Page 1

This .pdf document is bookmarked

Operating Instructions and Parts Manual

6-inch Woodworking Jointer

Models 54 A and 54H H

54A (1791279DXK) serial # 8040543557 and up

54HH (1791317K) serial # 8010540313 and up

Powermatic

427 New Sanford Road

LaVergne, Tennessee 37086 Part No. M-1791279DX

Ph.: 800-274-6848 Revision C2 04/2014

www.powermatic.com Copyright © 2014 Powerm atic

Page 2

Warranty and Service

Powermatic warrants every product it sells against manufacturers’ defects. If one of our tools needs service or repair,

please contact Technical Service by calling 1-800-274-6846, 8AM to 5PM CST, Monday through Friday.

Warranty Period

The general warranty lasts for the time period specified in the literature included with your product or on the official

Powermatic branded website.

• Powermatic products carry a limited warranty which varies in duration based upon the product. (See chart

below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable within a

reasonable amount of use and are covered by a 90 day limited warranty against manufacturer’s defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defects in workmanship or materials subject to the limitations stated below. This warranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

Warranty Limitations

Woodworking products with a Five Year Warranty that are used for commercial or industrial purposes default to a

Two Year Warranty. Please contact Technical Service at 1-800-274-6846 for further clarification.

How to Get Technical Support

Please contact Technical Service by calling 1-800-274-6846. Please note that you will be asked to provide pro of

of initia l p u rch a s e whe n calling. If a product requires further inspection, the Technical Service representative will

explain and assist with any additional action needed. Powermatic has Authorized Service Centers located throughout

the United States. For the name of an Authorized Service Center in your area call 1-800-274-6846 or use the Service

Center Locator on the Powermatic website.

More Informa t io n

Powermatic is constantly adding new products. For complete, up-to-date product information, check with your local

distributor or visit the Powermatic website.

How S tate Law Applies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

POWERMATIC LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH

PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS ON HOW

LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

POWERMATIC SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR

FOR INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF

OUR PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Powermatic sells through distributors only. The specifications listed in Powermatic printed materials and on the official

Powermatic website are given as general information and are not binding. Powermatic reserves the right to effect at

any time, without prior notice, those alterations to parts, fittings, and accessory equipment which they may deem

necessary for any reason whatsoever.

Product Listing with Warranty Period

90 Days – Parts; Consumable items

1 Year – Motors, Machine Accessories

2 Year – Woodworking Machinery used for industrial or commercial purposes

5 Year – Woodworking Machinery

NOTE: Powermatic is a division of JPW Industries, Inc. References in this document to Powermatic also apply to

JPW Industries, Inc., or any of its successors in interest to the Powermatic brand.

2

Page 3

Table of Contents

1.0 Warranty and Service ....................................................................................................................... 2

Table of Contents .................................................................................................................................... 3

Warnings ................................................................................................................................................. 4

Unpac king ............................................................................................................................................... 8

Shipping Contents ................................................................................................................................ 8

Assembly ................................................................................................................................................ 9

Unpacking and Cleanup ....................................................................................................................... 9

Installing B ed to Stand ......................................................................................................................... 9

Install ing Fe nce to Bed ....................................................................................................................... 10

Installing the Drive Belt....................................................................................................................... 10

Installing the Pulley Cover .................................................................................................................. 11

Installing Cutterhead Guard ................................................................................................................ 11

Installing A ccess Door and Dust Chute ............................................................................................... 11

Electrical ............................................................................................................................................... 1 2

Grounding Inst r uc tions ....................................................................................................................... 12

115 Volt Operati on ............................................................................................................................. 12

230 Volt Operati on ............................................................................................................................. 12

Adjustments .......................................................................................................................................... 13

Fence Mov ement ............................................................................................................................... 13

Fence Stop Adjustments .................................................................................................................... 14

Infeed Table Height Adjustment ......................................................................................................... 15

Infeed Table T r av el Limiter ................................................................................................................. 15

Table Gib Adjustment ......................................................................................................................... 16

Outfeed Table Height Adjustment ....................................................................................................... 1 6

Setting Cutt erhead Knives (Model 54A only) ...................................................................................... 17

Replacing Kniv es (M odel 54A only ) .................................................................................................... 19

Setting Knives for Rabbeting and Nicks (Model 54A only) ................................................................... 2 0

Replacing or Rotating Knife Inserts (Model 54HH only) ...................................................................... 2 0

Determining Correct Table Height ...................................................................................................... 21

Hand Placement ................................................................................................................................ 23

Direction of Grai n ............................................................................................................................... 23

Surfacing ..................................................................................................................... ...................... 24

Jointing .............................................................................................................................................. 24

Beveling ............................................................................................................................................. 25

Skewing (Shear Cutting) .................................................................................................................... 25

Rabbet Cuts (Straight Knife only) ....................................................................................................... 2 6

Push Blocks ....................................................................................................................................... 26

Blade Care ......................................................................................................................................... 26

Cutterhead Rem ov al .......................................................................................................................... 2 7

Optional Accessories ............................................................................................................................. 29

Replacement Parts ................................................................................................................................ 2 9

Stand – Parts List (All M odels) ........................................................................................................... 30

Stand –Assembly (All Models) ............................................................................................................ 31

Bed – Parts List (All Models) .............................................................................................................. 32

Fence – Parts List and Assembly (All Models) .................................................................................... 34

Cutterhead – Parts and Assembly (model 54A only) ........................................................................... 35

Cutterhead – Parts and Assembly (model 54HH only) ........................................................................ 36

Wiring Diagrams .................................................................................................................................... 37

Wiring Diagram – Serial # 05060540312 and lower ............................................................................ 37

Wiring Diagram – Serial # 05060540313 and higher ........................................................................... 38

3

Page 4

Warnings

1. Read and understand the ent ire owner's manual before att empting assembly or operation.

2. Read and understand the warnings po sted on the m achine and i n thi s manual. Fail ure to comply wit h

all of these warnings m ay cause seriou s i njury.

3. Replace the warning labels if they become obscured or removed.

4. This woodworking Jointer is designed and intended for use by properly trained and experienced

personnel only . If y ou are not familiar wit h the pr oper and saf e operat ion of a joint er, do not use unti l

proper trai ning and k nowledge have been obtained.

5. Do not use this machine for other than its intended use. If used for other purposes, Powermatic

disclaim s any real or i mplied warrant y and h olds itsel f harml ess from any injury t hat may r esult f rom

that use.

6. Always wear approved safety glasses/f ace shields while usi ng this j ointer. Everyday eyegl asses only

have impact resistant lenses; they are not safet y gl asses.

7. Before operating t hi s machine, remov e tie, rings, watc hes and ot her j e welry, and rol l sl eev es up past

the elbows. Remove all l oose clothing and confine long hair. Non- slip foot wear or ant i-skid fl oor str ips

are recommended. Do not wear gloves.

8. Wear ear protector s (plugs or muffs) during extended periods of oper ation.

9. Some dust created by power sanding, sawing, grinding, drilling and other construction activities

contain chemi cals known to cause cancer , bir th defects or other r eproductiv e harm . Some exampl es

of these chemic als are:

• Lead from lead based paint.

• Crystalli ne sil ic a from bricks, cement and other masonry pr oduc ts.

• Arsenic and chromium from chemically treated lumber.

Your risk of exposure varies, depending on how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated area and work with approved safety

equipment, such as face or dust masks that are specifically designed to filter out microscopic

particles.

10. Do not oper ate this machine while tired or under t he i nfluence of drugs, alcohol or any medic ation.

11. Make c er tain the switch is in the OFF position before connecting the machine to the power source.

12. Make c er tain the machine is properly grounded.

13. Make all machine adjustment s or maintenance wi th the machine unplugged from the power source.

14. Remove adjusting keys and wrenches. Form a habit of checking to see that keys and adjusting

wrenches are removed from the machine before turning i t on.

15. Keep safety guards in place at all times when the machine is in use. If removed for maintenance

purposes, use extreme caution and replace the guards immediately after maintenance i s complete.

16. Make sure the jointer is firmly secured to the stand or a bench before use.

17. Check damaged parts. Before further use of the machine, a guard or other part that is damaged

should be carefully checked to determine that it will operate properly and perform its intended

function. Chec k for alignment of moving par ts, binding of moving parts, breakage of parts, mounting

and any other condi ti ons that m ay affect its operati on. A guard or ot her part that i s damaged should

be properly repaired or replaced.

18. Prov ide for adequate space surrounding work area and non-glare, ov er head lighting.

19. Keep t he floor around the machine clean and free of scrap mat er ial, oil and grease.

4

Page 5

20. Keep visitors a safe distance from the work area. Keep children away.

21. Make y our workshop child proof with padlocks, master switches or by removi ng starter k eys.

22. Giv e your work undivi ded attention. Looki ng around, carryi ng on a conversati on and “horse-play” ar e

careless acts that can r esul t in serious injury.

23. Maint ain a bal anced stance at al l tim es so that you d o not f all or lean agai nst t he cutt erhead or other

moving part s. Do not over r eac h or use excessive force to perform any machine oper ation.

24. Use the right tool at the correc t speed and f eed rat e. Do not force a t ool or attac hment to do a job for

which it was not designed. T he ri ght tool will do the job better and saf er.

25. Use recommended accessories; improper accessories may be hazardous.

26. Mai ntain tools with care. K eep knives sharp and clea n for the best and saf est performance. Foll ow

instructions for lubricating and changi ng accessories.

27. Tur n off the machi ne before cleaning. Use a brush or compressed air to remove chips or debris — do

not use your hands.

28. Do not stand on the machine. Serious injury c ould oc cur if the machine tips over.

29. Bef ore turning on machi ne, remove all ext ra equipment such a s keys, wrenches, scrap, stock, and

cleaning rags away from the machine.

30. Never leave the machine r unning unatt ended. Turn the power off and do not leave t he machine until

the cutter head c om es to a complet e stop.

31. A lways use a hol d-down or push bl ock when surf acing stock less than 12" i nches long, or 3 i nches

wide, or 3 inches thic k.

32. Do not perf orm jointi ng operations on mat erial shorter than

8", narrower than 3/4" or less than 1/4" thick.

33. The hands must never be closer than 3 inches to the

cutterhead (see Figure at right).

34. Never apply pr essure to stock dir ectly over the cutterhead.

This may r esul t in the stock tipping into the c utterhead along

with the operator's fingers. Position hands away from

extreme ends of stock, and push through with a smooth,

even motion. Never back workpiece toward the infeed table.

35. Do not make cut s deeper than 1/2" when rabbeti ng. On other cuts such as edgi ng, surf acing, etc.,

depth of cut should not be over 1/8" to avoid overloadi ng the machine and to m inimize chance of

kickback.

36. To avoid k ickback, the grain must run i n the same direction you are cut ting. Before attempting to

joint, or pl ane, each work piece must be carefully examined for stock c ondition and grain orientati on.

37. When worki ng wit h a s wirl grai n wood or burl s, m aki ng it nec essary t o plane agai nst the grai n, use a

lesser depth of c ut and a slow rate of f eed.

38. Move the hands in an alternate m otion from front to back as the work continues through the cut.

Never pass the hands dir ectly over the cutter kniv es. As one hand approache s the kniv es remove it

from the stock in an arc motion and place it back on the stock in a position beyond the cutter knives.

39. At all times hold the stock firmly.

5

Page 6

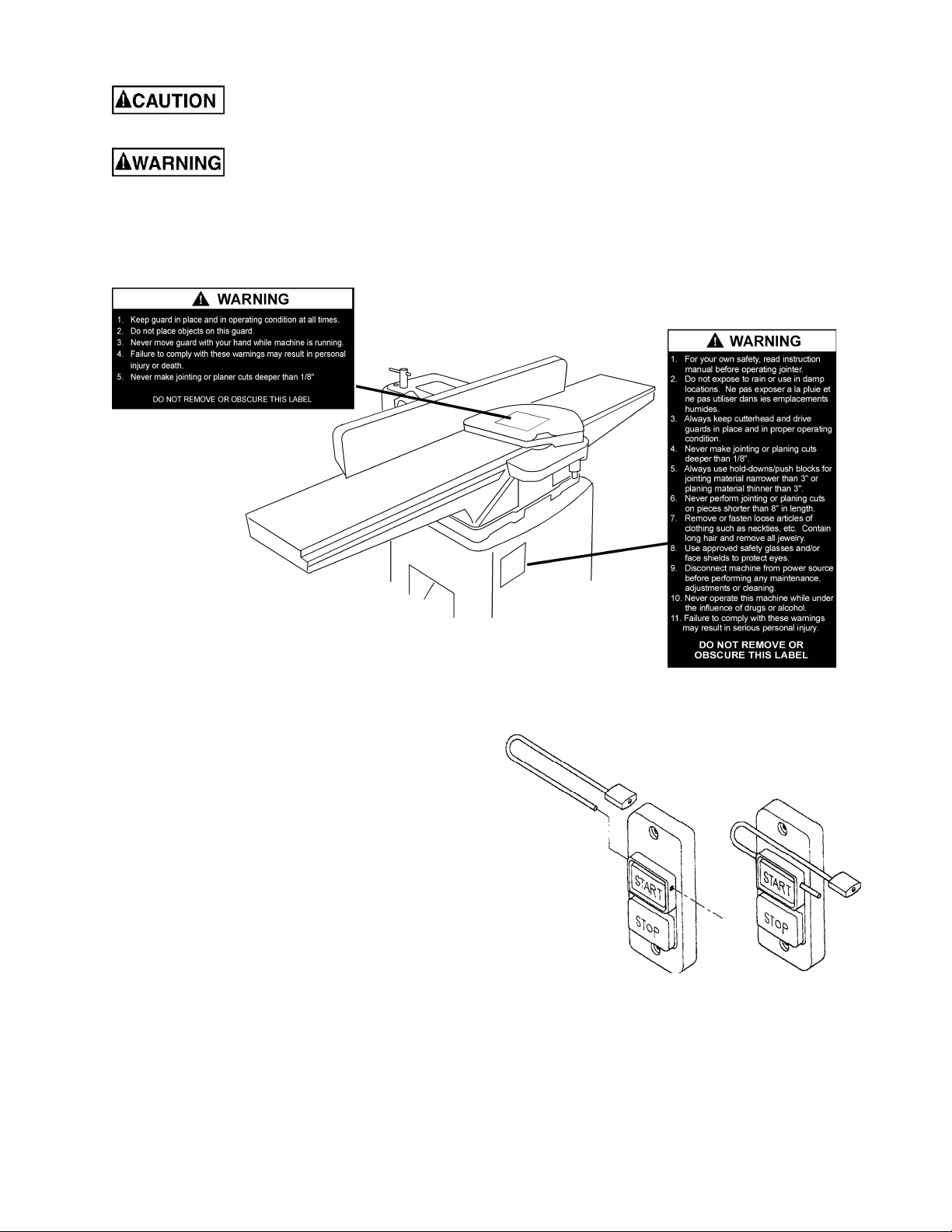

Familiariz e y our self with the following safety noti c es used in this manual:

This means that if precautions are not heeded, it may result in minor injury and/or

possible machine damage.

This means that if precauti ons are not heeded, it may result in serious injury or possibly

even death.

On-Off Switch Padlock

The jointer is equipped with a push-button

switch that will accept a safety padlock (not

included). To safeguard your machine from

unauthorized operation and accidental starting

by young chil dren, the use of a padlock i s highl y

recommended – see figur e at right.

On-Off S wi tch Pad l o c k

6

Page 7

Introduction

This manual is provi ded by Powermatic covering the saf e operation and maint enance procedures f or the

Powermatic Model 54A and 54HH Jointers. This manual contains instructions on installation, safety

precautions, gener al oper ati ng procedur es, mai ntenance i nstructi ons and parts breakdo wn. Thi s mac hine

has been designed and con structed t o provide year s of troubl e free operation if used in accordanc e with

instructi ons set forth in thi s manual. If there are any questions or c omments, please contact your local

supplier or Powermatic, or visit our web site: www.powermatic.com.

Specifications

Model ................................................................................... 54A........................................ ............. 54 HH

Stock Number:

Jointer and Stand............................................... 1791279DXK.............................................. 1791317K

Jointer only .......................................................... 2365013DX.................................................1791317

Table Size (in.) ............................................................ 7-1/4 x 66............................................... 7-1/4 x 66

Table support .................................................... dove-tailed ways.................................... dove-tailed ways

Cutterhead Style ................................ straight w/ quick-set knives.................................................... helical

Knives ................................................................ 3 double-edged............................... 40 four-sided inserts

Number of cutterhead r ows ....................................................... --............................................................ 6

Cutterhead Speed (RP M ) .................................................... 6000...................................................... 6000

Cuts per Minute ................................................................ 18,000......................................... not applicable

Cutting capacity (in.) ....................................................... 1/2" x 6"................................................. 1/2” x 6”

Blade Size (in.) ..............................................6-1/16" x 3/4 x 5/64 ................................ 0.10T x 0.59 x 0.59

Switch ...................................................................... pu sh button............................................ push button

Fence size overall (i n.) ....................................................... 4 x 38..................................................... 4 x 38

Fence tilt (degrees) .............................................................+/- 45..................................................... +/- 45

Stops ..................................................... - 45, 45, and 90 degrees........................ - 45, 45, and 90 degrees

Table Surface Height (in.) .................................................. 31-1/2.................................................... 31-1/2

Motor .................................. TEFC, 1 HP, 1 PH, 115/230V*, 60Hz......TEFC, 1 HP, 1 PH, 115/230V*, 60Hz

Overall Dimensions (LxWxH)(in.) ........................ 66 x 24 x 37-1/2..................................... 66 x 24 x 37-1/2

Jointer Be d We ig h t ( lbs.)........................................................ 254........................................................ 254

Stand Weight (lbs.) .................................................................. 80.......................................................... 80

* (pre-wired 115V )

The above specifications were current at the time this manual was published, but bec ause of our policy of

continuous im provement, Powerm atic reserves the right t o change specific ations at any time and without

prior notic e, wit hout incurring obligations.

7

Page 8

Unpacking

Upon deliv ery, open shi pping c ontai ners and c heck

that all parts are in good condition. Any damage

should be reported to y our distribut or and shipping

agent immedi ately. Bef ore proceeding f urther, read

your manual and familiarize yourself thoroughly

with assembly, maintenance and safety

procedures.

Compare the contents of your container with the

following part s list to make sure all parts are intact.

Missing parts, if any, should be reported to your

distribut or. Read the instruction manual thoroughly

for assembly, maintenance and safety instructions.

Shipping Contents

Note: This unit is shipped in two cartons.

Stand Carton

1 Jointer Stand

1 Door with Mounting Hardware

1 Dus t Chute with Mounting Hardware

Main Unit Carton

1 Jointer Assembly

1 Fence Assembly

1 Pulley Cover

1 Belt

1 Cutterhead Guard

2 Push Blocks

1 Fence Handle

1 Hardware Package

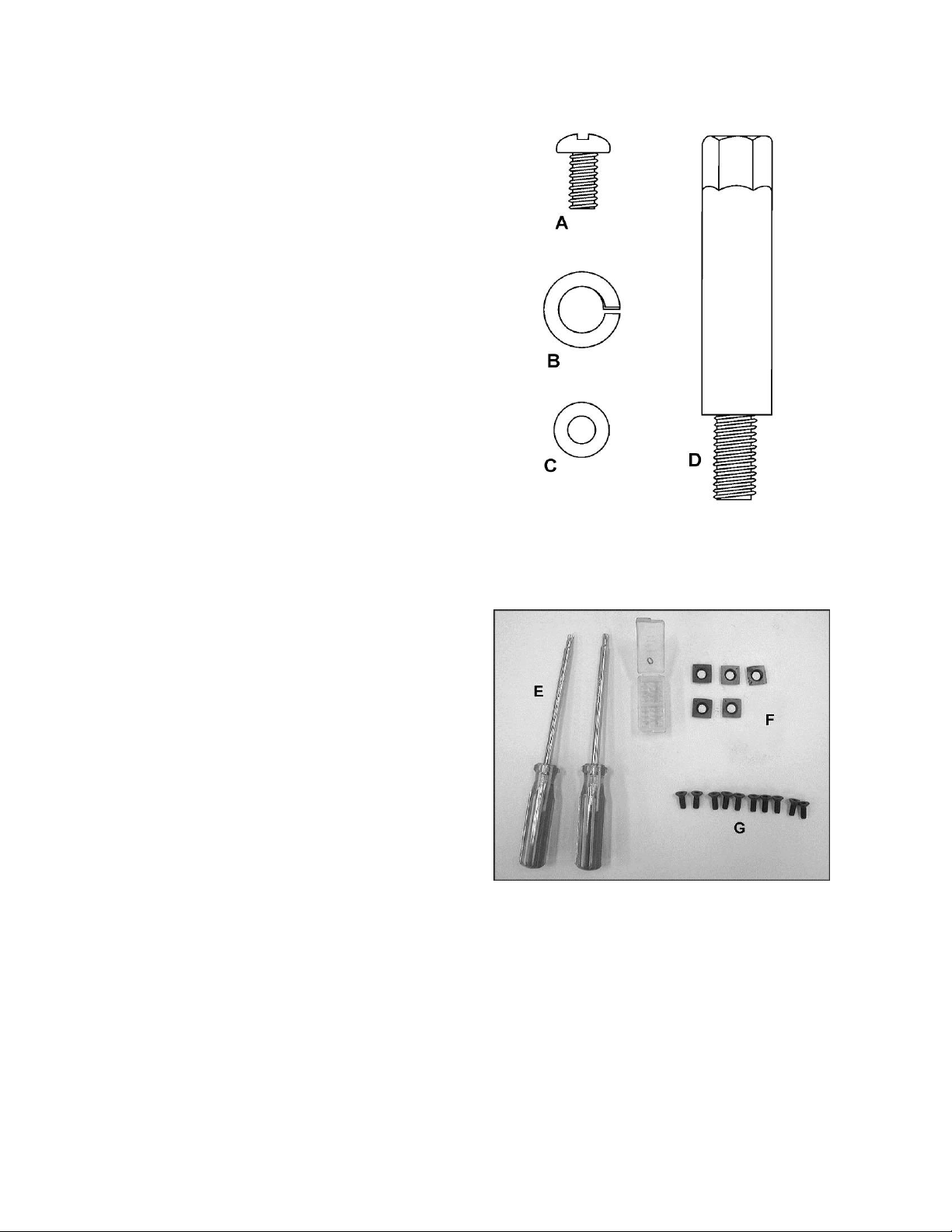

Hardware Package (all models):

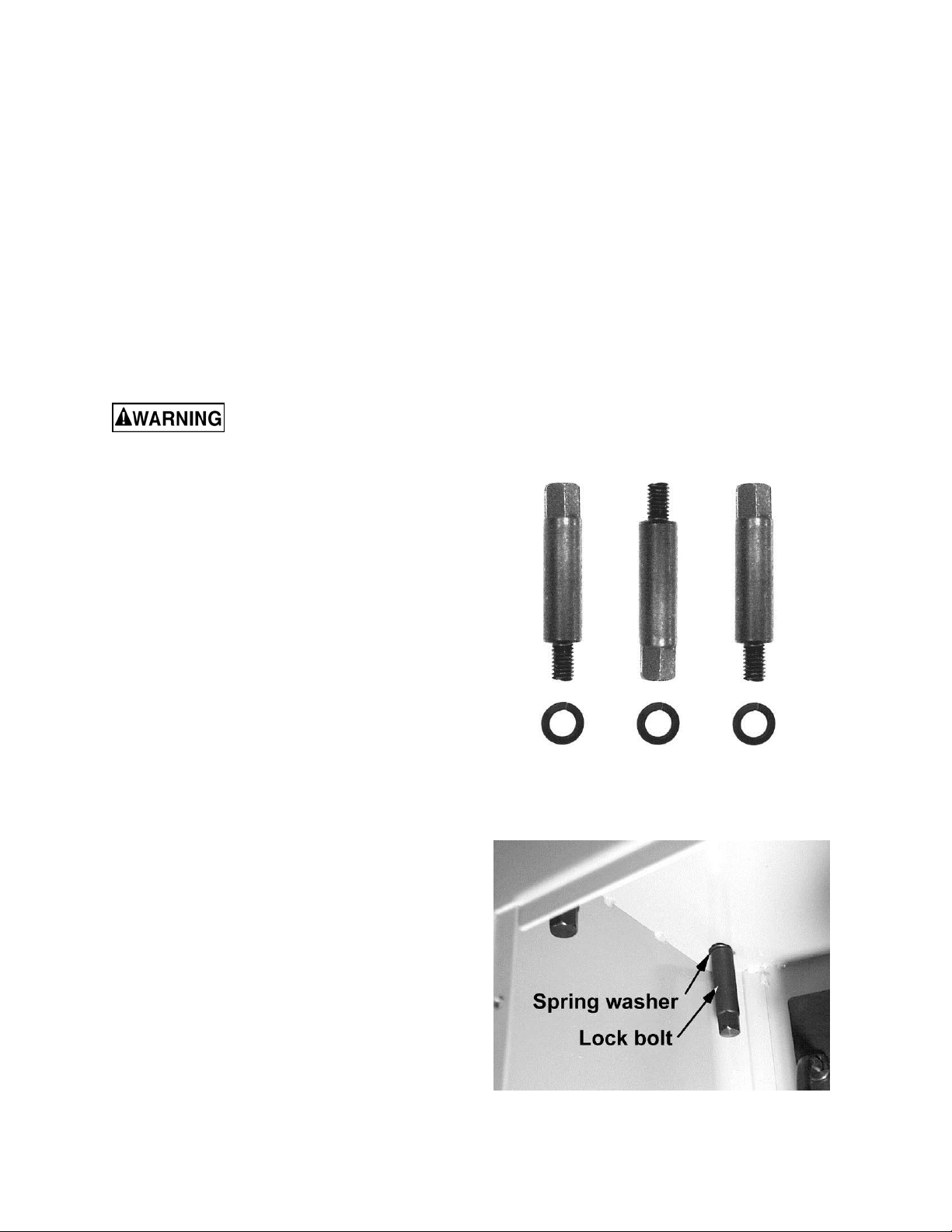

(p/n PM54A-HP, see Figure 1)

4 1/4-20 x 1/2” Pan Head Screws (A)

3 3/8” x 5/8” Spring Washers (B)

4 1/4-20 x 1/2” Flat Washers (C)

3 Lock Bolts (D)

Hardware Package - model 54A only

(p/n PM54A-HP2)

1 8/10mm Open End Wrench

1 12/14mm Open End Wrench

1 3mm Hex Wrench

1 4mm T-Hex Wrench

1 8mm Hex Wrench

1 Cro ss Point Scr ewdriv er

Hardware Package - model 54HH only

(p/n PM54HH-HP, see Figure 2)

1 8/10mm Open End Wrench

1 12/14mm Open End Wrench

1 3mm Hex Wrench

2 Star Point Screwdrivers (E)

5 Knife Inserts (F)

10 Knife Insert Screws (G)

1 Cross Point Screwdriver

Figure 1

PM54A-HP Hardware P ac k age c ontents

(all models)

Figure 2

PM54HH-HP Hardware Package partial contents

(54HH only)

Tools Required

open end wrenches (8, 10, 12, 14, & 19mm)

hex wrenches (3 & 6mm)

8

Page 9

Assembly

Unpacking and Cleanup

Locate the jointer in an area that is level and

provides a solid foundation. Make sure that any

potential kickback is not in line with aisles,

doorways, wash stati ons or ot her work ar eas.

1. Carefully fini sh rem oving all content s f rom bot h

shipping cartons. Compare contents of the

shipping cartons with the list of contents on

page 8. Place parts on a prot ec ted surface.

2. Set packing material and shipping cartons to

the side. Do not discard until machine has

been set up and is running properly.

Cutterhead knives are

dangerously sharp; use

extreme caution when cleaning. Failure to

comply may cause seriou s injury!

3. Moisten a soft cloth wit h kerosene and remov e

the protective coating from all machined

surfaces of the jointer. Do NOT use an

abrasive pad. Do not use g asol i ne, acet one or

lacquer thinner , as these may damage paint ed

surfaces.

4. Apply a thin lay er of paste wax to t he exposed

surfaces of the fence and tables to prevent

rust. Alt ernatively, white talcum powder rubbed

in vigorously once a week with a blackboard

eraser will fill any casting pores and form a

moisture barrier. Talcum powder will not stain

wood or mar finishes.

Installing Bed to Stand

1. Position the jointer on the stand so that the

pulley att ached to the cut terhead on the joi nter

is direct ly above and on the same si de as the

motor pulley.

2. Use three lock bolts and spring washers

(Figure 3) to firmly fasten the jointer to the

stand. The bolts are threaded up through the

holes in the stand into the base of the jointer

(Figure 4).

3. Use a 14mm wrench to tight en the lock bolts.

Figure 3

9

Figure 4

Page 10

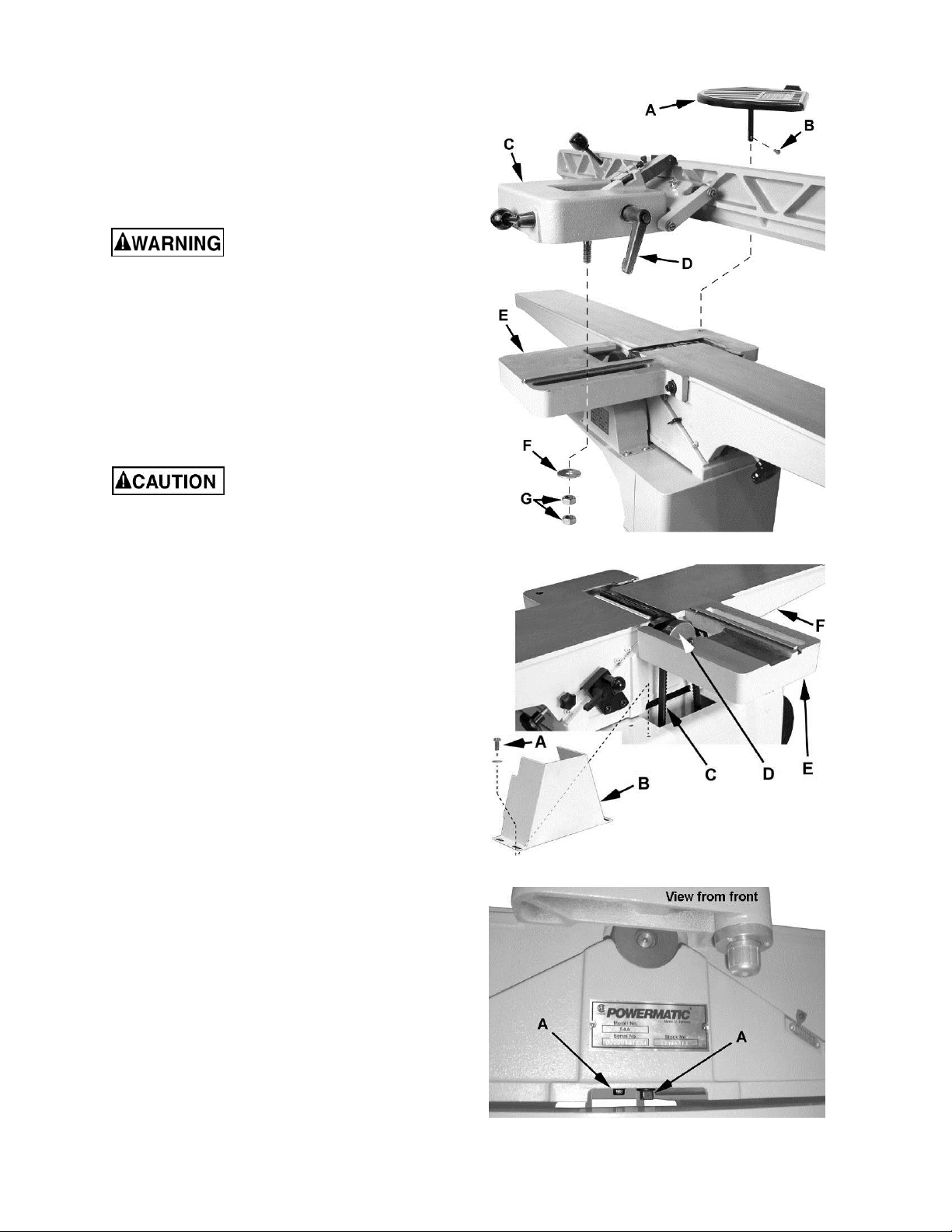

Installing Fence to Bed

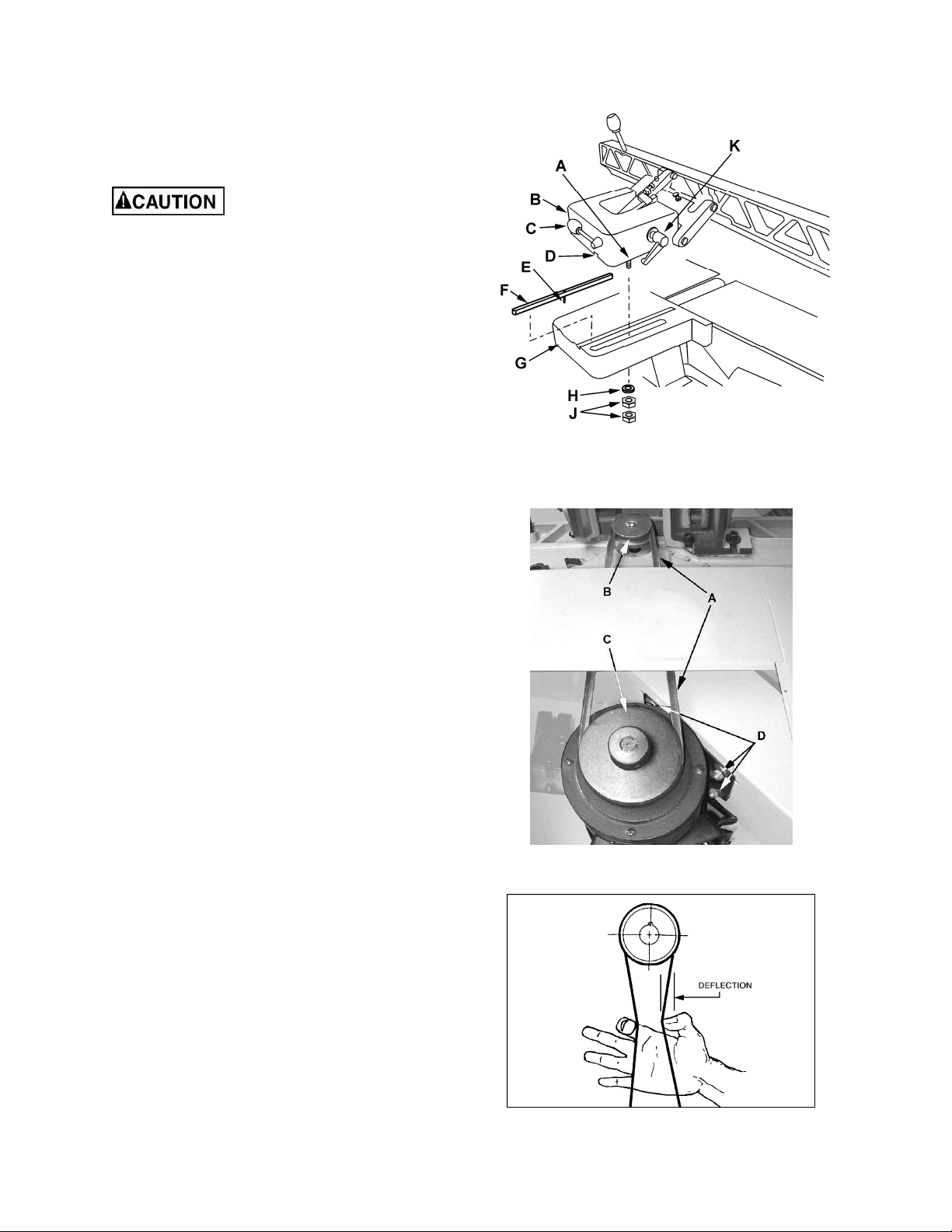

Referring to Fi gur e 5:

1. Before moving t he fence assembly, secure t he

tilt lock handle (K).

Secure the tilt lock handle to

avoid personal injury from moving parts.

2. Place the key (F) into the machined slot of t he

fence support ( G) as shown. The s pring pin (E)

should go into t he hole in the slot. The key (F)

should be firml y seated i n the slot.

3. Lightly coat the mating surfaces of the fence

support (G) and fenc e s lide bas e (B) with oil.

4. Place the fence slide base (B) on the fence

support (G), aligning the machined slot (D) in

the fence slide base with t he key (F).

5. Attach the flat washer (H) and two hex nuts (J)

on to the locking screw (A) but do not tighten.

6. Orient the lock handle (C) in the position as

shown; then tighten the hex nuts (J) with a

19mm wrench.

Figure 5

This is the locked position for the fence

assembly. Rotating the lock handle (C)

clockwise loosens the fence assembly,

permitti ng you to slide the assem bly back and

forth. The hex nuts m ay need to be readjusted

to allow the fence to slide back and forth

(handle cloc kwise position) and still sufficiently

secure the fence (lock handle positioned as

shown in C).

When the locking screw (A) is tightened, the

fence should be secure.

Installing the Drive Belt

Referring to Fi gur e 6:

1. Place V-belt (A) onto cutterhead pulley (B) and

through opening i n st and.

2. Pull V-belt down and place onto the motor

pulley (C).

If the belt i s diff icult to roll on t he pulley, l oosen

the motor mounting sc rews (D). Then r aise the

motor as hi gh as possible and mount t he belt

on to both pul l eys. Al l ow the m otor t o drop and

create tension on the belt.

Figure 6

3. Check to make sure that motor pulley and

cutterhead pul ley are v ertic ally aligned and t he

V-belt does not contact the sides of the

opening in the base. If the pulleys are not

aligned, remove belt and adjust the motor

pulley in or out on the motor shaft and then r eattach the belt.

Figure 7

10

Page 11

4. Pull down on t he motor t o achieve t he desired

belt tension.

The V-belt is properly tensioned when finger

pressure on the bel t half way bet ween the two

pulleys causes 1/2" deflection (Figure 7).

5. Tighten the mounting bolts.

After two hours of operation, check belt tension

again. Readjust the tension if necessary.

Installing the Pulley Cover

Referring to Fi gur e 8:

1. Place the pulley cover (A) over the openi ng in

the stand.

2. Line up the hol es in the stand with t he holes in

the guard.

3. Attach the pulley cover to the stand using four

1/4-20 x 1/2” pan head screws and 1/4” flat

washers (B).

Installing Cutterhead Guard

1. Remove the screw from the guard post.

Referring to Fi gur e 9:

2. Turn spring knob (B) approximately one-half

revolution counter-clockwise (as viewed from

the top) and hold.

3. Insert the guard post into hole in table. Make

sure that the spring i nside the spring knob ( B)

engages the slot in guard post. If needed,

slightly turn the knob until the guard seats

itself.

4. Thread the screw (C) back into the guard post.

5. Check for proper operation. The cutterhead

guard (A) must return fully to the fence when

released. If guard does not return fully, pull

guard, apply more tension to the spring knob

(B) by turning it another half turn counterclockwise, and re- insert guard. If guard c loses

too quickl y and strikes f ence too hard, rev erse

the process.

6. Insert screw (C) back into the guard post.

Figure 8

Figure 9

Installing Access Door and Dust Chute

Referring to Fi gur e 10:

Install ac cess door (C) by placi ng bottom of panel

in the stand and f astening with four 1/8 x 3/8 pan

head screws (A) and four 1/8" flat washers (B).

Attach the dust chut e (D) to the base with four 1/4"

x 1/2" machine screws and four 1/4" flat

washers (D).

Figure 10

11

Page 12

Electrical

Grounding Instructions

This jointer must be

grounded while in use to

protect the operat or from electric shock.

In the event of a malfunction or breakdown,

grounding prov i des a path of least resistanc e f or

electric current to reduce the risk of electric

shock. This tool is equipped wit h an electric c or d

having an equipment-grounding c onduc tor and a

grounding plug. The plug must be inserted into a

matching outlet that is properly installed and

grounded in accord ance wit h all l ocal codes and

ordinances.

Do not modify the pl ug provided. If it will not fit

the outlet , have the proper outlet i nstalled by a

qualified el ectrician. Improper connecti on of the

equipment-grounding conductor can result in a

risk of electric shock. The conductor, with

insulati on having an outer surf ace that is green

with or without y ellow stripes, is the equipment grounding conduct or. If repai r or replac ement of

the electric cord or plug is necessary, do not

connect the equipment-grounding conductor to a

live terminal.

Check with a qualified electrician or service

personnel if the grounding instructions are not

completely understood, or if in doubt as to

whether the tool is properl y grounded. Use onl y

three wire ex tension cords that have three-prong

grounding plugs and t hree-pole recept acles that

accept the tool ’s pl ug.

Repair or replace a damaged or worn cord

immediately.

The temporary adapter should only be used unti l

a properly grounded outl et can be instal led by a

qualified electrician. This adapter is not

applicable in Canada. The green colored rigid

ear, lug, or tab, extending from the adapter,

must be connect ed to a permanent ground such

as a properly grounded outlet box.

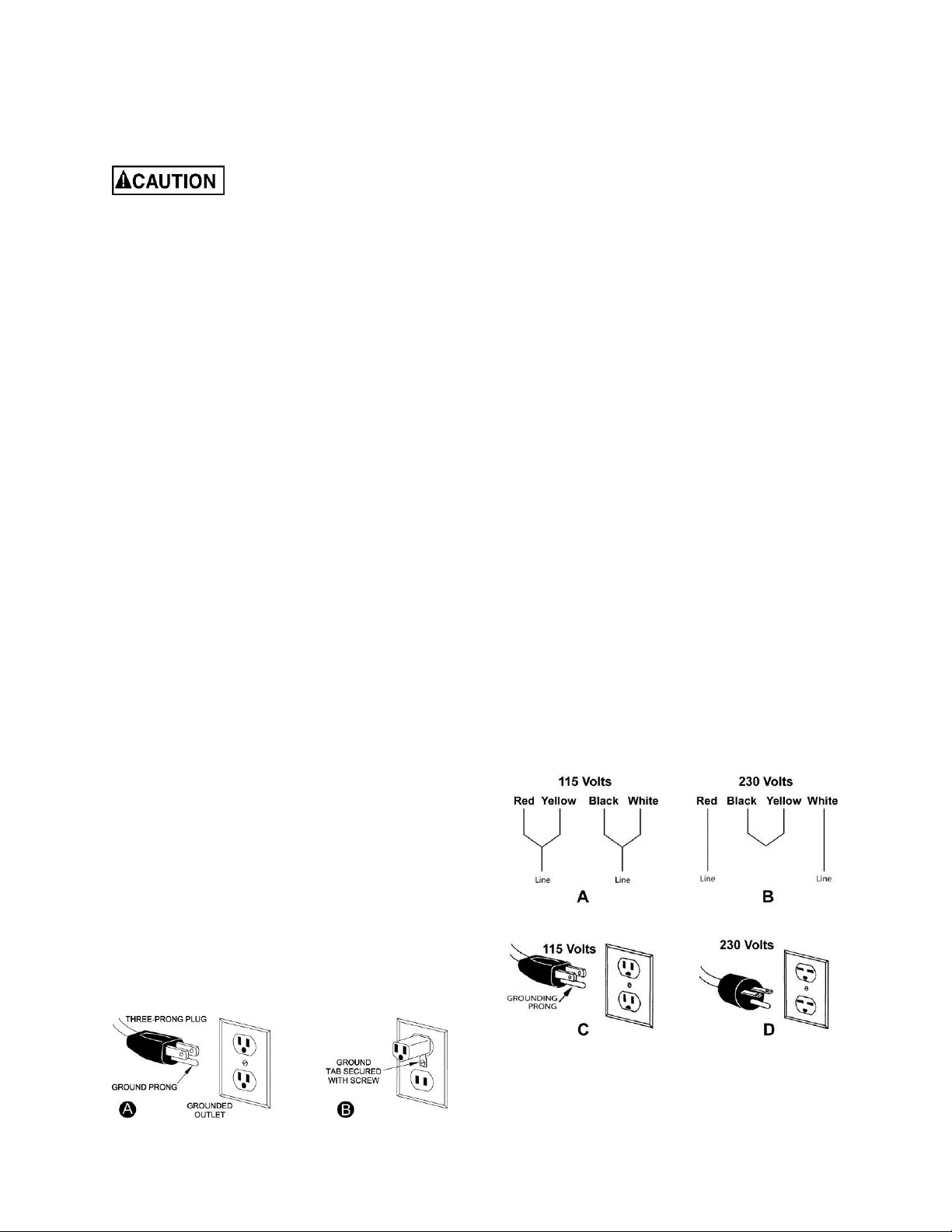

230 Volt Operation

Referring to Fi gur e 12:

If 230V, single-phase operation is desired, the

following inst r uc tions must be followed:

1. Disconnect the machine from the power

source.

2. The Jointer motor has f our numbered leads

that are factory connected for 115V

operation, as shown in (A). For 230V

operation reconnect the leads as shown in

(B). This is also shown in the diagram s on

pages 39 and 40.

3. The 115V att achment pl ug (C) supplied wit h

the Woodworking Jointer must be replaced

with a UL/CSA li sted plug suitable for 230V

operation (D) . Contact your local Authorized

Powermatic Service Center or qualified

electrician for proper procedures to install

the plug. The Woodworking Jointer must

comply wit h all loc al and national codes after

the 230-volt plug is installed.

4. The Jointer with a 230-volt plug should onl y

be connected to an outlet having the sam e

configurati on as shown in (D). No adapter is

available nor should be used with the 230volt plug.

115 Volt Operation

Referring to Fi gur e 11:

As receiv ed f rom t he f actory , your W oodworki ng

Jointer is ready to run at 115-volt operation. This

Jointer, when wired for 115 v olt, is intended f or

use on a circuit t hat has an outlet and a plug that

looks li ke the one illustrated in ( A). A temporary

adapter, which looks like the adapter shown in

(B), may be used to connect this plug to a twopole receptacle if a properly grounded outlet is

not available.

Figure 11

Figure 12

Page 13

Extension Cords

The use of ext ension cords is discouraged. T ry to

position equipment within reach of the power

source. If an extension cord becomes necessary,

make sure it is in good condition, and heavy

enough to carry t he current your machine will draw.

An undersized cord will cause a drop in the line

voltage resulting in power loss and overheating.

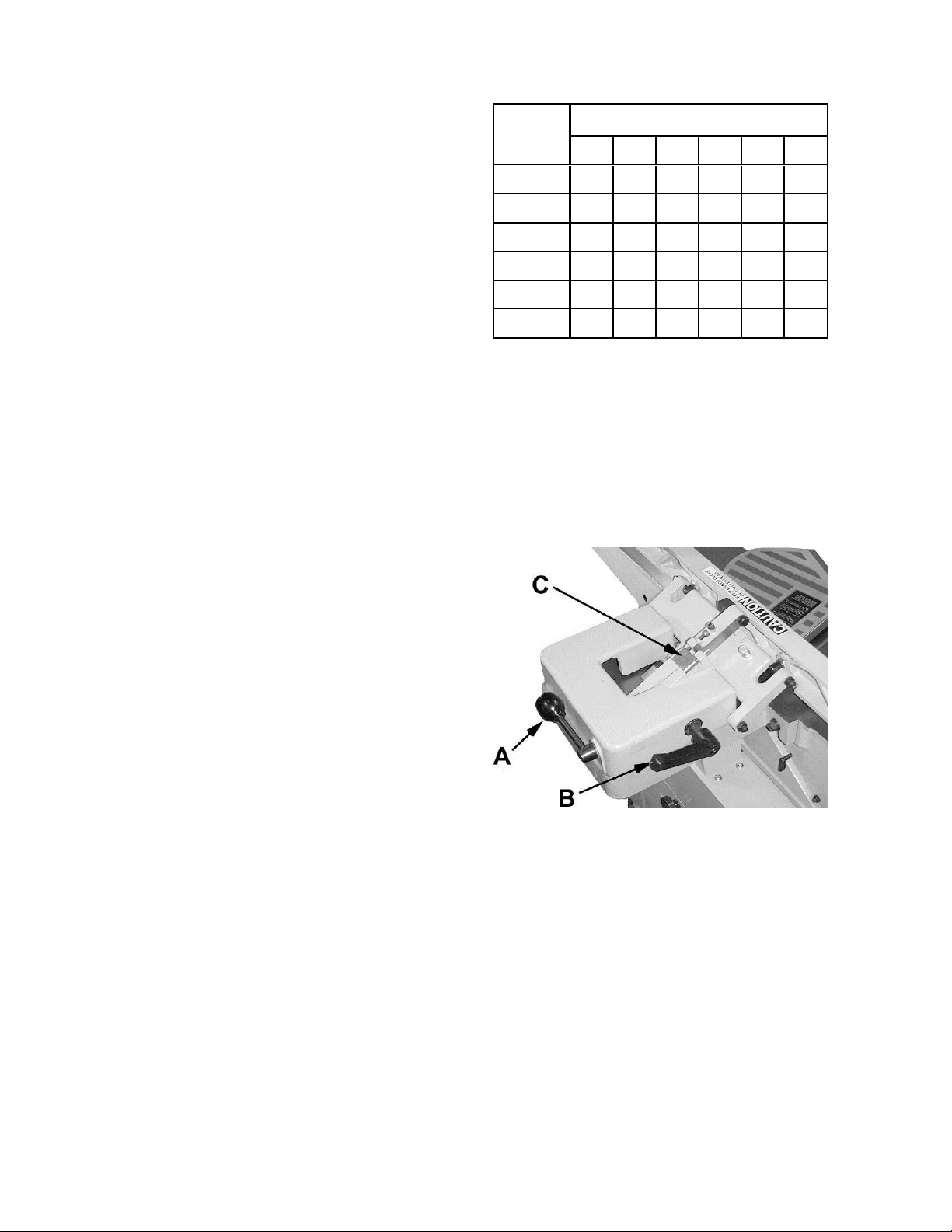

Table 1 shows the correct size to use depending

on the cord length and nameplate ampere rating.

If in doubt, use the next heavier gauge.

Remember, the smaller the gauge number, the

heavier the c or d.

Adjustments

Fence Movement

Recommended Extension Cord Gauges

Amps

8 to 12 14 14 12 10 NR NR

12 to 15 12 12 10 10 NR NR

15 to 20 10 10 10 NR NR NR

21 to 30 10 NR NR NR NR NR

*based on li miting the lin e voltage drop t o 5V at 150% of the

rated amp eres.

NR: Not Recommended.

Extension Cord Length in Feet *

25 50 75 100 150 200

< 5 16 16 16 14 12 12

5 to 8 16 16 14 12 10 NR

Table 1

The fence can be moved forward or backward

across the width of t he table. It also til ts up to 45

degrees forward and has a positive stop at 90

degrees.

The fence assem bly should peri odically be moved

to different positions when edge jointing to

distribute wear on the cutterhead knives.

Referring to Fi gur e 13:

To slide the fence forw ar d or bac kw ar d:

1. Loosen the lock handle (A).

2. Push the entire f ence assembly t o the desired

position, and tighten the locking handle.

To tilt fence forward:

The fence c an be tilted f orward to any angl e down

to 45 degrees.

1. Loosen the lock handle (B).

2. Adjust the fence to the desired level down to

45 degrees. Or you can place your reference

piece on the tabl e and against the fence, and

adjust the fence until the angle of the fence

matches the bev el of your gauge piec e.

3. Tighten lock handle (B).

To tilt fence backw ar d:

The fence c an be tilted backward up to 45° (that i s,

for a total included angle of 135° from table

surface).

Figure 13

1. Loosen lock handle (B).

2. Flip the 90° stop block (C) out of the way.

3. Adjust t he fenc e to the desired angl e up to 135

degrees. Or you can place your beveled

reference piece on the table and against the

fence, adjust ing the f ence until the angl e of t he

fence matches the bevel of your reference

piece.

5. Tighten lock handle (B).

Important: When the tilted operation is finished and

the fence is returned t o 90°, do not forget to flip the

90° stop block C) back to its original position.

13

Page 14

Fence Stop Adjustments

Periodically check the 90° and 45° backward

(135°) tilt accuracy of the fence with an angle

measuring device, such as an adju stable square or

machinist ’s prot r ac tor.

90º Stop Adjustment

Referring to Fi gur e 14:

The 90º stop is cont rolled by t he stop bolt (F ) and

the stop block (C).

1. Set the i nfeed t able t o approxim at ely the sam e

height as the outfeed table.

2. Move the fence by releasing lock handle (A)

and pushing the fence assembly until it

overlaps the tables.

3. Tighten lock handle (A).

4. Adjust the fence to a 90º angle by releasing

lock handle (B) , pul li ng up on the fenc e hand le

E), and tight ening the lock handle (B).

Note: The stop bolt (F) should be resting

against the st op bloc k (C).

Figure 14

5. Place an angle m easuring dev ice on the tabl e

and against the f ence to confirm a 90º setti ng

(A, Fig. 15).

6. If the fence is not square to the tabl e, release

the lock handle (B), loosen the lock nut (D) that

secures the stop bolt ( F), and turn the stop bolt

until the fence is square to t he table.

7. Tighten the lock nut (D) to secure the stop bolt

(F) which retai ns the setting.

8. Tighten the lock handle (B).

45º Forward Stop Adjustment

Position t he fence tilt lever (E, F ig. 14) toward the

operator.

The 45 degree forward stop is controlled by the

cap screw (G, Fig. 14) . The adjustment is done the

same way as for the 90 degree stop adjustment

except that a 45 degree protractor is used.

Figure 15

45º Fence Backward Stop Adjustment

Referring to Fi gur e 14:

The 45º fence backward stop is controlled by the

stop bolt (H).

1. Loosen the lock handl e ( B ).

2. Move the stop block (C) out of the way and

position the fence at the 135º angle; fence tilt

lever (E) is positioned away fr om the operator

as shown. Make sure the f ence sit s against the

stop bolt (H).

3. Tighten the lock handle (B).

4. Place an angle measuring device on the table

and against the f ence to confirm a 135º setti ng

(B, Fig. 15).

5. To adjust, loosen the lock nut (J) securing the

stop bolt (H) and t urn the stop bol t until a 135º

angle of the fence is obtained.

6. Tighten the lock nut (J).

14

Page 15

Infeed Table Height Adjustment

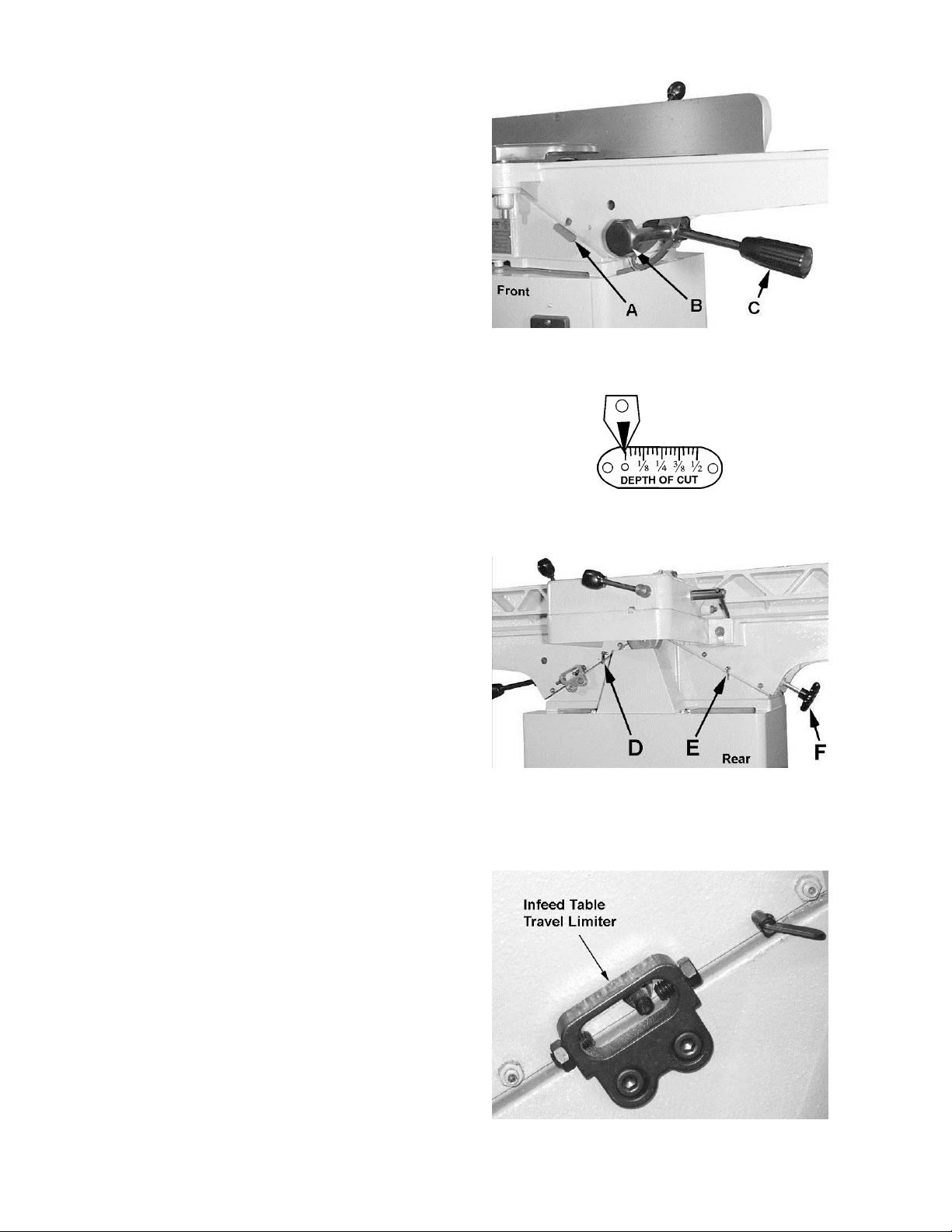

Refer to Figures 16 – 18.

Initial (Coarse) Adjust ment:

1. Loosen the rear thum b screw (D) and the lock

knob (B).

2. Raise or lower the height adjustment handle

(C) until the scale (A, Fig. 16 and Figure 17)

reads approxim ately the desired depth of cut.

If you can't adjust to zero or 1/8", see the

Helpful Hint below.

Fine Adjustment:

3. Turn the locking handle (B) until it is snug.

4. Rotate the height adjustment handle (C) until

the scale reads exact. Clockwise raises the

table, counter c lockwise lowers the table.

Note: The hei ght adjustm ent handl e (C) has a

fine adjustment of 1/16" travel per rotation.

5. When set, retighten the thumb screw (D).

Important: For normal operations, the dept h of cut

should never exceed 1/8", except for rabbetting

operations.

Figure 16

Figure 17

Helpful Hint: Occasionally you will find that you

cannot set the coarse adj ustment all the way up to

zero or all the way down to 1/2" on the Depth of

Cut scale (Figur e 17) when raising or lowering t he

handle (C, Fig. 16) . W hen this happens:

With the lock knob (B, Fig. 16) unlocked, rotate the

height adjustment handle (C, Fig. 16) a f ew times,

then raise or l ower it. Once you are abl e to reach

the zero or 1/2” setting (Figure 17), you will again

be able to swing the handle (C) through the full

range.

Infeed Table Travel Limiter

Referring to Fi gur e 19:

The infeed t able travel limiter l ocated on the back

of the tabl e sets the upper and lower rang e for t he

infeed table height adjustment and should not

require any adjustments. For infeed table height

adjustment refer to the preceding section.

Figure 18

Figure 19

15

Page 16

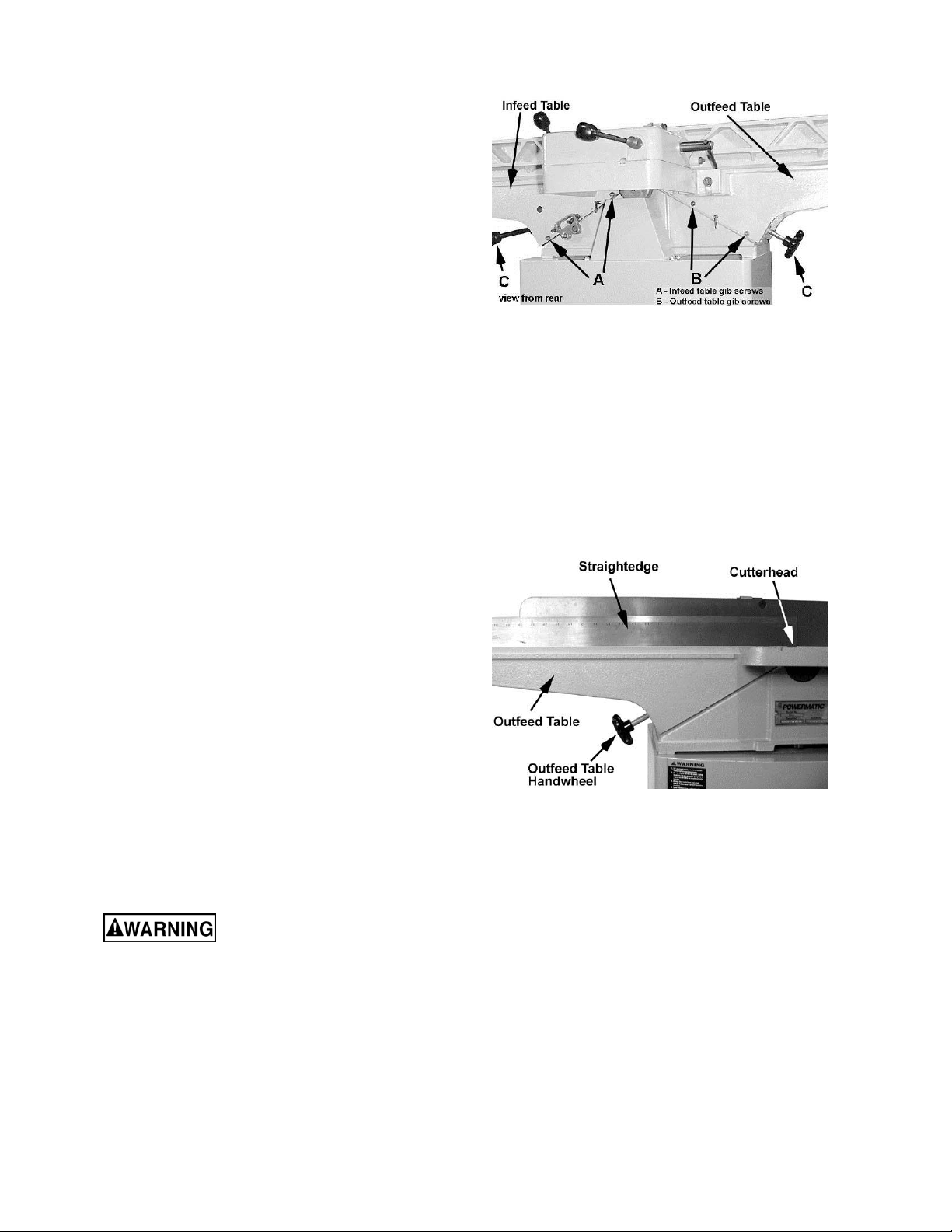

Table Gib Adjustment

The infeed an d outfeed table gibs on your m ac hine

are factory adjusted and initi ally should not requir e

re-adjustm ent. After a period of use, the gibs may

become loose, introducing play and causing the

tables to sag. This requires adjustment.

To adjust (refer to Figure 20):

1. W ith a 10mm wrench, loosen the jam nuts that

secure the gib set screws (A or B).

2. Have another person support the end of the

table, slightly raising it while you make

adjustments.

3. With a 3mm hex wrench, tighten each

setscrew 1/4 turn starting with the l ower one,

then the upper one. If a 1/4 turn does not

remove the table play, take another 1/4 turn.

Repeat a 1/4 turn at a tim e f or bot h set screws

until play is removed.

Note: If the gibs are too tight the adjustment

handles (C) will be difficul t to turn.

4. When adjustment is complete, hold the set

screws in positi on wit h the 3mm hex wrench to

maintain the setting while tightening the jam

nuts with the 10mm wrench.

Outfeed Table Height Adjustment

When you receive the jointer, the knives have

been pre-set at the factory. However, the height

and paralleli sm of the kniv es with t he outf eed tabl e

should be checked and any needed adjustments

made before putti ng the jointer into operation.

Adjust the height of t he outf eed table as follows:

Figure 20

1. Disconnect j ointer from power source.

2. Caref ully num ber each bl ade (m odel 54A onl y)

with a marker to make them easier to

differentiate.

3. Place a straightedge upon the outfeed table

and extend i t over the cutterhead (Figures 21

and 23).

Planer kni ves and knife inserts

are dangerously sharp. Do not

grab the cutterhead i t self to rotate it!

4. Rotate the cutterhead, using the drive belt or

pulley, unti l knife number one (or a knife insert

on the 54HH model ) is at i ts hi ghest point . T he

apex of the knife should just barely come in

contact wit h the straightedge.

If the apex of the knif e number one j ust makes

contact wit h the straightedge, no adjustment is

required f or the outfeed table. Proceed to the

Setting Cutt erhead Knives section.

Figure 21

16

Page 17

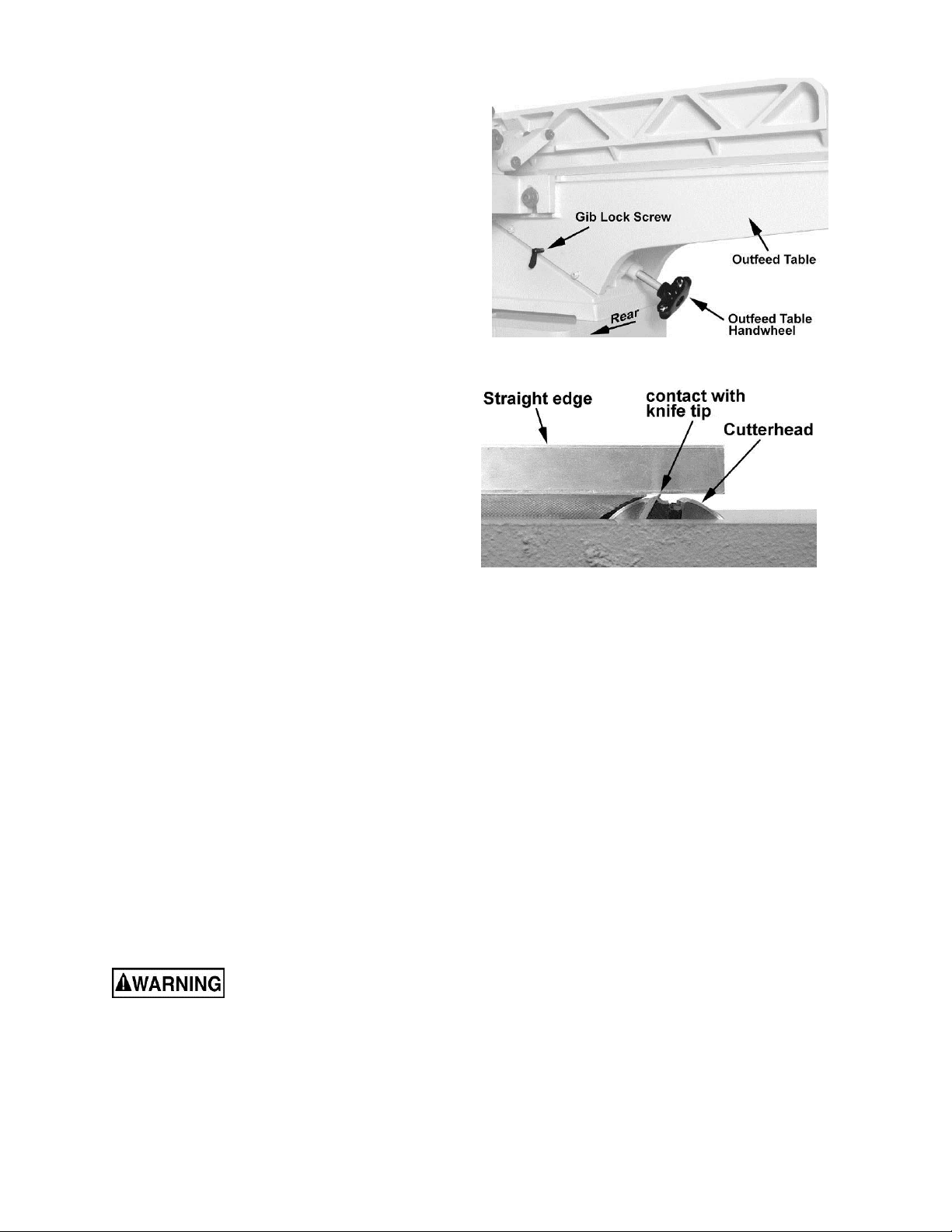

If the apex of the knife numbe

r

below the straightedge (a gap exists) or

pushes the straightedge up, proceed with the

following steps:

5. Loosen both gib lock screws (Figure 22).

6. With the outfeed table handwheel (Figure 21)

raise or lower the outfeed table until the

straight edge cont acts the knife tip, as shown

in Figure 23. Using the drive belt or pulley,

rock the cutterhead slightly to make sure the

apex of the knife i s just barely contacting the

straight edge.

one comes

When adjustment is complete:

7. Lock the outfeed table to thi s height setting by

tightening t he gib lock screw (Figure 22). The

outfeed tabl e adj ustm ent is complete.

The outfeed tabl e adjustment is only made against

one knife or knife insert (blade number one was

arbitrarily selected here). After the outfeed table

has been set at t he c or r ec t height, do not c hange it

except for special operations or after replacing

knives.

After this adjustment is completed on the model

54A, it is necessary to proceed to the Setting

Cutterhead Knives section to verify that all three

knives are at t he correct height and parallel to the

outfeed table. For the model 54HH, proceed to

Replacing or Rotating Knif e Ins er ts on page 20.

Setting Cutterhead Knives (Model 54A only)

Note: Before setting knives for the 54A Jointer, the

Outfeed Table Height Adjustment should be done

to ensure the proper knif e height in relation to t he

outfeed tabl e.

Knives for the 54A cutterhead are adjusted by

means of a cam. It is important to note that the

entire adjustment is accomplished within one

complete rotati on (360 degrees) of the cam. A full

rotation of the cam will cause the knife blade to

move a total of .015” from one extreme to the

other. Tur ning the cam more t han one full rotation

will not further adjust the knife setting, but will

simply begin the adjustment all over again. The

knife adjustment procedure is outlined below.

Cutterhead knives are

dangerousl y sharp! Use extreme caution when

inspecting, removing, sharpening or replacing

knives into the cutterhead. Failure to comply

may cause serious injury!

Figure 22

Figure 23

To adjust (refer to Figures 24 & 25):

1. Disconnect j ointer from power source.

17

Page 18

2. Carefully number each bl ade with a marker to

make them easier to diff erentiate.

3. Place a straightedge acros s the outf eed table

extending it over the cutterhead towards one

end of the knife.

Cutterhead knives are

dangerousl y sharp. Do no t grab the cu tterhead

itself to rotate it! Failure t o comply may cause

serious injury.

4. Rotat e the c utt erhead back and f ort h using the

drive belt or pull ey, until knif e number one is at

its highest poi nt. The apex of the knife should

just barely come in contact with the

straightedge.

5. Move the straightedge towards the other end

of the knife and repeat step 4.

The apex of t he knife at both ends of t he knife

must just make contact with the straightedge. If

the apex of the knife comes below the

straightedge (a gap exists) or pushes the

straightedge up, pr oc eed to the next step.

6. Using a 4mm hex wrench, slightly loosen the

four gib screws.

7. Using a 3mm hex wrench, loosen the cam

locking scre ws to per mit adjustment of the cam

(described in the next step).

Figure 24

Important: Always keep the cam locking

screws snug enough so that the cam can’t

rotate freely. This is especially important for

when the cam is rotated counterclockwise

since this action will cause the cam locking

screw to loosen f urther .

8. Using an 8mm hex wrench, adjust the cam

(see Figure 25). This is a very sensitive

adjustment. Start by rotating the cam in a

clockwise dir ec tion just a few degrees.

9. Next, keep the cutterhead steady by firmly

holding on to t he pul l ey, pl ace a pi ece of wood

pressed against t he knife’s edge and press to

properly seat t he blade.

10. Check your progress by repeat ing step s 4 and

5. If the knife becomes more out of adjustment,

turn the cam in the other direc tion.

11. The adjustment is almost complete when the

requirements described in Steps 4 and 5 are

met.

12. Next, while pressing the knife firmly against the

cam, snug the two inside gib screws that hold

the gib and knife i n place. Verify that t he knife

is still in adjustm ent (steps 4 and 5).

13. Tighten the two outside gib screws, then the

two inside gib screws.

Figure 25

18

Page 19

14. Verify that the knife is still in adj ustment (steps

4 and 5).

15. Tighten the gib lock screws.

16. Repeat this enti re procedure for the r emaining

two knives

Replacing Knives (M odel 54A only)

Joint er knives are dangerously

sharp. Use extreme caution when inspecting,

removing, sharpening, or replacing knives.

Failure to compl y may cause seri ou s injury.

To remove and replace a knife (Refer to

Figure 26):

1. Remove four gib screws (A) with a 4mm hex

wrench.

2. Remove the gib (B) and knife (C).

If the knif e is being re-used (knives are double-

edged), clean t he knife, gib and c utterhead of

all pitch and debris.

3. Lay the new knife or unused edge of the old

knife back onto the cutterhead (D).

4. Replace the gib (B) and screws (A). Finger-

tighten only at t his tim e.

5. Press against the cutting edge of the knif e at

the center of the blade with a piece of wood.

DO NOT USE FINGERS! This is to ensure that

the cam is making proper contact with the

knife.

6. Snug the inside two screws, then the outside

two screws.

7. Release the piece of wood pressing against

the knife and tight en the gib screws.

8. Replace the rem aining two blades by repeating

steps 1 – 7.

9. Determine if kniv es need to be set.

Follow the Outfeed Table Height Adjustment

section steps 3 and 4 only, to determine if

knives need to be set. Do not complete the

entire outfeed table adjustment. If knives

need to be set, proceed to the Setting

Cutterhead Knives sect ion.

Figure 26

19

Page 20

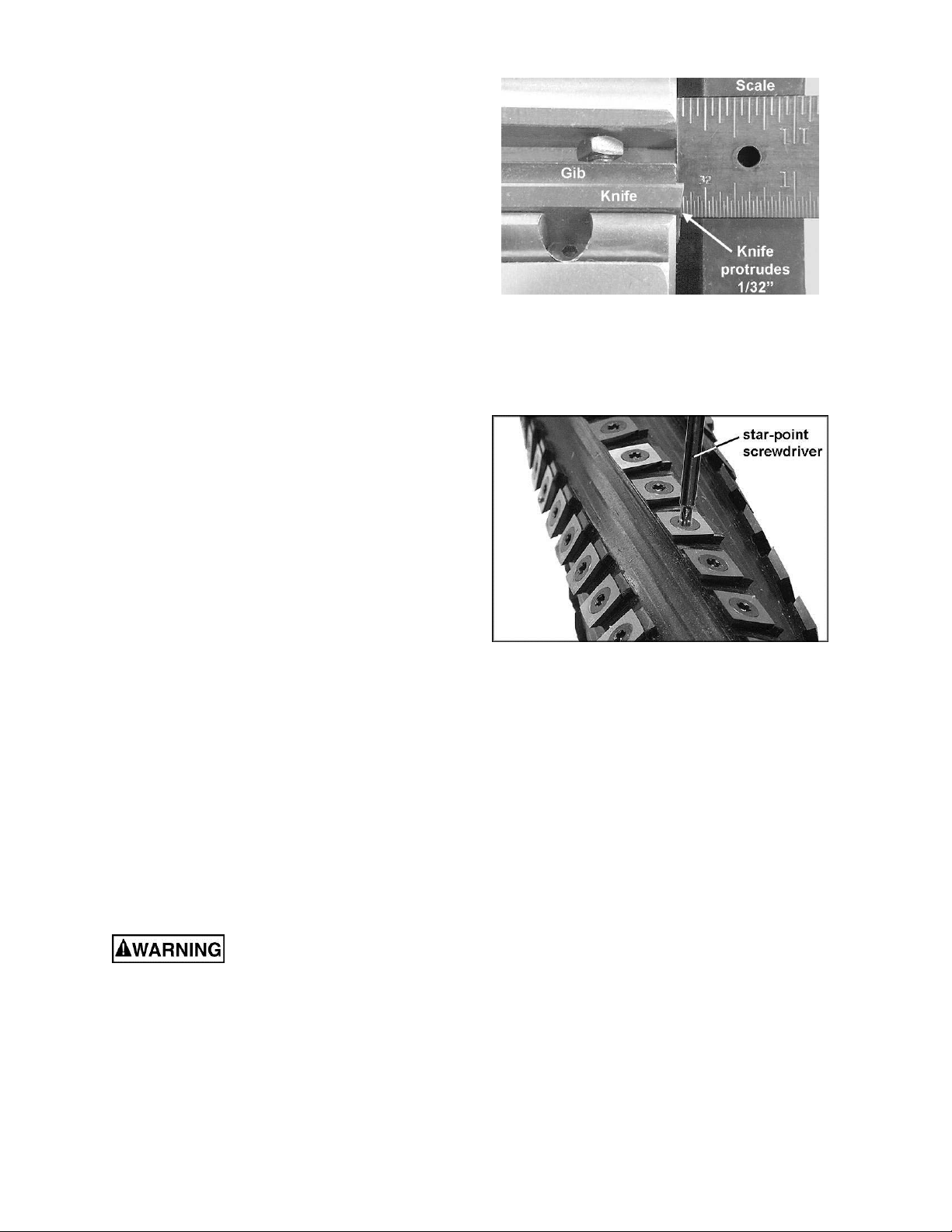

Setting Knives for Rabbeting and Nicks (Model 54A only)

NOTE: Rabbeting is not applicable on helical

cutterhead models.

To position t he kniv es for rabbet cuts, take a shop

scale with 1/32” graduations and place it against

the end of t he c utterhead. Sli de the knife out unt il it

is at the 1/32” mark on the scale; t hat is, the knife

will now be 1/32” beyond the edge of the

cutterhead. The gib should remain in normal

position, even with the edge of the cutterhead.

(Figure 27). This adjustment will ensure that the

knife clear s the end of the gib and cutterhead, and

has good contact with the workpiece. (See the

Rabbet Cuts section for further information.)

Note: This will also corr ect for small nicks without

requiri ng r eplac em ent of blades.

Replacing or Rotating Knife Inserts (Model 54HH only)

The knife inserts on the model 54HH Jointer are

four-si ded. When dull, sim ply remove eac h insert,

rotate it 90° for a fresh edge, and re- install it.

Figure 27

Use the two provided star point screwdrivers to

remove the k nife insert screw. See Figure 28. Use

one of the screwdriv ers to hel p hold the c utterhead

in positi on, and t he other to remove t he screw. It is

advisable to r otate all inserts at the same tim e to

maintain consistent cutting. However, if one or

more knife inserts develops a nick, rotate only

those inserts that are affected.

Each knife insert has an etched r eferenc e mark so

that you can keep trac k of the rotations.

IMPORTANT: When removing or rotating inserts,

clean saw dust fr om the screw, the insert, and t he

cutterhead platform. Dust accumulation between

these element s can prev ent the i nsert f rom seati ng

properly, and m ay affect the quality of the cut.

Before installi ng each screw, l ightly coat the screw

threads with mac hine oil and wipe off any excess.

Securely ti ghten each screw which hol ds the knif e

inserts befor e oper ating the planer!

Make sure all knife insert

screws are tightened securely. Loose inserts

can be propell ed at high speed from a rotating

cutterhead , cau sin g inju ry.

Figure 28

20

Page 21

Determining Correct Table Height

The Outfeed Table Height Adjustment section tells

you how to set t he correct table height with respect

to the cutterhead knives or knife inserts. This

section explains how to determine if the outfeed

table needs adjustm ent based upon the cuts being

produced.

When you receive the jointer, the knives have

been pre-set at the factory. However, the height

and paralleli sm of the kniv es with t he outf eed tabl e

should be checked and any needed adjustments

made before putti ng the jointer into operation.

The outfeed table and cutterhead knives (Model

54A only) are correctly adjusted when all three

blades are parallel to the outfeed table and all

three blades are set at the same height in the

cutterhead.

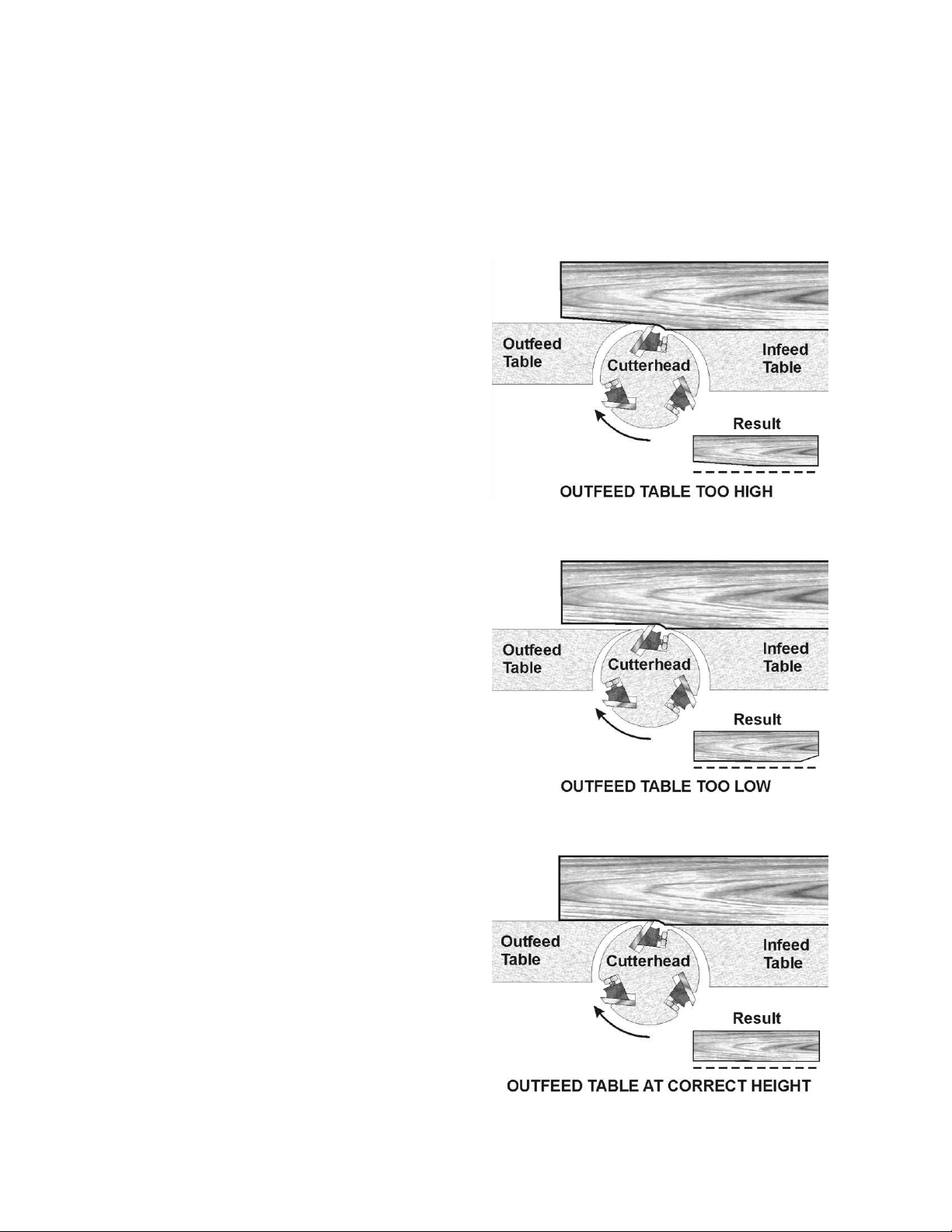

Outfeed table t oo high – If the outfeed tabl e is too

high, a curv ed finished surface results (Figure 29).

Outfeed table t oo low – If t he outfeed tabl e is too

low, the work will have a gouge, or snipe, at the

end of the cut (Figur e 30).

Outfeed table at correct setting – Figure 31

illustrat es the correct setting of outf eed table level

with the knives. The workpiece will rest firmly on

both tables with no open space under the f inished

cut.

Figure 29

Figure 30

Figure 31

21

Page 22

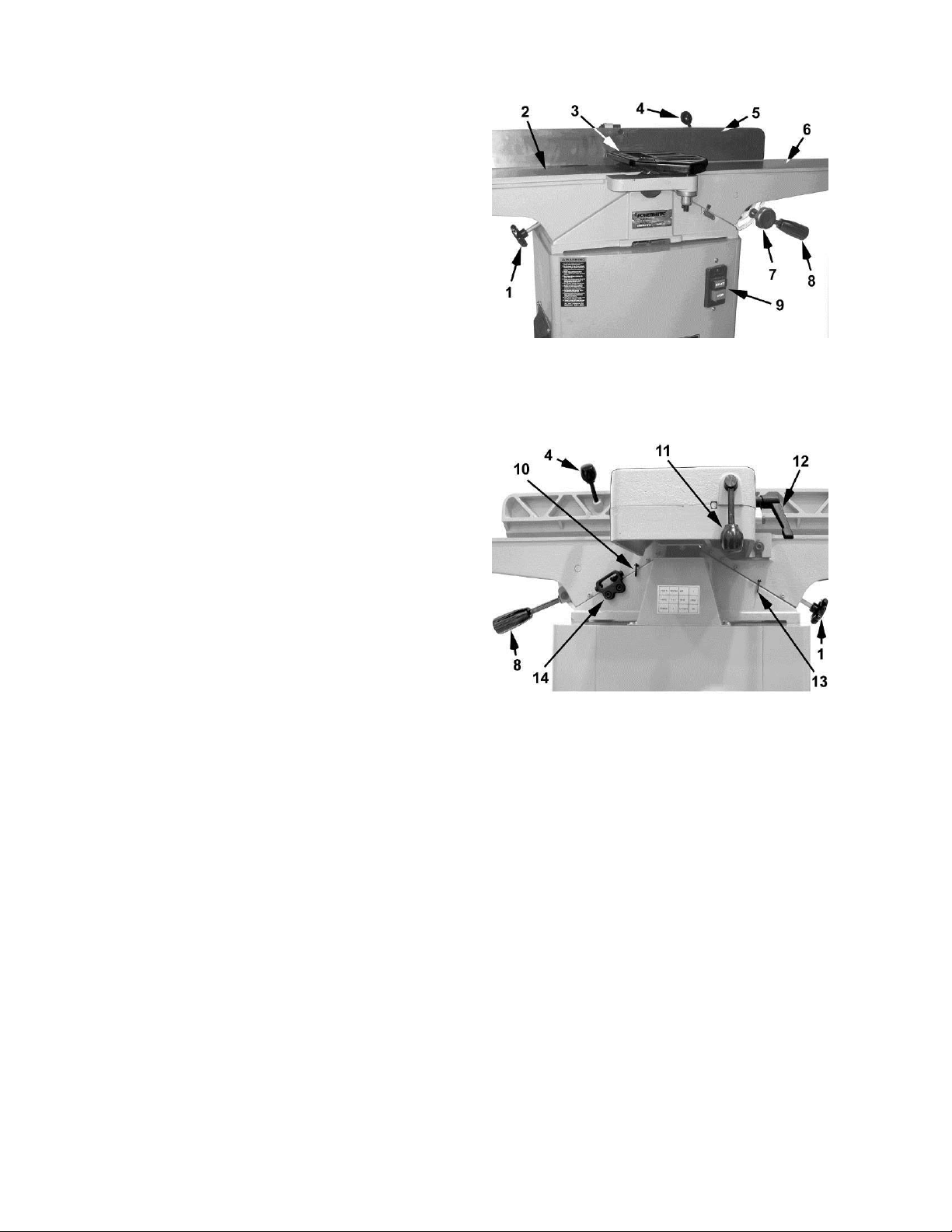

Operating Controls

1. Outfeed Table Height Adjust Hand Wheel

2. Outfeed Table

3. Cutter Guard

4. Fence Adjustm ent Handle

5. Fence

6. Infeed Table

7. Infeed Table Lock K nob

8. Infeed Table Hei ght Fine/Coarse Adjustment

9. On/Off Switch

10. Infeed Table Lock

11. Fence Travel Loc k Handl e

12. Fence Tilt Lock Handle

13. Outfeed Table Lock

14. Infeed Table T r av el Limiter

Operation

IMPORTANT: Make sure all knives or knife

inserts are tigh t before operating machine. On

the helical head model, veri fy t ightness o f each

insert (re-torque) before using the machine for

the first time.

Controls - Front V iew

Figure 32

If you are inexperienced at jointing, use scrap

pieces of lum ber to check settings and get t he feel

of operations bef or e att em pting regular work.

Stabilize l ong workpieces by using an a ssistant, or

roller stands set level with the outfeed or infeed

table surface.

The fence should be adjusted to create minimum

exposure to the cutterhead during the jointing

operation.

Check the following before operating the joint er:

Outfeed table must be set level with the high

point of the knives. This is a one-time

calibration and described in Outfeed Table

Height Adjustment on page 16.

Fence adjusted for minimum exposure of

cutterhead, and loc k ed at desir ed angle.

The cutterhead guard must be in place and

operating proper ly (except when rabbeting).

Infeed tabl e set for desired depth of cut . Refer

to Infeed Table Height Adjustm ent on page 15.

Controls – Rear View

Figure 33

Stand away from the cutterhead and turn the

machine on f or a f ew moments. Listen f or any

odd noises, rubbings, vibrations, etc. Correct

such problem s before at tempting oper ations on

the jointer.

Carefully c hec k y our workpiece for knots, holes,

staples or any foreign material that might

damage kniv es or pose a risk of kic kback. Also

check the workpiec e for grain orientation.

22

Page 23

Basic Operations

Before making any cuts on the stock, make a

few practice cuts by raising the infeed table to

"0" and with the power disconnected. In this

manner you will acquaint yourself with the feel of

jointer operations.

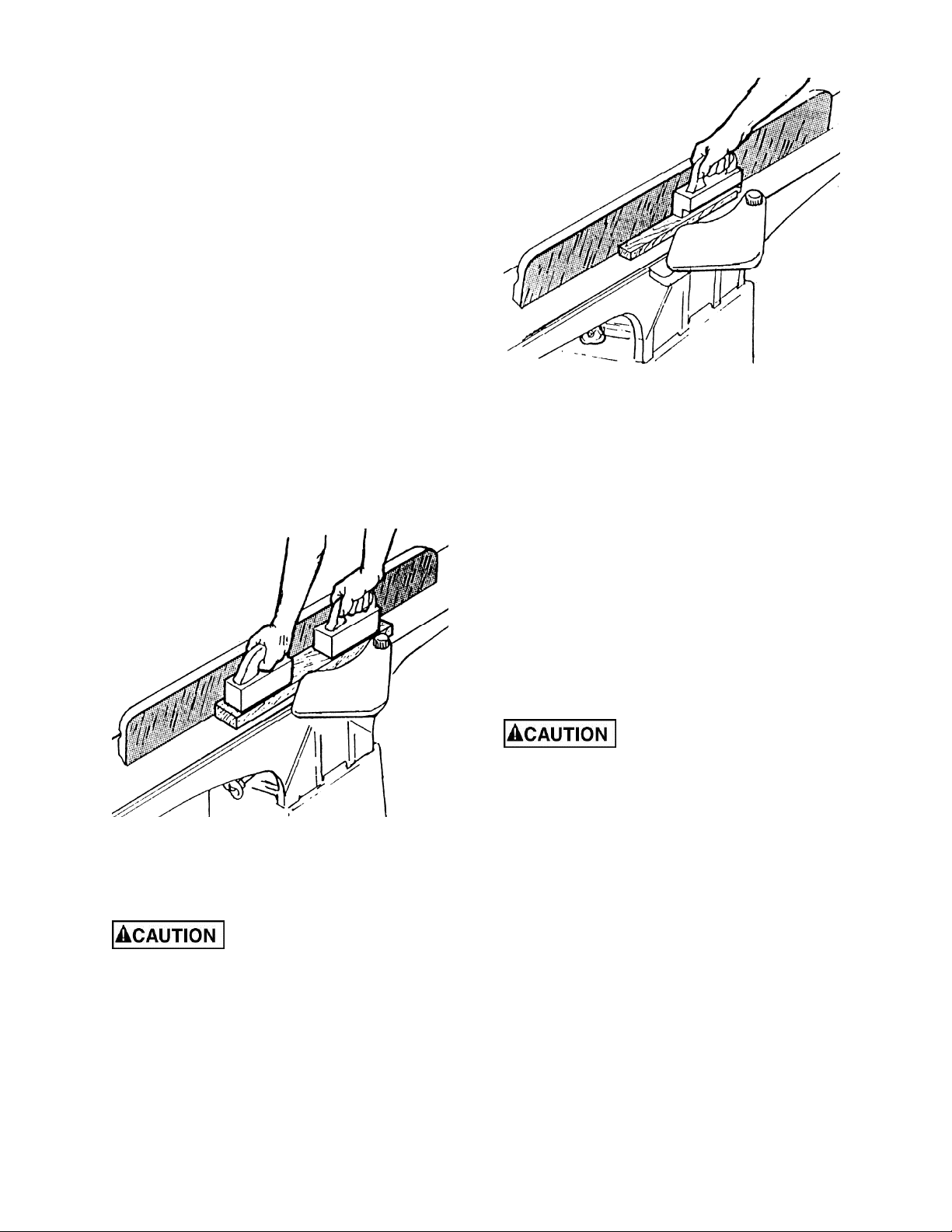

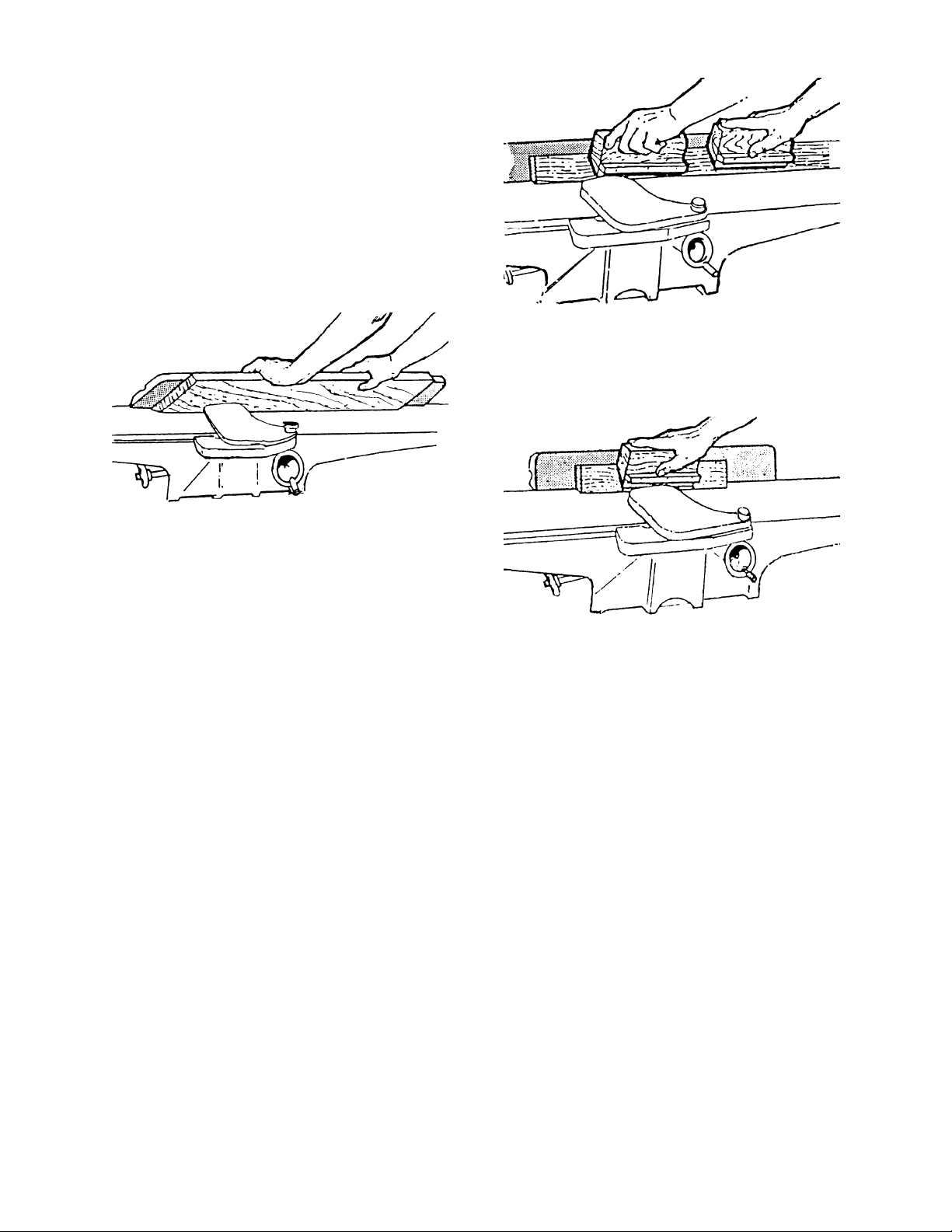

Hand Placement

Never pass hands directly

over the cutterh ead.

At the start of the cut, the left hand holds the

workpiece firmly against the infeed table and

fence whil e the ri ght hand pushes the work piec e

in a smooth, even moti on toward the c utterhead

(Figure 34). After the cut is under way, the new

surface rests fi rmly on the outf eed tabl e. The left

hand is transferred to the outfeed side and

presses down on this part of the workpiece, at

the same time maintaining flat contact with the

fence. The right hand presses the workpiece

forward and before the right hand reaches the

cutterhead it should be moved to the work on

the outfeed tabl e.

Figure 34

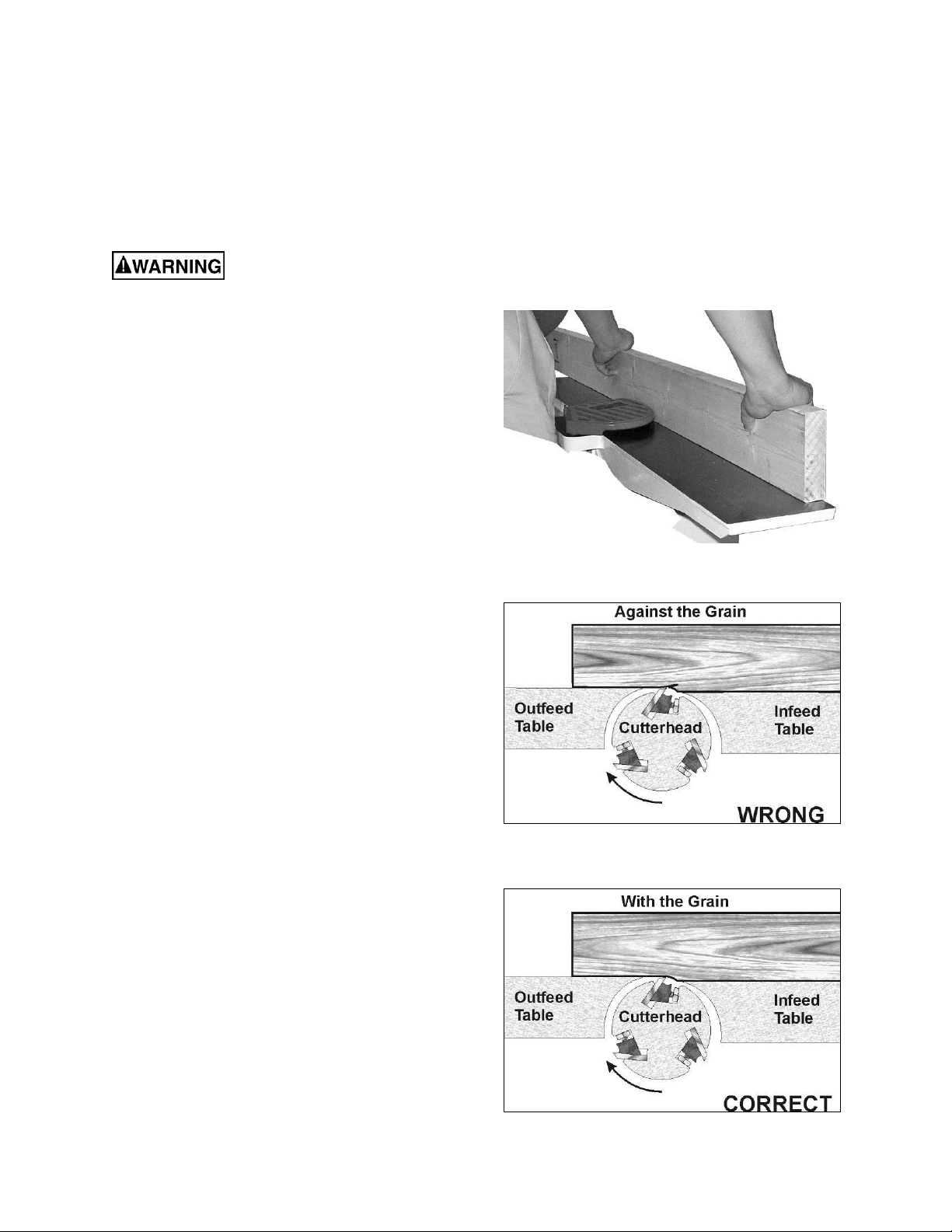

Direction of Grain

Avoid feeding work into the jointer against the

grain. T his m ay resul t i n chi pped and spli nter ed

edges. See Fi gure 35. Feed with the grain to

obtain a smooth surfac e, as shown in Figure 36.

Figure 35

Figure 36

23

Page 24

Surfacing

The purpose of planing on a jointer is to produce

one flat surface. The other side can then be

milled to precise, final dimensions on a

thickness planer resulting in a board that is

smooth and flat on both sides and each side

parallel to t he other.

If the wood to be jointed is cupped or

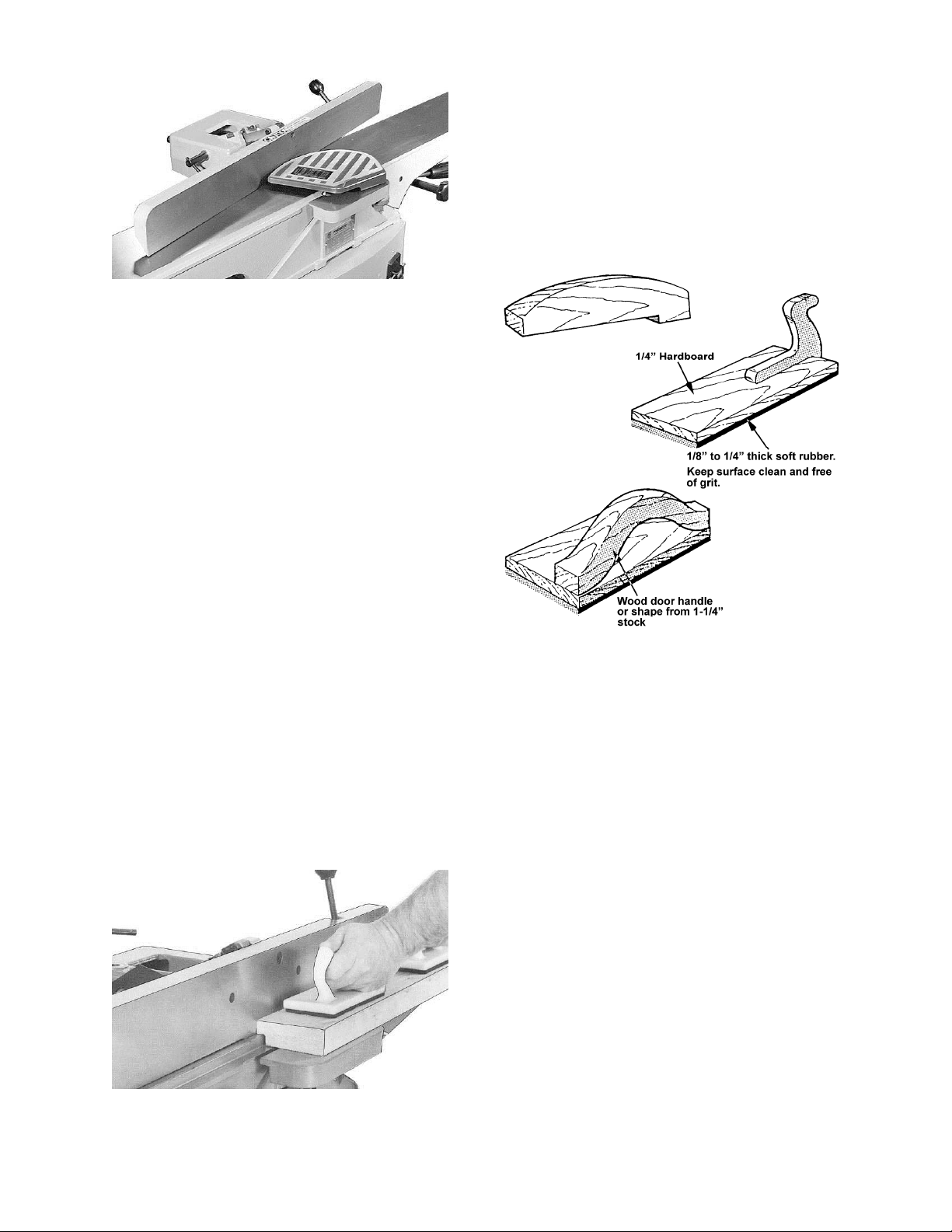

bowed, place the concave side down, and

take light cuts unti l the surface is flat.

Use push blocks to help insure against

hands coming in contact with cutterhead in

the event of a kickbac k.

Never surf ace pi eces shorter t han 12 inc hes

or thinner t han 3/8 inc h without the use of a

special work holding fixture.

Never surf ace pieces thinner than 3 inc hes

without the use of a push bloc k .

On stock longer than 12 inches use two

push blocks (Figur e 37) .

Figure 37

With narrow stock use the type push block

shown in Figure 38.

Figure 38

Jointing

Jointing (or edging) is the process of creati ng a

finished, flat edge surface that is suitable for

joinery or finishing. It is also a necessary step

prior to rippi ng stoc k to widt h on a table saw.

Never edge a board that is less than 3

inches wide, l ess than 1/4 i nch thick, or 12

inches long, without using a push block.

When edging wood wi der than 3 i nches, lap

the fingers over the top of the wood,

extending them back over the fence such

that they will act as a stop for the hands in

the event of a kickbac k.

Position t he fenc e (move f orward) t o ex pose

only the amount of cutter head r equired.

When workpiece is twice the

length of the jointer inf e e d or outf e ed table

use an infeed or outfeed support.

To edge:

1. Make sure the fence is set to 90°. Double

check it with a square.

2. Inspect stock for soundness and grain

direction (Refer to Direction of Grain on

page 23).

When the stock is longer

than twice the length of the infeed and

outfeed tables, another helper or support

table must be used to support the stock.

3. If the board is bowed (curved), place the

concave edge down on t he infeed table.

4. Set the infeed table for a cut of

approxim ately 1/16 inch.

5. Hold the stock firml y against the fence and

table, feed t he stock slowly and evenly over

the cutter head.

24

Page 25

Beveling

Beveling an edge is t he same operati on as edge

jointing, except that the fence is tilted to a

specified angle.

Make certain that the m aterial being beveled

is over 12 inches long, more than 1/4 inch

thick and 1 inch wide.

Although the f ence m ay be tilted i n or out, it

is recommended that the fence be tilted in

toward the operator (a s shown in Fi gure 39)

for safety reasons.

Figure 39

Figure 40

When beveling short material use one bevel

hold down and ap ply pressure towar d the f enc e.

Keep thumb above the ledge on hold down

block (Figure 41).

To bevel:

1. Use a bevel gauge to det ermine the desired

angle. Then set the f enc e to t he same angle.

2. Inspect stock for soundness and grain

direction (Refer to Direction of Grain on

page 23).

3. Set the infeed table for a cut of approximately 1/16.

4. If the board is bowed (curved), place the

concave edge down on t he infeed table.

5. Feed the stock through the cutterhead,

making sure the face of the stock is

completely flat against the fence and the

edge is making solid contact on the infeed

and outfeed tabl es (Figure 39).

For wood wider than 3 inches – hold with

fingers close together near the top of the

stock, lappi ng over the board and ex tending

over the fence.

For wood less than 3 inches wide – use

beveled push blocks and apply pressure

toward the fence. Keep fingers near top of

push block (Figure 40) .

Several passes may be required to achiev e the

full bevel.

Figure 41

Skewing (Shear Cutting)

When edging or facing burl or birds-eye mapl e, it

is not unusual to deface or mar the surface

being fini shed. Thi s is caused by t he cutter head

blades at times cutting against the grain. In

order to prev ent the defacing or marring of t his

type wood, it is necessary to skew, or angle

finish, the material being worked (see Figure

42).

1. Release the fence locking handle and

remove the two hex nuts and flat washer

holding the fenc e to the fence support (see

Figure 3 on page 10). Remov e the fence.

2. Remove the key from the f enc e sli de base.

3. Replace the fence assembly at the desired

angle across the cutterhead. Secure the

fence to the support with the two hex nuts

and flat washer, then tighten the fence

locking handl e.

25

Page 26

Figure 42

Rabbet Cuts (Straight Knife o nly)

IMPORTANT: Rabbeting can be done with the

straight knif e cutt erhead only ; it is not a pplicab le

with the helical cutterhead model.

A rabbet is a groove cut along the edge of a

board (Figure 43). It is usually m ade to accept

another board to f orm a strong, simple joint.

Note: The maximum rabbet depth is 1/2".

1. Unplug the jointer and remove the

cutterhead guard.

Push Blocks

Push blocks are simple yet necessary tools to

assist the oper ator, e speciall y when joi nting t hin

or short stock. Ill ustrated i n Figure 44 are t hree

types of push bl ocks com monly used in j oint ing.

Push blocks may be obtained commercially or

easily construc ted.

Note: The 54A Joi nter is supplied with t wo push

blocks for feeding stock.

2. Loosen the fence and slide it to the

rabbeting edge. S et the fence to the desired

width of the rabbet and lock down.

3. Inspect stock for soundness and grain

direction.

4. Place stock on the inf eed table and rabbet

table with the edge to be rabbeted firmly

against the fenc e.

5. Slowly and evenly feed stock through the

cutterhead.

6. Lower the infeed tabl e 1/16" at a time and

make successive cuts until the desired

depth of rabbet is obtained.

7. Re-install the cutterhead guard when

finished with rabbet ing operations.

Figure 44

Maintenance

Blade Care

Blades are extremely sharp! Use caution

when cleaning or changing. Failure to

comply may cause seriou s injury!

When gum and pitch collect on the blades,

carefully r emove with a strong solvent. Failur e to

remove gum and pitch build up may result in

excessiv e fric tion, blade wear and overheating.

When blades becom e dull, turn them t o the new

edge, or replac e them.

Lubrication

Use a good grade of light grease on the

steel adjusti ng screws located in the raising

and lowering mechanisms of the work

tables.

Figure 43

Occasionally, apply a few drops of light

machine oil to the i nfeed/outfeed gibs. This

permits the tables to slide freely.

The cutterhead ball bearings are lifetime

lubricated and need no further care.

26

Page 27

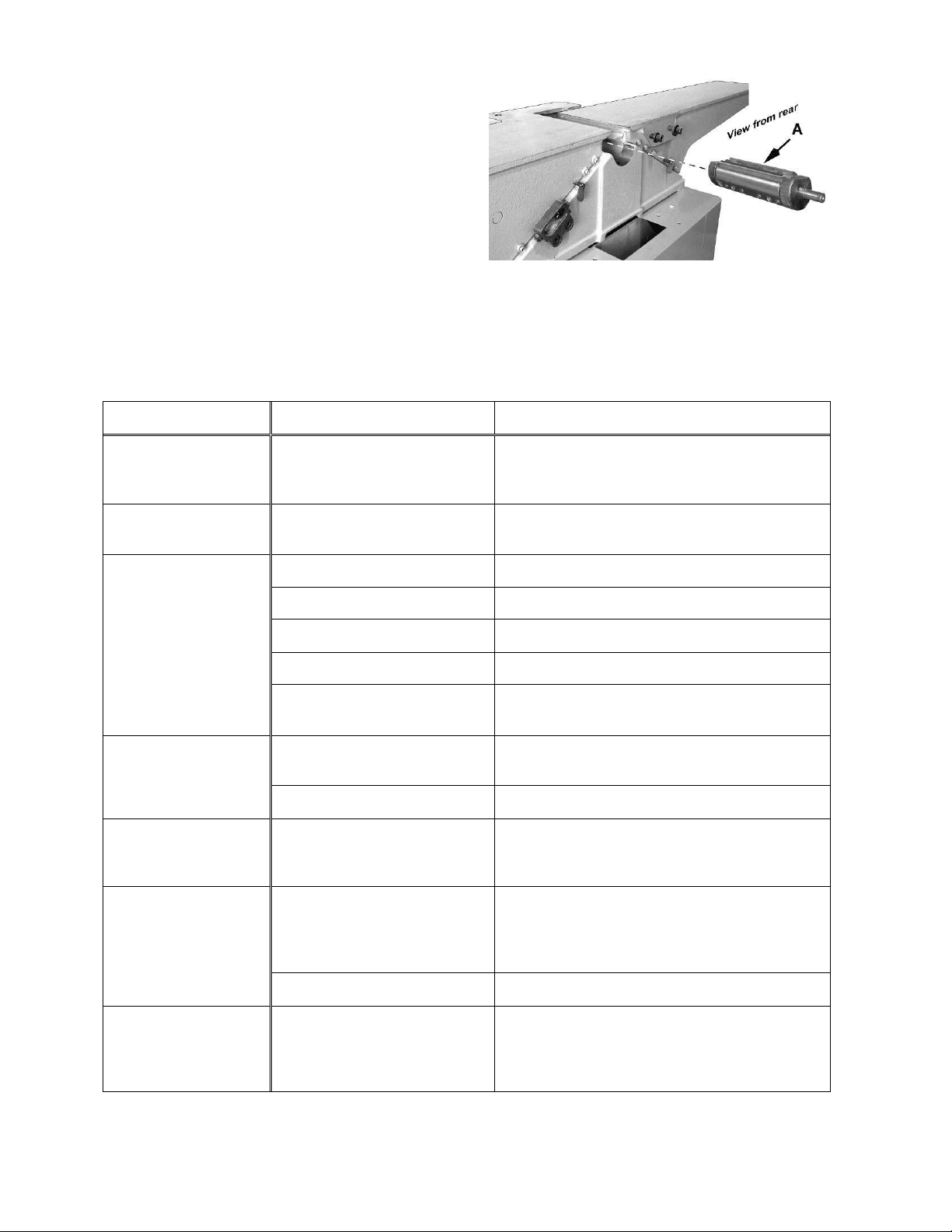

Cutterhead Removal

The entire cutterhead assembly may be removed

for cleaning or for bearing and bl ade replacement.

Some woodworkers keep a spare cutterhead with

replacement blades should the origi nal cutterhead

have to be repair ed.

Blades in the cutterhead are

sharp! Use extreme caution

when handling the removal of the cutterhead.

Failure to compl y may cause seri ou s injury!

To remove the cutterhead (including bearings,

studs, and housing) from the base casting:

Referring to Fi gur e 45:

1. Disconnect the machine from the power

source.

2. Remove the front blade guard (A) and

screw (B).

Lock the fence tilt lock handle

(D) to avoid injury from moving parts when

moving this assembl y.

3. Remove the t wo lock nuts (G) and washer (F)

securing the fence assembly (C) to the fence

base casting (E).

Figure 45

4. Lift the f ence assembly (C) from t he table and

set aside.

5. From the left side of the stand, remove the

dust chute. From the back of the machine

remove the cabinet ac c es s door.

Referring to Fi gur e 46:

6. Using an 8mm hex wrench, loosen two hex

cap screws underneath fenc e base casting (E)

that secure the casting to the table (F).

Remove the fence base casting and set aside.

7. Remove four screws and washers (A) securing

the belt guard (B). Remove the belt guard.

8. Using a 14mm wrench, remove two screws

(A, Fig. 47) and lock washers that secure the

cutterhead bearing housings to the base.

Note: These screws and lock washers are

more easily accessibl e through the dust chute.

9. Using a 3mm hex wrench, loosen two set

screws that secure the c utt erhead pul ley (D) to

the cutter head shaft. Do not attem pt to rem ove

pulley wi th belt at this time.

10. Slide the pulley from the shaft of the

cutterhead along with the V-belt. Set the

pulley, shaft k ey and V-belt aside.

Figure 46

Figure 47

27

Page 28

11. Carefully remove the cutterhead ( A , Fi g. 48) .

12. Before placing the new cutterhead back into

the casting, thoroughly clean the "saddle" and

the bearing hou sings of saw dust and grease

so that they seat properly.

13. T o re-install the cutt erhead, reverse the above

steps.

Note: When securi ng the fence base casting,

make sure it is level with the outfeed table.

Figure 48

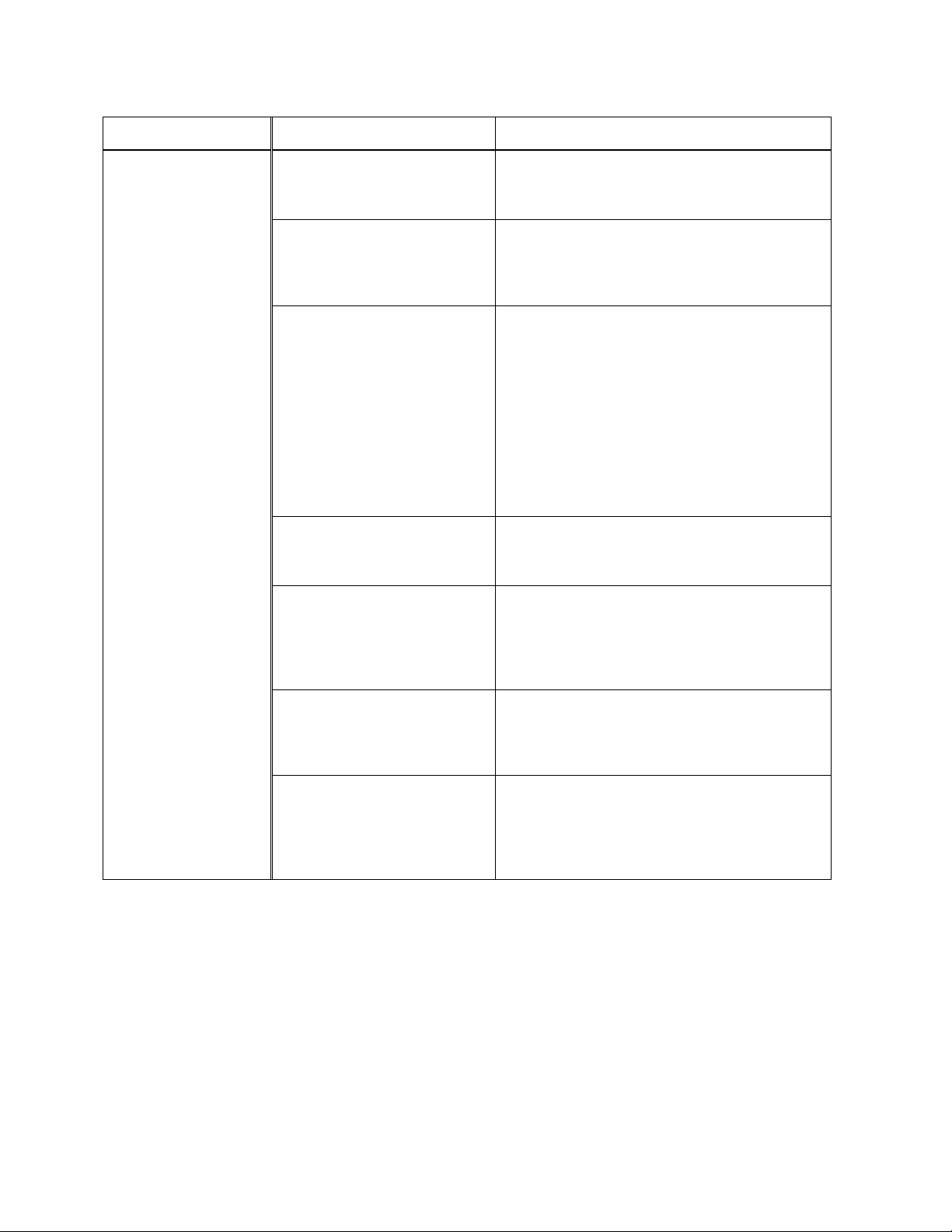

Troubleshooting Operating Problems

Trouble Probable Cause Remedy

Finished stock i s

concave on back

end.

Finished stock i s

concave on front end.

Chip out.

Knife is higher than outfeed

table.

Outfeed table is higher than

knife.

Cutting against the grain. Cut with the grain whenev er possible.

Dull knives. Sharpen or replac e k niv es.

Feeding workpiec e too fast. Use slower rate of feed.

Cutting too deeply. Make shallower cuts.

Raise outfeed table until it aligns with tip of

knife. See Outfeed Table Height Adjustment.

Lower outfeed table until it aligns with tip of

knife. See Outfeed Table Height Adjustment.

Fuzzy grain.

Cutterhead slows

while operating.

“Chatter” marks on

workpiece.

Uneven knife marks

on workpiece.

Knots, imperfections in wood.

Wood has high moistur e

content.

Dull knives. Sharpen or replac e k niv es/inserts.

Feeding workpiec e too

quickly, or applying too much

pressure to workpiece.

Knives incorr ectly set.

Feeding workpiec e too fast. Feed workpiece slowly and c onsi stently.

Knives are nicked, or out of

alignm ent.

Inspect wood closely for imperfections; use

different stoc k if necessary.

Allow wood to dry or use diff er ent stock.

Feed more slowly, or appl y l ess pressure to

workpiece.

Set knives properl y as descri bed in the

Setting Cutt erhead Knives section. Check that

knife slots are clean and free of dust or

debris.

Align knives per the S ett ing Cutterhead

Knives section. Replace nicked k niv es or

correct for small nicks – see Setting Knives

for Rabbeting and Nicks .

28

Page 29

Troubleshooting Mecha nical and Electrical Problems

Trouble Probable Cause Remedy

Machine will not

start/restart or

repeatedly trips

circuit breaker or

blo ws fuses.

No incoming power.

Building circuit breaker trips

or fuse blows.

Switch or motor failure (how

to distingui sh).

Motor overheat ed.

Motor failure.

Verify unit is connected to power, on-button is

pushed in completely, and stop-button is

disengaged.

Verify that jointer is on a circuit of correct size.

If circuit siz e is corr ect, there is probably a

loose electri c al lead. Check amp setting on

motor starter.

If you have access to a voltmeter, you can

separate a switch failure from a motor failure

by first, verifying incoming voltage at

110/220+/-10% and second, c hec k ing the

voltage between swit c h and m otor at

110/220+/-10%. If incoming voltage is

incorrect, y ou hav e a power supply pr oblem. If

voltage between swit c h and m otor is incorrect,

you have a switch problem . If v oltage between

switch and motor i s corr ect, you have a motor

problem.

Clean motor of dust or debri s to allow proper

air circulation. Allow motor to cool down

before restar ting.

If electric motor is suspect, you have two

options: Hav e a qualified electrician test the

motor for function or remove the motor and

take it to a qualifi ed el ec tric motor repair shop

and have it tested.

Unit in c orre ctly wired .

On/off switch failure.

Optional Accessories

2004017 ...........Dust Collector Adaptor

2042374 ...........Mobile Base

708801DX ........Knives (set of 3)

1791212 ...........Knife Inserts (set of 10)

6285991 ...........Tool Kit

Double check to confi rm all electrical

connections are cor r ec t. Refer to the Wiring

Diagram section t o m ak e any needed

corrections.

If the on/off switch is suspect, you have two

options: Hav e a qualified electrician test the

switch for function, or purchase a new on/off

switch and establish if that was the problem

on change out.

Replacement Parts

To order parts or reac h our servi ce department,

call 1-800-274-6848, Monday through Friday

(see our website for business hours;

www.powermatic.com). Having the Model

Number and Serial Number of your machine

available when you call will allow us to serve y ou

quickly and acc ur ately.

29

Page 30

Stand – Parts List (All Models)

Index No. Part No. Description Size Qty.

................. 6296131...................Stand Assembly .................................................................................... 1

1 ............... 6296121...................Stand .................................................................................................... 1

2 ............... 6285974...................Door ...................................................................................................... 1

3 ............... 6285822...................Lock Bolt ............................................................................................... 3

4 ............... 6285852...................Spring Was he r....................................................3/8 x 5/8 ..................... 3

5 ............... 6296122...................Screw .................................................................1/8-40 x 3/8 ................ 4

6 ............... 6296123...................Flat Washe r ........................................................1/8 x 3/8 x 1/32 ........... 4

7 ............... 6285975...................Screw Knob ........................................................................................... 1

8 ............... 6285976...................Door Lock .............................................................................................. 1

9 ............... 6285977...................Hex Nut ..............................................................3/8-16 ......................... 1

10 ............. 6285980...................Hex Screw ..........................................................5/16-18 x 3/4 .............. 4

11 ............. 6285805...................Flat Wash e r ........................................................5/16 x 3/4 x 1/16 ......... 8

12 ............. 6296124...................V-Belt .................................................................................................... 1

13 ............. 6296125...................Motor Pul l ey .......................................................................................... 1

14 ............. 6285865...................Set Screw ...........................................................1/4-20 x 1/4 ................ 2

15 ............. 6296126...................Motor ..................................................................1 HP, 1PH, 115V ........ 1

16 ............. 6285988...................Spring Was he r....................................................5/16 x 5/8 ................... 4

17 ............. 6285966...................Hex Nut ..............................................................5/16-18 ....................... 1

18 ............. 6296127...................Motor Cord ............................................................................................ 1

19 ............. 6296128...................Switch ................................................................................................... 1

20 ............. 6285963...................Strain Relief ........................................................SB7R-1 ...................... 1

21 ............. 6285962...................Power Cord ........................................................................................... 1

22 ............. 6296129...................Belt Guard ............................................................................................. 1

23 ............. 6285909...................Flat Washe r ........................................................1/4-20 UNC x 1/2 ........ 8

24 ............. 6285910...................Handle Screw .....................................................1/4-20 x 1/2 ................ 8

25 ............. 2004017

26 ............. 6285978...................Key.....................................................................5 x 5 x 30 ................... 1

27 ............. 6296133...................Switch Pushbutton ................................................................................. 1

28 ............. 6296134...................Switch Cover ......................................................................................... 1

29 ............. 6296135...................Switch Box ............................................................................................ 1

30 ............. 6296136...................Pan Head Screw ................................................#10-24 x 1/2 ............... 2

31 ............. 6296137...................Washer ...............................................................3 /1 6 x 1/2 x 1/32 ......... 2