Page 1

This Manual is Bookmarked

Operating Instructions and Parts Manual

8-inch Jointer

Model 60B

WMH TOOL GROUP

2420 Vantage Drive

Elgin, Illinois 60124 Part No. M-0460282

Ph.: 800-274-6848 Revision G 12/06

www.wmhtoolgroup.com Copyright © WMH Tool Group

Page 2

Warranty and Service

WMH Tool Group, Inc., warrants every product it sells. If one of our tools needs service or repair, one of our Authorized Service

Centers located throughout the United States can give you quick service. In most cases, any of these WMH Tool Group

Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or perform routine maintenance and

major repair on your POWERMATIC

MORE INFORMATION

WMH Tool Group is consistently adding new products to the line. For complete, up-to-date product information, check with your

local WMH Tool Group distributor, or visit powermatic.com.

WARRANTY

POWERMATIC products carry a limited warranty which varies in duration based upon the product.

WHAT IS COVERED?

This warranty covers any defects in workmanship or materials subject to the exceptions stated below. Cutting tools, abrasives

and other consumables are excluded from warranty coverage.

WHO IS COVERED?

This warranty covers only the initial purchaser of the product.

WHAT IS THE PERIOD OF COVERAGE?

The general POWERMATIC warranty lasts for the time period specified in the product literature of each product.

WHAT IS NOT COVERED?

The Five Year Warranty does not cover products used for commercial, industrial or educational purposes. Products with a Five

Year Warranty that are used for commercial, industrial or education purposes revert to a One Year Warranty. This warranty does

not cover defects due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear, improper repair or

alterations, or lack of maintenance.

HOW TO GET SERVICE

The product or part must be returned for examination, postage prepaid, to a location designated by us. For the name of the

location nearest you, please call 1-800-274-6848.

You must provide proof of initial purchase date and an explanation of the complaint must accompany the merchandise. If our

inspection discloses a defect, we will repair or replace the product, or refund the purchase price, at our option.

We will return the repaired product or replacement at our expense unless it is determined by us that there is no defect, or that the

defect resulted from causes not within the scope of our warranty in which case we will, at your direction, dispose of or return the

product. In the event you choose to have the product returned, you will be responsible for the handling and shipping costs of the

return.

HOW STATE LAW APPLIES

This warranty gives you specific legal rights; you may also have other rights which vary from state to state.

LIMITATIONS ON THIS WARRANTY

WMH TOOL GROUP LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH

PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OR MERCHANTABILITY AND FITNESS ARE

EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW LONG THE IMPLIED WARRANTY LASTS, SO THE

ABOVE LIMITATION MAY NOT APPLY TO YOU.

WMH TOOL GROUP SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR PRODUCTS.

SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO

THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

WMH Tool Group sells through distributors only. The specifications in WMH catalogs are given as general information and are

not binding. Members of WMH Tool Group reserve the right to effect at any time, without prior notice, those alterations to parts,

fittings, and accessory equipment which they may deem necessary for any reason whatsoever.

®

tools. For the name of an Authorized Service Center in your area call 1-800-274-6848.

2

Page 3

Table of Contents

Warranty and Service .............................................................................................................................. 2

Table of Contents .................................................................................................................................... 3

Warning...................................................................................................................................................4

Specifications..........................................................................................................................................7

Features of the 60B Jointer...................................................................................................................... 7

Receiving ................................................................................................................................................ 8

Installation and Assembly ........................................................................................................................ 8

Aligning Pulleys....................................................................................................................................9

Mounting Drive Belt.............................................................................................................................. 9

Mounting Pulley Guard......................................................................................................................... 9

Mounting Dust Chute ...........................................................................................................................9

Electrical Connections ........................................................................................................................... 10

Extension Cords.................................................................................................................................11

Adjustments .......................................................................................................................................... 12

Cutter Guard...................................................................................................................................... 12

Installing Knives.................................................................................................................................13

Leveling Tables..................................................................................................................................14

Adjusting Depth of Cut ....................................................................................................................... 15

Setting Outfeed Table ........................................................................................................................ 16

Spring Cutting.................................................................................................................................... 16

Fence Movement ............................................................................................................................... 17

Fence Stops....................................................................................................................................... 17

Basic Jointer Operation ......................................................................................................................... 18

Jointing Short or Thin Work................................................................................................................ 18

Direction of Grain............................................................................................................................... 19

Hand Placement ................................................................................................................................19

Surfacing ........................................................................................................................................... 19

Jointing Warped Surfaces .................................................................................................................. 19

Edge Jointing ..................................................................................................................................... 20

Beveling............................................................................................................................................. 20

Skewing (Shear Cutting) ....................................................................................................................20

Taper Cuts ......................................................................................................................................... 21

Rabbeting ..........................................................................................................................................21

Maintenance.......................................................................................................................................... 22

Sharpening Knives............................................................................................................................. 22

Cutterhead Repairs............................................................................................................................ 22

Table Removal................................................................................................................................... 23

Troubleshooting – Operating Problems .................................................................................................. 24

Troubleshooting – Mechanical and Electrical Problems.......................................................................... 25

Optional Accessories ............................................................................................................................. 26

Replacement Parts................................................................................................................................ 26

Parts List: Base Assembly..................................................................................................................27

Base Assembly.................................................................................................................................. 29

Parts List: Fence Assembly................................................................................................................ 30

Fence Assembly ................................................................................................................................ 31

Parts List: Cutterhead Assembly ........................................................................................................ 32

Parts List: Stand Assembly................................................................................................................. 33

Stand Assembly ................................................................................................................................. 35

Electrical Connections – 230 Volt, Single Phase ....................................................................................36

Electrical Connections – 230 Volt, 3 Phase ............................................................................................ 37

Electrical Connections – 460 Volt, Three Phase..................................................................................... 38

Preventive Maintenance ........................................................................................................................ 39

3

Page 4

Warning

1. Read and understand the entire owner’s manual before attempting assembly or operation. Know the

limitations and hazards in using the jointer. Decals are placed on each machine as reminders of good

safety practice.

2. Read and understand the warnings posted on the machine and in this manual. Failure to comply with

all of these warnings may cause serious injury.

3. Replace the warning labels if they become obscured or removed.

4. This jointer is designed and intended for use by properly trained and experienced personnel only. If

you are not familiar with the proper and safe operation of a jointer, do not use until proper training and

knowledge have been obtained.

5. Do not use this jointer for other than its intended use. If used for other purposes, WMH Tool Group

disclaims any real or implied warranty and holds itself harmless from any injury that may result from

that use.

6. Use extra care in the location of the jointer in the shop. Place the machine so that potential kickback

area is not in line with aisles, doorway, wash stations, or other work areas.

7. Always wear approved safety glasses/face shields while using this jointer. Everyday eyeglasses only

have impact resistant lenses; they are not safety glasses.

8. Before operating this jointer, remove tie, rings, watches and other jewelry, and roll sleeves up past

the elbows. Remove all loose clothing and confine long hair. Non-slip footwear or anti-skid floor strips

are recommended. Do not wear gloves.

9. Wear ear protectors (plugs or muffs) during extended periods of operation.

10. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contains chemicals known to cause cancer, birth defects or other reproductive harm. Some examples

of these chemicals are:

• Lead from lead based paint.

• Crystalline silica from bricks, cement and other masonry products.

• Arsenic and chromium from chemically treated lumber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

11. Do not operate this machine while tired or under the influence of drugs, alcohol or any medication.

12. Make certain the switch is in the OFF position before connecting the machine to the power supply.

13. Make certain the machine is properly grounded.

14. Make all machine adjustments or maintenance with the machine unplugged from the power source. A

machine under repair should be RED TAGGED to show that it should not be used until maintenance

is complete.

15. Remove loose items and unnecessary work pieces from the area before starting the machine.

Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning it on.

16. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme caution and replace the guards immediately upon completion of maintenance.

17. Make sure the jointer is firmly secured to the floor or bench before use.

18. Provide for adequate space surrounding work area and non-glare, overhead lighting.

19. Keep the floor around the machine clean and free of scrap material, oil and grease.

4

Page 5

20. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Check for alignment of moving parts, binding of moving parts, breakage of parts, mounting

and any other conditions that may affect its operation. A guard or other part that is damaged should

be properly repaired or replaced.

21. Keep visitors a safe distance from the work area. Keep children away.

22. Make your workshop child proof with padlocks, master switches or by removing starter keys.

23. Give your work undivided attention. Looking around, carrying on a conversation and “horse-play” are

careless acts that can result in serious injury.

24. Maintain a balanced stance at all times so that you do not fall or lean against the kniv es or other

moving parts. Do not overreach or use excessive force to perform any machine operation.

25. Use recommended accessories; improper accessories may be hazardous.

26. Maintain tools with care. Keep knives sharp and clean for the best and safest performance. Follow

instructions for lubricating and changing accessories.

27. Turn off the machine and disconnect from power before cleaning. Use a brush or compressed air to

remove chips or debris — do not use your hands.

28. Do not stand on the machine. Serious injury could

occur if the machine tips over.

29. Never leave the machine running unattended.

Turn the power off and do not leave the machine

until it comes to a complete stop.

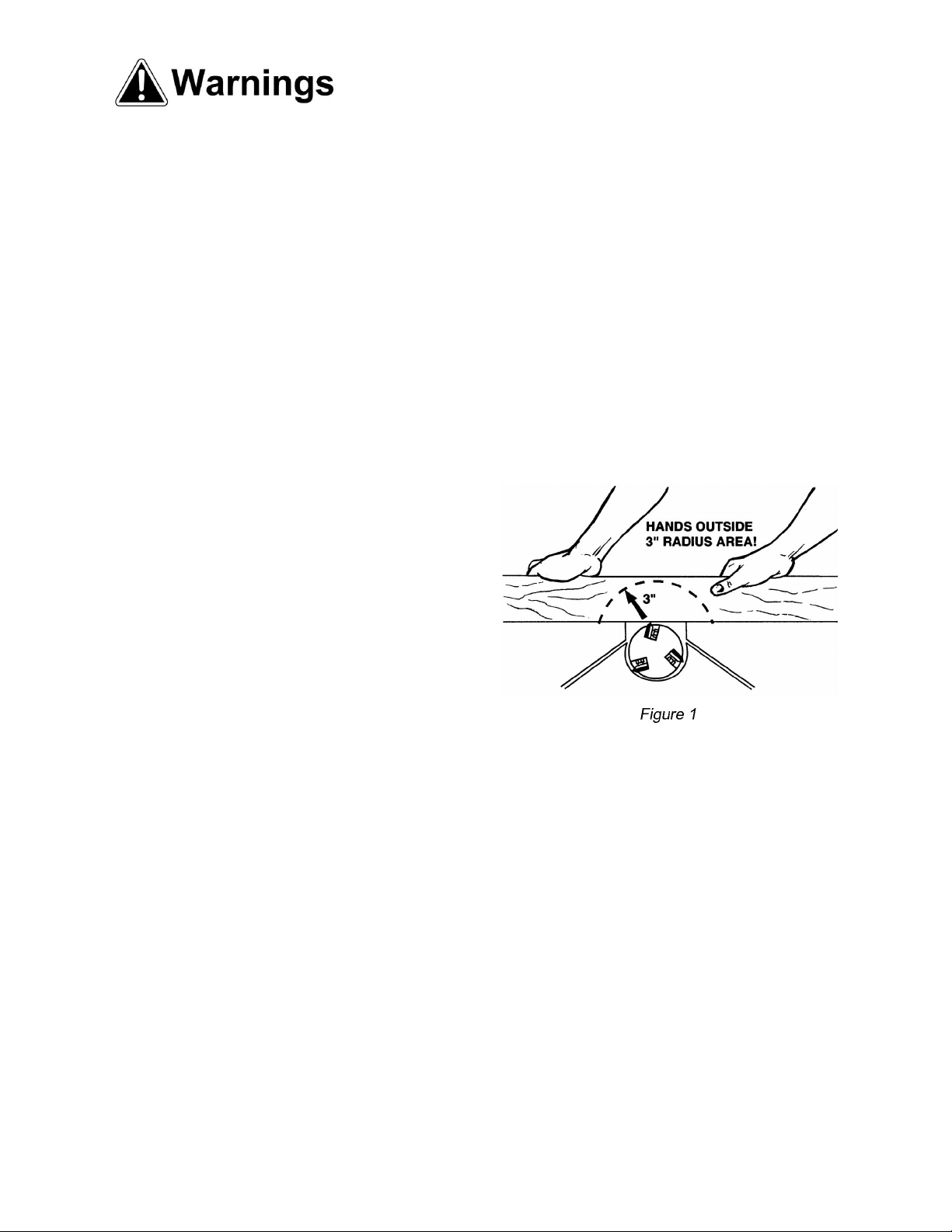

30. When working a piece of wood on the jointer,

follow the 3-inch radius rule: The hands must

never be closer than 3 inches to the cutterhead.

See Figure 1.

31. Always use a hold-down or push block when

surfacing stock less than 12 inches long, or 3

inches wide, or 3 inches thick.

32. Do not perform jointing operations on material shorter than 8 inches in length, narrower than 3/4

inches, or less than 1/4 inch thick.

33. Do not make cuts deeper than 1/8 inch to avoid overloading the machine and to minimize chance of

kickback.

34. Never apply pressure to stock directly over the cutterhead. This may result in the stock tipping into

the cutterhead along with the operator’s fingers. Position hands away from extreme ends of stock,

and push through with a smooth, even motion. Never back workpiece toward the infeed table.

35. “Pull-out” and the danger of kicked back stock can occur when the work piece has knots, holes, or

foreign materials such as nails. It can also occur when the stock is fed against the grain on the jointer.

The grain must run in the same direction you are cutting. Before attempting to joint or plane, each

work piece must be carefully examined for stock condition and grain orientation.

NOTE: At certain times it may be necessary to plane against the grain when working with a swirl grain

wood or burl. With this type of work the operator must use a lesser depth of cut and a slow rate of

feed.

5

Page 6

Familiarize yourself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precautions are not heeded, it may result in serious injury or possibly

even death.

Familiarize yourself with the location and content of these decals:

Figure 2

6

Page 7

Specifications

Model Number........................................................................... 60B................................................... 60B

Stock Number.................................................................. 1610077K......................................... 1610078K

Table (in.)..................................................................8-1/2 W x 72 L.................................. 8-1/2 W x 72 L

Cutting arc (in.).............................................................................. 3....................................................... 3

Knives, high speed steel .................. three @ 1/8" x 11/16" x 8-1/16"......... three @ 1/8" x 11/16" x 8-1/16"

Knife adjustment............................................ springs or jack screws....................... springs or jack screws

Maximum speed of cutterhead (RPM)......................................7,000................................................ 7,000

Knife cuts per minute.............................................................21,000.............................................. 21,000

Maximum depth of cut (in.) ......................................................... 1/2.................................................... 1/2

Maximum rabbeting cut (in.)...................................................1/2 x 8...............................................1/2 x 8

Fence size overall (in.)................................................4-3/4 x 38-1/4....................................4-3/4 x 38-1/4

Height, floor to outfeed table (in.) ................................................. 32..................................................... 32

Overall height, without stand (in.)........................................... 14-1/4............................................... 14-1/4

Overall height, with stand (in.)...................................................... 38..................................................... 38

Footprint (in.).................................................................24 x 17-1/2.......................................24 x 17-1/2

Motor..................................................................... 2 HP, 1Ph, 230V......................... 3HP, 3Ph, 230/460V

(pre-wired 230V)

Approx. Net Weight (Jointer Base) (lbs.).................................... 280................................................... 280

Approx. Net Weight (Stand) (lbs.) .............................................. 113 ................................................... 116

The above specifications were current at the time this manual was published, but because of our policy of

continuous improvement, WMH Tool Group reserves the right to change specifications at any time and

without prior notice, without incurring obligations.

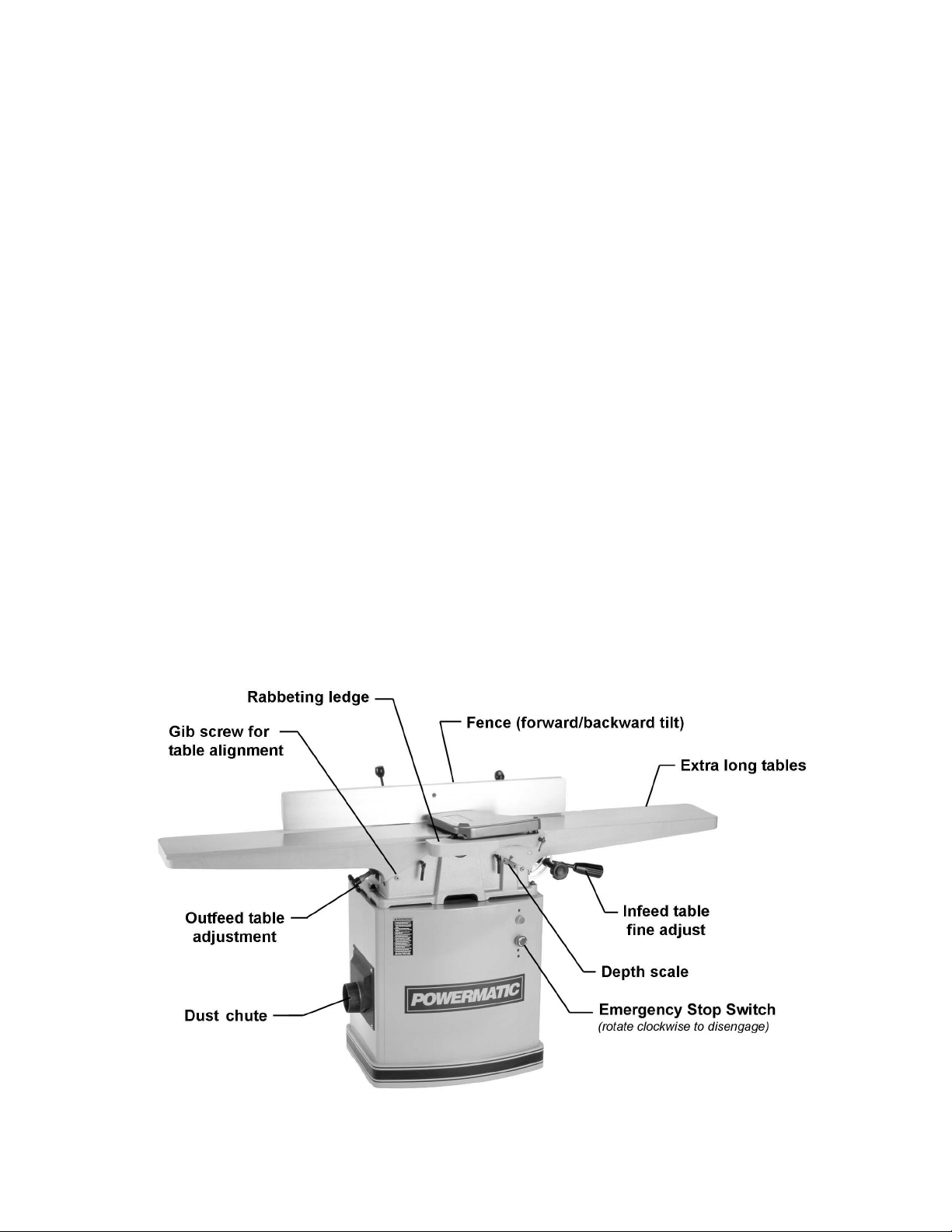

Features of the 60B Jointer

Figure 3

7

Page 8

Receiving

Open both shipping crates and check for

shipping damage. Report any damage

immediately to your distributor and shipping

agent. Before operating your jointer, read this

instruction manual thoroughly for assembly,

maintenance and safety instructions.

Crate #1 contents

1 jointer stand with motor

1 door

1 dust chute

Crate #2 contents

1 table and fence assembly

1 drive belt

1 belt guard

1 cutterhead guard

2 push pads

1 hardware bag

1 knife setting gauge

1 manual

1 warranty card

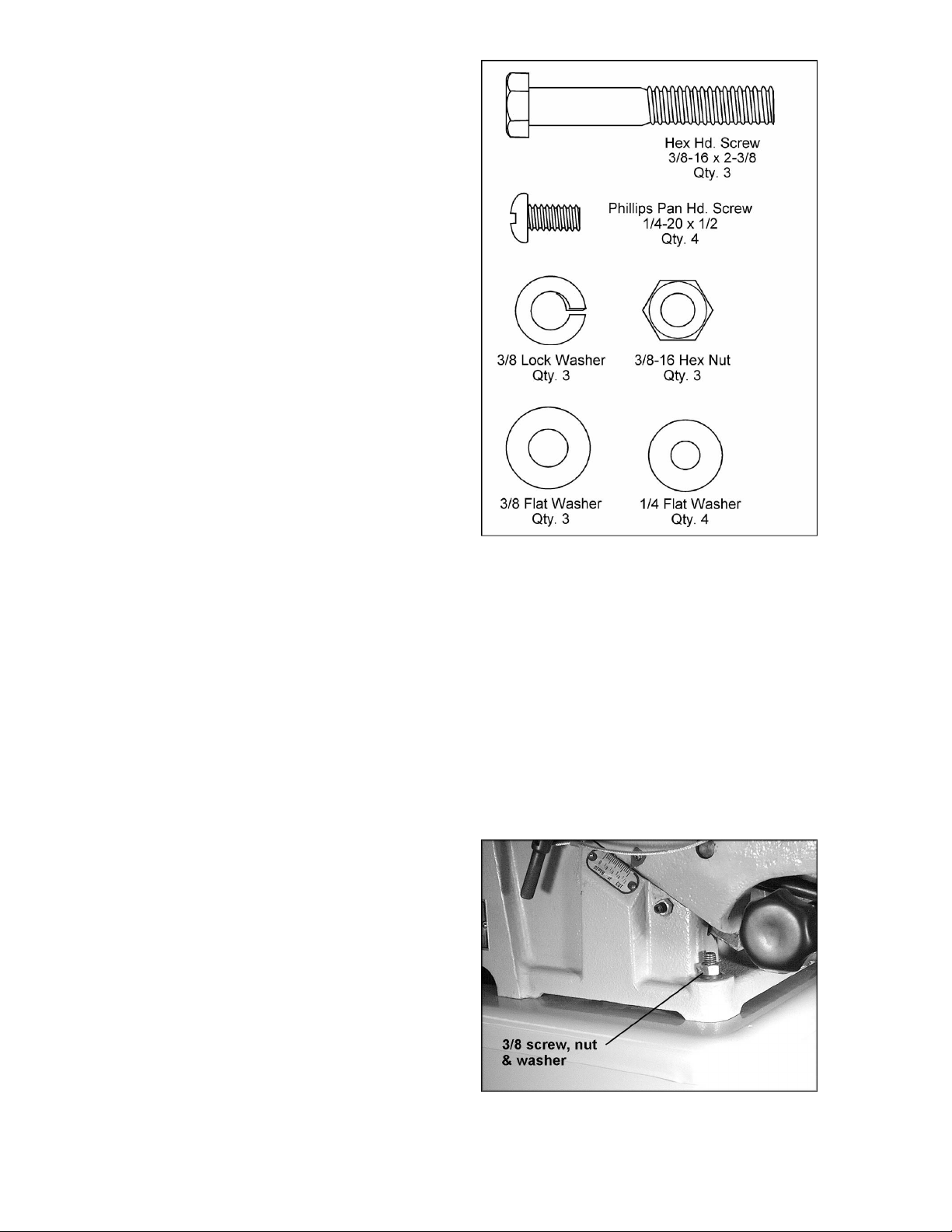

The contents of the hardware bag are shown in

Figure 4.

NOTE: Exposed metal surfaces such as the

table and fence have been given a protective

coating at the factory. This should be removed

with a soft cloth and solvent (such as mineral

spirits) once the machine has been assembled.

Do not use an abrasive pad.

Figure 4

Installation and Assembly

NOTE: If any procedure described below needs

further clarification, consult the assembly

drawings at the back of this manual.

Tools required for assembly:

9/16" wrench

12mm wrench

screwdriver (phillips or flat head)

Locate the jointer on a level floor. If using a

mobile base, be sure to lock the wheels before

assembling, operating or adjusting the jointer.

1. With help from an assistant, lift the jointer

base assembly onto the stand, matching the

3-hole pattern in the table base to that in the

stand.

2. Secure jointer base to stand with three 3/8 x

2-3/8 bolts, six 3/8 flat washers, three 3/8

lock washers and three 3/8 hex nuts (Figure

5). Tighten with 9/16" wrench.

Figure 5

8

Page 9

3. The stand can be secured to the floor using

two anchor bolts (not provided) through the

holes inside the bottom of the stand.

Aligning Pulleys

Place a straight edge against the motor pulley

and cutterhead pulley to make sure they are

aligned. If adjustment is necessary, loosen the

set screws in the motor pulley, and slide it as

needed until alignment is achieved. Re-tighten

set screws.

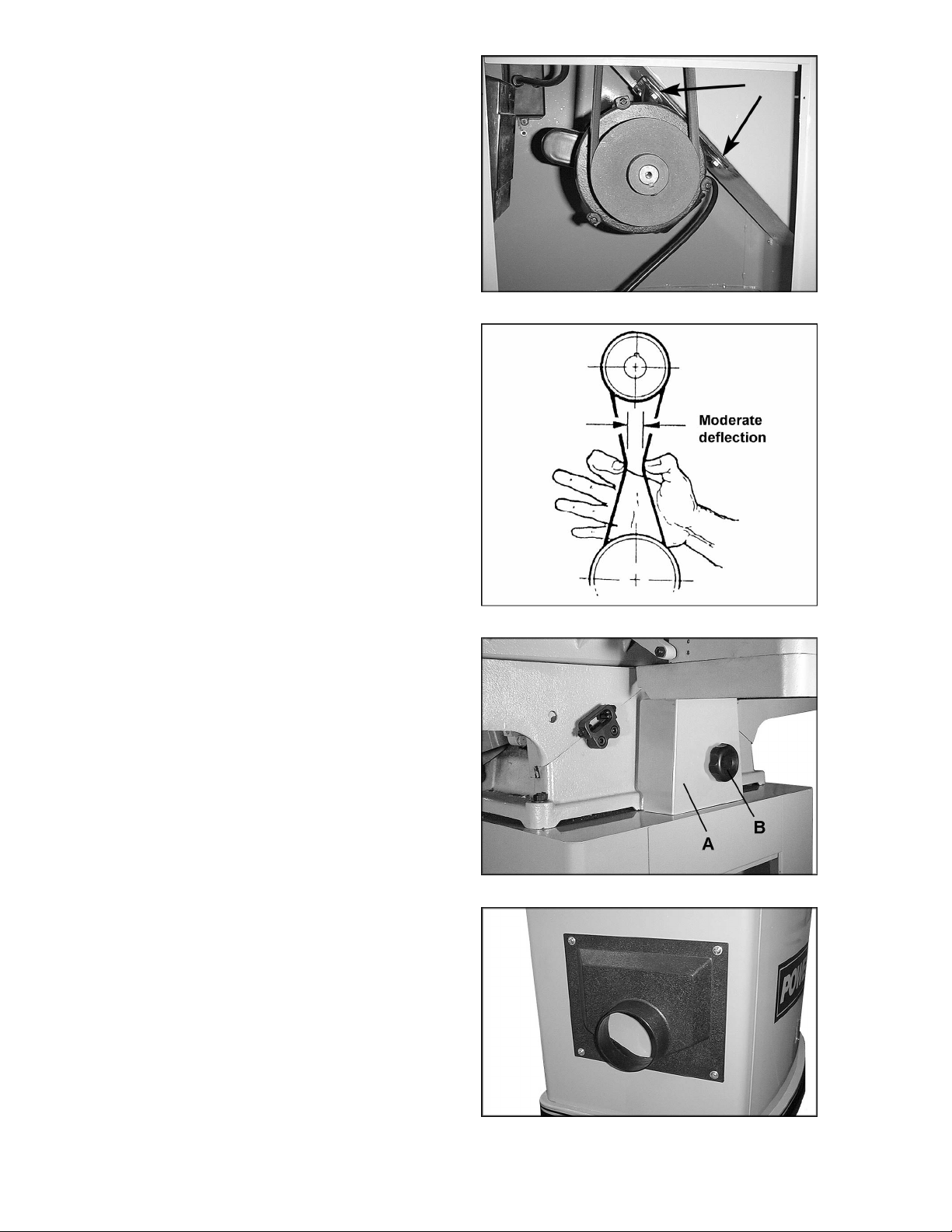

Mounting Drive Belt

1. Place the belt into the groove of the

cutterhead pulley.

2. Reach through the dust chute opening in the

side of the stand with a 12mm wrench, and

loosen the nuts on the motor mount screws

(Figure 6).

3. Lift up on the motor to provide slack, and

place the lower end of the driv e belt into the

motor pulley groove.

4. Let the motor slide down and push down on

it until the belt is properly tensioned. NOTE:

There should be only moderate deflection in

the belt midway between the pulleys when

using light finger pressure (Figure 7).

5. Tighten the four hex nuts on the motor

mount screws.

Mounting Pulley Guard

Place the pulley guard (A, Figure 8) as shown,

and secure with knob (B, Figure 8).

Figure 6

Figure 7

Mounting Dust Chute

It is strongly recommended that a dust collection

system (not provided) be connected to the

jointer. It will help keep your shop clean, and

reduce the risk of health problems due to wood

dust. The dust collector should have sufficient

capacity for this size jointer.

Place the dust chute over the opening in the

jointer stand, and secure with four 1/4-20 x 1/2

pan head screws and four 1/4 flat washers

(Figure 9)

Connect a dust collection hose to the dust chute

on the jointer and secure it with a hose clamp or

duct tape. NOTE: Dryer vent hose is not

acceptable for this purpose.

Figure 8

Figure 9

9

Page 10

Electrical Connections

Electrical connections must

be made by a qualified electrician in

compliance with all relevant codes. This

machine must be properly grounded to help

prevent electrical shock and possible fatal

injury.

The Jointer is equipped with either a single

phase, 230 volt motor; or a three phase,

230/460 volt motor. The single phase unit is

factory wired for 230 volts. You may either install

a UL/CSA listed plug suitable for 230 volt

operation, or “hard-wire” the jointer directly to a

service panel. The circuit for the machine should

be a dedicated circuit.

The three phase motor is pre-wired for 230 volt.

It may be re-connected for 460 volts by

changing the connections as illustrated in the

diagram in the motor wiring box (see

“Converting from 230 Volt to 460 Volt”). You

may either install a UL/CSA listed plug suitable

for the specific voltage, or “hard-wire” the jointer

directly to a service panel.

If the jointer is to be hard-wired to a panel, make

sure a disconnect is available for the operator.

During hard-wiring of the machine, make sure

the fuses have been removed or the breakers

have been tripped in the circuit to which the

jointer will be connected. Place a warning

placard on the fuse holder or circuit breaker to

prevent it being turned on while the machine is

being wired.

Grounding Instructions

This machine must be grounded. In the event of

a malfunction or breakdown, grounding provides

a path of least resistance for electric current to

reduce the risk of electric shock.

Improper connection of the equipmentgrounding conductor can result in a risk of

electric shock. The conductor with insulation

having an outer surface that is green with or

without yellow stripes, is the equipmentgrounding conductor. If repair or replacement of

the electric cord or plug is necessary, do not

connect the equipment-grounding conductor to a

live terminal.

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to

whether the tool is properly grounded. Repair or

replace a damaged or worn cord immediately.

10

Page 11

IMPORTANT: Make sure the electrical

characteristics are the same on the motor

nameplate and the power source, and make

sure the circuit on which the jointer will be used

is properly fused and that the wire size is

correct.

Converting from 230 Volt to 460 Volt

(Three Phase Only)

Consult the wiring diagram inside the starter box

cover. A diagram is also included on pages 3738 of this manual. The Jointer must comply with

all local and national codes after being wired.

1. Remove the starter box cover and adjust the

dial on the relay (see Figure 10) as close as

possible to the amperage of the Jointer

motor at 460V, as listed on the motor plate.

2. Move the fuse (Figure 10) from the 230V

slot to the 460V slot.

3. Re-connect the incoming leads to the motor

for 460 volt operation, as shown in the

wiring diagram.

4. If using a plug, install a proper UL/CSA

listed plug suitable for 460 volt operation.

Three-Phase Test Run

On the three-phase unit, after wiring has been

completed, you should check that the incoming

leads have been connected properly:

1. Connect machine to power source and

press the start button (make sure cutterhead

is clear of all obstructions!).

2. The cutterhead should rotate clockwise as

viewed from the front of the machine. If the

cutterhead rotation is incorrect, press the

stop button and disconnect machine from

power.

3. Switch any two of the three leads to the

motor.

Extension Cords

Make sure your extension cord is in good

condition. Always use a cord that is heavy

enough to carry the current your product will

draw; the cord rating must be suitable for the

amperage listed on the machine’s motor plate.

An undersize cord will cause a drop in line

voltage resulting in loss of power and

overheating.

Use the chart in Figure 11 as a general guide in

choosing the correct size cord. If in doubt, use

the next heavier gauge. The smaller the gauge

number, the heavier the cord.

Figure 10

Extension Cord Recommended Gauges (AWG)

Extension Cord Length *

25

50

75

100

150

Amps

< 5 16 16 16 14 12 12

5 to 8 16 16 14 12 10 NR

8 to 12 14 14 12 10 NR NR

12 to 15 12 12 10 10 NR NR

15 to 20 10 10 10 NR NR NR

21 to 30 10 NR NR NR NR NR

*based on limiting the line voltage drop to 5V at 150% of the

rated amperes.

NR: Not Recommended.

feet

feet

feet

feet

feet

200

feet

Figure 11

11

Page 12

Adjustments

Disconnect machine from

power source before making adjustments.

Tools required for adjustments:

8mm & 12mm wrenches

4mm hex wrench

machinist's protractor or adjustable square

steel straight edge

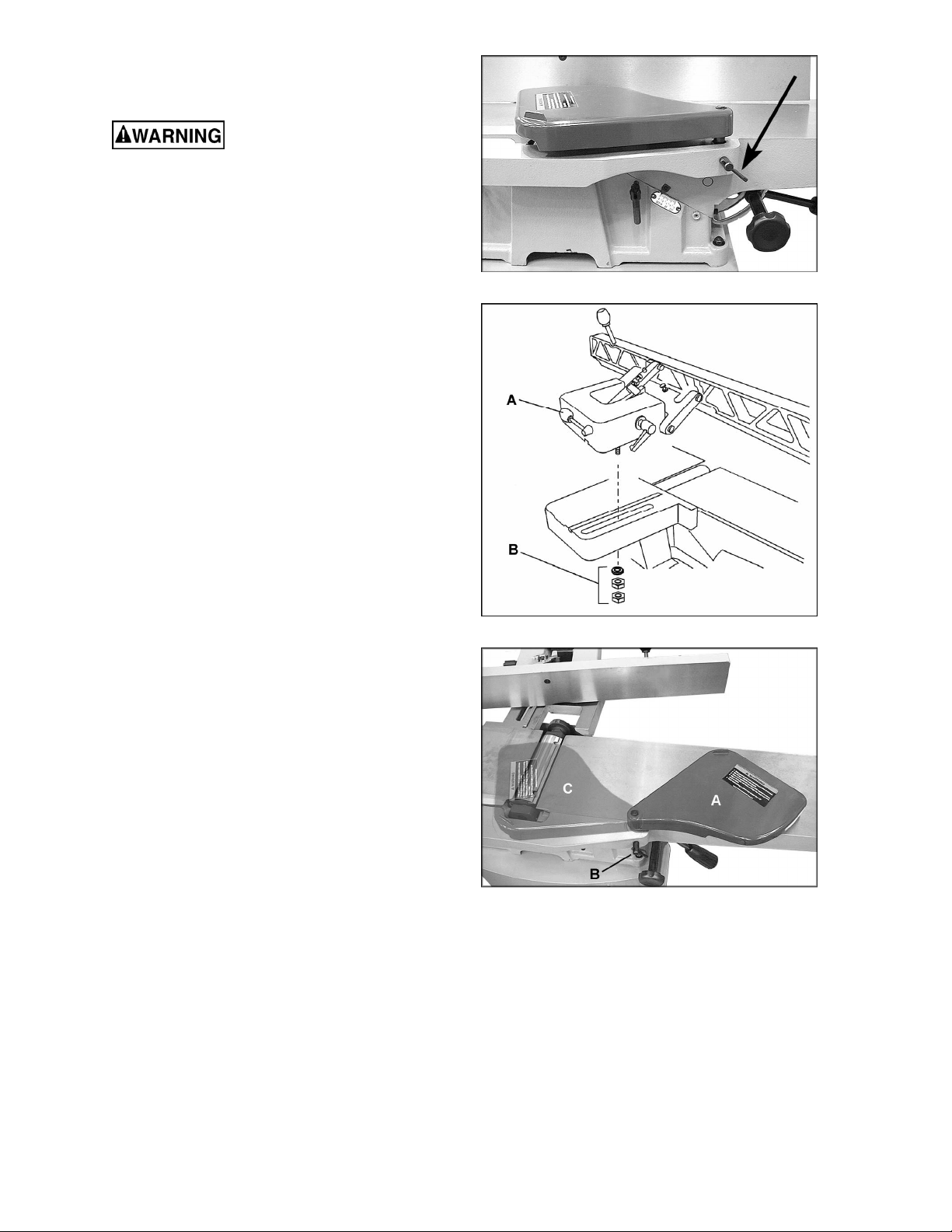

Cutter Guard

Removing Guard:

Some adjusting procedures, as well as

rabbeting operations, will require removal of the

guard. Simply loosen handle on rabbeting ledge

(Figure 12) and vertically lift guard out of the

hole.

Mounting Guard:

The guard is spring tensioned. When mounted,

it must have enough tension to completely cover

the cutterhead, and press firmly against the

fence. To adjust the guard tension:

Figure 12

1. Disconnect machine from power source.

2. Release the fence locking handle (A, Figure

13) and remove the two hex nuts and

washer (B, Figure 13) which hold the fence

to the fence support. Lift up the fence

assembly and set it out of the way of the

cutter guard.

3. Rotate the cutter guard (A, Figure 13) to the

right and set it into its hole as shown. Firmly

tighten the handle (B, Figure 13). The

farther to the right you set the guard, the

stronger tension it will have.

4. Rotate the guard counterclockwise (C,

Figure 14) until it covers the cutterhead.

NOTE: Keep hands away from knives!

Hold it in this position (using an assistant or

block of wood) and re-mount the fence.

5. Test the tension by swinging the guard

away from the fence and then releasing it.

The guard should snap back to the fence.

NOTE: The guard must operate freely and must

not drag on the rabbeting ledge or infeed table.

If dragging occurs, check that the handle (Figure

12) is tight. If guard still drags, the guard

assembly may need to be replaced.

Figure 13

Figure 14

12

Page 13

Installing Knives

Use care when working with

or around sharp knives. Make sure power to

the machine has been disconnected.

When installing new knives, remove only one

knife at a time. Clean the knife slot and install

the new knife. Adjust and snug new knife in

cutterhead before proceeding to next knife.

1. Disconnect machine from power source.

2. Remove the belt guard so that you can

rotate the cutterhead by turning the motor

pulley or by moving the drive belt. Do not

grab the cutterhead itself to rotate it.

3. Remove the old knives by loosening gib

screws with an 8mm wrench, and allowing

the springs to push the knife upward.

Remove knife and gib. See Figure 15.

4. Clean the gib and the knife slot. Sandwich

new knife and gib together and drop into

slot. Make sure the knife is oriented properly

as shown in Figure 15.

Figure 15

IMPORTANT: To position the knives for rabbet

cuts, take a shop scale with 1/32" graduations

and place it against the end of the cutterhead.

Slide the knife out until it is at the 1/32" mark on

the scale; that is, the knife will now be 1/32"

beyond the edge of the cutterhead. The gib

should remain in normal position, even with the

edge of the cutterhead. See Figure 16. This

adjustment will ensure that the knife clears the

end of the gib and cutterhead, and has good

contact with the workpiece. (See under “Basic

Jointer Operation” for further information on

rabbeting procedures.)

5. The height of the knife in the slot, both for

rabbeting and normal jointer work, must now

be set properly, to ensure correct operation

as well as minimize the hazard of kickback.

Proceed as follows:

6. Rotate the cutterhead (using the pulley) until

the tip of the knife is at the top of the

cutterhead arc. Place the knife setting

gauge (Figure 17) over the cutterhead so

the tip of the knife contacts the center of the

gauge, and all four "feet" of the gauge rest

firmly upon the cutterhead, as the knife is

pushed down into its slot. The gauge will set

the knives at approximately .070" above the

cutterhead. Knife height should not vary

more than .002-.003" across the length of

the cutterhead.

Figure 16

Figure 17

13

Page 14

7. Tightening the gib screws should be done in

increments, to prevent any distortion to the

cutterhead or buckling of knives. While

holding the gauge down on one knife, snug

down the five gib screws, beginning with the

center screw and working your way to the

ends. Do not fully tighten yet.

8. Rotate the cutterhead to the next slot and

repeat step #6, only making the knives

snug. Repeat for the third knife.

9. The tightening process should continue at

least two more times, each time tightening

the screws more on all three knives. On the

third time, they should all be firmly

tightened.

Before starting jointer, make

sure all gib screws are firmly tightened. A

loose knife thrown from the cutterhead can

cause severe or fatal injury.

10. After replacing knives, the outfeed table

must be checked and adjusted so that it is

level with the high point of the knives. See

“Setting Outfeed Table” on page 16.

Leveling Tables

The tables have been leveled with each other

from the factory, but this should be confirmed by

the user, and checked periodically, by placing a

steel straight edge across both tables. If tables

are not level, this may be the result of loose

gibs. Correct as follows:

1. Loosen hex nuts on the gib screws (A,

Figure 18) with a 12mm wrench, then

loosen the gib screws with a 4mm hex

wrench. Loosen the table lock handle (B,

Figure 18).

2. Remove lower hex nut and gib screw (A*,

Figure 18) and check screw hole to make

sure that punch mark in the gib is aligned

with the screw hole. If punch mark is not

visible, or it does not line up with screw

hole, use a screwdriver to lightly tap the gib

back into alignment.

3. Replace the lower gib screw (A*, Figure 18)

but do not tighten.

4. Carefully tighten the table lock screw (B,

Figure 18). The table will begin to move

toward the straight edge.

5. When aligned, re-set the gib screws (A,

Figure 18) until tight. If table does not align

with straight edge, use the adjusting arm (C,

Figure 18) for the infeed table, or handwheel

(D, Figure 18) for the outfeed table, until the

table is flush with the straight edge.

Figure 18

14

Page 15

6. Tighten the gib screws (A, Figure 18) then

back them off approximately 1/4 turn or until

the table moves freely, and re-set the lock

nuts on the gib screws.

If table will still not line up:

Remove gib screws and table locking handle

and remove gib (#16, page 29). Check gib to

see that set screws do not go all the way

through the gib or dimple the opposite side. If

either of these conditions exist, replace with a

new gib.

Also, check to be sure the ways are clean and

free of pitch and sawdust. Lubricate gib and way

with a good grade of non-hardening grease.

Replace the gib, making certain that the punch

mark lines up with the locking screw holes.

Replace gib screws. Repeat steps 3 through 6.

Adjusting Depth of Cut

Depth of cut is determined by the height of the

infeed table relative to the cutterhead. Setting

the infeed table is achieved with both a rapid

adjust and a fine adjust.

Rapid Adjust:

1. Loosen the lock screw (A, Figure 19) and

the locking handle (B, Figure 19).

2. Raise or lower the height adjustment handle

(C, Figure 19) until the scale (D-Figure 19)

reads approximately the correct depth of

cut.

Fine Adjust:

3. Rotate the locking handle (B, Figure 19)

until it is snug, then fine-tune the adjustment

by rotating the height adjustment handle (C,

Figure 19) until the scale reads exact.

(Clockwise raises the table, counterclockwise lowers the table.) A full rotation of

the fine adjustment handle equals 1/16"

travel of the infeed table.

4. When set, re-tighten lock screw (A, Figure

19).

Periodically check the accuracy of the depth of

cut scale (D, Figure 19) by raising the infeed

table until it is flush with the peak of the

cutterhead arc (using a straight edge across

table and cutterhead). The scale should read

zero depth. If it does not, re-adjust the pointer

above the scale.

Figure 19

15

Page 16

Setting Outfeed Table

For accurate work in most jointing operations,

the outfeed table must be exactly level with the

knives at their highest point of revolution.

1. Raise the outfeed table to its highest point,

and place a straight edge across it.

2. Rotate the cutterhead (using the belt or

pulley) until one knife is at its highest point.

3. Lower the outfeed table until the straight

edge contacts a knife. Rock the cutterhead

slightly to make sure the apex of the knife is

contacting the straight edge. Lock the

outfeed table at that setting.

After the outfeed table has been set at the

correct height, it should not be changed except

for special operations or after replacing knives.

Examples of incorrect settings:

If the outfeed table is too high, the finished

surface of the workpiece will be curved (Figure

20).

Figure 20

Figure 21

If the outfeed table is too low, the work will be

gouged at the end of the cut (Figure 21)

As a final check of the outfeed table adjustment,

run a piece of wood slowly over the knives for 6

to 8 inches; it should rest firmly on both tables

(Figure 22) with no open space under the

finished cut.

Spring Cutting

To spring cut, the outfeed table is lowered below

the level of the cutterhead, as in Figure 23.

Loosen both gib screws (A, Figure 23) on the

outfeed table. Amount of end-drop is controlled

with the table lock screw (B, Figure 23). Tighten

handle to reduce amount of drop. A 1/32" drop

usually creates the ideal concave for spring

joints. After completing a spring cut, return the

outfeed table in line with the cutterhead knives.

Figure 22

Figure 23

16

Page 17

Fence Movement

To slide the fence forward or backward on the

table, loosen lock handle (A, Figure 24), slide

the fence to desired position and tighten lock

handle to secure fence. Lift up on fence when

tilting or sliding, to prevent scratching the

table.

NOTE: The handle (A, Figure 24) may be

adjusted to a more convenient position by

loosening the hex nuts below the casting (see B,

Figure 31), turning the handle to the proper

position, and retightening the hex nuts.

To tilt the fence forward:

1. Loosen locking handle (B, Figure 24).

2. Place an angle measuring device on the

table and against the fence. Tilt the fence to

desired angle and tighten locking handle (B,

Figure 24) to secure the angle.

To tilt the fence back:

1. Loosen locking handle (B, Figure 24).

2. Flip the stop block (C, Figure 24) out of the

way.

3. Tilt the fence to desired angle and tighten

locking handle (B, Figure 24) to secure

angle.

When the tilted operation is

finished and the fence is returned to 90

degrees, do not forget to flip the stop block

back to its original position.

Fence Stops

Periodically check the 90 degree and 45 degree

tilt accuracy of the fence with an adjustable

square or machinist's protractor. If adjustments

are necessary, proceed as follows:

Figure 24

90 degree stop:

1. The 90 degree stop is controlled by the

screw (D, Figure 25).

2. Loosen the locking handle (B, Figure 25)

and the hex nut on the screw (D, Figure 25).

3. Set the square on the table and against the

fence, and move the fence to fit flush

against the 90 degree angle. Rotate the

screw (D, Figure 25) until it contacts the

stop block (C, Figure 25).

4. Tighten the hex nut (D, Figure 25) and the

locking handle (B, Figure 25).

Figure 25

17

Page 18

45 degree forward stop:

1. The 45 degree forward stop is controlled by

the screw (E, Figure 25).

2. Loosen the locking handle (B, Figure 25)

and the hex nut on the screw (E, Figure 25).

3. Set the 45 degree protractor on the table

and against the fence, and tilt the fence until

it is flush against the 45 degree angle.

4. Rotate the screw (E, Figure 25) until it

contacts the casting below it.

5. Tighten hex nut (E, Figure 25) and locking

handle (B, Figure 25).

45 degree back stop:

1. Flip the stop block (C, Figure 25) out of the

way.

2. The 45 degree back stop is controlled by the

screw (F, Figure 25).

3. Loosen the locking handle (B, Figure 25)

and the hex nut on the screw (F, Figure 25).

4. Use a protractor set at 45 degrees beyond

the right angle (a total of 135 degrees) and

place it on the table and against the fence.

Tilt the fence until it is flush with the

protractor.

5. Rotate the screw (F, Figure 25) to the

proper height.

6. Tighten hex nut (F, Figure 25) and locking

handle (B, Figure 25).

Basic Jointer Operation

Figure 25 (repeated)

NOTE: If you are inexperienced at jointing, use

scrap pieces of lumber to check settings and get

the feel of operations before attempting regular

work.

This section briefly discusses general rules as

well as some of the basic cuts using a jointer,

such as surfacing, edging, beveling, skewing,

rabbeting and taper cuts.

Always use cutterhead guard

(except during rabbeting) and keep hands

away from cutterhead.

Jointing Short or Thin Work

When jointing short or thin pieces, use a push

pad or push block to eliminate all danger to the

hands. Two push pads are included with your

jointer. You can also make your own push block

from scrap material. Three types are illustrated

in Figure 26.

Figure 26

18

Page 19

Direction of Grain

Avoid feeding work into the jointer against the

grain. This will result in chipped and splintered

edges (Figure 27). Feed with the grain to obtain

a smooth surface (Figure 28).

Hand Placement

At the start of the cut, the left hand holds the

work firmly against the infeed table and fence

while the right hand pushes the work toward the

knives. After the cut is under way, the new

surface rests firmly on the outfeed table. The left

hand should press down on this part, at the

same time maintaining flat contact with the

fence. The right hand presses the work forward

and before the right hand reaches the

cutterhead it is moved to the work on the

outfeed table. Follow the 3 inch rule. Never

pass hands directly over the cutterhead.

Surfacing

Jointing the face of stock, or surfacing, is shown

in Figure 29. The use of push blocks or pads will

help ensure against the operator's hands

coming into contact with the cutterhead in the

event of a kickback, or as the trailing end of the

board passes over the cutterhead.

Figure 27

Figure 28

Adjust the infeed table for depth of cut. Cuts of

approximately 1/16" at a time are

recommended, as this allows better control over

the material being surfaced. More passes can

then be made to reach the desired depth.

Never surface pieces shorter than 12" or thinner

than 3/8" without the use of a special work

holding fixture.

IMPORTANT: When stock is longer than twice

the length of the infeed and outfeed tables, an

assistant or support table must be used to

support the stock.

Always use a hold down or

push block when surfacing short stock or

stock less than 3 inches thick.

Jointing Warped Surfaces

If the wood to be jointed is dished or warped,

take light cuts until the surface is flat. Avoid

forcing such material down against the table;

excessive pressure will spring it while passing

the knives, and it will spring back and remain

curved after the cut is completed.

Figure 29

19

Page 20

Edge Jointing

This is the most common operation for the

jointer. Set guide fence square with the table.

Depth of cut should be the minimum required to

obtain a straight edge. Do not make cuts deeper

than 1/8" in a single pass. Hold the best face of

the piece firmly against the fence throughout the

feed. See Figure 30.

When edging stock wider than 3 inches, lap the

fingers over the top of the wood, extending them

back over the fence so that the fence casting will

act as a stop for the hands in the event of a

kickback.

Beveling

When beveling never make cuts deeper than

1/16 inch. Make certain material being beveled

is over 12 inches long, more than 1/4" thick and

1" wide.

Figure 30

Although the fence may be

tilted in or out for a bevel cut, It is

recommended for safety reasons that the

fence be tilted in toward the operator,

making a cradled cut.

Set fence to desired angle. For stock wider than

3", hold with the fingers close together near the

top of the stock, lapping over the board and

extending over the fence. When beveling

material less than 3" wide, use beveled push

blocks.

Skewing (Shear Cutting)

When edging or facing burl or birds-eye maple,

it is not unusual to deface or mar the surface

being finished. This is caused by the cutterhead

blades at times cutting against the grain. In

order to prevent the defacing or marring of this

type wood, it is necessary to skew, or angle

finish, the material being worked.

1. Release the fence locking handle (A, Figure

31) and remove the two hex nuts and

washer (B, Figure 31) holding the fence to

the fence support. Remove the fence

assembly.

Figure 31

2. Remove the key (C, Figure 31) from the

fence support.

3. Replace the fence assembly at the desired

angle across the cutterhead. See Figure 32.

Secure the fence to the support with the hex

nuts and washer (B, Figure 31), then tighten

the fence locking handle (A, Figure 31).

Figure 32

20

Page 21

Taper Cuts

A useful jointer operation is cutting an edge to a

taper. The method can be used on a wide

variety of work. Tapered legs of furniture are a

common example. Instead of laying the piece on

the infeed table, lower the forward end of the

work onto the outfeed table. Do this very

carefully, as the piece will span the knives, and

they will take a "bite" from the work with a

tendency to kick back unless the piece is firmly

held. Now push the work forward as in ordinary

jointing.

The effect is to plane off all the stock in front of

the knives to increasing depth, leaving a tapered

surface. The ridge left by the knives when

starting the taper may be removed by taking a

very light cut according to the regular method for

jointing, with the infeed table raised to its usual

position.

Practice is required in taper operations, and the

beginner is advised to make trial cuts on waste

material. Taper cuts over part of the length and

a number of other special operations can easily

be done as the operator gains experience.

Rabbeting

A rabbet cut requires

removal of the cutter guard. Use extreme

caution and keep hands clear of cutterhead.

Always replace guard immediately after

rabbeting operation is completed.

A rabbet is a groove cut along the edge of a

board. The width and thickness of the wood to

be rabbeted depends upon the width and length

of the rabbet. However, never rabbet a piece of

wood less than 12" long. Use push blocks to

rabbet cut whenever possible.

4. Disconnect machine from power source.

5. Set fence for the desired width of the rabbet.

6. Check the width of the rabbet by measuring

the distance from the end of a knife in the

cutterhead to the fence.

7. Lower infeed table 1/32" at a time and make

successive cuts until the desired depth of

rabbet has been obtained. See Figure 33.

NOTE: It is easier and safer to take a series

of shallow cuts.

When rabbeting long pieces, follow the same

procedure as for surfacing long pieces (page

19).

Figure 33

21

Page 22

Maintenance

Disconnect machine from

power source before doing any maintenance.

The table and fence surfaces must be kept

clean and free of rust for best results. Some

users prefer a paste wax coating. Another option

is talcum powder applied with a blackboard

eraser rubbed in vigorously once a week; this

will fill casting pores and form a moisture barrier.

This method provides a table top that is slick

and allows rust rings to be easily wiped from the

surface. Important also is the fact that talcum

powder will not stain wood or mar finishes as

wax pickup does.

The fence assembly should slide easily over the

fence support. Keep fence support greased.

The bearings in the cutterhead are sealed and

do not require lubrication.

Gum and pitch which collect on the knives

cause excessive friction as the work continues,

resulting in overheating of the knives, less

efficient cutting, and consequent reduction in the

life of the knives. Use an oven cleaner or gum

and pitch remover to wipe this off the knives.

Cutterhead Repairs

The entire cutterhead assembly may be

removed for bearing replacement or other

maintenance procedures.

1. Disconnect jointer from power source.

2. Remove fence assembly from jointer (see

page 12, Figure 13).

3. Loosen motor mounting and push up on

motor to create slack in belt (see page 9)

4. Remove drive belt from cutterhead pulley.

5. Lower both infeed and outfeed tables.

6. Loosen the two socket head cap screws on

the fence support and pivot the fence

support out of the way (Figure 34).

Sharpening Knives

Knives should be kept sharp. This will contribute

to better stock finish, longer machine life, and

safer operation.

A jointer knife hone provides a simple way to

sharpen knives. Hones are available from many

woodworking supply stores. Carefully read any

instructions that accompany the hone.

Use caution and proceed

slowly when sharpening knives. Disconnect

jointer from power source, and wear

approved eye protection.

When finished sharpening knives, they should

be re-set level to the outfeed table. See

“Installing Knives” on page 13.

Knives can usually be whetted several times in

the cutterhead before having to be removed and

re-ground.

TIP: If the jointer is used frequently, keeping a

spare set of knives on hand is recommended.

Extra knives (stock no. 6427002, set of 3) may

be obtained from your Powermatic distributor, or

by calling WMH Tool Group at 1-800-274-6848.

Figure 34

7. Remove rabbeting ledge by loosening the

two hex cap screws and washers (A, Figure

35).

Figure 35

8. Loosen the two bolts (B, Figure 35) that

secure the cutterhead to the bed – these are

accessed from the underside of the bearing

blocks.

9. Lift cutterhead straight up from base.

10. Remove pulley and both bearing housings.

22

Page 23

IMPORTANT: If the bearings need replacement,

this should be done by qualified service

personnel. The bearings are press fitted and

must be removed with an arbor press.

To re-install cutterhead, reverse the above

procedure. Before re-installing, make sure the

machine's curved seats of the base casting are

free of dirt, dust or grease, to help ensure a tight

fit.

NOTE: Whenever the cutterhead is re-installed

on the jointer, the tables must be leveled in

relationship to it.

You may wish to keep an extra cutterhead on

hand to maintain shop productivity.

Table Removal

1. Disconnect jointer from power source.

2. Remove fence assembly except for the

support casting.

3. Remove cutter guard.

4. Lower infeed and outfeed tables and remove

cutterhead.

5. Loosen the gib set screws and table lock

screws.

After gib screws are

loosened, table could suddenly slide down.

6. Remove infeed or outfeed table by sliding

upward.

23

Page 24

Troubleshooting – Operating Problems

Trouble Probable Cause Remedy

Finished stock is

concave on back

end.

Finished stock is

concave on front end.

Stock has slight bevel

after edge jointing.

Chip out.

Fuzzy, rough, or torn

grain.

Board thickness does

not match depth of

cut scale.

Knife is higher than outfeed table.

Outfeed table is higher than knife.

Fence not perpendicular to table. Square up fence with table.

Cutting against the grain. Cut with the grain whenever possible.

Dull knives. Sharpen or replace knives.

Feeding workpiece too fast. Use slower rate of feed.

Cutting too deeply. Make shallower cuts.

Knots, imperfections in wood.

Wood has high moisture content. Allow wood to dry or use different stock.

Dull knives. Sharpen or replace knives.

Knives are cutting against grain. Cut with the grain.

Depth of cut scale is incorrect. Adjust scale correctly.

Raise outfeed table until it aligns with

tip of knife. See page 16.

Lower outfeed table until it aligns with

tip of knife. See page 16.

Inspect wood closely for imperfections;

use different stock if necessary.

Cutterhead slows

while operating.

“Chatter” marks on

workpiece.

Uneven knife marks

on workpiece.

Feeding too quickly, or applying too

much pressure to workpiece.

Excessive depth of cut. Reduce depth of cut.

Dull knives. Sharpen or replace knives.

Knives incorrectly set.

Feeding workpiece too fast.

Knives are nicked, or out of

alignment.

Feed more slowly, or apply less

pressure to workpiece.

Set knives properly using provided knife

setting gauge. Check that knife slots

are clean and free of dust or debris.

Feed workpiece slowly and

consistently.

Replace nicked knives; align knives

properly using knife-setting gauge. See

page 13.

24

Page 25

Troubleshooting – Mechanical and Electrical Problems

Trouble Probable Cause Remedy

Machine will not

start/restart or

repeatedly trips

circuit breaker or

blows fuses.

No incoming power.

Overload automatic reset has not

reset.

Jointer frequently trips.

Verify unit is connected to power, onbutton is pushed in completely, and

stop-button is disengaged.

When jointer overloads on the circuit

breaker built into the motor starter, it

takes time for the machine to cool

down before restart. Allow unit to

adequately cool before attempting

restart. If problem persists, check

amp setting on the motor starter

inside the electrical enclosure – it

should match the amps on the motor

as indicated on the motor plate.

One cause of overloading trips which

are not electrical in nature is too

heavy a cut. The solution is to take a

lighter cut. If too deep a cut is not the

problem, then check the amp setting

on the overload relay. Match the full

load amps on the motor as noted on

the motor plate. If amp setting is

correct then there is probably a loose

electrical lead.

Motor overheated.

Building circuit breaker trips or fuse

blows.

Switch or motor failure (how to

distinguish).

Verify that jointer is on a circuit of

correct size. If circuit size is correct,

there is probably a loose electrical

lead. Check amp setting on motor

starter.

Examine motor starter for burned or

failed components. If damage is

found, replace starter. If no visible

damage found, have starter tested.

If you have access to a voltmeter, you

can separate a starter failure from a

motor failure by first, verifying

incoming voltage at 220+/-20 and

second, checking the voltage

between starter and motor at 220+/-

20. If incoming voltage is incorrect,

you have a power supply problem. If

voltage between starter and motor is

incorrect, you have a starter problem.

If voltage between starter and motor

is correct, you have a motor problem.

Clean motor of dust or debris to allow

proper air circulation. Allow motor to

cool down before restarting.

25

Page 26

Trouble Probable Cause Remedy

Machine will not

start/restart or

repeatedly trips

circuit breaker or

blows fuses.

Motor failure.

Electrical leads are attached

incorrectly.

Loose electrical connections.

On/off switch failure.

If electric motor is suspect, have it

tested by qualified service personnel.

Repair or replace as needed.

Double check to confirm all electrical

connections are correct. Refer to

appropriate wiring diagrams on pages

36 through 38 to make any needed

corrections.

Inspect all motor leads for tightness.

Look for any signs of electrical arcing

which would indicate loose

connections or circuit overload.

If the on/off switch is suspect, you

have two options: Have a qualified

electrician test the switch for function,

or purchase a new on/off switch and

establish if that was the problem on

changeout.

Optional Accessories

2042376 ....... Mobile Base

6296046 ....... Knives (set of 3)

6285917 ....... Push Block

Replacement Parts

Replacement parts are listed on the following pages. To order parts or reach our service department, call

1-800-274-6848 between 7:30 a.m. and 6:00 p.m. (CST), Monday through Friday. Having the Model

Number and Serial Number of your machine available when you call will allow us to serve you quickly and

accurately.

26

Page 27

Parts List: Base Assembly

Index No. Part No. Description Size Qty

................. 2365022...................Jointer Base Assembly (Items 1 thru 78 and fence & cutterhead assys.) 1

1............... 6296000...................Rear Table ............................................................................................ 1

2............... 6285865...................Set Screw...........................................................1/4”-20x3/8”................ 6

3............... 6296001...................Collar .................................................................................................... 1

4............... 6296002...................Bracket.................................................................................................. 1

5............... 6296003...................Key.....................................................................5x5x12 ....................... 1

6............... 6296004...................Lead Screw ...........................................................................................1

7............... 6296005...................Bracket.................................................................................................. 1

8............... 6285852...................Lock Washer ......................................................3/8”............................. 2

9............... 6296007...................Cap Screw..........................................................3/8”-16x1-1/4”............. 2

10............. 6296162...................Lock Washer ......................................................1/2”............................. 2

11............. 6296009...................Cap Screw..........................................................1/2”-12NCx1-1/2”........ 2

12............. 6296010...................Bolt........................................................................................................ 2

13............. 6285966...................Hex Nut..............................................................5/16”-18...................... 9

14............. 6296011...................Set Screw...........................................................1/4”-20x1”................... 6

15............. 60B-215...................Base...................................................................................................... 1

16............. 6296013...................Gib ........................................................................................................ 2

17............. TS-0208041.............Socket Head Cap Screw.....................................5/16”-18x3/4”.............. 3

18............. 6296015...................Retaining Ring....................................................ETW-6........................ 3

19............. 6296132...................Bar ........................................................................................................ 1

20............. 6296016...................Bolt........................................................................................................ 1

21............. 6296017...................Shaft .....................................................................................................1

22............. 6296018...................Lock Bracket .........................................................................................1

23............. 6296019...................Bracket.................................................................................................. 1

24............. 6296020...................Ball........................................................................................................ 2

25............. 6296021...................Shaft .....................................................................................................1

26............. 6296022...................Retaining Ring....................................................ETW-12...................... 2

27............. 6296023...................Worm .................................................................................................... 1

28............. 6296024...................Key.....................................................................5x5x20 ....................... 1

29............. 6296025...................Adjusting Base ...................................................................................... 1

30............. 6296160...................Flat Washer........................................................1/4”............................. 1

31............. 6296027...................Hex Head Bolt ....................................................1/4”-20x3/4”................ 1

32............. 6296029...................Worm Shaft ........................................................................................... 1

33............. 6296028...................Handle................................................................................................... 1

34............. 6296161...................Flat Washer........................................................1/4”............................. 2

35............. 6296031...................Cap Screw..........................................................1/4”-20x1/2”................ 6

36............. 6296163...................Lock Washer ......................................................1/4”............................. 5

37............. 6296033...................Clamp Knob .......................................................................................... 1

38............. 6296164...................Flat Washer........................................................1/2”............................. 1

39............. 6296035...................Lock Plate ............................................................................................. 1

40............. 6296036...................Plate...................................................................................................... 1

41............. 60B-241...................Front Table............................................................................................ 1

42............. 6296038...................Handwheel ............................................................................................ 1

43............. 6296039...................Pan Head Screw ................................................5/16”-18x1/2”.............. 1

44............. 6296165...................Flat Washer........................................................3/8”............................. 1

45............. 60B-245...................Rabbeting Ledge ................................................................................... 1

46............. 6296042...................Flat Washer........................................................................................... 3

47............. TS-0060051.............Hex Head Bolt ....................................................3/8”-16x1.................... 2

48............. 6096044...................Pointer...................................................................................................1

49............. 6296045...................Pan Head Screw ................................................#8-32x1/4”.................. 1

50............. 6296056...................Bolt........................................................................................................ 1

51............. 6296057...................Belt Guard............................................................................................. 1

52............. 6296058...................Knob .....................................................................................................1

53............. TS-0270091.............Set Screw...........................................................5/16”-18x1”................. 2

54............. 6296061...................Set Block............................................................................................... 1

55............. 6296062...................Bolt........................................................................................................ 1

56............. 6296063...................Collar ....................................................................................................1

27

Page 28

57............. 6296166...................Flat Washer........................................................5/16”........................... 6

59............. 6296167...................Depth Scale........................................................................................... 1

60............. VS020500................Rivet...................................................................2x5............................. 4

61............. 6296152...................Set Screw...........................................................1/4”-20x1/4”................ 4

62............. 6296151...................Collar ....................................................................................................2

63............. 6285917...................Push Block ............................................................................................ 1

64............. 6296168...................Cap Screw..........................................................5/16”-18x1/2”.............. 1

65............. 6296166...................Flat Washer........................................................5/16”x3/4”D ................ 2

66............. 6285931...................Cap Screw..........................................................3/8”-16x1-1/2”............. 2

67............. TS-1550071.............Flat Washer........................................................3/8”x3/4”D .................. 1

68............. 6296089...................Key.....................................................................9.5mmx273mm........... 1

69............. 6296088...................Spring Pin...........................................................4x14........................... 1

70............. 6296086...................Base Slide............................................................................................. 1

71............. 60B-271...................Stop Handle ..........................................................................................1

................. 60B-270...................Cutterhead Guard Assembly (Items 72 thru 77) ..................................... 1

72............. 60B-272...................Warning Label....................................................................................... 1

73............. 60B-273...................Cutterhead Guard.................................................................................. 1

74............. JSG96-223 ..............Retaining Ring....................................................STW-11...................... 1

75............. 60B-275...................Spring.................................................................................................... 1

76............. 60B-276...................Shaft ..................................................................................................... 1

77............. 60B-277...................Spring Pin...........................................................6x36........................... 2

78............. 60B-278...................I.D. Label............................................................1Ph ............................ 1

................. 60B-278A.................I.D. Label............................................................3Ph ............................ 1

28

Page 29

Base Assembly

29

Page 30

Parts List: Fence Assembly

Index No. Part No. Description Size Qty

................. 60B-100...................Fence Assembly (Items 1 thru 33) ......................................................... 1

1............... 6296143...................Locking Bolt........................................................................................... 1

2............... 6296066...................Flat Washer........................................................1/2”x1-1/8”D ............... 1

3............... 6296067...................Stop Block............................................................................................. 1

4............... 60B-104...................Fence Bracket....................................................................................... 1

5............... 6285945...................Knob ..................................................................................................... 2

6............... 6296069...................Locking Shaft......................................................................................... 1

7............... 6296070...................Pin......................................................................5mmx50mm ............... 1

8............... 6296071...................Cap Screw..........................................................1/4”-20x1-1/4”............. 2

9............... 6296072...................Hex Nut..............................................................1/4”-20........................ 2

10............. 6296073...................Screw.................................................................................................... 1

11............. 6285940...................Hex Nut..............................................................1/2”-20........................ 2

12............. 60B-112...................Fence Body........................................................................................... 1

13............. 6296076...................Bolt........................................................................................................ 2

14............. 6285966...................Hex Nut..............................................................5/16”-18...................... 1

15............. 6296077...................Hex Screw..........................................................5/16”-18x1-1/4”........... 1

16............. TS-0207061.............Socket Head Cap Screw.....................................1/4"-20x1”................... 2

18............. 6296080...................Locking Link .......................................................................................... 1

19............. 6296081...................Nut ........................................................................................................ 1

20............. 60B-120...................Fixed Block............................................................................................ 1

21............. 6296082...................Fence Link............................................................................................. 1

22............. 6285942...................Cone Point Screw.................................................................................. 4