Page 1

Operating Instructions and Parts Manual

10-inch Table Saw

Model 66

shown with optional extension table and legs,

mobile base, and motor cover

WMH TOOL GROUP

2420 Vantage Drive

Elgin, Illinois 60123 Part No. M-0460231NT

Ph.: 800-274-6848 Revision G 1/05

www.wmhtoolgroup.com Copyright © WMH Tool Group

Page 2

This manual has been prepared for the owner and operat ors of a Powerm atic 66 Table S aw. Its purpose,

aside from machine operation, is to promote safety using accepted operating and maintenance

procedures. To obtain maximum life and efficiency from your table saw and to aid in using it safely,

please read this manual thoroughly and follow the instruct ions carefully.

Warranty and Service

WMH Tool Gr oup warrants ever y product it sell s. If one of our tools needs s ervice or repai r, one of our

Authorized Repair St ations located throughout the United St ates can provide quick service or information.

In most cases, a WM H Tool Group Repair Station can assi st in authorizing r epair work, obtaining par ts, or

perform routi ne or m ajor maintenance repair on your Powermatic product.

For the nam e of an A uthoriz ed Repair St ation in your area, pl ease call 1-800-274-6848, or v isit our web

site at www.wmhtoolgroup.com

More Information

Remember, WMH Tool Group i s consistently adding new products to the li ne. For complete, up-to-dat e

product information, check with your local WMH Tool Group distributor, or visit our web site at

www.wmhtoolgroup.com

WMH Tool Group Warranty

WMH Tool Group makes every effort to assure that its products meet high qualit y and durability standards

and warrants to the original retail consumer/purchaser of our products that each product be free from

defects in mat erials and workmanship as foll ows: 1 YEA R LIMITED WARRANTY ON ALL PRODUCTS

UNLESS SPECIFIED OTHERWISE. This Warranty does not apply to defects due directly or i ndirectly to

misuse, abuse, negl igence or acc idents, norm al wear-and-tear , repair or alterati ons outside our f aciliti es,

or to a lack of maintenanc e.

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD SPECIFIED ABOVE,

BEGINNING FROM THE DATE THE PRODUCT WAS PURCHASED AT RETAIL. EXCEPT AS STATED

HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTABILITY AND FITNESS ARE EXCLUDED.

SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS,

SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU. IN NO EVENT SHALL WMH TOOL GROUP

BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR INCIDENTAL,

CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL

OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY

TO YOU.

To take advantage of this warranty, the product or part must be returned for examination, postage

prepaid, to an Authorized Repair Station designated by our office. Proof of purchase date and an

explanati on of the complaint m ust accompany the merchandi se. If our inspecti on discloses a defec t, we

will either repair or replace the product at our discret ion, or r efund t he purchase pri ce if we cannot readi l y

and quickly provide a repai r or replac ement. We will return the repai red product or replacem ent at WMH

Tool Group’s ex pense, but if it is determ ined there i s no defect, or that the def ect resulted f rom causes

not within the scope of WMH Tool Group’s warranty, then the user must bear the cost of storing and

returning t he product . This warranty gives you specifi c legal right s; you may also have ot her right s, which

vary from state t o state.

WMH Tool Group sells through distribut ors only. Members of the WMH Tool Group reserve the right to

effect at any time, wit hout prior notice, alter ations to parts, fittings and accessory equi pment, which they

may deem necessary for any reason whatsoever.

2

Page 3

Table of Contents

Warranty and Servic e ..............................................................................................................................2

Warning...................................................................................................................................................4

Introduction..............................................................................................................................................6

Specifications ..........................................................................................................................................6

Unpacking...............................................................................................................................................7

Contents of the Shipping Container......................................................................................................7

Installation and Assembly ........................................................................................................................8

Mounting Extensi on Wings...................................................................................................................8

Installing Blade.....................................................................................................................................9

Mounting Rails and Accu-Fence.........................................................................................................9

Optional Wood Extensi on Table ...........................................................................................................9

Splitter and Guar d Assembly................................................................................................................9

Motor Cover.......................................................................................................................................10

Grounding Instructions...........................................................................................................................10

Extensi on Cords.................................................................................................................................11

Adjustments...........................................................................................................................................11

Blade Raising and Tilting....................................................................................................................11

Miter Slot Alignment...........................................................................................................................11

Tilt Stop Adjustment...........................................................................................................................12

Miter Gauge Adjustm ent..................................................................................................................... 12

Belt Tensioning..................................................................................................................................12

Splitter Alignment...............................................................................................................................13

Insert Adjustment...............................................................................................................................13

Arbor and Arbor Beari ng Rem ov al......................................................................................................13

Blade Raisi ng Mechanism Adjustment................................................................................................13

Tilting Mechanism Adjustment............................................................................................................14

Operating Instructions for Table Saws....................................................................................................14

Rip Sawi ng.........................................................................................................................................16

Resawing...........................................................................................................................................17

Crosscutting .......................................................................................................................................17

Bevel and Miter Operat ions................................................................................................................18

Dado Cutting......................................................................................................................................19

Safety Devices...................................................................................................................................19

Maintenance..........................................................................................................................................20

Optional Accessories .............................................................................................................................23

Replacement Parts ................................................................................................................................23

Parts List: Trunnion Assembly............................................................................................................24

Trunnion Assembly.............................................................................................................................26

Parts List: Miter Gauge.......................................................................................................................27

Parts List: Spli tt er and Guard Assembly..............................................................................................28

Splitter and Guar d Assembly..............................................................................................................29

Parts List: Stand A ssembly.................................................................................................................30

Stand Assembly .................................................................................................................................31

Parts List: Table Extension and Legs (Optional Accessory)................................................................. 32

Electrical Connections ...........................................................................................................................33

Maintenance Checklist...........................................................................................................................37

3

Page 4

Warning

1. Read and understand the entire owners manual befor e attempti ng assembly or operation.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Failur e to comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or removed.

4. This table saw is desi gned and i nt ended f or use by properl y t rai ned and ex perienced per sonnel onl y.

If you are not familiar with the proper and safe operation of a table saw, do not use until proper

training and knowledge have been obtained.

5. Do not use this tabl e saw for other than its intended use. If used f or other purposes, WMH Tool Group

disclaim s any real or i mplied warrant y and h olds itsel f harml ess from any injury t hat may r esult f rom

that use.

6. Always wear approv ed safety glasses/face shiel ds whil e using this table saw. Everyday eyegl asses

only have impact resi stant lenses; they are not safet y glasses.

7. Before operating this table saw, remove tie, rings, watches and other jewelry, and r oll sleeves up past

the elbows. Remove all l oose clothing and confine long hair . Non-slip footwear or anti-ski d floor strips

are recommended. Do not wear gloves.

8. Wear ear protector s (plugs or muffs) during extended peri ods of oper ation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemi cals known to cause cancer , bir th defects or other r eproductiv e harm . Some examples

of these chemic als are:

• Lead from lead based paint.

• Crystalli ne sil ic a from bricks, cement and other masonry pr oduc ts.

• Arsenic and chromium from chemically treated lumber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not oper ate this machine while tir ed or under t he influence of drugs, alcohol or any m edic ation.

11. Mak e c er tain the switch is in the OFF position before connecting the machine to the power supply.

12. Mak e c er tain the machine is properly grounded.

13. Mak e all machine adj ustments or maintenance with the machine unplugged from t he power source. A

machine under repair should be RED TAGGED to show it must not be used until maintenance is

complete.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning i t on.

15. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme caution and replace the guards immediately.

16. Chec k the alignment of t he splitter, fence and miter slot to the blade. A caution decal is installed on

each guard and split ter to remind the operator of the dangers of misalignment.

17. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Check for alignment of moving part s, binding of moving parts, br eakage of parts, mounting

and any other condi ti ons that m ay affect its operati on. A guard or ot her part that i s damaged shoul d

be properly repaired or replaced.

18. Pr ov ide for adequate space surroundi ng work area and non-glare, ov er head lighting.

19. Keep the floor around the machine cl ean and fr ee of scrap material, oil and grease.

4

Page 5

blahblahblah

20. Keep v isitors a safe distance from the work area. Keep ch il dren away.

21. Mak e y our workshop child proof with padloc k s, m aster switches or by removing starter keys.

22. Giv e your work undivi ded attention. Looking ar ound, carryi ng on a conversation and “ horse-play” ar e

careless acts that can r esul t in serious injury.

23. Maintain a balanced stance at all times so that you do not fall or lean against the bl ade or other

moving part s. Do not over r eac h or use exc essive force to perform any machine operation.

24. Use the right tool at the corr ect speed and f eed rat e. Do not force a t ool or att achment to do a job for

which it was not designed. T he ri ght tool will do the job better and saf er.

25. Use recommended accessories; improper accessories may be hazardous.

26. Maintain t ools with care. Keep blade sharp and cl ean for the best and safest perf ormance. Follow

instructions for lubricating and changing accessories.

27. Check the saw blade for cracks or missing teeth. Do not use a cracked or dull blade or one with

missing teeth or im pr oper set. Mak e sure the blade is securely locked on the arbor.

28. Keep hands cl ear of t he bl ade area. Do not reach pa st the bl ade t o cl ear part s or scrap with t he sa w

blade running. Never saw fr eehand. Avoid awkward oper ations and hand p ositions where a sudden

slip coul d cause your hand to c ontact the blade.

29. Do not attempt to saw boards with l oose knots or with nails or other f oreign material, on its surface.

Do not attempt to saw twisted, warp ed, bowed or “in wind” stock unl ess one edge has been jointed for

guiding purposes prior to sawing.

30. Do not attempt to saw long or wide boards unsupported where spring or weight could cause the

board to shift position.

31. Always use the splitter, blade guard, push stick and other safety devices for all operations where they

can be used. On op erati ons such as dadoi ng or m ol ding where the bl ade guard cannot be u sed, u se

feather boards, f ixtures and other safety devi ces and use extrem e caution. Reinstall the splitter and

blade guard immediately after completi ng the operation that required their removal.

32. Be sure t he sa w blade rotates clockwise when viewed from the motor side (left si de) of t he machine.

33. T ur n off the machi ne before cleaning. Use a brush or compressed air t o r emove chips or debris — do

not use your hands.

34. Do not stand on the machine. Serious injury could occur if the machine tips over.

35. Never leave the machine running unattended. Turn t he power off and do not leave the machine until it

comes to a complete stop.

36. Remove loose items and unnecessary work pi ec es from the area before starting the machine.

Familiarize you r self with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in mi nor i njury and/or

possible machine damage.

This means that if precautions are not heeded, it may result in serious injury or possibly

even death.

- - SAVE THESE INSTRUCTIONS - -

5

Page 6

Introduction

This manual is provided by W MH Tool Group cov ering the safe oper ation and mai ntenance procedure s

for a Powermatic Model 66 Table Saw. This manual contains instructions on installation, safety

precautions, gener al oper ati ng procedur es, mai ntenance i nstructi ons and parts breakdo wn. Thi s mac hine

has been designed and con structed t o provide year s of troubl e free operation if used in accordance wi th

instructi ons set forth i n this manual . If there are any questions or comm ents, please contact either your

local supplier or WMH Tool Group. WMH Tool Group can also be reached at our web site:

www.wmhtoolgroup.com.

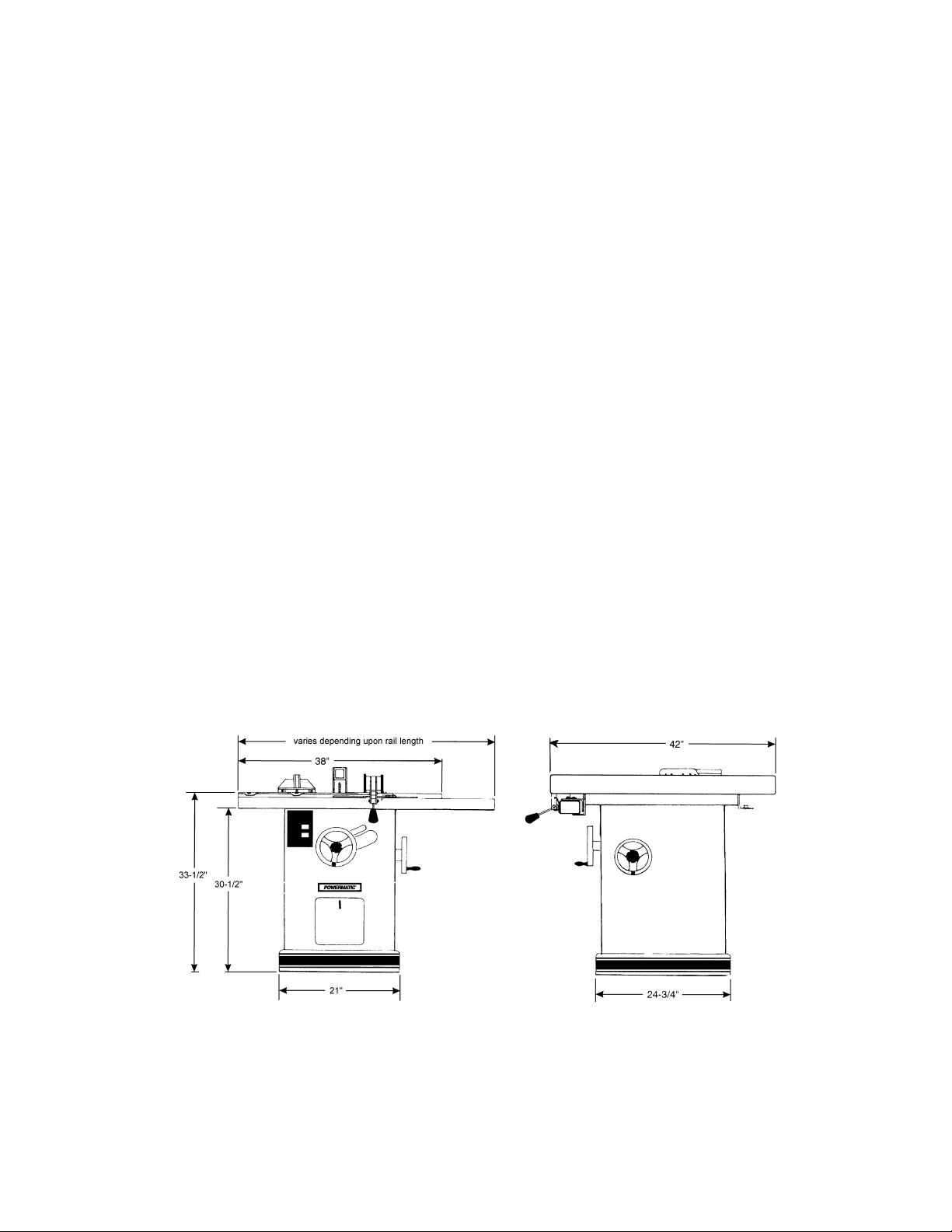

Specifications

Model number........................................................................................................................................66

Maximu m moto r size.........................................................................................................5HP, 3600 RPM

Table size with standard ex tensions (L x W)(in.) ....................................................................... 37-1/2 x 28

Table size without ex tension (L x W)(in.).................................................................................. 21-1/2 x 28

Rip fence (L x W x H)( in.)................................................................................................41-3/4 x 4 x 2-1/2

Arbor diameter (in.)...............................................................................................................................5/8

Saw blade diameter (i n.)........................................................................................................................10

Maximum speed of 10” saw blade (SFM ) ........................................................................................ 11,000

Blade tilt maxim um (deg. ) ......................................................................................................................45

Maximum depth of cut (in.).......................................................... 3-1/8 at 90-degrees; 2-1/8 at 45-degrees

Maximum cut to right of saw blade with st andar d extension (in.).............................................................25

Maximum width of cutoff in front of saw in 1” stock (i n.)..........................................................................15

Maximum width of cutoff in front of saw in 3-1/8” stock (in.)..............................................................12-1/4

Maximum diam eter of dado (in.)...............................................................................................................8

Maximum width of dado cut (i n.)........................................................................................................ 13/16

Drive belts ....................................................................................................................3VX (t wo required)

Table he igh t to flo o r ( in.)........................................................................................................................34

Dust port diameter (i n.) ............................................................................................................................4

Shipping weight wi th motor, fence and rails (lbs.).................................................................................614

The above specifications were current at the time this manual was publi shed, but because of our policy of

continuous im provement, WMH Tool Group reserv es the right to change specif ications at any tim e and

without pri or notic e, without incurring obligations.

6

Page 7

Unpacking

Open shipping cont ainer and check f or shipping

damage. Report any damage immediately to

your distributor and shipping agent. Do not

discard any shipping material until the Table

Saw is assembled and running properly.

Compare the cont ent s of y our cont ainer wit h the

following parts list to make sure all parts are

intact. Mi ssing parts, if any, should be reported

to your distributor. Read the instruction manual

thoroughly for assembly, maintenance and

safety instructions.

Contents of the Shipping Container

Box 1: 1 Table Saw

2 Extension Wings

1 Miter Gauge

1 Owner’s Manual

1 Warranty Card

Box 2: 1 Splitter and Guard Assembly

1 Splitter Support Shaft

Contents of Hardware Bag:

2 Arbor Wrenches

1 Hardware Bag*

Box 3: 1 Accu-Fence

1 Lock Handle

1 Accu-Fence Owner’s Manual

Box 4: 1 Front Rail

1 Rear Rail

1 Guide Tube

1 Hardware Bag

Box 5: 1 Motor Cover

2 Self-Tapping Screws

Optional:

Box 6: Formica Top Extension Table

Box 7: Legs for Extension Table

*The contents of the hardware bag are

illustrated below. The contents of the Accu-

Fence

Accu-Fence

and Rail hardware can be found in the

manual.

Read and understand the entire contents of this manual before attemp ting set-up

or operation! Failure t o co mpl y may cause seri ous injury.

7

Page 8

Installation and Assembly

Tools required for assembly:

7/16, 9/16, 3/8 and 1/ 2” wrenche s

1/8 and 3/32” hex wrenches

Flat head screwdriver

Hammer and wood block (or r ubber hammer)

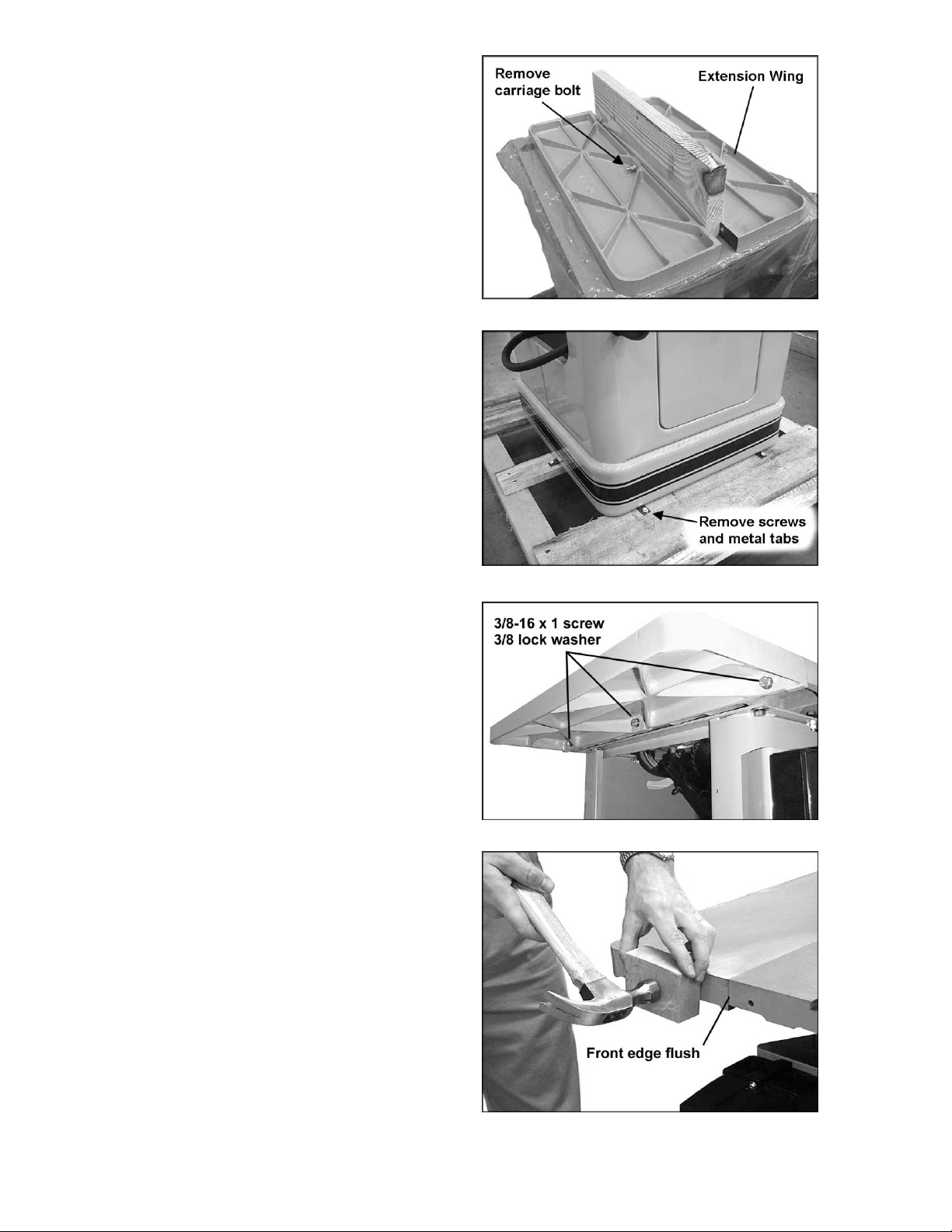

1. Remove box and wood crating completely

from around saw.

2. Use a 9/16” wrench t o remove the car riage

bolt, hex nut and washer holding the

extension wings together (Figure 1). Set

extension wings aside for later installation.

3. With a 7/16” wrench, rem ov e t he lag screws

(Figure 2) holding the saw to the wood

pallet. Caref ully sli de the saw from the pallet

onto the floor.

4. Tilt the saw, and pop off the metal tabs

(Figure 2) that secured the saw to the pallet,

by pushing down on them with y our foot .

The Table Saw sho uld be placed in an area with

a sturdy level floor, good ventilation and

sufficient lighting. Leave enough space around

the machi ne for mounting extension wing s and

rail assemblies, and loading and off-loading

stock and general maintenance work.

Figure 1

Figure 2

Exposed metal surfaces, such as the table top

and extension wings, have been given a

protectiv e coating at the fact ory. This should be

removed with a soft cloth moistened with

kerosene. Do not use acetone, gasoline, or

lacquer thinner for this purpose. Do not use

solvents on plastic parts, and do not use an

abrasive pad because it may scratch the

surfaces.

Mounting Extension Wings

1. Mount the cast iron extension wings using

six 3/8-16 x 1 hex head screws and six 3/8

lock washers. See Figure 3. Have an

assistant hold t he extension wing up to the

table, and insert the screws and washers.

Finger tighten only.

NOTE: If an assistant i s not avail able, hold

the wing in vertical position up to the saw

table, insert the middle screw and lock

washer finger tight, then pivot the wing to

level position. Insert the other two screws

and washers fi nger tight .

2. It is important that the front edge of the wing

is flush with the front edge of saw table. S ee

Figure 4.

Figure 3

Figure 4

8

Page 9

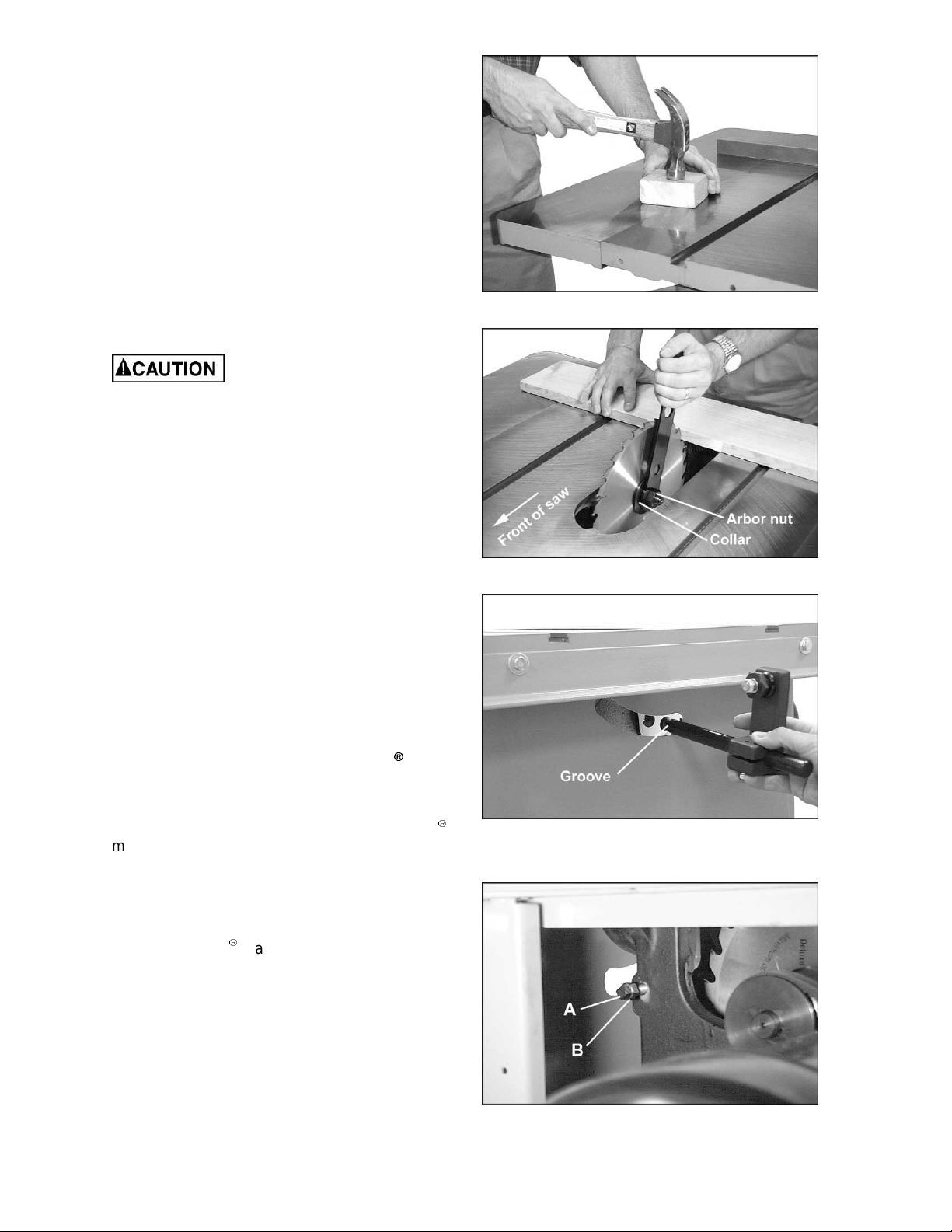

3. Level t he extension wing with the sa w table

across its enti re widt h, using a strai ght edge

and hammer with block of wood (or rubber

hammer). See Fi gure 5. As each area of the

wing becomes flush with the table, tighten

the screw under t hat area. Cont inue unti l all

three screws are fully tightened.

4. Repeat for the other ex tension wing.

Installing Blade

NOTE: The blade m ust be mounted first bef ore

rails can be adjusted.

To install or replac e a blade, proceed as follows:

Use care wh en working with

or around sharp saw blade.

1. Disconnect machine from power source.

2. Rem ove tabl e insert, then rem ove arbor nut

and collar.

3. Install blade, making sure the cutting teeth

at the top of t he blade poi nt toward the f r ont

of the saw.

Figure 5

4. Sli de the coll ar on to the ar bor and start the

arbor nut on the threads. (NOTE: Righthand threads; turn clockwise to tighten.)

Snug the arbor nut against the collar and

blade with the pr ovided arbor wrench, while

holding blade wit h thumb and finger tips.

5. Wedge a block of wood between the blade

and table to prevent blade rotation, then

tighten t he arbor nut securel y with the ar bor

wrench. See Figur e 6.

Mounting Rails and Accu-Fence

With the extension wings properly aligned, the

rail and f ence assem bl y can no w be m ounted t o

the saw. Consult the separate Accu-Fence

manual for instructions.

Optional Wood Extension Table

For instructions on mounting the accessory

wood extension table, or router table, consult

your Accu-F enc e

manual.

Splitter and Guard Assembly

Figure 6

Figure 7

1. Insert the grooved end of the splitter support

shaft through slot in rear of saw and into

hole in trunnion. See Figure 7. Make sure

the square head setscrew (A, Figure 8) is

backed out enough to allow easy insertion

of the splitter support shaft.

Figure 8

9

Page 10

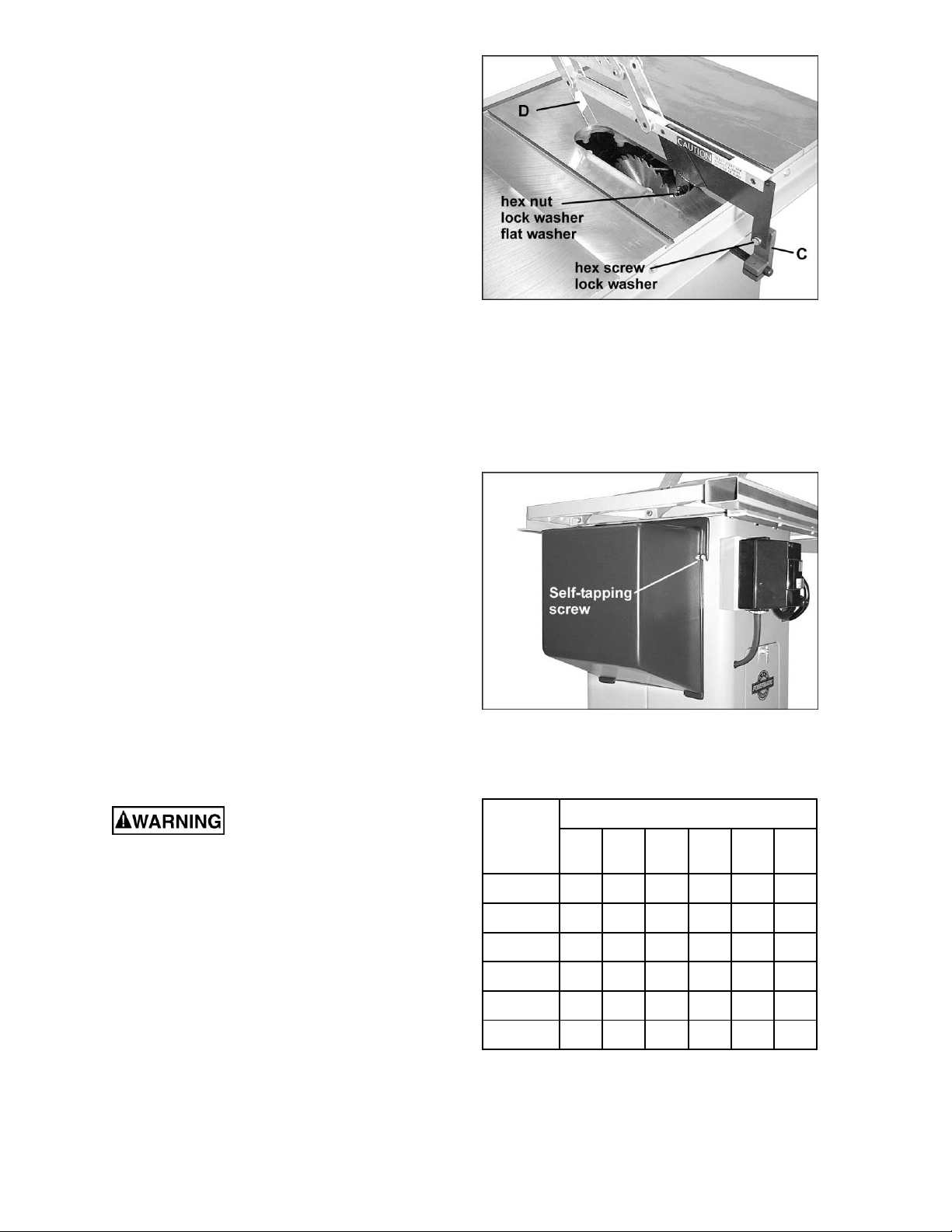

2. With a 3/8" wrench, reach through the motor

s

opening in the stand and tight en the square

head setscrew (A, F igure 8) into the groov e

of the shaft. (NOTE: The groove will be in

the proper posi tion if the end of the shaf t is

made flush with the opposite side of the

trunnion hol e.) Then tighten the hex nut (B,

Figure 8) up against the trunnion.

3. The upright member of the rear splitter

support (C, Figure 9) must be oriented

toward the right of the shaft, as observed

from the rear of the saw.

4. Mount the splitter assembly to the two

adjusting screws. See Figure 9. Place the

two flanges of t he spli tter assem bl y onto t he

crews as shown. S nug the scre ws. (NOT E:

Make sure the front shield (D, Figure 9)

faces in toward the blade)

5. The splitter and guard assembly must be

aligned wit h the blade before operati ng the

saw. Adjust the splitter according to the

directions on page 13, " S plitter Alignment."

Moto r Cover

Figure 9

1. Locate the two 1/4-20 self tapping sheet

metal screws and install them in the

punched holes on the saw cabinet. Do not

screw down all the way, but leave t he heads

about 1/4" fr om the surf ac e. See Figure 10.

2. Lift the m otor cover over these scre ws with

the cover's bottom lip inside the saw's

cabinet.

3. Tighten the two screws.

Grounding Instructions

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. This

machine must be properly grounded to help

prevent electrical shock and possible fatal

injury.

A power plug is not prov ided wit h the Model 66.

You may either connect the proper UL/CSA

listed pl ug or “hardwire” the mac hine directly t o

your electrical panel provided there is a

disconnect near the machine for the operator.

Consult electrical drawings on pages 33-36 for

further clarification of wiring setup.

This machine must be grounded. Grounding

provides a path of least resi stance to hel p divert

current away from the operator in case of

electrical malfunction.

Figure 10

Recommended Gauges (AWG) of Extension Cords

Extension Cord Length *

25

50

75

100

150

Amps

< 5 16 16 16 14 12 12

5 to 8 16 16 14 12 10 NR

8 to 12 14 14 12 10 NR NR

12 to 15 12 12 10 10 NR NR

15 to 20 10 10 10 NR NR NR

21 to 30 10 NR NR NR NR NR

*based on li miting the line voltag e dr op to 5V at 15 0% of t h e

rated amp eres.

NR: Not Recommended.

feet

feet

feet

feet

feet

200

feet

Figure 11

10

Page 11

Make sure the voltage of your power supply

matches the specif ications on the m otor plate of

the machine.

Extens ion Cords

If an extension cord is necessary, make sure the

cord rating i s suitable for the am perage listed on

the machine's motor plate. An undersize cord

will cause a drop in line voltage resulting in loss

of power and overheating.

The chart in Figure 11 shows the correct size

cord to use based on cord length and motor

plate amp rating. If in doubt, use the next

heavier gauge. The smaller the gauge number

the heavier the cor d.

Adjustments

Blade Raising and Tilting

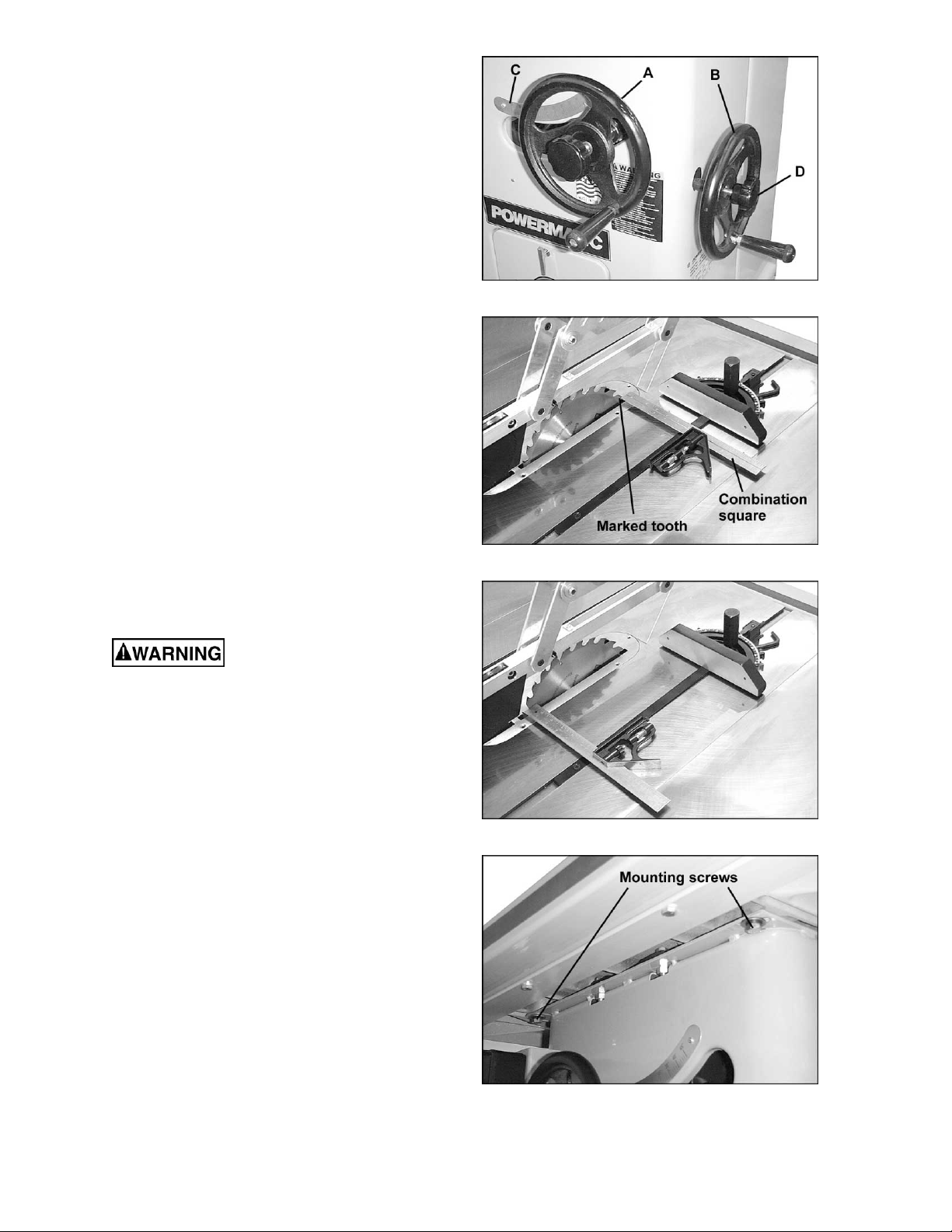

The front handwheel ( A, Figure 12) controls the

raising and lowering of the blade. The side

handwheel (B, Figure 12) controls blade tilt,

which is indicated by the scale (C, Figure 12).

The lock k nobs (D, Figure 12) are use d to lock

the setting of the handwheel s.

Figure 12

Figure 13

Miter Slot Alignment

Disconnect machine from

power source before making this

adjustment.

1. To check the alignment of the mitre slot to

the blade, raise the blade to its maximum

height at the 0 degree (vertical) position.

2. Mark one tooth with a grease pencil and

position the tooth slightly above the top

edge of the table at the front.

3. Raise the m iter gauge sli ghtly out of its slot

to serve as a shoul der. Using a com bi nat ion

square against the si de of the bar, slide t he

scale over until it touches the tip of the

blade, and lock the scale in position. See

Figure 13.

4. Rotat e the m arked t ooth so that i t is sl ightly

above the table top at the rear and, using

the square as before, check whether the

distance to the blade is the same. See

Figure 14. If the distance is not the same,

loosen the three m ounting screws that lock

the table t o the cabinet ( two in front , one in

back) as shown in Fi gure 15, and nudge the

table to bring the miter slot in line with the

blade.

Figure 14

Figure 15

11

Page 12

5. The blade must be kept centered with the

b

slot in the table insert to ensure clearance at

oth the 90 degree and 45 degree posi tions.

After alignment, secure the table to the

cabinet by re-tightening the three mounting

screws (Figur e 15) .

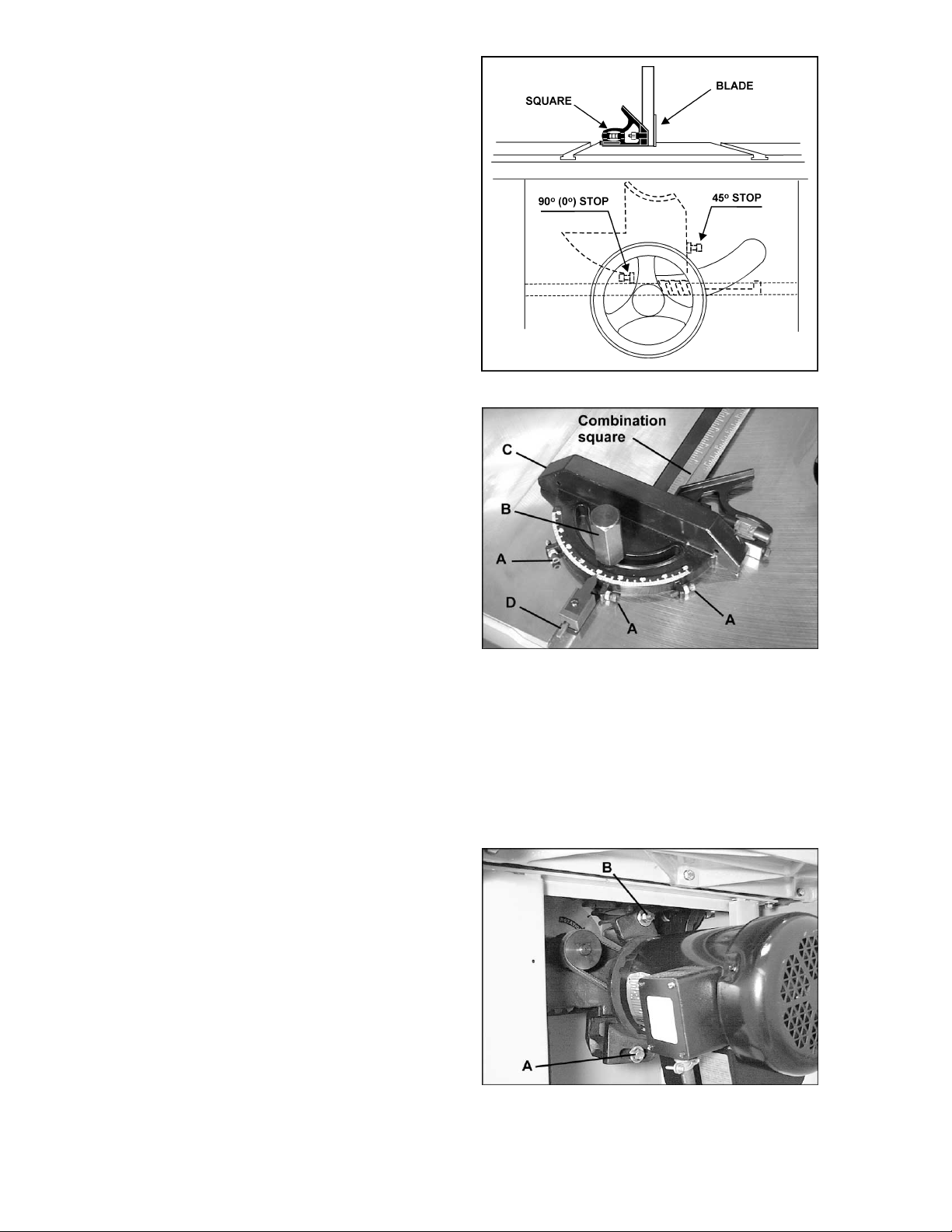

Tilt Stop Adjustment

Using a combination square, check the 90

degree (0) and 45 degree stops. (Figure 16

shows the 90 degree stop being checked.)

Adjust stop positi ons if required, using the stop

screws as shown. Check the accuracy of the

pointer at 90 degrees (0) and re-adjust if

required.

Miter Gauge Adjustment

1. Slide the miter gauge into one of the slots

on the table top.

2. The miter gauge is equipped with

individually adjustable index stops at 90

degrees and 45 degrees right and l eft. The

index stops can be adjusted by loosening

the hex nuts and turning t he three adjusting

screws (A, Figure 17) as needed. After

setting each stop, r etighten the hex nut.

Figure 16

3. To operate the miter gauge, loosen lock

handle (B, Fi gure 17) and move t he body of

the miter gauge (C, Figure 17) to the

desired angle. T he miter gauge body is set

to stop at 0 degrees and 45 degrees l eft or

right. To move the miter gauge beyond

these points, the stop rod (D, Figure 17),

must be pulled out.

4. If accurate crosscutting work is to be done

using the mit er gauge, check i t s squareness

to the slot wit h a square as shown in F igure

17. Re-adjust the st op posi tion as required.

Belt Tensioning

The saw is equipped with a set of two matched

belts. If they should need repl acement, replace

the complete set.

To tension the belts:

Loosen the hex screw (A, Figure 18) and nut (B,

Figure 18) on t he motor brac ket. Piv ot the mot or

and bracket to the right. Retighten screw (A,

Figure 18) and nut (B, Figure 18).

To remove and replace the belts, loosen the

screw (A, Fi gure 18) and nut (B , Fi gure 18) and

rotate t he mot or and brack et t o the l eft as f ar as

possible. Remove one belt at a time. After

installi ng new bel ts, re-tension as indicat ed.

Figure 17

Figure 18

12

Page 13

Splitter Alignment

One of the most critical adjustments to help

avoid kickback is the splitter adjustment. It

should be checked and readjusted, if required,

after each blade change.

1. Lift the miter gauge bar slightly out of its

slot. Place a combination square against the

side of the raised up miter gauge bar and

slide the scal e against the top of the blade

tooth and against the splitter as shown in

Figure 19.

2. Check the splitter for parallelism and for

clearance to the miter slot. If adjustment is

necessary, use the screws at the front

flange and at the rear splitter support.

3. Move the miter gauge to the opposite side

of the blade and using the combination

square, sli de the scale against the top of the

tooth and the splitter. Again check for

parallelism and clearance. Clearance should

be approxim ately equal on both si des of the

blade.

Insert Adjustment

Adjust the setscre ws in the insert wit h a 1/8 hex

wrench to ensure that the insert is stable and

flush with or slightly below the table top. See

Figure 20.

Arbor and Arbor Bearing Removal

1. To remove the saw arbor, first remove the

fence and rails, then remove the three

mounting screws holding the table to the

base (see Figure 15). Lift off the table.

Figure 19

Figure 20

2. Loosen the two set screws in the arbor

sheave (A, Figure 21) and remove the

sheave and key.

3. Loosen the set scre w (B, Figure 21) on the

saw raising arm. The arbor assembly and

bearings will slide out of the arm housing.

Blade Raising Mechanism

Adjustment

If bindi ng occ urs, cl ean off all sawdust and pi tc h

buildup and re-lubricate with a good nonhardening grease. If binding continues, check

the fit-up of the worm and worm gear segment.

The worm m ust be center ed wit h the worm gear

segment. If it is not centered, loosen the saw

raising arm set screws, move the arm as

required, and r e-l ock t he set screws. See Fi gure

22.

Figure 21

Figure 22

13

Page 14

If the saw raising arm has been re-locat ed, the

table may have t o be realigned so a s to provi de

clearance between the saw blade and table

insert slot. The splitter will also have to be

realigned.

NOTE: The saw arm set screw must be tight to

avoid the possibility of movement which could

cause the blade to hit the insert.

Tilting Mechanism Adjustment

If binding occ urs in the tilting m echanism, clean

off the saw dust and pitch ac cumulation and regrease. If binding continues, check the

alignment and readjust as required to center

worm with the worm gear segment on the

trunnion.

If there is excessive play, loosen bracket

mounting screws (A, Figure 23) and turn

adjustment screw (B, Figure 23) clockwise to

raise pinion. A tight mesh without binding is

ideal. Re-tighten mounting screws and check

over the 90 degree t o 45 degree range of tilt f or

excessive pl ay or binding. Re-adjust if required.

Operating Instructions for

Tabl e Saws

1. Familiarize yourself with the location and

operation of all controls and adjustments

and the use of accessories such as the

miter gauge and ri p fence.

2. Serious injury can result from kickbacks

which occur when a work piece binds on the

saw blade or binds bet wee n the saw blade

and rip fence or other fixed object. This

binding can cause the work piece to lift up

and be thrown toward the operator. Listed

below are the conditions which can cause

kickbacks:

• Confining the cutoff piece when

crosscutting or ripping.

• Releasing the work piece before

completing t he operation or not pushing

the work piece all the way past the saw

blade.

• Not using the splitter when ripping or not

maintaining alignment of the splitter with

the saw blade.

• Using a dull saw blade.

• Not maintaining alignment of the rip

fence so that it tends to angle toward

instead of away from the saw blade

front to back.

Figure 23

14

Page 15

• Applying feed f orce when ripping to the

r

cutoff (free) section of the work piece

instead of t he section between t he saw

blade and fence.

• Ripping wood that is twisted (not flat ), or

does not have a strai ght edge, or has a

twisted grain.

3. To minimize or prevent injury from

kickbacks:

Avoid conditions listed above.

Wear a safety face shield, goggles, or

glasses.

Do not use the miter gauge and rip

fence in the same operation unless

provision is made by use of a facing

board on the fence so as to allow the

cutoff secti on of the workpiece to com e

free befor e the next cut is started (See

Figure 32).

As the machine receives use, the

operation of the anti-kickback pawls

should be checked periodically. See

Figure 24. If the pawls do not stop the

reverse motion of a workpiece, resharpen all the point s.

Where possible, keep your face and

body out of l ine wit h potenti al kick backs

including when starting or stopping the

machine.

4. Dull, badl y set, improper, or im properly filed

cutting tools and cutting tools with gum or

esin adhering to t hem can cause acci dents.

Never use a cracked saw blade. T he use of

a sharp, well m aintained, and correct c utti ng

tool for the operation will help to avoid

injuries.

5. Support the workpiece properly and hold it

firmly against the gauge or fence. Use a

push stick or push block when ri pping short,

narrow (6" width or less), or thi n workpieces.

Use a push block or miter gauge hold-do wn

when dadoing or mol ding.

Figure 24

6. For incr eased safety in crosscutti ng, use an

auxiliary wood facing attached to the miter

gauge using the holes provided in the

gauge, Figure 25.

7. Never use the fence as a lengt h stop when

crosscutting. Do not hold or touch the free

end or cutoff section of a workpiece. On

through-sawing operations, the cutoff

section must NOT be confined.

8. Always keep your hands out of the line of

the saw blade and nev er reach back of the

cutting blade with either hand to hold the

workpiece.

Figure 25

15

Page 16

9. Bevel ripping cuts should always be made

with the fence on the right side of the saw

blade so that the blade tilts away from the

fence and minimizes the possibility of the

work binding and the r esul ting kickback.

Rip Sawing

1. Ripping i s where the work piece is fed wit h

the grain i nto the saw blade using the f ence

as a guide and a positioning device to

ensure the desired widt h of cut. See Figure

26.

Before starting a rip cut, be

sure the fence is clamped securely and

aligned properly.

Never rip freehand or use the miter gauge in

combination with the fence.

Never rip workpieces shorter than the saw

blade diamet er.

Never reach behind the blade with either

hand to hold down or remove the cutoff

piece with the saw blade rotat ing.

2. Al ways use the sa w guard, spli tter and ant ikickback pawls. Make sure the splitter is

properly aligned. When wood is cut along

the grain, the kerf tends to close and bind

on the blade and kick bac k s can occ ur.

Figure 26

NOTE: A caution decal is installed on the

guard and split ter assembly, warning of the

hazard of misalignment.

3. The ri p fence should be set for the width of

the cut by using the scale on the front rail, or

by measuring the distance between the

blade and fenc e. See Figure 27. Stand out

of line wi th the saw blade and workpiece to

avoid sawdust and splinters coming off the

blade or a kickbac k, if one should oc c ur .

4. If the workpiece does not have a straight

edge, provide one by nailing an auxiliary

straight edged board on i t to sli de along t he

fence. To cut properly, the boar d must make

good contact with the t able. If it is warped,

turn the hollow side down.

5. In ripping, use one hand to hold the board

down against the fence or fixture, and the

other to push i t into the blade between t he

blade and the fence. If the workpiece is

narrower than 6" or short er than 12", use a

push stick or push bl ock to push it through

between the fence and saw blade. See

Figure 28.

Figure 27

Figure 28

16

Page 17

6. Never push in a location such that the

r

t

pushing hand is in li ne with the blade. Move

the hand serving as a hold-down a safe

distance from the blade as the cut nears

completion.

7. For very narrow ri pping where a push stick

cannot be used, use a push block or

auxiliary fence. Always push the workpiece

completely past the blade at the end of a cut

to minimize the possibility of a kickback.

8. When ri pping long boards, use a support at

the front of the table, such as a roll er stand,

and a support or "tailman" at the rear as

shown in Figure 29.

9. Never use the rip fence beyond the point

where the carriage is flush with the end of

the rails.

10. Have t he bl ade extend about 1/8" abov e the

top of the workpiece. Exposing the blade

above this point can be haz ar dous.

Resawing

1. Resawing is a ripping operation in which

thick boa

Narrow boards up to 3" can be resawn in

one pass. Wider boards up to 6" must be

resawn in two pas ses.

2. In resawing wider boards, adjust the blade

height so as to over lap the two cuts by 1/2"

as shown in Fi gure 30. Too d eep a fi rst cut

can result i n binding and possibl e kickbacks

on the second cut. Always use the same

side of the boar d against the f ence f or both

cuts.

ds are cut into thinner ones.

Figure 29

Figure 30

Crosscutting

1. Crosscutting is where the workpiece is fed

cross grain into the saw blade using the

miter gauge to support and position the

workpiece. See Figure 31. Crosscutting

should never be done fr eehand nor should

the fence be use d as a n end stop unl ess an

auxiliary block is clamped in front of the

blade area such that t he cutoff piece comes

free of the block before cutting starts. See

Figure 32. Length stops should not be used

on the free end of the workpiece in the

cutoff area.

2. Do not

Before starting a cut, be sure the miter

gauge is securely clamped at the desired

angle. Hold the workpiece f irmly against the

able and back against the miter gauge.

Always use the saw guard and splitter and

make sure the splitt er is properly aligned.

crosscut workpieces shorter than 6" .

Figure 31

Figure 32

17

Page 18

3. For 90 degree crosscutting, most operators

prefer t o use the left-hand m iter gauge slot.

When using it in this position, hold the

workpiece against t he miter gauge with the

left hand and use t he right hand to adv ance

the workpiece, as sho wn in Figure 32. When

using the right hand slot for miter and

compound crosscutting so that the blade

tilts away from the miter gauge, the hand

positions are reversed.

4. When usi ng the miter gauge, t he workpiece

must be held fi rmly and advanced sm oothly

at a slow rate. If the workpiece is not held

firmly, it can vibr ate causing i t to bi nd on the

blade and dull the saw teeth.

5. To improve the effectiveness of the miter

gauge in crosscutting, some user s mount an

auxiliary wooden extension face (with a

glued-on strip of sandpaper) to the miter

gauge as shown in Figur e 33.

6. Prov ide auxiliary support f or any workpiece

extending beyond the table top with a

tendency to sag and lift up off the t abl e.

7. Stop rods can be used in the holes provi ded

in the miter gauge for repetitive work of

equal length. Do not use a stop rod on the

free end of a workpiece. It should be used

on the side of the miter gauge opposit e the

saw blade.

Figure 33

8. Have the blade ext end about 1/ 8" abov e t he

top of the workpiece. Exposing the blade

above this point can be haz ar dous.

Bevel and Miter Operations

1. A bevel cut is a special type of operation

where the saw blade is tilted at an angle

less than 90 degrees to the table top. See

Figure 34. Oper ations are performed in the

same manner as ripping or crosscutting

except the fence or miter gauge should be

used on the right -hand side of the saw blade

to provide added safety in avoiding a

binding action between the saw blade and

the table top. When beveling wi th the miter

gauge, the workpi ece must be hel d fi rmly to

prevent creeping.

2. Crosscuts made at an a ngle to the edge of

the workpiece are cal led miters. S ee Figure

35. Set and secure the miter gauge at the

required angl e, and make the cut the same

as a normal crosscut exc ept the workpiece

must be held extra firmly to prevent

creeping.

Figure 34

Figure 35

18

Page 19

NOTE: When making compound miters

(with blade t ilt ed) use the m i ter gauge in t he

right hand slot to provide more hand

clearance and safety.

3. Hav e the blade extend only 1/8" abov e the

top of the workpiece. Exposing the blade

above this point can be haz ar dous.

Dado Cutting

Dadoing is cutting a wide groove into a

workpiece or cutt ing a rabbet al ong the edge of

a workpiece. A dado i nsert, shown i n Figur e 36,

is necessary f or this ty pe of operation.

Do not use the standard

table insert for dadoing operations.

The process of cutti ng 1/8" to 13/ 16" groov es in

workpieces is accomplished by the use of a

stacked dado blade set or an adjustable blade

mounted on the saw arbor.

By using various combinations of the stacked

dado blades, or properly setting the dial on an

adjustable blade, an accurate widt h dado c an be

made. This is very useful for shelving, making

joints, tenoning, etc.

The guard, splitter, and anti-kickback pawls

supplied with the saw should be used for all

cutting operations where they can be used.

When performing operations where the guard

can not be used, as in some dadoing

operations, alternativ e safety precautions should

be taken. These include push sticks, feather

boards, fill er pieces, fixtures, jigs and any other

appropriate device that can be utilized to keep

operator's hands away from the blade.

Figure 36

Upon completion of the operation requiring

removal of the guard, the ent i re guard a ssem bl y

must be placed back on the machine in its

proper working order.

Never use a dado head in a

tilted position. Never operate the saw

without th e guard, splitter an d anti-kickback

pawls for operations where they can be

used.

Safety Devices

Feather Board (Figure 37).

The feather board should be made of straight

grain hardwood approx imately 1" thick and 4" to

8" wide depending o n the size of t he machine.

The length is developed in accordance with

intended use.

Feather boards can be fastened t o the table or

rip fence by use of C-clam ps.

Figure 37

19

Page 20

Alternatively, drilled and tapped holes in the

l

table top allow the use of wing nuts and washers

as a method of clamping. If this method of

fastening is used, provide slots in the feather

board for adjustm ent.

Figure 37 shows a m ethod of at taching and use

of the feather board as a vertical comb. The

horizontal application is essentially the same

except that the attachment is to the table top.

Filler Piece (Fi gur e 38) .

A filler piec e is necessary f or narr ow rippi ng and

permits the guar d to remain on the machi ne. It

also provi des space for the safe use of a push

stick.

Push Block & Push Stick (Figures 39 & 40).

These items help feed the workpiece along

fence and blade while keeping the operator's

hands at a safe distance from the blade.

Maintenance

Good saw operation requires periodic pr ev entive

maintenance.

Keep the inside of the c abinet and t runnion area

clean. A stif f brush will remove sawdust before

it cakes and pi tch or gum is easil y rem oved wit h

a commercial solvent or with a good oven

cleaner. To accomplish this, remove the tabl e

by removing the three mounting screws (see

Figure 15) and exposing the working

mechanisms of the saw. After c leaning the tilting

and raising worm and worm gear segm ents and

the trunnions, grease these three areas with a

good grade non-hardening grease.

Check periodically for excessive play in the

tilting and raising mechanism and in the saw

arbor and re-adjust as required.

Check periodical

Readjust or repl ac e belts as required.

The table surf ac e m ust be k ept clean and free of

rust for best result s. Apply a coat of paste wax

to the surface to facilitate this. An alternative is

to apply white talcum powder, rubbed in

vigorously once a week with a blackboard

eraser; this will fill casting pores and form a

moisture barrier. This method provides a table

top that is slick and all ows rust rings to be easi ly

wiped from the surface. Important also is the

fact that talcum powder will not stain wood or

mar finishes as wax pi ckup does.

y for belt tension and wear.

Figure 38

Figure 39

20

Page 21

Figure 40

21

Page 22

Troubleshooting

Trouble Probable Cause Remedy

Excessive vibration.

Cuts out-of- square

when crosscutting.

Motor stalls or

workpiece binds or

burns.

Cuts not true at 90 or

45 degrees.

Tilt or raising cl am p k nobs not

tightened.

Blade out of balance. Change blade. [page 9]

Bad motor. Replace motor.

Loose arbor or motor sheave. Tighten set screws. [page 13]

Miter gauge out of adj ustm ent. Reset stops and pointer. [page 12]

Miter slot mi sali gned. Realign table. [page 11]

Excessive feed. Reduce feed.

Bad motor. Replace motor.

Dull or incorrec t blade. Replace blade. [page 9]

Miter slot mi sali gned. Realign miter sl ot. [page 11]

Fence misalignment. Realign fence. [see Fence manual]

Stop screws not set properl y . Readust stop screws. [ page 12]

Lock knob not released. Loosen lock knob.

Tighten knobs.

Tilt or saw raising

handwheels diff icult

to turn.

Motor overheat s.

Motor starts slowly or

fails to come up to

speed.

Motor fails to develop

full power.

Worm and worm gear segment caked

with sawdust and pit c h.

Worm and worm gear segment out of

alignment.

Motor overloaded.

Improper cooling of motor.

Low voltage.

Centrifugal swit c h not operating. Replace switch.

Bad motor. Replace motor.

Power line overloaded. Correct overload c ondition.

Undersize wires in supply system. Increase supply wir e si z e.

Low voltage.

Clean and re-grease.

Realign worm and worm gear

segment. [page 13]

Correct overload c ondition such as

reducing the feed rate.

Clean sawdust from fan and duct

areas of motor.

Request voltage check from power

company and correct low voltage

condition.

Request voltage check from power

company and correct condition.

Bad motor. Replace motor.

22

Page 23

Optional Accessories

709689 Scoring Saw attachment retrofit kit.

2042335 M obile base extended for Model 66 Saw (closed stand).

2042336 M obile base standard (fits saw stand only ) .

2042342 M obile base open bottom for Model 66 Saw (open stand).

2042372 M obile base with 30" fence with Rout-R-Lift.

2195042K Accu-Fence

2195079 Accu-Fence

2195049K Accu-Fence

2195063K Accu-Fence

2250116 B lade guard and Splitter Assembl y . Wt. 10 lbs. (4.5 kg).

2328001 Table Insert.

2328002 Dado Insert Plate for 8" dado head. Wt. 1 lb. (.45 kg).

2726008 Replacement side panel kit for Model 66 Accu-Fence

2440020 Rear Loc k A ssem bly for Accu-Fence

2471015 M iter Gauge. Wt. 4 lbs. (1.8kg).

3104663 M otor cover (old style).

3104667 M otor cover for serial # 95662522 and up

3186008 8" ( 203.2 mm) Cast Iron Extension Wing.

6080143 B lade 35 tooth carbide tip.

6080144 B lade 50 tooth carbide tip.

6253118K S liding Table Retrofi t Kit, 50" crosscut capac ity.

6284600 Tenoning Jig.

2328003 Zero Clearance Insert.

6441000 S et of 2 legs for 6827028 table.

6682004 Rout-R-Lift with delux e fence.

6827028 Formica topped table f or 50" c apaci ty T-square system.

6827031 Table 28" x 35-3/8" with Rout- R- Lift hole for model 66 saw.

6827032 Table 28" x 24" with Rout-R-Lif t hole for model 66 saw.

and rail system for rippi ng 50" to ri ght and 12" to left of saw blade.

- fence assembly only, no rails - for Model 66.

and rail system for Model 66 w/sli ding table.

and rail system for rippi ng 30" to ri ght and 12" to left of saw blade.

.

.

Replacement Parts

Replacement part s are li sted on the f ollowing page s. To order par ts or reac h our servi ce depar tment, call

1-800-274-6848 between 7:00 a.m. and 6:00 p.m. (CST), Monday through Friday. Having the Model

Number and Serial Number of your machine available when you call will allow us to serve you quickly and

accurately.

23

Page 24

Parts List: Trunnion Assembly

Index No. Part No. Description Size Qty

................. 2810012.................. Trunnion Assembly (Items 1 thr u 65) ............ .........................................1

................. 2271035.................. Handwheel Assembl y (Item s 2 thr u 7).......... .........................................2

2............... 2271036.................. Handle Assembly (It em s 4, 6, 7) .................. .........................................2

3............... 3271084.................. Handwheel ..................................................8” diameter.......................2

4............... 3271085.................. Handle......................................................... .........................................2

5............... TS-1524031 ............ Socket Set Screw*.......................................M8 x 12.............................2

6............... 6716221.................. Slotted Fillister Head Cap Screw* ................M10 x 95.25......................2

7............... 6516029.................. Hex Jam Nut*..............................................M10 ..................................2

8............... 2810013.................. Center Trunnion Sub-Assembly .................. .........................................1

(Items 9, 25, 29, 30, 35, 40 thru 43, and 46)

9............... 3810041.................. Center Trunnion with Fasteners (Item s 29, 30, 59, 60) ...........................1

................. 2701010.................. Tilting Bracket Assembly (Items 11 thru 18, 64)......................................1

................. 2865001.................. Tilting Shaft Assembly (Items 13, 15, 16)..... .........................................1

11.............3065006.................. Tilting Br a ck e t.............................................. .........................................1

13.............3701031.................. Tilting Sh aft ................................................. .........................................1

14.............6861901.................. Nylon Washe r*.............................................E12, 3/4 I.D.......................4

15.............6626080.................. Spring Pin* ..................................................5mm dia. x 28...................2

16.............3865001.................. Worm........................................................... .........................................2

17.............3096247.................. Shaft Collar with Fasteners.......................... .........................................2

18.............TS-1520411............ Socket Set Screw*.......................................M8 x 8...............................4

19.............3582222.................. Shaft Locking Pin......................................... .........................................2

20.............3237360.................. Gear Segment with Fasteners (I tems 21 thru 24) ...................................1

21.............TS-1491061............ Hex Head Cap Screw*.................................M10 x 40...........................1

22.............TS-2210451............ Hex Head Cap Screw*.................................M10 x 45...........................1

23.............TS-1550071............ Flat Washer*................................................M10..................................2

24.............TS-2361101............ Lock Wash e r *..............................................M10..................................2

25.............2025039.................. Bearing Arm Assembly (Items 26 thru 34).... .........................................1

26.............3025265.................. Bearing Arm ................................................ .........................................1

27.............6714273.................. Stud*...........................................................M12 x 67...........................1

28.............6714274.................. Square Head Set Screw* .............................M10 x 25...........................1

29.............TS-149105.............. Hex Head Cap Screw*.................................M10 x 35...........................1

30.............6516029.................. Hex Jam Nut................................................M10..................................1

31.............2087001.................. Dust Chute .................................................. .........................................1

32.............TS-1490011............ Hex Cap Scre w* ..........................................M8 x 12.............................1

33.............TS-1551051............ Lock Wash e r *..............................................M8....................................1

34.............TS-1525021............ Socket Set Screw*.......................................M10 x 12...........................1

35.............2690067.................. Screw Assembly Splitter* (Items 36 thru 39). .........................................1

36.............3691046.................. Adjusting Screw........................................... .........................................1

37.............6572007.................. Spanner Nut ................................................M20 x 1.5..........................1

38.............TS-1491021............ Hex Head Cap Screw ..................................M10 x 20...........................1

39.............TS-2361101............ Lock Wash e r ................................................M10..................................1

40.............3711005.................. Pivot Shaft................................................... .........................................1

41.............6811327.................. Spacer......................................................... .........................................2

42.............6578006.................. Hex Nut*......................................................1

43.............6670092.................. Retainer Ring*............................................. .........................................1

44.............3480015.................. Motor Mount................................................ .........................................1

45.............3810023.................. Front Trunnion............................................. .........................................1

46.............2865002.................. Raising Shaft Assembly (Items 15, 16, 47)... .........................................1

47.............3701032.................. Raising Shaft............................................... .........................................1

48.............3735075.................. Spacer......................................................... .........................................1

................. 2024018.................. Arbor Assembly (Items 52 thru 58)............... .........................................1

52.............3700123.................. Arbor Shaft .................................................. .........................................1

53.............6670015.................. Retainer Ring...............................................#5100-78 ..........................2

54.............3737214.................. Spacer......................................................... .........................................1

55.............6060009.................. Bearing NSK................................................6204 .................................2

56.............6863004.................. Wavy Wash er..............................................W1819-020.......................1

57.............3838006.................. Collar........................................................... .........................................1

1

/8 -12..............................1

24

Page 25

Index No. Part No. Description Size Qty

58.............3530006.................. Nut..............................................................5/8-12 ACME....................1

59.............3604036.................. Pointer......................................................... .........................................1

60.............6780015.................. Button Head Socket Cap Screw*..................M4 x 10.............................1

61.............6780016.................. Square Head Set Screw* .............................M10 x 65...........................1

63.............3810040.................. Rear Trunnion.............................................. .........................................1

64.............6420002.................. Woodruff Key...............................................#608 .................................3

65.............3868032.................. Arbor Wren ch.............................................. .........................................2

66.............3700090.................. Splitter Support Shaft................................... .........................................1

67.............6716035.................. Hex Head Screw..........................................3/8-16 x 1-3/4....................4

68.............6861300.................. Lock Was h e r................................................3/8..................................10

69.............6516001.................. Hex Nut.......................................................3/8-16...............................6

70.............6714159.................. Socket Set Screw........................................1/4-20 x 3/8.......................1

71.............6807132.................. Arbor Sheave...............................................2-Groove........................... 1

72.............6716031.................. Hex Head Screw..........................................3/8-16 x 1..........................1

73.............6861501.................. Flat Washer.................................................1/2....................................2

74.............6518001.................. Hex Nut.......................................................1/2-13...............................2

75.............6472028.................. Electric Motor, 3HP, 1Ph, 3600 RPM, 230V, 145 TC Frame...................1

................. 6472033.................. Electric Motor, 3HP, 1Ph, 3600 RPM, 230V, 145 TC Frame (50Hz)

................. 6471720.................. Electric Motor, 2HP, 3Ph, 3600 RPM, 230/460V, 145 TC Frame

................. 6471723.................. Electric Motor, 2HP, 1Ph, 3600 RPM, 115/230V, 145 TC Frame

................. 6472024.................. Electric Motor, 3HP, 3Ph, 3600 RPM, 200V, 147 TC Frame

................. 6472025.................. Electric Motor, 3HP, 3Ph, 3600 RPM, 230/460V, 145 TC Frame

................. 6472307.................. Electric Motor, 5HP, 3Ph, 3600 RPM, 230/460V, 184 C Frame

................. 6472335.................. Electric Motor, 5HP, 1Ph, 3600 RPM, 230V, 184 C Frame

76.............6718017.................. Hex Head Cap Screw..................................1/2-13 x 1-3/4....................1

77.............6807133.................. Motor Sheave..............................................2-Groove...........................1

78.............6715013.................. Socket Set Screw........................................5/16-18 x 3/8.....................1

79.............6077225.................. Belt (2 required)........................................... .........................................2

80.............6516009.................. Hex Jam Nut................................................3/8-16...............................1

81.............6716079.................. Square Head Screw .....................................3/8-16 x 1..........................1

82.............6716082.................. Square Head Screw .....................................3/8-16 x 2-1/2....................1

................. 2380019.................. Hardware Kit* (not shown) .......................... ...........................................

* Items included with hardware kit.

25

Page 26

Trunnio n Assembly

26

Page 27

Parts List: Miter Gauge

Index No. Part No. Description Size Qty

................. 2471015.................. Mitre Gauge Assembly (Item s 1 Thru 14)........... ...................................1

1............... 3044053.................. Mitre Gauge Bar................................................ ...................................1

2............... 3230038.................. Mitre Gauge....................................................... ...................................1

3............... 3604035.................. Mitre Gauge Pointer........................................... ...................................1

4............... 3585221.................. Stop Pin............................................................. ...................................1

5............... 3841202.................. Mitre Gauge Bar Washer ................................... ...................................1

6............... 6506001.................. Hex Nut............................................................. # 6-32.........................3

7............... 6623012.................. Dowel Pin ..........................................................1/4 x 1 ........................1

9............... 6706015.................. Fillister Head Machi ne Screw............................. 6-32 x 5/8...................3

11.............6714053.................. Flat Head Cap Screw......................................... 1/4-20 x 3/8 ................1

12.............6861101.................. Plain Flat Washer.............................................. 1/4..............................1

13.............3695221.................. Locking Screw................................................... 1/4 x 3-3/8..................1

14.............3268050.................. Mitre Gauge Handle Knob.................................. ...................................1

15.............3055435.................. Pointer Blo ck ..................................................... ...................................1

27

Page 28

Parts List: Splitter and Guard Assembly

Index No. Part No. Description Size Qty

................. 2787008.................. Splitter Rear Support Assembly (It em s 1 thru 7) ...................................1

1............... 6715034.................. Hex Head Cap Screw........................................ 5/16-18 x 1-1/4...........1

2............... 6861200.................. Lock Was h e r......................................................5/16............................1

3............... 3776050.................. Splitter Rear Support ........................................ ...................................1

4............... 6572007.................. Spanner Lock Nut.............................................. 3/4-16 ........................1

5............... 3690232.................. Adjustm ent Screw.............................................. 3/4-16 x 1-1/2 ............1

6............... 2406001.................. Knob Assembly.................................................. ...................................1

7............... 3700090.................. Splitter Support Shaft ........................................ ...................................1

................. 2250116.................. Guard and Splitter Assembly (Items 8 thru 28)... ...................................1

8............... 6851101.................. Flat Washer.......................................................1/4..............................2

9............... 6714158.................. Hex Head Cap Screw........................................ 1/4-20 x 5/8 ...............1

10.............6714192.................. Flat Head Socket Screw.....................................1/4 x 20 x 7/8..............8

11.............3250112.................. Blade Guard ..................................................... ...................................2

12.............3838015.................. Pivot Was h e r..................................................... ...................................4

13.............6514012.................. Lock Nut............................................................ 1/4-20.........................4

14.............6626029.................. Spring Pin.......................................................... 3/16 x 1 ......................1

15.............6626050.................. Spring Pin.......................................................... 3/8 x 1-3/4..................1

16.............3720018.................. Guard Shi eld...................................................... ...................................1

17.............6710032.................. Round Head Machine Screw.............................. No. 10-24 x 1/4...........2

18.............3720017.................. Front Shield....................................................... ...................................1

19.............6714053.................. Flat Head Machine Screw.................................. No. 10-24 x 3/8...........2

20.............3055095.................. Pivot Bl ock......................................................... ...................................1

21.............3025074.................. Pivot Arm........................................................... ...................................4

22.............3070108.................. Pivot Bushing..................................................... ...................................8

23.............6514001.................. Hex Nut............................................................. 1/4-20.........................2

24.............3581006.................. Anti-kickback Pawl............................................. ...................................2

25.............3044307.................. Splitter Bar......................................................... ...................................1

26.............3750011.................. Splitter............................................................... ...................................1

27.............3735203.................. Spacer............................................................... ...................................2

28.............3837206.................. Washer.............................................................. ...................................4

29.............6861301.................. Flat Plain Washer.............................................. 3/8 ............................1

30.............3330285.................. Caution Label (not shown) ................................. ...................................1

28

Page 29

Splitter and Guard Assembly

29

Page 30

Parts List: Stand Assembly

Index No. Part No. Description Size Qty

1............... 6716031.................. Hex Head Screw................................................ 3/8-16 x 1...................9

2............... 6861300.................. Lock Was h e r......................................................3/8..............................9

3............... 3186008.................. Standard Extension ........................................... 8"................................2

................. 2328002.................. Dado Insert Assembl y (Item s 4 & 5) .................. ...................................1

4............... 6714081.................. (Pkg of 5) Socket Set Screw (Nylok).................. 1/4-20 x 3/8................1

5............... 3328026.................. Dado Insert........................................................ ...................................1

................. 2136002.................. Door Assembly (Items 21 & 22).......................... ...................................1