiser is equipped with a

forward/backward movement adjustable fence (B)

and hold-down clamp (F, K, L) for securing the

workpiece during m or tising operations.

Fence Adjust ment

To adjust the fence ( B) f or ward or back ward:

1. Loosen two clamps (A) that lock the fence.

2. Turn the knob (C) and adjust the fence (B)

forward or backward (D) to the desired

position.

3. Lock the clamps (A).

Hold-down Clamp

There are two ways that t he hold-down clamp c an

be used. Both options are described below.

Option One – workpiece securely clamped to the

table. If multiple mortises are needed, this will

require the clamp to be loosened, workpiece

moved, and clamp secured again.

To clamp the workpiece:

1. Loosen the clamp lock knob (H) and clamp

position lock knob (G).

2. Place the workpiece on t he table (E) u nder the

prongs of the clamp (F) (see Note below) and

against the fence.

3. Tighten the clamp lock knob (H) until the

workpiece is secured.

Option two – workpiece partially clamped. If

multiple mortises are needed, the workpiece can

be moved by hand without repetitively loosening

and tightening t he cl am p.

To clamp the workpiece:

1. Loosen the clamp lock knob (H) and clamp

position lock knob (G).

2. Place the workpiece on the table (E) (see Note

below) under the pr ongs of the clamp (F ) and

against the fence (B).

3. Bring the clamp down so the prongs rest on

the workpiece, but do not press against the

workpiece.

4. Tighten the clamp position lock knob (G).

This will constr ain t he workpiec e and prev ent it

from being lif ted when the chisel is raised, yet

still all ow the workpiece t o be repositioned by

hand. However, the operator will still need to

hold the workpiece in position against the

fence.

Figure 13

The following step i s an option which will hold the

workpiece securely agai nst the f ence yet still allow

operator to repositioning by hand.

5. Loosen the roller guides lock knobs (K).

6. Press the tabs (L) to secure the workpiece

between the wheels (M) and fence (B).

7. Tighten the lock knobs (K).

Note: If needed, the hold-down clamp can be

reversed (K, L) to accommodate a wide range of

wood thi ckne sses.

14

Page 15

Operation

1. Set the depth stop t o the requir ed depth of cut

(refer to the Depth Stop Adjust ment secti on on

page 12).

2. Place workpiece on table and against the

fence.

3. Adjust the fence until the workpiece is in the

correct position (see the Fence and Clamp

section on page 14).

4. Clamp the workpiece or set the clamp to the

desired height as de scribed in the Fence and

Clamp section on page 14)

Before turn ing the machine on,

verify that the chu ck key is not in the chu ck.

5. Turn on the m achine and feed the c hisel and

auger steadily int o workpiece by pulling down

the operating handle.

After the first cut, move the workpiece along for

each successive cut. The direction of movement

must allow the chips to clear freely. Move the

workpiece so that the sl ot in t he chisel is rel easing

chips into the already cut part of the workpiece

(Figure 14).

Do not have the chisel slot

against the blind end of the mortise, as the

chips will not be able to clear the chisel. This

can cause overheating and possible breakage

of chisel or auger.

When cutting deep mortises, make the cut in

several stages of approximately 1" each, to allow

chips to clear . To prevent breakout at the back of

the workpiece when cutti ng through mortises, use

a piece of scrap material under the workpiece as

support.

Rotating Column

Referring to Figur e 15:

The column can be rotated 180º as shown to

permit m ortising large workpieces off the table. To

rotate the column:

1. Using a 4mm hex wrench, r em ov e four screws,

lock washers and flat washers (C) Note: onl y

one screw is visible in Figure 15.

2. Rotate the column (A) 180º.

3. Replace the four screws, loc k washer s and fl at

washers.

The base must be secured to

the work be nc h.

Figure 14

Figure 15

15

Page 16

Maintenance

Before any intervention on the

machine, disconnect it from the electrical

supply by pulling out the plug or switching off

the main switch ! Failure to comply may cause

serious injury.

General

A coat of paste wax applied to the table and

column will hel p to keep the surfaces clean.

If the power cord i s worn, cut, or damaged i n any

way, have it replaced immediately.

The Mortiser requires only minor maintenance,

such as cleaning and lubrication and routine

adjustment and sharpening of the chisel and

auger.

Dust the machine down after each use and, as

necessary, use l ight applic ations of oil or grease to

lubricate linkages, moving parts, etc.

Sharpening Chisel and Auger

Figure 16

The chisel and auger should be k ept sharp for best

performance. Blunt edges will give inaccurate

mortises and can lead to overheating and

breakage to chisel or auger . If c hisel and auger ar e

badly worn and become difficult to sharpen, they

should be replaced.

Auger

Sharpen the auger by using a small, smooth file,

following the original shape of the auger. File the

inside edge of the spur, the sides of the brad point,

and the cutting edge inwards toward the flute of

the auger (Figure 16) .

Do not file t he outside edge of the spur, as thi s wil l

affect the diamet er of t he auger.

Chisel

Referring to Figur e 17:

Sharpen the chisel (A) with the chisel sharpening

cone (B) located on the top of the column next to

the tool holder. Set the chisel (A) on the

sharpening cone (B) and rotate back and forth until

sharpened (C).

Note: Make sure the set-screw is tight to prev ent

the cone from spinni ng.

Using a fine stone or micro-abrasive on a flat

surface, lap t he outside faces of the mortise bit to

remove any burrs.

Figure 17

Lubrication

All of the ball beari ngs are packed with gr ease at

the factory. They require no further lubrication.

Periodically grease the gears, racks, and table

pivot points with a #2 tube gr ease.

Periodically clean and oil any exposed machine

surfaces, such as: dove-tail ways and slides, and

table surface.

16

Page 17

Parts List

Index No. Part No . Description Size Qty

1 ............... 701-101 ...................Base ........................................................................................................... 1

2 ............... 701-102 ...................Shaft Cap ................................................................................................... 1

3 ............... 701-103 ...................T- Nut ......................................................................................................... 2

4 ............... 701-104 ...................Hex Cap Screw (Special) ............................................................................ 2

5 ............... 701-105 ...................Slide Plate .................................................................................................. 2

6 ............... 701-106 ...................Bushing ...................................................................................................... 2

7 ............... 701-107 ...................Knob .......................................................................................................... 2

8 ............... 701-108 ...................Roller ..................................................................................................... .... 2

9 ............... TS-1550061 .............Flat Washer ........................................................M8 ................................... 2

10 ............. TS-1503041 .............Socket Head Cap Screw .....................................M6x16 ............................. 4

11 ............. 701-111 ...................Bar ............................................................................................................. 1

12 ............. 701-112 ...................Rack ........................................................................................................... 1

13 ............. TS-2245122 .............Button Head Socket Screw .................................M5x12 ............................. 2

14 ............. 701-114 ...................Fence ......................................................................................................... 1

15 ............. TS-1523031 .............Set Screw ...........................................................M6x10 ............................. 1

16 ............. TS-1550061 .............Flat Washer ........................................................M8 ................................... 2

17 ............. 701-117 ...................Bolt............................................................................................................. 2

18 ............. 701-118 ...................Roll Pin...............................................................M4x25 ............................. 2

19 ............. 701-119 ...................Cam Handle ............................................................................................... 2

20 ............. 701-120 ...................Post ............................................................................................................ 1

21 ............. 701-121 ...................Work Hold-down ......................................................................................... 1

22 ............. 701-122 ...................Knob .......................................................................................................... 1

23 ............. 701-123 ...................Knob .......................................................................................................... 1

24 ............. 701-124 ...................E-Cl ip .................................................................E-12 ................................ 2

25 ............. 701-125 ...................Gear ........................................................................................................... 1

26 ............. 701-126 ...................Sha ft .......................................................................................................... 1

27 ............. 701-127 ...................Key .....................................................................5x5 x12 ............................ 2

28 ............. 701-128 ...................Ext. Retaining Ring .............................................S-15 ................................ 2

29 ............. 701-118 ...................Roll Pin...............................................................M4x25 ............................. 2

30 ............. 701-130 ...................Knob .......................................................................................................... 2

31 ............. 701-131 ...................Depth Stop ................................................................................................. 1

32 ............. TS-1550061 .............Flat Washer ........................................................M8 ................................... 5

33 ............. 701-133 ...................Locking Handle ........................................................................................... 1

34 ............. TS-1551061 .............Lock Washer ......................................................M8 ................................... 4

35 ............. TS-1504061 .............Socket Head Cap Screw .....................................M8x30 ............................. 4

36 ............. 701-136 ...................Column....................................................................................................... 1

37 ............. TS-1523021 .............Set Screw ...........................................................M6x8 ............................... 1

38 ............. TS-1502031 .............Socket Head Cap Screw .....................................M5x12 ............................. 2

39 ............. 701-139 ...................Too l Tra y .................................................................................................... 1

40 ............. 701-140 ...................Roll Pin...............................................................M6x20 ............................. 1

41 ............. 701-141 ...................Rack ........................................................................................................... 1

42 ............. TS-1551041 .............Lock Washer ......................................................M6 ................................... 7

43 ............. 701-143 ...................Cylinder Head............................................................................................. 2

44 ............. 701-144 ...................Upper Cylinder Fitting ................................................................................. 1

44-1 .......... 701-144A .................Lower Cylinder Fitting ................................................................................. 1

45 .............

46 ............. 701-146 ...................Knob .......................................................................................................... 1

47 ............. TS-1550041 .............Flat Washer ........................................................M6 ................................... 1

48 ............. 23011063 .................Spring......................................................................................................... 1

49 ............. 701-149 ...................Handle Hub ................................................................................................ 1

50 ............. 701-150 ...................Gib ............................................................................................................. 1

51 ............. TS-1523071 .............Set Screw ...........................................................M6x25 ............................. 3

52 ............. TS-1540041 .............Hex Nut ..............................................................M6 ................................... 3

53 ............. 701-153 ...................Handle........................................................................................................ 1

54 ............. 701-154 ...................Lock Handle ............................................................................................... 1

55 ............. 701-155 ...................Handle Grip ................................................................................................ 1

701-145 ...................E-Cl ip .................................................................E-7 .................................. 2

17

Page 18

Index No. Part No . Description Size Qty

56 ............. 701-156 ...................He ad ........................................................................................................... 1

57 ............. TS-1503051 .............Socket Head Cap Screw .....................................M6x20 .............................. 3

58 ............. 701-158A .................Gear ............................................................................................................ 1

59 ............. 701-159 ...................Co llar .......................................................................................................... 1

60 ............. TS-1523011 .............Set Screw ...........................................................M6x6 ................................ 1

61 ............. 701-161 ...................Pinion Shaft ................................................................................................. 1

62 ............. 701-162 ...................Chuck Access Cover ................................................................................... 1

63 ............. TS-2246122 .............Button Head Socket Screw .................................M6x12 .............................. 2

64 ............. 701-164 ...................Motor ..................................................................3/4 HP, 1Ph, 115/230V ..... 1

................. 701-164A .................Fan (not shown) .......................................................................................... 1

................. 701-164B .................Fan Cover (not shown) ................................................................................ 1

................. 701-164C .................Starting Capacitor (not shown) ............................200MFD 125V A C ............. 1

................. 701-164D .................Running Capacit or ( not shown) ...........................30µF 250VAC ................... 1

65 ............. 701-165 ...................Switch Box .................................................................................................. 1

66 ............ TS-081C052 ............Pan Head Screw ................................................#10-24x3/4” ...................... 2

67 ............. 701-167 ...................Strain Relief ................................................................................................. 1

68 ............. 701-168 ...................Power Cord ................................................................................................. 1

69 ............. 701-169 ...................On/O ff S witch .............................................................................................. 1

70 ............. 701-170 ...................Chuck .................................................................1/2" .................................. 1

71 ............. 6294204...................Chuck Key ................................................................................................... 1

72 ............. 701-172 ...................Locking Handle ............................................................................................ 1

73 ............. 701-173

74 ............. 701-174 ...................Wave Washer .....................................................M5 .................................... 1

75 ............. TS-1502051 .............Socket Head Cap Screw .....................................M5x20 .............................. 1

76 ............. 701-176 ...................Bushing ..............................................................I.D. 5/8” ............................ 1

77 ............. 701-177 ...................Bushing ..............................................................I.D. 3/4” ............................ 1

78 ............. 701-178 ...................Cylinder ....................................................................................................... 1

................. 701-178A .................Cylinder Assembly (#43, #78) ...................................................................... 1

79 ............. 23011020 .................Chuck Extension Adapter ............................................................................ 1

80 ............. 701-180 ...................Chisel Sharpening Cone .............................................................................. 1

81 ............. 701-181 ...................Ext. Retaining Ring .............................................S-20 ................................. 1

...................Bushing Spacer ........................................................................................... 2

18

Page 19

Assembly Drawing

Patent No. 7,509,984

19

Page 20

Wiring Diagram

115V

230V

Optional Accessories

Optional acc essori es can be purc hased by calling the service department at the number below.

1791311 701S Stand

1791312 701-RB Riser Block Kit

Ordering Replacement Parts

To order replacement parts or reach our service department, call 1-800-274-6848, Monday through

Friday (see our websi te for business hours, www.power m atic.com ). Having the M odel Num ber and Serial

Number of your machi ne av ailable when you call will allow us to serve you quic kl y and ac c ur ately.

WALTER M EIE R (Manufac turing) Inc.

427 New Sanford Road

LaVergne, Tennessee 37086

Phone: 800-274-6848

www.powermatic.com

www.waltermeier.com

20

Loading...

Loading...