Page 1

EDGE SANDER

Model 6108

Instruction Manual & Parts List

M-0460222

(800) 274-6848

www.powermatic.com

Page 2

This manual has been prepared for the owner and operators of a Powermatic Model 6108 Edge

Sander. Its purpose, aside from machine operation, is to promote safety through the use of

accepted correct operating and maintenance procedures. Completely read the safety and maintenance instructions before operating or servicing the machine. To obtain maximum life and

efficiency from your sander, and to aid in using the machine safely, read this manual thoroughly

and follow all instructions carefully.

Warranty & Service

The WMH Tool Group warrants every product it sells. If one of our tools needs service or repair, one of our

Authorized Repair Stations located throughout the United States can give you quick service.

In most cases, any one of these WMH Tool Group Repair Stations can authorize warranty repair, assist you in

obtaining parts, or perform routine maintenance and major repair on your JET, Powermatic, Performax, or

Wilton tools.

For the name of an Authorized Repair Station in your area, please call 1-800-274-6848.

More Information

Remember, the WMH Tool Group is consistently adding new products to the line. For complete, up-to-date

product information, check with your local WMH Tool Group distributor.

WMH Tool Group Warranty

The WMH Tool Group makes every effort to assure that its products meet high quality and durability standards

and warrants to the original retail consumer/purchaser of our products that each product be free from defects in

materials and workmanship as follow: 1 YEAR LIMITED WARRANTY ON ALL PRODUCTS UNLESS SPECIFIED OTHERWISE. This Warranty does not apply to defects due directly or indirectly to misuse, abuse,

negligence or accidents, normal wear-and-tear, repair or alterations outside our facilities, or to a lack of maintenance.

THE WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD SPECIFIED ABOVE, FROM

THE DATE THE PRODUCT WAS PURCHASED AT RETAIL. EXCEPT AS STATED HEREIN, ANY IMPLIED

WARRANTIES OR MERCHANTIBILITY AND FITNESS ARE EXCLUDED. SOME STATES DO NOT

ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY

NOT APPLY TO YOU. THE WMH TOOL GROUP SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES

TO PERSONS OR PROPERTY, OR FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL

DAMAGES ARISING FROM THE USE OF OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR

EXCLUSION MAY NOT APPLY TO YOU.

To take advantage of this warranty, the product or part must be returned for examination, postage prepaid, to an

Authorized Repair Station designated by our office. Proof of purchase date and an explanation of the complaint

must accompany the merchandise. If our inspection discloses a defect, we will either repair or replace the

product, or refund the purchase price if we cannot readily and quickly provide a repair or replacement, if you are

willing to accept a refund. We will return repaired product or replacement at WMH's expense, but if it is

determined there is no defect, or that the defect resulted from causes not within the scope of WMH's warranty,

then the user must bear the cost of storing and returning the product. This warranty gives you specific legal

rights; you may also have other rights which vary from state to state.

The WMH Tool Group sells through distributors only. Members of the WMH Tool Group reserve the right to

effect at any time, without prior notice, those alterations to parts, fittings, and accessory equipment which they

may deem necessary for any reason whatsoever.

Page 3

TABLE OF CONTENTS

SAFETY: General Rules ...................................................................................................................... 4

Specific Rules ...................................................................................................................... 5

Decal Instruction .................................................................................................................. 5

SPECIFICATIONS ................................................................................................................................5

RECEIVING THE SANDER .................................................................................................................. 6

INSTALLATION .................................................................................................................................... 6

Electrical Connections .................................................................................................................. 6

OPERATION ........................................................................................................................................ 6

ADJUSTMENTS .................................................................................................................................. 6

Changing Sanding Belt ................................................................................................................. 6

Sanding Belt Tension Spring Fatigue Compensation .................................................................... 7

Front Work Table Inclination ......................................................................................................... 7

Steel Platen Adjustment ............................................................................................................... 8

Motor/Sanding Belt Alignment ...................................................................................................... 8

MAINTENANCE ................................................................................................................................... 9

Lubrication .................................................................................................................................... 9

Sanding Belt Selection .................................................................................................................. 9

TROUBLE SHOOTING ................................................................................................................. 10-11

PARTS LIST & EXPLODED VIEW ................................................................................................ 12-13

ELECTRICAL SCHEMATICS ....................................................................................................... 14-15

OPTIONAL ACCESSORIES .............................................................................................................. 16

Page 4

SAFETY: General Rules

12. USE SAFETY GLASSES. Also use face or

dust mask if cutting operation is dusty.

As with all power tools there is a certain amount of

hazard involved with the operation and use of the

tool. Use the tool with the respect and caution demanded where safety precautions are concerned.

This will considerably lessen the possibility of personal injury. When normal safety precautions are

overlooked or completely ignored, personal injury

to the operator can result.

1. KNOW YOUR TOOL. Read the owner’s

manual carefully. Learn the tools applications and

limitations, as well as the specific potential hazards peculiar to it.

2. KEEP GUARDS IN PLACE and maintained

in working order.

3. GROUND ALL TOOLS. If tool is equipped

with three-prong plug, it should be plugged into a

three-hole electrical receptacle. If an adapter is

used to accommodate a two-prong receptacle, the

adapter plug must be attached to a known ground.

Never remove the third prong.

4. REMOVE ADJUSTING KEYS AND

WRENCHES. Form habit of checking to see that

keys and adjusting wrenches are removed from

tool before turning it on.

5. KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

6. AVOID DANGEROUS ENVIRONMENT.

Don’t use power tools in damp or wet locations, or

expose them to rain. Keep work area well lighted.

7. KEEP CHILDREN AND VISITORS AWAY. All

children and visitors should be kept a safe distance

from work area.

8. MAKE WORKSHOP CHILDPROOF - with

padlocks, master switches, or by removing starter

keys.

9. DON’T FORCE TOOL. It will do the job bet-

ter and be safer at the rate for which it was designed.

10. USE RIGHT TOOL. Don’t force tool or attachment to do a job it was not designed for.

11. WEAR PROPER APPAREL. Do not wear

loose clothing, gloves, neckties, or jewelry that can

get caught in moving parts. Nonslip footwear is

recommended. Wear protective hair covering to

contain long hair.

4

13. SECURE WORK. Use clamps or a vise to

hold work when practical. It’s safer than using your

hand and frees both hands to operate tool.

14. DON’T OVERREACH. Keep your proper foot-

ing and balance at all times.

15. MAINTAIN TOOLS IN TOP CONDITION.

Keep tools sharp and clean for best and safest performance. Follow instructions for lubricating and

changing accessories.

16. DISCONNECT TOOLS before servicing and

when changing accessories such as chisel and bit.

17. USE RECOMMENDED ACCESSORIES.

Consult the owner’s manual for recommended accessories. The use of improper accessories may

cause hazards.

18. AVOID ACCIDENTAL STARTING. Make sure

switch is in “OFF” position before plugging in cord.

19. NEVER STAND ON TOOL. Serious injury

could occur if the tool is tipped or if the cutting tool

is accidentally contacted.

20. CHECK DAMAGED PARTS. Before further

use of the tool, a guard or other part that is damaged should be carefully checked to ensure that it

will operate properly and perform its intended function - check for alignment of moving parts, binding

of moving parts, breakage of parts, mounting, and

any other conditions that may affect its operation.

A guard or other part that is damaged should be

properly repaired or replaced.

21. NEVER LEAVE TOOL RUNNING UNAT-

TENDED. TURN POWER OFF. Don’t leave tool

until it comes to a complete stop.

22. DRUGS, ALCOHOL, MEDICATION. Do not

operate tool while under the influence of drugs, alcohol, or any medication.

23. ADDITIONAL HEALTH HAZARDS. Some

dust created by power sanding, sawing, grinding,

drilling and other construction activities contains

chemicals known to cause cancer, birth defects or

other reproductive harm. Some examples of these

chemicals are:

* Lead from lead-based paint.

* Crystalline silica from bricks and cement and

other masonry products

* Arsenic and chromium from chemically-treated

lumber.

Page 5

Your risk from these exposures varies, depending

on how often you do this type of work. To reduce

your exposure to these chemicals, work in a wellventilated area, and work with approved safety

equipment, such as those dust masks that are specifically designed to filter out microscopic particles.

SAFETY: Specific Rules

5. Make sure the abrasive belt is tracking properly.

6. Support your workpiece with the work table.

7. When front work table is to be used at an incline, check that the work table is firmly fixed on

the machine.

1. Before you turn on the machine, make sure

everyone is clear of it. Keep hands away from

abrasive belt.

2. Never remove safety guards during operation.

3. Make sure the abrasive belt is not torn or

loose.

4. Make sure the direction of rotation is the same

as that marked on the machine label. If not, the

power connection must be changed.

SAFETY: Decal Instruction

8. Sand with the grain of the wood.

9. Hold the workpiece firmly, to prevent it being

driven from your hands.

10. Feed workpiece against rotation of abrasive

belt.

11. Do not put excess pressure on the abrasive

belt. It is not necessary and will only lead to damage to the belt or the workpiece.

CAREFULLY READ INSTRUCTION MANUAL

BEFORE OPERATING MACHINE.

DO NOT OPERATE WITHOUT ALL GUARDS AND

COVERS IN POSITION.

BE SURE MACHINE IS ELECTRICALLY GROUNDED.

REMOVE OR FASTEN LOOSE ARTICLES OF CLOTHING

SUCH AS NECKTIES, ETC. CONFINE HAIR.

USE SAFETY FACE SHIELD, GOGGLES, OR GLASSES

TO PROTECT EYES AND OTHER PERSONAL SAFETY

EQUIPMENT AS REQUIRED.

STOP MACHINE BEFORE MAKI NG ADJUSTMENTS OR

CLEANING CHIPS FROM WORK AREA.

KEEP THE FLOOR AROUND THE MACHINE CLEAN AND

FREE FROM SCRAPS, SAWDUST, OIL OR GREASE TO

MINIMIZE THE DANGER OF SLIPPING.

SPECIFICATIONS (6108 Edge Sander)

Sanding belt size ............................................................. 6" x 108"

Front table ................................................................... 37" x 7-3/4"

Side table ........................................................................ 19" x 12"

Dust chute ........................................................................... 4" dia.

Belt speed ................................................................. 3,150 SFPM

Overall dimensions ......................... 64-1/2" L x 23" W x 43-1/4" H

Motor .......................... 1-1/2 HP, 1 Ph, 115/230V (prewired 115V)

2 HP, 3 Ph, 230/460V (prewired 230V)

Drive wheel ................................................................. 7" O.D. x 6"

Net weight ........................................................................ 491 lbs.

5

Page 6

RECEIVING THE SANDER

Remove sander from its crate. Check for damage

and ensure all parts are intact. Any damage should

be reported immediately to your distributor and

shipping agent. Before assembling, read the

manual thoroughly, familiarizing yourself with correct assembly and maintenance procedures and

proper safety precautions.

of the three power leads. If single-phase, check the

motor connection (refer to wiring diagram in connection box.)

ADJUSTMENTS

CAUTION: Disconnect sander from power

source before making adjustments.

Contents:

1 Sander

2 Work tables

1 Dust chute

1 Steel platen

1 Hardware bag containing 1 phillips screwdriver,

1 open-end wrench, 4 allen wrenches

INSTALLATION

Remove the bolts securing the sander to the shipping base. Install the machine on firm, level ground

with 5/16" lag bolts through the holes in the bottom of the base. Use shims if necessary to level

the machine before tightening the lag bolts.

Remove any protective coating from exposed metal

surfaces with a soft cloth moistened with a good commercial solvent. DO NOT use acetone, gasoline, lacquer thinner or any type of flammable solvent. Do

not use solvents on plastic parts.

ELECTRICAL CONNECTIONS

Wire the sander to a grounded, metal-enclosed wiring system in accordance with the requirements of

the National Electric Code (ANSI/NFPA70).

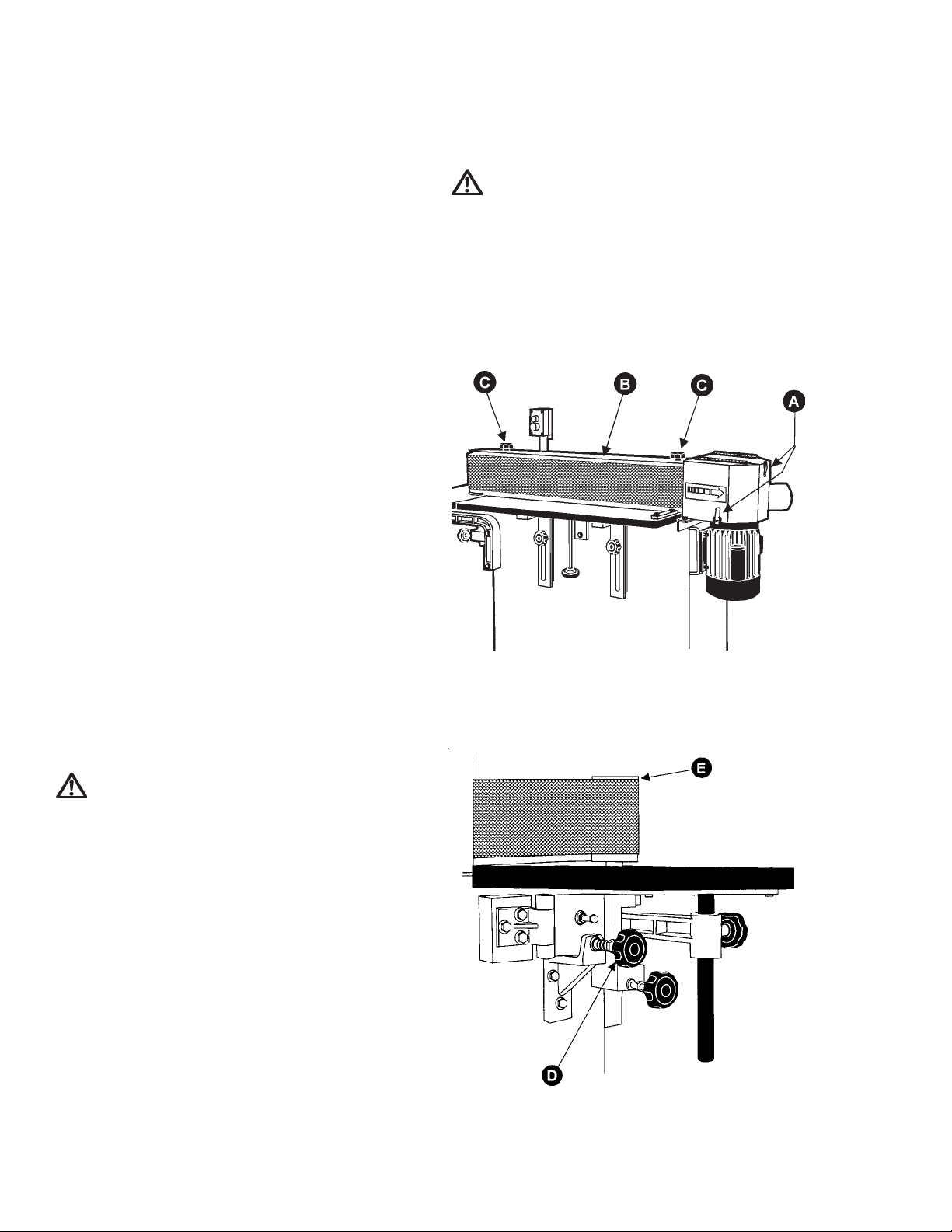

CHANGING SANDING BELT

1. Loosen the two latches (A), on the dust chute,

and open the dust hood, Figure 1.

2. Remove the sanding belt safety guard (B) by

removing the two knobs (C) which are on the guard.

FIGURE 1

3. Rotate the sanding belt tension adjustment knob

(D) clockwise to release idler pulley device (E). See

Figure 2. Remove the old belt.

WARNING: ELECTRICAL WIRING SHOULD

BE DONE BY A QUALIFIED ELECTRICIAN. THE

MACHINE MUST BE PROPERLY GROUNDED TO

HELP AVOID ELECTRIC SHOCK AND ASSOCIATED HAZARDS INCLUDING POSSIBLE DEATH.

If your edge sander is 3-phase, there is a four conductor power source cable. If single-phase, it has a

three conductor power source cable. On both models, the ground conductor is green or yellow & green.

NEVER connect the green wire to a live terminal.

OPERATION

The sander is equipped with a push-button magnetic

control system.

When starting the machine, make sure the rotational

direction is correct. If it is not, the power connection

will have to be changed: If 3-phase, change any two

6

FIGURE 2

Page 7

NOTE: Identify the sanding belt direction before you

install the belt, because the belt's rotational direction

must be the same as the machine. An arrow on the

reverse side of the belt shows the proper direction

and should match the arrow direction on the machine

guard. If the belt has no arrow indicator, find the

joint of the belt (where it is layered) and install it according to Figure 3.

FIGURE 3

4. Place the new sanding belt between the contact wheel and idler pulley, then adjust the tension

adjustment knob (D). Counterclockwise will maximize the tension, clockwise will minimize it.

5. Check that the new belt is tracking correctly by

rotating it with one hand, Figure 4, and use your other

hand to make any adjustments to the track adjustment knob (F). To lower the abrasive belt, rotate the

track adjustment knob clockwise. To raise it, rotate

counterclockwise.

NOTE: The track adjustment mechanism is

very sensitive - make these corrections gently.

6. Replace safety guard (B), close dust hood and

re-tighten knobs (A).

7. Turn machine on and off quickly several times

to check that the sanding belt rotation is normal and

that it tracks properly. If not, repeat the above procedure.

SANDING BELT TENSION SPRING

FATIGUE COMPENSATION

Adjustment of the sanding belt will cause spring fatigue when used for a long period. If this happens,

it's not necessary to change the spring. Simply rotate the tension adjustment screw (A), Figure 5, clockwise until you achieve the proper tension compensation.

FIGURE 5

When properly adjusted, the sanding belt should keep

the same steady level during rotation without moving too high or too low.

FIGURE 4

FRONT WORK TABLE INCLINATION

Using the inclined table method on this edge sander

may give you better sanding surface contact, decreased sanding marks and burr residue, with results equal to that of an oscillating sanding machine.

To adjust the front work table:

1. Loosen the two fixed knobs (A), Figure 6.

2. Raise the front work table (B) by rotating the

adjustment knob (C) and incline it to the degree desired.

3. Re-tighten the fixed knobs (A).

7

Page 8

FIGURE 6

FIGURE 8

STEEL PLATEN ADJUSTMENT

The steel platen is located between the motor contact wheel and the idler pulley. The surface of the

steel platen should protrude about 1/8"-1/4" past the

motor contact wheel and the idler pulley in order to

assure that the sanding belt will be in contact totally

with the steel platen.

Adjust as follows:

1. Remove sanding belt (refer to "Changing Sanding Belt").

2. Loosen the two fixed screws (A), Figure 7, on

the steel platen at the rear of the machine.

MOTOR/SANDING BELT ALIGNMENT

The motor and sanding belt on the edge sander were

factory aligned. However, if they are out of alignment due to shipping, adjust as follows:

1. Adjust front work table to its lowest position.

2. Loosen the two fixed screws on the dust chute

and remove chute from machine.

3. Remove safety guard.

4. Rotate the belt by hand to ensure that it is completely parallel with the steel platen, top left to top

right. Use a straight edge if necessary to measure

this.

5. If the sanding belt left to right is not parallel with

the steel platen, then the motor is not adjusted properly. Loosen the motor mounting screws (A), Figure

9, and adjust with the two jack screws (B).

FIGURE 7

3. Using a straight edge (B), to measure the protruding distance between the surface of the steel

platen and the two pulleys (i.e. motor contact wheel

& idler pulley). See Figure 8.

4. Tap the steel platen with your hand until the protruding distance is 1/8" to 1/4". The platen/motor

contact wheel & platen/idler pulley distances should

be the same.

5. Re-tighten the fixed screws (A) on the platen,

and replace sanding belt.

8

FIGURE 9

6. If the right side of the sanding belt (near the

motor) is too high, adjust motor inclination inward,

until the sanding belt is parallel with the steel platen.

Then tighten the four motor fixed screws (E).

7. Rotate the sanding belt by hand again to make

sure it is completely parallel with steel platen.

8. Replace safety guard and dust hood, and adjust the sanding belt tracking if necessary.

Page 9

MAINTENANCE

LUBRICATION

CAUTION: Disconnect sander from power

source before performing maintenance.

Do not operate the sander until it is properly lubricated.

All ball bearings are sealed for life and do not require

lubrication.

Apply a drop of light machine oil occasionally on the

hinge of the tension mechanisms as shown in Figure 10. Service the machine every 6 weeks.

SANDING BELT SELECTION

Use the chart, Figure 11, for selecting an abrasive

belt. Aluminum oxide is recommended for general

use in the home workshop.

Figure 12 groups abrasives into five classes, indicating the grit numbers that fall into each.

FIGURE 10

EVISARBAESUESRAOC

munimulAdoowdraH04-0308-06021-001

edixOmunimulA0408-06001

reppoC05-04001-08021-001

leetS03-4208-06001

yrovI08-06021-001082-021

citsalP08-05081-021042

TIRG

MUIDEM

FIGURE 11

EPYTENIFYREVENIFMUIDEMESRAOC

edixOmunimulA063-022081-021001-0806-0463-42

FIGURE 12

ENIF

YREV

ESRAOC

9

Page 10

TROUBLE SHOOTING

MELBORPESUACELBISSOPNOITULOS

.tratstonlliwrednaSrekaerbtiucricronwolbesuF.1

.deppirt

.degamaddroC.2

.yltneuqerftuoskcikdaolrevOootrothgilootdrocnoisnetxE.1

.gnol

erusserpdeefroetibevissecxE.2

.taergoot

tcerrocrofderiwtonrotoM.3

.egatlov

otpuemoctonseodtlebgnidnaS

.deeps

.ylevissecxesetarbivenihcaM.roolfnevenunohcnebrodnatS.1

.gnol

.tnerruc)esuoh(woL.2

.egatlov

.taergoot

.yltcerroc

noisnetrofgnirpsehT.4

ootrothgilootdrocnoisnetxE.1

tcerrocrofderiwtonrotoM.3

erusserpdeefroetibevissecxE.4

.gnitnuomrotomreporpmI.2

denoisnettontlebgnidnaS.3

.nekorbrodeugitafsimsinahcem

.esoolootsileehwtcatnoC.5

.rekaerb

.naicirtcele

.droc

.ecroftonod

.gniriwtcerroc

.droc

.gniriwtcerroc

.ecroftonod

.gnitnuom

sitlebfogninoisneT.3

.gnikrowsignirpsehtfo

tiucricteserroesufecalpeR.1

deifilauqybdecalperdrocevaH.2

ezisetauqedahtiwecalpeR.1

-yleerftucottlebgnidnaswollA.2

rofetalpemanrotomotrefeR.3

ezisetauqedahtiwecalpeR.1

.naicirtceledeifilauqatcanoC.2

rofetalpemanrotomotrefeR.3

-yleerftucottlebevisarbawollA.4

.ecafrusleveltalfnonoitisopeR.1

.yrassecenfiroolfotnetsaF

rotomtsujdadnakcehC.2

bonkehthguorhtdehsilpmocca

erusekaM.gnirpsehtslortnoctaht

noisnetllufehtosdesaelersibonk

.gnirpswenhtiwecalpeR.4

rotomniwercspacnethgiT.5

.tfahs

.nekorbtlebgnidnaS.6

.tlebgnidnaswenhtiwecalpeR.6

10

.tlebgnidnasdaB.7

.tlebgnidnaswenhtiwecalpeR.7

.latemnobojetauqedanI.tlebgnidnasgnorW.1nocilisroedixomunimulaesU.1

rotnilfton,stlebgnidnasedibrac

.tenrag

.krownoskramgnidnaSrofesraocoottlebgnidnaS.1

.deriuqerhsinif

.hsiniflanif

.tirgtlebgnidnasgnorW.2

roftlebgnidnasenifyrevesU.1

kcotsroftirgresraocesU.2

.lavomer

.niargssorcadednaskroW.3

esu,gnidnasecafrusnehW.3

hsinifnehttlebgnidnasenifyrev

fonoitceridnignikrow,dnahyb

.niarg

ffoburylkciuqsniarggnidnaS

.tleb

.seitreporplanigiro

stitsolsahtlebgnidnaS.1

stlebgnidnaserotstonoD.1

erehwroyrdylemertxesitierehw

.hgihylemertxeeraserutarepmet

.egarotstcerrocnI.2

.ylreporptlebgnidnaserotS.2

.tidloftonoD

Page 11

TROUBLE SHOOTING (continued)

MELBORPESUACELBISSOPNOITULOS

.sezalgtlebgnidnaS.ecafrusdetniapgnidnaS.1

.ymmugrotewsidooW.2

.snrubkroW.ecafrustlebgnidnasgnorW.1

.lavomer

.taergooterusserpdeeF.2

.netalp

.sselnoitomdlehkroW.3

.krownoskramgnidnaS.sselnoitomdlehkroW.1.gnivomkrowpeeK.1

ylkciuqsgolc,snrubtlebgnidnaS

.gnidnasssenkcihtno

.krownisnoitatnednIenonisselnoitomdlehkroW.1

.tops

.strotsidyellupreldidnegnidnaSdeefroetibevissecxE.1

.erusserp

.dnahmorfdellupkroW.troppusoN.1tnorfehtnopotskrowehtesU.1

ehttanekorbsahtlebgnidnaS

.tnioj

.peedootgnitiB.1noitcagnidnasthgilsroftsujdA.1

.elbat

.noitceridgnorwnigninnurtleB.1htiwnoitceridnoitatorhctaM.1

.gnivomkrowpeeK.3

.gnivomkrowpeeK.1

.ecroftonod,yleerf

.tlebtnilf/niargdne-nepoesU.1

.kcotstnereffidesU.erucoN.2

kcotsroftirgresraocesU.1

leetsotnikrowecrofreveN.2

.sessapdetaeperekamdna

dnasottlebgnidnaswollA.1

.draugenihcamnoworra

.erauqstonegdedednaS.gnidnasdnaheerffotluseR.1

.derisedsi

.dengilasimelbaT.2

.ylgnidroccatsujdA

.levebsahtlebgnidnaS.dengilasimrotoM.1.tnemngilarotomtsujdA.1

elihwdeppordsahtlebgnidnaS

.gnidnas

.ylirotcafsitasnugnidnasrednaSleetsfogninoitisoptcerrocnI.1

.yltcerroc

.nekorbrodeugitaf

.yltcerroc

.netalp

denoisnettontlebgnidnaS.1

.bonkhtiw

signirpsmsinahcemnoisneT.2

gnikcarttontlebgnidnaS.3

.yellup

.gnikcarttsujdA.3

elbatnotalfeceipkrowpeeK.1

egdeerauqsanehwsemitllata

leetsottnemngilaelbatkcehC.2

.seerged09ebdluohstI.netalp

noisnettlebgnidnastsujdA.1

.gnirpswenhtiwecalpeR.2

"4/1ot"8/1netalpleetstsujdA.1

reldidnaleehwtcatnocehtevoba

11

Page 12

PARTS LIST: Model 6108 Edge Sander

NO. PART NO. DESCRIPTION

1 6294030 TABLE, END

4 6294031 PLATE, STEEL END

5 6294032 SCREW, HEX. HD. WOOD,

1/4-20 X 1-1/4

6 6294033 BAR, SUPPORT

7 6294034 SUPPORT, TABLE

8 6294035 KNOB

9 6294036 WASHER, 3/8"

10 6294037 SCREW, HEX HD. 3/8-16 X 1-1/2"

11 6294038 KNOB

12 6294039 NUT, WING

13 6294040 HOLDER, SPRING

14 6294041 SCREW, HEX HD. 3/8-16 X 1-5/8"

15 6294042 NUT, HEX 3/8

16 6294043 SPRING

17 6294044 PLATE, COVER

18 6294045 BOLT, SOC. HD. CAP,

5/16-18 X 2"

19 6294046 HOLDER, IDLER PULLEY

20 6294047 SCREW, SOC. HD. CAP,

1/4-20 X 5/8"

21 6294048 TABLE, FRONT

22 6294049 PLATE, FRONT STEEL

23 6294050 ANGLE, TABLE

24 6294051 SCREW, HEX HD., 3/8-16 X 1"

25 6294052 SCREW, HEX HD., 3/8-16 X 5/8"

26 6294053 HOLDER, HINGE

27 6294054 BLOCK, SPRING ADJUSTING

28 6294055 SPRING

29 6294056 SUPPORT,SWITCH

30 6294057 BOLT, KNOB

31 6294058 RING, RETAINING

32 6294059 BEARING, #6205-LB

33 6294060 GUARD, SAFETY

34 6294061 PULLEY

35 6294062 BELT, ABRASIVE

36 6294063 SUPPORT, GUARD

37 6294064 SHAFT, PULLEY

38 6294065 PLATEN, STEEL

39 6294066 GRAPHITE

40 6294067 RING, RETAINING

41 6294068 SHAFT, HINGE

42 6294069 ANGLE, SUPPORT

43 6294070 BASE

44 6294071 KNOB, TABLE ADJUSTING

45 6294072 SCREW, HEX HD., 1/4-20 X 3/8"

46 6294073 WASHER, 1/4"

47 6294074 SCREW, HEX HD., 5/16-18 X 5/8"

NO. PART NO. DESCRIPTION

48 6294075 WASHER, 5/16"

49 6294076 COVER, BACK

50 6294077 SCREW, WING, 1/4-20 X 5/8"

51 6294078 PIECE, CLAMPING

52 6294079 SCREW, SOC. HD. CAP,

5/16-18 X 1"

53 6294080 WHEEL, CONTACT

54 6294081 SCREW, HEX HD.,

1/2-12 X 2-1/2"

55 6294082 NUT, HEX 1/2"

56 6294083 SCREW, SET, 5/16-18 X 3/8"

57 6294084 MOTOR, 2 HP, 3 PH

6294085 MOTOR, 1-1/2 HP, 1 PH

58 6294086 KEY

59 6294087 HOOD, DUST

60 6294088 ASSEMBLY, PUSH BUTTON

61 6294089 BOX, SWITCH

62 6294090 WASHER

63 6294091 CONTACTOR w/ THERMAL

OVERLOAD RELAY (2 HP)

64 6294092 CONTACTOR w/ THERMAL

OVERLOAD RELAY (1-1/2 HP)

65 6294093 TRANSFORMER 115/230V

6294122 TRANSFORMER 230/460V

66 6294115 STOP, WORK

67 6294116 SCREW, HEX HD 5/16-18 X 2-1/2"

68 6294117 WASHER, 5/16"

69 6294118 NUT, HEX 5/16"

70 6294119 WASHER, 1/2"

71 6294120 LABEL, DIRECTION

72 6294121 WASHER, SPRING, 5/16"

73 6294101 WIRE, MOTOR

74 6294102 CORD, POWER

75 6294103 PROTECTOR, WIRE

76 6294104 SCREW, SOC. HD. CAP,

1/4-24 X 3/8"

77 6294105 WIRE

78 6294106 SCREW, ROUND HD.,

3/16-24 X 5/8"

79 6294107 LABEL, WARNING

80 6294108 CARD, I.D.

81 6294109 LABEL, CAUTION

82 6294110 LABEL, LOGO

83 6294111 STRIPE, COLOR

84 6294112 WASHER, 3/8"

85 6294113 SCREW, HEX HD., 3/8-16 X 3/4"

86 6294114 SCREW, HEX HD., 3/8-16 X 2-1/4"

12

Page 13

EXPLODED VIEW: Model 6108 Edge Sander

13

Page 14

ELECTRICAL SCHEMATIC (6108 Edge Sander)

14

Page 15

ELECTRICAL SCHEMATIC (6108 Edge Sander)

15

Page 16

OPTIONAL ACCESSORIES

6294094 Abrasive Belt, 6" x 108", 40 Grit.

6294095 Abrasive Belt, 6" x 108", 60 Grit.

6294096 Abrasive Belt, 6" x 108", 80 Grit.

6294062 Abrasive Belt, 6" x 108", 100 Grit.

6294098 Abrasive Belt, 6" x 108", 120 Grit.

6294099 Abrasive Belt, 6" x 108", 150 Grit.

6294100 Abrasive Belt, 6" x 108", 200 Grit.

16

Page 17

171819

Page 18

Page 19

To order parts or reach our service department, please call our toll free number between 8:00 A.M. and

4:30 P.M. (CST), Monday through Friday. Having the Model Number and Serial Number of your machine

available when you call will allow us to serve you quickly and accurately. Locating the stock number of the

part(s) required from your parts manual will also expedite your order.

Phone: (800) 274-6848

Fax: (800) 274-6840

If you are calling from Canada, please call 800-238-4746

E-mail: powermatic@wmhtoolgroup.com

Website: www.powermatic.com

Page 20

02/02

WMH Tool Group

P.O. Box 1349

Auburn, WA 98071-1349

Phone: (800) 274-6848

Fax: (800) 274-6840

E-mail: powermatic@wmhtoolgroup.com

Website: www.powermatic.com

C

POWERMATIC ALL RIGHTS RESERVED

Loading...

Loading...