Page 1

POWERMATIC 54A/54HH 6” Jointer

Creating flat, straight surfaces is crucial in the quest to build elegant

projects. Virtually all forms of joinery and the tools that cut them

depend on straight edges and square cuts. The POWERMATIC

54A/54HH 6” Jointer makes it easy to achieve the high levels of

accuracy you need in this always-crucial operation.

Base Cabinet

The 21”-wide by 13”-deep all steel base cabinet provides stable footing

for the POWERMATIC 54A/54HH 6” Jointer and puts the table

The Powermatic 54A/54HH

6” Jointer has been designed

and built to provide the

u7ltimate in accuracy and

dependability.

surface at a comfortable 32” above the floor.

The 1 HP, 1Ph, 115/230V motor (pre-wired 115V) is factory-mounted

within the base cabinet and can be converted to use 230V power should

that be desirable. The motor is on a special mount within the base cabinet

that allows the user to adjust belt tension should that become necessary.

The base also contains the dust collection chute that evacuates debris

from below the cutterhead. The chute guides that debris to the exterior

The all-steel base cabinet

not only provides stable

footing for the jointer, it

houses the motor and dust

collection outlet.

4”-diameter port near the floor. Locating the outlet port near the floor

helps keep the hose out of the way and puts it at a similar height as the

inlet of our popular dust collectors such as the PM1300.

3-Knife Cutterhead (54A Model)

The POWERMATIC 54A Jointer features a 3-knife cutterhead fitted

with adjustment cams that make setting critical knife height easy

and extremely accurate. Each knife is 6 1/16”-long, ¾”-tall and

5/64”-thick and made from high quality steel.

The knives are secured by a set of 4 gib screws and a gib plate.

Below each knife are two adjustment cams. The included manual

provides complete instructions (with illustrations) that make

changing and setting the knives easy. They even show how to offset

The 54A cutterhead (top in this

photo) features our Quick Set

knife system that uses cams to

position the knives precisely so

they cut smoothly and work

together equally to disperse wear.

one or more of the knives for cutting small rabbets or to compensate for small nicks in a knife.

Helical Cutterhead (54HH Model)

There are many cutterhead designs that carry the helical moniker, including simple straight

blades broken into segments and dispersed around the cutterhead cylinder. However, despite the

name, they retain many of the liabilities of the long blade designs. While designing the

POWERMATIC 54HH 6” Jointer we wanted to incorporate the performance of a true

segmented, shear-cutting helical head.

Page 2

The helical cutterhead is so effective because its carbide inserts are

arranged in spiral-shaped rows. The inserts have a 4” radius ground

into them and are mounted so they approach the wood at a 14-degree

angle. That creates a true shear cut that eliminates much of the

impact and the resulting fiber disturbance other cutterhead designs

deliver to the wood.

The helix head (right side of the

image) uses full carbide inserts

that greatly extend durability as

well as the quality of the cut.

Sound is also drastically reduced

over nearly all other cutter

configurations.

The helical cutterhead cuts so efficiently that it dramatically reduces

the noise made when cutting wood. In fact, it is so quiet, new

POWERMATIC 54HH 6” Jointer users often think it is not cutting

wood at all, until they see the results. The shearing effect of the

helical cutterhead produces a remarkably smooth surface on even

heavily figured wood.

The helical cutterhead inserts are precisely machined from solid high-grade carbide, each with

four identical cutting edges. If an edge eventually goes dull, you simply index it to the next

cutting edge! Each insert has a marking at one edge that makes indexing all or any number of

them the same way very easy, though needing to do that is unlikely.

Because the inserts themselves and the seats into which they fit are so precisely machined, there

is no adjustment or “fitting” necessary. Indexing or replacing an insert takes just seconds. Simply

loosen its retaining screw, turn the insert to its new position and tighten the screw.

The durability of the carbide combined with the low impact, shear cutting action mean the inserts

have an extremely long life, far exceeding that of straight blades. The potential life span of these

carbide inserts means that many woodworkers may go years before having to index them. Should

a hidden piece of metal be encountered and actually damage a few of the carbide inserts only the

ones actually contacting the metal need to be indexed or replaced.

Tables

At 7 ¼”-wide and 66”-long the cast iron POWERMATIC

54A/54HH Jointer table is one of the longest available in this class

and provides plenty of support for even large work pieces. The

tables are precision-ground to insure flatness and each is mounted

on dovetailed ways that keep them perfectly aligned through height

changes. The ways are equipped with gib screw adjusters that allow

the user to adjust out any wear-related play should that occur in

years to come. The outfeed table is equipped with a ½” by ½”

rabbeting channel along its outer edge.

The outfeed table height is adjusted with a handwheel mounted

below the table. A finger-operated gib screw locks the table in

position once it is set.

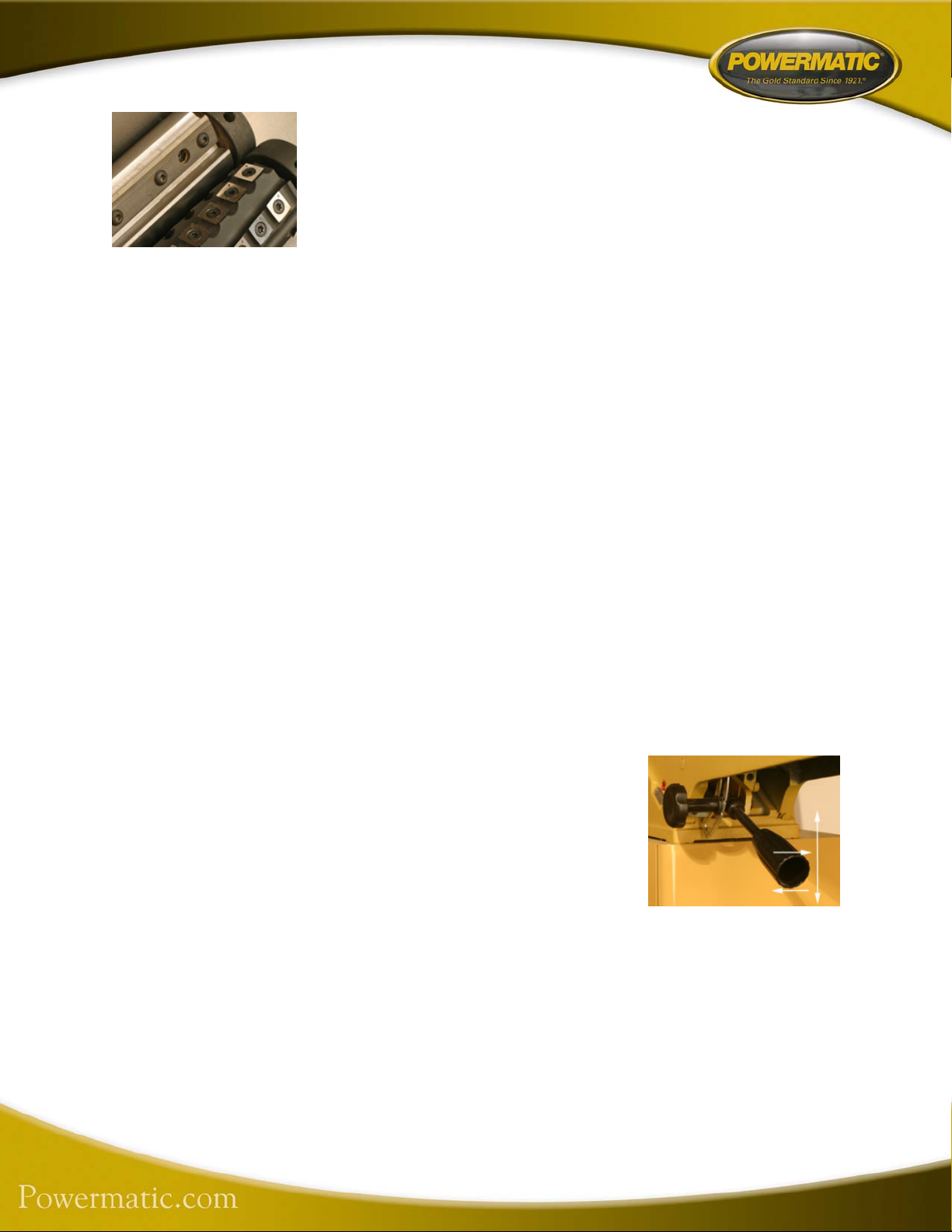

The infeed table height

adjustments are truly unique. The

handle can be moved up and

down for coarse height changes

or, after snugging the locking

knob (to the left) the long handle

can be rotated to make very fine,

precise infeed table height

adjustments.

Page 3

The infeed table height is adjusted using a unique lever system. This single lever provides both

coarse and fine adjustment capabilities that make tiny changes simple to make with a new level

of accuracy. After loosening the handwheel on the side of the machine, the infeed table

adjustment lever can be used for major infeed table height changes. Snug the locking knob down

and the same adjustment lever can now be rotated (twist the handle) to make very small infeed

table height changes with extreme accuracy. Each full turn of the adjustment lever handle creates

1/16” of infeed table height change. When the infeed table is set to the desired height, a

thumbscrew on the rear can be engaged to secure it.

An easy to read scale on the front side of the infeed table allows setting specific cut changes

quickly and precisely.

Versatile Fence

The all cast iron 4”-tall by 38”-long fence

system is, like the tables, precisely ground to

assure straightness. Even the supporting and

tilt mechanism is made up of large cast iron

pieces that make this system as accurate and

repeatable as it is durable.

The fence tilts up to 45-degrees towards and

Whether used in the full vertical (left) or 45-degree position

(right) in or out, the Powermatic 54A/54HH fence provides

plenty of support for truly accurate cuts.

away from the tables. Fully adjustable stops at

90-degrees (vertical) and each 45-degree

position make setup fast and help keep the

POWERMATIC 54A/54HH Jointer accurate

with minimal maintenance. The 90-degree stop

is a simple flip-out design that makes releasing or engaging it fast and tool free. An easy to use

locking handle secures the fence at the desired angle.

An easy to use handle locks and releases the cross-table movement of the fence. The handle

easily locks the fence in any position across the table and holds it there securely.

Mobility

If being able to move the POWERMATIC 54A/54HH Jointer around

within your shop is important we offer the #2042374 mobile base.

This base is heavily built and makes moving the POWERMATIC

54A/54HH Jointer surprisingly easy. All of the wheels can be locked

to keep the POWERMATIC 54A/54HH Jointer stable when in use.

The POWERMATIC 54A/54HH Jointer has been designed and built

to make your wood straightening tasks easy and accurate. The heavyduty construction and materials mean that the POWERMATIC

When you need to move the

54A/54HH jointer around in

your shop, our specially

designed mobile base makes

that an easy task.

54A/54HH Jointer will remain an important part of your woodworking shop for many years to

come.

Loading...

Loading...